Page 1

EPSON

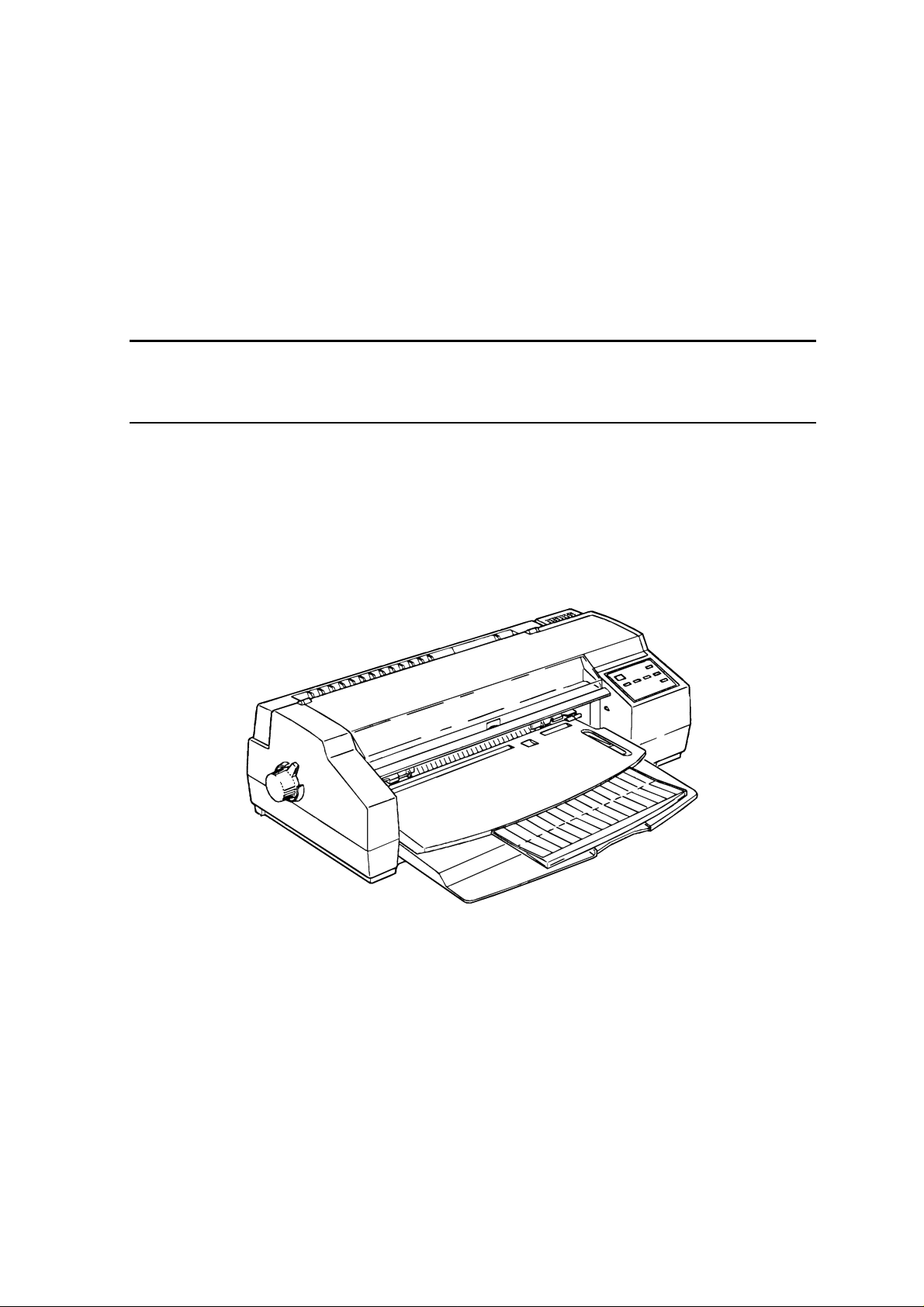

EPSON Stylus COLOR 1520

SERVICE MANUAL

COLOR INK JET PRINTER

SEIKO EPSON CORPORATION

4007394

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever

without SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility f or any errors

in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies.

Copyright 1997 by SEIKO EPSON CORPORATION

Nagano, Japan

ii

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

WARNING

CAUTION

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could res ult in ser ious or f atal per sonal injury.

Great caution should be exercised in performing procedures preceded by

WARNING Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

WARNING

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL. DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

POWER SUPPLY CABLE MUST BE CO NNECTED, USE EXT REME CAUT ION IN W O RKING

ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

CAUTION

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED O NLY BY EPSON CERTIFIED

REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT T HE SOURCE VOLT AGE IS THE SAME AS T HE RATED VOLT AGE,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT T HE EPSON PRODUCT HAS BEEN DISCONNECT ED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

iii

Page 4

PREFACE

This manual descr ibes functions , theory of electrical and m echanical operations , maintenanc e, and

repair of Stylus COLOR 1520.

The instructions and procedur es included herein are intended for the experience r epair technician,

and attention should be given to die precautions on the preceding page. The Chapters are

organized as follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the

printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENT

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides EPSON-approved techniques for troubleshooting.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to

service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and

exploded diagram.

The contents of this manual are subject to change without notice.

iv

Page 5

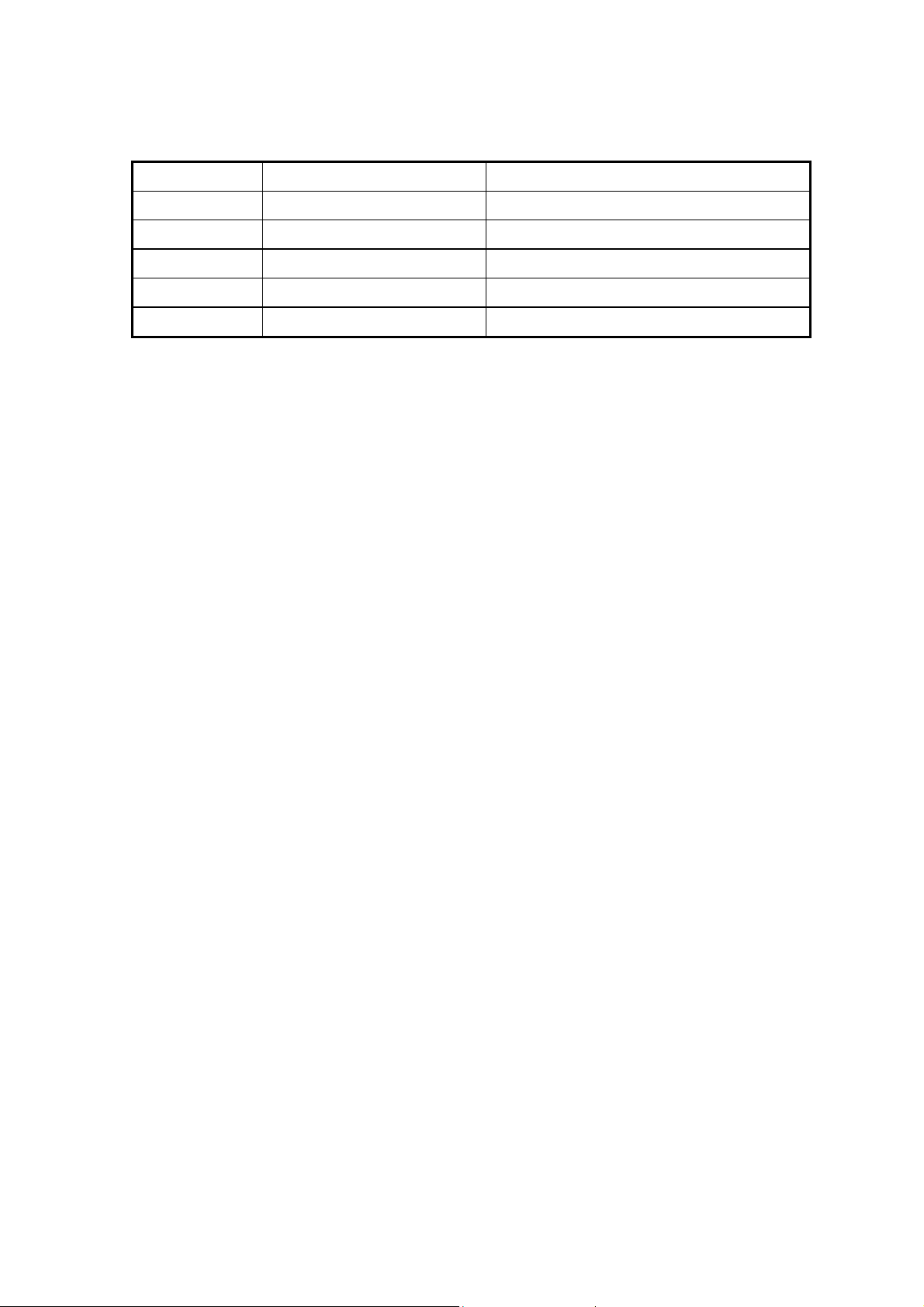

REVISION SHEET

Revision Issued Data Contents

Rev. A FEBRUARY 25 1997 First issue

v

Page 6

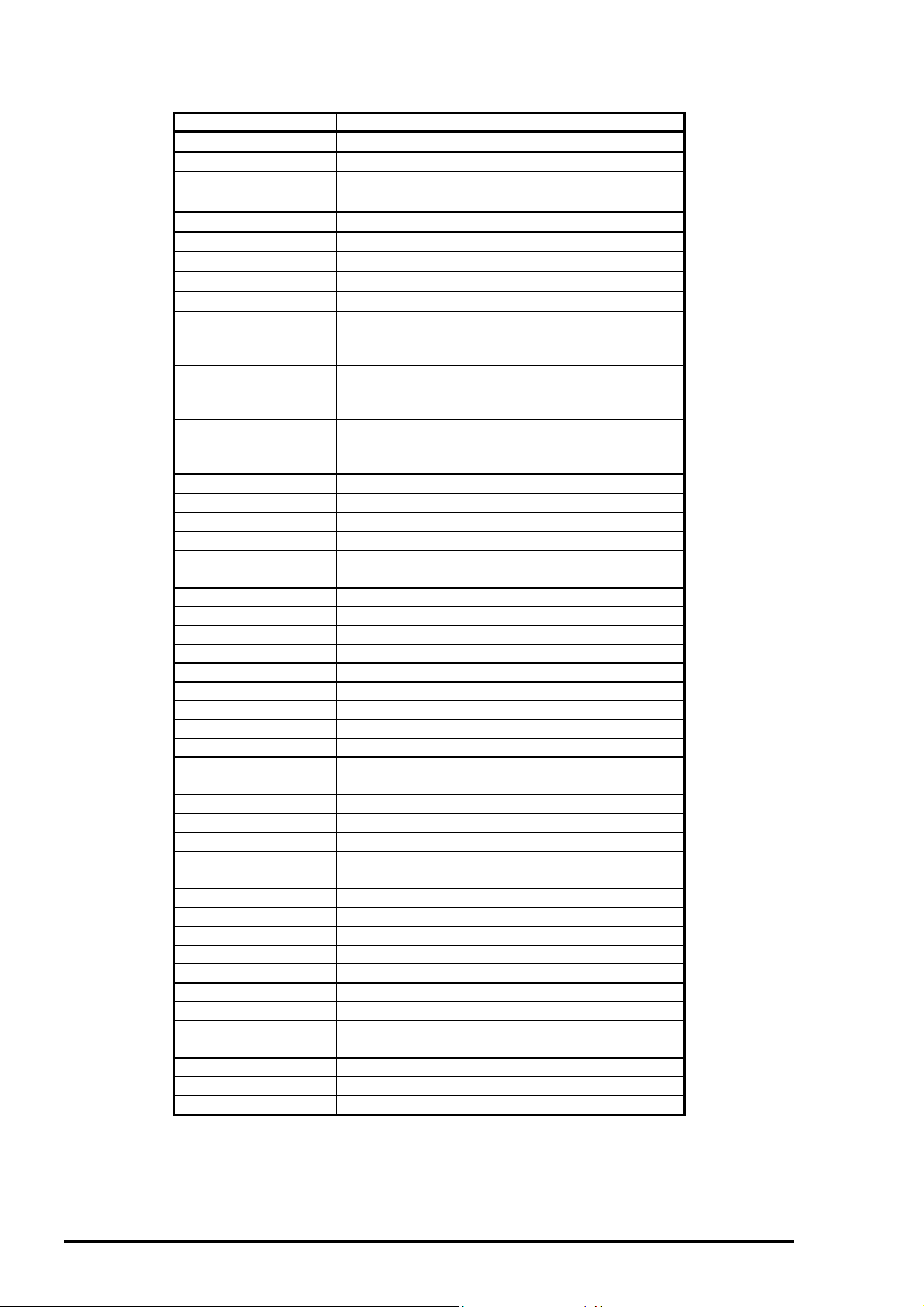

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENT

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

vi

Page 7

Chapter 1

Product Description

1.1 Features....................................................................................................................1

1.2 Specification............................................................................................................3

1.2.1 Printing Specifications.............................................................................................................. 3

1.2.2 Control codes ............................................................................................................................ 4

1.2.3 Character tables......................................................................................................................... 4

1.2.4 Paper Feeding............................................................................................................................ 5

1.2.5 Paper Specification ................................................................................................................... 6

1.2.5.1 Cut Sheet...................................................................................................................... 6

1.2.5.2 Transparency ............................................................................................................... 6

1.2.5.3 Envelope....................................................................................................................... 6

1.2.5.4 Index Card.................................................................................................................... 6

1.2.5.5 Labels (Cut Sheet) ....................................................................................................... 7

1.2.5.6 Continuous Paper......................................................................................................... 7

1.2.5.7 Labels (Continuous).....................................................................................................7

1.2.5.8 Banner.......................................................................................................................... 7

1.2.6 Printable Area ............................................................................................................................ 8

1.2.7 Adjust Lever............................................................................................................................. 11

1.2.8 Ink Specification...................................................................................................................... 12

1.2.8.1 Black ink cartridge...................................................................................................... 12

1.2.8.2 Color ink cartridge...................................................................................................... 12

1.2.9 Input Data Buffer ........................................................................................................ ............. 12

1.2.10 Electric Specifications .......................................................................................................... 13

1.2.11 Environmental Conditions.................................................................................................... 13

1.2.12 Reliability................................................................................................................................ 14

1.2.13 Safety Approvals ................................................................................................................... 14

1.2.14 CE Marking............................................................................................................................. 14

1.2.15 Acoustic Noise....................................................................................................................... 14

1.3 Interfaces................................................................................................................15

1.3.1 Parallel Interface...................................................................................................................... 15

1.3.1.1 Forward Channel Specifications................................................................................. 15

1.3.1.2 Reverse Channel Specifications ................................................................................ 17

1.3.2 Mac Serial Interface................................................................................................................. 18

1.3.2.1 Serial Interface Specifications.................................................................................... 18

1.3.3 Optional Interface.................................................................................................................... 19

1.3.4 Prevention Hosts from Data Transfer Time-out ................................................................... 20

1.3.5 Interface Selection................................................................................................................... 20

1.3.6 Printer language and Control Codes..................................................................................... 20

1.4 Operation................................................................................................................21

1.4.1 Control Panel ........................................................................................................................... 21

1.4.2 Panel Functions at Power On................................................................................................. 23

1.4.3 Printer Condition and Panel Status....................................................................................... 24

1.4.4 Cover Open Sensor Operation...............................................................................................25

1.4.5 Default Setting ......................................................................................................................... 25

1.4.5.1 Setting Method ........................................................................................................... 25

1.4.5.2 Setting Menus............................................................................................................. 27

Page 8

1.4.6 Printer Adjustment Mode ........................................................................................................29

1.4.6.1 Adjustment Method.....................................................................................................29

1.4.6.2 Adjustment patterns.................................................................................................... 29

1.4.7 Printer Initialization..................................................................................................................30

1.4.8 Self-test Printing Mode............................................................................................................ 30

1.4.9 Hexadecimal Dump Function.................................................................................................. 30

1.4.10 Monochrome Printing Mode.................................................................................................30

1.5 Physical Specification .......................................................................................... 31

1.6 Main Components................................................................................................. 32

1.6.1 C211 MAIN Board..................................................................................................................... 32

1.6.2 C172 PSB/PSE Board...............................................................................................................33

Page 9

Product Description

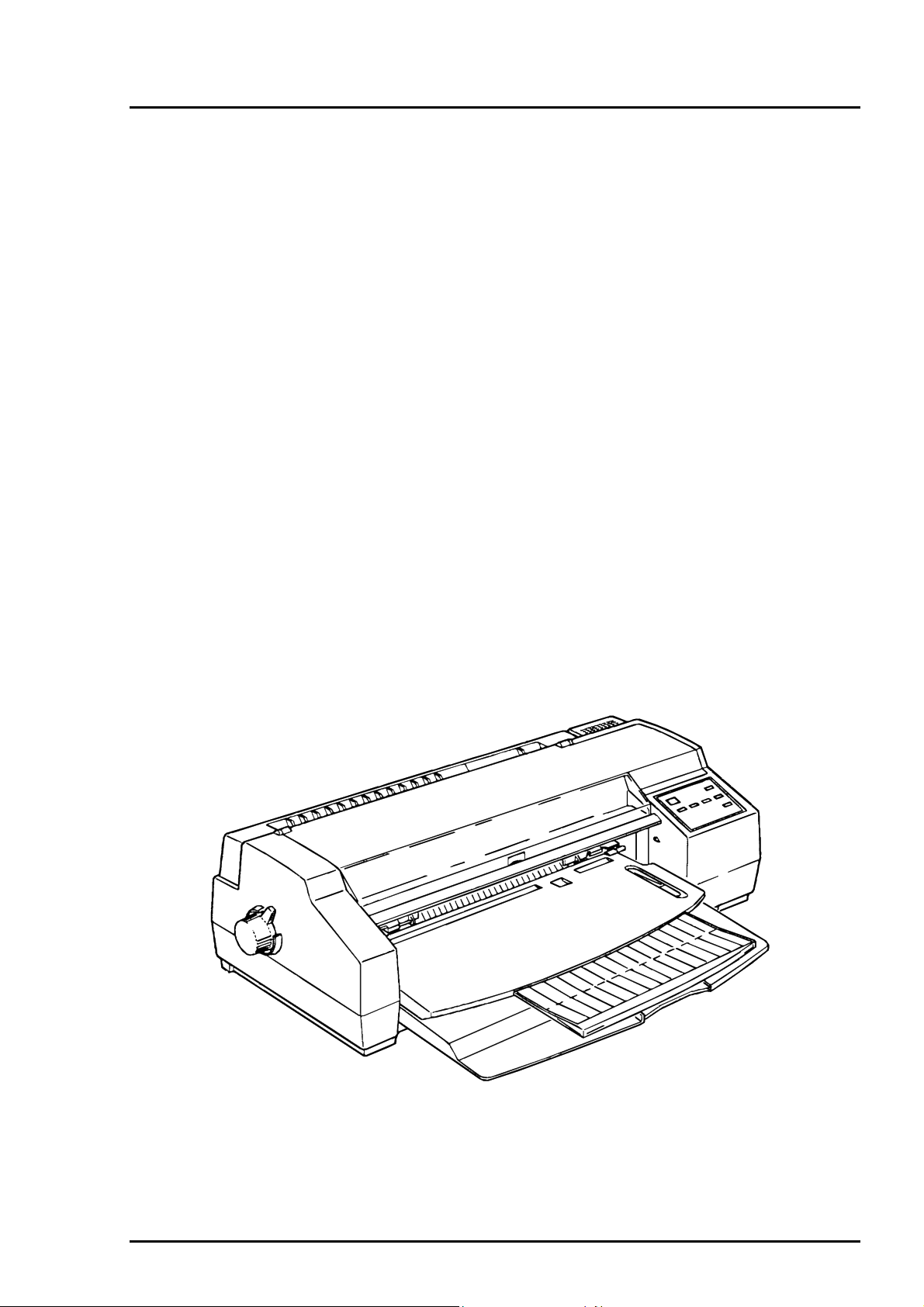

1.1 Features

The EPSON Stylus COLOR 1520 is a business-use, high speed, and high-quality color ink jet printer. The

main features of this printer are:

High Speed Printing

400 cps for LQ mode

800 cps for draft mode

High print quality for color graphics

High Resolution :1440 (H) X 720 (V) dpi printing

Colors :Cyan, Magenta, Yellow, Black

Printing Method :Traditional and new micro weave printing

Smaller dot diameter for image improvement

Built-in auto sheet feeder with a wide availability and high capacity

This printer holds :Envelope up to A2 size portrait

:100 cut sheets (55 g/‡u)

:10 envelopes

:50 transparency films

:70 special paper

Built-in 2 interfaces and 1 optional interface card

Mac serial interface ( up to approximately 900 kbps)

Bi-directional parallel interface (IEEE1284 level 1 device)

Optional Type-B interface card

4 scalable fonts and 5 LQ fonts

Scalable fonts :Roman T, Sans Serif H, Roman, Sans Serif

LQ fonts :Roman, Sans Serif, Courier, Prestige, Script

Useful character tables :Italic, PC437, PC850, PC860, PC861, PC863, PC865, BRASCII,

Abicomp, Roman 8, ISO Latin 1

PC437 Greek, PC852, PC853, PC855, PC857, PC866, PC869,

MOZOAWIA, Code MJK, ISO 8559-7, Latin 1T, Bulgaria, PC774,

Estonia, ISO 8859-2, PC866 LAT

Rev. A

Figure 0-1. Exterior View of the EPSON Stylus COLOR 1520

1

Page 10

EPSON Stylus COLOR 1520

2

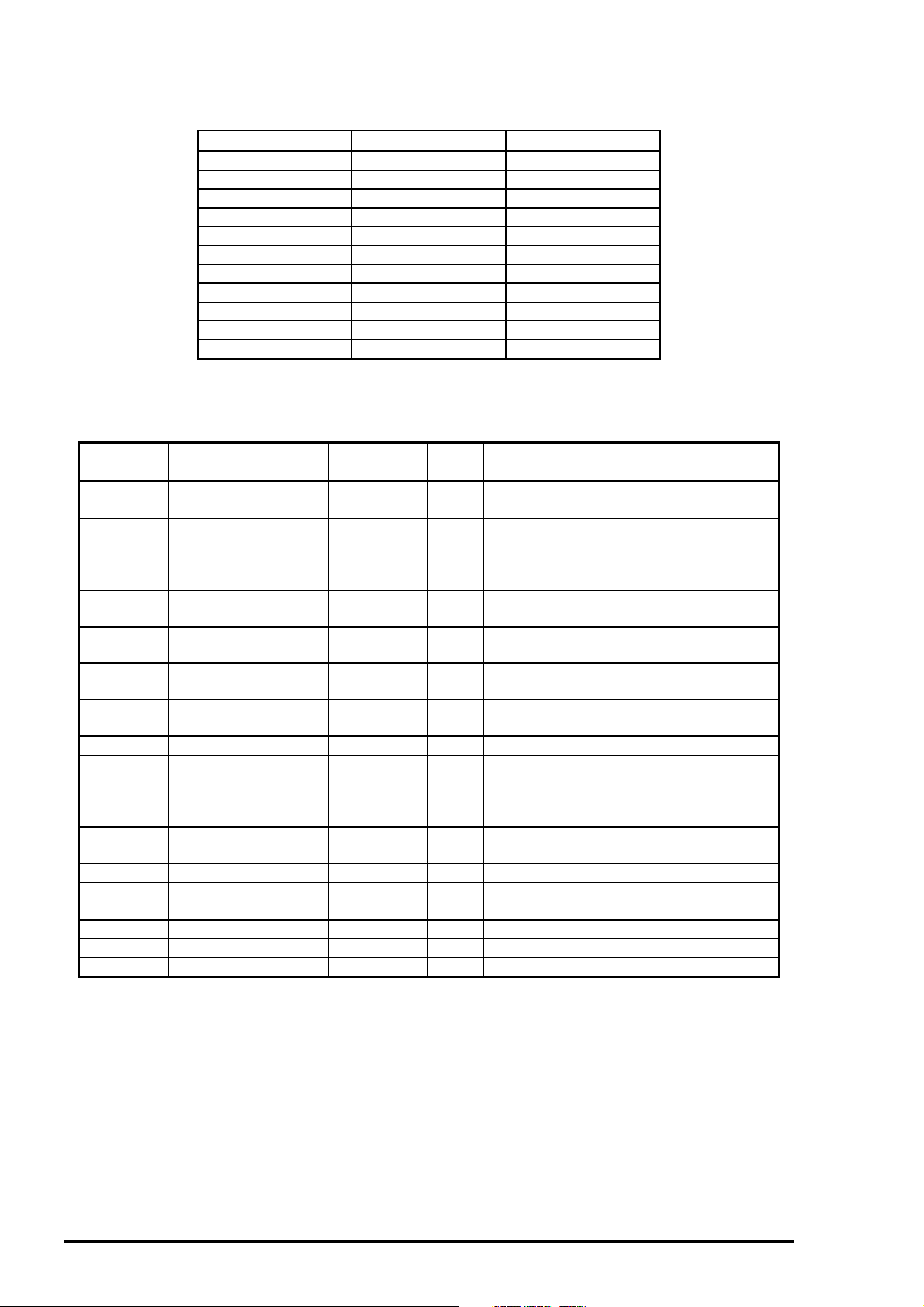

Model Description

C82305∗/C82306∗

C82307∗/C82308∗

C82310∗

C82313∗

C82315∗

C82314∗

C82312∗

C82331∗

C82345∗

C83602∗

C83603∗/C83604∗

C83605∗/C83606∗

C811**∗

S020108 Black ink cartridge

S020089 Color ink cartridge

S041059 / S041025 EPSON 360 dpi ink jet paper (A4)

S041060 EPSON 360 dpi ink jet paper (Letter)

S041065 EPSON 360 dpi ink jet paper (A3)

S041066 EPSON 360 dpi ink jet paper (Super A3/B)

S041061 / S041026 EPSON photo quality ink jet paper (A4)

S041062 EPSON photo quality ink jet paper (Letter)

S041067 EPSON photo quality ink jet paper (Legal)

S041068 EPSON photo quality ink jet paper (A3)

S041070 EPSON photo quality ink jet paper (B)

S041069 EPSON photo quality ink jet paper (Super A3/B)

S041054 EPSON photo quality ink jet card (A6)

S041121 EPSON photo quality ink jet card (5 X 8 inch)

S041122 EPSON photo quality ink jet card (8 X10 inch)

S041071 EPSON photo quality glossy film (A4)

S041072 EPSON photo quality glossy film (Letter)

S041107 EPSON photo quality glossy film (A6)

S041073 EPSON photo quality glossy film (A3)

S041075 EPSON photo quality glossy film (B)

S041074 EPSON photo quality glossy film (Super A3/B)

S041126 EPSON photo quality glossy paper (A4)

S041124 EPSON photo quality glossy paper (Letter)

S041125 EPSON photo quality glossy paper (A3)

S041123 EPSON photo quality glossy paper (A2)

S041063 EPSON ink jet transparencies (A4)

S041064 EPSON ink jet transparencies (Letter)

S041106 EPSON photo quality self adhesive sheet (A4)

S041103 EPSON 360 dpi ink jet banner paper

S041102 EPSON photo quality banner paper

S041*** EPSON ink jet canvas

S041*** EPSON back light film (A3)

S041*** EPSON back light film (A2)

Note) The asterisk is a substitute for the last digit of the product number,

which varies by country.

Table 0-1. Options and Consumables

Serial interface card

32 KB serial interface card

32 KB parallel interface card

32 KB EEE-488 interface card

Twinax interface card

Coax interface card

LocalTalk™ interface card

Ethernet interface card

Type-B Bidirectional parallel interface card

Parallel interface cable (shielded)

from D-SUB 25-pin (computer) to Amphenol 57

(printer)

Serial interface cable

from D-SUB 25-pin (computer) to D-SUB 25-pin

(printer)

Serial interface cable

from D-SUB 9-pin (computer) to D-SUB 25-pin

(printer)

Banner paper holder and cutting guide

Rev. A

Page 11

3

1.2 Specification

This section provides detailed information on the EPSON Stylus COLOR 1520.

1.2.1 Printing Specifications

Printing method :On demand Ink jet

Nozzle configuration :Monochrome 128 nozzles (32 x 4 staggered)

:Color 64 nozzles each (magenta, cyan, yellow)

320/360 inch

32/360 inch

144/360 inch

#127#128

32/360 inch

#125#126

32/360 inch

144/360 inch

#64

32/360 inch

#63

144/360 inch

#64

32/360 inch

#63

#64

Product Description

#63

#2 #3#4#1

Black

Paper feed direction

#2

Cyan

#1

#2

Magenta

#1

#2

Yellow

Figure 0-2. Nozzle Configuration

Printing direction :Bi-directional with logic-seeking

Printing speed and Printable columns

Table 0-2. Print Speed and Printable Columns for Character Mode

Character Pitch Printable Columns LQ Speed Draft Speed

10 cpi (Pica) 136 400 cps 800 cps

12 cpi (Elite) 163 480 cps 960 cps

15 cpi 204 600 cps 1200 cps

17.1 cpi(Pica condensed) 233 684 cps 1378 cps

20 cpi(Elite dondensed) 272 800 cps 1600 cps

Table 0-3. Print Speed and Printable Columns for Raster Graphic Mode

Print Mode Printable Area Available Dot CR Speed

180 dpi X 180 dpi 11 inch 1980 40 ips

360 dpi X 360 dpi 11 inch 3960 20 ips

720 dpi X 720 dpi 11 inch 7920 20 ips

1440 dpi X 1440 dpi *

1

11 inch

7920 *

2

Note) 1: 1440 dpi X 720 dpi is available when using driver micro weave only.

2: 1440 dpi X 720 dpi can be printed by sending Following command sequence.

1. Set the print speed to 10 IPS.

2. Print 180 X 720 raster image.

3. Paper feed 31/720 inch.

4. Move 1/1440 inch print position.

5. Print 180 X 720 raster image.

6. Paper feed 31/720 inch.

Repeat the steps from 2 to 6.

#1

10 ips

Rev. A

Page 12

EPSON Stylus COLOR 1520

4

1.2.2 Control codes

ESCP/2 and expanded raster graphics code

EPSON Remote command

IBMX24E emulation

1.2.3 Character tables

Legal and 14 international character sets

Standard version: 27 character tables

Italic table PC 437 (US, Standard Europe)

PC 850 (Multilingual) PC 860 (Portuguese)

PC 861 (IceLandic) PC 863 (Canadian-French)

PC 865 (Nordic) Abicomp

BRASCII Roman 8

ISO Latin 1 PC 437 (Greek)

PC 852 (East Europe) PC 853 (Turkish)

PC 855 (Cyrillic) PC 857 ( Turkish)

PC 866 (Russian) PC 869 (Greek)

MOZOAWIA (Poland) Code MJK (CSFR)

ISO 8559-7 (Latin, Greek) ISO Latin 1T (Turkish)

Bulgaria (Bulgaria) PC 774

Estonia ISO 8859-2 (ISO Latin 2)

PC 866 LAT

Typeface

Bit map LQ font EPSON Roman 10 cpi, 12 cpi, 15 cpi, Proportional

EPSON Sans Serif 10 cpi, 12 cpi, 15 cpi, Proportional

EPSON Courier 10 cpi, 12 cpi, 15 cpi,

EPSON Prestige 10 cpi, 12 cpi, 15 cpi,

EPSON Prestige 10 cpi, 12 cpi, 15 cpi

Scalable font EPSON Roman 10.5 pt., 8 pt. − 32 pt. (every 2 pt.)

EPSON Sans Serif 10.5 pt., 8 pt. − 32 pt. (every 2 pt.)

EPSON Courier 10.5 pt., 8 pt. − 32 pt. (every 2 pt.)

EPSON Prestige 10.5 pt., 8 pt. − 32 pt. (every 2 pt.)

EPSON Script 10.5 pt., 8 pt. − 32 pt. (every 2 pt.)

Note) Each typeface has 4 variations:

Normal, Bold, Italic, and Bold Italic

An example of variations for Epson Roman is as follows:

Epson Roman normal

Epsom Roman bold

Epson Roman italic

Epson Roman bold italic

Rev. A

Page 13

5

Combinations of Character tables and typefaces (font)

Table 1-14 shows the available combinations of character tables and Typefaces.

Table 0-4. Character Tables and Fonts

Bitmap Fonts Scalable Fonts Scalable Fonts

Character Tables

Italic

PC 860 (Portuguese))

PC 861 (IceLandic)

PC 863 (Canadian-French)

PC 865 (Nordic)

BRASCII

Abicomp

Roman 8

ISO Latin 1

Italic table

PC 437 (US Standard Europe)

PC 850 (Multilingual)

PC 437 (Greek)

PC 852 (East Europe)

PC 853 (Turkish)

PC 855 (Cyrillic)

PC 857 (Turkish)

PC 866 (Russian)

PC 869 (Greek)

MAZOWIA (Poland)

Code MJK (CSFR)

ISO 8859-7 (Latin/Greek)

ISO Latin 1T (Turkish)

Bulgaria (Bulgaria)

PC 774

Estonia

ISO 8859-2 (ISO Latin 2)

PC 866 LAT

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

Supported Supported Supported

Supported Supported

EPSON Roman

EPSON Sans Serif

Product Description

EPSON Roman T

EPSON Sans Serif H

Not

Supported

1.2.4 Paper Feeding

Paper transport method :Friction feed with built-in auto sheet feeder (ASF)

Line spacing :1/6, 1/8 inch or programmable at 1/360 inch

Paper path :Cut-sheet ASF (Front entry)

:FF Rear tractor

Feed speed :66 ms / line (1 line = 1/6 inch)

88.9 mm / sec

3.5 inch / sec

Rev. A

Page 14

EPSON Stylus COLOR 1520

6

1.2.5 Paper Specification

1.2.5.1 Cut Sheet

Size Width Length

A4 210 mm (8.3”) 297 mm (11.7”)

Letter 215.9 mm (8.5”) 279.4 mm (11.0”)

B5 182 mm (7.2”) 257 mm (10.1”)

Legal 215.4 mm (8.5”) 355.6 mm (14.3”)

B4 257 mm (10.1”) 364 mm (14.0”)

A3 297 mm (11.7”) 420 mm (16.5”)

Ledger 279.4mm (11.0”) 431.8 mm (17.0”)

A3 wide 329 mm (13.0”) 483 mm (19.0”)

A2 420 mm (16.5”) 594 mm (23.4”)

US-C 431.8 mm (17.0”) 558.8 mm (22.0”)

B5 (ISO) 176 mm (6.9”) 250 mm (9.8”)

B4 (ISO) 250 mm (9.8”) 353 mm (13.9)”

Table 0-5. Cut Sheet Size

Paper Thickness :0.065 mm (0.0025”) to 0.11 mm (0.004”)

Paper Weight :64 g/ m

:52 g/ m

Quality :Exclusive paper *

2

(17 lb.) to 90 g/ m2 (24 lb.) (ASF)

2

(14 lb.) to 90 g/ m2 (24 lb.) (Manual insertion)

2

, Bond paper, PPC

Note) 1. A2 portrait and US-C portrait are used by manual insertion only.

2. Be sure to use the designated side of exclusive paper.

1.2.5.2 Transparency

Table 0-6. Transparency Size

Size Width Length

A4 210 mm (8.3”) 297 mm (11.7”)

Letter 215.9 mm (8.5”) 279.4 mm (11.0”)

Paper thickness :0.075 mm (0.003”) to 0.085 mm (0.0033”)

Note) Transparency printing is only available at normal temperatures.

Transparency paper must be printed on the designated side.

1.2.5.3 Envelope

Table 0-7. Envelope Size

Size Width Length

No.10 241.3 mm (9 1/2”) 104.8 mm (4 1/8”)

DL 220 mm (8.7”) 110 mm (4.3)

C5 229 mm (9”) 162 mm (6.4)

Paper Thickness :0.16 mm (0.006”) to 0.52 mm (0.02”)

Paper Weight :45 g/m

Quality :Bond paper, Plain paper, Air mail

2

(12 lb.) to 90 g/ m2 (24 lb.)

Note) Envelope printing is only available at normal temperatures.

Place the longer side of the envelope horizontally when setting.

1.2.5.4 Index Card

Table 0-8. Index Card Size

Size Width Length

A6 index card 105 mm (4.1”) 148 mm (5.82”)

Card Thickness :0.23 mm (0.0091”)

Rev. A

Page 15

7

1.2.5.5 Labels (Cut Sheet)

Table 0-9. Label Size

Size Width Length

A4 210 mm (8.3”) 297 mm (11.7”)

Letter 216 mm(8.5”) 279 mm (11.0”)

Paper thickness :0.2 mm (0.0079”) including base sheet

Quality :Page printer label

Note) Label must be printed at normal room temperature.

1.2.5.6 Continuous Paper

Paper size :Paper width 101.6 mm (4”) to 406.4 mm (16”)

:Folding length 101.6 mm (4”)

Paper thickness :0.065 mm (0.0026”) to 0.11 mm (0.0043”)

Paper Weight :52 g/ m

2

(14 lb.) to 82 g/ m2 (22 lb.)

1.2.5.7 Labels (Continuous)

Paper size

Base sheet :Paper width 101.6 mm (4”) to 406.4 mm (16”)

:Folding length 101.6 mm (4”)

Label :Width 63.5 mm (2.5”)

:Length 23.9 mm (0.94”)

Paper thickness :0.2 mm (0.0079”) or less including base sheet

:0.12 mm (0.0047”) or less without base sheet

Quality :Plain paper

Note) Label (continuous) must be printed under normal room temperatures.

Product Description

1.2.5.8 Banner

Size :Width :210 mm (8.32) to 432 mm (17.0”)

:Length :5.0 m or less (196.9”)

Thickness :0.08 mm (0.0031”) to 0.1 mm (0.0039”)

Weight :64 g/m

Quality :Plain paper

2

(17 lb.) to 82 g/ m2 (22 lb.)

Rev. A

Page 16

EPSON Stylus COLOR 1520

8

1.2.6 Printable Area

Cut Sheet

PW

LM RM

TM

Printable Area

PL

BM

Figure 0-3. Printable Area for Cut Sheet

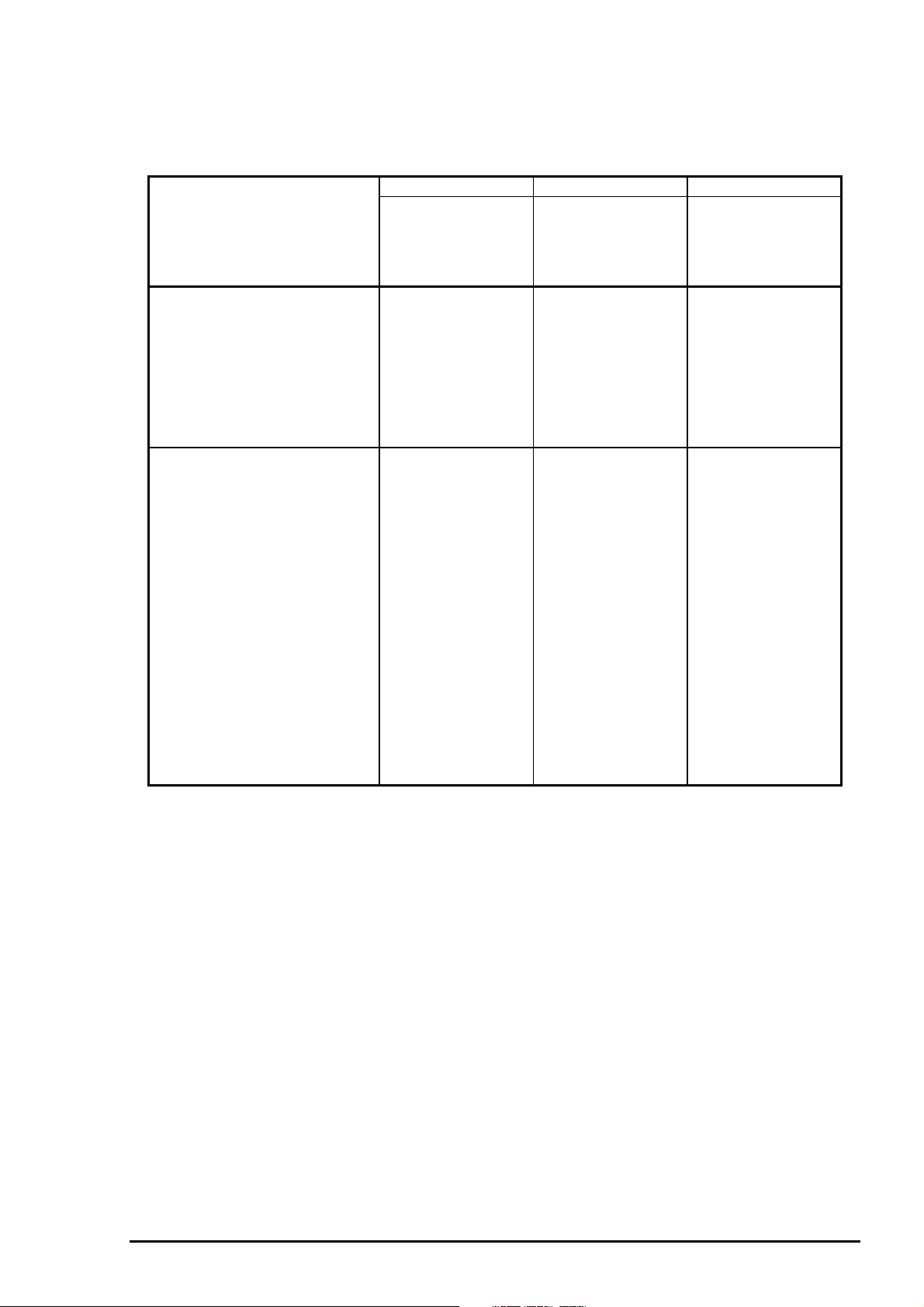

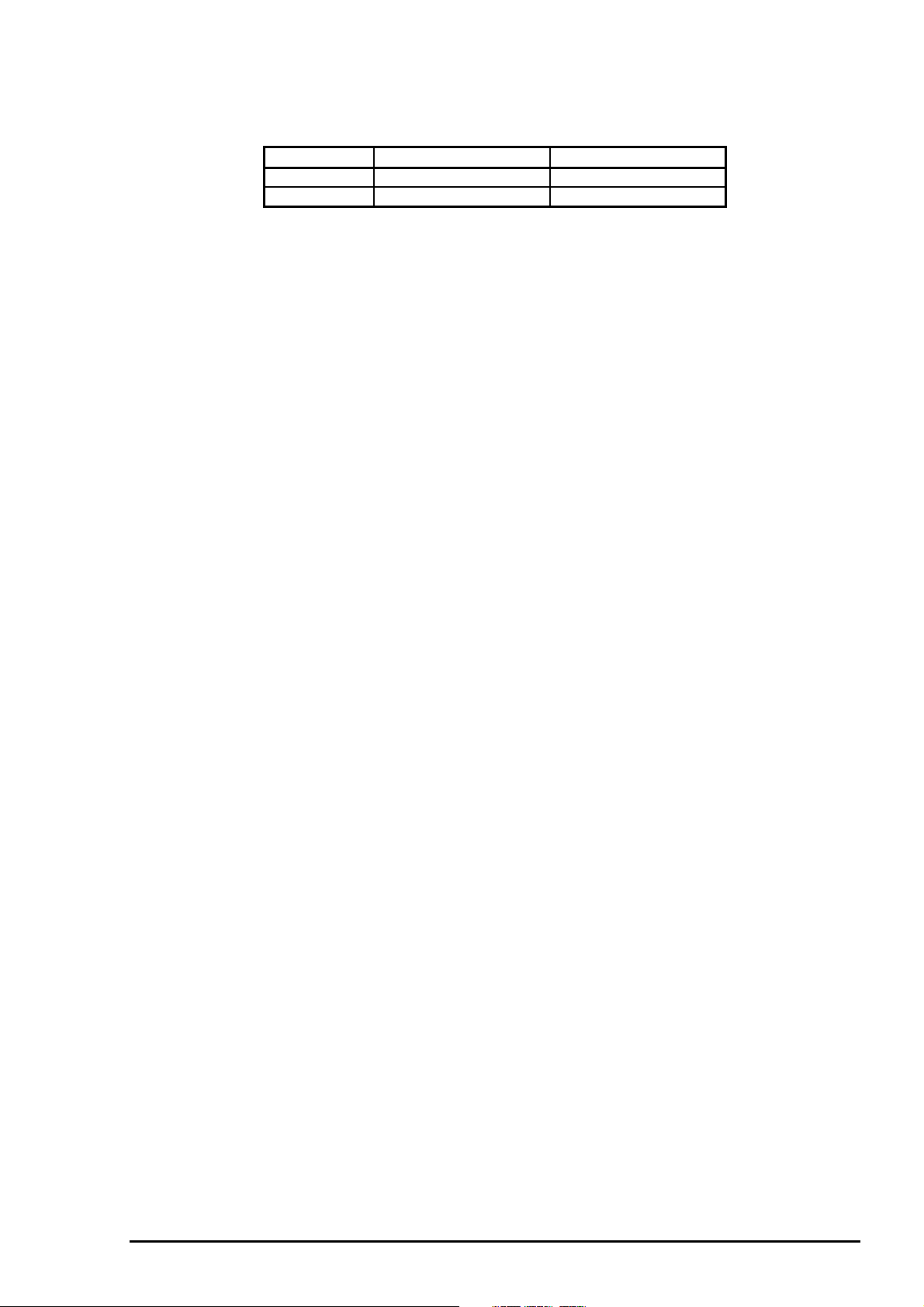

Table 0-10. Minimum Margins for Different Cut Sheet Sizes

PW LM (Left Margin) RM (Right Margin) TM BM

(Paper

Width)

A4

297 mm

Set to right

edge

3 mm

(0.12”)

Set to left

edge

3 mm

(0.12”)

Set to right

edge

3 mm

(0.12”)

Set to left

edge

3 mm

(0.12”)

(Top Margin) (Bottom

3 mm

(0.12”)

(11.87”)

Legal (L)

356 mm

3 mm

(0.12”)

5 mm

(0.20”)

5mm

(0.20”)

3 mm

(0.12”)

3 mm

(0.12”)

(14.0”)

B4 (L)

364mm

3 mm

(0.12”)

16 mm

(0.51”)

16 mm

(0.51”)

3 mm

(0.12”)

3 mm

(0.12”)

(14.3”)

A3 (L)

420 mm

13 mm

(0.51”)

25 mm

(0.98”)

62 mm

(2.32”)

50 mm

(1.85”)

3 mm

(0.12”)

(16.5”)

Ledger (L)

432 mm

25 mm

(0.98”)

25 mm

(0.98”)

62 mm

(2.32”)

62 mm

(2.32”)

3 mm

(0.12”)

(17.0”)

Note) 1. (L) : When the paper is placed in landscape orientation.

2. Printable are of label (cut sheet) is as same as cut sheet.

Margin)

14 mm

(0.54”)

14 mm

(0.54”)

14 mm

(0.54”)

14 mm

(0.54”)

14 mm

(0.54”)

Rev. A

Page 17

9

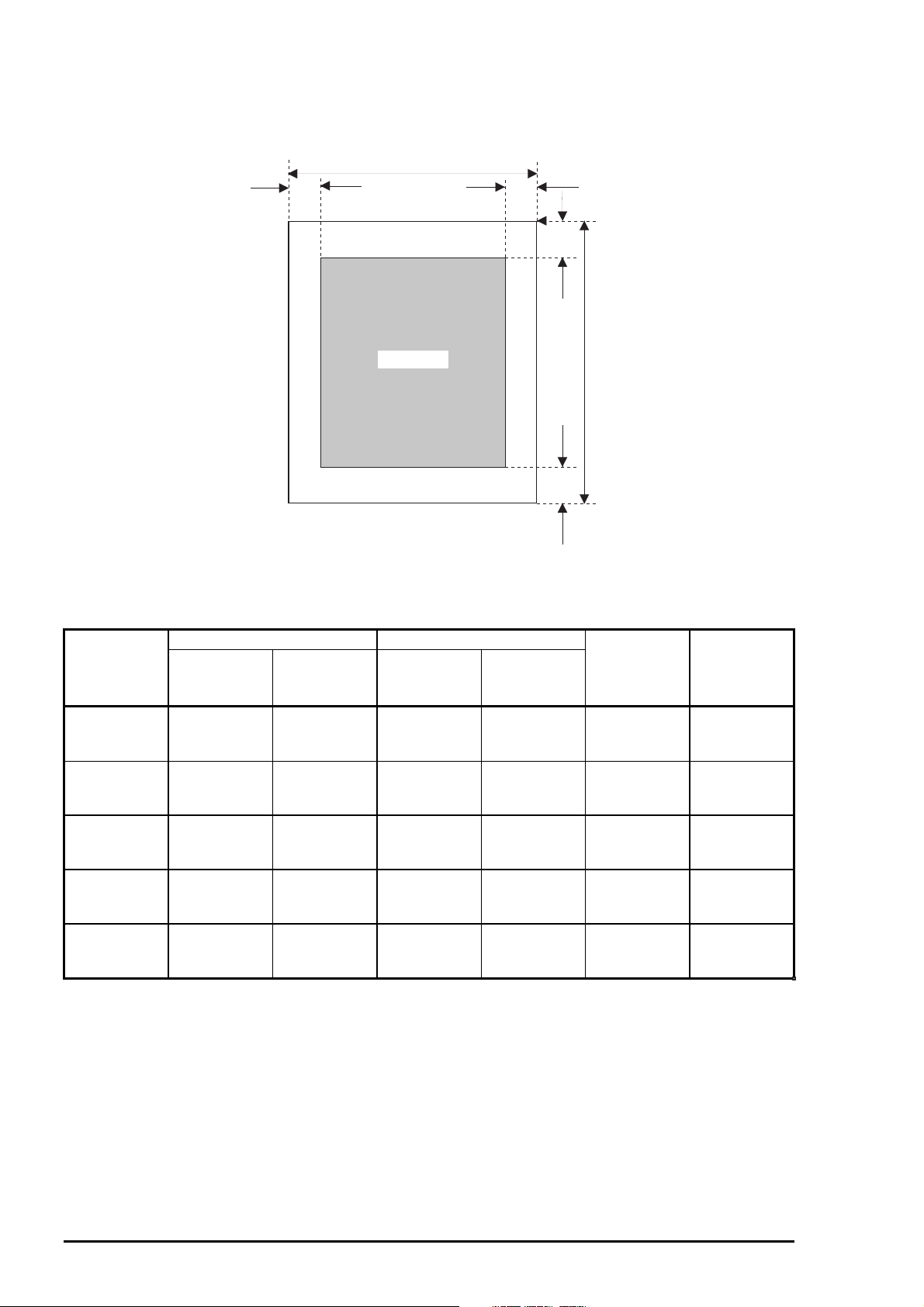

Envelope

Product Description

LM

LM (Left Margin)

(minimum)

3 mm

(0.12”)

Printable area

Figure 0-4. Printable Area for Envelopes

Table 0-11. Minimum Margin for Envelope

RM (Right Margin)

(minimum)

3 mm

(0.12”)

TM (Top Margin)

(minimum)

3 mm

(0.12”)

RM

TM

BM

BM

(Bottom Margin)

(minimum)

14 mm

(0.55”)

Rev. A

Page 18

EPSON Stylus COLOR 1520

0

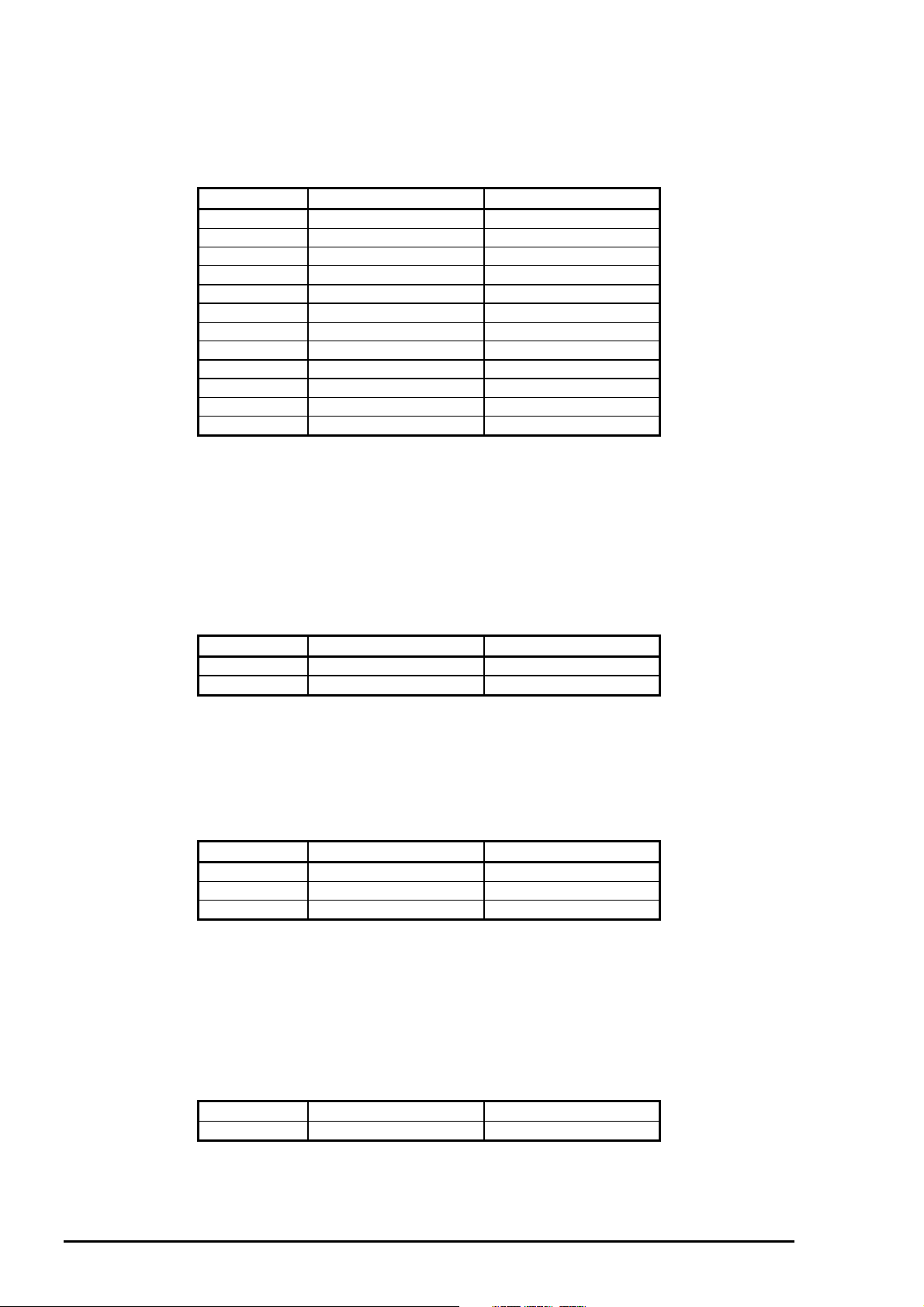

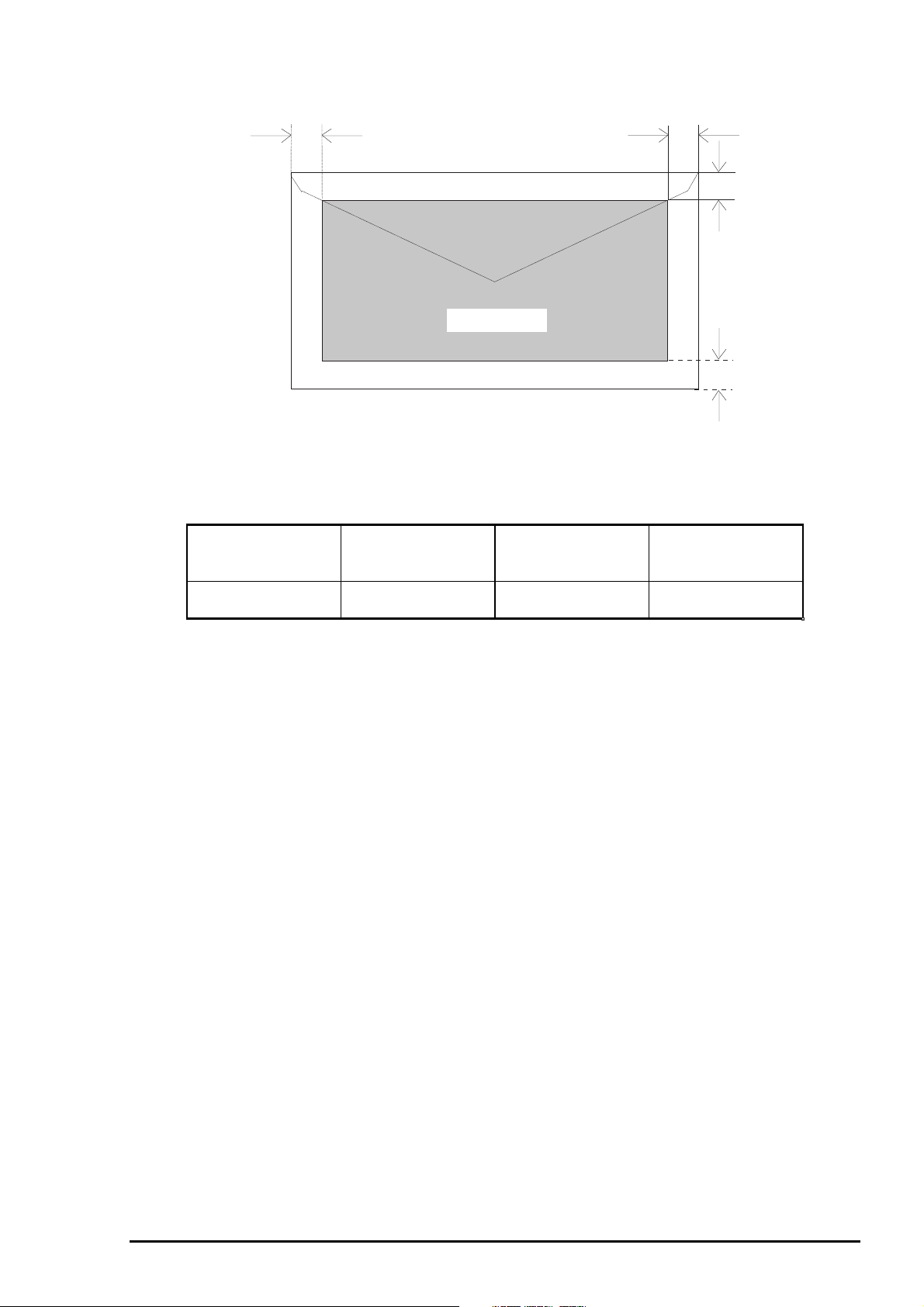

Continuous Paper

Note) 1. Printable area of label (continuous) is as same as for continuous paper.

2. Base sheet of label (continuous) is not within the printing area.

More than

3 mm (0.12 ")

Perforation

Perforation

More than

13 mm (0.51") *1

Printable are 1

Printable area 2

Printable are 1

Printable area 2

Printable area 2

Printable are 1

More than

13 mm (0.51") *1

More than

12.5 mm (0.49")

More than

9 mm (0.35")

More than

9 mm (0.35")

More than

9 mm (0.35")

More than

9 mm (0.35")

More than

14 mm (0.55")

*1 : When the paper width is more than 406.4 mm (16"), this width is more than

38 mm (1.50").

Printable area 2

Printable are 1

Perforation

Printable Area 1: Paper feed pitch is not guaranteed in this area.

Printable Area 2: Paper feed pitch is guaranteed in this area.

Perforation

Perforation

Figure 0-5. Printable Area for Continuous Paper

More than

134 mm (5.28")

1

Rev. A

Page 19

Product Description

1.2.7 Adjust Lever

The adjust lever , located at the left and upper side of the printer , is used to adjust the gap between the

paper and platen. The adjust lever must be set to the proper position the paper type in order to prevent the

paper from smudging.

Table 0-12. Adjust Lever Position

Paper

Type

Cut sheet

Transparency

Continuous paper

Index card

Envelopes Near side (+) + 0.7 mm

Lever

Position

Far side (0) 0 mm

Platen Gap Adjustment

Value

Adjust lever

+

0

Figure 0-6. Adjust Lever Settings

Rev. A

11

Page 20

EPSON Stylus COLOR 1520

2

1.2.8 Ink Specification

1.2.8.1 Black ink cartridge

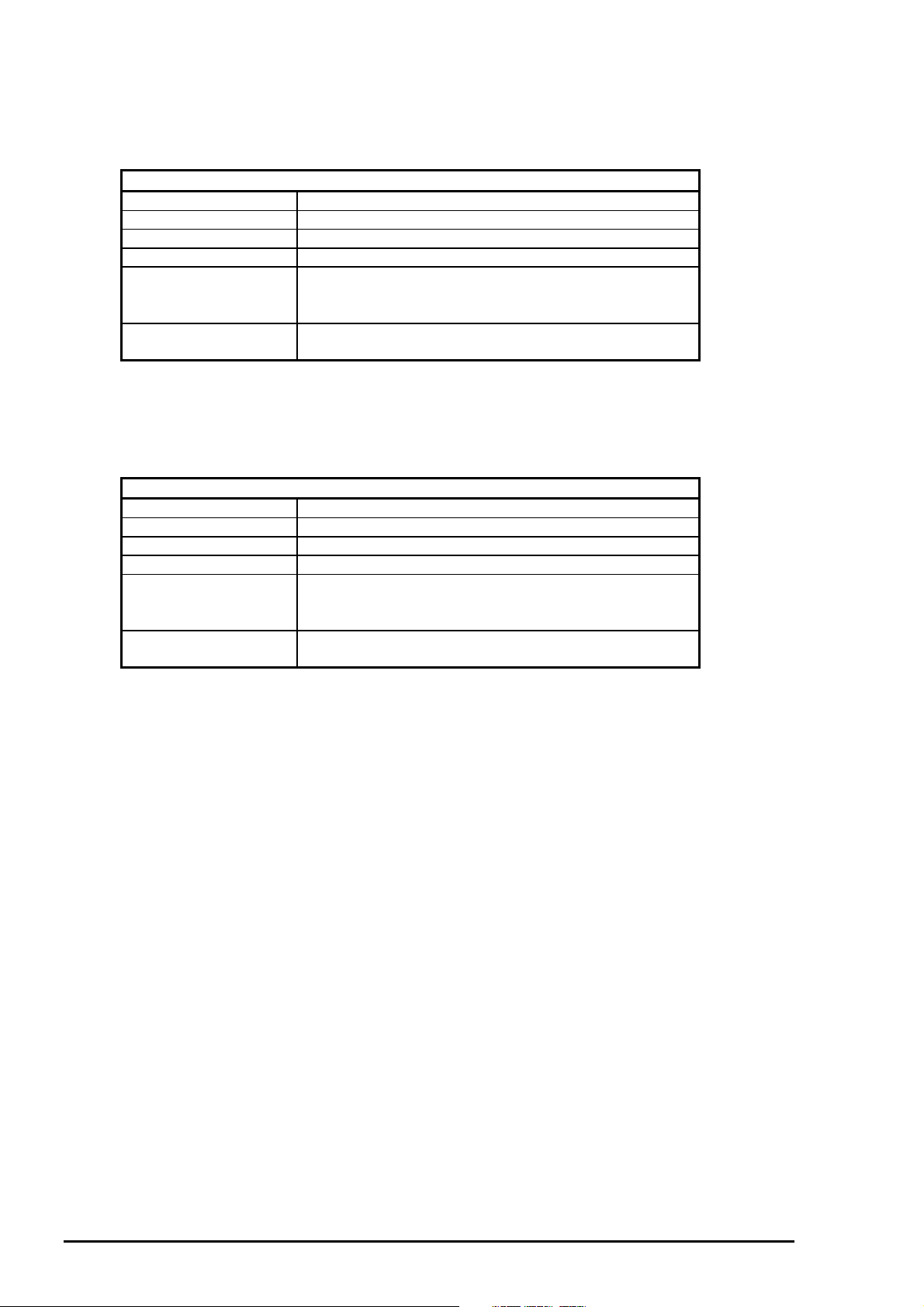

Table 0-13. Black Ink Cartridge Specifications

Black Ink Cartridge

Type Exclusive ink cartridge

Color Black

Print capacity 900 pages / A4 (ISO/IEC10561 Letter Pattern at 360 dpi)

Ink life 2 years from indicated production date

Storage Temperature

At storage : -20 •• to 40 ••

At packing storage : -30 •• to 40 ••

At transit (Packed) : -30 •• to 60 ••

Dimension 30 mm (W) X 58 mm (D) X 38.5 mm (H)

(1.22” X 2.36” X 1.57”)

*1 : Within a month at 40 ••

*2 : Within 120 hours at 60 •• for more than 120 hours.

1.2.8.2 Color ink cartridge

Table 0-14. Color Ink Cartridge Specifications

Color Ink Cartridge

Type Exclusive ink cartridge

Color Magenta, Cyan, Yellow

Print capacity 300 pages A4 (at 360 dpi, 5 % duty each color)

Ink life 2 years from indicated production date

Storage Temperature

Dimension 42.9 mm (W) X 56.5 mm (D) X 38.5 mm (H)

*1 : Within a month at 40 •• for more than a month.

*2 : Within 120 hours at 60 •• for more than 120 hours.

Note)

1. The cartridge must not be refilled. Only ink cartridge is prepared for article of consumption.

2. Do not used the cartridge that has exceeded the ink life.

3. When the ink is frozen under -4°C, leave it for more than 3 hours at the room temperature to defrost

before using.

At storage : -20 •• to 40 ••

At packing storage : -30 •• to 40 ••

At transit (Packed) : -30 •• to 60 ••

(1.75”X 2.30” X 1.57”)

* 1

* 1

* 1 *2

* 1

* 1

* 1 *2

1.2.9 Input Data Buffer

Input data buffer :64 Kbytes

1

Rev. A

Page 21

Product Description

3

1.2.10 Electric Specifications

120 V version

Rated voltage :AC 120 V

Input voltage range :AC 103.5 to 132 V

Rated frequency renege :50 to 60 Hz

Input frequency range :49.5 to 60.5 Hz

Rated current :0.7 A (maximum)

Power consumption :Approximately 21 W (ISO/IEC 10561 Letter pattern)

Conforms to Energy Star program

Insulation resistance :10 M ohms min. (Between AC line and chassis, DC 500 V))

Dielectric strength :AC 1,000 V rms. (1 minute) or AC 1,200 V rms. (1 second)

(Between AC line and chassis)

220 - 240V version

Rated voltage :AC 220 to 240 V

Input voltage range :AC 198 to 264 V

Rated frequency renege :50 to 60 Hz

Input frequency range :49.5 to 60.5 Hz

Rated current :0.4 A (maximum)

Power consumption :Approximately 21 W (ISO/IEC 10561 Letter pattern)

Conforms to Energy Star program

Insulation resistance :10 M ohms min. (Between AC line and chassis, DC 500 V)

Dielectric strength :AC 1,500 Vrms. (1 minute) (Between AC line and chassis)

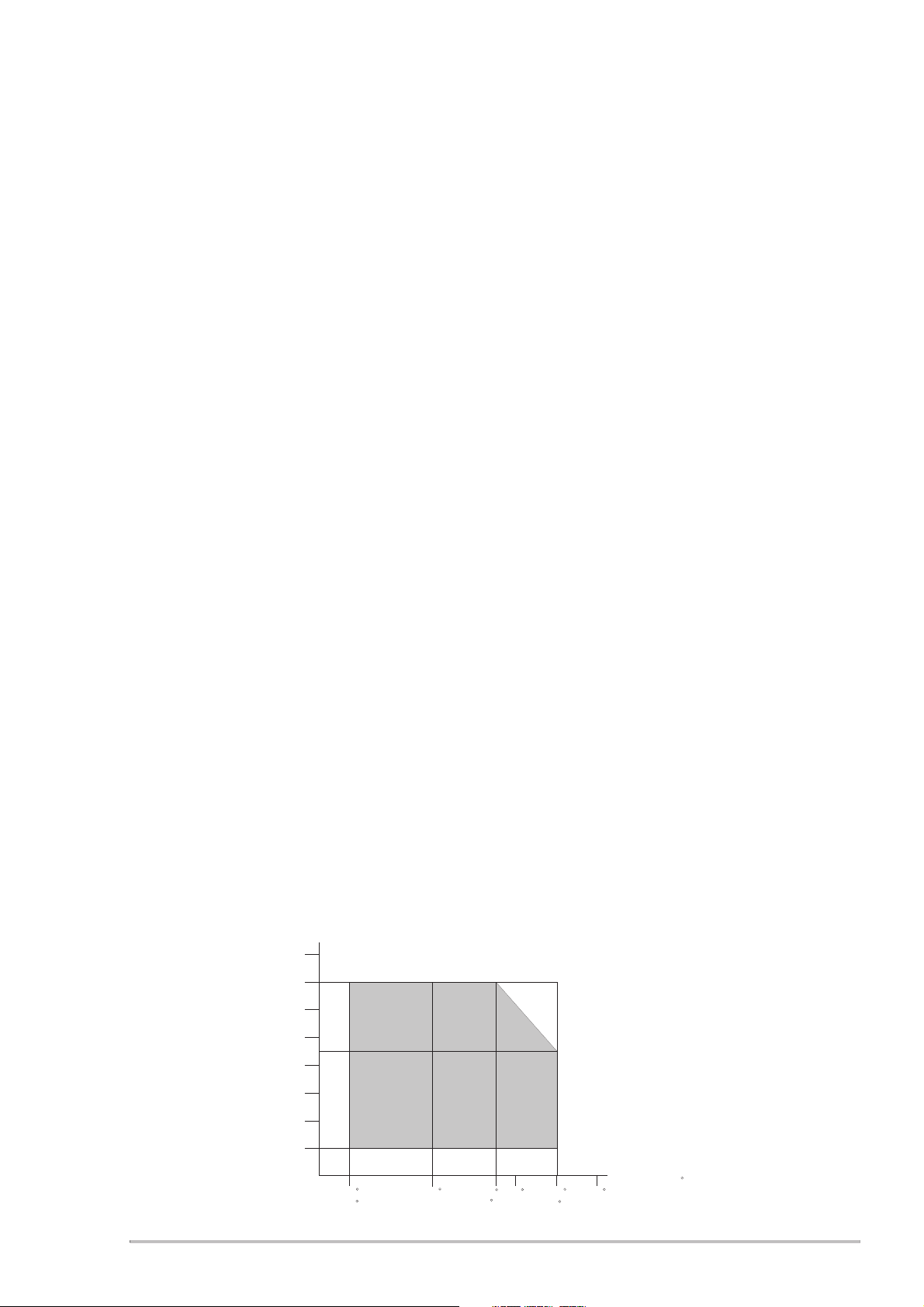

1.2.11 Environmental Conditions

Temperature

Operating*

Non operating*

Humidity

Operating*

Non operating*

Resistance to vibration

Operating :0.15 G

Non-operating*

Resistance to shock

Operating :1 G within 1 ms

Non-operating*

*1 :Refer to the table below for guaranteed range.

*2 :In shipment container.

*3 :Without condensation

1

1

*

2

3

3

2

*

2

2

Humidity (%)

90

80

:10•• to 35••

:-20•• to 40•• ( 1 month at 40••)

-20•• to 60•• (120 hours at 60••)

:20% to 80% RH (without condensation)

:5% to 85% RH (without condensation)

:0.50 G

:2 G within 2 ms

70

60

50

40

30

20

C

10 20

(50 H)

C

27

(80 H)

30

C

C

35

C

(95 H)

Temperature ( )

40

C

C

Figure 0-7. Environmental Conditions

Rev. A

1

Page 22

EPSON Stylus COLOR 1520

4

1.2.12 Reliability

Total print volume :75,000 pages (A4/Lletter)

Print head life :2,000 million dots /nozzle

1.2.13 Safety Approvals

120 V version

Safety standards :UL1950 with D3

CSA22.2 No. 950 with D3

EMI :FCC part15 subpart B class B

220 - 240 V version

Safety standards :EN 60950 (TÜV, NEMKO)

EMI :EN 55022 (CISPR Pub.22) class B

:AS/NZS 3548 class B)

1.2.14 CE Marking

220 - 240 V version

Low Voltage Directive 73/23/EEC :EN60950

EMC Directive 89/336/EEC :EN55022 class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

1.2.15 Acoustic Noise

Noise level :Approximately 45 dB (A) (According to ISO 7779)

1

Rev. A

Page 23

Product Description

5

1.3 Interfaces

1.3.1 Parallel Interface

1.3.1.1 Forward Channel Specifications

Transmission mode :8 bit parallel , IEEE-P1284 compatibility mode

Synchronization :/STROBE pulse

Handshaking :BUSY and /ACKNLG signal

Signal level :TTL compatible level (IEEE-P1284 Level 1 device)

Table 0-15. Signal level of TTL Compatible (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5 V

VOL* -0.5 V -

IOH* - 0.32 mA VOH = 2.4 V

IOL* - 12 mA VOL = 0.4 V

CO - 50 pf

VIH - 2.0 V

VIL 0.8 V -

IIH - 0.32 mA VIH = 2.0 V

IIL - 12 mA VIL = 0.8 V

CI - 60 pf

Note) * : A low logic level on the Logic H signal is as follows:

2.0 V or less when the printer is powered off.

3.0 V or more when the printer is powered on.

The receiver shall provide an impedance equivalent to 7.5 K ohm top ground.

Adaptable connector :57-30360 (Amphenol) or equivalent

The BUSY signal is set high before setting either /ERROR low or PE high and held high until all these

signals return to the inactive state.

The BUSY signal is at high level in the following cases:

During data entry (see Figure 0-8. Data Transmission Timing below.)

When the input data buffer is full

While /INIT signal is at low level or during hardware initialization

During a printer error condition (See /ERROR signal)

During test printing

When the printer is in default setting mode

When the parallel interface is not selected

The ERROR signal is at low level when one of the following errors has occurred:

Printer hardware error (fatal error)

Paper-out error

Paper-jam error

Ink-out error

The PE signal is high level during paper-out error.

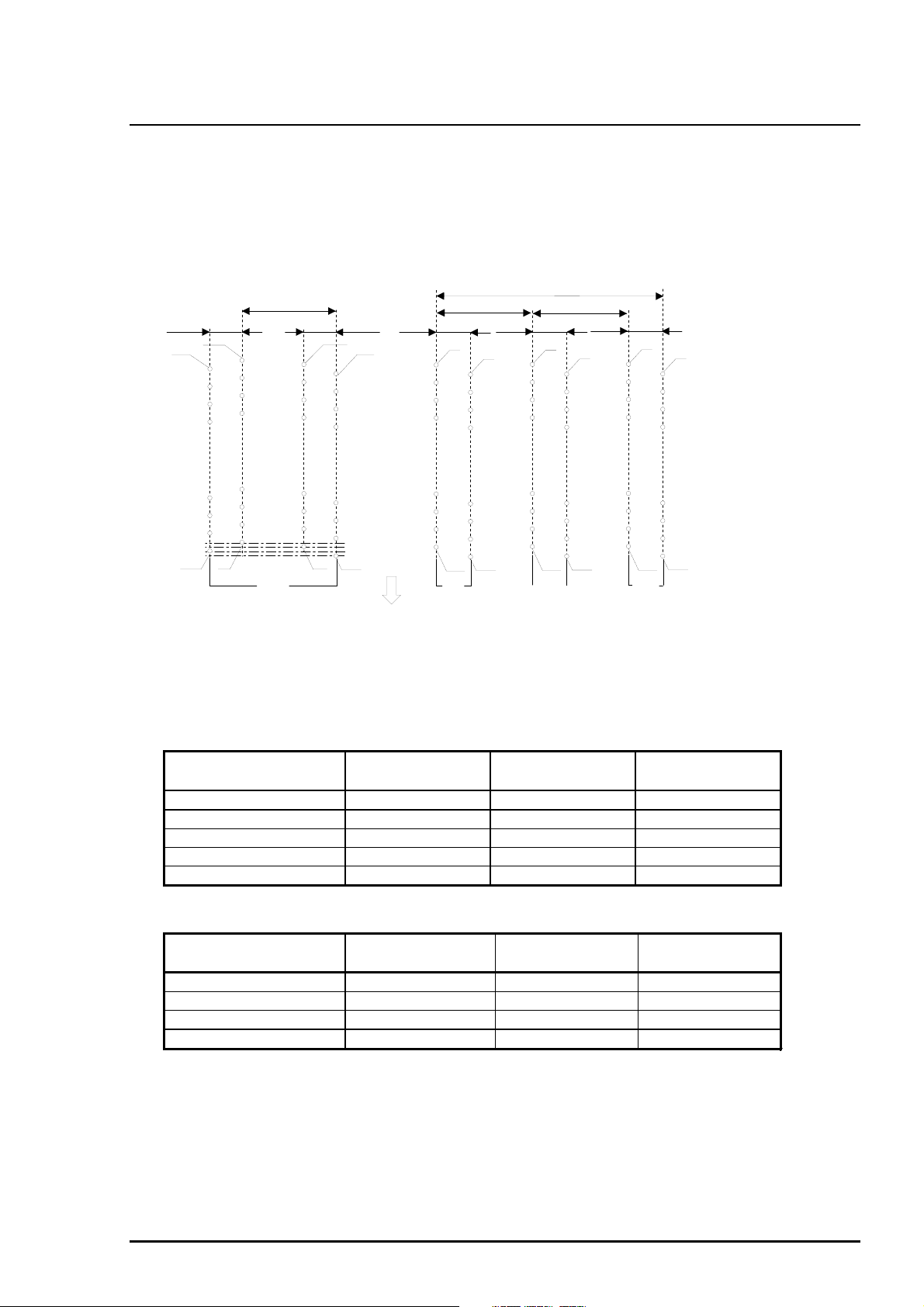

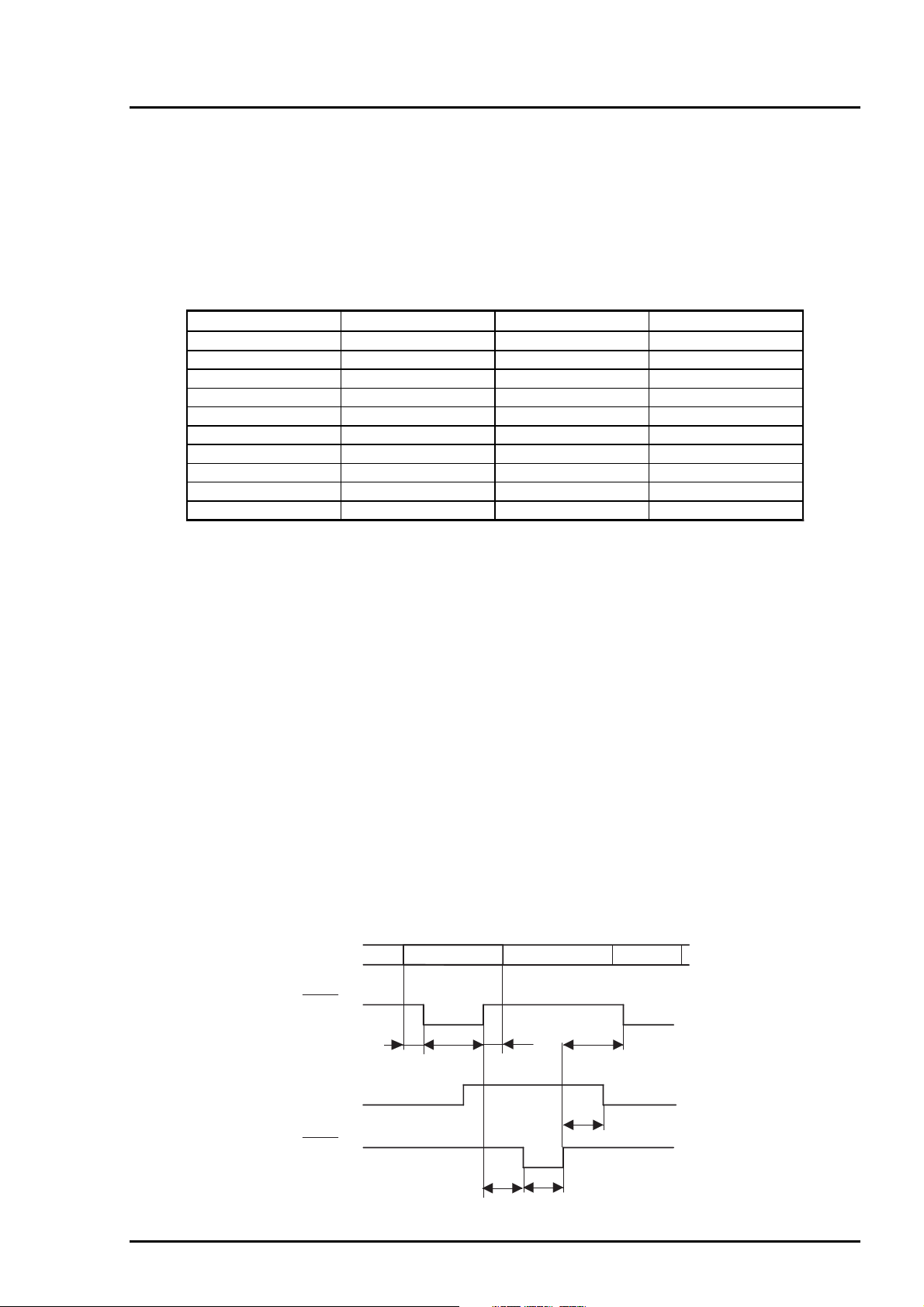

DATA

STORBE

0.5 us (min.)

BUSY

ACKNLG

DATA (n)

0.5 us (min.)

0 (min.)

DATA (n+1)

0.5 us (min.)

0 (min.)

0 (min.)

5 us (type.)

Figure 0-8. Data Transmission Timing

Rev. A

1

Page 24

EPSON Stylus COLOR 1520

6

Table 1-16 shows the connector pin assignment and signals for forward channel of the parallel interface.

Table 0-16. Data Transmission Timing

Parameter Minimum Maximum

tsetup 500 ns -

thold 500 ns -

tstb 500 ns -

tready 0 -

tbusy - 500 ns

tt-out* - 120 ns

tt-in** - 200 ns

treply - -

tack 500 ns 10 us

tnbusy 0 -

tnext 0 -

Note) * : Rises and falls in time of every output signals.

**: Rises and falls in time of every input signal.

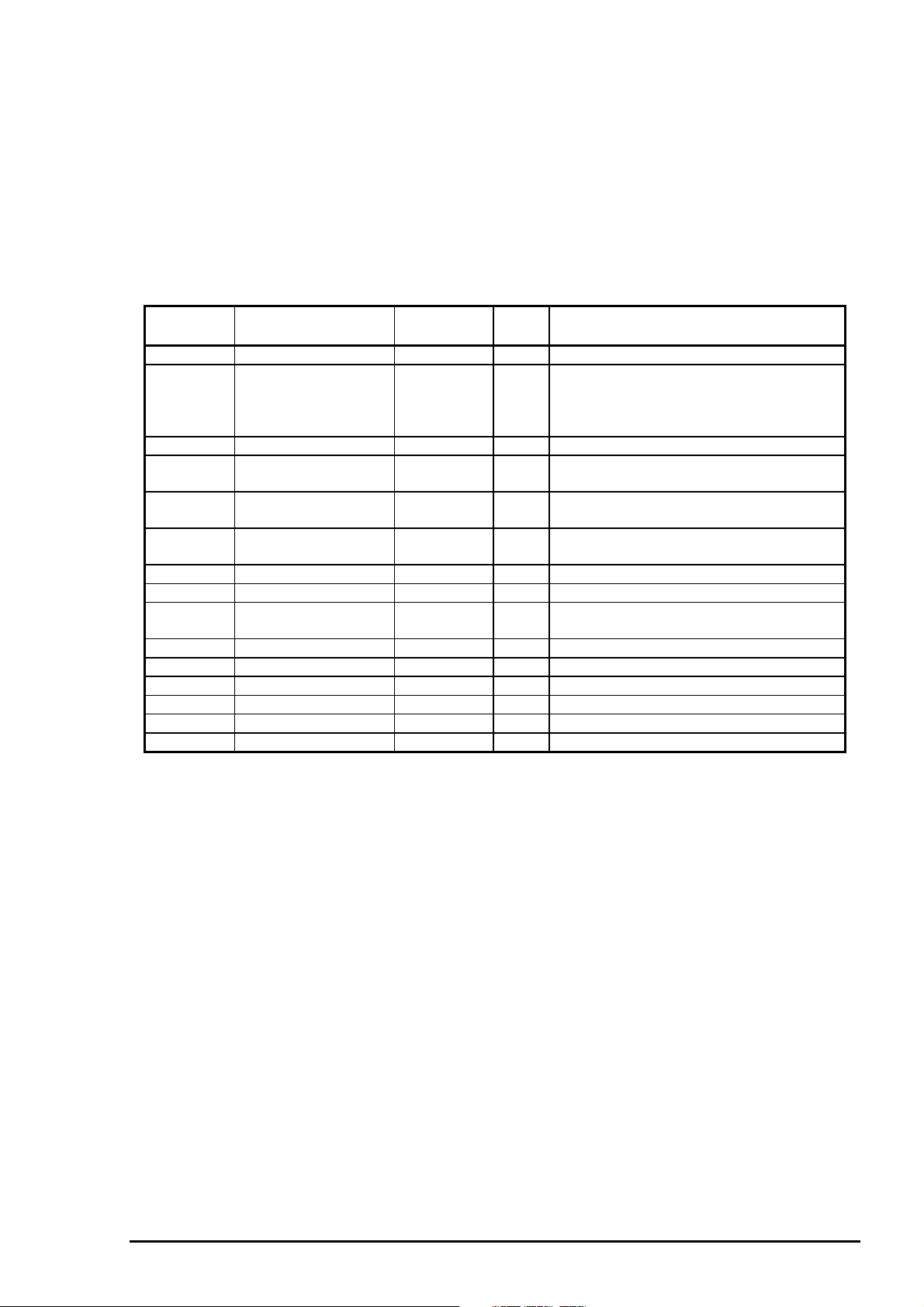

Table 0-17. Connector Pin Assignments and Signals (Forward Channel)

Pin No. Signal Name Return

GND Pin

1 /STROBE 19 I

2-9 DATA 0-9 20-27 I

10 /ACKNLG 28 O This signal is a negative pulse indicating

11 BUSY 29 O When this signal is at high level, the

12 PE 28 O When this sign is at high level, the paper

13 SLCT 28 O Always at high level when the printer is

14 /AFXT 30 I Not used.

31 /INIT 30 I The falling edge of a negative pulse or a

32 /ERROR 29 O When the printer detects an error, this

36 /SLIN 30 I Not used.

18 Logic H - O Pulled up to +5V via 3.9 K ohm resistor.

35 +5V - O Pulled up to +5V via 3.3 K ohm resistor.

17 Chassis GND - - Chassis ground.

16,33,19-30 GND - - Signal ground.

15,34 NC - - Not connected.

I/O Description

The strobe pulse. Read-in of data is

performed at the falling edge of this pulse.

The data 0 to data 7 signals represent

data bits 0 to 7, respectively. Each signal

is at high level when data is logical 1 and

low level when data is logical 0.

that the printer can again accept data.

printer is not ready to accept data.

empty status is detected.

powered on.

low signal on this line causes the printer to

initialize. Minimum 50 us pulse is

necessary.

signal goes low.

Note) 1. */* at the beginning of a signal means active low.

2. The I/O column indicates the diction of the signal as viewed form the printer.

1

Rev. A

Page 25

Product Description

7

1.3.1.2 Reverse Channel Specifications

Transmission mode :IEEE-1284 nibble mode

Adaptable connector :Same as for the forward channel

Synchronization :Refer to the IEEE-1284 specification

Handshaking :Refer to the IEEE-1284 specification

Data transmission timing :Refer to the IEEE-1284 specification

Signal level :IEEE-1284 level 1 device

See the forward channel specification.

Table 1-18 shows the connector pin assignment and signals for reverse channel of the parallel interface.

Table 0-18. Connector Pin Assignment and Signals (Reverse Channel)

Pin No. Signal Name Return

GND Pin

1 HostClk 19 I Clock signal from the host computer.

2-9 DATA 0-7 20-27 I These signals represent parallel data

10 PtrClk 28 O Clock signal from the printer

11 PtrBusy /

Data bits 3,7

12 AckDatareq /

AckData Bits 2,6

13 Xflag/Data bit 1,5 28 O X flag signal.

14 HostBusy 30 I Busy signal from the host computer

31 /INIT 30 I Not used

32 /Data Avail /

Data bits 0,4

36 1284-Active 30 I 1284 active signal.

18 Logic-H - O Pulled up to +5V via 3.9 K ohm resistor.

35 +5V - O Pulled up to +5V via 3.3 K ohm resistor.

17 Chassis GND - - Chassis ground for the printer.

16,33,19-30 GND - - Signalground.

15,34 NC - - Not connected.

29 O Busy signal from the printer.

28 O Acknowledge request signal.

29 O Data available signal.

I/O Description

information on bits 2 to 9.Each signal is

High when the data is logical 1 and low

when the data is logical 0.

Data bit 3 or 7 in reverse channel.

Data bit 2 or 6 in reverse channel.

Data bit 1 or 5 in reverse channel.

Data bit 0 or 4 in reverse channel.

Note) The symbol */* at the beginning of a signal means active low.

Extensibility Request

The printer responds affirmatively when the extensibility request values are 00H or 04H, as follows:

00H :Request Nibble Mode Reverse Channel Transfer.

04H :Request Device ID;

Return Data Using Nibble Mode Rev Channel Transfer.

Device ID

The printer sends following device ID string when it is requested.

[00H] [xxH]

MFG :EPSON;

CMD :ESCP2E, PRPXL;

MDL :Stylus COLOR 1520;

CLS :PRINTER

Note) [00H] denotes a hexadecimal values of zero.

Rev. A

1

Page 26

EPSON Stylus COLOR 1520

8

1.3.2 Mac Serial Interface

1.3.2.1 Serial Interface Specifications

Standard :RS-423 compliance

Synchronization :Synchronous

Bit rate :Approximately 900 Kbps, 1.8 Mbps

Word format :Start bit 1 bit

:Data bit 8 bit

:Parity bit No parity bit

:Stop bit 1 bit

Handshaking :X-ON/XOFF, DTR protocol

Adaptable connector :8-pin mini circular connector

Recommended I/F cable :Apple System Peripheral-8 cable

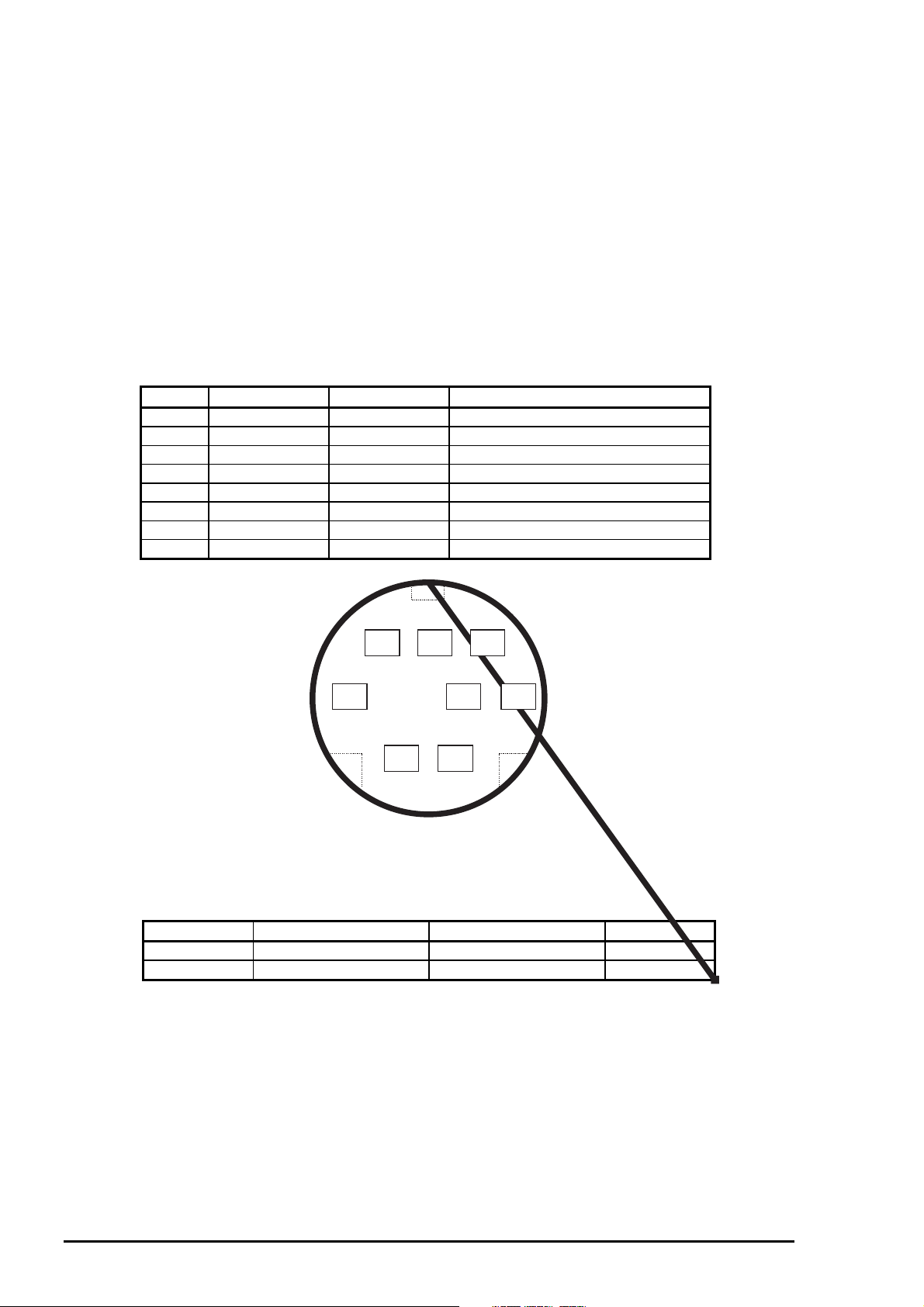

Table 0-19. Connector Pin Assignment for Serial Interface

Pin No. Signal Name I/O Function Description

1 SCLK O Synchronous clock

2 CTS I Clear to send

3 TxD- O Transmit data 4 S.G. I Signal Ground

5 RxD- I Receive data 6 TxD+ O Balanced Transmit +

7 DTR O Data terminal ready

8 RxD+ I Balanced Receive +

8

7

5

2

Figure 0-9.

Serial Interface Connector Pin Assignment

Table 0-20. X-ON/X-OFF, DTR Protocol

State Buffer space X-ON/X-OFF DTR

Busy Less than 1024 bytes Send X-OFF code Off

Ready More than 2048 bytes Send X-ON code On

6

34

1

1

Rev. A

Page 27

Product Description

9

1.3.3 Optional Interface

The EPSON Stylus COLOR 1520 supports an optional Type-B interface (Level 2) with the following

characteristics.

Reply message

When ESC/P2 is selected:

Main type :MTP48p, PW136cl10cpi, PRG(W0xxxx)rev, AP800ma, SPD0fast

Product name :Stylus COLOR 1520

Emulation type :ESCPL2-00

Entity type :EPSONLQ2

When X24E is selected:

Main type :MTP48p, PW136cl10cpi, PRG(W0xxxx)rev, AP800ma, SPD0fast

Product name :Stylus COLOR 1520

Emulation type :PRPXL24-00

Entity type :EPSONPRPXL24

Table 0-21.Reply for Option Command

Option command No. command name Reply-A Reply-B

00h No Operation Accept None

01h Start Hard Ware Reset Accept Excute OK

02h Start Soft Ware Reset Reject

03h Send Main System Type Accept

04h Send Name Data Reject

05h Inquire Name Data Accept

06h Send Product Name Accept

07h Send Soft Ware Emulation Type Accept

08h Complete Buffered Data Accept Check Condition

09h Stop Procedure Reject Execute OK

0Ah Return Buffered Data Reject

0Bh Send Entity Type Accept

0Ch Send Status Accept

0Dh Quit Procedure Reject

0Eh Inquire ASCII Message Reject

0Fh Send ASCII Message Accept None

10h - 13h Unknown None

14h Inquire Emergency Message Accept Execute OK

15h Send Emergency message Accept

16h - 1Fh Unknown None

20h - FFh Reserved None

Table 0-22. Supported Main Command and Sending Timing

Main Command No. Command name Sending Timing

01h Start Software Reset /INIT signal on the std. parallel I/F

Type-B I/F option command : 01h

Cold Start

04h Send Name Data Type-B I/F command : 05h

07h Inquire Software Emulation Name Changing software Emulation Type

0Eh Inquire ASCII Message Writing to DBIN register

14h Inquire Emergency Reply Reply for Emergency command

15h Send Emergency Message Receive Emergency Command

Emergency Command

0X00 :Get device ID

0X01 :Get all status

Sending BDC-ST through DBIN register

When State-Reply is set “ON”, by ST from Type-B I/F, sending BDC-ST through DBIN register is

started. When State-Reply is started, “Start” and “End” of BDC-ST characters are announced by

sending the Main command 0Eh.

Rev. A

1

Page 28

EPSON Stylus COLOR 1520

0

1.3.4 Prevention Hosts from Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when a peripheral is in the busy state for dozens of

seconds continuously. To prevent hosts from this kind of time-out, the printer receives data very slowly,

several bytes par minute, even the printer is in busy state. This slowdown starts when the rest of input

buffer drops under several hundreds of bytes. Finally, the printer is in the busy state continuously when the

input buffer is full.

1.3.5 Interface Selection

The EPSON Stylus COLOR 1520 has three types of interface available :Parallel, Serial, and optional

interfaces. Each interface can be selected manually or automatically. Both modes are selected thorough

the default setting mode.

Manual selection

The interface selected through the default setting mode always prints out data from the host.

Automatic selection

When the printer is in this mode, the printer is initialized to the idle state when it is turned on. Then the

interface that receives data first will print. When the host stops data transfer and the printer is in the

stand-by state for the specific time, the printer returns to the idle state. As long as the host sends data

or the printer interface is buy state, the selected interface remains active.

Interface State and Interface Selection

When the parallel interface is not selected, the interface goes into the busy state. When the serial

interface is not selected, the interface sets the DTR signal MARK. When the printer is initialized or

returned to the idle state, the parallel interface goes into the ready state and the serial interface sets the

DTR signal SPACE. Caution that the interrupt signal such as the /INIT signal on the parallel interface is

not effective while that interface is not selected.

1.3.6 Printer language and Contr ol Codes

Printer languages and control codes :ESC/PC

:IBM X24E

:EPSON Remote

2

Rev. A

Page 29

Product Description

1.4 Operation

This section describes the controls, settings and adjustment used to operate the EPSON Stylus COLOR

1520.

1.4.1 Control Panel

The control panel of this printer consists of 6 non-lock push switches, 1 lock type push switch, and 6 LED

indicators for easy operation of the various printer functions. Refer to

Figure 0-10 for button and LEDs descriptions and how they are arranged.

(1)

(2)

(3)

(4)

(5)

(6)

Indicators

(1) Cover Open

(2) Operate

(3) Ink Out (Black)

(4) Ink Out (Color)

(5) Paper Out

(6) Pause

5sec

Reset

Operate

Cover Open

Micro Feed

Ink Out

Ink Out

Paper Out

Micro Feed

Figure 0-10. Control Panel Appearance

Alt

LF/FF

Cleaning

Load/Eject

Cleaning

Rev. A

21

Page 30

EPSON Stylus COLOR 1520

2

Panel Functions :The function of each button is described below.

1

Power Function :Turns the printer off or on *

Available condition :Always

Load/Eject Function :Loads and ejects the paper.

Available condition :Pause/Stand-by

LF/FF Function :Feeds one line or page.

Available conditions :Pause / Stand-by

Pause Function :Alternates the printer state between printing and non-

printing.

Available conditions :Pause / Stand-by

Function : Pressing this button for 3 seconds resets the printer.

Available condition :Pause / Stand-by

.

Micro-adjust ↑ Function :Feeds paper forward and is used to execute TOF

adjustment *

Available conditions :Pause / Stand-by

Micro-adjust ↓ Function :Feeds paper backward and performs TOF adjustment *

and Tear off adjustment *3.

Available conditions :Pause / Stand-by

Cleaning (Black)

Function :Executes the black ink cartridge cleaning.

Available condition :Pause

Cleaning (Color)

Function :Executes the color ink cartridges cleaning.

Available condition :Pause

Alt Function :Enters ink cartridge change mode. Pressing this button

for 3 seconds moves the ink cartridge to the position to

be replaced.

Available conditions :Pause / Ink out

2

and Tear off adjustment *3.

Note)

1. Before the printer power is off, the printer executes the capping function.

2. When the micro adjust is performed at the TOF (Top Of Form position) for the ASF manual and

tractor feed, the new setting is stored in the corresponding address in the EEPROM.

3. When the micro adjust is performed at the tear off position, the new setting is stored in the

corresponding address in the EEPROM

2

CAUTION

;

The power switch is connected to the secondary side of the electrical circuit. Since it has a delay

circuit, voltage is still applied for the specified period of time after the printer power is off.

;

As long as the printer is plugged in, voltage is applied to the primary side of the electrical circuit.

Therefore be sure to unplug the printer before servicing or replacing the interface.

2

Rev. A

Page 31

Product Description

3

1.4.2 Panel Functions at Power On

This printer also enters various functions by turning on the printer while holding down a button

( buttons). Each combination and corresponding function is described in the table below.

Table 0-23. Panel Functions at Powered On

Switch *

(while turning on the printer)

Micro adjust ↓

Pause Enters printer adjustment mode. (See Section 1.4.5.)

Load /Eject Enters LQ self-test printing mode.

LF/FF Enters draft self-test printing mode.

LF/FF + Load/Eject Enters hex-dump mode.

Alt + LF/FF + Load/Eject

+ Micro adjust ↑

Note) 1.”+” means to press one button while holding down the other button(s).

2.EEPROM and Timer IC must be reset only by qualified service personnel.

1

Enters default setting mode. (See Section 1.4.4.)

Enters EEPROM and Timer IC reset *

Function

2

mode.

CAUTION

When performing EEPROM reset operation, waste ink drain pads must be replaced. Therefore

EEPROM reset is to be performed by a qualified service person only. (See Chapter 3.)

Rev. A

2

Page 32

EPSON Stylus COLOR 1520

4

1.4.3 Printer Condition and Panel Status

This printer has several printer conditions that are indicated by the LEDs on the control panel When any of

the errors listed below occurs, the printer indicates an error condition and the /ERROR signal goes “Low”

and Busy signal goes “High” to stop data transfer. This condition automatically puts the printer into

“Pause” status.

The carriage moves abnormally. (Fatal error)

Paper out or Paper jam condition is detected.

The PG for the paper currently loaded is inaccurate.

No ink cartridge or Ink end condition is detected.

Maintenance is required.

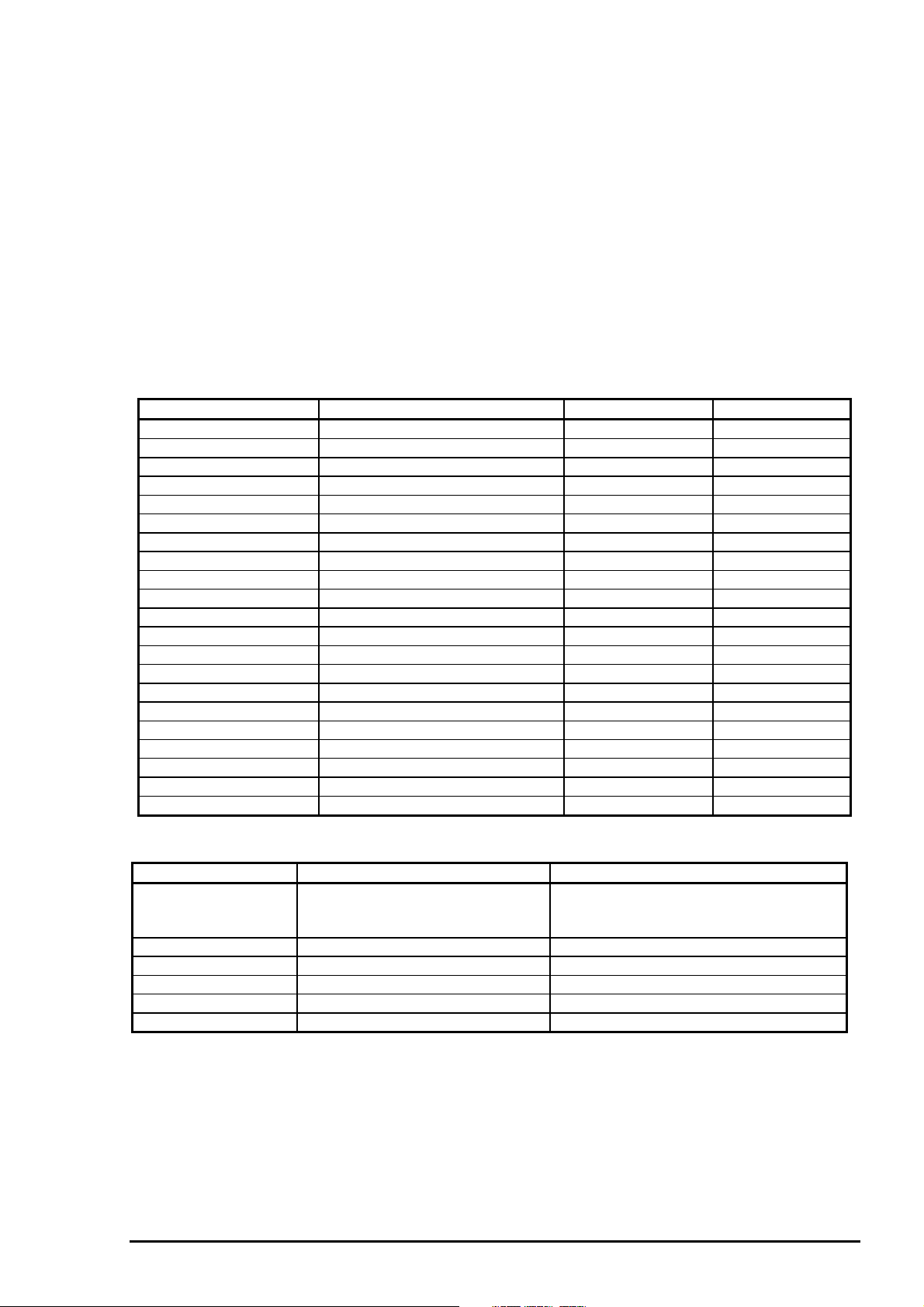

Table 0-24. Printer Condition and Panel Status

Indicators

Printer status Power Cover Open Ink out

(black)

Power on On „Ÿ „Ÿ „Ÿ „Ÿ „Ÿ

Cover open „Ÿ On „Ÿ „Ÿ „Ÿ „Ÿ

Paper out „Ÿ „Ÿ „Ÿ „Ÿ On „Ÿ

Paper jam „Ÿ „Ÿ „Ÿ „Ÿ Blinks „Ÿ

No ink cartridge or

ink end (black)

Ink level low (black) „Ÿ „Ÿ Blinks „Ÿ „Ÿ „Ÿ

No ink cartridge or

ink end (color)

Ink level low (color) „Ÿ „Ÿ „Ÿ Blinks „Ÿ „Ÿ

Enter EEPROM and

Timer IC reset

Maintenance request Blinks Blinks Blinks Blinks Blinks Blinks

Fatal error „Ÿ Blinks „Ÿ „Ÿ „Ÿ Blinks

Lever error „Ÿ „Ÿ „Ÿ „Ÿ Blinks Blinks

Capping function in

the power off

Data exit Blinks „Ÿ „Ÿ „Ÿ „Ÿ „Ÿ

In the sequence of

ink cartridge change

mode

Default setting mode Blinks „Ÿ „Ÿ „Ÿ „Ÿ „Ÿ

„Ÿ „Ÿ On „Ÿ „Ÿ „Ÿ

„Ÿ „Ÿ „Ÿ On „Ÿ „Ÿ

On

1 second

Blinks „Ÿ „Ÿ „Ÿ „Ÿ „Ÿ

„Ÿ „Ÿ „Ÿ „Ÿ „Ÿ Blinks

On

1 second

On

1 second

Note)

1. “” means no effect.

2. Fatal error is cleared by turning off and back on the printer or by inputting the /ITIT signal after the

problem is solved.

3. Maintenance is required when the wasted ink drain pads are filled with the wasted ink to the specified

limit. On this condition servicing is needed. To clear the condition, perform EEPTOM reset operation.

(See Section 1.4.2 “Panel function at power on”) Refer to Chapter 2 or Chapter 3.

Ink out

(color)

On

1 second

Paper Out Pause

On

1 second

On

1 second

2

Rev. A

Page 33

Product Description

5

1.4.4 Cover Open Sensor Operation

The cover open sensor equipped with this printer controls the carriage movement which has a possibility

to hurt the user. The sensor performs followings:

The printer cover opens during printing:

The CR returns to the home position slowly after executing printing for the current pass. The cover

open LED lights up and the printer goes into the stand-by status.

To recover, close the cover and press the pause button to continue to print. The cover open LED

goes off with the recovery.

The printer cover opens during cleaning:

The printer completes the cleaning sequence. If the cover is still open after the cleaning, the cover

open LED lights up and the printer goes into the stand-by status.

To recover, close the cover and press the pause button to continue to print. The cover open LED

goes off with the recovery.

The printer cover opens While the printer is in the stand-by status:

The cover open LED lights up and the printer stops functioning. *

To recover, close the printer cover.

*1 :The interface is in the Busy status and the switches on the control panel are effective.

1

1.4.5 Default Setting

This printer has user-selectable default settings to which it refers at initialization. This section describes

setting method and setting menus.

1.4.5.1 Setting Method

See the flow chart in Page 1-26 for the default setting method.

CAUTION

;

Be sure to turn off the printer off once after the default setting operation is executed, since

adjustment values are not stored in the EEPROM until the printer is turned off.

;

The latest adjustment values set before power-off are stored in the EEPROM.

Rev. A

2

Page 34

EPSON Stylus COLOR 1520

6

Start

Press the Pause button,

on the printer.

The printer prints the instruction

sheet on how to select the language.

1.Move through the languages listed

by pressing the alt button.

2.Select the language by pressing

the Pause button.

The printer prints the instruction

sheet on how to adjust the printer.

Adjust a patterns ?

NO

and

turn

YES

1. Select the appropriate test by

pressing the Alt button.

2. Press the Load/Eject button.

The printer prints the test patterns.

Select the most closely aligned pattern

by pressing the Pause button.

Press the Load/Eject button.

More adjustment ?

NO

Turn the printer off once to save the new settings into the EEPROM.

Figure 0-11. Default Setting Flow Chart

YES

2

Rev. A

Page 35

7

1.4.5.2 Setting Menus

The default setting menus are described in the table below.

Table 0-25. Default Setting Menu

Menu Setting *

Print direction*

Font

2

/ Bi-d / Uni-D

Auto

Roman / Sans Serif /

Courier

/ Prestige / Script/

Roman T / Sans Serif H / Draft

Pitch

I/F mode

Auto I/F wait mode

Software

Auto CR (IBM mode only)

AGM (IBM mode only)

Character tables

Standard version

10 cpi

Auto

10 seconds

ESC/P2

On /

On /

Italic

PC 437

/ 12 cpi / 15 cpi / 17.1 cpi / 20 cpi / Proportional

/ Parallel / Mac Serial / Option

/ 30 seconds

/ IBM X24E

Off

Off

, PC 850

PC 860, PC 863

PC 865, PC 861

BRASCII, Abicomp

Roman 8, ISO Latin 1

PC 437 (Greek), PC 853

PC 855, PC 852

PC 857, PC 866

PC 869, MOZOAWIA

Code MJK, ISO 8559-7

ISO Latin 1T, Bulgaria

PC 774, Estonia

ISO 8859-2, PC 866 LAT

International character set

for Italic table

Italic USA

Italic Germany, Italic U.K

, Italic France

Italic Denmark, Italic Sweden

Italic Italy, Italic Spain 1

Auto line feed

On /

Off

Network I/F mode This mode is for network environment.

: Used in usual environment

Off

On: Used in network environment

0 slash 0 / 0 with slash

Page length 11 inch / 12 inch / 8.5 inch / 70/6 inch / other

Skip over perforation

Auto tear off

Banner mode *

3

Parallel I/F transfer rate

On /

On

On /

Fast

Off

/ Off

Off

/ Normal

Note) 1. Underlined parameters in bold letter are factory default settings.

2. Refer to Table 1-26 and Table-27.

3. Refer to Table 1-28..

1

Product Description

Rev. A

2

Page 36

EPSON Stylus COLOR 1520

8

Table 0-26. Print Direction Mode Characteristics

Black and White Printing YMCK Printing (color)

Auto y Throughput and quality is better. y Throughput is better.

Bi-D y Throughput is the best.

y Print quality may be down.

Uni-D y Throughput is worse.

y Print quality is the best.

Table 0-27. Printing Direction and ESC U Command

y Color quality with special paper is

worse.

(Color correction depends on the print

direction.)

y Throughput is the best.

y Color quality with special paper is worse.

(Color correction depends on the print

direction.)

y Throughput is worse.

y Color quality is the best.

Character Mode

(for DOS)

ESC U 0 Auto Bi-D

Auto ESC U 1 Auto Uni-D

ESC U 2 Auto Auto

ESC U 0 Bi-D Bi-D

Default Bi-D ESC U 1 Uni-D Uni-D

Setting Mode ESC U 2 Auto Auto

ESC U 0 Uni-D Bi-D

Uni-D ESC U 1 Uni-D Uni-D

ESC U 2 Uni-D Auto

Table 0-28. Vertical Print Position in the manual Insertion

Trigger Banner mode Off

(manual insertion operation)

Command FF 1. Case that page length is set

by ESC (C

→ Eject

2. Case that page length is not

set by ESC (C

→ Advances to the top margin of the next page

ESC EMR No operation No operation

Switch FF Eject Advances to the top-margin position

Eject Eject (maximum 44 inches) Advances to the top-margin position

Data Over the page length

set by command

Over the paper

length

1. Case that page length is set

by ESC (C

→ Eject

2. Case that page length is not

set by ESC (C

→ No operation

Eject Eject

Auto Auto

Bi-D Bi-D

Uni-D Uni-D

Function

Advances to the top-margin position

of the next page.

of the next page.

of the next page.

No operation

Taster Graphics Mode

(for Windows / Mac)

Banner mode On

2

Rev. A

Page 37

Product Description

9

1.4.6 Printer Adjustment Mode

The EPSON Stylus COLOR 1520 allows users to adjust the printing direction and head gap without a

special program. The following chart shows the adjustments method .

1.4.6.1 Adjustment Method

Start

Press the Pause button,

on the printer.

The printer prints the instruction

sheet on how to select the language.

1.Move through the languages listed

by pressing the alt button.

2.Select the language by pressing

the Pause button.

The printer prints the instruction

sheet on how to adjust the printer.

Adjust a patterns ?

NO

and

turn

YES

1. Select the appropriate test by

pressing the Alt button.

2. Press the Load/Eject button.

The printer prints the test patterns.

Select the most closely aligned pattern

by pressing the Pause button.

Press the Load/Eject button.

Turn the printer off once to save the new settings into the EEPROM.

Figure 0-12. Printer Adjustment Flow Chart

1.4.6.2 Adjustment patterns

Table 0-29. Printer Adjustment Patterns

Pattern Menu

Pattern 1 Uni-dir adjustment at 400 cps (with an increment of 1/1,440 inch)

Pattern 2 Bi-dir adjustment at 400cps (with an increment of 1/1,440 inch)

Pattern 3 Bi-dir adjustment at 200cps (with an increment of 1/1,440 inch)

Pattern 4 Head gap adjustment between black and color to the cross feed

direction at 200 cps (with an increment of 1/720 inch)

Pattern 5 Head gap adjustment between black and color to the cross feed

direction at 100 cps (with an increment of 1/720 inch)

More adjustment ?

NO

YES

Rev. A

2

Page 38

EPSON Stylus COLOR 1520

0

1.4.7 Printer Initialization

This printer has three initialization types: Power-on initialization, Operator initialization, and Software

initialization.

Power-on Initialization

This printer is initialized when turning on the printer. Then the printer recognizes the cold reset command

(Remote RS command). When the printer is initialized, following actions are performed:

Initialize the printer mechanism.

Clears input data buffer.

Clears download character set.

Clears print buffer.

Sets default values.

Operator Initialization

This printer is initialized when Pause button is pressed for 3 seconds, or the printer recognizes the /INIT

signal (negative pulse) of parallel interface. When the printer is initialized, following actions are performed:

Clears input data buffer.

Clears download character set.

Clears print buffer.

Sets default values.

Software Initialization

This initialization is performed by the ESC @ commend and the following actions are performed:

Clears print buffer.

Sets default values.

1.4.8 Self-test Printing Mode

This printer has the self-test printing mode. Following items are checked by performing this mode.

Function for the control circuit board

Function for the printer mechanism

Print quality

The printer enters the LQ self-test printing mode by pressing the Load/eject button while turning on the

printer. To enter the draft self-test printing mode by pressing the LF/FF button while turning on the printer.

1.4.9 Hexadecimal Dump Function

Pressing the LF/FF and Load/Eject buttons while turning on the printer activates the hexadecimal dump

mode. Each line has Hexadecimal codes, along with their corresponding letters printed in the right

column. If a received code denotes an unprintable character. Such as a control code, “.” (period) is printed

in the right column. This function enables users to check whether the data from the host is properly

transferred. Turn off the printer to exit the mode.

1.4.10 Monochrome Pri nti ng Mode

When the printer is in the ink end (color) condition, the black ink is substituted to continue to work. In order

to switch to monochrome printing mode, turn the printer off and back on. This mode is also selected by

the command “

ESC (K)

“. The Color select command “

ESC r

” is ignored in this mode.

3

Rev. A

Page 39

1.5 Physical Specification

Weight :6.5 Kg

Dimension :666 mm (W) X 554 mm (D) X 202 mm (H)

(26.2” X 21.8” X 7.9”)

Refer to Appendix for details.

Product Description

Rev. A

31

Page 40

EPSON Stylus COLOR 1520

2

1.6 Main Components

The main components of the EPSON Stylus COLOR 1520 are designed for easy removal and repair.

They are as follows:

Main control board :C211 MAIN Board

Power supply board :C172 PSB/PSE Board

Control panel bard

Printer mechanism :M-4160

Housing

1.6.1 C211 MAIN Board

This board consists of a 16-bit CPU (IC7) (clock wave : 19.66Mhz), gate arrays B05B33 (IC8) and B05B34

(IC6), PROM (IC14), MROM (IC12), DRAMs (IC9, 10), RESET ICs (IC1, 4), EEPROM (IC2), two motor

drive ICs, printhead drive circuit, and so on.

Serial Interface IC

MROM

DRAM 4M

PROM 8M

Reset IC

Timer IC

Gate Array E05B33CPULithium Battery

PF Motor Drive IC

Gate Array E05B34

EEPROM

Figure 0-13. C211 MAIN Board Component Layout

Printhead Common Drive Circuit

CR Motor Drive IC

3

Rev. A

Page 41

Product Description

3

1.6.2 C172 PSB/PSE Board

This board consists of a transformer, switching FET, regulator IC, diode bridge, fuse, and so on.

Fuse

Regulator IC

Transformer

Diode Bridge

Figure 0-14. C211 PSB/PSE Board Component Layout

Switching FET

Rev. A

3

Page 42

Chapter 2

Operating Principles

2.1. Overview...............................................................................................................2-1

2.2. Printer Mechanism Operating Principle ............................................................2-1

2.2.1.1. M-4I60 Printer Mechanism .......................................................................................2-1

2.2.2. Printing Mechanism ..............................................................................................................2-2

2.2.2.1. Printhead Structure .................................................................................................. 2-2

2.2.2.2. Printing Process .......................................................................................................2-3

2.2.2.3. Printing Methods.......................................................................................................2-3

2.2.3. Carriage (CR) Mechanism..................................................................................................... 2-5

2.2.4. Paper Feed Mechanism.........................................................................................................2-6

2.2.4.1. ASF (Auto Sheet Feeder) Mechanism ..................................................................... 2-7

2.2.4.2. Tractor Mechanism................................................................................................... 2-8

2.2.4.3. Manual Feed Mechanism......................................................................................... 2-8

2.2.5. Platen Gap (PG) Adjust Mechanism .................................................................................... 2-9

2.2.6. Ink System............................................................................................................................ 2-10

2.2.6.1. Pump Mechanism....................................................................................................2-11

2.2.7. Capping Mechanism............................................................................................................ 2-14

2.2.7.1. Wiping/CR Lock Mechanism..................................................................................2-15

2.3. Electrical Circuit Operation Principles............................................................2-16

2.3.1. C172 PSB/PSE Electrical Circuit Board............................................................................. 2-16

2.3.2. C211 MAIN Control Board................................................................................................... 2-18

2.3.2.1. Reset Circuits.........................................................................................................2-20

2.3.2.2. Sensor Circuits.......................................................................................................2-20

2.3.2.3. CR Motor Driver Circuits ........................................................................................ 2-22

2.3.2.4. PF Motor Driver Circuit........................................................................................... 2-23

2.3.2.5. Printhead Driver Circuit .......................................................................................... 2-24

2.4. Ink System Management...................................................................................2-27

2.4.1. Ink System Operations........................................................................................................ 2-27

2.4.2. Counters............................................................................................................................... 2-28

Page 43

Operating Principles

2.1 Overview

This chapter describes the operating principle of the printer mechanism and electrical circuit.

2.2 Printer Mechanism Operating Principle

2.2.1.1 M-4I60 Printer Mechanism

This printer is composed of the printhead unit, paper feeding m echanism, CR m echanism and the pump

mechanism. T he block chart for the printer mechanism is shown in Figure 2-1. T he printer mec hanism of

this printer has 2 motors: CR m otor and PF motor. The torque from the CR motor m oves the CR in the

column direction. The torque from the PF motor is transm itted to 2 ways: to the paper feeding m echanism

and to the pump mechanism . T he direction is determ ined by the CR position. T he release lever trans mits

the torque from the PF motor to the tractor side to feed continuous paper.

Release Lever

Disengage Mechanism

Push Tractor Mechanism

PF Motor

Paper Feed Mechanism

CR Motor

ASF Mechanism

(For Cut sheet only.)

`Pump Mechanism

CR Unit

Black

Color

Figure 2-1. Printer Mechanism Block Diagram

Rev. A

2-1

Page 44

EPSON Stylus

2

&2/25

1520

2.2.2 Printing Mechanism

The printing method used for this printer is On-dem and ink jet, sam e as for other EPSON ink jet printer s.

The new method used for the printhead enables the printer to produce output in high quality at a higher

speed. The printing mechanism has 2 parts: ink cartridge and printhead. The ink cartridge is filled with ink.

2.2.2.1 Printhead Structure

The printhead for this printer has the black head and color head. The structures of the printheads are

basically the same except for the nozzle configuration. The black head, used for the black ink only, is

composed of 128 nozzles (32 nozzles for each of 4 rows) The color head, composed of 3 heads for

Magenta, Cyan, and Yellow, has 64 nozzles (32 nozzles for each of 2 rows) for each color.

Printhead Driver Circuit Board

Nozzle Plate

To the ink cartridge.

Piezo

Cavity

2-

Nozzle

Figure 2-2. Printhead Structure

Rev. A

Page 45

Operating Principles

3

2.2.2.2 Printing Process

Steps bellow describe how the ink is ejected from each nozzle with the on-demand ink jet system.

<

Step 1>Normal state

No print signal is applied to the PZT. In this state, the PZT does not displace and no pressure is added

inside the cavity. Therefore the pressure in the cavity is kept at a constant level.

<

Step 2>Ejecting state

Print signal is applied to a specific nozzle by the head driver circuit to drive the PZT of the nozzle. The

voltage which drives the PZT is produced in the common driver circuit board on the control board. W hen

the voltage is applied to the PZT, the PZT displaces and the press ure in the cavity changes. T hen the ink

is ejected as a result.

Normal State

Cavity

Nozzle

Figure 2-3. Printing Operation States

When no print s ignal is applied to the PZT, the PZT recovers f rom the displaced s tatus . With this proc es s,

the cavity also returns to its normal size, which brings the pressure negative. T he negative press ure in the

cavity then absorbs the ink from the cartridge to fill the cavity with the ink again for the next printing

motion. The ink which was not us ed for printing adheres on the nozzle surface and increases viscosity in

the nozzles, and it causes printing malfunction. T herefor e the ink is per iodically absorbed and wasted into

the waste ink drain pads by the pump mechanism . Ink viscosity varies depending on the temperatures

around the head. Since the change in the ink viscosity causes decreas in the print quality, the thermistor is

attached to the black head driver circ uit board to control the drive voltage at the proper level ref erring to

the detected head temperature.

Piezo

Ejected Ink

Ejecting State

2.2.2.3 Printing Methods

This printer has following special printing modes to print various types if graphic image.

Double Firing Normal dot / One dot printing mode

This printer forms 1 dot with double ink ejections in the ANK or bitmap image mode. In the raster

graphics mode which requires a high-resolution-printing, however, forms 1 dot with a single ink

ejection.

EPSON Micro dot printing

Both black and color printings can be performed in the normal dot printing mode and EPSON micro

dot printing mode. In the normal dot printing mode, the printer uses less ink to create sharper dots.

Therefore the gradation range is expanded with more delicate tone. This mode is available when the

1440X720-dpi-paper or glossy film is selected.

Micro Weave Printing

In this mode, nozzles to be activated are divided and only specific nozzles are used for each pass.

The paper is also fed in a smaller increment for this operation. This mode eliminates white banding

that occurs between lines to improve graphic images. Decrease in paper feed speed is, however,

inevitable. The Micro Weave printing can be selected through the printer driver.

Rev. A

2-

Page 46

EPSON Stylus

4

Paper Type 180 dpi 360 dpi 720 X 360 dpi 720 dpi 1440X720 dpi

&2/25

1520

Table 2-1. Special Printing Availability

Black printing for the raster data

360 dpi

exclusive paper

720 dpi

exclusive paper

OHP sheet

Glossy film

Glossy paper

Normal paepr 2 dot printing

Normal dot

Micro Weave

2 dot printing

Normal dot

Micro Weave

2 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

Color printing for the raster data

360 dpi

exclusive

720 dpi

exclusive

OHP sheet

Glossy film

Glossy paper

Normal paepr 2 dot printing

Normal dot

2 dot printing

Normal dot

Micro Weave

2 dot printing

Normal dot

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

1 dot printing

Normal dot

Micro Weave

For ANK, Bitmap image data

360 dpi

exclusive

2 dot printing

Normal dot

2 dot printing

Normal dot

2-

Rev. A

Page 47

Operating Principles

5

2.2.3 Carriage (CR) Mechanism

The CR mechanism is composed of the CR unit, timing belt, CR guide shaft, paper eject frame, HP

sensor (Home Position s ensor) and CR m otor. The CR motor sends torque to the timing belt to m ove the

CR unit in the both right and left directions along the paper eject fr ame and CR guide shaft. A stepping

motor used for the CR m otor enables the CR unit to move and stop at any position. The CR is primarily

detected at the home position by HP sensor when the printer is turned on and its position is then

controlled by the open loop. Table 2-2 and Table 2-3 show the specification for the CR motor and the CR

motor drive terms, respectively.

Table 2-2 CR Motor Specification