Page 1

Service Manual

Color Image Scanner

EPSON Perfection 4490 Photo

Automatic Document Feeder

SESC05004

Page 2

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical, photocopying, or

otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All

The contents of

The ab

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:Other product names used herein are for identification pu

Copyright © 2005 SEIKO EPSON CORPORATION.

effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

this manual are subject to change without notice.

ove not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

tive owners. EPSON disclaims any and all rights in those marks.

I&I CS/Quality Management & PL Department

rpose only and may be trademarks or registered trademarks of their respec-

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

DANGER Signals

WARNING Signals a precau

The precautionary measures itemized below s

a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

tion which, if ignored, could result in damage to equipment.

hould always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE

POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE

UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONEN

COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE WARRANTY OFFERED

BY EPSON.

DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

TS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR OTHER

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

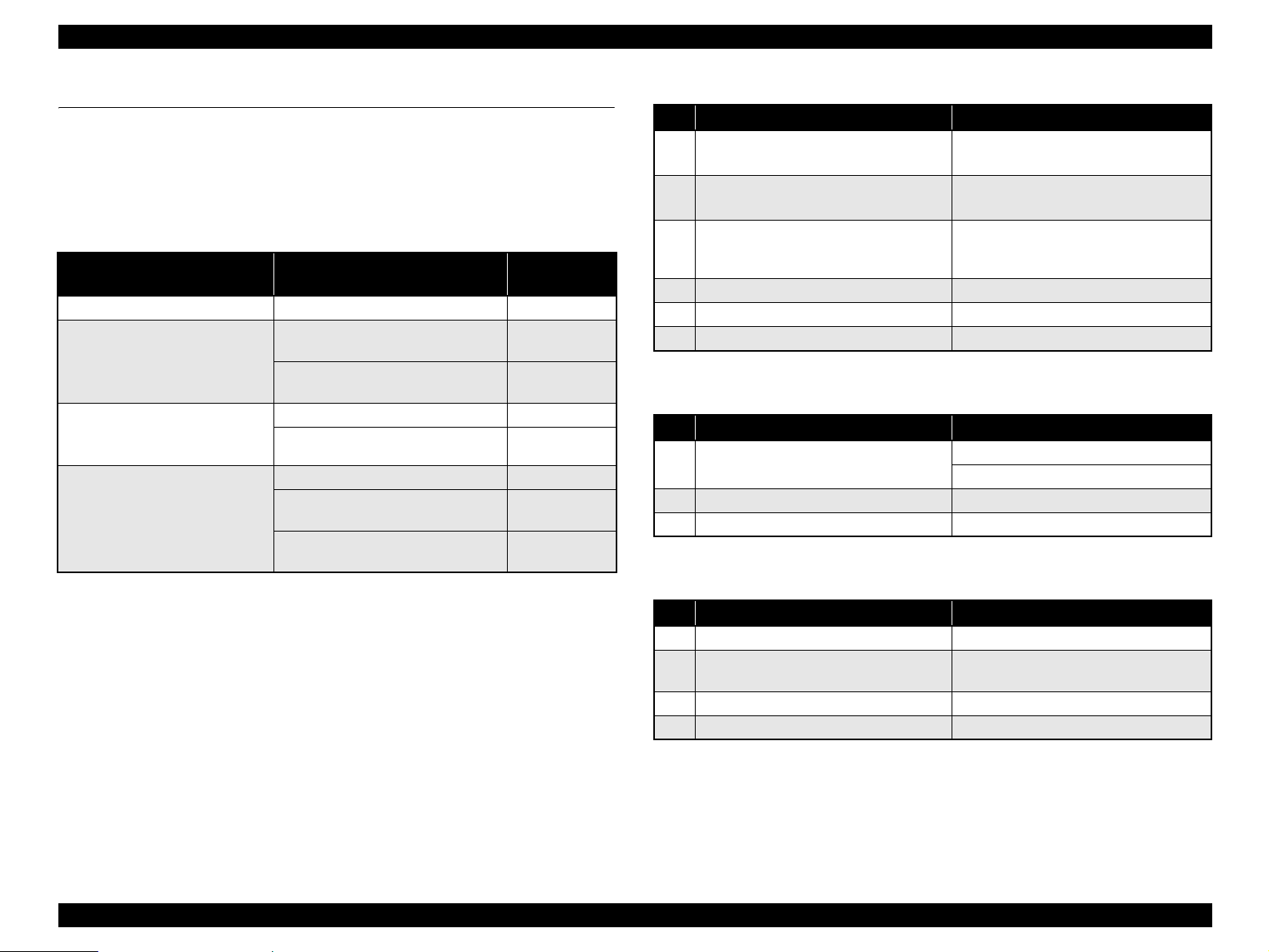

Manual Configuration

This manual consists of four chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTION

Describes the features and basic specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the electrical and mechanical basic operating principles of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY/ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANC E

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram

•Parts List

• Optional part: ADF

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maint

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

con

dition that, if not strictly observed, could result in damage to, or

destruction of, equipment.

May indicate an operating or maint

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maint

condition that, if not strictly observed, could result in injury or loss

of life.

enance procedure, practice or

enance procedure, practice or

enance procedure, practice or

Indicates a product reassembly procedure, practice or condition

must be executed in accordance with the specified standards to keep

the product's quality.

that

Page 5

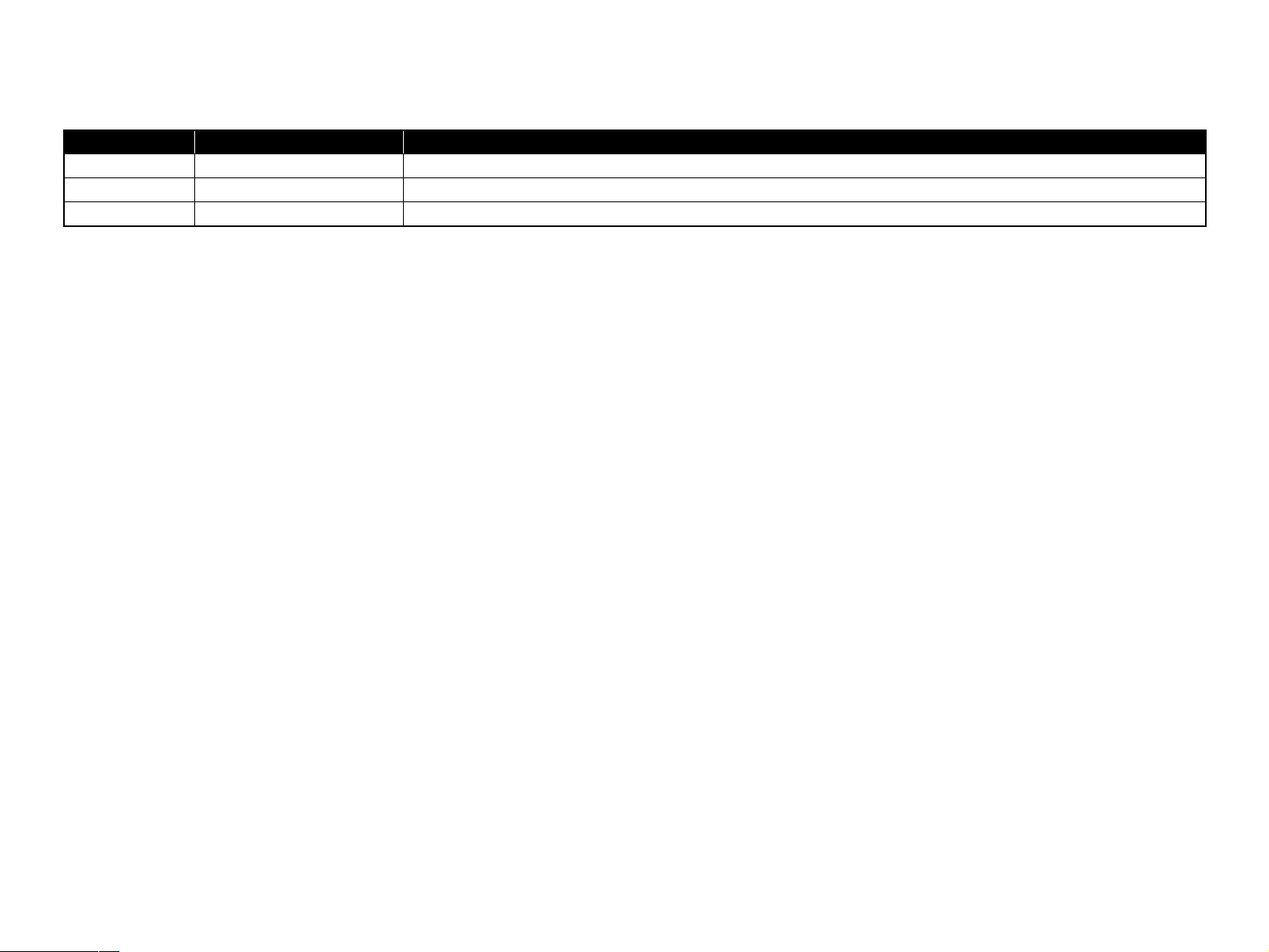

Revision Status

Revision Date of Issue Description

A May 31, 2005 First release

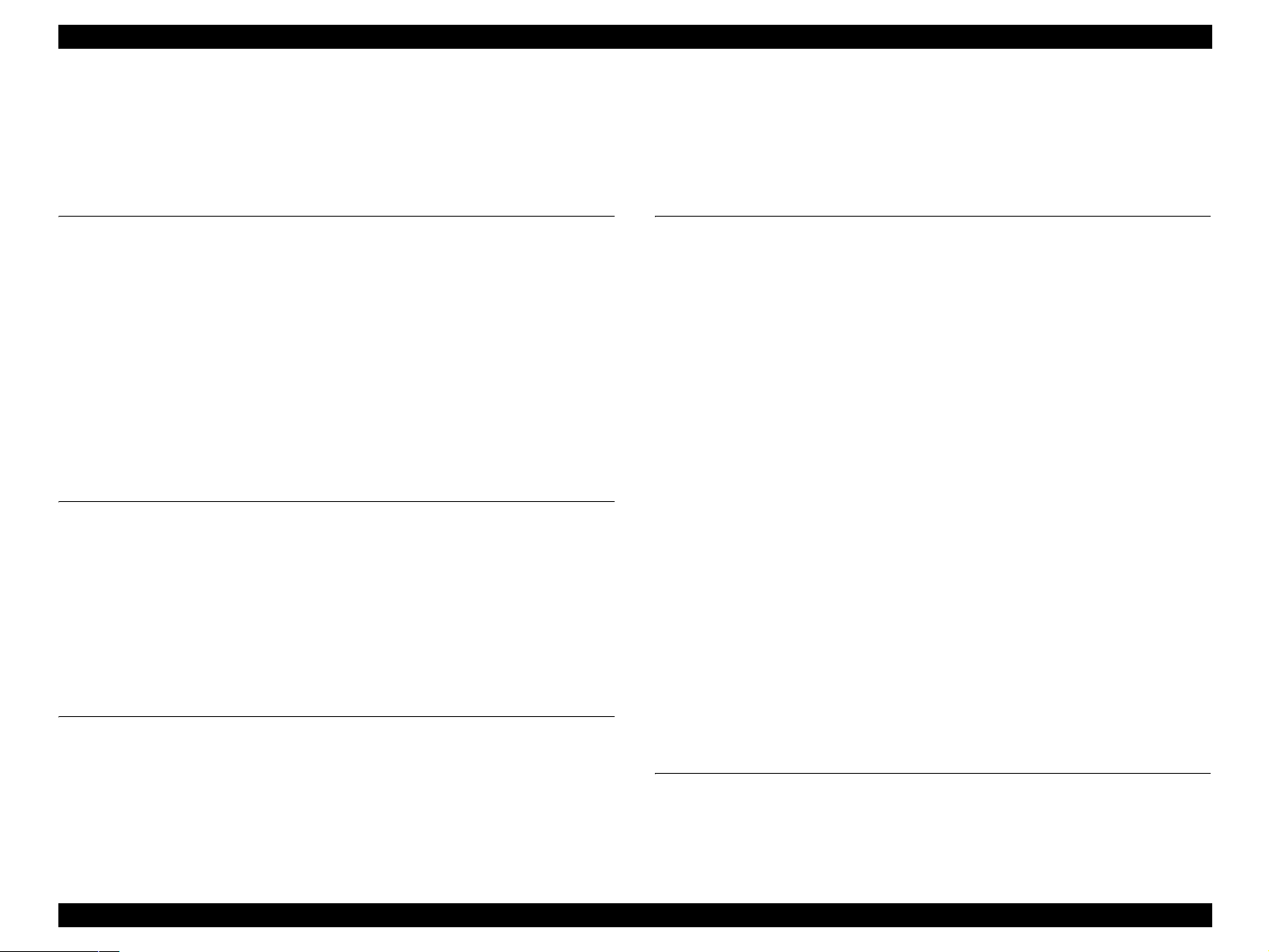

Page 6

EPSON Perfection 4490 Photo Revision A

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features.................................................................................................................. 9

1.2 Specifications ...................................................................................................... 10

1.3 Detailed Specifications........................................................................................ 12

1.4 Interface............................................................................................................... 12

1.5 Exterior Specifications ........................................................................................ 13

1.5.1 Explanation of Switches............................................................................. 13

1.5.2 Explanation of LED Indicators........................................... ........................ 13

1.5.3 Dimensions................................................................................................. 14

1.5.4 Maximum Document Size and Placement..................................................

1.6 Control Codes............................................... ................................................ ....... 16

1.7 Error-Time Processing......................................................................................... 17

15

Chapter 2 OPERATING PRINCIPLES

2.1 Engine Operation Outline.................................................................................... 19

2.1.1 Carriage Unit outline .................................................................................. 19

2.1.2 TPU Carriage Unit Outline......................................................................... 20

2.1.3 Carriage Moving Mechanism Operation .................................................... 21

2.1.4 TPU Carriage Drive Mechanism Operation............................................... 22

2.2 Digital ICE Function Operation .......................................................................... 23

2.2.1 Digital ICE for Film Overview................................................................... 23

2.3 Operation Principle of Electric Circuit................................................................ 24

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................. 26

3.1.1 Self-Diagnosing.......................................................................................... 26

3.2 Troubleshooting................................................................................................... 27

Chapter 4 Disassembly / Assembly

4.1 Overview................................................................................... .......................... 30

4.1.1 Precautions..................................................................................................

4.1.2 Recommended Tools.................................................................................. 30

4.1.3 Recommended Screws................................................................................ 30

4.2 Disassembly Procedure ....................................................................................... 31

4.2.1 Removing the TPU Unit............................................................................. 32

4.2.2 Removing the Upper Housing.................................................................... 33

4.2.3 Removing the Carriage Unit....................................................................... 34

4.2.4 Removing the Panel Board......................................................................... 36

4.2.5 Removing the Main Board ......................................................................... 37

4.2.6 Removing the Power Switch ...................................................................... 40

4.2.7 Removing the Panel FFC............................................................................ 41

4.2.8 Removing the Driven Pulley, Driven Pul

Holder Assy.......................................................... ..................................... 42

4.2.9 Removing the CR Motor Unit, Motor Tension Belt, and the CR Tension Belt

43

4.2.10 Removing TPU Lower Housing............................................................... 45

4.2.11 Removing the Sensor Board..................................................................... 46

4.2.12 Removing the Hinge Assy........................................................................ 46

4.2.13 Removing the TPU Unit Cable................................................................. 47

4.2.14 Removing the DRV Board ....................................................................... 48

4.2.15 Removing Torsion Spring ........................................................................ 49

4.2.16 Removing the TPU Carriage Unit............................................................ 50

4.2.17 Removing the TPU Inverter Board........................................................... 51

4.2.18 Removing the SUB_C Board, SUB_D Board, and the

4.2.19 Removing the TPU CR Motor.................................................................. 55

ley Spring, and the Driven Pulley

Lamp.................. 53

30

Chapter 5 ADJUSTMENT

5.1 Overview................................................................................... .......................... 58

5.1.1 Adjustment item ......................................................................................... 58

5.1.2 Adjustment method..................................................................................... 58

5.1.3 Adjustment of Torsion Springs on the

TPU CR Drive Belt....................... 58

6

Page 7

EPSON Perfection 4490 Photo Revision A

Chapter 6 Maintenance

6.1 Overview ............................................................................................................. 60

6.1.1 Cleaning...................................................................................................... 60

6.1.2 Lubrication.................................................................................................. 60

Chapter 7 APPENDIX

7.1 Connectors........................................................................................................... 64

7.1.1 Connector Reference Table ........................................................................ 64

7.1.2 Connector Configuration ............................................................................ 64

7.2 Circuit Diagrams ................................................................................................. 65

7.3 Exploded diagram................................................................................................ 73

7.4 Parts List......................................... ..................................................................... 78

7.5 Optional Part; Auto Document Feeder....... ..

7.5.1 Overview..................................................................................................... 79

7.5.2 Basic specifications .................................................................................... 79

7.5.3 Interface...................................................................................................... 81

7.6 ADF; Disassembly............................................................................................... 82

7.6.1 Removal of B81334 Main Board................................................................

7.6.2 ASF Part...................................................................................................... 83

7.6.3 Disassembly of ASF and Frame.............

7.6.4 Disassembly of ASF Assembly..............

7.7 ADF; Lubrication ................................................................................................ 97

....................................................... 79

82

.................................................... 89

.................................................... 91

7

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

EPSON Perfection 4490 Photo Revision A

1.1 Features

The main features of the EPSON Perfection 4490 Photo are as follows.

Hig

Hig

Easy

h Quality

Opt

ical Resolution

4800 dpi (with 6-line color CCD, 124200 pixels)

Pi

xel Depth

16 bits per pixel (input and output)

h-Speed Scanning

11 second

12 second

*

When scanning a film at A4 300 dpi.

s for monochrome

s for color

-To-Use

EPSON Creativi

• Supports for a wide variety of file types; BMP, JPEG, TIFF, RAW,

ty Suites

PICT, PDF

• Thumbnail view support

• Link indicator function for easy scanning

• Multiple exposure levels from Natural to Vivid are preset for Auto

Exposure

Digital ICE for Film

Dust and scratch removal with hardware

Bui

High-Speed USB 2.0

Op

lt-in 2.7" x 9.3" transparency unit (TPU)

• 35 mm (135) strip film: 12 frames

• 35 mm (135) mounted film: 4 frames

• Medium format film (120/220): 1 frame

tion

A4 and legal size document can be scanned with the optional ADF unit

EPSON Scan

• Graphic user interface:

Full Auto Mode, Home Mode and Professional Mode

• Stand-alone application:

In addition to TWAIN driver function, saving images without using a

graphic application such as Photoshop is available

• Additional image editing tools:

histogram, multi-level unsharp mask, de-screening and tone-curve

editor

• Image enhancement functions:

dust remover, photo restoration and grain reduction

• Full automatic mode (flatbed and film)

• Thumbnail view support

• Supports both positive and negative monochrome films

PRODUCT DESCRIPTION Features 9

Page 10

EPSON Perfection 4490 Photo Revision A

1.2 Specifications

BASIC SPECIFICATIONS

Scanner type

Flatbed, color

Scan

Photoelectric device

Effe

Maxim

Op

Maxim

Note *: The maximum hardware resolution of 4800 x 9600 dpi is achieved using EPSON's

Output Resolution

Sp

Pi

Com

ning method

Moving carriage, stationary document

6-line color CCD

(2.2 µm) with micro lens

ctive pixels

40,800 x 56,160 pixels at 4800 dpi

um document size and type

Flatbed: US letter or A4 size

8.5 x 11.7 inches (216 x 297 mm)

(Paper type for ADF: Fine quality paper, Bond paper, Check paper,

Recycled paper)

TPU: 35 mm (135) strip film x 12 frames (positive and negative films)

35 mm (135) mounted film x 4 frames (positive films)

Medium format film (120/220) x 1 frame (positive and negative films)

tical resolution

4800 dpi

um resolution

*

4800 dpi (main scan) x 9600 dpi hardware (sub scan)

Micro Step Drive technology. The motor basic step is 2400 dpi.

50 to 6400 dpi in 1 dpi increments, 9600 dpi, 12,800 dpi

eed (color)

16.832 msec/line at 4800 dpi in Draft mode

xel depth

16 bits per pixel (input and output)

mand level

ESC/I-D2, FS

Interfaces

USB 1.1/2

Ligh

.0

t source

White cold cathode fluorescent lamp

Reli

ability (MCBF)

36,000 cycles of carriage movement

Op

tion

ADF unit

Op

eration buttons

4 push buttons

Power Supply

AC adaptor

Document setting position

Rear-side right corner on the document glass ( Scanning home position )

ELECTRICAL

Main Unit

Rat

Input

Power co

ed voltage 24 VDC

voltage 24 to 26.4 VDC

nsumption

• Operation: 20 W

• Standby mode: 13.5 W

• Sleep mode: 3.8 W

Rated current 1.1 A

AC Ad

aptor

Rated

input voltage 100 - 120 VAC (100 V Model)

220 - 240 VAC (220 V Model)

Rated

Rated

input frequency 50 - 60 Hz (100 V, 200 V)

input current 0.7 A at 100 VAC

0.4 A at 200 VAC

Ou

tput voltage 24 - 26.4 VDC

PRODUCT DESCRIPTION Specifications 10

Page 11

EPSON Perfection 4490 Photo Revision A

Rated ou tput current 1.1 A

Current

resistance 500 VDC: > 100 MΩ

(AC input terminal and DC output terminal)

Vol

tage resistance 3000 VAC for 1 min.

(AC input terminal and DC output terminal)

TP

U

Rated vo

In

Input

ltage 24 VDC

put voltage 24 - 26.4 VDC

current 0.3 A at 24 V

0.07 A at 5 V

ADF

Rated vo

In

Input

ltage 24 VDC, 5 VDC

put voltage 24 - 26.4 VDC, 5 VDC

current 0.8 A at 24 V

0.2 A at 5 V

Energ

y conservation International Energy Star Program compliant

Static electricity Contact discharge: 4.5 kV

Air discharge: 8.5 kV

ENVIRONMENTAL

Temperature

Operatio

St

n: 41 to 95 °F (5 to 35 °C)

orage: -13 to 140 °F (-25 to 60 °C)

EMC AND SAFETY STANDARDS COMPLIANCE

Scanner 100 V • FCC15B Class B (USA)

• CSA108.8 Class B (Canada) (FCC represents)

200 V • E N55022 (CISPR Pub22) Class B

• EN61000-3-2

• EN61000-3-3

• EN55024

• AS/NZS3548 Class B (Australia)

• Korea EMC

ection law

ection law

AC Adaptor

USB 2.0 I/F

• Russia consumer prot

• CCC (China)

100 V • UL1950/CSA C22.2 No.950 (North American, UL/CSA

Obtain by each other)

• UL1310/CSA C22.2 No.223 (As above)

• NOM (Mexico)

200 V • IEC60950 (Get CB report)

•GS (German)

• AS/NZS3260 (Australia)

• GOST (Russia)

• Singapore safety standard (Singapore)

• Russia consumer prot

• Korea safety regulation (Korea)

• Polish safety (Poland)

• Argentina safety (Argentina)

• SASO (Saudi Arabia)

• CCC (China)

Hum

idity (non-condensing)

Operatio

n: 10% to 80% (ADF: 20% to 80%)

Storage: 10% to 85%

OPERATING CONDITIONS

Ordinary office or home conditions; avoid extreme dust, direct sunlight, and strong

light sources

PRODUCT DESCRIPTION Specifications 11

Page 12

EPSON Perfection 4490 Photo Revision A

1.3 Detailed Specifications

IMAGE PROCESSING FUNCTION

Gamma Correction 1 User defined level

Colo

Line Art

Operatin

USB 1.1 I/F • Microsoft

USB 2.0 I/F • Microsoft Windows 2000 Professional/XP Home Edition/XP

Note *: USB2.0 Host Driver by Microsoft is required

r Correction 1 User defined level

Fixed threshold

g System Compatibility

Interface Operating System

Windows 98SE/Me/2000 Professional/XP Home

Edition/ XP Professional(Pre-installed model or upgrade of

Windows 98/Me/2000 Professional pre-installed model)

• Mac OS X 10.2 or later

• Mac OS 9.1 or later (Only EHC)

Professional*

(Pre-installed model or upgrade of Windows

-installed model)

• Mac OS X 10.2.7 or later

2000 Professional pre

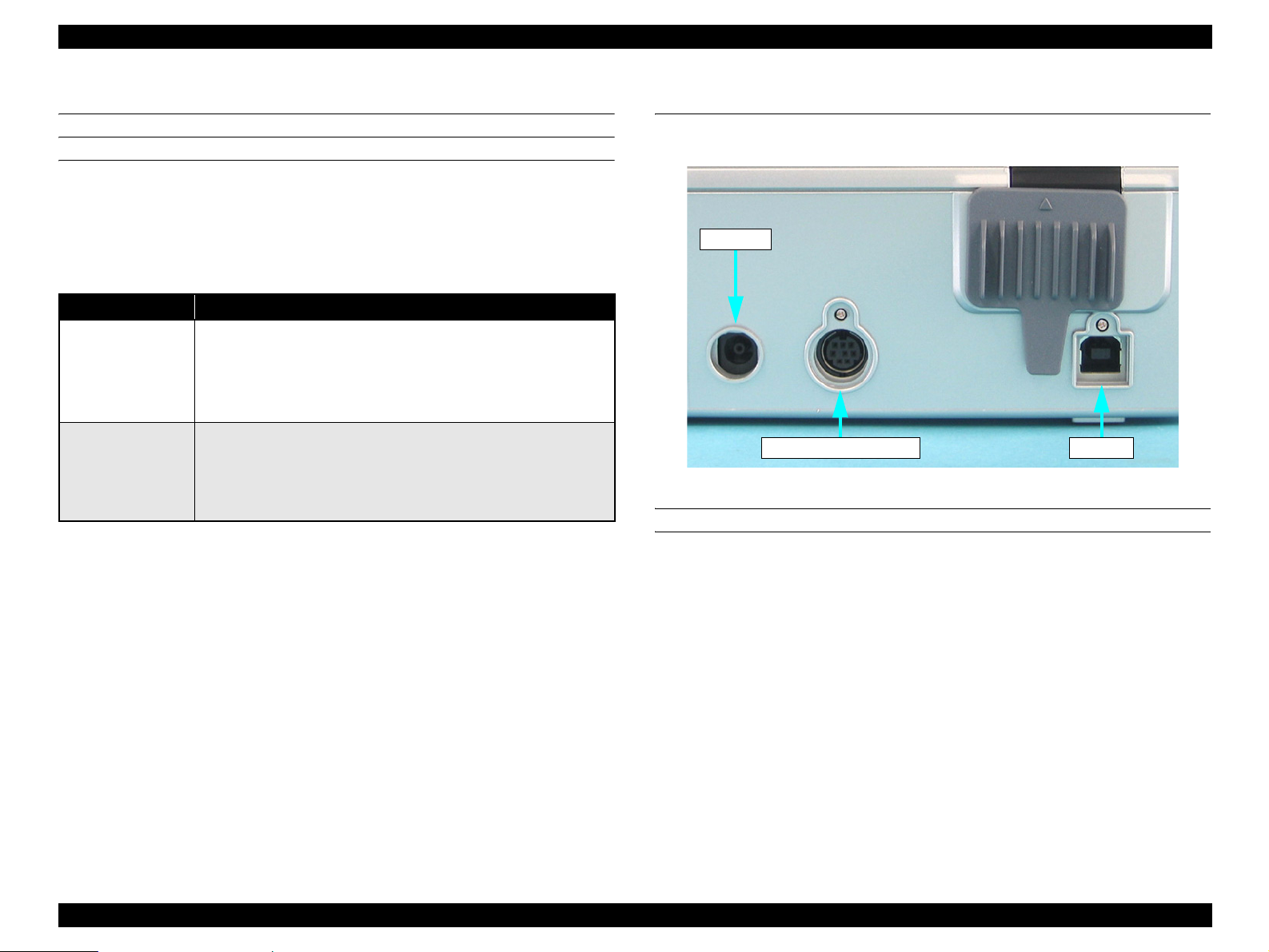

1.4 Interface

The interfaces of this scanner are shown below.

AC Input

TPU Unit Connector

Figure 1-1. Interface

USB INTERFACE

Interface type Universal Serial Bus Specification Revision 2.0

USB2.0

Ven

Prod

dor ID: 04B8h

uct ID: 0119h

Connector type One self-powered receptacle, Type B. Must be

connected directly to the host or to tier 1 in a hub

with a recommended USB cable.

PRODUCT DESCRIPTION Detailed Specifications 12

Page 13

EPSON Perfection 4490 Photo Revision A

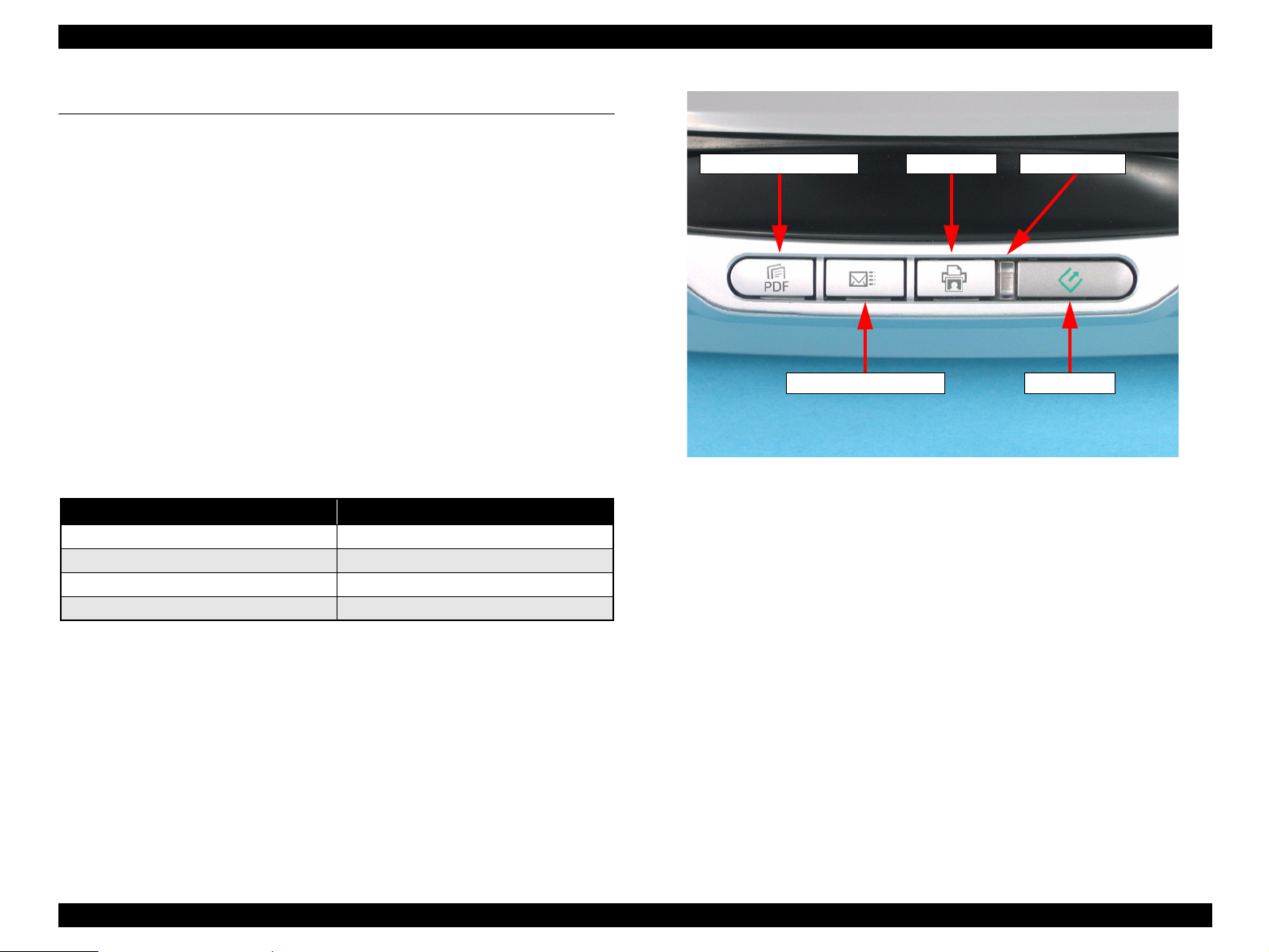

1.5 Exterior Specifications

1.5.1 Explanation of Switches

Start Button

Starts the EPSON Smart Panel.

Copy

Button

Prints photos and makes prints from films.

S

can to E-mail Button

Sends the scanned image by an e-mail.

Scan

to PDF Button

Starts scanning and stores the sccanned data.

1.5.2 Explanation of LED Indicators

Status LED

Located to the left of the Start Button. Indicates

light as shown in the table below.

LED Indication Status

Lit Green

Flashing green slowly Busy

Flashing red fast Error

Off Operate off:

Note *1: Warm up, scanning, initializing, etc.

Certain error conditions, such as Option Error, may not cause the Status LED to turn

*2:

red.

scanner statuses with a green or red

Ready

Scan to PDF Button

Scan to E-mail Button

Copy Button

Status LED

Start Button

Figure 1-2. Switches and LEDs

*1

*2

PRODUCT DESCRIPTION Exterior Specifications 13

Page 14

EPSON Perfection 4490 Photo Revision A

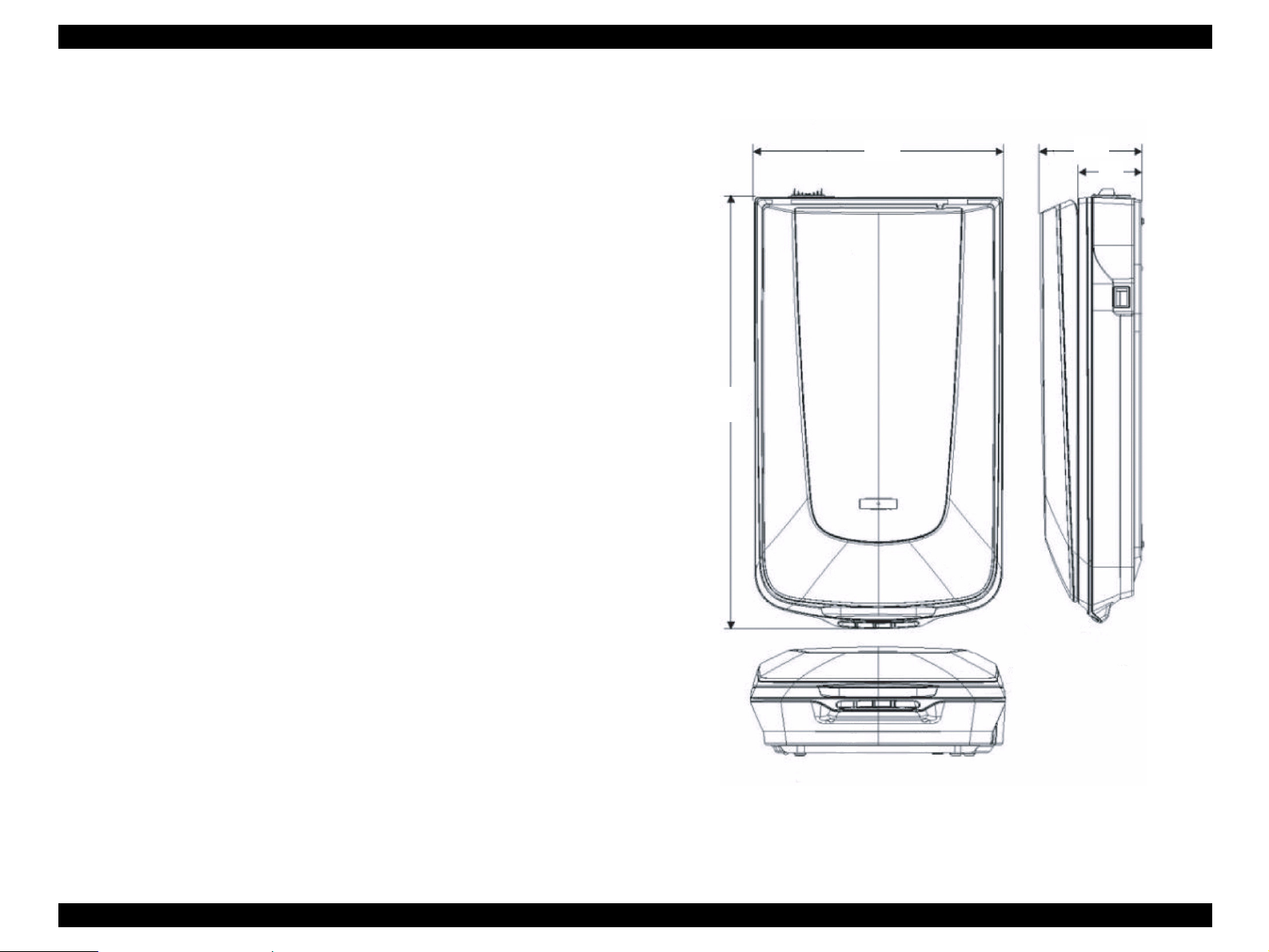

1.5.3 Dimensions

Dimensions and Weight

Dim

Weig

ensions 272 x 475 x 113mm (W x D x H)

ht Approx. 4.0 kg (without AC adaptor)

4.113 kg (with AC adaptor)

External Drawing

475

272

113

70

Unit: mm

Figure 1-3. External Dimensi

ons of Perfection 4490 Photo

PRODUCT DESCRIPTION Exterior Specifications 14

Page 15

EPSON Perfection 4490 Photo Revision A

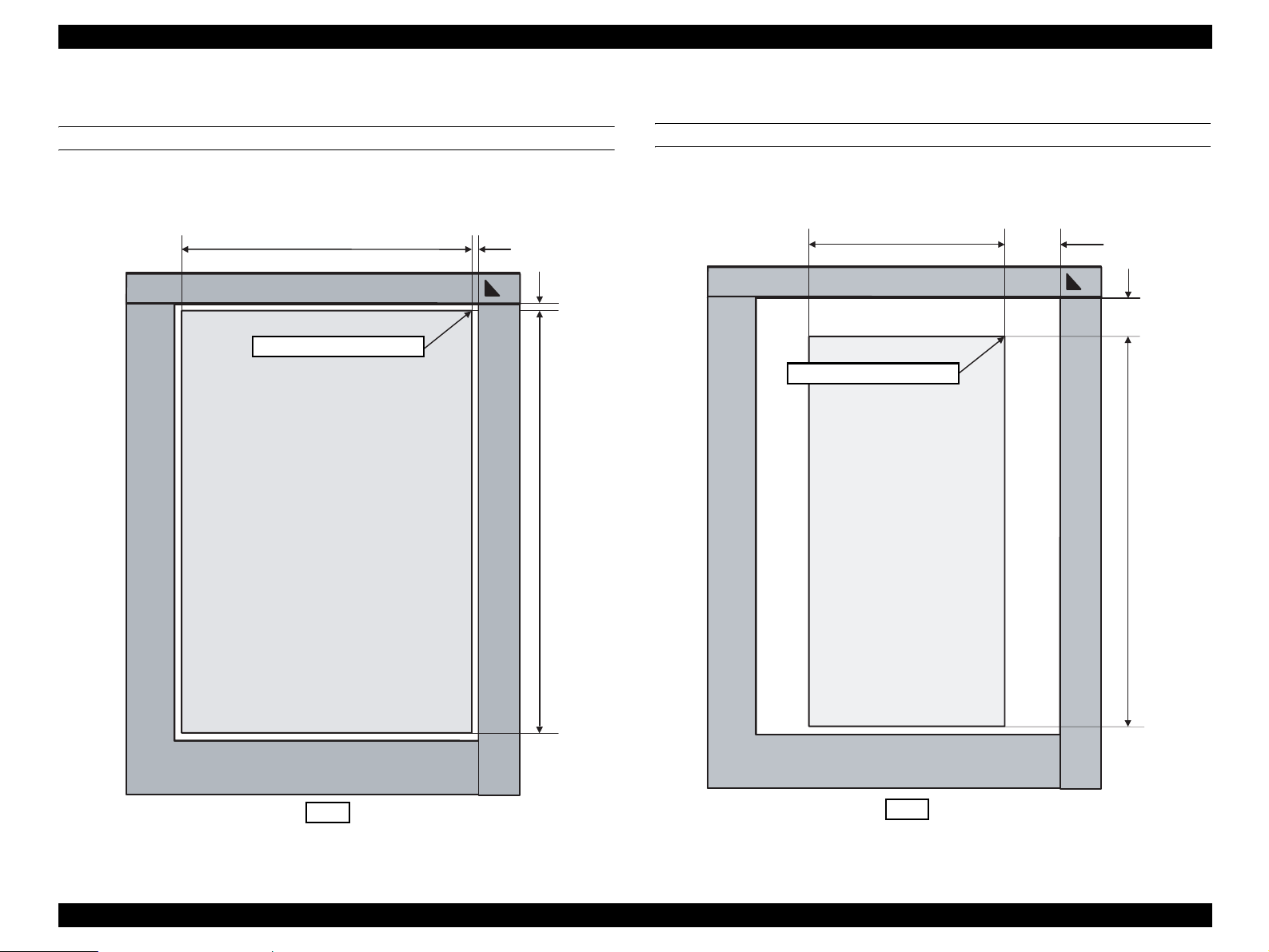

1.5.4 Maximum Document Size and Placement

REFLECTIVE DOCUMENT

Size : 8.5 in (216 mm) W x 11.7 in (297 mm) H

8.5 in (216 mm) 1 ± 0.5 mm

Scanning home position

1.6 ± 0.5 mm

11.7 in (297 mm)

TRANSPARENT DOCUMENT

Size : 2.72 in (68 mm) W x 9.44 in (236 mm) H

67.56 ± 1.5 mm

2.72 in (68 mm)

13.48 ± 1.5 mm

Scanning home position

9.44 in (236 mm)

Front

Figure 1-4. Reflective Document Scanning Range

Figure 1-5. Transparent Docu

Front

ment Scanning Range

PRODUCT DESCRIPTION Exterior Specifications 15

Page 16

EPSON Perfection 4490 Photo Revision A

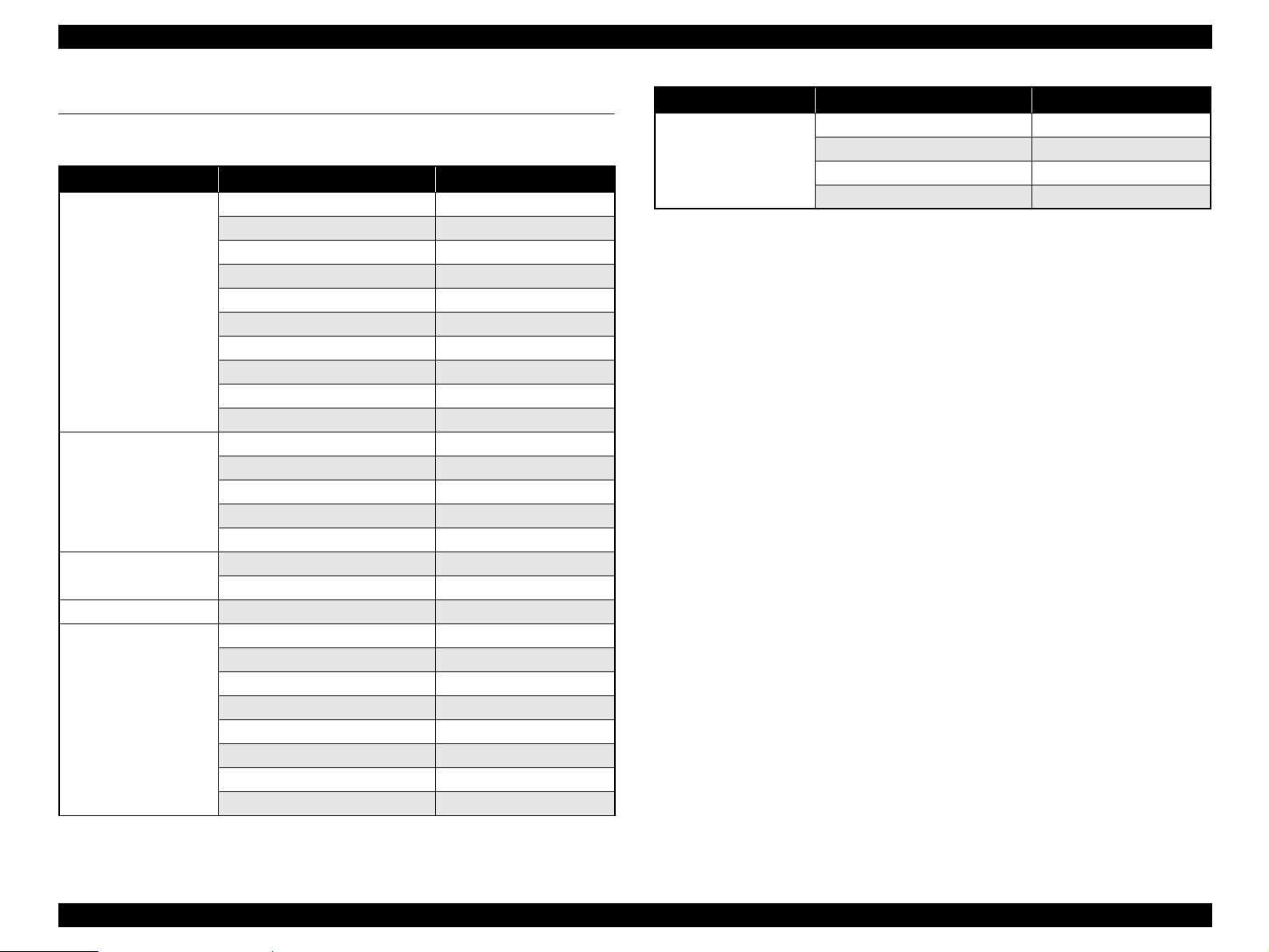

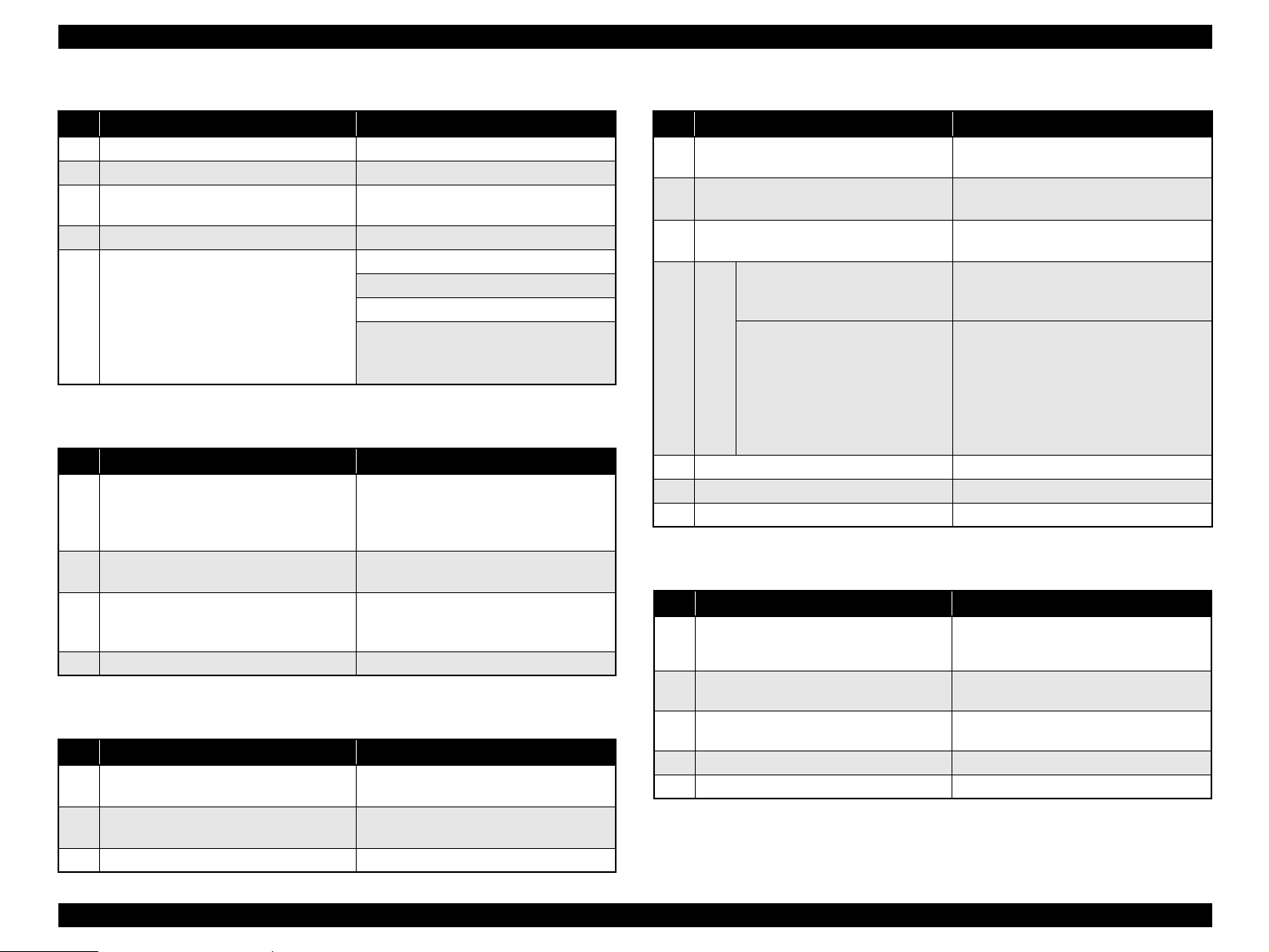

1.6 Control Codes

The following table is the list of control codes by the scanner.

Category Command Name Code

Execution command ID request

Status request ESC F

Extended status request

Status setting request ESC S

Scan start

Push button status request ESC !

Extended ID request

Scanner status request FS F

Scanning parameter request

New scan start FS G

Data form setting Data format setting ESC D i

Resolution setting ESC R n1 n2

Scanning area setting

Color setting ESC C i

Parameter setting

Correction Processing Gamma correction setting ESC Z i

Gamma correction table setting

Image Processing Threshold value setting ESC t I

Support and

Miscellaneous

Scan mode setting ESC g i

Initialization ESC @

Line counter setting

Option control ESC e i

Film type designation

Paper exit FF

Paper loading

Warm-up cancel ESC w

ESC I

ESC f

ESC G

FS I

FS S

ESC A n1 n2 n3 n4

FS W

ESC z i d [256]

ESC d i

ESC N i

PF

Category Command Name Code

Control Normal response ACK

Abnormal response NACK

Scanning stop

Header STX

CAN

PRODUCT DESCRIPTION Control Codes 16

Page 17

EPSON Perfection 4490 Photo Revision A

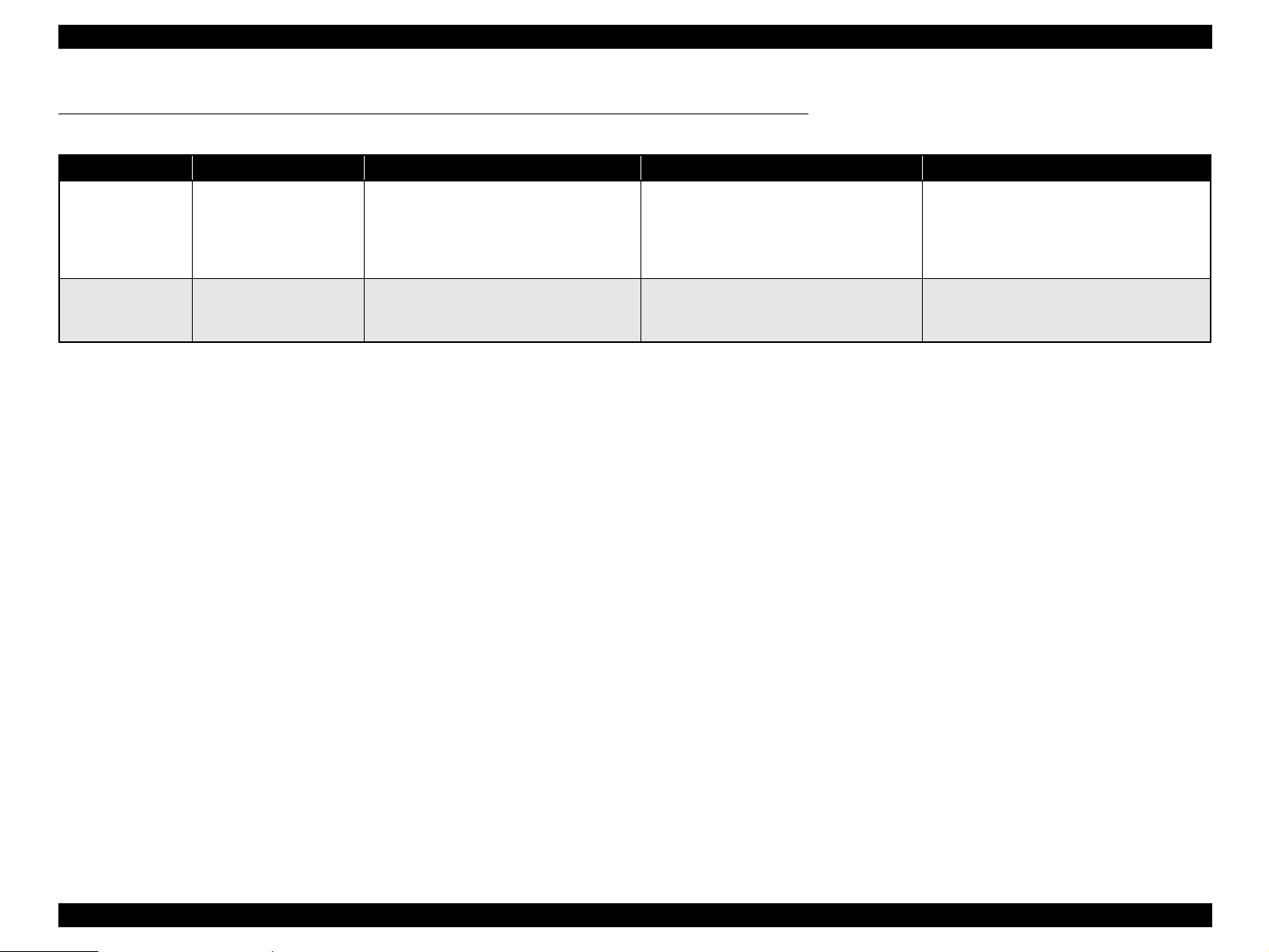

1.7 Error-Time Processing

Table 1-1. Error Definition and Remedy List

Category LED Indication Cause Scanner response Recovery

Command error None An invalid command or invalid

parameter was detected.

Fatal error Red LED flashes rapidly • The lamp is burnt out.

• The main unit is faulty.

• Firmware downloading failed.

command

• The scanner (interpreter) ignores the

incorrect command or parameter. Current

setting maintained.

• The Scanner (interpreter) returns NACK,

and waits for the next command parameter.

• The Scanner turns the carriage lamp off and

stops the operation.

• The Scanner sets Bit 7 of the status bit.

The error condition is cleared when the scanner

(interpreter) receives a valid command.

Turn the scanner off and then back on.

PRODUCT DESCRIPTION Error-Time Processing 17

Page 18

OPERATING PRINCIPLES

CHAPTER

2

Page 19

EPSON Perfection 4490 Photo Revision A

2.1 Engine Operation Outline

This section explains the functions and operating principles of the Perfection 4490

Photo Engine. The Engine is roughly divided into the Carriage Unit and Carriage

Moving Mechanism.

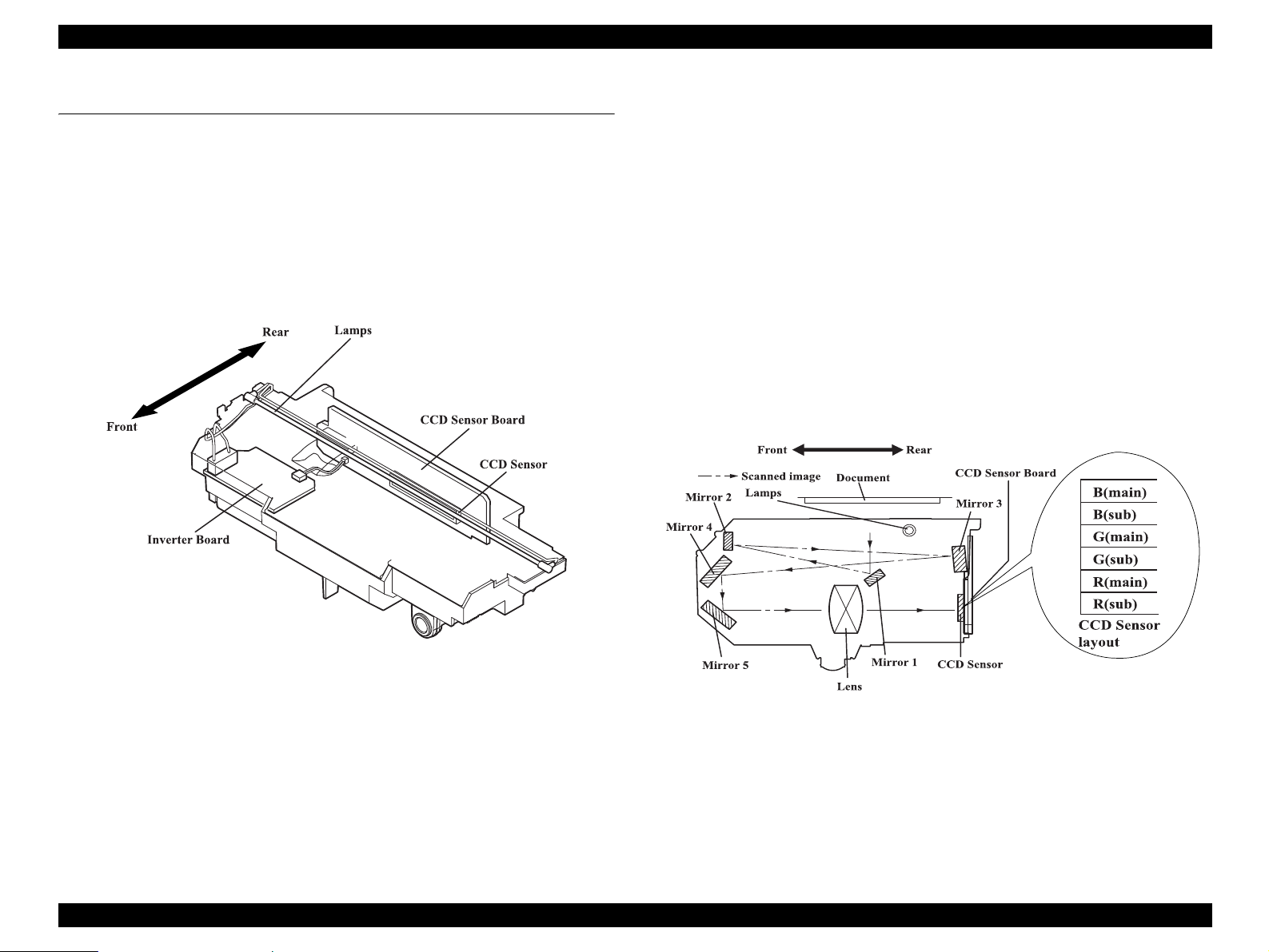

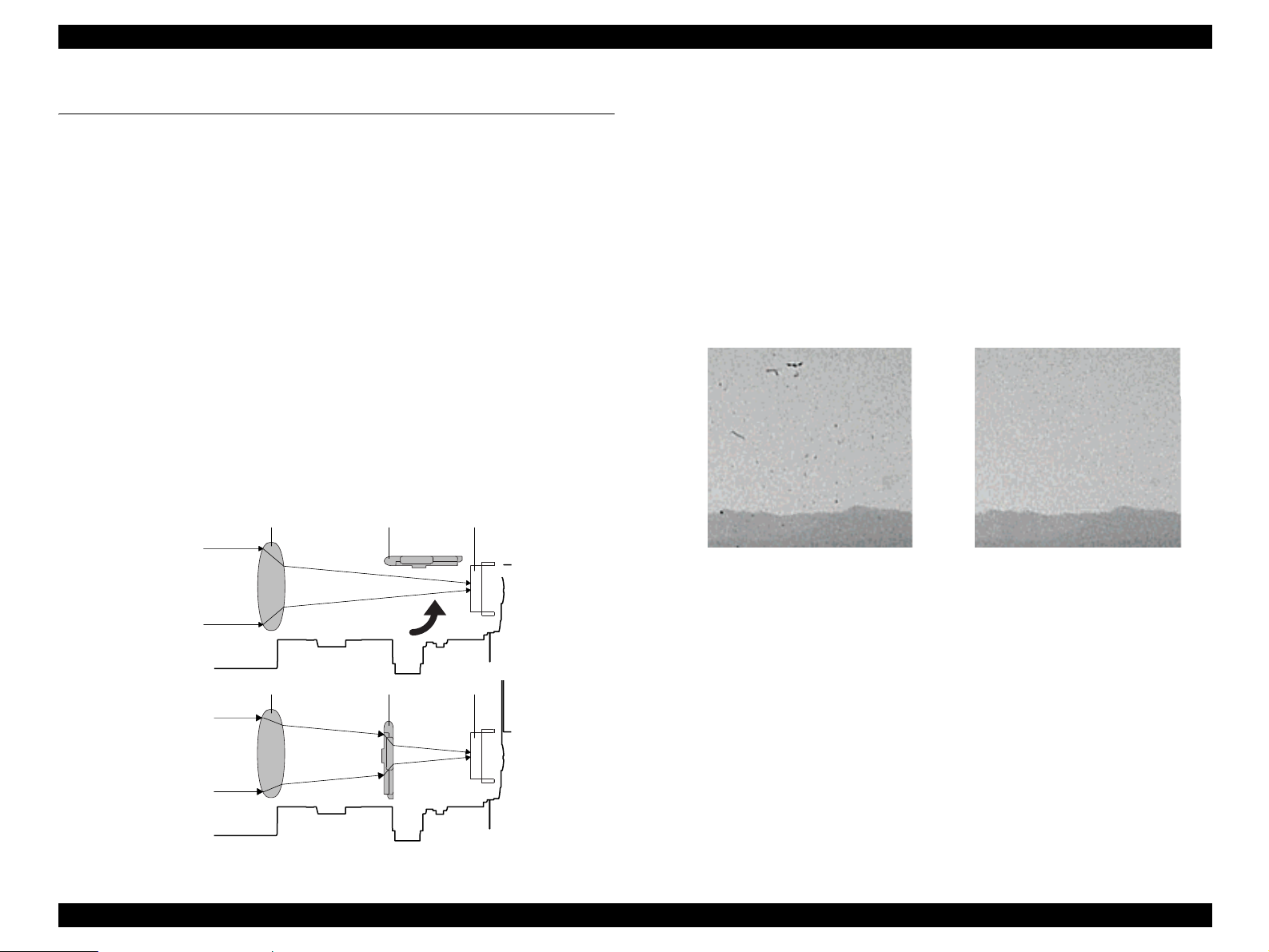

2.1.1 Carriage Unit outline

The Carriage Unit can be divided into the CCD Sensor Board, Inverter Board, Lamps

(light source), and Mirror/Lens Mechanism. (Refer to Fugure 2-1, 2-2.)

CCD

Inverter

Lamp

Mirror/Lens Mechanism

Sensor Board Forms an alternative six-lines color CCD (R, G, B

Board Boosts +24VDC and converts DC to AC to generate

s White cool cathode fluorescent lamps are used as a

independent) and its control and drive circuits.

the voltage for driving the Lamps (white cool cathode

fluorescent lamps).

light source. When the amount of light is not stable, the

Panel LED flashes and enter the standby mode until it

becomes stable.

The beam applied to the scanned document is reflected,

passes through the Mirror/Lens Mechanism in the

Carriage Unit for correction of the beam axis, and then

reaches the CCD Sensor. The light components R, G, B

are extracted by the Color CCD Sensor itself, not by

switching between R, G and B of the light source as

previously.

Figure 2-1. Carriage Unit Configuration

Figure 2-2. Mirror/Lens Mechanism

OPERATING PRINCIPLES Engine Operation Outline 19

Page 20

EPSON Perfection 4490 Photo Revision A

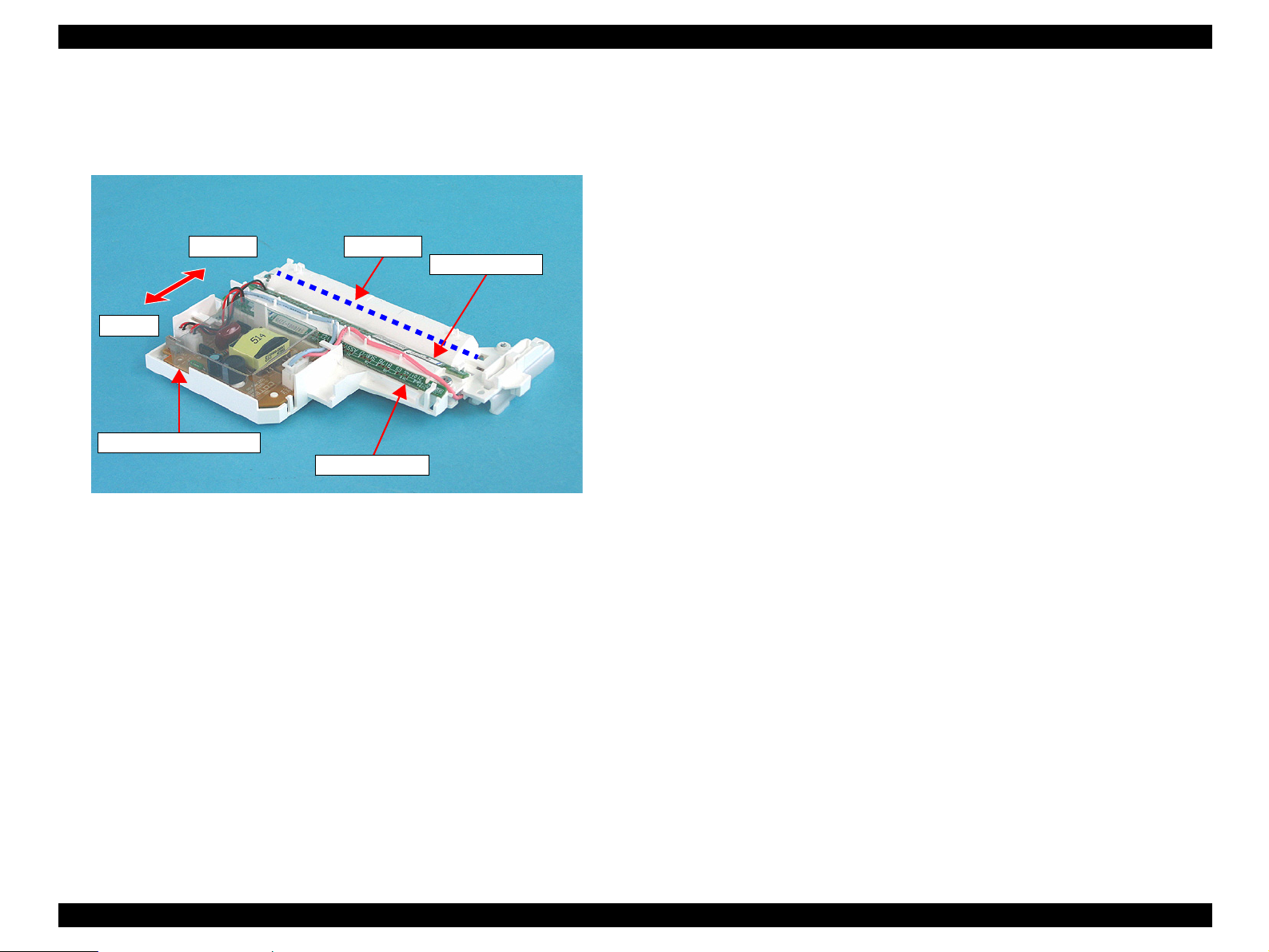

2.1.2 TPU Carriage Unit Outline

The TPU Carriage Unit consists of TPU Inverter Board, Lamps (light source), SUB_C

Board, and SUB_D Board. (Refer to Fugure 2-3.)

Front

Rear

TPU Inverter Board

Figure 2-3. TPU Carriage Unit Configuration

Inverter Board

necessary to power the Lamps.

Lamps used as

the light output becomes unstable, the Panel LED flashes and the scanner enters

standby mode until it becomes stable.

SUB_C Board and SUB_D Board each

converts DC to AC and boosts the voltage to generate the current

the primary light source are white cool-cathode fluorescent lamps. If

Lamps

SUB_C Board

SUB_D Board

contain LEDs to generate infrared light.

OPERATING PRINCIPLES Engine Operation Outline 20

Page 21

EPSON Perfection 4490 Photo Revision A

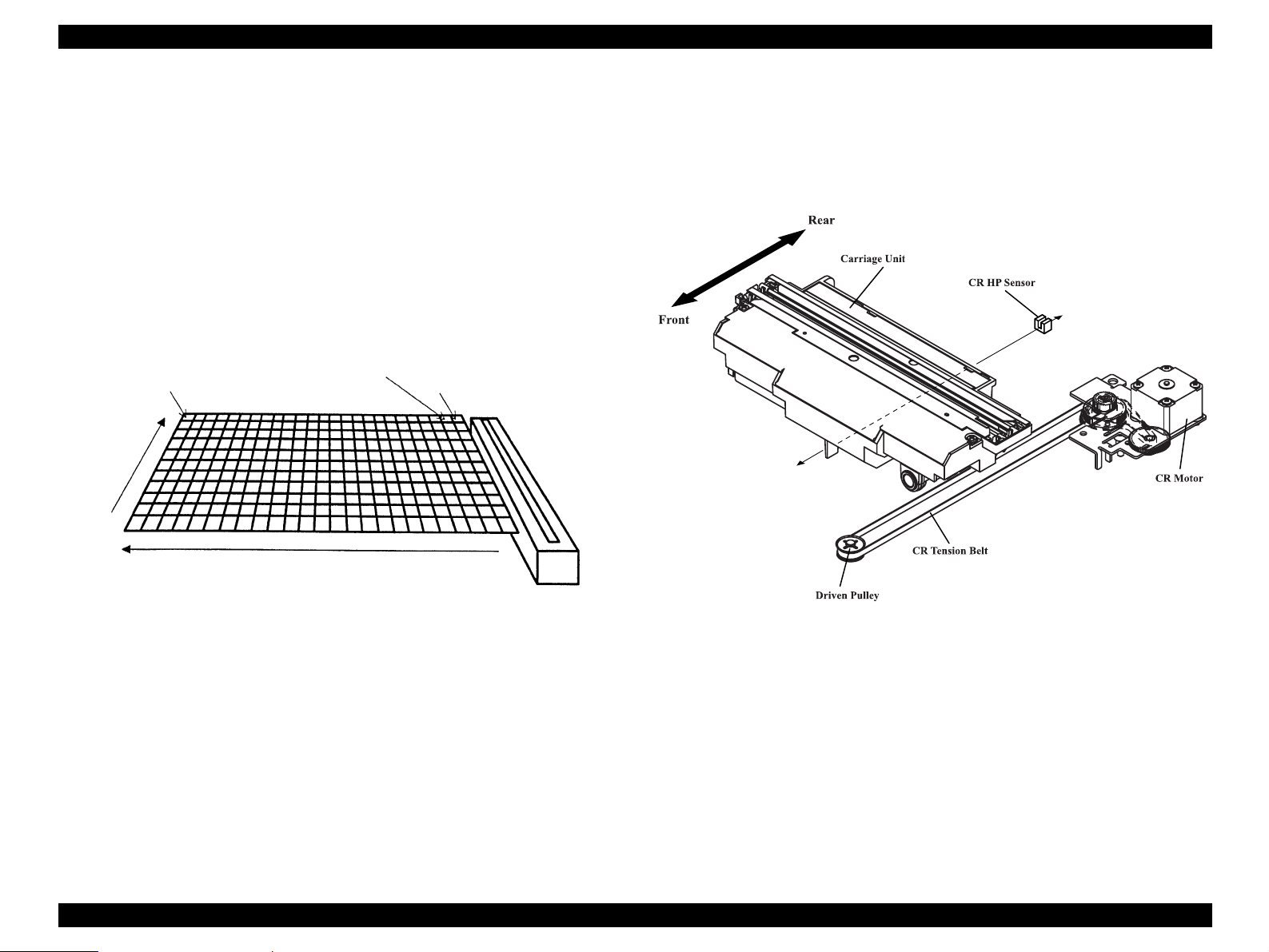

2.1.3 Carriage Moving Mechanism Operation

The image data of a document are scanned in the combination of the main scanning

direction (one line: CCD Sensor) and sub scanning direction (multiple lines: Carriage

Unit movement). (Refer to Fugure 2-4.)

The line type color CCD Sensor can only scan t

direction (in parallel with the Carriage Unit) at one time. To scan the data of the second

and latter lines in the sub scanning direction, the Carriage Unit having a built-in CCD

Sensor is moved by CR drive. The scanned data are sent to the Control Board. The

scanning of Line n data and the processing of Line n-1 image data are performed

consecutively at the same time.

1 pixel

Document

Main

scanning

he data of one line in the main scanning

Second line

First line

The Carriage Unit slides along the guide rail in the sub scanning direction. To perform

is sliding operation, the CR (Carriage) Motor transmits its drive power to the Timing

th

Belt, which is fixed to the Carriage Unit, via the Drive Pulley and Deceleration Gear.

The image data scanning start position is determined by the CR HP Sensor located on

the Control Board. A stepping motor used as the CR Motor is driven under open loop

control. (Refer to Fugure 2-5.)

Sub scanning (by Carriage movement)

Scanner Head

(Carriage)

Figure 2-5. Carriage Operation

Figure 2-4. Carriage Movement

OPERATING PRINCIPLES Engine Operation Outline 21

Page 22

EPSON Perfection 4490 Photo Revision A

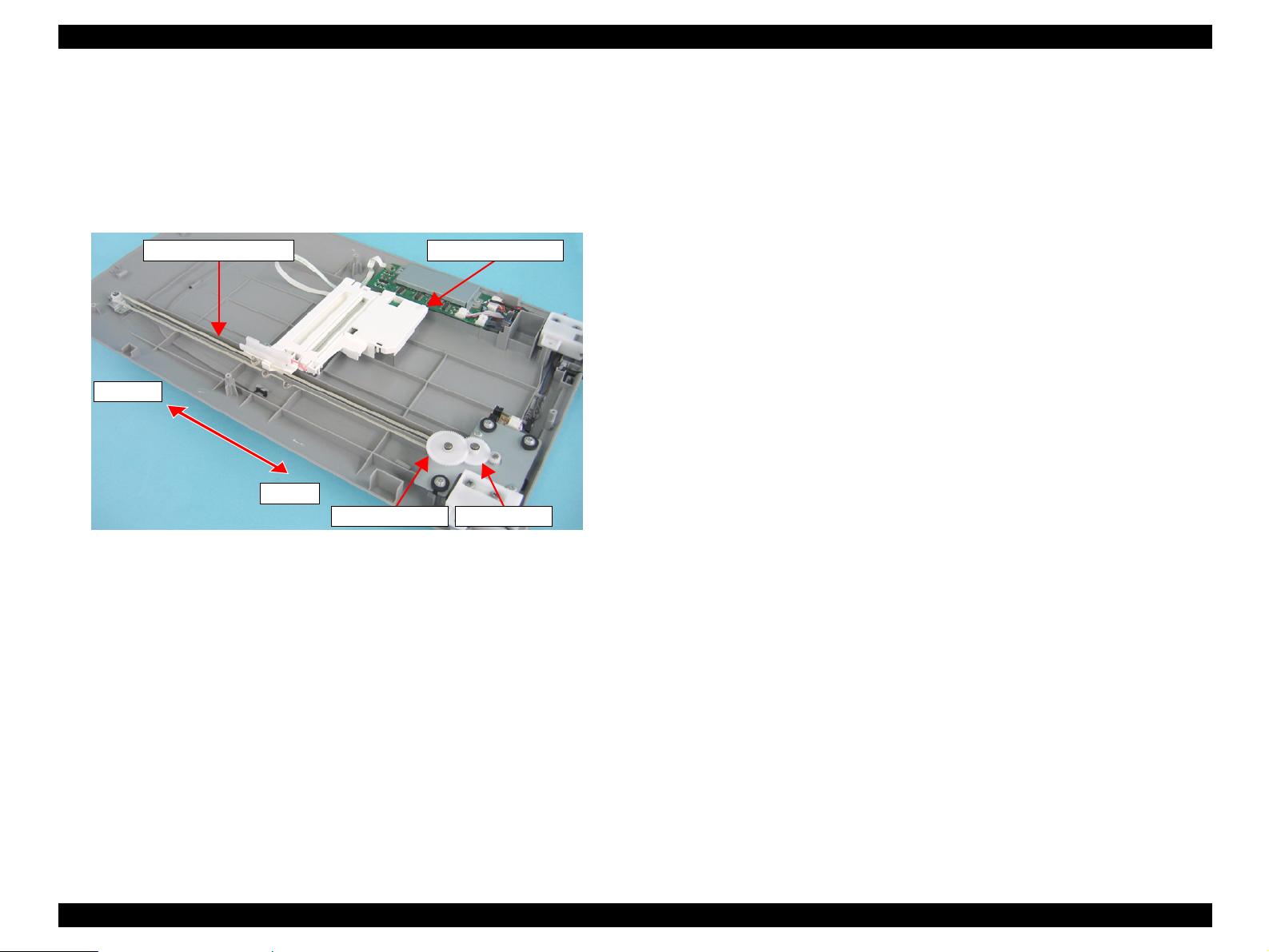

2.1.4 TPU Carriage Drive Mechanism Operation

The TPU Carriage Unit slides along the guide shaft in the secondary scanning direction

as the TPU CR (Carriage) Motor transmits its drive power to the TPU CR Drive Belt

connected to the TPU Carriage Unit, via the Idle Pulley and Drive Pulley. (Refer to

Fugure 2-6.) The TPU CR Motor uses a stepper motor and is driven under open loop

control.

TPU CR Drive Belt TPU Carriage Unit

Front

Rear

Drive Pulley Idle Pulley

Figure 2-6. TPU Carriage Operation

OPERATING PRINCIPLES Engine Operation Outline 22

Page 23

EPSON Perfection 4490 Photo Revision A

2.2 Digital ICE Function Operation

This scanner features Digital ICE for Film, an image correction process that uses a

combination of hardware and software to detect and eliminate physical flaws, dust or

dirt, either on the Film or the scanner itself. (Film includes color or monochrome

negative, and color positive.)

2.2.1 Digital ICE for Film Overview

Because of its longer wavelength, infrared light normally passes completely through

film media, such as negatives or slides, during a scan. Physical flaws or dust, however,

do block infrared light. When a film document with dust or physical flaws is scanned

using infrared light, the light is physically blocked by the flaw or dust, and the resulting

image clearly shows only the dust and/or flaws present. By superimposing the images

scanned with infrared light and visible light, the Film-ICE software is able to detect the

inconsistency in the digitized data caused by the flaw and automatically remove it

using interpolated image data to overwrite and correct the image. Because of the

difference in wavelength between infrared light and visible light, a secondary lens

("Glass Plate" in the images below) must be employed during the Film-ICE visiblelight scan to compensate for the resulting difference in the size of the images so that

they can be superimposed accurately. The Glass Plate is moved into and out of position

by a solenoid.

Lens CCDGlass Plate

Digita

1. Read the visible light position. Two holes in the upper housing are scanned with

2. Move the secondary lens (Glass Plate) into posi

3. Retract the secondary lens and scan the film

4. Electronically superimpose the images obt

5. Replace the "flaw" image data with image data interpolated

l ICE for Film Process Sequence

vi

sible light in order to register the home position of image being scanned.

tion and scan the film in visible-

light.

in infrared-light.

ained from each light source and

identify the physical flaws and/or foreign matter.

from adjacent areas.

Dirt on the Slide After Correction

Infrared Light

Lens CCDGlass Plate

Visible Light

Figure 2-7. Refraction of Infrared Light and Visible Light

Figure 2-8. Extraction/Correction of

Dust by Film-ICE Function

OPERATING PRINCIPLES Digital ICE Function Operation 23

Page 24

EPSON Perfection 4490 Photo Revision A

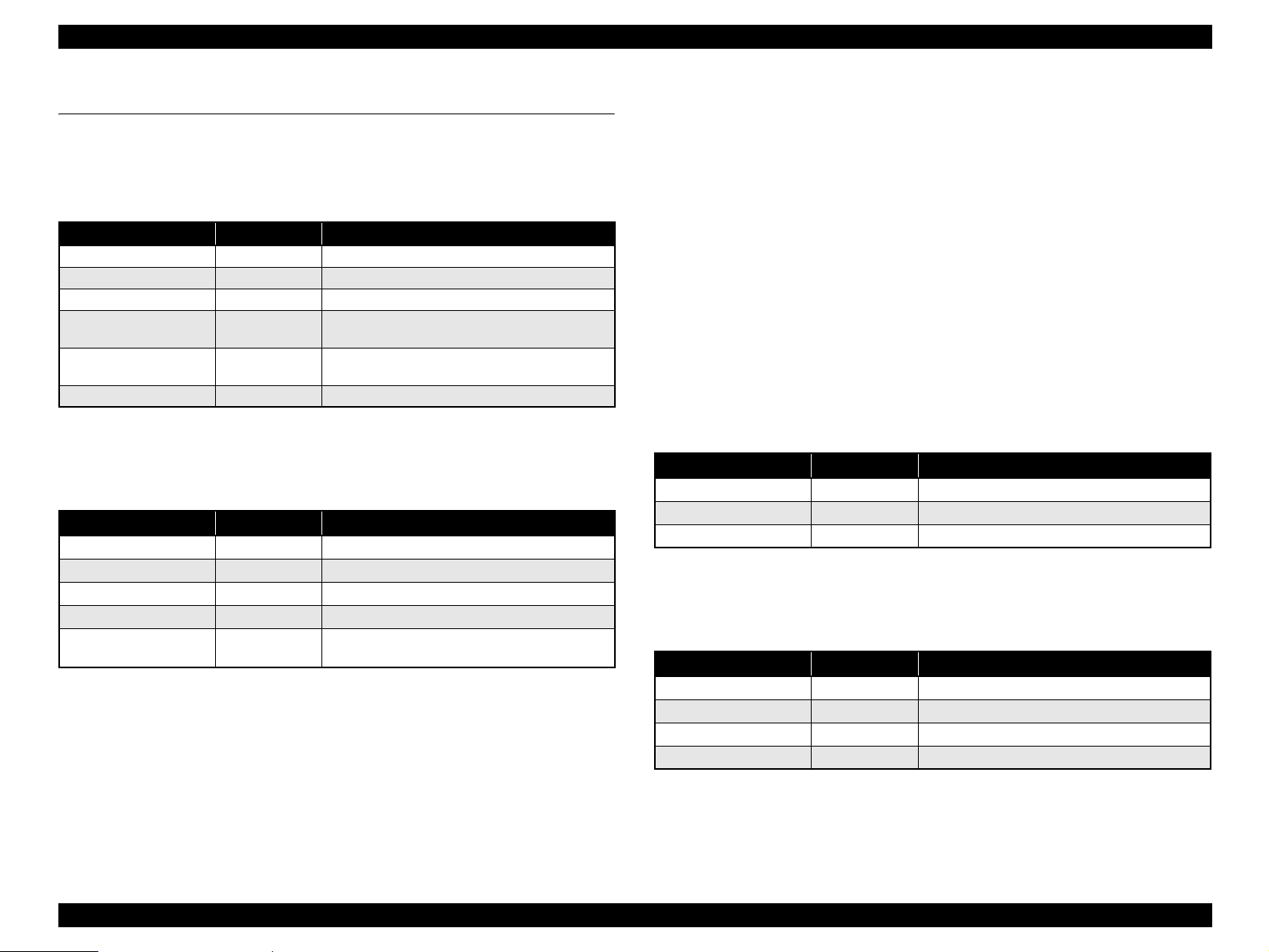

2.3 Operation Principle of Electric Circuit

The following electric circuits are used in the scanner.

Main Board

Table 2-1. Main Board IC

Name Location Details

S1R77001F00A2 IC4 ASIC: Host base scanner controller

S1R720G0F00A0 IC6 ASIC: UTM (USB2.0 interface)

EDS6416AHTA-75-E IC3

TB62205F IC1

AP1120SLA IC2

M74HC595AM13TR IC5 Serial-Parallel converter

CCD Board

Table 2-2. CCD Board IC

Name Location Details

ILX580K IC1 CCD

AK8415 IC4 16bit A/D converter

E02A41YA IC5

SN74ACT244NSR IC2, IC3 CCD drive buffer

KIA78M05F-RTF/P IC6

Pan

el Board

This board has four buttons (Start/Copy/Scan to E-mail/Scan to PDF) and LED

lamp.

SDRAM 1M x16bit x4bank

Motor Driver + DC-DC converter CR Motor Drive

+24V IN, +12V/+5V OUT

DC-DC converter

+5V IN, +3.3V/+2.5V OUT

ASIC: CCD/AFE drive signal generator

DC-DC converter

+12V IN, +5V OUT

Power supply

canner is powered with 24 VDC voltage from the AC adapter.

The s

AC adap

• Rated output DC24 1.1A

• Input Voltage AC100-120V ± 15% (100V)

ter rated voltage

AC220-240V ± 10% (200V)

• Rated Input Current 0.7A (AC 100V system)

0.4A (AC 200V system)

• Input Frequency Range 50 to 60Hz ± 0.3Hz

• Output Voltage DC24 to 26.4V

The 24 VDC voltage is supplied to CN4 on the Main Board. A

between the DC jack and the Main Board.

DRV

Board (TPU Unit)

Table 2-3. DRV Board IC

Name Location Details

M74HC595RM13TR IC1, IC2 8bit Shift Register

LB11847L-E IC3 TPU CR Motor Driver

CD74HC75M96 IC5 Lamp/LED controller

AD

F Board (Option)

Table 2-4. ADF Board IC

Name Location Details

M54670P IC2 ADF Motor driver

MM74HC165M IC3 Parallel-Serial Converter

M66311FP-250D IC1

MM74HCT04M IC4 Buffer IC

Serial-Parallel Converter

power switch is located

OPERATING PRINCIPLES Operation Principle of Electric Circuit 24

Page 25

TROUBLESHOOTING

CHAPTER

3

Page 26

EPSON Perfection 4490 Photo Revision A

3.1 Overview

This chapter explains the remedies for errors detected by the scanner’s self-diagnostic

function, and provides a troubleshooting guide based on observed ploblems.

3.1.1 Self-Diagnosing

This scanner has a self-diagnostic function that automatically diagnoses the operating

status of major components, and uses an LED indication to show the error status. This

function detects the following error statuses shown in the table below. The corrective

action is also listed.

COMMAND ERROR

Table 3-1. Command Error

LED Indication Cause Disposition

• Unidentifed command is

detected.

(None)

Recovery The error condition is canceled upon receipt of a valid command.

• T he scanner (interpreter)

ignores the incorrect command

or parameter. The current

settings are maintained.

• Scanner (interpreter) returns

NACK, and waits for the next

command or parameter.

OPTION ERROR

(Only when the Option Unit is fitted and the scanner is ready to operate under the

control command (ESC e))

Table 3-3. Option Error

LED Indication Cause Disposition

• T he cover is open.

• Document is not loaded.

(None)

Recovery Remove the error cause to recover.

Receivable command [ESC F, ESC f, ESC @]

• The Scanner sets Bit 7 of the

status bit.

FATAL ERROR

Table 3-2. Fatal error

LED Indication Cause Disposition

• The lamp is burnt out.

• The main unit is faulty.

• Firmware downloading failed.

(Rapid flashing, red)

Recovery Turn the scanner off and then back on.

• T he Scanner turns the carriage

lamp off and stops the operation.

• T he Scanner sets Bit 7 of the

status bit.

TROUBLESHOOTING Overview 26

Page 27

EPSON Perfection 4490 Photo Revision A

3.2 Troubleshooting

This section provides troubleshooting procedures based on observed faults.

Refer to Tab

the table, find the Problem that most closely matches what you observe and follow the

procedures given in the table cross referenced in the right-hand column.

Scanned image quality error. Scanned image is not clear.

The main unit does not operate

when powered-on.

Fatal error. (The LED flashes red.)

Recovery cannot be made when

power is switched on again.

The TPU does not work at all. The TPU does not operate. 3-10

le 3-4, and choose the table describes the general fault indication. Within

Table 3-4. Trouble Phenomenon, Cause and Troubleshooting Table

Problem Definition

Troubleshooting

Table

3-5

The Main Unit does not perform

initialization operation.

The host does not recognize the

scanner when power is switched on.

The Carriage Unit does not operate. 3-8

The Fluorescent Lamps are not lit.

The TPU Carriage Unit does not

operate.

The Fluorescent Lamps of the TPU do

not light up.

3-6

3-7

3-9

3-11

3-12

Table 3-5. Scanned Image Quality Error.

Step Possible Cause Corrective Action

The Document Glass is not clean. (Image

1

has white spots)

The mirror in the Carriage is not clean.

2

(Vertical bands appear on the image.)

Upper Housing failure

3

(

The white document mat is deformed or is

not clean.)

4 CCD Sensor Board failure Replace the Carriage Unit.

5 Main Board failure

6 Carriage mechanism failure Replace the Carriage mechanism.

Clean the glass.

(Refer to 6.1.1 Cleaning)

Clean the mirror.

(Refer to 6.1.1 Cleaning)

Replace the Upper Housing.

Replace the Main Board

Table 3-6. The Main Unit does not perform initialization operation.

Step Possible Cause Corrective Action

There are some connectors that are not

1

connected correctly

2 CR Motor failure Replace the CR Motor.

3 Main Board failure Replace the Main Board

Connect them correctly.

Replace the Main Board

Table 3-7. The host does not recognize the scanner when power is switched on.

Step Possible Cause Corrective Action

1 The host computer does not support USB.

The TWAIN Driver supplied with the

2

scanner has not been installed correctly.

3 The USB cable is damaged.

4 Main Board failure Replace the Main Board

Replace or modify the host computer.

Install (reinstall) the TWAIN Driver for the

Perfection 4490 Photo.

Replace the USB cable.

TROUBLESHOOTING Troubleshooting 27

Page 28

EPSON Perfection 4490 Photo Revision A

Table 3-8. The Carriage Unit does not operate.

Step Possible Cause Corrective Action

1 The Carriage Lock has not been released.

2

The Upper Housing is not installed corr ectly.

Connector CN1 on the Main Board is not

3

conn

ected.

4

The Carriage FFC is not connected correctly.

Carriage Mechanism failure

5

Release the Carriage Lock.

Install it normally.

Connect it correctly.

Connect the FFC correctly.

Replace the Main Board

Does the CR Motor operate normally?

↓

Yes

→ Disassemble and reassemble the

scanner, or replace the corresponding part(s).

No → Replace the CR Motor.

Table 3-9. The Fluorescent Lamps are not lit.

Step Possible Cause Corrective Action

Connector CN1 on the Main Board is not

ected.

conn

1

Connector CN1 and CN2 on the CCD

Board are not connected.

The lamp is not set on the Inverter Board

2

correctly.

Carriage Unit failure ( The Carriage FFC is

3

4 Main Board failure Replace the Main Board

nected to the Main Board and the

not con

Carriage.)

Connect the disconnected connectors.

Set the lamp on the board correctly.

Replace the Carriage Unit.

Table 3-10. The TPU does not operate.

Step Possible Cause Corrective Action

The TPU Unit Cable is not connected to the

1

in unit.

ma

Connector CN5 is not connected to the

2

Main Board.

3 Main Board failure

Connect the Cable to the main unit.

Connect it correctly.

Replace the Main Board

Table 3-11. The TPU Carriage Unit does not operate.

Step Possible Cause Corrective Action

The TPU Unit Cable is not connected to the

1

ma

in unit.

The TPU Carriage Lock has not been

2

released.

The TPU Lower Housing

3

correctly.

The three torsion springs are not

attached to the TPU CR Drive Belt

correctly.

• The TPU CR Motor does not

4

5 TPU CR Motor failure Replace the TPU CR Motor.

6 DRV Board failure Replace the DRV Board.

7 Main Board failure Replace the Main Board

move normally when poweredon with the TPU Lower Housing

removed.

• The TPU Carriage Unit does not

move normally with the TPU CR

Motor removed.

The TPU Carriage Mechanism

Failure.

is not installed

Connect the TPU Cable to the main unit.

Release the TPU Carriage Lock.

Reinstall it correctly.

Attach them to the belt correctly.

Replace the TPU Carriage Unit.

Table 3-12. The Fluorescent Lamps of the TPU do not light up

Step Possible Cause Corrective Action

The DRV Inverter FFC is not connected to

1

N1 on the TPU Inverter Board and CN3

C

on the DRV Inverter Board.

CN2, CN3, and CN4 on the TPU Inverter

2

Board are not connected.

Failure of the SUB_C Board and the

3

SUB_D Board

4 DRV Board failure Replace the DRV Board.

5 Main Board failure

Connect the FFC to CN1 and CN3

Connectors.

Connect the connectors.

Replace the SUB_C Board and the SUB_D

Board.

Replace the Main Board

TROUBLESHOOTING Troubleshooting 28

Page 29

DISASSEMBLY / ASSEMBLY

CHAPTER

4

Page 30

EPSON Perfection 4490 Photo Revision A

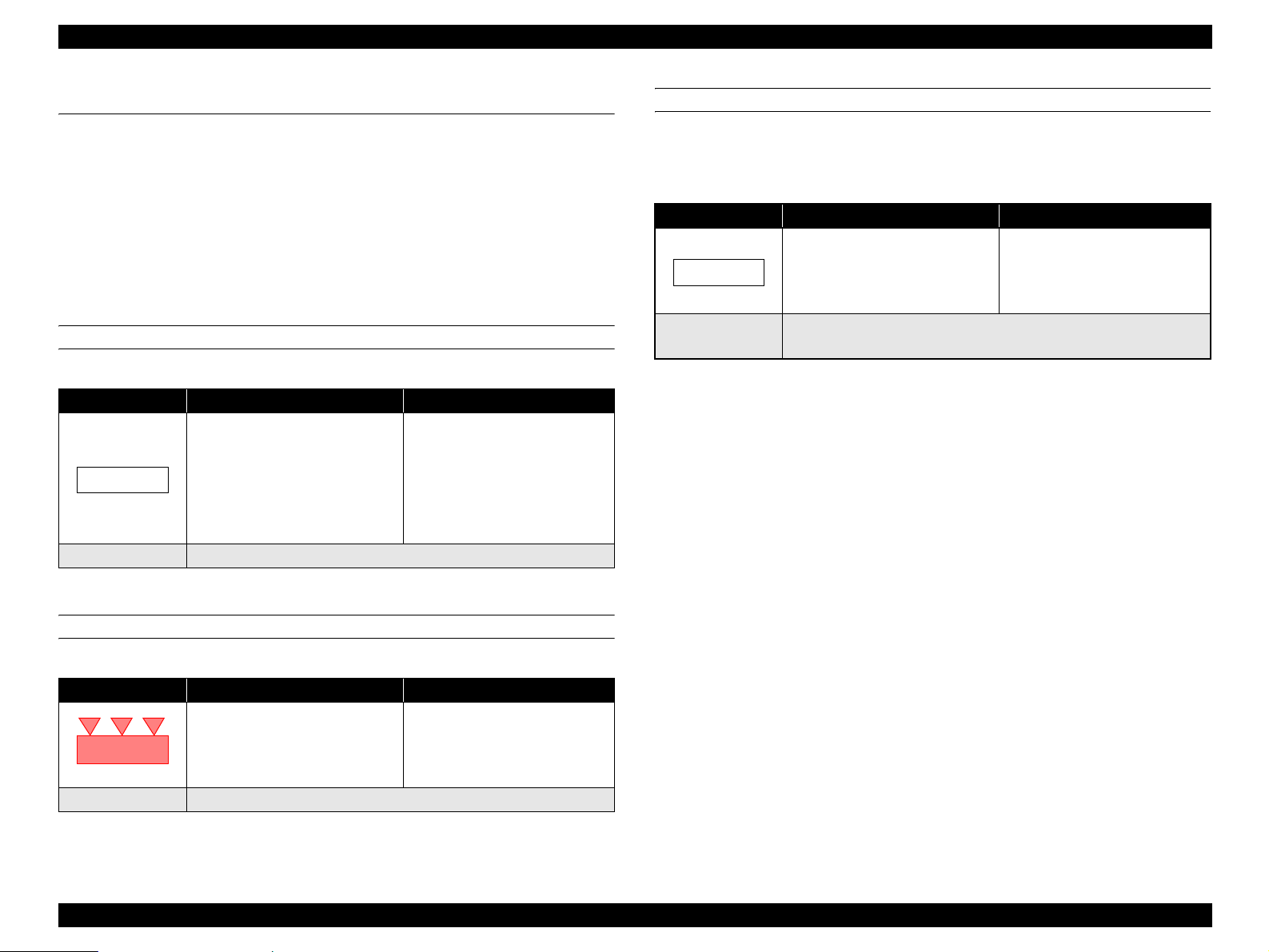

4.1 Overview

This chapter explains the procedures for disassembling the major units and parts of the

product. Unless otherwise explained, reassembly should be carried out in the reverse

order of the disassembly procedure. When you have to remove any parts or

components that are not described in this chapter, refer to the exploded diagram in the

Appendix.

Before starting disassembly, always read the

4.1.1 Precautions

Before starting the disassembly or reassembly of the product, read the following

precautions given under the headings WARNING and CAUTION.

W A R N I N G

C A U T I O N

Before disassembling or reassembling this product, always

disconnect the Power Cable and Interface Cable. When you

have to work with power on for voltage measurement, etc., use

extreme care not to get an electric shock and do the work in

accordance with the procedures given in this manual.

To prevent your hands from being cut by sharp edges, always

wear gloves before starting disassembly or reassembly.

When touching any internal components, use static electricity

discharge equipment such as anti-static wrist straps.

Provide sufficient work space for disassembling and

reassembling.

Always use only the recommended tools for disassembly,

reassembly and adjustment.

Be sure to tighten the screws to the specified torque.

Use the specified grease for lubrication. Refer to Chapter 6 for

details.

Since a prototype was used to illustrate these disassembly and

assembly procedures, the appearance of some parts may differ

from those on an actual product. The procedures themselves,

however, are accurate for the retail model.

precautions described in the next section.

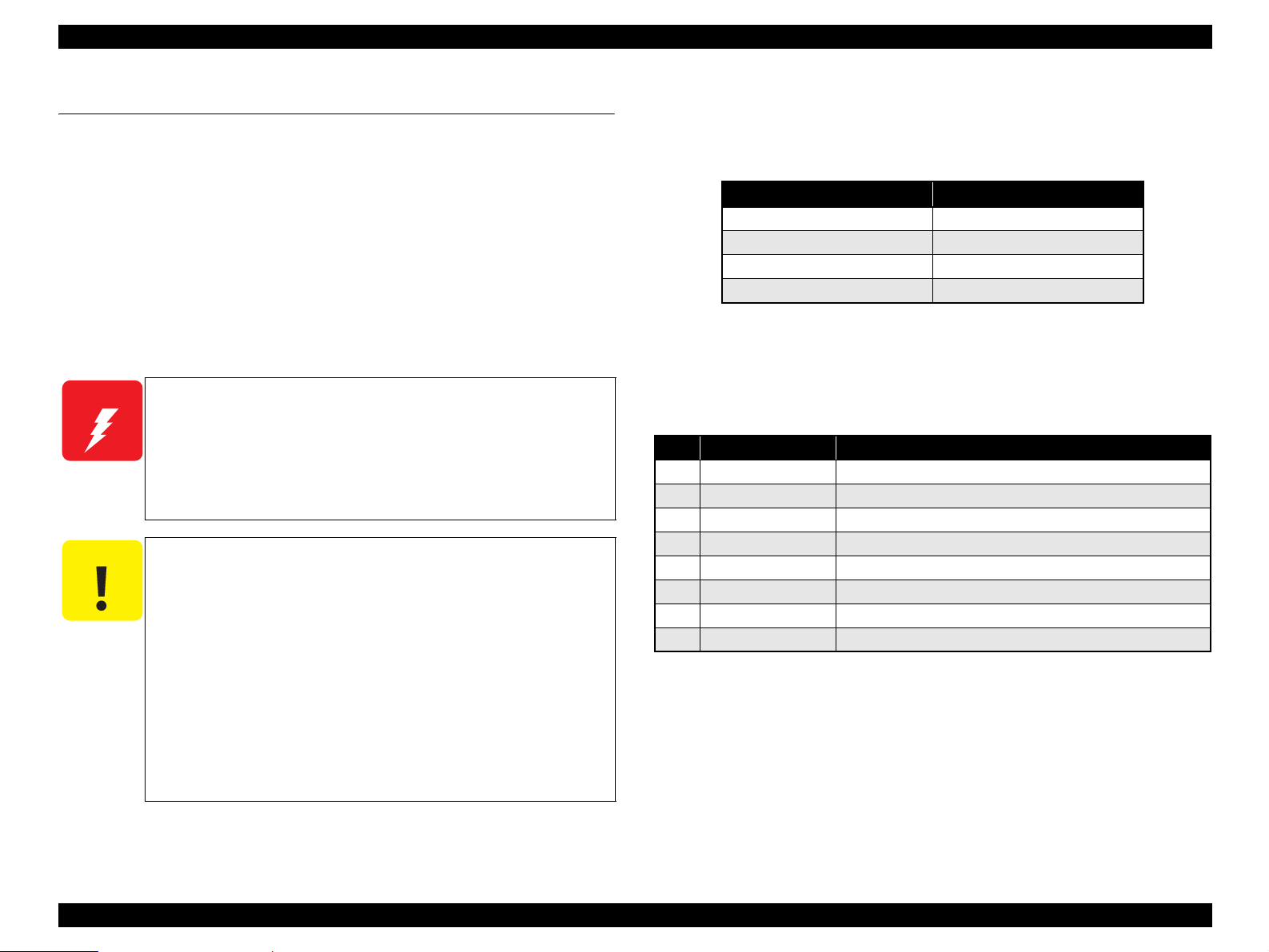

4.1.2 Recommended Tools

To protect this product from damage, use the tools indicated in the following table.

Table 4-1. Specified Tools

Name Epson Part Number

Phillips screwdriver, No. 2

Flat-blade screwdriver 1080527

Tweezers

Long-nose pliers 1080561

1080532

1080561

4.1.3 Recommended Screws

The following table indicates the screws used in the EPSON Perfection 4490 Photo

Scanner.

Table 4-2. Recommended Screws

No. Name Type

1 C.B.P. 3 x 6

2 C.B.P. 3 x 8 Phil lips Bind P-tit e Screw, size M3, 8 mm length

3 C.B.P. 3 x 12

4 C.P. 3 x 8 Phillips Pan Head Screw, size M3, 4 mm length

5 C.B. 3 x 3

6 C.B.P. 4 x 12 Phillips Bind P-tite Screw, size M3, 8 mm length

7 C.B.S. 3 x 5

8 C.P.F.P. 3 x 8 Phillips Pan Flange Head P-tite Screw, size M3, 8 mm length

Phillips Bind P-tite Screw, size M3, 8 mm length

Phillips Bind P-tite Screw, size M3, 8 mm length

Phillips Bind Screw, size M3, 3 mm length

Phillips Bind S-tite Screw, size M3, 5 mm length

Disassembly / Assembly Overview 30

Page 31

EPSON Perfection 4490 Photo Revision A

4.2 Disassembly Procedure

This section illustrates how to remove the main components of this product. Unless otherwise specified, the reassembly procedure is the reverse of the disassembly procedure. For

additional assembly illustrations, refer to the exploded diagrams in the Appendix.

The following flowchart shows the disassembly procedure step-by-step,

Start

Removing the TPU Unit(P.32)

Removing TPU Lower

Housing(P.45)

Removing Torsion Spring(P.49)

Removing the TPU Carriage

Unit(P.50)

Removing the Upper

Housing(P.33)

Removing the Panel Board(P.36) Removing the Main Board(P.37)

Removing the Power

Switch(P.40)

Removing the DRV Board(P.48) Removing the Hinge Assy.(P.46)

and the section and page number where the procedure is described.

Removing the Carriage

Unit(P.34)

Removing the Driven Pulley, Driven

Pulley Spring, and the Driven Pulley

Holder Assy.(P.42)

Removing the Panel FFC(P.41)

Removing the TPU Unit

Cable(P.47)

Removing the CR Motor Unit, Motor

Tension Belt, and the CR Tension

Belt(P.43)

Removing the Sensor

Board(P.46)

Removing the TPU Inverter

Board(P.51)

Removing the SUB_C Board,

SUB_D Board, and the

Lamp(P.53)

Removing the TPU CR

Motor(P.55)

Figure 4-1. Disassembly Flowchart

Disassembly / Assembly Disassembly Procedure 31

Page 32

EPSON Perfection 4490 Photo Revision A

4.2.1 Removing the TPU Unit

1. Disconnect the TPU Unit cable from the Main Unit.

Main

TPU Unit Cable

Figure 4-2. Removing the TPU Unit (1)

2. Open the TPU Unit.

3. Hold both ends of the TPU Unit and then lift and remove it.

TPU Unit

3

2

Figure 4-3. Removing the TPU Unit (2)

Disassembly / Assembly Disassembly Procedure 32

Page 33

EPSON Perfection 4490 Photo Revision A

4.2.2 Removing the Upper Housing

1. Remo ve the TPU Unit. See Section 4.2.1 on page 32.

2. Remove the four C.B.P. M3 x 8 screws that secure the Upper Housing to remove

it.

Upper Housing

C.B.P. 3 x 8

(7±1 kgf.cm)

Viewed from the outside

Figure 4-4. Removing the Upper Housing

Disassembly / Assembly Disassembly Procedure 33

Page 34

EPSON Perfection 4490 Photo Revision A

4.2.3 Removing the Carriage Unit

1. Release the Carriage Lock at the rear of the main unit.

Unlock

Carriage Lock

Figure 4-5. Releasing the Carriage Lock

2. Remove the Upper Housing. See Section 4.2.2 on page 33.

3. Move the Carriage Unit to the front of the main unit.

Lock

Carriage Unit

4. Disconnect the Carriage FFC from the Main Board. See Section 4.2.5 Step 5 - Step 7

5. Remove the two-sided tape that secure the Carriage FFC to the Upper Housing.

6. Rem ove the Ferrite Core from the Carriage FFC.

Lower Housing

Tape Position

Carriage FFC

Ferrite Core

Figure 4-7. Removing the Carriage FFC

Secure the Carriage FFC with a piece of two-sided tape at the

position shown in Figure 4-7

3

Figure 4-6. Moving the Carriage Unit

.

Disassembly / Assembly Disassembly Procedure 34

Page 35

EPSON Perfection 4490 Photo Revision A

7. Move th e A part on the Driv en Pulley Holder Assy. in the direction of the arrow

and remove the CR Tension Belt from the Driven Pulley.

A part

Driven Pulley

CR Tension Belt

Figure 4-8. Removing the CR Tension Belt

8. Hold the Carriage Unit and release one end

bushing of the Lower Housing, then pull the other end out of the front bushing of

the Lower Housing.

9. Remo ve the Carriage Shaft from the Carriage Unit.

8-1

Driven Pulley Holder Assy.

of the Carriage Shaft from the rear

Carriage Unit

Carriage Shaft

10. Push up the B part of the Lock Plate attached on the rear of the Carriage Unit to

re

move the Lock Plate from the Carriage Unit.

Lock Plate

B part

Figure 4-10. Removing

the Carriage Unit

Rear

Bushing

Front

Bushig

8-2

Figure 4-9. Removing the Carriage Shaft

Disassembly / Assembly Disassembly Procedure 35

Page 36

EPSON Perfection 4490 Photo Revision A

4.2.4 Removing the Panel Board

1. Remo ve the Carriage Unit. See Section 4.2.3 on page 34.

2. Pull the ground terminal out of the front bushing of the Lower Housing.

3. Lift the Panel Board and disconnect the Panel FFC Connector CN1, then remove

the Panel Board.

Notch

Front Bushing

Positioning Holes

Notch

CN1

Ground Cable

2

Panel Board

When reinstalling the Panel Board, pay attention to the followings.

Pu t the ground terminal into the front bushing of the Lower

Housing as shown in Figure 4-11

Route the ground cable through the notches as shown in Figure

4-11.

Insert the two constricted parts on both left and right ends of

the Panel Board into the tabs of the Lower Housing and match

the three notches of the board with the three tabs of the Lower

Housing as shown in Figure 4-11

.

.

3

Constricted Parts and Tabs

Figure 4-11. Removing the Panel Board

Disassembly / Assembly Disassembly Procedure 36

Page 37

EPSON Perfection 4490 Photo Revision A

4.2.5 Removing the Main Board

1. Release the Carriage Lock. See Section 4.2.3 Step 1

2. Remove the Upper Housing. See Section 4.2.2 on page 33.

3. Move the Carriage Unit to the front of the main unit. See Section 4.2.3 Step 3

4. Remo ve the Carriage Lock from the Lower Housing.

Carriage Lock

Figure 4-12. Removing the Carriage Lock

5. Remove the Main Board Cover in the following procedure.

1. Rem ove the C.B.P. M3 x 8 screw and C.B.P. M3 x 12 screws that secure the

Main Board Cover.

2. Remove the two C.B.P. M3 x 8 screw that secure the Main Board from the

rear of the main unit.

C.B.P. 3 x 8

(4±1 kgf.cm)

Rear of the Main Unit

C.B.P. 3 x 12

(6.5±0.5 kgf.cm)

C.B.P. 3 x 8

(6.5±0.5 kgf.cm)

Main Board Cover

Figure 4-13. Removing the Main Board Cover (1)

Disassembly / Assembly Disassembly Procedure 37

Page 38

EPSON Perfection 4490 Photo Revision A

3. Release the tab of the Main Board Cover with a flat-blade screwdriver and lift

one side (tab side) of the Main Board Cover.

4. Slide the Main Board Cover in the direction of the arrow to release it from the

two tabs and remove the Main Board Cover.

3-1

Tab

Main Board Cover

3-2

When reinstalling the Main Board Cover, match the two tabs and

two interfaces with the holes of the Main Board Cover as shown

below.

Tabs

I/F

Figure 4-15. Installing the Main Board Cover

4

Tab

Figure 4-14. Removing the Main Board Cover (2)

Disassembly / Assembly Disassembly Procedure 38

Page 39

EPSON Perfection 4490 Photo Revision A

6. Remove the four C.B.P. M3 x 8 screws that secure the Main Board.

7. Disconnect the all connectors on the Main

CN1: Carriage FFC

CN2: CR Motor Cable

CN3: Power Switch Connector

CN6: Panel FFC

C.B.P. 3 x 8

(7±1 kgf.cm)

CN1

Board and remove the Main Board.

CN2

CN3

CN6

Figure 4-16. Removing the Main Board

Main Board

Disassembly / Assembly Disassembly Procedure 39

Page 40

EPSON Perfection 4490 Photo Revision A

4.2.6 Removing the Power Switch

1. Move the Carriage Unit to the front of the main unit. See Section 4.2.3 Step 1 -

Step 3

2. Discon nect the Power Switch Conn ector CN3 from the Main Board. See Section

4.2.5 Step 5 - Step 7

3. Remove the Power Switch Connector Cable from the cable trench.

Power Switch Connector Cable

4. Push the Power Switch toward the ou tside whi le releasin g the two tabs, and

rem

ove the Power Switch by pushing it out through the hole on the Lower

Housing.

4-2

Power Switch

4-1

Tabs

Cable Trench

Figure 4-17. Removing the Po

When reinstalling the Power Switch, route the Power Switch

Connector Cable through the cable trench as shown in Figure

4-17.

wer Supply Cable Cover

4-1

Figure 4-18. Removing the Power Switch

Disassembly / Assembly Disassembly Procedure 40

Page 41

EPSON Perfection 4490 Photo Revision A

4.2.7 Removing the Panel FFC

1. Move the Carriage Unit to the front of the main unit. See Section 4.2.3 Step 1 -

Step 3

2. Discon nect the Panel FFC from the Main Board. See Section 4.2.5 Step 1 - Step 7

3. Move the Carriage Unit to its home position, and remove the two-si ded tape that

secure the Panel FFC.

4. Discon nect the Panel FFC from CN1 Connector on the Panel Board.

CN1

4

Panel Board

Carriage Unit

Wh en installing the Panel FFC, attach the Ferrite Core as

shown in the figure below.

Ferrite Core

Figure 4-20. Installing the Ferrite Core

Secure the Panel FFC with a piece of two-sided tape at the

position shown in Figure 4-19

.

3

Panel FFC

Tape Position

Figure 4-19. Removing the Panel FFC

Disassembly / Assembly Disassembly Procedure 41

Page 42

EPSON Perfection 4490 Photo Revision A

4.2.8 Removing the Driven Pulley, Driven Pulley Spring,

and the Driven Pulley Holder Assy.

1. Remo ve the Carriage Unit. See Section 4.2.3 on page 34.

2. Hold the A part of the Driven Pulley Holder Assy. and slide it in the direction of

the arrow to remove the assy. from the two tabs on the Lower Housing.

A part

Tabs

Driven Pulley Holder Assy.

Figure 4-21. Removing the Driven Pulley Holder Assy.

3. Remove the Driven Pulley Spring from the Driven Pulley Holder Assy.

4. Remove the washer and remove the Driven Pulley

Pulley Holder Assy.

Driven Pulley Spring

Figure 4-22. Removing the Driven Pulley and

from the shaft of the Driven

Washer

Driven Pulley

the Driven Pulley Spring

Disassembly / Assembly Disassembly Procedure 42

Page 43

EPSON Perfection 4490 Photo Revision A

4.2.9 Removing the CR Motor Unit, Motor Tension Belt, and the CR Tension Belt

1. Remo ve the Carriage Unit. See Section 4.2.3 on page 34.

2. Disconnect the CR Motor Connector CN2 from the Main Board. See Section 4.2.5

Step 1 - Step 5

3. Remove the two C.B.P. M3 x 8 screws that secure the CR Motor Unit and remove

it together with the ground plate.

CR Motor UnitPositioning Hole and Guide Pin

Install the ground plate in the following procedure.

1. Match the positioning hole of the ground plate with the guide

pin of the Lower Housing.

2. Place the CR Motor Unit as shown

secure the CR Motor Unit and the ground plate to the Lower

Housing.

When installing the CR Motor Unit, match the positioning hole

and the guidepin as shown in Figure 4-23

Route the CR Motor Cable through the tabs and slot as shown

in the figure below.

Positioning Hole and Guide Pin

Ground Plate

in the figure below and

.

C.B.P. 3 x 8

(7±1 kgf.cm)

Figure 4-23. Removing the CR Motor Unit

CN2

Ground Plate

Tabs and Slot

Figure 4-24. Routing the CR Motor Cable

Disassembly / Assembly Disassembly Procedure 43

Page 44

EPSON Perfection 4490 Photo Revision A

3. Remo ve the torsion spring and the C.B. M3 x 3 screw that secure the Tensioner,

and remove the Pulley.

A D J U S T M E N T

R E Q U I R E D

When installing the Tensioner, make sure to perform the Tensioner

Adjustment. See Section 5.1.2.1 on page 58.

4. Remove the Motor Tension Belt and the CR Tension Belt from the CR Motor Unit

in th

at order.

CR Tension Belt

Torsion Spring

C.B. 3 x 3

(6±1kgf.cm)

Tensioner

Pulley

Motor Tension Belt

Figure 4-25. Removing the Motor Tension Belt and the CR Tension Belt

Disassembly / Assembly Disassembly Procedure 44

Page 45

EPSON Perfection 4490 Photo Revision A

4.2.10 Removing TPU Lower Housing

1. Remo ve the TPU Unit. See Section 4.2.1 on page 32.

2. Slide the Housing Mat (Document Cover) to the front of the main unit and remove

it from the four slots of the TPU Unit.

3. Release the TPU Carriage Lock.

Unlock

Lock

Slots

4. Rem ove the six C.B.P. M3 x 12 screws and the two C.B.P. M3 x 8 screws that

secure th

5. Lift the rear (hinge side) of the TPU Lower Housing and slide it in the direction of

the

e TPU Lower Housing.

C.B.P. 3 x 8

Tabs

Figure 4-27. Removing the TPU Lower Housing (1)

arrow to release the two tabs and remove the TPU Lower Housing.

(7±1 kgf.cm)

C.B.P. 3 x 12

(7±1 kgf.cm)

5-2

Housing Mat

Figure 4-26. Removing the Housing Mat (Document Cover)

TPU Lower Housing

5-1

Tabs

Figure 4-28. Removing TPU Lower Housing (2)

Disassembly / Assembly Disassembly Procedure 45

Page 46

EPSON Perfection 4490 Photo Revision A

4.2.11 Removing the Sensor Board

1. Remo ve the TPU Lower Housing. See Section 4.2.10 on page 45.

2. Remove the C.B.P. M3 x 8 screw that secures the Sensor Board.

3. Disconnect the Sensor Connector CN1 while li

the Sensor Board.

Sensor Board

Figure 4-29. Removing the Sensor Board

fting the Sensor Board, and remove

C.B.P. 3 x 8

CN1

4.2.12 Removing the Hinge Assy.

1. Remove the TPU Lower Housing. See Section 4.2.10 on page 45.

2. Remove the four C.B.P. M4 x 12 screws that secure the left and right Hinge Assy.s

and remove them.

C.B.P. 4 x 12

(9±1kgf.cm)

Figure 4-30. Removing the Hinge Assy.

Disassembly / Assembly Disassembly Procedure 46

Page 47

EPSON Perfection 4490 Photo Revision A

4.2.13 Removing the TPU Unit Cable

1. Remo ve the TPU Lower Housing. See Section 4.2.10 on page 45.

2. Remo ve the left and right Hinges. See Section 4.2.12 on page 46.

3. Remove the C.B.P. M3 x 8 screw that secures the TPU Unit Cable.

4. Disconnect the TPU Unit Connector CN1 from the DRV Board.

5. Release the TPU Unit Cable from the not

Cable Tie

ches shown in the figure below.

C.B.P. 3 x 8

DRV Board

(7±1kgf.cm)

Wh en installing the TPU Unit Cable, put the cable and the

cable tie into the notches as shown in Figure 4-31

When connecting the TPU Unit Cable to the DRV Board, route

the cable as shown in the figure below.

TPU Unit Cable

.

Notches

TPU Unit Cable

Figure 4-31. Removing the TPU Unit Cable (2)

CN1

DRV Board

Figure 4-32. Routing the TPU Unit Cable

Ground

Disassembly / Assembly Disassembly Procedure 47

Page 48

EPSON Perfection 4490 Photo Revision A

4.2.14 Removing the DRV Board

1. Remo ve the TPU Lower Housing. See Section 4.2.10 on page 45.

2. Remo ve the two C.B.P. M3 x 8 screws that secure the DRV Board Cover and

remove the ground to remove the DRV Board Cover.

CN2

CN1

3. Disconnect the all connectors on the DRV

CN1: TPU Unit Cable

CN2: TPU Motor Connector

CN4: Sensor

CN3: DRV Inverter FFC

CN4 C.B.P. 3 x 8

Ground

Figure 4-33. Removing the DRV Board (1)

DRV Board Cover

CN3

Board and remove the DRV Board.

Disassembly / Assembly Disassembly Procedure 48

Page 49

EPSON Perfection 4490 Photo Revision A

4.2.15 Removing Torsion Spring

C A U T I O N

1. Remo ve the TPU Lower Housing. See Section 4.2.10 on page 45.

2. Remo ve the TPU CR Drive Belt from the TPU Driven Pulley.

When performing the procedure given below, be careful not to lose

the three torsion springs that apply tension to the TPU CR Drive

Belt .

2-2

2-1

TPU CR Drive Belt

TPU Driven Pulley

A D J U S T M E N T

R E Q U I R E D

To adjust the tension of the TPU CR Drive Belt, attach the three

torsion springs in the following procedure.

1. Move the TPU Carriage Unit

2. Attach the three torsion springs orienting

to the center.

each as shown in

the figure below.

3. Loop the TPU CR Drive Belt over the TPU

4. Slide the three torsion springs

to the positions shown in the

Driven Pulley.

figure below.

TPU Carriage Unit

TPU Driven Pulley

TPU CR Drive Belt

Figure 4-34. Removing the TPU CR Drive Belt (2)

3. Remove the two torsion springs attached

to the outer TPU CR Drive Belt.

Figure 4-35. Installing the Torsion Springs

Disassembly / Assembly Disassembly Procedure 49

Page 50

EPSON Perfection 4490 Photo Revision A

4.2.16 Removing the TPU Carriage Unit

C A U T I O N

1. Remo ve the TPU Lower Housing. See Section 4.2.13 on page 47.

2. Remo ve the torsion springs. See Section 4.2.15 on page 49.

C A U T I O N

3. Remove the flat washer that secures the Driven Pulley of the TPU CR Motor Assy.

and remove the Driven Pulley and TPU CR Drive Belt in that order.

When performing the procedure given below, be careful not to lose

the three torsion springs that apply tension to the TPU CR Drive

Belt .

When performing the next step, be careful not to lose the flat

washer that secures the Driven Pulley.

TPU Carriage Unit

4. Remove the CN3 Connector from the DRV Board,

to remove the TPU Carriage Unit.

Tape Position

CN3

Figure 4-37. Removing the DRV Inverter FFC

Wh en installing the DRV Inverter FFC, make sure to align the

positioning lines both on the FFC and the TPU Upper Housing

as shown in Figure 4-37

sided tape.

DRV Inverter FFC

before attaching the FFC with the two-

and remove the two-sided tape

Positioning Lines

4.2.15 on page 49 for information how to attach the

TPU CR Drive Belt

TPU CR Motor Assy.

Figure 4-36. Removing the TPU CR Drive Belt

Drive Pulley

Flat Washer

See Section

torsion springs.

Disassembly / Assembly Disassembly Procedure 50

Page 51

EPSON Perfection 4490 Photo Revision A

4.2.17 Removing the TPU Inverter Board

1. Remove the TPU Carriage Unit. See Section 4.2.16 on page 50.

2. Disconnect the Connector CN1 from the TPU Inverter Board.

3. Release the DRV Inverter FFC from the DRV Inverter FFC Ta

Carriage Frame and remove the acetate tape that secures the DRV Inverter FFC.

DRV Inverter FFCAcetate Tape

DRV Inverter FFC Tab

TPU Inverter Board

CN1

Figure 4-38. Removing the

DRV Inverter FFC

b of the TPU

4. Release Connector Cables from the tabs of the Ca rriage Frame shown in the figure

below.

5. Disconnect the all connectors (CN2, CN3, CN4) from the TPU Inverter Board.

6. Remove the C.B.P. M3 x 8 screw that secures the TPU Inverter Board.

7. Lift the TPU Inverter Board to release it from the tab of the TPU Carriage Frame,

and remove the TPU Inverter Board.

Tabs of the Carriage Frame

C.B.P. 3 x 8

(6.5±0.5kgf.cm)

CN4

CN2

Figure 4-39. Removing the

CN3

Tab

TPU Inverter Board (1)

Disassembly / Assembly Disassembly Procedure 51

Page 52

EPSON Perfection 4490 Photo Revision A

8. Remove the Protective Cover from the TPU Inverter Board.

When installing the TPU Inverter Board to the TPU Carriage

Protective Cover

Frame, match the positioning holes and the guide pins as shown

in the figure below.

When connecting CN2 and CN3 Connector Cables, route them

under the tab (DRV Inverter FFC Tab) as shown in the figure

below.

Tab (DRV Inverter FFC Tab)

Figure 4-40. Removing the TPU Inverter Board (2)

CN2

Positioning Holes and Guide Pins

Figure 4-41. Routing the DRV Inverter Cables

When connecting the DRV Inverter FFC to the TPU Inverter

Board, put the FFC through the tab (DRV Inverter FFC Tab)

as shown in Figure 4-38

Secure the DRV Inverter FFC with a piece of acetate tape at the

position shown in Figure 4-38

CN3

.

.

Disassembly / Assembly Disassembly Procedure 52

Page 53

EPSON Perfection 4490 Photo Revision A

4.2.18 Removing the SUB_C Board, SUB_D Board, and the Lamp

1. Remove the TPU Carriage Unit. See Section 4.2.16 on page 50.

2. Remo ve the TPU Inverter Board. See Section 4.2.17 on page 51.

3. Remo ve the SUB_C and SUB_D Boards in the following procedure.

1. Pull up the A tabs and slide each of the SUB_C and SUB_D Boards in the

direction of the arrows (3-1).

2. Slide the SUB_C and SUB_D Boards in the direction of the arrows (3-2) and

release them from the B tabs to remove the boards.

SUB_C Board

3-2

Tab B

3-2

Tab A

4. Remove the two C.B.P. M3 x 6 screws that secure the TPU Lamp Cover to remove

it

.

C.B.P. 3 x 6

TPU Lamp Cover

SUB_D Board

Notches and Tabs

Figure 4-42. Removing the SUB_C Board and SUB_D Board

3-1

Figure 4-43. Removing the TPU Lamp Cover

Disassembly / Assembly Disassembly Procedure 53

Page 54

EPSON Perfection 4490 Photo Revision A

5. Remo ve the Lamp from the two tabs on each end of the TPU Carriage Unit.

Wh en installing the SUB_C Board and SUB_D Board, match

Lamp

Tabs

the notches and tabs as shown in Figure 4-42

Wh en installing the TPU Lamp Cover, match the positioning

holes and the guide pins as shown in the figure below.

Route the Lamp cables as shown in the figure below.

Positioning Hole and Guide Pin

Lamp Cables

.

Figure 4-44. Removing the Lamp

Figure 4-45. Routing the Lamp Cables

Disassembly / Assembly Disassembly Procedure 54

Page 55

EPSON Perfection 4490 Photo Revision A

4.2.19 Removing the TPU CR Motor

C A U T I O N

1. Remo ve the Hinge Assy.s. See Section 4.2.12 on page 46.

2. Remove the TPU Carriage Unit. See Section 4.2.16 on page 50.

3. Disconnect the TPU CR Motor Connector CN2 from the DRV Board.

4. Release the Ferrite Core and CN2 Connector Cable from the notch and tabs shown

in Figure 4-46

When performing the procedure given below, be careful not to lose

the three torsion springs that apply tension to the TPU CR Drive

Belt .

.

DRV Board

CN2

Ferrite Core

5. Remove the three C.P.F.P. M3 x 8 screws th

remove it.

C.P.F.P. 3 x 8

(4.5±0.5kgf.cm)

Figure 4-47. Removing the TPU CR Motor Unit (1)

6. Remove the TPU CR Drive Belt from the TPU Driven Pulley and remove the TPU

CR Motor Unit.

TPU Driven Pulley

at secure the TPU CR Motor Unit and

Tabs

Figure 4-46. Removing the TPU CR Motor Connector

Notch

TPU CR Drive Belt

Figure 4-48. Removing the TPU CR Motor Unit (2)

Disassembly / Assembly Disassembly Procedure 55

Page 56

EPSON Perfection 4490 Photo Revision A

7. Remo ve the three TPU CR Motor Dam pers.

8. Remove the flat washer and remove the Driven Pu

the Idle Pulley in that order.

C A U T I O N

9. Remove the two C.B. M3 x 5 screws that secure the TPU CR Motor and remove it.

When performing the next step, be careful not to lose the flat

washer that secures the Driven Pulley and Idle Pulley.

C.B. 3 x 5

(9±1kgf.cm)

Flat Washer

Idle Pulley

lley, TRU CR Drive Belt, and

TPU CR Motor Dampers

Driven Pulley

Route the TPU CR Motor Cables through the groove and

notches as shown in the figure below.

Groove and Notches

Figure 4-50. Routing the TPU CR Motor Cables

If the torsion springs come off, be sure to reattach them

correctly. See Section 4.2.15 on page 49.

Figure 4-49. Removing the TPU CR Motor

Dampers and TPU CR Motor

Disassembly / Assembly Disassembly Procedure 56

Page 57

ADJUSTMENT

CHAPTER

5

Page 58

EPSON Perfection 4490 Photo Revision A

5.1 Overview

This section explains the adjustment required when this product is disassembled.

5.1.1 Adjustment item

The adjustment item necessary for this product is as indicated below.

Table 5-1. Adjustment Item

Adjustment Item Condition

Adjustment of Motor Tension Belt

sion

ten

Adjustment of the torsion springs on the

TPU CR Drive Belt

When the Motor Tension Belt is removed or

loosened

After removing and reinstalling the springs which

apply tension to the TPU CR Drive Belt.

5.1.2 Adjustment method

5.1.2.1 Motor Tension Belt tension adjustment

1. Press the Pulley against the Motor Tension Belt, and temporarily fit the Tensioner.

2. Install the Torsion Spring as shown in Fig

tension.

Motor Tension Belt

Tensioner

ure 5-1 to secure the Tensioner under

Pulley

Torsion Spring

Figure 5-1. Tension Adjustment

5.1.3 Adjustment of Torsion Springs on the TPU CR

Drive Belt

See Section 4.2.15 on page 49 for information on how to adjust the torsion springs.

ADJUSTMENT Overview 58

Page 59

MAINTENANCE

CHAPTER

6

Page 60

EPSON Perfection 4490 Photo Revision A

6.1 Overview

This chapter explains the maintenance work necessary to keep this product in the best

condition and to prevent problems.

6.1.1 Cleaning

Clean the outside of the product with a neutral detergent, and clean its inside with a

vacuum cleaner. Special care must be taken when cleaning the Document Glass since it

affects the quality of image scanning. If it is dirty, wipe it with a clean, soft and dry

cloth.

C A U T I O N

Exterior

After wetting a clean cloth with water and then completely s

it, wipe the exterior with that close. If the exterior is extremely dirty, wipe it with a

cloth moistened with a small amount of detergent.

Document Glass

Clean it

has foreign matter on its surface, wipe it with a cloth moistened with a small

amount of pure water. If the Document Glass has traces of wiping after cleaning,

completely wipe it with a dry, clean cloth again.

Never use organic solvents, such as thinner and benzene, because

they may deteriorate or degrade the plastic and rubber parts.

queezing water out of

with a clean, dry cloth. When the Document Glass is especially dirty or

6.1.2 Lubrication

Lubrication is required when any part of the Carriage Unit of the scanner has been

replaced or the Carriage moves with noticeably large operation noise. The specified

grease is indicated in Table 6-1, and the lubrication points are shown in Figure.

Table 6-1. Specified Grease

Type Name Part Number Supplier

EPSON

C A U T I O N

Grease G-26 1080614

Note that a failure to strictly observe the specified amount of

application will contaminate the mechanisms or lead to a

malfunction.

If the oil contaminate components, wipe it off with a cloth

impregnated with alcohol and let the component dry

completely before reassembling.

Scan

ner inside

Before reinstall the Upper Housing after it had been removed, make sure to

remove the dust inside of the scanner and the Upper Housing. Squirt them with

plenty of air.

Maintenance Overview 60

Page 61

EPSON Perfection 4490 Photo Revision A

Figure 6-1. Lubricating the CR moter Unit

Applying Point

Driven Pulley Holder Assy

Applying Point

[Lubrication Point]

Pulley shaft of the CR Motor

Unit

[Lubrication Type]

G-26

[Lubrication Amount]

Adequate dose

[Remarks]

Use a brush to apply it

[Lubrication Point]

Shaft of the Driven Pulley

[Lubrication Type]

G-26

[Lubrication Amount]

Adequate dose

[Remarks]

Use a brush to apply it

Applying Point

Carriage Lock

Figure 6-3. Lubricating the Carriage Lock

Applying Point:B Applying Point:A

[Lubrication Point]

Concave portion of the Carriage

k

Loc

[Lubrication Type]

G-26

[Lubrication Amount]

Adequate dose

[Remarks]

Use a brush to apply it

[Lubrication Point]

A: Idle Pulley shaft on the TPU

CR Motor Assy.

B: Driven Pulley shaft on the

TPU CR Motor Assy.

[Lubrication Type]

G-26

[Lubrication Amount]

Adequate dose

[Remarks]

Use a brush to apply it

Figure 6-2. Lubricating the Driven Pulley Holder Assy

Figure 6-4. Lubricating the TPU CR Moter Assy

Maintenance Overview 61

Page 62

EPSON Perfection 4490 Photo Revision A

[Lubrication Point]

Applying Point

Figure 6-5. Lubricating the TPU Lower Housing

Carriage guide rail on the TPU

Lower Housing

[Lubrication Type]

G-26

[Lubrication Amount]

Adequate dose

[Remarks]

Use a brush to apply it

[Lubrication Point]

Carriage guide rail on the TPU