Endress+Hauser TH13, TH14, TH15 Technical Information

Technical Information

RTD TH13, TH14 and TH15

RTD assemblies in Thermowells with spring loaded insert and

enclosure for process industry

Areas of application

The TH13, TH14 and TH15 temperature sensors are RTD

assemblies installed in Thermowells and designed for use in

all types of process industries, including harsh environments,

due to their rugged design.

The sensor is made up of a measurement probe with an

insulated RTD element, sheath and a thermowell made of

bar-stock material.

The sensor assemblies can be used in process industries such

as:

• Chemicals

• Petrochemical

• Power plants

• Refineries

• Offshore Platforms

Head transmitters

Instead of directly wiring your temperature sensors to your

control system, use transmitters to reduce wiring and

maintenance costs while increasing measurement accuracy.

Field transmitters

Temperature field transmitters with HART

FOUNDATION Fieldbus™ protocol for highest reliability in

harsh industrial environments. Blue backlit display with large

measured value, bargraph and fault condition indication for

ease of reading.

Your benefits

• One source shopping for temperature measurement

solutions. World class transmitter with integrated sensor

offering for heavy process industry applications.

• Remove and install straight out of the box!

• Improved galvanic isolation on most devices (2 kV)

• Simplified model structure: Competitively priced, offers

great value. Easy to order and reorder. A single model

number includes sensor, thermowell and transmitter

assembly for a complete point solution

• All iTEMP

stability ≤ 0.05 % per year

®

transmitters provide long term

®

or

TI110R/24/ae

TH13, TH14, TH15

Function and system design

Measuring principle The RTD (Resistance Temperature Detector) element consists of an electrical resistance with a value of 100 Ω

at 0 °C (called Pt100, in compliance with IEC 60751), which increases at higher temperatures according to a

coefficient characteristic of resistor material (platinum). In industrial thermometers that comply with the

IEC 60751 standard, the value of this coefficient is α = 0.00385 °C

(32 and 212 °F).

Measuring system

-1

, calculated between 0 and 100 °C

Example of an application of the temperature assemblies

Water - heat Differential

Calculation of heat quantity which is emitted or absorbed by a water flow in a heating or cooling system. The quantity of

heat is calculated from the process variable for ∆p flow (Q) and the differential from the feed and return temperature

(T

- T1). Bidirectional energy calculations, such as the calculating systems with changing flow direction (charging/

2

discharging the heat accumulator) are also possible.

Energy manager RMS621

Energy conservation and cost expenditures are significant issues in today's industry. Accurate flow monitoring

and calculation is the basis for thorough analysis and billing of energy. This data can serve as a basis to maximize

savings potential and help in controlling operational costs on a daily basis. Endress+Hauser's energy managers

provide accurate and reliable calculations for the monitoring and control of energy consumption (both

produced and consumed) according to international standards, e.g. IAPWS-IF 97, AGA8, ISO 5167 etc. For

RMS621 details see Technical Information.

®

iTEMP

TMT162 Temperature Field Transmitter

Aluminum or stainless steel dual compartment explosion - proof enclosure and compact, fully potted

electronics provide the ultimate protection in harshest environments. TMT162 prevents costly plant

shutdowns by detecting corrosion on RTDs or thermocouples before it corrupts the measured value.

Endress+Hauser's Field Temperature Transmitters with backlit display and sensor backup functionality are

designed with safety in mind to keep your plant, equipment and personnel safe. For TMT162 details see

Technical Information.

Deltabar S/Cerabar S

The evolution series of Cerabar S/Deltabar S represents a decisive step ahead in making pressure

instrumentation better and safer for the process industry. The development of new products thrives especially

on the knowledge, commitment and experience of staff members. Permanent high performance can only be

achieved if dedicated and enthusiastic people provide their ideas. Endress+Hauser's instruments are not only

supposed to distinguish themselves for customers and users by technological novelties but also by the presence

of people supporting this progress, be it in service, sales or production. For Deltabar S & Cerabar S details see

Technical Information.

2 Endress+Hauser

TH13, TH14, TH15

Equipment architecture The single and duplex element RTDs are designed to measure temperature in a variety of processes and

laboratory applications. These RTDs are specifically designed for use in two different process temperature

ranges and they will provide accurate and repeatable temperature measurement through a broad temperature

range of -328 to 1112 °F (-200 to 600 °C). Low range thin film RTDs -58 to 392 °F (-50 to 200 °C) are

constructed using silver plated and copper internal leads, PTFE wire insulations with potting compounds to

resist moisture penetration. High range RTDs -328 to 1112 °F (-200 to 600 °C) are constructed with nickel

internal leads inside swaged MgO insulated cables to allow higher temperature measurements at the RTD

element and to provide higher temperature lead protection along the sheath.

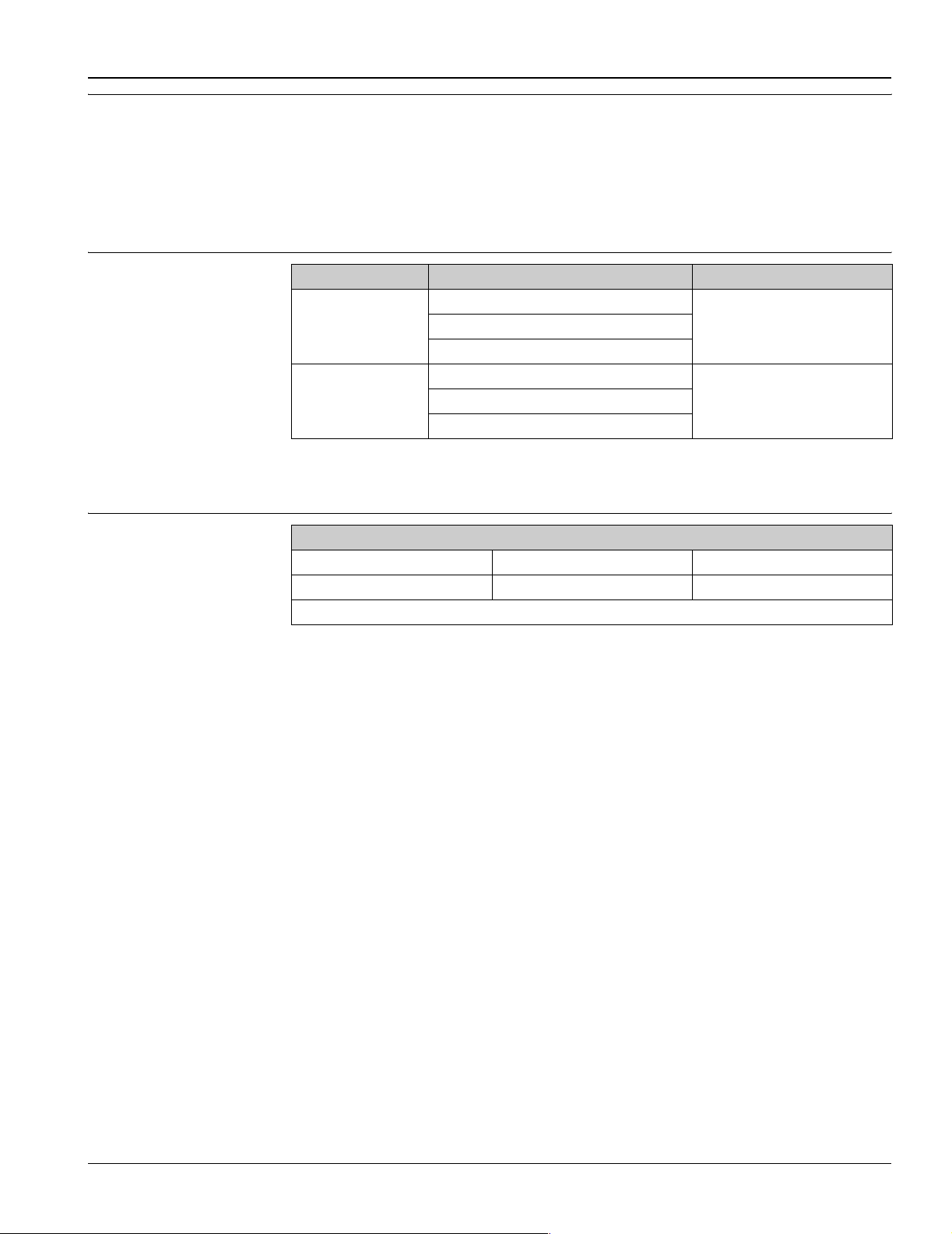

Measurement range

!

Calibration specifications

!

Construction Model code (class and type of sensor) max. range

TH13-_ _ _ _ _ (A/C/E/G/J/L) _ _ _ _ _

Low temperature range

TH15-_ _ _ (A/C/E/G/J/L) _ _ _ _ _

TH13-_ _ _ _ _ (B/D/F/H/K/M) _ _ _ _ _

High temperature range

TH15-_ _ _ (B/D/F/H/K/M) _ _ _ _ _ _

Note!

Options J, K, L, M are duplex platinum elements of two sensors inside the same sheath.

3 point sensor calibration

-40 to 0 °C 0 to 100 °C +40 to 215 °C

-40 to 32 °F 32 to 212 °F 104 to 420 °F

Minimum length requirements for calibrated sensors = 6"

Note!

Use option code ’B’ (Block: Test; calibration) for RTD calibration, the three temperature points need to be

specified in 5 °C (9 °F) increments.

The manufacturer provides comparison temperature calibrations from -40 to +215 °C (-40 to +420 °F) on the

international temperature scale of 1990. Calibrations are traceable to standards maintained by the national

institute of standards and technology (NIST). Calibration services are in conformance with ASTM E220, IEC

17025 and ANSI/NCSL Z540-1-1994. The report of calibration is referenced to the serial number of the RTD

assembly.

Three point calibrations are provided, given that the specified temperatures are within the recommended range

and the minimum length requirements are met as specified. The minimum length is based on overall length ’x’

of the spring loaded insert.

-58 to 392 °F (-50 to 200 °C)TH14-_ _ _ _ _ (A/C/E/G/J/L) _ _ _ _ _

-328 to 1112 °F (-200 to 600 °C)TH14-_ _ _ _ _(B/D/F/H/K/M) _ _ _ _ _

Endress+Hauser 3

Electronics

TH13, TH14, TH15

Family of temperature transmitters

PC programmable devices TMT180 and TMT181

HART® TMT182 head

transmitter

Field transmitter TMT162 Dual compartment housing

Field transmitter TMT142 Single compartment housing

Measurement assemblies with iTEMP® transmitters are an installation ready solution to improve the

functionality of temperature measurement by increasing accuracy and reliability when compared to direct

wired sensors. Overall installation costs are lower than with direct wired sensors, since an inexpensive pair of

signal (4 to 20 mA) wires can be run over long distances.

PC programmable head transmitters offer you extreme flexibility and help control costs with the ability to stock

one device and program it for your needs. Regardless of your choice of output, all iTEMP

configured quickly and easily with a PC. To help you with this task, Endress+Hauser offers free software

ReadWin® 2000 which can be downloaded from our website. Go to www.readwin2000.com to download

ReadWin

HART® communication is all about easy, reliable data access and getting better information more

inexpensively. iTEMP

access to preventative diagnostic information.

Configuration with a DXR275 or 375 hand-held or a PC with configuration program (FieldCare, ReadWin®

2000) or configure with AMS or PDM. For details, see Technical Information.

Field transmitter with HART

Can be read easily from a distance, in sunlight and at night. Large measurement value, bargraph and fault

indication display. Benefits are: dual sensor input, highest reliability in harsh industrial environments,

mathematic functions, thermometer drift monitoring, sensor back-up functionality, corrosion detection and

sensor transmitter matching by accepting Callendar Van Dusen constants. For details, see Technical

Information.

Field transmitter with HART

of smaller transmitters with tiny display and old style analog transmitters. Large and brilliant blue backlit

display. Regardless of whether you install the transmitter in a dark location or in direct sunlight, you still get a

clear temperature reading. Reliable temperature measurement through advanced diagnostics. For details, see

Technical Information.

®

2000 today. For details see Technical Information.

®

transmitters integrate seamlessly into your existing control system and provide painless

®

communication, FOUNDATION Fieldbus™ protocol and blue backlit display.

®

communication. The one channel TMT142 allows for cost effective replacement

®

transmitters can be

PROFIBUS

transmitter

PA TMT184 head

Universally programmable head transmitter with PROFIBUS®-PA fieldbus communication. Converting various

input signals into a digital output signal. High accuracy in the total ambient temperature range. Swift and easy

operation, visualisation and maintenance using a PC direct from the control panel, e. g. using operating

software such as FieldCare, Simatic PDM or AMS. DIP switch for address setting, makes start up and

maintenance save and reliable. For details, see Technical Information.

®

Performance characteristics

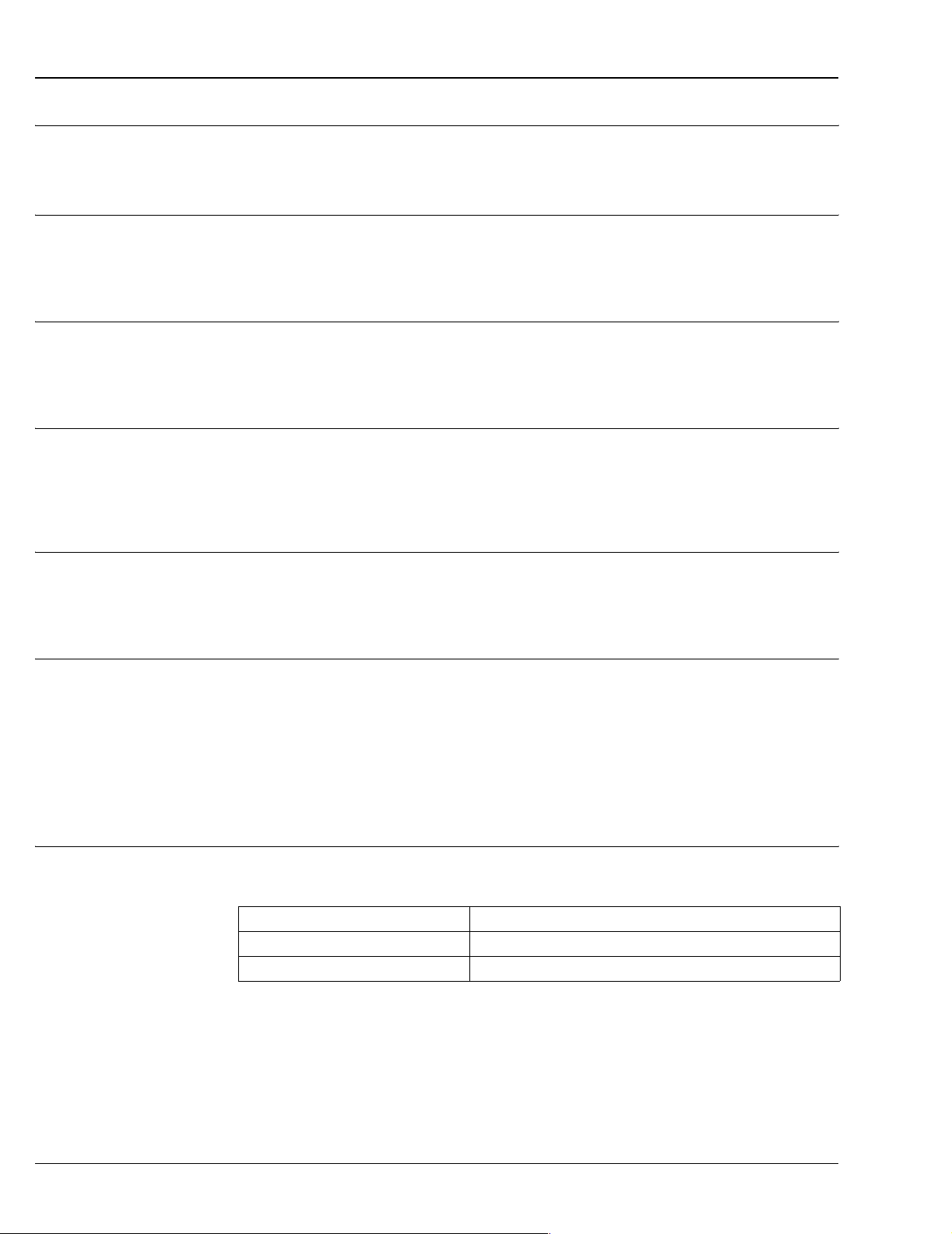

Response time 63% response time per ASTM E644

RTD assembly TH15 without thermowell

Construction RTD insert ø ¼"

High temperature range 3 s

Low temperature range 9 s

!

Note!

Response time for the sensor assembly without transmitter.

4 Endress+Hauser

TH13, TH14, TH15

Response time examples for RTD assemblies with thermowell TH13 and TH14

Construction Stepped thermowell Tapered thermowell ¾" straight thermowell

High temperature range 20 s 25 s 30 s

Low temperature range 25 s 30 s 35 s

!

Note!

Response times for RTD assemblies with thermowell are provided for general design guidance without

transmitter

When the temperature of a process media changes, the output signal of a RTD assembly follows this change

after a certain time delay. The physical cause is the time related to heat transfer from the process media through

the thermowell and the insert to the sensor element (RTD). The manner in which the reading follows the

change in temperature of the assembly over time is referred to as the response time. Variables that influence

or impact the response time are:

• Wall thickness of thermowell

• Spacing between RTD insert and thermowell

• Sensor packaging

• Process parameters such as media, flow velocity, etc.

Maximum measured error RTD corresponding to IEC 60751

Class max. Tolerances (°C)

A ±(0.15 + 0.002 · |t|1), Temperature range: -100 °C to 450 °C

B ±(0.3 + 0.005 · |t|

1) |t| = absolute value °C

!

Note!

For measurement errors in °F, calculate using equation above in °C, then multiply the outcome by 1.8.

1

), Temperature range: -200 °C to 600 °C

Measurement accuracy transmitter

Transmitter long-term stabiltiy

TMT180

Pt100 PCP

0.36 °F (0.2 °C)

or 0.08%

1) % is related to the adjusted measurement range (the larger value applies)

2) % relates to the set span. Accuracy = digital + D/A accuracy

≤ 0.18 °F / year (≤ 0.1 °C/year) or ≤ 0.05% / year

Data under reference conditions; % relates to the set span. The larger value applies.

TMT181 multi-

functional PCP

0.36 °F (0.2 °C)

1

or 0.08%

0.36 °F (0.2 °C)

2

TMT182

®

HART

or 0.08%

2

TMT184

PROFIBUS

PA

0.27 °F

(0.15 °C)

TMT162 FF

®

-

Field trans-

mitter

0.18 °F

(0.1 °C)

Insulation resistance Insulation resistance between terminals and probe sheath, test voltage 250 V.

• ≥100 MΩ at 77 °F (25 °C)

• ≥10 MΩ at 572 °F (300 °C)

TMT142 and TMT162

®

HART

Field transmitter

Accuracy

Digital D/A

0.18 °F

(0.1 °C)

0.02%

2

Endress+Hauser 5

TH13, TH14, TH15

Self heating RTD elements are not self-powered and require a small current be passed through the device to provide a

voltage that can be measured. Self-heating is the rise of temperature within the element itself, caused by the

current flowing through the element. This self-heating appears as a measurement error and is affected by the

thermal conductivity and velocity of the process being measured; it is negligible when an Endress+Hauser

®

temperature transmitter is connected.

iTEMP

®

Sensor current Sensor current of Endress+Hauser iTEMP

Transmitter type Sensor current

TMT180 & TMT181 PCP ≤ 0.6 mA

TMT182 HART

TMT184 PROFIBUS

TMT162 HART

TMT142 HART® Field transmitter ≤ 0.3 mA

®

®

-PA ≤ 0.2 mA

®

, FF Field transmitter ≤ 0.3 mA

transmitters

≤ 0.2 mA

Galvanic isolation Galvanic isolation of Endress+Hauser iTEMP

Transmitter type Galvanic isolation

TMT181 PCP Û = 3.75 kV AC

TMT182 HART

TMT184 PROFIBUS®-PA

TMT162 HART®, FF Field transmitter

TMT142 HART

®

®

Field transmitter

®

transmitters (input/output)

U = 2 kV AC

6 Endress+Hauser

TH13, TH14, TH15

Wiring

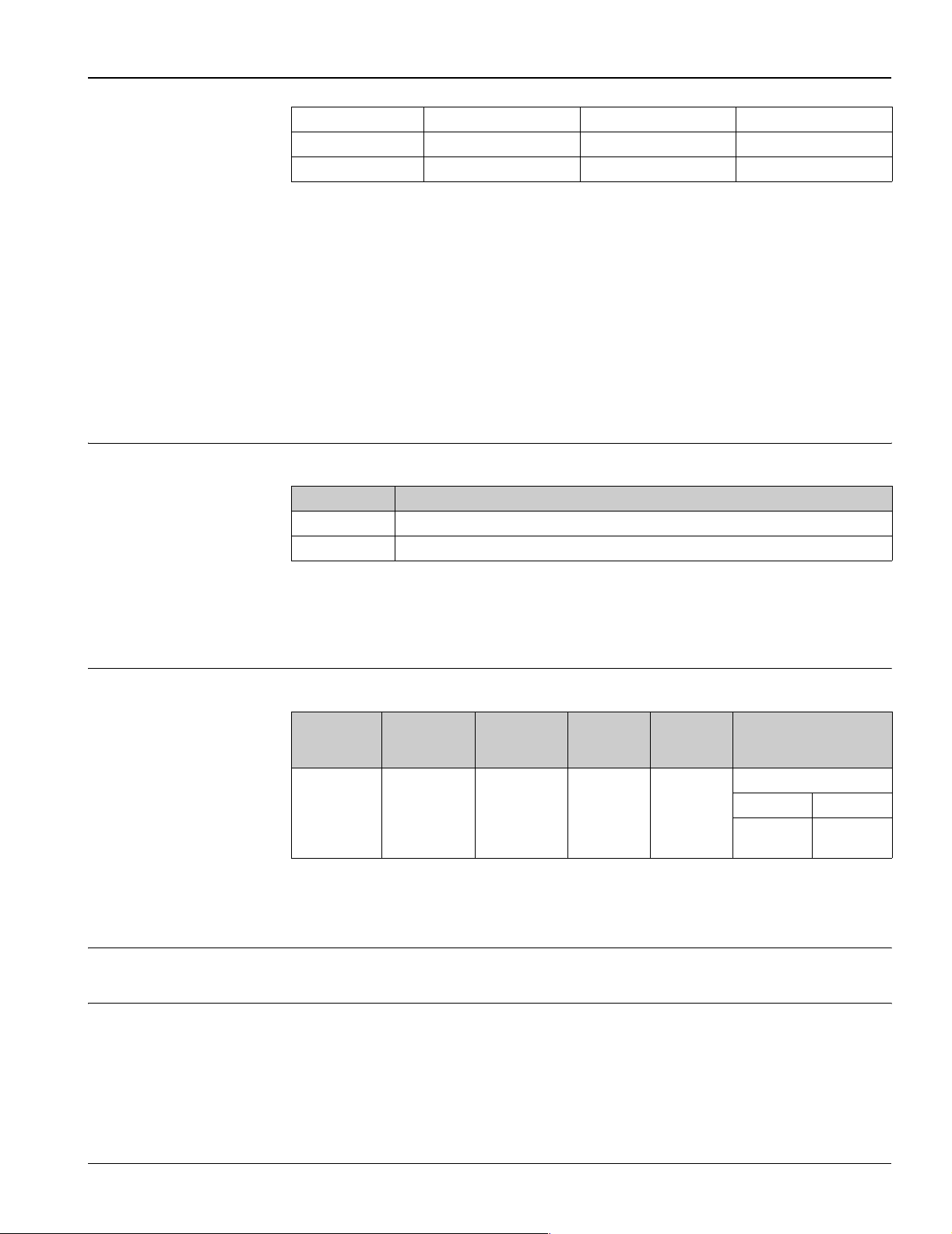

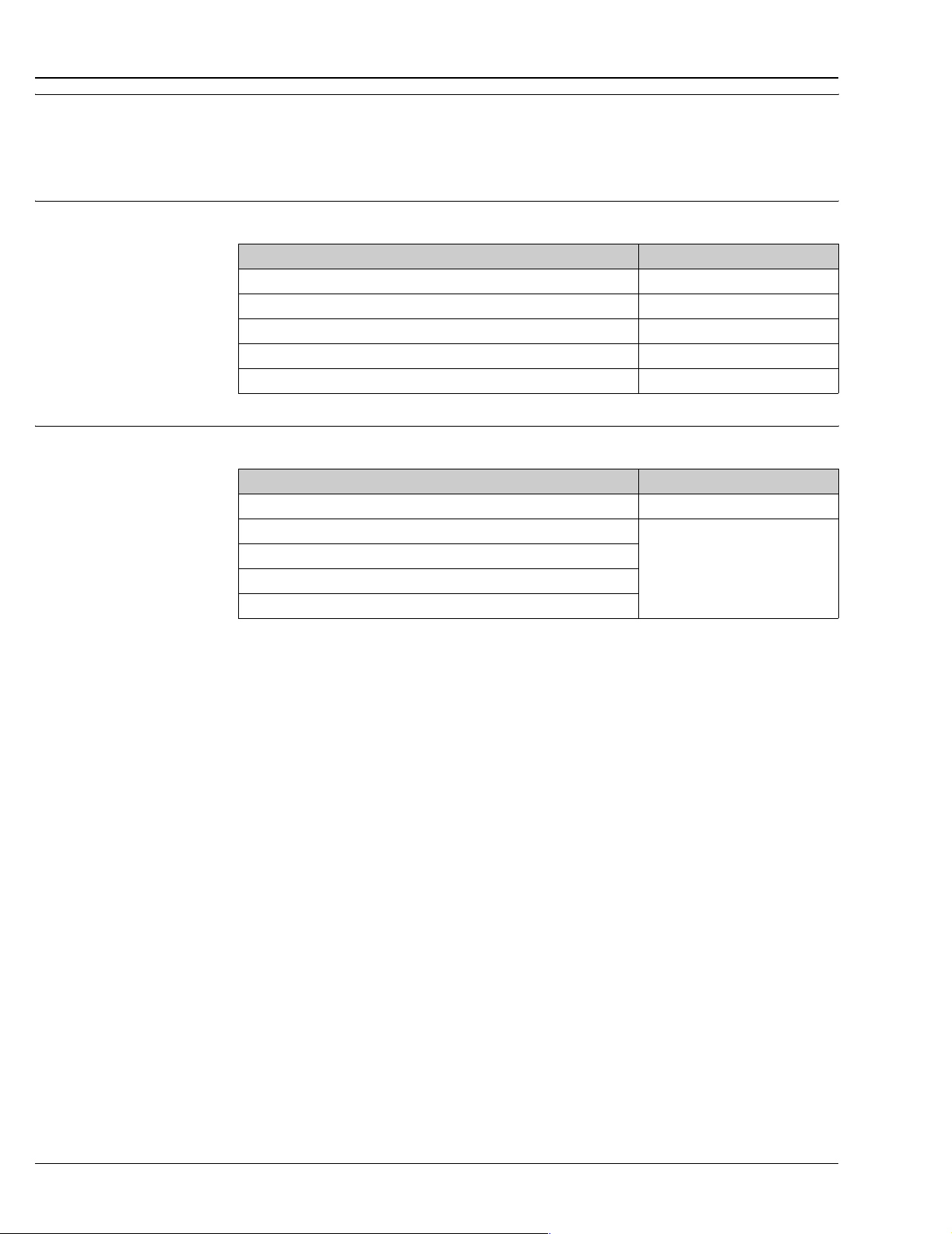

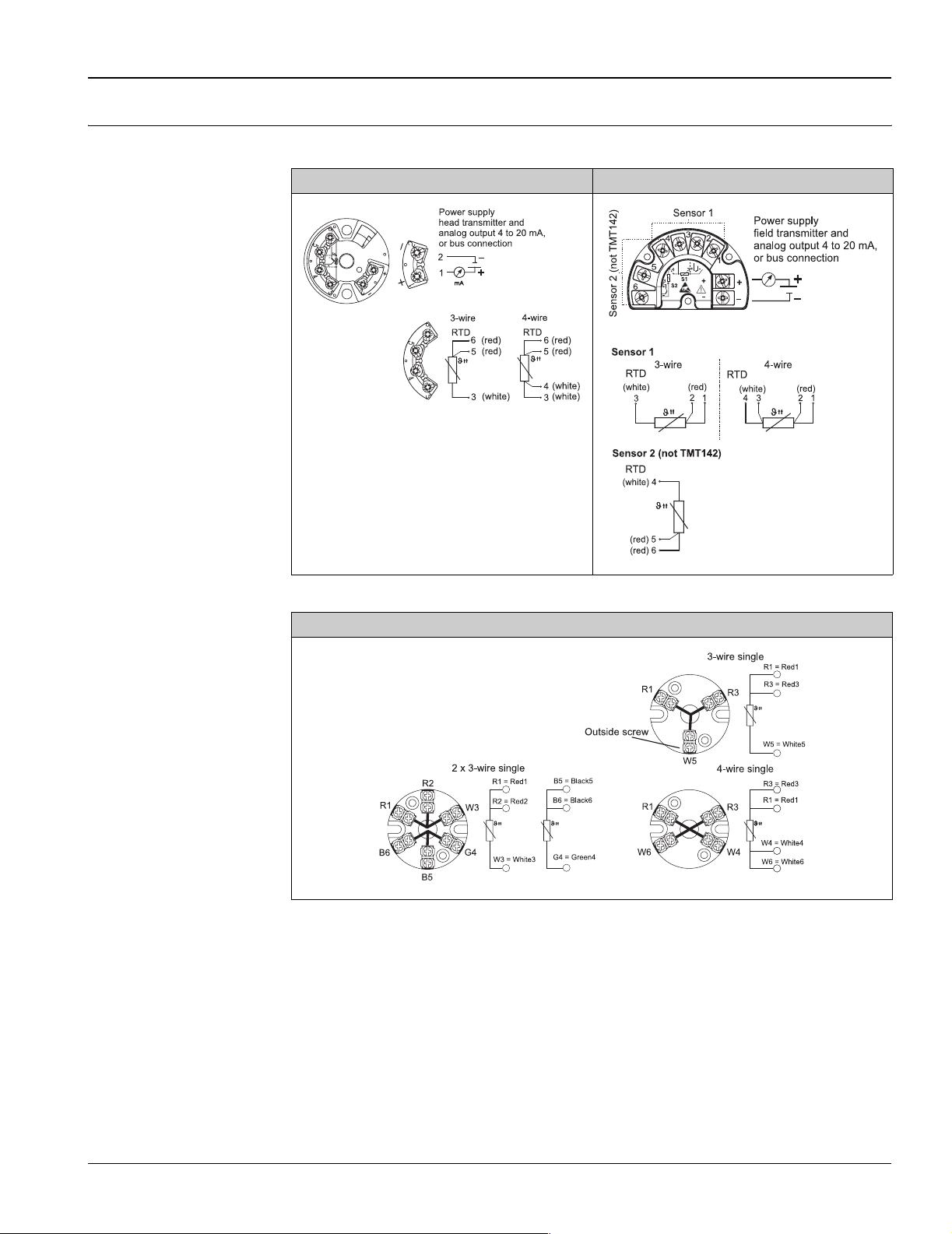

Wiring diagrams Type of sensor connection

Head mounted transmitter Field mounted transmitter

!

T09-TH1112xx-04-xx-XX-ae-000

Terminal block mounted

Note!

The blocks and transmitters are shown as they sit inside the heads in reference to the conduit opening.

T09-TH131415-04-xx-xx-ae-000

T09-TH1112xx-04-xx-XX-ae-001

Endress+Hauser 7

Wire specifications 24AWG, 19 strand silver plated copper with 0.010” PTFE extruded outer.

Electrical connection

Flying leads, standard 3" for wiring in connection head, head mounted transmitter or terminal block mounted

Flying leads, 5½" for wiring with TMT162 or TMT142 assemblies

Design of leads

Flying leads 3" or 5½" with

brass crimped sleeves

Installation conditions

Orientation No restrictions for installation orientation.

TH13, TH14, TH15

Installation instructions

T09-TH1314x15-11-xx-xx-ae-000

Examples for pipe installation - In pipes with a small cross section the sensor tip should reach or extend slightly past the

center line of the pipe (=U).

A: TH13 assembly socket weld installation

B: Threaded, tilted installation of TH13 assembly

C: Flange installation of TH14 assembly

8 Endress+Hauser

Loading...

Loading...