Epson 1600, 1600 Pro Service manual

EPSON

EPSON

EPSON France S.A.

Expression 1600

SERVICE MANUAL

PRODUIT

®

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Color image scanner

EPSON Expression 1600/1600 Pro

SESC99007

EPSON Expression 1600/1600 Pro Revision A

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

2

EPSON Expression 1600/1600 Pro Revision A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR

OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

3

EPSON Expression 1600/1600 Pro Revision A

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of EPSON Expression 1600/1600 Pro. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector Pin Assignments

• B109 MAIN Board Component Layout

• B109 MAIN Board Circuit Diagram

4

EPSON Expression 1600/1600 Pro Revision A

Revision Status

Revision Issued Date Description

A October 28, 1999 First Release

5

EPSON Expression 1600/1600 Pro Revision A

Contents

PRODUCT DESCRIPTIONS

Features ......................................................................................................... 8

Specifications ................................................................................................. 8

Interfaces...................................................................................................... 10

SCSI Interface ......................................................................................... 10

USB Interface .......................................................................................... 11

IEEE1394 Serial Bus Interface................................................................ 11

Buttons and Lamps....................................................................................... 12

Buttons .................................................................................................... 12

Indicators................................................................................................. 13

Physical Specifications ............................................................................ 13

Scanning Area......................................................................................... 14

Control Codes and Commands .................................................................... 15

Errors............................................................................................................ 16

OPERATING PRINCIPLES

Mechanism Operating Principles.................................................................. 18

Fixed Type Two Focuses Mechanism..................................................... 18

Control Circuit Operation .............................................................................. 19

TROUBLESHOOTING

Overview....................................................................................................... 24

DISASSEMBLY AND ASSEMBLY

“GLASS ASSEMBLY, FOCUS” Removal................................................ 30

“MOTOR ASSEMBLY, FOCUS” Removal .............................................. 31

Bottom Plate Removal ............................................................................ 31

B109 PSH Board Removal...................................................................... 32

B109 SUB-B Board Removal .................................................................. 32

B109 MAIN Board Removal .................................................................... 33

B109 SUB Board Removal...................................................................... 34

ADJUSTMENT

Overview ...................................................................................................... 36

MAINTENANCE

Overview ...................................................................................................... 38

APPENDIX

Overview ...................................................................................................... 40

Interconnection of the Major Components .............................................. 40

Connector Summary ............................................................................... 41

B109 MAIN Board Connector Pin Assignment........................................ 42

Component Layout ....................................................................................... 47

Exploded Diagrams and Parts List ............................................................... 48

Exploded Diagrams ................................................................................. 48

Parts List ................................................................................................. 51

Circuit Diagrams ........................................................................................... 52

Overview....................................................................................................... 28

Tools........................................................................................................ 28

Disassembly Procedures .............................................................................. 29

LED Board Removal................................................................................ 29

Operate Switch Board Removal .............................................................. 29

6

PRODUCT DESCRIPTIONS

CHAPTER

1

EPSON Expression 1600/1600 Pro Revision A

1.1 Features

This specifications are applied to the EPSON Color Image Scanner Expression 1600/1600

Pro.

The best Color Image Scanner for both graphics and office usage.

Maximum document size: 8.5 x 11.7 inches (216 x 297 mm)

Scanning speed: Line art =3.1mS/line

Gray scale=3.1mS/line

Color=9.2mS/line

(1600dpi, Draft Mode)

High image quality

Scanning resolution: 1600dpi(main) x 3200dpi’sub)

Pixel depth: In 12bit, Out 1-12bit

Max. OD Value: 3.3D

Focus control: 2position

Many types of IF available

SCSI (Standard)

USB (Standard)

IEEE 1394 Board (Optional)

1.2 Specifications

GENERAL SPECIFICATIONS

Product type: Flatbed Color Image Scanner

Sub-scanning method: Movement of the Scanner-Head

Photoelectric device: Alternative 6-line CCD (40800 pixel)

Maximum document size: 8.5 x 11.7 inches (216 x 297 mm)

Maximum picture element: 13,600(main) x 18,720(sub) pixels (1600dpi)

Scanning Resolution:

Main: 1600dpi (Optical resolution by 6 line CCD with

40800 pixel)

Sub: 3200dpi with micro step

Output resolution: 50 ~ 4800dpi (1dpi step)

Pixel depth: In 12-bit / pixel, Out 1-12bit/pixel

Color separation method: By the color filter of CCD

Zoom: 50 ~ 200% (1% step)

Scanning speed (1600dpi,Draft Mode):

Start bottom

Starts scanning (In case of network connection)

Wakes up scanner application software (In case of local connection)

Command Level

ESC/I-B8

FS

Option

ADF (Same as the GT-9600’s)

TPU (Same as the GT-9600’s, but Film holder is added)

IEEE 1394 Board

Color: 9.2ms/line

Monochrome: 3.1ms/line

Command level: ESC/I-B8, FS

Image processing functions:

Gamma correction: CRT (A, B)

Printer (A, B, C)

User Defined Table

Color correction: Impact Dot Printer

Thermal Printer

Ink Jet Printer

CRT Display

User Defined Matrix

PRODUCT DESCRIPTIONS Features 8

EPSON Expression 1600/1600 Pro Revision A

Brightness: 7 levels

Line art: Fixed threshold

TET

Halftone: Error diffusion (A, B, C)

Dither (A, B, C, D)

User defined dither (A, B)

Area separation: AAS

Interface:

SCSI (50-contact high-density connector, standard)

USB (Type-B Receptacle Connector, standard)

IEEE 1394 Serial Bus Interface (Optional)

Light source: Xenon gas fluorescent lamp

ELECTRICAL SPECIFICATIONS

Rate voltage: Universal Power Supply

AC100-120V

AC220-240V

Input voltage: AC100-120V±10%

AC220-240V±10%

SAFETY, EMC, EPA

Safety: UL1950 (+D3): USA

CSA C22.2 NO.950 (+D3): Canada

EN60950 (VDE)

IEC950 (ROSTEST, PSB)

EMC: FCC Part15 Subpart B Class B: USA

CSA C108.8 Class B: Canada

AS/NZS3548 Class B: Australia

CISPR Pub22 Class B: Korea

CNS13438 Class B: Taiwan

CE marking:

Low Voltage Directive 73/23/EEC EN60950

MC Directive 89/336/EEC EN55022 Class B

EN61000-3-2

EN61000-3-3

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

EPA: Energy Star ProgramAPI=On

Rated current: 0.8 A (Input AC110V)

0.4 A (Input AC220V)

Rated frequency range: 50-60Hz

Input frequency range: 49.5-60.5Hz

Power consumption: Approx.30 W (without optionan unit)

Approx.50 W (without optionan unit)

Approx.10 W (without optionan unit)

Insulation resistance: 10MW at 500VDC

(between AC line and chassis)

Dielectric strength: AC1.2kV, 1min

(between AC line and chassis)

RESISTANCE TO ELECTRIC NOISE

Static electricity: Panel 10kV

Metal 7kV/150pF, 150W

ENVIRONMENTAL CONDITIONS

Temperature: Operating 5 ~ 35°C

Storage -25 ~ 60°C

Humidity: Operating 10 ~ 80%, no condensation

Storage 10 ~ 85%, no condensation

RELIABILITY

Main unit: MCBF 100,000 cyclear CSA C108.

PRODUCT DESCRIPTIONS Specifications 9

EPSON Expression 1600/1600 Pro Revision A

OPERATING CONDITIONS

Dust:

Illumination:

DOCUMENT

Reflective type:

Ordinary office or home conditions. Extreme dust

should be avoided.

Operation under direct sunlight or near strong light

source is not guaranteed and should be avoided.

Documents which has a smooth surface such as a

printing and photograph.

1.3 Interfaces

This section includes the specifications for the interfaces equipped with this scanner.

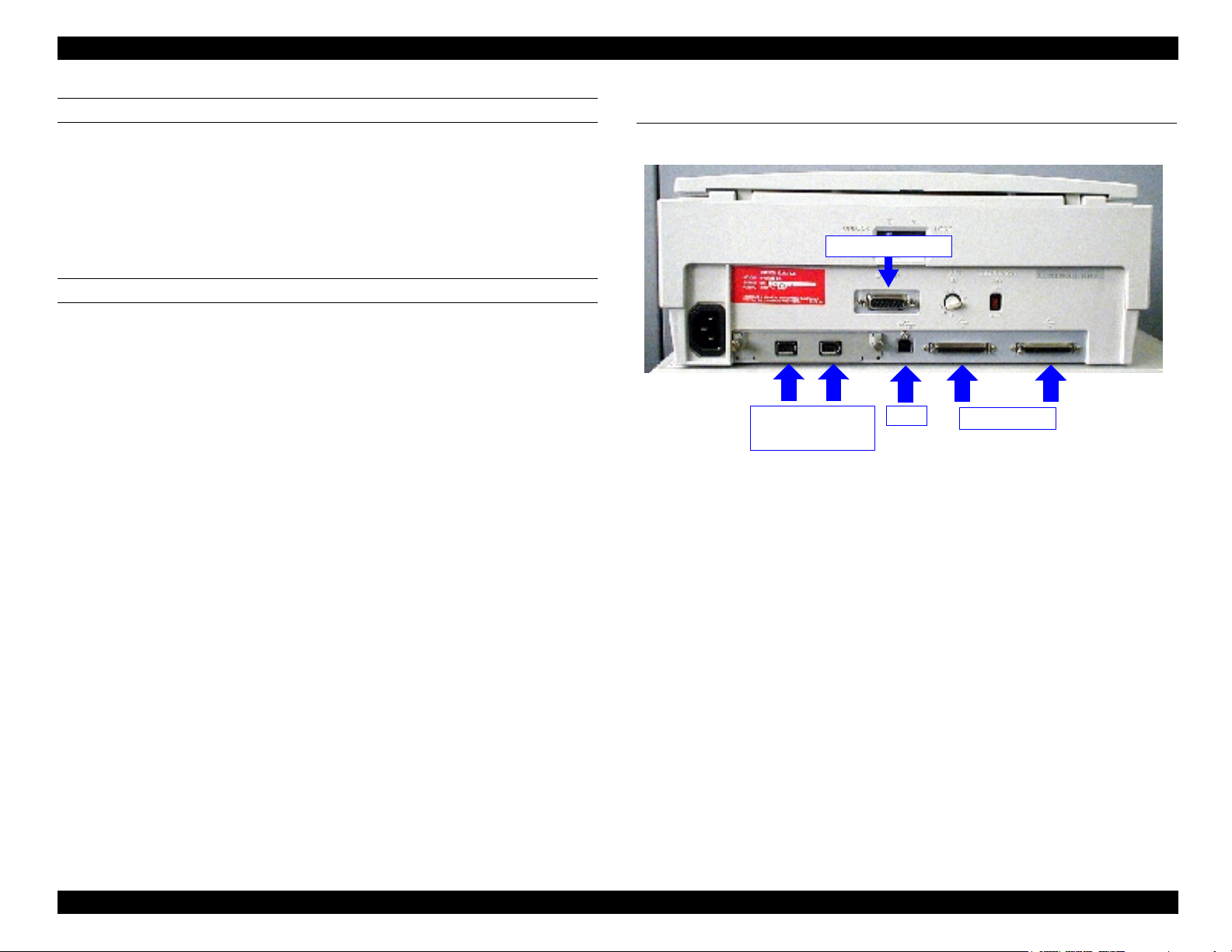

ADF/TPU Connector

IEEE1394 Interface

(Optional)

Figure 1-1. Interface Location

1.3.1 SCSI Interface

USB

SCSI Interface

See the GT-10000 Service Manual / Section 1.3.1 for the specifications and functions of the

SCSI Interface equipped with the Expression 1600/1600 Pro.

PRODUCT DESCRIPTIONS Interfaces 10

EPSON Expression 1600/1600 Pro Revision A

1.3.2 USB Interface

Basic specifications

Device:

Class:Vender specific

Sub class:Vender specific

Protocol:Vender specific

Maximum packet size for end point 0:0x04B8

Product ID:0x0107

Number of formation:1

Configuration:

Alternate setting value:None

Number of end points:2

Class:Vender specific

Sub class:Vender specific

Protocol:Vender specific

End point 1:Bulk IN transmission

Maximum packet size: 64 byte

End point 2:Bulk OUT transmission

Maximum packet size: 64 byte

String descriptor:Manufacturer: EPSON

Product name: Expression 1600/1600 Pro

Electrical specifications: Compliant with the high speed mode

(12Mbps)

1.3.3 IEEE1394 Serial Bus Interface

Refer to the IEEE 1394 optional board service manual.

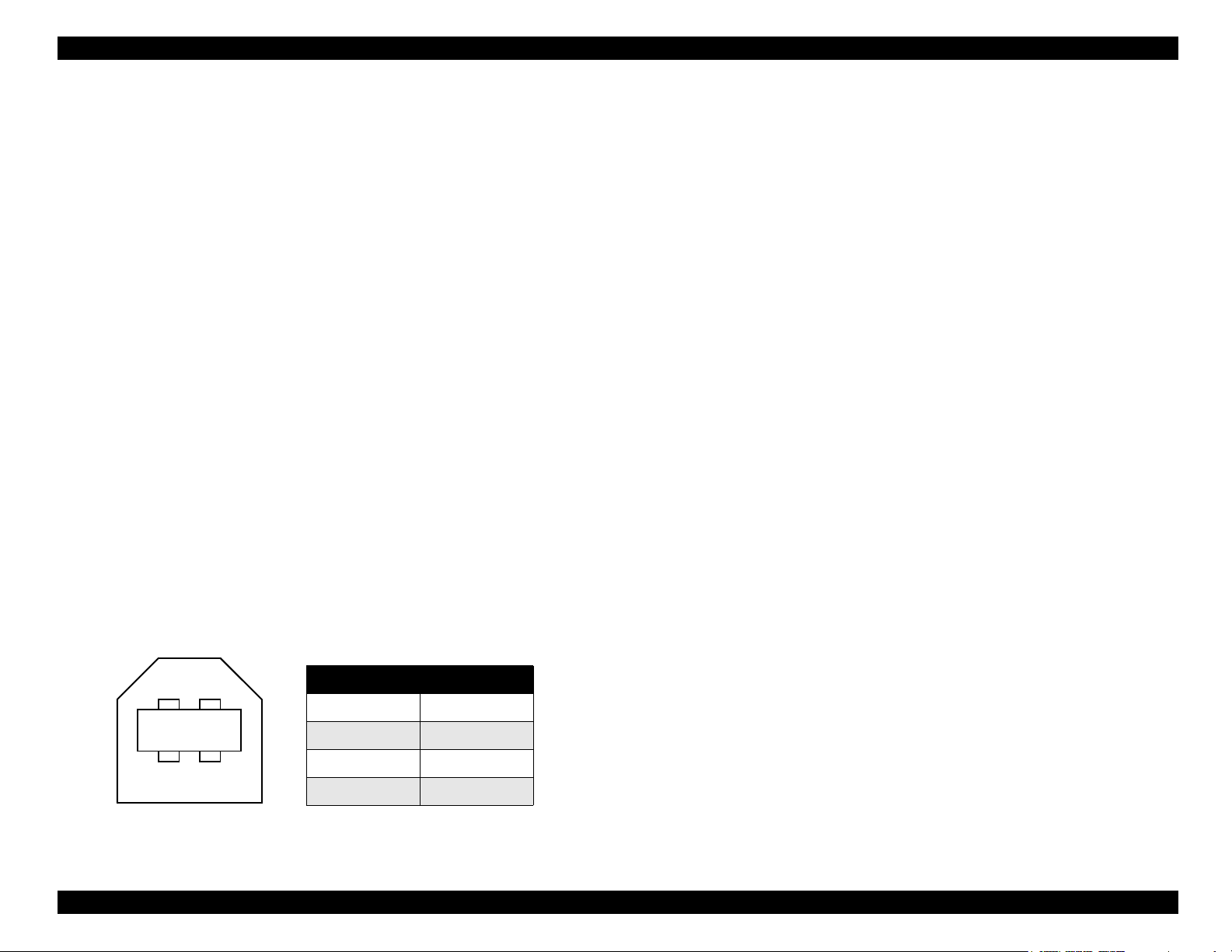

Connector: B receptacle (1)

Pin arrangement, Pin assignment:

Table 1-1. USB Pin Assignment

Pin No. Signal

2 1

3 4

1VCC

2 -Data

3-Data

4 GND

PRODUCT DESCRIPTIONS Interfaces 11

EPSON Expression 1600/1600 Pro Revision A

1.4 Buttons and Lamps

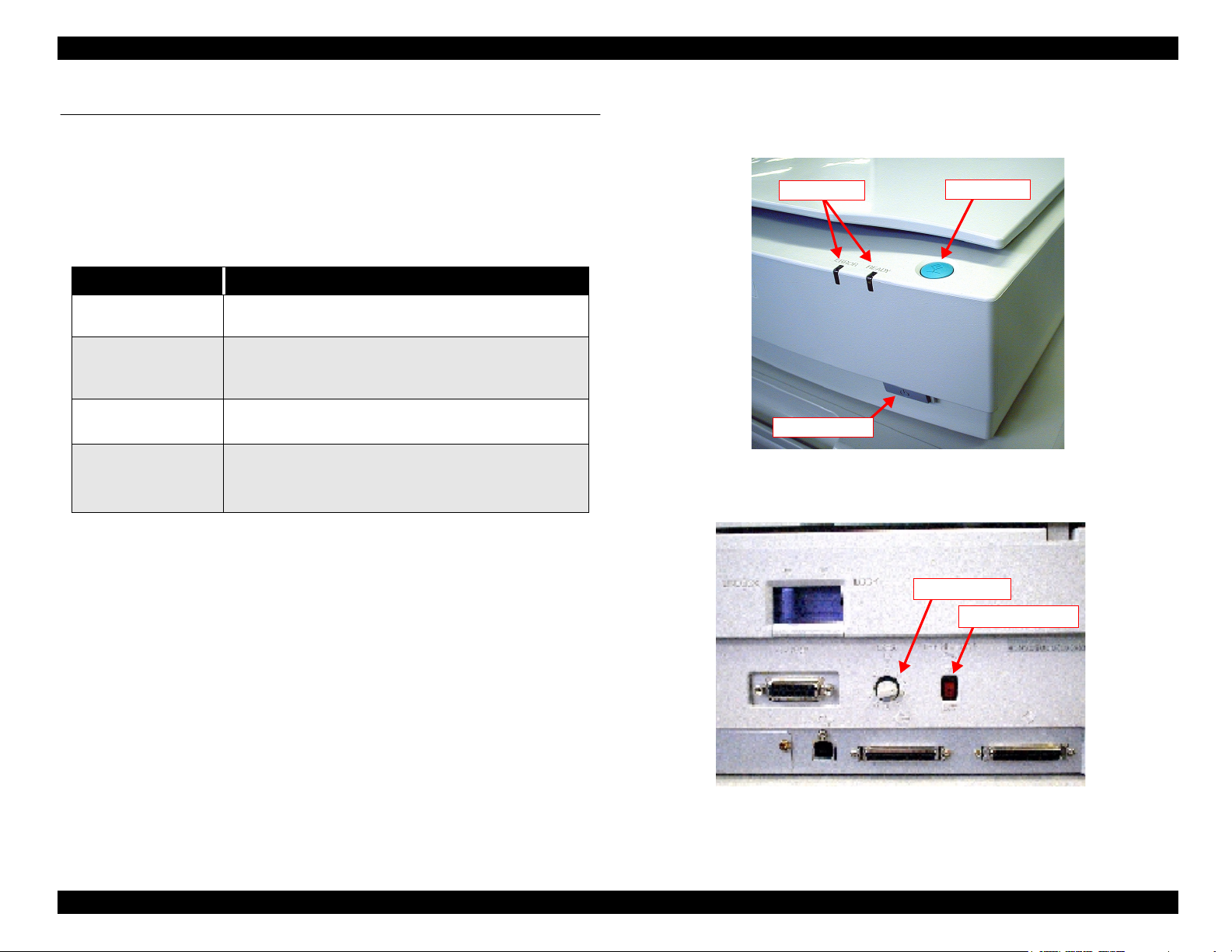

See the figures below for the locations of the buttons and switches.

1.4.1 Buttons

The buttons equipped with this scanner and their functions are as shown below:

Table 1-2. Buttons and Functions

Buttons Functions

Operate switch

Start bottom

SCSI ID switch (Rotary

switch)

Terminator switch Sets the SCSI terminator.

• Turns the scanner ON and OFF.

• Initializes the scanner when the scanner power is turned on.

• Starts scanning (In case of network connection)

• Starts scanner application software (In case of local

connection)

• 0 ~ 7: SCSI ID (Factory default ID=2)

• Others: Reserved

• ON: Terminator on (Default)

• OFF: Terminator off

LED Lamps

Operate Switch

Start Button

Figure 1-2. Location of the Button and Switches

SCSI ID Switch

Terminator Switch

Figure 1-3. Locations of the SCSI/Terminator Switches

PRODUCT DESCRIPTIONS Buttons and Lamps 12

EPSON Expression 1600/1600 Pro Revision A

1.4.2 Indicators

The table below lists the indicator lamps equipped with this scanner. (See Figure 1-1 for the

location.)

Table 1-3. Lamps and their Functions

Lamps Functions

READY

(Greed LED)

ERROR

(Red LED)

The scanner shows several error conditions by turning on/off each lamp as shown in the

table below:

Table 1-4. Error Indication by LEDs

READY (Green LED)

Lights up Lights up Command Error

• Lights up when the scanner is ready to send and

receive data.

• During scanning, goes on and off in accordance with

data transmission.

• Blinks in combination with the ERROR LED when an

error occurs.

Indicates an error condition.

ERROR (Red LED)

Error Type

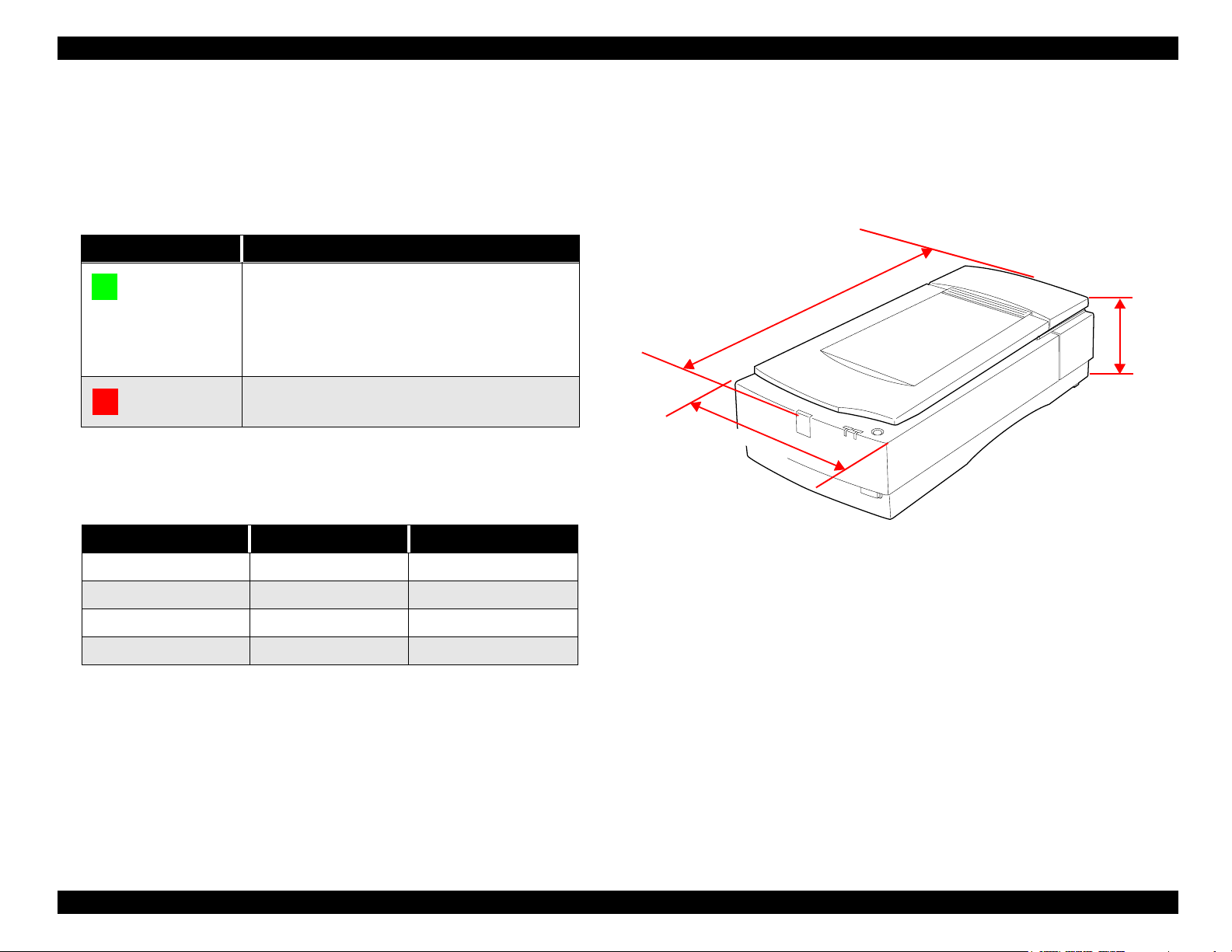

1.4.3 Physical Specifications

External view

m

m

2

6

5

3

3

2

m

m

Figure 1-4. External View of the Expression 1600/1600 Pro

133 mm

Off Blinks Interface Error

Blinks Blinks Fatal Error

Off Off Option Error

Dimensions: 332 x 562 x 133 mm (W x D x H)

Weight: Approximately 8.5kg

PRODUCT DESCRIPTIONS Buttons and Lamps 13

EPSON Expression 1600/1600 Pro Revision A

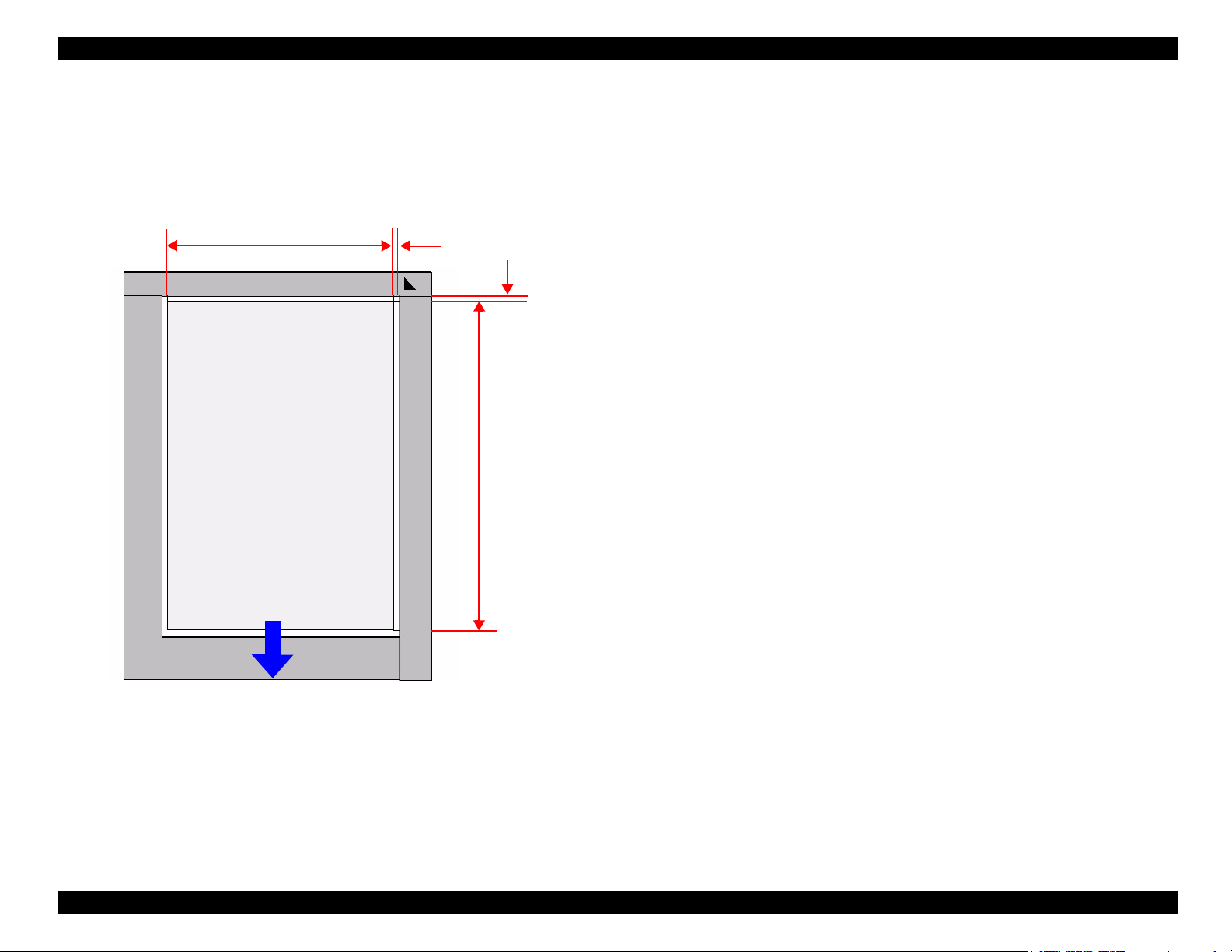

1.4.4 Scanning Area

The effective scanning area of the scanner is 216 x 297 mm (main scan x sub scan). See the

figure below:

216 mm

Front

1.0 - 1.5 mm

1.6 - 0.5 mm

297 mm

Figure 1-5. Maximum Scanning Area

PRODUCT DESCRIPTIONS Buttons and Lamps 14

EPSON Expression 1600/1600 Pro Revision A

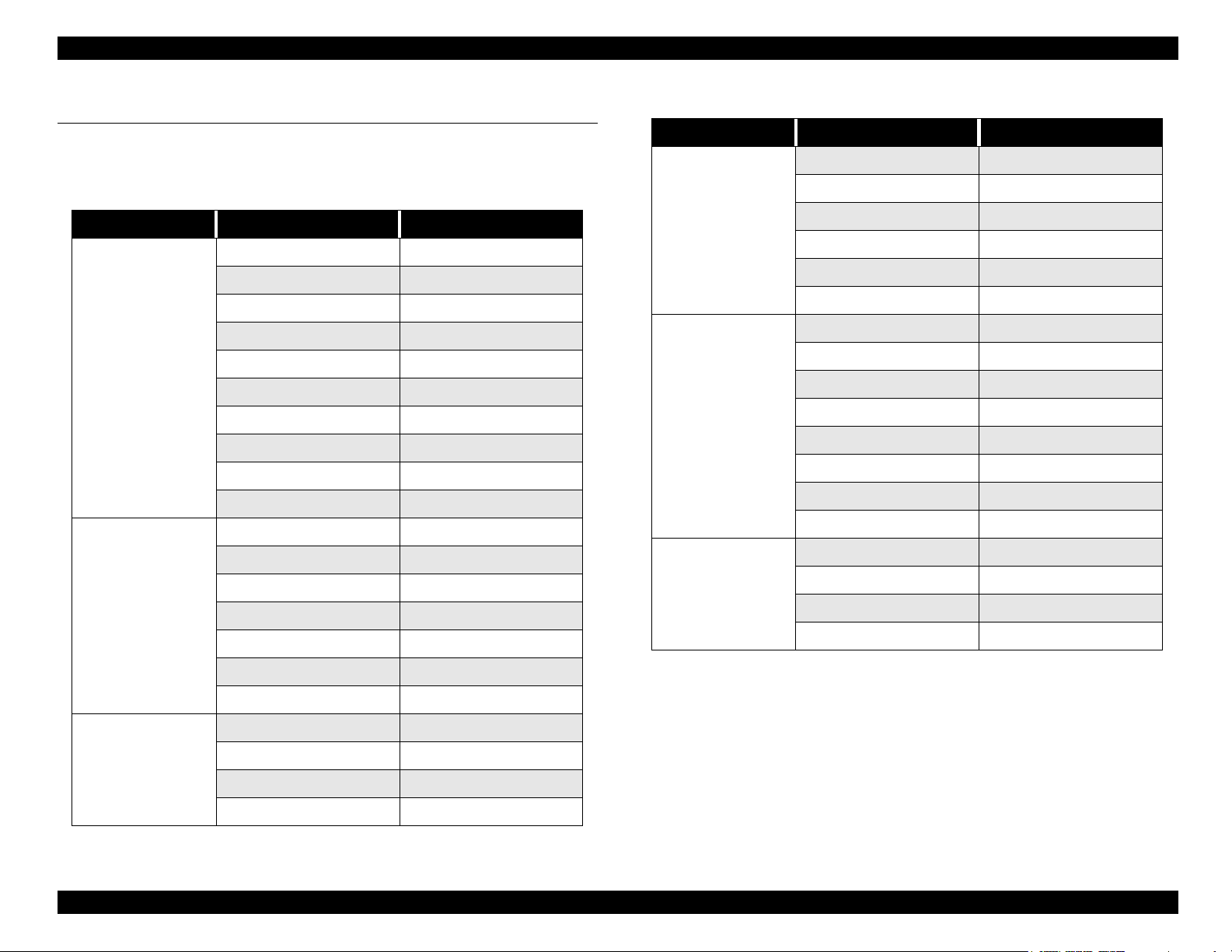

1.5 Control Codes and Commands

The control codes and commands of the scanner are as listed in the following table:

Table 1-5. Control Code Commands

Classification Name Code

Command

Set data form

ID request ESC I

status request ESC F

extended status request ESC f

request command parameters ESC S

start scanning ESC G

Push Button status request ESC !

extended ID request FS I

scanner status request FS F

scanning parameter request FS S

start new scanning FS G

set data format ESC D i

set resolution ESC R n1 n2

set zooming ESC H i1 i2

set scanning area ESC A n1 n2 n3 n4

set color ESC C i

Table 1-5. Control Code Commands (continued)

Classification Name Code

Image disposition

Support, and others

Control

set half-tone processing ESC B i

set auto area segmentation ESC s i

down load dither pattern ESC b i j d[j^2]

set color correction ESC M i

down load color correction ESC m d[9]

set threshold ESC t i

set scanning mode ESC g i

initialize ESC @

set line counter ESC d i

option control ESC e i

set film type ESC N i

set focus position ESC p i

request focus position ESC q

eject paper FF

normal response ACK

abnormal response NACK

stop scanning CAN

header STX

set mirroring ESC K i

set scanning parameter FS W

Correction

set brightness ESC L i

set gamma correction ESC Z i

down load gamma table ESC z i d[256]

set sharpness control ESC Q i

PRODUCT DESCRIPTIONS Control Codes and Commands 15

EPSON Expression 1600/1600 Pro Revision A

1.6 Errors

COMMAND ERROR

[Cause] Unidentified command is detected.

[Disposition] The scanner sends NACK and waits for the next command. When the scanner

receives a wrong command or parameter, it disregards a value and

maintains the former value.

[Indicator] READY LED lights up.

ERROR LED lights up.

[Remedy] The error condition is cleared when the scanner receives a correct command.

INTERFACE ERROR

[Cause] Wrong operation in the communication procedure is detected.

In case of SCSI, a time-out error occurred.

[Disposition] The lamp goes off and the operation stops.

[Indicator] READY LED goes off.

ERROR LED blinks.

[Indicator] READY LED blinks.

ERROR LED blinks.

[Remedy] Turn the scanner off and then back on.

Send Initialize command code (ESC @) to the scanner.

Complete BUS DEVICE RESET message in SCSI.

The RESET signal of SCSI is asserted.

[Acceptable commands] ESC F, ESC f, ESC @, FS F

OPTION ERROR (In Case Option Unit is Installed)

[Cause] Unit cover is open.

Paper empty condition

[Disposition] The bit7 of the status byte is set.

[Indicator] READY LED goes off.

ERROR LED goes off.

[Remedy] Remove the cause of the error condition.

[Remedy] Turn the scanner off and then back on.

The RESET signal of SCSI is asserted.

[Acceptable commands] None

FATAL ERROR

[Cause] The lamp is broken.

Power is turned on before removing the transportation lever.

System breakdown.

[Disposition] The lamp goes off and the operation stops.

The bit 7 of the status byte is set.

PRODUCT DESCRIPTIONS Errors 16

Loading...

Loading...