Endress+Hauser RA33 Specifications

TI00163K/09/EN/03.18

71416504

2018-12-29

Products

Solutions Services

Technical Information

RA33

Batch Controller

Batch Controller for the batching and dosing of

mass and volume

Applications

Recording and control of slow batch processes with a duration of longer than 10

seconds. Typical applications include:

• Food industry

• Chemical industry

• Pharmaceutical industry

• Oil and gas industry

Your benefits

• Swift commissioning and easy operation with plain text in language of your choice

• Valve control for single-stage and two-stage batching

• Automatic after-run correction for constant, highly accurate results

• Temperature/density compensation as per ASTM D1250-04

• Standard models are suitable for connecting and supplying all common flow

transmitters, temperature sensors and density sensors

• Detailed logging of batch reports as well as error messages, limit value violations

and changes to operating parameters

• Advanced error diagnostics for leakage, fill deviation and "no flow"

• Industry-compliant compact housing for field or wall mounting, panel mounting or

DIN rail mounting

• Remote control option to start and abort batch runs

• Daily, monthly and annual statistics on the batch run size and quantity

• Remote readout via Ethernet and fieldbuses

Function and system design

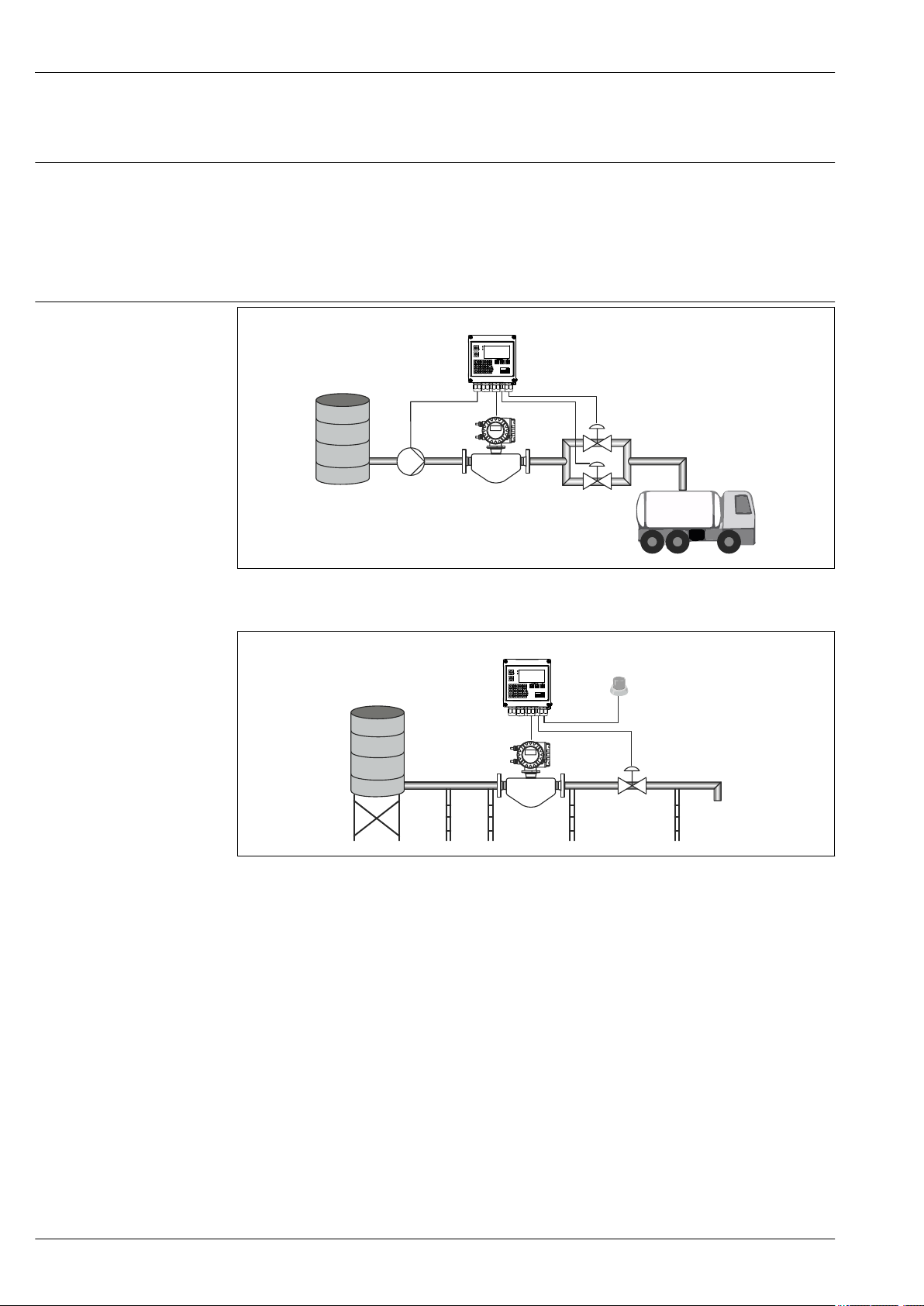

E

Storage

Tank

Batch controller

Flow meter

Pump

Valves

E

Storage

Tank

Batch controller

Flow meter

Valve

Push

button

RA33

Measuring principle

Measuring system

The Batch Controller RA33 is designed to record flow and control output signals for valves and

pumps to ensure the exact dosing of predefined batch quantities. The calculation is based on

measuring the current rate of flow and then totalizing or recording the quantity using pulses. The

measured volume can be corrected with the temperature/density compensation function. Here,

mineral oils can be corrected according to the ASTM D1250-04 standard. The volumes of other

media can be corrected using expansion coefficients, or the volume can be converted to mass by

measuring the density.

A0014353-EN

1 Application: Batch Controller RA33 with two-stage batching to fill a tank truck

2 Application: manual batching without a pump with the Batch Controller RA33

2 Endress+Hauser

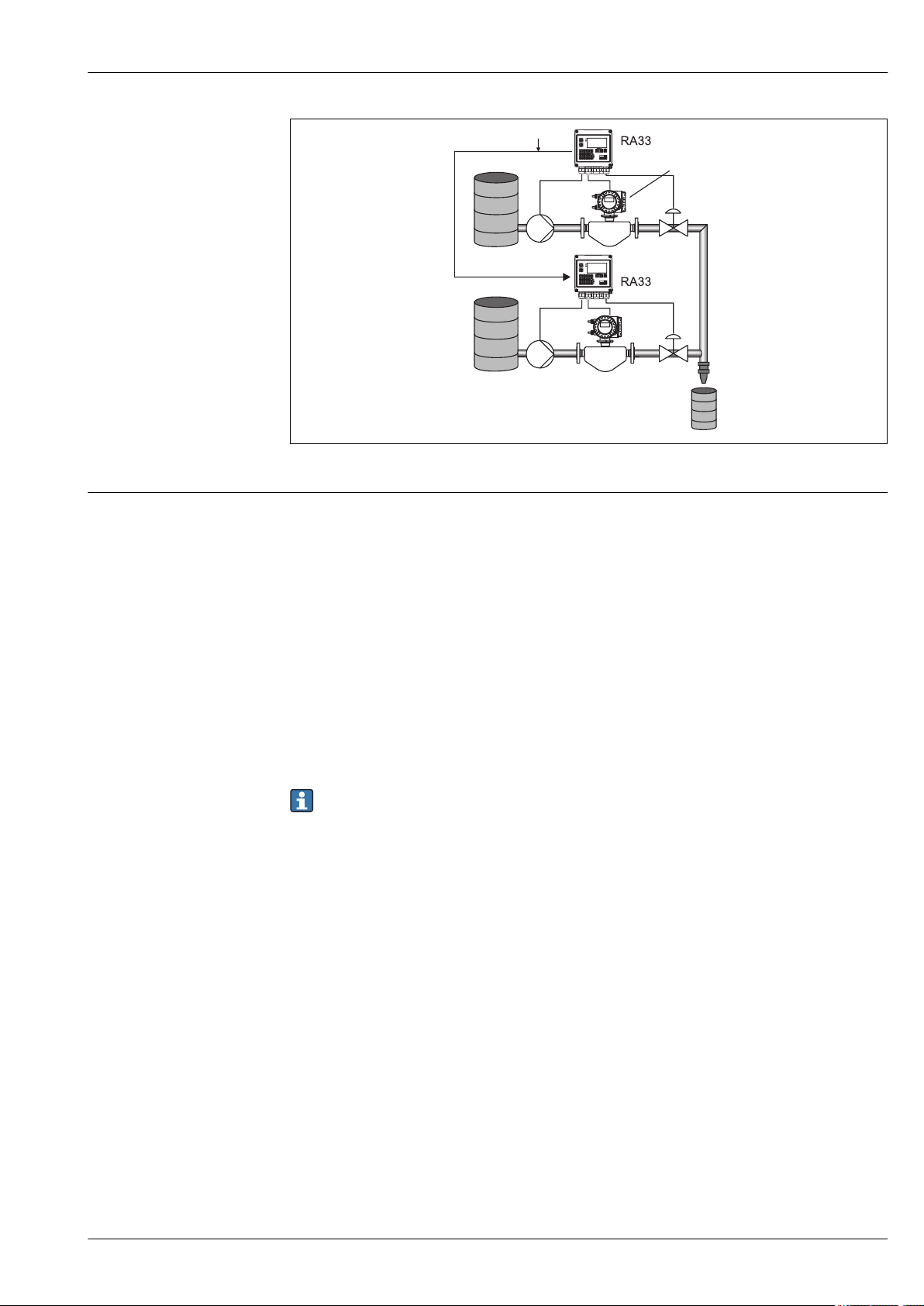

A0014354-EN

RA33

Flowmeter

Start

Valve

Valve

Flowmeter

Supply

vessel 1

Supply

vessel 2

Pump

Pump

3 Application: blending of two liquids when batching with the Batch Controller RA33

Functions Batch control

The function of the Batch Controller RA33 is to control valves and pumps using the measured rate of

flow and to fill a precise volume of the medium into a container.

Three different batch modes are available to perform this task:

• Standard mode: A value for the preset counter must be entered before batching commences.

Batching can then be started by pressing the start button or via the digital input. The flow is

measured, the counter calculates the volume and the pumps and valves are stopped as soon as the

specified volume is reached. The value on the preset counter remains for the next run but can be

changed manually.

• Automatic restart: In this scenario, the system repeatedly fills the selected fill quantity until the

sequence ends. It is also possible to define an interval between the individual fill quantities. For

added safety, a control input can also be assigned a blocking function which prevents the batching

operation from restarting automatically.

• Manual mode: In the manual mode, it is possible to perform batching without a preset counter.

The device registers the total flow between the start and end of a batch. The batch must be started

and ended by pressing a button or via the control input.

The device is suitable for the automatic control of slow batch processes with a duration of

longer than 10 seconds..

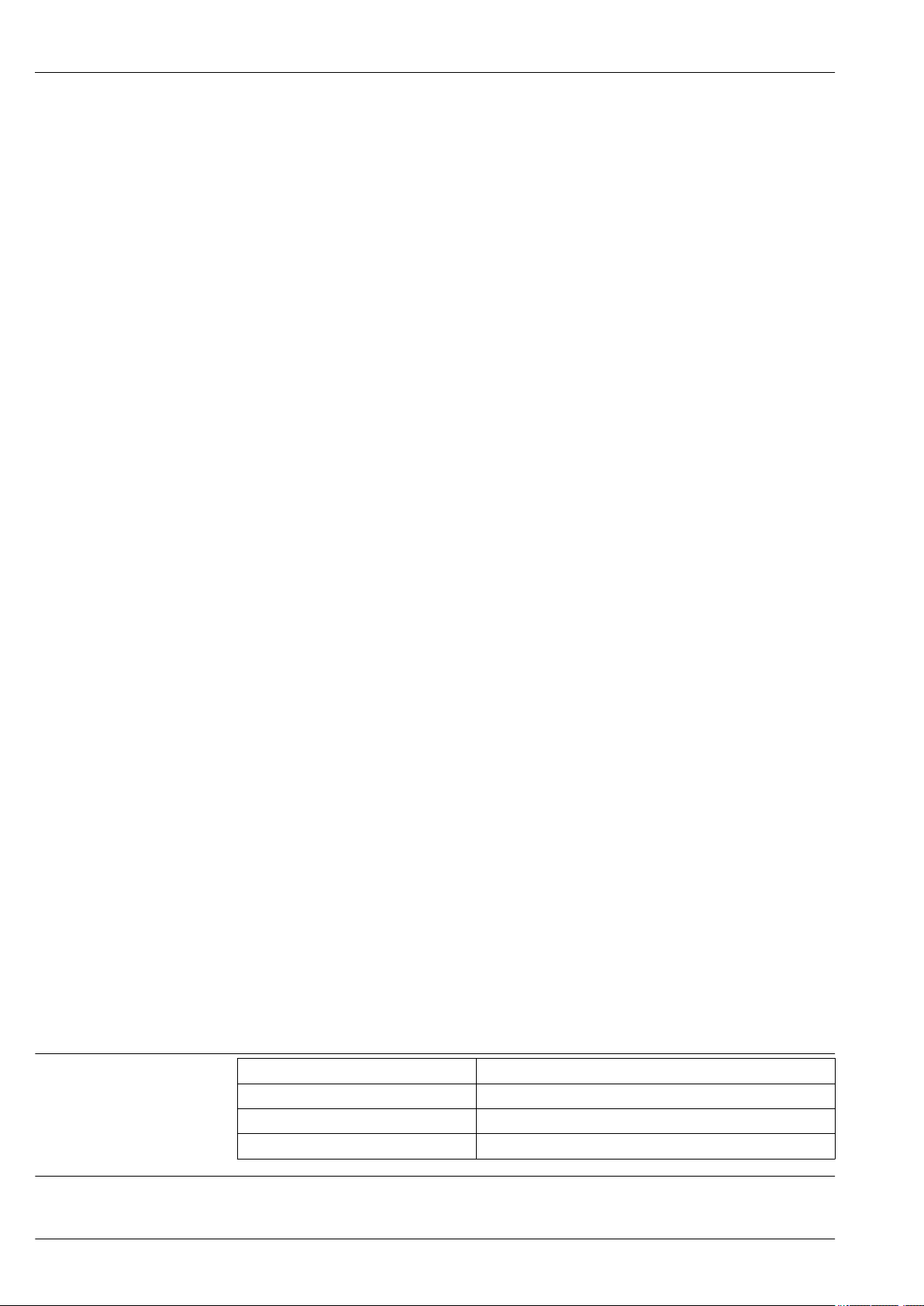

A0014357-EN

After-run correction

The after-run correction is a volume that is determined by the system response time. On the basis of

this volume, the stop command from the batch control system is executed earlier in order to achieve

maximum batching accuracy. Two correction capabilities, which build on one another, are

implemented in the device.

• Fixed after-run correction: A fixed value can be specified if the system response time is known, or

in order to keep the after-run quantity as low as possible when initially teaching the device and

configuring it for the automatic correction function.

• Automatic after-run correction: It is advisable to enable automatic after-run correction. It

complements manual correction and constantly optimizes the lead time before the valve is closed

and the pump is switched off in order to permanently obtain precise batching results, and to

compensate for possible system changes brought about by aging or external influencing factors.

Outputs (optional)

The additional output package comprises two more digital outputs (open collector) and a pulse/

analog output. These digital outputs are non-wearing and are thus suitable for a high number of

switching cycles. Furthermore, a counter, a flow or a user-definable ramp function to indicate the

progress of the batching can be output with the additional pulse/analog output.

Endress+Hauser 3

RA33

Temperature/density compensation (optional)

The temperature/density compensation enables compensation for various kinds of media.

Compensation via temperature measurement, or temperature and density measurement, can be

selected for mineral oils. The values measured are then converted to a compensated volume at 15 °C,

20 °C or 60 °F using the ASTM D1250-04 standard.

The compensation of user-defined media is a second possibility. A volume can be corrected by

measuring the temperature and applying an expansion coefficient, or by measuring the density.

Volume can also be converted to mass with a density measurement. The preset counter can also be

set for this mass unit.

Data logging/logbook

Data logging comprises three specific areas. Batching reports, daily, monthly and annual statistics,

and a log of events are stored in the device.

• Batch report: A batch report is created for each batch run. This report contains any error messages

that might have occurred. The preset counter value, the volume actually filled, the batch name and

number, as well as the date and time are saved in every report.

• Statistics: Daily, monthly and annual statistics are generated internally. They contain information

on the number of batches executed, the number of batches without errors, and the total amount.

• Event logbook: All the relevant device events are logged in the event logbook. These include setup

changes, power outages, sensor errors and firmware updates.

Real time clock (RTC)

The device has a real time clock that can be synchronized via a free digital input or using the Field

Data Manager software MS20.

The real time clock continues running even in case of a power outage, the device documents power

on and off; the clock switches either automatically or manually from daylight saving to standard

time.

Display

To display measured values, counters and calculated values, six groups are available. Each group can

be assigned up to 3 values or meter readings as desired.

Analyzing the stored data–Field Data Manager software MS20

The Field Data Manager software allows the saved measured values, alarms and events, as well as

the device configuration to be read out from the device (automatically) and backed up securely in an

SQL database in such a way that they are tamper-proof. The software offers centralized data

management with a variety of visualization functions. Using an integrated system service, analyses

and reports can be compiled, printed and saved fully automatically. Security is guaranteed by the

FDA-compliant audit trail of the software and by the extensive user management functionality.

Simultaneous access to and analysis of data from different workstations or different users is

supported (client-server architecture).

Communication interfaces

A USB interface (with CDI protocol), and optionally Ethernet, are used to configure the device and

read out the values. ModBus is optionally available as a communication interface.

None of the interfaces has a modifying effect on the device in accordance with PTB Requirement

PTBA 50.1.

USB device

Ethernet TCP/IP

Terminal: Type B socket

Specification: USB 2.0

Speed: "Full Speed" (max. 12 MBit/sec)

Max. cable length: 3 m (9.8 ft)

The Ethernet interface is optional and cannot be combined with other optional interfaces. It is

galvanically isolated (testing voltage: 500 V). A standard patch cable (e.g. CAT5E) can be used for

4 Endress+Hauser

RA33

the connection. A special cable gland is available for this purpose which allows users to guide preterminated cables through the housing. Via the Ethernet interface, the device can be connected to

office equipment using a hub or a switch.

standard: 10/100 Base-T/TX (IEEE 802.3)

Socket: RJ-45

Max. cable length: 100 m (328 ft)

RS232 printer interface

RS485

Modbus TCP

Modbus RTU

The RS232 interface is optional and cannot be combined with other optional interfaces. A

commercially available serial ASCII printer can be connected via the RS232 interface to print out

batching reports directly from the device.

Terminal: 3-pin plug-in terminal

Transmission protocol: serial

Transmission rate: 300/1200/2400/4800/9600/19200/38400/57600/76800

Terminal: 3-pin plug-in terminal

Transmission protocol: RTU

Transmission rate: 2400/4800/9600/19200/38400

Parity: choose from none, even, odd

The Modbus TCP interface is optional and cannot be ordered with other optional interfaces. It is used

to connect the device to higher-order systems to transmit all measured values and process values.

Form a physical point of view, the Modbus TCP interface is identical to the Ethernet interface.

The Modbus RTU (RS-485) interface is optional, and cannot be ordered with other optional

interfaces.

It is galvanically isolated (testing voltage: 500 V) and is used to connect to higher-order systems to

transmit all measured values and process values. It is connected via a 3-pin plug-in terminal.

Current/pulse input

Input

This input can be used either as a current input for 0/4 to 20 mA signals or as a pulse or frequency

input. Sensors for volume or mass flow measurement can be connected to the Batch Controller.

The input is galvanically isolated (500 V testing voltage towards all other inputs and outputs).

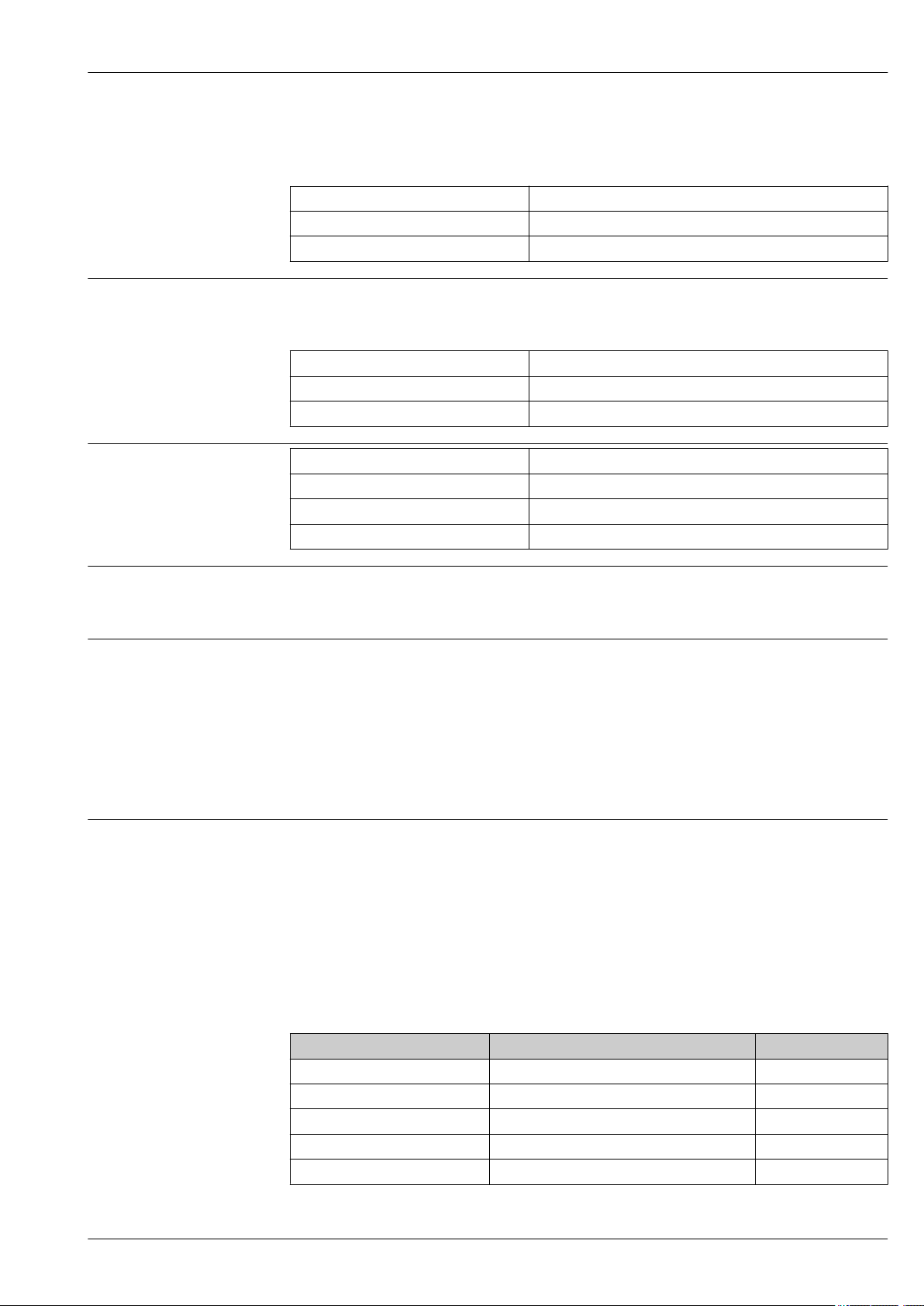

Cycle time

The cycle time is 125 ms.

Response time

In the case of analog signals, the reaction time is the time between the change at the input and the

time when the output signal is equivalent to 90 % of the full scale value.

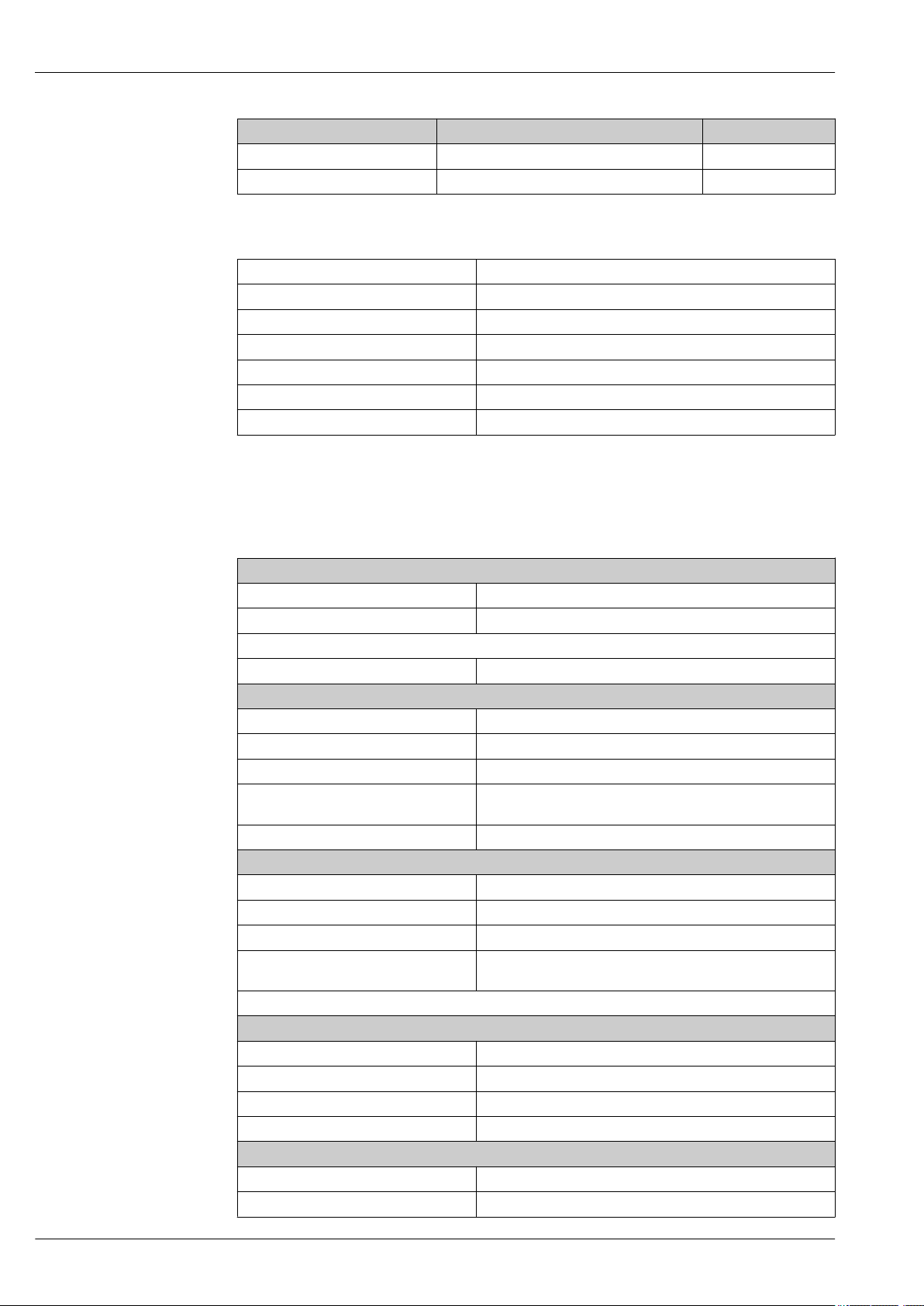

Input Output Reaction time [ms]

Current Current ≤ 440

Current Relay/digital output ≤ 250

RTD Current/ relay/digital output ≤ 440

Cable break detection Current/ relay/digital output ≤ 440

Cable open circuit detection, RTD Current/ relay/digital output ≤ 1100

Endress+Hauser 5

Input Output Reaction time [ms]

Pulse input Pulse output ≤ 600

Pulse input Relay/digital output ≤ 250

Current input

Measuring range: 0/4 to 20 mA + 10 % over range

Accuracy: 0.1 % of full scale value

Temperature drift: 0.01 %/K (0.0056 %/°F) of full scale value

Loading capacity: Max. 50 mA, max. 2.5 V

Input impedance (load): 50 Ω

HART® signals Not affected

A/D converter resolution: 20 bit

Pulse/frequency input

The pulse/frequency input can be configured for different frequency ranges:

• Pulses and frequencies 0.3 Hz to 12.5 kHz

• Pulses and frequencies 0.3 to 25 Hz (filters out bounce contacts, max. bounce time: 5 ms)

RA33

Minimum pulse width:

Range up to 12.5 kHz 40 µs

Range up to 25 Hz 20 ms

Maximum permissible contact bounce time:

Range up to 25 Hz 5 ms

Pulse input for active voltage pulses and contact sensors as per EN 1434-2, Class IB and IC:

Non-conductive state ≤ 1 V

Conductive state ≥ 2 V

No-load supply voltage: 3 to 6 V

Current limiting resistance in the power

supply (pull-up at input): 50 to 2 000 kΩ

Maximum permissible input voltage: 30 V (for active voltage pulses)

Pulse input for contact sensors as per EN 1434-2, Class ID and IE:

Low-level ≤ 1.2 mA

High-level ≥ 2.1 mA

No-load supply voltage: 7 to 9 V

Current limiting resistance in the power

supply (pull-up at input): 562 to 1 000 Ω

Not suitable for active input voltages

Current/pulse input:

Low-level ≤ 8 mA

High-level ≥ 13 mA

Loading capacity: Max. 50 mA, max. 2.5 V

Input impedance (load): 50 Ω

Accuracy during frequency measurement:

Basic accuracy: 0.01 % of measured value

Temperature drift: 0.01 % of measured value over entire temperature range

6 Endress+Hauser

Loading...

Loading...