England's Stove Works 28-3500, 50-SHW35, 50-TRW35 Owner's Manual

INSTALLATION AND OPERATION MANUAL

MODELS: 28-3500 , 50-SHW35 & 50-TRW35

WOOD ADD-ON FURNACE

Thank you for purchasing this product from a fine line of heating equipment.

Please read this manual before attempting to move or install your unit.

We wish you many years of safe heating pleasure with your new heating appliance.

Visit our web site at www.englanderstoves.com

questions, parts & accessory orders and more.

Please Note the Following Precautionary Statements:

England’s Stove Works highly recommends the use of smoke detectors and Carbon

Monoxide detectors with any hearth product, including this unit. Follow all manufacturer’s

instructions when using smoke and Carbon Monoxide detectors.

CAUTION:

This unit must be installed in accordance with these instructions and must comply with local

building and fire codes. Failure to do so could result in a chimney or house fire.

Keep children, furniture, fixtures and all combustible materials away from any heating appliance.

Maintain a minimum clearance of 18” (18 inches) from the flue pipe to any combustibles. Refer

to information in this manual and on the unit, and to all pipe manufacturers’ instructions.

This unit is not mobile home approved.

Do not install this unit in a mobile home!

READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLING THIS MODEL.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

INSTALLATION SHOULD BE PERFORMED BY A QUALIFIED INSTALLER.

NOTE:

IF YOU HAVE A PROBLEM WITH THIS UNIT, DO NOT RETURN IT TO THE

DEALER. PLEASE CONTACT CUSTOMER SERVICE at (800) 245-6489.

FUEL: WOOD

HEATING CAPACITY: Approx. 3,000 SQ. FT (when fed into existing ductwork)

TESTED TO: UL 391, CSA-B366.1, ETLM 78.1

Rev: 2/12/2013

for helpful information, frequently asked

A letter from our Technical Support department:

Thank you

for purchasing this fine product from England’s Stove Works!

England's Stove Works was started, and is still owned by, a family that

believes strongly in a "Do It Yourself" spirit – that’s one reason you found

this product at your favorite “Do It Yourself” store.

We intentionally design and build our stoves so that any homeowner can

maintain his or her unit with basic tools, and we're always more than

happy to show you how to do the job as easily and as inexpensively as

possible.

From our free,

downloadable service sheets; to our Pellet Service Video; to

our new "wizard-style," click-through Troubleshooting guide on our web

site, we have always tried to help our customers stay "heat-ready,"

especially when oil and electricity prices continue to skyrocket.

Please look at our vast Help section on our web site and call our Customer

Service department at (800) 245-6489 if you need any help with your unit.

We are nearly always

able to help “walk you through” any repairs,

problems or questions you may have.

PLEASE NOTE

: While information obtained on our web site and through

our 800 number is always free of charge, there will be a service charge

incurred with any “on-site” repairs or maintenance that we may arrange.

Wishing you years of efficient, quality and “comfy” heating,

England’s Stove Works

Technical Support Department

www.englanderstoves.com

(800) 245-6489

IF YOU HAVE A PROBLEM WITH THIS UNIT DO NOT RETURN IT TO THE DEALER.

CONTACT CUSTOMER SERVICE at 1 (800) 245-6489.

2

SAFETY NOTICE

IF THIS UNIT IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR

SAFETY AND PROTECTION, FOLLOW ALL OF THE INSTALLATION INSTRUCTIONS.

INSTALLATION SHOULD BE PERFORMED BY A QUALIFIED INSTALLER.

CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS FOR RESTRICTIONS AND

INSTALLATION INSPECTIONS REQUIRED IN YOUR AREA.

IMPORTANT: DO NOT OVER-FIRE. SEE “DO NOT OVER-FIRE YOUR UNIT” IN THE

“OPERATING INSTRUCTIONS” SECTION.

CAUTION – Hot Surfaces: Keep children away. Do not touch during operation.

SECTION I: FLUE SYSTEM

Note: Flue systems and flue pipe are not furnished with the unit; they must be

purchased separately. Follow all manufacturers’ instructions.

THE UNIT IS NOT TO BE CONNECTED TO A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

This appliance requires a masonry or pre-manufactured chimney listed to

UL103HT, sized correctly.

A. Existing Flue System

The Add-On furnace is designed to connect to an existing flue system, such as

masonry or HT Pipe premanufactured flue pipe. If you have a masonry flue system,

you need to inspect the inner liner very carefully for cracks. If there is no liner in your

chimney, we recommend you install a stainless steel liner, or have one installed. If

you have an existing premanufactured flue system, it should be inspected to ensure

there are no cracks, buckling or warping. We strongly recommend that you have a

qualified chimney sweep clean and inspect your flue system.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE. Always try to position the unit as close as possible to the flue servicing

the unit. The fewer total pipes that are installed, the better the stove will draw.

B. Flue Size Required

The proper flue size is determined by the inside diameter of the flue collar on the

unit. This furnace is equipped with a 6” (6 inch) TOP EXHAUST flue collar. The

connector pipe should be six inches or larger, but never less in diameter than the

collar on the stove. The area of the chimney liner must be equal to or greater than

the area of the collar on the stove.

Example: The area of a 6” (6 inch) diameter flue collar is 28.87 square inches;

therefore, the connector pipe should be at least a 6” (6 inch) diameter pipe and the

chimney liner must be at least 28.87 square inches but no greater than 84.8 square

inches.

Connector pipe should be (at minimum) 24-gauge steel and 18” (18 inches) from a

combustible wall or ceiling. This unit is tested with single-wall pipe only.

IMPORTANT: Be sure to refer to the data label and other markings on the

appliance for additional information, including clearances to combustibles.

3

C: Installation of a New Flue System

p

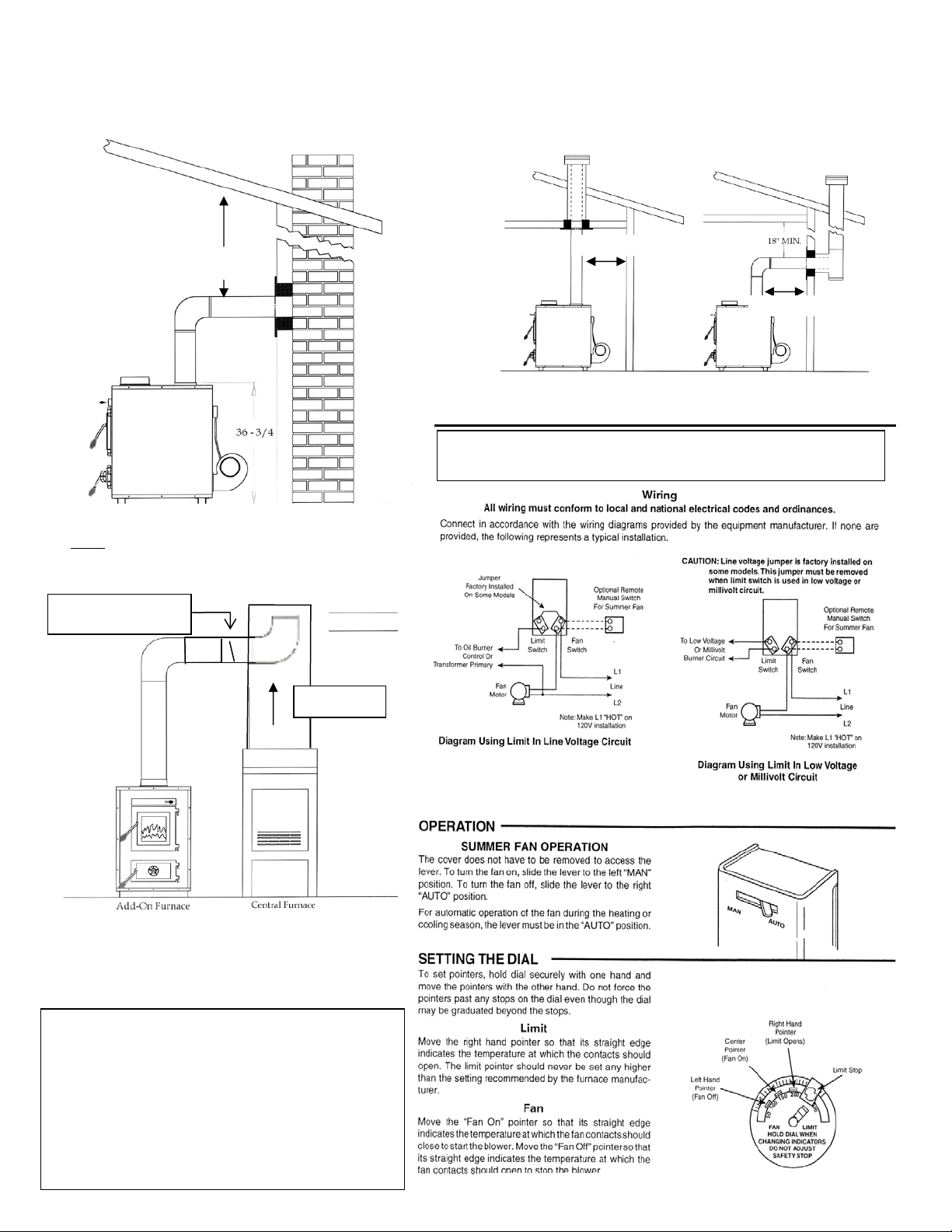

1. Masonry Flue: If you are considering a masonry flue (see Figure 1), you should

contact your local building officials for the proper procedures required in the

construction. We recommend that you consult with and have your flue built by a

licensed, bonded contractor.

Most masonry flues are placed against the outside wall and extend up the side of

the house. A flue thimble is then inserted through the wall making the connection

with the vertical flue and the stove flue pipe. Extreme caution should be

exercised when drilling through the wall. You must maintain proper clearances

between the connecting liner and any combustible wall. We do recommend that

you have a flue clean out door at least 2’ (two feet) below the flue thimble for

easy access and cleaning. This door should be made as air tight as possible. It is

the customer’s responsibility to be sure the chimney (or flue system) is in a safe

operating condition. The manufacturer will not be held responsible for an

accident attributed to a unit connected to a faulty chimney or flue system.

2. Premanufactured Flue System: In the past few years, premanufactured flue

systems have become very popular. This type system is fairly easy to install and

when installed correctly, it is a very safe. There are many premanufactured flue

systems on the market from which to choose. In making your choice, be sure the

system has a recognized label of approval such as U.L., B.O.C.A. or I.C.B.O.

Any of these labels will ensure the flue system is constructed of the proper

materials and meets the required safety standards. Your local dealer will

normally handle an approved, high-quality flue system.

NOTE: Be sure to use “HT” Pipe.

There are two very popular methods of installing a premanufactured flue system.

The first, which is the least expensive, is up through the ceiling and out the roof

(see Figure 2). This is the most direct route and creates more draft because less

pipe is normally used. Single wall pipe (24 gauge) is used up to the ceiling, with

triple walled pipe through the attic and out the roof.

The second

method of installation is to go through the wall and up the outside of

your home or structure (see Figure 2). This method is more expensive because it

requires more pipe, and once outside the home insulated or triple wall pipe is

required. Extreme care should be used in any installation, and the manufacturers’

instructions should always be followed. If you choose this type installation, a

qualified contractor or bonded chimney sweep should install this system. It is the

customers’ responsibility to be sure the flue system is in a safe operating

condition.

*IMPROPER INSTALLATION: The manufacturer will not be held responsible for damage

caused by the malfunction of a stove due to improper venting or installation. Call

800-245-6489 and/or consult a

4

rofessional installer if you have any questions.

Installation Diagrams and Thermostat Wiring

A

p

This appliance requires a masonry or pre-manufactured chimney listed to UL103HT, sized

correctly.

18” Min.

18” Min.

18” Min.

Figure 1 – Installation into a Masonry Flue

NOTE: 13” required from back of unit to a combustible.

16” required from sides of unit to a combustible.

See Floor and Wall Protection sections and data label

Recommended position

of Backflow Damper

on stove for all clearances.

ir Flow

Figure 3 – Hot air outlet hook-up to ductwork.

NOTE: Be sure to connect to ductwork from

furnace’s 8” hot air outlet only (see Section V)

.

To prevent air flow from central furnace

being directed back into the Add-on furnace:

A Backflow Damper is required in the 8” hot air

outlet pipe that connects from the Add-On

Furnace to the Central Furnace (see Figure 3).

We also recommend a 8” (eight inch), 90

5

lenum or ductwork.

degree elbow (a slightly larger hole will be

required for installation) inside central furnace

Figure 2 – Installation into a HT Pipe Flue System.

– Through the Roof RIGHT – Through the Wall

LEFT

IMPORTANT NOTE: Do NOT connect this furnace to

an external thermostat.

Figure 4 – Blower thermostat wiring diagram.

SECTION II: FLOOR AND WALL PROTECTION

A. Floor Protection

There is no protection required if your floor is constructed of a

noncombustible material such as concrete. If your floor is constructed of a

combustible material such as hardwood, carpet or linoleum some type of

floor protection will be required. When selecting the required floor

protection it is important that you install a U.L. approved board. The

approved floor protection should be placed underneath the furnace, and

should be large enough to provide a minimum of 8” (8 inches) behind the

unit, 8”(8 inches) on both sides, and 16” (16 inches) at the front door(s)

location. It should also be placed underneath the chimney connector and

extend at least 2” (2 inches) on either side of the chimney connector.

B. Wall Protection

Your furnace can be placed as close as 16” (16 inches) from a

combustible wall (such as paneling, wallpaper or drywall) to the side of the

unit; from the back of the unit, 13” (13 inches) is required to a combustible.

The single-wall pipe would need to remain at least 18” (18 inches) from

combustible surfaces.

In corner installations, the unit should be placed so that the stove is at

least 12” (12 inches) from any combustibles, and the single-wall pipe

should be at least 23” (23 inches) from any combustibles in a corner

installation.

Wall protection will be required if you need to place you furnace closer

than the allowed measurements stated above, and this can be

accomplished by adding a protective board to the wall. The board can be

mounted to the wall leaving a one-inch air space between the wall and the

board. This can be done by using metal spacers, and should allow you to

place your unit so that the sides of the unit are at least 12” (12 inches)

from the protective board – be sure to check and follow the board

manufacturer’s instructions and any local codes.

SECTION III: FREESTANDING PLACEMENT AND HOOK-UP

Once you have completed your flue system and installed the floor

protection, you are now ready to place the unit. All of our stoves are well

constructed, making them very heavy. We recommend using a handcart

for moving the unit; the door and firebrick can be removed to make the

unit slightly lighter (first make a diagram of the firebrick layout for later

reference). Never attempt to handle this product alone.

After the unit is in place the flue collar, spring handles and any optional

equipment can be added.

6

Loading...

Loading...