Page 1

Technical Information

Omnigrad S TMT142C

Compact Thermometer

Temperature transmitter for thermocouples, adjustable via HART

protocol

®

Application

The temperature assembly TMT142C from the

Omnigrad S family is a compact thermometer specifically

designed to fulfill the requirements of different process

industries such as the chemical, petrochemical and

energy but even suitable to other general purpose

applications.

The thermometer assembly TMT142C consists of a

thermocouple sensor insert (Type J or K) and an

electronic two-wire temperature transmitter providing a

4 to 20 mA output, configurable via HART

Thanks to the versatility of its product structure, the

TMT142C is easily adaptable to various applications in

many different industrial processes.

Your benefits

•HART® protocol for operating the device on site using

handheld terminal (DXR375) or remotely via the PC

• Illuminated display, rotatable

• Operation, visualization and maintenance with PC,

e.g. using FieldCare or ReadWin® 2000 operating software

• 2-wire transmitter, analog output 4 to 20 mA

• Undervoltage detection responds immediately, output

of falsified measured values is prevented

• Highly accurate in entire operating temperature range

®

protocol.

• Sensor monitoring:

Failure conditioning, corrosion detection to NAMUR

NE 89; Failure conditioning in event of sensor break or

sensor short-circuit, adjustable to NAMUR NE 43

• EMC to NAMUR NE 21, CE

• Sensor insets with thermocouple (Type J or K) made by

mineraloxide cables, replaceable

• Thermocouple sensing element type J or K, accuracy

class 1 or 2 (IEC 60584)

• Single or double TC element

• Aluminum or Stainless steel (optional) housing with

ingress protection degree IP67 or NEMA 4x

• Calibration certificate can be ordered in the product

structure

• Output simulation

• Min./max. process value recorded

• Customized measuring range setup or expanded

SETUP, see questionnaire

• Approvals: ATEX (EEx ia, EEx d and Staub-Ex), CSA

(IS, NI, XP and DIP)

0 1

TI129R/09/en

71022417

Page 2

TMT142C

Function and system design

Measuring principle In the thermocouple thermometer the sensing element is created by the physical junction of two homogeneous

but different alloys (wires) isolated for the entire length, except in the junction point. The two wires are welded

on one side, named ‘measuring or hot junction’, while the free wires side, named ‘reference or cold junction’

is connected to an electrical circuit measuring the electromotive force (mVolts) generated by the different

thermoelectric characteristics of the two thermocouple wires when a temperature difference between the hot

junction (T1) and the cold junction (T0) occurs. The function linking the electromotive force to the

temperatures T1 and T0 depends on the materials utilized in the alloys. These functions are standardized

curves, for different alloys couples, by the following international standards: IEC 60584 and ANSI MC96.1.

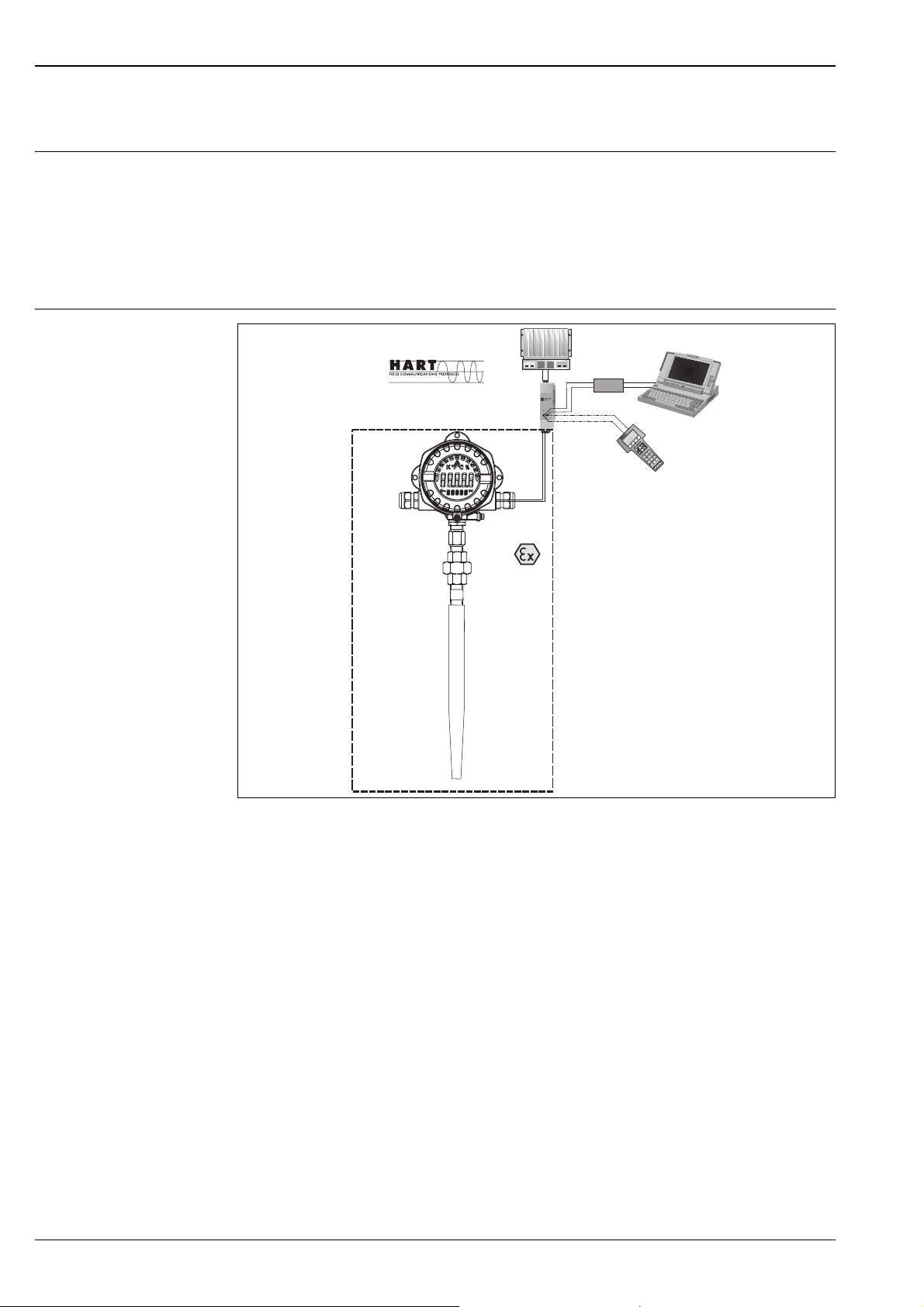

Measuring system

TMT142R,

TMT142C

FieldCare,

®

®

RN221N

Commubox

ReadWin 2000

PMC731:PIC0001

Online

1>GroupSelect

2PV 0.7bar

HELP

DXR375

O

I

®

HART Communication

Example of an application of the compact thermometer

The Omnigrad S HART® TMT142C is a compact thermometer with a two-wire transmitter and an input for

thermocouples (Type J or K) and an analog output. The LC display shows the current measured value digitally

and as a bar graph with an indicator for limit value violation. The TMT142C can be operated via the HART

protocol using a handheld terminal (DXR375) or PC (FieldCare or ReadWin

®

2000 operating software).

The sensor construction is based on the IEC 60751 standard, giving high reliability and performance in all the

typical industrial environment conditions.

The TC sensing elements are created by two types of alloy couples: the type J (Fe-CuNi) or the type K (NiCrNi). The measuring ranges of this temperature sensing elements have different values depending on the couple

types. The measuring probe (TC replaceable insert) is installed in a suitable thermowell.

Thanks to the spring load construction method, the thermometer insert stays always in contact with the inner

tip of the thermowell in order to guarantee the best heating transfer from the process to the sensing element.

The transmitter housing is available either in coated aluminum or stainless steel (optional), with or without LC

display. The fit between housing, thermowell and cable gland ensures a minimum IP65 (Ingress Protection)

grade.

The thermowell can be either welded or made from bar-stock material. The thermowells are available in

different forms and with many process connections: threads, flanges or weld-in types (see the paragraph

“Thermowell”).

Corrosion detection

Sensor connection line corrosion can corrupt the measured value. For this reason, the device gives you the

opportunity to detect corrosion for thermocouples and resistance thermometers with a 4-wire connection

before measured value corruption takes place.

2 Endress+Hauser

®

Page 3

TMT142C

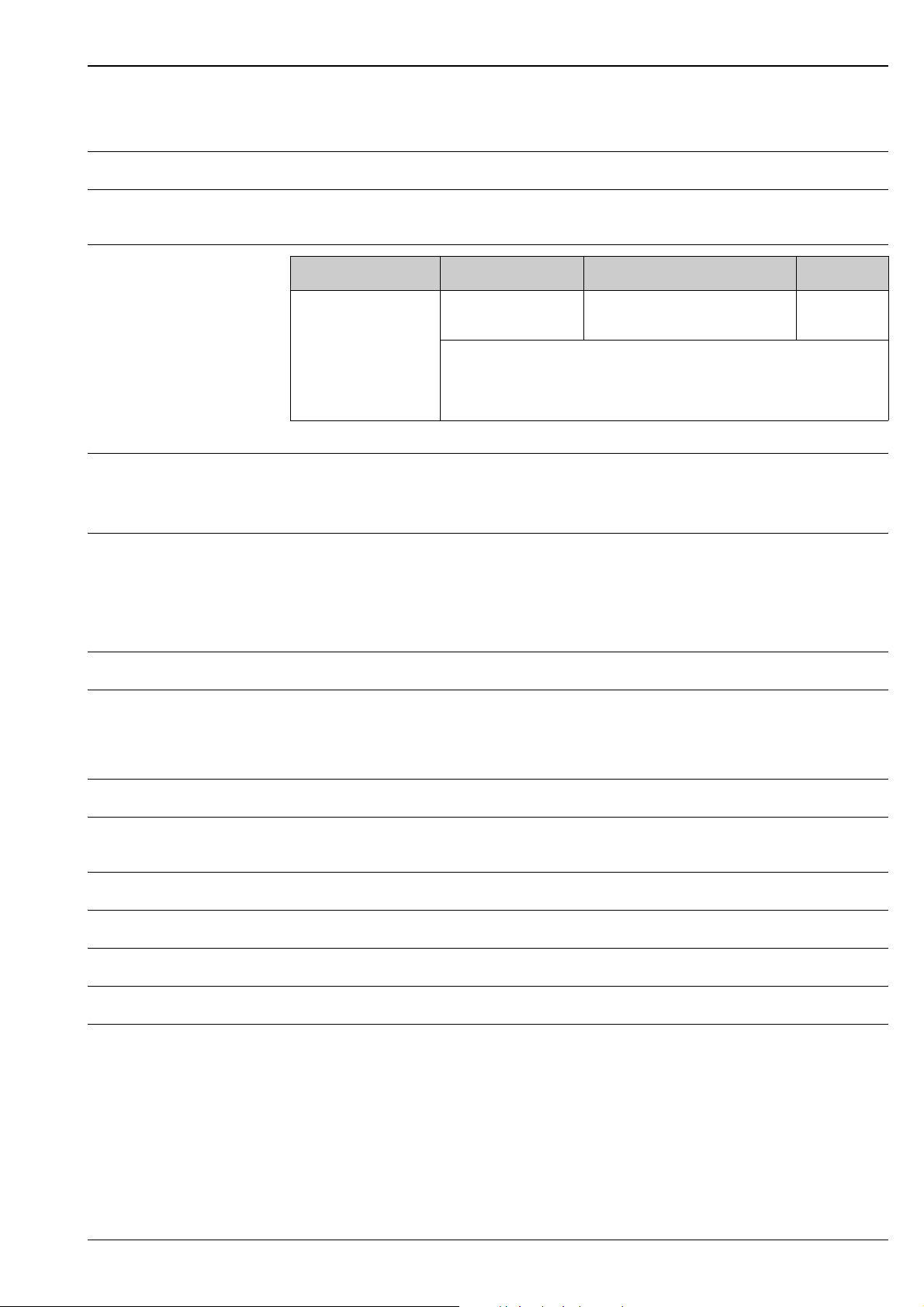

Input

Measured variable Temperature (temperature linear transmission behavior)

Measuring range The transmitter records different measuring ranges depending on the sensor connection and input signals (see

'Type of input').

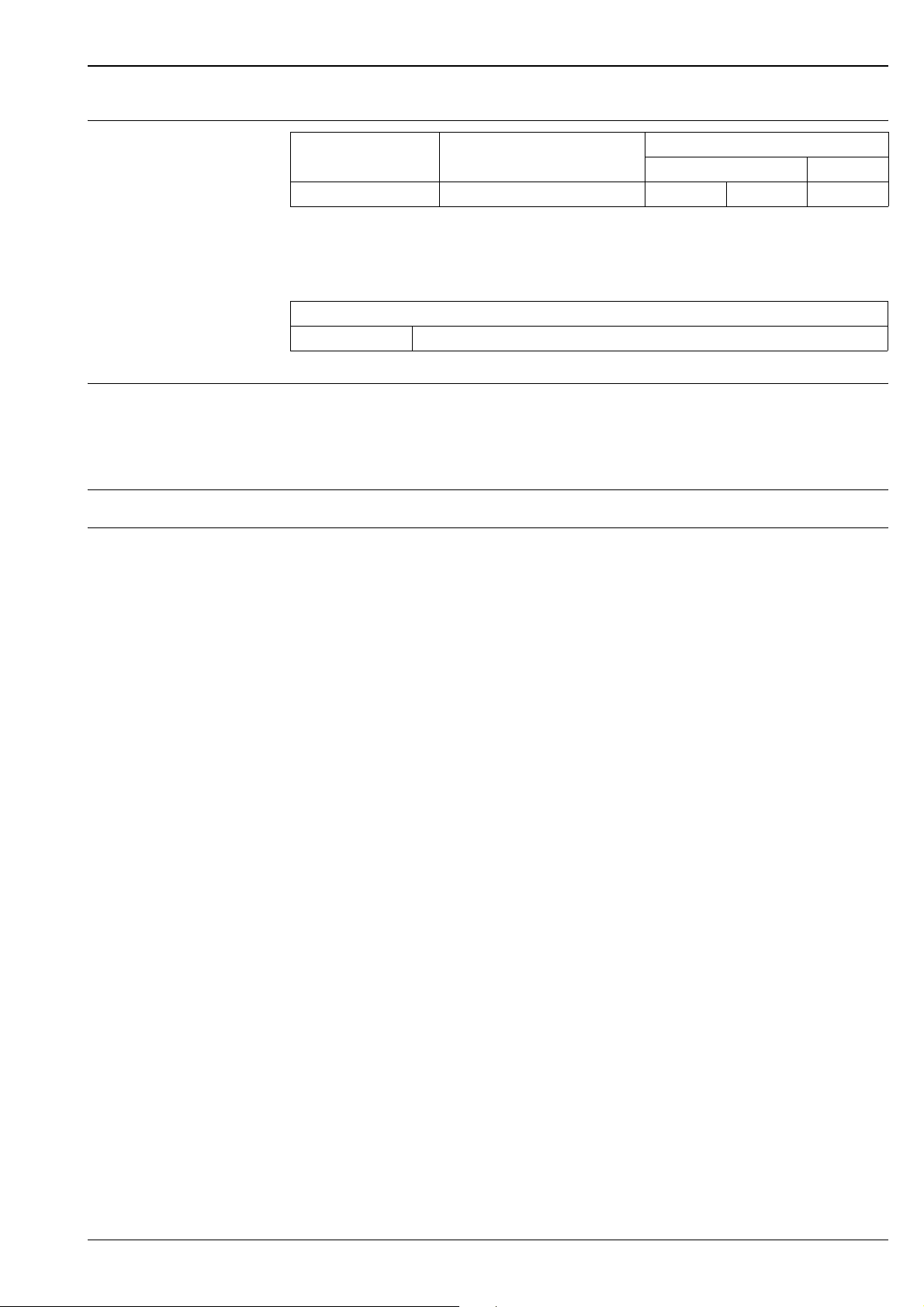

Type of input

Input Designation Measuring range limits Min. span

Thermocouples (TC)

to NIST Monograph 175,

IEC 584

Type J (Fe-CuNi)

Type K (NiCr-Ni)

• Internal cold junction (Pt100)

• Accuracy of cold junction: ± 1 K

• Max. sensor resistance 10 kΩ (if sensor resistance is greater than 10 kΩ, error message

as per NAMUR NE 89)

-210 to +1200 °C (-346 to 2192 °F)

-270 to +1372 °C (-454 to 2501 °F)

Response time Tests in water at 0.4 m/s (according to IEC 60751; 23 to 33°C step changes), without thermowell:

• t50: 2.5 s

• t90: 7 s

Self heating Negligible

Output

Output signal analog 4 to 20 mA, 20 to 4 mA

Signal on alarm • Underranging:

Linear drop to 3.8 mA

• Overranging:

Linear rise to 20.5 mA

50 K

50 K

Load max. (V

Linearization/transmission

Temperature linear, resistance linear, voltage linear

power supply

- 11 V) / 0.022 A (current output)

behavior

st

Filter 1

order digital filter: 0 to 60 s

Galvanic isolation U = 2 kV AC (input/output)

Input current required ≤ 3.5 mA

Current limit ≤ 23 mA

Switch-on delay 4 s (during switch-on operation I

= 4 mA)

a

Endress+Hauser 3

Page 4

Power supply

TMT142C

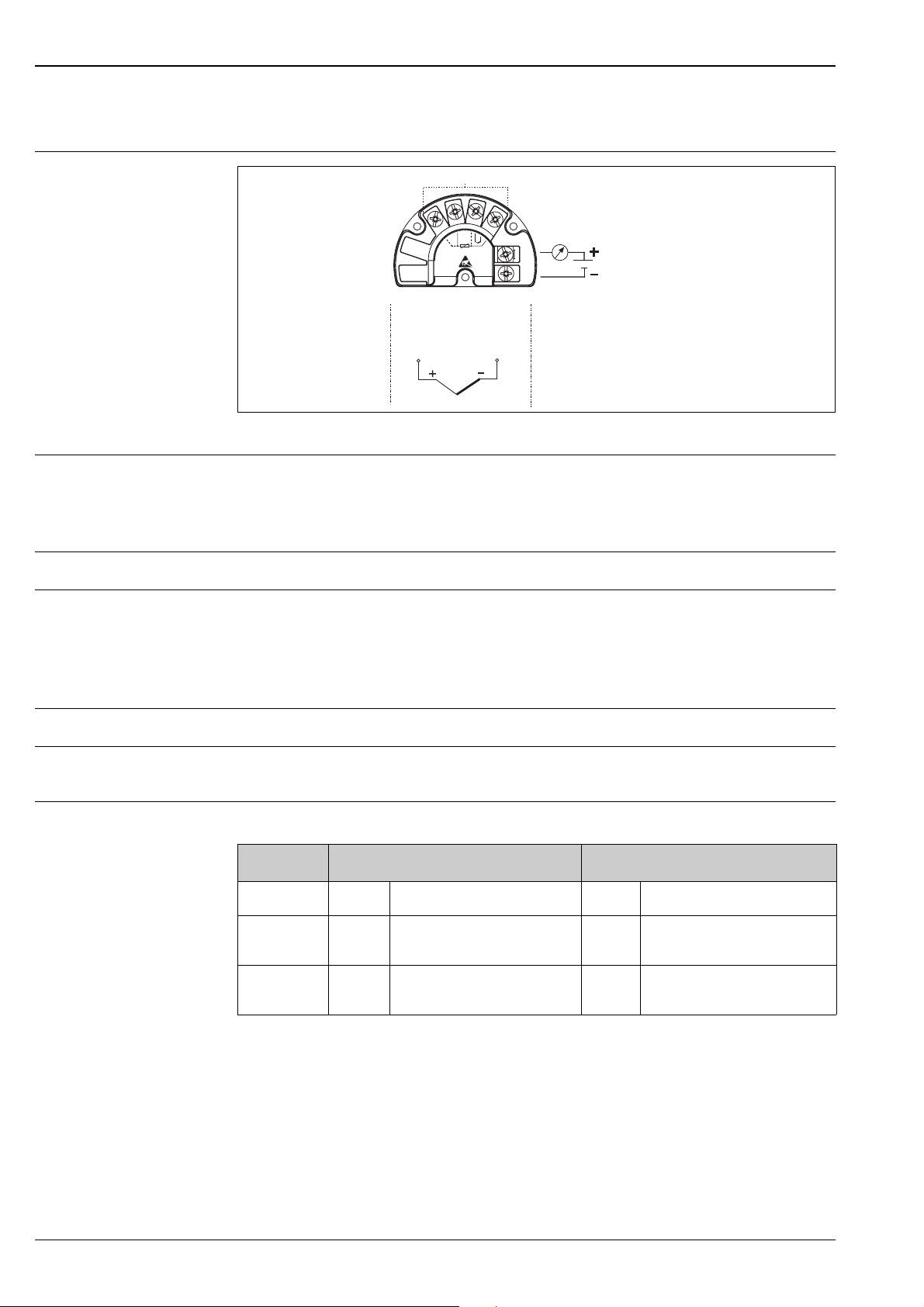

Electrical connection

Supply voltage U

= 11 to 40 V (8 to 40 V without display), reverse polarity protection

b

Warning!

Power must be fed to the device from an 11 to 40 VDC power supply in accordance with NEC Class 02 (low

voltage/current) with short-circuit power limit to 8 A/150 VA.

Cable entry see "Product structure"

Residual ripple Perm. residual ripple U

Sensor

3

4

+

4

3

S1

Sensor

TC

2

≤ 3 V at Ub ≥ 13.5 V, f

ss

2

1

-

+

+

#

-

-

1

= 1 kHz

max.

11...40 V

11...30 V Ex

4...20 mA

®

HART - Signal

Accuracy

Response time 1 s per channel

Reference operating conditions

Maximum measured error The accuracy values defined by the IEC 60584 standard, are as follows:

Calibration temperature: +25 °C ± 5 K (77 °F ± 9 °F)

Type Standard tolerance (IEC 60584) Reduced tolerance (IEC 60584)

Class Deviation Class Deviation

J (Fe-CuNi) 2 +/-2.5 °C (-40...333 °C)

+/-0.0075 |t| (333...750 °C)

K (NiCr-Ni) 2 +/-2.5°C (-40...333°C)

+/-0.0075 |t| (333...1200 °C)

(ItI=absolute temperature value in °C)

1 +/-1.5 °C (-40...375 °C)

1 +/-1.5 °C (-40...375 °C)

+/-0.004 |t| (375...750 °C)

+/-0.004 |t| (375...1000 °C)

4 Endress+Hauser

Page 5

TMT142C

Transmitter maximum measured error

Thermocouples (TC) K, J typ. 0.5 K typ. 0.25 K

1) % relates to the set span. Accuracy = digital + D/A accuracy

2) Only with the "Advanced Electronics" option

Physical input range of the sensors

-20 to 100 mV Thermocouples type: J, K

Designation

Repeatability 0.03% of the physical input range (15 Bit)

Resolution A/D conversion: 18 Bit

With the "Advanced Electronics" option:

0.015% of the physical input range (16 Bit)

Influence of supply voltage ≤ ±0.005%/V deviation from 24 V, related to the full scale value

Long-term stability ≤ 0.1 K/year or ≤ 0.05%/year

Data under reference conditions. % relates to the set span. The larger value applies.

Accuracy

digital D/A

2

0.02%

1

Endress+Hauser 5

Page 6

TMT142C

Influence of ambient temperature (temperature drift)

Total temperature drift = input temperature drift + output temperature drift

Effect on the accuracy when ambient temperature changes by 1 K (1.8 °F)

Input 10 to 400 Ω 0.002% of measured value 0.001% of measured value

Input 10 to 2000 Ω 0.002% of measured value 0.001% of measured value

Input -20 to 100 mV typ. 0.002% of measured value (maximum

value = 1.5 x typ.)

Input -5 to 30 mV typ. 0.002% of measured value (maximum

value = 1.5 x typ.)

Output 4 bis 20 mA typ. 0.002% of measured value (maximum

value = 1.5 x typ.)

1) Only with the "Advanced Electronics" option

Typical sensor resistance change when process temperature changes by 1 K (1.8 °F):

J: 55 µV

K: 40 µV

typ. 0.001% of measured value1 (maximum

value = 1.5 x typ.)

typ. 0.001% of measured value

value = 1.5 x typ.)

typ. 0.001% of span

1.5 x typ.)

1

1

1

(maximum

1

(maximum value =

Examples for calculating the accuracy:

• Example 1 (without the "Advanced Electronics" option):

Input temperature drift ∆ϑ = 10 K (18 °F), thermocouple type K with span 0 to 600 °C (32 to 1112 °F)

Maximum process value: 600 °C (1112 °F)

Measured thermoelectric voltage: 24905 µV (see IEC584)

Typ. influence in µV: (0.002% of 24905 µV) * 10 = 5 µV

Conversion Ω to °C: 5 µV / 40 µV/K = 0.12 K (0.216 °F)

• Example 2 (without the "Advanced Electronics" option):

Output temperature drift ∆ϑ = 10 K (18 °F), measuring range 0 to 100 °C (32 to 212 °F)

Span: 100 K (180 °F)

Typical influence: (0.002% of 100 K) * 10 = 0.02 K; (0.002% of 180 °F) * 10 = 0.036 °F

∆ϑ = deviation of ambient temperature from the reference operating condition

Total measuring point error = max. possible measured error + temperature sensor error

Influence of cold junction Pt100 DIN IEC 751 Cl. B (internal cold junction with thermocouples TC)

Installation

Installation instructions Mounting location

Direct mounting on the temperature sensor or indirect mounting using mounting bracket (see 'Accessories').

6 Endress+Hauser

Page 7

TMT142C

Environment

Ambient temperature limits • without display: -40 to +85 °C (-40 °F to +185 °F)

• with display: -40 to +70 °C (-40 °F to +158 °F)

For use in hazardous areas, see Ex certificate

Note!

The display can react slowly for temperatures < -20 °C (< -4 °F).

Readability of the display cannot be guaranteed at temperatures < -30 °C (-22 °F).

Process temperature The operating range depends on sensor and thermowell.

Storage temperature • Without display: -40 to +100 °C (-40 °F to +212 °F)

• with display: -40 to +85 °C (-40 °F to +185 °F)

Operating height Up to 2000 m above MSL

Climate class As per IEC 60 654-1, Class C

Degree of protection IP 67, NEMA 4x

Shock and vibration resistance 3g / 2 to 150 Hz as per IEC 60 068-2-6

Electromagnetic compatibility

(EMC)

Condensation Permitted

Installation category I

Pollution degree 2

Maximum process pressure Maximum pressure values at various temperatures are indicated in the Technical Information of the different

Maximum flow velocity The maximum flow velocity depends on the insertion length, the mechanical strength of the thermowell, and

Interference immunity and interference emission as per EN 61 326-1 (IEC 1326) and NAMUR NE 210.08 to

2 GHz 10 V/m; 1.4 to 2 GHz 30 V/m to EN 61000-4-3

thermowells (see TI documentation codes at the end of this document).

on pressure and temperature of the measuring point.

Endress+Hauser 7

Page 8

TMT142C

Mechanical construction

Installation The Omnigrad S resistance thermometer model TMT142C can be mounted on the wall of pipes or vessels or

other plant parts. In the case of ATEX/FM/CSA certified components (transmitter + insert), please refer to the

relevant documentation (see "Documentation").

The immersion length may have an effect on the accuracy of the measurement. If the immersion is too small,

an error may be generated in the temperature detected due to the lower temperature of the process fluid near

to the walls and the heat transfer, which takes place through the sensor shaft. The incidence of such an error

is not negligible if there is a big difference between the process temperature and the ambient temperature. In

order to avoid this source of inaccuracy,the thermowell should have a small diameter and the immersion length

(L) should be, if possible,at least 100-150 mm.

In pipes of a small cross-section the axis line of the duct must be reached and if possible slightly exceeded by

the tip of the thermowell (refer to fig. A and C). Another solution may be a tilted installation (see fig. Band D).

Examples of installation

In the case of two-phase flows, please pay special attention to the choice of the measurement point, as there

may be fluctuations in the value of the detected temperature. With regard to corrosion, the base material of the

wetted thermowells is important.

In case that the sensor components are disassembled and than re-mounted the proper assembling torque must

be applied in order to guarantee the defined ingress protection.

Housing The housing of the TMT142C is a single compartment container.

Microcontroller controlled display in single chamber housing with illuminated LC display. Parameterization of

measuring range, decimal point and offset of the display can be done comfortably using a PC with the PC

software ReadWin

for power supply.

Extension neck The function of the extension neck between the sensor and the transmitter (electronic with display) is to

protect the transmitter from overheating due to high process temperatures.

The extension neck consists of various couplings (nipples, union) suitable to adapt the temperature sensor to

the different thermowells.

The neck material is usually stainless steel 316L/1.4404.

The standard lengths (N) and the extension neck versions are selectable amongst the following options:

• 52 mm (2.05") (only 1/2” NPT, Type L)

• 102 mm (4.02") (nipple+union, Type LU)

• 96 mm (3.78") (nipple+coupling, Type LC)

• 144 mm (5.67") (nipple+union+nipple, Type LUN)

• 138 mm (5.43") (nipple+coupling+nipple, Type LCN)

®

2000. The display is continuously rear-illuminated and does not require additional wiring

8 Endress+Hauser

Page 9

TMT142C

Process connection to thermowell: threads

Type Thread Digit C (mm) Detail Extension neck type

G 1/2" D 15

1/2" NPT N 8

3/4" NPT P 8.5

Male

1/2” NPT U 8

M24x1.5 5 16

Female

Caution!

* Extension necks available only with 1/2” NPT threads

Besides the standard neck options indicated it is possible to order a specific neck by entering the length in the

order code.

The mechanical coupling situated in the upper part of the neck allows for orientation of the sensor head. As

illustrated by the figure below, the length of the extension neck influences the temperature in the head. The

extension neck length has to be chosen in such a way that the temperature within the head remains below the

maximum permissible operating temperature.

Heating of the head due to the process temperature

Endress+Hauser 9

Page 10

TMT142C

Thermowell The thermowell already exists in the plant or has to be ordered separately. To this end the extension neck is

available with different forms.In order to easily select the right mechanical fitting for the thermowell you are

kindly requested touse the table list and the ML values described at the chapter “Probe”.

Probe In the TMT142C compact thermometer the probe consists of a mineral oxyde insert which is inserted and fixed

into the thermowell.

The length of the sensor is freely selectable inside the predefined lengths range (50 to 990 mm / 1.97" to 39").

Sensors exceeding the 990 mm (39") length are available on request.

The immersion length (ML) must be defined as a function of the type and length of the relevant thermowell.

In case of spare inserts to be ordered please read carefully the following table (table valid for standard thickness

tip):

Thermowell

type

TW10* ML = A - 8 TA535 ML = A - 8 TA560 ML = A - 11

TW11* ML = A - 8 TA562 ML = A - 11

TW12* ML = A - 8 TA540 ML = A - 10 TA565 ML = A - 11

TW13* ML = A - 8 TA541* ML = A - 10 TA566 ML = A - 11

TW10** ML = A - 15 TA570 ML = A - 11

TW11** ML = A - 15 TA550 ML = A - 11 TA571 ML = A - 11

TW12** ML = A - 15 TA555 ML = A - 10 TA572 ML = A - 11

TW13** ML = A - 15 TA556 ML = A - 10 TA575 ML = A - 11

TW15** TW15** TA557 ML = A - 10 TA576 ML = A - 10

ML Thermowell

type

ML Thermowell

type

Caution!

* TMT142C with connection to thermowell NPT female

** TMT142C with connection to thermowell metric female (M24x1.5)

ML

System components

10 Endress+Hauser

Page 11

TMT142C

Design, dimensions of the connection head

Data in mm (data in Inches in brackets)

• Display rotatable in 90° stages

Weight • 1.6 kg to 5 kg (3.5 to 11 lbs) (standard options with aluminum housing)

• 4.2 kg to 8 kg (9.4 to 17.6 lbs) (standard options with stainless steel housing)

Material • Housing: die-cast aluminium housing AlSi10Mg with powder coating on polyester basis or stainless steel

1.4435 (AISI 316L)

• Sheathing: 1.4404 (AISI 316L)

• Nameplate: 1.4301 (AISI 304)

2

Terminals Cables / wires up to max. 2.5 mm

(AWG 13) plus ferrule

Human interface

Display elements

50

40

60

!

°C

%

70

80

90

100

30

20

°F

K

10

0

Ê

Ë

Ì

Í

Î

Ï

Ð

LC display of the field transmitter (illuminated, can be rotated in 90 stages)

Item 1: Bar graph display in 0 % stages with indicators for overranging/underranging

Item 2: 'Caution' display

Item 3: Unit display K, °F, °C or %

Item 4: Measured value display (digit height 20.5 mm / 0.81 ")

Item 5: Status and information display

Item 6: 'Communication' display

Item 7: 'Programming disabled' display

Operating elements No operating elements are present directly on the display. The device parameters of the field transmitter are

configured using the DXR375 handheld terminal or a PC with Commubox FXA191 and operating software

(e.g. FieldCare or ReadWin® 2000).

Endress+Hauser 11

Page 12

TMT142C

Remote operation Configuration

see ’Operating elements’

Interface

®

communication via transmitter power supply (e.g. RN221N; see 'Measuring system').

HART

Configurable device parameters (selection)

Sensor type and type of connection, engineering units (°C/°F), measuring ranges, internal/external cold

junction, compensation of wire resistance with 2-wire connection, failure mode, output signal (4 to 20/20 to

4 mA), digital filter (damping), offset, TAG+descriptor (8+16 characters), output simulation, customized

linearization, recording of min./max. process value, analog output: channel 1 (C1)

Option: customized linearization

Certificates and approvals

CE mark The device meets the statutory requirements of the EC directives. Endress+Hauser confirms successful testing

of the device by affixing to it the CE mark.

Ex approval Information about currently available Ex versions (ATEX, FM, CSA, etc.) can be supplied by your E+H Sales

Center on request. All explosion protection data are given in a separate documentation which is available upon

request.

Other standards and guidelines

• IEC 60529:

Degrees of protection through housing (IP code)

• IEC 61010:

Protection measures for electrical equipment for measurement, control, regulation and laboratory procedures

• IEC 1326:

Electromagnetic compatibility (EMC requirements)

•NAMUR

Association for Standards for Control and Regulation in the Chemical Industry

12 Endress+Hauser

Page 13

TMT142C

Questionnaire

Ordering information

Questionnaire Endress+Hauser iTEMP temperature transmitter

Customer specific setup / Kundenspezifische Einstellung

Standard setup / Standardeinstellung

Sensor 1 (S1)

TC ()B ()C ()D ()E ()J

RTD

()K ()L ()N ()R ()S

()T ()U

( ) Pt100

( ) Pt500 ( ) Pt1000

( ) Ni100 ( ) Ni500 ( ) Ni1000

()mV

( ) 2 wire

( ) 10...400 Ohm

( ) 3 wire

Unit / Einheit

Range / Messbereich

(not / nicht PROFIBUS-PA)

Bus address / Busadresse

(only / nur PROFIBUS-PA)

( ) 10...2000 Ohm

( ) 4 wire

Low scale

Anfang

High scale

Ende

()°C

( )°F ( )K ( )°R ( )mV ( )Ohm

Bitte beachten!:

,

,

Messbereich und min. Spanne

(s. Techn. Daten)

Note!:

Range and min. span

(s. Techn. data)

[0...126]

Expanded setup / Erweiterte Einstellung

Reference junction /

( ) intern

( ) extern

Vergleichsstelle [0...80°C; 32...176°F]

Compensation wire resistance /

Kompensation Leitungswiderstand

Failure mode / ( )

S1

<

3,6 mA ()

21,0 mA

>

[

...30 Ohm]

0

(not / nicht PROFIBUS-PA)

Fehlerverhalten

Output / Ausgang

( ) 4...20 mA

( ) 20...4 mA

(not / nicht PROFIBUS-PA)

Filter

Offset

S1

Line voltage filter/Netzspannungsfilter

,

( ) 50 Hz

( ) 60 Hz

[-10...0...+10 K/-18...0...+18 °F]

(only / nur TC)

(only / nur RTD 2 wire)

[0, 1, 2,..., 60s]

TAG

(8 char. TAG + 16 char. Descriptor)

DESCRIPTOR

Endress+Hauser 13

Page 14

TMT142C

Product structure

TMT142C

Omnigrad S TMT142C TC Thermometer

Approval

A Non-hazardous area

B ATEX II1G EEx ia IIC T4/T5/T6

D CSA IS, NI I/1+2/A-D

E ATEX II2GD EEx d IIC T6

G CSA XP, DIP I,II,III/1+2/A-D

H ATEX EEx d EEx ia

K CSA XP, DIP, IS, NI, I, II, III/1+2/A-D

L ATEX II 3G EEx nA IIC T4/T5/T6

M ATEX II 1/2GD EEx d IIC T6

Cable connection; Display

A 2xM20x1.5, on top; w/o display

B 2xM20x1.5, on top; + display

C 2x1/2"NPT, on top; w/o display

D 2x1/2"NPT, on top; + display

1 2xM20x1.5, sidewise; w/o display

2 2xM20x1.5, sidewise; + display

3 2x1/2"NPT, sidewise; w/o display

4 2x1/2"NPT, sidewise; + display

Configuration

A Standard

Y Special version, to be specified

Neck length N; type

1 52 mm; nipple type L

2 104 mm; nipple + union type LU

3 96 mm; nipple + coupl. type LC

4 156 mm; nipple + union + nipple type LUN

5 148 mm; nipple + coupl. + nipple type L

9 ..... mm, as specified

Thermowell type

0 not needed

1 Bar stock

2 Pipe

Thermowell connection

D Thread G1/2"

N Thread 1/2"NPT-M

P Thread 3/4"NPT-M

U Thread M24x1.5-F

5 Thread 1/2"NPT-F

9 Special version, to be specified

TC Type; Material

A 1x K IEC584, 6mm; INCONEL600

B 2x K IEC584, 6mm; INCONEL600

C 1x J IEC584, 6mm; 316

D 2x J IEC584, 6mm; 316

G 1x K ANSI, 6mm; INCONEL600

H 2x K ANSI, 6mm; INCONEL600

J 1x J ANSI, 6mm; 316

K 2x J ANSI, 6mm; 316

9 special version, to be specified

TC Class; hot junction

1 purity cl.2; grounded

2 purity cl.1; grounded

5 purity cl.2; ungrounded

6 purity cl.1; ungrounded

9 special version, to be specified

TMT142C ⇐ Order code (Part1)

14 Endress+Hauser

Page 15

TMT142C

Insertion length ML

X .... mm

Y .... mm, as specified

Factory test

0 not needed

1 Inspection sensor

2 Inspection TC+TMT

TMT142C- ⇐ Order code (complete)

Customized options

Order No. 51003527 TAG print/configuration 8 char

Order No. 51003546 Descriptor print/configuration 16 char

Order No. 51002393 Metal TAG

Accessories

Optional accessories

Mounting bracket • Mounting bracket, stainless steel pipe 1.5-3", 316L

Order No. 51007995

Cable gland • Cable gland M20x1.5

Order No. 51004949

• able gland NPT 1/2" D4-8.5, IP68

Order No. 51006845

• Cable entry adapter M20x1.5 to NPT 1/2"

Order No. 51004387

Overvoltage protection • Surge arrester HAW569

Order code: HAW569-A11A for non-hazardous areas

Order code: HAW569-B11A for Ex areas ATEX 2(1)G EEx ia IIC

Active barrier • Active barrier RN221 for non-hazardous areas or as Ex version

Order code: RN221-... see "Documentation"

Documentation

FA brochure 'Temperature measuring technology' (FA006T/09/en)

Installation instructions, FieldCare configuration software (BA031S/04/a4)

Operating Instructions iTEMP® HART® TMT142 (BA191R/09/a3)

Operating Instructions 'Fieldgate FXA520' (BA258F/00/en)

Technical Information 'Fieldgate FXA520' (TI369F/00/en)

Supplementary Ex documentation:

ATEX II2G EEx d: XA048R/09/a3

ATEX II1/2D: XA049R/09/a3

ATEX II1G: XA050R/09/a3

ATEX EEx ia + EEx d: XA051R/09/a3

ATEX II3G: XA052R/09/a3

Technical Information 'Active barrier RN221' (TI073R/09/en)

Technical Information 'Surge arrester HAW569' (TI103R/09/en)

Endress+Hauser 15

Page 16

TMT142C

International Head Quarter

Endress+Hauser

GmbH+Co. KG

Instruments International

Colmarer Str. 6

79576 Weil am Rhein

Germany

Tel. +49 76 21 9 75 02

Fax +49 76 21 9 75 34 5

www.endress.com

info@ii.endress.com

TI129R/09/de/02.06

71022417

FM+SGML6.0 ProMoDo

Loading...

Loading...