Endress+Hauser Thermophant T TTR35 Operating Manual

Operating manual

Thermophant T TTR31, TTR35

Temperature switch

BA201R/09/en/02.05

51009833

Release 01.01.00

TTR31, TTR35

Table of contents

1 Safety instructions. . . . . . . . . . . 3

1. 1 Designated use . . . . . . . . . . . . . . . . . . . . . . 3

1. 2 Installation, commissioning and operation . . 3

1. 3 Operational safety . . . . . . . . . . . . . . . . . . . . 3

1. 4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Device identification . . . . . . . . . 4

2. 1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Installation . . . . . . . . . . . . . . . . 5

3. 1 Incoming acceptance, storage . . . . . . . . . . . 5

3. 2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 5

3. 3 Process connection . . . . . . . . . . . . . . . . . . . 6

3. 4 Installation instructions . . . . . . . . . . . . . . . 7

4 Wiring . . . . . . . . . . . . . . . . . . . . 8

4. 1 DC voltage version with M12 connector . . . 8

4. 2 DC voltage version with valve connector . . 8

5 Operation . . . . . . . . . . . . . . . . . 9

5. 1 On-site operation . . . . . . . . . . . . . . . . . . . . 9

5. 2 Operation with PC and Readwin® 2000 . 17

9 Dangerous good sheet . . . . . . .27

6 Accessories . . . . . . . . . . . . . . . 18

6. 1 Adapter concept for TTR35 . . . . . . . . . . . 18

6. 2 Welding bosses and coupling . . . . . . . . . 20

6. 3 Electrical connection . . . . . . . . . . . . . . . . 21

6. 4 Configuration kit . . . . . . . . . . . . . . . . . . . 22

7 Trouble-shooting. . . . . . . . . . . 23

7. 1 Errors and warnings . . . . . . . . . . . . . . . . . 23

7. 2 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. 3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. 4 Change status (release) . . . . . . . . . . . . . . . 24

7. 5 Release history . . . . . . . . . . . . . . . . . . . . 24

8 The most important

technical data . . . . . . . . . . . . . 25

8. 1 Power supply . . . . . . . . . . . . . . . . . . . . . . 25

8. 2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8. 3 Operating conditions . . . . . . . . . . . . . . . . 25

2 Endress+Hauser

TTR31, TTR35 Safety instructions

1 Safety instructions

1. 1 Designated use

The Thermophant T is a temperature switch for monitoring, displaying and regulating process

temperatures. The device has been safely built with state-of-the-art technology and meets the

applicable requirements and EC Directives. It can, however, be a source of danger if used incorrectly or for anything other than the designated use.

1. 2 Installation, commissioning and operation

Installation, electrical connection, commissioning, operation and maintenance of the measuring

system must be carried out by trained, qualified specialists authorised to perform such work by

the facility's owner-operator. The specialist must have read and understood these Operating Instructions and must follow the instructions they contain. The device may only be modified and

repair work carried out if this is explicitly permitted in the Operating Instructions. Damaged devices which could be a source of danger may not be commissioned and must be labelled and

identified as defective.

1. 3 Operational safety

• Functional safety

The Thermophant T temperature switches were developed according to the standards IEC

61508 and IEC 61511-1 (FDIS). The device version with PNP switch output and additional

analog output is equipped with fault detection and fault prevention facilities within the

electronics and software. This device version can therefore be used to monitor temperature

up to SIL 2 (Safety Integrity Level). The attainable SIL value is determined by the safety

technical characteristics of probability of failure, hardware fault tolerance and the safe failure

fraction. Details on this may be found in the Functional Safety Manual (in development).

• Ex-area

The Thermophant T is not approved for use in Ex-areas.

1. 4 Return

The following procedures must be carried out before a device is returned to Endress+Hauser:

• Always enclose a fully completed “Declaration of Contamination” form with the device. Only

then can Endress+Hauser transport and examine a returned device. A copy of the “Declaration of Contamination” can be found on the second last page of these Operating Instructions.

• Remove all fluid residues. This is particularly important if the fluid is hazardous to health, e.g.

flammable, toxic, caustic, carcinogenic, etc.

Warning!

#

Do not return a measuring device if you are not absolutely certain that all traces of hazardous

substances have been removed, e.g. substances which have penetrated crevices or diffused

through plastic.

Endress+Hauser 3

Device identification TTR31, TTR35

2 Device identification

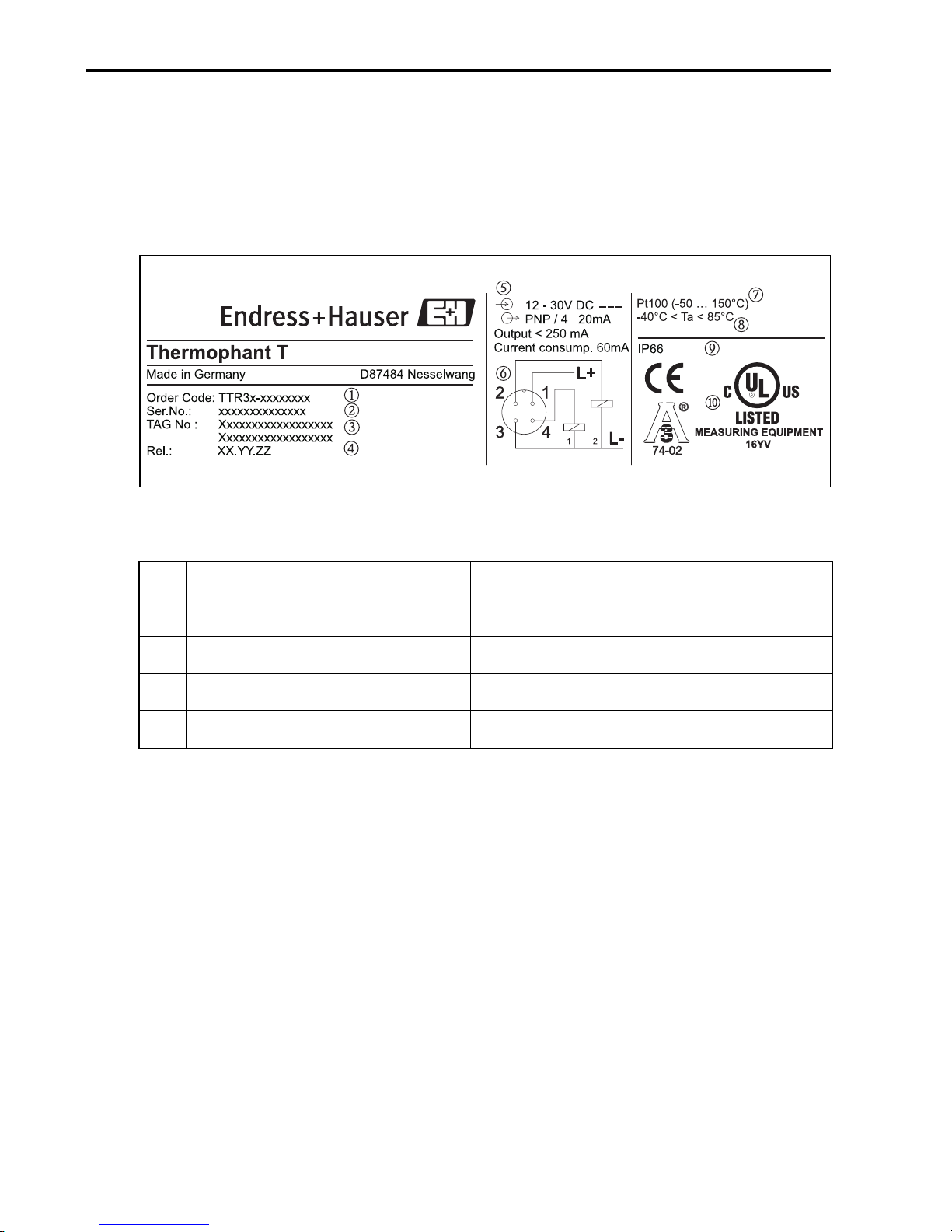

2. 1 Nameplate

To identify your device, compare the complete order code and the version information on the

delivery papers with the data on the nameplate.

T09-TTR31xxx-18-xx-xx-xx-000

Fig. 1: Nameplate for device identification (as example)

!

m Order code r Connection diagram

n Serial number s Measuring range

o TAG number t Ambient temperature

p Release number (change status) u Degree of protection

q Connection values v Approvals

Note!

The release number indicates the change status of the device. A change in the last two figures

does not have any affect on the compatibility - see also → Chap. 7.

4 Endress+Hauser

TTR31, TTR35 Installation

3 Installation

3. 1 Incoming acceptance, storage

• Incoming acceptance:

Check the packaging and the device for damage. Check that the goods delivered are complete

and nothing is missing.

• Storage:

Storage temperature −40 °C to +85 °C (-40 °F to +185 °F).

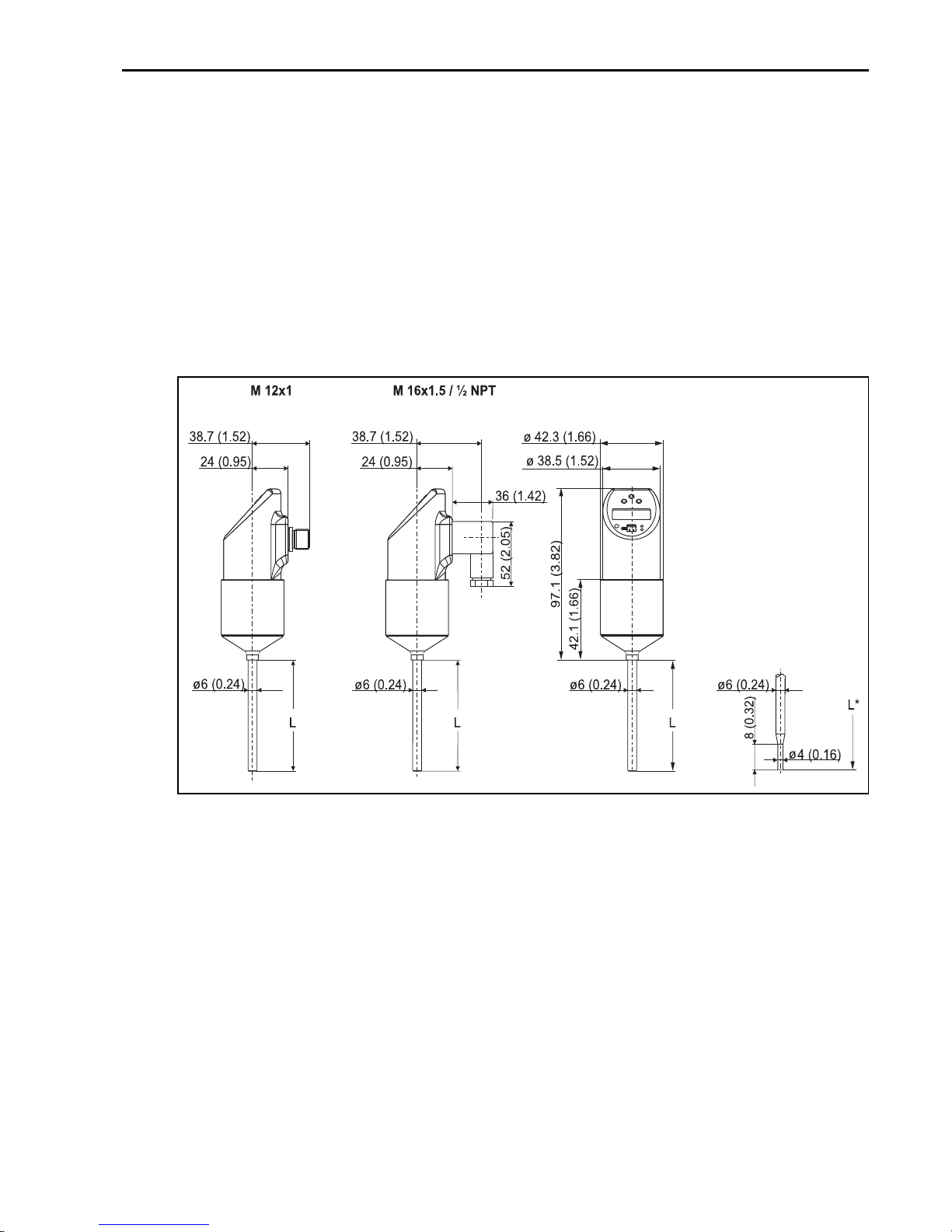

3. 2 Dimensions

Fig. 2: Dimensions in mm (inches)

Version L in 100 and 200 mm (3.94 and 7.87"), version L* = 50 mm (1.97") with reduced sensor tip

M 12x1 connector as per IEC 60947-5-2

M 16x1.5 or ½ NPT valve plug as per DIN 43650A/ISO 4400

Endress+Hauser 5

T09-TTR31xxx-06-xx-xx-en-000

Installation TTR31, TTR35

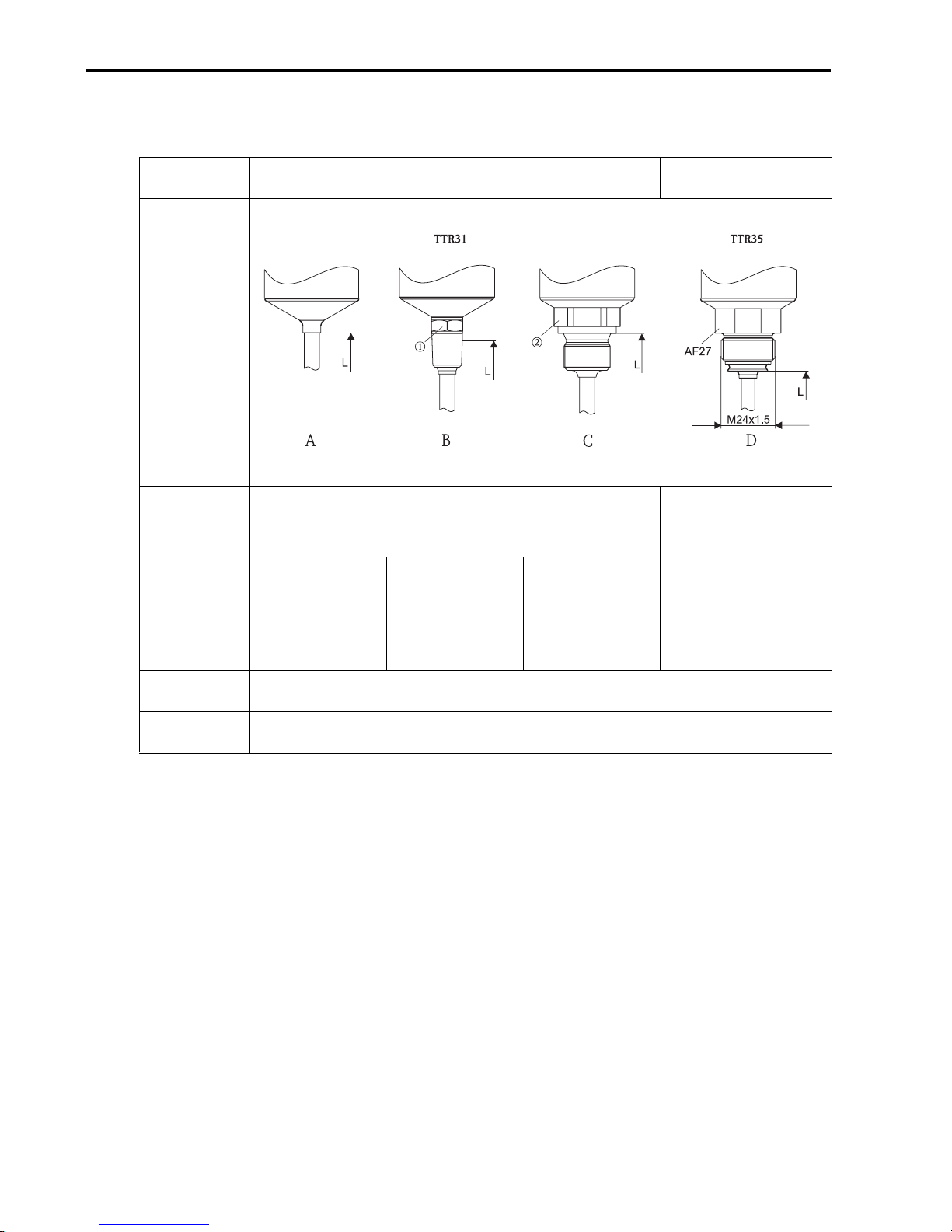

3. 3 Process connection

The following table illustrates the versions of Thermophant T.

TTR31 TTR35

T09-TTR31xxx-17-xx-xx-en-000

Field of application

Process connection

Sensor length L Version L in 100 and 200 mm (3.94 and 7.87"), version L = 50 mm (1.97") only with reduced sensor tip

Measuring range -50 °C to +150 °C (-58 °F to 302 °F)

Version without proc-

ess connection (’w’).

bosses and coupling

Monitoring, display and control of process temperatures Monitoring, display and con-

Item A

Suitable welding

(see Section 6)

Item B

Version with thread

process connection

ANSI ¼" NPT

(m = AF14) and

½" NPT (m = AF27)

Item C

Version with thread

process connection

G ¼A (n = AF14) and

G ½A (n = AF27) as

per ISO 228

trol of process temperatures

in hygienic processes

Adapter concept - version

with M24x1.5 thread for

adapters with process con-

nection for hygienic processes

(see Section 6.1.2)

Item D

6 Endress+Hauser

TTR31, TTR35 Installation

3. 4 Installation instructions

T09-TTR31xxx-11-00-xx-xx-000

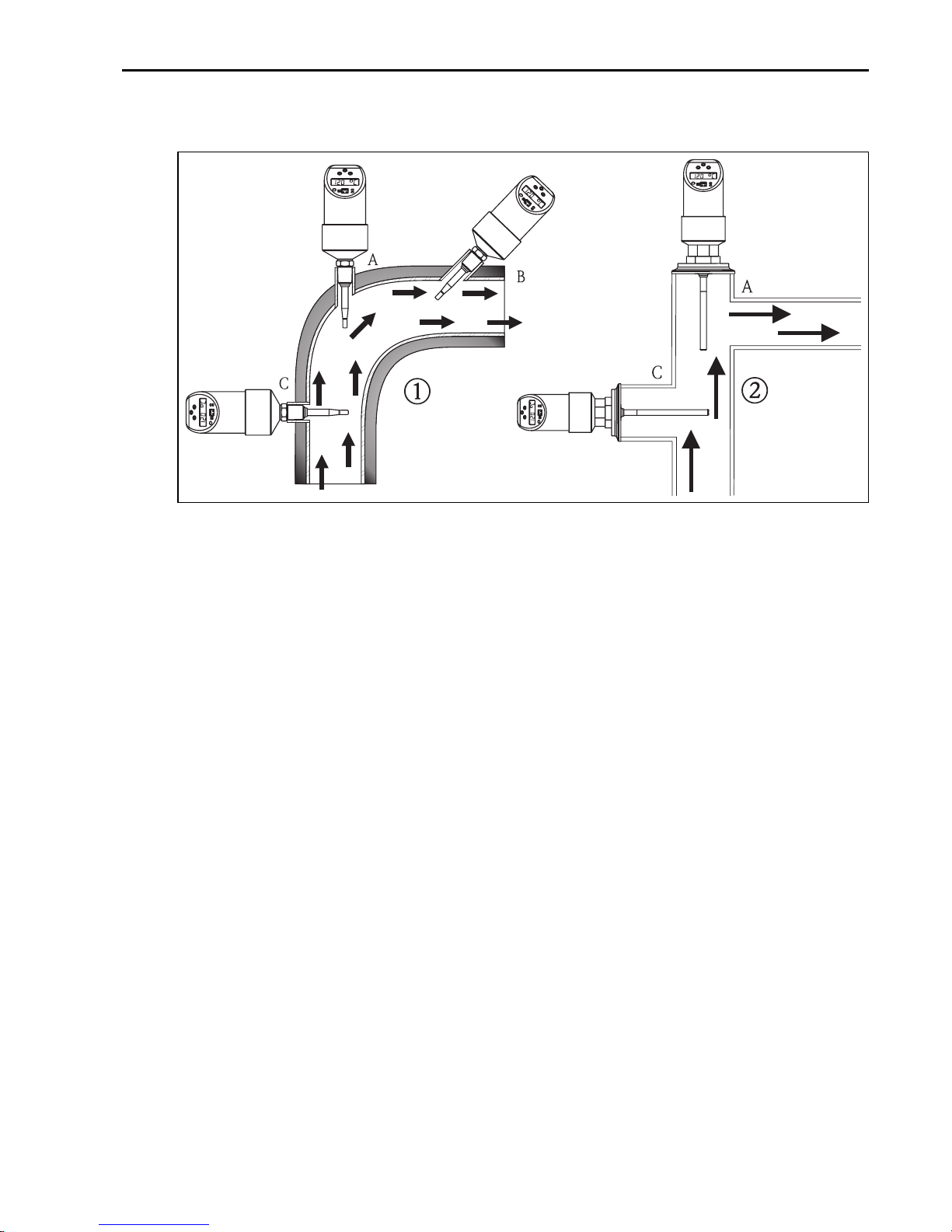

Fig. 3: Possible installation options for temperature monitoring in pipes

m TTR31

n TTR35 for use in hygienic processes

Mounting instructions:

• Installation at angle pieces, against the direction of flow (Fig. 3, Item A)

• Installation in smaller pipes, inclined against the direction of flow (Fig. 3, Item B)

• Installation vertical to the direction of flow (Fig. 3, Item C)

• The on-site display can be rotated electronically 180° − see Section 5. 1 "On-site operation"

• The housing can be rotated up to 310°

Endress+Hauser 7

Wiring TTR31, TTR35

4Wiring

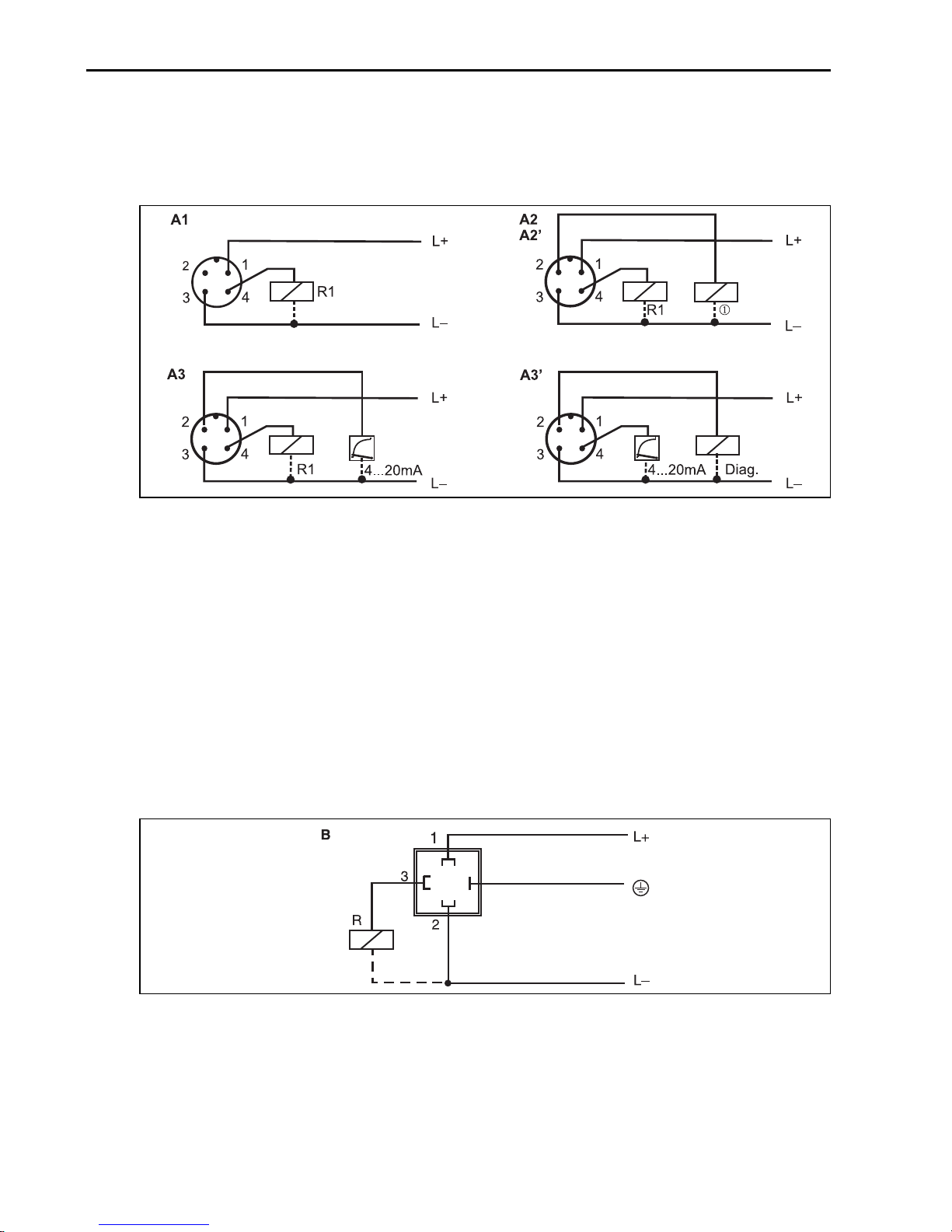

4. 1 DC voltage version with M12 connector

!

P01-PTx3xxxx-04-xx-xx-xx-002

Fig. 4: Thermophant T with M12x1 connector

A1: 1x PNP switch output

A2: PNP switch outputs R1 and m(R2)

A2’: PNP switch outputs R1 and m (diagnosis/break contact with adjustment "DESINA")

A3: PNP switch output with additional analog output

A3’: PNP switch output with additional analog output (PIN assignment with "DESINA" setting)

Note!

DESINA (→ Chap. 5.1.3 Basic settings):

R2 = Diagnosis/break contact (more informations about DESINA see www.desina.de)

4. 2 DC voltage version with valve connector

Fig. 5: Thermophant T with M 16x1.5 or ½ NPT valve plug

B: 1x PNP switch output

8 Endress+Hauser

P01-PTx3xxxx-04-xx-xx-xx-003

TTR31, TTR35 Operation

5 Operation

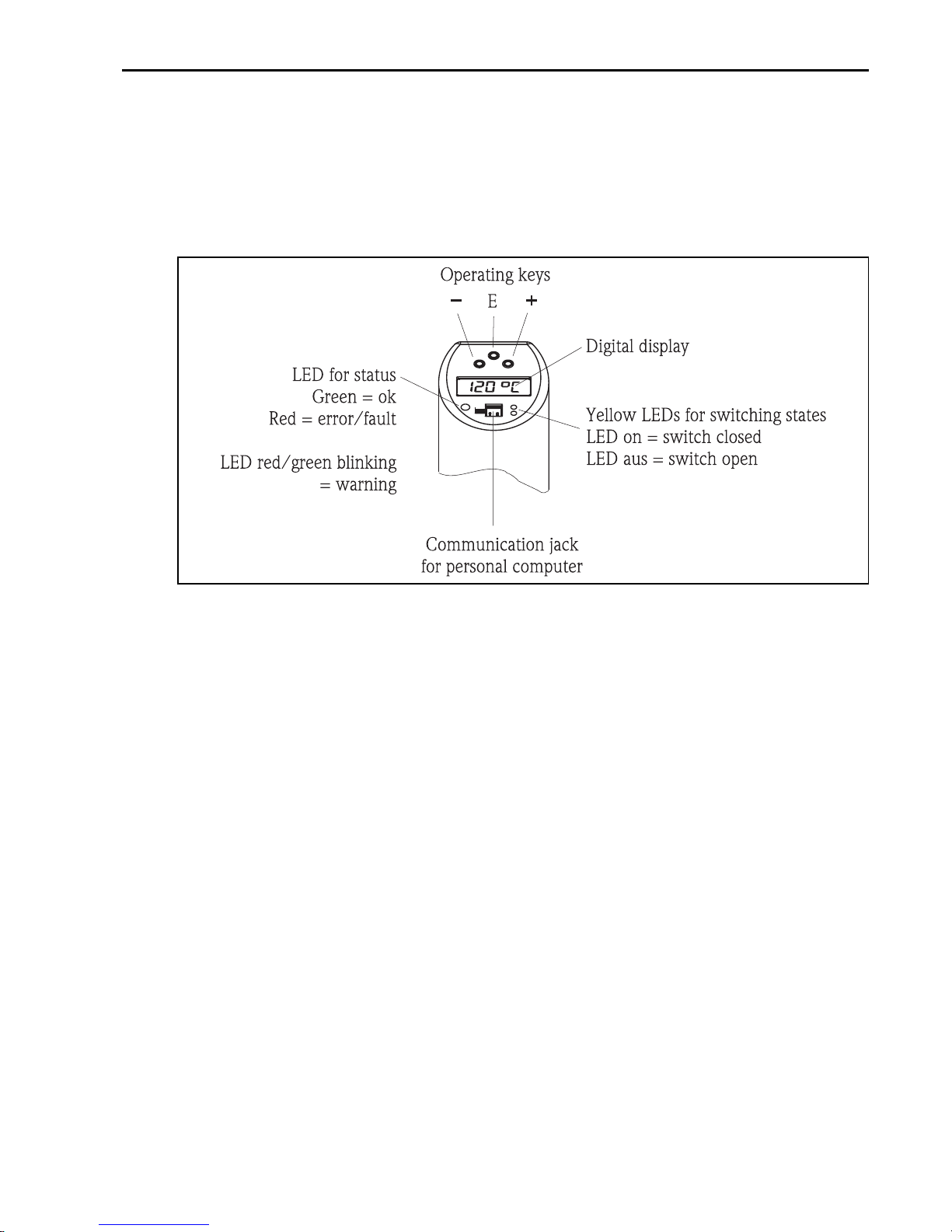

5. 1 On-site operation

The Thermophant T is operated by means of three keys. The digital display and the light emitting

diodes (LED) support navigation in the operating menu.

Fig. 6: Position of operating elements and possibilities for display

Background illumination of the digital display:

– White = OK status

– Red = error status

T09-TTR31xxx-19-xx-xx-en-001

Endress+Hauser 9

Loading...

Loading...