Page 1

SERVICE MANUAL

Large Format Color Inkjet Printer

EPSON Stylus Pro 7400/7450/7800/7880/7880C

9400/9450/9800/9880/9880C

SEIJ05002

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2007 SEIKO EPSON CORPORATION.

Imaging Product CS,PL & Environmental Management

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) Damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO

THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN AIR DUSTER IS USED ON THE REPAIR AND THE MAINTENANCE WORK, THE USE OF THE AIR DUSTER PRODUCTS CONTAINING

THE INFLAMMABLE GAS IS PROHIBITED.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Page 5

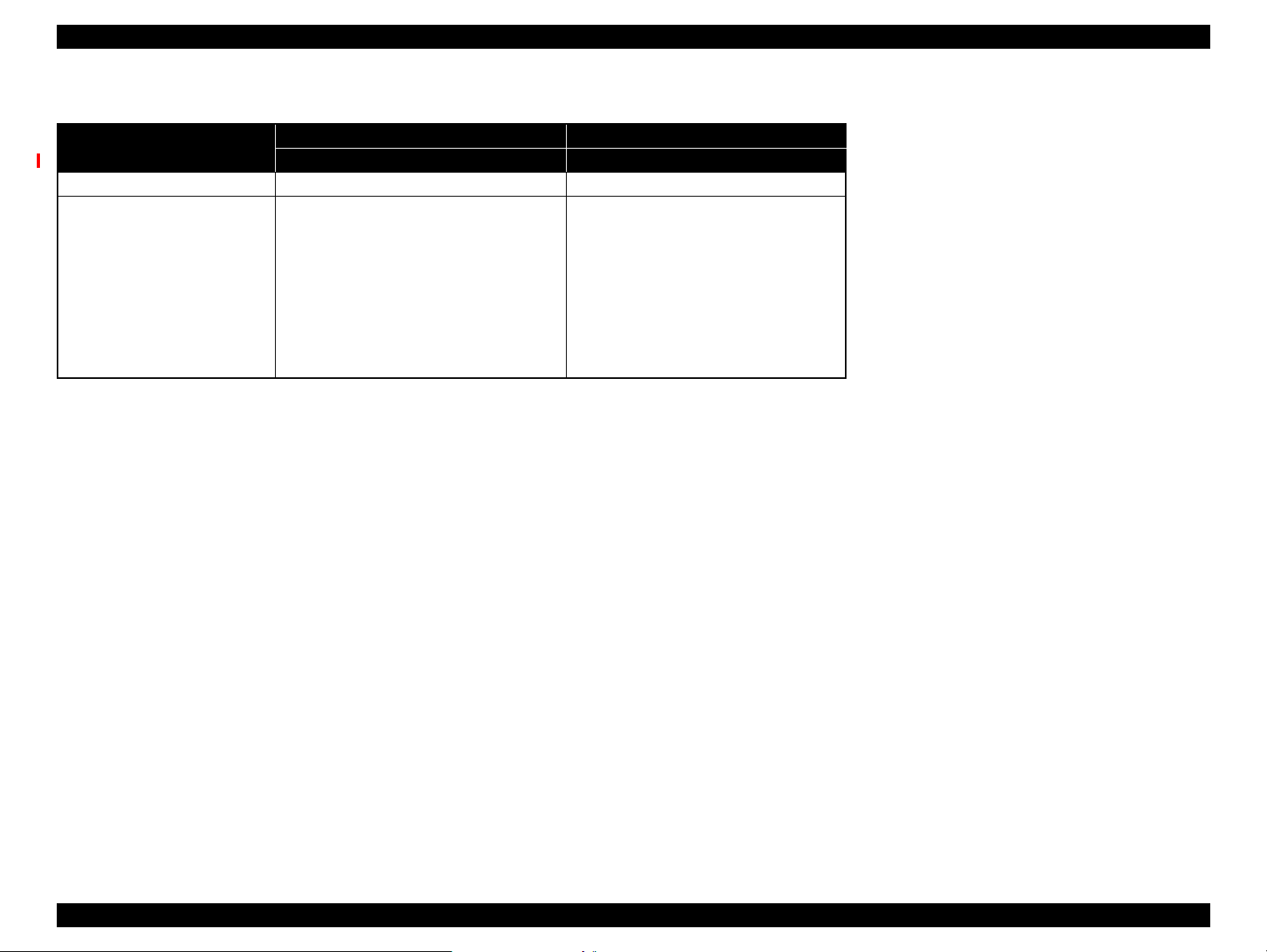

Revision Status

Revision Date of Issue Description

A July 29, 2005 First release

B September 2, 2005 Revised Contents

[All chapters]

• “Weight” has been changed to “mass”.

[Chapter 1]

• “Service Personnel Mode” has been changed to “SERVICEMAN MODE”.

• Descriptions have been added in 1.4.4.35 Power Cleaning (Page 99).

•“CAUTION” in Edge Sensor Level Measurement (Page 118) has been deleted.

[Chapter 2]

• Made changes in 2.2.4 Cleaning Mechanism (Page 171) .

• 2.5 Colorimetric Calibration (Color ID) Overview (Page 178) has been added.

[Chapter 4]

• “ADJUSTMENT REQUIRED” has been added in 4.2.4.2 P/S BOARD ASSY. (Page 243).

• “ADJUSTMENT REQUIRED” has been added in 4.2.4.4 BOARD ASSY., SUB (Page 245).

• Made changes and added “REASSEMBLY” in 4.2.5.2 CR MOTOR ASSY. (Page 252).

• “CAUTION” has been added in 4.2.7.4 PUMP CAP ASSY. (Page 298).

Page 6

Revision Date of Issue Description

B September 2, 2005 [Chapter 5]

• Descriptions have been added in Table 5-1. Parts and Units that Require Adjustments (Page 307).

• Descriptions have been added in Table 5-2. Required Adjustments in the Order of Execution (Page 308).

• Descriptions have been added in Basic Adjustment (Page 311).

• Made changes in Table 5-3. Tools for Adjustments (Page 313).

• Made changes in “System Requirements” in 5.1.7 Adjustment Program Basic Operations (Page 314).

• Made changes in 5.2.2 Cutter Position/Height Adjustment (Page 316).

• Made changes in 5.2.3 Paper Thickness Sensor Position Adju stment (Page 318).

• “Shield Cap” has been changed to “Seal Cap” in 5.2.8 Air Leak Check (Page 324).

• Made changes in 5.3.4 T&B&S (Roll Paper) (Page 334).

• Made changes in 5.3.5 T&B&S + 980mm Band Feed (Page 336).

• Made changes in 5.3.7 Nozzle Bi-D Adjustment (Page 339).

• Made changes in 5.3.8 Print Head Slant Adjustment (PF) (Page 340).

• Made changes in 5.3.9 Print Head Slant Adjustment (CR) (Page 343).

• Made changes in 5.3.10 Ink Mark Sensor Level Adjustment (Page 346).

• Made changes in 5.3.11 Auto Uni-D Adjustment (Page 347).

• Made changes in 5.3.12 Auto Bi-D Adjust ment (P.G. 0.8/1.6) (Page 348).

• Made changes in 5.3.13 Ink Mark Sensor Adjustment for Au to Nozzle Check (Page 349).

• Made changes in 5.3.14 Skew Check (Page 351).

• Made changes in 5.3.15 Platen Position Adjustment (Page 352).

• Made changes in 5.3.16 980mm Band Feed Adjustment (Page 354).

• 5.3.22 Colorimetric Calibration (Color ID) (Page 359) have been added.

• Made changes in 5.4.1 Auto Bi-D Adjustme nt (Page 375).

• Made changes in 5.4.2 Manual Bi-D Adjustment (Page 376).

• Made changes in 5.5.1 Check Nozzle (Page 380).

• Made changes in 5.5.2 Check Alignment (Page 381).

• Made changes in 5.5.3 Print Adjustment Check Pattern (Page 382).

• Made changes in 5.5.4 Check Cutting (Page 383).

• 5.8 Model Setting (when replacing the Main Board) (Page 390) have been added.

Page 7

Revision Date of Issue Description

C December 15, 2006 Revised Contents

[Chapter 1]

• Table 1-28. Button Functions (Page 35) was modified.

[Chapter 4]

• 4.2.5.8 CARRIAG E UN IT (Page 26 1) was added.

[Chapter 7]

• 7.2 Circuit Diagrams (Page 405) was revised.

D June 15, 2007 Revised Contents

[All chapters]

• T.B.D. items have been determined.

[Chapter 2]

• Figure 2-2. Carriage Mechanism (Page 159) was modified.

• Figure 2-3. Carriage Mechanical Unit and PG Adjustment Unit (Page 161) was modified.

[Chapter 3]

• Remedy (Page 188) was revised.

[Chapter 4]

• REASSEMBLY was added in 4.2.7.1 PRINT HEAD (Page 281)

[Chapter 5]

• 5.1.4 Required Adjustments by Part or Unit (Page 308) was changed.

• 5.1.6 Tools for Adjustments (Page 313) was changed.

• A misdescription was corrected in 5.2.3 Paper Thickness Sensor Position Adjustm e nt (Page 318)

• A misdescription was corrected in 5.3.6 Cutter Pressure Adjustment (Page 338)

• Required Tool was added in 5.3.16 980mm Band Feed Adjustment (Page 354)

• “Tiny mode” was changed to “F/W update mode” in 5.3.18 NVRAM Back Up and Write (Page 356)

• A misdescription was corrected in 5.3.21 Rear Sensor Adjustment (Page 358)

• 5.8 Model Setting (when replacing the Main Board) (Page 390) was changed.

E September 12, 2007 Revised Contents

[All chapters]

• Information on Stylus Pro 7880/7880C/7450/9880/9880C/9450 has been added.

Page 8

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Contents

Chapter 1 Product Description

1.1 Product Description ............................................................................................ 12

1.1.1 Features ...................................................................................................... 12

1.1.2 Difference between 8 color and 4 color machines ..................................... 15

1.2 Basic Specifications ........................................... ... ....................................... ... .... 16

1.2.1 Print Specifications .................................................................................... 16

1.2.2 Character Specifications ............................................................................ 17

1.2.3 Operability Specifications ......................................................................... 17

1.2.4 Paper Specifications ................................................................................... 18

1.2.5 Mechanism Specifications ......................................................................... 20

1.2.6 Electrical Related Information ................................................................... 24

1.2.7 Reliability .................................................................................................. 24

1.2.8 Environmental Conditions ......................................................................... 26

1.2.9 Overall Dimensions ................................................................................... 27

1.2.10 Accessories/Options/Consumables .......................................................... 29

1.3 External View and Parts Names ......................................................................... 32

1.4 Control Panel .............................................................. ....................................... . 34

1.4.1 Buttons and Functions ............................................................................... 34

1.4.2 Panel Display ............................................................. ................................ 37

1.4.3 Job Information .......................................................................................... 46

1.4.4 Panel Setting .......................................... ........................................ ............ 48

1.4.5 Maintenance Mode .................................................................................. 105

1.4.6 SERVICEMAN MODE ........................................................................... 111

1.4.7 MIB Function ........................................................................................... 142

1.4.8 Function to Prevent Irregular Printing ..................................................... 142

1.4.9 Initialization ............................................................................................. 143

1.4.10 Default Setup Values ............................................................................. 143

1.5 Controller .......................................................................................................... 144

1.6 Interface ............................................................................................................ 145

1.6.1 USB interface ........................................................................................... 145

1.6.2 IEEE1394 Interface ................................................................................. 146

1.6.3 Optional Interface .................................................................................... 147

1.6.4 Network Interface .................................................................................... 149

1.6.5 Received Buffer Full Operation .............................................................. 150

1.6.6 Interface Selection ................................................................................... 150

1.7 Optional Units and Consumables ........................................................... .......... 151

1.7.1 Ink Cartridge ............................................................................................ 151

1.7.2 Cleaning Cartridge .............................................................. ..................... 152

1.7.3 Conversion Cartridge .......................................................... ..................... 152

1.7.4 Maintenance Tank ............................... .......................................... .......... 153

Chapter 2 Operating Principles

2.1 Overview ................................................ ........................................ ... ............... 155

2.2 Print Mechanism Components ............................................................... .......... 156

2.2.1 Print Mechanism (Print Head) .......................................................... ....... 157

2.2.2 Carriage (CR) Mechanism ....................................................................... 159

2.2.3 Paper Feed Assembly .............................................................................. 168

2.2.4 Cleaning Mechanism ............................................................................... 171

2.2.5 Ink Supply Mechanism ............................................................................ 173

2.2.6 Others .......................................... ........................................ ..................... 174

2.3 Outline of Main Board ......................................... ............................................ 175

2.4 Outline of Power Supply Circuit Board ........................................................... 177

2.5 Colorimetric Calibration (Color ID) Overview ................................................ 178

8

Page 9

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Chapter 3 Troubleshooting

3.1 Overview .......................................................................................................... 180

3.1.1 Preliminary Check ................................................................................... 180

3.1.2 Troubleshooting Procedure ...................................................................... 180

3.2 Troubleshooting based on Panel Messages ...................................................... 181

3.2.1 List of Panel Messages ............................................................................ 181

3.2.2 Remedies for Warning Messages ............................................................ 187

3.2.3 Remedies for Error Messages .................................................................. 190

3.2.4 Remedies for Service Call Errors ............................................................ 197

3.3 Troubleshooting based on Printed Result ......................................................... 212

Chapter 4 Disassembly & Assembly

4.1 Overview .......................................................................................................... 217

4.1.1 Precautions ............................................................................................... 217

4.1.2 Recommended Tools ............................................................................... 219

4.1.3 Recommended Screws ............................................................................. 220

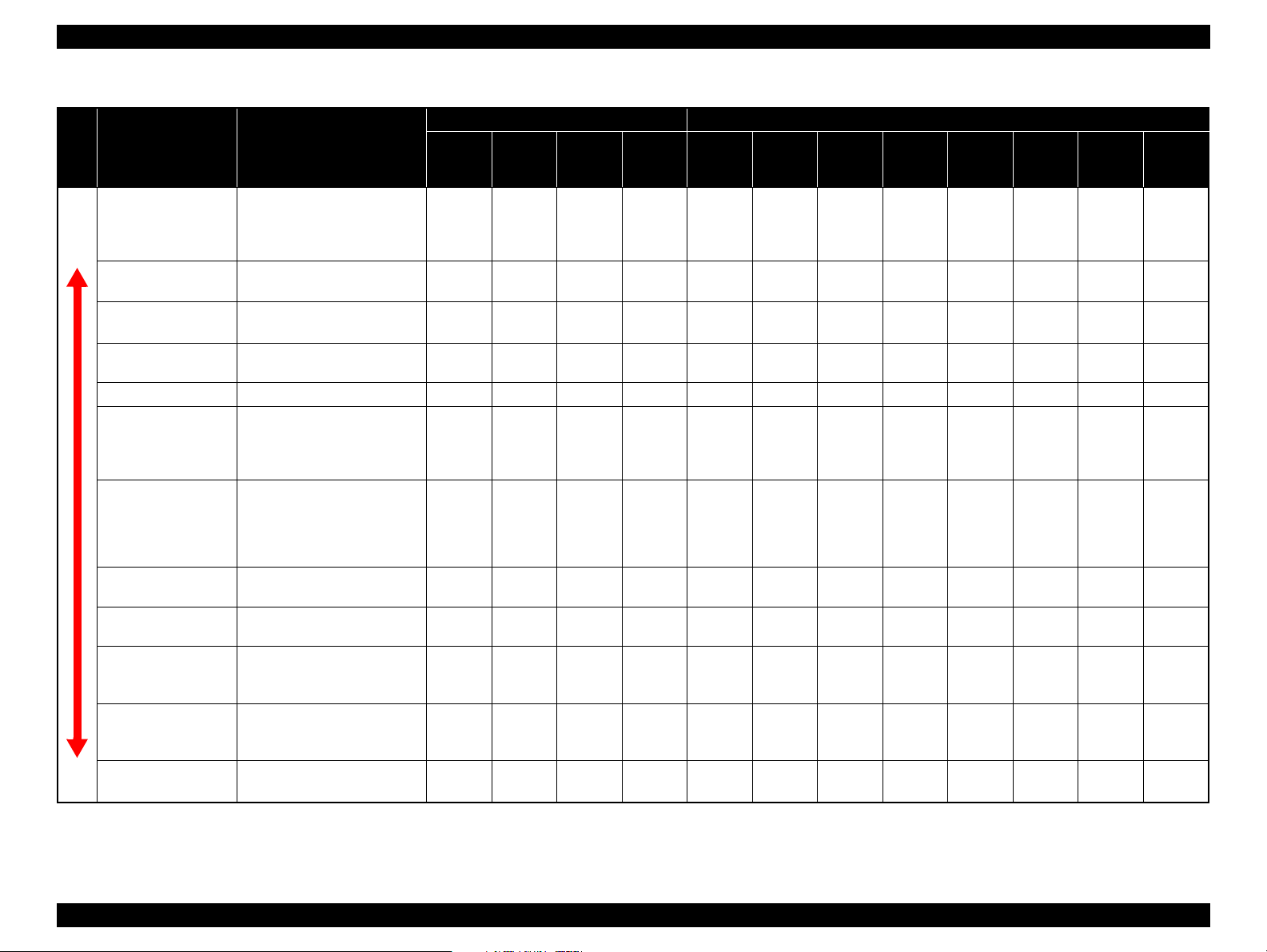

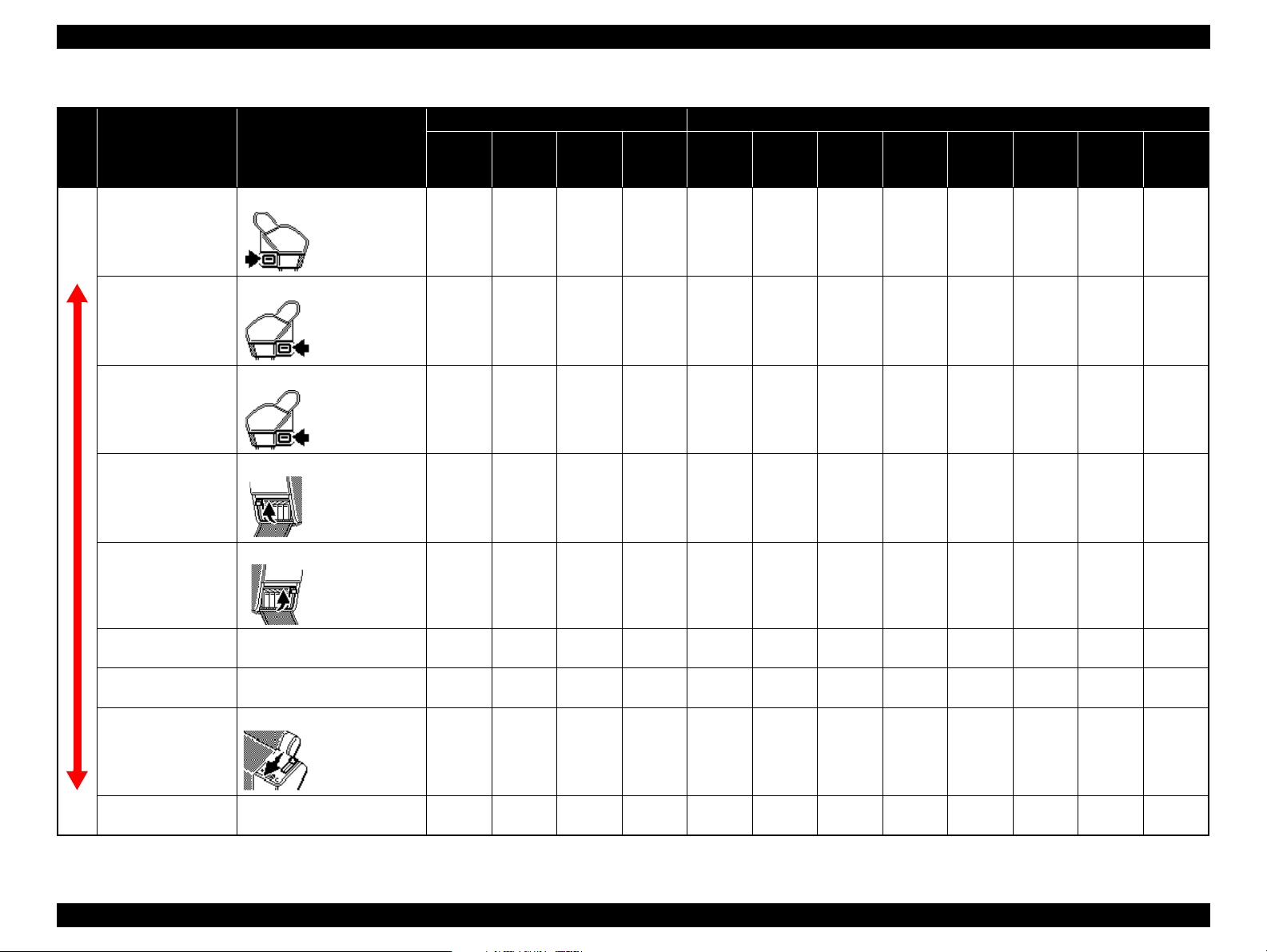

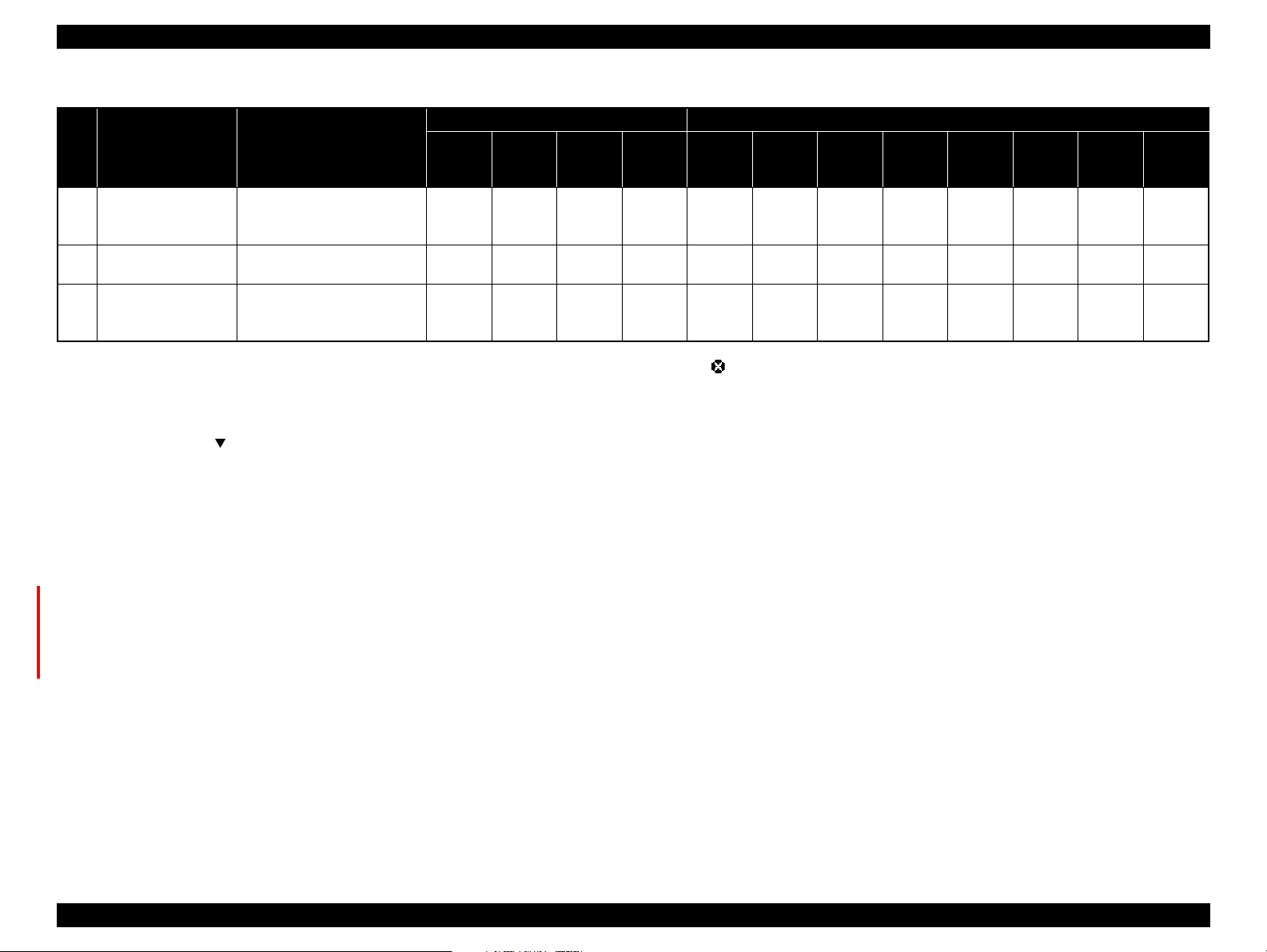

4.2 Disassembly Procedure .................................................................................... 221

4.2.1 Basic Operations ...................................................................................... 223

4.2.2 Consumables ............................................................................................ 225

4.2.3 Removing the Panel Unit and Housing ................................................... 229

4.2.4 Removing the Circuit Boards .................................................................. 241

4.2.5 Removing the Carriage Mechanism ........................................................ 249

4.2.6 Removing the Paper Feed Mechanism .................................................... 266

4.2.7 Removing the Ink System Mechanism .................................................... 281

Chapter 5 Adjustment

5.1 Overview ................................................ ........................................ ... ............... 307

5.1.1 Precautions ............................................................................................... 307

5.1.2 Adjustment Workflow ....................................... ...................................... 307

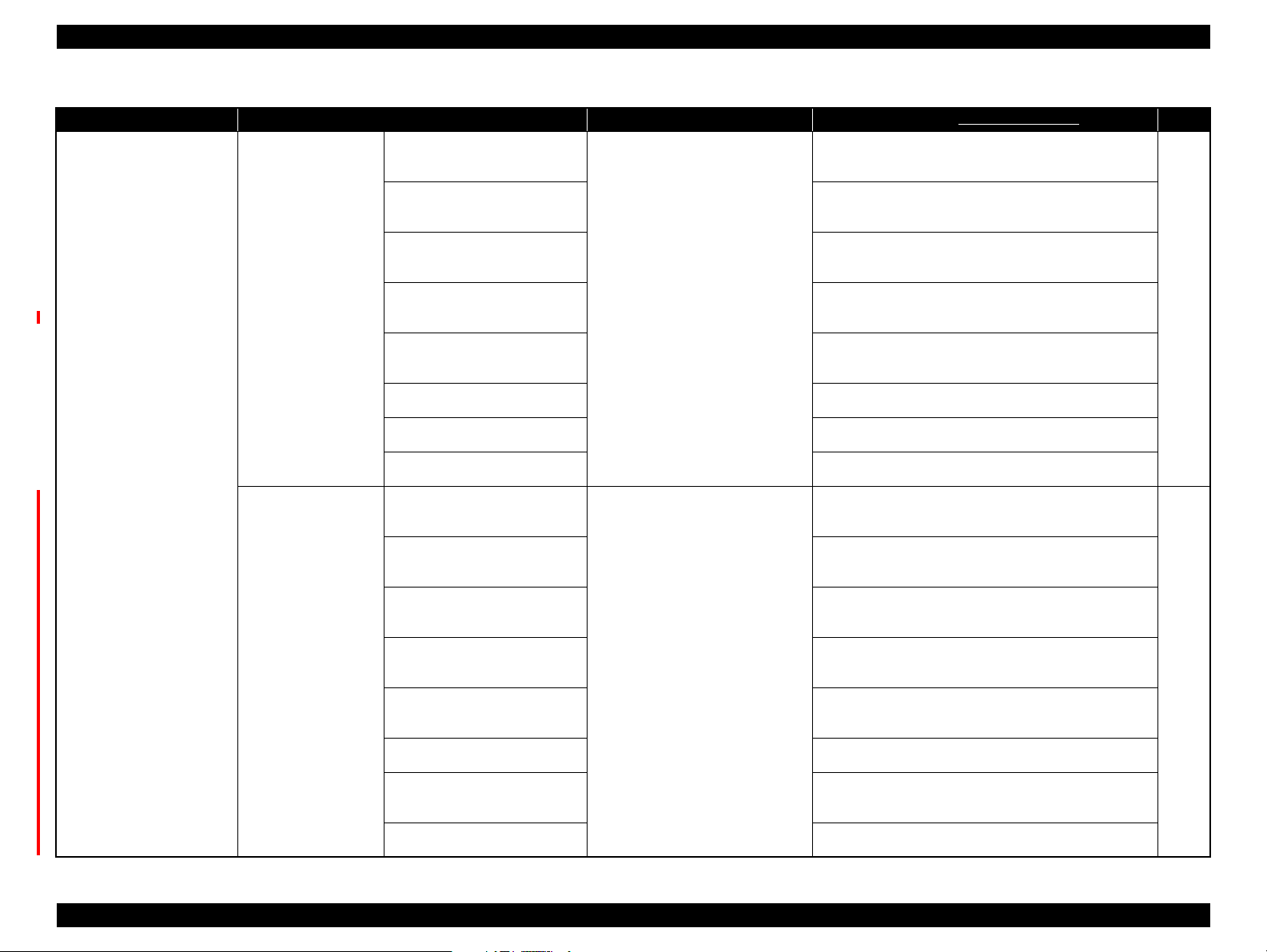

5.1.3 Parts and Units that Require Adjustments ............................................... 307

5.1.4 Required Adjustments by Part or Unit .................................................... 308

5.1.5 Description of Adjustments ..................................................................... 310

5.1.6 Tools for Adjustments ............................................................................. 313

5.1.7 Adjustment Program Basic Operations ......................................... .......... 314

5.2 Mechanical Adjustment .................................................................................... 315

5.2.1 Ink Mark Sensor Height Adjustment ....................................................... 315

5.2.2 Cutter Position/Height Adjustment ......................................................... 316

5.2.3 Paper Thickness Sensor Position Adjustment ......................................... 318

5.2.4 CR Timing Belt Tension Adjustment ...................................................... 320

5.2.5 PF Timing Belt Tension Adjustment ....................................................... 321

5.2.6 CR Encoder Sensor Adjustment .............................................................. 322

5.2.7 PF Encoder Sensor Adjustment ............................................................... 323

5.2.8 Air Leak Check ........................................................ ... ............................. 324

5.2.9 PG Adjustment .................................... .................................................... 327

5.3 Basic Adjustment ...................................... ....................................................... 331

5.3.1 RTC&USB ID&IEEE1394 ID ................................................................ 331

5.3.2 Head Rank ID ...................................... ....................................... ............. 332

5.3.3 Input Serial Number ................................................................................ 333

5.3.4 T&B&S (Roll Paper) ............................................................................... 334

5.3.5 T&B&S + 980mm Band Feed ................................................................. 336

5.3.6 Cutter Pressure Adjustment ........................................................ ............. 338

5.3.7 Nozzle Bi-D Adjustment ....................................................... .................. 339

5.3.8 Print Head Slant Adjustment (PF) ........................................................... 340

5.3.9 Print Head Slant Adjustment (CR) .......................................................... 343

5.3.10 Ink Mark Sensor Level Adjustment ....................................................... 346

5.3.11 Auto Uni-D Adjustment ........................................................................ 347

5.3.12 Auto Bi-D Adjustment (P.G. 0.8/1.6) .................................................... 348

5.3.13 Ink Mark Sensor Adjustment for Auto Nozzle Check .......................... 349

5.3.14 Skew Check ........................................................................................... 351

5.3.15 Platen Position Adjustment ................................................................... 352

5.3.16 980mm Band Feed Adjustment ............................................................. 354

5.3.17 Initial Ink Charge Flag ON/OFF ............................................ ............... 355

5.3.18 NVRAM Back Up and Write ................................................................ 356

5.3.19 Initial Ink Charge ................................................................................... 357

9

Page 10

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

5.3.20 Cleaning ................................................................................................. 357

5.3.21 Rear Sensor Adjustment ........................................................................ 358

5.3.22 Colorimetric Calibration (Color ID) ...................................................... 359

5.4 Advanced Adjustment ...................................................................................... 375

5.4.1 Auto Bi-D Adjustment ............................................................................. 375

5.4.2 Manual Bi-D Adjustment ........................................................................ 376

5.4.3 Destination Setting ................................................................................... 378

5.4.4 PF Micro Feed Adjustment (Bi-D) .......................................................... 379

5.5 Check Results ................................................................................................... 380

5.5.1 Check Nozzle ........................................................................................... 380

5.5.2 Check Alignment ..................................................................................... 381

5.5.3 Print Adjustment Check Pattern .............................................................. 382

5.5.4 Check Cutting .......................................................................................... 383

5.5.5 Print Image ............................................................................................... 384

5.6 Reset Counters .................................................................................................. 385

5.6.1 Reset PG Switching Counter ................................................................... 385

5.6.2 Reset PF Motor Counter .......................................................................... 385

5.6.3 Reset When CR Unit Change .................................................................. 386

5.6.4 Reset When Cleaning Unit Change ......................................................... 386

5.6.5 Reset When PrintHead Change ............................................................... 387

5.6.6 Reset When Cutter Solenoid Change ...................................................... 387

5.6.7 Reset Pump Counter ................................................................................ 388

5.6.8 Reset Ink Information .............................................................................. 388

5.7 Installing Firmware .......................................................................................... 389

5.8 Model Setting (when replacing the Main Board) ............................................. 390

5.9 Writing MAC Address ..................................................................................... 392

Chapter 6 Maintenance

6.1 Overview ................................................ ........................................ ... ............... 394

6.1.1 Product Life Information ......................................................................... 395

6.1.2 Required Maintenance Items ............................................................ ....... 396

6.2 Lubrication .............................................................. ......................................... 397

Chapter 7 Appendix

7.1 Connectors ............................................................... ... ...................................... 401

7.2 Exploded Diagrams ................................... ....................................................... 406

7.3 ASP List (Parts List) ......................................................................................... 462

7.3.1 ASP List for Stylus Pro 7400/7800 ................................. ........................ 462

7.3.2 ASP List for Stylus Pro 9400/9800 ................................. ........................ 465

7.3.3 ASP List for Stylus Pro 7450/7880/7880C .............................................. 469

7.3.4 ASP List for Stylus Pro 9450/9880/9880C .............................................. 472

10

Page 11

PRODUCT DESCRIPTION

CHAPTER

1

Page 12

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.1 Product Description

1.1.1 Features

Large sheet

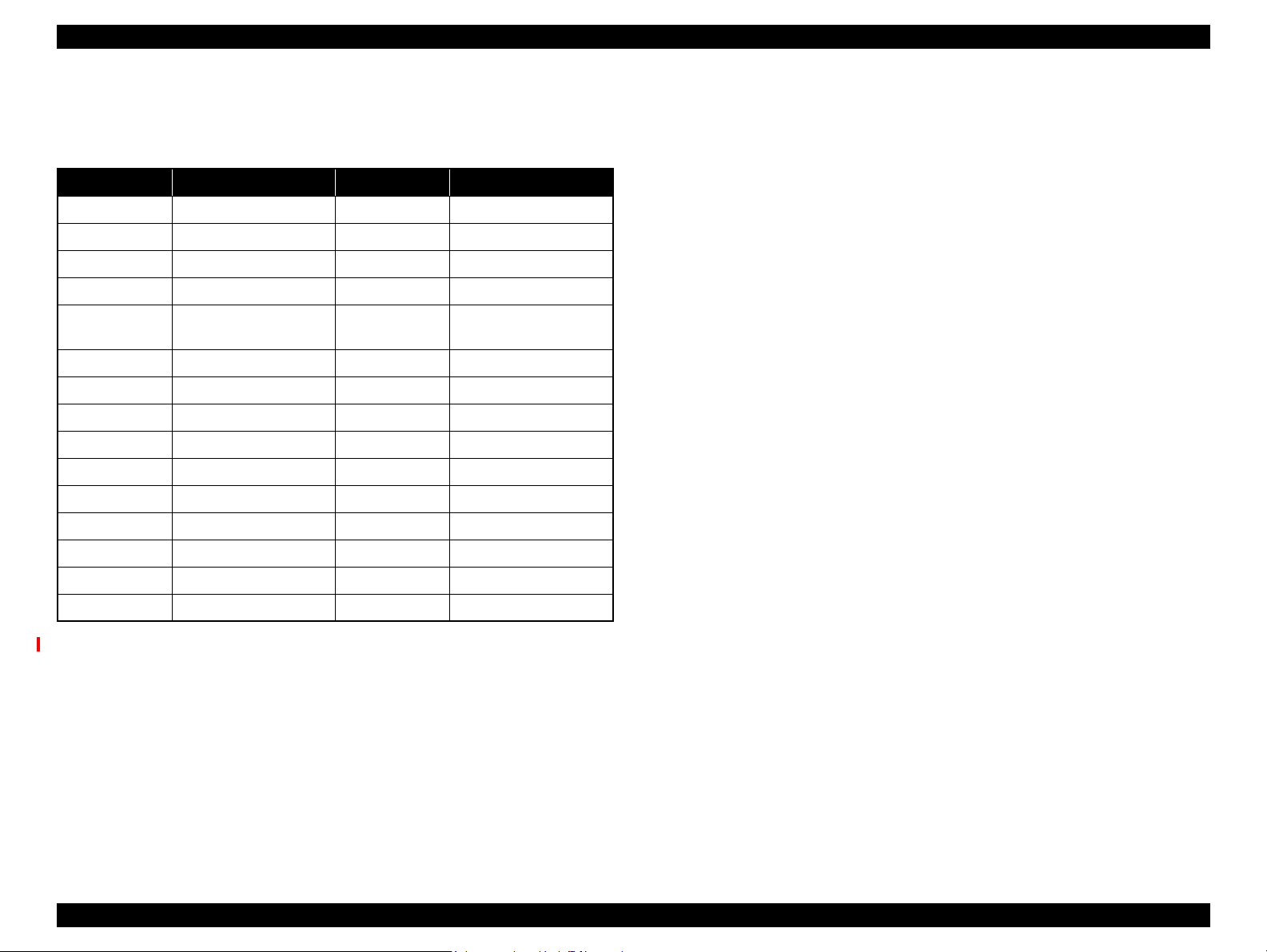

Table 1-1. Large sheet

Model name Large sheet

Stylus Pro 7400 610 mm (Approx. 24 inches), A1+ response

Stylus Pro 7450

Stylus Pro 7800

Stylus Pro 7880

Stylus Pro 7880C

Stylus Pro 9400 1118 mm (Approx. 44 inches), B0 + response

Stylus Pro 9450

Stylus Pro 9800

Stylus Pro 9880

Stylus Pro 9880C

Super-high definition

Super-high resolution of 2880 x 1440 dpi

Smallest droplet size: 3.5 picoliter

Variable droplet technology can produce multiple different sizes per print line

Low running cost

Independent ink cartridges for each color with large capacity of 110 ml

Optional ink cartridge with larger capacity of 220ml can be used

Media handling

Various types of media can be used

Built-in automatic cutting system and a manual media cutter

Accurate automatic loading of cut sheet media

Borderless printing (full-bleed print on all four sides) with roll paper

Up to 1.5 mm thick paper can be used

Compatibility with other large sheet printers

Upper compatibility with;

Stylus Pro 7400

Stylus Pro 7800

Stylus Pro 9400

Stylus Pro 9800

• Stylus Pro 4000

• Stylus Pro 7000

• Stylus Pro 9000

• Stylus Pro 10000

• Stylus Pro 4400

• Stylus Pro 7500

• Stylus Pro 9500

• Stylus Pro 10600

• Stylus Pro 4800

• Stylus Pro 7600

• Stylus Pro 9600

Stylus Pro 7450

Stylus Pro 7880

Stylus Pro 7880C

Stylus Pro 9450

Stylus Pro 9880

Stylus Pro 9880C

• Stylus Pro 4000

• Stylus Pro 7000

• Stylus Pro 7600

• Stylus Pro 9400

• Stylus Pro 9800

• Stylus Pro 4400

• Stylus Pro 7400

• Stylus Pro 7800

• Stylus Pro 9500

• Stylus Pro 10000

• Stylus Pro 4800

• Stylus Pro 7500

• Stylus Pro 9000

• Stylus Pro 9600

• Stylus Pro 10600

The latest RIP

Genuine: NorthFlight Plus ver. 3

Others: Stylus Rip Profeshinal 3

Product Description Product Description 12

Page 13

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

High-speed throughput

Stylus Pro 7400/7800/9400/9800:

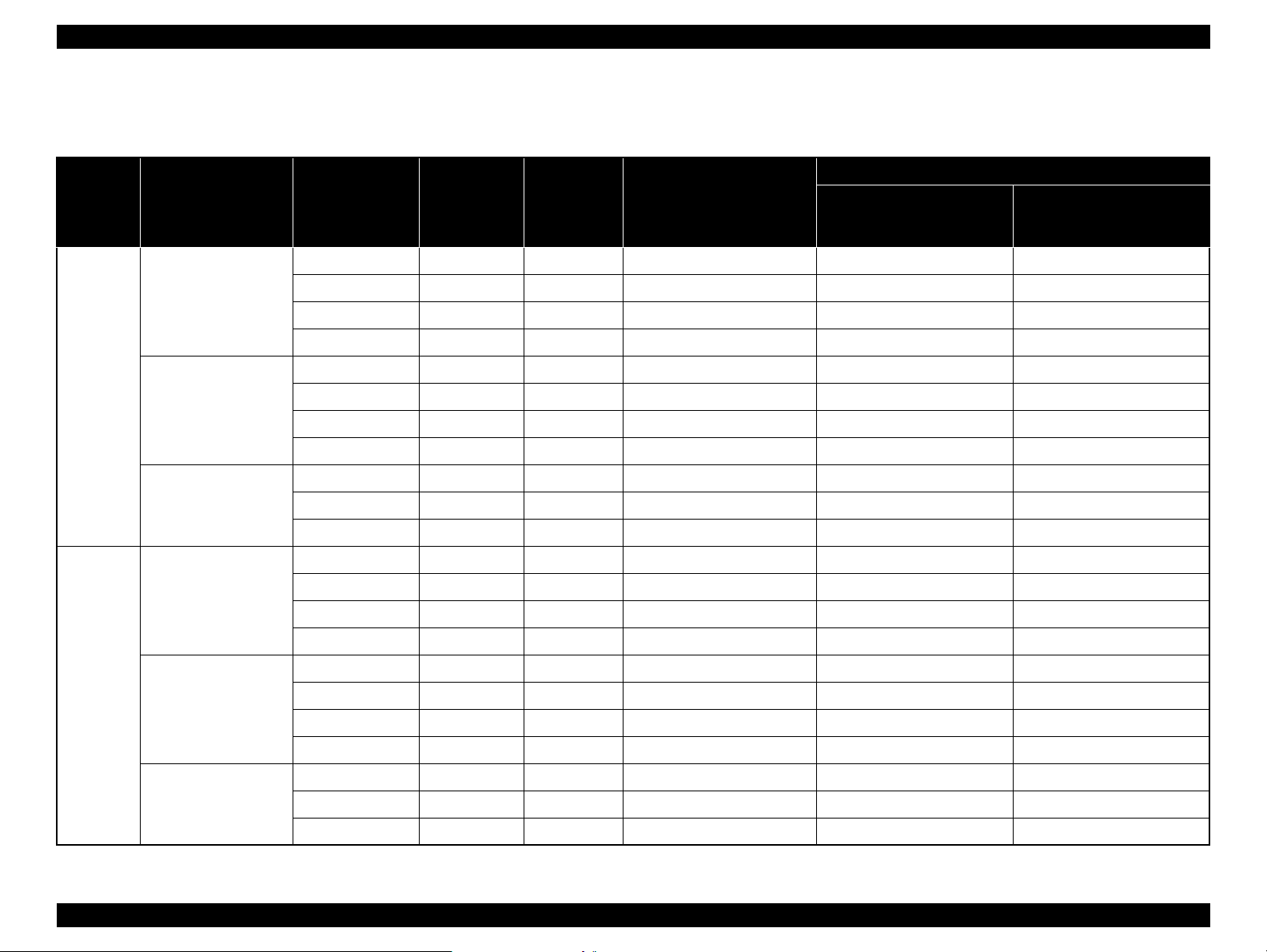

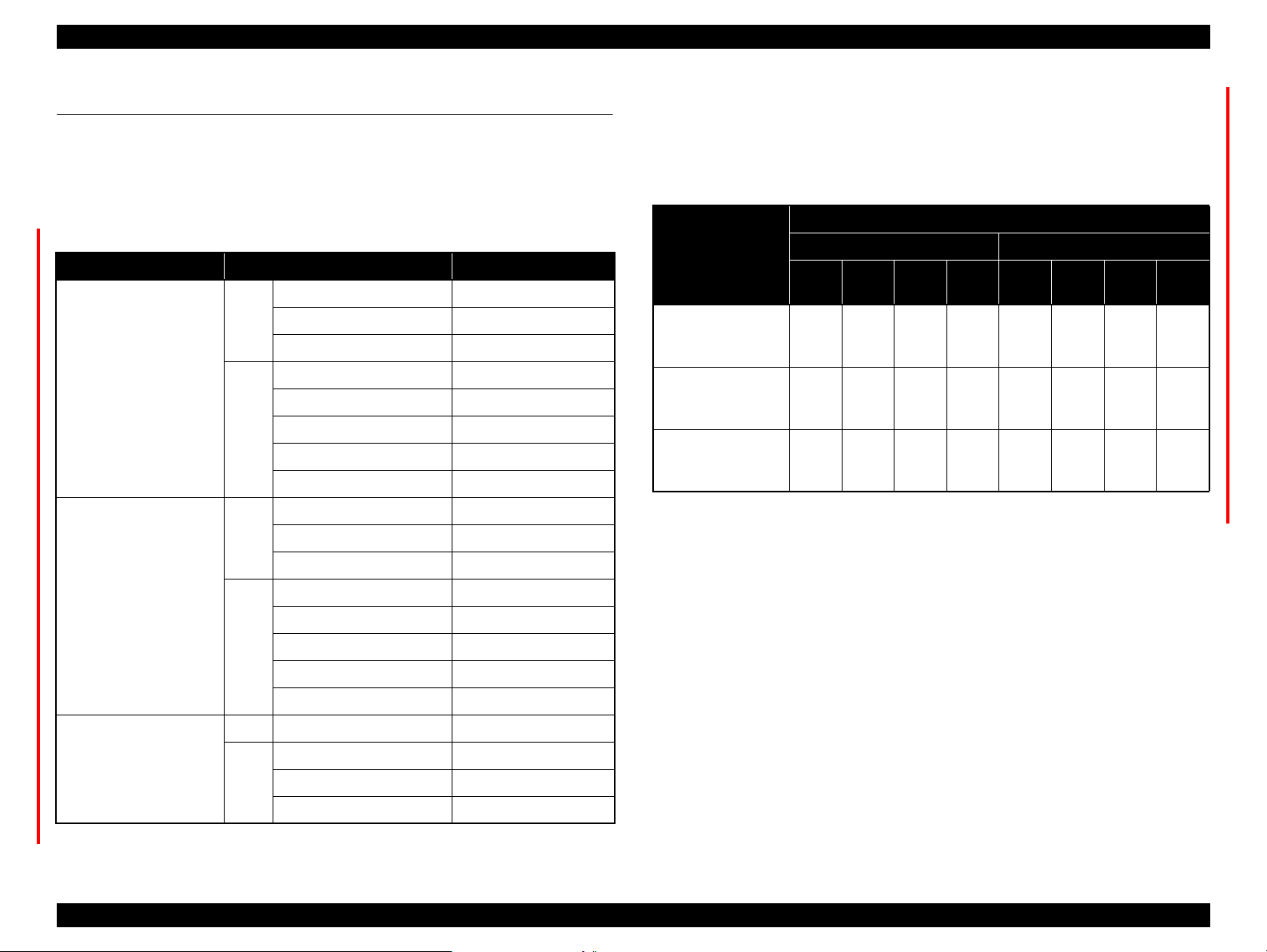

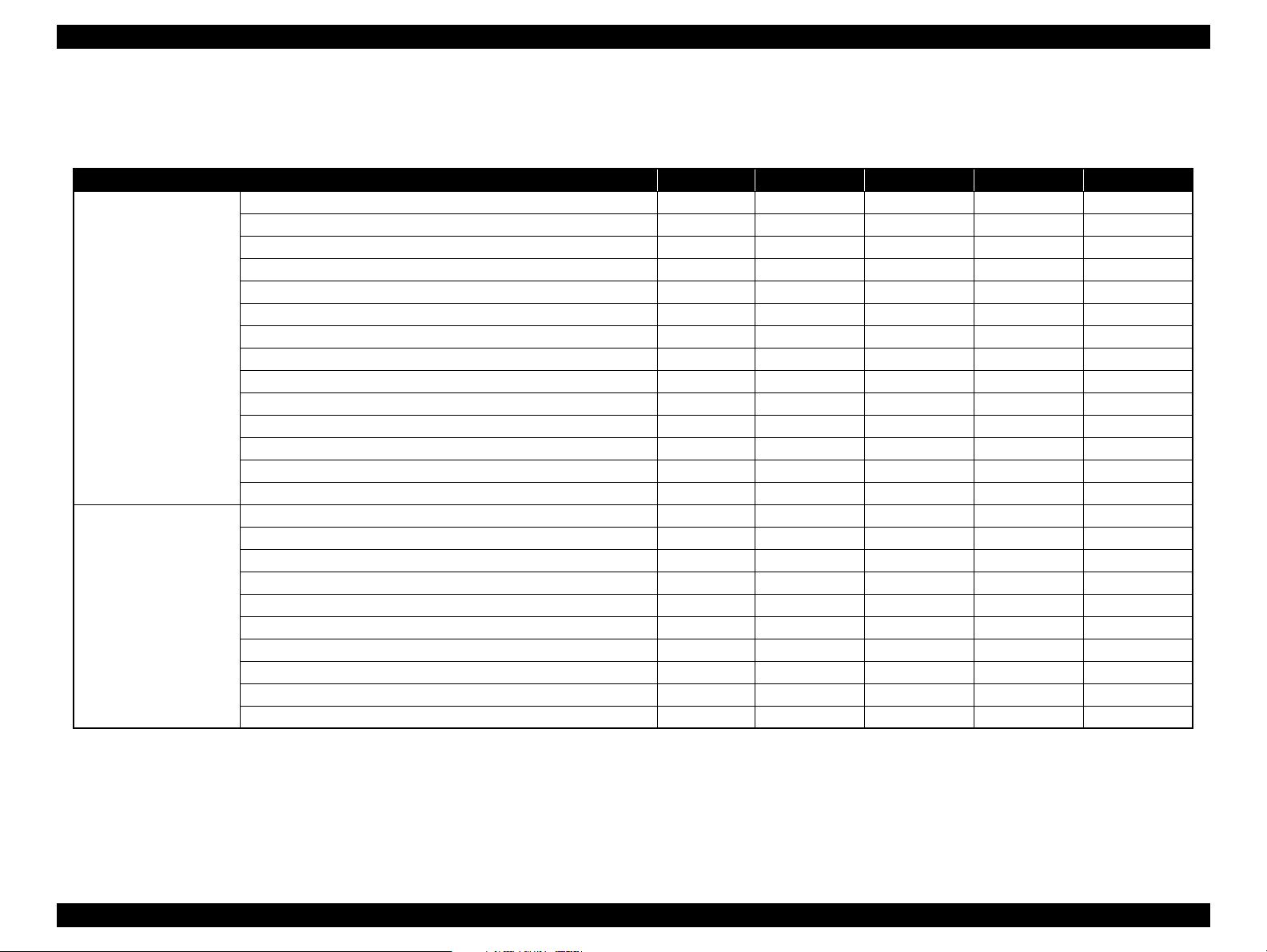

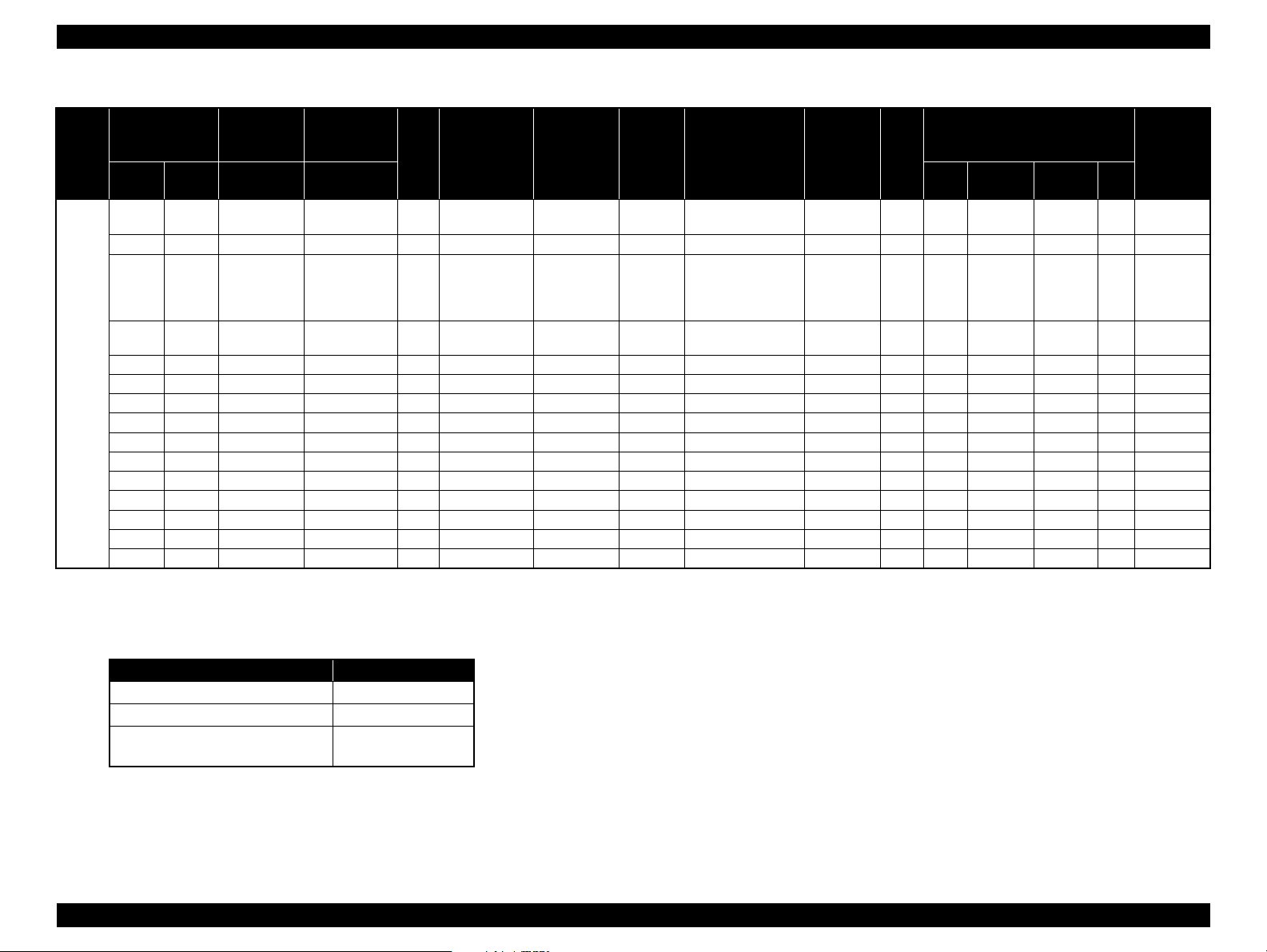

Table 1-2. Throughput

Throughput

Ink type Paper Image quality Dot Size

Pigment

8 color

Plain paper Economy VSD1 360 x 360 Bi-D MF 320CPS 2.2 Minutes 5.1 Minutes

Fast VSD1 360 x 360 Bi-D FD 320CPS 4.2 Minutes 10.9 Minutes

Quality VSD2 720 x 360 Bi-D MW 240CPS 5.0 Minutes 13.6 Minutes

High quality VSD3 720 x 720 Bi-D FOL 240CPS 9.9 Minutes 29.0 Minutes

Matte paper Fast VSD1 720 x 360 Bi-D FOL 320CPS 4.2 Minutes 10.9 Minutes

Quality VSD2 720 x 720 Bi-D FOL 240CPS 9.9 Minutes 29.0 Minutes

High quality VSD3 1,440 x 720 Bi-D FD4 pass 240CPS 14.3 Minutes 42.5 Minutes

Super fine detail VSD3 1,440 x 720 Bi-D FD8 pass 240CPS 25.7 Minutes 78.1 Minutes

Glossy photo paper,

FA paper

Quality VSD2 720 x 720 Bi-D FOL 240CPS 9.9 Minutes 29.0 Minutes

High quality 1440 VSD3 1,440 x 720 Bi-D FD4 pass 240CPS 14.3 Minutes 42.5 Minutes

Resolution

(dpi)

Mode

Stylus Pro 7800 /

Stylus Pro 7400

(Time for printing on A1 cut sheet)

Stylus Pro 9800 /

Stylus Pro 9400

(Time for printing on B0 cut sheet)

High quality 2880 VSD3_HR 2,880 x 1,440 Bi-D 4 pass 240CPS 26.9 Minutes 81.7 Minutes

Pigment

4 color

Plain paper Economy VSD1 360 x 360 Uni-D band 320CPS 1.8 Minutes 4.3 Minutes

Fast VSD1 360 x 360 Bi-D MW 320CPS 2.7 Minutes 6.6 Minutes

Quality VSD2 720 x 360 Bi-D FOL 240CPS 3.2 Minutes 8.3 Minutes

High quality VSD3 720 x 720 Bi-D FOL 240CPS 6.4 Minutes 18.5 Minutes

Matte paper Fast VSD1 360 x 720 Bi-D FD 320CPS 3.9 Minutes 10.4 Minutes

Quality VSD2 720 x 720 Bi-D FOL 240CPS 6.4 Minutes 18.5 Minutes

High quality VSD3 1,440 x 720 Bi-D FD4 pass 240CPS 9.4 Minutes 27.7 Minutes

Super fine detail VSD3 1,440 x 720 Bi-D FD8 pass 240CPS 13.1 Minutes 39.0 Minutes

Glossy photo paper,

FA paper

Quality VSD2 720 x 720 Bi-D FOL 240CPS 6.4 Minutes 18.5 Minutes

High quality VSD3 1,440 x 720 Bi-D FD4 pass 240CPS 9.4 Minutes 27.7 Minutes

Super fine detail VSD3 1,440 x 720 Bi-D FD8 pass 240CPS 13.1 Minutes 39.0 Minutes

Product Description Product Description 13

Page 14

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

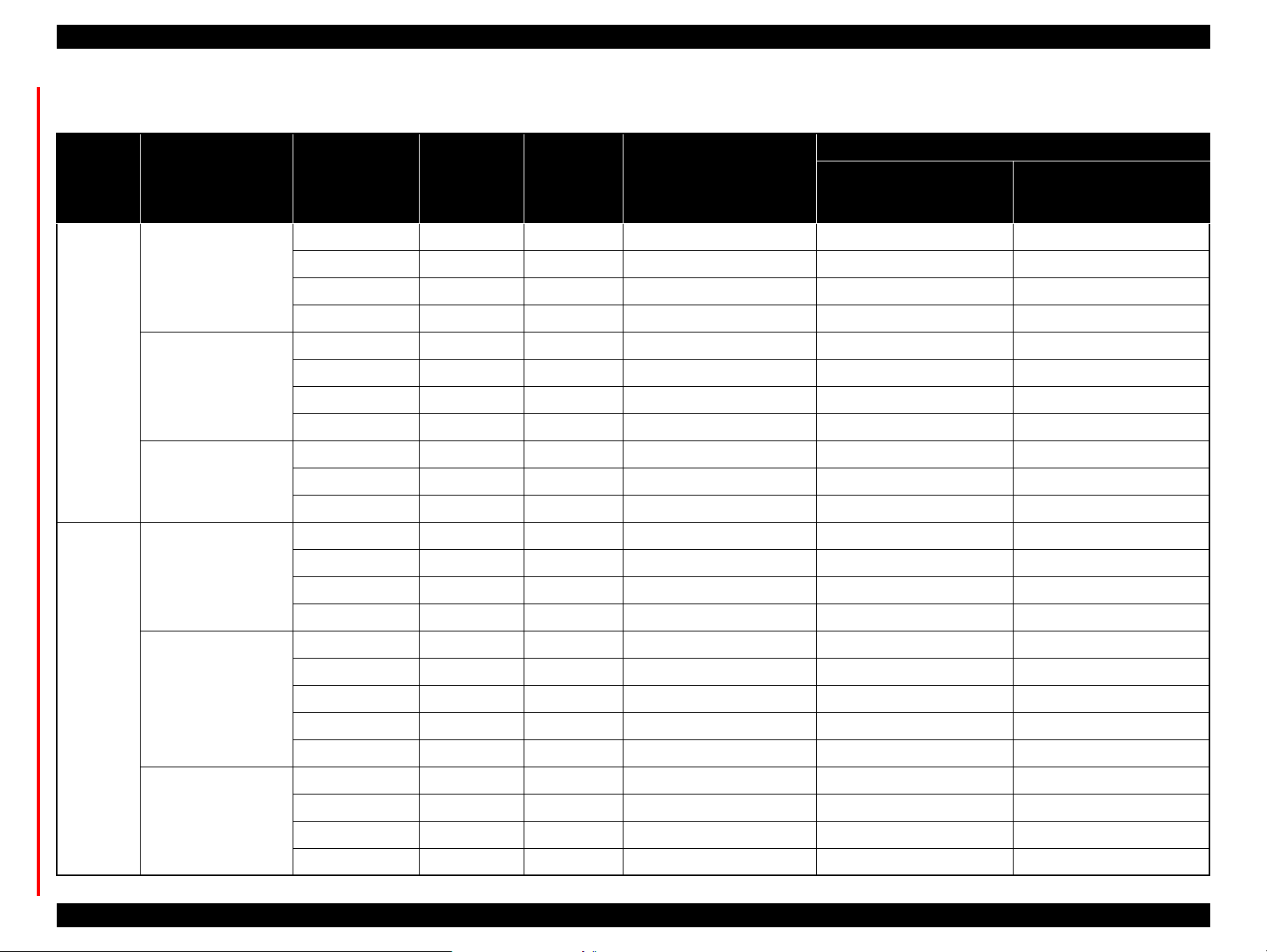

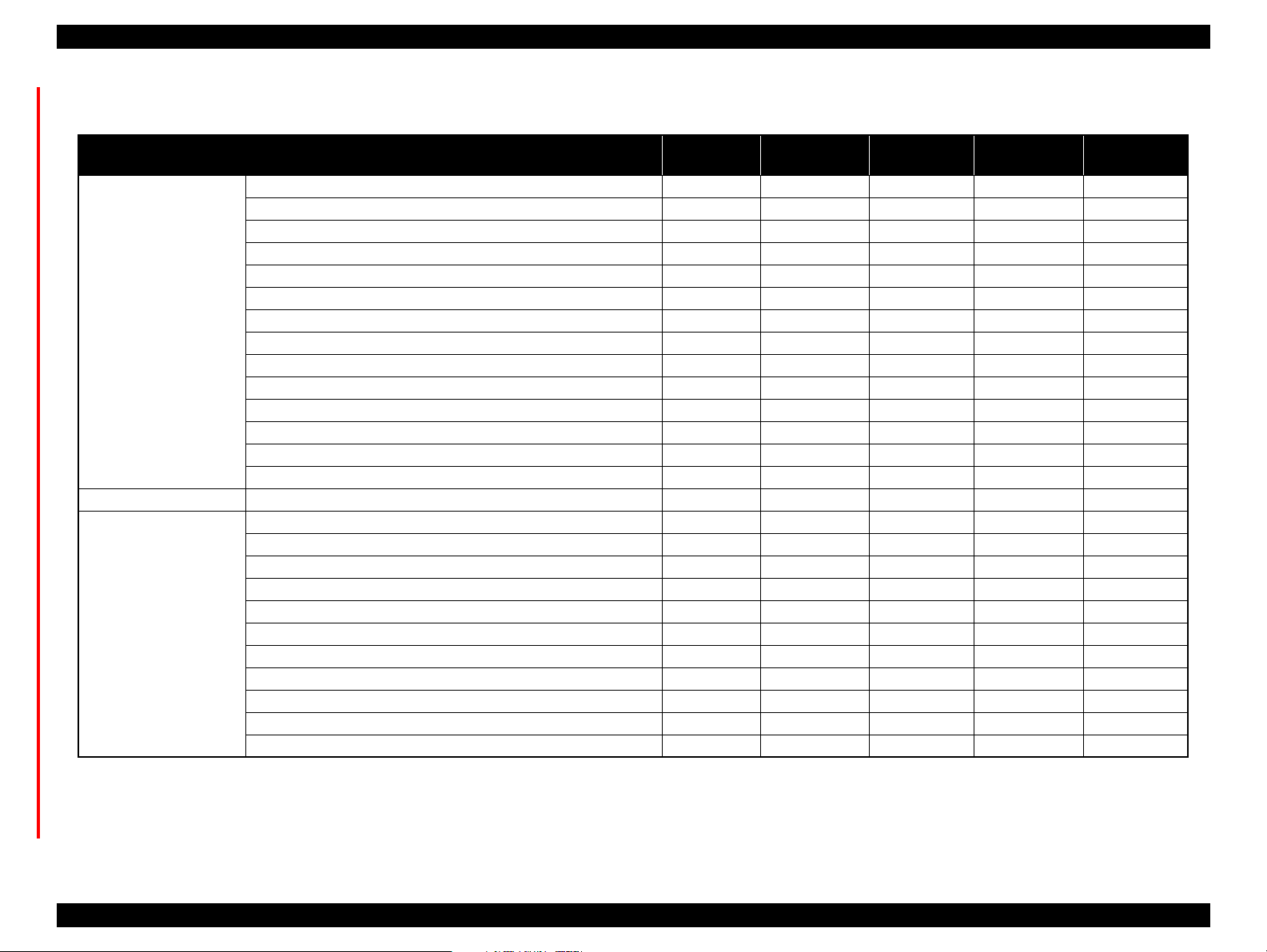

Stylus Pro 7450/7880/7880C/9450/9880/9880C:

Table 1-3. Throughput

Throughput

Ink type Paper Image quality Dot Size

Pigment

8 color

Plain paper Economy VSD1 360 x 360 Bi-D MF 320CPS 2.0 Minutes 4.6 Minutes

Fast VSD1 360 x 360 Bi-D FD 320CPS 3.8 Minutes 9.7 Minutes

Quality VSD2 720 x 360 Bi-D MW 240CPS 4.5 Minutes 12.1 Minutes

High quality VSD3 720 x 720 Bi-D FOL 240CPS 8.9 Minutes 25.7 Minutes

Matte paper Fast VSD1 720 x 360 Bi-D FOL 320CPS 3.8 Minutes 9.7 Minutes

Quality VSD2 720 x 720 Bi-D FOL 240CPS 8.9 Minutes 25.7 Minutes

High quality 1440 VSD3 1,440 x 720 Bi-D FD4 pass 240CPS 12.9 Minutes 38.0 Minutes

High quality 2880 VSD3_HR 2,880 x 1,440 Bi-D FD8 pass 240CPS 24.5 Minutes 73.6 Minutes

Glossy photo paper,

FA paper

Quality VSD2 720 x 720 Bi-D FOL 240CPS 8.9 Minutes 25.7 Minutes

High quality 1440 VSD3 1,440 x 720 Bi-D FD4 pass 240CPS 12.9 Minutes 38.0 Minutes

Resolution

(dpi)

Mode

Stylus Pro 7400/7450/7800/

7880/7880C

(Time for printing on A1 cut sheet)

Stylus Pro 9400/9450/9800/

9880/9880C

(Time for printing on B0 cut sheet)

High quality 2880 VSD3_HR 2,880 x 1,440 Bi-D 4 pass 240CPS 24.5 Minutes 73.6 Minutes

Pigment

4 color

Plain paper Economy VSD1 360 x 360 Uni-D band 320CPS 1.7 Minutes 4.0 Minutes

Fast VSD1 360 x 360 Bi-D MW 320CPS 2.0 Minutes 4.6 Minutes

Quality VSD2 720 x 360 Bi-D FOL 240CPS 3.8 Minutes 9.9 Minutes

High quality VSD3 720 x 720 Bi-D FOL 240CPS 6.1 Minutes 17.1 Minutes

Matte paper 1 (Fast) VSD1 360 x 720 Bi-D FD 320CPS 3.2 Minutes 8.0 Minutes

2 (POP Print) VSD2 720 x 720 Bi-D FOL 1POL 240CPS 4.5 Minutes 12.2 Minutes

3 (Quality) VSD2 720 x 720 Bi-D FOL 3POL 240CPS 6.1 Minutes 17.1 Minutes

4 ( - ) VSD3 1,440 x 720 Bi-D 4 pass 1POL240CPS 7.2 Minutes 20.6 Minutes

5 (High quality) VSD3 1,440 x 720 Bi-D 4 pass 3POL240CPS 8.7 Minutes 25.1 Minutes

Glossy photo paper,

FA paper

1 (POP Print) VSD2 720 x 720 Uni-D FOL 1POL 240CPS 6.5 Minutes 19.2 Minutes

2 (Quality) VSD2 720 x 720 Uni-D FOL 3POL 240CPS 9.2 Minutes 27.5 Minutes

3 ( - ) VSD3 1,440 x 720 Uni-D 4 pass 1POL240CPS 11.1 Minutes 33.5 Minutes

4 (High quality) VSD3 1,440 x 720 Uni-D 4 pass 3POL240CPS 13.6 Minutes 41.4 Minutes

Product Description Product Description 14

Page 15

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

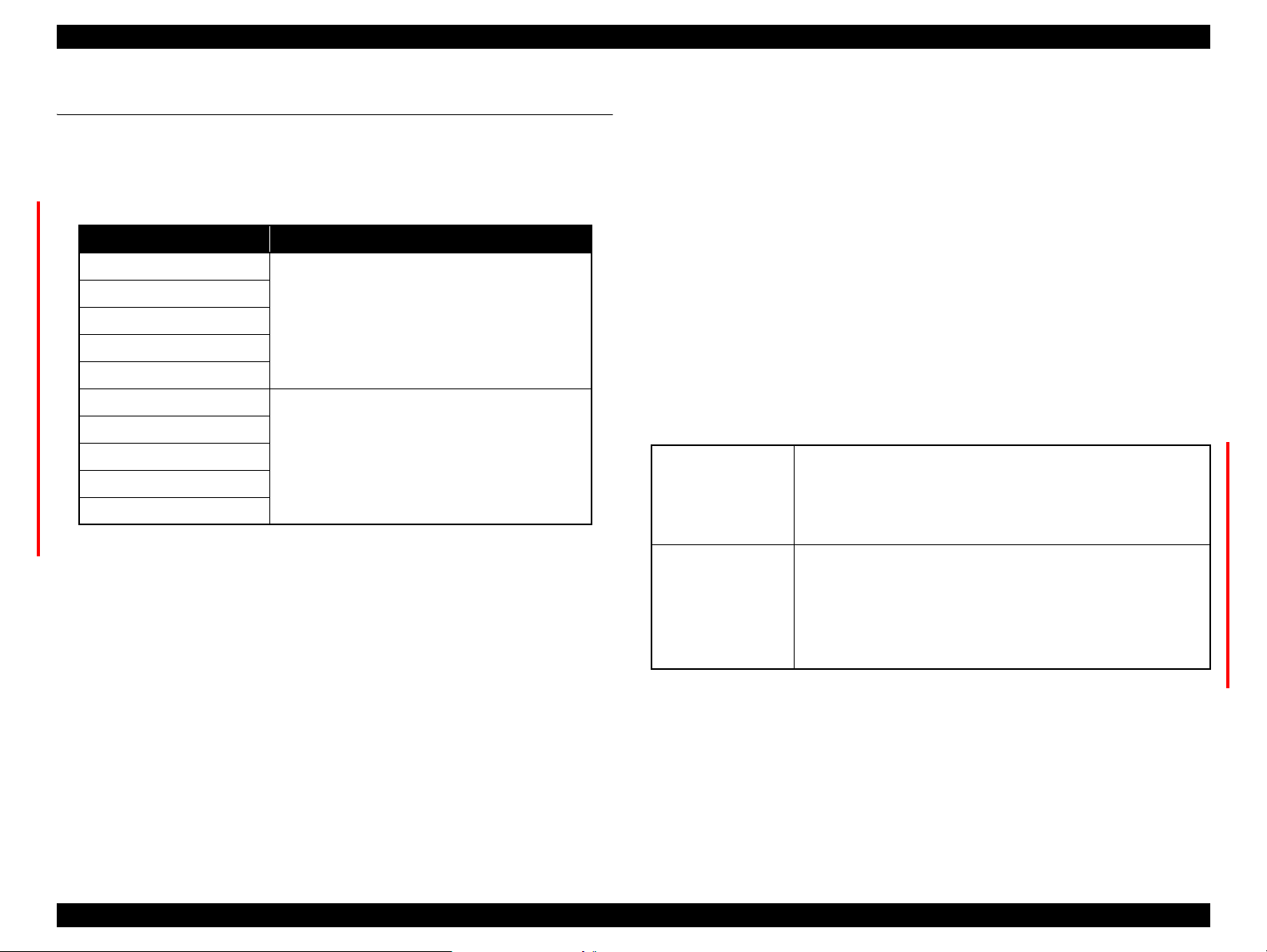

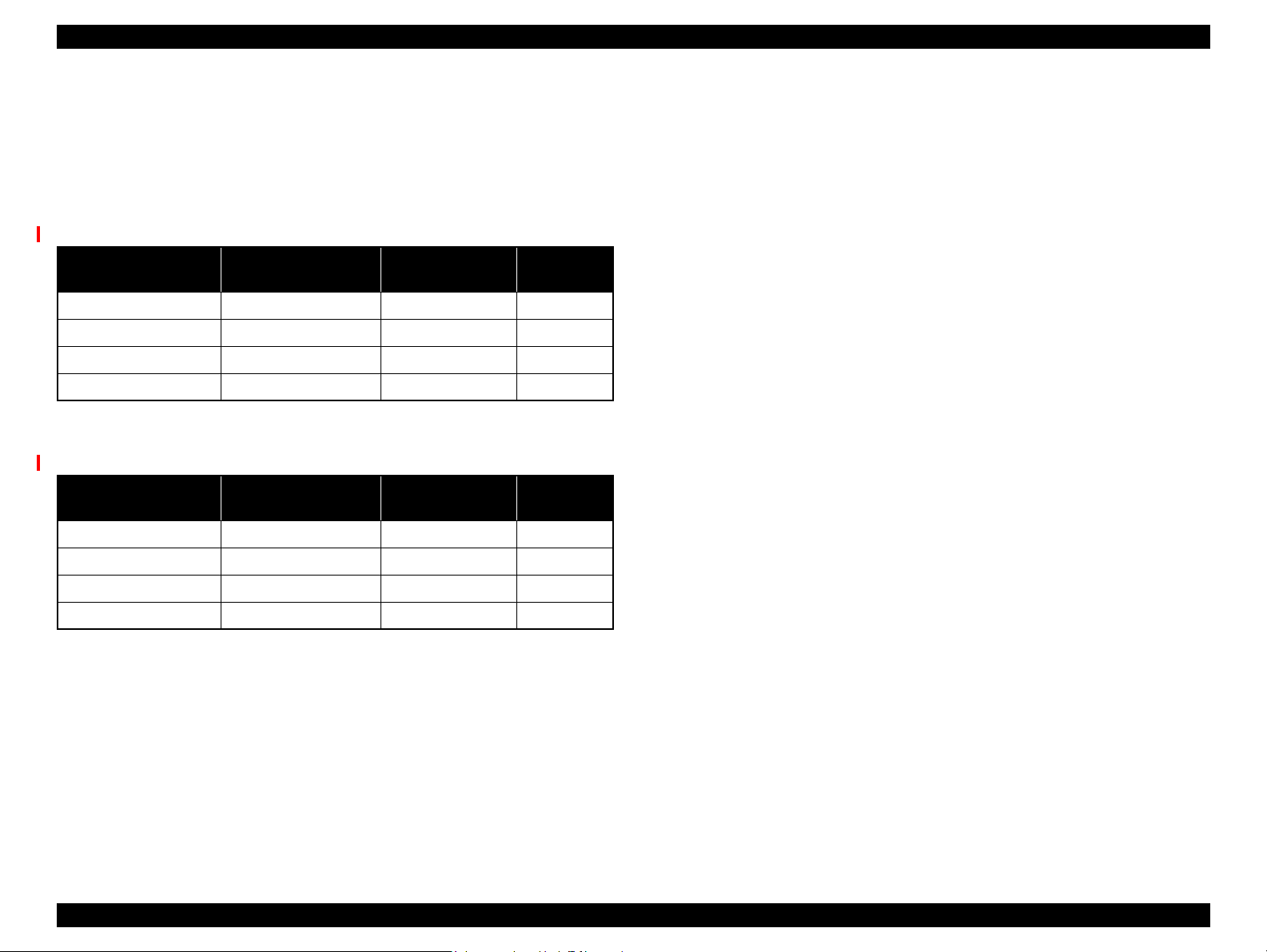

1.1.2 Difference between 8 color and 4 color machines

Item

Stylus Pro 7800/7880/7880C/9800/9880/9880C Stylus Pro 7400/7450/9400/9450

8 color machine 4 color machine

Ink configuration LLk, Lm, Lc, Lk, Pk (Mk), C, M, Y Mk, M, C, Y

Ink Type

PX-P/K3 ink

with following improvements:

Consistent gray balance

Accurate color control

Minimized metamerism

Extremely fine blends and photographic

PX-Pink

Rick color reproduction

Extremely wide color gamut

Lightfastness and ozone-proof has

improved

transitions

The maximum density level is raised

Glossiness has improved

Product Description Product Description 15

Page 16

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2 Basic Specifications

1.2.1 Print Specifications

Print method: On-demand Ink Jet Method

Nozzle configuration:

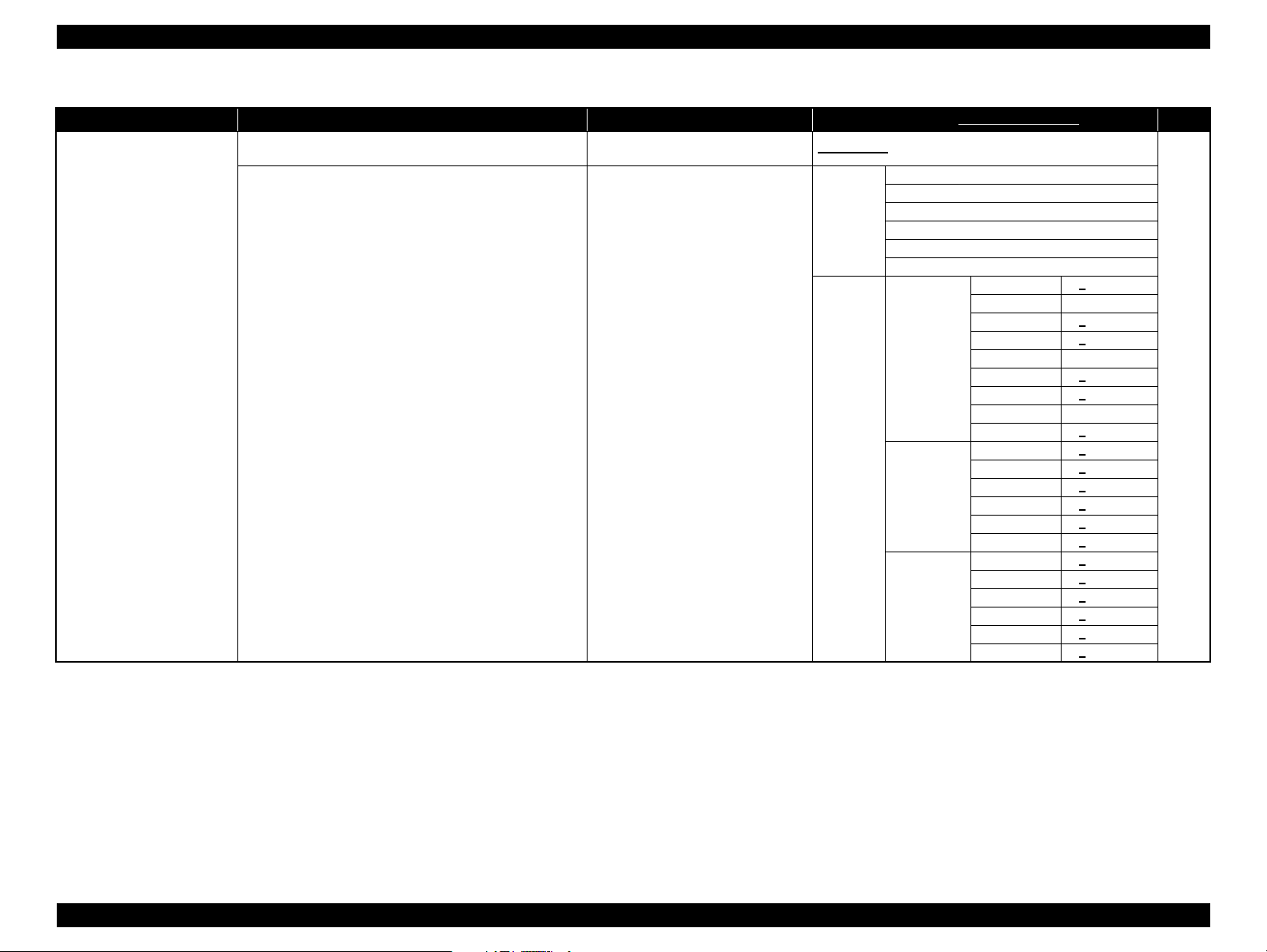

Table 1-4. Nozzle Configuration

Mode Ink Number of Nozzles

8 color machine

(Stylus Pro 7800/9800)

8 color machine

(Stylus Pro 7880/7880C/

9880/9880C)

4 color machine

(Stylus Pro 7400/7450/

9400/9450)

Note "*": Photo Black and Matte Black can be changed by the user.

Black Photo Black / Matte Black * 180

Light Light Black 180

Light Black 180

Color Cyan 180

Magenta 180

Light Cyan 180

Light Magenta 180

Yellow 180

Black Photo Black / Matte Black * 180

Light Light Black 180

Light Black 180

Color Cyan 180

Vivid Magenta 180

Light Cyan 180

Vivid Light Magenta 180

Yellow 180

Black Matte Black 360 (180 x 2)

Color Cyan 360 (180 x 2)

Magenta 360 (180 x 2)

Yellow 360 (180 x 2)

Ink configuration

As for 4-color models, two each ink cartridges are installed for every color.

As for 8-color models, the standard of black is Photo Black. Matt Black is

optional and user-replaceable.

Table 1-5. Ink Configuration

Ink Cartridge

Mode

8 Color mode

(Stylus Pro 7800/

9800)

8 Color mode

(Stylus Pro 7880/

7880C/9880/9880C)

4 Color mode

(Stylus Pro 7400/

7450/9400/9450)

1st

column

LLk Lm Lc Lk Pk / Mk C M Y

LLk VLm Lc Lk Pk / Mk C VM Y

MK MK M M C C Y Y

Left Slot Right Slot

2nd

column

3rd

column

4th

column

5th

column

6th

column

7th

column

Print direction:

Bidirectional with logic seeking (high speed return and high speed skip only)

Resolution:

Maximum 2880 x 1440 dpi

Control code

ESC/P Raster Photographic Driver

Paper feed method:

Friction feed (roll and cut sheet)

Line spacing:

1/6 inch (default). Programmable in 1/1440-inch increments

Paper path:

Roll paper or cut sheets with manual insertion

Paper feed speed:

245 ± 10 milliseconds per 1/4-inch line

8th

column

Nozzle pitch: 0.141mm (1/180 inch) for each color

Product Description Basic Specifications 16

Page 17

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Printing speed

Text print mode

• Maximum 320 CPS (characters per second)

(1 CPS = 2.54 mm/s)

• Maximum 10 CPI (characters per inch)

Graphic print mode

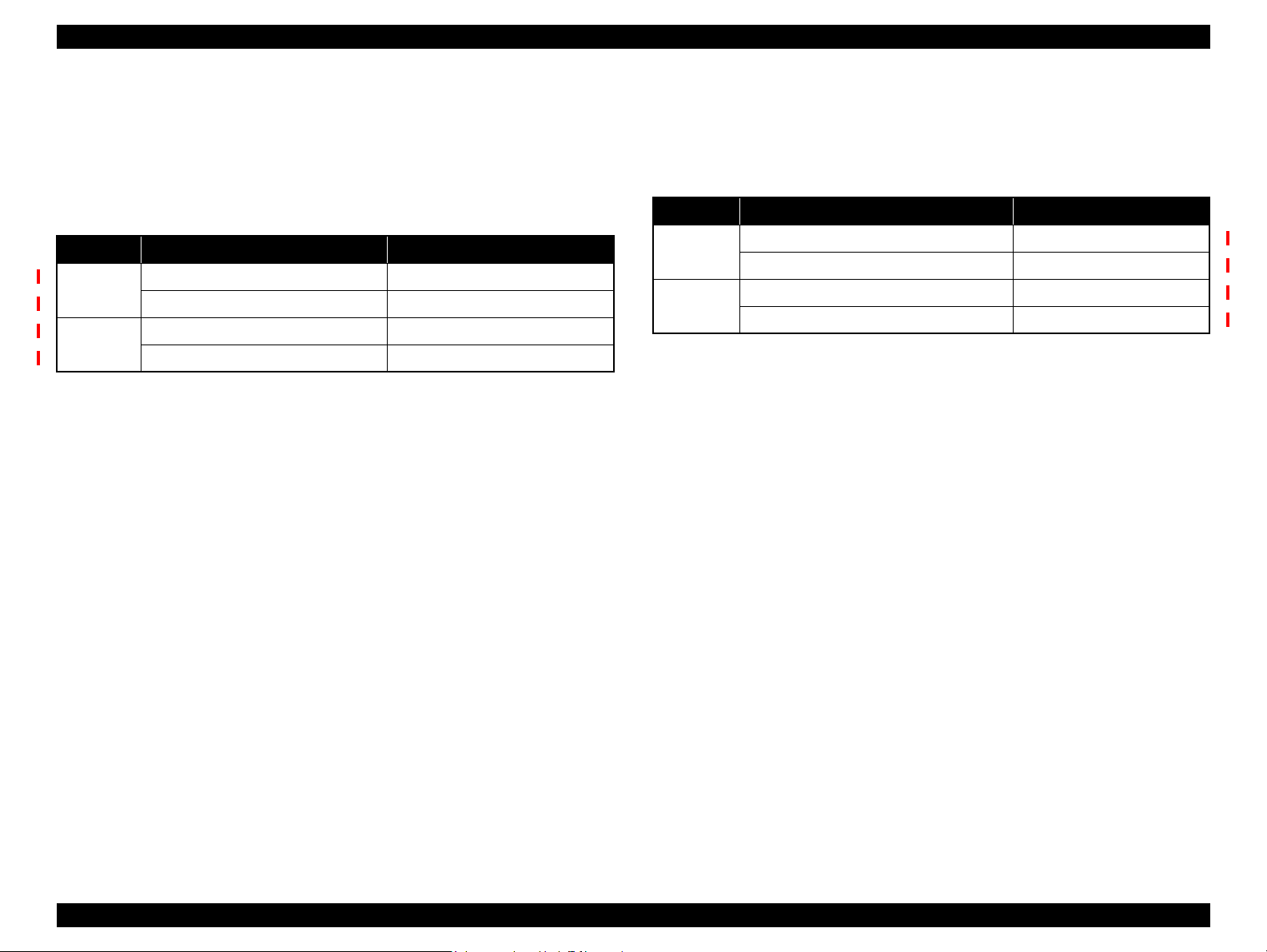

Table 1-6. Graphics Modes (Stylus Pro 7400/7450/7800/7880/7880C)

Horizontal Definition

(dpi)

360 617.6mm (24.31inch) 8,753 320cps

720 617.6mm (24.31inch) 17,506 240cps

1440 617.6mm (24.31inch) 35,013 210cps

2880 617.6mm (24.31inch) 70,027 210cps

Note : The printing ranges shown in the table include max. 8mm (bleeding width for printing

off both left and right edges)

Printing range

Table 1-7. Graphics Modes (Stylus Pro 9400/9450/9800/9880/9880C)

Horizontal Definition

(dpi)

360 1125.6mm (44.31inch) 15,953 320cps

Printing range

Printable number of

dots

Printable number of

dots

Printing

speed

Printing

speed

1.2.2 Character Specifications

Character code:

Alphanumeric characters extension graphics (PC437)

Multilingual (PC850)

Typeface:

EPSON original typeface

Alphanumeric characters Courier

1.2.3 Operability Specifications

Initialize time when power supply is switch ed ON:

Within 60 seconds (Excluding TLC etc Wait Time)

Initial charging time:

Less than 9 minutes 30 seconds

(* Time from lowering the lever to completion of initial charging)

720 1125.6mm (44.31inch) 31,906 240cps

1440 1125.6mm (44.31inch) 63,813 210cps

2880 1125.6mm (44.31inch) 127,627 210cps

Note : The printing ranges shown in the table include max. 8mm (bleeding width for printing

off both left and right edges)

Product Description Basic Specifications 17

Page 18

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.4 Paper Specifications

1.2.4.1 Roll Paper

The allowable roll paper dimensions are shown in the table below.

Paper size *:

Table 1-8. Roll Paper Sizes

Core Model Paper size

2-inch core Stylus Pro 7400/7450/7800/7880/7880C 203mm~610mm (W) x ~45m (H)

Stylus Pro 9400/9450/9800/9880/9880C 203mm~1,118mm (W) x ~45m (H)

3-inch core Stylus Pro 7400/7450/7800/7880/7880C 203mm~610mm (W) x ~220m (H)

Stylus Pro 9400/9450/9800/9880/9880C 203mm~1,118mm (W) x ~220m (H)

Note : The core sizes are their interior diameters.

Note "*": Auto nozzle check cannot be carried out on paper with a width less than 210mm.

Roll paper size:

2 Inch core: Outer diameter within 103mm/

1 roll set possible

3 Inch core: Outer diameter within 150mm/

1 roll set possible

Paper thickness:

Special paper: 3.15 to 19.67 mi l (0.08 to 0.50 mm)

Plain paper: 3.15 to 4.33 mil (0.08 to 0.11 mm)

Paper basis mass:

Special paper: 64 to 260 gf/m

Plain paper: 64 to 90 gf/m

2

2

1.2.4.2 Cut Sheet

The allowable cut sheet paper dimensions are shown in the table below.

Paper size *:

Table 1-9. Cut Sheet Sizes

Core Model Paper size

Paper width Stylus Pro 7400/7450/7800/7880/7880C 203mm~610mm

Stylus Pro 9400/9450/9800/9880/9880C 203mm~1,118mm

Paper length Stylus Pro 7400/7450/7800/7880/7880C 279mm~1,580mm

Stylus Pro 9400/9450/9800/9880/9880C 279mm~1,580mm

Note "*": Auto nozzle check cannot be carried out on paper with a width less than 210mm.

Paper thickness:

Paper length more than 279 mm up to 728 mm:

3.15 to 59 mil (0.08 to 1.50 mm)

Paper length exceeding 728 mm up to 1580 mm:

3.15 to 19.67 mil (0.08 to 0.50 mm)

Plain paper: 3.15 to 4.33 mil (0.08 to 0.11 mm)

Paper basis mass:

Special paper: 64 to 260 gf/m

Plain paper: 64 to 90 gf/m

NOTE • Basically, portrait printing only.

• Do not use curled, folded, or deckle-edge paper.

• For best resul t, use paper under the followi ng conditions:

Temperature: 59 to 77 ºF (15 to 25 ºC)

Humidity: 40 to 60 % RH

2

2

NOTE • Do not use curled, folded, or deckle-edge paper.

• Be sure to use the Type 3 adapter included in the package when using the 3-

inch core roll paper.

• For best result, use paper under the following conditions:

Temperature: 59 to 77 ºF (15 to 25 ºC)

Humidity: 40 to 60 % RH

Product Description Basic Specifications 18

Page 19

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.4.3 Selectable Paper Size

The following paper sizes can be selected in the driver for Roll paper/cut sheet. *

Table 1-10. Selectable Paper Size

Paper Size Size (W x H) Paper Size Size (W x H)

Letter 8 1/2 x 11 in B4 257 x 364 mm

US B 11 x 17 in 11 x 17 in B3 364 x 514 mm

US B 17 x 24 in 17 x 24 in B2 515mm x 728mm

US C 17 x 22 in 17 x 22 in B1 728 mm x 1,030 mm

US D 22 x 34 in 22 x 34 in B1 (Landscape)

US E 34 x 44 in 34 x 44 in B0 1,030 mm x 1,456 mm

A4 210 x 297 mm Super B0 1,118 mm x 1,580 mm

A3 297 x 420 mm 30 x 24 in 30 x 24 in

Super A3 / B 329 x 483 mm 3.5 x 4.5 in*

A2 420 x 59 4mm 8 x 10 in 8 x 10 in

A1 594 x 841 mm 11 x 14 in 11 x 14 in

Super A1 24 x 36 in 16 x 20 in 16 x 20 in

A0 841 mm x 1,189 mm 60 x 90 cm 60 x 90 cm

2

*

728 mm x 1,030 mm

3

3.5 x 4.5 in

1

Super A0 914 mm x 1,292 mm 40 x 60 cm 40 x 60 cm

B5 182 x 257 mm 30 x 40 cm 30 x 40 cm

Note : The sizes in bold type are for the Stylus Pro 9400/9450/9800/9880/9880C.

Note "*1": Basically, load cut sheet on the printer in portrait orientatio n. And the paper grain

direction should run vertically for best result.

"*2": When using media other than paper loading it in landscape orientation, the allowable

media thickness is 3.15 to 59 mil (0.08 to 1.5 mm).

"*3": The printer does not support this sized media. Note that the sizes given in the table

are printable area sizes, not media sizes.

Product Description Basic Specifications 19

Page 20

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.5 Mechanism Specifications

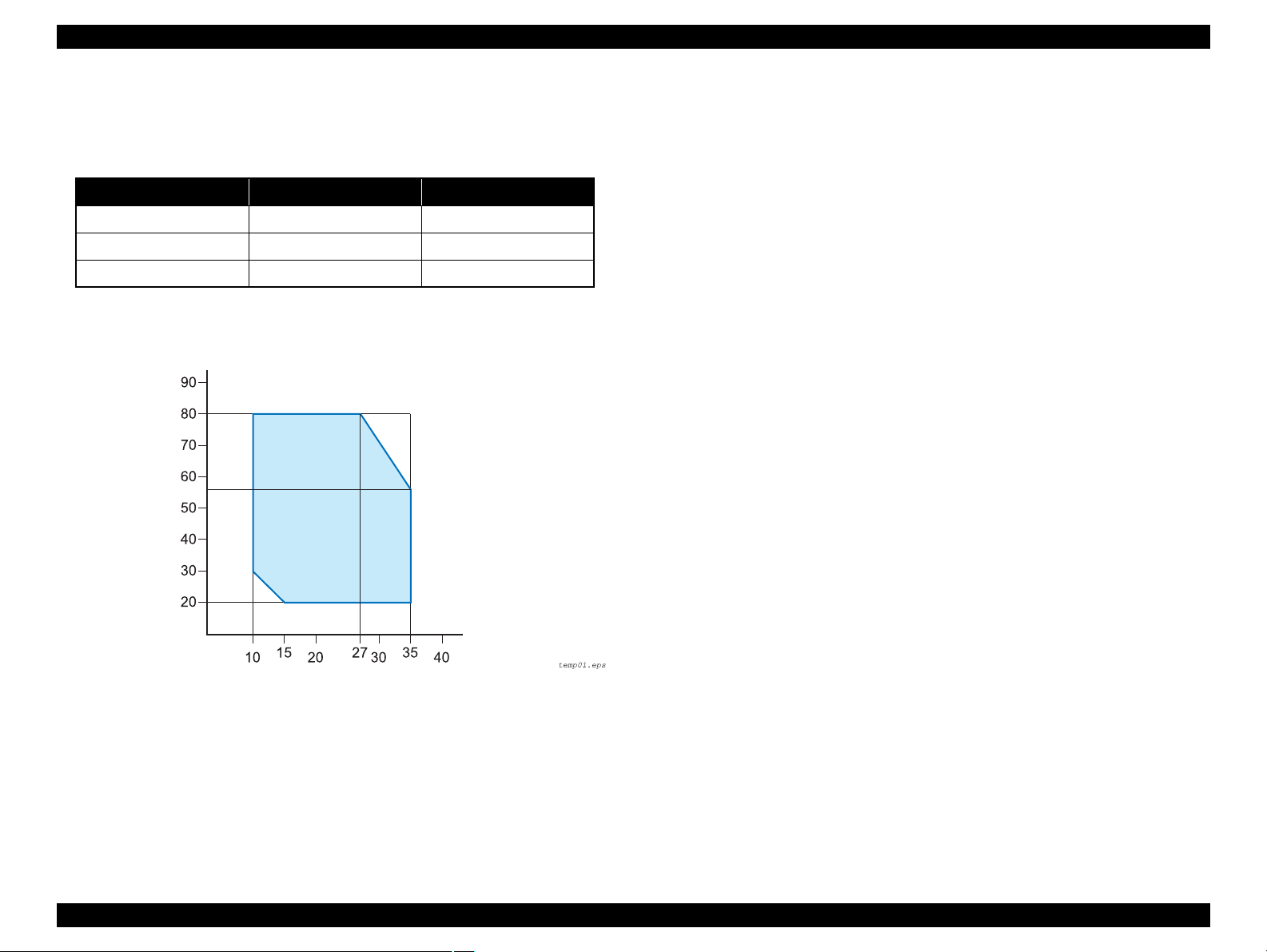

1.2.5.1 Printable Area

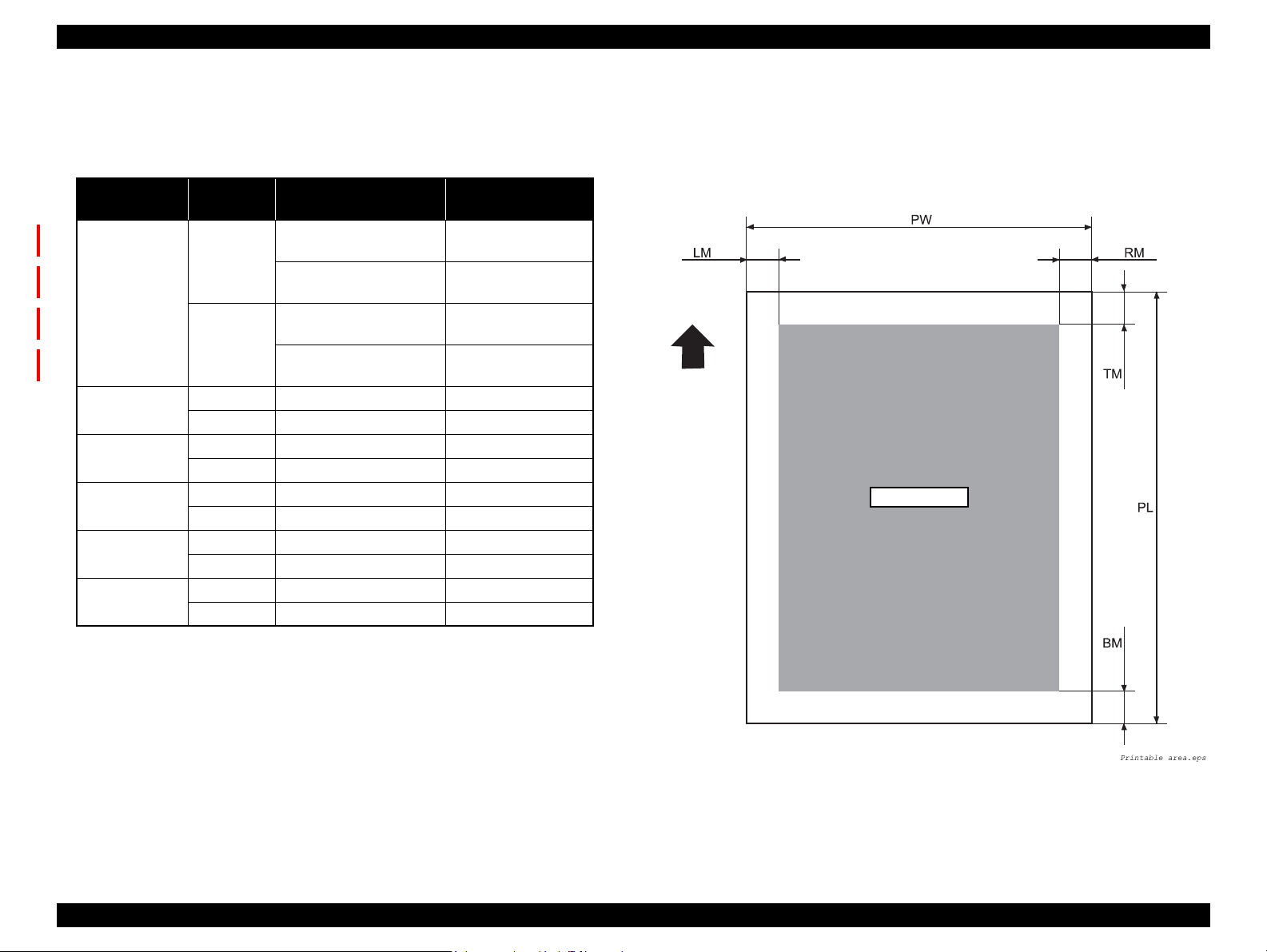

Table 1-11. Printable Area

Item

PW

(Paper width)

PL

(Paper length)

TM

(Top margin)

BM

(Bottom margin)

LM

(Left margin)

RM

(Right margin)

Roll paper

/Cut Sheet

1

Roll paper *

Cut Sheet Stylus Pro 7400/7450/7800/

Roll paper All models Maximum 202m

Cut Sheet All models 279mm~1,580mm

Roll paper All models 3mm / 15mm / 35mm*

Cut Sheet All models 3mm

Roll paper All models 3mm / 15mm

Cut Sheet All models 14mm

Roll paper All models 0mm / 3mm / 15mm

Cut Sheet All models 0mm / 3mm

Roll paper All models 0mm / 3mm / 15mm

Cut Sheet All models 0mm / 3mm

Stylus Pro 7400/7450/7800/

Stylus Pro 9400/9450/9800/

Stylus Pro 9400/9450/9800/

Model Dimension

7880/7880C

9880/9880C

7880/7880C

9880/9880C

203mm~610mm

203mm~1,118mm

203mm~610mm

203mm~1,118mm

3: When printing off both left and right edges of the media, the bleed on both sides is set to

3 mm as the automatic skew detection functio n can sense 3 mm or more horizontal shift

of the media during printing. If the printer detects that the bleeding width (from left or

right edge of media to the platen edge) is less than 3 mm, it reduces the bleed print

amount to avoid printing on the platen.

2

Paper Feed Direction

Printable Area

Note "*1": The printer automatically detects paper width when the paper is set if the automatic

detection function is set to ON.

"*2": Some types of roll paper have exceptional TM of over 15mm.

Note • Images that exceed the detected paper width, or exceed the specified printing range in

the size settings, are not printed.

(If the paper width detection settings are OFF, the printer may print to the platen.)

*At this time, a rainbow phenomenon is not generated.

• The margin settings can be changed using the panel as shown below for roll paper.

TM, BM 15mm LM, RM 3mm/ TM, BM, LM, RM 3mm/ TM, BM, LM, RM 15mm/

TM 35mm BM 15mm LM, RM 3mm

*In the special conditions below, it is possible to set the lef t and right margins (LM,

RM) to zero.

Figure 1-1. Printable Area

Product Description Basic Specifications 20

Page 21

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.5.2 Borderless Printing Specifications

BORDERLESS PRINTING WIDTH

The printer is capable of printing off both left and right edges of roll or cut sheet

media with widths shown in the table below.

Table 1-12. Paper Width

Size

inches mm

10” 254mm --- {{

--- 300mm --- {{

13” 329mm A3+ {{

16” 406.4mm --- {{

17” 431.8mm --- {{

--- 515mm B2 {{

--- 594mm A1 {{

24” 609.6mm --- {{

--- 728mm B1 --- {

36” 914.4mm --- --- {

44” 1,117.6mm --- --- {

Note • The borderless printing is not guaranteed for all types of media, and it cannot be made

properly under some conditions. See “Borderless printing guarantee conditions (p.22)”

for more information.

• Print data extend off the borderless printable area is aut o ma tically cut off.

regular

size

Stylus Pro 7400/7450/

7800/7880/7880C

Stylus Pro 9400/9450/

9800/9880/9880C

BORDERLESS PRINTING MODE

The following borderless printing modes are supported by command transmission from

the driver.

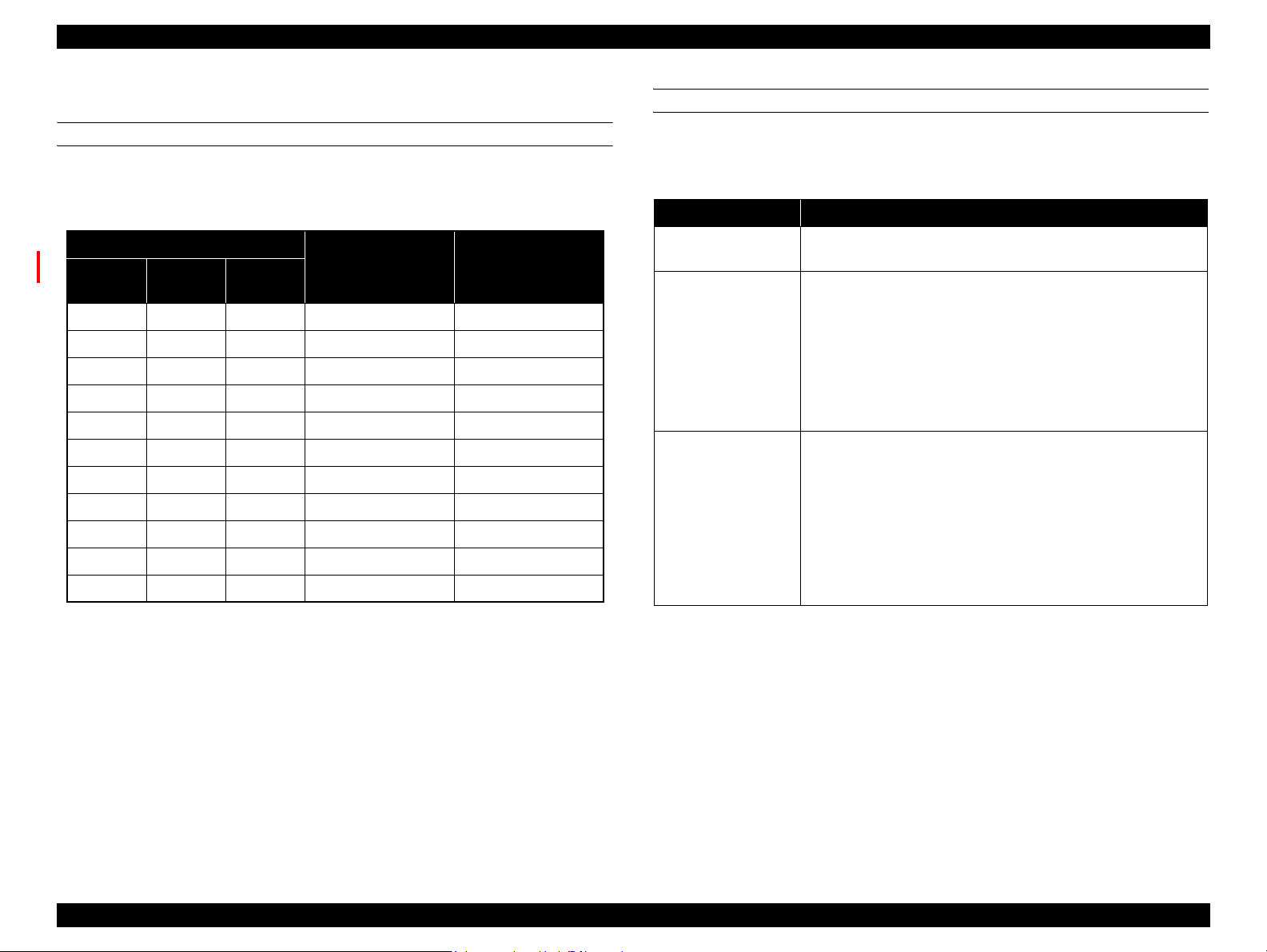

Table 1-13. Borderless Printing Mode

Mode Operation

Right/left borderless

(default) *

4 sides borderless/

Single Cut *

4 sides borderless/

Double Cut *

Note "*1": When the roll paper cutter is OFF and cut line printing is ON, a cut line is printed on

1

1, *2, *3

1, *2, *3

each cut position including the one for cutting the top edge.

"*2": After the 4 sides borderless cut, the actual printed size is approximately 2mm smaller

in the vertical direction.

"*3": When roll paper borderless print for 4 sides is performed on the media types shown

below, irregular coloring may occur when the edges are cut.

• Double Weight Matte Paper

• Single Weight Matte Paper

• Enhanced Matte Paper

• Textured Fine Art Paper

• Ultra Smooth Fine Art Paper

Left and right margins can be set to zero. In this case the upper and

lower margins are set by the roll paper margin settings.

Cuts the top and bottom edges in the way as described below to

create a printout without margins on all four sides:

• The top edge of the first page is cut off leaving “minimum cut

margin”.during the printing.

• No margin is created between pages and the printer cuts on the

boundary to separate the pages.

• The bottom edge of the last page is cut off after the printing is

complete.

Cuts the top and bottom edges in the way as described below to

create a printout without margins on all four sides.

• The top edge of the first page is cut off leaving “auto refresh

margin” during the printing.

• Each time printing one page is complete, the bottom edge is cut

off and the paper is fed a little (create a minimum cut margin

between pages), and the top edge of the next page is cut off

during printing. This mode is more accurate than the Single Cut

mode as it cuts the paper twice to separate pages.

Product Description Basic Specifications 21

Page 22

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

BORDERLESS PRINTING SETTING PROCEDURES BORDERLESS PRINTING GUARANTEE CONDITIONS

Table 1-14. Borderless Printing Setting

Borderless

print mode

Printer

operation

Driver

setting

Remarks Defined as default • As the top edge of the

Right/left borderless

Borderless print • Borderless print

4 sides borderless

Single Cut

• Single Cut

first page is cut by

interrupting the printing

operation, off-registration

may occur causing

irregular color on the

printed image depending

on the print job.

• As this mode cuts the

paper on the boundary of

pages, slight amount of

image of the previous or

the next page may be left

on the top or bottom edge

of the printout due to

cutter position deviation.

4 sides borderless

Double Cut

• Borderless print

• Double Cut

• As the top edge of the

first page is cut by

interrupting the printing

operation, off-registration

may occur causing

irregular color on the

printed image depending

on the print job.

• The cutting position is set

to a line 1 mm inside from

the actual top and bottom

edges allowing for cutter

position deviation. So the

length of the printout

becomes about 2mm

smaller than the specified

size.

Borderless printing guarantee conditions

Environmental:

Temperature: 59 to 77ºF (15 to 25 ºC), Humidity: 40 to 60 % RH

Media type *

Media size *

• Photo type media: 10”, 300mm, 13”, 16”, 17 ”, 24”, 36”, 44”

• POP • poster type media: A1, B1, B2

3

: Photo type media (roll paper),

POP • poster type media (roll paper)

3

*1, *2

NOTE "*1": There are no borderless printing guarantees for cut sheet paper.

"*2": Borderless printing is not guaranteed if a number of outer layers of th e

roll surface have stretched due to moisture absorption.

"*3": Borderless printing on media and sizes other than those listed above are

guaranteed the same way as the Stylus Pro 7600/9600 do. However, if

media that has been stretched by humidity and other environmental

conditions is used, it is possible that borders on the right and left hand

sides may occur.

Bleeding print width for pri nti ng off both left and right edges

The bleeding print width for the left and right edges can be selected among the

following settings using the printer driver.

Left (opposite home side) = 1.5mm/ Right (home side) = 1.5mm

Left (opposite home side) = 3.0mm/ Right (home side) = 3.0mm (Default)

Left (opposite home side) = 5.0mm/ Right (home side) = 3.0mm *

NOTE "*1": If humid environmental conditions have caused the media to stretch,

“Left (opposite home side) = 5.0mm/ Right (home side) = 3.0mm”

selection is recommended to prevent left and right edge margins

occurring.

"*2": The “Left (opposite home side) = 5.0mm/ Right (home side) = 3.0mm”

setting shifts the center position of the image 1 mm away from that of

the print data.

1, *2

Product Description Basic Specifications 22

Page 23

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.5.3 Cut Specifications

Both automatic and manual cut are available on this printer.

C A U T I O N

ROLL PAPER AUTOMATIC CUT

This function is enabled by setting “Roll Auto Cut” in the Panel Setting menu to ON.

Mechanical condition

Distance between the cutting position and paper setting position:L0 = 187mm

Distance between the cutting position and cutter mark: L1 = 34mm

Minimum cut length: L2 = 127mm

Sheet edge standby location: L3 = 130mm

ROLL PAPER MANUAL CUT

The automatic cutting prohibited media can be cut manually following the procedure

described below.

1. Press the [Paper Select ] button to select the [Roll Auto Cut Off ] and press

the [Enter ] button.

2. Paper is automatically fed to the cutter guide, then the printer will go offline. At

this point, “PAUSE” will be displayed on the panel.

3. If required, fine adjustments on the cut position can be performed using the [Paper

feed ( )] buttons.

4. The user can then use the manual cutter unit and cut the paper along the cutter

guide.

There are some types of media which are not allowed to be cut

automatically. Be sure not to perform the automatic cutting with

them, or may result in damaging the printhead.

1.2.5.4 Paper Set Lever

Table 1-15. Paper Set Lever

Lever Position Description

Backward Position for paper setting

(Paper holding is released, and paper can be set.)

Forward Ready-to-print position

(Paper is fixed, and it becomes ready to be printed.)

5. After cutting the paper, cancel the pause status (press the [Pause] button). The

paper will back feed and the printer will go back online.

C H E C K

P O I N T

For manual cutting of roll paper, use the manual cutter available as

an option.

Product Description Basic Specifications 23

Page 24

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.6 Electrical Related Information

Rated voltage: 100 to 240 VAC

Input voltage range: 90 to 264 VAC

Rated frequency range: 50 to 60 Hz

Input frequency range: 49 to 61 Hz

Rated current: 1.0 to 0.5 A

Power consumption

Operating:

• Stylus Pro 7400/7450/7800/7880/7880C: 50 W

• Stylus Pro 9400/9800: 55 W

• Stylus Pro 9450/9880/9880C: 58 W

Power off mode: Less than 6 W

(Shifting time 15 minutes)

When power switch is OFF:

Less than 1 W

Insulation resistance: More than 10 M ohms

(500 VDC between AC line and chassis)

Dielectric strength: AC1.0 kV rms 1minute or AC1.2 kVrms 1 second

(between AC line and chassis)

Leakage: Less than 0.25 mA [Adapts Japan National Electronics

Development Incorporated Association “Personal

Computer Industry Standard” (PC-11-1988)].

Energy conservation:

International Energy Star Program compliant

(Measure for harmonic component suppression guideline)

Electromagnetic interference standards compliance

VCCI class B

1.2.7 Reliability

1.2.7.1 Main Body Life

Stylus Pro 7400/7450/7800/7880/7880C:

6,300,000 carriage movement cycles

(Approx. 20,000 pages of A1-size plain paper in “Quality” (Bi-D FOL) mode)

Stylus Pro 9400/9450/9800/9880/9880C:

3,700,000 carriage movement cycles

(Approx. 20,000 pages of B0-size plain paper in “Quality” (Bi-D FOL) mode)

1.2.7.2 Print Head Life

Monochrome: 8 billion segment/nozzle

Color: 8 billion segment/nozzle

1.2.7.3 Maintenance Tank Life-span Guide

Stylus Pro 7800/7880/7880C:

Approx. 1,300 sheets

(A1+ size plain paper, Quality mode, Continuous printing)

Stylus Pro 7400/7450:

Approx. 2,000 sheets

(A1+ size plain paper, Quality mode, Continuous printing)

Stylus Pro 9800/9880/9880C

CR HP side: Approximately 1,000 sheets

(B0+ size plain paper, Quality mode, Continuous printing)

Anti HP side:Approximately 7,800 sheets

(B0+ size plain paper, Quality mode, Continuous printing)

Stylus Pro 9400/9450

CR HP side: Approximately 1,700 sheets

(B0+ size plain paper, Quality mode, Continuous printing)

Anti HP side:Approximately 26,000 sheets

(B0+ size plain paper, Quality mode, Continuous printing)

Product Description Basic Specifications 24

Page 25

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

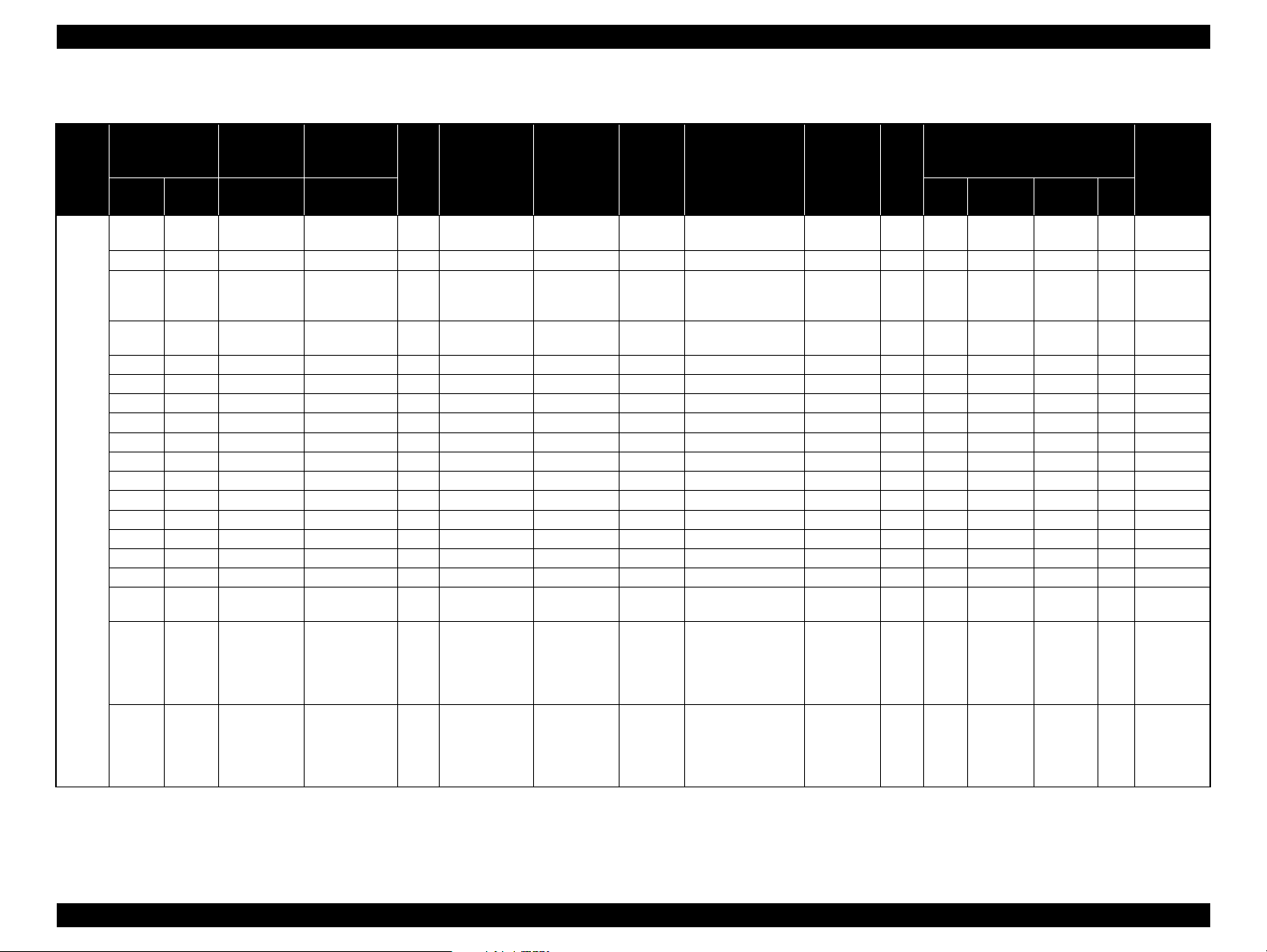

1.2.7.4 Cutter Life-span

Table 1-16. Cutter Life-span

Stylus Pro 7400/7450/7800/

Paper type

Coated paper Approximately 2000 sheets Approximately 2000 sheets

Film Approximately 1000 sheets Approximately 1000 sheets

When performing 4 stage cut

7880/7880C

on 24” standard roll paper

Stylus Pro 9400/9450/9800/

9880/9880C

When performing 4 stage cut

on 44” standard roll paper

1.2.7.5 Replacement Parts Life-span

Table 1-17. Replacement Parts Life-span

Replacement parts

RTC backup battery Approx. from 5 to 10 years or more

Cleaning unit

• Cap assembly

• Pump assembly

• Flashing box

•Wiper

CR Motor Approx. 20,000 sheets

• Driven pulley

• Carriage unit

• Tubes

• FFC

Note "*1": A1 size plain paper, "Quality mode, Continuous printing)

"*2": B0 size plain paper, "Quality mode, Continuous printing)

Stylus Pro 7800/

7880/7880C*

Approx.

17,000 sheets

Stylus Pro

1

7400/7450*

Approx.

25,000 sheets

Stylus Pro 9800/

1

9880/9880C*

Approx.

11,000 sheets

Approx. 20,000 sheets

Stylus Pro

2

9400/9450*

Approx.

18,000 sheets

1.2.7.6 MTBF (Mean Time Between Failures)

20,000 POH (with no malfunction of electric parts and fans)

Table 1-18. Conditions

Item

Environment Normal room temperature and humidity

Printing Duty • Approx. 18%

2

1.2.7.7 MPBF (Mean Pages Between Failure)

Stylus Pro 7400/7450/7800/

7880/7880C

• Power supply ON time:

11.0 hours/day

• Operation (printing) time:

2.0 hours/day

Stylus Pro 7400/7450/7800/7880/7880C:

More than 22 sheets of A1 by continuous printing

Stylus Pro 9400/9450/9800/9880/9880C:

More than15 sheets of B0 by continuous printing

NOTE: Without running a cleaning, no dot missing, and no skew.

Table 1-19. Conditions

Item

Printing mode • 720 x 720dpi FOL, Bi-D

• 7 sheets/day x 3days

• 7 sheets/day x 22 sheets/day

Print ratio Single color 5%, and single color 30%

Environment Under the following three kinds of

environmental conditions:

• Temperature: 10 °C, Humidity: 20%

• Normal room temp. and humidity

• Temperature: 35 °C, Humidity: 20%

Stylus Pro 9400/9450/9800/

9880/9880C

• Approx. 32%

• Power supply ON time:

11.0 hours/day

• Operation (printing) time:

3.5 hours/day

All Models

Product Description Basic Specifications 25

Page 26

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

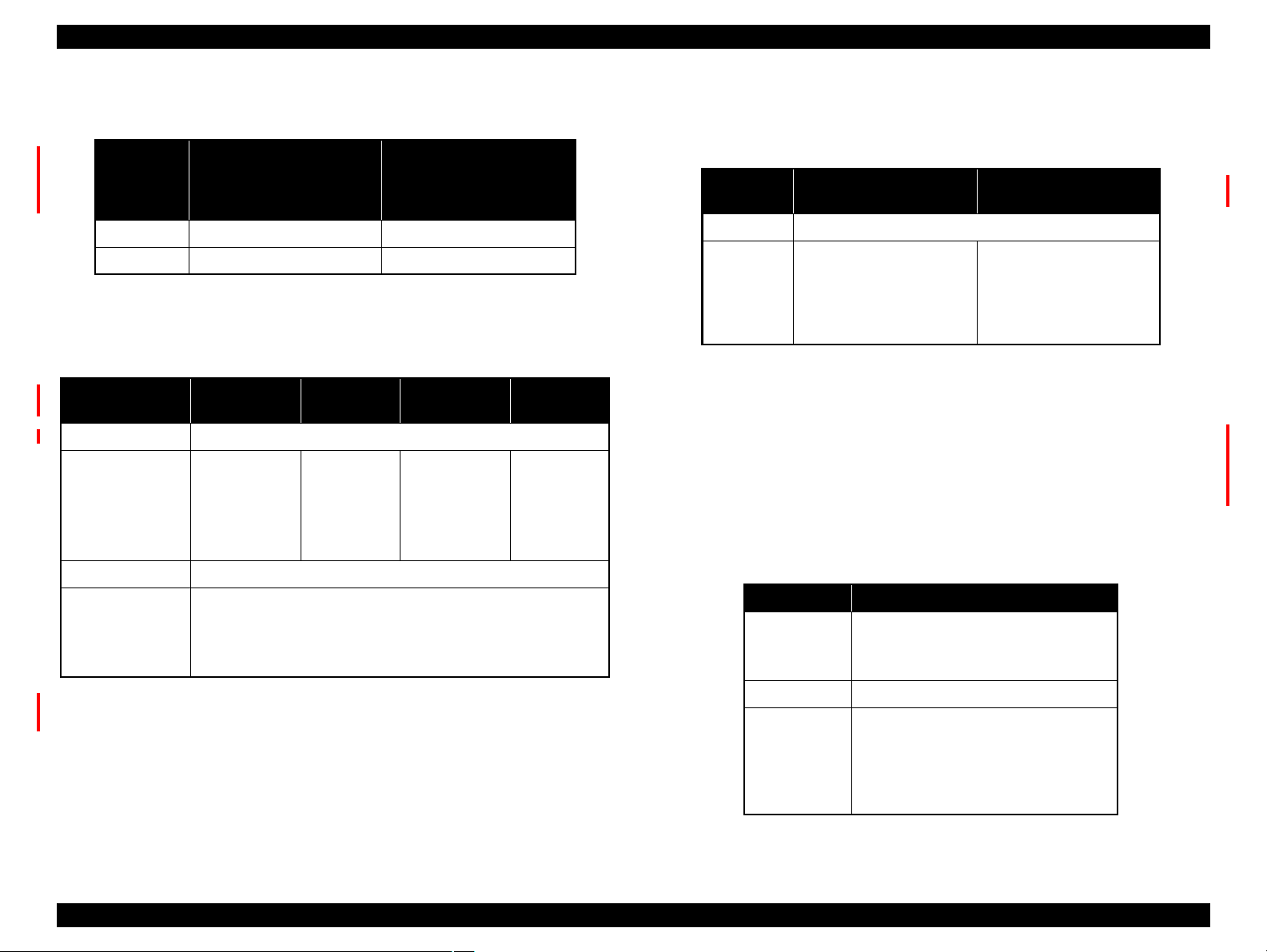

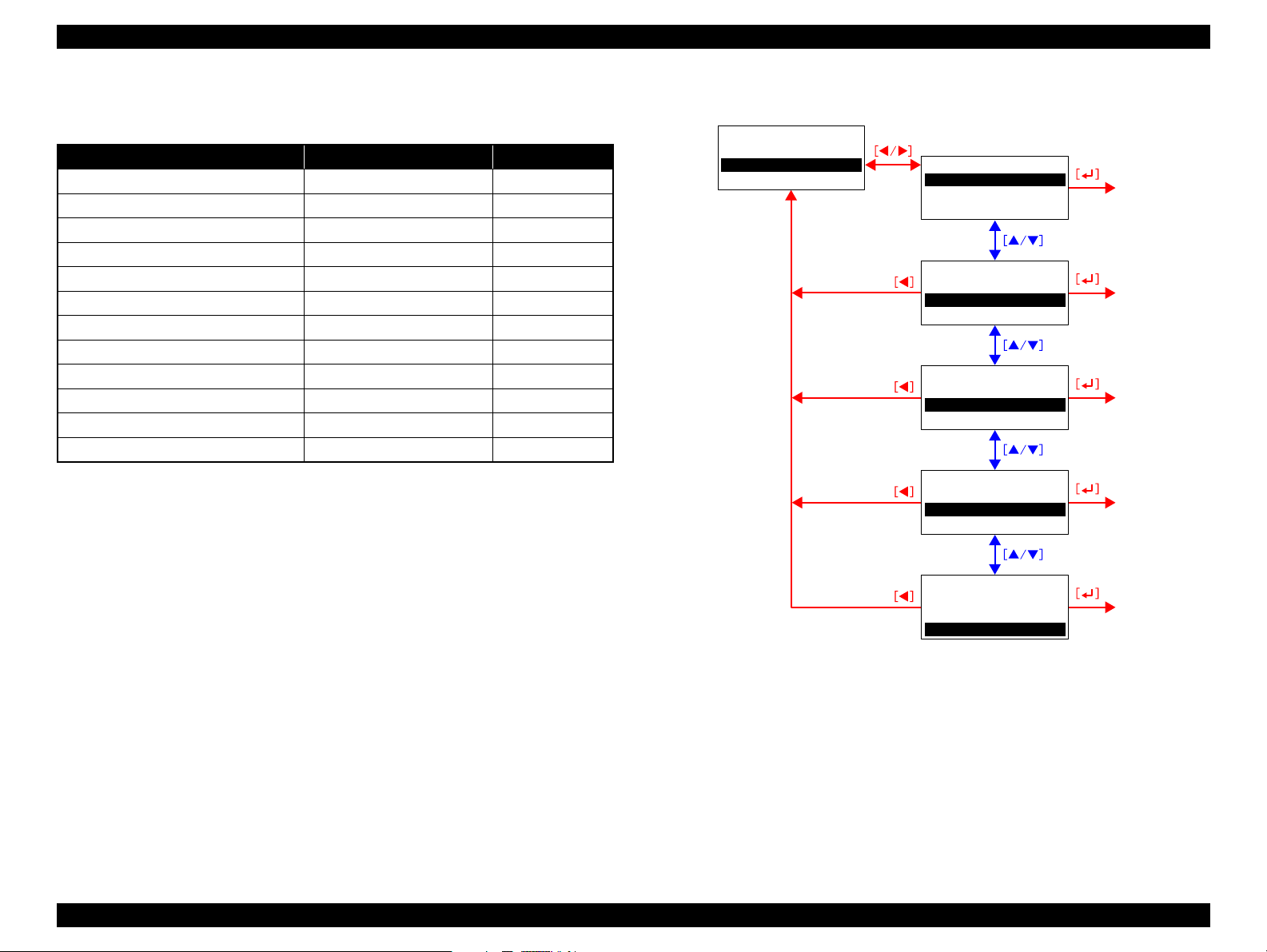

1.2.8 Environmental Conditions

1.2.8.1 Temperature/Humidity

Table 1-20. Temperature/Humidity

Condition Temperature*

Operating 10 το 35 °C 20 to 80 %

Storage –20 το 40 °C 20 to 85 %

Transporting –20 το 60 °C 5 to 85 %

Note "*1": 40°C is for less than 1 month, 60°C is for less than 120 hours)

"*2": Should be no condensation and be within the range shown on the graph below.

Humidity (%)

1

Humidity*

1.2.8.2 Vibration Resistance

Operating: 0.15 G, 10 to 55 Hz in X, Y, Z direction

Store: 0.50 G, 10 to 55 Hz in X, Y, Z direction

2

1.2.8.3 Shock Resistance

Operating: 1G within 1 mi llisecond in X, Y, Z direction

Store: 2G within 2 milliseconds in X, Y, Z direction

NOTE • Check that the printhead is capped when storing the printer for a long

period of time.

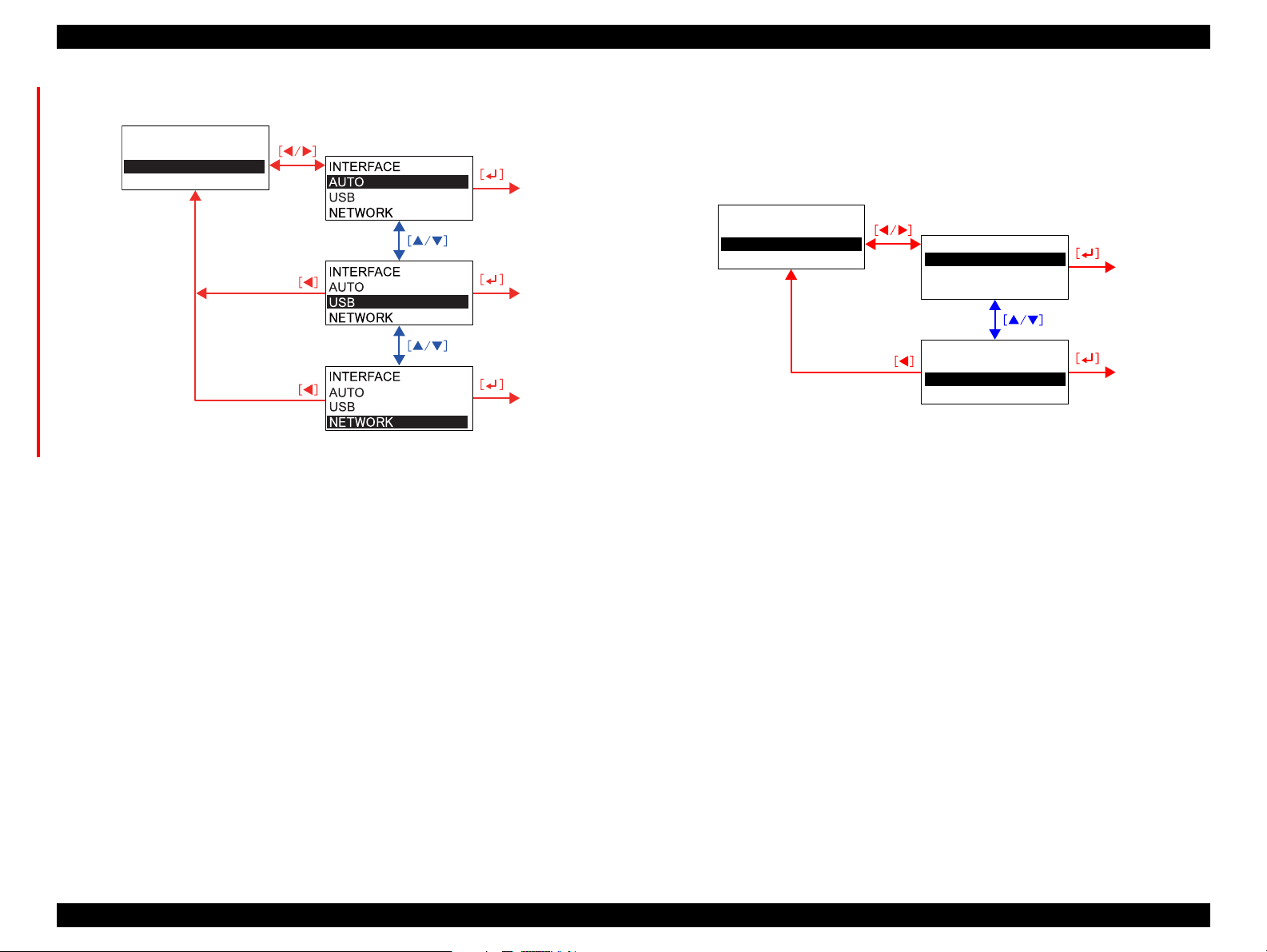

• When transporting the printer, check that the printhead is capped, all ink

cartridges are removed, and the ink cartridges covers are closed and fixed.

• If the printhead are not capped, turn the power back ON with the ink

cartridges installed, and then turn the power OFF again after confirming

the capping operation is complete.

• If the printer is left under an ambient temperature of minus 15

the printhead and ink cartridges will freeze.

If this happens, move the printer, or heat the room so that the ambient

temperature is 25

°

C, and leave the printer under the temperature for

approximately 3 hours to melt the ink.

°

C, ink inside

Temperature (°C)

Figure 1-2. Allowable Range of Temperature and Humidity

Product Description Basic Specifications 26

Page 27

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.2.9 Overall Dimensions

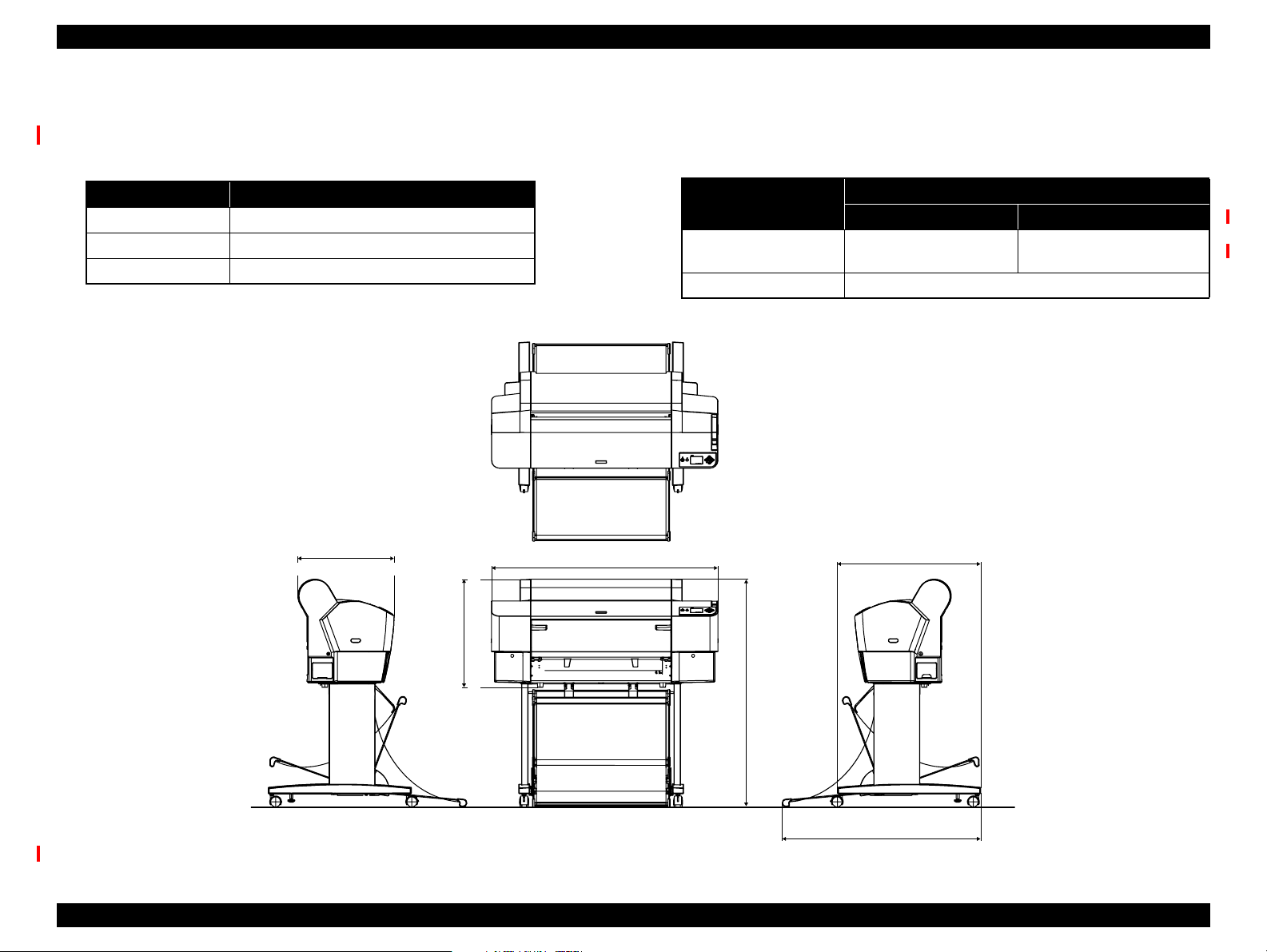

1.2.9.1 Stylus Pro 7400/7450/7800/7880/7880C Overall Dimensions

Dimensions of Unit

Mass

Conditions Width (W) x Depth (D) x Height (H) (mm)

Printer body 1,178 x 501 x 560

Rearward paper eject 1,178 x 745 x 1,180

Frontward paper eject 1,178 x 1,035 x 1,180

Note • For “rearward paper eject”, the paper exit tray is brought down toward the rear.

• For “frontward paper eject”, the paper exit tray is brought down toward the front.

501

(When no base is mounted)

560

1,178

Conditions

Main body

(without base mounted)*

Base Approx. 10.5kg

Note "*": Excluding ink cartridges and papers

Stylus Pro 7400/7800 Stylus Pro 7450/7880/7880C

Approx. 48.9kg Approx. 49.1kg

745

Mass

(When no base is mounted)

1,181

1,033

Figure 1-3. External Dimension of the Stylus Pro 7400/7450/7800/7880/7880C

Product Description Basic Specifications 27

Page 28

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

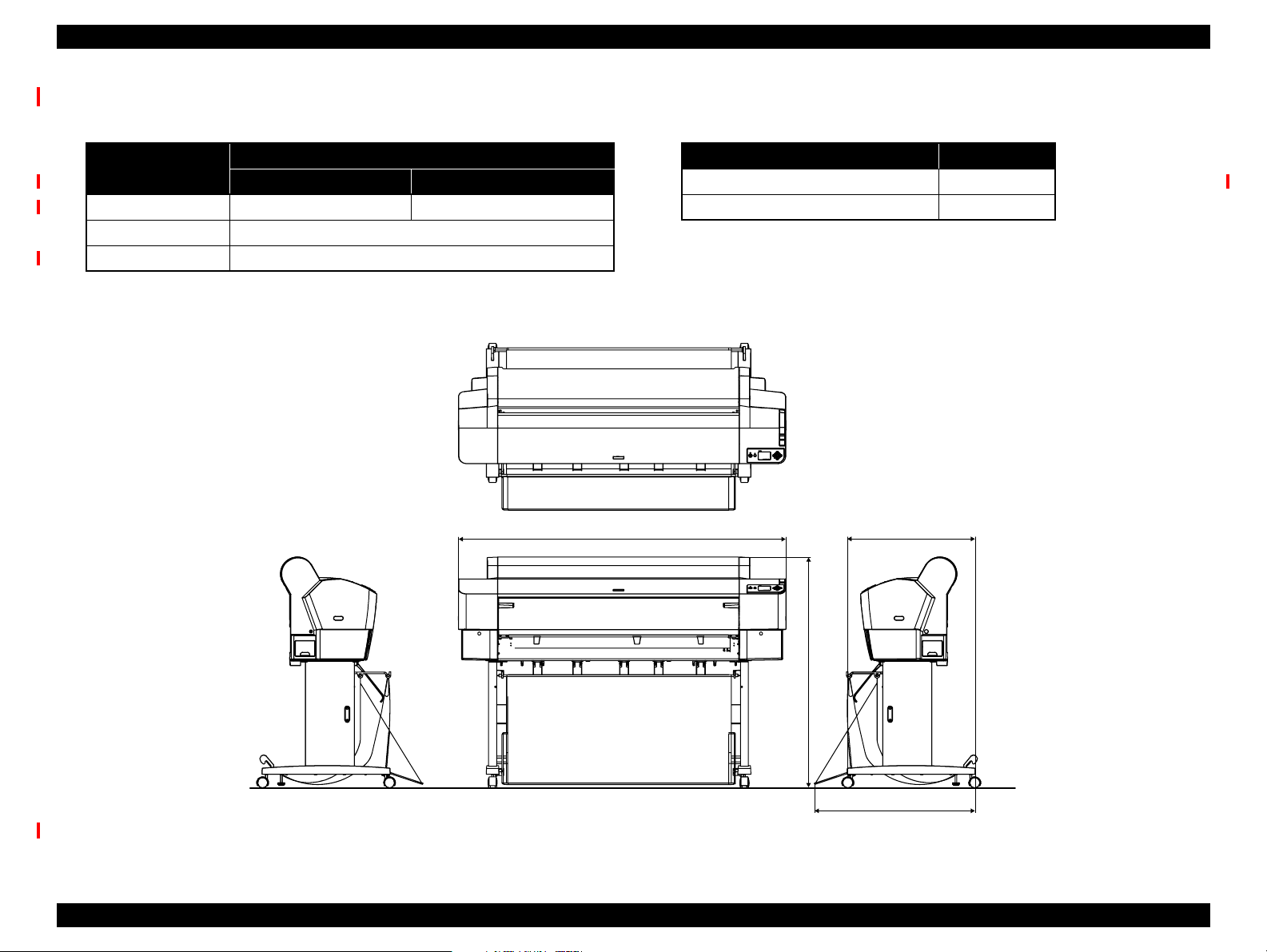

1.2.9.2 Stylus Pro 9400/9450/9800/9880/9880C Overall Dimensions

Outer dimensions

Mass

Conditions

Printer body 1,702 x 667 x 1,196 1,702 x 678 x 1,196

Rearward paper eject 1,702 x 681 x 1,196

Frontward paper eject 1,702 x 849 x 1,196

Note • For “rearward paper eject”, the paper exit tray is brought down toward the rear.

• For “frontward paper eject”, the paper exit tray is brought down toward the front.

Width (W) x Depth (D) x Height (H) (mm)

Stylus Pro 9400/9800 Stylus Pro 9450/9880/9880C

1,702

Conditions Mass

Main body (without base mounted)* Approx. 90.2kg

Base Approx. 22.5kg

Note "*": Excluding ink cartridges and papers

667

1,196

838

Figure 1-4. External Dimension of the Stylus Pro 9400/9450/9800/9880/9880C

Product Description Basic Specifications 28

Page 29

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

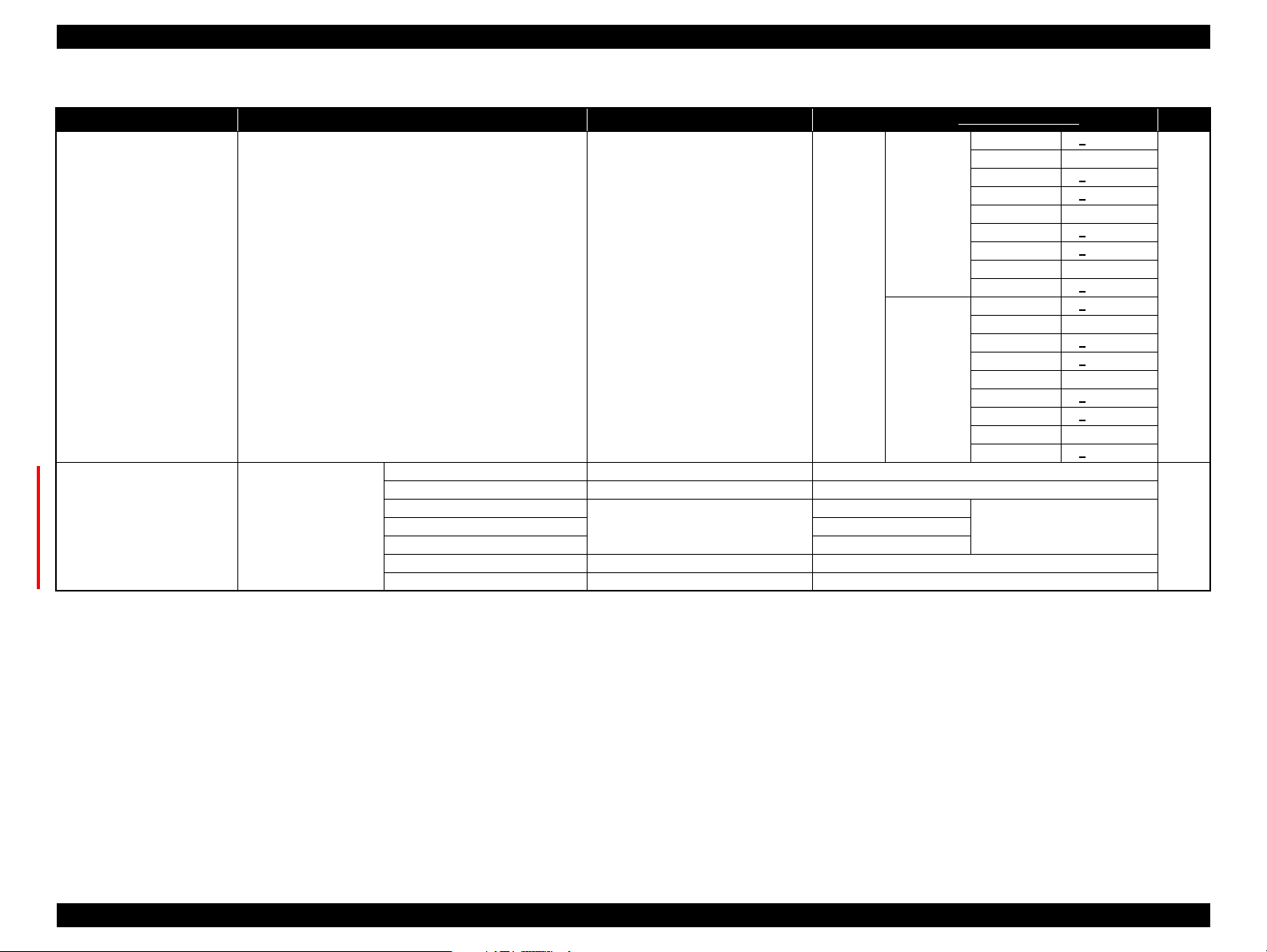

1.2.10 Accessories/Options/Consumables

Accessories/Options (Stylus Pro 740 0/7800/9400/9800)

Table 1-21. Accessories/Options

Item

Standard accessories Power cord --- {{{{

Specialized Stand (base unit) --- { --- --- ---

2/3 inch Dual Roll Feed Spindle (24”) --- {{--- ---

2/3 inch Dual Roll Feed Spindle (44”) --- --- --- {{

Test roll paper (MC matte paper: Shared) --- {{{{

Roll Paper Belt --- {{{{

1

2

Options common with

other models

Ink Cartridge (110ml)*

Maintenance Tank*

Instruction Manual --- {{{{

Printer Software CD-ROM (Printer driver, maintenance utilities) --- {{{{

Application CD-ROM (Bundled software) --- {{{{

Guarantee Issuance Invoice --- {{{{

Business Card Holder --- {{{{

Individual Packaging --- {{{{

Specialized Stand (base unit) C12C84408 {{--- ---

2/3 inch Dual Roll Feed Spindle (24”) C12C811161 {{--- ---

2/3 inch Dual Roll Feed Spindle (44”) C12C811151 --- --- {{

2/3 inch Dual Roll Feed Spindle (High Tension) (24”) C12C811155 {{--- ---

2/3 inch Dual Roll Feed Spindle (High Tension) (44”) C12C811152 --- --- {{

Manual Cutter Unit (24”) C12C815231 {{--- ---

Manual Cutter Unit (44”) C12C815182 --- --- {{

Auto Take-Up Reel Unit C12C815251 --- --- {{

Auto Cutter Spare Blade C12C815241 {{{{

EpsonNet 10/100 Base Tx Int. Print Server 5 C12C82434 {{{{

Part No.

--- {{{{

--- {{{{

Stylus Pro 7800 Stylus Pro 7400 Stylus Pro 9800 Stylus Pro 9400

Note "*1":

Stylus Pro 7800, Stylus Pro 9800 (1 of each color Pk, Mk, Lk, LLk, C, M, Lc, Lm, Y)

Stylus Pro 7400, Stylus Pro 9400 (2 of each color Mk, C, M, Y)

"*2": Stylus Pro 7400/7800: 1 tank,

Stylus Pro 9400/9800: 2 tanks

Product Description Basic Specifications 29

Page 30

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Accessories/Options (Stylus Pro 7450/7880/7880C/9450/9880/9880C)

Table 1-22. Accessories/Options

Item

Standard accessories Power cord --- {{{{

2/3 inch Dual Roll Feed Spindle (24”) --- {{--- ---

2/3 inch Dual Roll Feed Spindle (44”) --- --- --- {{

Test roll paper (MC matte paper: Shared) --- {{{{

Roll Paper Belt --- {{{{

Ink Cartridge (110ml)*

Maintenance Tank*

Instruction Manual --- {{{{

Printer Software CD-ROM (Printer driver, maintenance utilities) --- {{{{

Application CD-ROM (Bundled software) --- {{{{

Guarantee Issuance Invoice --- {{{{

Business Card Holder --- {{{{

Individual Packaging --- {{{{

Conversion cartridge kit --- { --- { ---

Special option Conversion cartridges (C, M, Y) --- {{{{

Options common with

other models

Note "*1":

Stylus Pro 7880/7880C/9880/9880C (1 of each color Pk, Mk, Lk, LLk, C, VM, Lc, VLm, Y)

Stylus Pro 7450/9450 (2 of each color Mk, C, M, Y)

"*2": Stylus Pro 7450/7880/7880C: 1 tank,

Stylus Pro 9450/9880/9880C: 2 tanks

Specialized Stand (base unit) C12C84408 {{--- ---

2/3 inch Dual Roll Feed Spindle (24”) C12C811161 {{--- ---

2/3 inch Dual Roll Feed Spindle (44”) C12C811151 --- --- {{

2/3 inch Dual Roll Feed Spindle (High Tension) (24”) C12C811155 {{--- ---

2/3 inch Dual Roll Feed Spindle (High Tension) (44”) C12C811152 --- --- {{

Manual Cutter Unit (24”) C12C815231 {{--- ---

Manual Cutter Unit (44”) C12C815182 --- --- {{

Auto Take-Up Reel Unit C12C815251 --- --- {{

Auto Cutter Spare Blade C12C815241 {{{{

Roll paper fixation holder --- {{{{

EpsonNet 10/100 Base Tx Int. Print Server 5 C12C82434 {{{{

1

2

Part No.

--- {{{{

--- {{{{

Stylus Pro 7800/

7880/7880C

Stylus Pro

7400/7450

Stylus Pro 9800/

9880/9880C

Stylus Pro

9400/9450

Product Description Basic Specifications 30

Page 31

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Consumables

Ink cartridge (110 ml/220 ml)

Table 1-23. Ink Cartridges of Stylus Pro 7800/9800

Part Number

Cartridge

110 ml (Standard) 220 ml (Option)

Photo Black (Pk) C13T562130 C13T563130

Matte Black (Mk) C13T566830 C13T567830

Light Black (Lk) C13T562730 C13T563730

Light Light Black (LLk) C13T562930 C13T563930

Cyan (C) C13T562230 C13T563230

Magenta (M) C13T562330 C13T563330

Light Cyan (Lc) C13T562530 C13T563530

Light Magenta (Lm) C13T562630 C13T563630

Yellow (Y) C13T562430 C13T563430

Table 1-24. Ink Cartridges of Stylus Pro 7400/9400

Part Number

Cartridge

110 ml (Standard) 220 ml (Option)

Matte Black (Mk) C13T566830 C13T567830

Cyan (C) C13T566230 C13T567230

Magenta (M) C13T566330 C13T567330

Yellow (Y) C13T566430 C13T567430

Table 1-25. Ink Cartridges of Stylus Pro 7880/7880C/9880/9880C

Part Number

Cartridge

110 ml (Standard) 220 ml (Option)

Photo Black (Pk) C13T602100 C13T603100

Matte Black (Mk) C13T611800 C13T612800

Light Black (Lk) C13T602700 C13T603700

Light Light Black (LLk) C13T602900 C13T603900

Cyan (C) C13T602200 C13T603200

Vivid Magenta (VM) C13T602300 C13T603300

Light Cyan (Lc) C13T602500 C13T603500

Vivid Light Magenta (VLm) C13T602600 C13T603600

Yellow (Y) C13T602400 C13T603400

Table 1-26. Ink Cartridges of Stylus Pro 7450/9450

Part Number

Cartridge

110 ml (Standard) 220 ml (Option)

Matte Black (Mk) C13T611800 C13T612800

Cyan (C) C13T611200 C13T612200

Magenta (M) C13T611300 C13T612300

Yellow (Y) C13T611400 C13T612400

Special paper for paper type and size.

Maintenance tank

Product Description Basic Specifications 31

Page 32

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.3 External View and Parts Names

EXTERNAL VIEW

Stylus Pro 7400/7800 /9400/9800

Optional Interface Card Slot Cover

Paper Feed Slot

Ink Cartridge

Compartment (left)

Front Cover

Roll Paper Spindle

Paper Lever

Releases paper

Sets paper

Control Panel

Ink Cartridge

Compartment (right)

Roll Paper

Cover

IEEE1394 Interface

Connector

USB Interface

Connector

AC Inlet

Maintenance Tank

Stylus Pro 7400/7800: only one on the right side

Stylus Pro 9400/9800: one each on the left and right side

Figure 1-5. External View and Parts Names (Stylus Pro 7400/7800/9400/980 0)

Product Description External View and Parts Names 32

Page 33

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Stylus Pro 7450/7880/7880C/9450/9880/9880C

Paper Feed Slot

Ink Cartridge

Compartment (left)

Front Cover

Roll Paper Spindle

Paper Lever

Releases paper

Sets paper

Control Panel

Ink Cartridge

Compartment (right)

Network Interface

Connector

Roll Paper

Cover

USB Interface

Connector

AC Inlet

Maintenance Tank

Stylus Pro 7450/7880/7880C: only one on the right side

Stylus Pro 9450/9880/9880C: one each on the left and right side

Figure 1-6. External View and Parts Names (Stylus Pro 7450/7880/7880C/9450/9880/9880C)

Product Description External View and Parts Names 33

Page 34

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

1.4 Control Panel

1.4.1 Buttons and Functions

LED

Power Pause Menu

Pause

LED

Paper check

LED

Ink check LED

Figure 1-7. Panel Design

Paper Feed Enter Power

Paper Feed Paper Source LCD

1.4.1.1 LED

The following table describes the LED displays and status.

Table 1-27. LED

LED Color Displays Status

Power Green ON The power is ON.

1

Flashing*

OFF The power is OFF.

Pause Yellow ON*

Flashing*

OFF Ready for printing.

Paper

Check

Red ON Impossible to make a print due to the paper status

Flashing*

OFF The papers are in normal condition without an error or

Ink

Check

Red ON An ink-related error is occurring

Flashing*

2

Receiving data or executing power off sequence

Temporarily stopping the operation (The yellow light also

turns on when an error occurs).

1

---

1

• A paper feeding or ejecting error is occurring

• The Paper Near-End warning is occurring

• A maintenance call error is occurring.

warning.

1

An ink-related warning is occurring

OFF The inks are in normal condition without an error or

Message

Roll Paper Margin

Custom Paper No.

Paper Source

Roll Paper Counter

Note "*1": Alternately turns On and Off every 500 ms. In the case of maintenance call error,

they light for 100 ms at intervals of five seconds.

"*2": When a printer error occurs, printing operation is disabled and the Pause LED turns

ON.

warning.

Note : When a service call error occurs, the all LEDs flash.

Platen Gap setting Ink Counter

Maintenance Tank Counter

(One bar is displayed on Stylus

Pro 7400/7450/7800/7880/7880C)

Figure 1-8. LCD Panel

Product Description Control Panel 34

Page 35

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

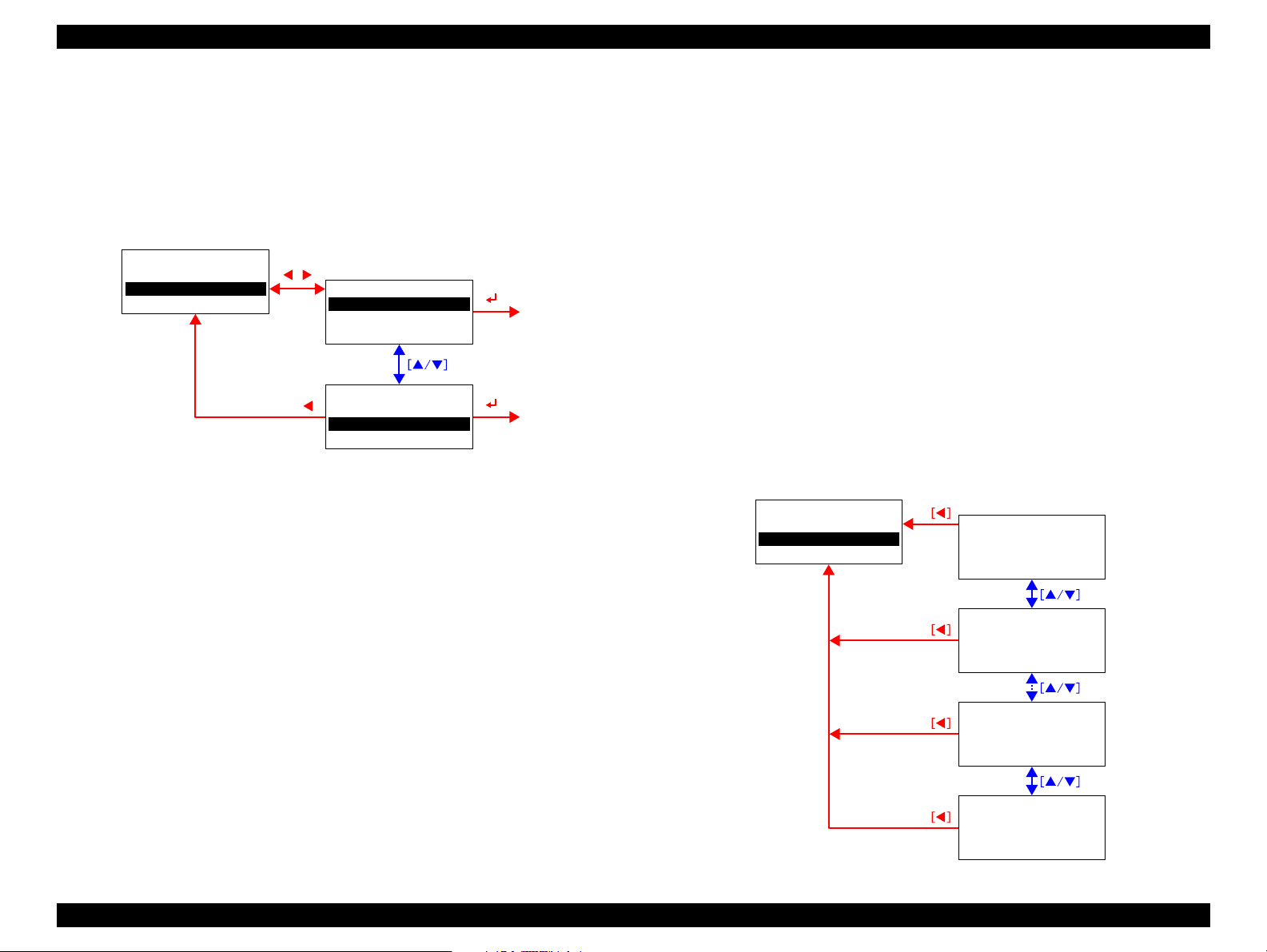

1.4.1.2 Buttons

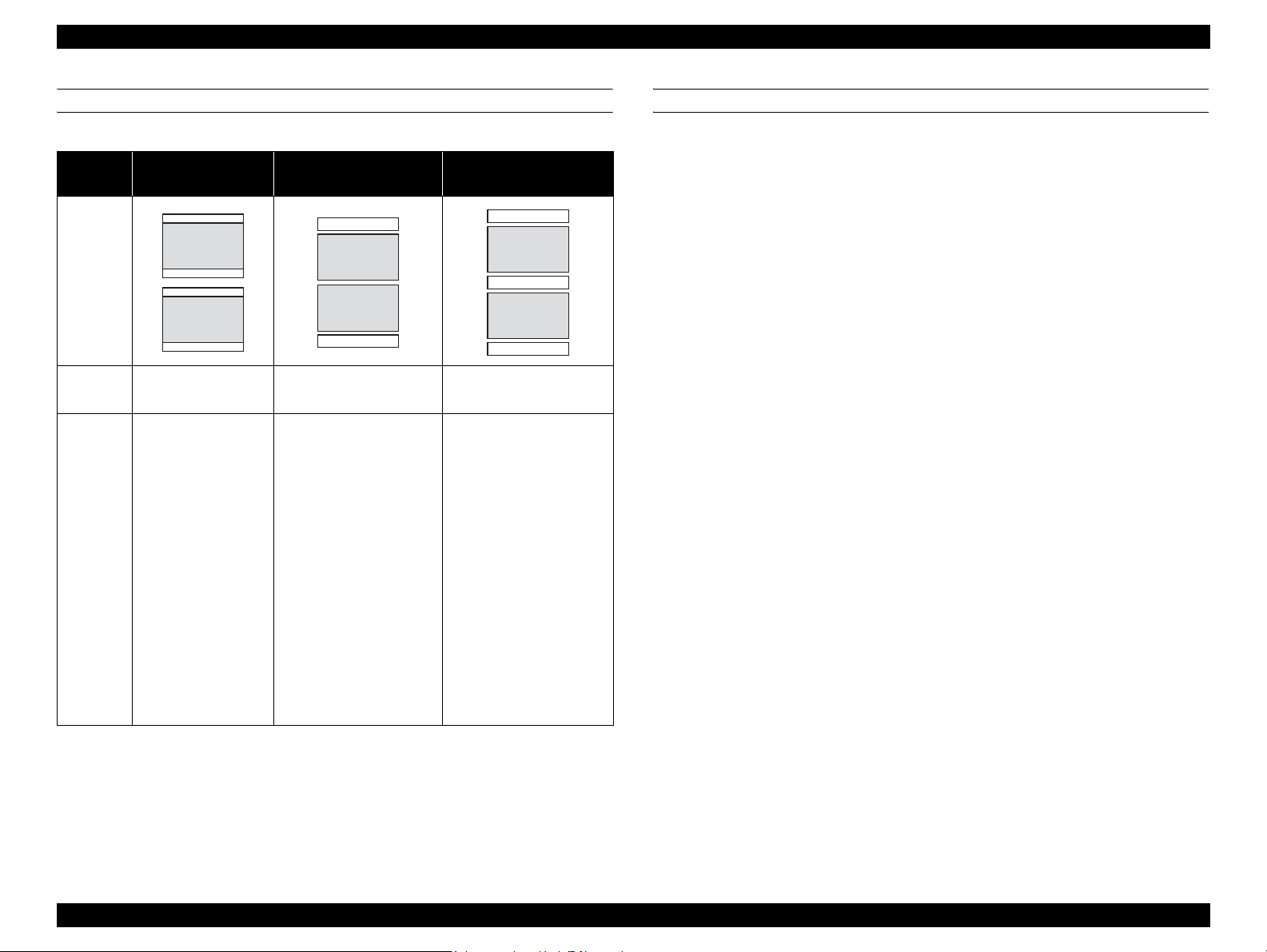

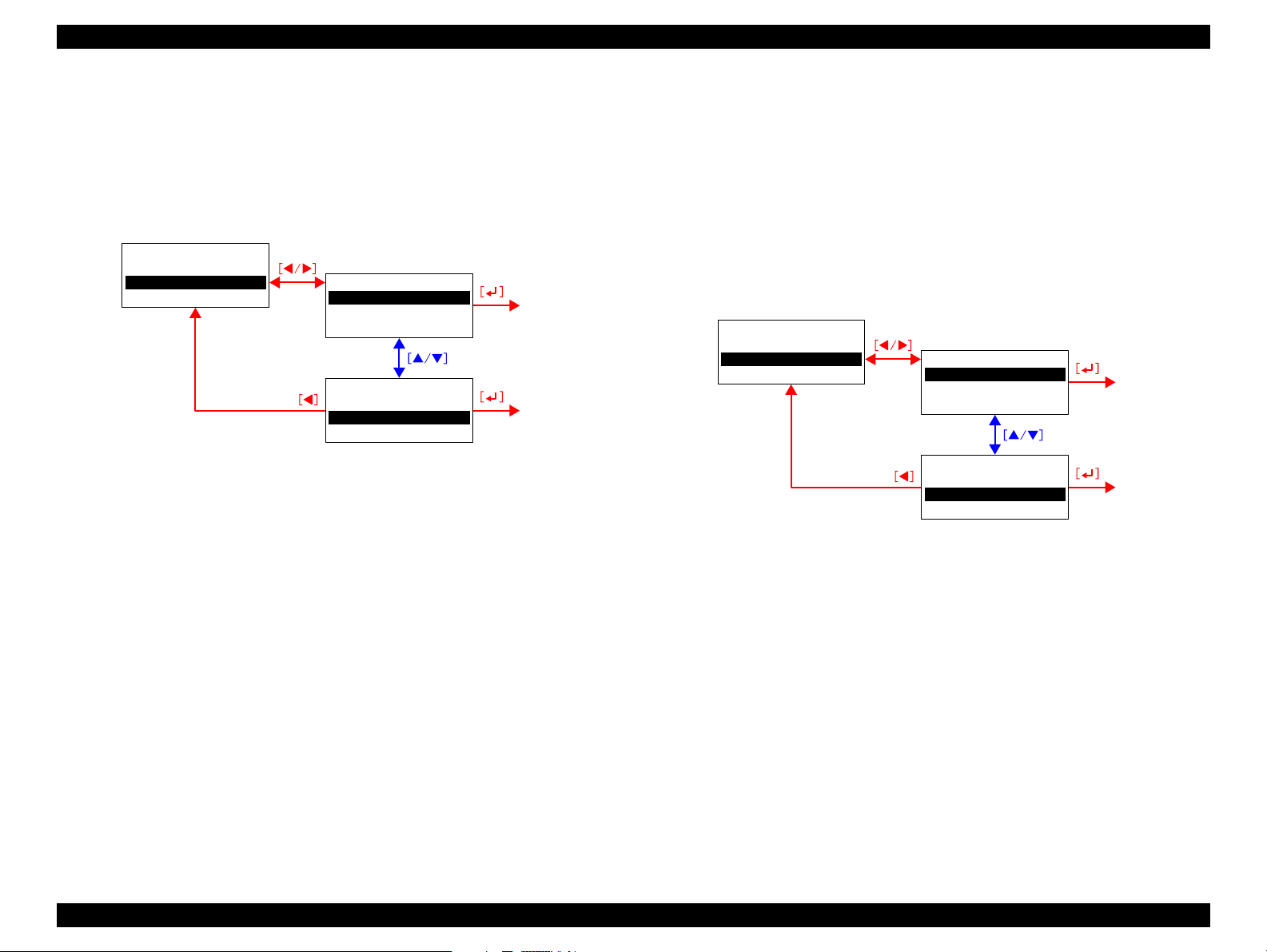

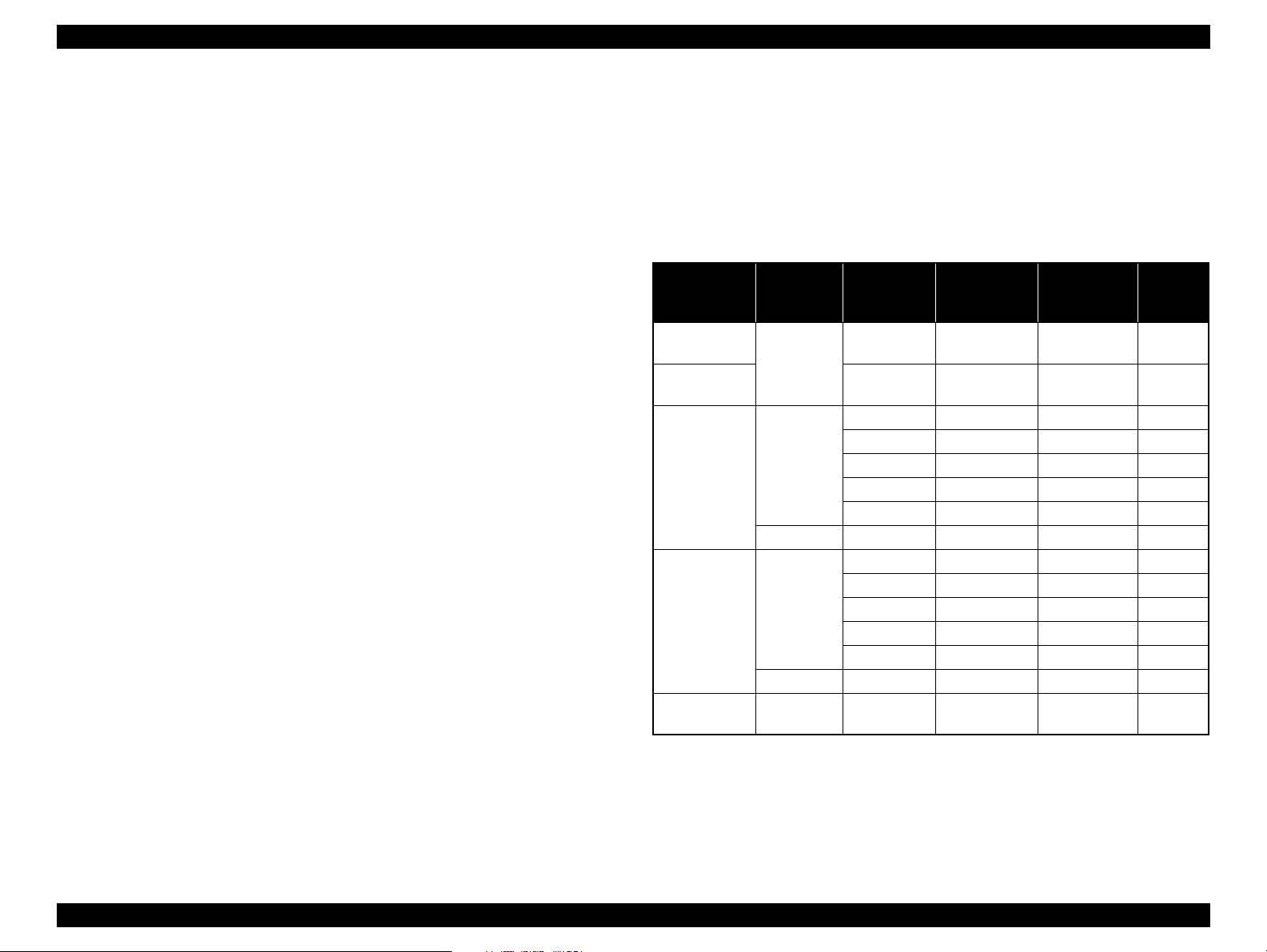

Table 1-28. Button Functions

Button

Normal One Press Hold Down for Three Seconds*

Power Turns the power ON or OFF *

Pause

Menu

Stops or restarts the printer operation*

Waiting for paper initialization trigger*

During printing

Changes the panel display to the Status Menu*

When Not printing

Shifts the printer into the Panel Setting Mode *

Paper Select

During printing

Does not function

When Not printing

Changes the paper type

Paper Feed *

6

When roll paper is set

Back-feeds the roll paper

*Does not work when roll paper is not set

When releasing the paper set lever

Increases suction of the Paper Suction fan

Paper Feed *

6

When roll paper is set

Feeds the roll paper

*Does not work when roll paper is not set

When releasing the paper set lever

Decreases suction of the Paper Suction fan

When A4 to A3+ size d cut shee t is manually loaded

Feeds the cut sheet

When a cut sheet is set

Ejects the cut sheet

Functions

1

2

3

3

3

3

Reset Interrupts panel

When the paper thickness sensor detects less than 0.8mm.

Runs a head cleaning*

When the paper thickness sensor detects 0.8mm or more

Runs a cleaning after a cleaning unavailable error is

--- Power OFF ---

4

removed.

* When the paper thickness sensor detects 0.8mm or more

during printing.

Does not function

Execute the Cutter Replacement Sequence*

5

When roll paper is set

Performs high-speed back-feeding of the roll paper

*Does not work when roll paper is not set

When roll paper is set

Performs high-speed feeding of the roll paper

*Does not work when roll paper is not set

Function at the

panel setting

setting

Moves to the next

menu item

Moves to the

previous menu

item

Increases the

setting value

Decreases the

setting value

Continued to next page

Function

(+ Power On)

Maintenance

mode

---

---

---

---

Product Description Control Panel 35

Page 36

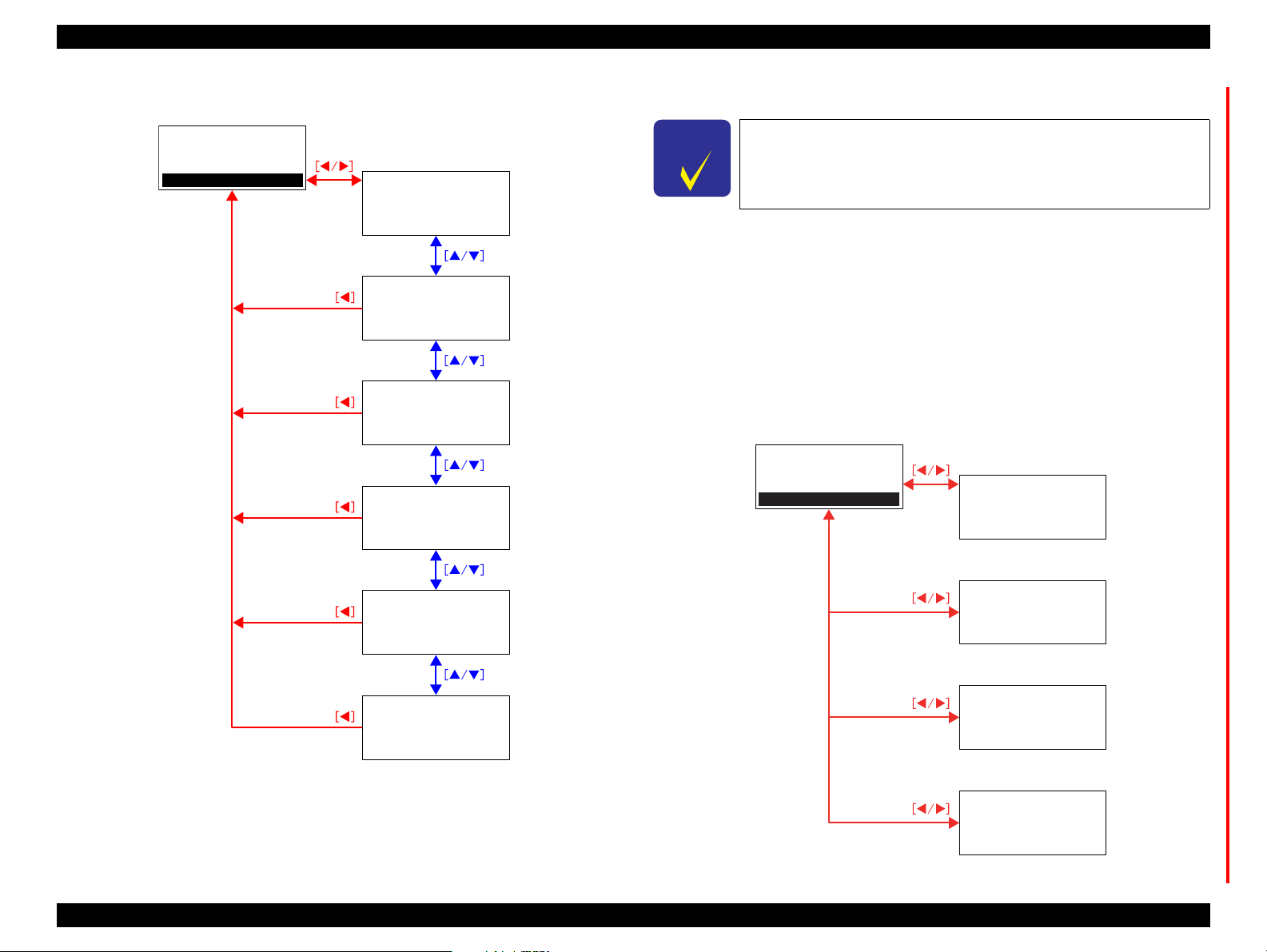

EPSON Stylus Pro 7400/7450/7800/7880/7880C/9400/9450/9800/9880/9880C Revision E

Table 1-28. Button Functions (continued)

Button

Normal One Press Hold Down for Three Seconds*

Enter Ejects a cut sheet when it is loaded after printing

*Does not function under conditions other than above.

When paper is loaded during printing with no error.

Roll paper: Cuts and ejects the paper

Cut sheet: Ejects the paper

During drying ink on paper

1

Stops drying ink and ejects the paper

*Does not function under conditions other than above.

Functions

Pause + Paper Select Enables or disables the Roll Paper Counter function when the

printer is in “Ready” mode.*

Menu + Paper Feed +

7

--- --- --- SERVICEMAN

--- --- ---

Pause

Menu + Paper Select +

--- --- --- F/W UPDATE

Paper Feed + Paper Feed

Note "*1": In actual operation, two seconds are enough. (It does not mean that the printer works immediately after the two seconds.)

"*2": The printer is always turned OFF regardless of operation status.

"*3": The printer starts to function within 3 seconds after the switch is released.

"*4": The cleaning is conducted when the printer is idling during printing.

"*5": The Cutter Replacement Sequence can be executed in “Ready” status, and even when a warning error or Paper Out error is occurring.