Endress+Hauser Prosonic S FDU91, Prosonic S FDU91F, Prosonic S FDU92, Prosonic S FDU95, Prosonic S FDU96 Technical Information

Technical Information

FDU92

FDU93

FDU95

FDU96

FDU91

FDU90

FDU91F

Prosonic S

FDU90/91/91F/92/93/95/96

Ultrasonic sensors for non-contact continuous

level and flow measurement,

for connection to the transmitters FMU90 and FMU95

Application

• Continuous, non-contact level measurement of fluids,

pastes, sludges and powdery to coarse bulk materials

• Flow measurement in open channels and measuring

weirs

• Maximum measuring range

– FDU90: 3 m (9.8 ft) in fluids

1.2 m 3.9 ft) in bulk materials

– FDU91/FDU91F: 10 m (33 ft) in fluids

5 m (16 ft) in bulk materials

– FDU92: 20 m (66 ft) in fluids

10 m (33 ft) in bulk materials

– FDU93: 25 m (82 ft) in fluids

15 m (49 ft) in bulk materials

– FDU95: 45 m (148 ft) in bulk materials

– FDU96: 70 m (230 ft) in bulk materials

• Suited for explosion hazardous areas

Your benefits

• Non-contact measurement method; minimizes service

requirements

• Integrated temperature sensor for time-of-flight

correction. Accurate measurements are possible, even

if temperature changes are present

• Hermetically welded PVDF sensors FDU91/92 for

fluid measurement, for highest chemical resistance

• Integrated automatical sensor detection for

transmitters FMU90, simple commissioning

• Can be installed up to 300 m (984 ft) from the

transmitter

• Suited for rough ambient conditions thanks to separate

installation from the transmitter

• Reduced build-up formation because of the selfcleaning effect

• Integrated heating against a build-up of ice at the

sensor (optional), ensures reliable measurement

• Weather resistant and flood-proof (IP68)

• Dust-Ex and Gas-Ex certificats available (ATEX, FM,

CSA)

TI00396F/00/EN/15.12

71197998

Table of Contents

Prosonic S FDU90/91/91F/92/93/95/96

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Time-of-flight correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Blocking distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Signal transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sensor heater (for FDU91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connection hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Extension cables for the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shortening the sensor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation options (Examples) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation conditions for level measurements . . . . . . . . . . . . . . 11

Installation conditions for flow measurements . . . . . . . . . . . . . . . 12

Flush mounting with slip-on flange FAU80 . . . . . . . . . . . . . . . . . 13

Nozzle installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ultrasound guide pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Certificates and Approvals . . . . . . . . . . . . . . . . . . . . . 22

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

External standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . 22

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 23

Product structure FDU90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Product structure FDU91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Product structure FDU91F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Product structure FDU92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Product structure FDU93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Product structure FDU95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Product structure FDU96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Extension cable for sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Protective cover for FDU90 and FDU91 . . . . . . . . . . . . . . . . . . . 31

Screw in flange FAX50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Flooding protection tube for FDU90 . . . . . . . . . . . . . . . . . . . . . . 33

Cantilever with mounting frame or wall bracket . . . . . . . . . . . . . 34

Mounting bracket for ceiling mounting . . . . . . . . . . . . . . . . . . . . 36

Alignment unit FAU40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power supply RNB130 for the FDU90/FDU91 sensor heater . . . 38

IP66 protective housing for the power supply RNB130 . . . . . . . . 38

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Operating instructions (for transmitter FMU90) . . . . . . . . . . . . . 38

Description of Instrument Functions (for transmitter FMU90) . . . 39

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Process temperature, Process pressure . . . . . . . . . . . . . . . . . . . . 16

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 17

Counter nut G 1" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions FDU90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions FDU91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions FDU91F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions FDU92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions FDU93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions FDU95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dimensions FDU96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Endress+Hauser

Prosonic S FDU90/91/91F/92/93/95/96

100%

0%

D

L

F

E

BD

V

Q

D

1

2

2

1

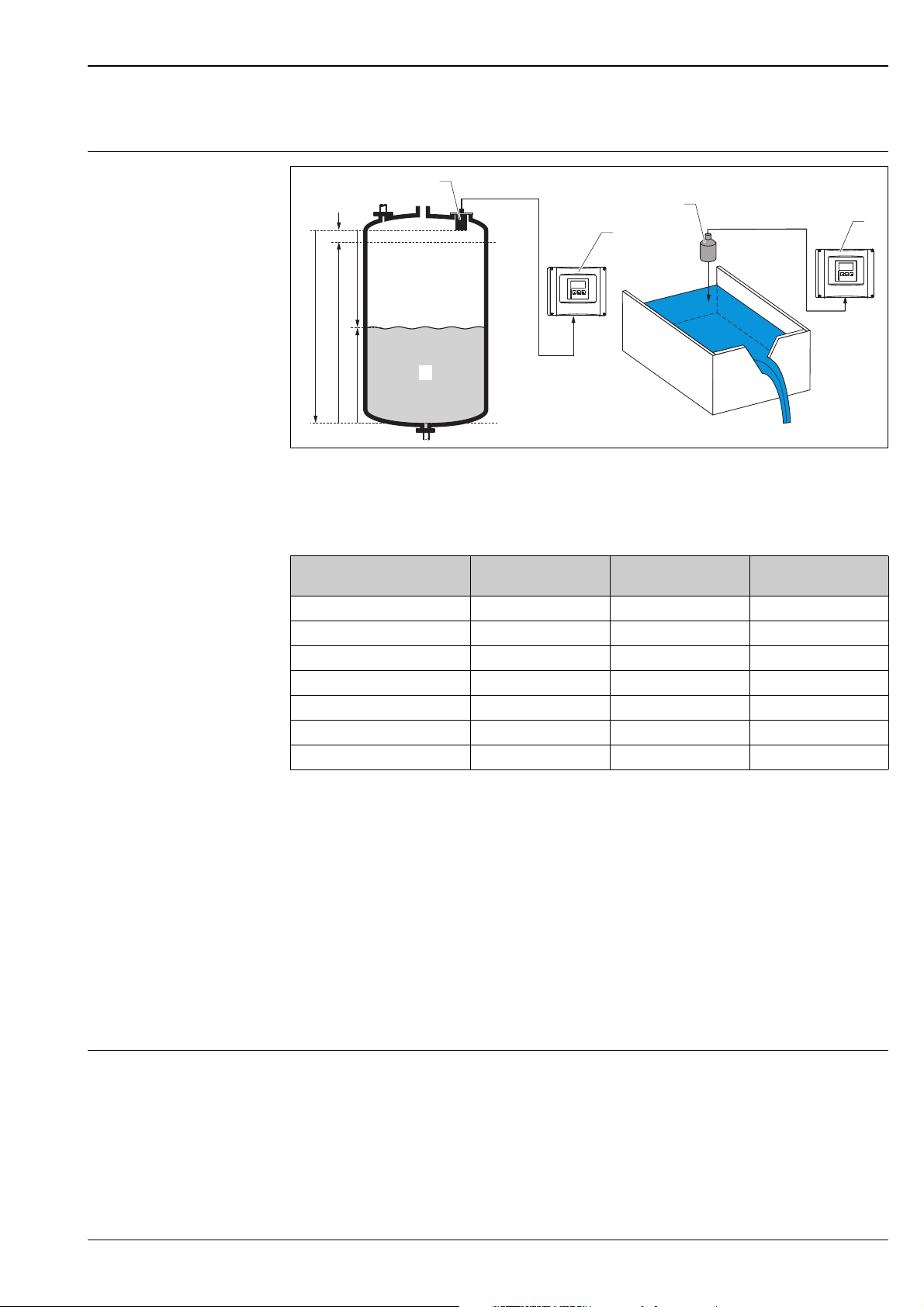

Function and system design

Measuring principle

1FDU9x

2 Prosonic S FMU90

BD: blocking distance, D: distance from sensor membrane to fluid surface, E: empty distance F: span (full distance),

L: level, V: volume (or mass), Q: flow

L00-FMU90xxx-15-00-08-xx-900

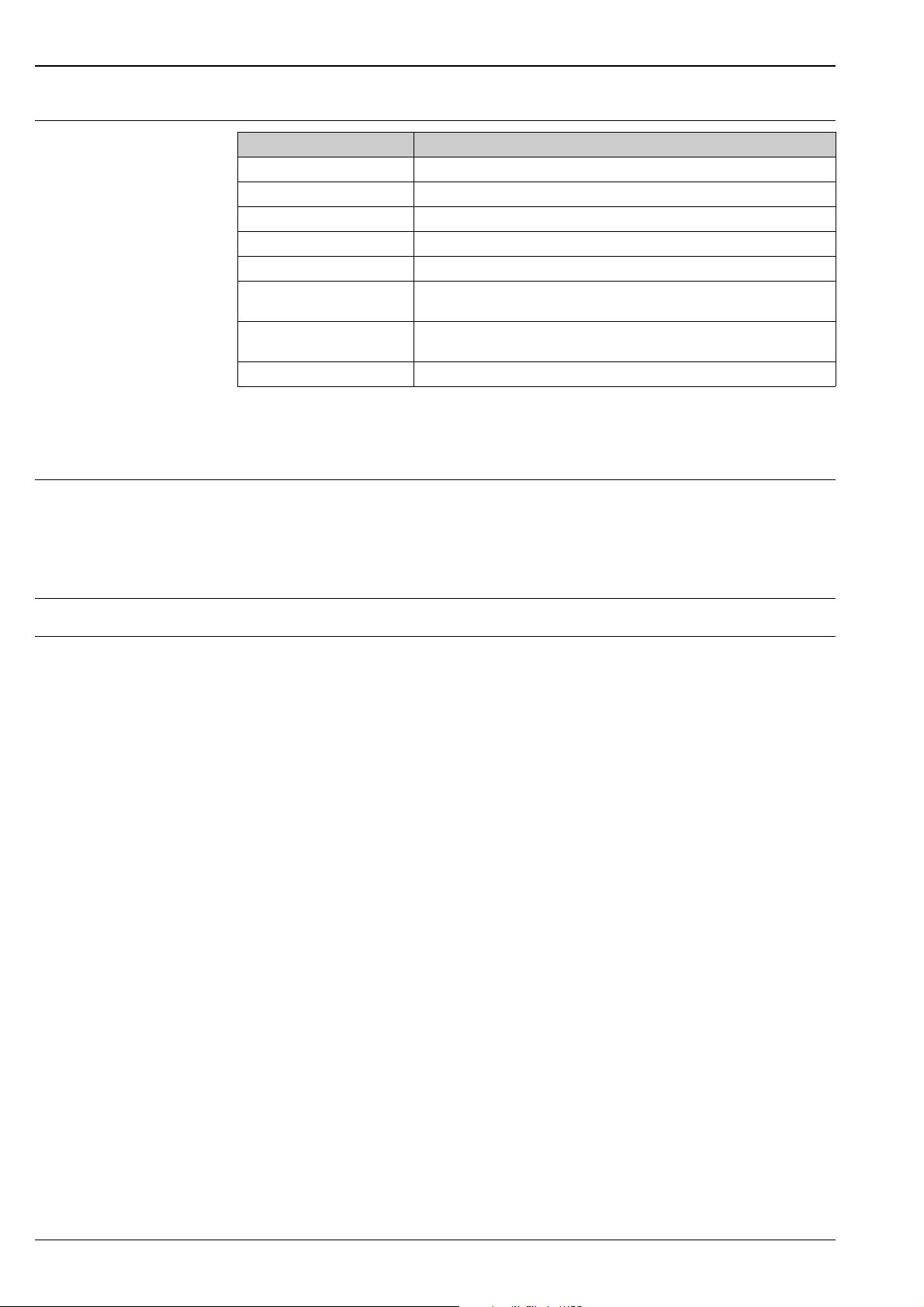

Sensor BD Maximum range

fluids

FDU90 0.07 (0.2) 3 (9.8) 1.2 (3.9)

FDU91 (F) 0.3 (1.0) 10 (33) 5 (16)

FDU92 0.4 (1.3) 20 (66) 10 (33)

FDU93 0.6 (2.0) 25 (82) 15 (49)

FDU95 (low temperature version) 0.7 (2.3) 45 (148)

FDU95 (high temperature version) 0.9 45 (148)

FDU96 1.6 70 (230)

m (ft)

Maximum range

bulk materials

Time-of-flight method

The sensor transmits ultrasonic pulses in the direction of the product surface. There, they are reflected back

and received by the sensor. The transmitter Prosonic S measures the time t between pulse transmission and

reception. From t (and the velocity of sound c) it calculates the distance D from the reference point (see the

figure ä 4) to the product surface:

D = c · t/2

From D results the desired measuring value:

• Level L

•Volume V

• Flow Q across measuring weirs or open channels

Time-of-flight correction In order to compensate for temperature dependent time-of-flight changes, a temperature sensor (NTC) is

integrated in the ultrasonic sensors.

Endress+Hauser 3

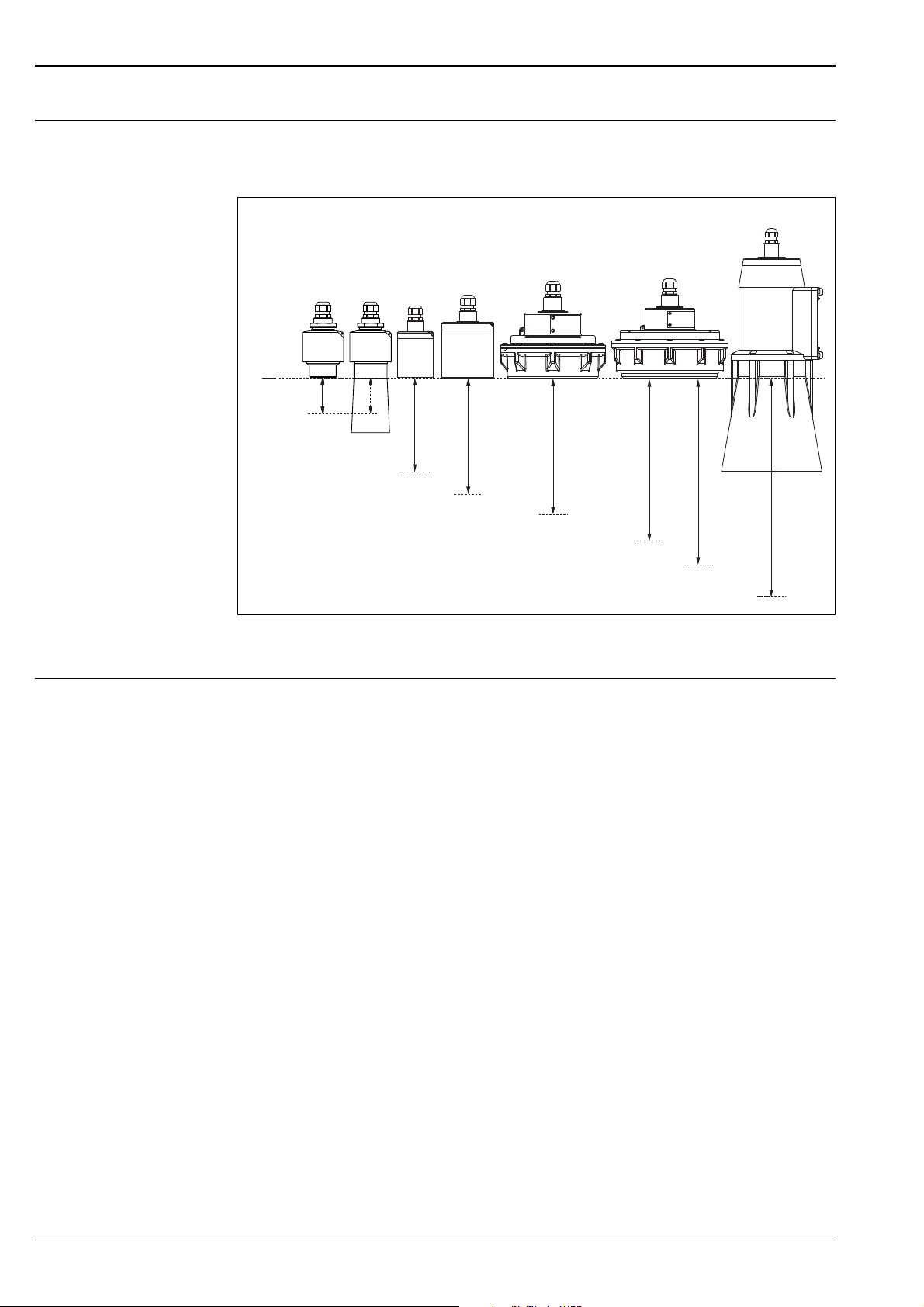

Prosonic S FDU90/91/91F/92/93/95/96

FDU91

FDU92

FDU90

0.07

(0.23)

0.3 (1.0)

0.4 (1.3)

FDU93

0.6 (2.0)

AB

FDU96

FDU95

1.6 (5.25)

FDU95-#2###: 0.9 (3.0)

FDU95-#1###: 0.7 (2.3)

C

m (ft)

Blocking distance The level L may not extend into the blocking distance BD. Level echoes within the blocking distance can not

be evaluated due to the transient characteristics of the sensor and thus a reliable measurement is not possible.

The blocking distance BD is dependent on the type of sensor:

L00-FDU9xxxx-05-00-00-xx-002

A: Without flooding protection tube, B: With flooding protection tube, C: Reference point of the sensor

Transmitter The sensors can be connected to the transmitter FMU90 and FMU95. The transmitter recognizes the type of

sensor automatically.

4 Endress+Hauser

Prosonic S FDU90/91/91F/92/93/95/96

0 20 40 60 80 100

11 0

45

70

25

20

10

0

FDU95

FDU96

FDU93

FDU92

A[dB]

R [m]

FDU90

3

FDU91 F

50

( )

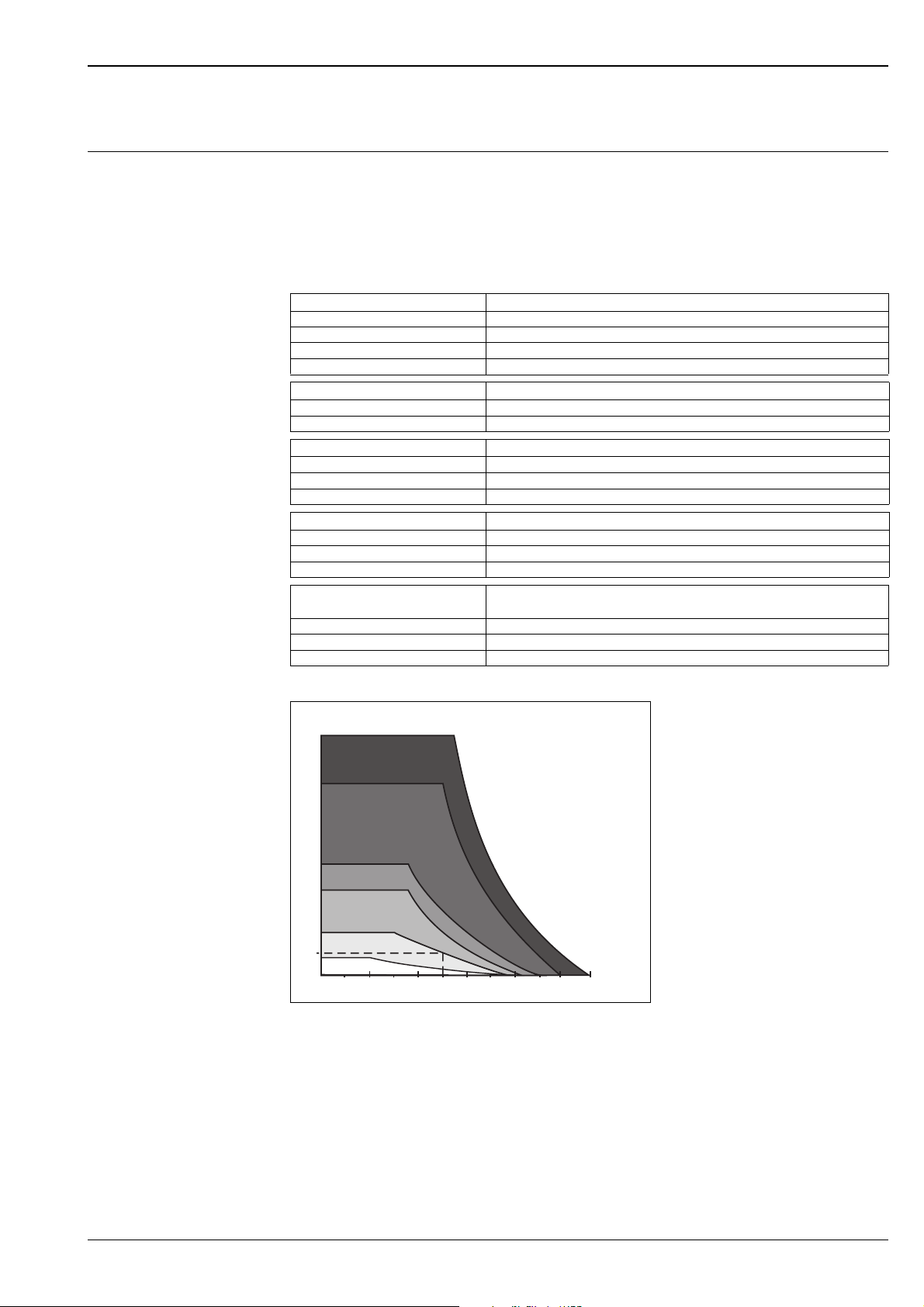

Input

Measuring range The effective range of the sensors is dependent on the operating conditions. To estimate the range, proceed as

follows (see also the example):

1. Determine which of the influences shown in the following table are appropriate for your process.

2. Add the corresponding attenuation values.

3. From the total attenuation, use the diagram to calculate the range.

Fluid surface Attenuation

calm 0 dB

waves 5 to 10 dB

strong turbulence (e.g. stirrers) 10 to 20 dB

foaming Please contact your Endress+Hauser sales representative.

Bulk material surface Attenuation

hard, rough (e.g. rubble) 40 dB

soft (e.g. peat, dust-covered clinker) 40 to 60 dB

Dust Attenuation

no dust formation 0 dB

little dust formation 5 dB

heavy dust formation 5 to 20 dB

Filling curtain in detection range Attenuation

none 0 dB

small quantities 5 dB

large quantities 5 to 20 dB

Temperature difference between

sensor and product surface

to 20 °C (68 °F) 0 dB

to 40 °C (104 °F) 5 to 10 dB

to 80 °C (176 °F) 10 to 20 dB

Attenuation

Example for FDU91(F)

• Silo with rubble: ~ 40dB

• Small quantities of

filling curtain: ~ 5dB

• Little dust: ~ 5dB

total: ~ 50dB

Range approx. 5 m (16 ft)

L00-FDU9xxxx-05-00-00-xx-100

A: Attenuation (dB)

R: Range (m)

These measuring conditions have been taken into account during the calculation of the maximum measuring

range in solid applications.

Endress+Hauser 5

Prosonic S FDU90/91/91F/92/93/95/96

Operating frequency

Sensor Operating frequency

FDU90 90 kHz

FDU91 43 kHz

FDU91F 42 kHz

FDU92 30 kHz

FDU93 27 kHz

FDU95 - *1***

(low temperature version)

FDU95 - *2***

(high temperature version)

FDU96 11 kHz

Output

Signal transmission analogue voltages

Power supply

17 kHz

18 kHz

Power supply supplied by the transmitter FMU90

Sensor heater (for FDU91) The FDU90 and FDU91 sensors are optional available in a version with heater. The power for this heater must

be provided by an external power supply unit. The supply voltage is connected to the brown (BN) and blue

(BU) strands of the sensor cable.

Technical data

• 24 VDC ±10 %; residual ripple < 100 mV

• 250 mA per sensor

Note!

• If the sensor heater is applied, the integrated temperature sensor can not be used. Instead, an external

temperature sensor (Pt100 or FMT131 from Endress+Hauser) must be used. The transmitter FMU90 is

available in a version with an input for the external temperature sensor. For details refer to Technical

Information TI00397F.

• The power for the sensor heater can be supplied by the power supply RNB130 from Endress+Hauser

( ä 31 "Accessories").

6 Endress+Hauser

Prosonic S FDU90/91/91F/92/93/95/96

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU90/91/92

(FDU80/80F/81/81F/82)

BK

YE

RD

1

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU91F/93/95/96

(FDU83/84/85/86)

BK

YE

RD

GNYE

2

3

FMU90

2

3

FMU90

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU90/91

(FDU80/81)

BK

YE

RD

FMU90

BN BU

24VDC

+

-

A

B

C

YE

9

(12)

BK

10

(13)

RD

11

(14)

FDU91F/93/95/96

(FDU83/84/85/86)

BK

YE

RD

GNYE

FMU90

D

FDU90/91/92

(FDU80/80F/81/81F/82)

FDU91F/93/95/96

(FDU83/84/85/86)

300 m

(984 ft)

≤

≤30 m

(98 ft)

1

300 m

(984 ft)

≤

≤30 m

(98 ft)

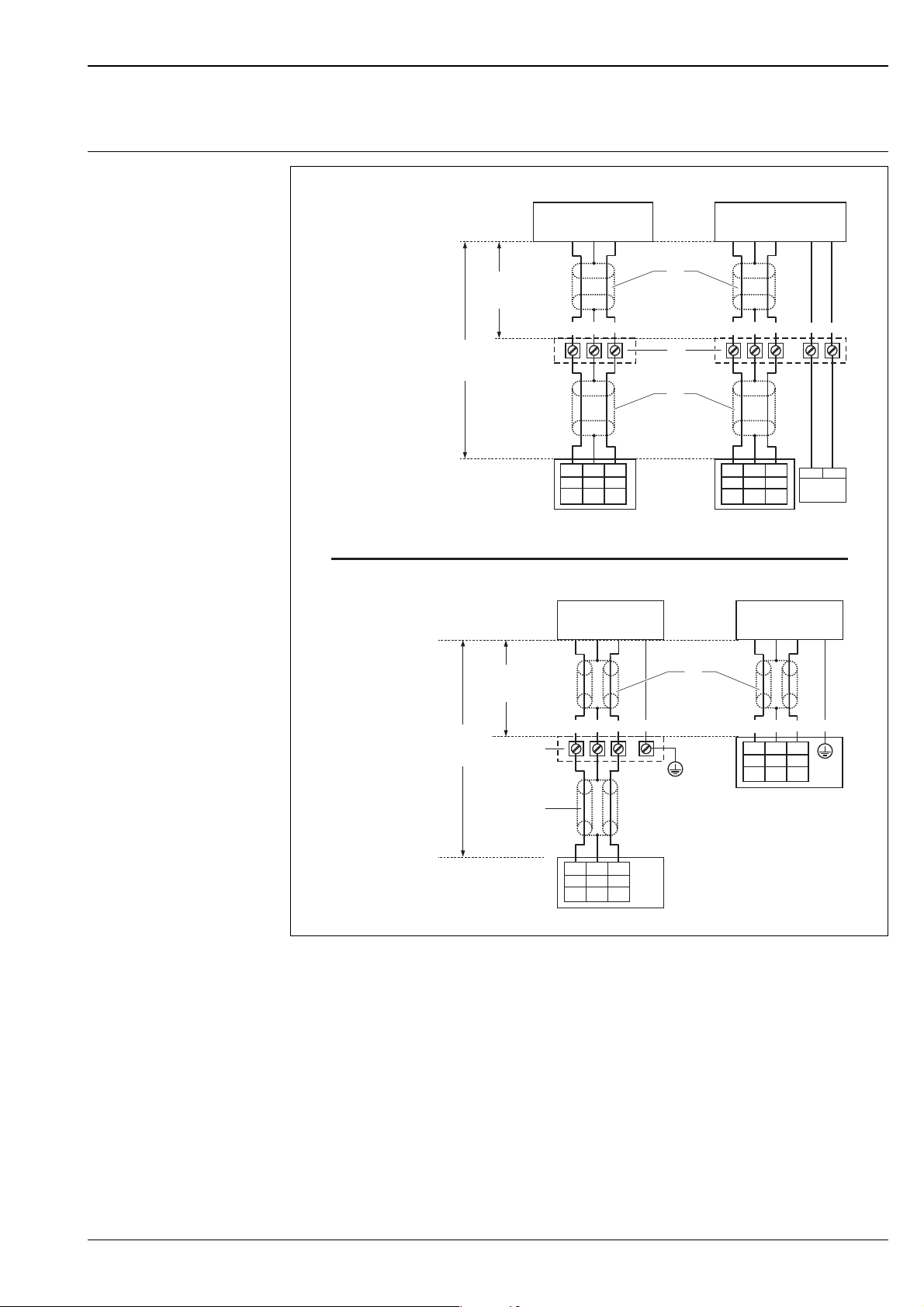

Electrical connection

Connection diagram

A Without sensor heater

B With sensor heater

C Grounding at the terminal box

D Grounding at the transmitter FMU90

L00-FDU9xxxx-04-00-00-xx-002

1 Screen of the sensor cable

2 Terminal box

3 Screen of the extension cable

Colours of the strands: YE = yellow; BK = black; RD = red; BU = blue; BN = brown; GNYE = green-yellow

Endress+Hauser 7

Connection hints Caution!

• In order to avoid interference signals, the sensor cables should not be laid parallel to high voltage electric

power lines. The cables may not be laid in the proximity to frequency converters.

• The cable screen serves as a return cable and must be connected to the transmitter without any electrical

break. With the pre-assembled cables, the screen ends in a black strand (BK). With the extension cable, the

screen must be twisted together and connected to the "BK" terminal. The cable screen must not be

connected to the local potential equalization.

Warning!

• The sensors FDU83, FDU84, FDU85 and FDU86 with an ATEX, FM or CSA certificate are not certified for

connection to the FMU90 transmitter.

• for the sensors FDU91F/93/95/96 and FDU83/84/85/86:

The ground lead (GNYE) must be connected to the local potential equalization after a maximum distance

of 30 m (98 ft). This can be done either

– at the terminal box or

– at the transmitter FMU90 or in the cabinet (if the distance to the sensor does not exceed 30 m (98 ft)).

Note!

For easier mounting it is advisable to use the sensors FDU90/91/92 and FDU80/80F/81/81F/82 with a

maximum cable length of 30 m (98 ft) as well. For longer distances an extension cable with a terminal box

should be used.

Prosonic S FDU90/91/91F/92/93/95/96

Extension cables for the sensors

For distances up to 30 m (98 ft) the sensor can be directly connected by the sensor cable. For longer distances,

it is recommended to use an extension cable. The extension cable is connected via a terminal box. The total

length (sensor cable + extension cable) may be up to 300 m (984 ft).

Caution!

If the terminal box is installed in explosion hazardous areas, all applicable national guidelines must be observed.

Suitable extension cables can be obtained from Endress+Hauser ( ä 31 "Accessories")

Alternatively, cables with the following properties can be used:

• Number of cores according to the connection diagram ( ä 7 "Connection diagram")

• braided wire screen for the yellow (YE) and red (RD) core (no foil screen)

• Length: up to 300 m (984 ft), sensor cable + extension cable

• Cross section: 0.75 mm

2

to 2.5 mm2 (18 to 14 AWG)

• up to 8 per core

• max. 60 nF (between core and screen)

• for FDU91F/93/95/96 and FDU 83/84/85/86: The earth lead must not be within the screening.

8 Endress+Hauser

Prosonic S FDU90/91/91F/92/93/95/96

FDU90/91/92

(FDU80/80F/81/81F/82)

FDU91F/93/95/96

(FDU83/84/85/86)

RD

BK

YE

RD

BK

YE

24VDC

BN (+)

BU(-)

GNYE

BN

BU

RD

YE

GNYE

RD

YE

Shortening the sensor cable If required, the sensor cable can be shortened. Please note:

• Do not damage the cores when removing the insulation.

• The cable is shielded by a metallic braiding. This shielding serves as a return cable and corresponds to the

black (BK) strand of the unshortened cable. After shortening the cable, loosen the metallic braiding, twist it

together securely and connect it to the "BK" terminal.

Caution!

The protective earth conductor (GNYE), which is present in some of the sensor cables, may not be electrically

connected to the cable shield.

L00-FMU90xxx-04-00-00-xx-015

Colours of the strands: YE = yellow; BK = black; RD = red; BU = blue; BN = brown; GNYE = green-yellow

Note!

The blue (BU) and brown (BN) strands is only present for sensors with heater.

Endress+Hauser 9

Installation options

ABC

-

-

.

3

2

1

A

B

C

1

1

ABC D

41 mm

(Examples)

Prosonic S FDU90/91/91F/92/93/95/96

Installation

L00-FDU9xxxx-17-00-00-xx-001

1FAU40

2Zone 20

3Zone 21

A: at girder or angle bracket, B: with alignment unit FAU40, in ATEX Zone 20 the alignment unit can be used for zone

separation, C: with a 1" sleeve welded to a grating

L00-FDU9xxxx-17-00-00-xx-007

1 FDU9x

A: Installation with cantilever and wall bracket, B: Installation with cantilever and mounting frame, C: The cantilever can

be turned in order to position the sensor over the centre of the flume.

Cantilever, wall bracket and mounting frame are available as accessories ( ä 31).

L00-FDU90xxxx-17-00-00-xx-001

A: FDU90: Ceiling mounting

B: FDU90: Mounted at front thread (G 1½" or NPT 1½" )

C: FDU9x: Mounted at rear thread (G 1" or NPT 1")

D: FDU90, FDU91, FDU92: Mounting with G 1" counter nut

1)

Caution!

• The cable of the sensors is not designed as a supporting cable. Do not use it as a suspension wire.

1) The counter nut with gasket is supplied for the sensors FDU90, FDU91 and FDU92 with a metric thread G 1" at the process connection.

• The sensor membrane is part of the measuring system and must not be damaged during installation.

10 Endress+Hauser

Prosonic S FDU90/91/91F/92/93/95/96

1

4

5

1/6D

r

a

L

BD

6

BD

23

D

BD

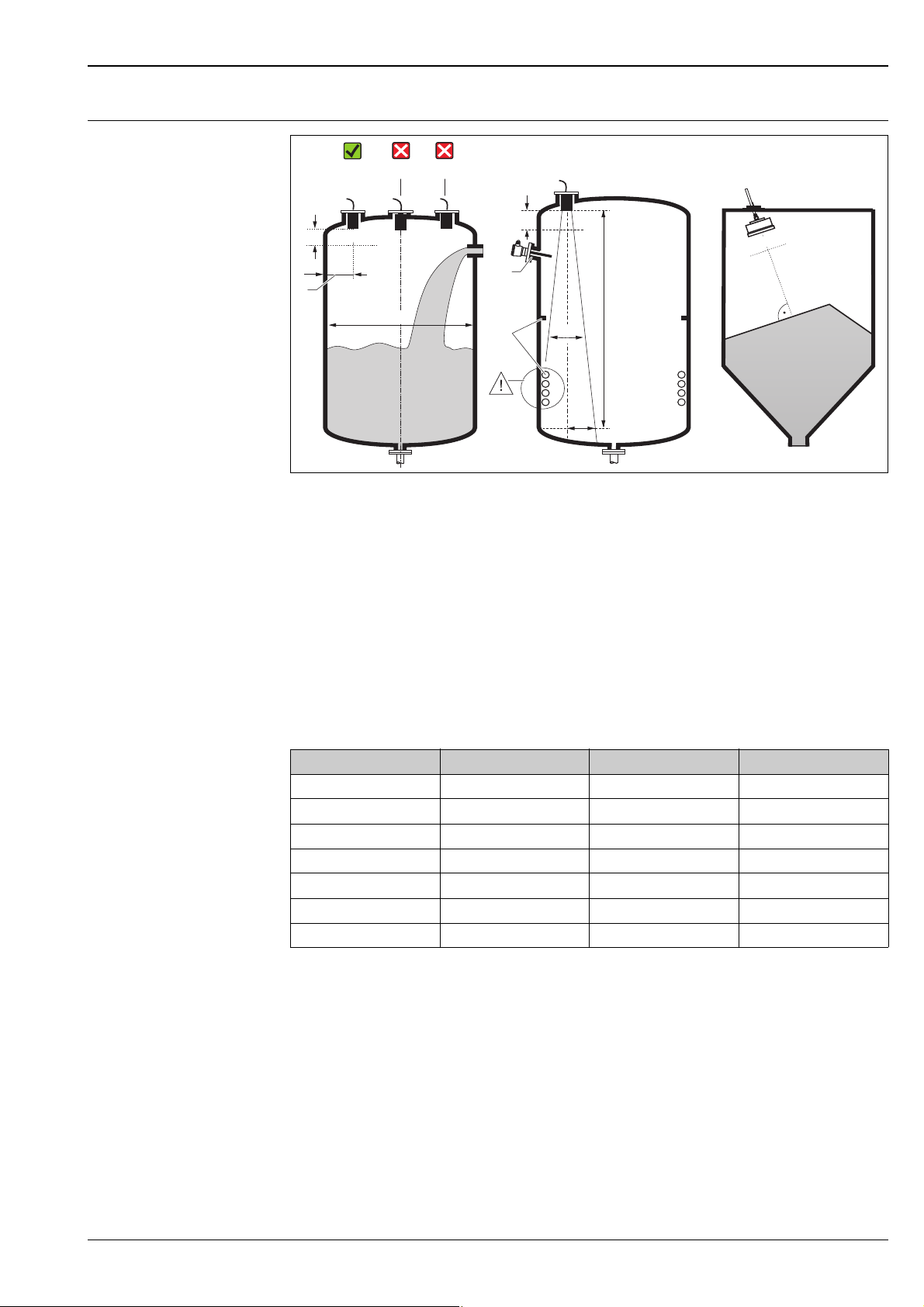

Installation conditions for level measurements

L00-FDU9xxxx-17-00-00-xx-003

• If possible, install the sensor so that its lower edge projects into the vessel.

• Make sure, that the maximum level does not reach into the blocking distance (BD, see table).

• Do not install the sensor in the middle of the tank (2). We recommend leaving a distance (1) between the

sensor and the tank wall measuring 1/6 of the tank diameter.

• Avoid measurements through the filling curtain (3).

• Make sure that equipment (4) such as limit switches, temperature sensors, baffles etc. are not located within

the emitting angle . Emitting angles of the individual sensors are given in the table below. In particular,

symmetrical equipment (5) such as heating coils etc. can influence the measurement.

• Align the sensor vertically to the product surface (6). An alignment unit (FAU40) is available as an accessory

( ä 31).

• If the two-channel version of the transmitter FMU90 or the multi-channel version of the transmitter FMU90

is used, both sensors can be mounted in one vessel.

• To estimate the detection range, use the 3 dB emitting angle :

Sensor (typically) L (max) r (max)

FDU90 12° 3 (9.8) 0.31 (1.0)

FDU91 9° 10 (33) 0.79 (2.6)

FDU91F 12° 10 (33) 1.05 (3.4)

FDU92 11° 20 (66) 1.92 (6.3)

FDU93 4° 25 (82) 0.87 (2.9)

FDU95 5° 45 (148) 1.96 (6.4)

FDU96 6° 70 (230) 3.6 (12)

m (ft)

Endress+Hauser 11

Warning!

All national guidelines applicable must be observed in explosion hazardous areas.

Prosonic S FDU90/91/91F/92/93/95/96

BD

A

E

BC

H

max

=F

1 x b

0

b

0

V

max

min. 3 H

BD

H

max

E

(= F)

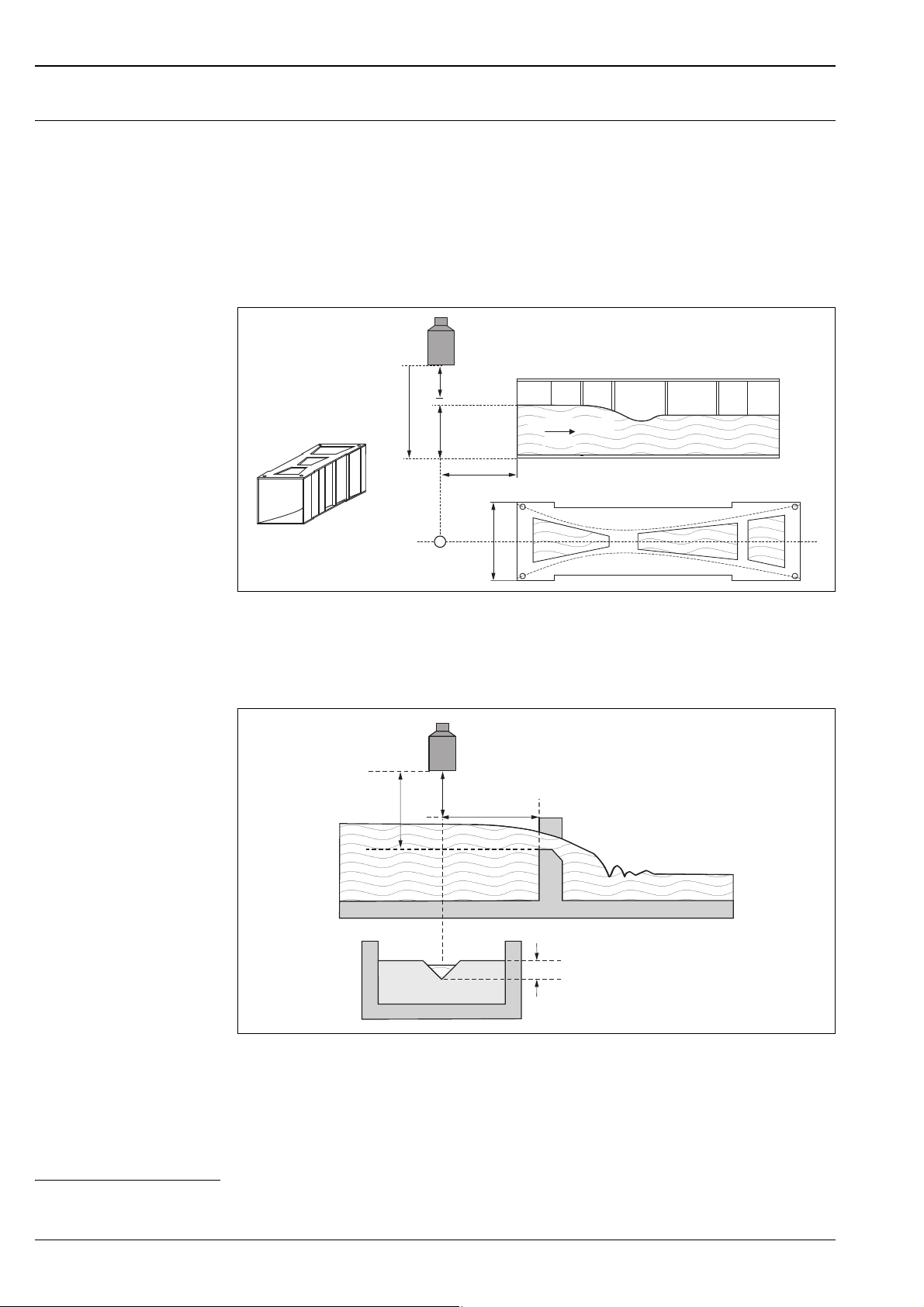

Installation conditions for flow measurements

• Install the sensor at the inflow side (B), above the maximum water level H

(=F) plus the blocking distance

max

BD.

• Position the sensor in the middle of the channel or weir.

• Align the sensor vertically to the water surface.

• Comply to the installation distance of the channel or weir.

2)

• Use a protective cover, in order to protect the sensor from direct sun or rain. A protective cover is available

for the sensors FDU90 and FDU91 ( ä 31).

Example: Khafagi-Venturi flume

L00-FDU9xxxx-17-00-00-xx-004

A: Khafagi-Venturi flume, B: inflow, C: outflow, BD: blocking distance, E: empty calibration, F: full calibration,

V: direction of flow

Example: V-notch weir

L00-FDU9xxxx-17-00-00-xx-005

BD: blocking distance, E: empty calibration, F: full calibration

2) The installation distances of important flumes and weirs are specified in the Operating Instructions BA00289F (FMU90 with HART) and BA00293F (FMU90

with PROFIBUS).

12 Endress+Hauser

Loading...

Loading...