Page 1

®

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Color Image Scanner

EPSON Perfection 1640SU

1640SU PHOTO

1640SU OFFICE

SESC00-010

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or tran smi tted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change witho ut notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the conse quences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2000 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations through out the text are categorized relative to 1)Personal injury and 2) damage to equipment.

W A R N I N G

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures .

Signals a precaution which, if ignored, could result in serious or

fatal personal injury. Great caution should be exercised in

performing procedures preceded by a WARNING heading.

C A U T I O N

Signals a precaution which, if ignored, could result

in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of Perfection 1640SU,

Perfection 1640SU PHOTO and Perfection 1640SU OFFICE. The instructions and procedures included herein are intended for the experienced

repair technicians, and attent ion should be given to the precautions on the preceding page. The chapters are organi zed as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENT

This product reqires no adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures.

APPENDIX

Provides the following addition information for reference:

- Connector Pin Assignments

- Parts lists

- Exploded Diagrams

Page 5

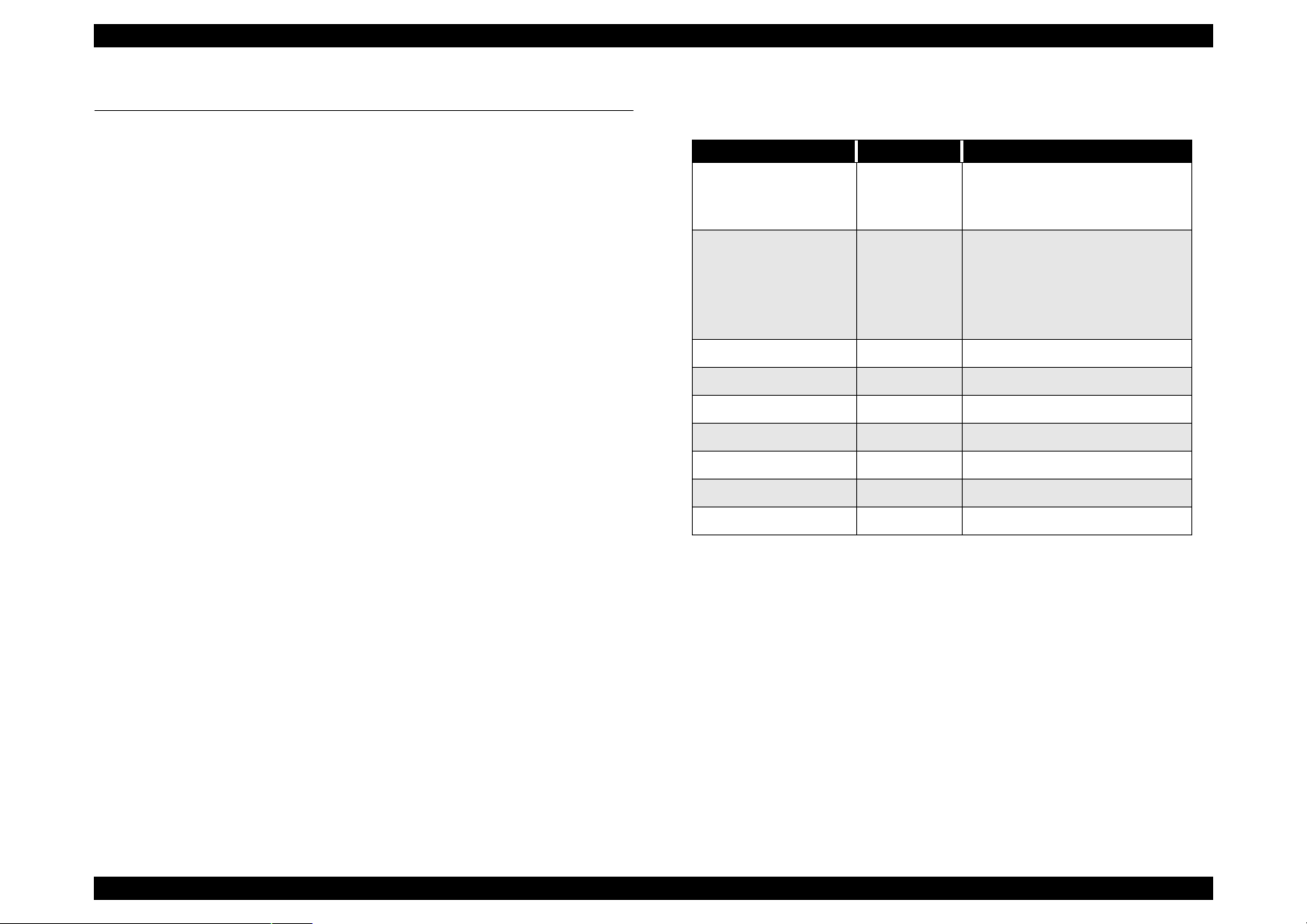

Revision Status

Revision Issued Date

A August 9, 2000 First Release

Description

Page 6

EPSON Perfection 1640SU Revision A

Contents

Chapter 1 Product Description

1.1 Features ................................................................................................... 9

1.2 Product Description ................................................................................ 10

1.3 Interface Specification............................................................................ 12

1.3.1 SCSI Interface............................................................................... 12

1.3.2 USB Interface................................................................................ 14

1.4 Control Code .......................................................................................... 15

1.5 Exterior Function .................................................................................... 16

1.5.1 Switch Specification ...................................................................... 16

1.5.2 Indicators....................................................................................... 16

1.6 Process when an error happens............................................................. 17

Chapter 2 Operating Principles

2.1 Engine Mechanism................................................................................. 19

2.1.1 Carriage Unit ................................................................................. 19

2.1.2 Carriage Move Mechanism ........................................................... 20

2.2 Power Supply Circuit .............................................................................. 21

2.3 Control Circuit......................................................................................... 23

2.3.1 Control Circuit Overview................................................................ 23

Chapter 3 Troubleshooting

3.1 Overview................................................................................................. 26

3.2 Self-Diagnostic Function......................................................................... 26

3.3 Troubleshooting...................................................................................... 27

Chapter 4 Disassembly and Assembly

4.1 Overview................................................................................................. 31

4.1.1 Precaution ..................................................................................... 31

4.1.2 Tools.............................................................................................. 31

4.1.3 Screws .......................................................................................... 31

4.2 Disassembly Procedures........................................................................ 33

4.2.1 Carriage Lock Release.................................................................. 33

4.2.2 Document Cover Removal............................................................ 34

4.2.3 Upper Cover Removal................................................................... 35

4.2.4 Panel Board Removal ................................................................... 37

4.2.5 Inverter Lamp/Inverter Board Removal......................................... 38

4.2.6 Main Board Removal..................................................................... 40

4.2.7 Carriage Unit Removal.................................................................. 42

4.2.8 Carriage Motor Removal ............................................................... 46

4.2.9 Sub Board Removal ...................................................................... 47

4.2.10 Power Supply Board Removal .................................................... 49

Chapter 5 adjustment

Chapter 6 Maintenance

6.1 Overview ................................................................................................ 54

6.1.1 Cleaning........................................................................................ 54

6.1.2 Lubrication..................................................................................... 54

Chapter 7 Appendix

7.1 Overview ................................................................................................ 56

7.1.1 Interconnection.............................................................................. 56

7.1.2 Connector Assignment.................................................................. 56

7.1.3 Connector...................................................................................... 57

7.2 Circuit Diagram....................................................................................... 59

7.3 Parts List & Exploded Diagram .............................................................. 61

7.4 TPU; Parts List ....................................................................................... 65

7.5 Exploded Diagram for TPU .................................................................... 66

7.6 Optional Part; ADF ................................................................................. 67

6

Page 7

EPSON Perfection 1640SU Revision A

7.6.1 General Description....................................................................... 67

7.6.2 Specification.................................................................................. 67

7.6.3 Interface ........................................................................................ 69

7.7 ADF: Disassembly.................................................................................. 70

7.7.1 B81314 Main Board Removal ....................................................... 70

7.7.2 ASF Part........................................................................................ 71

7.7.3 Disassembling the ASF and Frame............................................... 76

7.8 Parts List of ADF .................................................................................... 78

7.9 ADF Exploded Diagram.......................................................................... 80

7

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

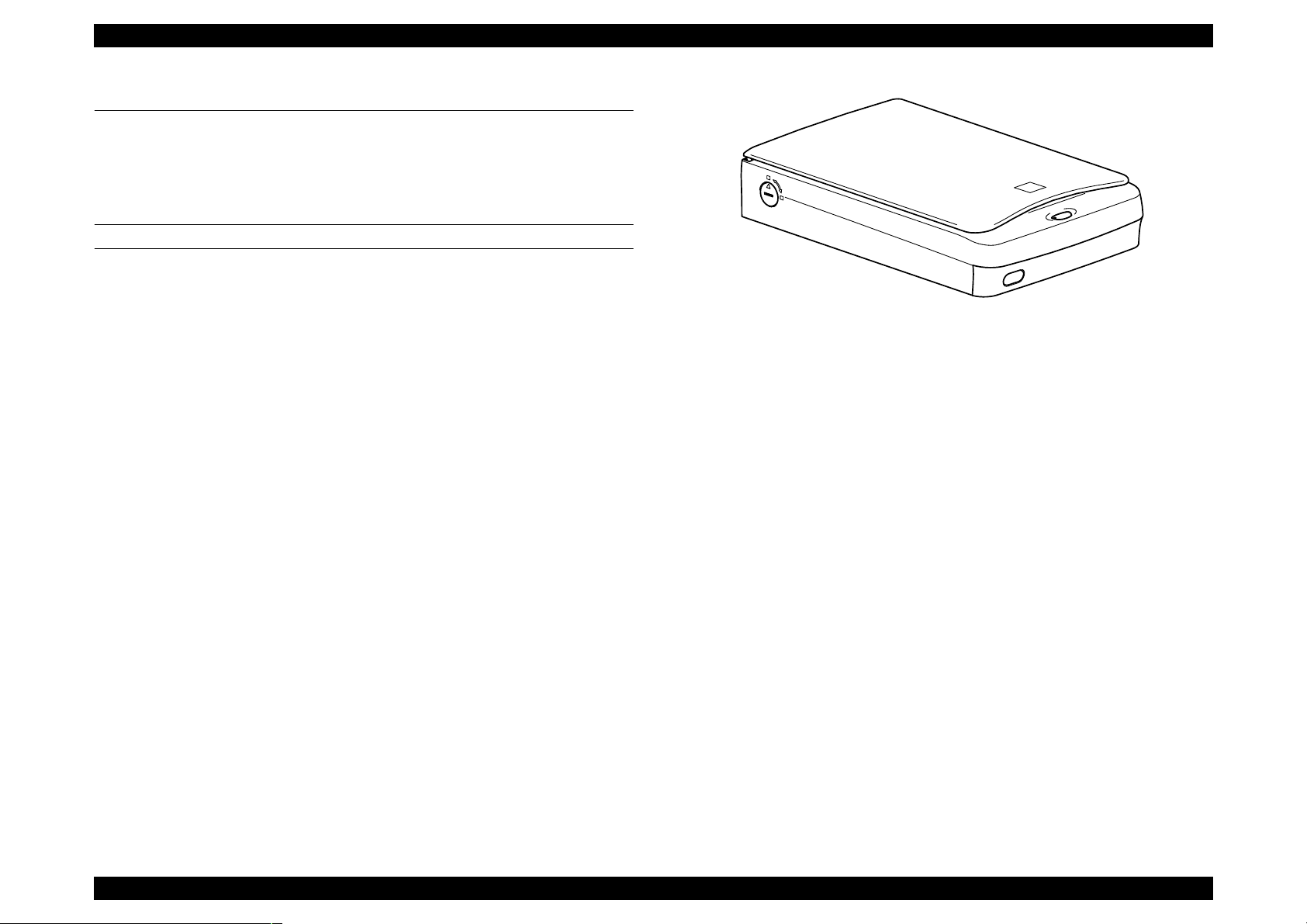

EPSON Perfection 1640SU Revision A

1.1 Features

EPSON Perfection 1640 consists of three models: 1640SU, 1640SU PHOTO

and 1640SU OFFICE. Major features are as follows. Perfection 1640SU

PHOTO has the TPU (transparency unit) as standard unit. Perfection 1640SU

OFFICE has the ADF (automatic document feeder) as standard unit.

MAJOR FEATURES

High quality:

Resolution: 1600 dpi (Optical resolution by 6 line CCD with

High speed:

Ease of Use

40800 pixels)

depth: 14 bit (14 bit-in, 14 bit-out)

Monochrome: 3.0 msec/line

Color: 8.7 msec/line

( Equivalent to ’Perfection 1200U/S’ )

Figure 1-1. Exterior View of Perfection 1640SU

EPSON Smart Panel

-Same functions as ’Stylus Scan 2000/2500’.

-Achieve easy scanning with a start button.

-Export a image data to applications easily.

Instant Photo Print Utility

Modify from ’Perfection 1200’

New Twain functions

-ITR(Image Type Recognition)

-Auto skew correction

Hybrid Interface

Include both USB and SCSI interfaces in one

Option

ADF(Based on ’Perfection 636 ADF’, and change external design

according to ’Perfection 1640SU’)

Film Adapter (Same sa ’Perfection 1200 Film Adapter’)

Product Description Features 9

Page 10

EPSON Perfection 1640SU Revision A

1.2 Product Description

GENERAL SPECIFICATION

Product Type: Flatbed color image scanner

Sub-scanning method: Movement of the Scanner-Head

Photoelectric device: 6 line alternate color CCD

Maximum Read Area: 8.5 x 11.7 (216 x 297mm)

Maximum effective picture element:

13600 x 18720 pixels (1600 dpi)

Scanning Resolution:

Main 1600 dpi (Optical resolution by 6 line CCD with 40800 pixels)

Sub 3200 dpi with Micro Step

Output resolution: 50 ∼ 6400 dpi (1 dpi step)

(12800dpi scanning is achieved by

6400dpi x 200%)

Gray scale levels: 14 bits/pixel (Input 14 bits/pixel, Output 1-8/bits/

pixel)

Color Separation: By the color filter of CCD

Zoom: 50 ∼ 200% (1% step)

Scanning Speed:

Color: 8.7 msec/line

Monochrome (bi-level): 3.0 msec/line

Command level: ESC/I (B8), FS

Gamma Correction: CRT 2 level (A, B)

PRINTER 3 level (A, B, C)

User defined 1 level

Color Correction: Impact-Dot Printer

Thermal Printer

Ink-Jet Printer

CRT Display

User defined

Brightness: 7 levels

Line Art: Fixed threshold

TET (Text Enhancement Technology)

Digital halftoning: AAS

Error Diffusion 3 modes (A, B, C)

(Bi-level, Quad-level)Dither (Resident) 4 modes (A, B, C, D)

Dither (User defined) 2 modes (A, B)

Interface (Resident):SCSI (50-pin Half pitch Connectors) x 1pcs

USB (Type-B Receptacle Connector) x 1pc

USB Hosts: All of USB ports work correctly. (The functionality of

the USB port (s) must be ensured by the vendor of the

Host)

Number of Hub: This device must be in the Tier 1 or 2 with

recommended USB cable. (Tier1:Host-this device

Tier2: Host-Hub-this device)

Light Source: White Cold cathode Fluorescent Lamp

Option : ADF, Film Adapter

Start button: Ease of use with EPSON Smart Panel

Operating System:

SCSI I/F: Microsoft Windows 95/98, Windows NT4.0/Windows2000

Microsoft Windows Millennium Edition

Macintosh System 8.0 or later

USB I/F: Microsoft Windows 98 (Pre-install model)

Microsoft Windo w s2 000 (Pre-install mo de l or up gr ad e

model from Windows 98 pre-install model)

Microsoft Windows Millennium Edition (Pre-install model

or upgrade mo del from Window s 98 pre-install mode l)

Apple System 8.1 or later (USB equipped model)

Product Description Product Description 10

Page 11

EPSON Perfection 1640SU Revision A

ELECTRICAL SPECIFICATIONS

Rated voltage: AC100-120V

AC220-240V

Input voltage: AC 100 -120V ±10%

AC 220 - 240V ±

Rated Current : 0.5A (Input AC100V)

0.3A (Input AC200V)

Rated Frequency Range:50-60 Hz

Input Frequency Range:49.5-60.5 Hz

Power consumption: Approx. 25W (Operating)

Approx. 10W (Stand-by)

Insulation resistance: 10 MΩ at 500VDC (between AC line and chassis)

Dielectric strength: AC.1.2kV, 1 min (between AC line and chassis)

10%

SAFETY, EMC, EPA

Safety: UL 1950 (UL)

CSA C22.2 NO.950 (CSA)

EN60950 (VDE)

IEC950 (ROSTEST, PSB)

EMC: FCC Part15 Subpart B Class B

CSA C108.8 Class B

AS/NZS3548 Class B

CISPR Pub22 Class B

CNS 1348 Class B

RESISTANCE TO ELECTRIC NOISE

Static electricity: panel - 10 kV

metal - 7kV/150 pF, 150Ω

ENVIRONMENTAL CONDITIONS

Temperature:

Operating: 5 °C to 35 °C

Storage: -25 °C to 60 °C

Humidity:

Operating: 10 to 80%, no condensation

Storage: 10 to 85%, no condensation

RELIABILITY

MCBF: 30, 000 cycle

OPERATING CONDITIONS

Dust: Ordinary office or home conditions. Extreme dust

should be avoided.

Illumination: Operation under direct sunlight or near strong light

source is not guaranteed and should be avoided.

DOCUMENT

CE Marking:

Low Voltage Directive 73/23/EEC EN60950

EMC Directive 89/336/EEC EN55022 Class B

EN6100-3-2

EN6100-3-3

EN50082-1

IEC60801-2/801-3/801-4

EPA: Energy Star Program

Reflective type: Documents which has a smooth surface such as a

printing and photograph.

Transparency type (with transparency unit)

Reversal film

Negative film

Product Description Product Description 11

Page 12

EPSON Perfection 1640SU Revision A

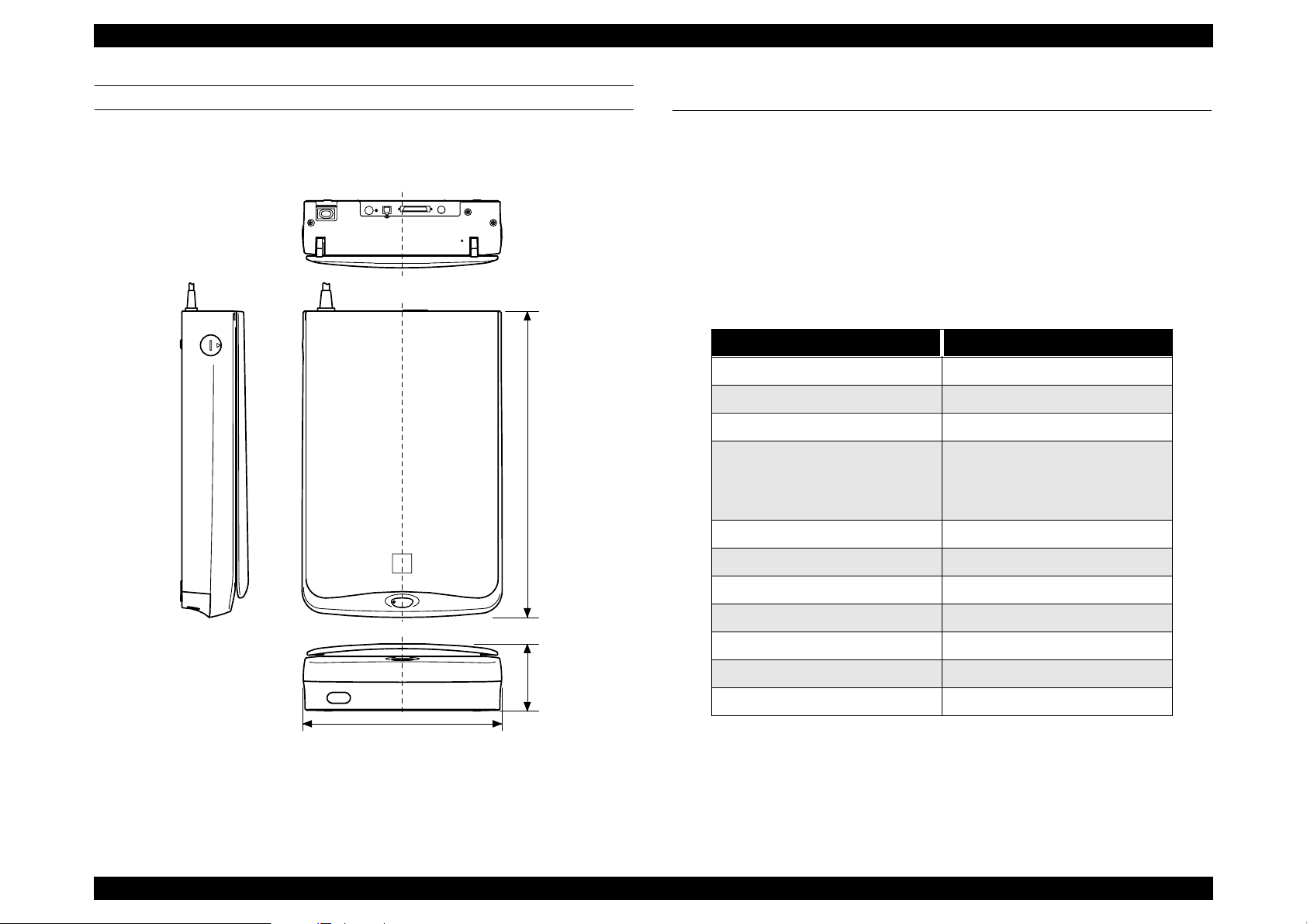

PHYSICAL DIMENSIONS AND WEIGHT

Dimensions: 289(W) x 442(D) x 96(H) mm

Weight: Approx. 4.5 Kg

442mm

1.3 Interface Specification

1.3.1 SCSI Interface

Basic specifications

Any items not included in this specification shall be in compliance with

ANSI X 3T9.2/375R Revision 10L (SCSI 2)

Function

The following functions are available, which are included in ANSI X3T9.2/

375R Revision 10L (SCSI 2)

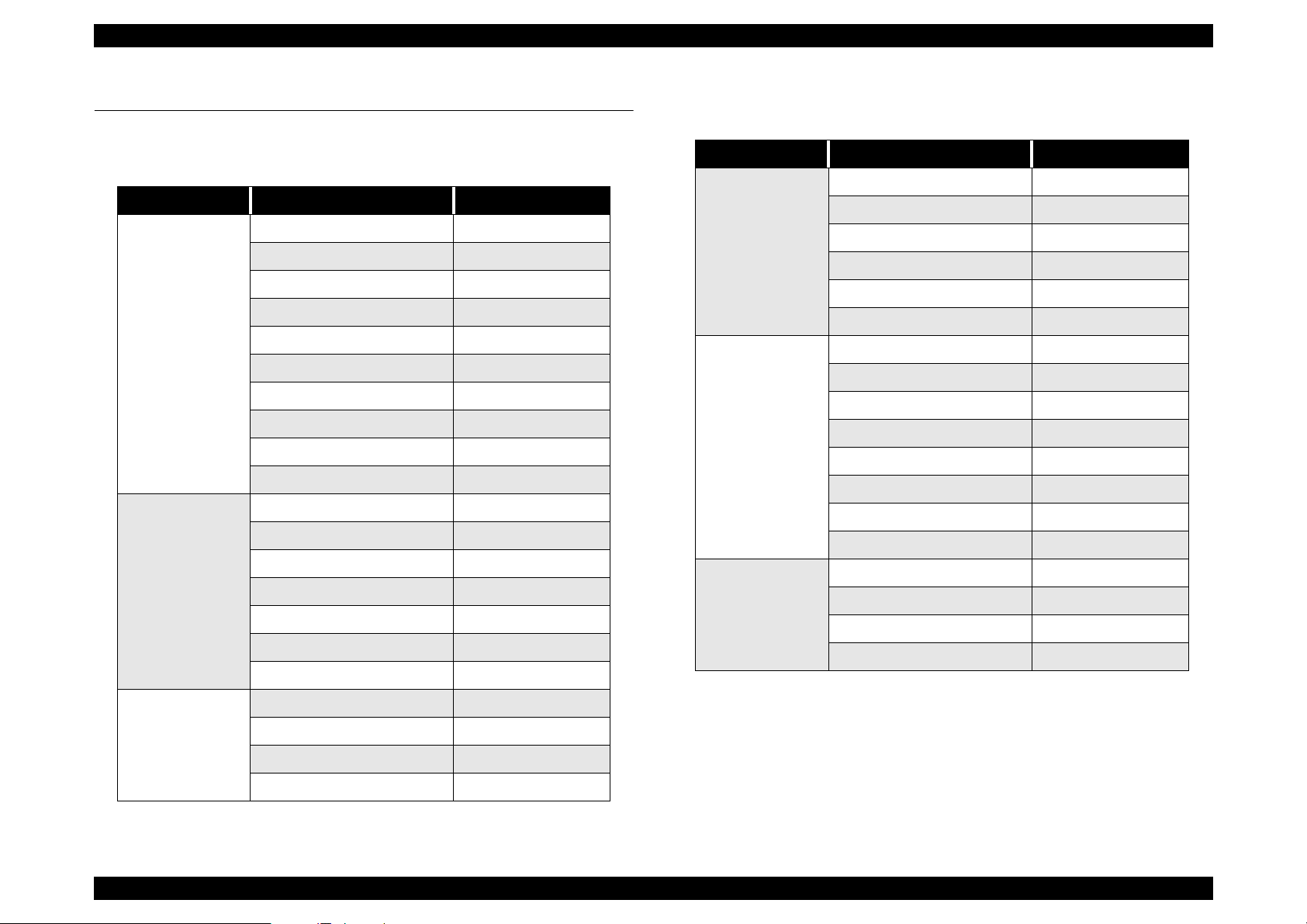

Table 1-1. SCSI Interface Function

Function Note

Bus Free Phase

Arbitration phase

Selection /Re-selection phase

The LUN (Logical Unit Number) is

Command phase

Data in phase

fixed at “0” in this device. The

Command Link Function is not

supported.

Data out phase

Status phase

Message in phase

96mm

289mm

Figure 1-2. Size

Message out phase

Attention condition

Reset condition

SCAM (SCSI Configured Auto Magically specification) [X3T9.2/93109r5]

Electric specification

Compliant to ANSI X3T9.2/375R Revision 10L (SCSI 2)

Single ended

Product Description Interface Specification 12

Page 13

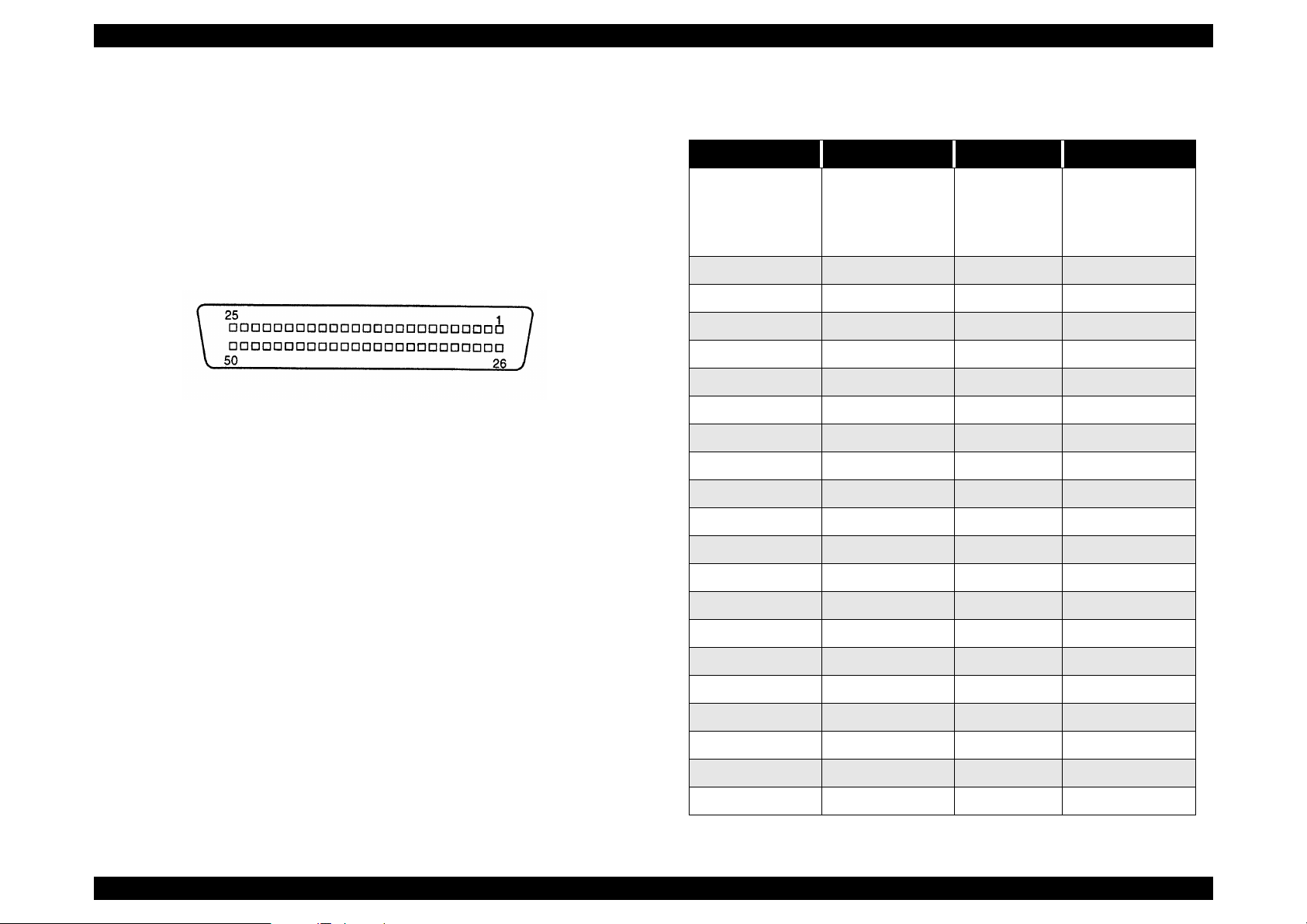

EPSON Perfection 1640SU Revision A

Connector: Two 50-pin connectors

Terminator: Internal terminator

(always ON ----terminator available)

SCSI ID: The SCSI ID is set with a rotary switch on the rear panel.

The switch numbers are corresponded to the available

address and can be set from 0 to 7.

Others are reserved

Factory setting ID=2

Table 1-2. SCSI Connector Pin Assignment

Signal I/O Pin No. Specification

1 ∼12

GND

NC 13

DB0 I/O 26 Data Bus 0

DB1 I/O 27 Data Bus 1

DB2 I/O 28 Data Bus 2

14 ∼ 25

35 ∼ 37

39, 40, 42

50pin connector

Figure 1-3. SCSI Connector Pin Assignment

DB3 I/O 29 Data Bus 3

DB4 I/O 30 Data Bus 4

DB5 I/O 31 Data Bus 5

DB6 I/O 32 Data Bus 6

DB7 I/O 33 Data Bus 7

DBP I/O 34 Data Bus Parity

TERMPWR 38 Terminator Power

ATN I 41 Attention

BSY I/O 43 Busy

ACK I 44 Acknowledge

RST I 45 Reset

MSG O 46 Message

SEL I/O 47 Select

C/D O 48 Command/Data

REQ O 49 Request

I/O O 50 Input/Output

Product Description Interface Specification 13

Page 14

EPSON Perfection 1640SU Revision A

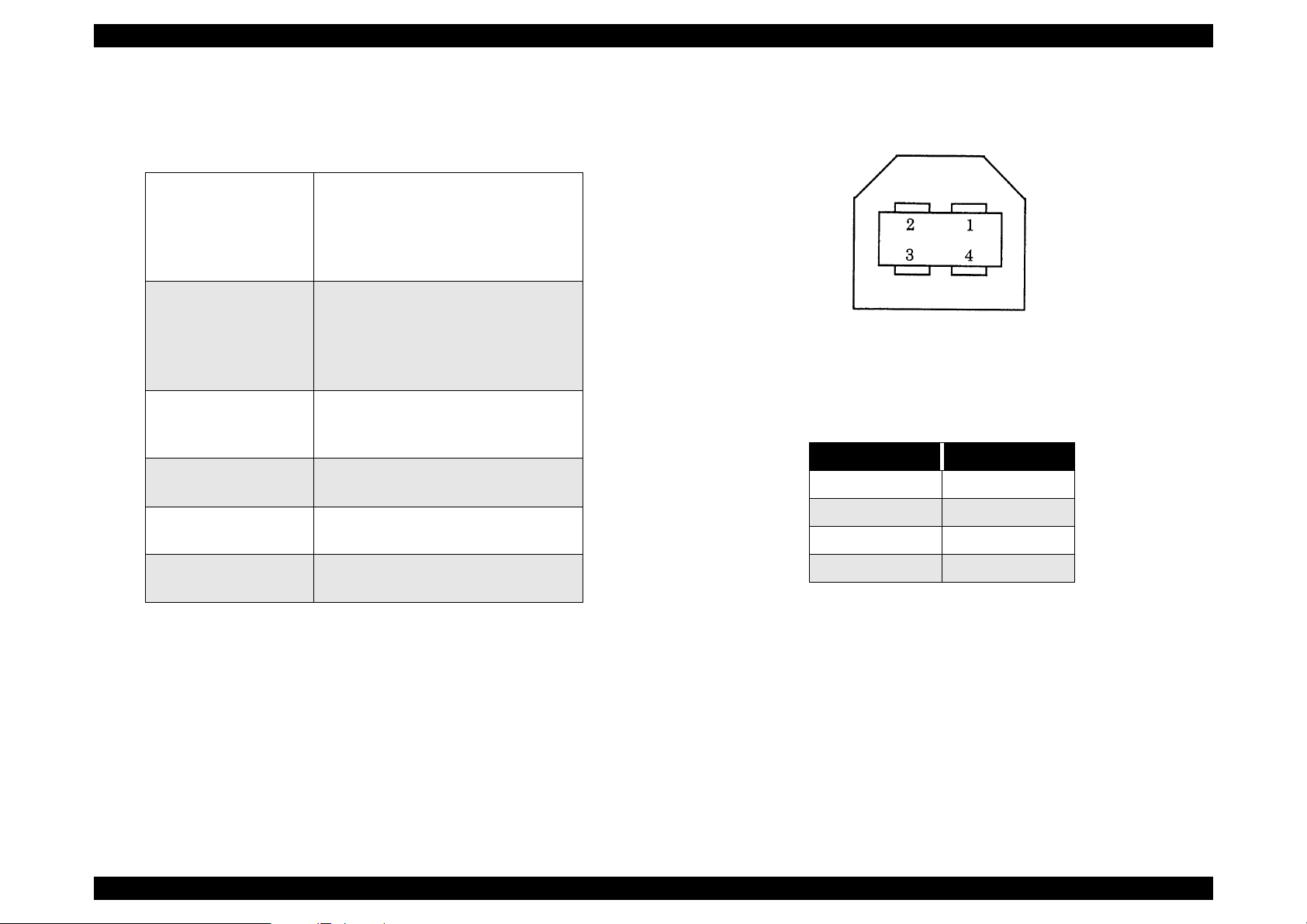

1.3.2 USB Interface

Component: This device supports the following configurations.

Table 1-3. Configurations

Class: Vender-specific

Max. packet size of endpoint 0: 64 byte

Device

Component

Interface 0

End point 1

End point 2

Vender ID: 0x04B8

Product ID: 0x010A

No.of component: 1

Supported Interface: 1

Characteristic

• Self power

• Remote wake up function support

Power consumption:2mA

substitutes setting value: NO

Endpoint: 2

Class: Vender-specific

Bulk IN transfer

Max. packet size: 64 byte

Bulk out transfer

Max. packet size: 64 byte

Figure 1-4. Receptacle (Series B)

Table 1-4. Connector Pin Assignment

Pin No. Signal

1VCC

2 - Data

3+ Data

String descriptor

Electric specification: Compliant to the high speed (12M bps) mode of

Producer: “EPSON”

Product Name: Perfection 1640

4 GND

Universal Serial Bus Specification Rev.1.1.

Connector: Receptacle (Series B) (Figure 1-4 and Table1-4)

Product Description Interface Specification 14

Page 15

EPSON Perfection 1640SU Revision A

1.4 Control Code

The command level is ESC/I-B7 and supported commands are shown below.

Table 1-5. Control Codes

Category Command Name Code

ID request ESC I

Status request ESC F

Extension status request ESC f

Status setting request ESC S

Execute Command

Data format

setting

Read start command ESC G

Push Button Status request ESC !

Expansion ID request FS I

Scanner Status request FS F

Read parameter request FS S

New read start FS G

Sets Data format ESC D i

Sets resolution rate ESC R n1 n2

Sets zoom rate ESC H i1 i2

Sets the reading range ESC A n1 n2 n3 n4

Sets the color ESC C i

Mirroring ESC K i

Sets reading parameter FS W

Table 1-6. Control Codes

Category Command Name Code

Set Digital Halftoning ESC B i

Set Auto Area Segmentation ESC s i

Download Dither Pattern ESC b ijd (j2)

Image process

Color correction ESC M i

Download Color Correction ESC m df d2...d9

Set Threshold ESC t i

Set scanning mode ESC g i

Initialize ESC @

Set line counter ESC d i

Control option ESC e i

Auxiliary

Focus adjustment ESC p i

Focus position status request ESC q

Eject paper FF

Film type ESC N i

Normal response ACK

Abnormal response NACK

Control

Abort scanning CAN

Header STX

Set brightness ESC L i

Correction process

Set Gamma correction ESC Z i

Set Gamma correction table ESC z i d0 d1...d255

Set sharpness ESC Q i

Product Description Control Code 15

Page 16

EPSON Perfection 1640SU Revision A

1.5 Exterior Function

1.5.1 Switch Specification

OPERATE Switch

Turns the scanner ON/OFF

Pressing this switch at power ON initializes the scanner

PUSH Button

The status of this button can be checked by [ESC !].

SCSI ID switch (rotary type)

0 - 7: SCSI ID (Factory setting ID=2)

Other: Reserved

1.5.2 Indicators

Indicator display

OPERATE (Green LED)

OPERATE switch is ON and power is ON.

READY (Green LED)

*This lamp becomes ON when the command or receiving/sending the

data is available. (During scanning, READY lamp repeats blinking,

according to the data transfer)

*READY lamp blinks with with ERROR LED when an error occurs.

ERROR (Red LED)

This lamp blinks when an error (s) is detected.

READY LED

(green)

ON ON Command error

OFF Blink

OFF Blink Fatal error

Blink Blink Option error

Table 1-7. Error Indication

ERROR LED (red) Error ty pe

Communication

error

Product Description Exterior Function 16

Page 17

EPSON Perfection 1640SU Revision A

Remedy: Turn the scanner off and then back on. Send ESC@

1.6 Process when an error happens

Command error

Cause: Unidentified command or unidentified command

parameter is detected.

Disposition: The scanner ignores the wrong command or parameter.

(Therefore, the current setting or the default value remain

effective.)

Scanner sends NACK, and waits for the next command or

parameter.

Indicator: Red LED ON

Remedy: The error condition is cleared when the scanner receives

a correct command.

Interface error (Communication error)

Cause: Wrong procedure is detected in the interface

communication. In the case of SCSI, a transmission is

frozen more than 30 seconds except BUS FREE phase.

Disposition:The lamp goes off and the scanner stops operation.

code to the scanner. RESET signal in SCSI turns active.

Complete BUS DEVICE RESET message in SCSI.

Acceptable command: ESC F, ESC f, ESC @

Option error:

This error occurs by the following causes, when an optional unit is installed

and its operation is available by the optional control command (ESC e).

Cause: Unit cover open

Paper Empty

Disposition:The bit 7 of the status byte is set to “1”

Indicator: READY LED Blink

ERROR LED Blink

Remedy: Remove the error condition

Acceptable command: ESC F, ESC f, ESC @

Indicator: READY LED Off

ERROR LED (red) blinking (short interval)

Remedy: Turn the scanner off and then back on. RST signal in SCSI

turns active.

Acceptable command : Nothing

Fatal error

Cause: The lamp is broken. Power is turned on before removing

the transportation screw.

Disposition: The lamp goes off and the scanner stops operation.

The bit 7 of the status byte is set.

Indicator: READY LED Off

ERROR LED Blinks

Product Description Process when an error happens 17

Page 18

OPERATING PRINCIPLES

CHAPTER

2

Page 19

EPSON Perfection 1640SU Revision A

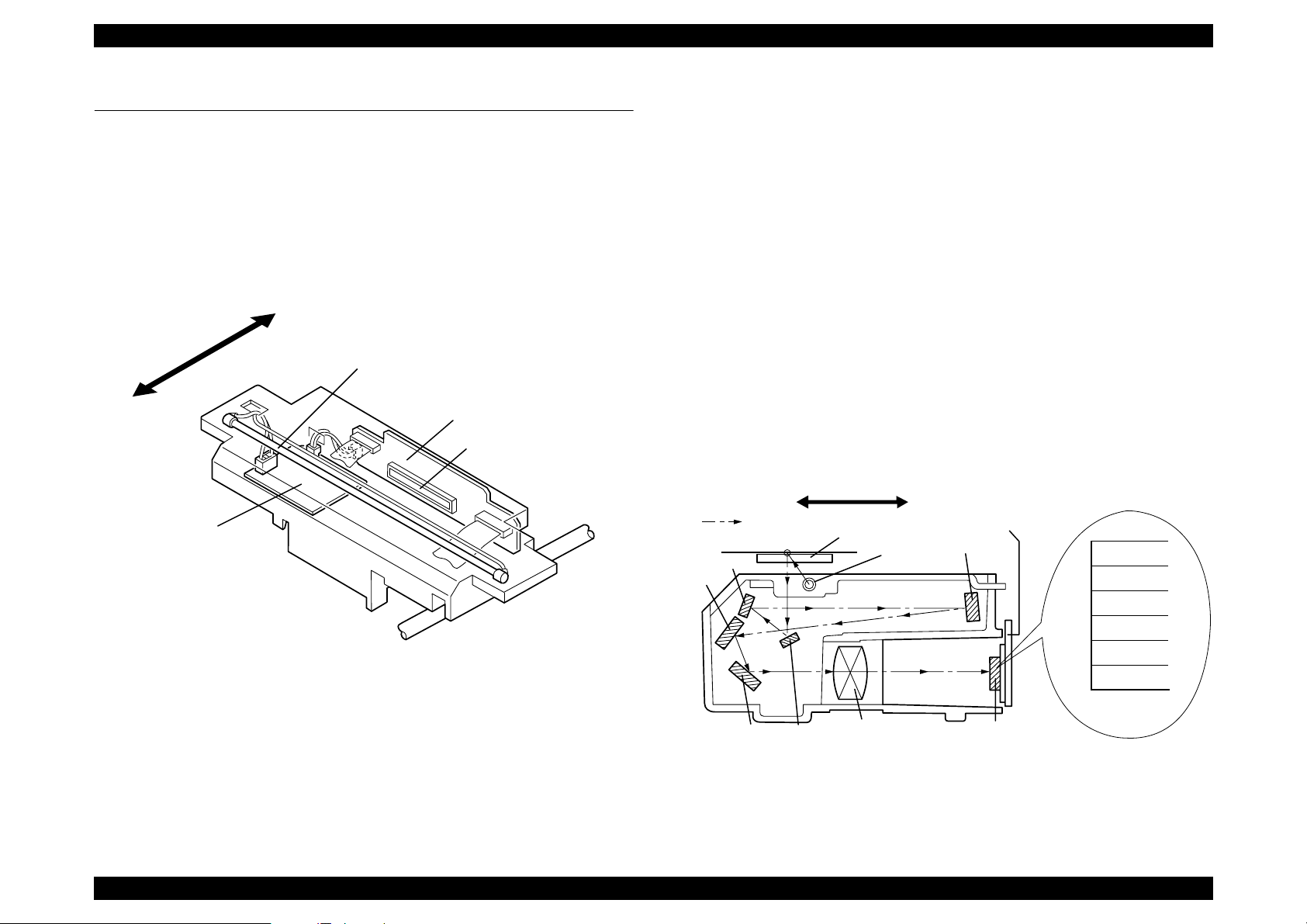

CCD Sensor Board: This board has Color CCD line sensor

2.1 Engine Mechanism

This section explains the engine function and operating principles. Engine can

be divided into Carriage Unit and Carriage Move Mechanism.

2.1.1 Carriage Unit

Carriage unit is mainly composed of CCD sensor board, Inverter board, Lamp

(light source), Mirror and Lens mechanism.

Rear

Lamp

CCD Sensor

Front

Board

CCD Sensor

(independent R,G,B), and controls it and drives

circuit.

Inverter Board: This board generates voltage to drive the lamp

by pressuring up to the +24VDC and converting it

from direct current to alternating current.

Lamp: White cold fluorescent Lamp is used as light

source. When the light quantity is not stable,

the scanner blinks the Operate light until the

light becomes stable and goes to stand-by mode.

Mirror and Lens Mechanism:The light emitted to the document

reaches the CCD sensor after being

reflected on some mirrors one after

another. Not by changing the light

source to create R/G/B light component

which can be found in the previous

models, Color CCD itself creates each

R/G/B light component.

CCD Sensor

Mirror3

Board

B(main)

B(sub)

G(main)

G(sub)

R(main)

R(sub)

Inverter Board

Mirror2

Mirror4

Front

Scanned image

Document

Rear

Lamp

Figure 2-1. Carriage Unit Component

Mirror5

Mirror1

Lens

CCD Sensor

Figure 2-2. Mirror, Lens Mechanism

Operating Principles Engine Mechanism 19

Page 20

EPSON Perfection 1640SU Revision A

n

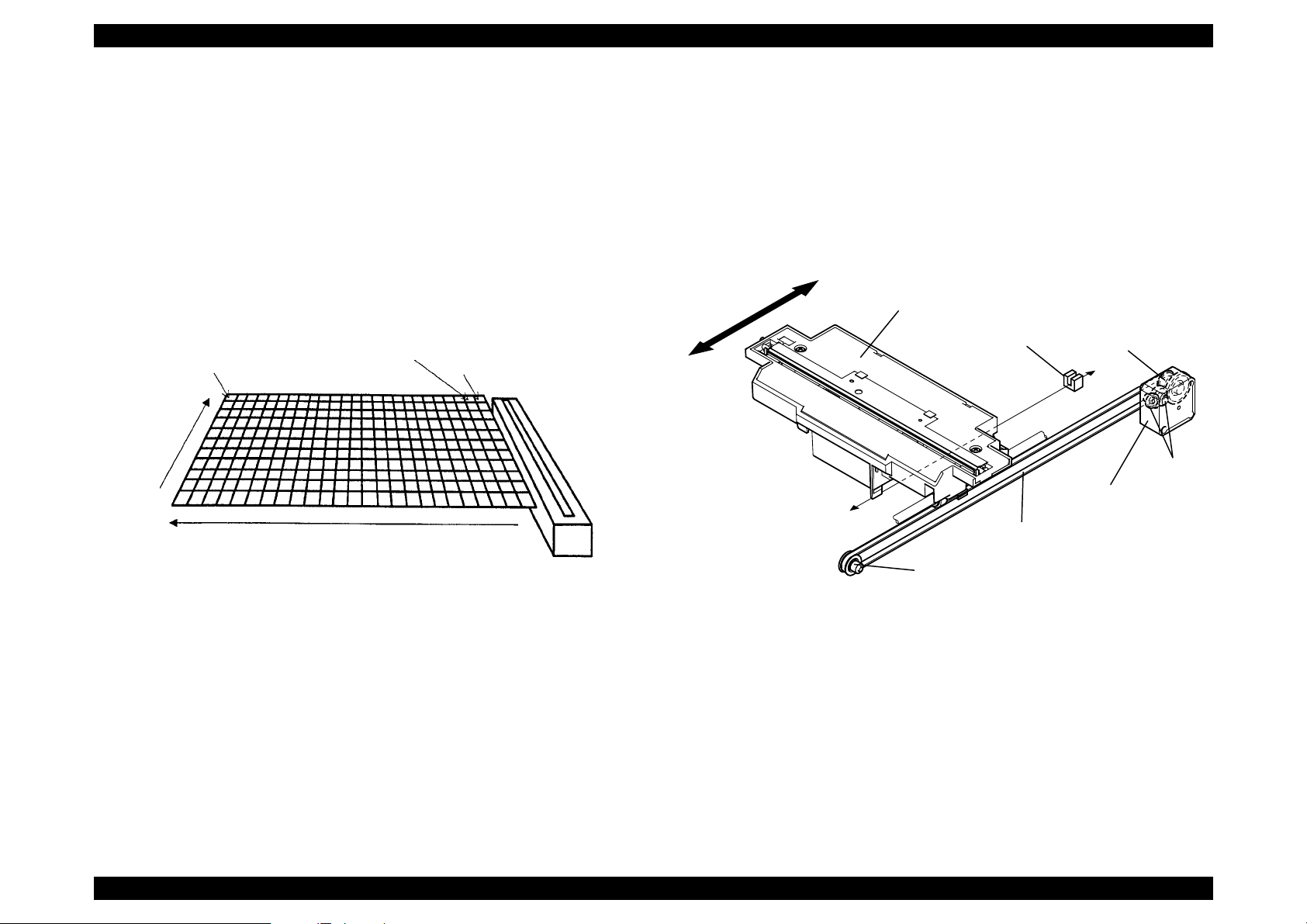

2.1.2 Carriage Move Mechanism

Scanning image is performed in the main scan direction (=1 line) by the CCD

sensor and in the sub-scan direction (=several lines) combined with carriage

unit movement. (See the figure below)

Line type, color CCD sensor can scan 1 line in main scan direction (parallel to

the carriage unit) by one time. When scanning next lines after the second line

in sub-scan direction, CR driving moves the carriage unit, which has CCD

sensor inside, and scan the other lines. The scanned data is sent to the control

board. The scanned data for “n” lines and “n-1” line are processed

consecutively.

Second

1 pixel

Document

Main Scan

Direction

Sub-scan Direction by

CR Movement

Line

First Line

Scanner Head

(Carriage)

Carriage Unit slides into sub-scan direction along with the guide rail. For this

sliding operation, the carriage motor drives the timing belt attached to the

carriage unit by conveying the driving force through the drive pulley and

reduction gear. Scanning start position is determined by CR HP sensor, which

is located on the control board. Since the stepping motor is used for CR motor,

carriage home position is controlled under the open loop system. (See the

figure below)

Rear

Carriage Unit

CR HP

Sensor

Front

Timing Belt

Drive Pulley

Drive Pulley

CR Motor

Reductio

Gear

Figure 2-3. Carriage Movement

Figure 2-4. Carriage Operation

Operating Principles Engine Mechanism 20

Page 21

EPSON Perfection 1640SU Revision A

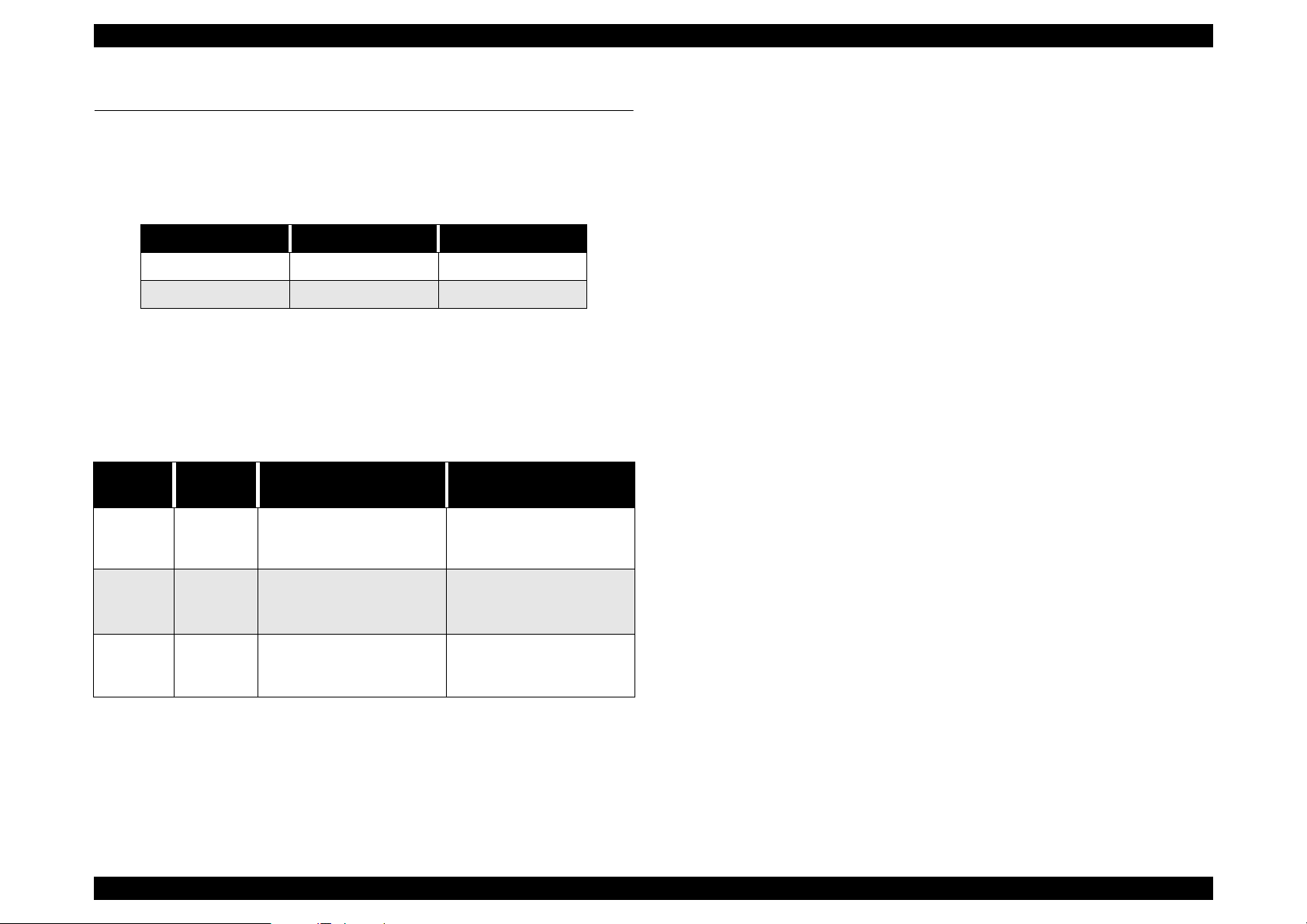

2.2 Power Supply Circuit

Power supply circuit in this scanner generates direct current DC power

necessary for driving the controller board and scanner engine. Table below

shows each power supply circuit for different destinations.

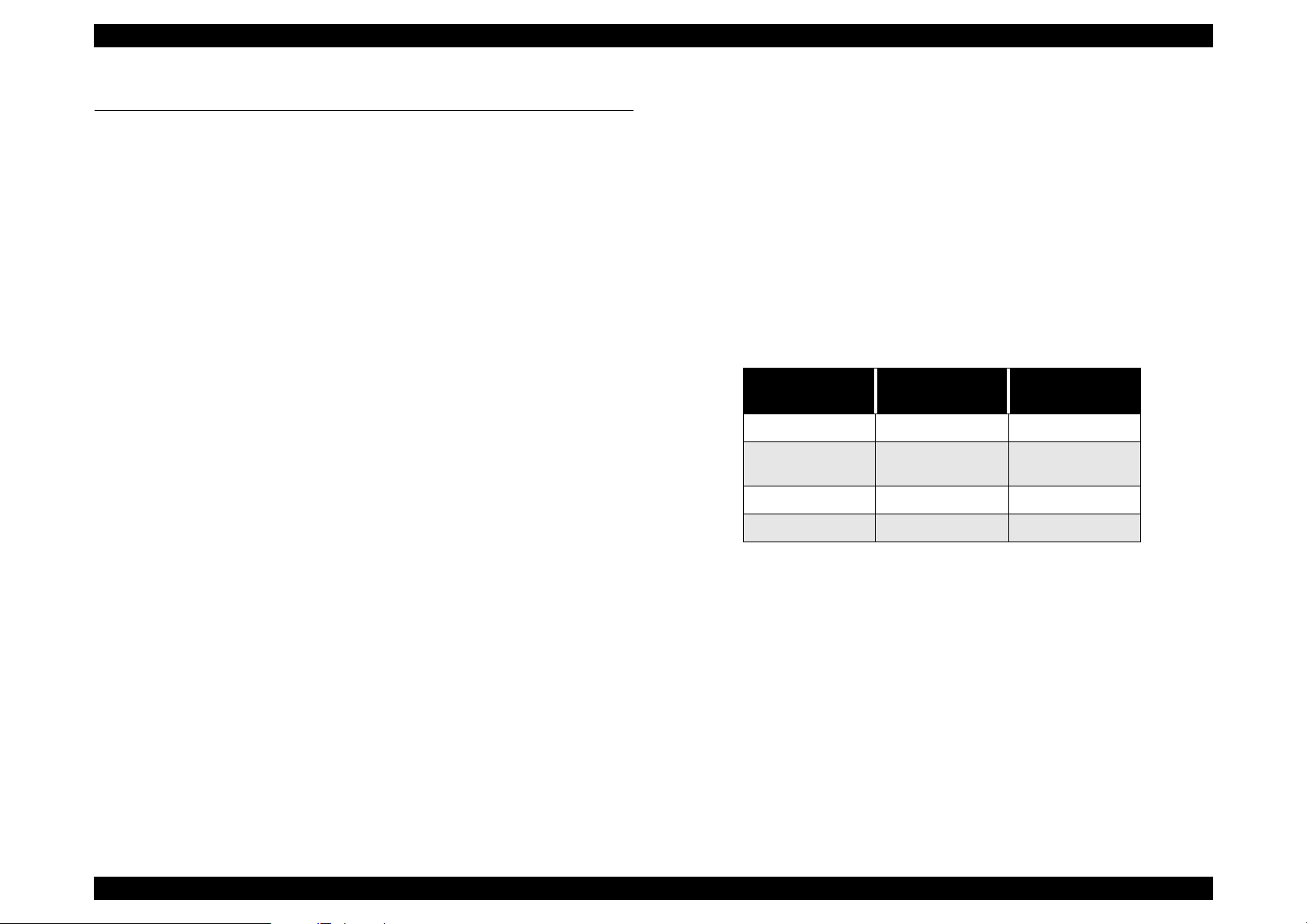

Table 2-1. Power Supply Circuit Board for Destination

Specification Unit Part No. Fuse

100-120 VAC Range 2031592 2.5 A/125 VAC

220-240 VAC Range 2031593 T2.5AH/250 VAC

Figure 2-5 shows diagram of power supply circuit.

Output from the power supply circuit is performed by closing or opening the No.

4 pin of CN102 connector. When opening, as it is shown in the Table below,

each output voltage becomes active. Also, each output voltage has over

current protection and over voltage protection circuit.

Table 2-2. Output and Protection Function

Output

Voltage

5 VDC 1.2A

12 VDC 0.2A

24 VDC 0.7A

Output

Current

Over Current Protection

(Current value to activate)

Fold-back characteri st ic.

Automatic Recove ry. (Less

than 1A)

Constant current limiting.

Automatic Recovery.

(less than 0.5 A)

Shut down. Turn off the

power and back on to

recover.

Over voltage Protection

(Voltage value to activate)

Shut down. Turn off the

power and back on to

recover. (5.5 -7.5 VDC)

Shut down. Turn off the

power and back on to

recover. (14 -17 VDC)

Shut down. Turn off the

power and back on to

recover. (28 -33 VDC)

NOTE: 1. If a part of output is shut down, all the other output are also shut

down.

2. Off time required to recover is maximum 5 minutes.

Operating Principles Power Supply Circuit 21

Page 22

EPSON Perfection 1640SU Revision A

F u l l W a v e

R e c t i f i e r C i r c u i t

F i l t e r C i r c u i t

A C V o l t g e I n p u t

S m o o t h i n g

C i r c u i t

S w i t c h i n g

C i r c u i t

S m o o t h i n g

C i r c u i t

+ 1 2 V D C

R e g u l a t o r I C

+ 5 V D C

R e g u l a t o r

C i r c u i t

O v e r C u r r e n t

P r o t e c t i o n

C i r c u i t

S m o o t h i n g

C i r c u i t

+ 2 4 V D C

C o n t r o l C i r c u i t

+ 2 4 V D C O v e r

C u r r e n t P r o t e c t i o n C i r c u i t

+ 5 / + 1 2 / + 2 4 V D C

O v e r V o l t a g e

P r o t e c t i o n C i r c u i t

+ 1 2 V D C

+ 5 V D C

+ 2 4 V D C

P o w e r S u p p l y

S W C i r c u i t

P o w e r S W

( P W - S W )

Figure 2-5. Power Supply Circuit Block Diagram

Operating Principles Power Supply Circuit 22

Page 23

EPSON Perfection 1640SU Revision A

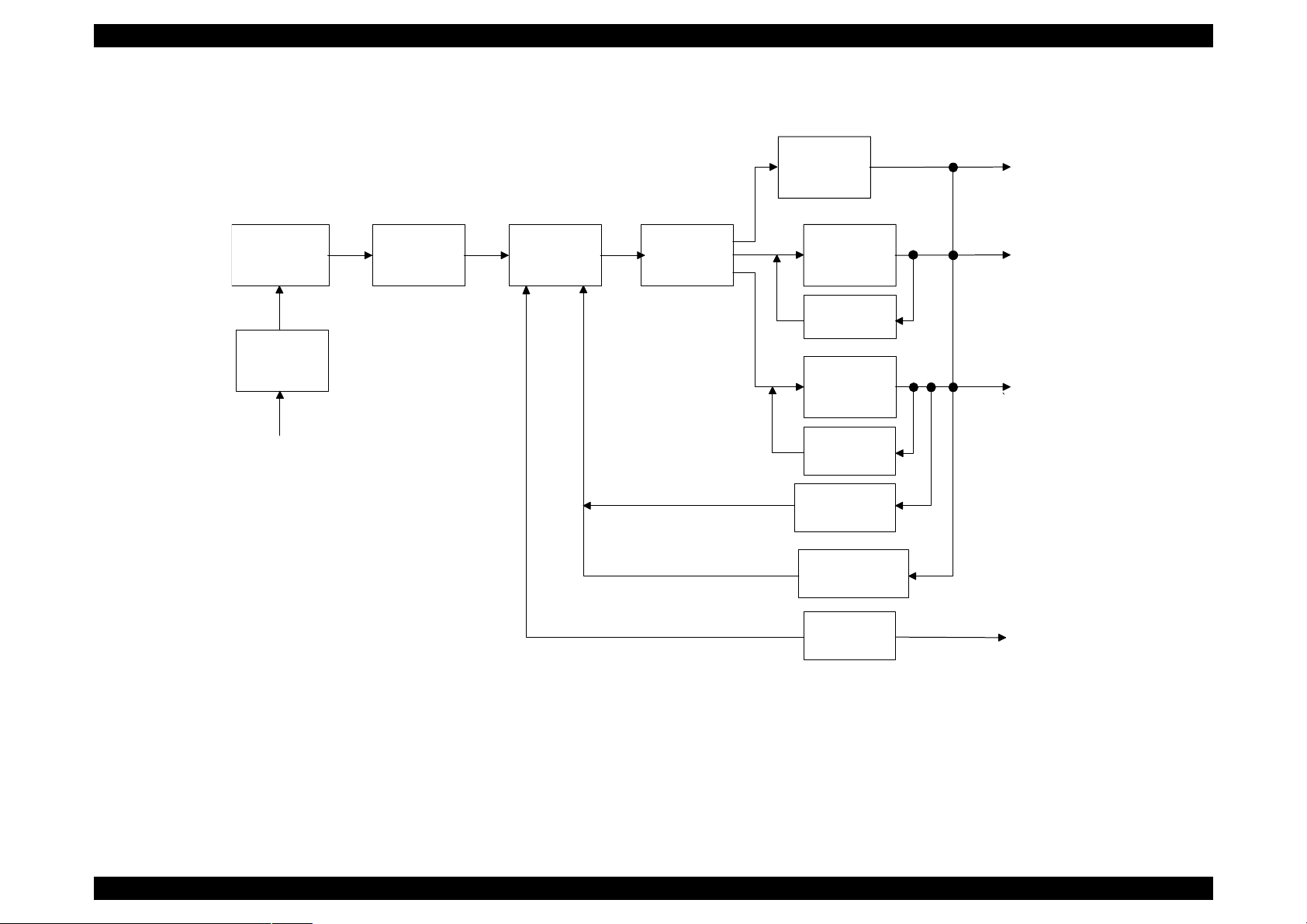

2.3 Control Circuit

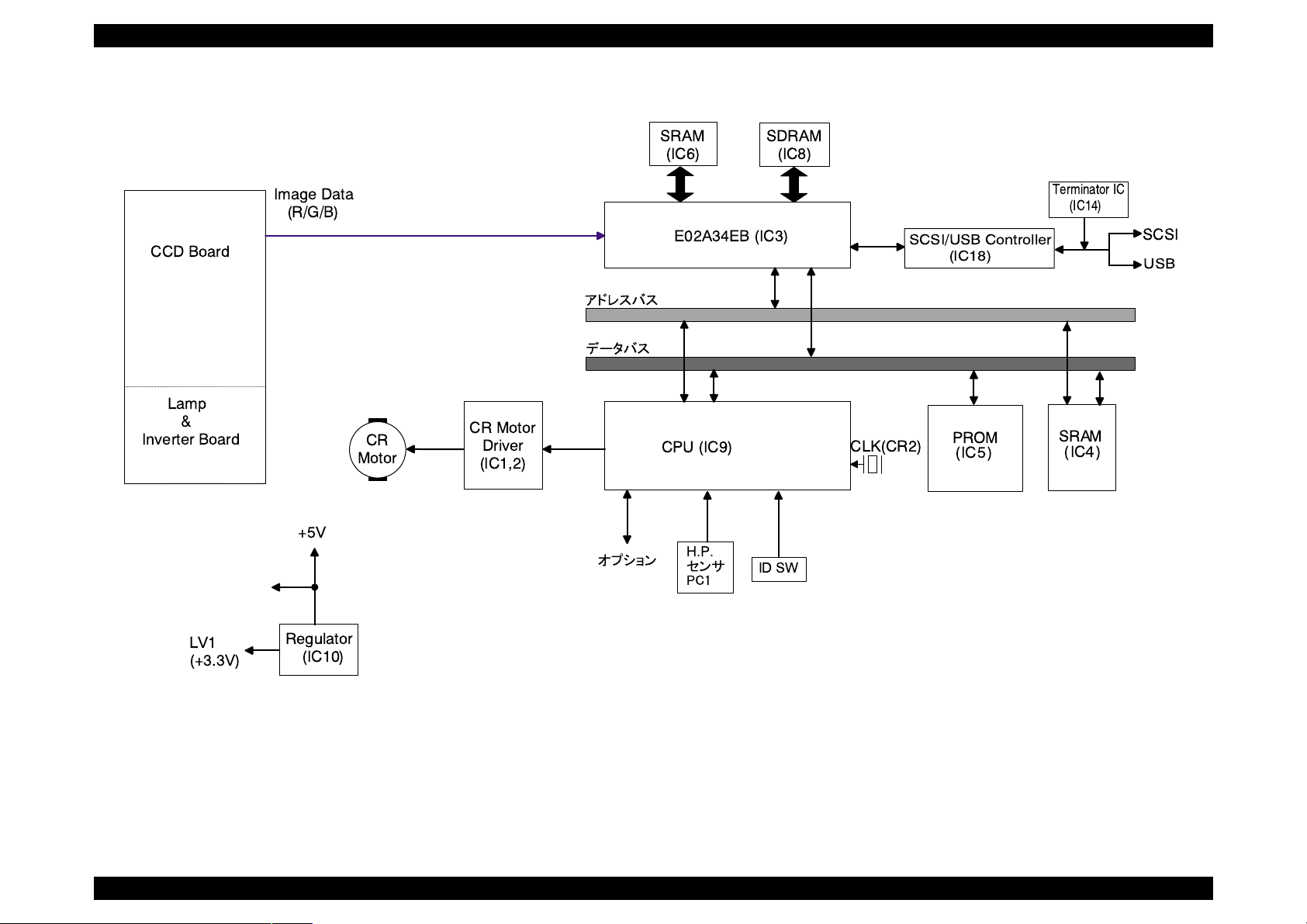

Table 2-3. Major ICs

2.3.1 Control Circuit Overview

This scanner uses the one-tip 16-bit bus CPU (IC9) at 20MHz frequency.

Image data processing, correction, CCD sensor board, A/D converter control

are operated at ASIC (IC3). Table 2-3 shows major IC functions.

H8S/2350 IC9

E02A34EB IC3

MB81F641642D IC8 SDRAM 64Mbit

IS61C256AH IC4, IC6

A3957SLB IC1, 2 CR motor driver IC

MBM28F200B IC5 PROM

BH9596FP-Y IC14 Terminator IC

IC Location Function

CPU

24-bit Address Bus

16-bit Data Bus

ASIC

• CCD Control

• Line (sharpness) Control

• Image Processing

• Memory Control

SRAM 32k x 8 bit

SPC7215F0A IC18 SCSI/USB Controller

SSA20.00BR CR2 2 0 MHz clock for CPU

Operating Principles Control Circuit 23

Page 24

EPSON Perfection 1640SU Revision A

CCD Board

Lamp

&

Inverter Board

Image Data

(R/G/B)

+5V

CR

Motor

CR Motor

Driver

(IC1,2)

SRAM

(IC6)

E02A34EB (IC3)

CPU (IC9)

H.P.

SDRAM

(IC8)

ID SW

SCSI/USB Controller

CLK(CR2)

(IC18)

PROM

(IC5 )

Terminator IC

(IC14)

SRAM

(IC

4

)

SCSI

USB

LV1

(+3.3V)

Regulator

(IC10)

Figure 2-6. Control Circuit Block Diagram

Operating Principles Control Circuit 24

Page 25

TROUBLESHOOTING

CHAPTER

3

Page 26

EPSON Perfection 1640SU Revision A

3.1 Overview

This chapter explains the troubleshooting of this scanner.

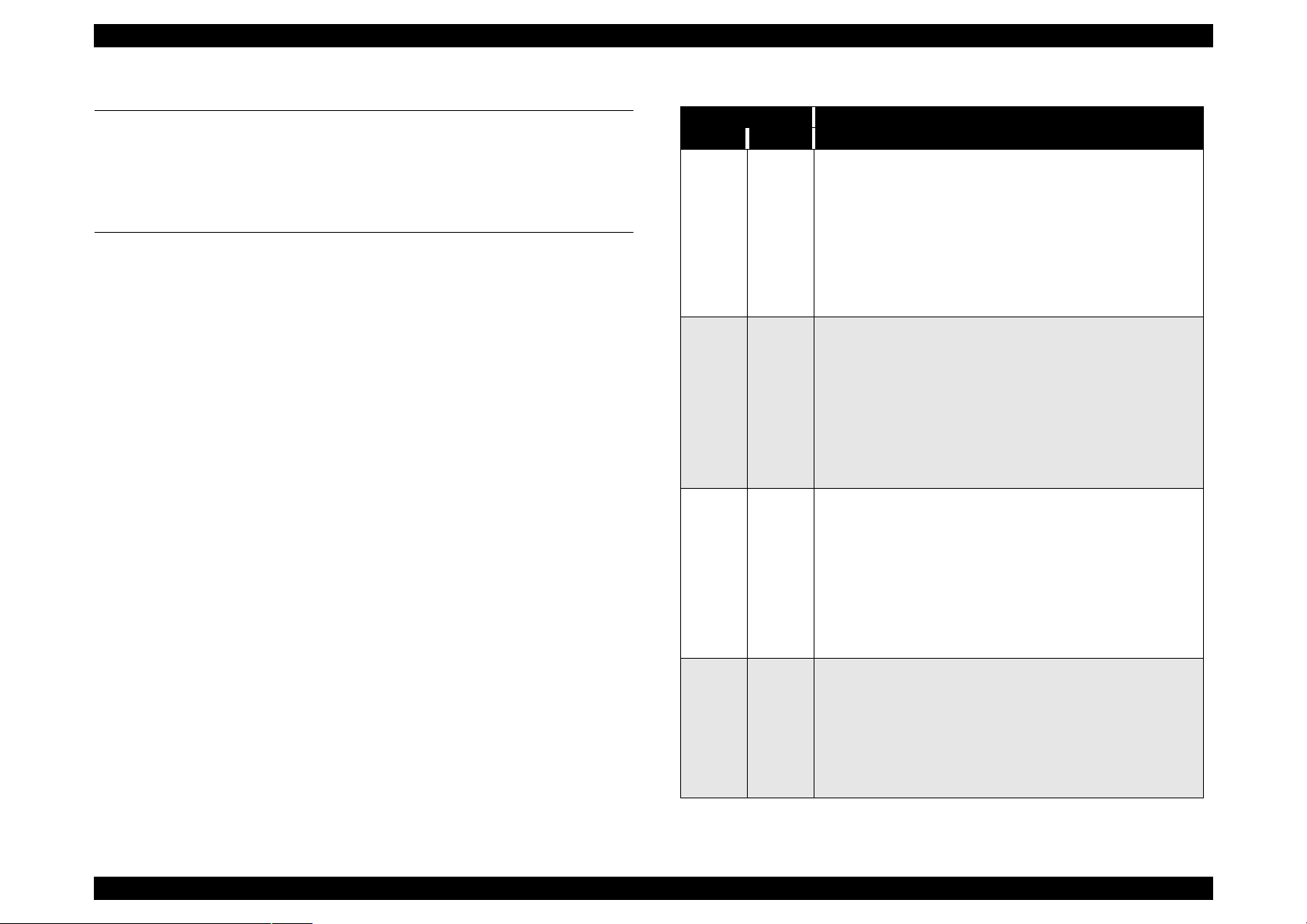

3.2 Self-Diagnostic Function

The self-diagnostic function of this scanner lets the scanner to check the

condition of each component automatically. If it detects a faulty component, it

indicates the status using the Operate light. See Table3-1.

Table 3-1. Self-Diagnostic Indication

LED Light Error Type (Cause, Remedy)

Green Red

Command Error

• Cause: Unidentified command or unidentified command

parameter is detected.

• Disposition: The scanner ignores the wrong command or

OFF ON

OFF Blink

OFF Blink

Blink Blink

parameter. (Therefore, the current settings or the default

value remain effective) Scanner sends NACK, and waits

next command or parameter.

• Remedy: The error condition is cleared when the scanner

received a correct command.

Interface Error

• Wrong pr ocedure is detected in the interfa c e

communication. In the case of SCSI, a transmission is

frozen more than 30 seconds except BUS FREE phase.

• Disposition: The lamp goes off and the scanner stops

operation.

• Turn off the scanner and then b ack on. RST si gnal in SCS I

turns active.

• Acceptable command: Nothing

Fatal Error

• Cause: The lamp is broken. Power is turned on before

removing the transportation screw. System break down.

• Disposition: The lamp goes off and the scanner stops

operation. The bit 7 of the status is set.

• Remedy: Turn the scanner off and then back on. Send

ESC@ codes to the scanner. RESET signal in SCSI turns

active. Complete BUS DEVICE RESET message in SCSI.

• Acceptable command: [ESC F, ESC f, ESC @]

Option Error

(Only when the optional unit is installed and operation is

available by [ESC e].)

• Cause: Unit cover open, or paper Empty

• Disposition: The bit 7 of the status byte is set to “1”.

• Remedy:Remove the error condition.

• Acceptable command:[ESC F, ESC f, ESC @]

Troubleshooting Overview 26

Page 27

EPSON Perfection 1640SU Revision A

3.3 Troubleshooting

This section describes troubleshooting from the abnormal phenomenon. You

can isolate the faulty unit based on the abnormal phenomenon. See the table

below to find the closest phenomenon and the corresponding table to refer to.

Table 3-2. Abnormal Phenomenon and corresponding Tables

Phenomenon Description Ref, Table

Scanner does not

operate even its power i s

On.

Fatal Error occurs and is

not cleared after turning

off and back on the

scanner.

Scanned image is

unclear.

“Interface Error” is

indicated.

“Option Error” occurs.

Optional unit (ADF/TPU)

does not operate.

• Operate Light on the control panel

does not come On.

• Scanner does not operate the

initialization.

• Carriage Unit does not operate.

• Carriage Unit crashes into the front or

rear frame and then the error is

indicated.

• The lamp does not light up.

Scanned image is unclear. 3-8

• SCSI Interface Error

• USB Interface Error

• Optional unit does not operate

correctly.

3-3

3-4

3-5

3-6

3-7

3-9

3-10

3-11

Table 3-3. Panel LED does not turn On.

Cause Step Checkpoint Finding Solution

Connector CN1 on

the power board is

disconnected.

Connector CN101 or

CN102 on the power

board disconnected.

Fuse on the power

board has blown out.

The power board.is

broken.

Connector CN7 on

the power board is

disconnected.

The control board is

broken.

1 Is the connector

CN1 on the power

board

disconnected?

2 Is the connector

CN101 or CN102

on the power board

disconnected?

3 Has the fuse on the

power board blown

out?

4 With the scanner

On, check the

voltage output leve l

between pins 8/

9(+) and pins 6/7(-)

on the power

board. Is the

voltage +5VDC?

5 Is the connector

CN7 on the control

board

disconnected?

6 --- --- Replace the control

Yes Connect CN1

Yes Connect CN101 or

Yes Replace the fuse.

No Replace the power

Yes Connect CN7

properly.

102 properly.

board.

properly.

board.

Table 3-4. Scan n e r is no t in itialized

Cause Step Checkpoint Finding Solution

Connector CN1 on

the power board is

disconnected.

1 Is the connector

CN1 on the power

board

disconnected?

Yes Connect CN1

properly.

Troubleshooting Troubleshooting 27

Page 28

EPSON Perfection 1640SU Revision A

Table 3-5. Carriage Unit does not operate Table 3-6. Carriage moves but an error is indicated

Cause Step Checkpoint Finding Solution

Power

board is

broken.

Carriage

Unit (or CR

move

mechanism)

is broken.

CR Motor is

broken

Main board

is broken.

1 With the scanner power on,

check the voltage output level

between the Pins 4/5(+) and

Pins 6/7 (- ) for CN101 on the

power board. Is it +24VDC?

2

Is grease (G-26) applied

correctly?

3 • With power ON and the

scanner upper case

removed, does CR motor

move?

• With the CR motor

removed, does the

carriage unit move

smoothly?

4 Disconnect the connector

CN6 on the main board, then

use the tester and check the

coil resistance between Pin2

and 4 and between Pin1 and

3. Is the resistanc e of 2 points

about 6.2

5 If any motor coil is shorted,

check the CR motor drive

circuit in the order below.

1.)Set the tester on Ohms.

2.)Place the (-) lead of the

tester on any of Pins 1,2, 3 or

4 of CN6 on the main board.

3.)Place the (+) lead of the

tester on Pin 6/7 of CN7 on

the main board.

With the scanner off, doe s the

meter show “

6 --- --- Replace the main

Ω?

”?

∞

No Replace the power

board.

No Apply the grease to

the appointed

position. (See Ch6)

No Check the carriage

move mechanism

and replace the

corresponding parts

or disassemble and

assemble the part.

No Replace the CR

motor.

No Replace the main

board.

board.

Cause Step Checkpoint Finding Solution

CR home position

sensor is broken.

1 Check the signal

level.

•Check the

signal/status

level between

C(+) and E(-) of

PC1.

H (about 4.5V)/

when C-E of PC1 is

closed.

L (0.3V)/when C-E

of PC1 is opened.

-- Replace the CR

Table 3-7. Lamp does not light up

Cause Step Checkpoint Finding Solution

Connector CN4 on

the control board is

disconnected.

Connector CN1 or

CN2 on the CCD

board disconnected.

Lamp is not

connected properly

to the connector on

the inverter board.

Lamp is broken. 4 Does the lamp light

Inverter board is

broken.

Main board is

broken.

1 Is the connector CN4

on the control board

disconnected?

2 Is the connector CN1

or CN2 on the CCD

board disconnected?

3 Is the lamp connected

properly to the

connector on the

inverter board?

after it is replaced?

5 Does it operate

properly after

replacing it?

6 --- --- Replace the main

Yes Connect CN4

Yes Connect CN1 or 2

No Connect the lamp

Yes Replace the

Yes Replace the

home position

sensor (PC1) on

the main board.

properly.

properly.

properly.

lamp.

inverter board.

board.

Troubleshooting Troubleshooting 28

Page 29

EPSON Perfection 1640SU Revision A

Table 3-8. Scanned image is unclear

Cause Step Checkpoint Finding Solution

Mirror in the carriage

unit is dirty.

CCD sensor board is

broken.

Main board is

broken.

1 Is the image

scanned clearly

after cleaning the

mirror?

2 --- -- Replace the CCD

3 --- --- Replace the main

No Clean the lamp

Table 3-9. SCSI Interface Error

Cause Step Checkpoint Finding Solution

Terminator switch is

set wrong.

SCSI setting is

wrong.

TWAIN driver, which

comes with the

scanner is not

installed correctly.

SCSI cable is

defective.

Main board is

broken.

1 Check the user’s

guide for the

correct setting. Is

the setting correct?

2 Check the user’s

guide for the

correct setting. Is

the setting correct?

3 Is the TWAIN driver

installed correctly?

4 Replace the SCSI

cable. Is the

operation normal?

5 --- --- Replace the main

No Set the terminator

No Set the SCSI

No Install the TWAIN

Yes Replace the SCSI

surface.

board.

board.

correctly.

correctly.

driver correctly (or

reinstall)

cable.

board.

Table 3-10. USB Interface Error

Cause Step Checkpoint Finding Solution

Host and O/S does

not support the USB.

TWAIN driver, which

comes with the

scanner is not

installed correctly

USB cable is broken. 3 Replace the USB

Main board is

broken.

1 On the Windows,

go to “My

”Prope

Computer”

rty”

Manager”, then,

check if “Universal

serial bus

controller” is

effective.

2 Is the TWAIN driver

installed correctly?

operation normal?

4 --- --- Replace the main

→

”Device

→

cable. Is the

No Replace the host.

No Install the TWAIN

Yes Replace the USB

Table 3-11. Option TPU/ADF does not operate

Cause Step Checkpoint Finding Solution

The cable of the

optional unit is

disconnected.

Main board is

broken.

Optional unit is

broken.

1 Is the connector

CN3 on the control

board

disconnected?

2 --- --- Replace the main

3 +24V line:Lamp,

Motor

+5V line: Sensor,

logic circuit.

Yes Connect the CN3

--- Replace the

driver correctly (or

reinstall)

cable.

board.

properly.

board.

defective part of the

optional unit.

Troubleshooting Troubleshooting 29

Page 30

DISASSEMBLY AND ASSEMBLY

CHAPTER

4

Page 31

EPSON Perfection 1640SU Revision A

4.1 Overview

This chapter describes for disassembling Perfection 1200 and precaution to

take during transportation.

4.1.1 Precaution

W A R N I N G

C A U T I O N

Before servicing, make sure that the power cable is

disconnected from the AC power socket and the interface

cable is removed.

Wear a pair at gloves to protect your hand from the sharp

edge in the scanner mechanism.

Use the stable and level table which has enough strength

for disassembling and assembling the scanner.

Get yourself enough room for servicing, considering the

size of the scanner.

Middle

Rear

4.1.2 Tools

Tools used for servicing are as listed in the table below.

Table 4-1. Tools

Description Availability SE Part No.

(+) Screw Driver O B743800200

(-) Screw Driver O B743000100

A pair of Tweezers O B641000100

Cutting Plier O B740400100

4.1.3 Screws

Screws used in this scanner are listed in the table below. Be sure to use the

correct types and numbers of screws for each part when assembling the

scanner.

Table 4-2. Abbreviation for Screws

Abbreviation Name

CP Cross-recessed Pan head screw

CBS Cross-recessed Binding head S-tite screw

CCP Cross-recessed Cup head P-tite

NOTE: Refer to Table 4-3 for screw shapes.

Left

Front

EPSON

Right

Figure 4-1. Notations

Disassembly and Assembly Overview 31

Page 32

EPSON Perfection 1640SU Revision A

Table 4-3. Screws

Head Shape Type Washer

Hole Appearance

Cross-recessed Binding

Pan

Cup

Standard

------

S-Tite

B-Tite

P-Tite

With Outside

toothed lock

washers

With Spring lock

washers

Disassembly and Assembly Overview 32

Page 33

EPSON Perfection 1640SU Revision A

4.2 Disassembly Procedures

4.2.1 Carriage Lock Release

1. Release the carriage lock located at left side of the scanner body by using

(-) screw driver.

Release

Lock

Figure 4-2. Carriage Lock Position

C A U T I O N

When you need to lock again for transportation, lock it while

letting the carriage be at home position.

Disassembly and Assembly Disassembly Procedures 33

Page 34

EPSON Perfection 1640SU Revision A

4.2.2 Document Cover Removal

1. Open the document cover vertically and pull it out upward.

Document

Cover

Hooks

Figure 4-3. Document Cover Removal

Disassembly and Assembly Disassembly Procedures 34

Page 35

EPSON Perfection 1640SU Revision A

4.2.3 Upper Cover Removal

1. Release the carriage lock. (see Section 4.2.1)

2. While holding the original cover with both hands so that it does not come

off, turn the main unit upside down.

3. Remove the two screws (CCS, M3x6) which are securing the front cover,

and then remove the front cover.

4. While holding the original cover with both hands so that it does not come

off, return the main unit to its original position.

5. Remove the document cover. (see Section 4.2.2)

6. Release two silver screws (CBS, M3x6) from the back of the scanner.

Front Cover

CCS (M3x6)

Figure 4-4. Front Cover Removal

CBS (M3x6)

Figure 4-5. Upper Cover Removal (1)

Disassembly and Assembly Disassembly Procedures 35

Page 36

EPSON Perfection 1640SU Revision A

7. Lift up the rear side of the upper cover and remove the upper cover toward

yourself, reeleasing three hooks securing the upper cover.

8. Disconnect the connector (CN2) from the sub board.

2 Hooks at

front side

Figure 4-6. Upper Cover Removal (2)

Connector

Sub Board

Figure 4-7. Upper Cover Removal (3)

Figure 4-8. After removing the upper cover

Disassembly and Assembly Disassembly Procedures 36

Page 37

EPSON Perfection 1640SU Revision A

4.2.4 Panel Board Removal

1. Release the carriage lock. (See Section 4.2.1)

2. Remove the upper cover. (See Section 4.2.3)

3. Remove the two screws (CBP, M3x8), then remove the panel board.

CBS (M3x6)

Figure 4-9. Panel Board Removal

Figure 4-10. Panel Board

Disassembly and Assembly Disassembly Procedures 37

Page 38

EPSON Perfection 1640SU Revision A

4.2.5 Inverter Lamp/Inverter Board Removal

1. Release the carriage lock. (see Section 4.2.1)

2. Remove the upper cover. (see Section 4.2.3)

3. Remove 2 black screws (CCP, M3x8) on the carriage unit.

4. Remove the carriage unit upper cover by lifting it up and pulling it front by

the (-) screw driver.

Figure 4-11. Disassembly of the Carriage Unit (1)

CCP (M3x8)

Figure 4-12. Disassembly of the Carriage Unit (2)

Disassembly and Assembly Disassembly Procedures 38

Page 39

EPSON Perfection 1640SU Revision A

)

5. Remove the inverter lamp connector from the inverter board.

6. Remove one black screw and a connector (2-pin) for CCD sensor board,

then remove the inverter board.

7. Remove the inverter lamp from the upper cover.

Inverter Board

C A U T I O N

When installing the inverter lamp, locate the wire as it is

shown in figures 4-13 and 4-14.

Connector (2-pin

Connector

Black screw

Figure 4-13. Disassembly of the Carriage Unit (3)

Upper Cover

Inverter Lamp

Inverter Board

Figure 4-14. Inverter Lamp Removal

Disassembly and Assembly Disassembly Procedures 39

Page 40

EPSON Perfection 1640SU Revision A

4.2.6 Main Board Removal

1. Release the carriage lock. (See Section 4.2.1)

2. Remove the upper cover. (See Section 4.2.3)

Carriage Unit

3. After removing 3 gold screws (CBS, M3x5) and 2 rear hooks, remove the

shield cover.

CBS

(M3x5)

Shield Cover

2 Hooks

Figure 4-15. Main Board Removal (1)

Disassembly and Assembly Disassembly Procedures 40

Page 41

EPSON Perfection 1640SU Revision A

4. Remove 2 screws (CP, M2.5x6) located around the I/F connector behind

the scanner body and 2 screws (CP, M3x5).

5. Remove each cable from CR motor connector (CN6), carriage FFC

connector (CN4, 5) and power supply unit connector (CN7).

6. Remove the four screws (CBS, M3x5) which are securing the main board

to the main unit.

7. Lift up the front part of the main board, pulling it toward you, and remove

the connector from the scanner body. Then, remove the main board.

CBS

(M3x5)

Carriage FFC

Connector

Power Supply Unit

Connector

CBS

(M3x5)

CP(M2.5x6)

CP (M3x5)

Figure 4-16. Main Board Removal (2)

CR Motor

Connector

CBS

(M3x5)

Figure 4-17. Main Board Removal (3)

Figure 4-18. Main Board

Disassembly and Assembly Disassembly Procedures 41

Page 42

EPSON Perfection 1640SU Revision A

4.2.7 Carriage Unit Removal

1. Release the carriage lock. (See Section 4.2.1)

2. Remove the upper cover. (See Section 4.2.3)

3. Remove the hexagon nut located back of the carriage guide shaft.

4. Remove the two screws (CBS, M3x5) which are securing the driven pulley

assembly.

Hexagon Nut

Figure 4-19. Hexagon Nut Removal

Carriage Unit

CBS(M3x5)

Figure 4-20. Driven Pulley Assembly Removal (1)

Disassembly and Assembly Disassembly Procedures 42

Page 43

EPSON Perfection 1640SU Revision A

5. Remove the driven pulley assembly from the frame toward the arrowed

direction.

6. Remove the carriage guide shaft from the driven pulley assembly, and then

remove the carriage guide shaft from the carriage unit.

Figure 4-21. Driven Pulley Assembly Removal (2)

Carriage Guide Shaft

Figure 4-22. Carriage Guide Shaft Removal

Disassembly and Assembly Disassembly Procedures 43

Page 44

EPSON Perfection 1640SU Revision A

7. Remove the timing belt from the carriage driven pulley and the CR motor

unit.

8. Remove the timing belt from the carriage.

Driven

Pulley

Timing Belt

Timing Belt

CR Motor Unit

Figure 4-23. Timing Belt Removal (1)

Timing Belt

Figure 4-24. Timing Belt Removal (2)

Disassembly and Assembly Disassembly Procedures 44

Page 45

EPSON Perfection 1640SU Revision A

9. Disconnect the two FFCs (white) from the rear of the carriage unit

(connectors and fixing tabs), and then remove the carriage unit.

FFC tab

Connector

FFC

Figure 4-25. Carriage Unit Removal

Figure 4-26. Carriage Unit

Disassembly and Assembly Disassembly Procedures 45

Page 46

EPSON Perfection 1640SU Revision A

4.2.8 Carriage Motor Removal

1. Release the carriage lock. (See section 4.2.1)

2. Remove the upper cover. (See section 4.2.3)

3. Remove the carriage unit. (See section 4.2.6)

4. Remove 3 gold screws (CBS, M3x5)and 2 rear hooks, and remove the

shield cover for the main board.

5. Remove 2 gold screws (CBS, M3x5) fixing the CR motor unit.

CBS(M3x5)

6. Remove CR motor unit cable from the connector of the main board, and

remove the CR motor unit.

Shield Cover

Hooks

Figure 4-27. Removing the Shield for the Main Board

CR Motor

Unit

Connector

CBS (M3x5)

Figure 4-28. CR Motor Unit Removal

Disassembly and Assembly Disassembly Procedures 46

Page 47

EPSON Perfection 1640SU Revision A

4.2.9 Sub Board Removal

1. Release the carriage lock. (See Section 4.2.1)

2. Remove the upper cover. (See Section 4.2.3)

3. Remove one gold screw (CBS, M3x6), and the shield cover for the panel

board.

C A U T I O N

4. Disconnect the connector of the sub board from the power unit, then

remove the sub board assembly.

In the next steps, move the carriage back and forth slowly

by hand, according to your necessity.

CBS (M3x6)

Figure 4-29. Sub Board Removal (1)

Sub Board

Assembly

Connector

Figure 4-30. Sub Board Removal (2)

Disassembly and Assembly Disassembly Procedures 47

Page 48

EPSON Perfection 1640SU Revision A

5. Remove one gold screw (CBS, M3x6), then remove the sub board.

CBS (M3x6)

Figure 4-31. Sub Board Removal (3)

Figure 4-32. Sub Board

Disassembly and Assembly Disassembly Procedures 48

Page 49

EPSON Perfection 1640SU Revision A

4.2.10 Power Supply Board Removal

1. Release the carriage lock. (See Section 4.2.1)

2. Remove the upper cover. (See Section 4.2.3)

Connector

C A U T I O N

3. Remove the cable of the sub board from the power supply board

connector (See figure 4-30)

4. Remove AC cable connector (lock type;Pick and release) from the power

supply board.

In the next steps, move the carriage back and forth slowly

by hand, according to your necessity.

Figure 4-33. Power Supply Board Removal (1)

AC Cable

Disassembly and Assembly Disassembly Procedures 49

Page 50

EPSON Perfection 1640SU Revision A

5. Remove 2 gold screws (CBS, 3x5) securing the shield board of the power

supply board, and remove the shield board toward inside of the body.

6. Disconnect the connector (lock type; push and release) and remove 5 gold

screws (CBS, 3x4) and power supply board from the shield board.

Shield Board

CBS(M3x5)

Figure 4-34. Power Supply Board Removal (2)

CBS (M3x4)

Connector

CBS (M3x4)

Figure 4-35. Power Supply Board Removal (3)

Figure 4-36. Power Supply Board

Disassembly and Assembly Disassembly Procedures 50

Page 51

ADJUSTMENT

CHAPTER

5

Page 52

EPSON Perfection 1640SU Revision A

This scanner needs no adjustment at the level of the service, including part

replacement, specified in Chapter 4 “Disassembly and Assembly”.

adjustment 52

Page 53

MAINTENANCE

CHAPTER

6

Page 54

EPSON Perfection 1640SU Revision A

6.1 Overview

This chapter provides information necessary to keep the scanner function in

optimum condition constantly and to prevent troubles.

6.1.1 Cleaning

Perform cleaning when stain is noticeable. Stain on the document glass,

particularly, has direct effect on the scanned image. Therefore, be sure to

clean the glass well to remove stain thoroughly.

C A U T I O N

Outer Cases

Wipe stain off with a clean cloth which is moisted with water and then

squeezed tightly. To remove sever stain, use neutral detergent.

Document Glass

Remove dust and paper debris with a dry clean cloth. If stain is severe or

foreign object is stuck, use a cloth absorbed with neutral detergent. If trace

is left, wipe it off well with a dry, clean cloth again.

Never apply any organic solvent such as thiner and

benzine, since there may damage deteriorate plastic and

rubber parts.

Table 6-2. Lubrication Points

Figure Lubrication Points Lubrication

6-1 Transmission Gear Shaft of the CR motor and

Drive pulley shaft

6-1 Driven Pulley Shaft G-26 (1x3mm)

C A U T I O N

Excessive lubrication may damage the mechanism part or

cause the malfunction of the operation.

G-26 (1x3mm)

G-26

6.1.2 Lubrication

When the carriage unit needs to be replaced, or the operation sound of the

carriage movement becomes noisy, it is necessary to apply lubrication.

Following tables show the recommended grease type and lubrication points.

G-26

Table 6-1. Recommended Grease

Supply

Type Name

Grease G-26 40g B702600001 E*

NOTE: “E” means exclusive product for EPSON. (Not available on the

market)

Quantity

Part No. Specification

Maintenance Overview 54

Figure 6-1. Lubrication Points

Page 55

APPENDIX

CHAPTER

7

Page 56

EPSON Perfection 1640SU Revision A

B126 ISN

CN1

CN3

2pin

Inverter Board

2pin

CN2

Lamp

CN4

CN 5

CN1

CN2

19 pin

15 pin

CN 2

CN1

4pin

B126 MAIN

CN1

CN1

01

Power Supply Board

12 pin

CN7

5pin

CN102

AC Plug

2pin

CN1

SUB Board

Panel Board

4pin

CN6

CN1

4pin

CN2

50 pin

CN3

8pin

Option TPU

USB

/ADF

SCSI

CR

Motor

7.1 Overview

This section provides useful information for servicing this scanner.

7.1.1 Interconnection

Following figures show interconnection of the scanner.

Figure 7-1. Interconnection

7.1.2 Connector Assignment

The table below shows the connections for each connector.

Table 7-1. Connector Summary

Board Connector Connected to Pin No.

CN1 USB connector 4 1-4

CN2 SCSI connector 50 1-2

CN3 To option 8 7-2

Main Board

(B126 Main)

Power

supply

board

CCD board

(B126 ISN)

Inverter

board

Sub board

CN4 CCD board 19 7-3

CN5 CCD board 15 7-4

CN6 CR motor 4 7-5

CN7

Power supply

board

12 7-6

CN1 AC input 2 7-7

CN101 Main board 12 7-6

CN102 Sub board 5 7-8

CN1 Main board 19 7-3

CN2 Main board 15 7-4

CN3 Inverter board 2 7-9

CN1 CCD board 2 7-9

CN2 Lamp 2 7-10

CN1

Power supply

board

5 7-8

CN2 Panel board 4 7-11

Tables to

refer

Appendix Overview 56

Page 57

EPSON Perfection 1640SU Revision A

7.1.3 Connector

Pin No. Signal I/O

1+5VO

2, 5 GND --

3+24O

4 L0D O

6RXDI

7 TxD O

8SCKO

Pin No. Signal I/O

1+5VO

2 LCMP O

3 ADCK O

4,10,19 GND --

5SNCK4O

6 SNCK3 O

7LOADO

Table 7-2. Main Board CN3

Table 7-3. Main Board CN4

Pin No. Signal I/O

15 D4 I

16 D5 I

17 D6 I

18 D7 I

Table 7-4. Main Board CN5

Pin No. Signal I/O

1 INV_GND --

2 +24V O

3,6 GND -4,5 +12V O

7SHBO

8 SHG O

9SHRO

10 SH O

11 SNCK2 O

12 SNCK1B O

13 SNCK1A O

14 SNCK1C O

15 CD_EN O

8 SD O

9SCKO

11 D0 I

12 D1 I

13 D2 I

14 D3 I

Appendix Overview 57

Page 58

EPSON Perfection 1640SU Revision A

Table 7-5. Main Board CN6

Pin No. Signal I/O

1BXO

2 AX O

3BO

4 A O

Table 7-6. Main Board CN7

Pin No. Signal I/O

1OP-LEDO

2 ERR-LED O

3 RP-SW I

4, 5 +24V I

6,7,11,12 GND --

8, 9 +5V I

10 +12V I

Table 7-8. Power Supply Board CN102

Pin No. Signal I/O

1 GREEN O

2 RED O

3Push-SWI

4 PW-SW I

5GND--

Table 7-9. CCD Board CN3

Pin No. Signal I/O

124VO

2 GND --

Table 7-10. Inverter Board CN2

Pin No. Signal I/O

1LAMPO

2 LAMP O

Table 7-7. Power Supply Board CN1

Pin No. Signal I/O

1AC (H)I

2 AC (L) I

Pin No. Signal I/O

Table 7-11. Sub Board CN2

1 GREEN I

2 RED I

3Push-SWO

4 GND --

Appendix Overview 58

Page 59

EPSON Perfection 1640SU Revision A

7.2 Circuit Diagram

The figure on the next page shows the circuit diagram of B126 MAIN.

B126 MAIN BOARD

Appendix Circuit Diagram 59

Page 60

EPSON Perfection 1640SU Revision A

Appendix Circuit Diagram 60

Page 61

EPSON Perfection 1640SU Revision A

7.3 Parts List & Exploded Diagram

Table 7-12. Parts List

Diagram Number Parts Name

100 FRAME,BASE

101 HOUSING,ASSY.,UPPER;ASP

102 KNOB,MOUNT,CARRIAGE;B

103 MAT,COVER,DOCUMENT

104 COVER,DOCUMENT

105 COVER,MAIN BOARD

106 HOUSING,FRONT

107 KEYTOP,POWER SWITCH

110 LEVER,MOUNT,CARRIAGE

111 COVER,PS BOARD

112 SHEET,P/S BOARD

113 TIMING BELT

114 PULLEY,DRIVE

115 FLANGE,PULLEY

116 PULLEY,IDLE,A

117 HOLDER SUB ASSY.,PULLEY DRIVE

118 PULLEY,IDLE,B

119 6N,3,F/ZN

120 HOLDER SUB ASSY.,PULLEY DRIVEN

121 PULLEY,DRIVEN

122 LOGO PLATE 27.5X27.5

123 PLANE WASHER,4.5X0.5X8,L/NA

124 FOOT

Table 7-12. Parts List (continued)

Diagram Number Parts Name

125 BUSHING,HOUSING

128 COVER,INLET

130 FERRITE CORE

131 DOUBLE SIDE TAPE,22X10

132 HOLDER,SWITCH BOARD

133 6N,5,F/ZN

134 SHAFT,CR

135 SHEET,SLIDE

136 RAIL,CR

137 SUPPORT,P-SW

138 BOARD ASSY.,PANEL

140 SHEET,COVER,P/S BOARD

141 C.P. SCREW

142 C.P.SCREW

143 C.B.S. SCREW

144 C.C.S. SCREW

145 C.B.S-TITE R.SCREW,3X5,F/ZN

147 C.B.S-TITE R.SCREW,3X6,F/ZN

148 C.B.(O) SCREW,4X4,F/ZG

149 C.B.P-TITE SCREW,3X8,F/ZN

150 MOTOR,CR

151 DAMPER,MOTER

180 LABEL,CARRIAGE LOCK

200 BOARD ASSY., MAIN

201 BOARD ASSY.,SUB

Appendix Parts List & Exploded Diagram 61

Page 62

EPSON Perfection 1640SU Revision A

Table 7-12. Parts List (continued)

Diagram Number Parts Name

300 BOARD ASSY.,POWER SUPPLY

330 HARNESS

400 POWER CABLE ASSY.

401 I/F CABLE

500 CARRIAGE,ASSY.

501 C.C.P-TITE,3X8,F/ZB

502 COVER,CARRIAGE

503 FERRITE CORE

504 HARNESS,FFC(A)

505 HARNESS,FFC(B)

506 LAMP SET,ASP

Appendix Parts List & Exploded Diagram 62

Page 63

EPSON Perfection 1640SU Revision A

143

330

143

147

132

143

135

140

300

112

145

145

140

111

145

See next page.

500

122

104

137

201

147

124

145

130

131

136

145

145

128

100

118

105

123

145

141

142

121

116

200

123

119

115

145

123

113

115

114

119

145

145

117

120

107

133

151

150

144

134

for 100/120V

148

400

180

106

102

138

149

for 220/230V/240V

148

331

103

147

147

101

110

for USB

401

125

124

400

GT-8700/GT-8700F/Perfection 1640SU/Photo/Office No.01 Rev.01 10237

Figure 7-2. Exploded Diagram No. 1

Appendix Parts List & Exploded Diagram 63

Page 64

EPSON Perfection 1640SU Revision A

501

501

506

501

502

503

504

505

GT-8700/GT-8700F/ Perfection 1640SU/Photo/Office No.02 Rev.01 10237

Figure 7-3. Exploded Diagram No. 2

Appendix Parts List & Exploded Diagram 64

Page 65

EPSON Perfection 1640SU Revision A

7.4 TPU; Parts List

Table below shows the parts list of TPU (Transparency Unit).

Table 7-13. TPU Parts List

Number Parts Name

800 Housing Assembly, Upper

801 Back Light Assembly

802 Cover, Illumination

803 Housing, Lower

804 Housing, Base

805 Housing, Fasten, R

806 Housing, Fasten, L

807 Board Assembly, Inverter

808 Harness

809 Foot

810 Sheet, Spacer

811 +, Binding B-tite 3X10 F/NI

812 +, Binding B-tite 4X8 F/ZN

813 +, Binding B-tite Screw

814 +, Binding P-tite Screw

815 Label, Caution TPU

816 Label, UL;B

Appendix TPU; Parts List 65

Page 66

EPSON Perfection 1640SU Revision A

7.5 Exploded Diagram for TPU

810

804

816 (FOR EAI)

808

814

B

A

807

B

815

810

809

809

803

811

811

809

806

A

800

801

802

809

813

813

812

811

805

GT-8700F/ Perfection 1640SU PHOTO FILM ADAPTER No.04 Rev.01 10237

Figure 7-4. Exploded Diagram for TPU

Appendix Exploded Diagram for TPU 66

Page 67

EPSON Perfection 1640SU Revision A

7.6 Optional Part; ADF

7.6.1 General Description

Features

Compact and Light weight (319(W) x 508(D) x 137(H) mm), Approx.

2.2Kg

Capacity of paper setting is up to 30 pieces.

Scanning speed is 5.5 PPM (at A4, Line art, 300 dpi, and Draft mode)

Using a transparency film to scanning area. User can change the

transparency film. (10 k-pieces of paper are readable by one

transparency film)

Connectivity

This automatic document feeder (ADF) can be used with models which are

compatible with the previous GT70ADF as well as with the R4C5950

(Perfection 1640SU).

7.6.2 Specification

7.6.2.1 General Specification

Product type: Sheet through

Paper supply: Face up load

Paper out: Face down eject

Separate paper way: Friction by roller

Paper setting quantities: 30 pcs (at 55g/m2 paper, Maximum total

thickness is l ess than 6mm)

Original point: Opposite side against Scanner original point

Scanning area: Scanning through a Transparency sheet

Document setting position: Set the left side of Document to the left

side of ADF’s paper setting and support

the right side of Document by ADF’s

paper guide.

7.6.2.2 Efficiency

Noise: 54dB or lower, No unpleasant and abnormal noise

Miss feed ratio: 1% or lower

Jam ratio: 1% or lower (0.1% or lower, at XEROX-Paper and

room temperature)

Pile up feed ratio: 1% or lower

Skew: Less than ± 0.5°C

Original point accuracy: 0 ± 3mm, from Document left edge and

Document top edge

Feeding pitch accuracy: Less than ±1%

Figure 7-5. Scanner with ADF

Color deviation: Less than 1 dot (at 600dpi)

Less than 2 dot (the document area of top

and bottom 5cm)

Appendix Optional Part; ADF 67

Page 68

EPSON Perfection 1640SU Revision A

7.6.2.3 Document

Applied color: Color and Monochrome

Paper quality: High quality paper, Bond paper, Check paper,

(Recycled paper)

Paper thickness: Thickness: 0.07- 0.16mm

Ream Weight: 50 - 105 Kg/m

Paper size: Minimum width:85mm

Maximum width:216mm

Minimum length:127mm

Maximum length:356mm

No match paper: Transparency paper, Coating paper, Cutting

paper, Label sheet (with past), OHP film,

Carbon paper, Japanese paper, Catalog

paper.

The document with staples or other objects.

The document with holes or ripped.

The document which has curled and folded.

2

7.6.2.4 Electrical Specification

Rated input Voltage: DC 24V ±10%

Rated input Current: 24V:0.8A

DC 5V ±

5V :0.2A

5%

7.6.2.5 Environmental Conditions

Temperature: Operating 10 ∼ 32 °C

Storage -20 ∼

Humidity: Operating 20 ∼ 80%, no condensation

Storage 20 ∼

60 °C

85%, no condensation

7.6.2.7 Operating Conditions

Dust: Ordinary office or home conditions, Extreme

dust should be avoided.

Illumination: Operation under direct sunlight or near strong

light source is not guaranteed and should be

avoided.

7.6.2.8 Safety, EMC, EPA

Safety: UL1950 (UL)

CSA C22.2 NO.950 (CSA)

EN60950 (VDE)

IEC950 (ROSTEST, PSB)

EMC: FCC Part 15 Subpart B Class B

CSA C108.8 Class B

AS/NZS3548 Class B

CISPR Pub22 Class B

CNS13438 Class B

CE Marking:

Low Voltage Directive 73/23/EEC: EN60950

EMC Directive 89/336/EEC EN55022 Class B

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

EPA Energy Star Program

7.6.2.9 Resistance to Electric Noise

Static electricity: Casing 10kV

Metal 7kV/150pF, 150 Ohms

7.6.2.6 Reliability

Load/Eject: MCBF 20000 sheets (Transparency film:

MCBF 10000 sheets)

MCBF 12000 cycle

Appendix Optional Part; ADF 68

Page 69

EPSON Perfection 1640SU Revision A

7.6.2.10 Physical Dimensions and Weight

Dimensions: 319(W) x 508(D) x 137(H) mm

Weight: Approx. 2.2Kg

96mm40mm

508mm

7.6.3 Interface

Connector shape: 8 pin DIN connector (Male)

Figure 7-7. Connector Shape

Pin Assignment

Table 7-14. Pin Assignment

Pin No. Signal I/O

1+5V PWR

I F

Description

2 GND PWR

3+24VPWR

137mm

319mm

4 LOD IN Serial data latch

5GNDPWR

6 SO OUT Serial out data

7 SI IN Serial in data

8 SCK IN Serial clock

Figure 7-6. ADF Size

Appendix Optional Part; ADF 69

Page 70

EPSON Perfection 1640SU Revision A

7.7 ADF: Disassembly

Here explains disassembly procedures of ADF. Unless otherwise specified,

disassembled units or parts can be reassembled by reversing the disassembly

procedure.

7.7.1 B81314 Main Board Removal

1. Remove the tray.

2. Flip over the ADF so that you can see the bottom of the ADF. Remove 2

screws (silver, P-tite, M3x6) securing the cover of the bottom of the main

board.

Remove 5 cables.

Figure 7-9. Removing the B81314 Board (1)

Remove

2 screws

Figure 7-8. 2 screws on the back of ADF

3. Disconnect 5 cables from B81314 Main board and remove 5 screws (gold,

P-tite).

4. Remove B81314 main board.

Remove

5 screws.

Figure 7-10. Removing B81314 Board (2)

Appendix ADF: Disassembly 70

Page 71

EPSON Perfection 1640SU Revision A

7.7.2 ASF Part

1. Remove 6 cables from the B81314 Main Board.

2. Open the cover and remove a guide bar. Also, disengage right

and left connections of the interior paper guide and remove the cover from

the case shaft.

ASF release lever

Open the cover and remove

the guide bar (black)

Figure 7-11. Guide Removal

3. Open the ASF release lever.

Open

Remove 2 screws and

2 metal parts.

Figure 7-12. Removing Screws and Metal Parts

4. Remove 2 screws (gold, P tite) and 2 metal parts.

Appendix ADF: Disassembly 71

Page 72

EPSON Perfection 1640SU Revision A

7.7.2.1 Disassembly of ASF Part

1. In order to remove the cover, remove 2 screws (black, CB + washer)

located on the right and left edges of the front cover. Flip over and remove

2 screws (gold, P-tite+ washer) from the bottom, then remove the cover.

Remove 2

black screws

Figure 7-13. Removing Screws (1)

2. Remove 4 screws (gold, P-tite + washer), and remove Motor/ Solenoid

Assembly.

C A U T I O N

Since one of the screws** is used as a stopper at the

slide gear part, be careful when removing the screw

because all gears will jump out.

(See figure7-16 on the next page)

Figure 7-15. Removing Motor/Solenoid Assembly

Remove 2 screws

Figure 7-14. Removing screws (2)

Appendix ADF: Disassembly 72

Page 73

EPSON Perfection 1640SU Revision A

7.7.2.2 Gear Frame

1. Release the lock of 2 shaft supports (white plastic parts) and remove 2

3 screws

One screw

See “Note” on

previous page

screws.

Release the lock of

shaft support (white)

Figure 7-16. Motor/Solenoid Assembly Removal

These

parts are

installed at

the shaft in

this order.

Figure 7-17. Inside Parts

Remove 2 screws

Figure 7-18. Roller Removal (1)

2. Remove the roller shaft (front).

Remove the

roller shaft

Figure 7-19. Roller Removal (2)

Appendix ADF: Disassembly 73

Page 74

EPSON Perfection 1640SU Revision A

3. Insert (-) driver into the gap shown in the figure below, and remove the

white standard board by pushing it to the arrowed direction.

Slide the white standard board to

this direction strongly and release

the hook.

Removed white

standard

White

standard

board

Insert (-) driver into

this gap and push

Figure 7-20. Removing the white standard board (1)

4. Release the lock of the shaft supports at right and left and remove the

roller shaft (rear).

Release the lock of

shaft supports.

Figure 7-21. Removing the white standard board (2)

Remove the

roller shaft (rear)

Figure 7-22. Roller Removal

Appendix ADF: Disassembly 74

Page 75

EPSON Perfection 1640SU Revision A

5. Remove one metal part and 3 screws. (When you remove one of the

screws, push the release lever to the arrowed direction.

Remove3

screws

Remove these 4 gears.

Remove this

screw after

moving this lever

Remove this

metal part

F i g u r e 7 - 2 3. Re m o v i n g g e a rs

6. Remove 4 gears. One of the gear is fixing the hook to the PF roller shaft.

7. Remove 2 screws (gold, P-tite). After removing screws, remove the black

plastic frame.

Remove this black

Remove 2

screws

plastic frame after

removing screws

Figure 7-24. Removing the plastic frame

Appendix ADF: Disassembly 75

Page 76

EPSON Perfection 1640SU Revision A

7.7.3 Disassembling the ASF and Frame

1. After moving the paper edge guide in the direction of the arrow, remove the

screw (silver, P-tite + washer). Remove the two screws shown in Figure

7-18 now if they have not yet been removed.

2. Separate ASF Assembly and frame part.

Remove a screw

Figure 7-25. Disassembly of ASF and Frame (1)

Move the paper

edge guide

ASF

Assembly

Frame

Part

Figure 7-26. Disassembly of ASF and Frame (2)

Appendix ADF: Disassembly 76

Page 77

EPSON Perfection 1640SU Revision A

3. Remove the actuator and PE board assembly.

Figure 7-27. Removing Actuator and PE Board Assembly (1)

PE Board

Assembly

Actuator

Figure 7-28. Removing Actuator and PE Board Assembly (2)

Appendix ADF: Disassembly 77

Page 78

EPSON Perfection 1640SU Revision A

7.8 Parts List of ADF

Table 7-15. ADF Parts List

Number Name

101 MAT

102 DOUBLE SIDE TAPE,215X5

108 COVER,LOWER

109 LEVER,OPEN

110 SHEET,INSULATUIIN

111 FRAME,BASE

112 HOLDER,HINGE,R

113 GUIDE,HINGE

114 HOLDER,HINGE,L

115 METAL FITTINGS,RELEASE

116 MOUNTING PLATE,PAPER GUIDE

117 SHEET GUIDE;C

118 SHEET GUIDE,ADAPTER

119 ROLLER,DRIVEN,EJ

120 ROLLER,EJ,SUPPORT

121 SHAFT,ROLLER,EJ

122 COMPRESSION SPRING,3.91

123 ROLLER,DRIVEN,PF

124 SHAFT,ROLLER,PF