Page 1

Installation Instructions: Epson 1430 CFS

Prerequisite -

Before starting this installation, you MUST test your printer to make sure it is printing

100% correctly. The best way to do this is to first print a Nozzle pattern, using the

printer utility provided by Epson. Once a perfect nozzle pattern is achieved, print 5

copies of the MIS purge6.tif image using the Plain Paper and 360 dpi settings on the

printer. All 5 pages must print without banding or skipping (white spaces). If your

printer cannot do this, do not install the CFS. If you need to run no more than 3

cleaning cycles, get new cartridges. Do not proceed until you can pass these tests. The

Purge6 image can be found on our Purging Procedures page

(http://www.inksupply.com/purging.cfm

)

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 2

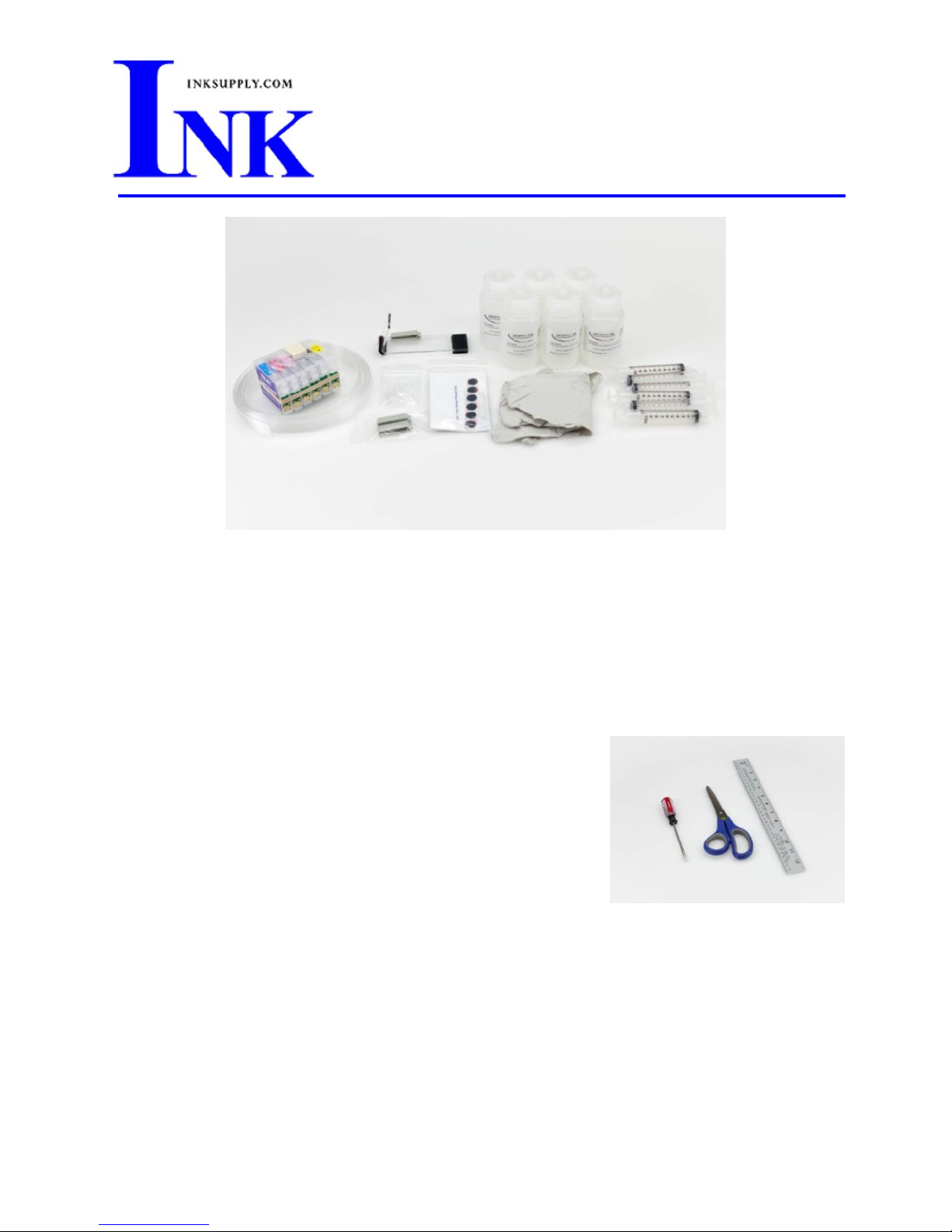

The CFS kit contains:

1x Empty CFS cartridges with tubes.

1x Acrylic Bridge Bracket.

1x Pair gloves.

2x Beige clips.

Installation Instructions

Step 1:

Gather the recommended tools below;

∑ Flat tip screwdriver (1/8" - 1/4")

∑ Scissors

∑ Ruler or Tape Measure

Papers towels and a marker may also be useful.

6x Velcro Dots.

6x Bottles with CFS caps.

6x 10ml syringes (MIS-SYRINGE).

6x Bottom Fill Adapter (MIS-FADP).

Fig. 1

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 3

Step 2:

With the printer on, press the ink change button indicated by

the ink droplet. In Fig. 2, the button is located to the far right.

Step 3:

Fig. 2

Without

powering off the printer, unplug the printer from the

wall.

Step 4:

At this point the printer carriage will be centered in the right

opening in the printer top as shown in Fig. 4-1.

The printer carriage lid is removed in 2 parts. The first involves

removing the right most hinge clip, then releasing the left

hinge pivot point.

Fig. 4-2 shows the location of the right clip. Using the

screwdriver as shown in Fig. 4-3, gently pry the clip to the right

to release it. It may take some force as the clip is held in place

by a plastic barb.

Fig. 3

Fig. 4-1

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Fig. 4-2

Page 4

After the clip is removed, the left side of the cover is easily

removed by inserting the screwdriver into the pivot point and

turning it. This is shown in Fig. 4-3.

Fig. 4-5 shows the cover and the right side clip once they are

removed from the printer.

Fig. 4-3

Fig. 4-4

Step 5:

With the ruler or measuring tape, measure 4.75" from the left

edge of the cross member on the top of the printer as shown in

Fig. 5.

Remove the protective film from the clear acrylic Bridge Bracket

and install it with the right edge of the Bracket lined up with

the edge on the ruler. The Beige Clip on the Bracket should be

on the topside, left as shown if Fig. 5.

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Fig. 4-5

Fig. 5

Page 5

Step 6:

Install the CFS Assembly into the printer carriage routing the

tubes under the cross member as depicted in Fig. 6.

Step 7:

Fig. 7-1 gives a better angle on the routing of the tubes after

the installation of the CFS Cartridge Assembly.

The 2 Beige Clips are used to align the tubes and will be

installed in such a way as to keep the tubes in line from the

Bridge Bracket to the right edge of the printer.

Fig. 6

As shown in Fig. 7-2, the first Beige Clip is installed on the left

side of the cross member in the top of the printer. Fig. 7-3

shows the location and orientation of the second Beige Clip on

the right side top of the printer. This will create a straight line

for the tubing from the Bridge Bracket on the left to the Beige

Clip on the right.

Before closing the Beige Clips on the tubing, slide the printer

carriage to the far right and adjust the tubing to ensure that

the tubing is not pulled tight at the Bridge Bracket, but also

does not hang loose. You will need to slide the printer carriage

from right to left to ensure that the carriage is able to move

with no restriction or resistance from the tubing. If the tubing

becomes tangled or twisted at any point during the carriage's

travel, the tension will need to be adjusted.

Fig. 7-1

Fig. 7-2

Fig. 7-3

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 6

Too Tight Correct Too Loose

Step 8:

Pour the ink from each of your ink bottles into the

corresponding CFS Bottle. This step is very important as

mixing up the inks will irreparably contaminate the CFS

Assembly.

Step 9:

Attach each of the CFS Bottles to the printer using the included

Velcro Dots. To fit all six bottles the first bottle must be

installed at the very front edge of the printer.

From Front to Back the bottle order is as follows;

Cyan - Magenta - Lt. Magenta - Lt. Cyan - Black - Yellow

Fig 8

Fig. 9

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 7

Step 10:

Verify, from Front to Back the bottle order is as follows;

Cyan - Magenta - Lt. Magenta - Lt. Cyan - Black - Yellow

Next, split the excess tubing back to the right most Beige Clip.

Route the front most tube to the Cyan Bottle and using the

scissors, snip the tuba and plug it onto the Cyan Bottle fitting.

Repeat for the remaining tubes. The end result should look like

Fig. 10.

Note: The tubing should route cleanly into the bottle with our

being pulled tight, but also should not be loose enough to

allow the tubes to sag.

Step 11:

Attach a Bottom Fill Adapter (MIS-BADP) to each of the 10cc

Syringes (MIS-Syringe).

Remove the CFS Assembly from the printer carriage and flip it

upside down.

Fig. 10

Using the 10cc Syringe draw 20cc's of air from the Cyan

Fig. 11-1

Cartridge. This will fill the cartridge with ink, but should leave

a 1/2" - 1/4" gap of air in the cartridge. Repeat on the

remaining cartridges using a clean syringe on each cartridge. It

may be helpful to mark the color position on each of the

syringes to keep them organized.

Note: The air gap is critical to proper CFS function. Overfilling

the cartridge can damage the CFS unit or printer.

Fig. 11-2

After filling all six cartridges, flip the CFS right side up and,

starting with the Cyan Cartridge, use the 10cc syringe to draw

2cc's of ink from the bottom of the cartridge. Again, it is

important to use the same syringe that was used to prime the

Cyan Cartridge. Repeat with the remaining cartridges.

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 8

Once primed, the CFS Assembly can be reinstalled into the

printer carriage.

The ink removed during the priming procedure is clean and can

be put back into the corresponding bottle.

Once complete, the syringes can be rinsed with warm water and

air dried before storing.

Step 12:

Fig. 11-3

Fig. 11-4

Using your hand, push the printer carriage all of the way to the

right. This

must be completed before plugging the printer in

or turning the printer back on.

Fig. 12

Step 13:

Plug the printer back into the wall.

Fig. 13

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 9

Step 14:

Turn the printer on by pressing the power button. The printer

carriage will slowly move from right to left several times to recalibrate its' position.

Step 15:

It may require 2-3 cleaning cycles to fully prime the system and

printer. Run several MIS purge6 prints after installation to

ensure that no banding is present.

Fig. 14

Fig. 15

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Page 10

The Care and Feeding of a CFS -

There are a couple of things you should know that will keep your system

running trouble free.

These systems work best if they are used often. Daily use is best, but at least

one print every 2-3 days is the minimum. If you are an infrequent printer or

only print once or twice a week, a CFS unit might not be a good fit for you.

If you have to do cleaning cycles, do them in groups of 3 and be certain to print

something after the 3rd cleaning. We recommend printing a copy of the Purge6

pattern after every 3 cleaning cycles. This resets the printer firmware so that

you get a medium, long, and short duration cleaning cycle. If you don't do this,

you will only get short cleaning cycles after the 3rd one.

Running several short cleaning cycles will cause nozzles to drop out. If you are

still having problems after about 3 or 4 sets of 3 cleanings, then let the printer

rest for a few hours or overnight and try again later. This has worked on many

Epson printers in the past. It gives the air bubbles in the ink a chance to rise to

the surface and get out of the print head.

Don't let your ink bottles run empty. Refill them when they are at the 1/4 full

level. Before pouring new ink into your bottle, transfer the ink that is left into a

clean glass or jar. Then wash out the CFS ink bottle with soap and water. Once

the bottle is dry, refill with leftover ink and new ink. This keeps algae from

building up on the walls of the bottle and causing premature ink failure. An

easier method is to order a spare set of empty bottles, and keep them on hand.

If an ink does not print. Remove the tube from the bottle, lift the cartridge out,

and use the syringe to suck out a little ink, not more than 2 cc, to eliminate any

air locks that may be present. Use the syringe and bottom fill adapter, then

reinstall. If you have all colors printing but you are having problems getting a

perfect nozzle pattern after several cleaning cycles, then let the printer rest

overnight and try a few cleaning cycles in the morning.

S a v e M o n e y a n d I m p r o v e Y o u r P r i n t i n g

MIS Associates Inc 2901 Auburn Rd. Auburn Hills, MI 48326 800-445-8296

http://www.inksupply.com Fax: 248-289-6013 Email: sales@inksupply.com

Loading...

Loading...