Endress+Hauser Prosonic M FMU40, Prosonic M FMU41, Prosonic M FMU42, Prosonic M FMU43, Prosonic M FMU44 Brief Operating Instructions

KA01063F/00/EN/13.11

71145352

Brief Operating Instructions

Prosonic M FMU40/41/42/43/44

Ultrasonic Level Measurement

These Instructions are Brief Operating Instructions; they do not replace the

Operating Instructions included in the scope of supply.

For detailed information, refer to the Operating Instructions and other

documentation on the CD-ROM provided or visit "www.endress.com/

deviceviewer".

Prosonic M PROFIBUS PA

2

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Installation, commissioning and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Operational safety and process safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Safety icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Incoming acceptance, storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Installation hint for FMU40/41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Turn housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Wiring in F12/F23 housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Wiring in T12 housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Wiring with M12 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Pin assignment of the M12 plug connector (PROFIBUS PA plug) . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6 Cable specification PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.7 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.8 Recommended connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.9 Checking the connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Operating options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 General structure of the operating menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Display and operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Device address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Switching on the measuring device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Prosonic M PROFIBUS PA Safety instructions

Endress+Hauser 3

1 Safety instructions

1.1 Designated use

The Prosonic M is a compact measuring device for continuous, non-contact level measurement.

Depending on the sensor, the measuring range is up to 20 m (66 ft) in fluids and up to 10 m

(33 ft) in bulk solids. By using the linearisation function, the Prosonic M can also be used for

flow measurements in open channels and measuring weirs.

1.2 Installation, commissioning and operation

• The device must only be installed, connected, commissioned and maintained by qualified and

authorized specialists (e.g. electrical technicians) in full compliance with the instructions in

this manual, the applicable norms, legal regulations and certificates (depending on the

application).

• The specialist must have read and understood this manual and must follow the instructions it

contains. If you are unclear on anything in these Brief Operating Instructions, you must read

the Operating Instructions (on the CD-ROM). The Operating Instructions provide detailed

information on the device/measuring system.

• The device may only be modified or repaired if such work is expressly permitted in the

Operating Instructions (→ see CD-ROM).

• If faults cannot be rectified, the device must be taken out of service and secured against

unintentional commissioning.

• Do not operate damaged devices. Mark them as defective.

1.3 Operational safety and process safety

• Alternative monitoring measures must be taken to ensure operational safety and process safety

during confiugration, testing and maintenance work on the device.

• The device is safely built and tested according to state-of-the-art technology and has left the

factory in perfect condition as regards technical safety. The applicable regulations and

European standards have been taken into account.

• Pay particular attention to the technical data on the nameplate.

• If the device is to be installed in an explosion hazardous area, then the specifications in the

certificate as well as all national and local regulations must be observed. The device is

accompanied by separate "Ex documentation", which is an integral part of this Operating

Instructions. The installation regulations, connection values and Safety Instructions listed in

this Ex document must be observed. The documentation number of the related Safety

Instructions is also indicated.

• If using devices for applications with safety integrity level, the separate manual on functional

safety must be observed thoroughly (→ see CD-ROM).

Mounting Prosonic M PROFIBUS PA

4 Endress+Hauser

1.4 Return

Follow the instructions on returning the device as outlined in the Operating Instructions on the

CD-ROM provided.

1.5 Safety icons

2 Mounting

2.1 Incoming acceptance, storage

2.1.1 Incoming acceptance

Check the packing and contents for any signs of damage. Check the shipment, make sure

nothing is missing and that the scope of supply matches your order.

2.1.2 Storage

Pack the measuring instrument so that is protected against impacts for storage and transport. The

original packing material provides the optimum protection for this.

The permissible storage temperature is -40 °C to +80 °C (-40 °F to +176 °F).

Symbol Meaning

#

Warning!

A warning highlights actions or procedures which, if not performed correctly, will lead to personal injury,

a safety hazard or destruction of the instrument.

"

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal injury or

incorrect functioning of the instrument.

!

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect operation

or may lead to an instrument response which is not planned.

Prosonic M PROFIBUS PA Mounting

Endress+Hauser 5

2.2 Installation

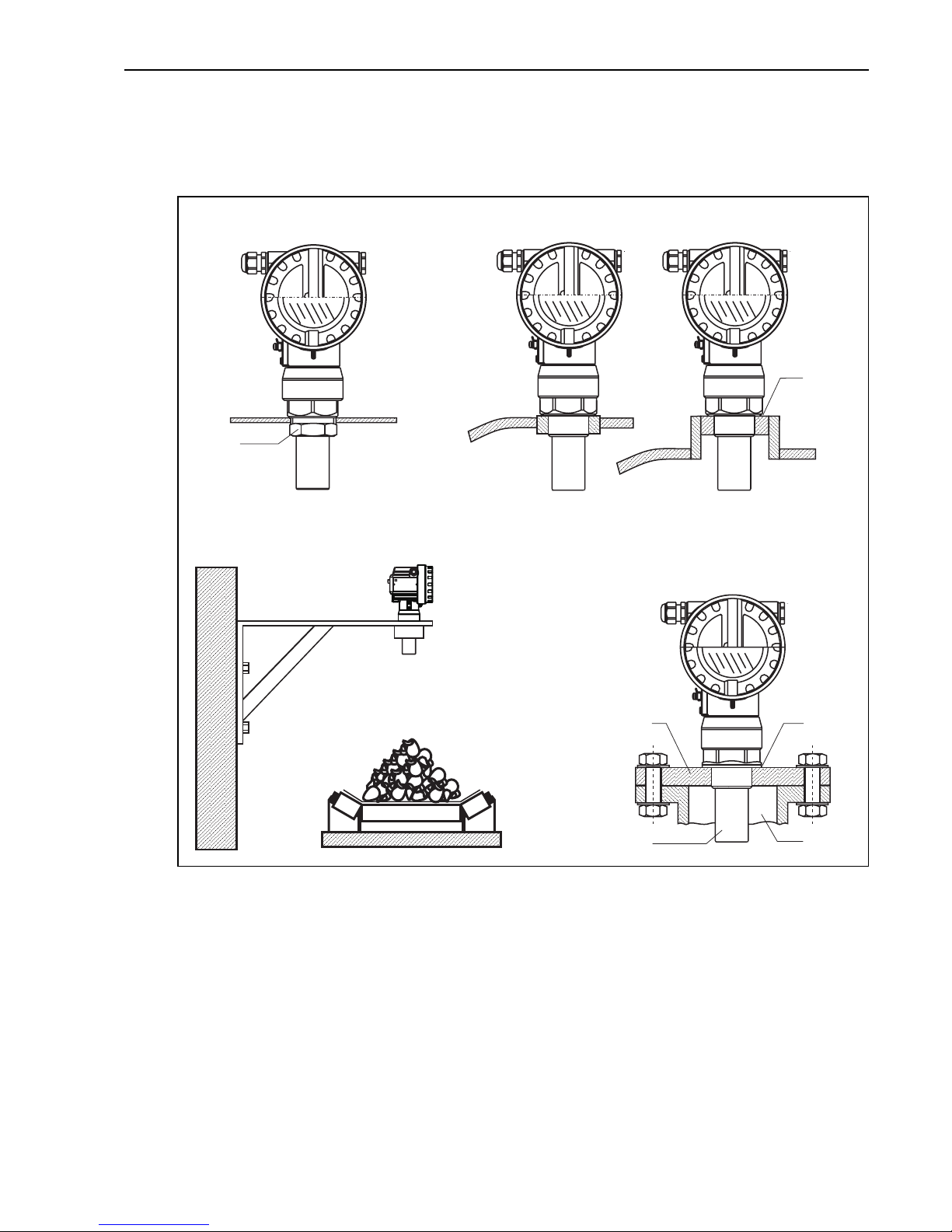

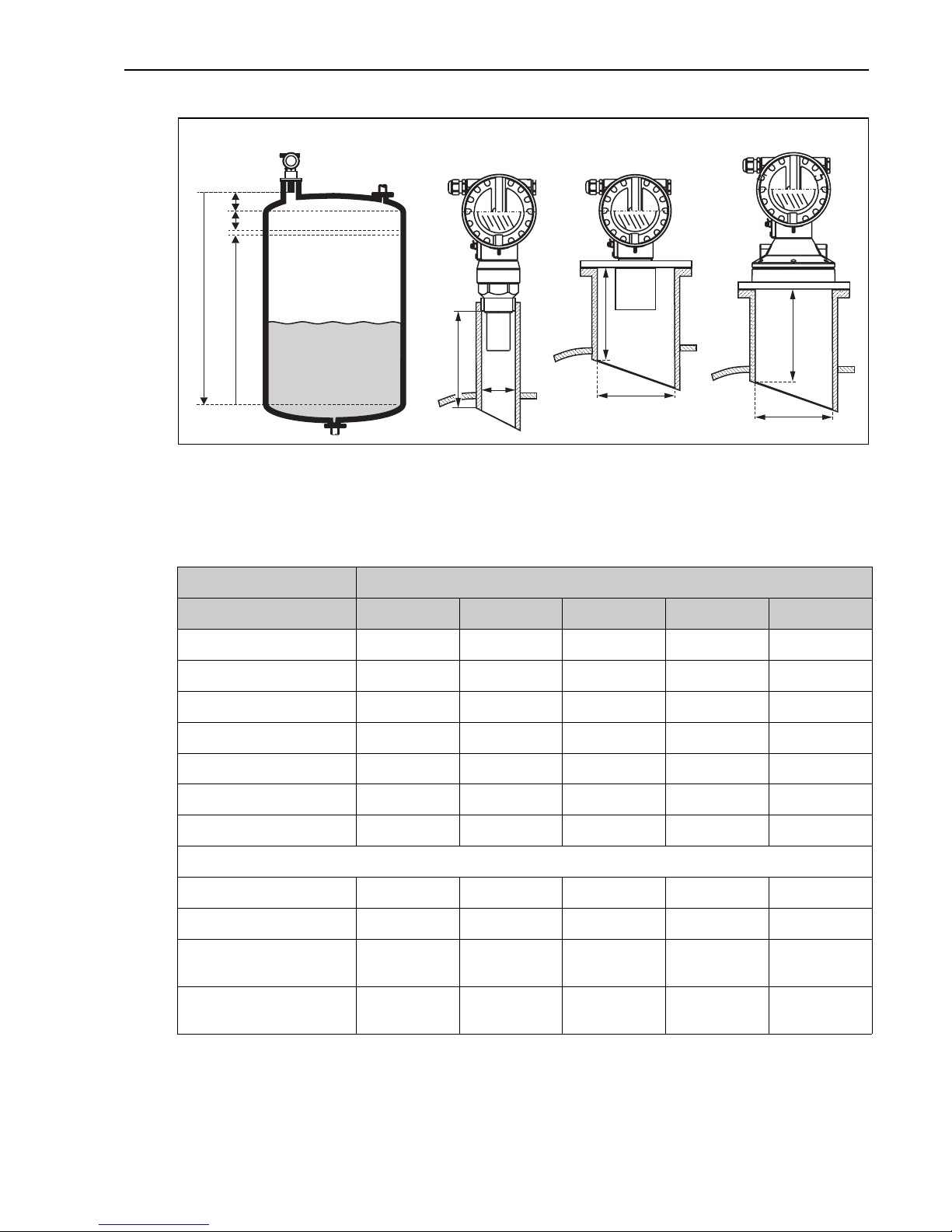

2.2.1 Installation variants FMU40, FMU41

L00-FMU4xxxx-17-00-00-yy-002

A Installation with counter nut

1 Counter nut (PC) supplied for G1½ and G2 instruments

B Installation with sleeve

1 Sealing ring (EPDM) supplied

C Installation with installation bracket

D Installation with screw in flange

1 Sealing ring (EPDM) supplied

2 Nozzle

3Sensor

4 Screw in flange

ENDRESS+HAUSER

Prosonic M

AB

C

D

1

1

1

2

3

4

Mounting Prosonic M PROFIBUS PA

6 Endress+Hauser

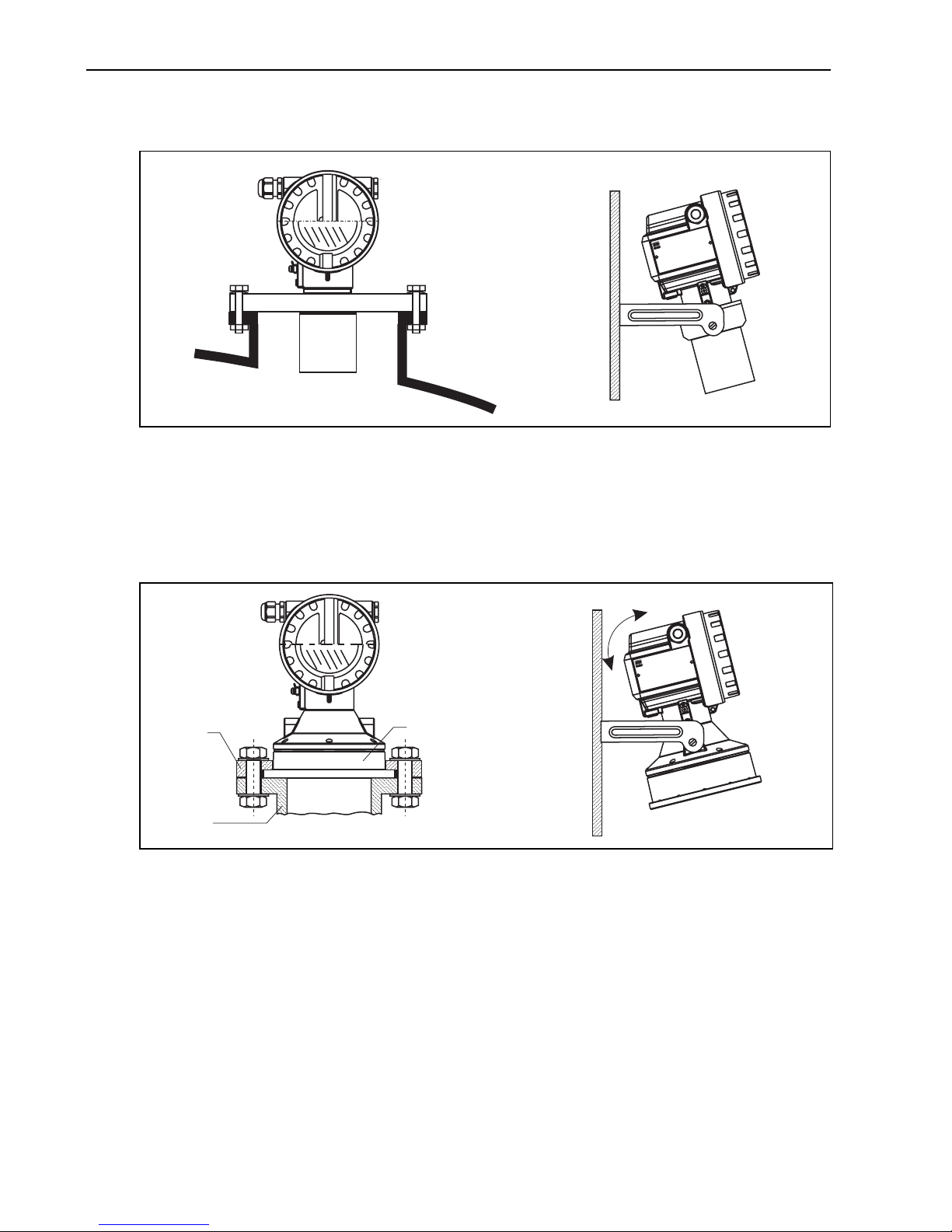

2.2.2 Installation variants FMU42, FMU44

L00-FMU42xxxx-17-00-00-xx-002

A Installation with universal flansch

B Installation with mounting bracket

2.2.3 Installation variants FMU43

L00-FMU43xxxx-17-00-00-x-002

A Installation with universal slip-on flange (option)

1Sensor

2 Nozzle

3 Slip-on flange

B Installation with mounting bracket

ENDRESS+HAUSER

ProsonicM

AB

ENDRESS+HAUSER

ProsonicM

1

3

2

A

B

Prosonic M PROFIBUS PA Mounting

Endress+Hauser 7

2.3 Installation conditions

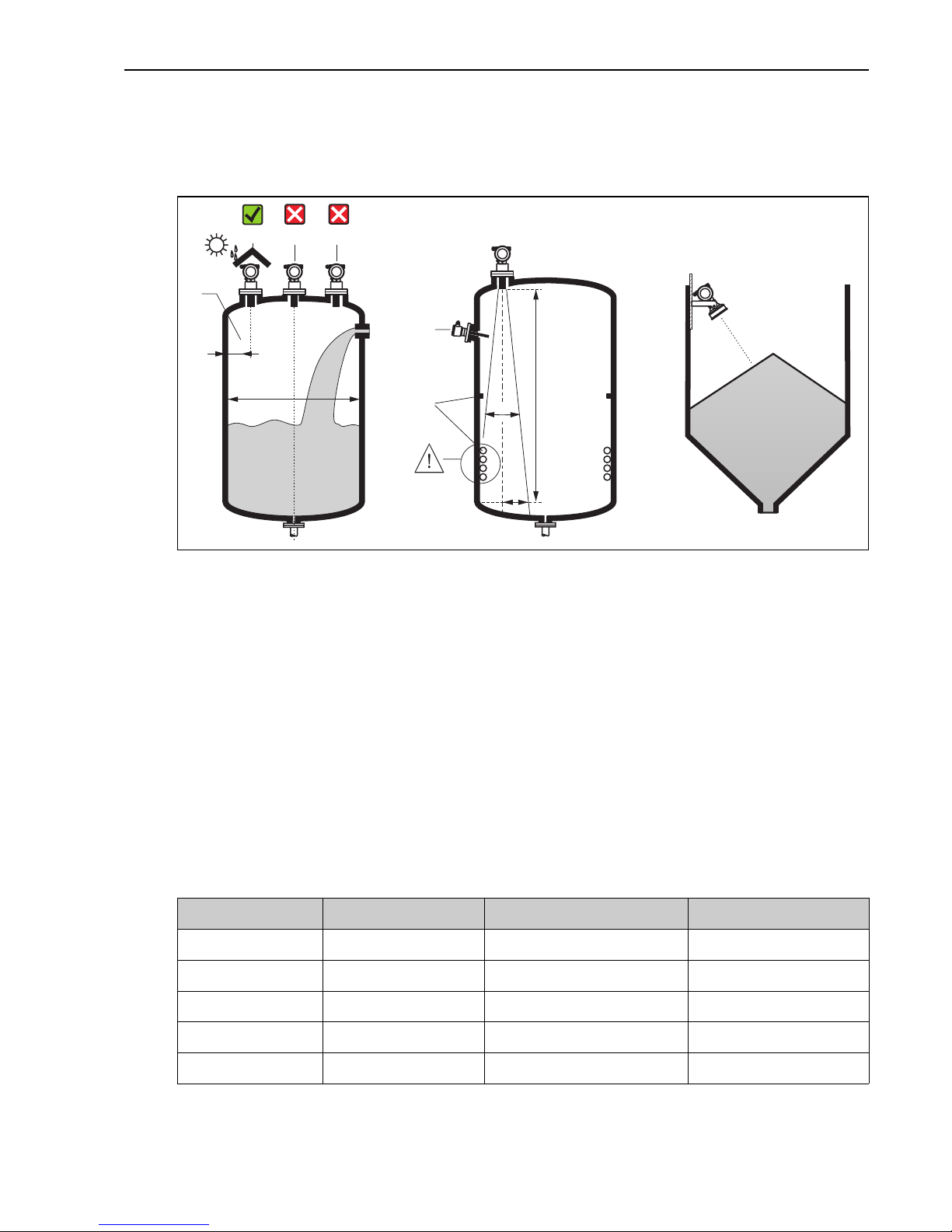

2.3.1 Installation conditions for level measurements

L00-FMU4xxxx-17-00-00-yy-005

• Do not install the sensor in the middle of the tank (3). We recommend leaving a distance

between the sensor and the tank wall (1) measuring 1/6 of the tank diameter.

• Use a protective cover, in order to protect the device from direct sun or rain (2) see the

Technical Information TI00365F, Chapter "Accessories" on the CD-ROM provided.

• Avoid measurements through the filling curtain (4).

• Make sure that equipment (5) such as limit switches, temperature sensors, etc. are not located

within the emitting angle α. In particular, symmetrical equipment (6) such as heating coils,

baffles etc. can influence measurement.

• Align the sensor so that it is vertical to the product surface (7).

• Never install two ultrasonic measuring devices in a tank, as the two signals may affect each

other.

• To estimate the detection range, use the 3 dB emitting angle α.

Sensor α L

max

r

max

FMU40 11° 5 m (16 ft) 0.48 m (1.6 ft)

FMU41 11° 8 m (26 ft) 0.77 m (2.5 ft)

FMU42 9° 10 m (33 ft) 0.79 m (2.6 ft)

FMU43 6° 15 m (49 ft) 0.79 m (2.6 ft)

FMU44 11 ° 20 m (66 ft) 1.93 m (6.3 ft)

1

234

5

6

1/6D

7

D

r

a

L

Mounting Prosonic M PROFIBUS PA

8 Endress+Hauser

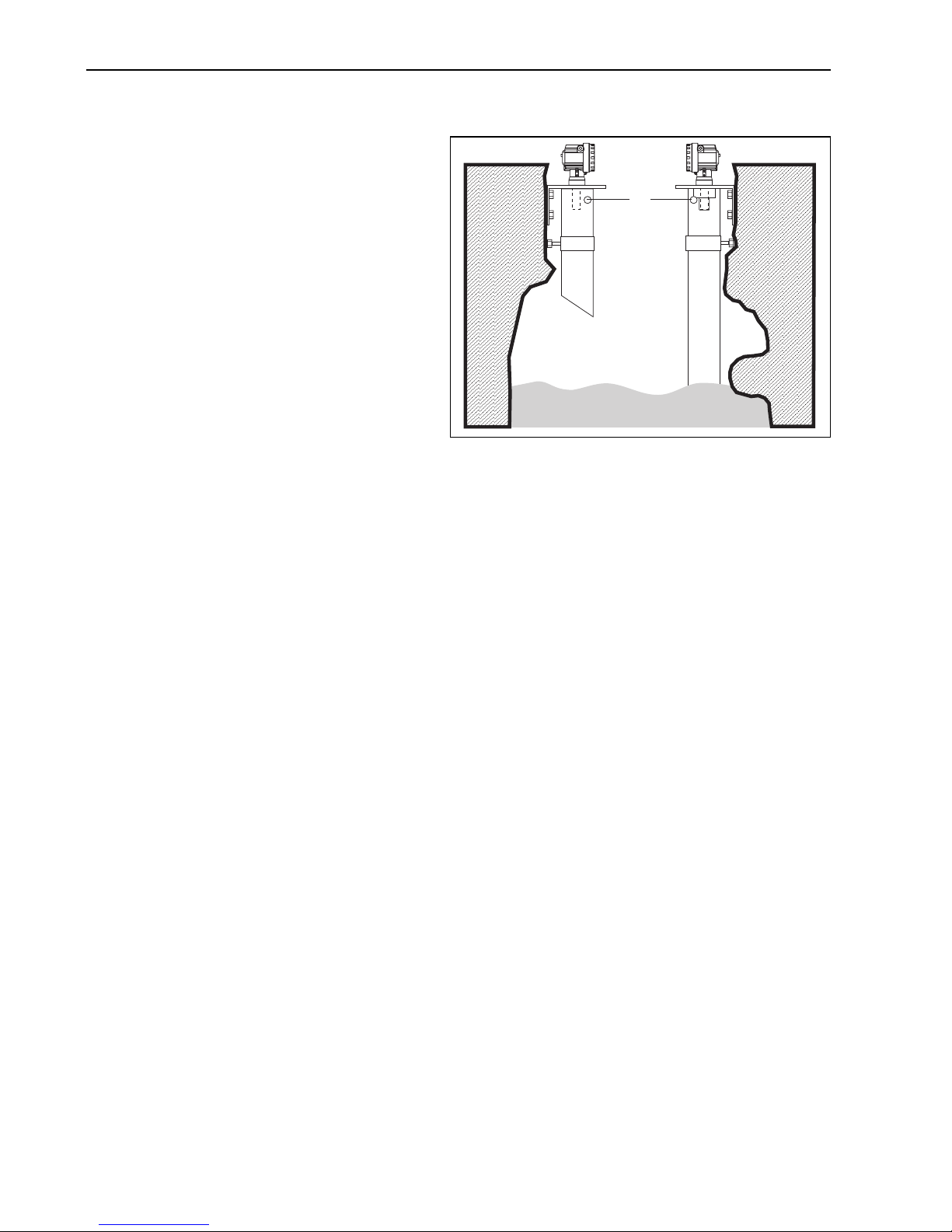

2.3.2 Installation in narrow shafts

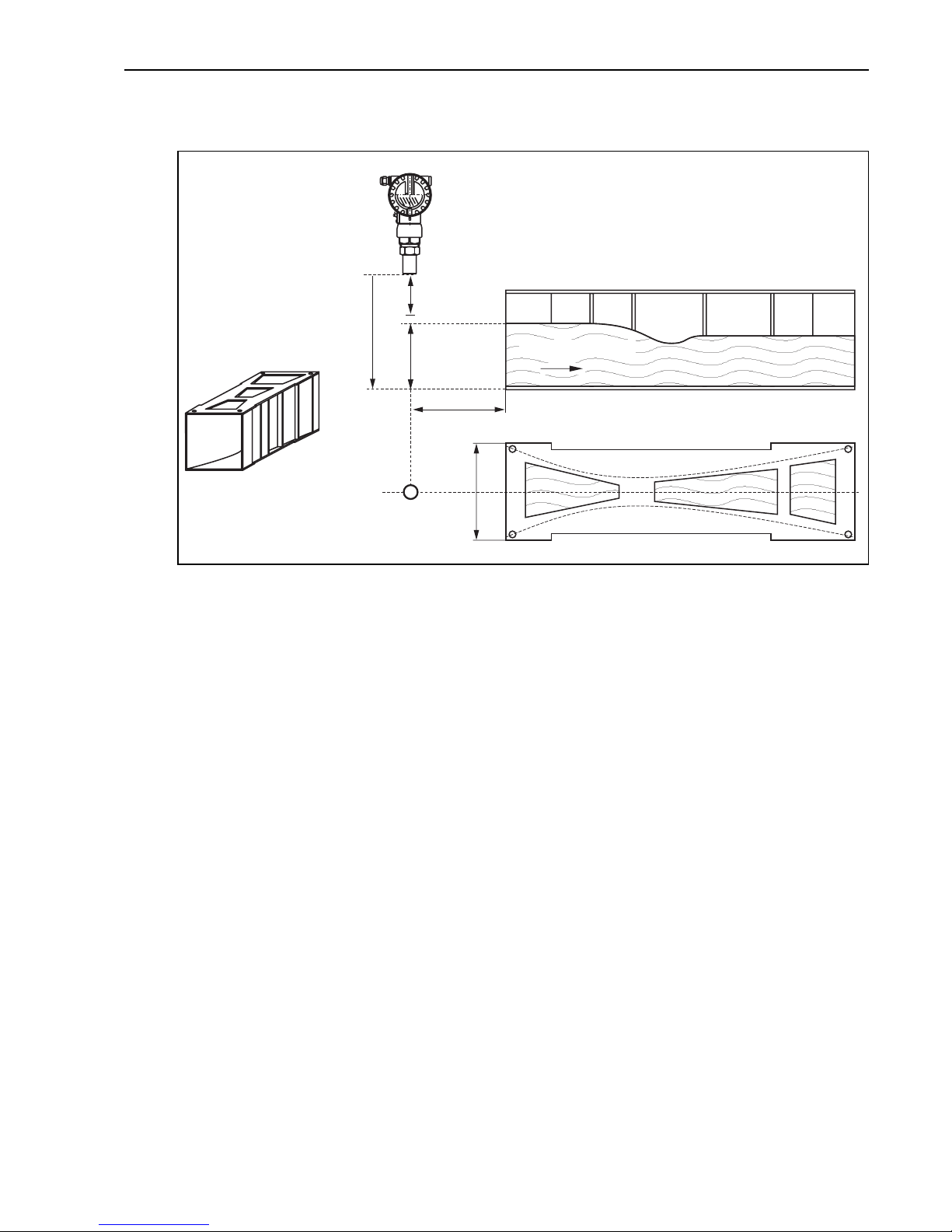

2.3.3 Installation conditions for flow measurements

• Install the Prosonic M at the inflow side, as close above the maximum water level H

max

as

possible (take into account the blocking distance BD).

• Position the Prosonic M in the middle of the channel or weir.

• Align the sensor membrane parallel to the water surface.

• Keep to the installation distance of the channel or weir.

• You can enter the "Flow to Level" linearisation curve ("Q/h curve") using operating program

FieldCare or manually via the on-site display.

In narrow shafts with strong

interference echoes, we recommend

using an ultrasound guide pipe (e.g. PE

or PVC wastewater pipe) with a

minimum diameter of 100 mm

(3.94 in).

Make sure that the pipe is not soiled by

accumulated dirt. If necessary, clean

the pipe at regular intervals.

L00-FMU4xxxx-17-00-00-yy-010

1Venting hole

1

Prosonic M PROFIBUS PA Mounting

Endress+Hauser 9

Example: Khafagi-Venturi flume

L00-FMU4xxxx-17-00-00-xx-003

A Khafagi-Venturi flume

BInflow

C Outflow

BD Blocking distance

E Empty calibration

F Full calibration

V Direction of flow

1xb

0

b

0

BD

A

E

BC

V

H

max

=F

Mounting Prosonic M PROFIBUS PA

10 Endress+Hauser

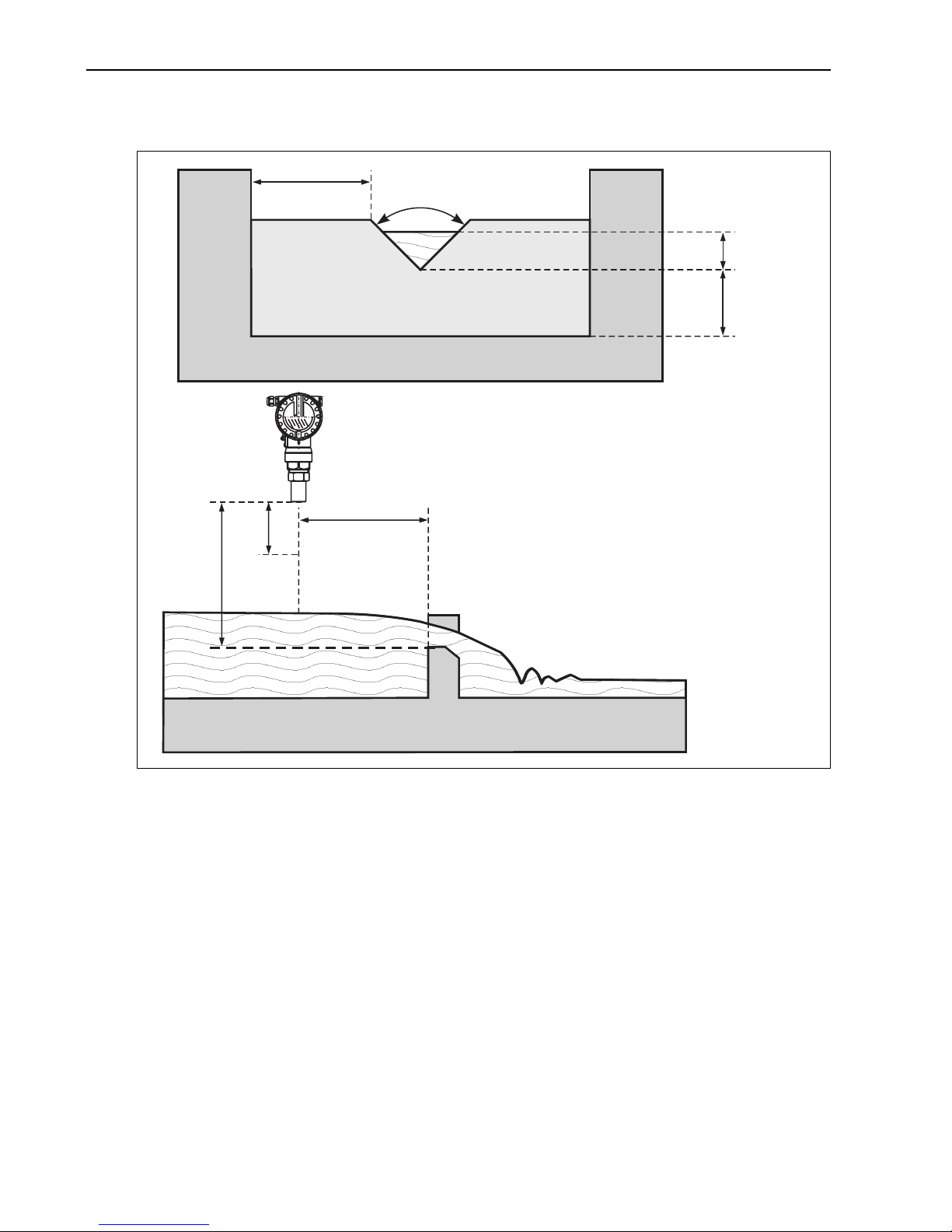

Example: Triangular weir

L00-FMU4xxxx-17-00-00-xx-012

BD Blocking distance

E Empty calibration

F Full calibration

2.4 Measuring range

2.4.1 Blocking distance, Nozzle mounting

Install the Prosonic M at a height so that the blocking distance BD is not undershot, even at

maximum fill level. Use a pipe nozzle if you cannot maintain the blocking distance in any other

way. The interior of the nozzle must be smooth and may not contain any edges or welded joints.

In particular, there should be no burr on the inside of the tank side nozzle end. Note the

specified limits for nozzle diameter and length. To minimise disturbing factors, we recommend

an angled socket edge (ideally 45°).

max

max

max

max

(= F)

min. 3 H

H

min. 2 H

a

min. 2 H

BD

E

Prosonic M PROFIBUS PA Mounting

Endress+Hauser 11

L00-FMU4KAxx-17-00- 00-yy-004

BD Blocking distance F Full calibration (span)

SD Safety distance D Nozzle diameter

E Empty calibration L Nozzle length

"

Caution!

If the blocking distance is undershot, it may cause device malfunction.

F

E

BD

SD

L

D

FMU40/41

L

D

FMU43

L

D

FMU42/44

Maximum nozzle length [mm (in)]

Nozzle diameter FMU40 FMU41 FMU42 FMU43 FMU44

DN50/2" 80 (3.15)

DN80/3" 240 (9.45) 240 (9.45) 250 (9.84)

DN100/4" 300 (11.8) 300 (11.8) 300 (11.8) 300 (11.8)

DN150/6" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

DN200/8" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

DN250/10" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

DN300/12" 400 (15.7) 400 (15.7) 400 (15.7) 300 (11.8) 400 (15.7)

Sensor characteristics

Emitting angle α 11° 11° 9° 6° 11°

Blocking distance [m (ft)] 0.25 (0.8) 0.35 (1.1) 0.4 (1.3) 0.6 (2.0) 0.5 (1.6)

Max. range [m (ft)]

in liquids

5 (16.0) 8 (26.0) 10 (33.0) 15 (49.0) 20 (66.0)

Max. range [m (ft)]

in solids

2 (6.6) 3.5 (11.0) 5 (16.0) 7 (23.0) 10 (33.0)

Loading...

Loading...