Page 1

BA182R/09/en/08.05

51009170

Software version:

3.0

Operating Instructions

RMS621

Energy Manager

Page 2

RMS621

2 Endress+Hauser

Brief overview

For quick and easy commissioning:

Safety instructions Page 8

⇓

Installation Page 11

⇓

Wiring Page 13

⇓

Display and operating elements Page 23

⇓

Commissioning Page 28

Quick start via the navigator to device configuration for standard operation.

Device configuration - explanation and use of all configurable device

functions with the associated value ranges and settings.

Application example - configuration of the device.

Applications for the Energy Manager

The device compensates flow measurements of steam and water according to the international standard for calculation

IAPWS IF-97 (ASME tables).

Page 3

RMS621

Endress+Hauser 3

Brief operating instructions

"

Caution!

The information contained in these Operating Instructions serves as a guide to help you commission

your device easily, i.e. the most important settings are listed here but special functions (e.g. tables,

corrections etc.) are not.

Configuring a measurement - Set-up example

Example 1: Steam heat (or steam mass)

Sensors: DPO10 (orifice), Cerabar T, TR 10

1. Connect device to the power source (terminal L/L+, 230 V)

2. Press any key → Setup (all parameters)

3. Basic set-up

Date-time (set up date and time) Æ

Z

Select system eng. units (select metric or American)

4. Flow inputs (flow 1)

Flow meter: Differential pressure

Diff. device: Orifice corner tap

Signal: 4 to20 mA

Terminals: Select A10 and connect DP transmitter to terminals: A10(-)/82(+) (because of

passive signal)

Curve: linear (also set up linear curve at the DP transmitter)

Set up start- and end-value (in mbar!)

Tube data: enter internal tube diameter and diameter ratio (ß) as found on the maufacturers

data sheet.

"

Caution!

If tube data is not known, for flow meter: select operating volume

Curve: linear (set up square rooted curve on the DP transmitter)

Set up start- and end-values (m

3

/h)

5. Pressure input (Pressure 1)

Signal type: e.g. 4 to 20 mA

Terminals: Select A110 and connect Cerabar T to terminals: A110(-)/A83(+) (passive signal)

Type: Select absolute (-pressure measurement) or relative (-pressure measurement)

Set up start- and end-values of the pressure transmitter Æ

Z

6. Temperature inputs (temp. 1.1)

Signal type: Pt100

Sensor type: 3- or 4-wire

Select terminals E1-6 and connect Pt100 Æ

Z

Æ Z.

7. Application

Application 1: Steam heat

Steam type: super heated steam

Allocate flow 1, pressure 1 and temp. 1.1 to the steam measurement.

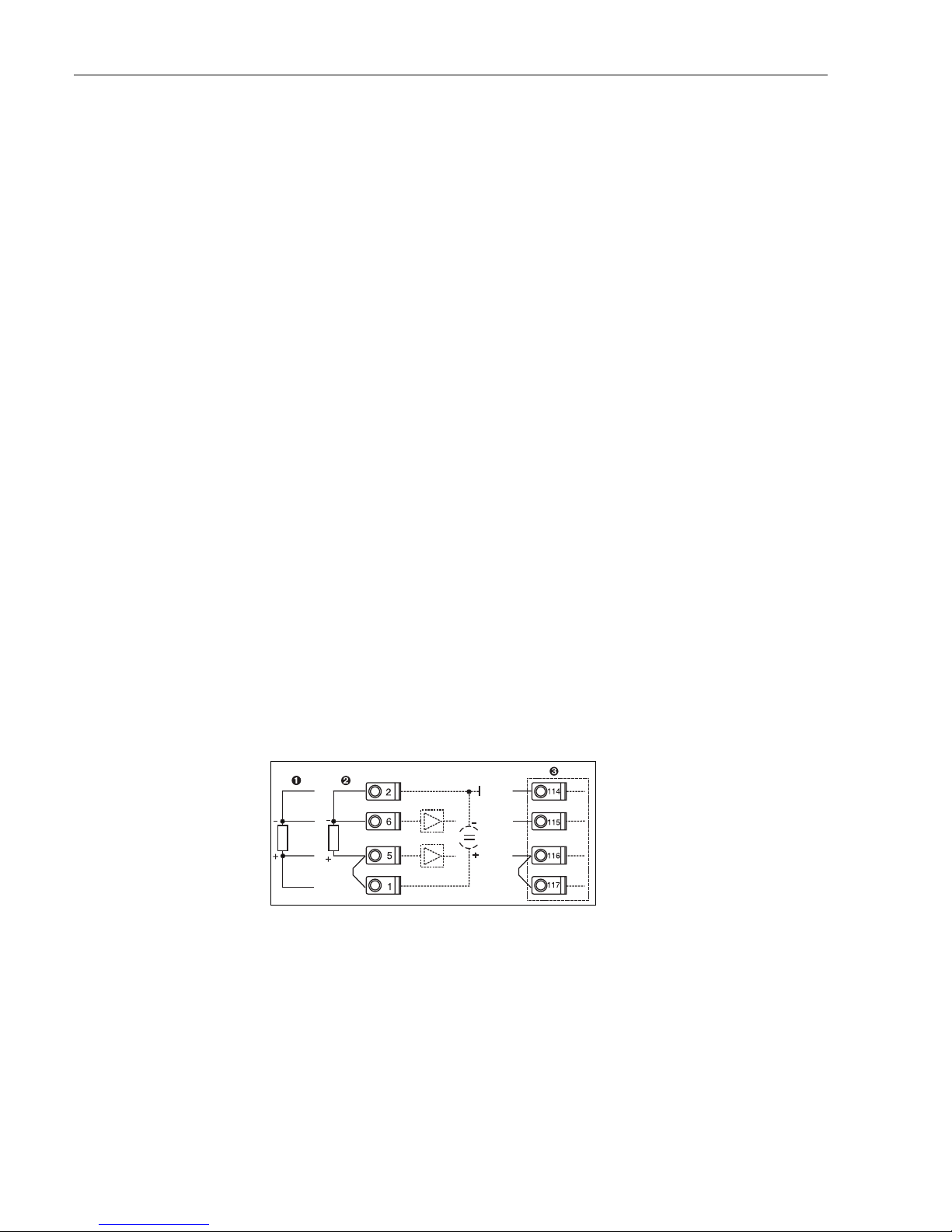

Fig. 1: Temperature sensor connection, e.g. to input 1 (Slot E I)

Pos. 1: 4-wire input

Pos. 2: 3-wire input

Pos. 3: 3-wire input e.g. optional

temp. expansion card (Slot B I)

Page 4

RMS621

4 Endress+Hauser

8. Display

Group 1

Display mask: 3 values

Value 1 (...4): Mass flow, Mass sum, Heat sum Æ

Z

Group 2: select to above system e.g. flow 1, pressure 1, temperature 1.1, heat flow 1.

9. Exit set-up

Exit set-up by operating ESC

Z

a number of times and acknowledging with F.

Display

By operating any key you can enter the main menu and select the required group including all the

relative display values: Display -> Group -> Group 1. All can also be displayed in an automatic scroll

function: Setup -> Display -> Scrolled display (scroll using the arrow under group 6).

If a fault occurs the display automatically changes colour (blue/red). Detailed fault finding and

elimination can be found in the relative chapter of these operating instructions.

Example 2: Water heat difference

Sensors: 2 x TST90, Promag 50

1. Connect device to the power source (terminal L/L+, 230 V)

2. Press any key → Menu → Setup (all parameters)

3. Basic set-up

Date-time (set up date and time) Æ

Z

Select system eng. units (metric or American)

4. Flow input (flow 1)

Flow meter: Operating volume

Signal type: 4 to20 mA

Terminals: select A10 and connect the Prowirl to terminals: A10(+)/11(-) (active signal)

Set up start- and end-values

5. Temperature inputs (temp. 1.1 and temp. 1.2)

Signal type: Pt100

Sensor type: 3- or 4-wire

Terminals: select E1-6 and connect TST90 (temp. 1.1) Æ

Z

Terminals: select E3-8 and connect TST90 (temp. 1.2)Æ Z Æ

Z

6. Applications

Application 1: Water heat difference

Operating mode: Heating

Select "Flow 1"

Installation point: Cold (means return)

Allocate temperature sensors 1.1 and 1.2 to heat and cooling section.

7. Display

Group 1

Display mask: 3 values

Value 1 (...4): Flow 1, heat flow 1 and mass sum 1 Æ

Z

Fig. 2: Temperature sensor connection, e.g. to input 1 (Slot E I)

Pos. 1: 4-wire input

Pos. 2: 3-wire input

Pos. 3: 3-wire input e.g. optional

temp. expansion card (Slot B I)

Page 5

RMS621

Endress+Hauser 5

Group 2: select to above system e.g. temp. 1.1, temp. 1.2, mass flow 1, mass sum 1.

8. Exit set-up

Exit set-up by operating ESC

Z

a number of times and acknowledging with F.

Display

By operating any key you can enter the main menu and select the required group including all the

relative display values: Display -> Group -> Group 1. All groups can also be displayed in an

automatic scroll function: Setup -> Display -> Scrolled display (scroll using the arrow under group

6).

If a fault occurs the display automatically changes colour (blue/red). Detailed fault finding and

elimination can be found in the relative chapter of these operating instructions.

An example of steam mass measurement using a Prowirl 77 can be found in the appendix of this

operating manual.

Example 3

!

Note!

You will find a further example for a steam mass calculation using a Prowirl 77 in chapter 6.4.1 of

the operating instructions.

Basic application settings

The values shown are only an indication in order to simplify the commissioning of the device, this

means that only the most necessary settings are shown. Special functions (e.g. tables, corrections,

etc.) are not shown.

Water applications

Input values: Flow, temperature 1, (temperature 2)

Only one temperature is required for water heat quantity. A direction signal teriminal is required on

changing flow direction (bi-directional operating mode).

Flow

Pulse/PFM (e.g. ProWirl)

Analog (e.g. Promag) Differential pressure (e.g. Orifice)

Flow input Flow input Special flow meters

Flow meter: Operating volume Flow meter: Operating volume Differential pressure/Orifice/water

Terminals:

– Flow meter with active signal connect to e.g. terminals A10(+)/11(-).

– Flow meter with passive signal select e.g. terminals A10 and connect to terminals A10(-)/82(+). Terminal 82 is 24 V sensor power supply.

k factor Start/end value (m

3

/h) Start/end value (mbar)

Temperature

Select signal type and connect sensor(s) (see example). 2 temperature sensors are required for heat differential measurements.

Application

Application: Medium: water/steam

Liquid application: e.g. water heat difference

Operating mode: e.g. heating (this means inflow warm, return cold)

Allocate sensors for flow and pressure measurement

Allocate installation point, T warm/cold

Page 6

RMS621

6 Endress+Hauser

Steam applications

Input variables: flow, pressure, temperature1, (temperature2)

Flow

Pulse/PFM (e.g. Vortex)

Analog (e.g. Vortex) Differential pressure (e.g. orifice)

Flow input Flow input Special flow meters

Flow sensor: operating volume Flow sensor: operating volume Differential pressure/orifice.../steam

Terminal connection

– Flow transmitter with active signal: e.g. select terminal A10 and connect flow meter to terminal A10(+)/11(-).

– Flow transmitter with passive signal: e.g. select terminal A10 and connect flow meter to terminal A10(-)/82(+). Terminal 82 is 24 V sensor power supply.

K-factor Start value/end value: ... (m

3

/h) Start value/end value: ...(mbar)

Pressure

Select signal type and terminal connection and connect sensor (see example).

Type: Relative or absolute pressure?

Temperature

Select signal type and connect sensor(s) (see example). 2 temperature sensors are required for steam difference measurements.

Application

Application(1); medium: water/steam

Application: e.g. steam mass/heat

Steam type: e.g. superheated

Allocate sensors for flow, pressure and temperature measurement

Page 7

RMS621 Table of contents

Endress+Hauser 7

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 8

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Installation, commissioning and operation . . . . . . . . 8

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Notes on safety conventions and icons . . . . . . . . . . . 9

2 Identification . . . . . . . . . . . . . . . . . . . 10

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . 11

3.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Installation instructions . . . . . . . . . . . . . . . . . . . . . 11

3.3 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 12

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Connecting the measuring unit . . . . . . . . . . . . . . 14

4.3 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 22

5 Operation . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Display and operating elements . . . . . . . . . . . . . . . 23

5.2 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Error message display . . . . . . . . . . . . . . . . . . . . . . 26

5.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Commissioning. . . . . . . . . . . . . . . . . . 28

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Switching on the measuring device . . . . . . . . . . . 28

6.3 Device configuration . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 User-specific applications . . . . . . . . . . . . . . . . . . . . 51

7 Maintenance. . . . . . . . . . . . . . . . . . . . 53

8 Accessories. . . . . . . . . . . . . . . . . . . . . 53

9 Trouble-shooting . . . . . . . . . . . . . . . . 54

9.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . 54

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . . 54

9.3 Process error messages . . . . . . . . . . . . . . . . . . . . . 55

9.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10 Technical data . . . . . . . . . . . . . . . . . . 60

11 Appendix . . . . . . . . . . . . . . . . . . . . . . 67

11.1 Definition of important system units . . . . . . . . . . . 67

11.2 Flow measurement configuration . . . . . . . . . . . . 67

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 8

Safety instructions RMS621

8 Endress+Hauser

1 Safety instructions

Safe operation of the Flow and Energy Manager is only guaranteed if these Operating Instructions

have been read and the safety instructions have been observed.

1.1 Designated use

The Energy Manager is a unit for monitoring energy and flows in water and steam applications. It

can be used in both heating and cooling systems. A large variety of different flow sensors,

temperature and pressure sensors can be connected to the unit. The energy manager accepts the

current/PFM/pulse or temperature signals from the individual sensors and from these calculates

the liquid and energy values:

–Volume and mass

– Heat flow or energy

– Heat energy differential

all using the international calculation standard IAPWS-IF 97.

– The unit is classified as additional equipment and may not be used in a hazardous area.

– The manufacturer cannot take responsibility for any damage caused by misuse of the unit. It is not

permitted to make any changes or reconstruction to the unit.

– The energy manager has been designed for use in an industrial environment and may only be used

in an appropriately installed condition.

1.2 Installation, commissioning and operation

The unit is safely manufactured using state-of-the-art technology and complies with the respective

EU regulations. The unit could be dangerous if it is incorrectly installed or used.

Mechanical and electrical installation, commissioning and maintenance of the unit must only be

carried out by skilled and qualified personnel. The skilled personnel must have read and understood

these operating instructions and followed them carefully. Always make sure that the unit is correctly

connected following the electrical connection diagrams (see Chap. 4 "Electrical installation"). When

the unit covers are removed, all electrical contact protection is lost (danger of electrical shock). The

housing must only be opened by qualified skilled personnel.

1.3 Operational safety

Technical advancement

The manufacturer reserves the right to improve and update the technical details. For details of

improvements or additions to these instructions, please contact your local sales organisation.

1.4 Return

For a return, e.g. in case of repair, the device must be sent in protective packaging. The original

packaging offers the best protection. Repairs must only be carried out by your supplier's service

organisation.

!

Note!

When sending for repair, please enclose a note with a description of the error and the application.

Page 9

RMS621 Safety instructions

Endress+Hauser 9

1.5 Notes on safety conventions and icons

The safety instructions in these Operating Instructions are labelled with the following safety icons

and symbols:

"

Caution!

This symbol draws attention to activities or procedures that can lead to defective operation or to

destruction of the device if not carried out properly.

#

Warning!

This symbol draws attention to activities or procedures that can lead to injuries to persons, to a safety

risk or to destruction of the device if not carried out properly.

!

Note!

This symbol draws attention to activities or procedures that have an indirect effect on operation, or

can trigger an unforeseen device reaction if not carried out properly.

Page 10

Identification RMS621

10 Endress+Hauser

2 Identification

2.1 Device designation

2.1.1 Nameplate

Compare the nameplate on the device with the following diagram:

Fig. 3: Energy manager legend plate (example)

1 Order code and unit series number

2 Protection class and allowable ambient temperature

3 Power supply

4 Temperature sensor input with measurement range

5 Approvals with accuracy details

6 Available in/outputs

2.2 Scope of delivery

The scope of delivery of the Energy Manager comprises:

• Energy Manager for top-hat rail mounting

• Operating Instructions

• CD-ROM with PC configuration software and interface cable RS232 (optional)

• Remote display for panel mounting (optional)

• Extension cards (optional)

!

Note!

Please note the device accessories in Section 8 ’Accessories’.

2.3 Certificates and approvals

CE mark, declaration of conformity

The Energy Manager has been constructed and tested to state-of-the-art operational safety standards

and left the factory in perfect condition as regards technical safety. The device meets the relevant

standards and directives as per EN 61 010 "Safety requirements for electrical equipment for

measurement, control and laboratory use".

Thus, the device described in these Operating Instructions meets the legal requirements of the EU

Directives. The manufacturer confirms successful testing of the device by affixing to it the CE mark.

The device has been developed in accordance with the requirements of the Directives OIML R75

(heat counter) and EN-1434 (flow measurement).

Page 11

RMS621 Installation

Endress+Hauser 11

3 Installation

3.1 Installation conditions

The permitted ambient temperature (see "Technical data" Section) must be observed when

installing and operating. The device must be protected against the effects of heat.

3.1.1 Dimensions

Observe the device length of 135 mm (corresponds to 8TE). More dimensions can be found in

Section 10 "Technical data".

3.1.2 Mounting location

Top-hat rail mounting as per EN 50 022-35 in the cabinet. The mounting location must be free from

vibrations.

3.1.3 Orientation

No restrictions.

3.2 Installation instructions

First remove the plug-in terminals from the device slots. Now snap the housing onto the top-hat rail

by firstly hanging the device on the top-hat rail and then pressing it down gently until it engages

(see Fig. 4, item 1 and 2).

Fig. 4: Mounting device on top-hat rail

Page 12

Installation RMS621

12 Endress+Hauser

3.2.1 Installing extension cards

You can equip the device with various extension cards. A maximum of three slots are available in

the device for this. The slots for the extension cards are marked with B, C and D (→ Fig. 5) on the

device.

1. Make sure that the device is not connected to the power supply when installing and removing

an extension card.

2. Remove the blanking cover from the slot (B, C or D) of the basic unit by pressing together the

catches on the bottom of the Energy Manager (see Fig. 5, item 2), while at the same time

pressing in the catch on the rear of the housing (e.g. with a screwdriver) (see Fig. 5, item 1).

Now you can pull the blanking cover up out of the basic unit.

3. Insert the extension card into the basic unit from above. The extension card is not correctly

installed until the catches on the bottom and rear of the device (see Fig. 5, items 1 and 2) lock

into place. Ensure that the input terminals of the extension card are on top and the connection

terminals are pointing to the front, as with the basic unit.

4. The device automatically recognises the new extension card once the device has been

corrected wired and has been commissioned (see ’Commissioning’ Section).

!

Note!

If you remove an extension card and do not replace it with another card, you must seal the empty

slot with a blanking cover.

Fig. 5: Installing an extension card (example)

Item 1: catch on the rear of the device

Item 2: catches on the bottom of the device

Items A - E: identifier for slot assignment

3.3 Post-installation check

When using extension cards, ensure that the cards are sitting correctly in the device slots.

!

Note!

When using the device as a heat counter, observe the installation instructions EN 1434 Part 6 when

mounting the device. This also includes the installation of the flow and temperature sensors.

Page 13

RMS621 Wiring

Endress+Hauser 13

4 Wiring

4.1 Quick wiring guide

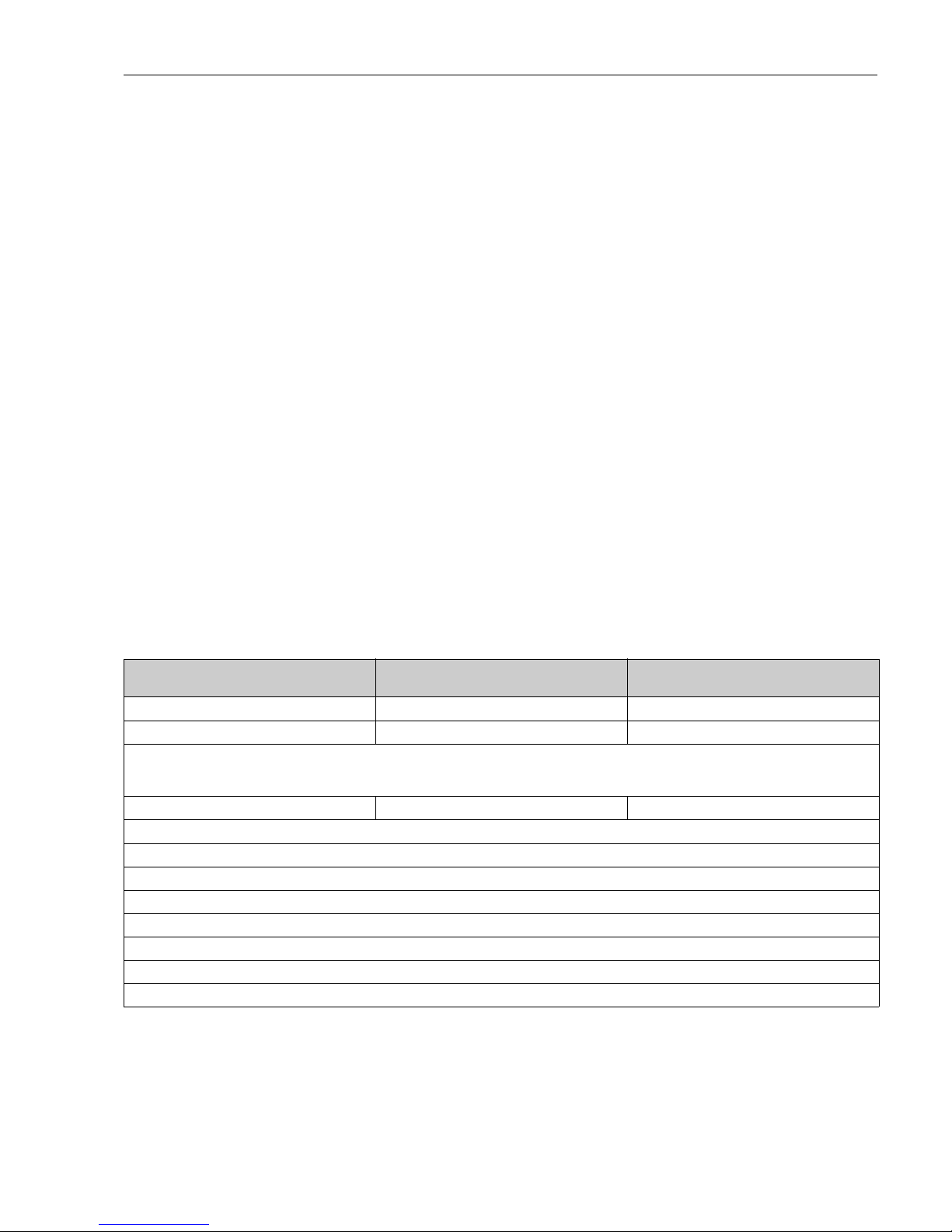

Fig. 6: Slot assignment (basic unit)

Terminal assignment

Terminal (item no.) Terminal assignment Slot Input

10 + 0/4 to 20 mA/PFM/pulse input 1 A top, front (A I) Current/PFM/pulse input 1

11 Ground for 0/4 to 20 mA/PFM/pulse input

81 Sensor power supply ground 1

82 24 V sensor power supply 1

110 + 0/4 to 20 mA/PFM/pulse input 2 A top, rear (A II) Current/PFM/pulse input 2

11 Ground for 0/4 to 20 mA/PFM/pulse input

81 Sensor power supply ground 2

83 24 V sensor power supply 2

1 + RTD power supply 1 E top, front (E I) RTD input 1

2 - RTD power supply 1

5 + RTD sensor 1

6 - RTD sensor 1

3 + RTD power supply 2 E top, rear (E II) RTD input 2

4 - RTD power supply 2

7 + RTD sensor 2

8 - RTD sensor 2

Terminal (item no.) Terminal assignment Slot Output - interface

101 + RxTx 1 E bottom, front (E III) RS485

102 - RxTx 1

103 + RxTx 2 RS485 (optional)

104 - RxTx 2

Page 14

Wiring RMS621

14 Endress+Hauser

!

Note!

The current/PFM/pulse inputs or the RTD inputs in the same slot are not galvanically isolated.

There is a separation voltage of 500 V between the aforementioned inputs and outputs in various

slots. Terminals with the same second digit are jumpered internally (Terminals 11 and 81).

4.2 Connecting the measuring unit

"

Caution!

Do not install or wire the device when it is connected to the power supply. Not conforming with

this can lead to the destruction of electronic components.

131 + 0/4 to 20 mA/pulse output 1 E bottom, rear (E IV) Current/pulse output 1

132 - 0/4 to 20 mA/pulse output 1

133 + 0/4 to 20 mA/pulse output 2 Current/pulse output 2

134 - 0/4 to 20 mA/pulse output 2

52 Relay Common (COM) A bottom, front (A III) Relay 1

53 Relay normally open (NO)

91 Sensor power supply ground Additional sensor power supply

92 + 24 V sensor power supply

L/L+ L for AC

L+ for DC

A bottom, rear (A IV)

Power supply

N/L- N for AC

L- for DC

Connection overview, top (inputs) Connection overview, bottom (outputs, interfaces)

Page 15

RMS621 Wiring

Endress+Hauser 15

4.2.1 Power supply connection

"

Caution!

• Before wiring the device, ensure that the supply voltage corresponds to the specification on the

nameplate.

• For the 90 to 250 V AC version (mains connection), a switch marked as a separator, as well as an

overvoltage organ (rated current ≤ 10 A), must be fitted in the supply line near the device (easy

to reach).

Fig. 7: Power supply connection

4.2.2 Connecting external sensors

!

Note!

Active and passive sensors with analog, PFM or pulse signal and RTD sensors can be attached to the

device.

Depending on the type of signal of the sensor in question, the terminals can be freely selected which

means the Energy Manager can be used with great flexibility. This means that the terminals are not

fixed to the sensor type, e.g. flow sensor-terminal 11, pressure sensor-terminal 12 etc. If the device

is used as a heat counter in accordance with EN 1434, the connection regulations mentioned there

apply.

Active sensors

Connection method for an active sensor (i.e. external power supply).

Fig. 8: Connecting an active sensor, e.g. to input 1 (Slot A I).

Item 1: pulse signal

Item 2: PFM signal

Item 3: 2-wire transmitter (4 to 20 mA)

Item 4: active sensor connection, e.g. optional Universal extension card in slot B (slot B I, → Fig. 13)

Page 16

Wiring RMS621

16 Endress+Hauser

Passive sensors

Connection method for sensors which are supplied with power by means of the sensor power supply

integrated in the device.

Fig. 9: Connecting a passive sensor, e.g. to input 1 (slot A I).

Item 1: pulse signal

Item 2: PFM signal

Item 3: 2-wire transmitter (4-20 mA)

Item 4: passive sensor connection, e.g. optional Universal extension card in slot B (slot B I, → Fig. 13)

Temperature sensors

Connection for Pt100, Pt500 and Pt1000

!

Note!

Terminals 1 and 5 (3 and 7) must be jumpered when connecting 3-wire sensors (see Fig. 6).

Abb. 10: Connecting a temperature sensor, e.g. to input 1 (slot E I)

Item 1: 4-wire input

Item 2: 3-wire input

Item 3: 3-wire input, e.g. optional temperature extension card in slot B (slot B I, → Fig. 13)

E+H-specific devices

Flow sensors with PFM output

!

Note!

Set the Prowirl measuring device to PFM output (Æ FU 20:

ON, PF)

Page 17

RMS621 Wiring

Endress+Hauser 17

Flow sensor with open collector output

!

Note!

Select an appropriate dropping resistor R, so that

I

max.

= 20 mA is not exceeded.

Flow sensor with passive current output (4 to 20 mA)

Flow sensor with active current output (0/4 to 20 mA)

Flow sensor with active current output and passive

frequency output (measurement of bidirectional flow)

!

Note!

Select an appropriate dropping resistor R, so that

I

max.

= 20 mA is not exceeded.

• Item A: direction signal

•Item B: flow

Temperature sensor via temperature head transmitter

(4 to 20 mA)

Page 18

Wiring RMS621

18 Endress+Hauser

4.2.3 Connection of outputs

The device has two galvanically isolated outputs which can be configured as an analog output or an

active pulse output. In addition, an output for connecting a relay and transmitter power supply is

available. The number of outputs increases accordingly when the extension cards are installed

(see Section 4.2.4).

Fig. 11: Connection of outputs

Item 1: pulse and current outputs (active)

Item 2: passive pulse output (open collector)

Item 3: relay output (NO), e.g. slot A III (slot BIII, CIII, DIII on optional extension card)

Item 4: transmitter power supply (transmitter power supply unit) output

Interface connection

• RS232 connection

The RS232 is contacted by means of the interface cable and the jack socket on the front of the

housing.

• RS485 connection

• Optional: additional RS485 interface

Plug-in terminals 103/104, the interface is only active as long as the RS232 interface is not used.

• PROFIBUS connection

Optional connection of Energy Manager to PROFIBUS DP via the serial RS485 interface with the

external module HMS AnyBus Communicator for Profibus (see Section 8 ’Accessories’).

Fig. 12: Interface connection

Pressure sensor with passive current output (4 to

20 mA)

Page 19

RMS621 Wiring

Endress+Hauser 19

4.2.4 Extension card connection

Fig. 13: Extension card with terminals

Terminal assignment of Universal extension card

Terminal assignment of temperature extension card

Terminal (item no..) Terminal assignment Slot Input and output

182 24 V sensor power supply 1 B, C, D top, front (B I, C

I, D I)

Current/PFM/pulse input 1

181 Sensor power supply ground 1

112 + 0/4 to 20 mA/PFM/pulse input 1

111 Ground for 0/4 to 20 mA/PFM/pulse input

183 24 V sensor power supply 2 B, C, D top, rear (B II, C

II, D II)

Current/PFM/pulse input 2

181 Sensor power supply ground 2

113 + 0/4 to 20 mA/PFM/pulse input 2

111 Ground for 0/4 to 20 mA/PFM/pulse input

142 Relay 1 Common (COM) B, C, D bottom, front (B

III, C III, D III)

Relay 1

143 Relay 1 normally open (NO)

152 Relay 2 Common (COM) Relay 2

153 Relay 2 normally open (NO)

131 + 0/4 to 20 mA/pulse output 1 B, C, D bottom, centre (B

IV, C IV, D IV)

Current/pulse output 1 active

132 - 0/4 to 20 mA/pulse output 1

133 + 0/4 to 20 mA/pulse output 2 Current/pulse output 2 active

134 - 0/4 to 20 mA/pulse output 2

135 + pulse output 3 (open collector) B, C, D bottom, rear (B V,

C V, D V)

Passive pulse output

136 - pulse output 3

137 + pulse output 4 (open collector) Passive pulse output

138 - pulse output 4

Terminal (item no..) Terminal assignment Slot Input and output

117 + RTD power supply 1 B, C, D top, front (B I, C

I, D I)

RTD input 1

116 + RTD sensor 1

115 - RTD sensor 1

114 - RTD power supply 1

Page 20

Wiring RMS621

20 Endress+Hauser

!

Note!

The current/PFM/pulse inputs or the RTD inputs in the same slot are not galvanically isolated.

There is a separation voltage of 500 V between the aforementioned inputs and outputs in various

slots. Terminals with the same second digit are jumpered internally. (Terminals 111 and 181)

4.2.5 Connecting remote display/operating unit

Functional description

The remote display is an innovative addition to the powerful RMX 621 top-hat rail devices. The user

has the opportunity to optimally install the arithmetic unit to suit the installation and mount the

display and operating unit in a user-friendly way at easily accessible locations. The display can be

connected to both a top-hat rail device without, as well as a top-hat rail device with, an installed

display/operating unit. A 4-pin cable is supplied to connect the remote display with the basic unit;

other components are not necessary.

!

Note!

Only one display/operating element can be attached to a top-hat rail device and vice versa (pointto-point).

121 + RTD power supply 2 B, C, D top, rear (B II, C

II, D II)

RTD input 2

120 + RTD sensor 2

119 - RTD sensor 2

118 - RTD power supply 2

142 Relay 1 Common (COM) B, C, D bottom, front (B

III, C III, D III)

Relay 1

143 Relay 1 normally open (NO)

152 Relay 2 Common (COM) Relay 2

153 Relay 2 normally open (NO)

131 + 0/4 to 20 mA/pulse output 1 B, C, D bottom, centre (B

IV, C IV, D IV)

Current/pulse output 1 active

132 - 0/4 to 20 mA/pulse output 1

133 + 0/4 to 20 mA/pulse output 2 Current/pulse output 2 active

134 - 0/4 to 20 mA/pulse output 2

135 + pulse output 3 (open collector) B, C, D bottom, rear (B V,

C V, D V)

Passive pulse output

136 - pulse output 3

137 + pulse output 4 (open collector) Passive pulse output

138 - pulse output 4

Terminal (item no..) Terminal assignment Slot Input and output

Page 21

RMS621 Wiring

Endress+Hauser 21

Installation/dimensions

Mounting instructions:

• The mounting location must be free from vibrations.

• The permitted ambient temperature during operation is -20 to +60C (-4 to +140 °F).

• Protect the device against the effects of heat.

Procedure for panel mounting:

1. Provide a panel cutout of 138+1.0 x 68+0.7 mm (5.43"+0.04" x 2.68"+0.03") (as per DIN

43700), the installation depth is 45 mm (1.77").

2. Push the device with the sealing ring through the panel cutout from the front.

3. Hold the device horizontal and, applying uniform pressure, push the securing frame over the

rear of the housing against the panel until the retaining clips engage. Make sure the securing

frame is seated symmetrically.

Fig. 14: Panel mounting

Wiring

Fig. 15: Terminal plan of remote display/operating unit

The remote display/operating unit is connected directly to the basic unit with the cable supplied.

Page 22

Wiring RMS621

22 Endress+Hauser

4.3 Post-connection check

After completing the device's electrical installation, carry out the following checks:

Device status and specifications Notes

Is the device or cable damaged (visual inspection)? -

Electrical connection Notes

Does the supply voltage match the information on the nameplate? 90 to 250 V AC (50/60 Hz)

20 to 36 V DC

20 to 28 V AC (50/60 Hz)

Are all of the terminals firmly engaged in their correct slots? Is the coding on the

individual terminals correct?

-

Are the mounted cables relieved of tension? -

Are the power supply and signal cables connected correctly? See wiring diagram on the

housing

Are all of the screw terminals well-tightened? -

Page 23

RMS621 Operation

Endress+Hauser 23

5Operation

5.1 Display and operating elements

!

Note!

Depending on the application and version, the Flow and Energy Manager offers a wide range of

configuration options and software functions.

Help text is available for nearly every operating item to assist when programming the device. This

help text can be called up by pressing th e "?" button. (The help text can be called up in every menu).

Please note that the configuration options described below refer to a basic unit (without extension

cards).

Fig. 16: Display and operating elements

Item 1: operating display: LED green, lights up when supply voltage applied.

Item 2: fault indicator: LED red, operating status as per NAMUR NE 44

Item 3: serial interface connection: jack socket for PC connection for device configuration and measured value read-out

with the PC software

Item 4: display 132 x 64 dot-matrix display with dialog text for configuring as well as measured value, limit value and fault

message display. Should a fault occur, the background lighting changes from blue to red. The size of the characters

displayed depends on the number of measured values to be displayed (see Section 6.3.3 ’Display configuration’).

Item 5: input keys; eight soft keys which have different functions, depending on the menu item. The current function of

the keys is indicated on the display. Only the keys which are required in the operating menu in question are assigned with

functions or can be used.

Page 24

Operation RMS621

24 Endress+Hauser

5.1.1 Display

Fig. 17: How the display of the energy computer appears

Item: 1: measured value display

Item: 2: display of configuration menu item

– A: row of key icons

– B: current configuration menu

– C: configuration menu activated for selection (highlighted in black).

5.1.2 Key icons

5.2 Local operation

5.2.1 Entering text

There are two ways of entering text in the operating items (see: Setup → Basic set-up→ Text

input):

a) Standard: individual characters (letters, numbers, etc.) in the text field are defined by scrolling

through the entire row of characters with the up/down cursor until the desired character is

displayed.

b) Palm: a visual key field appears for entering text. The characters on this keyboard are selected

with the cursors. (see "Setup Æ Basic set-up")

Key icon Function

E Change to submenus and select operating items. Edit and confirm configured values.

Z Exit the current editing mask or the menu item currently active without saving any

changes.

↑ Move the cursor up a line or a character.

↓ Move the cursor down a line or a character.

→ Move the cursor a character to the right.

← Move the cursor a character to the left.

? If Help text is available on an operating item, this is indicated with the question mark. The

Help is called up by actuating this function key.

ΑΒ Change to the editing mode of the Palm keyboard

ij/iJ Key field for upper case/lower case (only with Palm)

½ Key field for numerical entries (only with Palm)

Page 25

RMS621 Operation

Endress+Hauser 25

Using the Palm keyboard

Fig. 18: Example: editing an identifier with the Palm keyboard

1. Using the cursor keys, place the cursor in front of the character before which another character

should be entered. If the entire text should be deleted and rewritten, move the cursor

completely to the right. (see Fig. 18, graphic 1)

2. Press the AB key to enter the editing mode

3. Use the ij/IJ and ½ key to select upper/lower case or numerals. (see Fig. 18, graphic 2)

4. Use the cursors to select the key required and use the tick sign to confirm. If you want to delete

text, select the key in the top right. (see Fig. 18, graphic 2)

5. Edit other characters in this way until the desired text has been entered.

6. Press the Esc key to switch from the editing mode to the display mode and accept changes with

the 'tick' key. (see Fig. 18, graphic 1)

Notes

• The cursor cannot be moved in the editing mode (see Fig. 18, graphic 2)! Use the Esc key to go

to the previous window (see Fig. 18, graphic 1) to move the cursor to the character which should

be changed. Then confirm the AB key again.

• Special key functions:

in key: change to overwrite mode

key (top right): delete character

5.2.2 Lock configuration

The entire configuration can be protected against unintentional access by means of a four-digit code.

This code is assigned in the submenu: Basic set-up → Code. All the parameters remain visible. If

the value of a parameter should be changed, you are first asked for the user code.

In addition to the user code, there is also the alarm limit code. When this code is entered, only the

alarm limits are enabled for change.

Fig. 19: Configuring the user code

Page 26

Operation RMS621

26 Endress+Hauser

5.2.3 Operating example

A detailed description of on-site operation with an application as an example can be found in Section

6.4 ’User-specific applications’.

5.3 Error message display

The device differentiates between two types of errors:

• System error: this group comprises all the device errors, e.g. communication errors, hardware

errors, etc. System errors are always signalled by fault messages.

• Process error: this group comprises all application errors, e.g. “range overshoot”, including limit

value alarms etc.

For process errors, you can configure how the device reacts in the event of an error, i.e. whether a

fault message or a notice message is displayed.

On leaving the factory, all process errors are preset as notice messages with a colour change.

Fault messages

A fault is signalled by the display changing colour from blue to red and by an exclamation mark

(!) along the top edge of the display. The error is displayed as plain text. The fault is acknowledged

by actuating any key. Via the Navigator menu, you can get to the error list and to the Main menu

to rectify the error if necessary. When a fault message occurs, all measurements and the counters

are stopped. The input signals behave as per their configured failsafe mode (see Section 6.3.3 ’Main

menu - Setup’). The device does not resume normal operation until all the faults are rectified.

Notice messages

Configuring the error type for process errors

Process errors are defined as notice messages in the factory setting. You can change the alarm

response of process errors, i.e. process errors are indicated by a fault message.

1. Configure as Setup Æ Basic set-up Æ Alarm response Æ Random

2. Individual alarm responses for the inputs and applications can then be defined in the device

menu for inputs (Q, P, T), applications and outputs.

The following process errors can be configured:

•Inputs:

Open circuit, sensor signal range violation

• Applications:

Wet steam alarm, phase transition

A notice is signalled by an exclamation mark (!) in the

display. It can also be signalled (as an option) by a colour

change and by displaying an alarm on the display. The

exclamation mark is along the top edge of the display. In

addition, some errors are signalled by an icon beside the

corresponding measured values. Notices do not have any

affect on the operation and counters but rather merely

indicate that a certain event has arisen (e.g. range has been

overshot).

Icons appear along the top edge of the display next to the display parameter affected by the error which has occurred.

Signal overshooting (x > 20.5 mA) or undershooting (x < 3.8 mA)

Error:

fault or notice pending; Æ error list

Phase transition:

steam condensing, water boiling

Page 27

RMS621 Operation

Endress+Hauser 27

Event buffer

Main menu Æ Diagnosis Æ Event buffer

In the event buffer, the last 100 events, i.e. fault messages, notices, limit values, power failure etc.

are recorded in chronological order with the time of occurrence and counter reading.

Error list

The error list provides assistance in quickly localising current device errors. Up to ten alarms are

listed in the error list in chronological order. In contrast to the event buffer, only the errors currently

pending are displayed, i.e. rectified errors are cleared from the list.

Quick overview of the error concept

Fig. 20: Procedure when a system or process error occurs

5.4 Communication

In all devices and device versions, the parameters can be configured, altered and read out via the

standard interface with the aid of PC operating software and an interface cable (see Section 8

’Accessories’). This is recommended in particular if extensive settings are to be made (e.g. when

commissioning).

There is the additional option of reading out all the process and display values via the RS485

interface with an external PROFIBUS module (HMS AnyBus Communicator for PROFIBUS-DP)

(see ’Accessories’ Section).

!

Note!

Detailed information for configuring the device using the PC operating software can be found in the

accompanying Operating Instructions which are also located on the data carrier.

System error

Process error

Event buffer

Hint (!)

Fault (!)

Display red

Display blue

Error list

Do not display

Display & acknowledge

Colour change (yes/no)

Current errors

Display & acknowledge

Colour change

Page 28

Commissioning RMS621

28 Endress+Hauser

6 Commissioning

6.1 Function check

Make sure that all post-connection checks have been carried out before you commission your

device:

• See Section 3.3 ’Post-installation check’

• Checklist Section 4.3 ’Post-connection check’

6.2 Switching on the measuring device

6.2.1 Basic unit

Once the operating voltage is applied, the green LED (= device operating) lights up if no fault is

present.

• When the device is first commissioned, the prompt "Please set up device" appears on the display.

Program the device as per the description → Chap. 6.3.

• When commissioning a device already configured or preset, measuring is immediately started as

per the settings. The values of the display group currently set appear on the display. By pressing

any key, you get to the navigator (quick start) and from there back to the Main menu

(see Section 6.3).

6.2.2 Extension cards

When the operating voltage is applied, the device automatically recognises the installed and wired

extension cards. You can now follow the prompt to configure the new connections or perform the

configuration at a later date.

6.2.3 Remote display and operating unit

The remote display/operating unit is preconfigured at the factory - device address 01, baudrate

56.7k, RS485-Master. Once the supply voltage has been applied and after a short initialisation

period, the display unit automatically starts communication to the connected basic unit. Make sure

that the device address of the basic unit and of the remote display match.

Fig. 21: Start Setup menu

You can get to the Setup menu of the display/operating unit by pressing the left and right top key

at the same time for 5 seconds. Here, the baudrate and device address for communication, as well

as the contrast and display viewing angle can be configured. Press ESC to exit the Setup menu of

the display/operating unit and to get to the display window and the Main menu to configure the

Energy Manager.

!

Note!

The Setup menu for configuring the basic settings of the display/operating unit is only available in

English.

Page 29

RMS621 Commissioning

Endress+Hauser 29

Error messages

After switching on or configuring the device, the message "Communication problem" appears

briefly on the remote display/operating unit until a stable connection has been established.

If this error message is displayed during operation, please check the wiring to the Energy Manager

and ensure that the baudrate and the device address match the Energy Manager.

6.3 Device configuration

This section describes all the configurable device parameters with the associated value ranges and

factory settings (default values).

Please note that the parameters available for selection, e.g. the number of terminals, depend on the

device version (see Section 6.2.2 Extension cards).

Function matrix

Fig. 22: Function matrix (extract) for on-site Energy Manager configuration. A detailed function matrix can be found in

the Appendix.

6.3.1 Navigator (quick start)

Fig. 23: Quick start to configuration via the Navigator menu of the Energy Manager.

In the operating mode of the Energy Manager (measured value displayed), the operating window

"Navigator" opens up by pressing any key: the Navigator menu offers quick access to important

information and parameters. Pressing one of the keys available takes you directly to the following

items:

Display

Navigator

Groups

Error list

Counter val

Menu

Diagnosis

Terminal info

Event buffer

Setup (all

parameters)

Basic set-up

Outputs

Inputs

(T, p, V etc.)

ProgramInfo

Applications

Communication

Display

Service

Page 30

Commissioning RMS621

30 Endress+Hauser

The contents of the groups with display values can only be defined in the Setup → Display menu.

A group comprises a maximum of eight process variables which are displayed in a window in the

display. When commissioning the device, 2 groups with the most important display parameters are

automatically created when an application is selected. Automatically created groups are also marked

with a value in brackets (A1..3) which refers to the application, e.g. Group 1 (A1) means Group 1

with display values for Application 1.

The settings for the display functionalities, e.g. contrast, scrolling display, special groups with display

values etc. are also made in the menu Setup → Display.

!

Note!

When commissioning, the prompt "Please set up device" is displayed. Confirming this message

takes you to the Navigator menu. Select ’Menu’ here to get to the Main menu.

A device already configured is in the display mode as standard. The device changes to the Navigator

menu as soon as one of the eight operating keys is pressed. From here, you get to the Main menu

by selecting ’Menu’.

!

Note!

If you continue navigating through the Main menu, the message "If you change the application,

the respective counters will be reset" is displayed. Confirming this message takes you to the

Main menu.

6.3.2 Main menu - Diagnosis

The Diagnosis menu is used to analyse the device functionality, such as locating device

malfunctions.

Function (menu item) Description

Group For selecting individual groups with display values.

Display For displaying the groups alternately, setting in the setup menu"Display".

Error list For quickly localising current device errors.

Counter val For reading off and, if necessary, resetting all the totalizers.

Menu Main menu for configuring the device.

Function (menu item) Parameter setting Description

Terminal info A10 Lists all the terminals of the device and the connected sensors.

Display the signal values present (in mA, Hz, Ohm) by pressing

the

key i.

Event buffer Log of all the events, e.g. error messages, parameter changes,

etc. in chronological order. (ring buffer with approx. 100

values, cannot be deleted!)

Program info Displays the device data such as program, name, software

version, date and time.

Page 31

RMS621 Commissioning

Endress+Hauser 31

6.3.3 Main menu - Setup

The Setup menu is used for configuring the Energy Manager. The following subsections and tables

list and describe all the configuration parameters of the Energy Manager.

Procedure when configuring the Energy Manager

1. Select system units (device settings).

2. Configure inputs (flow, pressure, temperature), i.e. assign terminals to the sensors and scale

the input signals, if necessary configure default values for pressure and temperature.

3. Select application (e.g. steam mass/heat).

4. Configure application, i.e. assign the configured inputs (sensors) .

5. Configure outputs (analog, pulse or relay/limit values).

6. Check display settings (values are preset automatically).

7. Make optional device settings (e.g. communication settings).

"

Caution!

If you change configuration parameters, check whether this has an affect on other parameters and

your overall measuring system.

Set-up → Basic set-up

!

Note!

Factory settings are indicated in bold.

The basis data of the device are defined in this submenu.

Function (menu item) Parameter setting Description

Date-Time

Date DD.MM.YY

MM.DD.YY

For configuring the current date (country-specific).

!

Note!

Important for summertime/wintertime changeover

Time SS:MM Current time for the real time clock of the device.

Summertime/normal time changeover

• Changeover Off - Manual - Auto. Kind of time changeover.

• Region Europe - USA Displays the changeover date from normal time (NT) to

summertime (ST) and vice versa. This function depends on the

region selected.

•NTÆST

STÆNT

–Date

–Time

• 31.03 (Europe)

07.04 (USA)

• 27.10 (Europe

27.10 (USA)

• 02:00

Takes into consideration the summertime/normal time

changeover in Europe and USA at different times. This can

only be selected if summertime/normal time changeover is not

set to ’Off’.

Time of changeover. This can only be selected if summertime/

normal time changeover is not set to ’Off’.

System eng. units

System eng. units Metric

American

Random

Sets the unitary system. "Random" means that a picklist with

different unitary systems, incl. time basis and format, appears

in the individual operating items.

Code

•User

• Alarm lim.

0000 - 9999

0000 - 9999

Device operation is only enabled once the previously defined

code has been entered.

Only the alarm limits are enabled for configuration. All other

parameters remain locked.

Page 32

Commissioning RMS621

32 Endress+Hauser

Alarm response

Fault category Default set-up -

Random

Alarm response when process errors occur. As per the factory

setting, all process errors are signalled by a warning message.

By selecting "Random", additional operating items appear in

the inputs and the application to assign a different fault

category (fault message) to the individual process errors (see

Section 5.3 ’Error message display’).

Text input

Standard

Palm

Selects the way of entering text:

•Standard:

Per parameter item, runs up or down the row of characters

until the desired character appears.

•Palm:

The desired character can be selected from the visual key

field with the cursors.

General info

Unit ID Assigns a device name (max. 12 characters long).

TAG number Assigns a TAG number, as in wiring diagrams for example

(max. 12 characters long).

Prog. name Name which is saved in the PC operating software along with

all the settings.

SW version Software version of your device.

SW option Information as to which extension cards are installed.

CPU No.: The CPU number of the device is used as an identifier. It is

saved with all the parameters.

Series No.: This is the serial number of the device.

Run time

1. Unit

2. LCD

1. Information on how long the device has been in operation

(protected by service code.)

2. Information on the operating time of the device display

(protected by service code.)

Function (menu item) Parameter setting Description

Page 33

RMS621 Commissioning

Endress+Hauser 33

Setup → Inputs

!

Note!

Depending on the version, 4 to 10 current, PFM, pulse and RTD inputs are available in the energy

computer to record the flow, temperature and pressure signals.

Flow inputs

The Energy Manager processes all common flow measurement methods (volume, mass, differential

pressure). You can connect up to three flow transmitters at the same time. There is also the option

of using just one flow transmitter in various applications, see ’Terminals’ menu item).

Special flow meters

Item for very exact flow based on differential pressure method with compensation calculation as per

ISO 5167 as well as splitting range function for extending the measuring range, e.g. for orifice

measurement (up to three DP transmitters) and possibility of computing the mean value from

several DPTs.

Pressure inputs

A maximum of three pressure sensors can be connected. One sensor can also be used for two or all

three applications, see the ’Terminal’ item in the related table.

Temperature inputs

For connecting between two and six (max.) temperature sensors (RTD). A sensor can be used in

several applications here, see the ’Terminal’ item in the related table.

Flow inputs

Function (menu item) Parameter setting Description

Flow inputs Flow 1, 2, 3 Configuration of individual flow transmitters.

Identifier Name of the flow transmitter (max. 12 characters).

Flow measurement device Volumetric

Mass

Setting of the measuring principle of your flow transmitter or as

to whether the flow signal is in proportion to the volume, (e.g.

vortex, EFM, turbine) or mass (e.g. Coriolis).

(For details, see Section 11.2 'Flow measurement

configuration')

Signal Select

4-20 mA

0-20 mA

PFM

Pulse

Default

Selects the signal of the flow transmitter.

Terminals None

A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113

Defines the terminal to which the flow transmitter in question

is connected. It is possible to use a transmitter (flow signal) for

several applications. For this, in the application in question,

select the terminal where the transmitter is located (multiple

selection possible).

Curve Linear

Sqr. root

Select the curve of the flow transmitter used.

Unit l/...; hl/...; dm

3

/...; m3/

...; bbl/...; gal/...; igal/...;

ft

3

/...; acf/...

Flow unit in format: selected unit by X

!

Note!

Only visible if the "Random" system unit has been selected.

kg, t, lb, ton (US) Can only be selected for flow transmitter/mass

Time base .../s; .../min; .../h; .../d Time basis for the flow unit in the format: X per time unit

selected.

!

Note!

Only visible if the "Random" system unit has been selected.

Page 34

Commissioning RMS621

34 Endress+Hauser

gal/bbl 31.5 (US), 42.0 (US), 55.0

(US), 36.0 (Imp), 42.0

(Imp), User def.

31.0

Definition of technical unit Barrel (bbl), given in gallons per

barrel.

US: US gallons

Imp: Imperial gallons

User def.: free to set the conversion factor.

Format 9; 9.9; 9.99; 9.999 Number of places after the decimal point

!

Note!

Only visible if the "Random" system unit has been selected.

Meter coeff. Pulse value

K-factor

Select the reference variable for the pulse value.

Pulse value (unit/pulse)

K-factor (pulse/unit)

Pulse value 0.001 to 99999 Setting as to what volume flow (in dm

3

or litre) a pulse of the

flow transmitter corresponds to.

!

Note!

Only available for Pulse signal.

K Fact. unit Pulse/dm

3

Pulse/ft

3

K-factor 0.001 to 9999.9 Enter the pulse value of the vortex sensor. You can find this

value on your flow sensor.

!

Note!

This can only be selected for the PFM signal.

For vortex sensors with pulse signal, the reciprocal value of the

K-factor (in pulse/dm

3

) is entered as a pulse value.

Start value 0.0000 to 999999 Start value for the volume flow (differential pressure) with 0 or

4mA.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

End value 0.0000 to 999999 End value for the volume flow (differential pressure) with 20

mA.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Flow cut off 0.0 to 99.9%

4.0 %

Below the set value, the flow is no longer recorded or 0 is set.

Depending on the type of flow transmitter, the flow cutoff can

be set in % of the full scale value of the flow measuring range

or as a fixed flow value (e.g. in m

3

/h).

Correction Yes

No

Possibilities for correcting the flow measurement by offset,

signal damping, flow cut off, sensor expansion coefficient and

correction table for curve description.

Signal damp 0 to 99 s Time constant of the first order low pass for the input signal.

This function is used to reduce display fluctuations in the event

of severely fluctuating signals.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Offset -9999.99 to 9999.99 Shifts the zero point of the response curve. This function is

used to adjust sensors.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Correction Yes

No

Possibility for correcting the flow measurement. If "YES" is

selected, the sensor curve can be defined in the correction

table and there is the possibility of compensating the

temperature effect on the flow transmitter (see "Exp. coeff.")

Function (menu item) Parameter setting Description

Page 35

RMS621 Commissioning

Endress+Hauser 35

Expan. coeff. 0 to 9.9999e-XX Correction factor for compensating the temperature effect on

the flow transmitter. This factor is often indicated on the

nameplate for vortex flowmeters, for example. If no value is

known for the expansion coefficient or if this has already been

compensated by the device itself, please set 0 here.

Default: 4.88e-05

!

Note!

Note! Only active if correction setting is active.

Table Use

Not used

If the flow curve of your transmitter deviates from the ideal

pattern (linear or square root), this can be compensated by

entering a correction table.

For details, see the 'Correction tables' in Section 11.2.1.

No. of rows 01 - 15 Number of points in the table.

Corr. tab. pulse Point (used/delete)

Current/flow frequency/

k-factor

If the flow curve of your transmitter deviates from the ideal

pattern (linear or square root), this can be compensated by

entering a correction table. The parameters in the table depend

on the flow transmitter selected.

• Analog signal, linear curve

Up to 15 value pairs (current/flow)

• Pulse signal, linear curve

Up to 15 value pairs (frequency/k-factor or frequency/pulse

value).

For details, see the 'Correction tables' in Section 11.2.1.

Sums Unit

Format

Total

Signal reset

Terminals

Possibility of configuring or resetting the totalizers for the

volume flow. Signal reset, i.e. resetting the totalizer by an

input signal (e.g. remote read-out of totalizers with subsequent

reset).

(Terminal for this input signal only active if "Signal Reset =

YES")

Alarm response

Range violation

Open circuit

Alarm type

Colour change

Fault text

For this input, individually specify which alarms should be

displayed when faults occur: range violation (as per

NAMUR43) or open circuit.

!

Note!

Only active if the option Random was selected in the 'Alarm

response' menu item in Setup Æ Basic set-up.

Alarm type Fault

Hint

Fault message, totalizer stop, colour change (red) and message

in plain text.

Colour change Yes

No

Select whether the alarm should be signalled by a colour

change from blue to red.

!

Note!

Only active if the ’Hint’ alarm type has been selected.

Fault text Display+acknowledge

Do not display

Select whether an alarm message should appear to describe the

fault when a fault occurs. This is cleared (acknowledged) by

pressing a key.

!

Note!

Only active if the ’Hint’ alarm type has been selected.

Function (menu item) Parameter setting Description

Page 36

Commissioning RMS621

36 Endress+Hauser

Special flow meters

Function (menu item) Parameter setting Description

Special flow meters Differential pressure 1, 2,

3

Mean flow

Configuration of individual or several differential pressure

transmitters (DPT).

!

Note!

Only use if your DP transmitter outputs a pressure-scaled

signal (mbar, inH

2

0 etc.)

Identifier Name of the flow transmitter (max. 12 characters).

Meas. point Select

DPT

Splitting Range

Select whether one DP transmitter or several DPTs are used for

extending the measuring range (Splitting Range).

(See Section 11.2.1 for details of the 'Splitting Range')

Differential pressure transmitter

Flow type Pitot

Orifice corner tap

Orifice D2

Orifice flange tap

ISA 1932 nozzle

Long rad. nozzle

Venturi nozzle

Venturi tube (cast)

Venturi tube (mach.)

Venturi tube (steel)

V-cone

Type of differential pressure transmitter

The data in brackets refer to the type of Venturi tube.

Medium Water

Steam

Select the medium for which the flow should be measured.

Signal Select

4-20 mA

0-20 mA

PFM

Pulse

Default

See Setup ’Flow inputs’

Terminals None

A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113

See Setup ’Flow inputs’

Curve Linear

Sqr. root

Curve of the DP transmitter used.

!

Note!

Please observe information in Section 11.2.1!

Time base .../s; .../min; .../h; .../d See Setup ’Flow inputs’

Unit l/...; hl/...; dm

3

/...; m3/

...; bbl/...; gal/...; igal/...;

ft

3

/...; acf/...

See Setup ’Flow inputs’

!

Note!

Only visible if the "Random" system unit has been selected.

kg, t, lb, ton (US) Can only be selected for flow transmitter/mass

gal/bbl 31.5 (US), 42.0 (US), 55.0

(US), 36.0 (Imp), 42.0

(Imp), User def.

31.0

See Setup ’Flow inputs’

Format 9; 9.9; 9.99; 9.999 See Setup ’Flow inputs’

!

Note!

Only visible if the "Random" system unit has been selected.

Rng. units mbar

in/H

2

0

Unit of differential pressure

Range start mbar

in/H

2

0

Start value for the differential pressure with 0 or 4 mA.

Range end mbar

in/H

2

0

End value for the differential pressure with 20 mA.

Page 37

RMS621 Commissioning

Endress+Hauser 37

Factor K-factor for describing the resistance coefficient of E+H Pitot

tubes (see data sheet).

Correction Yes

No

Possibilities for correcting the flow measurement by offset,

signal damping, flow cut off, expansion coefficient of the

device (e.g. orifice plate) and correction table for curve

description.

Flow cut off 0.0 to 99.9%

4.0 %

Below the set value, the flow is no longer recorded or 0 is set.

Depending on the type of flow transmitter, the flow cutoff can

be set in % of the full scale value of the flow measuring range

or as a fixed flow value (e.g. in m

3

/h).

Signal damp 0 to 99 s Time constant of the first order low pass for the input signal.

This function is used to reduce display fluctuations in the event

of severely fluctuating signals.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Offset -9999.99 to 9999.99 Shifts the zero point of the response curve. This function is

used to adjust sensors.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Table Use

Not used

If the flow curve of your transmitter deviates from the ideal

pattern (linear or square root), this can be compensated by

entering a correction table.

For details, see Setup ’Flow inputs’.

Pipe data Inner dia.

Geom. ratio

Enter the internal diameter of the pipe.

Enter the diameter ratio (d/D = ß) of the differential pressure

transmitter, data in the data sheet of the DP transmitter.

!

Note!

In dynamic pressure measurements, the K-factor must be given

to describe the resistance coefficient of the probe (see Section

11.2.1 for details).

Coefficient Fixed value

Table

Flow coefficient c for calculating the flow.

!

Note!

Only if using a V-cone flow transmitter.

Coeff. (c) 0.0001 to 99999 Enter the flow coefficient c.

Num. coeff. 01 - 15 Number of points in the table.

Coeff. tab. Points

(used/delete)

Reynolds No./coefficient

Table for describing the flow coefficient depending on the

Reynolds number.

For details on the V-cone calculation method, see

Section 11.2.1

Sums Unit

Format

Actual

Total

Signal reset

Terminals

See Setup ’Flow inputs’

Splitting range

Splitting range Splitting range or automatic measuring range switching for

differential pressure measuring devices.

See Section 11.2.1 for details of the 'Splitting Range'.

Rng.1 Term. A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113

Terminal for connecting the differential pressure transmitter

with the smallest measuring range

Rng.2 Term. A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113

Terminal for connecting the differential pressure transmitter

with the second largest measuring range

Rng.3 Term. A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113

Terminal for connecting the differential pressure transmitter

with the largest measuring range

Function (menu item) Parameter setting Description

Page 38

Commissioning RMS621

38 Endress+Hauser

Range 1 (2, 3) start 0.0000 to 999999 Start value for the differential pressure at 0 or 4 mA, defined

for the pressure transmitter in range 1 (2, 3)

!

Note!

Only active after a terminal has been assigned.

Range 1 (2, 3) end 0.0000 to 999999 End value for the differential pressure at 20 mA, defined for the

pressure transmitter in range 1 (2, 3)

!

Note!

Only active after a terminal has been assigned.

Correction Yes

No

Possibilities for correcting the flow measurement by offset,

signal damping, flow cut off, sensor expansion coefficient and

correction table for curve description.

see Setup ’Differential pressure transmitter’

Pipe data Units (mm/inch)

Inner dia.

Geom. ratio

K-factor

See Setup ’Differential pressure transmitter’.

Sums Unit

Format

Actual

Total

Signal reset

Terminals

See Setup ’Flow inputs’.

Alarm response See Setup ’Flow inputs’.

Mean flow

Identifier Mean flow Name for computing the mean value from several flow signals

(max. 12 characters).

Number Unused

2 sensors

3 sensors

Mean value computed from several flow signals

(See Section 11.2.1 for details of the 'Mean value

computation')

Sums Unit

Format

Actual

Total

Signal reset

Terminals

See Setup ’Flow inputs’.

Function (menu item) Parameter setting Description

Page 39

RMS621 Commissioning

Endress+Hauser 39

Pressure inputs

Function (menu item) Parameter setting Description

Identifier Pressure 1-3 Name of pressure sensor, e.g. ’pressure in’ (max. 12

characters).

Signal Select

4-20 mA

0-20 mA

Default

Selects the signal of the pressure sensor. If ’Default’ is set, the

device works with a fixed default pressure.

Terminals None

A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113

Defines the terminal for connecting the pressure sensor. It is

possible to use a sensor signal for several applications. For this,

in the application in question, select the terminal where the

sensor is located. (multiple selection possible)

Unit bar; kPa; kg/cm

2

; psi; bar

(g); kPa (g); psi (g)

Physical unit of the measured pressure.

• (a) = appears on the display if ’absolute’ was selected as the

type. Refers to the absolute pressure.

• (g) = gauge, appears on the display if ’relative’ was selected

as the type. Refers to the relative pressure.

(a) or (g) appears automatically on the display depending on

the type selected.

!

Note!

Only visible if the "Random" system unit has been selected.

Type Absolute

Relative

Indicates whether the measured pressure is absolute or relative

(gauge) pressure. With relative pressure measurement, the

atmospheric pressure has to be entered afterwards.

Format 9; 9.9; 9.99; 9.999 Number of places after the decimal point

!

Note!

Only visible if the "Random" system unit has been selected.

Start value 0.0000 to 999999 Start value for the pressure with 0 or 4 mA.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

End value 0.0000 to 999999 End value for the pressure with 20 mA.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Signal damp 0 to 99 s Time constant of the first order low pass for the input signal.

This function is used to reduce display fluctuations in the event

of severely fluctuating signals.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Offset -9999.99 to 9999.99 Shifts the zero point of the response curve. This function is

used to adjust sensors.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Atm. press. 0.0000 to 10000.0

1.013

Configuration of the ambient pressure (in bar) present at the

device installation location.

!

Note!

Item is only active if ’relative’ is selected as the type.

Default -19999 to 19999 Sets the default pressure which is worked with if the sensor

signal fails and the ’Default’ signal is set.

Alarm response See Setup ’Flow inputs’.

Mean value Unused

2 sensors

3 sensors

Mean value computed from several pressure signals

(See Section 11.2.1 for details of the 'Mean value

computation')

Page 40

Commissioning RMS621

40 Endress+Hauser

Temperature inputs

Function (menu item) Parameter setting Description

Identifier Temperature 1-6 Name of temperature sensor, e.g. ’Temp 1’ (max. 12

characters).

Signal Select

4-20 mA

0-20 mA

Pt100

Pt500

Pt1000

Default

Selects the signal of the temperature sensor. If ’Default’ is set,

the device works with a fixed default temperature.

Sensor type 3-wire

4-wire

Configures the sensor connection in 3-wire or 4-wire

technology.

!

Note!

Can only be selected for the Pt100/Pt500/Pt1000 signal.

Terminals None

A-10; A-110; B-112;

B-113; C-112; C-113; D112; D-113; B-117; B121; C-117; C-121; D117; D-121; E-1-6;

E-3-8

Defines the terminal for connecting the temperature sensor. It

is possible to use a sensor signal for several applications. For

this, in the application in question, select the terminals where

the sensor is located (multiple selection possible).

!

Note!

The term in brackets X-1X (e.g. A-11) describes a current

input, the term X-2X (e.g. E-21) a pure temperature input. The

type of input depends on the extension cards.

Unit °C; K; °F Physical unit of the measured temperature.

!

Note!

Only visible if the "Random" system unit has been selected.

Format 9; 9.9; 9.99; 9.999 Number of places after the decimal point

!

Note!

Only visible if the "Random" system unit has been selected.

Signal damp 0 to 99 s

0 s

Time constant of the first order low pass for the input signal.

This function is used to reduce display fluctuations in the event

of severely fluctuating signals.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Start value -9999.99 to 999999 Start value for the temperature with 0 or 4 mA.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

End value -9999.99 to 999999 End value for the temperature with 20 mA.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Offset -9999.99 to 9999.99

0.0

Shifts the zero point of the response curve. This function is

used to adjust sensors.

!

Note!

This can only be selected for the 0/4 to 20 mA signal.

Default -9999.99 to 9999.99

20 °C or 70 °F

Sets the temperature which is worked with if the sensor signal

fails and the ’Default’ signal is set.

Alarm response See Setup ’Flow inputs’.

Temperature mean value Unused

2 sensors

3 to 6 sensors

Mean value computed from several temperature signals

(See Section 11.2.1 for details of the 'Mean value

computation')

Page 41

RMS621 Commissioning

Endress+Hauser 41

Setup → Applications

Energy Manager applications:

•Steam:

Mass - heat quantity - net heat quantity - heat difference

•Water:

Heat quantity - heat difference

Up to three different applications can be calculated simultaneously. The configuration of an

application is possible without restricting the applications available up to now in the operating

status. Please note that when you have successfully configured a new application or changed the

settings of an already existing application, the data are not accepted until the user enables the

application at the end (question before exiting the setup).

Function (menu item) Parameter setting Description

Identifier Application 1-3 Name of the configured application, e.g. ’boiler room 1’.

Application Select

Steam mass/heat

Net steam

S-heat diff

Water heat quantity

Water-heat diff

Select the desired application (depending on the type of

media). If an application in operation should be switched off,

choose ’Select’ here.

Flow Select

Flow 1-3

Assign a flow sensor to your application. Only the sensors that

were configured previously (see ’Setup: Inputs - Flow inputs’)

can be selected here.

Pressure Select

Pressure 1-3

Assign the pressure sensor. Only the sensors that were

configured previously (see ’Setup: Inputs - Pressure inputs’)

can be selected here.

Temperature Select

Temperature 1-6

Assign the temperature sensor. Only the sensors that were