Page 1

BA00300K/09/EN/05.19

71416522

Software version:

01.03.xx

Products Solutions Services

Operating Instructions

RA33

Batch controller

Page 2

Page 3

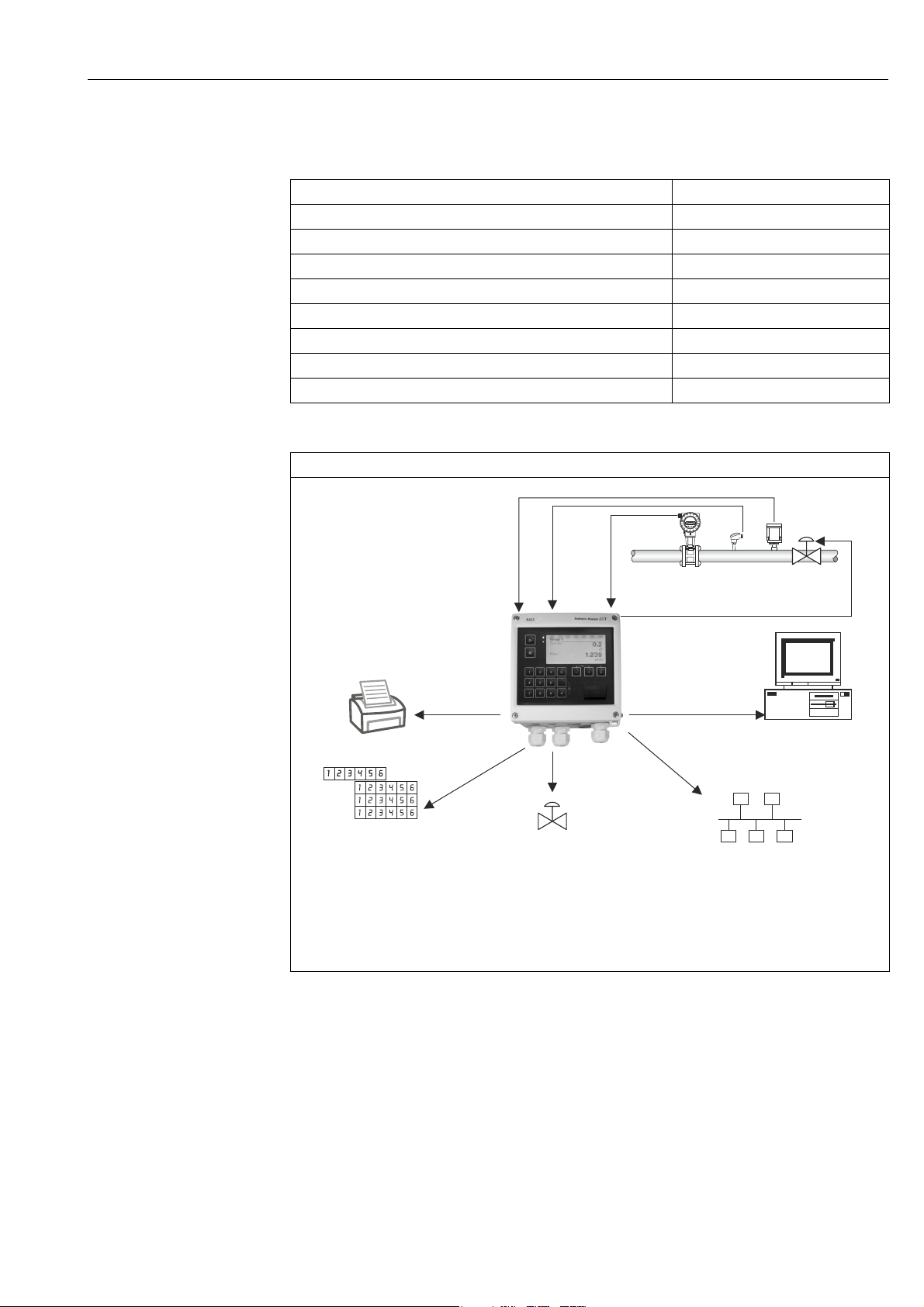

Batch Controller RA33

Q

T

ρ

RS232

Interfaces (USB, Ethernet)

Open collector /

pulse output

Analog output

Counter

Relay

outputs

Ethernet, web server

ModBus TCP

RTUModBus

Valve

Printer

Brief overview

For quick and easy commissioning:

Safety instructions ä 6

▾

Installation ä 10

▾

Wiring ä 15

▾

Display and operating elements ä 22

▾

Commissioning ä 26

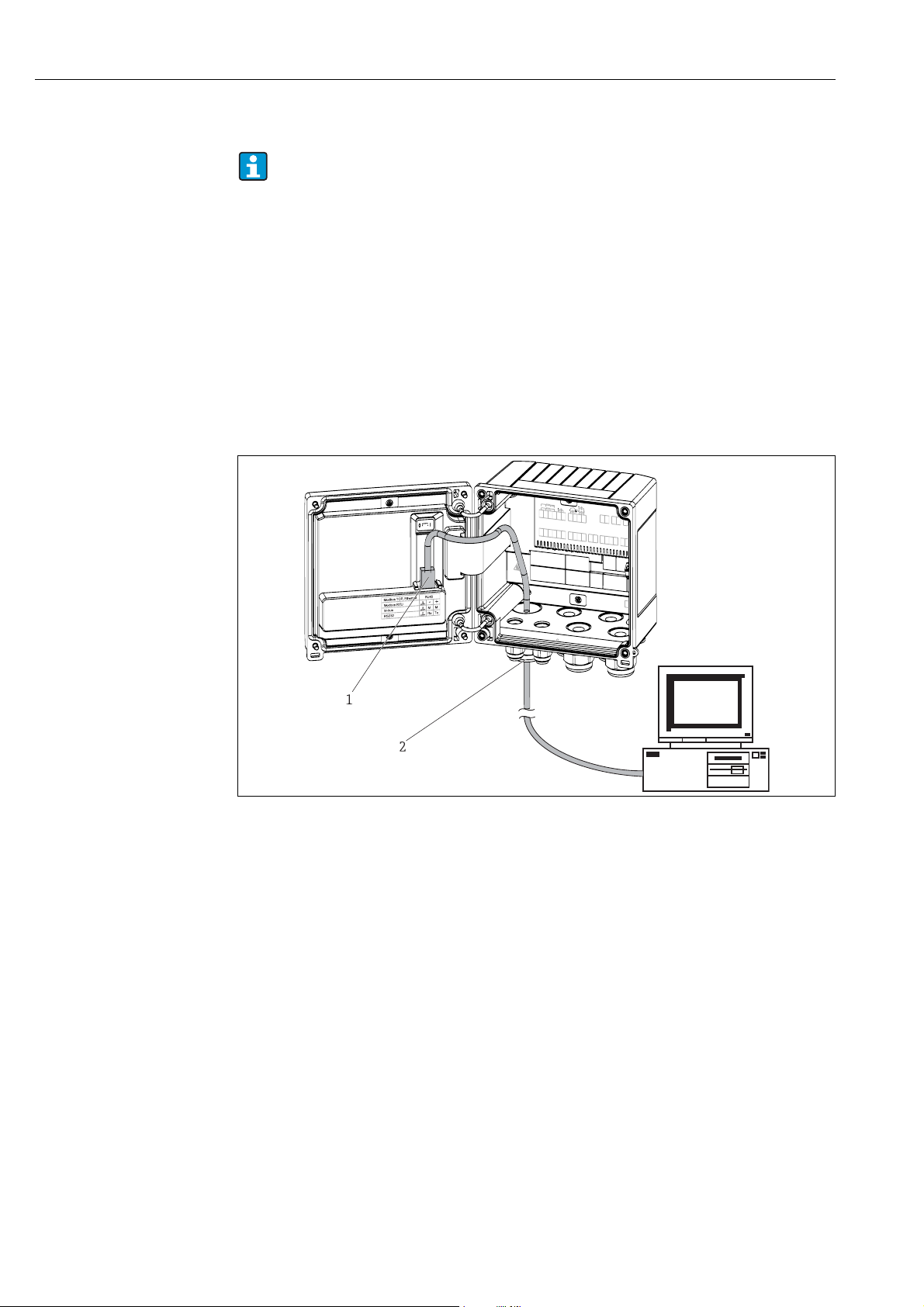

Applications for the batch controller

Endress+Hauser 3

1: Brief overview of applications

a0014548-EN

Page 4

Batch Controller RA33

4 Endress+Hauser

Page 5

Batch Controller RA33

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 6

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Installation, commissioning and operation . . . . . . 6

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and icons . . . . . . . . . 7

2 Identification . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Device tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Incoming acceptance, transport and storage . . . 10

3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 14

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Connection requirements . . . . . . . . . . . . . . . . . . . 15

4.2 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Connecting the sensors . . . . . . . . . . . . . . . . . . . . 17

4.4 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6 Post-connection check . . . . . . . . . . . . . . . . . . . . . 21

9.4 Output function test . . . . . . . . . . . . . . . . . . . . . . . . 52

9.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10 Technical data . . . . . . . . . . . . . . . . . . . . 56

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . 65

11.1 Operating functions and parameters . . . . . . . . . . 65

11.2 Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.3 Units used in the device . . . . . . . . . . . . . . . . . . . . . 80

11.4 Definition of important system units . . . . . . . . . . 81

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 General notes for operation . . . . . . . . . . . . . . . . . 22

5.2 Display and operating elements . . . . . . . . . . . . . 22

5.3 Operating matrix . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Commissioning. . . . . . . . . . . . . . . . . . . . 26

6.1 Quick commissioning/make it run . . . . . . . . . . . 26

6.2 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Configuring the basic parameters/general device

functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4 Optional device settings/special functions . . . . 45

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . 46

8 Accessories . . . . . . . . . . . . . . . . . . . . . . . 46

8.1 Device-specific accessories . . . . . . . . . . . . . . . . . . 46

8.2 Communication-specific accessories . . . . . . . . . 46

8.3 Service-specific accessories . . . . . . . . . . . . . . . . . 47

8.4 System components . . . . . . . . . . . . . . . . . . . . . . . 48

9 Troubleshooting. . . . . . . . . . . . . . . . . . .49

9.1 Instrument diagnostics and troubleshooting . . . 49

9.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.3 Diagnosis list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Endress+Hauser 5

Page 6

Safety instructions Batch Controller RA33

1 Safety instructions

Safe operation of the device is only guaranteed if the Operating Instructions have been read

and the safety instructions they contain have been observed.

1.1 Designated use

The batch controller is a batching and dosing manager for the batching of any media or

mineral oils.

– The manufacturer cannot take responsibility for any damage caused by misuse of the

device. It is not permitted to make any changes or reconstruction to the device.

– The device may be operated in built-in state only.

1.2 Installation, commissioning and operation

The batch controller is safely manufactured using state-of-the-art technology and complies

with the respective regulations and EU Directives. The device could be dangerous if it is

incorrectly installed or used.

Installation, wiring and maintenance of the device must be carried out only by trained,

skilled personnel authorized to perform such work and instructed by the facility's owneroperator. The skilled personnel must have read and understood these Operating Instructions

and it is mandatory for them to follow the instructions they contain. The operator must

ensure that the measuring system is correctly wired in accordance with the wiring diagrams.

When the housing cover is removed, the shock protection is disabled (danger of

electrocution). The housing may be opened by trained skilled personnel only.

The batch controller may be operated in a closed and secure state only.

1.3 Operational safety

Technical improvement

The manufacturer reserves the right to improve and update the technical details. For details

of improvements or additions to these instructions, please contact your local sales

organization.

1.4 Return

For a return, e.g. in case of repair, the device must be sent in protective packaging. The

original packaging offers the best protection. Repairs must only be carried out by your

supplier's service organization.

When sending for repair, enclose a note with a description of the error and the

application.

6 Endress+Hauser

Page 7

Batch Controller RA33 Safety instructions

1.5 Notes on safety conventions and icons

The safety instructions in these Operating Instructions are labeled with the following safety

icons and symbols:

Symbol Meaning

WARNING!

A0011190-EN

A0011191-EN

A0011192-EN

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in minor or medium injury.

NOTE

This symbol contains information on procedures and other facts which do not

result in personal injury.

ESD - Electrostatic discharge

Protect the terminals from electrostatic discharge. Failure to observe this may

result in destruction or malfunction of parts of the electronics.

Additional information, tip

A0011193

Endress+Hauser 7

Page 8

Identification Batch Controller RA33

2 Identification

2.1 Device tag

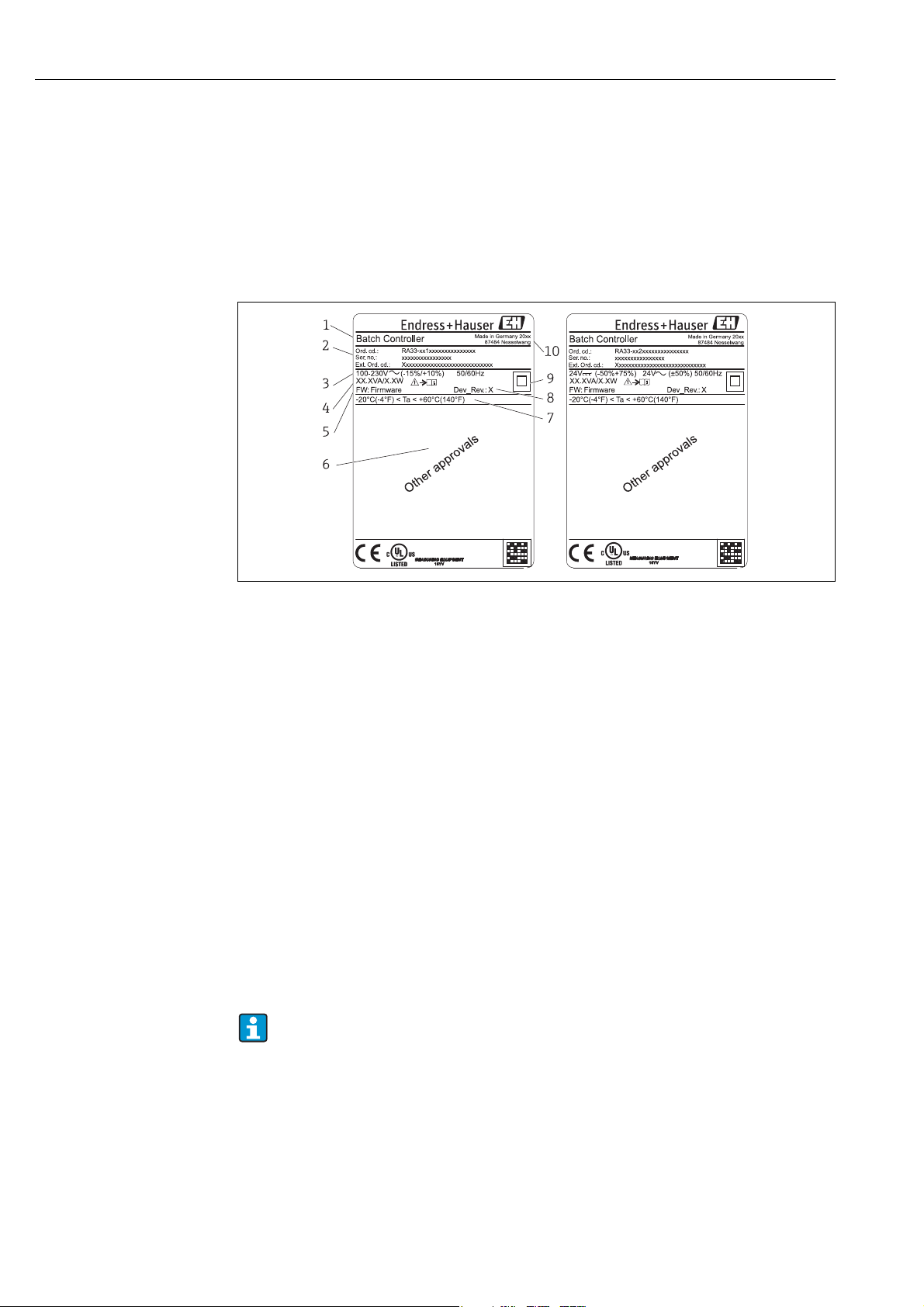

2.1.1 Nameplate

Compare the nameplate on the device with the following diagram:

a0014625

2: Nameplate of the batch controller (example)

1Device tag

2 Order code and serial number

3 Supply voltage

4Power consumption

5 Firmware version

6 Approvals, if available

7 Ambient temperature range

8Device revision

9 Device protected by double or reinforced seal

10 Place and year of manufacture

2.2 Scope of delivery

The scope of delivery of the batch controller comprises:

• Batch controller (field housing)

•Wall mountig plate

• Brief Operating Instructions in paper form

• Optional 3 pcs. connection clamps (5 positions apiece)

• Optional interface cable and DVD set with FieldCare Device Setup parameter configuration

software

• Optional Field Data Manager software

•Optional mounting hardware for DIN rail, panel mounting, pipe mounting

• Optional overvoltage protection

Please note the device accessories in Section 8 ’Accessories’.

8 Endress+Hauser

Page 9

Batch Controller RA33 Identification

2.3 Certificates and approvals

CE mark, Declaration of Conformity

The device is safely built and tested according to state-of-the-art technology and has left the

factory in perfect condition as regards technical safety. The device complies with the

applicable standards and regulations in accordance with EN 61010-1 "Safety requirements

for electrical equipment for measurement, control and laboratory use".

Thus, the device described in these Operating Instructions meets the legal requirements of

the EU Directives. The manufacturer confirms successful testing of the device by affixing to

it the CE mark.

Endress+Hauser 9

Page 10

Installation Batch Controller RA33

3Installation

3.1 Incoming acceptance, transport and storage

The permitted environmental, storage and transportation conditions must be complied with.

For detailed specifications, refer to the "Technical data" chapter ( ä 56).

3.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Are the packaging or contents damaged?

• Are the delivered goods complete? Compare the scope of delivery with your order

information.

3.1.2 Transport and storage

Observe the following points:

• Pack the device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

• The permitted storage temperature range is -40 to +85 °C (-40 to +185 °F); storage in the

temperature limit ranges is possible for a limited time only (maximum of 48 hours).

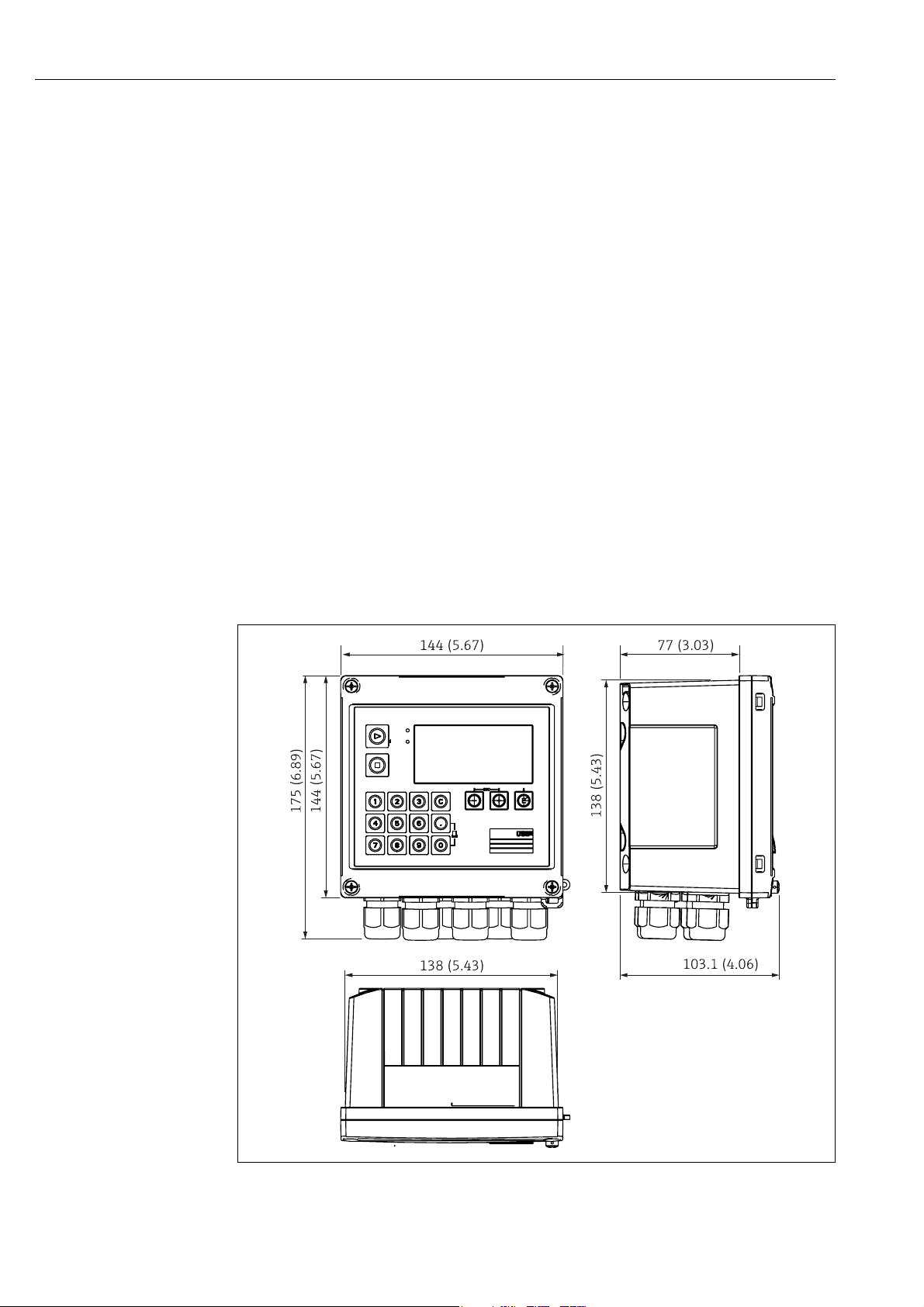

3.2 Dimensions

a0014119

3: Dimensions of the device in mm (in)

10 Endress+Hauser

Page 11

Batch Controller RA33 Installation

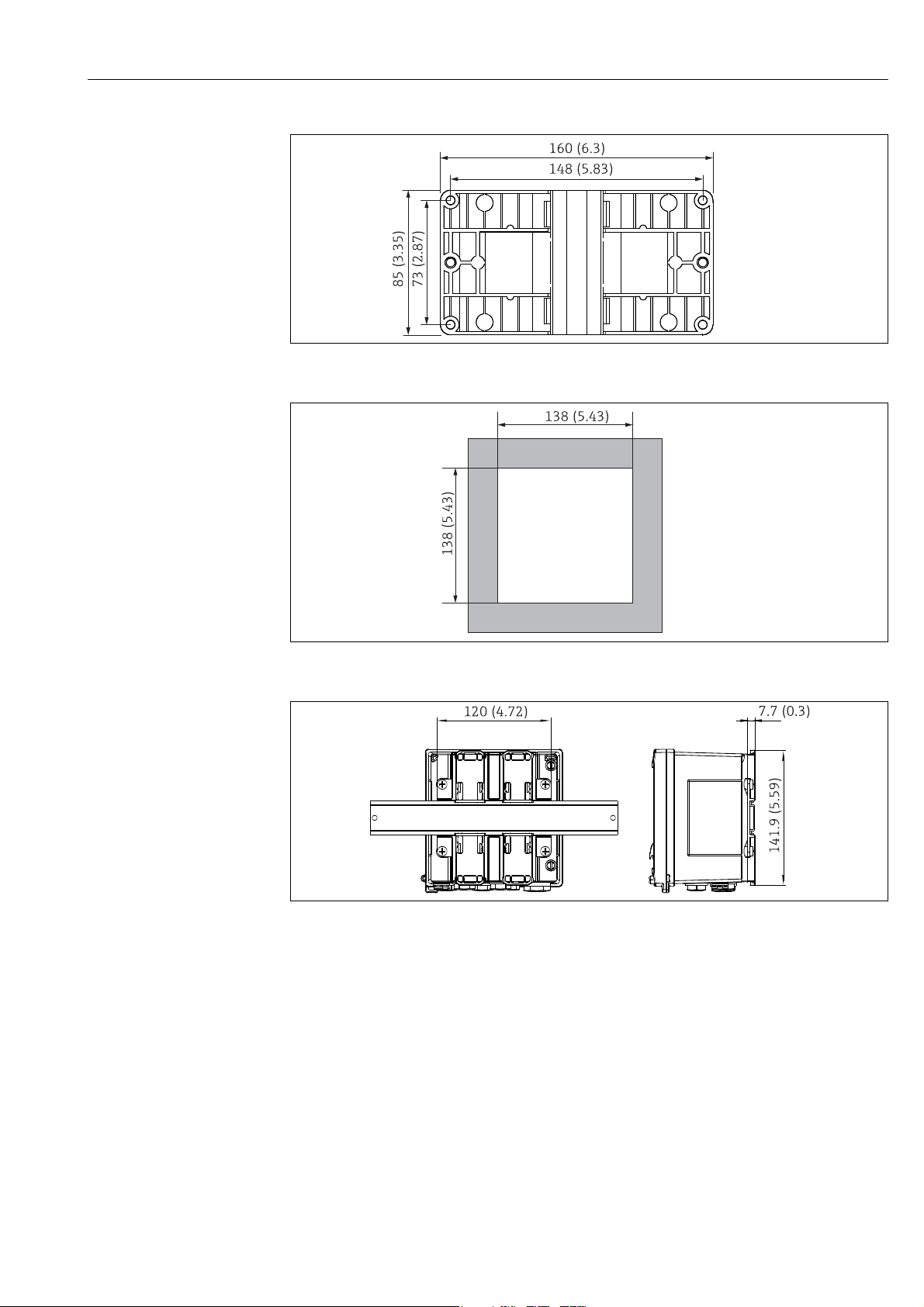

a0014169

4: Mounting plate for wall, pipe and panel mounting, dimensions in mm (in)

a0014171

5: Panel cutout, dimensions in mm (in)

a0014610

6: Dimensions of the DIN rail adapter in mm (in)

3.3 Installation

With the appropriate accessories ä 46, the device with field housing is suitable for wall

mounting, pipe mounting, panel mounting and DIN rail installation.

The orientation is determined by the legibility of the display. Connections and outputs are

fed out of the bottom of the device. The pipes are connected via coded clamps.

Operating temperature range:

-20 to 60 °C (-4 to 140 °F)

Endress+Hauser 11

Page 12

Installation Batch Controller RA33

NOTICE

High temperatures reduce the operating life of the device

‣ To prevent heat build-up, do not expose the device to extreme heat or strong direct

sunshine.

‣ Operation in the upper temperature limit range decreases the operating life of the

display.

3.4 Installation

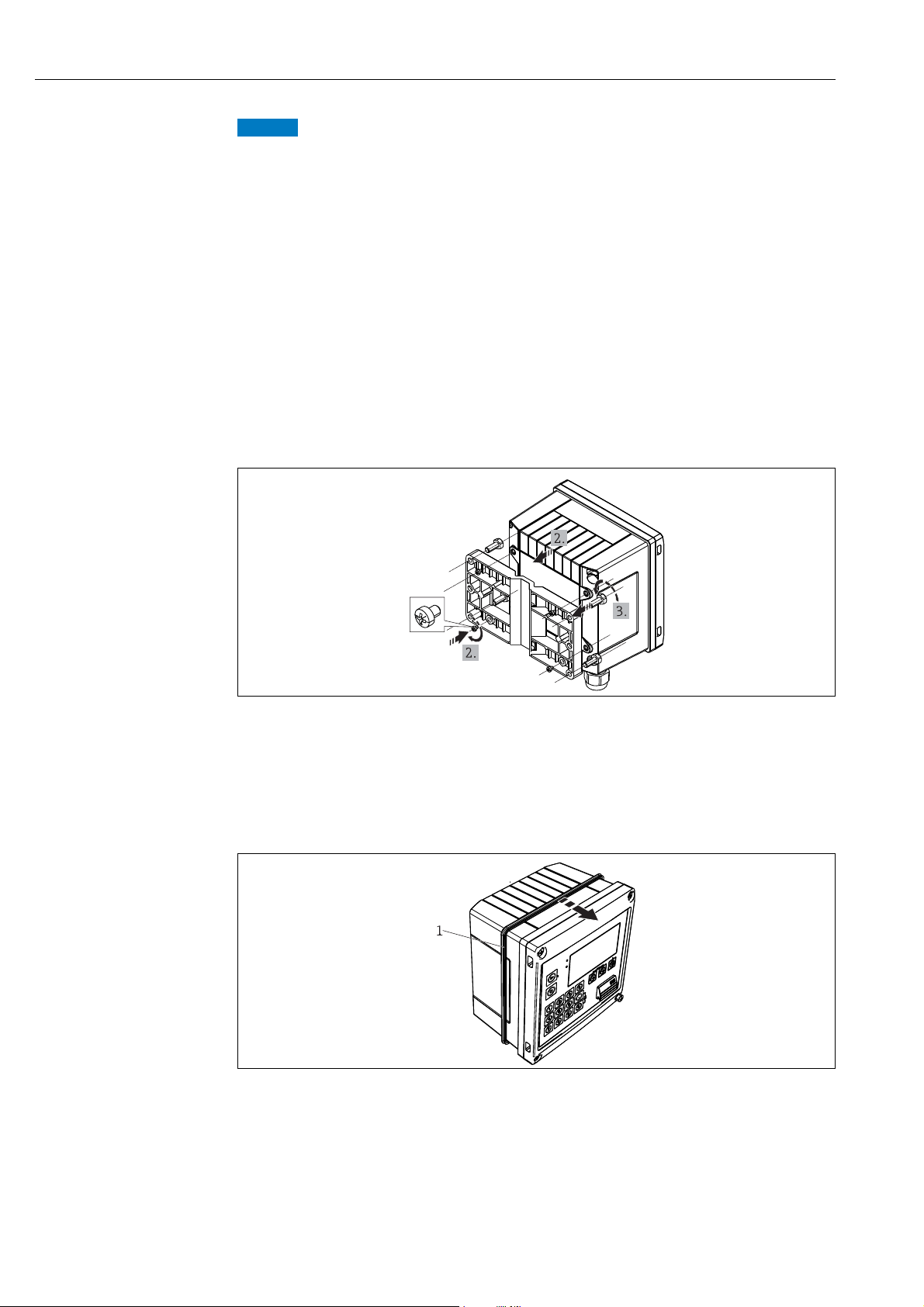

3.4.1 Wall mounting

1. Use the mounting plate as the template for drilled holes, dimensions å 4, ä 11

2. Attach the batch controller to the mounting plate and fasten it in place from the rear

using 4 screws.

3. Fasten the mounting plate to the wall using 4 screws.

a0014170

7: Wall mounting

3.4.2 Panel mounting

1. Make the panel cutout in the required size, dimensions å 5, ä 11.

2. Attach the seal (item 1) to the housing.

a0014283

8: Panel mounting

3. Screw the threaded rods (item 2) into the mounting plate (dimensions å 4, ä 11).

12 Endress+Hauser

Page 13

Batch Controller RA33 Installation

a0014173

9: Preparing the mounting plate for panel mounting

4. Push the device into the panel cutout from the front and attach the mounting plate to

the device from the rear using the 4 screws provided (item 3).

5. Fasten the device in place by tightening the threaded rods.

a0014284

10: Panel mounting

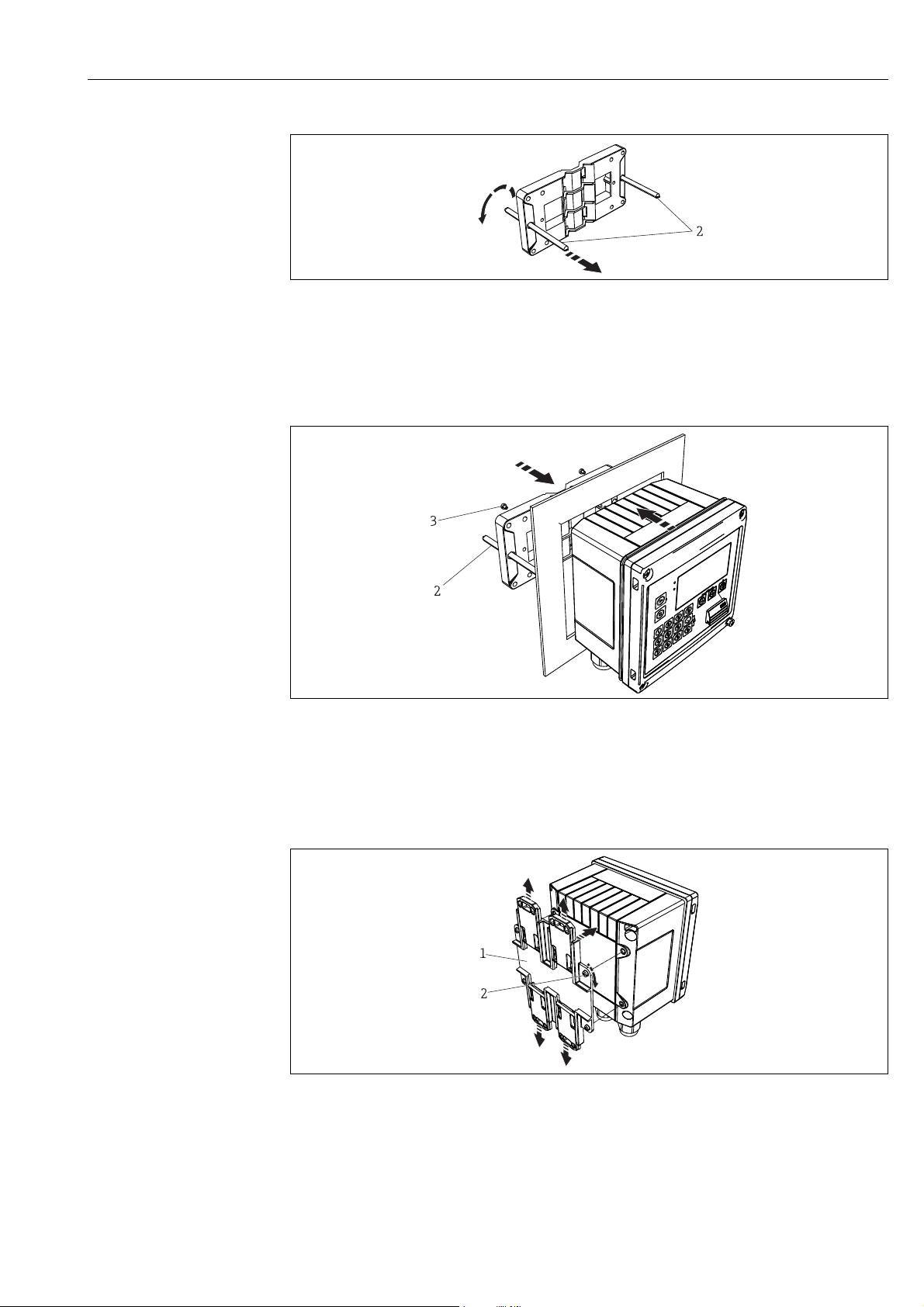

3.4.3 Support rail/DIN rail (to EN 50 022)

1. Fasten the DIN rail adapter (item 1, dimensions å 6, ä 11) to the device using the

screws provided (item 2) and open the DIN rail clips.

a0014176

11: Preparing for DIN rail mounting

2. Attach the device to the DIN rail from the front and close the DIN rail clips.

Endress+Hauser 13

Page 14

Installation Batch Controller RA33

a0014177

12: DIN rail mounting

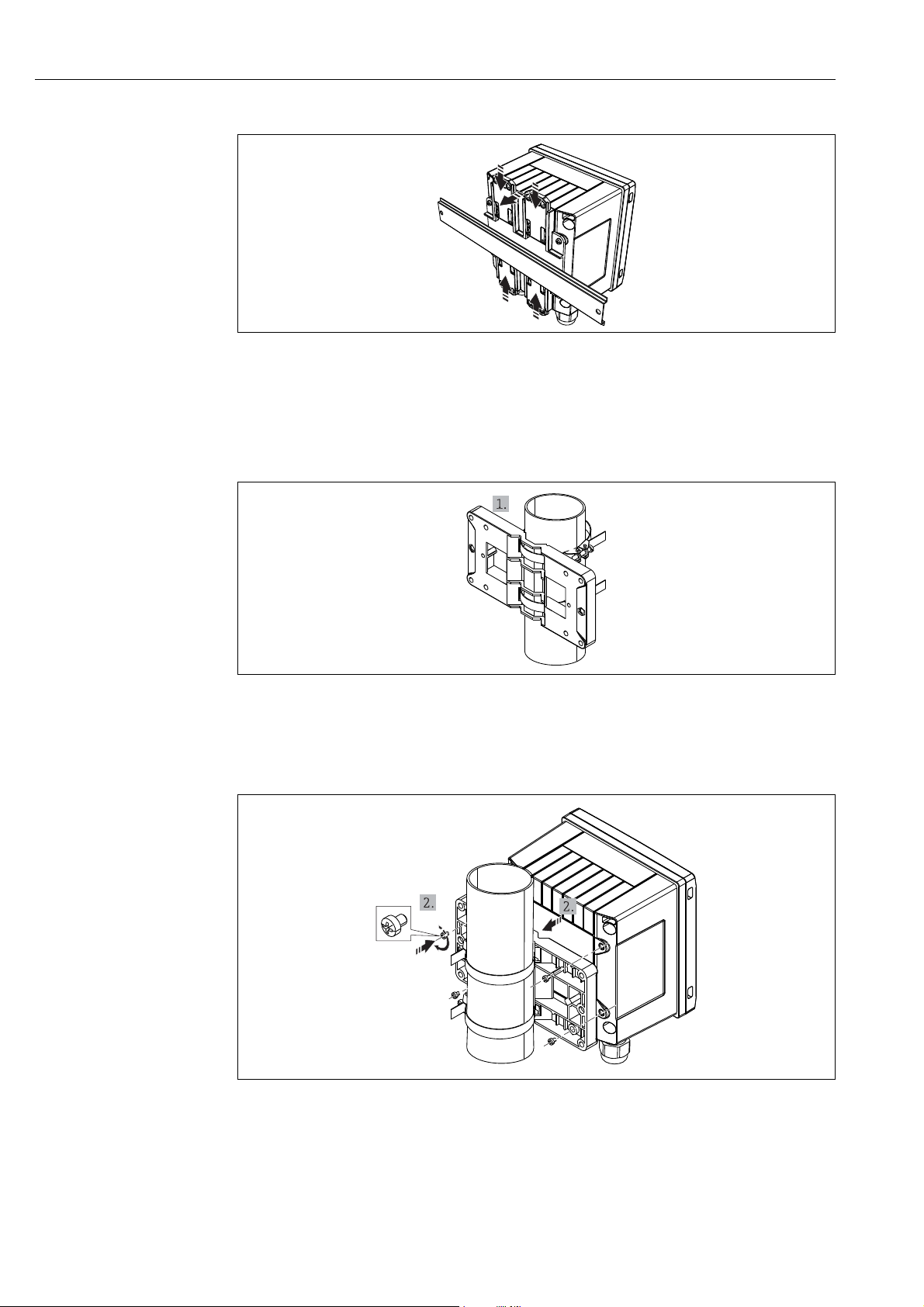

3.4.4 Pipe mounting

1. Pull the steel belts through the mounting plate (dimensions å 4, ä 11) and fasten

them to the pipe.

13: Preparing for pipe mounting

2. Attach the device to the mounting plate and fasten it in place using the 4 screws

provided.

14: Pipe mounting

a0014178

a0014179

3.5 Post-installation check

For installing the batch controller and the associated temperature sensors, observe the

general installation instructions according to EN 1434 Part 6.

14 Endress+Hauser

Page 15

Batch Controller RA33 Wiring

WARNING

!

CAUTION

!

4 Wiring

4.1 Connection requirements

Danger! Electric voltage!

‣ The entire connection of the device must take place while the device is de-energized.

Incorrect power supply can cause malfunctions

‣ Before commissioning the device, make sure that the supply voltage matches the voltage

specifications on the nameplate.

‣ Provide a suitable switch or power-circuit breaker in the building installation. This switch

must be installed close to the device (so that it is easily accessible) and marked as a circuit

breaker.

‣ An overload protection unit (rated current = 10 A) is required for the power cable.

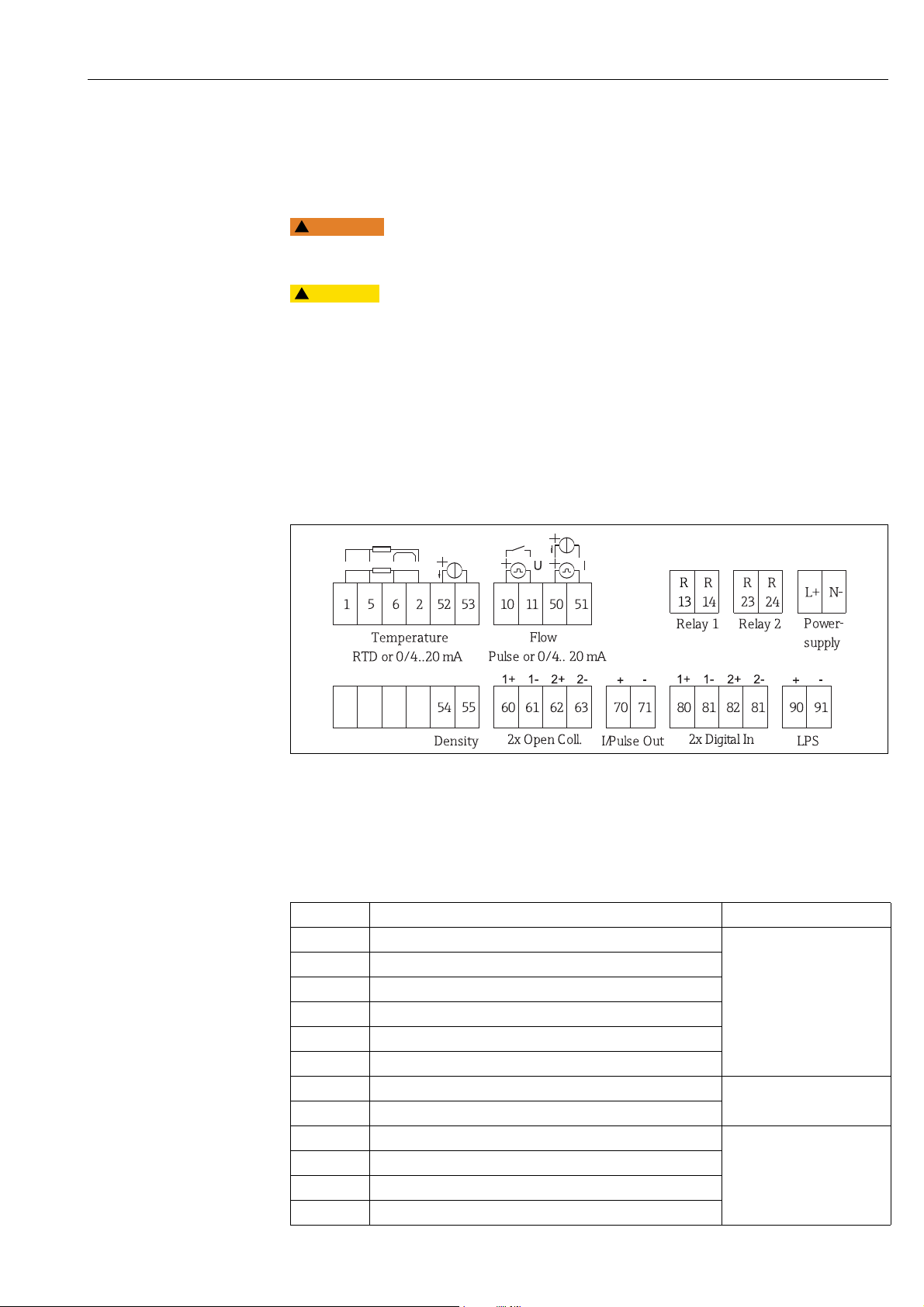

4.2 Quick wiring guide

15: Connection diagram of the batch controller

For the connection of the communication interfaces, see the "Communication" section,

ä 20.

Terminal assignment

Terminals Terminal assignment Inputs

1 + RTD power supply Temperature, ä 19

2 - RTD power supply

5+ RTD sensor

6- RTD sensor

52 + 0/4 to 20 mA input

53 Ground for 0/4 to 20 mA input

54 + 0/4 to 20 mA input Density

55 Ground for 0/4 to 20 mA input

10 + pulse input (voltage or contact) Flow, ä 17

11 - pulse input (voltage or contact)

50 + 0/4 to 20mA or current pulse (PFM)

51 Ground for 0/4 to 20 mA input, flow

(Optionally RTD or current

input)

(Current input)

(Optionally pulse or current

input)

a0014120

Endress+Hauser 15

Page 16

Wiring Batch Controller RA33

80 + digital input 1 (switch input) • Time synchronization

81 - digital input (terminal 1)

82 + digital input 2 (switch input) • Time synchronization

81 - digital input (terminal 2)

60 + status/pulse output 1 (open collector) Batch control: pump/valve,

61 - status/pulse output 1 (open collector)

62 + status/pulse output 2 (open collector)

63 - status/pulse output 2 (open collector)

70 + 0/4 to 20mA/pulse output Current values (e.g. power) or

71 0/4 to 20mA/pulse output

13 Relay 1 normally open (NO) Batch control: pump/valve,

14 Relay 1 normally open (NO)

23 Relay 2 normally open (NO)

24 Relay 2 normally open (NO)

90 24V sensor power supply (LPS) 24 V power supply

91 Power supply ground

L/+ L for AC

+ for DC

N/- N for AC

- for DC

• Start batch

• Stop batch

•Reset batch

Outputs

volume counter, signal for end

of batch, fault

counter values (e.g. energy)

fault

(e.g. for sensor power supply)

Power supply

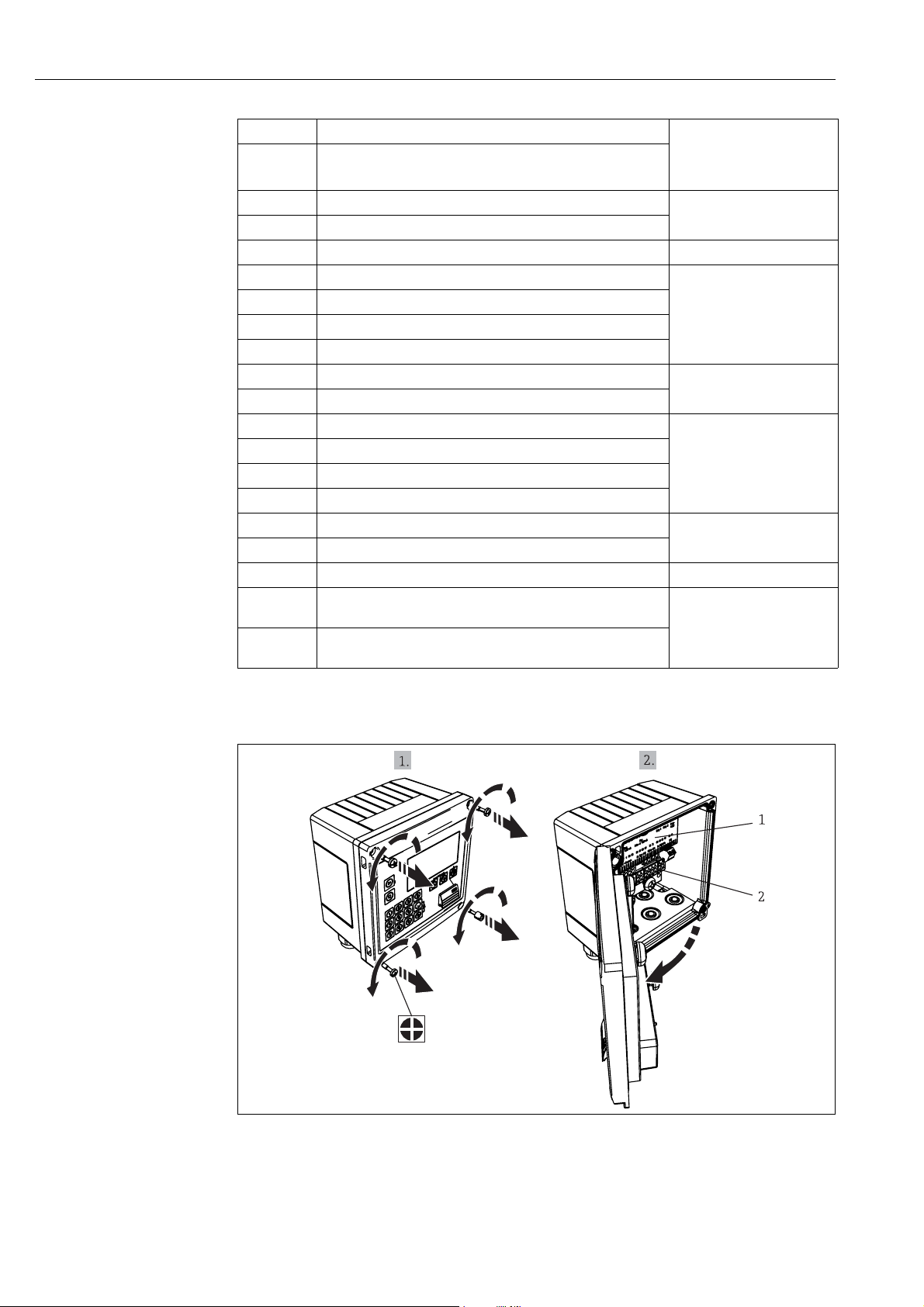

4.2.1 Open housing

16: Opening the housing of the batch controller

1 Terminal assignment labeling

2Terminals

a0014368

16 Endress+Hauser

Page 17

Batch Controller RA33 Wiring

4.3 Connecting the sensors

4.3.1 Flow

Sensors for volume or mass flow measurement can be connected to the batch controller.

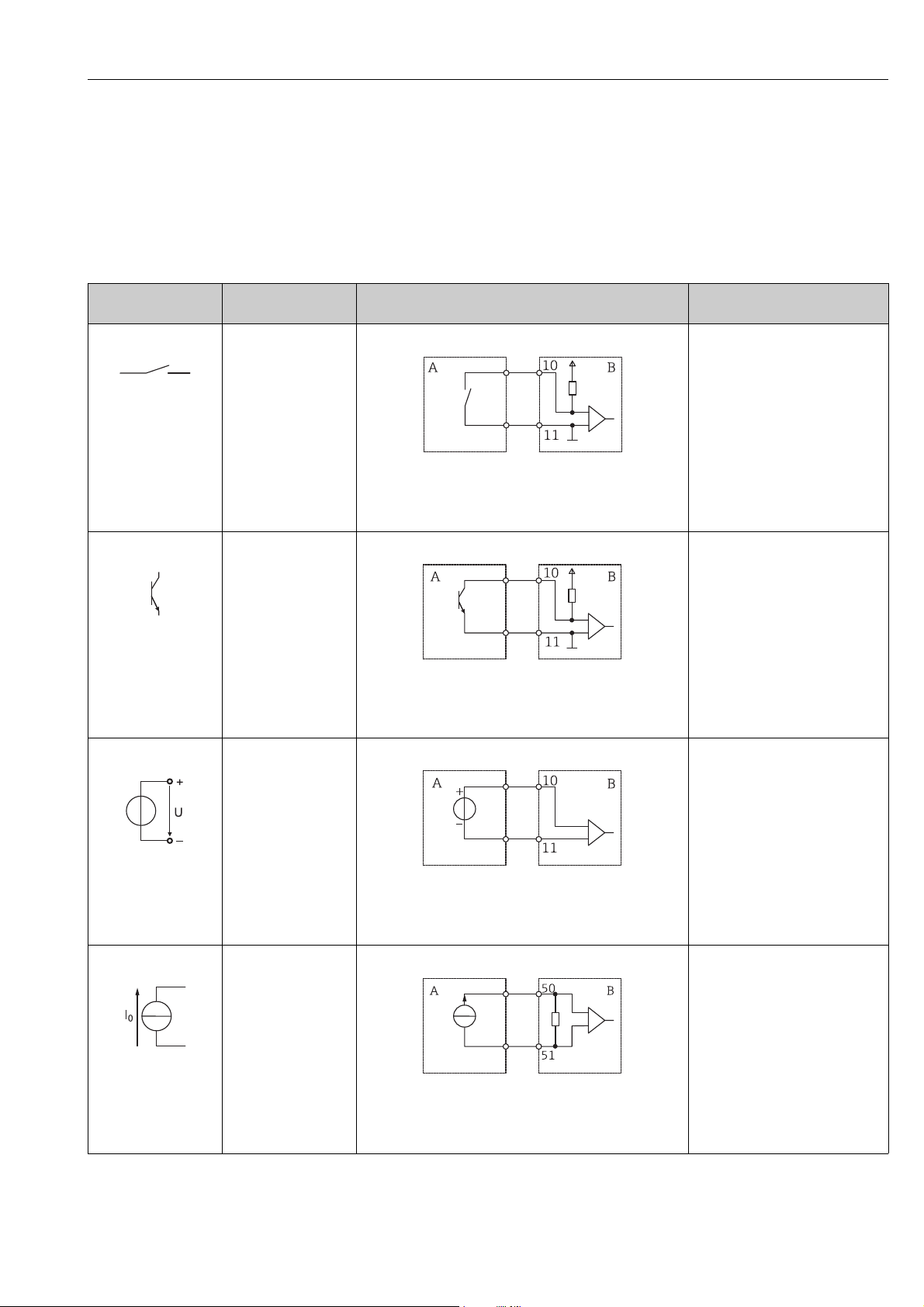

Connecting flow sensors with a pulse output

Pulse output of the

flow sensor

Mechanical contact

a0015360

Open collector (NPN)

a0015361

Active voltage

Setting at the Rx33 Electrical connection Notes

Pulse ID/IE up to 25 Hz

As an alternative, it is possible to

choose "Pulse IB/IC+U" up to 25 Hz.

The current flow via the contact is

then lower (approx. 0.05 mA

instead of approx. 9 mA).

Advantage: lower power

consumption, disadvantage: less

immunity to interference.

a0015354

A = Sensor

B = Rx33

Pulse ID/IE up to 25 Hz

or up to 12.5 kHz

As an alternative, it is possible to

choose "Pulse IB/IC+U". The current

flow via the transistor is then lower

(approx. 0.05 mA instead of approx.

9 mA). Advantage: lower power

consumption, disadvantage: less

immunity to interference.

a0015355

A = Sensor

B = Rx33

Pulse IB/IC+U

The switching threshold is between

1V and 2 V.

a0015362

a0015356

A = Sensor

B = Rx33

Active current

Pulse I

The switching threshold is between

8mA and 13 mA.

a0015363

a0015357

A = Sensor

B = Rx33

Endress+Hauser 17

Page 18

Wiring Batch Controller RA33

Pulse output of the

flow sensor

Namur sensor (as per

EN60947-5-6)

Setting at the Rx33 Electrical connection Notes

Pulse ID/IE up to 25 Hz

or up to 12.5 kHz

No monitoring for short circuit or

line break takes place.

a0015359

1 = Sensor

2 = Rx33

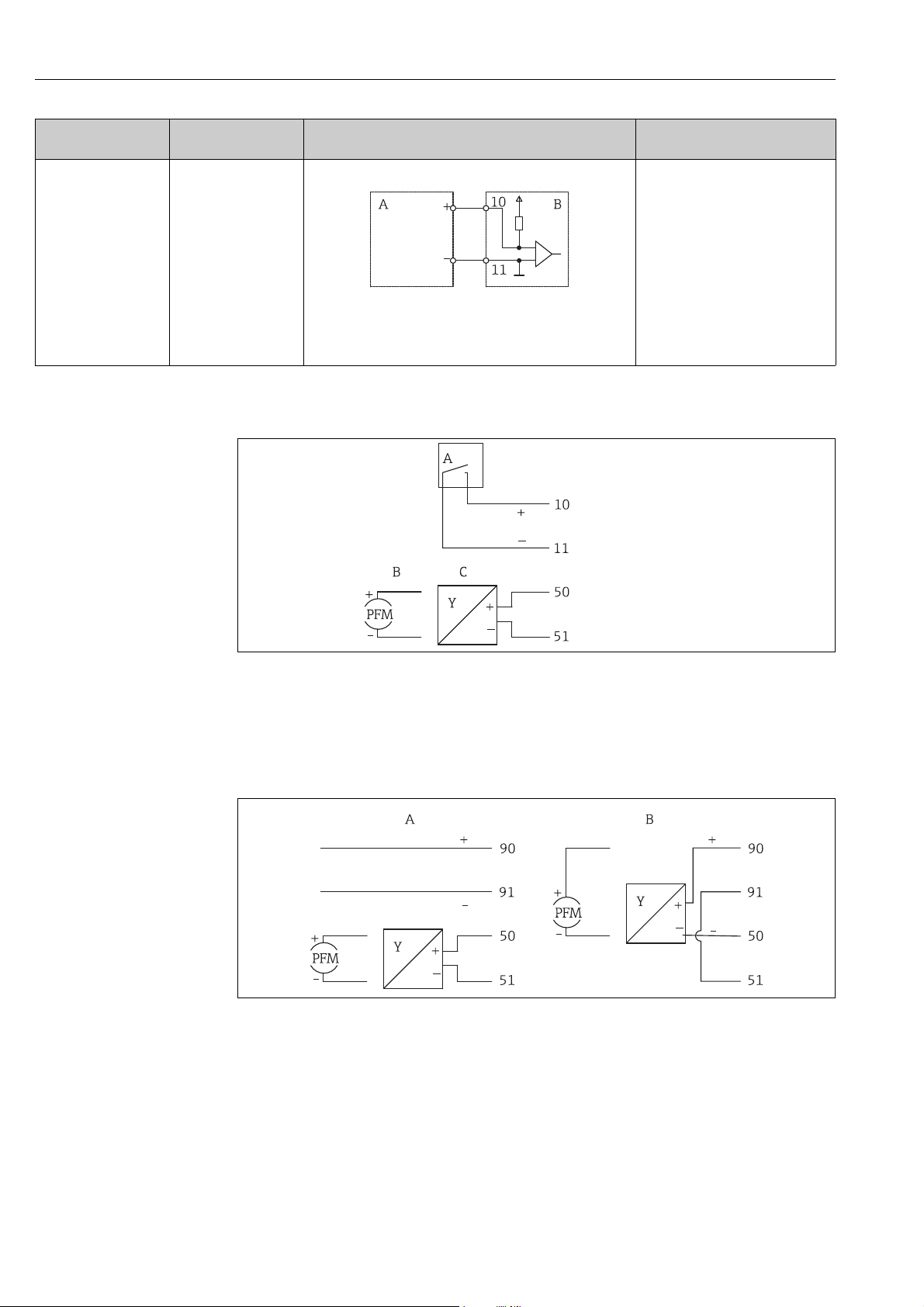

Flow sensors with external power supply

17: Connecting a flow sensor

A Voltage pulses or contact sensors including EN 1434 Type IB, IC, ID, IE

B Current pulses

C 0/4 to 20 mA signal

Flow sensors with power supply via the batch controller

18: Connecting active flow sensors

A4-wire sensor

B2-wire sensor

a0013521

a0014180

18 Endress+Hauser

Page 19

Batch Controller RA33 Wiring

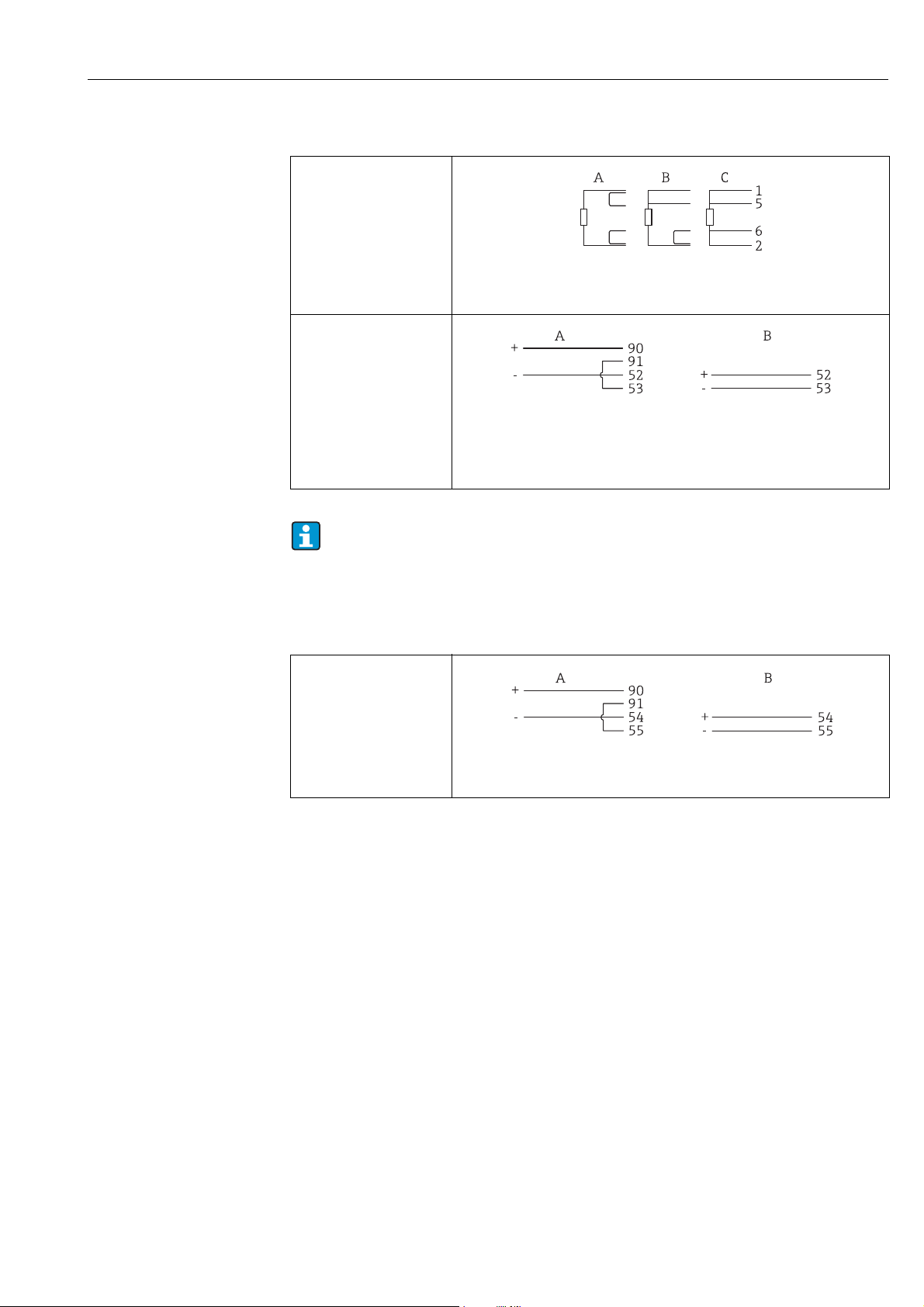

4.3.2 Temperature

Connecting the RTD sensors

A0014529

A = 2-wire connection, B= 3-wire connection, C = 2-wire connection

Terminals 1, 2, 5, 6: temperature

Temperature transmitter

connection

A0014528

A = without external power supply of the transmitter, B = with external power

supply of the transmitter

Terminals 90, 91: transmitter power supply

Terminals 52, 53: temperature

To ensure the highest level of accuracy, we recommend using the RTD 4-wire

connection, as this compensates for measurement inaccuracies caused by the

mounting location of the sensors or the line length of the connecting cables.

Density

Density sensor connection

a0015152

A = without external power supply of the density sensor, B = with external power

supply of the density sensor

4.4 Outputs

4.4.1 Analog output (active)

This output can be used either as a 0/4 to 20 mA current output or as a voltage pulse output.

The output is galvanically isolated. For the terminal assignment, refer to ä 15.

4.4.2 Pulse output (active)

Active voltage pulses are output at the pulse output.

Voltage level:

• 0 to 2 V corresponds to Low level

• 15 to 20 V corresponds to High level

Maximum output current: 22 mA

4.4.3 Open collector output

The two digital outputs can be used as status or pulse outputs. Make the selection in the

following menus: Setup → Advanced setup or Expert → Outputs → Open collector

Endress+Hauser 19

Page 20

Wiring Batch Controller RA33

4.5 Communication

The USB interface is always active and can be used independently of other interfaces.

Parallel operation of multiple optional interfaces, e.g. fieldbus and Ethernet, is not

possible.

4.5.1 Ethernet TCP/IP (optional)

The Ethernet interface is galvanically isolated (testing voltage: 500 V). A standard patch

cable (e.g. CAT5E) can be used to connect the Ethernet interface. A special cable gland is

available for this purpose which allows users to guide pre-terminated cables through the

housing. Via the Ethernet interface, the device can be connected using a hub or a switch or

directly to office equipment.

• Standard: 10/100 Base-T/TX (IEEE 802.3)

• Socket: RJ-45

• Max. line length: 100 m

a0014600

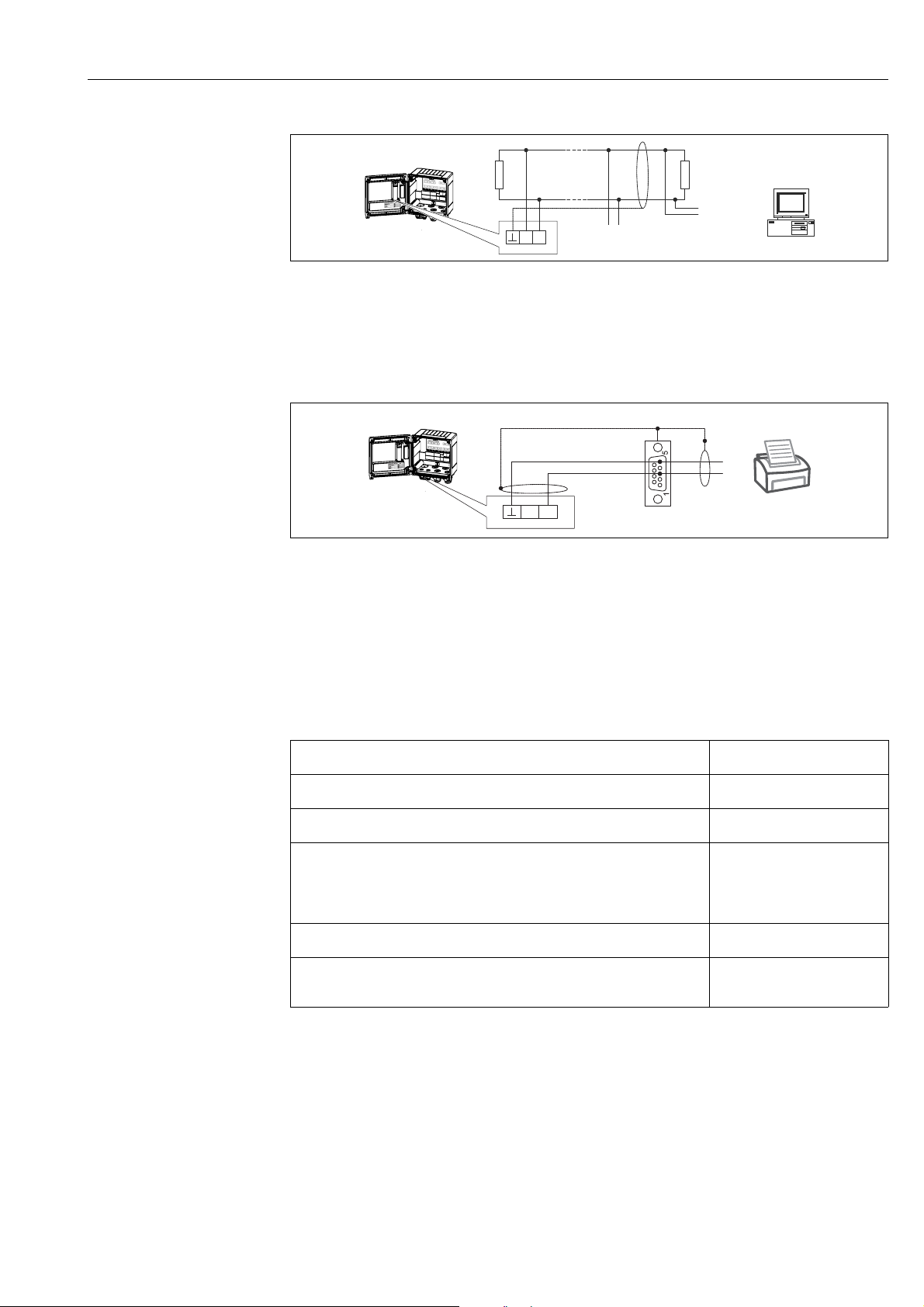

19: Ethernet TCP/IP, Modbus TCP connection

1 Ethernet, RJ45

2 Cable entry for Ethernet cable

4.5.2 Modbus TCP (optional)

The Modbus TCP interface is used to connect the device to higher-order systems to transmit

all measured values and process values. The Modbus TCP interface is physically identical to

the Ethernet interface ( ä 20). Connection å 19, ä 20.

4.5.3 Modbus RTU (optional)

The Modbus RTU (RS-485) interface is galvanically isolated (testing voltage: 500 V) and

used to connect the device to higher-order systems to transmit all measured values and

process values. It is connected via a 3-pin plug-in terminal in the housing cover.

20 Endress+Hauser

Page 21

Batch Controller RA33 Wiring

-

+

RxD/TxD (+)

RxD/TxD (-)

R

L

R

L

further instrumentation

GND

Rx

5

3

Rx

Tx

a0014603-EN

20: Modbus RTU connection

4.5.4 Printer interface / RS232 (optional)

The printer/RS232 interface is galvanically isolated (testing voltage: 500 V) and is used to

connect a printer. It is connected via a 3-pin plug-in terminal in the housing cover.

21: Printer connection via RS232

The following printers have been tested with the batch controller:

• GeBE MULDE Mini thermal printer

4.6 Post-connection check

After completing the device's electrical installation, carry out the following checks:

Device status and specifications Notes

Is the device or cable damaged (visual inspection)? -

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate? 100 to 230 V AC/DC (±10%)

(50/60 Hz)

24 V DC (-50% / +75%)

24 V AC (±50%) 50/60 Hz

Are the mounted cables relieved of tension? -

Are the power supply and signal cables correctly connected? See wiring diagram on the

housing

a0014602

Endress+Hauser 21

Page 22

Operation Batch Controller RA33

5Operation

5.1 General notes for operation

The batch controller can be configured using keys or using the "FieldCare" operating

software.

The operating software, including the interface cable, is available as an order option, i.e. it is

not part of the basic scope of delivery.

The configuration is locked if the device is locked by the locking switch ( ä 23) or the user

code.

5.2 Display and operating elements

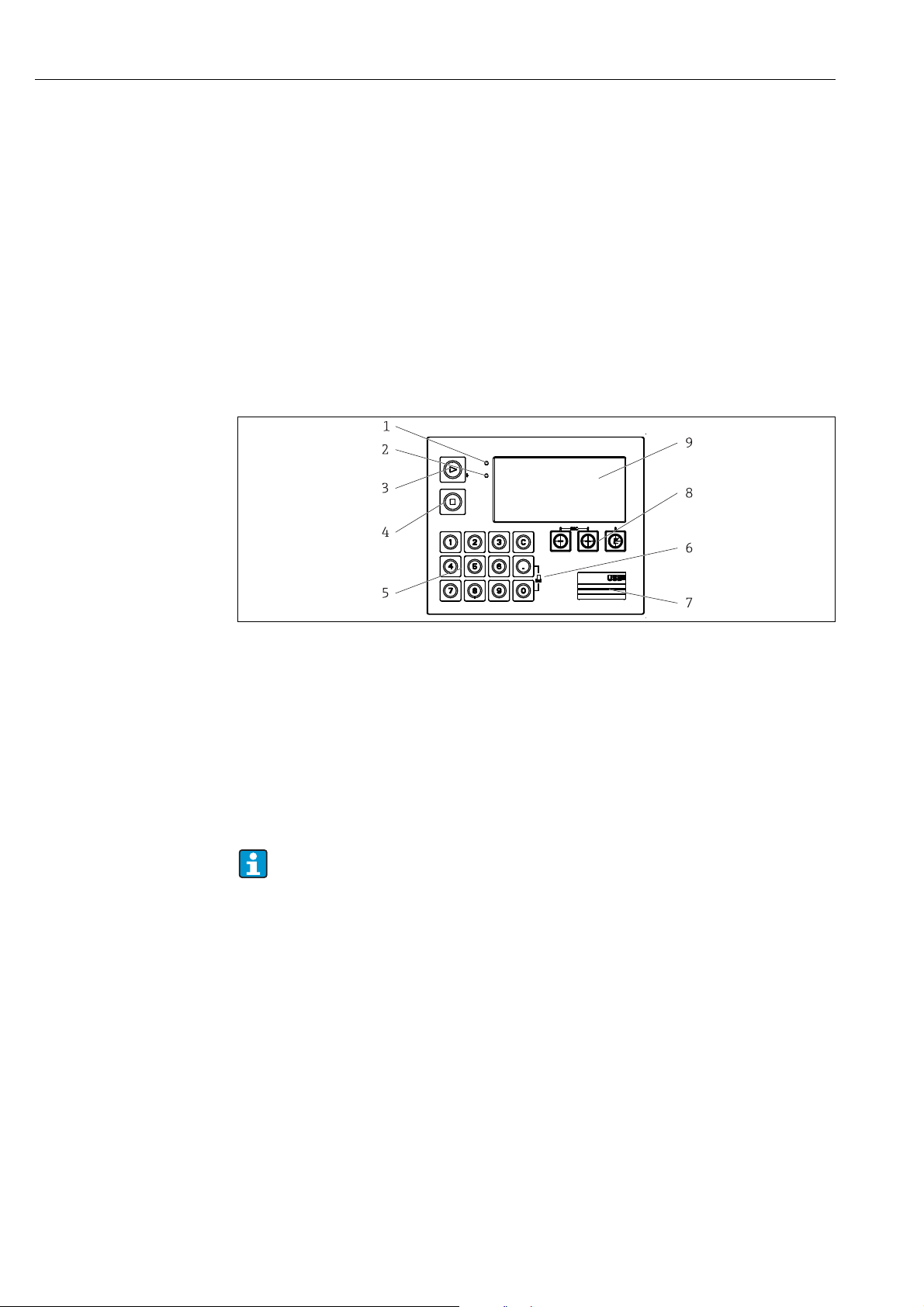

22: Display and operating elements of the batch controller

1LED green, "Operation"

2 LED red, "Fault indicator"

Function keys:

3Start

4 Stop

5 Numerical keypad

6 Start printing

Interface:

7 USB connection for configuration

Operating keys:

8-, +, E

Display:

9160 x80 DOT matrix display

Green LED for voltage, red LED for alarm/error. Green LED is always illuminated as

soon as power is supplied to the device.

Slow flashing of the red LED (approx. 0.5 Hz): the device has been put into

bootloader mode.

Fast flashing of the red LED (approx. 2 Hz): in normal operation: maintenance

required. During firmware update: data transmission active.

Red LED illuminated constantly: device error.

5.2.1 Operating elements

a0014276

3 operating keys, "-", "+", "E".

Esc/back function: press "-" and "+" simultaneously.

Enter/confirm entry: press "E"

22 Endress+Hauser

Page 23

Batch Controller RA33 Operation

14 function keys:

Start/stop function: Pressing the "Start" button starts a batching operation. Press the "Stop"

button once to pause the batching operation currently in progress. Press "Stop" a second time

to abort the batch. Pressing start again restarts the batch cycle.

C function: Press "C" when batching is stopped to reset the counters on the display to their

original values.

Print function: Press "0" and "." simultaneously to print out the last batch cycle. The "RS232

printer interface" feature must be purchased to be able to use this function.

Locking switch

a0015168

23: Locking switch

1 Locking switch on the back of the housing cover

5.2.2 Function for entering a value for the preset counter

A value for the preset counter can be entered any time. This value can either be entered in

the Display menu, or by pressing one of the keys 0-9 or period. It does not matter whether a

batching process is currently active when you enter the value. The new preset counter value

is used when the next batching process is started.

If the preset counter is part of a display group, the preset counter value which is valid

for the current batch is always displayed. If the value is changed when the batching

process is stopped, the new value appears immediately on the display. However, if

the value is changed during an active batching operation, the old value of the preset

counter, which still applies for the current batch run, is displayed until this batching

operation is finished. The new value, which is valid for the next batching operation,

is displayed directly afterwards.

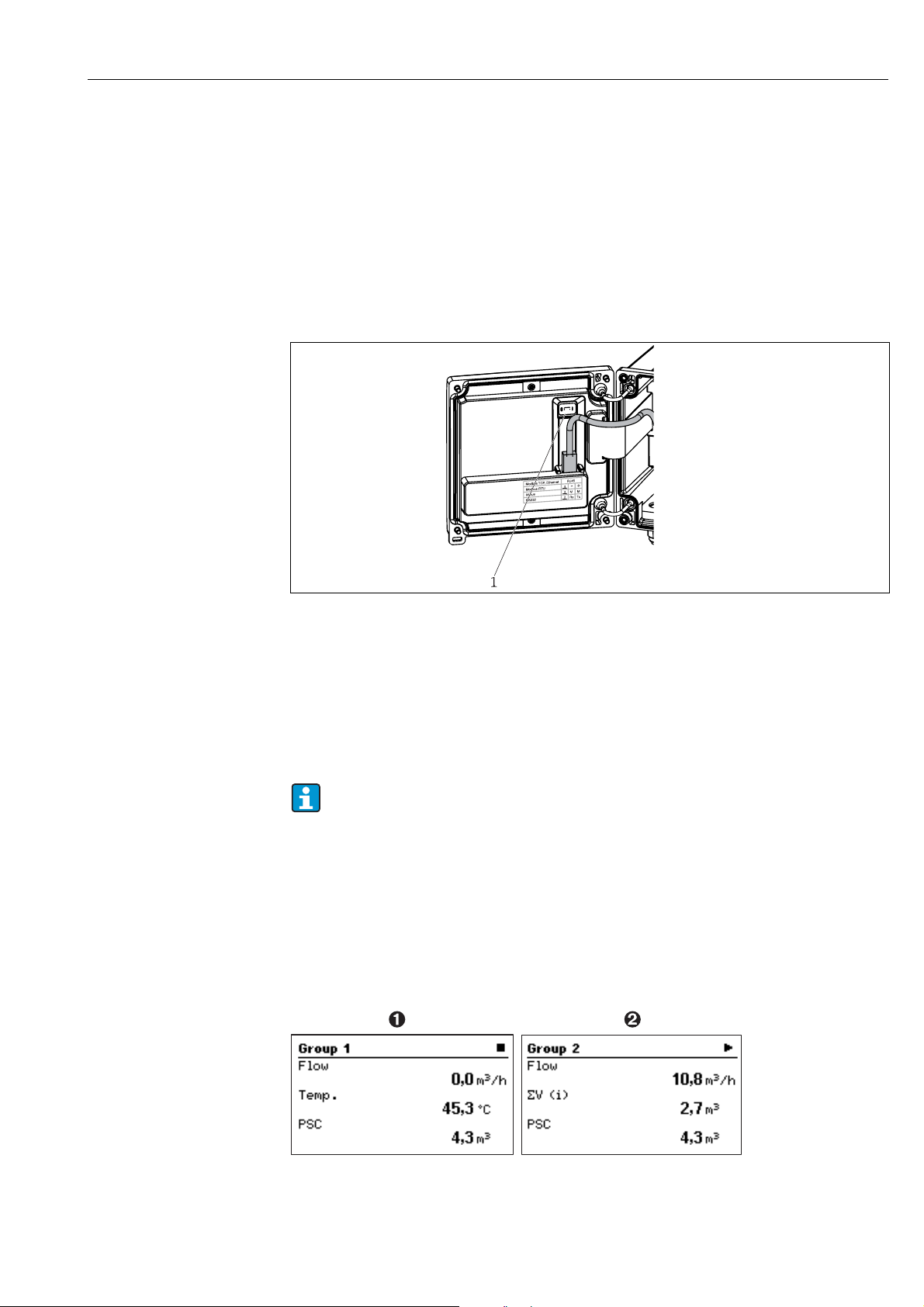

5.2.3 Display

a0014551

24: Display of the batch controller (example)

1: Display group 1: no batch active. Flow, temperature, preset counter

2: Display group 2: batch active. Flow, volume counter, preset counter

Endress+Hauser 23

Page 24

Operation Batch Controller RA33

A list of the icons is provided in the Appendix, ä 79.

5.2.4 "FieldCare Device Setup" operating software

For configuring the device using the FieldCare Device Setup software, connect the device to

your computer via the USB interface.

Establishing a connection

Proceed as follows:

1. Start FieldCare.

2. Connect the device to the computer via USB.

3. Generate project via File/New.

4. Select communication DTM (CDI Communication USB).

5. Add Rx33.

6. Click "Establish connection".

7. Start online configuration.

Carry out the rest of the configuration of the device according to these Operating

Instructions for the device. The entire Setup menu, i.e. all parameters listed in these

Operating Instructions, is also included in the FieldCare Device Setup.

During configuration with FieldCare, the device can enter undefined states! This can

result in undefined switching of outputs and relays.

24 Endress+Hauser

Page 25

Batch Controller RA33 Operation

5.3 Operating matrix

For a complete overview of the operating matrix including all configurable parameters,

ä 65.

Language Drop-down list with all available operating languages. Select the

Display/operation menu • Select the group for display (automatic change or fixed display

Setup menu In this Setup, you can configure the parameters for quick

language of the device.

group)

• Setting for the display brightness and contrast

• Display the stored analyses and batch reports

• Enter a value for the preset counter

• Recipe selection

commissioning of the device. Advanced setup includes all important

parameters for configuring the instrument function.

•Units

•Signal type

• Pulse value, value (for pulse signal

type) or

• Start of measuring range (for current

signal type)

• End of measuring range (for current

signal type)

•Unit

•Counter unit

• Date and time

• Advanced setup (settings that are not essential for basic

operation of the device)

Special settings can be configured via "Expert".

Parameters for

quick commissioning

Diagnostics menu Device information and service functions for a swift device check.

• Diagnostic messages and list

• Event logbook

• Device information

•Simulation

• Measured values, outputs

Expert menu The Expert menu offers access to all operating options of the device,

including fine tuning and service functions.

• Jump directly to parameters via Direct Access (only on the device)

• Service code for displaying service parameters (via PC operating

software only)

•System (settings)

•Inputs

•Outputs

•Application

•Diagnostics

Endress+Hauser 25

Page 26

Commissioning Batch Controller RA33

6 Commissioning

Make sure that all post-connection checks have been carried out before you commission

your device:

• See 'post-installation check', ä 14

• Checklist for 'post-connection check’, ä 21

After the operating voltage is applied, the display and the green LED are illuminated. The

device is now ready to operate and can be configured via the keys or the "FieldCare Device

Setup" parameter configuration software ( ä 24).

Remove the protective foil from the display, as otherwise legibility is impaired.

6.1 Quick commissioning/make it run

For quick commissioning of the "standard" batch controller application, you only have to

enter a few operating parameters in the menu Setup.

Prerequisites for quick commissioning:

• RTD temperature sensor, 4-wire direct connection

Menu/setup

→ Units: Select unit type (SI/US)

→ Signal type: Select the signal type for flow (pulse or current)

→ Unit: Select the flow unit

3

→ Counter unit: Specify the unit for the flow counter, e.g. m

→ Pulse value, value: Enter the unit and value for the pulse value of the flow transmitter

(for "pulse" signal type)

→ Meas. range start and Meas. range end (for "current" signal type)

→ Date/time: Set the date and time

The device is now operational and ready to control batching.

You can configure device functions, such as data logging, tariff function, bus connection and

the scaling of current inputs for flow or temperature, in the "Advanced setup" menu.

, kg

6.2 Applications

The device is suitable for the automatic control of slow batch processes with a

duration of longer than 10 seconds.

The following is an explanation of the application possibilities, including brief operating

instructions for the respective device settings.

• Batch controller with flow measurement and 1-stage batching, ä 27

• Batch controller with flow measurement and 2-stage batching, ä 28

• Batch controller with API temperature compensation, ä 29

• Batch controller with API temperature/density compensation, ä 30

• Batch controller with mass calculation, ä 31

• Batch controller with volume calculation, ä 32

•Manual batching, ä 33

26 Endress+Hauser

Page 27

Batch Controller RA33 Commissioning

E

Storage

Tank

Batch controller

Flow meter

Valve

Push

button

6.2.1 Batch controller with flow measurement and 1-stage batching

This application describes the standard application of the batch controller RA33. It is

presented as a metering instrument in this application. The flow is measured and the valve

is controlled in such a way that the specified quantity of medium is batched precisely.

a0014354-EN

25: Batch controller with flow measurement and 1-stage batching

Input signals:

Flow, (pulse input or current input)

Output signals:

Valve control (relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Valve control: Set the choice of filling stages to 1-stage. Assign the selected output to

control the filling stage.

c. Preset counter: Before starting a batch for the first time, a value must be entered for the

preset counter ( ä 23). Otherwise batching cannot commence. The preset counter

defines the quantity of medium which the Batch Controller RA33 batches as precisely

as possible. The last preset counter value to be used is stored in the device and applied

for new batching operations until the value is changed.

d. After-run correction: The first time the automatic after-run correction function of the

Batch Controller RA33 is used, the controller first has to learn what the after-run

quantity is. The after-run quantity is the volume of medium that still flows between the

time the control output switches to the time no more flow is recorded. The after-run

quantity thus depends on the switching delay and valve closing time. The batch

controller tries to correct the switch output by this amount to ensure that the batching

result is as accurate as possible.

To keep excess amounts to a minimum during these initial runs, it is advisable to enter

a value for the manual after-run quantity and to teach the device with smaller test

quantities as medium overflow can be expected.

Display variables:

Preset counter, batch counter, flow, daily, monthly and annual counters and totalizer for

batched quantity, number of batches.

Endress+Hauser 27

Page 28

Commissioning Batch Controller RA33

E

Storage

Tank

Batch controller

Flow meter

Pump

Valves

6.2.2 Batch controller with flow measurement and 2-stage batching

This application describes the standard application of the batch controller. It describes twostage batching with two valves. This application uses one valve with a higher rate of flow and

another valve with a lower rate of flow to dose the medium. The valve with the higher rate

of flow is used for fast filling and is closed earlier so that the device can then dose more

precisely with the second valve.

a0014353-EN

26: Batch controller with flow measurement and 2-stage batching

Input signals:

Flow, (pulse input or current input)

Output signals:

Valve control (relay or open collector)

Pump control (analog output, relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Valve control: Set the choice of filling stages to 2-stage. Assign the selected outputs to

control the filling stages.

Display variables:

Preset counter, batch counter, flow, daily, monthly and annual counters and totalizer for

batched quantity, number of batches.

Miscellaneous notes:

• Before starting a batch for the first time, a value must be entered for the preset counter

( ä 23). Otherwise batching cannot commence. Afterwards, the last preset counter

value to be used is stored in the device.

• To ensure that the after-run quantity is kept to a minimum during the first run even if the

automatic after-run correction function is activated (this function requires an initial

measurement), it is advisable to enter a measured value as the manual after-run

correction value, or to teach the device gradually with a small test quantity.

28 Endress+Hauser

Page 29

Batch Controller RA33 Commissioning

E

Storage

Tank

Batch controller

Flow meter

Pump

Valves

Temperature

sensor

6.2.3 Batch controller with API temperature compensation

This application describes the use of the batch controller with mineral oils and volume

correction. The volume can be corrected by simply measuring the temperature, or by

measuring the temperature and density. The first application example describes the

measurement process using temperature compensation only. The volume can be corrected

with any flow unit (volume flow or mass flow).

a0014370-EN

27: Batch controller with flow measurement, temperature compensation and 2-stage batching

Input signals:

Flow, (pulse input or current input)

Temperature (RTD or current input)

Output signals:

Valve control (relay or open collector)

Pump control (analog output, relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Temperature input: Select the RTD type and temperature range or enter temperature

measuring range for the 4-20 mA input.

c. Select the product group of the mineral oil.

d. Select the type of density measurement: Since the density is not measured, the

"Operating density" parameter has to be set to "Calculated".

e. Select the reference density: The reference conditions of the corrected volume must be

assigned for the reference density. Here, the volumes at 15 °C, 20 °C and 60 °F can be

selected.

f. Reference density value: In addition to the reference operating conditions, the actual

density value of the medium under the selected reference operating conditions must be

specified.

g. Pressure: If the relative pressure differs from the ambient pressure, you must enter a

pressure at which the flow is measured.

h. Valve control: Set the choice of filling stages to 2-stage. Assign the selected output to

control the filling stage.

Display variables:

Preset counter (corrected volume), batch counter (corrected volume), volume flow, daily,

monthly and annual counters and totalizer for batched quantity, number of batches.

Endress+Hauser 29

Page 30

Commissioning Batch Controller RA33

E

Storage

Tank

Batch controller

Flow meter

Pump

Valves

Temperature

sensor

Density

sensor

Miscellaneous notes:

• The pressure is entered relative to the ambient pressure. Since the pressure only has a

marginal effect on liquids, for the sake of efficiency it suffices to specify a value instead of

measuring the pressure.

6.2.4 Batch controller with API temperature/density compensation

This application describes the use of the batch controller with mineral oils and volume

correction. The second volume correction application describes the process for correcting the

volume by measuring both the temperature and the density. The volume can be corrected

with any flow unit (volume flow or mass flow).

28: Batch controller with flow measurement, temperature compensation, density compensation and 2-stage batching

Input signals:

Flow, (pulse input or current input)

Temperature (RTD or current input)

Density (current input)

Output signals:

Valve control (relay or open collector)

Pump control (analog output, relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Temperature input: Select the RTD type and temperature range or enter temperature

c. Select the product group of the mineral oil.

d. Select the type of density measurement: The "Operating density" is set to "Measured"

e. Select the reference density: The reference conditions of the corrected volume must be

f. Valve control: Set the choice of filling stages to 2-stage. Assign the selected output to

Display variables:

Preset counter (corrected volume), batch counter (corrected volume), volume flow, daily,

monthly and annual counters and totalizer for batched quantity, number of batches.

a0014372-EN

measuring range for the 4-20 mA input.

since a density meter is used in this application example.

assigned for the reference density. Here, the volumes at 15 °C, 20 °C and 60 °F can be

selected.

control the filling stage.

30 Endress+Hauser

Page 31

Batch Controller RA33 Commissioning

E

Storage

Tank

Batch controller

Flow meter

Pump

Valves

Density

sensor

6.2.5 Batch controller with mass calculation

In addition to performing volume correction for mineral oils, the mass of any medium can

also be calculated. If this function is enabled, then the volume is converted to mass and the

counter and preset counter are also available in the selected mass units.

a0014373-EN

29: Batch controller with mass calculation

Input signals:

Flow, (pulse input or current input)

Density (current input)

Output signals:

Valve control (relay or open collector)

Pump control (analog output, relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Set the product group to "User-defined".

c. Select the type of density measurement: The "Operating density" is set to "Measured"

since a density meter is used in this application example.

d. Set the "The result is" parameter to "Mass" to enable the calculation of the mass.

e. Valve control: Set the choice of filling stages to 2-stage. Assign the selected output to

control the filling stage.

Display variables:

Preset counter (mass), batch counter (mass), volume flow, daily, monthly and annual

counters and totalizer for batched quantity, number of batches.

Endress+Hauser 31

Page 32

Commissioning Batch Controller RA33

E

Storage

Tank

Batch controller

Flow meter

Pump

Valves

Density

sensor

6.2.6 Batch controller with volume calculation

If a flow sensor is used for mass flow measurement, it is possible to calculate the volume

batched. This requires a density measurement (alternatively: a fixed density value is

specified or the temperature is measured and this information is used to calculate the

operating density internally on the basis of the reference conditions, reference density and

expansion coefficient). If this function is enabled, then the mass is converted to volume and

the counter and preset counter are also available in the selected volume units.

a0014373-EN

30: Batch controller with volume calculation

Input signals:

Flow, (pulse input or current input)

Density (current input)

Output signals:

Valve control (relay or open collector)

Pump control (analog output, relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Set the product group to "User-defined".

c. Select the type of density measurement: The "Operating density" is set to "Measured"

since a density meter is used in this application example.

d. Set the "The result is" parameter to "Volume" to enable the calculation of the volume.

e. Valve control: Set the choice of filling stages to 2-stage. Assign the selected output to

control the filling stage.

Display variables:

Preset counter (volume), batch counter (volume), mass flow, daily, monthly and annual

counters and totalizer for batched quantity, number of batches.

32 Endress+Hauser

Page 33

Batch Controller RA33 Commissioning

E

Storage

Tank

Batch controller

Flow meter

Valve

Push

button

6.2.7 Manual batching

In addition to batching based on a value entered for the preset counter beforehand, the

device can also be used as a volume counter or mass counter (depending on the type of flow

sensor) with manual control. This allows batching to be started and stopped locally on sight,

for example, or via the stop signal of an external signal transmitter.

a0014354-EN

31: Manual batching with the batch controller

Input signals:

Flow, (pulse input or current input)

Remote control (digital input)

Output signals:

Valve control (relay or open collector)

Required settings:

a. Flow input: Enter pulse value or measuring range of the 0/4 to 20 mA input.

b. Set the batch controller to "Manual" mode.

c. The digital inputs must be assigned a Start/stop function for remote control.

d. Valve control: Set the choice of filling stages to 1-stage. Assign the selected output to

control the filling stage.

Display variables:

Preset counter, batch counter, flow, daily, monthly and annual counters and totalizer for

batched quantity/mass, number of batches.

Endress+Hauser 33

Page 34

Commissioning Batch Controller RA33

6.3 Configuring the basic parameters/general device

functions

•Inputs ( ä 34)

•Outputs ( ä 35)

• Application ( ä 37)

• Data logging ( ä 38)

• Access protection ( ä 39)

• Logbooks ( ä 39)

• Communication/fieldbuses ( ä 40)

6.3.1 Inputs

Flow pulse transmitter

The pulse input can process different current and voltage pulses. The software can switch to

different frequency ranges:

• Pulses and frequencies up to 12.5 kHz

• Pulses and frequencies up to 25 Hz (for bounce contacts, max. bounce time: 5 ms)

The input for voltage pulses and contact sensors is divided into different types according to

EN1434 and provides a supply for switching contacts.

Voltage pulses and transmitters

according to Class IB and IC (low

switching thresholds, small

currents)

Transmitters to Class ID and IE for

higher currents and power supplies

1 V corresponds to Low level

2 V corresponds to High level

U max 30 V, U no-load: 3 to 6 V

1.2 mA corresponds to High level

2.1 mA corresponds to Low level

U no-load: 7…9 V

Floating contacts, reed transmitters

For all signal types, the pulse value of the flow transmitter has to be entered.

The calculation of the current value for the volume flow is floating; therefore, it decreases

continuously with slow pulses. After 100 seconds or if the value is less than the low flow cut

off, the flow value becomes 0.

The batching and statistics counters are summed up from the individual pulse values. The

current flow can also be calculated from the counters so that it can be shown on the display.

The required flow unit must first be selected in the flow settings.

Flow current signal

For flow transmitters with current signal output, the flow measuring range is scaled in

Advanced setup ( ä 66).

Adjustment/calibration of the current input

To adjust the current inputs, a two-point calibration can be carried out in the Expert menu,

for example to correct the long-term drift of the analog input.

3

Example: flow signal is 4 mA (0 m

3

enter the set point 0 m

/h, actual value: 0.2 m3/h, the device "learns" a new 4 mA value. The

/h), but the device displays 4.01 mA (0.2 m3/h). If you

set point must always be within the measuring range.

Low flow cut off

Volume flows below the configured low flow cut off value are evaluated as zero (not

measured on the counter). This is used to suppress measured values, for example at the

lower limit of the measuring range.

For the pulse input, the minimum permitted frequency can be determined from the low flow

3

cut off. Example: low flow cut off 3.6 m

/h (1 l/s), pulse value of the transmitter: 0.1 liter.

34 Endress+Hauser

Page 35

Batch Controller RA33 Commissioning

1/0.1 = 10 Hz. This means that after 10 seconds the value "0" is displayed for volume flow

and power.

For analog signals, two variants of low flow cut off exist:

3

• Positive flow measuring range, e.g. 0 to 100 m

/h: values less than the low flow cut off

value are valued at zero.

3

• Negative start of measuring range (bidirectional measurement), e.g. -50 to 50 m

/h:

values around the zero point (+/- low flow cut off value) are valued at zero.

Temperature (optional)

To measure the temperature, RTD sensors can be connected directly or via transmitter (4 to

20 mA). For the direct connection, sensors of types PT 100/500/1000 can be used. For PT

100 sensors, users can choose from different measuring ranges for high and low

temperature differences to ensure maximum accuracy (menu Setup→Advanced

setup→Inputs→Temperature→Range).

The measuring range can be scaled individually if a current signal is used (menu

Setup→Advanced setup→Inputs→Temperature).

Refer also to Compensation, ä 45.

Density (optional)

To measure the density, a density sensor can be connected to the current input marked

"Density" via 0/4 to 20 mA. In addition a fixed density value can be set. This is suitable for

media whose composition is known.

Refer also to Compensation, ä 45.

Digital inputs

Two digital inputs are available: Depending on the options of the device, the following

functions can be controlled via the digital inputs:

Function Description

Batch active (high) A batch is started when there is a switch from low→high. It runs until either the

value on the preset counter is reached or the signal drops from high→low. An active

batch is aborted and ended if the signal drops. If the value on the preset counter is

reached and a new batch should start, a switch must first take place from high→low

so that another change from low→high can kickstart the new batch run.

Batch start (edge) A batch is started when the edge changes from low→high. The function has exactly

the same effect as pressing the button locally.

Batch stop (edge) A batch is paused when the edge changes from low→high and aborted and then

Reset batch no. The batch number, which is automatically increased, is reset to the start value

Time synchronization Time synchronization is triggered by an edge change from low→high.

Status The device remains operational as long as there is a high signal (status=OK). Once

stopped with the next change from low→high. The function has exactly the same

effect as pressing the button locally.

specified in Setup when the edge changes from low→high.

the signal drops to low, any batching operation that is currently active is stopped and

the device is locked so that it cannot restart. The device remains locked until there is

a high signal again, which indicates that the system is operational.

6.3.2 Outputs

Relay

The two relays can be switched to control the filling stages and to signal fault messages.

They can be assigned to the relevant filling stages of the batch under Setup → Advanced

setup → Application → Batch settings → Switches fill phase 1/2.

Endress+Hauser 35

Page 36

Commissioning Batch Controller RA33

The service life of the relays is specified as 105 switching cycles at least. In the case

of intensive use, it is recommended to use the open collector outputs for batch

control.

Open collector outputs (optional)

The open collector outputs can be used as status and pulse outputs. If used as status outputs,

they serve to control the filling stages of the batch and to signal fault messages. Counters

and the signal to indicate the end of a batch can be output as pulses.

Universal output - current and active pulse output (optional)

The universal output can be used as a pulse output or analog output. It can output the volume

flow or the volume/mass counter.

Furthermore, the progress of the batch can be output in linear or curve form.

Batch progress

When the progress of the batch is displayed, the output value starts at 20 mA at the

beginning of the batch and moves down linearly until it reaches the lower limit of the current

output 0/4 mA at the end of the batch. The output's lower range limit is issued at the current

output if a batch is not active.

a0014340

32: Batch progress diagram

0 Batch starts at 0%

100 Quantity reached at 100%

Curve

The current value at the output is 0/4 mA if batching has stopped. The output adopts the

current defined in "Current start value" directly after a batching operation starts. The current

value then moves upwards linearly and reaches the 20 mA current value at a percentage

value of the entire batch quantity, "Start max.", specified in Setup. The current value at the

current output then remains 20 mA until the percentage value of the batch quantity

specified in "Stop max." is reached. The current value is then adjusted downwards linearly to

the output value. The output's lower range limit is issued at the current output if a batch is

not active.

a0014341

33: Curve diagram

0 Batch start

10 Start max.

90 Stop max.

100 Quantity reached

36 Endress+Hauser

Page 37

Batch Controller RA33 Commissioning

6.3.3 Application

Batch settings

All batching and control-related settings for batching must be made in Batch settings.

Batch mode

The main setting for batching functionality is to select the batch mode. It consists of the

following modes: "Standard", "Automatic restart" and "Manual".

Function Description

Standard "Standard" mode: A value must be entered for the preset counter after

commissioning. This value is then used for all batch cycles until it is changed. The

value for the preset counter can be changed during an active batch or when batching

has stopped. This preset counter value is then used when the next new batch is

started.

A batch can be started via control output or by pressing a button. It continues until

the value on the preset counter is reached or if the batch is first paused by means of a

stop command (button or control input). From this paused state, the batch can either

be restarted by means of a start command or aborted entirely by means of another

stop command.

Automatic restart "Automatic restart" functions like Standard mode with one addition, however; a batch

sequence is started which is restarted after a configurable restart delay time. This

continues until the batch sequence is paused and ended.

Manual In manual mode, a preset counter is not required. The batch is started and stopped by

pressing a button on the device or via the control input.

Counting direction

The counting direction is another basic setting. It is only relevant for showing values on the

display and refers to the direction of counting in which the preset counter is displayed. The

options for selection are forwards, in which case a totalizer is displayed, or backwards,

whereby the remaining quantity of the current batch is displayed.

Filling stages

The device has options for 1-stage and 2-stage batching. The main valve is for the first stage.

It supplies a lower flow rate and is opened at the beginning of the batch. It is used for

precision dosing at the end of the batch. The second filling stage, with a higher flow rate, is

also opened after a specified delay time so that the required batching quantity is achieved

faster. This stage is closed when a remaining pre-stop quantity is reached. The delay time

and pre-stop quantity must also be specified in the batch settings.

Fixed and automatic after-run correction

It is recommended to use after-run correction due to system response times. The command

to close the valves is thus given earlier to compensate for the response time. This enables

maximum batching accuracy.

Fixed after-run correction value is the basis. A fixed value can be specified and flow is

stopped in advance by this value.

Automatic after-run correction can be enabled in addition to fixed. It calculates the new

correction value based on the actual measured error of the last batch runs. This ensures

precise batching results permanently.

To ensure that the after-run quantity is kept to a minimum during the first run even

if the automatic after-run correction function is activated (this function requires an

initial measurement), it is advisable to enter a measured value as the manual afterrun correction value, or to teach the device gradually with a small test quantity.

Endress+Hauser 37

Page 38

Commissioning Batch Controller RA33

Maximum preset counter

Inputting the maximum preset counter value permitted reduces the risk of incorrect entries.

During operation, if a preset counter value is entered that is greater than the maximum

permitted value, the batch is not started and a message is output.

Batch information

All parameters for displaying and identifying stored batches are saved in batch information.

Batches are identified by means of a user-defined name and a batch number, which is

automatically incremented after each batch cycle. The start value of the batch number can

also be preset as well as the current number reset to this value.

Display groups

Display settings

Under Application/Grouping in the Setup menu, select which process values are shown in

the display. For this purpose, 6 display groups are available. A group can be assigned up to

3 values. For a three-line display, the values are displayed in a smaller font size. A userdefined name can be assigned to each group (max. 10 characters). This name is displayed in

the header. When the device is delivered, the display groups are preconfigured according to

the following table.

Display mode

The display mode is selected in the Display/operation menu. You configure the brightness,

contrast and the switching mode of the display, i.e. whether switching between the display

groups takes place automatically or by pressing a button. In this menu, you can also call up

the current values for data recording (batch reports, day, month and annual counter and

totalizer) under "stored values". (For details, refer to Data logging, ä 38)

No. of Sums/counter overflow

Counters are limited to max. 8 digits before the decimal point (for counters that require

signs, to 7 characters). If the counter reading exceeds this value (overflows), it is reset to

zero. The number of overflows for each counter is recorded on overflow counters. A counter

overflow is shown on the display with the "^" icon. The number of overflows can be called up

in the Display/operat. → Stored values menu.

Units

The units for scaling and displaying the process variables are configured in the respective

submenus (e.g. the unit for displaying the temperature is configured under Inputs/

Temperature). To make device setting easier, the unit system is selected at the beginning of

device commissioning.

•EU: SI units

• USA: imperial units

This setting sets the units in the individual submenus to a certain value (default), e.g. SI: m³/

h, °C, kWh. If a unit is converted subsequently, no automatic conversion of the associated

(scaled) value takes place! Conversion of the units, ä 81.

6.3.4 Data logging

The device stores relevant measured values and counter data at defined times.

Daily, monthly and annually, an analysis is stored with the number of batch cycles, error-free

batch cycles and batched volume for this time period.

38 Endress+Hauser

Page 39

Batch Controller RA33 Commissioning

The individual batch cycles are stored with the following details: date, time, batch name,

batch number, preset counter and volume counter. The device provides permanently reliable

data logging, which guarantees the security of data even after a power failure.

Current day, monthly and annual counters can be called up in the Display/operat → Stored

values menu. In addition the totalizer and the counter for the current batch can be shown as

a display value (can be allocated to a display group). The entire data archive, i.e. all stored

values, can be read out using the "Field Data Manager Software" only. Specifically, the

following data are stored in the device:

Analysis Calculation

Batch • Date, time

Daily, monthly and annual analysis • Volume counter for the time period

•Batch name

•Batch number

• Preset counter

• Volume counter

•Number of batches completed

• Number of error-free batches completed

General notes for data logging

The time of data logging (start time of the logging intervals) can be configured and/or

synchronized via the time of day.

The current counter can be reset to zero via setup. The archived values (completed

evaluations) can no longer be changed! To clear these out, the entire measured value

memory must be deleted.

Storage capacity

The device should be read out regularly using the "Field Data Manager Software" to ensure

seamless data logging. Depending on the storage depth, the counters are overwritten after

a certain time, see the table below.

Data Number

Batches Min. 1000

Events Min. 1500 (with an average of

40 characters)

Statistics day/month/year Min. 800/750/50

6.3.5 Access protection

The device can be locked to protect it against tampering by means of a user code or device

hardware switch ( ä 23).

Protection using code

The entire local operation can be protected by a 4-digit code (default is 0000, i.e. no

protection). If the device is not operated for 600s, it is locked again automatically.

It is still possible to enter a value for the preset counter.

6.3.6 Logbooks

Changes to the setup are recorded in entries in the event logbook.

Event logbook

The event logbook stores events such as alarms, setup changes etc. with date and time. The

memory is sufficient for at least 1600 messages (however, depending on the text length, it

Endress+Hauser 39

Page 40

Commissioning Batch Controller RA33

is possible for more messages to be stored). If the memory is full, the oldest messages are

overwritten. The logbook can be read out via the FDM data management software or on the

device. To exit the logbook quickly, press the +/- keys simultaneously.

6.3.7 Communication/fieldbuses

General notes

The device has (optional) fieldbus interfaces for reading out all process values. Values can be

written to the device only as part of configuration of the device (via FieldCare operating

software and USB or Ethernet interface) only. Process values such as flow cannot be

transmitted to the device via the bus interfaces.

Batch commands can be sent to the device via Modbus, for details, refer to "Modbus RTU".

Depending on the bus system, alarms or faults are displayed as part of data transmission

(e.g. status byte).

The process values are transmitted in the units that are also used for display on the device.

Only the counter readings of the most recently completed storage period (day, month, year)

can be read out of the memory.

For large counter readings, the places after the decimal point are truncated (e.g.

1234567.1234 → 1234567 or 234567.1234 → 234567.1).

The device can be read out via the following interfaces.

• Modbus RTU

• Ethernet/Modbus TCP

Modbus RTU/(TCP/IP)

The device can be connected to a Modbus system via RS485 or Ethernet interface. The

general settings for the Ethernet connection are made in the Setup / Advanced setup /

System / Ethernet menu or Expert / System / Ethernet menu, ä 42. Modbus

communication is configured in Setup / Advanced setup / System / ModBus or Expert /

System / Modbus.

Menu item RTU Ethernet

Device address: 1 to 247 IP address: manual or automatic

Baudrate: 2400/4800/9600/19200/38400 -

Parity: Even/Odd/None -

Port 502

Reg Register Register

Value Value to be transmitted Value to be transmitted

Transmission of values

The actual Modbus TCP protocol is between Layers 5 and 6 in the ISO/OSI Model.

To transmit a value, 3 registers of 2 bytes each are used (2 bytes status + 4-byte float). In the

setup, you can configure which register is to be written with which value. The most

important/most common values are already preconfigured.

Register 000 Status of first measured value (16-bit integer, high byte first)

Register 001 to 002 First measured value (32-bit float, high byte first)

Validity and limit value information are encoded in the status byte.

16 654321

not used 0000ok

0001Open circuit

40 Endress+Hauser

Page 41

Batch Controller RA33 Commissioning

0010Over range

0 0 1 1 Under range

0 1 0 0 Invalid measured value

0 1 1 0 Replacement value

0 1 1 1 Sensor error

1 Lower limit value violated

1 Upper limit value violated

1 Counter overflow

On receipt of the request from the master, the required start register and the number of

registers to be read are sent to the batch controller. Because a measured value always

requires three registers, the start register and the number must be divisible by 3.

From the master to batch controller:

ga fk r1 r0 a1 a0 c1 c2

ga Slave address (1 to 247 )

fk Function, always 03

r1 r0 Start register (high byte first)

a1 a0 Number of registers (high byte first)

c0 c1 CRC checksum (low byte first)

Response from the batch controller for successful request:

ga fk az s1 s0 w3 w2 w1 w0 s1 s0 w3 w2 w1 w0 . . . . . s1 s0 w3 w2 w1 w0 c1 c0

ga Device address

fk Function, always 03

az Number of bytes of all subsequent measured values

s1 s0 Status of first measured value (16-bit integer, high byte first)

w3 w2 w1 w0 First measured value in 32-bit float format, high byte first

s1 s0 Status of second measured value (16-bit integer, high byte first)

w3 w2 w1 w0 Second measured value (32-bit float, high byte first)

s1 s0 Status of last measured value (16-bit integer, high byte first)

w3 w2 w1 w0 Last measured value (32-bit float, high byte first)

c0 c1 CRC checksum, 16-bit (low byte first)

Response from Batch Controller for unsuccessful request:

ga fk fc c0 c1

ga Device address

fk Requested function + 80hex

fc Error code

c0 c1 CRC checksum, 16-bit (low byte first)

Error code:

01 : Function unknown

02 : Start register invalid

03 : Number of registers to be read invalid

For checksum or parity errors in the request from the master, the batch controller does not

respond.

For large counter readings, the decimal points are truncated.

Endress+Hauser 41

Page 42

Commissioning Batch Controller RA33

Transmission of batch commands to the batch controller/Reading the batch status

Batch commands can be transmitted to the batch controller and the batch status read via

Modbus. The following registers are available for this purpose:

Protocol

address

(base 0)

5000 5001 Set preset

5002 5003 Set start/stop UINT16 If a 1 is written, a batch is started.

52005201Read batch

PLC

address

(base 1)

Function Data type Description

FLOAT A new preset counter is set when these registers are

counter

UINT16 This register provides the status of the batch:

status

written to.

Modbus function 16 (Write Registers)

If a 0 is written, a batch is stopped.

Modbus functions 16 (Write Registers), 06 (Write

Single Register).

0: Batch stopped

1: Batch active

2: Batch paused

Modbus functions 16 (Write Registers), 06 (Write

Single Register).

The byte order must be followed according to the setting in the batch controller.

Ethernet/Web server (TCP/IP)

Configuration in the menu Setup → Advanced setup → System → Ethernet or

Expert → System → Ethernet

The IP address can be entered manually (fixed IP address) or assigned automatically via

DHCP.

The port for the data communication is set by default to 8000. The port can be changed in

the Expert menu.

The following functions are implemented:

• Data communication to PC software (Field Data Manager Software, FieldCare, OPC server)

• Web server

• Modbus TCP ( ä 40)

Up to 4 connections can be opened simultaneously, e.g. Field Data Manager software,

Modbus TCP and 2x Web server.

However, only one data connection via Port 8000 is possible.

As soon as t he m ax. num ber o f co nne cti ons is reached, new connection attempts are blocked

until an existing connection is terminated.

Web server

If the device is connected via Ethernet, you have the ability to read out the display values over

the Internet via Web server.

42 Endress+Hauser

Page 43

Batch Controller RA33 Commissioning

a0014191

34: Display values in the Web browser

Just as in the display, you can switch between the display groups in the Web server. The

measured values are updated automatically (direct via "link": off/5s/15s/30s/60s). In

addition to the measured values, status/limit value flags are also displayed.

The data can be read out via the Webserver in HTML or XML format.

When using an Internet browser, it suffices to enter the address http://<IP address> to

display the information as HTML in the browser. In addition, two versions of the XML format

are available. These versions can be integrated into additional systems as required. The two

XML versions contain all the measured values which are assigned to any group.

The decimal separator is always displayed as a period in the XML file. All times are

given in UTC. The time difference is indicated in minutes in the subsequent entry.

Version 1:

The XML file is available in ISO-8859-1 (Latin-1) encoding at the address http://<IP

address>/index.xml (alternatively: http://<IP address>/xml). However, this encoding

cannot display some special characters such as the sum sign. Strings such as digital status

information are not transmitted.

Version 2:

A UTF-8 encoded XML file can be retrieved at the address http://<IP address>/main.xml All

the measured values and the special characters can be found in this file.

The structure of the channel values in the XML file is explained below:

<device id="ID0104" tag="Flow" type="INTRN">

<v1>12.38</v1>

3

/h</u1>

<u1>m

<vstslv1>2</vstslv1>

<hlsts1>ErS</hlsts1>

<vtime>20120105-004158</vtime>

<man>Endress+Hauser</man>

<param />

</device>

Day Description

tag Channel ident.

v1 Measured value of the channel as a decimal value

u1 Unit of the measured value.

vstslv1 Status of the measured value

0 = OK, 1 = warning, 2= error

hlsts1 Error description

OK, OC = cable open circuit, Inv: invalid, ErV: error value, OR: over range, UR:

under range, ErS: error sensor

vtime Date and time

man Manufacturer

Endress+Hauser 43

Page 44

Commissioning Batch Controller RA33

Web server settings

Setup→Advanced setup→System→Ethernet→Web server→ Yes or

Expert→System→Ethernet→Web server→ Yes

Enter the address for retrieval in the Web browser: http://<IP address>

The following Web browsers are supported:

• MS Internet Explorer 6 and higher

• Mozilla Firefox 2.0 and higher

• Opera 9.x and higher

The operating language for the Web server is English. No other languages are offered.

No provision is made for authentication via ID/password.

Printer interface

The device can print a batch report directly on a connected ASCII printer via the RS232

interface.

Menu item Description

Printout You can initiate printing manually on-site if it is set to "Manual“. If it is set to

"Automatic", the configured number of printouts are additionally printed after every

batch cycle.

Baudrate Select the baudrate that is compatible with the printer.

Number of copies Use this option to specify the number of printouts for automatic printing at the end

of the batch.

Characters/line Use this option to enter the number of characters per line supported by the printer.

Number of headers Use this option to select the required number of lines for user-defined text at the

beginning of the printout.

Header line 1 to 4 Use this option to enter the free text.

Number of footers Use this option to select the required number of lines for user-defined text at the end

of the printout.

Header line 1 to 4 Use this option to enter the free text.

Blank rows at end Use this option to enter the required blank rows at the end of a printout, e.g. to allow

sufficient space for tearing off.

Print direction Use this option to select whether printing should start at the first line or the last line.

Test print Use this option to initiate a test printout.

a0014552

35: Batch controller test report

44 Endress+Hauser

Page 45

Batch Controller RA33 Commissioning

6.4 Optional device settings/special functions

•Compensation ä 45

• Batch printout ä 46

6.4.1 Compensation

Measured volumes can be corrected or converted to mass, or measured mass can be

converted to volume, using the additional compensation function. Depending on the type of

compensation, temperature and density sensors are required for this purpose.

The use of the temperature and density inputs is shown in the table below using the

measured product group (mineral oils or other) as are the expected results.

Volume flowmeter (conversion to mass / volume correction)

Product group Expected result "Operating density"

setting

User-defined Mass Measured Not required Required

Corrected volume Calculated Required Not required

Measured Not required Required

Mineral oils Corrected volume Calculated Required Not required

Measured Required Required

Temperature

sensor

Density sensor

Mass flowmeter (conversion to volume)

Product group "Operating density"

setting

User-defined - Not required Not required

Mineral oils Calculated Required Not required

Measured Required Required

Temperature

sensor

Density sensor

Volume correction via temperature measurement and/or density measurement is

possible for both product groups. The advantage of an additional density

measurement is that the system reacts to fluctuations in the medium independently.

If the correction is based on temperature measurement alone, the density value of

the medium must be checked at reference operating conditions where necessary and

adjusted.

Product group

The choice of product group determines the calculation standard at the same time. In the

case of user-defined media, a volume can be corrected or converted to mass using other

parameters. The volume is corrected in accordance with the API MPMS (Chapter 11)

standard for the following mineral oil product groups: crude oil, refined products and

lubricating oils.

Reference data

The reference condition specifies the ambient conditions at which the correction must be

calculated. The options available for selection are 15 °C, 20 °C or 60 °F.

The value that must be entered in the reference density parameter is the density of the

medium under the selected reference operating conditions. When using the density unit API°

and Gravity (G), 60 °F is automatically selected as the reference condition.