Endress+Hauser Prosonic T FMU30 Operating Instructions Manual

BA00387F/00/EN/14.14

71244271

Operating Instructions

Prosonic T FMU30

Ultrasonic Level Measurement

Brief operating instructions Prosonic T

2 Endress+Hauser

Brief operating instructions

L00-FMU30xx-05-00-00-en-001

Contents of the operating instructions

This operating instructions describes the installation and commissioning of the Prosonic T ultrasonic

level transmitter. It contains all the functions required for a normal measuring operation. Also, the

instrument provides additional functions for optimising the measuring point and for converting the

measured value. These functions are not included in this operating instructions.

You can find an overview of all the device functions in the Appendix.

You can find a detailed description of all the device functions in the operating instructions

BA00388F/00/EN "Prosonic T - Description of Instrument Functions". This is located on the

supplied documentation CD-ROM.

F

L

D

E

… …

KA290F/00/A2/12.09

71106912

BD

… …

100%

0%

100

333

… …

… …

71106912

SD

Prosonic T - Quick Setup

- dome

ceiling

- horizontal

cyl.

- bypass

…

- unknown

- liquid

->4mm

-<4mm

(> 0.16 in)

( 0.16 in)

<

- standard

- calm

surface

- add. agitator

…

input E

(see sketch)

input F

(see sketch)

-ok

- too small

- too big

- unknown

- manual

displayed

(see sketch)

D and L are

confirm

or specify

range

suggestion

000

measured value

Group

selection

00

basic setup

01

safety settings

0C

system

parameter

0E

Envelope curve

04

linearisation

05

extended calibr.

06

output

0A

diagnostics

0A0

present

error

002

tank shape

004

process

cond.

005

empty

calibr.

006

full

calibr.

008

dist./

meas value

051

check

distance

003

medium

property

052

range of

mapping

053

start

mapping

008

dist./

meas value

0E1

plot settings

0E2

recording

curve

0A1

previous

error

0A4

unlock

parameter

03

temperature

09

display

092

language

BD: blocking distance

and : increase contrast

and : decrease contrast

0A3

reset

0C0

tag no.

SD: safety distance

Prosonic T Table of contents

Endress+Hauser 3

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning, operation . . . . . . . . . . . 4

1.3 Operational safety and process safety . . . . . . . . . . . . 4

1.4 Notes on safety conventions and symbols . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . 6

2.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product structure . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 8

2.5 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 8

3 Installation . . . . . . . . . . . . . . . . . . . . . . 9

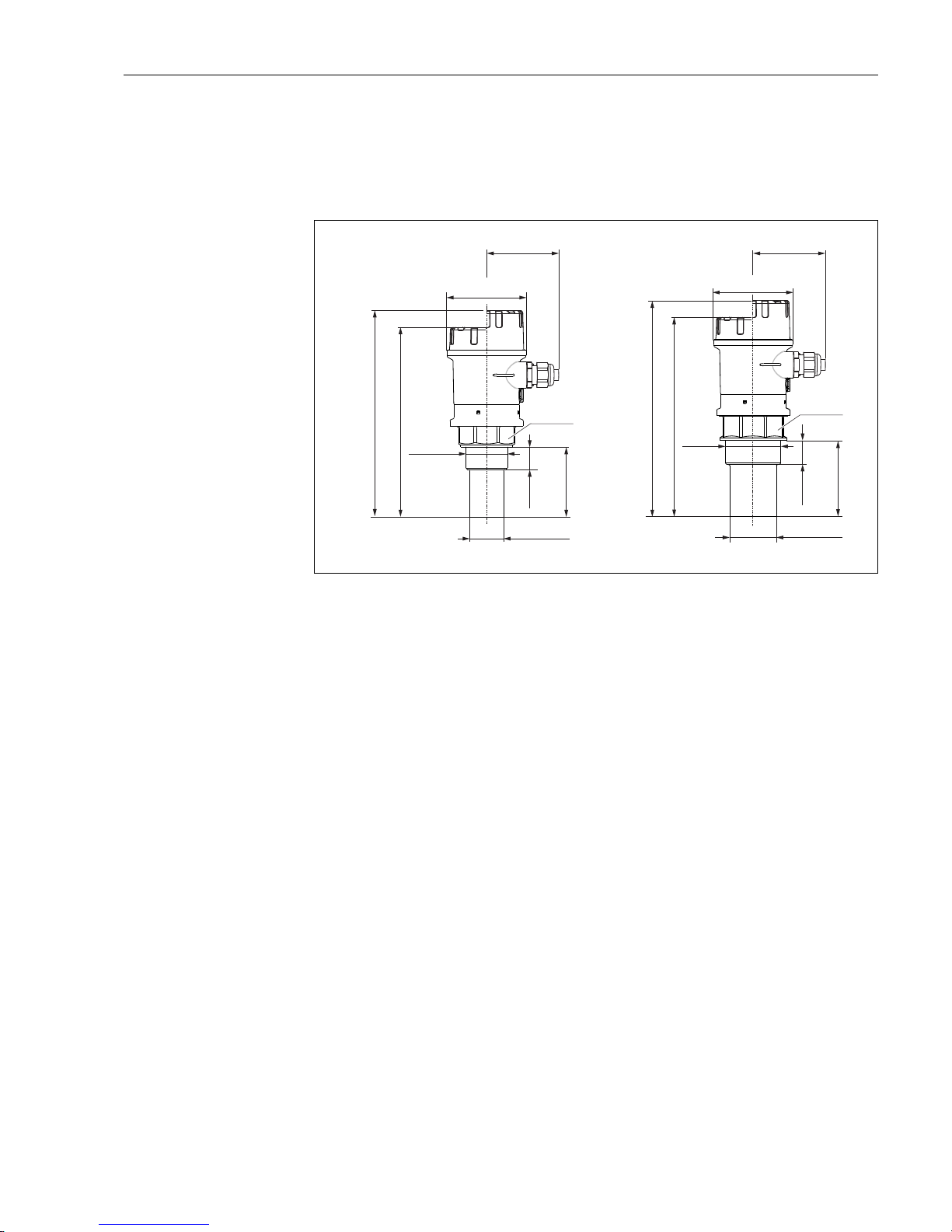

3.1 Design; dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Installation variants . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Installation hint . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Potential matching . . . . . . . . . . . . . . . . . . . . . . . . 18

4.5 Checking the connection . . . . . . . . . . . . . . . . . . . . 18

5 Operation . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Display and operating elements . . . . . . . . . . . . . . . 19

5.2 Function codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Operating options . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Operation using the on-site display . . . . . . . . . . . . 23

5.5 Operation using FieldCare . . . . . . . . . . . . . . . . . . . 24

5.6 Lock/unlock configuration . . . . . . . . . . . . . . . . . . 25

5.7 Resetting the customer parameters . . . . . . . . . . . . . 26

5.8 Resetting an interference echo suppression

(tank map) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Commissioning. . . . . . . . . . . . . . . . . . 27

6.1 Power up instrument . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Basic calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Envelope curve . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Troubleshooting . . . . . . . . . . . . . . . . . 36

7.1 System error messages . . . . . . . . . . . . . . . . . . . . . . 36

7.2 Application errors . . . . . . . . . . . . . . . . . . . . . . . . . 38

8 Maintenance and repairs . . . . . . . . . . 40

8.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Repairs to Ex-approved devices . . . . . . . . . . . . . . . 40

8.4 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.5 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.8 Contact addresses of Endress+Hauser . . . . . . . . . . . 42

9 Accessories . . . . . . . . . . . . . . . . . . . . . 43

9.1 Installation bracket . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2 Screw in flange . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.3 Cantilever with mounting frame or wall bracket . . . 44

9.4 Mounting Frame . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.5 Wall Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.6 Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . 47

9.7 ToF Adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . 47

10 Technical Data. . . . . . . . . . . . . . . . . . . 48

10.1 Technical data at a glance . . . . . . . . . . . . . . . . . . . 48

11 Appendix. . . . . . . . . . . . . . . . . . . . . . . 52

11.1 Operating menu . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.2 Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . 54

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Safety instructions Prosonic T

4 Endress+Hauser

1 Safety instructions

1.1 Designated use

The Prosonic T is a compact measuring device for continuous, non-contact level measurement.

Depending on the sensor, the measuring range is up to 8 m (26 ft) in fluids and up to 3.5 m (11 ft)

in bulk solids.

1.2 Installation, commissioning, operation

The instrument is fail-safe and is constructed to the state-of-the-art. It meets the appropriate

standards and EC directives. However, if you use it improperly or other than for its designated use,

it may pose application-specific hazards, e.g. product overflow due to incorrect installation or

configuration. Installation, electrical connection, start-up, operation and maintenance of the

measuring device must therefore be carried out exclusively by trained specialists authorised by the

system operator. Technical personnel must have read and understood these operating instructions

and must adhere to them. You may only undertake modifications or repair work to the device when

it is expressly permitted by the operating instructions.

1.3 Operational safety and process safety

Alternative monitoring measures must be taken to ensure operational safety and process safety

during configuration, testing and maintenance work on the device.

Hazardous areas

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with the

installation instructions and ratings as stated in this Additional documentation is mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local regulations.

Prosonic T Safety instructions

Endress+Hauser 5

1.4 Notes on safety conventions and symbols

In order to highlight safety-relevant or alternative operating procedures in the manual, the following

conventions have been used, each indicated by a corresponding symbol in the margin.

Safety conventions

#

Warning!

A warning highlights actions or procedures which, if not performed correctly, will lead to personal

injury, a safety hazard or destruction of the instrument

"

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal

injury or incorrect functioning of the instrument

!

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect

operation or may lead to an instrument response which is not planned

Explosion protection

0

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion hazardous

area

-

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in and wiring

entering areas with the designation “explosion hazardous areas” must conform with the stated type

of protection.

.

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas. Devices located in

safe areas still require a certificate if their outputs run into explosion hazardous areas

Electrical symbols

%

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied

&

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be applied or

supplied

)

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by means of an

earth grounding system

*

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to the

equipment

+

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or

equipotential line according to national or company practice

Identification Prosonic T

6 Endress+Hauser

2 Identification

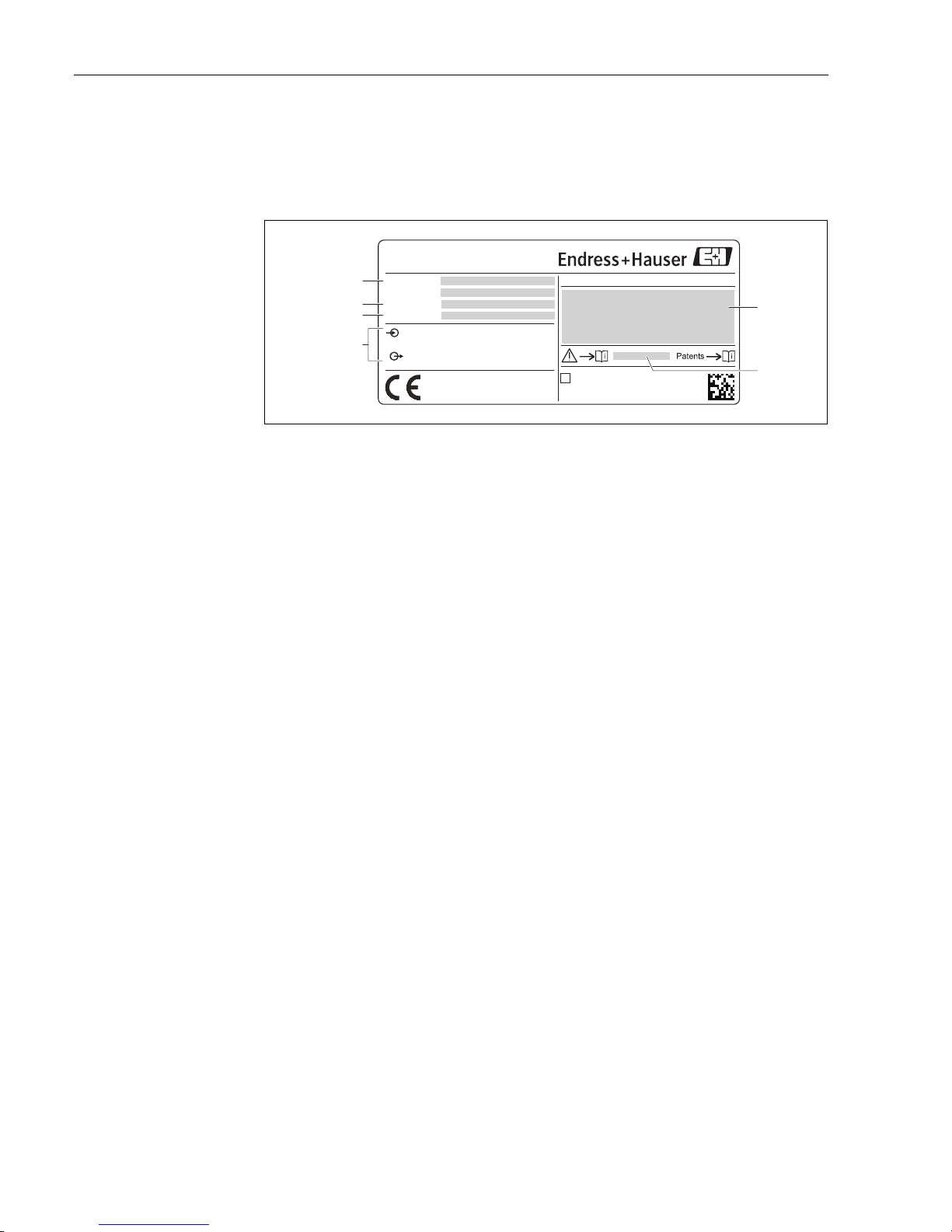

2.1 Nameplate

L00-FMU30xxx-18-00-00- xx-001

1 Designation according to Directive 94/9/EC and designation of the type of protection

(only for certified device variants)

2 Reference to additional safety-relevant documentation (only for certified device variants)

3 Supply voltage

4 Serial number

5Ident-No.

6 Order Code

Prosonic T

Order Code:

4 ... 20 mA

Made in Germany,D- 79689 Maulburg

Ser.No.:

Ident.-No.:

14 ... 35 V DC 0.8 W

IP68

Dat/Insp.:

250002891--

2-wire

if modification

see sep. label

X=

6

3

1

4

5

2

Prosonic T Identification

Endress+Hauser 7

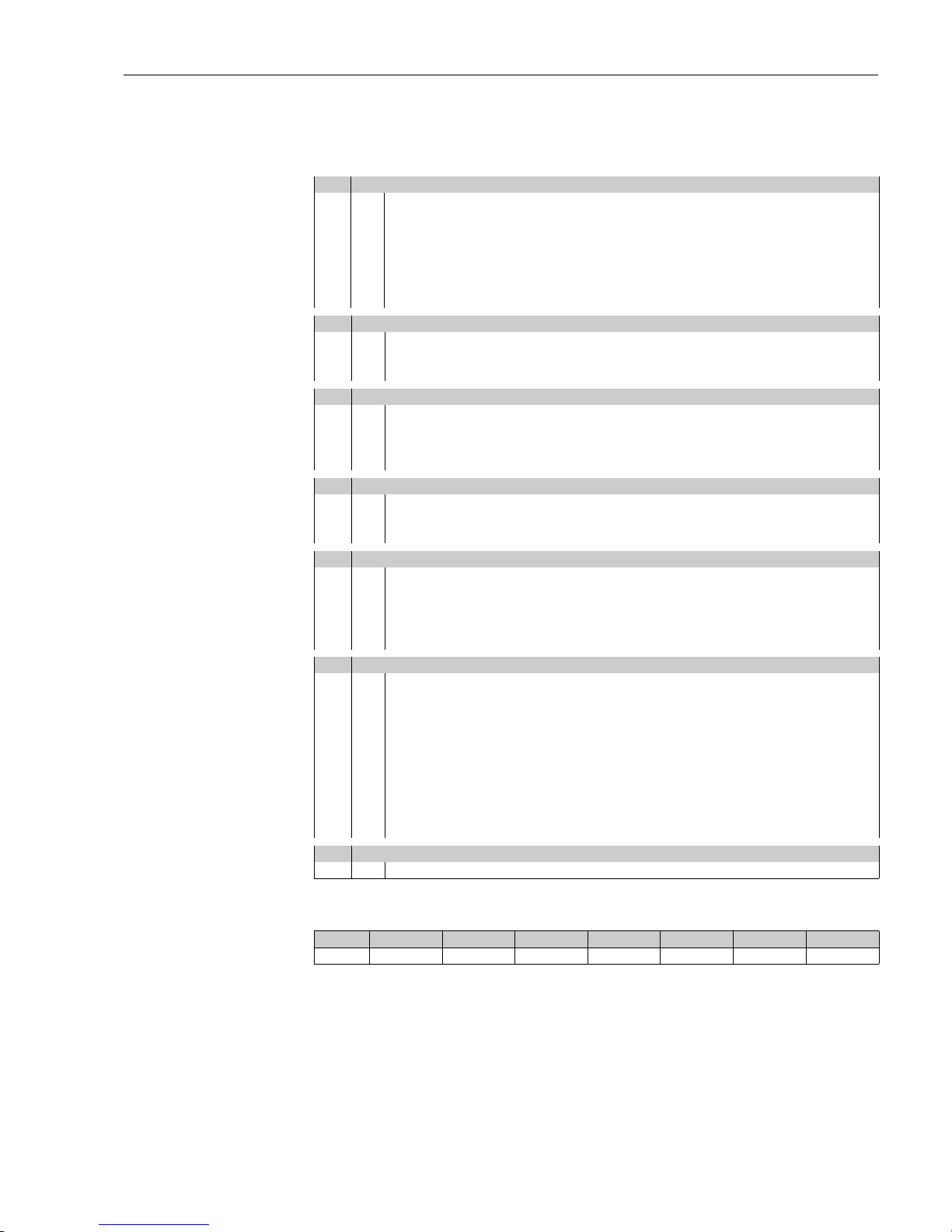

2.2 Product structure

Versions that mutually exclude one another are not marked.

You can fill in the options of the respective feature into the following table. The filled in options

result in the complete order code.

010 Approval:

AA Non-hazardous area

BB ATEX II 1/2G Ex ia IIC T5

CA CSA C/US General Purpose

CB CSA C/US IS CI.I Div.1 Gr.A-D

IB IEC Ex zone 0/1, Ex ia IIC T5 Ga/Gb

NB NEPSI zone 0/1, Ex ia IIC T5 Ga/Gb

99 Special version

020 Display; Operating:

G W/o; via spare part display FMU30

H Envelope curve display on site; push button

Y Special version

030 Electrical Connection:

E Gland M20, IP68

F Thread G1/2, IP68

G Thread NPT1/2, IP68

YSpecial version

040 Sensor; Max Range; Blocking Distance:

AA 1-1/2"; 5m liquid/2m solid; 0.25m

AB 2"; 8m liquid/3.5m solid; 0.35m

YY Special version

050 Process Connection:

GGF Thread ISO228 G1-1/2, PP

GHF Thread ISO228 G2, PP

RGF Thread ANSI MNPT1-1/2, PP

RHF Thread ANSI MNPT2, PP

YYY Special version

620 Accessory Enclosed:

RA UNI flange 2"/DN50/50, PP max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

RB UNI flange 2"/DN50/50, PVDF max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

RC UNI flange 2"/DN50/50, 316L max 4bar abs/58psia, suitable for 2" 150lbs/DN50 PN16/10K 50

RD UNI flange 3"/DN80/80, PP max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

RE UNI flange 3"/DN80/80, PVDF max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

RF UNI flange 3"/DN80/80, 316L max 4bar abs/58psia, suitable for 3" 150lbs/DN80 PN16/10K 80

RG UNI flange 4"/DN100/100, PP max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K 100

RH UNI flange 4"/DN100/100, PVDF max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K 100

RI UNI flange 4"/DN100/100, 316L max 4bar abs/58psia, suitable for 4" 150lbs/DN100 PN16/10K 100

R9 Special version

895 Marking:

Z1 Tagging (TAG), see additional spec.

010 020 030 040 050 620 895

FMU30 -

Identification Prosonic T

8 Endress+Hauser

2.3 Scope of delivery

• Instrument according to the version ordered

• Accessories ( ä 43)

• Brief operating instructions KA01054F/00/EN for quick commissioning

• Brief operating instructions KA00290F/00/A2 (basic setup/troubleshooting), housed in the

instrument)

• For certified instrument versions: Safety Instructions, Control- or Installation drawings

• counter nut (PC): option 50, versions GGF/GHF ä 7 "Product structure"

• sealing ring (EPDM): option 50, versions GGF/GHF ä 7 "Product structure"

• for gland M20x1.5: cable gland

The cable gland is mounted on delivery.

• CD-ROM with further documentation, e. g.

- Technical Information

- Operating Instructions

- Description of Intrument Functions

2.4 Certificates and approvals

CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements, has been tested and left the

factory in a condition in which it is safe to operate. The device complies with the applicable

standards and regulations as listed in the EC declaration of conformity and thus complies with the

statutory requirements of the EC directives. Endress+Hauser confirms the successful testing of the

device by affixing to it the CE mark.

2.5 Registered trademarks

FieldCare

®

Trademark of Endress+Hauser Process Solutions AG.

ToF

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PulseMaster

®

Trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

Prosonic T Installation

Endress+Hauser 9

3 Installation

3.1 Design; dimensions

L00-FMU30xxx-06-00-00-xx-006

A Sensor 1½"

B Sensor 2"

G 1½”

1½NPT ”

SW65

(AF65)

234 (9.21)

mm (in)

81 (3.19)

82

(3.23)

26

(1.02)

ø50 (1.97)

238 (9.37)

SW65

(AF65)

G 2”

2NPT ”

215 (8.46)

220 (8.66)

ø39 (1.54)

26

(1.02)

ø85 ( 3.35)ø

max. 76

(2.99)

max. 76

(2.99)

ø85 ( 3.35)ø

AB

Installation Prosonic T

10 Endress+Hauser

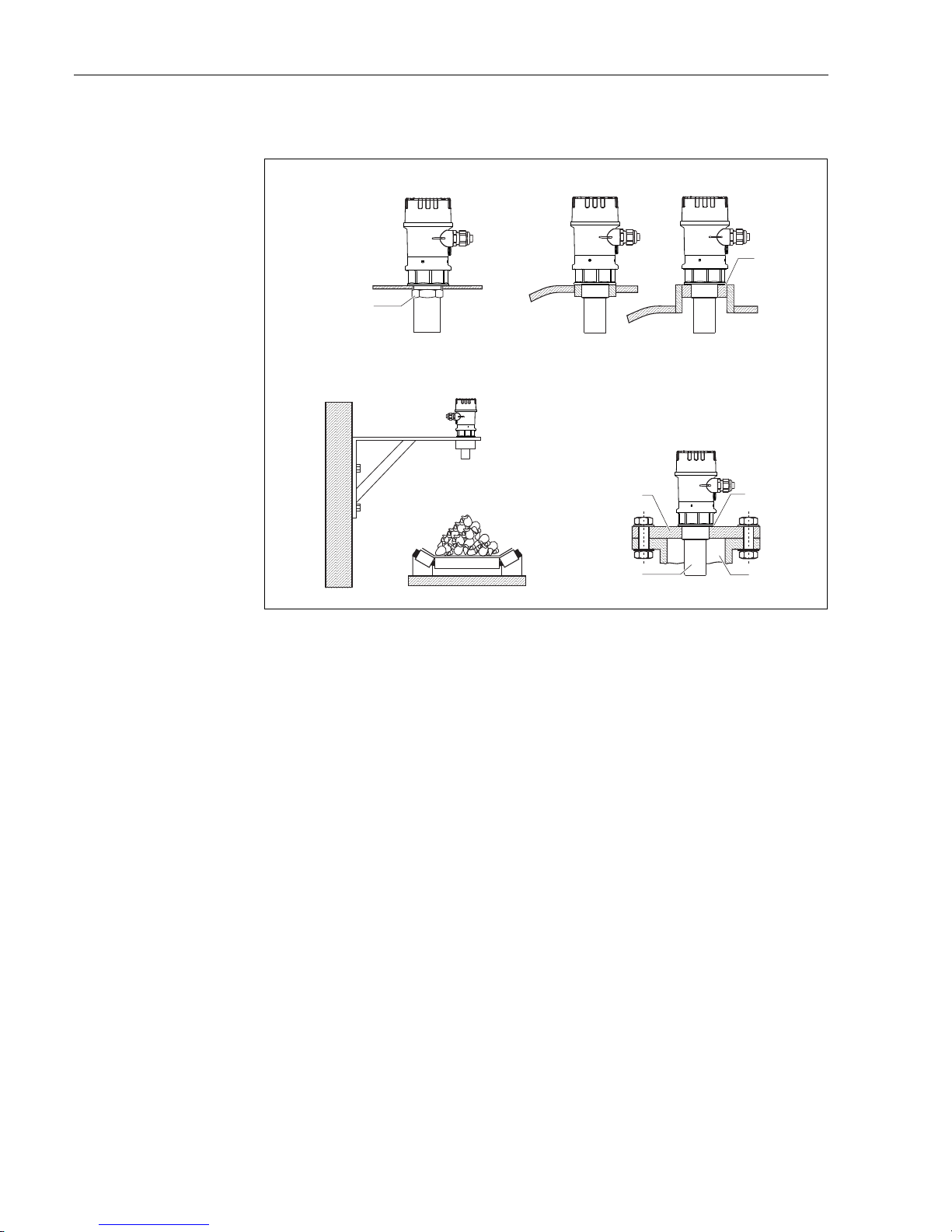

3.2 Installation variants

L00-FMU30xxx-17-00-00- xx-002

A Installation with counter nut

1 counter nut (PC) supplied for G1½ and G2 instruments

B Installation with sleeve

1 sealing (EPDM) supplied

C Installation with installation bracket

D Installation with screw in flange

1 sealing (EPDM) supplied

2 nozzle

3sensor

4 screw in flange

For installation bracket or screw in flange ä 43, "Accessories".

BA

C

D

1

1

1

2

3

4

Prosonic T Installation

Endress+Hauser 11

3.3 Installation conditions

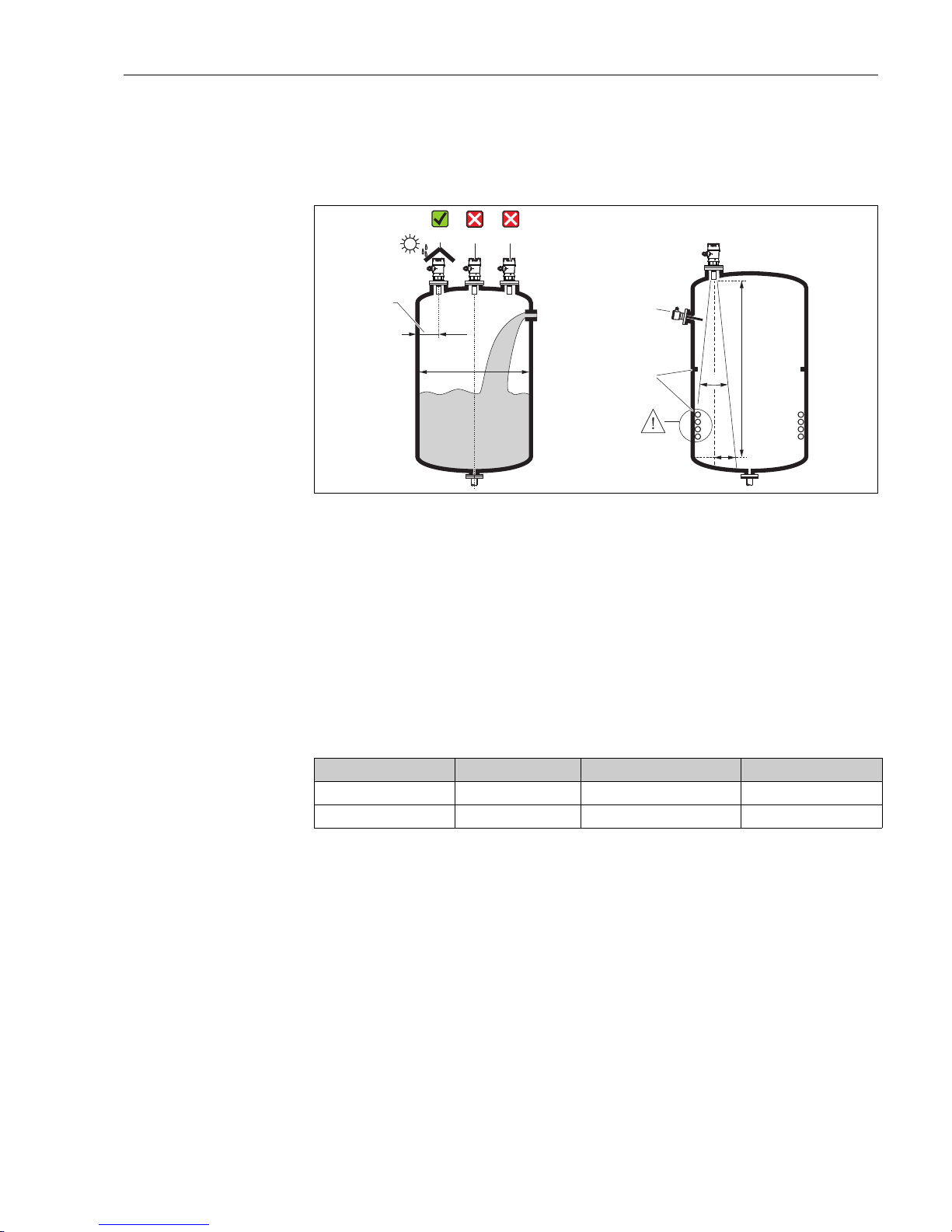

3.3.1 Installation conditions for level measurements

L00-FMU30xxx-17-00-00-xx-005

• Do not install the sensor in the middle of the tank (3). We recommend leaving a distance between

the sensor and the tank wall (1) measuring 1/6 of the tank diameter.

• Protect the device against direct sun or rain (2), e.g. with a weather protection cover, see the

technical information TI00440F, chapter "Accessories".

• Avoid measurements through the filling curtain (4).

• For solid application where bulk solid cones appear, align the sensor membrane perpendicular to

the surface.

• Make sure that equipment (5) such as limit switches, temperature sensors, etc. are not located

within the emitting angle . In particular, symmetrical equipment (6) such as heating coils, baffles

etc. can influence measurement.

• Never install two ultrasonic measuring devices in a tank, as the two signals may affect each other.

• To estimate the detection range, use the 3 dB emitting angle .

1

234

5

6

1/6D

D

r

a

L

Sensor L

max

r

max

1½" 11° 5 m (16 ft) 0.48 m (1.6 ft)

2" 11° 8 m (26 ft) 0.77 m (2.5 ft)

Installation Prosonic T

12 Endress+Hauser

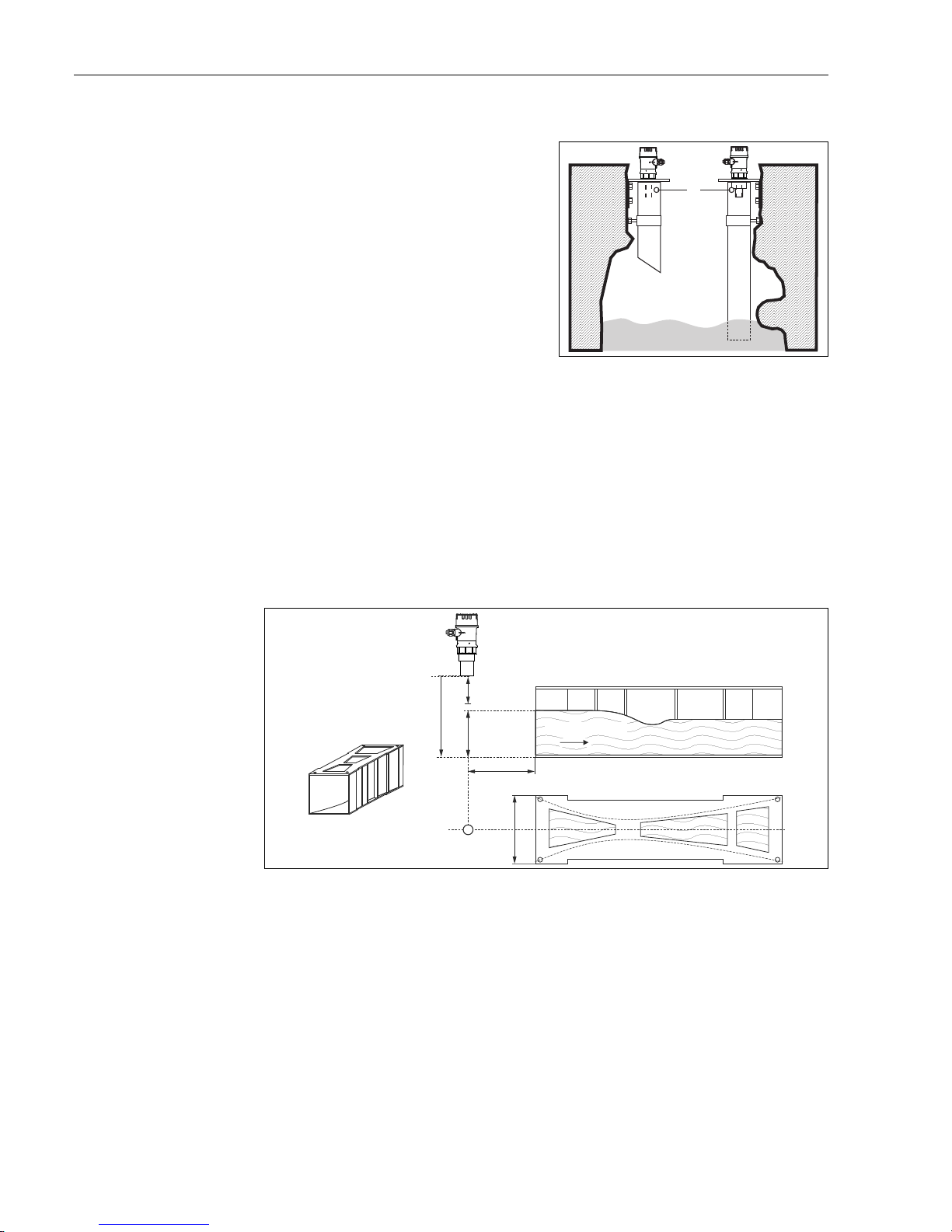

3.3.2 Installation in narrow shafts

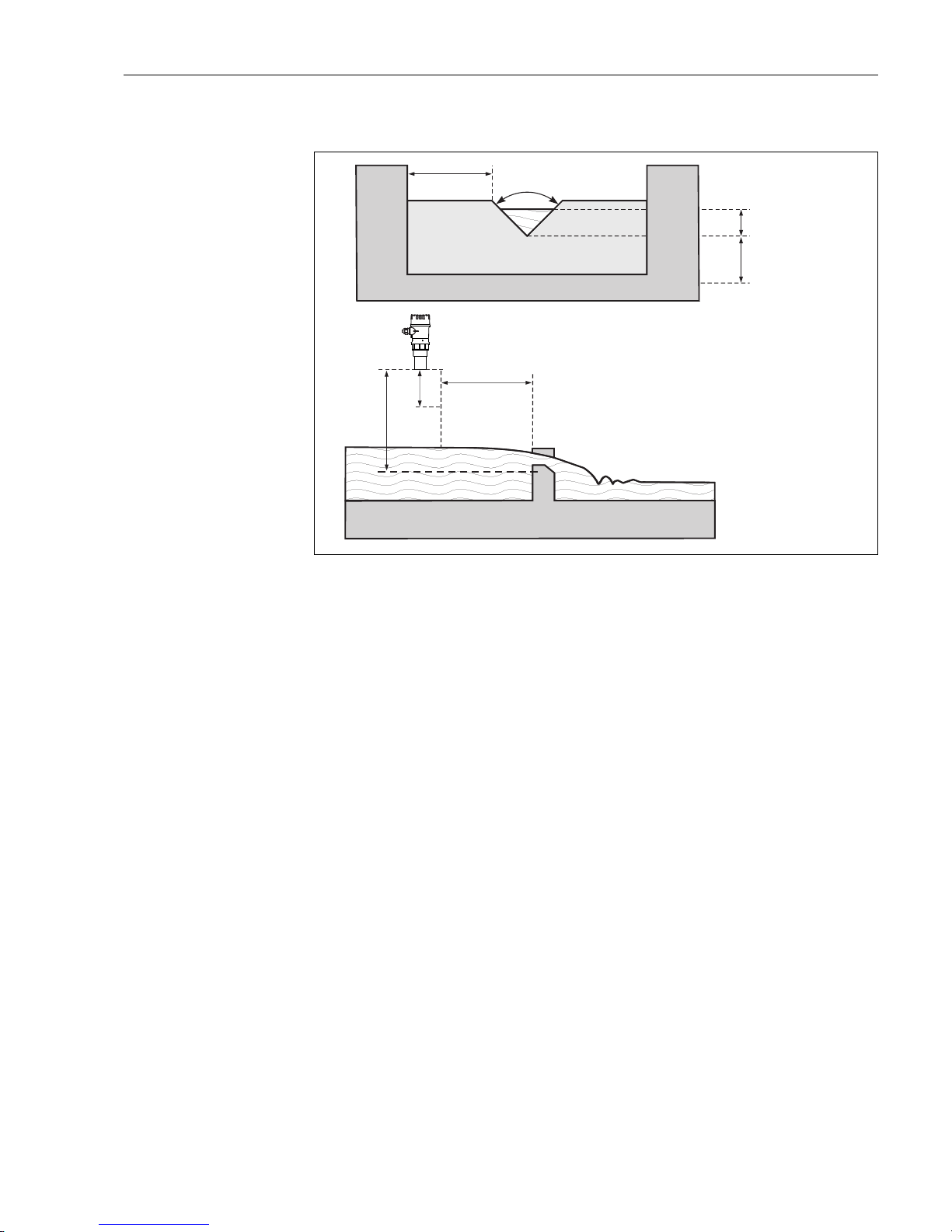

3.3.3 Installation conditions for flow measurements

• Install the device at the inflow side (B), as close above the maximum water level H

max

as possible

(take into account the blocking distance BD).

• Position the instrument in the middle of the channel or weir.

• Align the sensor membrane parallel to the water surface.

• Keep to the installation distance of the channel or weir.

Example: Khafagi-Venturi flume

A0019607

A Khafagi-Venturi flume BD Blocking distance

B Inflow E Empty calibration

C Outflow F Full calibration

V Direction of flow

In narrow shafts with strong interference

echoes, we recommend using an ultrasound

guide pipe (e.g. PE or PVC wastewater pipe)

with a minimum diameter of 100 mm (3.94 in).

Make sure that the pipe is not soiled by accumulated dirt. If necessary, clean the pipe at regular

intervals.

L00-FMU30xxx-17-00-00- xx-010

1 Venting hole

1

1 x b

0

b

0

BD

A

E

BC

V

H

max

=F

Prosonic T Installation

Endress+Hauser 13

Example: Triangular weir

L00-FMU30xxx-17-00-00-xx-012

BD Blocking distance

E Empty calibration

F Full calibration

min. 3 H

H

min. 2 H

a

min. 2 H

BD

max

max

max

max

E

(= F)

Installation Prosonic T

14 Endress+Hauser

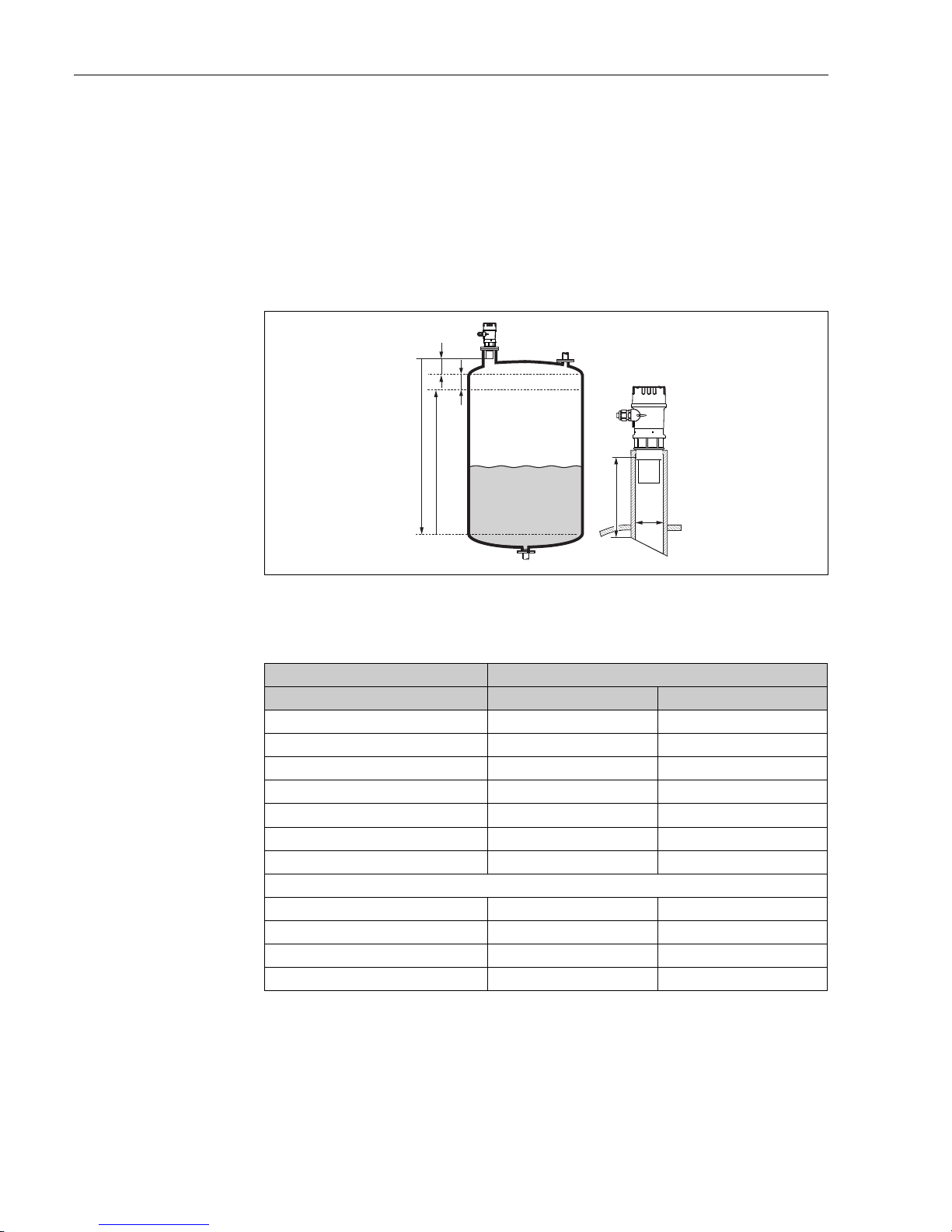

3.4 Measuring range

3.4.1 Blocking distance, Nozzle mounting

Install the instrument at a height so that the blocking distance BD is not undershot, even at

maximum fill level. Use a pipe nozzle if you cannot maintain the blocking distance in any other way.

The interior of the nozzle must be smooth and may not contain any edges or welded joints. In

particular, there should be no burr on the inside of the tank side nozzle end. Note the specified limits

for nozzle diameter and length. To minimise disturbing factors, we recommend an angled socket

edge (ideally 45°).

L00-FMU30xxx-17-00-00- xx-004

BD Blocking distance F Full calibration (span)

SD Safety distance D Nozzle diameter

E Empty calibration L Nozzle length

"

Caution!

If the blocking distance is undershot, it may cause device malfunction.

!

Note!

In order to notice if the level approaches the blocking distance, you can specify a safety distance

(SD). If the level is within this safety distance, the instrument outputs a warning or alarm message.

F

E

BD

SD

L

D

Maximum nozzle length mm (in)

Nozzle diameter 1½" sensor 2" sensor

DN50/2" 80 (3.15)

DN80/3" 240 (9.45) 240 (9.45)

DN100/4" 300 (11.8) 300 (11.8)

DN150/6" 400 (15.7) 400 (15.7)

DN200/8" 400 (15.7) 400 (15.7)

DN250/10" 400 (15.7) 400 (15.7)

DN300/12" 400 (15.7) 400 (15.7)

Sensor characteristics

Emitting angle 11° 11°

Blocking distance (m [ft]) 0.25 (0.8) 0.35 (1.1)

Max. range (m [ft]) in liquids 5 (16) 8 (26)

Max. range (m [ft]) in solids 2 (6.6) 3.5 (11)

Prosonic T Installation

Endress+Hauser 15

3.4.2 Safety distance

If the level rises to the safety distance SD, the device switches to warning or alarm status.

The size of SD can be set freely in the "Safety distance" (015) function.The "in safety distance"

(016) function defines how the device reacts if the level enters the safety distance.

There are three options:

• Warning: The device outputs an error message but continues measurement.

• Alarm: The device outputs an error message. The output signal assumes the value defined in the

"Output on alarm" (011) function (MAX, MIN, user-specific value or holds the last value). As

soon as the level drops below the safety distance, the device recommences measurement.

• Self holding: The device reacts in the same way as for an alarm. However, the alarm condition

continues after the level drops below the safety distance. The device only recommences

measurement when you cancel the alarm using the "Ackn. alarm" (017) function.

3.4.3 Range

The sensor range is dependent on the measuring conditions. Refer to Technical Information

TI00440F/00/EN for an estimation. The maximum range is shown in the above diagram (valid for

good conditions).

3.5 Installation hint

3.6 Installation check

After installing the device, carry out the following checks:

• Is the device damaged (visual inspection)?

• Does the device correspond to the measuring point specifications for process temperature, process

pressure, ambient temperature, measuring range etc.

• If available: Are the measuring point number and labelling correct (visual inspection)?

• Is the measuring device sufficiently protected against precipitation and direct sunlight?

• Are the cable glands tightened correctly?

• After aligning the housing, check the process seal at the nozzle or flange.

Sensor Maximum range

1½" 5 m (16 ft)

2" 8 m (26 ft)

"

Caution!

Use only the screw-in piece to screw in the

Prosonic T.

Screw the instrument at the screw-in piece

using an 65AF spanner.

L00-FMU30xxx-17-00-00-xx-009

1 65 AF, max. torque 7 Nm (5.16 lbf ft)

65

1

Wiring Prosonic T

16 Endress+Hauser

4 Wiring

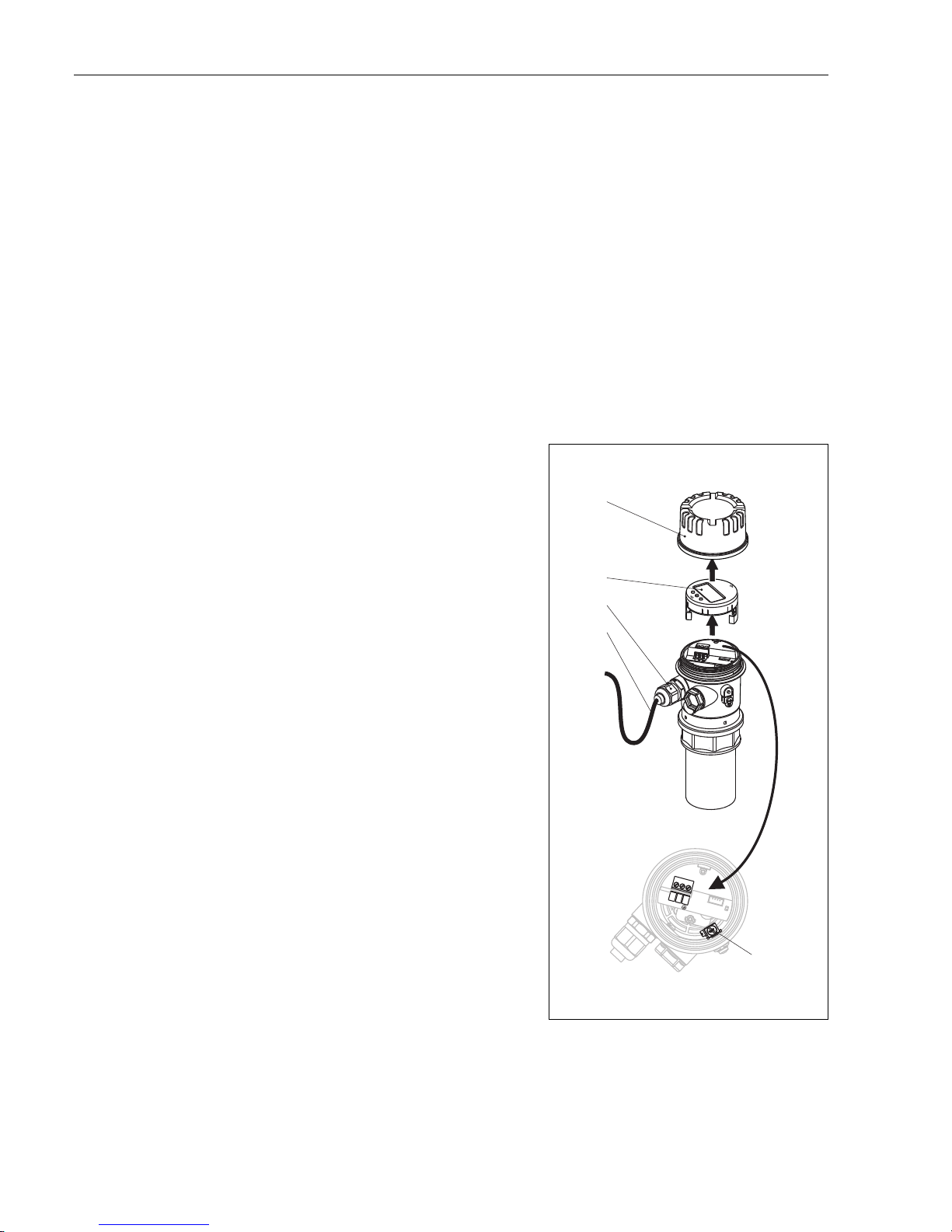

4.1 Electrical connection

"

Caution!

Before connection please note the following:

• The power supply must be identical to the data on the nameplate.

• Switch off power supply before connecting up the instrument.

• Connect equipotential bonding to devices ground terminal before connecting up the instrument

ä 18, "Potential matching".

#

Warning!

When you use the measuring system in hazardous areas, make sure to comply with national

standards and the specifications in the safety instructions (XA’s). Make sure you use the specified

cable gland.

4.1.1 Wiring

1. Unscrew housing cover (1).

2. Remove display (2) if fitted.

3. Insert cable (3) through gland (4).

"

Caution!

If possible, insert the cable from above and

let a draining loop in order to avoid

intrusion of humidity.

4. Installation cable screen to the grounding

terminal (5) within the terminal

compartment.

5. Make connection according to terminal

assignment, ä 17, "Terminal

assignment".

6. Tighten cable gland (4).

7. Insert display (2) if fitted.

8. Screw on housing cover (1).

9. Switch on power supply.

L00-FMU30xxx-04-00-00- xx-008

1

2

1

2

3

5

4

Prosonic T Wiring

Endress+Hauser 17

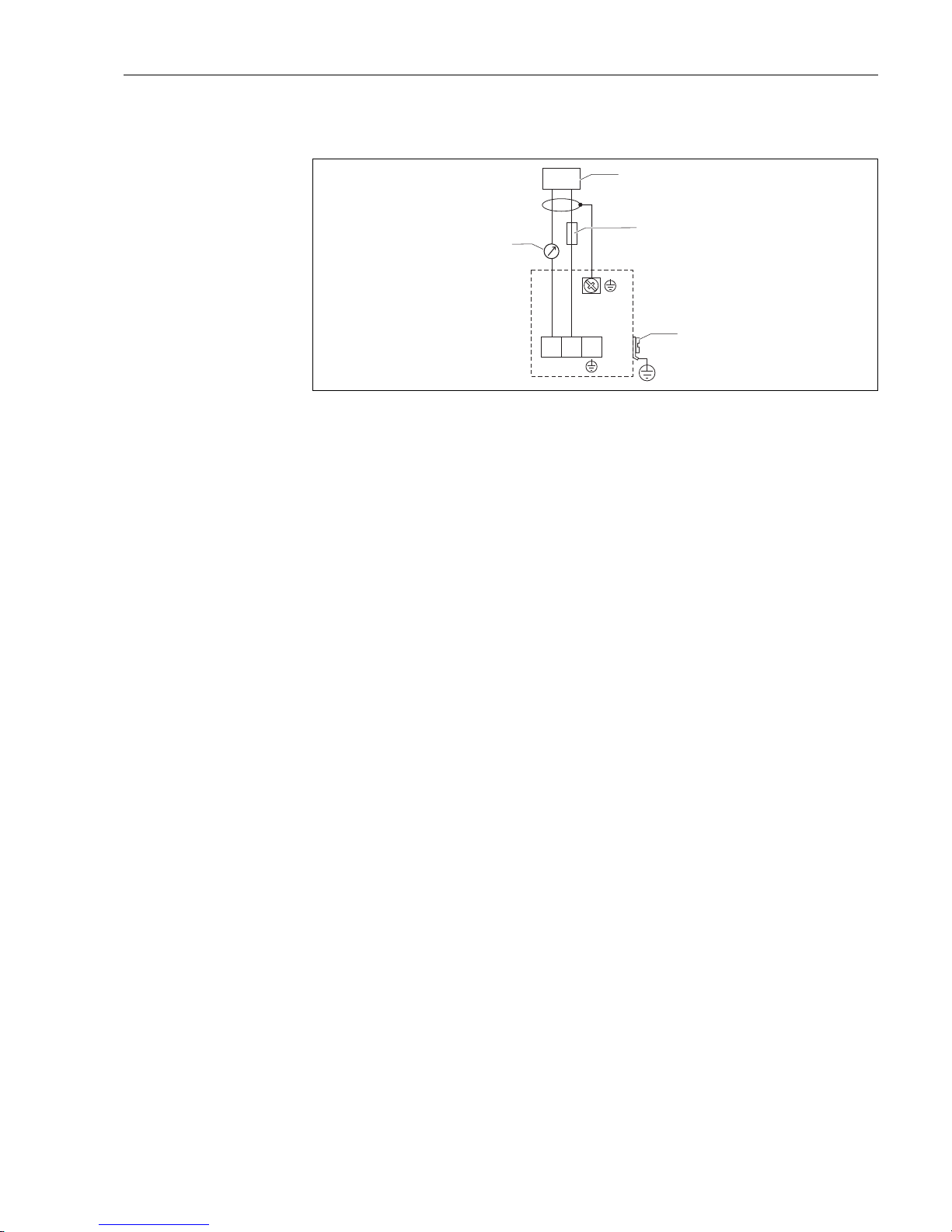

4.2 Terminal assignment

L00-FMU30xxx-04-00-00-de-015

1Power

2 Fuse as per IEC 60127, T 0.5 A

3 Plant ground

3 4...20 mA

4.3 Supply voltage

The voltages across the terminals directly at the instrument: 14-35 V

L-

L+

123

1

3

4

2

T 0.5A

Loading...

Loading...