Page 1

Operating Instructions

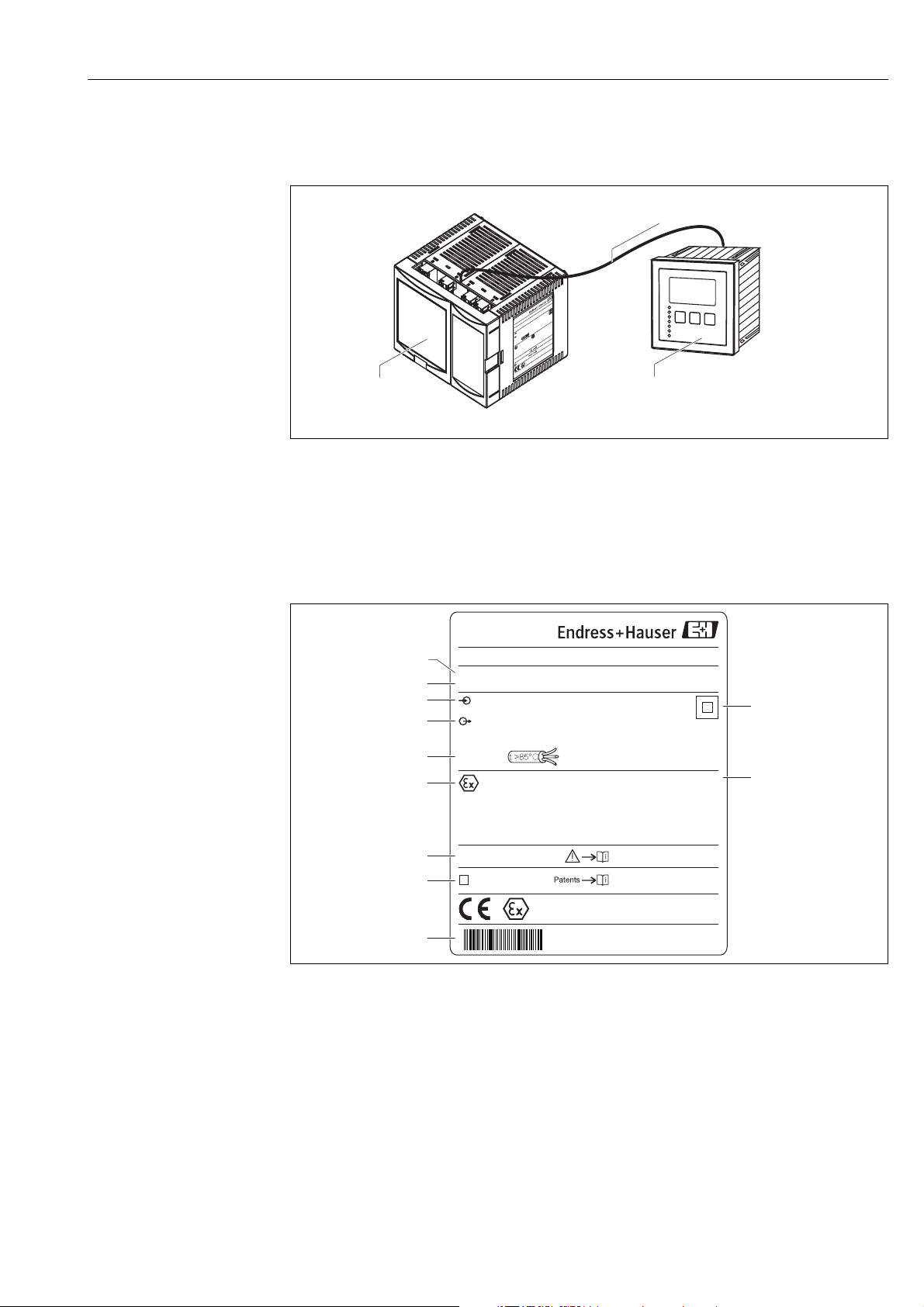

Prosonic S FMU95

Transmitter for 5 or 10 ultrasonic sensors

BA00344F/00/EN/13.12

71164423

Page 2

Page 3

Prosonic S FMU95 Table of Contents

Table of Contents

1 Safety Instructions . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning, operation . . . . . . . . . . . 4

1.3 Operational safety and process safety . . . . . . . . . . . . 4

1.4 Notes on safety conventions and symbols . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . 6

2.1 Parts of the Prosonic S FMU95 . . . . . . . . . . . . . . . . 6

2.2 Nameplate (Example) . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Product structure . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

2.6 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . 10

3.1 Incoming acceptance, transport, storage . . . . . . . . . 10

3.2 Mounting the field housing . . . . . . . . . . . . . . . . . . 10

3.3 Mounting the DIN-rail housing . . . . . . . . . . . . . . . 12

3.4 Mounting the remote display and operating module 13

3.5 Mounting of the sensors . . . . . . . . . . . . . . . . . . . . 14

3.6 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Maintenance . . . . . . . . . . . . . . . . . . . . 85

8.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.2 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.3 Repairs to Ex-approved devices . . . . . . . . . . . . . . . 85

8.4 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.5 Replacing a sensor . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.6 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.7 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.9 Contact addresses of Endress+Hauser . . . . . . . . . . . 87

9 Accessories . . . . . . . . . . . . . . . . . . . . . 88

9.1 Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . 88

9.2 Protection cover for the field housing . . . . . . . . . . . 88

9.3 Mounting plate for the field housing . . . . . . . . . . . . 88

9.4 Mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.5 Adaption plate for remote display . . . . . . . . . . . . . . 90

9.6 Overvoltage protection (in IP66 housing) . . . . . . . . 90

9.7 Overvoltage protection HAW562 . . . . . . . . . . . . . . 91

9.8 Extension cable for sensors . . . . . . . . . . . . . . . . . . 91

10 Technical Data. . . . . . . . . . . . . . . . . . . 92

10.1 Technical data at a glance . . . . . . . . . . . . . . . . . . . 92

4.1 Terminal compartment . . . . . . . . . . . . . . . . . . . . . 15

4.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Connection to a PROFIBIS DP network . . . . . . . . . 20

4.4 Sensor connection . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5 Shortening the sensor cable . . . . . . . . . . . . . . . . . . 23

4.6 Synchronization line. . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Connection of the separate display and operating

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.8 Potential equalization . . . . . . . . . . . . . . . . . . . . . . 26

4.9 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 28

5 Operation . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Operating options . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Operation via the display and operating module . . . 31

5.3 Operation via Endress+Hauser operating tool

"FieldCare" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6 Commissioning. . . . . . . . . . . . . . . . . . 44

6.1 Preparatory steps . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2 Configuration of the measurement . . . . . . . . . . . . . 49

6.3 Parametrization of the Analog Input Blocks . . . . . . 68

6.4 Parametrization of the cyclic data telegram . . . . . . 69

6.5 Parametrization of the on-site display . . . . . . . . . . . 71

11 Operating menu. . . . . . . . . . . . . . . . . . 96

11.1 "level" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

11.2 "safety settings" . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11.3 "outputs/calculations" . . . . . . . . . . . . . . . . . . . . . . 98

11.4 "device properties" . . . . . . . . . . . . . . . . . . . . . . . . . 99

11.5 "system information" . . . . . . . . . . . . . . . . . . . . . . 100

11.6 "display" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

11.7 "sensor management" . . . . . . . . . . . . . . . . . . . . . . 102

12 Appendix. . . . . . . . . . . . . . . . . . . . . . 103

12.1 Default Block Configuration . . . . . . . . . . . . . . . . . 103

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7 Troubleshooting . . . . . . . . . . . . . . . . . 74

7.1 System error messages . . . . . . . . . . . . . . . . . . . . . . 74

7.2 Possible calibration errors . . . . . . . . . . . . . . . . . . . 80

7.3 Envelope curve display . . . . . . . . . . . . . . . . . . . . . 81

7.4 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Endress + Hauser 3

Page 4

Safety Instructions Prosonic S FMU95

1Safety Instructions

1.1 Designated use

The Prosonic S FMU95 is a transmitter for up to 10 ultrasonic sensors FDU90, FDU91, FDU91F,

FDU92, FDU93, FDU95 and FDU96. The sensors of the class FDU8x can be connected as well.

Functions:

• display of up to 10 measuring values

• interference echo suppression for each connected sensor

• linearistaion for each sensor individually programmable

• configurable calculation of sums and average values

• measuring value transmission via PROFIBUS DP

1.2 Installation, commissioning, operation

The Prosonic S FMU95 is fail-safe and constructed to the state-of-the-art. It meets the appropriate

standards and EC directives. However, if you use it improperly or other than for its designated use,

it may pose application-specific hazards, e.g. product overflow due to incorrect installation or

configuration. Installation, electrical connection, start-up, operation and maintenance of the

measuring device must therefore be carried out exclusively by trained specialists authorised by the

system operator. Technical personnel must have read and understood these operating instructions

and must adhere to them. You may only undertake modifications or repair work to the device when

it is expressly permitted by the operating instructions.

#

1.3 Operational safety and process safety

Alternative monitoring measures must be taken to ensure operational safety and process safety

during configuration, testing and maintenance work on the device.

Hazardous areas

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with the

installation instructions and ratings as stated in this Additional documentation is mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local regulations.

The transmitter may only be installed in suitable areas. Sensors with a certificate for hazardous areas

may be connected to a transmitter without a certificate.

Warning!

The sensors FDU83, FDU84, FDU85 and FDU86 with an ATEX, FM or CSA certificate are not

certified for connection to the FMU90 transmitter.

For installations in the USA:

Installation should be in accordance with the National Electrical Code NFPA 70 (NEC)

For installations in Canada:

Installation should be in accordance with the Canadian Electrical Code (CEC)

4 Endress + Hauser

Page 5

Prosonic S FMU95 Safety Instructions

t >85°C

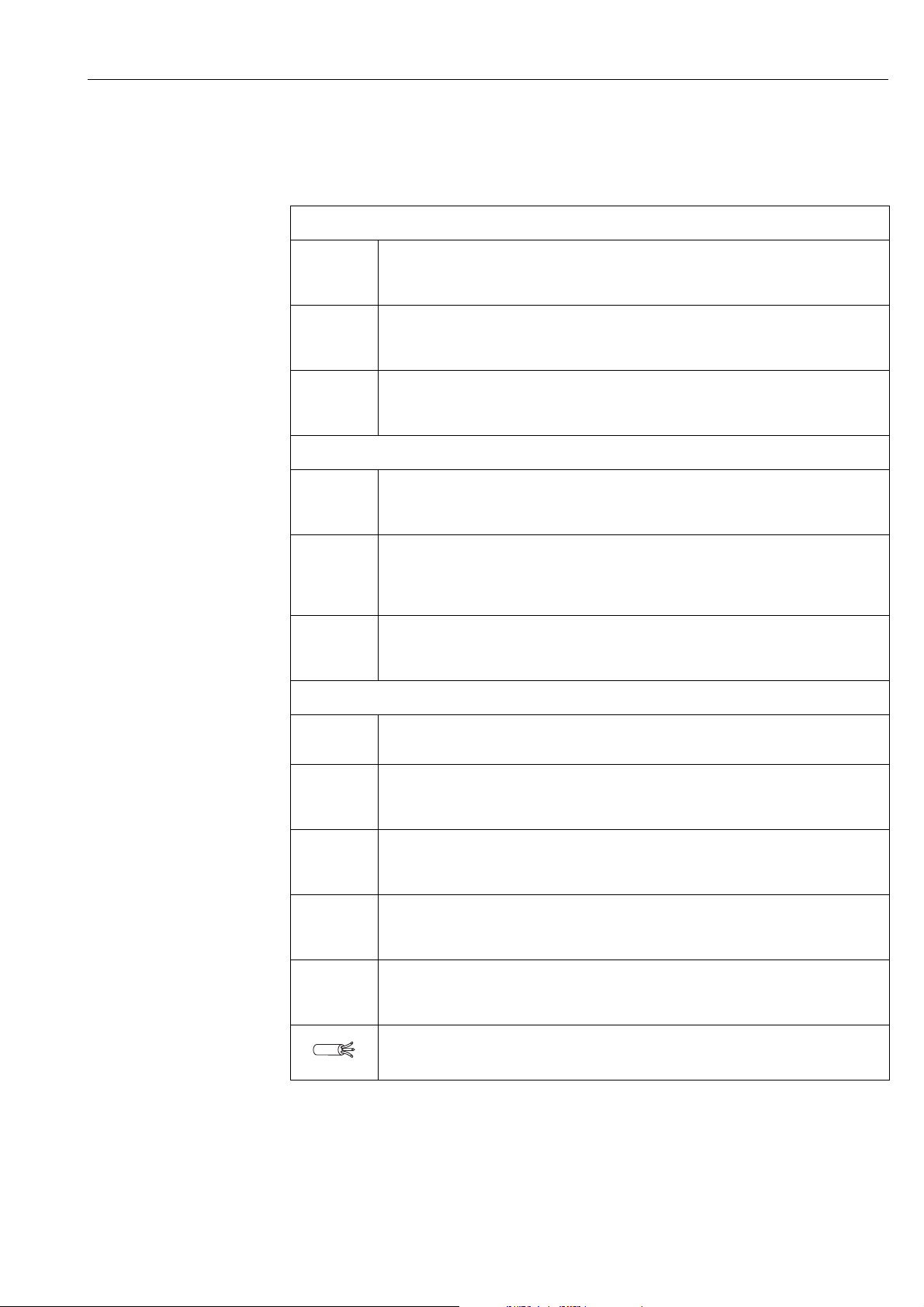

1.4 Notes on safety conventions and symbols

In order to highlight safety-relevant or alternative operating procedures in the manual, the following

conventions have been used, each indicated by a corresponding symbol in the margin.

Safety conventions

Warning!

#

"

!

Explosion protection

0

A warning highlights actions or procedures which, if not performed correctly, will lead to personal

injury, a safety hazard or destruction of the instrument

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal

injury or incorrect functioning of the instrument

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect

operation or may lead to an instrument response which is not planned

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion hazardous

area

-

.

Electrical symbols

%

&

)

*

+

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in and wiring

entering areas with the designation “explosion hazardous areas” must conform with the stated type

of protection.

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas. Devices located in

safe areas still require a certificate if their outputs run into explosion hazardous areas

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be applied or

supplied

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by means of an

earth grounding system

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to the

equipment

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or

equipotential line according to national or company practice

Temperature resistance of the connection cables

States, that the connection cables must be resistant to a temperature of at least 85 °C.

Endress + Hauser 5

Page 6

Identification Prosonic S FMU95

M

ade

inG

erm

an

y

D

-79

6

89

M

a

u

lb

u

rg

MadeinGer

m

a

ny

D-79689Maulbu

rg

P

r

o

s

o

n

i

c

S

Prosonic

S

T

a

>

6

0

°

C

:

T

a

>

60°C

:

II

3

D

T

=

x

x

x

°

C

II

3

D

T=xxx°C

I

P

6

6

/

N

E

M

A

4

X

I

P66

/

NEMA4X

X

A

xx

x

F

-

A

XAx

xxF-A

D

a

t.

/

I

n

s

p

.

:

Dat./Insp.:

ifm

od

ifi

cat

io

n

se

e

s

e

p.

la

be

l

if

mod

ification

seesep.la

b

el

X=X

=

1

0

,

5

…3

2

V

D

C

1

0

W

10,5…32

V

DC

10W

4…2

0

m

A

H

A

R

T

4…20

m

AHART

O

r

d

e

r

C

o

d

e

:

S

e

r

.-

N

o

.:

5

A

0

1

0

9

0

1

0

9

A

F

M

U

9

0

-

J

1

1

A

B

1

11

A

A

1

A

Order

Code:

Ser.-No.: 5A010901

0

9A

FMU

90

-J11A

B111AA1A

M

a

d

e

inG

e

r

m

a

n

y

D

-

7

9

6

8

9

M

a

u

l

b

u

r

g

MadeinGermany

D-79689Maulburg

P

r

o

s

o

n

i

c

S

Prosonic

S

O

r

d

e

r

C

o

d

e

:

S

e

r

.

-

N

o

.

:

5

A

0

1

0

9

0

1

0

9

A

F

M

U

9

0

-

J

1

1

A

B

1

11

A

A

1

A

Order

Code:

Ser.-

No

.: 5A01090109A

FMU90-J11AB111AA1A

4

3

9

2

5

10

8

1

7

6

M

a

d

e

i

n

G

e

r

m

a

n

y

D

-

7

9

6

8

9

M

a

u

l

b

u

r

g

ProsonicS

Ta

>

6

0

°C

:

II3

D

T=xxx°C

IP

66

/NEM

A4X

X

A

x

x

x

F

-

A

D

at./Insp.:

ifmodification

seesep.label

X=

10,5…32

V

D

C

10W

4…20 m

A

HART

O

rderC

ode:

Ser.-No.: 5A

0109

0109A

FM

U90-J1

1AB111AA1

A

M

a

d

e

i

n

G

e

r

m

a

n

y

D

-

7

9

6

8

9

M

a

u

l

b

u

r

g

ProsonicS

Ta

>

6

0

°

C

:

II3

D

T=xxx°C

IP

66

/NE

MA

4X

X

A

x

x

x

F

-

A

Da

t./Insp.:

ifmodification

seesep.label

X=

1

0,5…32

V

D

C

10W

4…20 m

A

HA

R

T

OrderC

ode:

Se

r

.-N

o.:

5

A0109

0109A

FM

U90

-J1

1

AB1

11AA

1

A

1

2

3

7

4

5

6

2 Identification

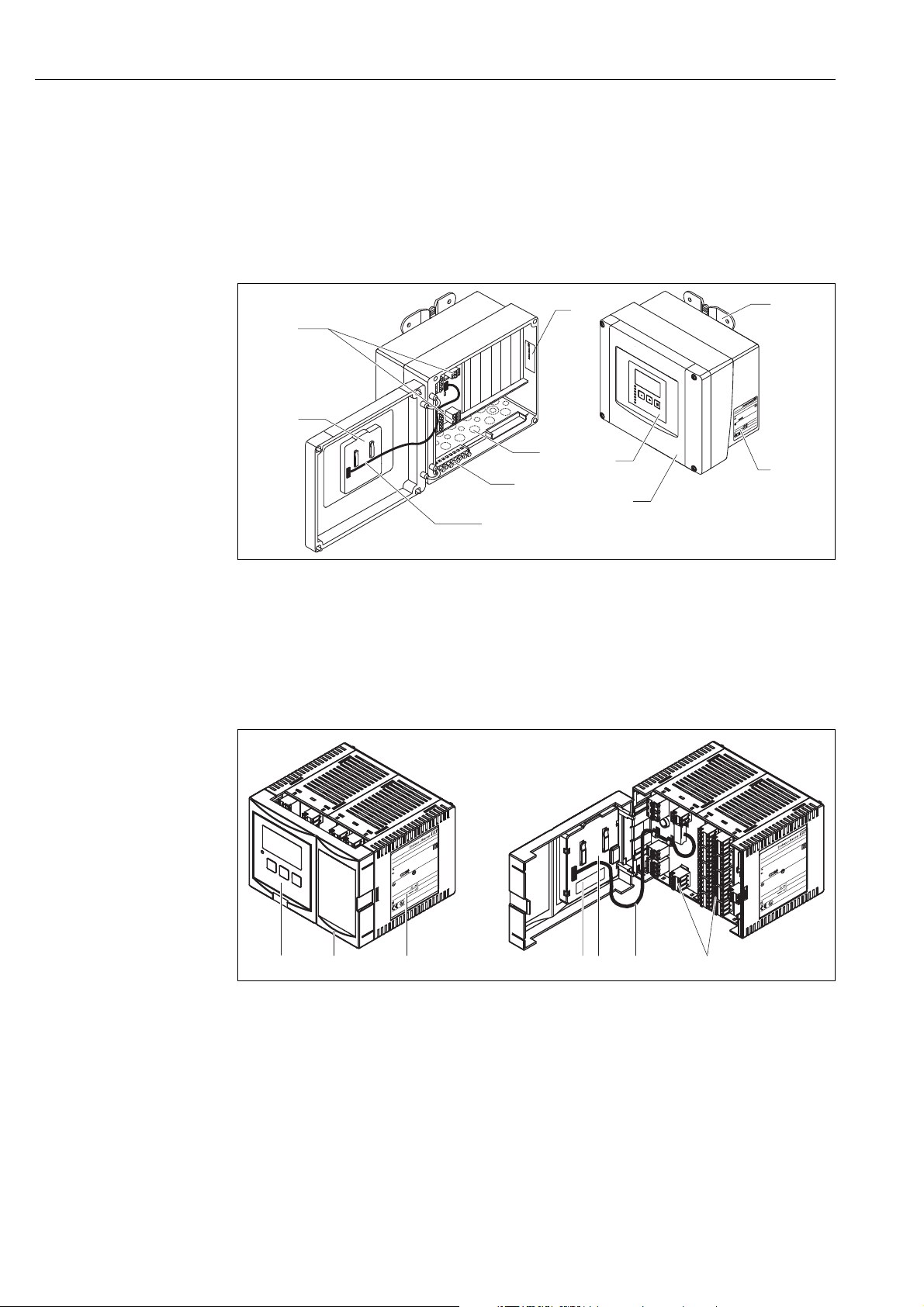

2.1 Parts of the Prosonic S FMU95

2.1.1 FMU95 in the field housing

L00-FMU90xxx-03-00-00 -xx-001

1 Terminals 6 Display and operating module

2 Instrument designation and identification 7 Prestamped openings for cable entries

3 Mounting help 8 Grounding terminals

4 Nameplate 9 Display cable

5 Cover of the terminal compartment 10 Short instructions

2.1.2 FMU95 in the DIN-rail housing

L00-FMU95xxx-03-00-00 -xx-001

1 Display and operating module 5 Display cable

2 Cover of the terminal compartment 6 Short instructions

3 Nameplate 7 Terminals

4 Terminals Instrument designation and identification

6 Endress + Hauser

Page 7

Prosonic S FMU95 Identification

M

a

d

e

inG

e

r

m

a

n

y

D

-

7

9

6

8

9

M

a

u

l

b

u

r

g

P

ro

s

o

n

ic

S

Ta

>

6

0

°C

:

II3D T=xxx°C

IP66/NEMA4X

X

A

x

x

x

F

-

A

Dat./Insp.:

if

m

o

dificatio

n

se

e

sep.

lab

el

X

=

10,5…32 V DC 10W

4…20 mA HART

OrderCode:

Ser.-No.: 5A01090109A

FMU90-J11AB111AA1A

1

2

3

Made in Germany

D-79689 Maulburg

Prosonic S

10,5 … 32 V DC 14W

Profibus DP

Order Code:

Ser.-No.: 5A01090109A

FMU95-J11CBA31A

II 3 D T=xxx°C

IP66 / NEMA4X

XAxxxF-A

if modification

see sep. label

X=

Ta > 60°C :

11

9

8

7

6

5

4

1

2

3

10

2.1.3 FMU95 with remote display and operating module for cabinet

door and switchboard mounting (96 x 96 mm (3.78 x 3.78 in))

L00-FMU95xxx-03-00-00-xx-002

1 DIN-rail housing without display

2 Remote display and operating module for cabinet mounting

3 The cable (3 m (9.8 ft)) is supplied

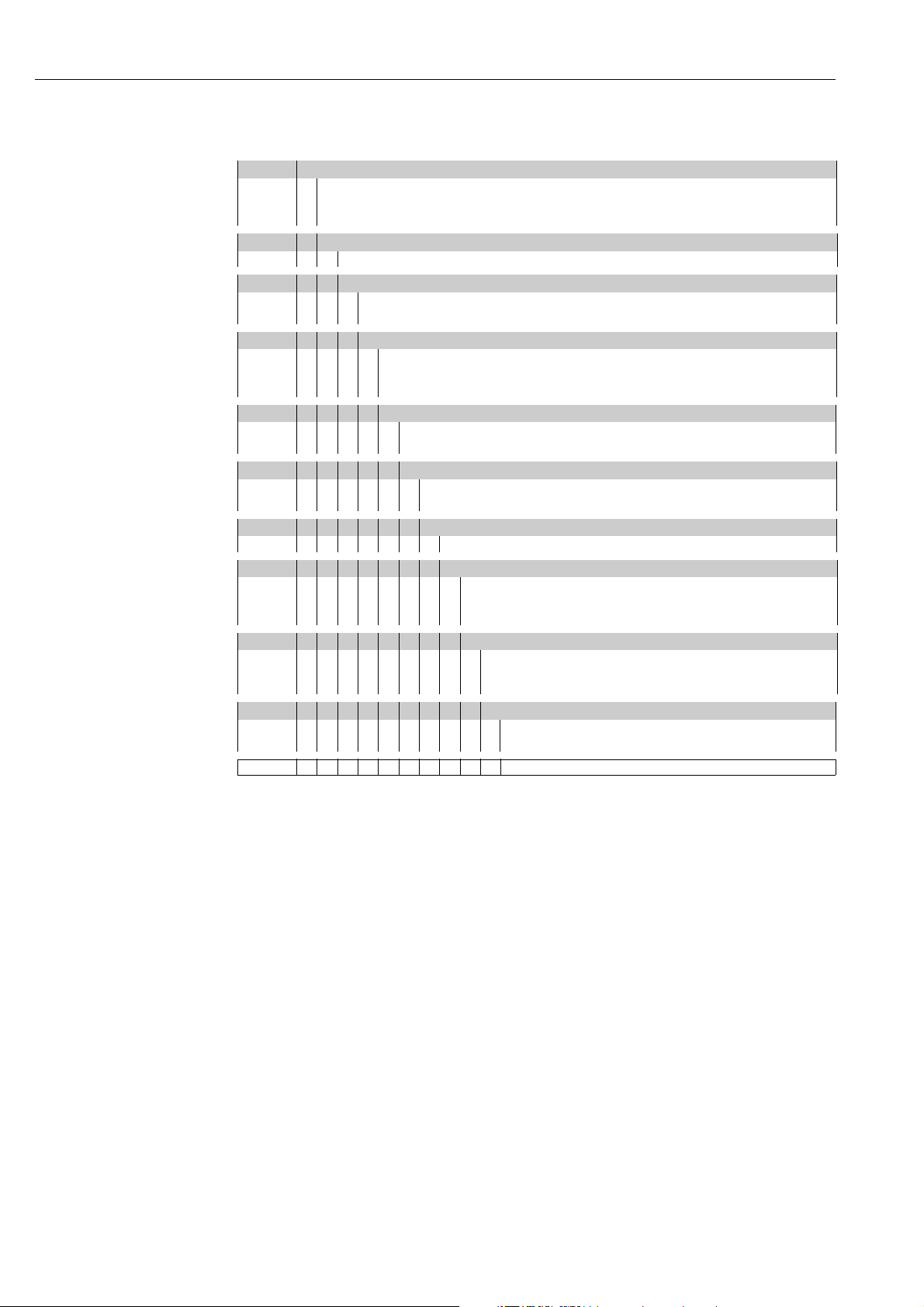

2.2 Nameplate (Example)

1 Specification of the electrical protection class (protective insulation)

2 Ingress protection

3 Barcode

4 Marked if a modification nameplate is present

5 Reference to additional safety-relevant documentation

6 Certificate-related data

7 Specification of required temperature resistance of the connection cables

8Output signal

9 Power supply

10 Serial number

11 Order code (as defined by the product structure)

L00-FMU95xxx-18-00-00-xx-001

Endress + Hauser 7

Page 8

Identification Prosonic S FMU95

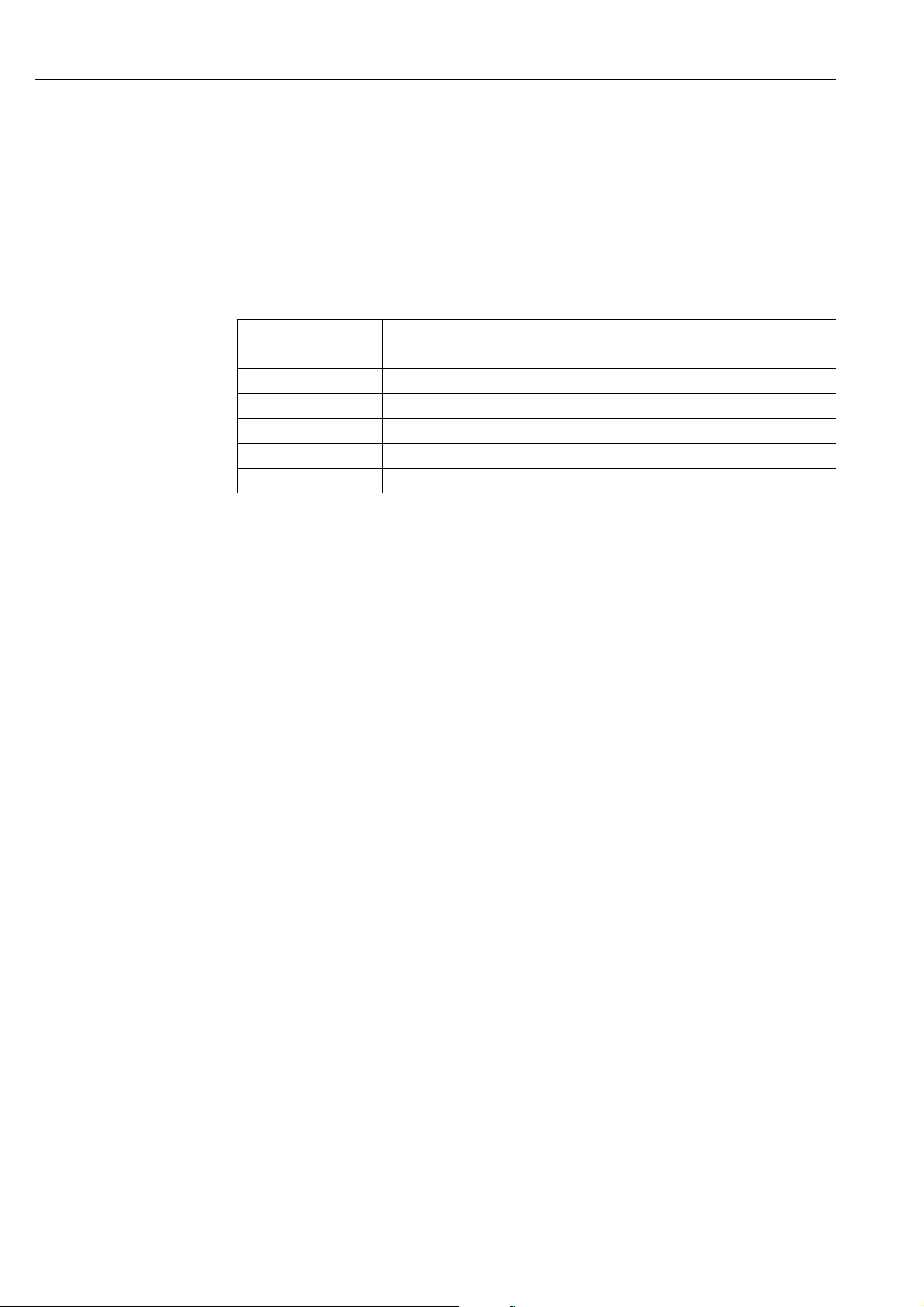

2.3 Product structure

010 Approval

R Non-hazarous area

JATEX II 3D

N CSA General Purpose

020 Application

1Level

030 Housing, material

1 Field mounting PC, IP66 NEMA 4x

2 DIN rail mounting PBT, IP20

040 Operation

C Illuminated display + keypad

E Illuminated display + keypad, 96x96, panel mounting, front IP65

K w/o display, via communication

050 Power supply

A 90-253 VAC

B 10.5-32 VDC

060 Level input

A 5x sensor FDU9x/8x

B 10x sensor FDU9x/8x

080 Output

3PROFIBUS DP

110 Language (*)

1 de, en, nl, fr, es, it, pt

2 de, en, ru, pl, cs

3 en, zh, ja, ko, th, id

120 Additional option

A Basic version

L 5-point linearity protocol only to order with FDU9x sensor +

5-point linearity protocol

995 Marking

1 Tagging (TAG)

2Bus address

FMU95 - complete product designation

(*): meaning of the language code:

cs: Czech; de: German; en: English; es: Spanish; fr: French; id: Bahasa (Indonesia, Malaysia); it:

Italian; ja: Japanese; ko: korean; nl: Dutch; pl: Polish; pt: Portuguese; ru: Russian; th: Thai; zh:

Chinese

8 Endress + Hauser

Page 9

Prosonic S FMU95 Identification

2.4 Scope of delivery

• Instrument according to the version ordered

• Endress+Hauser operating program on the enclosed CD-ROM

• For FMU95-***E*****:

remote display and operating module; retainers; connection cable (3 m (9.8 ft))

• Accessories ä 88

• Approval documentation: if this is not included in the operating manual (Refer to the nameplate

for the names of the safety instructions that apply to your device version.)

• CD-ROM with further documentation, e.g.

– Technical Information

– Operating Instructions

– Description of Instrument Functions

– Slot/Index tables

• Brief operating instructions for quick commissioning: KA01069F

2.5 Certificates and approvals

CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements, has been tested and left the

factory in a condition in which it is safe to operate. The device complies with the applicable

standards and regulations as listed in the EC declaration of conformity and thus complies with the

statutory requirements of the EC directives. Endress+Hauser confirms the successful testing of the

device by affixing to it the CE mark.

2.6 Registered trademarks

PROFIBUS

Registered trademark of the PROFIBUS Trade Organisation, Karlsruhe, Germany

ToF

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

FieldCare

Trademark of Endress+Hauser Process Solutions AG

®

®

®

Endress + Hauser 9

Page 10

Installation Prosonic S FMU95

215 (8.46)

180 (7.09)

150 (5.91)

15 (0.59)

170 (6.69)

190 (7.48)

80

(3.15)

100

(3.94)

ø6.5 (0.26)

10 (0.39)

A

B

»1,6 kg (3.53 lbs)

153 (6.02)

C

³55 (2.17)

³55 (2.17)

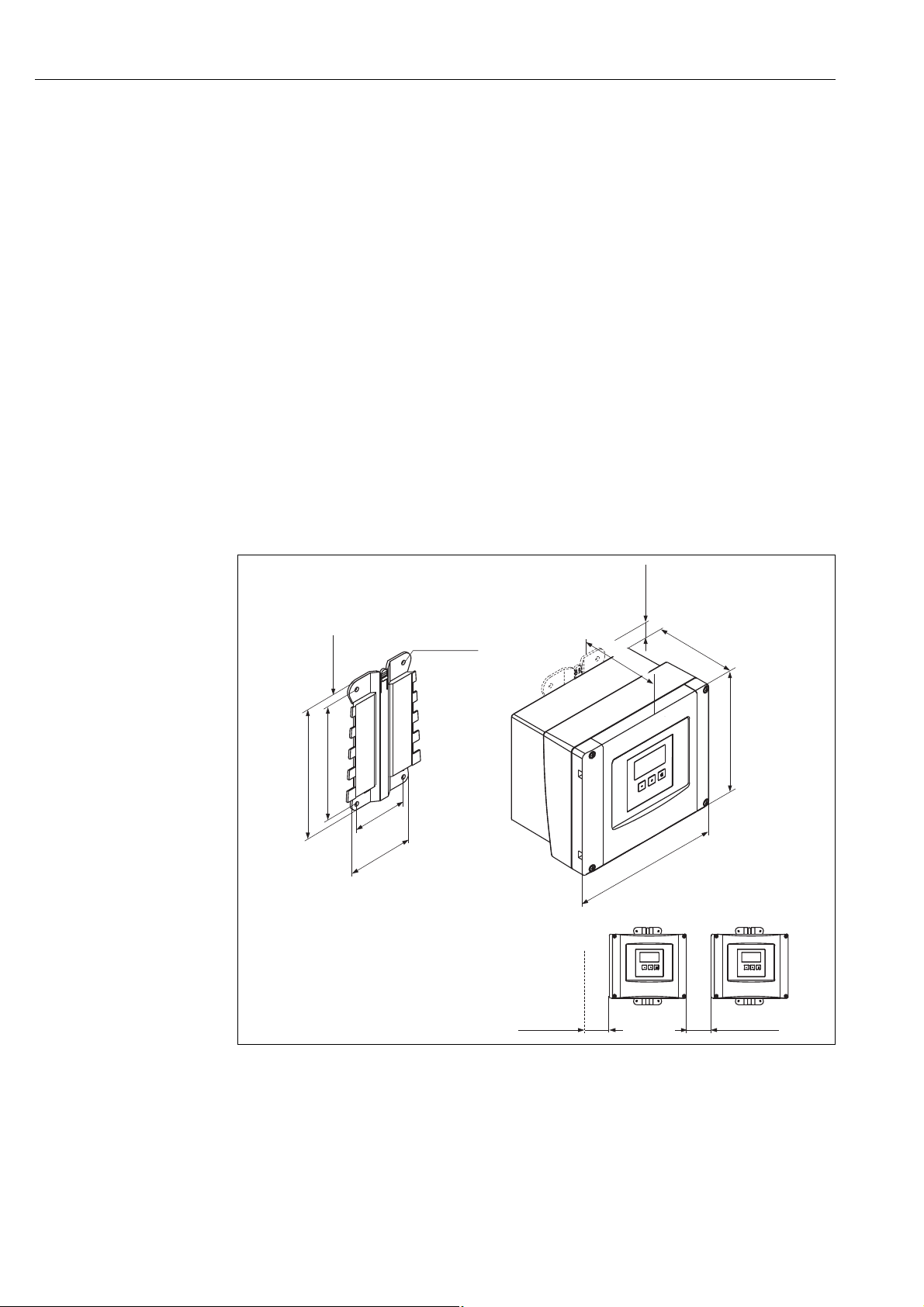

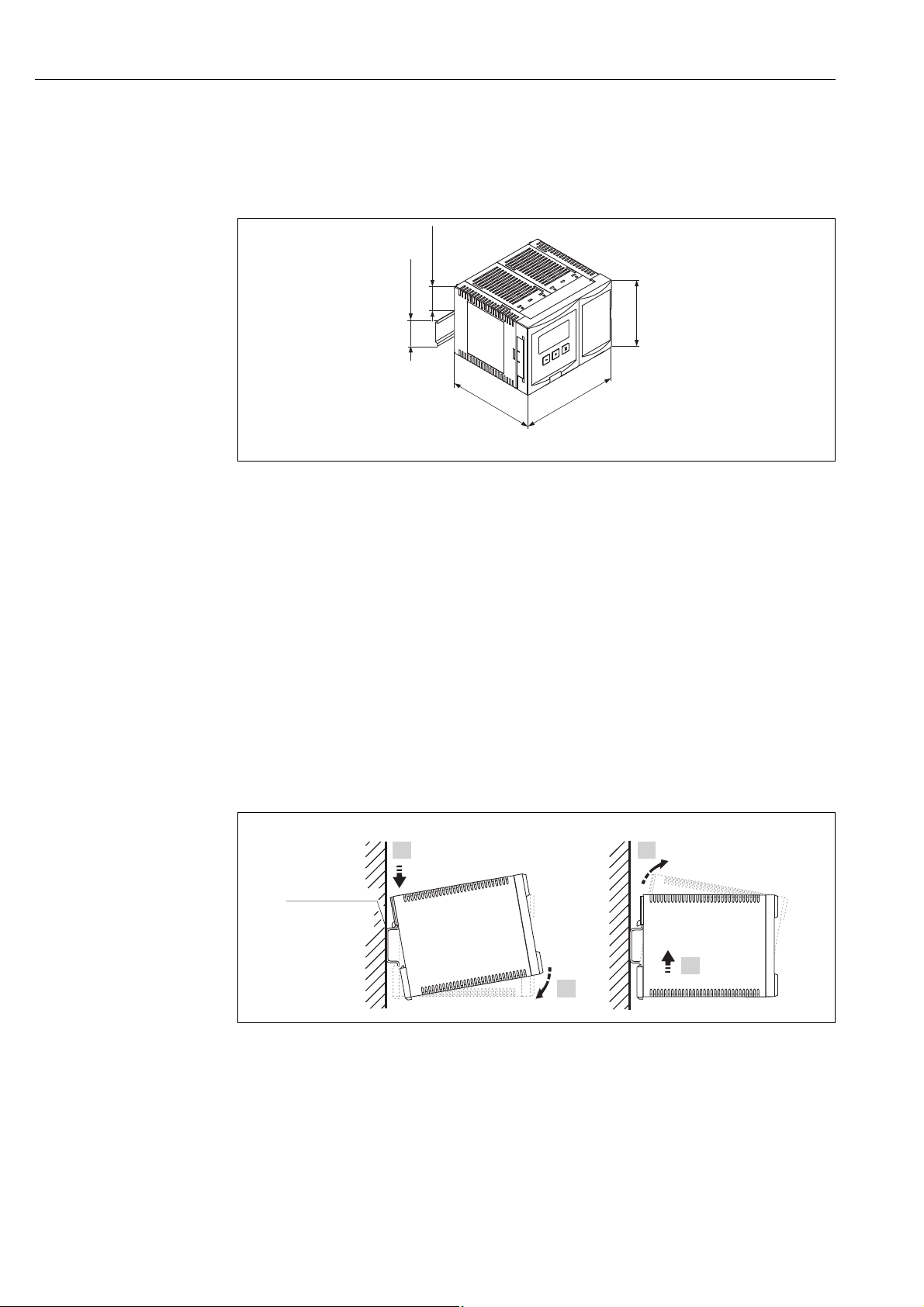

3 Installation

3.1 Incoming acceptance, transport, storage

3.1.1 Incoming acceptance

Check the packing and contents for any signs of damage.

Check the shipment, make sure nothing is missing and that the scope of supply matches your order.

3.1.2 Transport, storage

Pack the measuring instrument so that it is protected against impacts for storage and transport. The

original packing material provides the optimum protection for this.

Permissible storage temperature: -40 to +60 °C (-40 to +140 °F)

3.2 Mounting the field housing

3.2.1 Dimensions of the field housing

Dimensions in mm (in)

A Mounting help (supplied); can also be used as drilling template

B Field housing

C Minimum mounting distance

The dimensions of the field housing are the same for all instrument versions.

To open the housing, a minimum mounting distance of 55 mm (2.17 in) is required on the left.

L00-FMU90xxx-06-00-00 -xx-001

10 Endress + Hauser

Page 11

Prosonic S FMU95 Installation

1.

2.

3.

4.

1

3.2.2 Installation conditions

Weather protection

In order to avoid excessive sunlight exposure, the instrument should be mounted in a position

which is protected against direct sunlight or a protection cover should be applied ( ä 88,

"Accessories").

Overvoltage protection

In order to protect the Prosonic against overvoltages (especially if mounted outdoors), connection

of an overvoltage protection is recommended ( ä 88, "Accessories").

Wall mounting

A mounting help for wall mounting is supplied. It also serves as drilling template. The mounting

help should be mounted on a flat surface and may not become distorted.

Pipe mounting

A mounting plate is available for mounting of the field housing to 1" to 2" pipes ( ä 88,

"Accessories").

3.2.3 Installation

1 Wall mounting with mounting help

L00-FMU90xxx-17-00-00-xx-003

Endress + Hauser 11

Page 12

Installation Prosonic S FMU95

150 (5.91)

104 (4.09)

140 (5.51)

EN 60715

TH 35x7.5/15

(1.4x0.3/0.6)

35 (1.38)

»0,7 kg (1.54 lbs)

42 (1.65)

A

B

1.

2.

1.

2.

EN 60715

TH 35x7.5/15

(1.4x0.3/0.6)

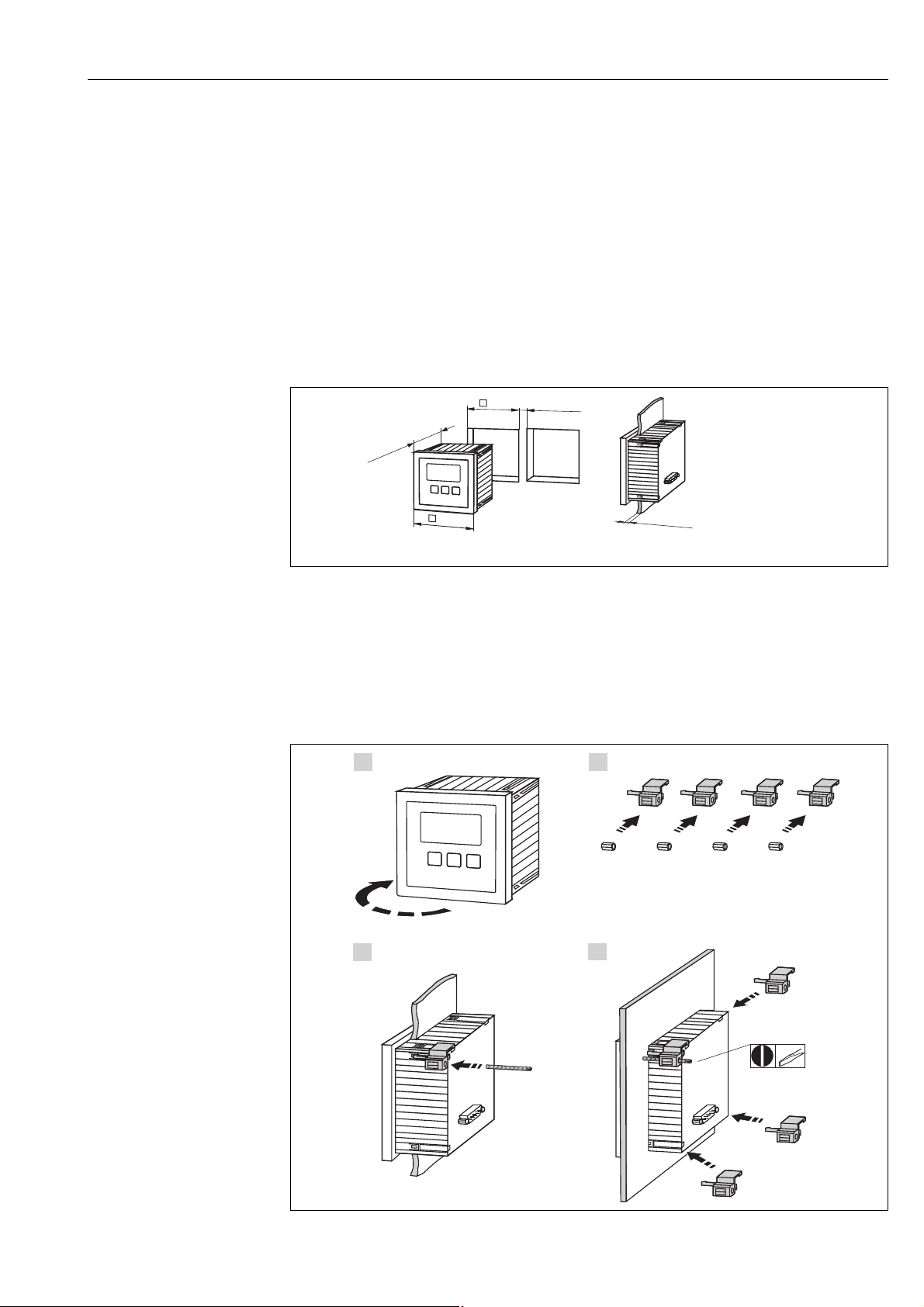

3.3 Mounting the DIN-rail housing

3.3.1 Dimensions of the DIN-rail housing

L00-FMU90xxx-06-00-00 -xx-005

Dimensions in mm (in)

3.3.2 Installation conditions

• The DIN-rail housing must be mounted outside hazardous areas in a cabinet.

• The housing is mounted on a DIN rail EN 60715 TH 35x7.5 or TH 37x15.

• Do not install the instrument in the vicinity of high-voltage lines, motor lines, contactors or

frequency converters. The installation regulations for high-voltage lines, motor lines, contactors

or frequency converters must be observed.

• To ensure easy mounting and opening of the housing, a distance of approx. 10 mm (0.39 in)

should be kept between the instruments.

• In order to avoid interference signals, the sensor cables must not be laid parallel to high voltage

or electric power lines.

• The cables may not be laid in the proximity to frequnecy converters.

3.3.3 Mounting

L00-FMU90xxx-17-00-00 -xx-001

A Attaching the instrument to the rail

B Detaching the instrument from the rail

12 Endress + Hauser

Page 13

Prosonic S FMU95 Installation

96

55

max. 6

92

min. 11

~0,5 kg (1.10 lbs)

(0.43)

(3.62)

(0.24)

(3.78)

(2.17)

mm (in)

1.

3.

4.

2.

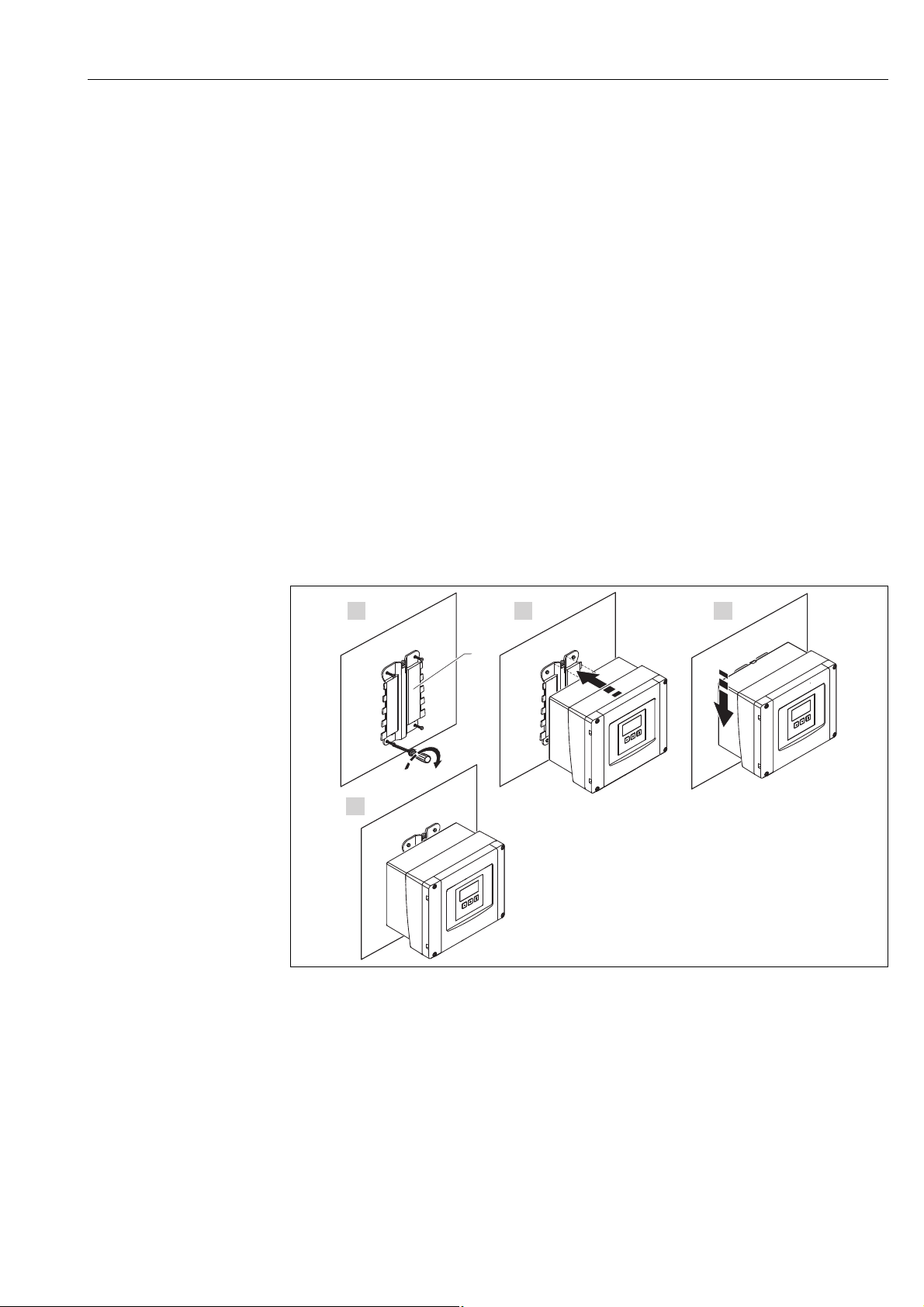

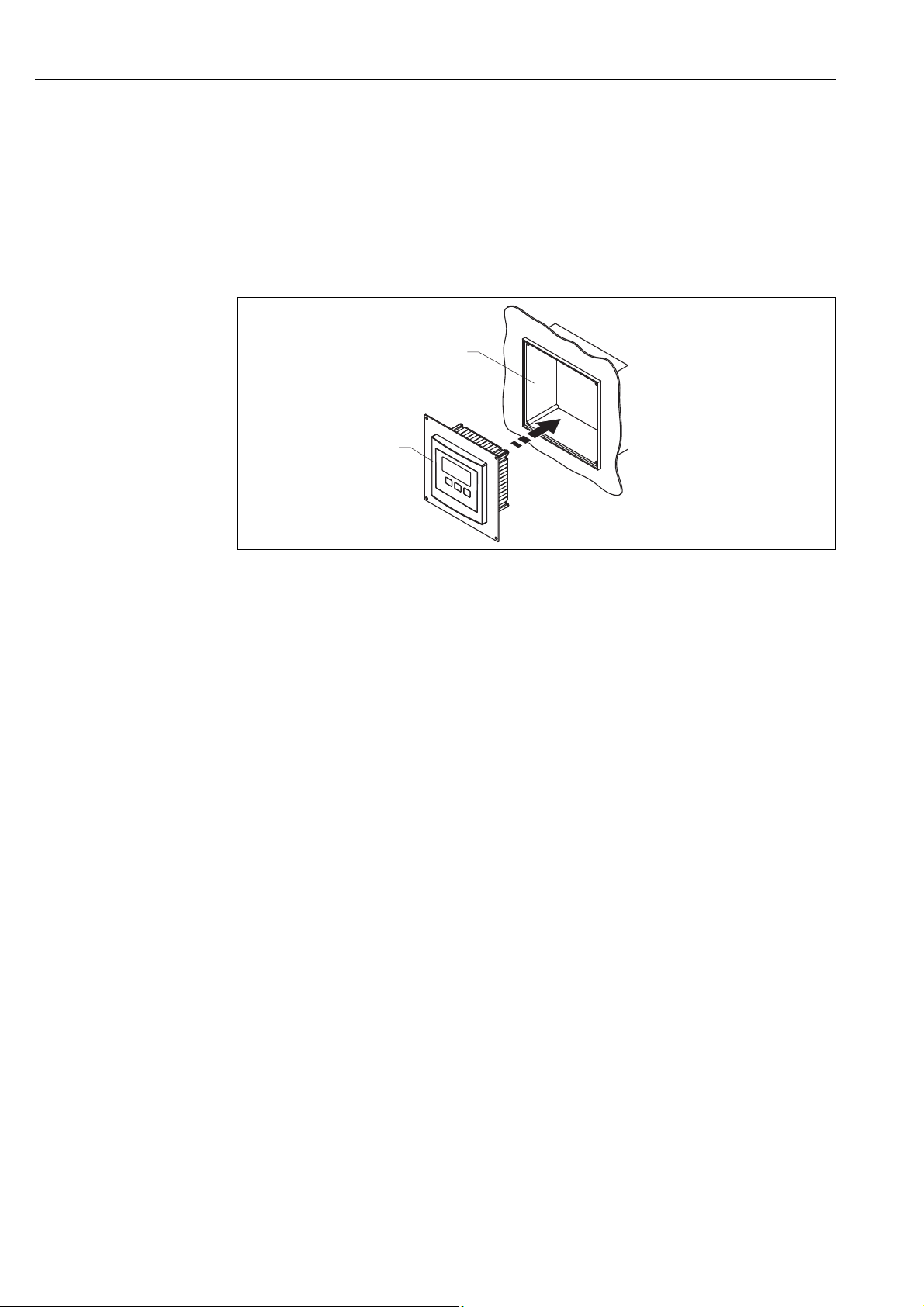

3.4 Mounting the remote display and operating module

3.4.1 Scope of delivery

If the Prosonic S is ordered with the display for cabinet door mounting, the following is contained

in the scope of delivery:

• Display and operating module, 96 x 96 mm (3.78 x 3.78 in)

• 4 retainers (with nuts and screws)

• Connection cable (3 m (9.8 ft)) for connection to the transmitter

(preassembled with suitable plugs).

3.4.2 Dimensions of the separate display and operating module

L00-FMU90xxx-06-00-00-xx-004

3.4.3 Mounting

1. Cut an opening of 92 x 92 mm (3.62 x 3.62 in) into the intended mounting position (e.g.

cabinet door).

2. Insert the remote display module into the opening and fix the retainers as shown in the

following figure:

Endress + Hauser 13

L00-FMU90xxx-17-00-00-xx-002

Page 14

Installation Prosonic S FMU95

1

2

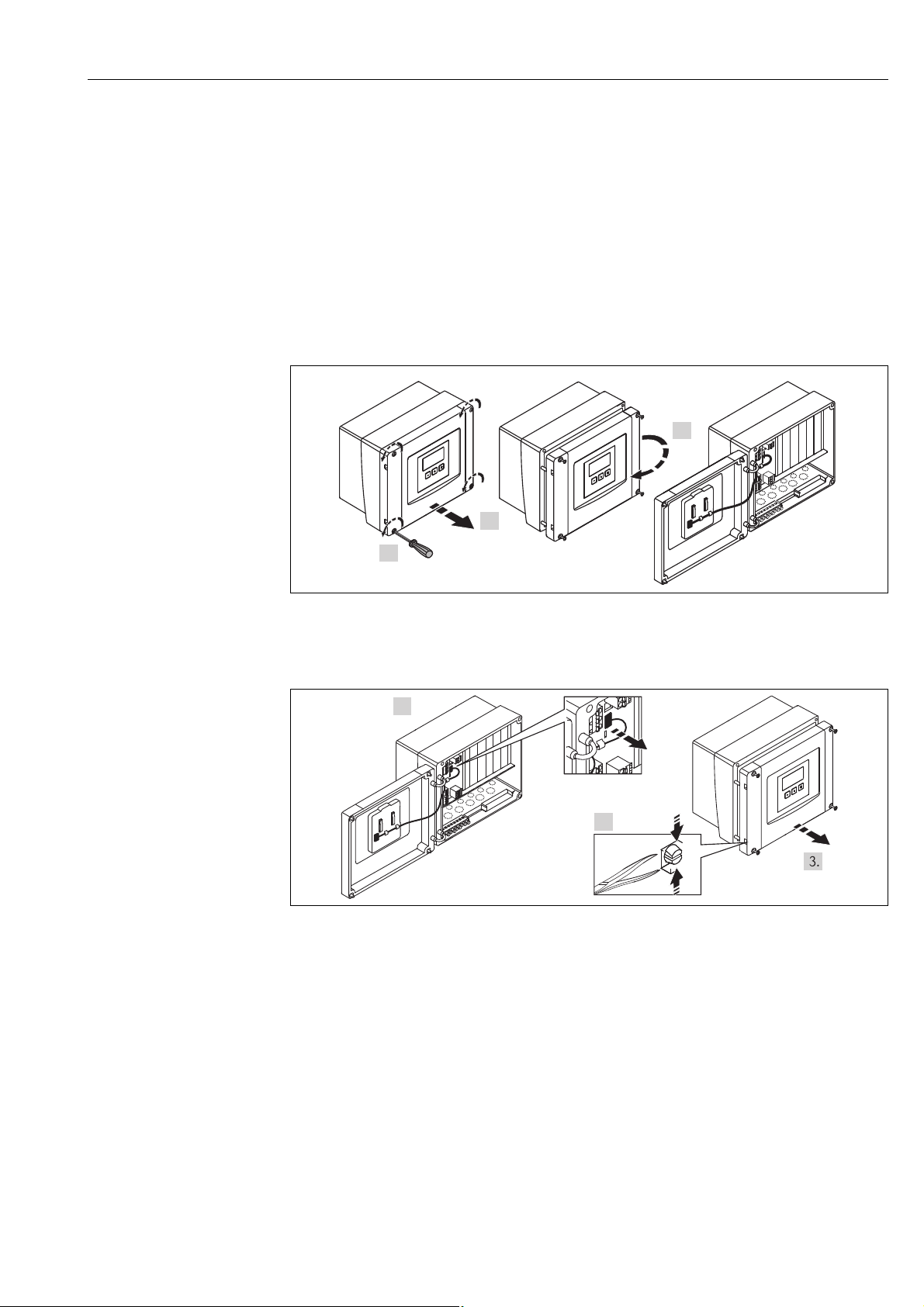

3.4.4 Adaption plate

If an opening of 138 x 138 mm and the remote display of the Prosonic FMU860/861/862 are

already present, you can use the adaption plate (Order Code: 52027441, ( ä 88, "Accessories").

It is inserted into the remote display of the FMU860/861/862.

!

Note!

The adapter plate is mounted directly in the housing of the old remote display of the FMU86x series.

The housing of the remote display of the FMU86x is the holder for the adapter plate and the new

remote display of the FMU90/FMU95 in the format 96 x 96 mm (3.78 x 3.78 in).

L00-FMU90xxx-06-00-00 -xx-006

1 Remote display of the FMU90 with adaption plate

2 Opening of the remote display of the FMU860/861/862

3.5 Mounting of the sensors

Information on the mounting of the sensors can be found in the following documents:

• Technical Information TI00189F (for FDU8x)

• Technical Information TI00396F (for FDU9x)

These documents are supplied with the sensors.

3.6 Installation check

After installing the device, carry out the following checks:

• Is the device damaged (visual inspection)?

• Does the device correspond to the meausring point specifications such as process temperature,

process pressure, ambient temperature, measuring range etc?

• If available: Are the measuring point number and labelling correct?

• Is the instrument sufficiently protected against rainfall and direct sunlight?

• For the field housing: Are the cable glands tightened correctly?

• Is the instrument securely mounted to the DIN rail or the mounting help (visual inspection)?

• For the field housing: Are the screws of the terminal compartment cover securely tightened

(visual inspection)?

14 Endress + Hauser

Page 15

Prosonic S FMU95 Wiring

1.

2.

3.

1.

2.

4 Wiring

#

Warning!

The instrument may only be installed if the supply voltage is switched off.

4.1 Terminal compartment

4.1.1 Terminal compartment of the field housing

The field housing has a separate terminal compartment. It can be opened after loosening the four

screws of the lid.

L00-FMU90xxx-04-00-00-xx-002

For easier wiring, the lid can be completely removed by unplugging the display plug (1) and loosening the hinges (2):

L00-FMU90xxx-04-00-00-xx-009

4.1.2 Cable entries of the field housing

The following openings for cable entries are prestamped on the bottom of the housing :

• M20x1,5 (10 openings)

• M16x1,5 (5 openings)

• M25x1,5 (1 opening)

The required number and types of cable entries depend on the application at hand.

The prestamped openings can be removed by a suitable tool (e.g. knife or boring bit) or by punching

them out cautiously.

Endress + Hauser 15

Page 16

Wiring Prosonic S FMU95

1.

2.

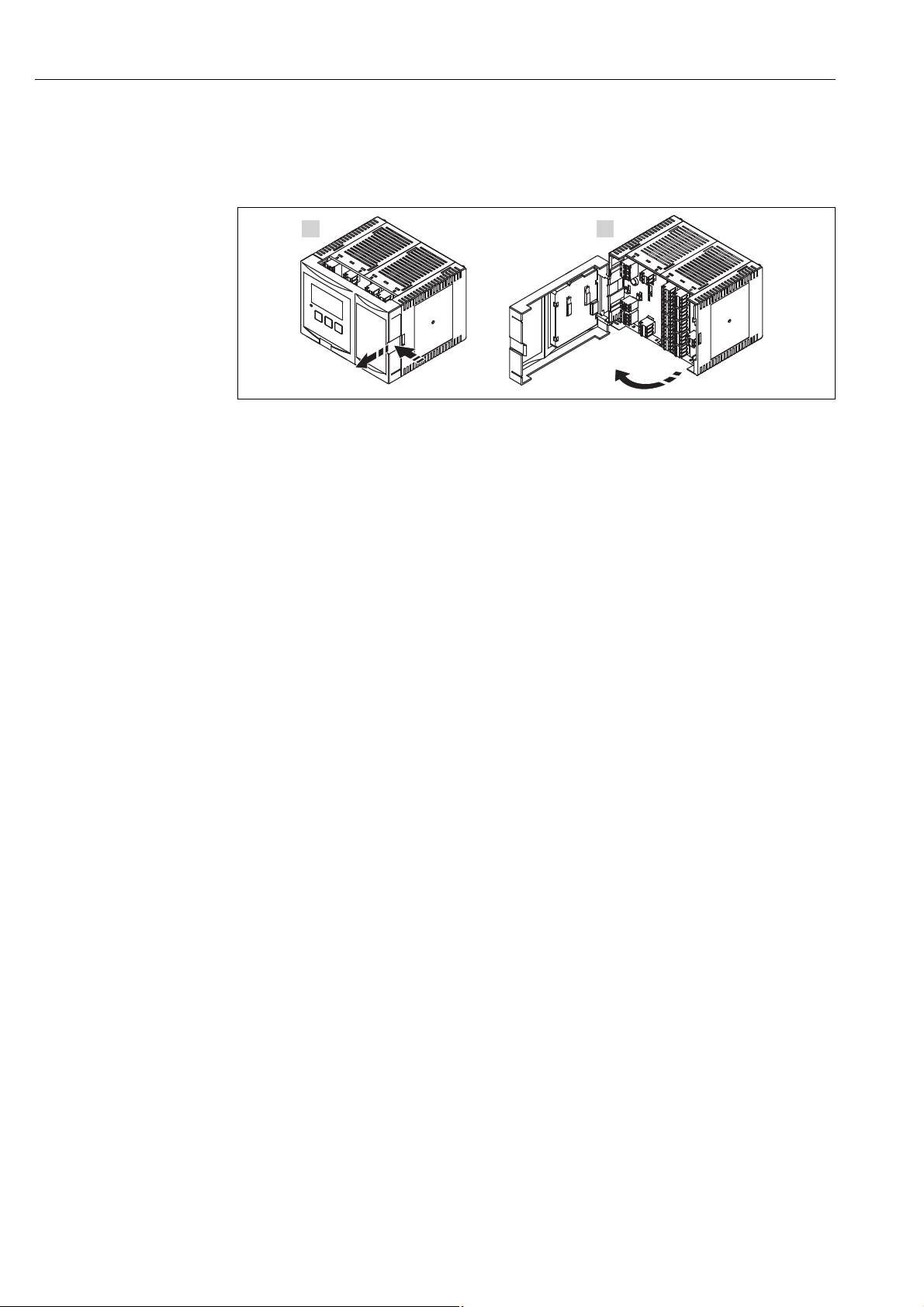

4.1.3 Terminal compartment of the DIN-rail housing

Single instrument

L00-FMU95xxx-04-00-00 -xx-005

The catch can be unlocked by slightly pressing onto the clip. Then, the cover of the terminal

compartment can be opened.

16 Endress + Hauser

Page 17

Prosonic S FMU95 Wiring

1.

2.

3.

1.

2.

3.

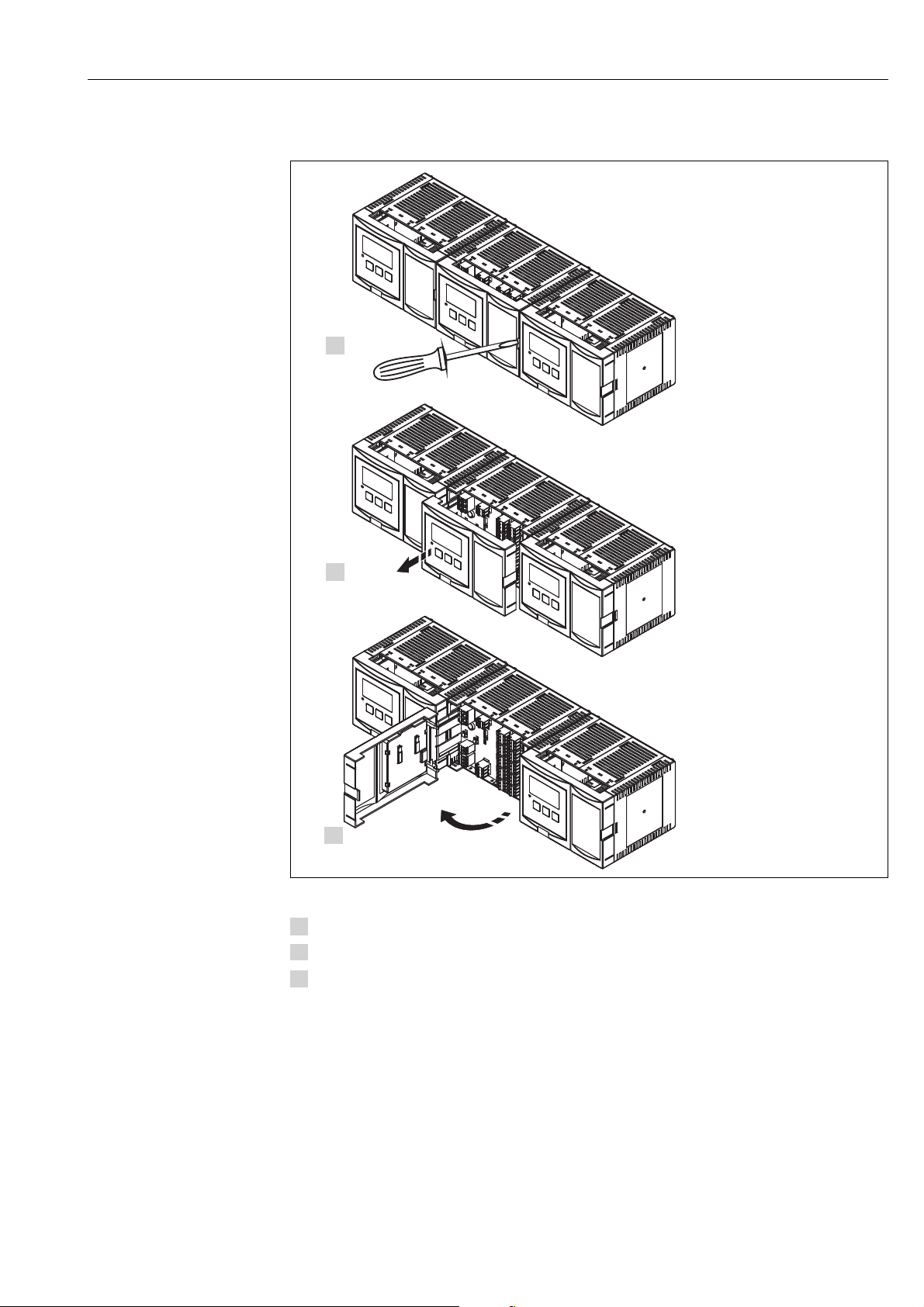

Several instruments mounted side by side

L00-FMU95KAx-04-00-00-xx-005

Open the catch of the cover (e.g. by a screwdriver).

Pull the cover out by approx. 20 mm (0.79 in) .

The cover can now be opened.

!

Note!

• The cables can be inserted into the housing from above or from below.

• If the instruments are mounted next to each other and if the sensor cables run in parallel, the

synchronization terminals (39 and 40) must be interconnected ( ä 18 "Terminal assignment"

und ä 24 "Synchronization line").

Endress + Hauser 17

Page 18

Wiring Prosonic S FMU95

Address

Term.

DP

off

on

off

on

SW

HW

1

2

3

4

5

6

7

8

1

2

3

4

A(N)

66

B(P)

65

Display

POWER

Sync

Fuse

40

39

Service

32

1

11

10

9

1

FDU-Sensor

YE BK RD

14

13

12

2

YE BK RD

17

16

15

3

YE BK RD

20

19

18

4

YE BK RD

23

22

21

5

YE BK RD

26

25

24

6

YE BK RD

29

28

27

7

YE BK RD

32

31

30

8

YE BK RD

35

34

33

9

YE BK RD

38

37

36

10

YE BK RD

FDU-Sensor

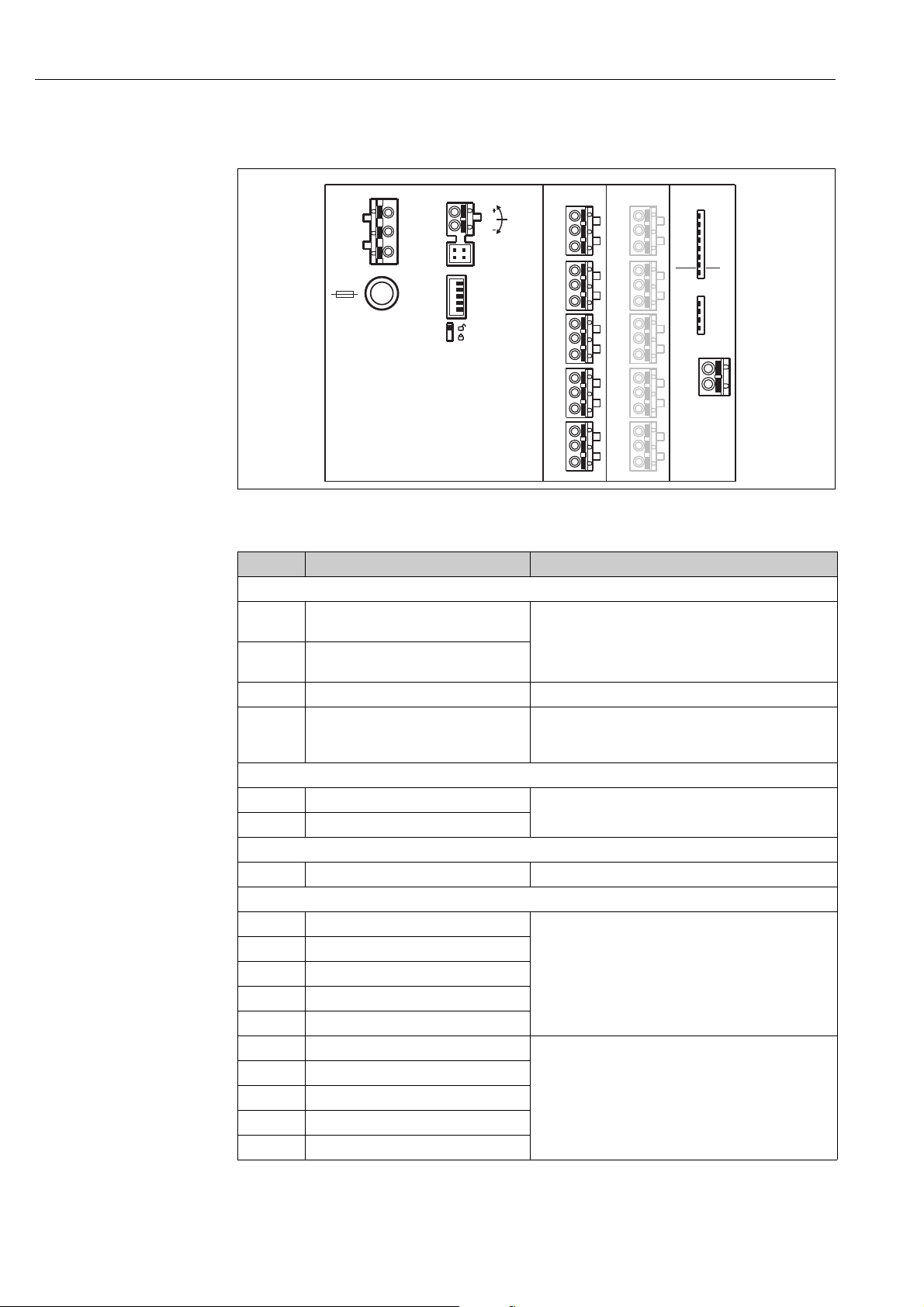

4.2 Terminal assignment

L00-FMU90xxx-04-00-00 -xx-001

Terminals of the Prosonic S FMU95; the terminals depicted in grey are not present in every instrument version.

Terminals Meaning Remarks

Auxiliary energy

1

2

•L (for AC version)

•L+ (for DC version)

•N (for AC version)

•L- (for DC version)

depending on instrument version:

• 90 ... 253 V

• 10,5 ... 32 V

AC

DC

3 Potential equalization

depending on instrument version:

Fuse

• 400 mA T (for AC)

•2 A T (for DC)

Bus communication

65 PROFIBUS A (RxT/TxD - N)

66 PROFIBUS B (RxT/TxD - P)

Synchronization

39, 40 Synchronization ä 24, "Synchronization line"

Level inputs

09,10,11 Sensor 1 (FDU8x/9x)

12, 13, 14 Sensor 2 (FDU8x/9x)

15, 16, 17 Sensor 3 (FDU8x/9x)

18, 19, 20 Sensor 4 (FDU8x/9x)

18 Endress + Hauser

21, 22, 23 Sensor 5 (FDU8x/9x)

24, 25, 26 Sensor 6 (FDU8x/9x)

27, 28, 29 Sensor 7 (FDU8x/9x)

30, 31, 32 Sensor 8 (FDU8x/9x)

33, 34, 35 Sensor 9 (FDU8x/9x)

36, 37, 38 Sensor 10 (FDU8x/9x)

YE: yellow strand

BK: black strand

RD: red strand

only available for the version with 10 sensor inputs

YE: yellow strand

BK: black strand

RD: red strand

Page 19

Prosonic S FMU95 Wiring

#

!

#

Warning!

When using the public supply mains, an easily accesible power switch must be installed in the

proximity of the device. The power switch must be marked as a disconnector for the device (IEC/

EN 61010)

Note!

• In order to avoid interference signals, the sensor cables should not be laid parallel to high voltage

or electric power lines.

• The cables may not be laid in the proximity to frequnecy converters.

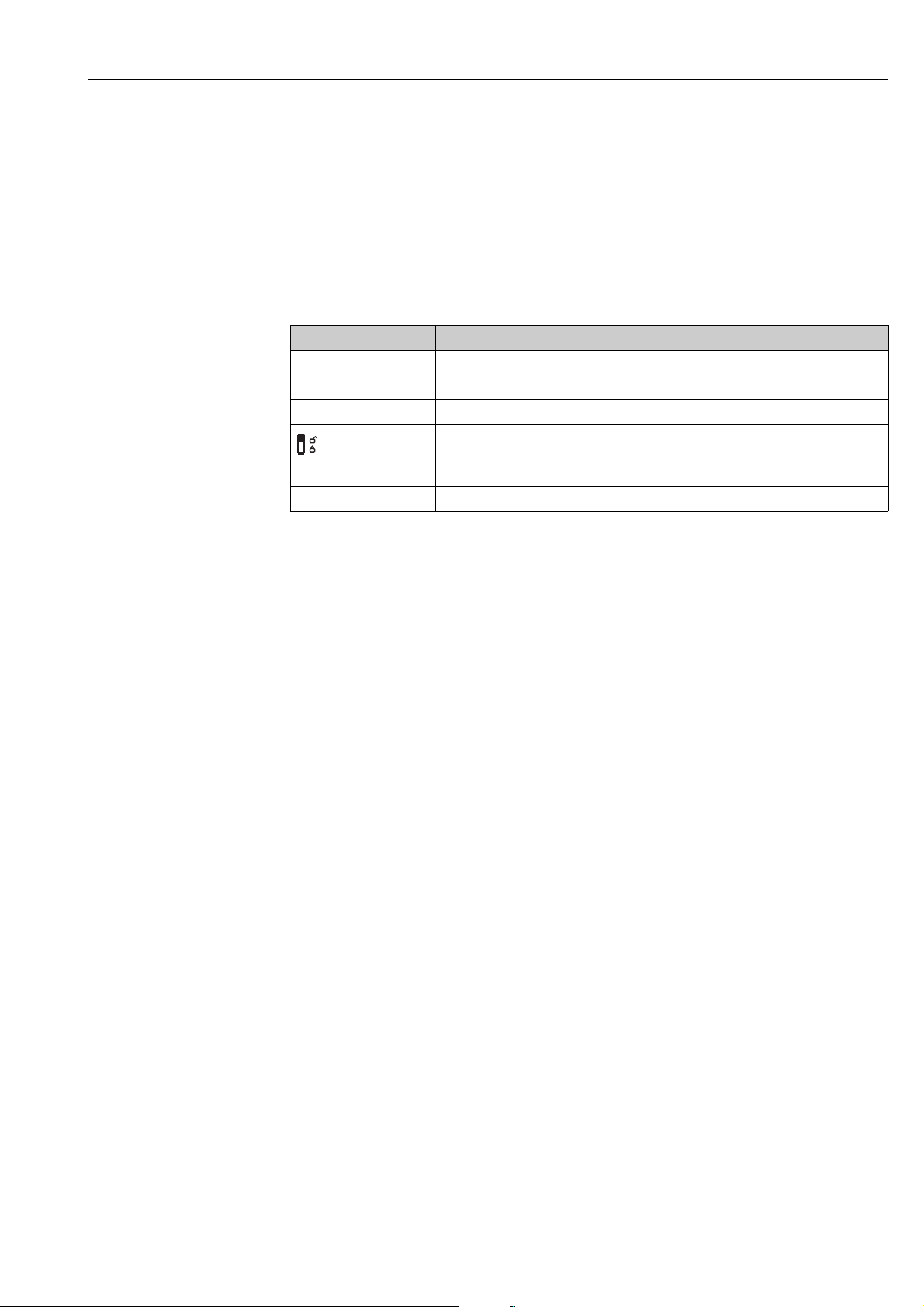

Additional elements on the terminal areas

Designation Meaning/Remarks

Fuse Fuse: 2 A T /DC or 400 mA T/AC

Display Connection of the display or the remote display and operating module ( ä 25)

Service Service interface for connection of a PC/Notebook via Commubox FXA291 ( ä 29)

Locking switch, ä 47 "Unlock configuration"

Term. Bus termination

Address Bus address

Warning!

On wiring, the supply voltage must be switched off.

Endress + Hauser 19

Page 20

Wiring Prosonic S FMU95

4.3 Connection to a PROFIBIS DP network

!

Note!

Information on the structure of a PROFIBUS DP network can be found in the Operating Instructions

BA 034S ("PROFIBUS PA/DP - Guidelines for planning and commissioning".

4.3.1 Cable specifications

For transmission rates up to 12 MBit/s cable type A according to EN 50170 can be used. The

specifications are summarized in the following table:

Terminator 135 to 165 at a measuring frequency from 3 MHz to 20 MHz

Cable capacitance < 30pF per meter

Core cross-section > 0.34 mm

Cable type twisted pairs, 1x2, 2x2 or 1x4 core

Loop resistance 110 per km

Siganl attenuation max. 9 dB over the entire length of the segment

Screening woven copper sheath or woven sheath and foil sheath

Pre-assembled cables are available from Endress+Hauser ( ä 88, "Accessories").

2

, corresponds to AWG 22

4.3.2 T-box

It is recommended to connect the Prosonic S to the bus by a T-box.

Suitable T-boxes are available from Endress+Hauser ( ä 88, "Accessories").

4.3.3 Spurs

Spurs are the connection cables from the bus to the instrument.

Caution!

"

Obeserve the following:

• Total length of all spurs < 6.6 m (22 ft), (for a maximum baudrate of 1.5 MBit/s)

• For baud rates > 1.5 MBit/s no spurs should be used. A spur is the cable between the connector

and the bus driver in the field instrument. Plant experience has shown that much care should be

taken when planning the spurs. It can not be guaranteed that the sum of all spurs at 1.5 MBit/s

may be 6.6 m (22 ft). The actual arrangement of the field intruments has a great influence on this.

Therefore it is strictly recommended to use no spurs for transmission rates > 1.5 MBit/s.

• If usage of spurs can not be avoided, these may not have a bus bus termination.

20 Endress + Hauser

Page 21

Prosonic S FMU95 Wiring

YE

BK

RD

FDU90/91/92

(FDU80/80F/81/81F/82)

BK

YE

RD

(1)

YE

BK

RD

FDU91F/93/95/96

(FDU83/84/85/86)

BK

YE

RD

GNYE

(2)

(3)

FMU95

(1)

(2)

(3)

FMU95

(A)

max.

300 m

YE

BK

RD

FDU91F/93/95/96

(FDU83/84/85/86)

BK

YE

RD

GNYE

(1)

FMU95

(B)

max.

30 m

max.

300 m

max.

30 m

FDU90/91/92

(FDU80/80F/81/81F/82)

FDU91F/93/95/96

(FDU83/84/85/86)

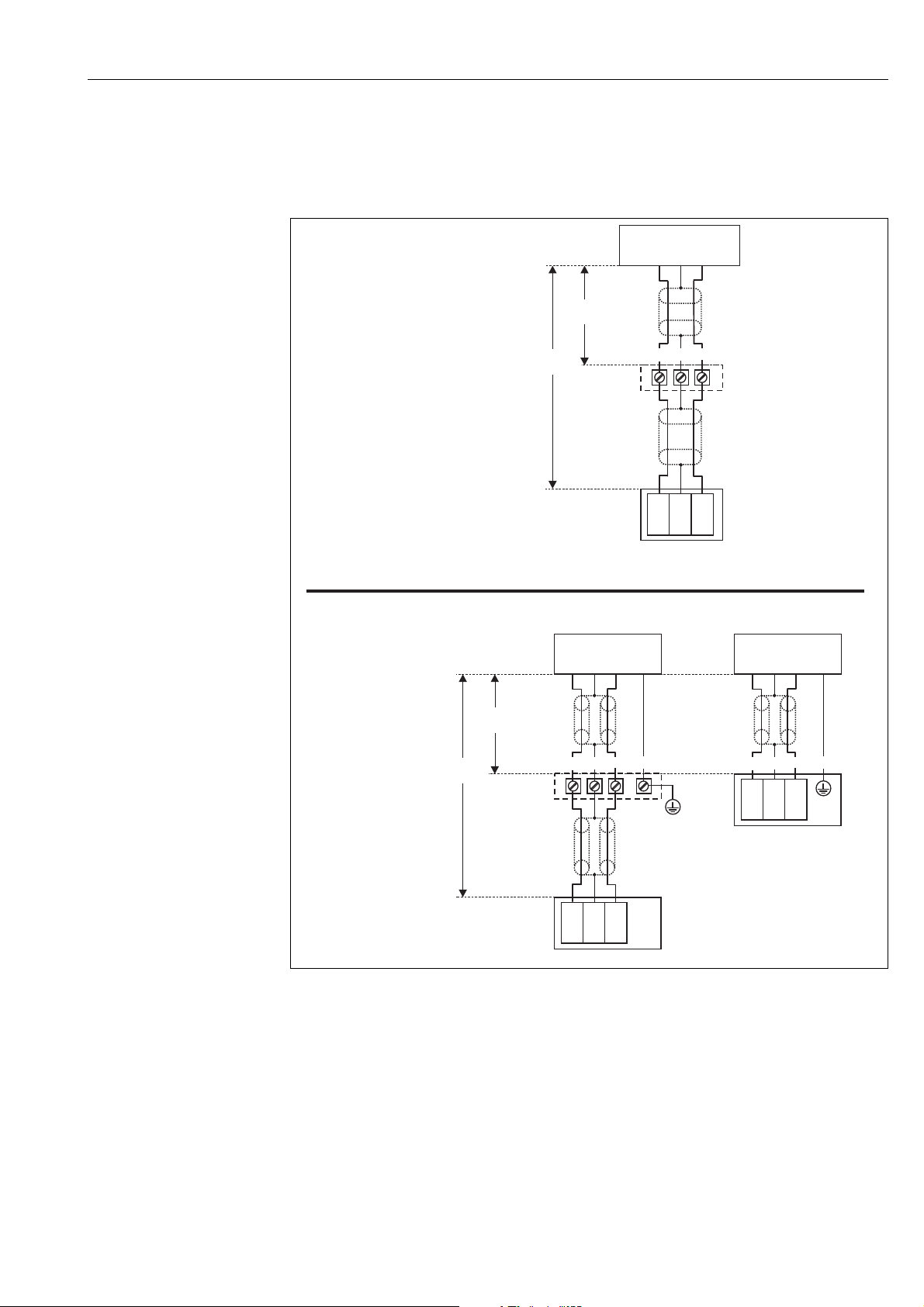

4.4 Sensor connection

4.4.1 Connection diagram

(A): grounding at the terminal box;

(B): grounding at the transmitter FMU90;

(1): Screen of the sensor cable;

(2): Terminal box;

(3): Screen of the extension cable;

Colours of the strands: YE = yellow; BK = black; RD = red; GNYE = green-yellow

L00-FMU95xxx-04-00-00-xx-004

Endress + Hauser 21

Page 22

Wiring Prosonic S FMU95

4.4.2 Connection hints

Caution!

"

• In order to avoid interference signals, the sensor cables should not be laid parallel to high voltage

electric power lines. The cables may not be laid in the proximity to frequency converters.

• The cable screen serves as a return cable and must be connected to the transmitter without any

electrical break. With the pre-assembled cables, the screen ends in a black strand (BK). With the

extension cable, the screen must be twisted together and connected to the "BK" terminal.

#

Warning!

• The sensors FDU83, FDU84, FDU85 and FDU86 with an ATEX, FM or CSA certificate are not

certified for connection to the FMU90 transmitter.

• for the sensors FDU91F/93/95/96 and FDU83/84/85/86:

The ground lead (GNYE) must be connected to the local potential equalization after a maximum

distance of 30 m (98 ft). This can be done

– either at the terminal box

– or at the transmitter FMU90 or in the cabinet (if the distance to the sensor does not exceed

30 m (98 ft).

!

"

Note!

For easier mounting it is advisable to use the sensors FDU90/91/92 and FDU80/80F/81/81F/82

with a maximum cable length of 30 m (98 ft) as well. For longer distances an extension cable with

a terminal box should be used.

4.4.3 Extension cables for the sensors

For distances up to 30 m (98 ft) the sensor can be directly connected by the sensor cable. For longer

distances, it is recommended to use an extension cable. The extension cable is connected via a

terminal box. The total length (sensor cable + extension cable) may be up to 300 m (984 ft).

Caution!

If the terminal box is installed in explosion hazardous areas, all applicable national guidelines must

be observed.

Suitable extension cables can be obtained from Endress+Hauser ( ä 88, "Accessories")

Alternatively, cables with the following properties can be used:

• Number of cores according to the connection diagram (see above)

• braided wire screen for the yellow (YE) and red (RD) core (no foil screen)

• Length: up to 300 m (984 ft), sensor cable + extension cable

• Cross section: 0.75 mm

•up to 8 per core

• max. 60 nF (between core and screen)

• for FDU91F/93/95/96 and FDU 83/84/85/86:

The earth lead must not be within the screening.

2

to 2.5 mm2 (18 to 14 AWG)

22 Endress + Hauser

Page 23

Prosonic S FMU95 Wiring

FDU90/91/92

(FDU80/80F/81/81F/82)

FDU91F/93/95/96

(FDU83/84/85/86)

RD

BK

YE

RD

BK

YE

GNYE

1. 1.

RD

YE

GNYE

RD

YE

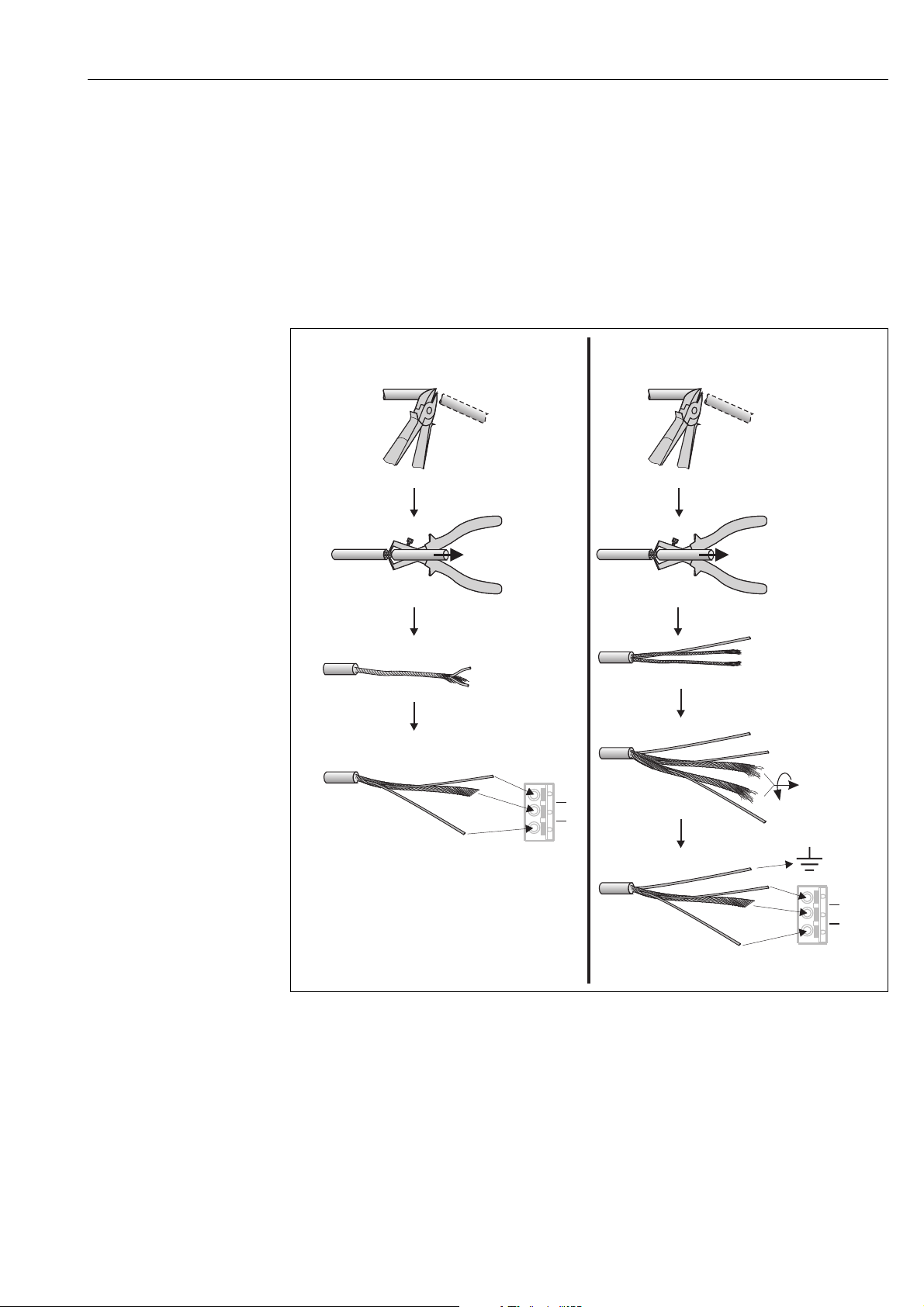

4.5 Shortening the sensor cable

If required, the sensor cable can be shortened. Please note:

• Do not damage the cores when removing the insulation.

• The cable is shielded by a metallic braiding. This shielding serves as a return cable and

corresponds to the black (BK) strand of the unshortened cable. After shortening the cable, loosen

the metallic braiding, twist it together securely and connect it to the "BK" terminal.

Caution!

"

The protective earth conductor (GNYE), which is present in some of the sensor cables, may not be

electrically connected to the cable shield.

Endress + Hauser 23

Colours of the strands: YE = yellow; BK = black; RD = red; GNYE = green-yellow

L00-FMU95xxx-04-00-00-xx-011

Page 24

Wiring Prosonic S FMU95

Prosonic S

FMU90/95

39 40

1

23

20

……

FMU90 FMU90 FMU90

Prosonic S

FMU90/95

39 40

Prosonic S

FMU90/95

39 40

Prosonic S

FMU90/95

39 40

Prosonic

FMU860/861/862

63 64

1

2

10

……

FMU90

VH

4.6 Synchronization line

• If wiring several Prosonic S (FMU90/FMU95)

which are mounted in a common cabinet and

if the sensor cables run in parallel, the

synchronization terminals (39 and 40) must

be interconnected.

• Up to 20 instruments can be synchronized in

this way.

• The synchronization causes the evaluation

units FMU9x to send the pulses

simultaneously. Only after all sensors have

received their signal, new simultaneous pulses

are sent. This prevents pulses in the sensor

cable of one sensor from influencing the

received signal on the cable of a different

sensor.

• If there are more than 20 instruments, groups

must be formed, each containing a maximum

of 20 instruments. For the instruments within

each group, the sensor cables may run in

parallel. The sensor cables of different groups

must be seperated from each other.

• Usual commercial screened cable can be used

for synchronization

– max. length: 10 m (33 ft) between the

individual instruments

– cross section: 2 x (0.75 to 2.5 mm

2

(18 to 14 AWG))

– for lengths up to 1 m (3.3 ft), an unscreened

cable can be used; for lenghts exceeding

1 m (3.3 ft), screening is required. The

screen must be connected to ground

• Instruments of the Prosonic FMU86x family

can be connected to the synchronization line

as well. In this case a maximum of 10

instruments can be connected to each

synchronisation line.

L00-FMU90xxx-04-00-00 -xx-004

L00-FMU90xxx-04-00-00 -xx-017

24 Endress + Hauser

Page 25

Prosonic S FMU95 Wiring

Address

Term.

DP

off

on

off

on

SW

HW

1

2

3

4

5

6

7

8

1

2

3

4

A(N)

66

B(P)

65

Display

POWER

Sync

Fuse

40

39

Service

32

1

11

10

9

1

FDU-Sensor

YE BK RD

14

13

12

2

YE BK RD

17

16

15

3

YE BK RD

20

19

18

4

YE BK RD

23

22

21

5

YE BK RD

26

25

24

6

YE BK RD

29

28

27

7

YE BK RD

32

31

30

8

YE BK RD

35

34

33

9

YE BK RD

38

37

36

10

YE BK RD

FDU-Sensor

1

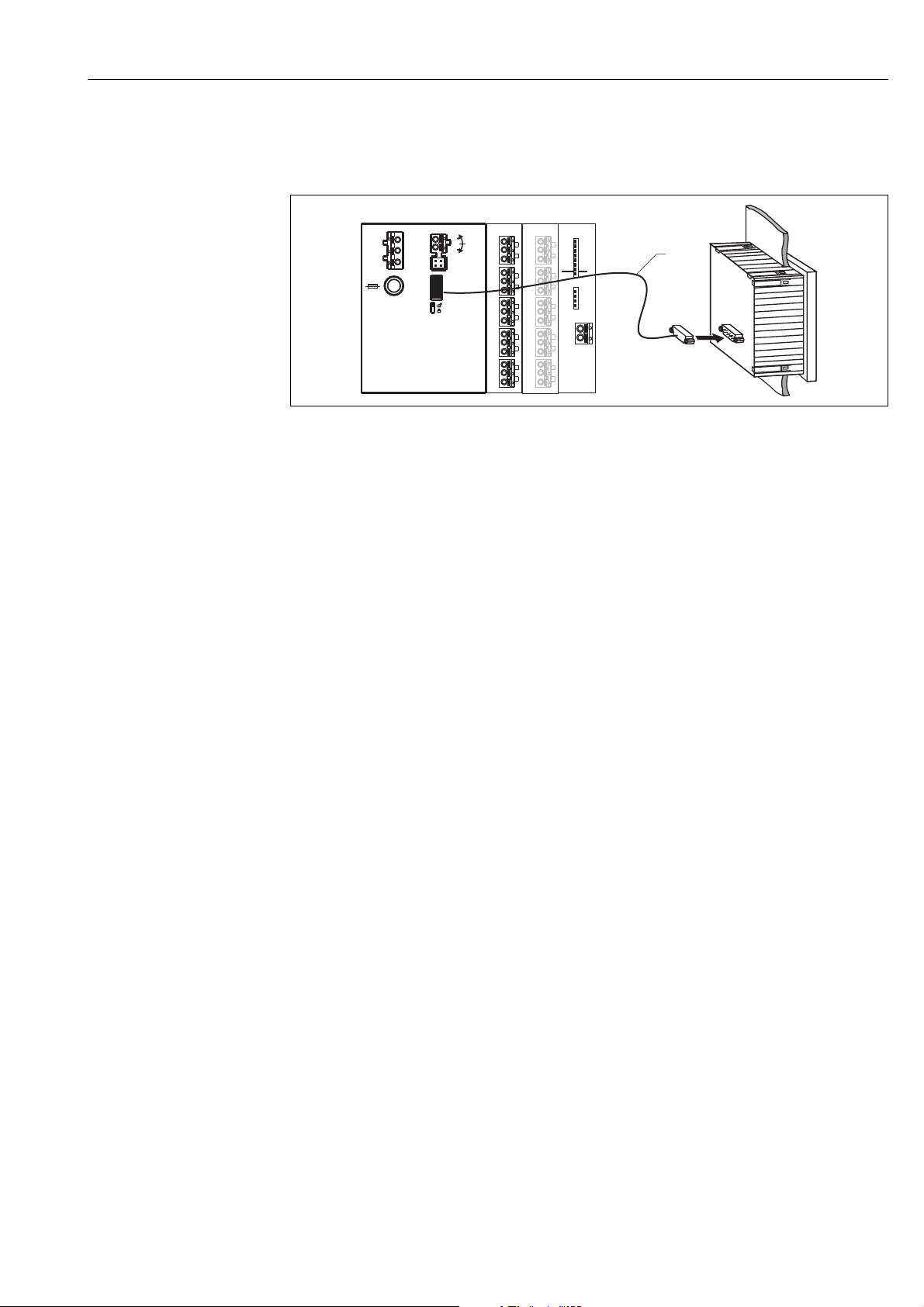

4.7 Connection of the separate display and operating

module

L00-FMU95xxx-04-00-00-xx-008

1 Connection of the display plug with the cable (3 m (9.8 ft))

For the version of the Prosonic S with a separate display for panel mounting, a pre-assembled

connecting cable (3 m (9.8 ft)) is supplied. The cable must be connected to the display plug of the

Prosonic S.

!

Note!

Minimum diameter for cable bushing: 20 mm (0.79 in).

Endress + Hauser 25

Page 26

Wiring Prosonic S FMU95

1

90 … 253 VAC

10,5 … 32 VDC

NLPE

FDU91F/93/95/96

(FDU83/84/85/86)

1

FMU95

Address

Term.

DP

off

on

off

on

SW

HW

1

2

3

4

5

6

7

8

1

2

3

4

A(N)

66

B(P)

65

Display

POWER

Sync

Fuse

40

39

Service

32

1

11

10

9

1

FDU-Sensor

YE BK RD

14

13

12

2

YE BK RD

17

16

15

3

YE BK RD

20

19

18

4

YE BK RD

23

22

21

5

YE BK RD

26

25

24

6

YE BK RD

29

28

27

7

YE BK RD

32

31

30

8

YE BK RD

35

34

33

9

YE BK RD

38

37

36

10

YE BK RD

FDU-Sensor

GNYE

FDU91F/93/95/96

(FDU83/84/85/86)

GNYE

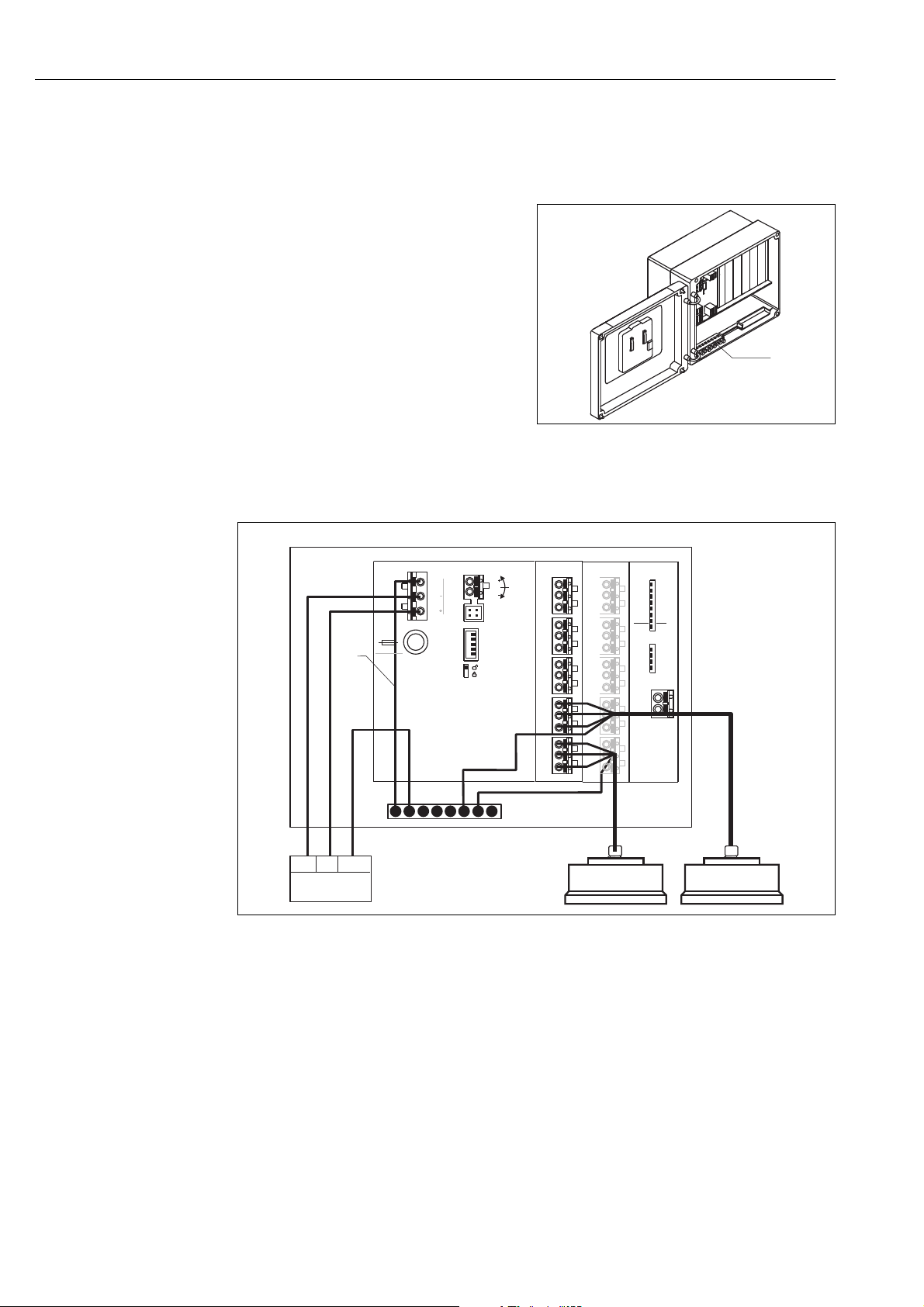

4.8 Potential equalization

4.8.1 Potential equalization in the field housing

Warning!

#

The grounding line of the sensors FDU91F/93/

95/96 and FDU83/84/85/86 must be

connected to the local potential equalization

system after a maximum of 30 m (98 ft),

( ä 20). The metallic terminal block (1) in

the field housing can be used for this.

L00-FMU90xxx-04-00-00 -xx-006

Example

L00-FMU95xxx-04-00-00 -xx-009

1 The wire is already connected on delivery

26 Endress + Hauser

Page 27

Prosonic S FMU95 Wiring

90 … 253 VAC

10.5 … 32 VDC

FMU95

Address

Term.

DP

off

on

off

on

SW

HW

1

2

3

4

5

6

7

8

1

2

3

4

A(N)

66

B(P)

65

Display

POWER

Sync

Fuse

40

39

Service

32

1

11

10

9

1

FDU-Sensor

YE BK RD

14

13

12

2

YE BK RD

17

16

15

3

YE BK RD

20

19

18

4

YE BK RD

23

22

21

5

YE BK RD

26

25

24

6

YE BK RD

29

28

27

7

YE BK RD

32

31

30

8

YE BK RD

35

34

33

9

YE BK RD

38

37

36

10

YE BK RD

FDU-Sensor

GNYE

FDU91F/93/95/96

(FDU83/84/85/86)

GNYE

PE

PE

PE

FDU91F/93/95/96

(FDU83/84/85/86)

L

N

1 2

3

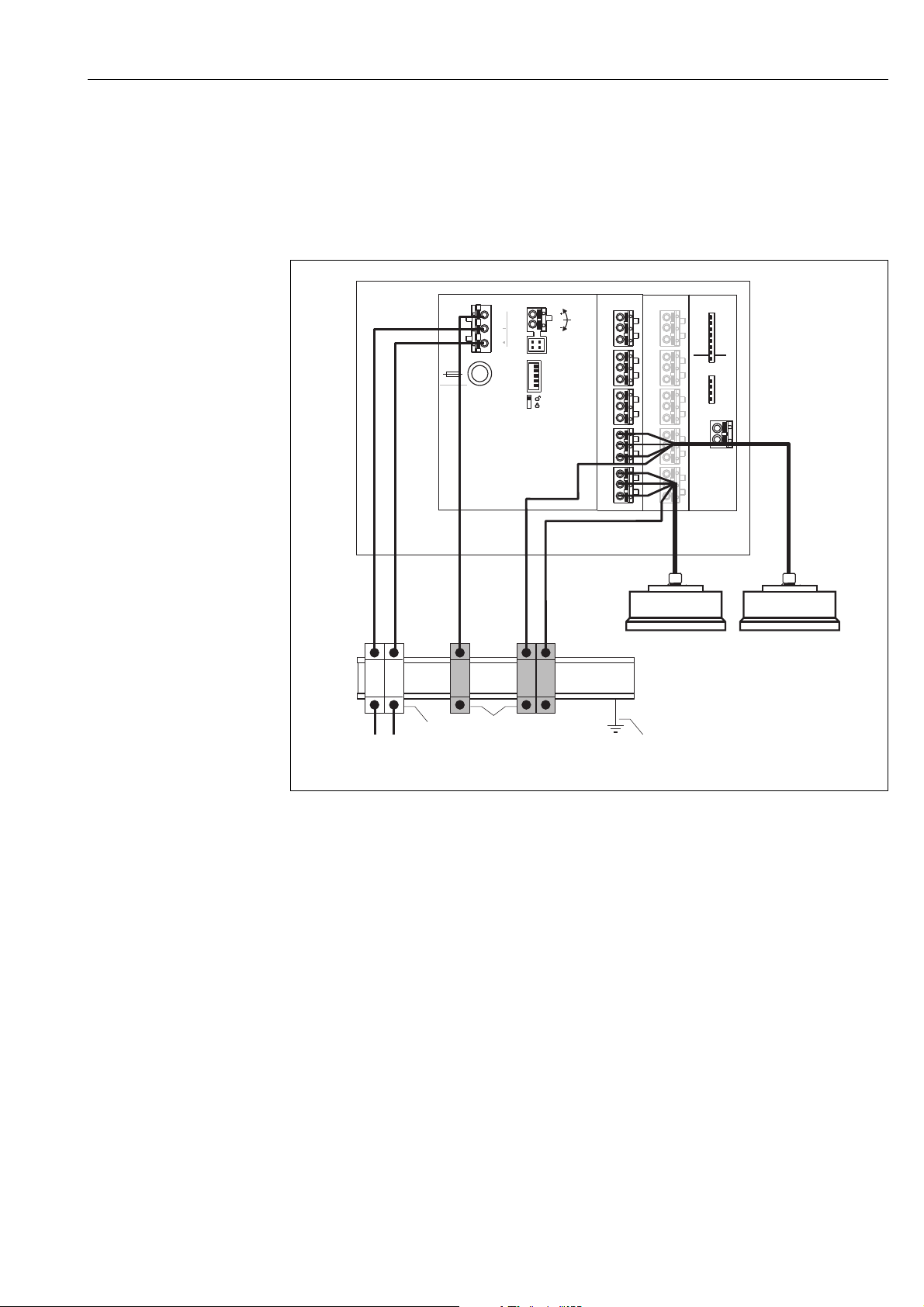

4.8.2 Potential equalization for the DIN-rail hosuing

If the DIN-rail housing is used, the potential equalization must be connected in the cabinet, e.g. at

a metallic DIN rail:

#

Warning!

The grounding line of the sensors FDU91F/93/95/96 and FDU83/84/85/86 must be connected

to the local potential equalization system after a maximum of 30 m (98 ft), ( ä 20).

L00-FMU95xxx-04-00-00-xx-010

1 Terminal (isolated from the DIN rail)

2 Protective earth terminal (with contact to the DIN rail)

3 Protective ground via DIN rail

Caution!

The signal evaluation electronics and its direct connections (display interface, service interface etc.)

are galvanically isolated from the supply voltage and the communication signals. Their electric

potential is identiacal to the potential of the sensor electronics.

Pay attention to the potential difference if the sensors are connected to ground!

Note!

• The longest required distance has to be taken into account when removing the jacket of the sensor

cable (GNYE in the above example).

"

!

• When shortening the sensor cable, comply to the notes ä 23.

Endress + Hauser 27

Page 28

Wiring Prosonic S FMU95

4.9 Post-connection check

After wiring the transmitter, carry out the following checks:

• Is the terminal assignment correct?

• For the field housing: Are the cable glands tight and is the cover of the terminal compartment

securely closed?

• If auxiliary energy is switched on: Does a display appear on the display module (if available) and

does the green LED light up?

28 Endress + Hauser

Page 29

Prosonic S FMU95 Operation

PROFIBUS DP

SPS /

PLC/

API

Ethernet

PDM

...

Prosonic S

PROFIboard

PROFIcard

PROFIusb

Commubox

FXA 291

FieldCare

T

T

FieldCare

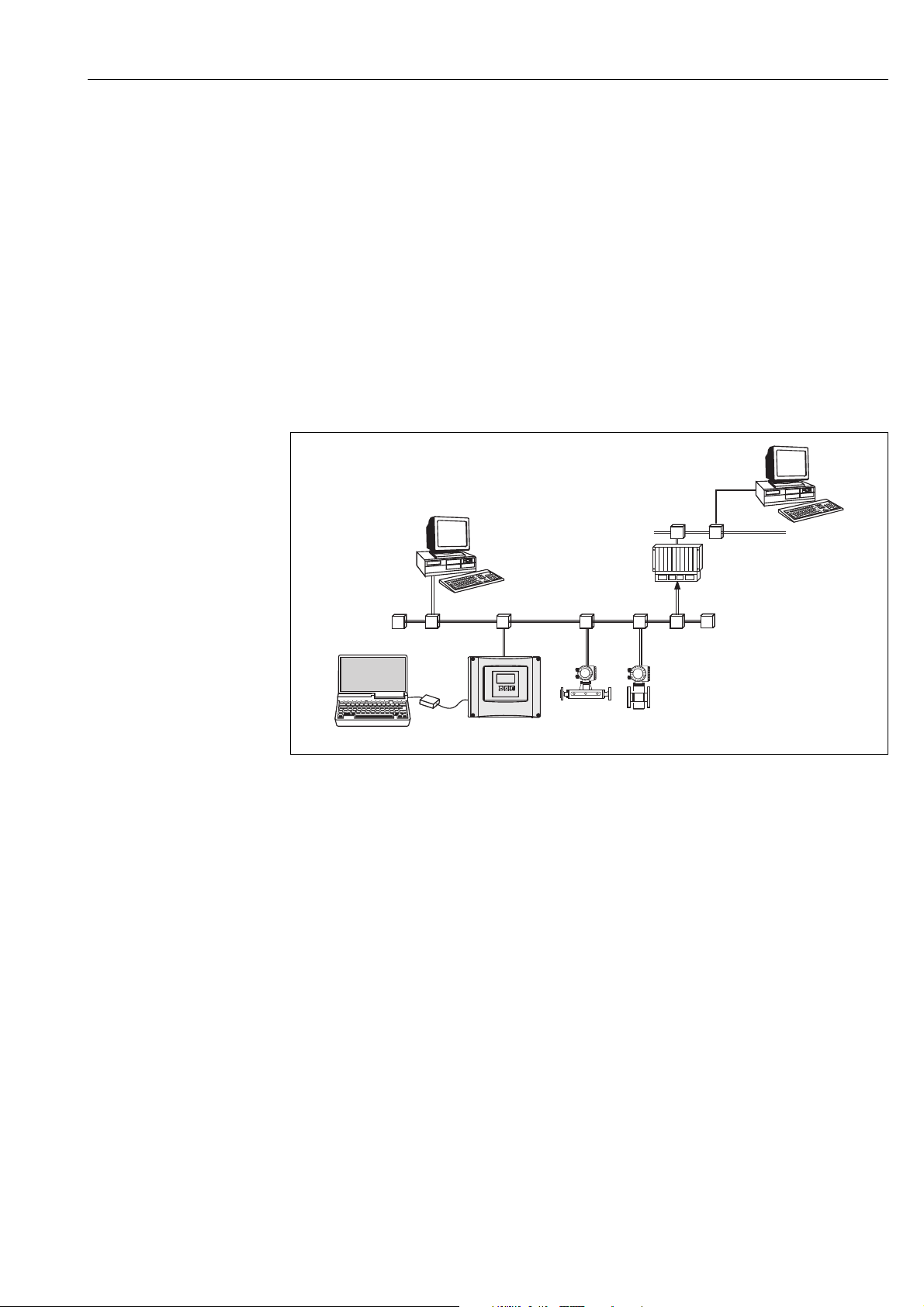

5Operation

This chapter gives an overview of the operating options for the intrument. It describes the different

methods of parameter access and states the pre-conditions for each case.

The measning of the individual parameters is not part of this chapter but can be found in:

• Chap. 6: "Commissioning"

• Operating Intructions BA00345F: "Prosonic S FMU95 - Description of Instrument Functions"

This chapter contains the following sections:

• Chap. 5.1 Operating options

• Chap. 5.2 Operation via the display and operating module

• Chap. 5.3 Operation via Endress+Hauser operating tool "FieldCare"

5.1 Operating options

!

!

L00-FMU90xxx-14-00-00-xx-021

5.1.1 On-site operation

• Display and operating module at the Prosonic S

• Endress+Hauser operating tool "FieldCare" with Commubox FXA291

Note!

Commubox FXA291 is an interface adapter from Endress+Hauser.

5.1.2 Remote oepration

Endress+Hauser operating tool "FieldCare" with PROFIcard, PROFIboard or PROFIusb

Note!

PROFIboard, PROFIcard and PROFIusb are interface adapters from Endress+Hauser.

Acyclic data exchange

Remote operation makes use of the acyclic data exchange, which allows device parameters to be

changed independently of the communication between the device and a PLC.

Acyclic data exchange is used

• to transmit device parameters during commissioning and maintenance;

• to display measured values that are not acquired in cyclic traffic.

The Prosonic S supports class 2 masters:

Endress + Hauser 29

Page 30

Operation Prosonic S FMU95

Acyclic communication with a Class 2 master (MS2AC)

In the case of MS2AC, a Class 2 master opens a communication channel via a so-called service

access point (SAP) in order to access the device. Class 2 masters is for example:

• FieldCare

Before data can be exchanged via PROFIBUS, however, the Class 2 master must be made aware of

the parameters contained within the field device. This can be done by:

• a device description (DD)

• a device type manager (DTM)

• a software component within the master, which accesses the parameters via slot and index

addresses.

!

Note!

• The DD or DTM is supplied by the device manufacturer.

• The Prosonic S has two Service Access Points. Therefore, it can be simultaneously accessed by

two Class 2 masters.

• The use of a Class 2 master increases the cycle time of the bus system. This must be taken into

consideration when the control system or PLC is programmed.

Slot-Index tables

The Slot-Index tables for the general acyclic data exchange are summarized in the document

BA00346F on the enclosed CD-ROM (can be downloaded from www.endress.com).

30 Endress + Hauser

Page 31

Prosonic S FMU95 Operation

FMU95

3

1

2

6

5

4

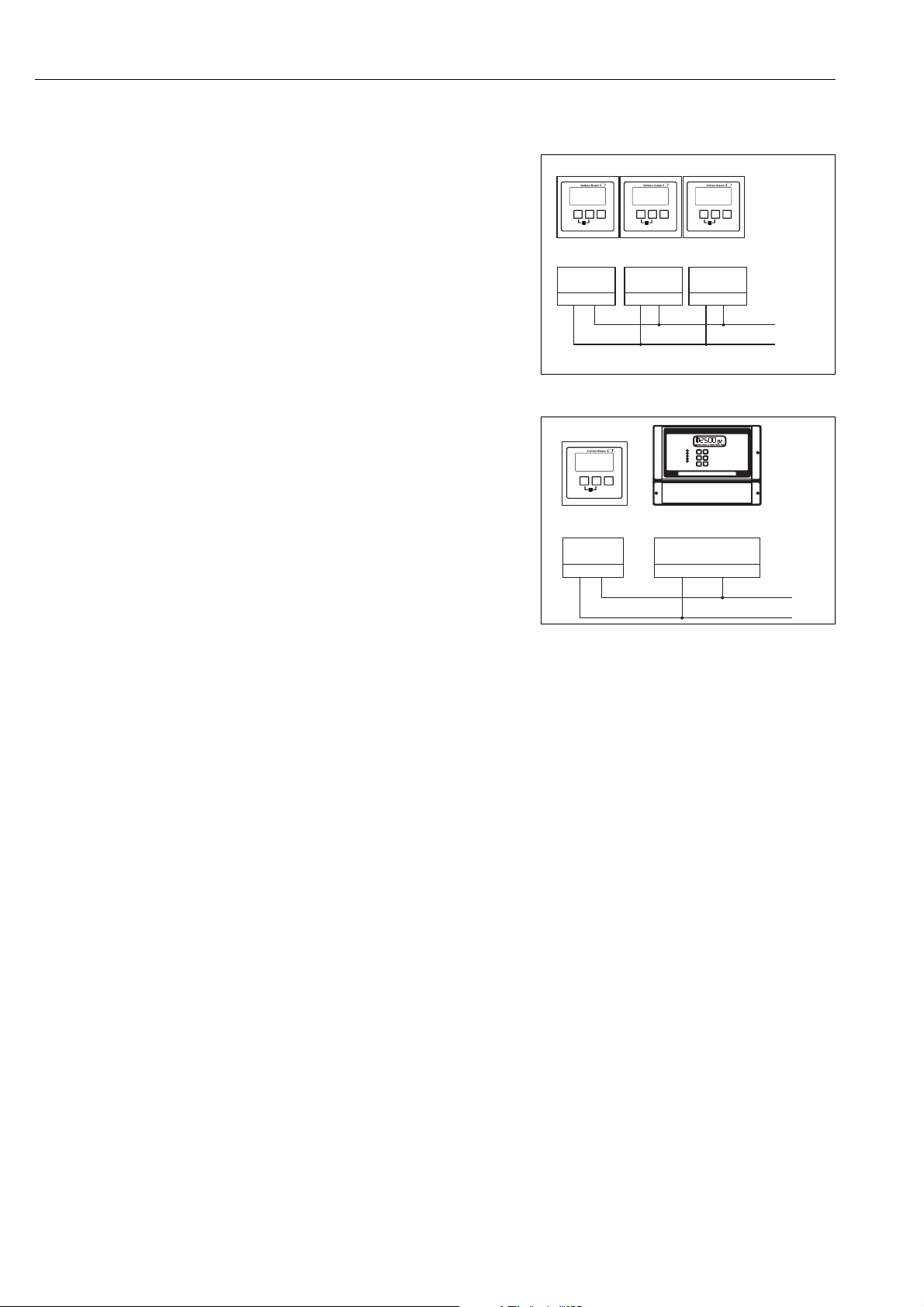

5.2 Operation via the display and operating module

5.2.1 Display and operating elements

L00-FMU95xxx-07-00-00-xx-001

1 Softkey symbol

2Key

3 LED indicating the operating state

4 Display symbols

5 Value of the parameter, including unit

6 Name of the parameter

Display symbols

Symbol Meaning

Operating mode of the instrument

User

User parameters can be edited. Service parameters are locked.

Diagnosis

The service interface is connected.

Service

User and service parameters can be edited.

Locked

All parameters are locked.

Locking state of the currently displayed parameter

Display parameter

The parameter can not be edited in the current operating mode of the instrument.

Editable parameter

The parameter can be edited.

Scroll symbols

Scroll list available

Indicates that the list contains more parameters than can be represented on the display. By pressing

V or W repeatedly, all parameters of the list can be accessed.

Navigation in the envelope curve display

Move left

Move right

Zoom in

Zoom out

Endress + Hauser 31

Page 32

Operation Prosonic S FMU95

LEDs

LED indicating the operating state (pos. 3 in the figure)

green normal measuring mode; no error detected

Warning:

red (flashing)

red

off supply voltage missing

An error is detected but the measurement continues. Reliability of the measured value is no longer

ensured.

Alarm:

An error is detected. The measurement is interrupted. The measured value assumes the value

specified by the user (parameter "output on alarm").

Keys (softkey operation)

The function of the keys depends on the current position within the operating menu (softkey

functionality). The key functions are indicated by softkey symbols in the bottom line of the display.

Symbol Meaning

Move downwards

Moves the marking bar downwards within a selection list.

Move upwards

Moves the marking bar upwards within a selection list.

Enter

• Opens the marked submenu, the marked parameter set or the marked parameter

• Confirms the edited parameter value

Previous parameter set

Reopens the previous parameter set within the submenu.

Next parameter set

Opens the next parameter set within the submenu.

Confirm selection

Selects the option of a selection list which is currently marked by the bar.

Increase value

Increases the active digit of an alphanumeric parameter.

Decrease value

Decreases the active digit of an alphanumeric parameter

Error list

Opens the list of all errors which are currently detected.

If a warning is present, this symbol flashes.

If an alarm is present, the symbol is displayed continuously.

Change Display

Change to the next page of measured values (only available if more than one pages of measured

values have been defined; see "display" menu)

Info

Opens the Shortcut Menu, which contains the most important information about the current state

of the instrument

Menu

Opens the Main Menu, which contains all parameters of the Prosonic S

32 Endress + Hauser

Page 33

Prosonic S FMU95 Operation

32

1

General key combinations

The following key combinations do not depend on the menu position:

Key combination Meaning

Escape

• While editing a parameter: Exit the editing mode without accepting the changes.

• Within the navigation: Move upwards to the previous layer of the menu.

Increase contrast

Increases the contrast of the display module.

Decrease contrast

Decreases the contrast of the display module.

Locking

Locks the instrument against parameter changes.

The instrument can only be unlocked again by the keys.

5.2.2 The operating menu

Structure of the menu

The parameters of the Prosonic S are organized in an operating menu (consisting of a main menu

and several submenus). Parameters which are related to each other are comprised in a common

parameter set. To simplify the navigation within the menu, a five-digit position code is displayed

with each parameter set.

LVL 1 appl.para L1004

tank shape :dome ceiling

medium property:liquid

process cond:standard liq.

Identification of the parameter sets:

1Submenu

2 Number of the associated input or output

3 Number of the parameter set within the submenus

•The first digit (1) specifies the submenu

– L: "level"

– A: "safety settings"

– O: "output/calculations"

– D: "device properties", "calibr. display" and "sensor management"

– I: "system information"

– S: "service" (only available if the service password has been entered)

1)

:

Diagrams of the submenus can be found in the chapter "Operating menu".

1) Depending on the instrument version, the installation environment and the selected operating mode, some of the submenus may not be present.

Endress + Hauser 33

Page 34

Operation Prosonic S FMU95

•The second digit (2) is used if the parameter set occurs several times within the Prosonic S (e.g.

for different inputs or outputs).

Example:

– L1002: level 1

– L2002: level 2

– ...

– L9002: level 9

– LA002: level 10

If the parameter set occurs only once wihtin the Prosonic S, "X" is indicated at this position.

•The last three digits (3) specify the individual parameter sets within the submenu.

Parameter types

Display parameters

Parameters for which the symbol is displayed in the left bottom corner of the display

module, are either locked or display-only parameters.

Editable parameters

L00-FMU90xxx-07-00-00-e n-041

L00-FMU90xxx-07-00-00-e n-044

Parameters, for which the symbol is displayed in the left bottom corner of the display

module, can be entered for editing by pressing

.

The editing procedure depends on the type of

parameter:

• when entering a selection parameter, the

associated selection list appears (see below:

"Editing a parameter with selection list").

• when entering a numerical or alphanume-

rical parameter, the text and number editor

appears (see below: "Entering numbers and

characters").

34 Endress + Hauser

Page 35

Prosonic S FMU95 Operation

CX001

main menu

level

flow

safety settings

ralay/controls

…

LX001

level

L1002

level 1

Return

input: sensor 1

sensor sel.: autom.

detected: FDU91

tank shape: dome

medium proper: liq.

proc. cond.: stand.

5.00 m

level (LVL) 1

...

...

basic setup

extended calibr.

simulation

L1004

LVL1 appl. para

tank shape: dome

medium proper: liq.

proc. cond.: stand.

L100A

tank shape

dome ceiling

horizontal cyl.

bypass

stilling well

L1004

LVL1 appl. para

L100A

tank shape

dome ceiling

horizontal cyl.

bypass

stilling well

L1004

LVL1 appl. para

tank shape: bypass

medium proper: liq.

proc. cond.: stand.

L1004

LVL1 appl. para

tank shape: bypass

medium proper: liq.

proc. cond.:stand.

L1005

LVL1 empty cal.

level 1

67.60 %

=

L1003

LVL1 sensor sel.

Menu

Main Menu

Submenus

Parameter Set

(here: with 3 parameters)

Editing a

parameter with

selection list

Navigation within the menu (Example)

Endress + Hauser 35

L00-FMU90xxx-19-00-00-en-050

Page 36

Operation Prosonic S FMU95

shortcut menu main menu

actual error

level

Warning 01802

safety settings

Alarm 01502

tag marking

envelope curve

language

device information

password/reset

...

...

...

...

FMU95

Entering the menu

The navigation always starts from the main screen (measured value display

2)

). From there, the

following menus can be opened by the keys:

• shortcut menu

The shortcut menu is accessed via the "Info" key. It allows quick access to device information:

–tag marking

– envelope curve: used to check the signal quality

– language: sets the display language

– device information: serial number, versions of software and hardware

– password/reset: used to enter the password or reset code

All parameters of the shortcut menu are contained in the main menu as well.

• main menu

The main menu is accessed via the "Menu" key. It contains all parameters of the Prosonic S. It

is divided into submenus. Some of the submenus consist of further submenus. Which submenus

are actually present, depends on the instrument version and the installation environment.

An overview of all submenus and parameters is given in the chapter "Operating menu".

• actual error

If the self-monitoring of the Prosonic S detects an error, the softkey symbol appears

above the middle key.

If the softkey symbol flashes, only "warnings" are present.

If the softkey symbol is displayed permanently, at least one "alarm" is present.

After pressing the key, a list of all currently present errors appears.

L00-FMU95xxx-19-00-00-en-002

2) Note: Depending on the configuration, the appearance of the measured value display may be differemt from the example in the figure.

36 Endress + Hauser

Page 37

Prosonic S FMU95 Operation

1.

2.

3.

main menu

“device properties”

submenu

“distance unit”

parameter set

Selecting a submenu

1. In the main menu press W or V until the

required submenu is marked by the bar.

Note!

!

The symbols indicate that the

selection list contains more items than can be

displayed on the module. Press W or V several

times, to mark one of the hidden items.

2. Press , in order to enter the marked

submenu.

3. If the submenu contains further submenus,

continue until you reach the level of the

parameter sets. This level is reached if the

softkey symbols U and T appear.

L00-FMU95xxx-19-00-00-en-005

!

Note!

If necessary, you can return to the previous level of the menu by pressing .

Endress + Hauser 37

Page 38

Operation Prosonic S FMU95

1.

1.

3.

2.

4.

Selecting a parameter

By pressing U or T you can switch between the parameter sets of the current submenu. For each

parameter set the values of all its parameters are displayed. In order to change one of the values,

proceed as follows:

1. Press U or T, until you have reached the

required parameter set.

2. Press , in order to enter the parameter set.

3. Select the required parameter by pressing

W or V.

(This step is not required if the set contains

only one parameter.)

4. Press , in order to enter the editing mode

of the parameter.

The editing method depends on the type of

parameter (selection list, numeric or

alphanumeric parameter). For details refer

to the following sections.

!

Note!

If necessary, you can exit the parameter and parameter set by pressing .

L00-FMU90xxx-19-00-00-e n-040

38 Endress + Hauser

Page 39

Prosonic S FMU95 Operation

1.

2.

3.

Editing a parameter with selection list

1. Press W or V, until the required option is

marked by the bar (in the example: "turb.

surface").

Note!

!

The symbols indicate that the

selection list contains more items than can

be displayed on the module. Press W or V

several times, to mark one of the hidden

items.

2. Press ✓, in order to select the marked

option. It is then stored in the instrument.

3. Press the left and middle keys

simultaneously in order to quit the

parameter.

The software key symbols U and T

reappear and you can switch to the next

parameter set.

!

Note!

By pressing before ✓ you can quit the parameter without accepting your changes.

L00-FMU90xxx-19-00-00-en-041

Endress + Hauser 39

Page 40

Operation Prosonic S FMU95

1.

2.

3.

4.

5.

6.

Entering numbers and characters

When you select a numeric parameter ("empty

calibration", "full calibration" etc.) or an alphanumeric parameter ("device marking" etc.), the

editor for numbers and text strings appears.

Enter the desired value in the following way:

1. The cursor is at the first digit. Press S or O

until this digit has the required value.

jump to the next digit.

3. Repeat the procedure for all relevant digits.

2. Press in order to confirm the value and to

4. If all relevant digits have been entered:

Press S or O, until appears at the cursor.

5. Press to store the complete value in the

device.

6. Press the left and middle keys simultaneously in order to quit the parameter.

L00-FMU90xxx-19-00-00-yy-042

40 Endress + Hauser

Page 41

Prosonic S FMU95 Operation

Special editing functions

Within the editor for alphanumeric characters, pressing S or O does not only lead to numbers and

characters but also to the following symbols for special editing functions. They simplify the editing

procedure.

L00-FMU90xxx-19-00-00-yy-043

Enter: The number left of the cursor is transferred to the instrument.

L00-FMU90xxx-19-00-00-yy-044

Escape: The editor is closed. The parameter maintains its former value. The same behavior can be achieved by pressing

the left and the middle key simultaneously ( ).

L00-FMU90xxx-19-00-00-yy-045

Next digit: The cursor moves on to the next digit.

L00-FMU90xxx-19-00-00-yy-046

Previous digit: The cursor moves back to the previous digit.

Endress + Hauser 41

Page 42

Operation Prosonic S FMU95

FMU95

L00-FMU90xxx-19-00-00-yy-047

Delete: The current digit and all digits to its right are deleted.

Return to the measured value display

By pressing the left and middle keys

simultaneously you can return

• from a parameter to the parameter set

• from the parameter set to the submenu

• from the submenu to the main menu

• from the main menu to the measured value

display

L00-FMU95xxx-19-00-00-e n-003

42 Endress + Hauser

Page 43

Prosonic S FMU95 Operation

1

2

5.3 Operation via Endress+Hauser operating tool

"FieldCare"

L00-FMU90xxx-19-00-00-en-087

Operation via the FieldCare is similar to the operation via the display module.

• The operating menu can be found in the navigation bar (1).

• Input fields for the parameters can be found in the parameter editor (2).

• When you click on a parameter name, the help pages appear. They contain a detailed description

of the respective parameter.

Endress + Hauser 43

Page 44

Commissioning Prosonic S FMU95

6 Commissioning

#

Warning!

For the version with field housing: The instrument may only be operated if the field housing is

closed.

This chapter describes the steps of the commissioning procedure:

• 6.1 Preparatory steps

– 6.1.1 Setting the device address

– 6.1.2 Bus termination

– 6.1.3 Loading the devic database files (GSD files)

– 6.1.4 Unlock configuration

– 6.1.5 Reset to the default configuration

• 6.2 Configuration of the measurement

– 6.2.1 First setup

– 6.2.2 Preparing the basic setup

– 6.2.3 Basic setup

– 6.2.4 Checking the measuring signal (envelope curve display)

– 6.2.5 Deactivation of unused sensor inputs

• 6.3 Parametrization of the Anaolg Input Blocks

• 6.4 Parametrization of the cyclic data telegram

• 6.5 Parametrization of the on-site display

6.1 Preparatory steps

6.1.1 Setting the device address

Selecting the device address

• Every PROFIBUS device must be given an address. If the address is not set correctly, the device

will not be recognised by the process control system.

• A device address may appear only once within a particular PROFIBUS network.

• Valid device addresses are in the range between 1 and 126. All devices are delivered from the

factory with the address 126, which is set by software.

• The default address can be used to check the function of the device and connect it to an operating

PROFIBUS system. Afterwards the address must be changed to allow other devices to be

connected to the network.

Software addressing

Software addressing comes into operation, when DIP-switch 8 on the PROFIBUS DP terminal area

is in the position "ON".

In this case, the address can be set by an operating tool ("FieldCare").

The address is displayed in the function "Output-calculations/PROFIBUS DP/instrument address".

44 Endress + Hauser

Page 45

Prosonic S FMU95 Commissioning

Address

Term.

DP

off

on

off

on

SW

HW

1

2

3

4

5

6

7

8

1

2

3

4

Address

off

on

SW

HW

1

2

3

4

5

6

7

8

8 + 2 = 10

A(N)

66

B(P)

65

Address

Term.

DP

off

on

off

on

SW

HW

1

2

3

4

5

6

7

8

1

2

3

4

A(N)

66

B(P)

65

Term.

off

on

1

2

3

4

Term.

off

on

1

2

3

4

AB

Hardware addressing

L00-FMU90xxx-04-00-00-xx-016

Hardware addressing comes into operation when DIP switch 8 is in the position "HW (OFF)". In this

case the address is determinded by the position of DIP-switches 1 to 7 according to the following

table:

Switch No. 1234567

Value in position "OFF"0000000

Value in Position "ON"1248163264

The new address becomes valid 10 seconds after switching.

6.1.2 Bus termination

The termination resistor must be activated for the last instrument on the bus. This is done by setting

all four termination switches into the "on" position.

L00-FMU90xxx-04-00-00-xx-018

A: termination off (factory setting); B: termination on

Endress + Hauser 45

Page 46

Commissioning Prosonic S FMU95

Prosonic_S/DP/Profile3/Revision1.0/

BMP/

Eh154E_d.bmp

Eh154E_n.bmp

Eh154E_s.bmp

DIB/

Eh154E_d.dib

Eh154E_n.dib

Eh154E_s.dib

GSD/

Extended/Eh3x154E.gsd

Info/

Liesmich.pdf

Readme.pdf

6.1.3 Loading the device database and type files (GSD)

Meaning of the GSD files

A device database file (GSD) contains a description of the properties of the PROFIBUS device, e.g.

the supported transmission rates and the type and format of the digital information output to the

PLC. Additional bitmap files are required in order to represent the device by an icon in the network

design software. The device database and bitmap files are needed for the commissioning of a

PROFIBUS DP network.

Name of the GSD file

Every device is allocated an identity code by the PROFIBUS User Organisation (PNO). This appears

in the device data base file name (.gsd).

The FMU95 has the ID number 154E(hex) = 5454 (dec).

Therefore, the name of the GSD file is: EH3x154E.gsd

Sources of supply

• www.endress.com

click on "Download" and enter "GSD" into the "Text search" field. The "Software" link opens a list

containing the links to all available GSD files.

• CD-ROM with GSD files for all Endress+Hauser devices. Order-Code: 50097200

• GSD library of the PROFIBUS User Organisation (PNO):http: //www.PROFIBUS.com

Directory structure

The files are organized in the following structure:

L00-FMU95xxx-02-00-00 -xx-001

Universal Database File

As an alternative to the device specific GSD file, the PNO provides an universal database file without

instrument specific features.

When the universal database file is used, the option "profile" must be selected in the "Output-

46 Endress + Hauser

calculation/PrOFIBUS DP/ident number" parameter.

Usage of the GSD files

The GSD files must be loaded to a specific subdirectory of the PROFIBUS DP configuration software.

Depending on the software, the GSD files must be copied into the directory or an import

functionality of the software may be used.

Detailed information about the appropriate file location can be obtained from the manual of the

respective configuration software.

Page 47

Prosonic S FMU95 Commissioning

6.1.4 Unlock configuration

If appears on the display, the instrument is locked against parameter changes. Before

commissioning the instrument must be unlocked.

For the Prosonic S there are three types of locking:

• Software locking

• Locking by key combination

• Hardware locking

Indication of the locking state

The current locking state of the instrument is displayed in the parameter "device properties/

password-reset/status". The following states may occur:

• unlocked

All parameters (except of service parameters) can be changed.

• code locked

The instrument has been locked via the operating menu. It can be unlocked by entering the

unlocking code into the "code" parameter.

• key locked

The key has been locked by a key combination. It can only be unlocked by pressing all three keys

simultaneously.

• switch locked

The instrument has been locked by the switch in the terminal compartment. It can only be

unlocked by this switch.

Software locking

Locking

Go to the parameter "device properties/passoword-reset/code" and enter a value 2457. The

instrument is locked against parameter changes.

The symbol appears on the display.

Unlocking

If you try to change a parameter, the "password-reset" parameter set appears. Select the "code"

parameter and enter "2457". Parameters can be changed again.

Locking by key combination

Locking

Press all three keys simultaneously. The instrument is locked against parameter changes.

The symbol appears on the display.

Unlocking

If you try to change a parameter, the "password/reset" parameter set appears. "key locked" is

displayed in the "status" parameter. Press all three keys simultaneously. Parameters can be changed

again.

Endress + Hauser 47

Page 48

Commissioning Prosonic S FMU95

Display

POWER

Sync

Fuse

40

39

Service

3

2

1

A

B

Hardware locking

The instrument can be locked against parameter changes by the locking switch in the terminal

compartment of the Prosonic S.

"

!

L00-FMU90xxx-19-00-00-yy-105

Switch position A: unlocked; parameters can be changed

Switch position B: locked; parameters can not be changed.

If the switch is in position B, appears on the display and parameters can not be changed. The

instrument can only be unlocked by the switch.

6.1.5 Reset to the default configuration

Caution!

A reset may lead to impairment of the measurement. As a rule, a basic calibration is required after

a reset.

Application of the Reset

It is advisable to reset the customer parameters if you want to use a device with an unknown history.

Effects of the Reset

• All parameters are reset to their default values.

• The linearisation type is switched to "none". If a linearisation table is present, it is not deleted. If

required, it can be reactivated at a later point of time.

• An interference echo curve is set "inactive". However, the curve is not deleted and can be

reactivated at a later point of time.

Note!

In the menu diagrams ( ä 96, "Operating menu") the default values of the parameters are printed

in bold.

Performing a Reset

In order to perform a reset, enter "33333" into the parameter "device properties/password-reset/

reset".

48 Endress + Hauser

Page 49

Prosonic S FMU95 Commissioning

5-point linearity protocol

!

!

Note!

The specified measuring accuracy is a typical value ä 94, "Performance characteristics".

With the production of the 5-point linearity protocol the measuring system (FDU9x sensor and

FMU9x transmitter electronic) is adjusted exactly to one another and the measuring accuracy is

optimized for the specified range.

To realize this, the parameter "zero distance" is fine adjusted. After a reset the value for the zero

distance has to be re-parameterized in the service menu according to the data on the associated 5point linearity protocol for the FDU9x sensor. Please contact the Endress+Hauser service.

6.2 Configuration of the measurement

6.2.1 First setup

Note!

This chapter describes the commissioning of the Prosonic S via the display and operating module.

Commissioning via FieldCare is similar. For further instructions refer the FieldCare Online Help.