Endress+Hauser S TC62 Specifications

Technical Information

71105556

Omnigrad S -TC62

Thermocouple thermometer EEx-d certified, replaceable inset , complete

from nipple and union to thermowell connection.

PCP (4...20 mA), HART® or PROFIBUS-PA® electronics

Range of uses

The Omnigrad S TC62 is an industrial thermometer (thermocouple TC: K or J) with a replaceable inset and a neck without

thermowell.

It is developed for heavy duty and/or generic industrial applications, assembled with a thermowell from bar stock or pipe.

In compliance to EN 50014/18/20 (ATEX certification) it is

therefore particularly suitable also for hazardous areas.

When required, it’s also available with a transmitter

(PCP, HART® or PROFIBUS-PA®) into the housing.

The TC62 is available in several standard versions and different

configurations, can also be configured with specific dimensions

and characteristics depending on process requirements.

The installation on the plants, require separately order of the

thermowell (form pipe or from bar-stock).

Application areas

• Chemicals industry

• Energy industry

• Gas Processing industry

• Petrochemical industry

• General industrial services

TI286T/02/en

Features and benefits

• Customized immersion length

• Aluminium housing, with protection grade from IP66 to IP68

• Thermocouple with hot junction grounded or ungrounded in

mineral oxide cable (MgO cable) diameter: 3 or 6 mm

• PCP, HART® and PROFIBUS-PA®,

(4...20 mA 2-wire transmitters)

• The accuracy of the thermocouple TC (K (NiCr-Ni)

and J (Fe-CuNi)) are:

Cl. 1 - 2 (EN 60584) or Cl. Special - Standard (ANSI MC96.1)

• The thermocouple TC (K or J) are available in single or double

element

• ATEX II 2 GD EEx-d IIC certification

4 0

Omnigrad S TC62

Function and system design

Measuring principle The thermocouple (TC) thermometer’s sensing element consists of two metal wires that are homogeneous but

different one from the other and insulated along their entire length. The two wires are welded together at one

end, known as the “measurement or hot junction”. The other end, where the wires are free, is known as the

“cold or reference junction” and is connected to a electromotive force measurement circuit where the force is

generated by the different thermoelectric power of each of the thermocouple’s wires if there is a temperature

difference between the hot joint (T1) and the cold joint (Seebeck effect). The cold junction has to be “compensated” with reference to the temperature of 0°C (T0). The function that links the electromotive force to the

temperatures T1 and T0 is a curve whose characteristics depend on the materials used in the construction of

the thermocouple. Some thermocouples curves, and particularly those most reliable for the purposes of industrial readings, are those compliant with standards EN 60584 and ANSI MC96.1.

Equipment architecture The construction of the TC62 temperature sensor is based on the following standards:

• EN 50014/18 (housing)

• Neck (Nipple and 3 elements)

• EN 60584 (insert).

The housing is in painted aluminium alloy; it is suitable

to contain a transmitter and/or the ceramic block of

the inset; the “Ingress Protection” is from IP66 to

IP68.

The neck composed by one or two nipple and one "3

union", standard or EEx- execution, it is the extension

between the head and the thermowell on the process.

The replaceable insert is placed inside the thermowell;

the insert is spring loaded to its base in order to

improve heat transfer.

The hot junction of the thermocouple (type K or J) are

positioned close to the tip of the probe. The thermocouple is available in two versions: grounded or

ungrounded hot junction. The electrical structure of

the thermocouple always complies with EN

60584/61515 or ANSI MC96.1/ASTM E585 standard rules.

Fig. 1: TC62 with the various types of thermowell connections and end parts of the probe

Material & Weight

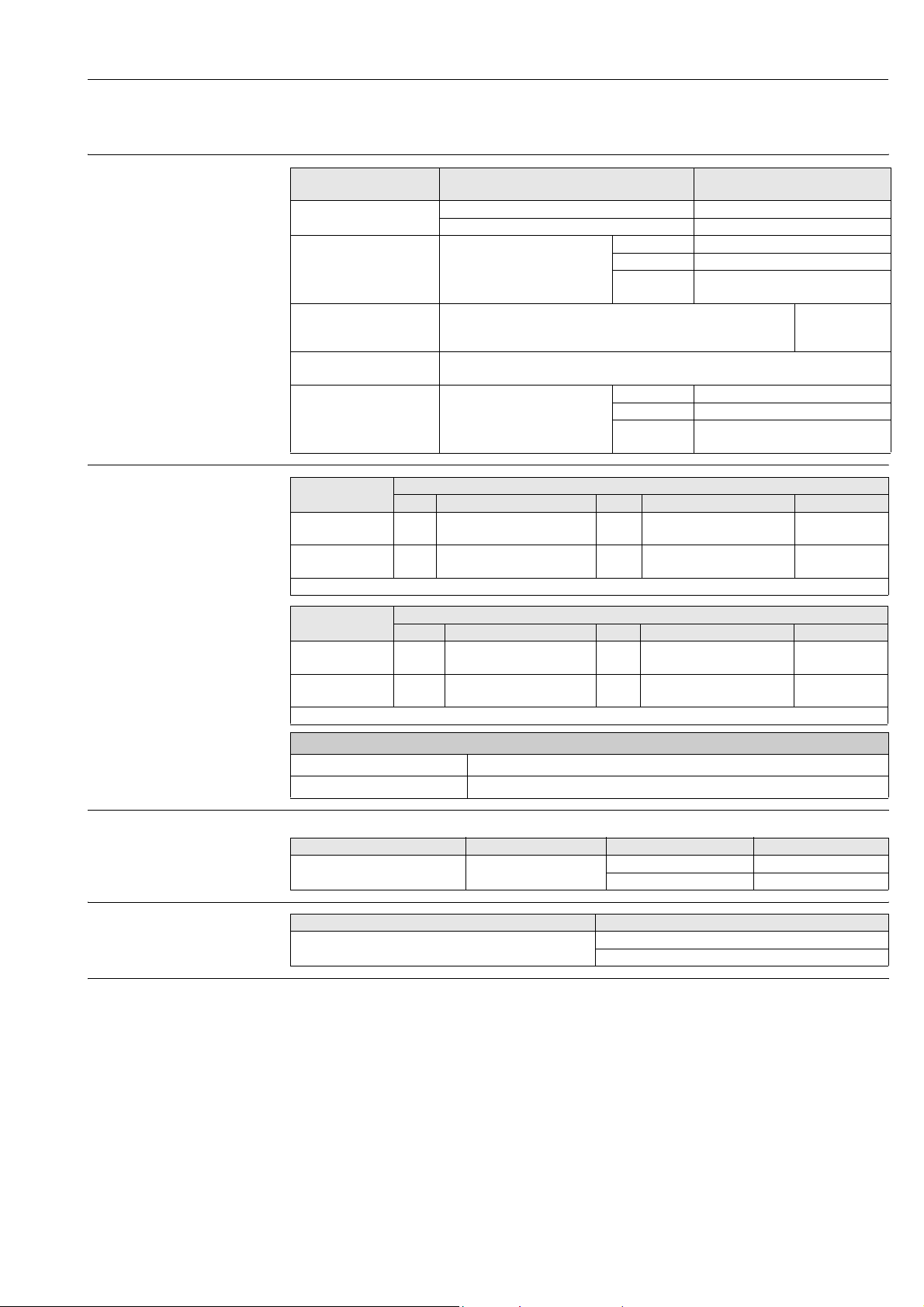

Housing Insert Extension neck Weight

aluminium epoxy

coated

sheath in SS 316L/1.4404

Inconel®600/2.4816

SS 316/1.4401 or A105 From 0.5 to 1.0 kg for standard

options

2 Endress+ Hauser

Performance

Omnigrad S -TC62

Operating conditions

Accuracy

Operating condition or

test

Ambient temperature housing (without head-mounted transmitter -40÷130°C

Process temperature It is restricted by the thermowell

Process pressure

(Maximum)

Maximum flow velocity The highest flow velocity, (of the stream or of the fluid), tolerated by the thermowell,

Shock and vibration resistance test

Thermocouple

and range °C

J (Fe-CuNi)

-40° ... 750°C

K (NiCr-Ni)

-40 ... 1200°C

Thermocouple

and range °C

J (Fe-CuNi)

0 ...750°C

K (NiCr-Ni)

0...1250°C

Product type or rules Value or data of test

housing (with head-mounted transmitter) -40÷85°C

< 600°C SS 316L/1.4404

material:

The pressure values to which the thermowell can be subjected at the

various temperatures. Example: for 9 mm diameter pipes, with a limited flow velocity, the maximum tolerated pressures are the following:

diminishes with increasing lengths, of the thermowell/probe exposed.

TC Inset in according to the rule

IEC 60751:

Class Max deviation Class Max deviation Cable colors

2 +/-2.5°C (-40...333°C)

+/-0.0075 |t| (333...750°C)

2 +/-2.5°C (-40...333°C)

+/-0.0075 |t| (333...1200°C)

ItI = absolute temperature value in °C

Class Max deviation Class Max deviation Cable colors

Stand-

ard

Stand-

ard

+/-2.2°C (0...293°C)

+/-0.75%o(293...750°C)

+/-2.2°C (0...293°C)

+/-0.75%o(293...1250°C)

ItI = absolute temperature value in °C

< 800°C SS 316Ti/1.4571

< 1100°C Hast.® C276/2.4819 -

Inc.600®/2.4816

50 bar to 20°C

33 bar to 250°C

24 bar to 400°C

Acceleration 3 g of peak

Frequency from 10Hz to 500Hz and back

Time of the

test

EN 60584

1 +/-1.5°C (-40...375°C)

1 +/-1.5°C (-40...375°C)

+/-0.004 |t| (375...1000°C)

ANSI MC96.1

Special +/-1.1°C (0...275°C)

Special +/-1.1°C (0...275°C)

10 hours

+/-0.004 |t| (375...750°C)

+/-0.4%o(275...750°C)

+/-0.4%o(275...1250°C)

+ black

- white

+ green

- white

+ black

- red

+ yellow

- red

Others errors

Transmitter maximum error See the corresponding documentation (codes at the end of the document)

Display maximum error 0.1% FSR + 1 digit (FSR = Full Scale Range)

Response time Tests, with the TC insert, in water at 0.4 m/s (according to IEC 60751) from 23 to 33°C:

Stem diameter of the insert Sensing element type Temperature of test Response time

Insulation

SS 316 - d. 6 mm K (NiCr-Ni), J (Fe-CuNi) t

Measurement Insulation type Result

Insulation resistance between terminals and probe sheath

according to EN 60584, test voltage 500 V

50

t

90

> 1GΩ at 25°C

> 5 MΩ at 500°C

2,5 s

7,0 s

Self heating Negligible when the E+H iTEMP® transmitters are employed.

Endress+Hauser 3

Loading...

Loading...