Endress+Hauser Proservo NMS 5 series, Proservo NMS 7 series Technical Information

TI 006N/08/en/04.09

Software Ver. 4.27C

Technical Information

Proservo NMS 5/7 series

Intelligent tank gauge with high accuracy performance

Liquid level, I/F, Density & Density Profile

Application

The Proservo NMS 5/7 series of intelligent tank gauges is

designed for high accuracy liquid level measurement in

storage and process applications.

They fulfill the exact demands of tank inventory

management, loss control, total cost saving and safe

operation.

Typical areas of application include:

• Oil (fuels)

• LPG/LNG

• Chemicals

• Water / chemical interface measurement

• Foods, Liquid Food

Tank mounted intelligence makes the Proservo NMS 5/7

series ideal for single or multi-task installation, converting a

wide range of measurement functions including:

• Liquid level

• Interface level

• Spot density

• Density profile

• Tank bottom

• Water dip

Features and benefits

• Measures liquid to an accuracy of +/- 0.7 mm

• Measures two clear interface levels and specific gravity of

up to three liquid phases

• Profiling of Iiquid density throughout the tank (Tank

profile) and upper layer (I/F profile)

• Latest microtechnology keeps the design simple,

lightweight and compact

• Wetted parts are completely separated from the

electronic circuit

• Tank top mounting with 3” flange weighing only 12 kg

(aluminum version)

• Wide range of output signals including V1, RS 485,

WM550, M/S, Enraf BPM and HART® protocol

• Material and pressure rating of the wetted parts can be

selected according to the application.

• Suitable for atmospheric and high pressure applications

up to 25 bar

• Maintenance prediction of the instrument

• Direct connection of spot or average temperature probes

• Easy to program using the E+H matrix system

• Robust IP67 housing

• Proactive safety diagnostics output to display and System

Operators (patent pending)

ProdName

2 Endress+ Hauser

Table of Contents

Function and system design . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Major Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Typical Tank installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Measurement terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Input for local devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Output 8

Output parameters based on communication protocol . . . . . . . . .8

RS485 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Bidirectional serial pulse (V1 protocol) . . . . . . . . . . . . . . . . . . . . .9

HART Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Whessoematic 550 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Mark / Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Enraf Bi Phase Mark (BPM) . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Analogue output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Safe electrical isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical for Primary output V1Serial Pulse

Modbus RS 485 HART Enraf BPM . . . . . . . . . . . . . . . . . . . . . .13

Electrical for Primary output WM 550 . . . . . . . . . . . . . . . . . . . .14

Electric for Primary output M/S . . . . . . . . . . . . . . . . . . . . . . . .15

Bus Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Rack Bus & Modbus (RS485 Output) . . . . . . . . . . . . . . . . . . . . .16

Sakura V1 Serial Pulse Ouput . . . . . . . . . . . . . . . . . . . . . . . . . .16

Enraf Bi Phase Mark Output . . . . . . . . . . . . . . . . . . . . . . . . . . .17

HART Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Whessoematic 550 (WM 550) Output . . . . . . . . . . . . . . . . . . .17

Varec Mark Space (M/S) Output . . . . . . . . . . . . . . . . . . . . . . . .18

Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . .19

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Ambient condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Liquid temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Design, dimensions Housing materials of Construction . . . . . . . 20

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Flange type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operating presse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Measuring wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Displacer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Display(LCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Memo function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Advanced Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Maintenance Prediction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Automatic Displacer Weight Compensation . . . . . . . . . . . . . . . 23

Automatic Compensation of Wire Length . . . . . . . . . . . . . . . . . 23

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Certificates and Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ex approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Custoday transfer approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Overspill protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

External standards and guidelines . . . . . . . . . . . . . . . . . . . . . . 24

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Proservo NMS5.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Proservo NMS7..(Sanitary version) . . . . . . . . . . . . . . . . . . . . . . 28

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Calibration Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power+Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ball Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Reducing Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Supplementary Documentation . . . . . . . . . . . . . . . . . . . . . .36

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Compact Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Stainless Steel conversion table . . . . . . . . . . . . . . . . . . . . . . . . 37

Proservo

Endress+Hauser 3

Function and system design

Measuring System The Proservo NMS 5/7 is an intelligent tank gauge for high accuracy liquid level measurement employing the

latest microprocessor technology. As well as level measurement, Proservo NMS 5/7 can determine the interfaces between three liquids, specific gravity of these liquids and tank bottom. To enable accurate volume calculation or simply for indication, Proservo NMS 5/7 will accept an input from either an average temperature

probe NMT 53x series (via twisted pair cables, HART protocol) or via spot temperature element (via 3 wire Pt.

100 RTD signal). Once installed, all calibration and operating functions can be made via the user friendly

Matrix program and touch sensitive keypad. Tank side monitoring and operation can be performed by the

Promonitor NRF 560.

Prothermo

Proservo

Power (AC / DC)

Outputs

HART

Promonitor

Level

Interface

Density

Water dip

Bottom

Power

(AC / DC)

HART

HART

to a HOST system

in a control room

Temp.

Power (AC / DC)

Power (AC / DC)

Proservo

4 Endress+ Hauser

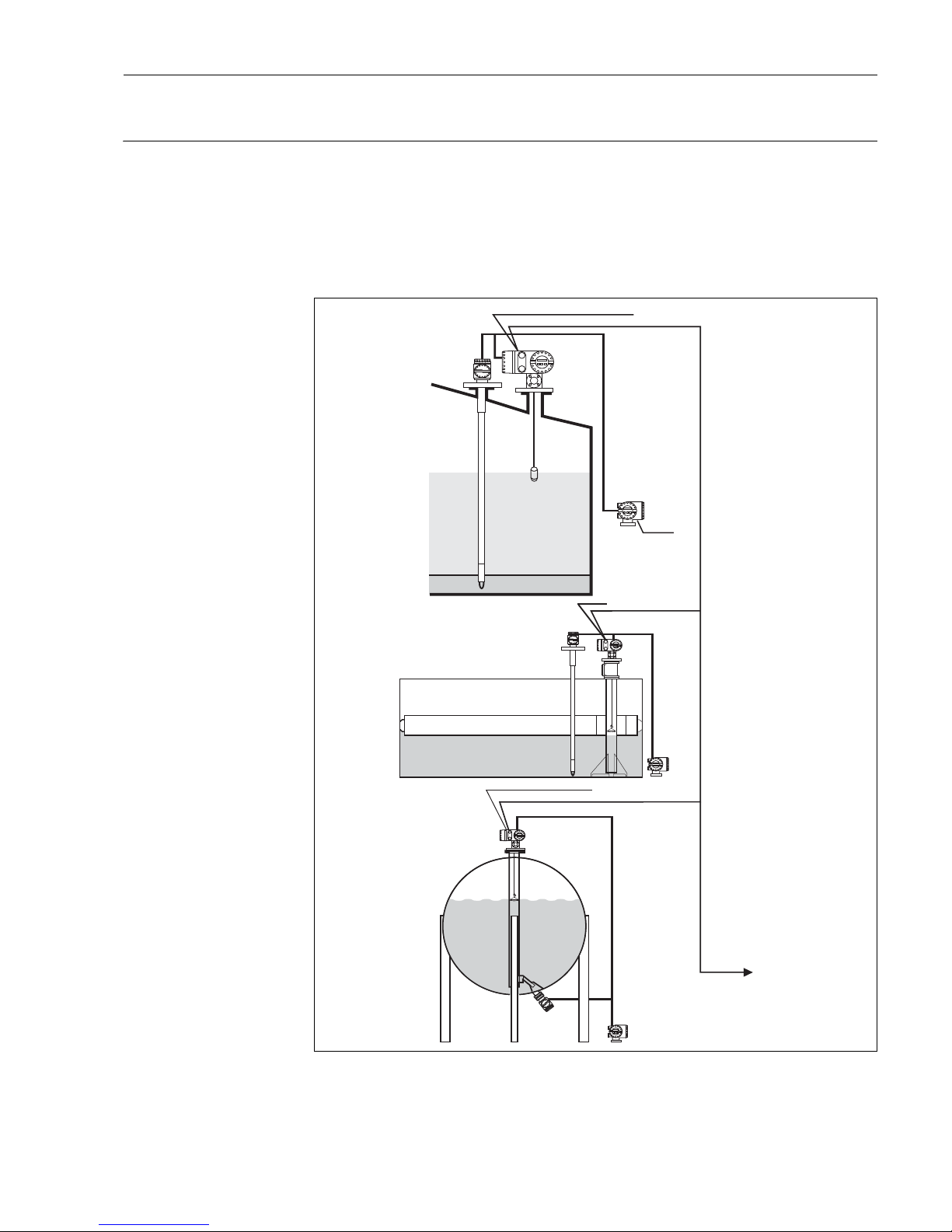

System Configuration • From single tank level measurement to the largest oil refinery application, Proservo is an integral part of tank

farm management solutions. A wide variety of data output protocols is available for seamless integration into

many commonly used systems.

• The primary example is Endress+Hauser’s revolutionary Tankvision, a scalable concept offering local tank

management for up to 225 tanks via Modbus, V1 or Whessomatic 550 protocols. Collected data is available

to DCS and other plant management systems via a Host Link.

• Other examples include Endress+Hauser’s legacy systems such as MDP V1 Interface, FuelsManager, Tank

Computers NRM571 and NRS57.

• Output protocols

•Modbus, RS485 or current loop

•V1 serial pulse

•Whessomatic 550

•HART

•Mark/Space

•

Enraf BPM

Proservo NMS 5/7 system configuration Serial pulse output

Major Application The number of measuring functions and output options as well as the lightweight compact design enables

Proservo NMS 5/7 to be installed in a wide range of applications at minimal cost.

Petroleum Industry

From the production of oil to storage at an oil depot, there is a need to measure and manage a wide variety of

products. A remote tank gauging and inventory management system combined with Proservo NMS 5 and a

receiving computer is an ideal way to measure and control the contents of the tanks.

Chemical Industry

For this industry, a wide choice of materials is available for the construction of the wetted parts, to ensure

chemical compatibility and long life.

Food Industry

In the brewing and beverage industries, where large volume of water or water-based products are being

handled, it is essential to obtain a precise level measurement to establish low cost production. Proservo NMS

7 can be supplied with a built in CIP nozzle if required.

Power Plant

Fuel oil levels are major applications where precise measurement is required to ensure safe operation.

Operating Principle The Proservo NMS 5/7 tank gauging system is based on the principle of displacement measurement.

A small displacer is accurately positioned in the liquid medium using a servo motor. The displacer is suspended

on a measuring wire which is wound onto a finely grooved drum housing within the instrument.

HART

HART

HART

Modbus

SCADA

DCS/PLC

ModbusModbus

SCADA

DCS/PLC

Device Config

Host Link

LAN

TCP/IP

Data Concentrator

Data Scanner

(Field Protcol)

V1, Modbus

Data Scanner

Proservo

Endress+Hauser 5

The drum is driven via coupling magnets which are completely separated by the drum housing. Outer magnets

are connected to the wire drum whilst the inner magnets are connected to the drive motor. As the magnets

turn, its magnetic attraction causes the outer magnets to turn as well, as a result turning the entire drum

assembly. The weight of the displacer on the wire creates a torque on the outer magnets generating the change

of magnetic flux. These changes generated between the drum assembly are detected by a unique

electromagnetic transducer on the inner magnet. The drive motor is actuated to balance the voltage generated

by the variations of magnetic flux to equal the reference voltage defined by the operating command.

When the displacer is lowered and touches the liquid, the weight of the displacer is reduced because of the

buoyant force of the liquid. As a result, the torque in the magnetic coupling is changed and this change is

measured by 5 sets of Hall sensors, (patented) chips which are temperature compensated. The signal, an

indication of the position of the displacer, is sent to the motor control circuit. As the liquid level rises and falls,

the position of the displacer is adjusted by the drive motor. The rotation of the wire drum is precisely evaluated

to determine the level value which is accurate to an outstanding +/- 0.7 mm.

Direct Torque Detection

Wire drum

Outside magnet

Inside magnet

Weight

signal

Weight data

Displacer

position

data

Encoder

Motor drive signal

Motor

Displacer

Measurement

wire

Hall element

Proservo

6 Endress+ Hauser

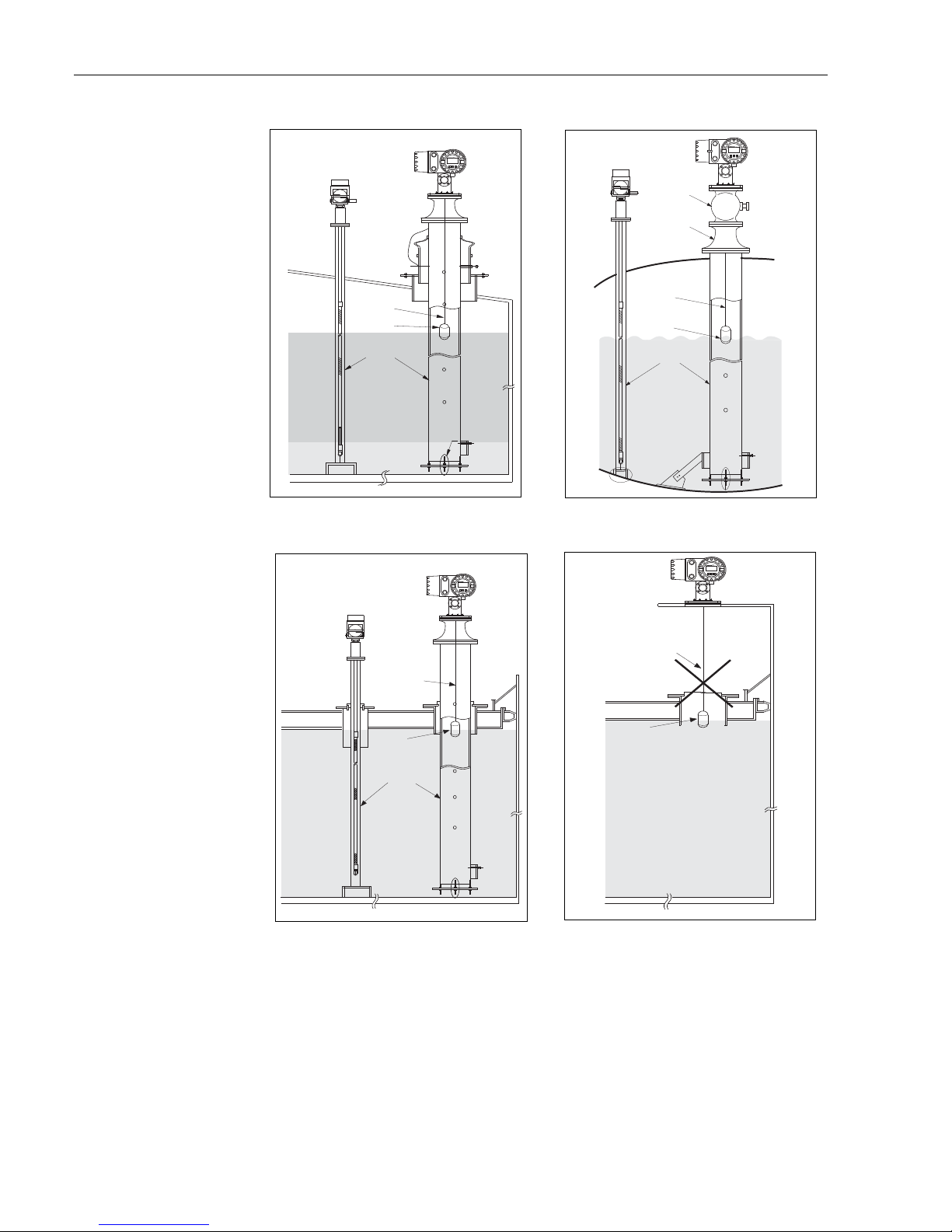

Typical Tank installation

E

-

+

Ball Valve

Reducer

Meas. Wire

Displacer

Still well

Proservo NMS5/7

Prothermo NMT

Measuring wire

Displacer

Still well

B

E

+

Prothermo NMT

Proservo NMS5/7

E

+

Measuring wire

Displacer

Still well

Proservo NMS5

Prothermo NMT

E

+

Measuring wire

Displacer

Proservo NMS5/7

Fixed roof tank with stilling well

High pressure tank with stilling well and ball valve

Floating roof tank and/or covered floating roof tank

Note: When the proservo is installed on Floating

roof tank, be sure to use Stilling Well

Proservo

Endress+Hauser 7

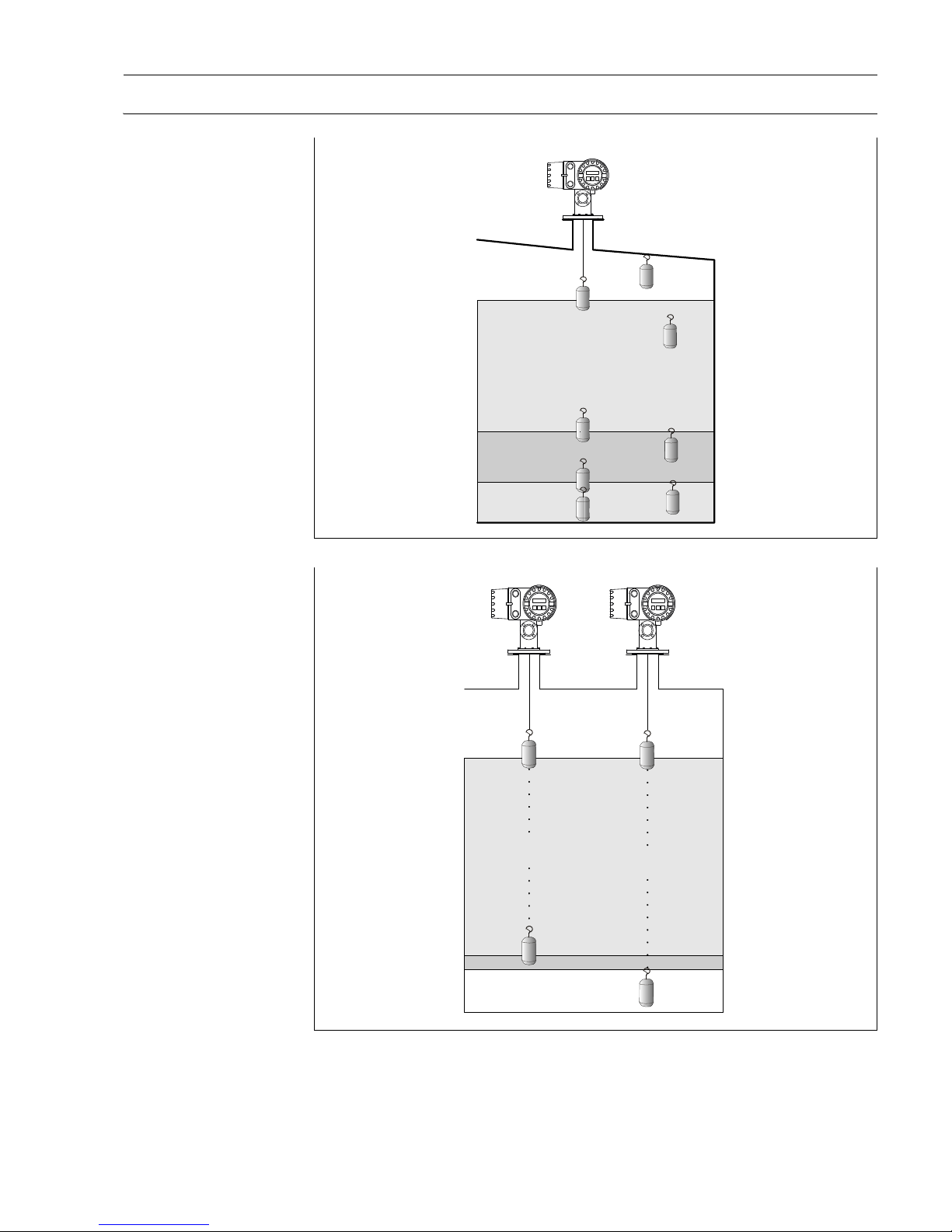

Measurement terminology

NMS 5/7 Proservo with standard level, I/F x 2, Tank bottom and spot density x 3 measurement

Left: Density Profile measurement "I/F (Interface) Profile" measurement range

Right: Density Profile measurement "Tank Profile" measurement range

Level

Upper I/F

Middle I/F

Upper

Density

Middle

Density

Lower

Density

Tank

Bottom

Level

Upper I/F

Tank

floor

Water

Emulsion

Oil

Density measured point

(2 ~ 16 points selecta ble)

between level to upper I/F

Density measured point

(2 ~ 16 po ints selectab le)

Throughout liquid

Tank Profile

True average

density throughout

the tank

I/F Profile

True average

density within

Upper layer

Proservo

8 Endress+ Hauser

Input

Input for local devices

Output

Output parameters based on

communication protocol

Remarks

1. Upper I/F output value can be either selected from the Proservo’s own displacer measurement or Water

Bottom measured value via the Prothermo NMT 539.

2. A single point density measurement within the upper layer liquid in the tank. The measurement position

is configured to 150mm below the liquid surface at default.

3. A single point density measurement within the middle layer liquid in the tank. The measurement position

is configured to 150mm below the upper interface level at default.

4. A single point density measurement within the lower layer liquid in the tank. The measurement position

is configured to 150mm below the middle interface at default

5. The value of this “Average Density” is based on the calculation after performing the Density Profile operation at the Proservo.

6. All of the selected number of density measured value from 1 ~ 16 points can be transmitted.

Signal Multi drop local HART® protocol max. 4 devices

Power supply DC 24V

Additional units NMT 53x average temperature sensor

NRF 560 field data processor

Other - compatible HART® devices

Spot temperature Pt 100 Ohm ISO standard three wire connection

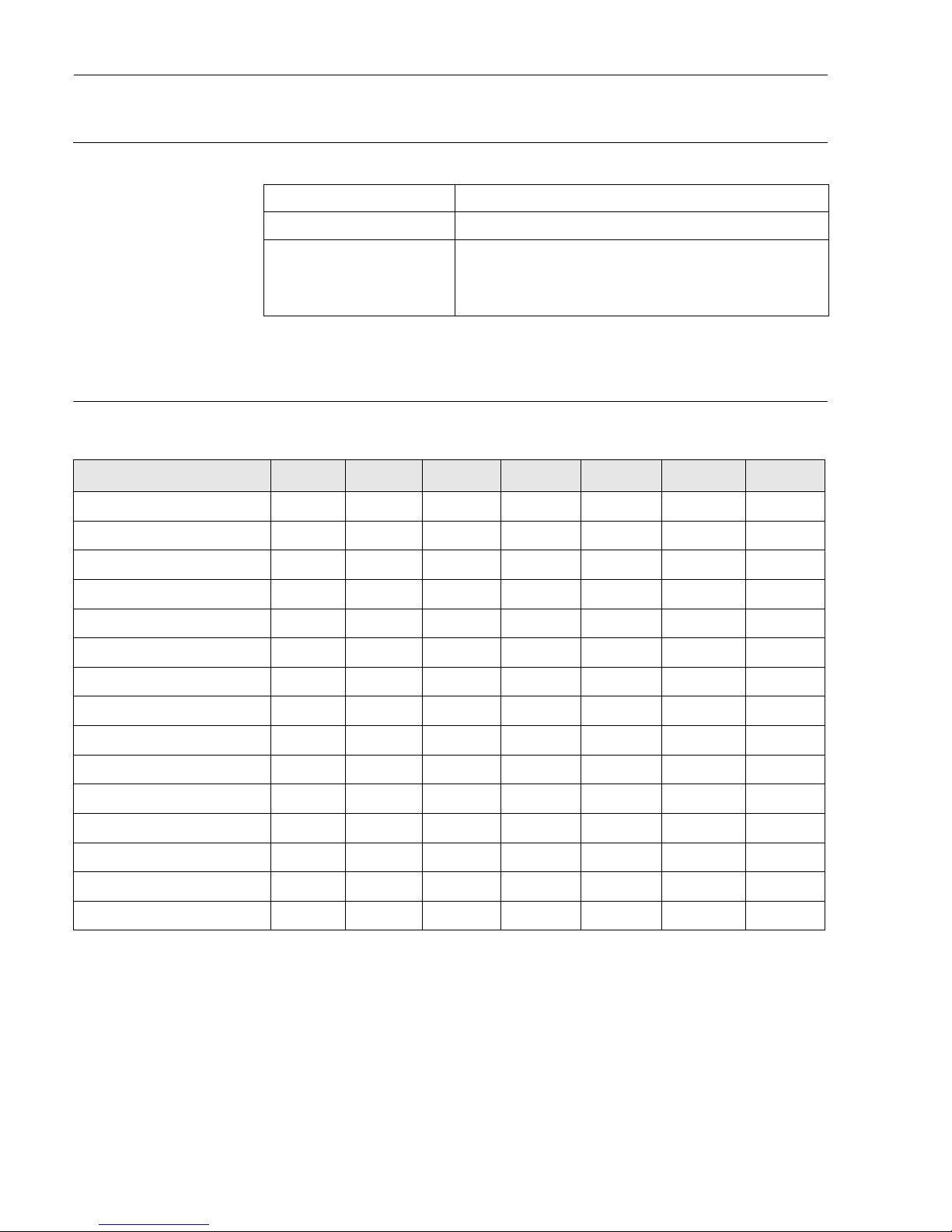

V1(new) V1 (old) MODBUS HART WM550 ENRAF M/S

Level Yes Yes Yes Yes Yes Yes Yes

Temperature (Product) Yes Yes Yes Yes Yes Yes Yes

Vapor Temperature Yes - Yes Yes Yes - -

Upper I/F (Water Level) *1 Yes - Yes Yes Yes Yes -

Middle I/F Yes - Yes Yes - - -

Upper D e nsity *2 Yes - Yes Yes Yes - -

Middle Densuty*3 Yes - Yes Yes - -

Lower Density*4 Yes - Yes Yes - -

Average Dens ity *5 Yes - Yes - Yes - -

1-16 points Individual Density *6 Yes - Yes - - - -

Multi-Element Temperature Yes - Yes Yes Yes -- -

HART device input (Device 1) Yes - Yes Yes Yes - -

HART device input (Device 2) Yes - Yes Yes Yes - -

Alarm / Discrete V alue Yes Yes Yes Yes Yes Yes -

Protocol Documentation - - KA0002N - KA001N - -

Proservo

Endress+Hauser 9

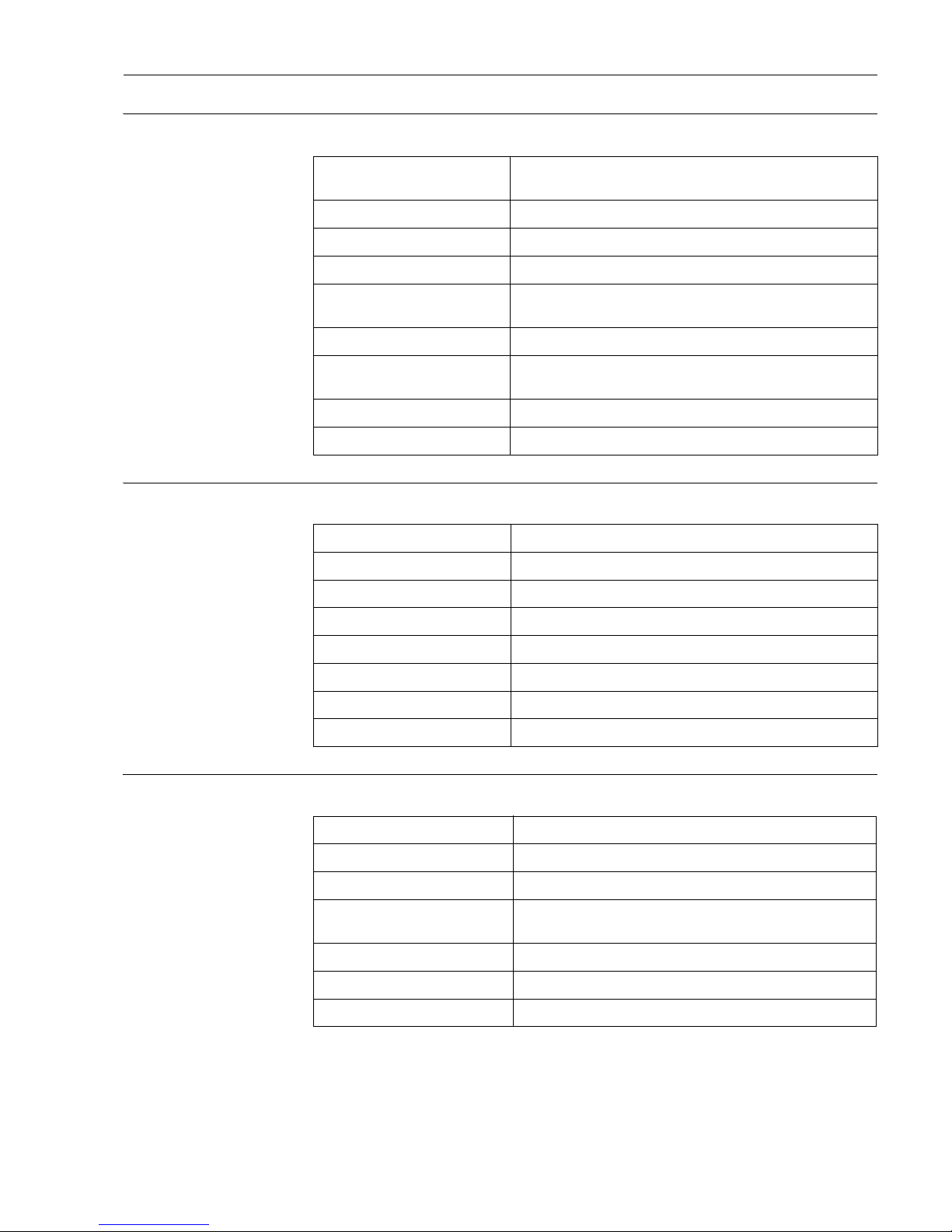

RS485 Modbus

Bidirectional serial pulse

(V1 protocol)

HART Protocol

Module name Commdule RS 485 communication module (~2008),

COM - 5 (2009~)

No. of unit Maximum 10 instruments per loop

Baud rate 600/1,200/ 2,400/ 4,800/ 9,600/ 19,200 bit/s, selectable

Parity Odd, Even, None, selectable

Cable Two wire twisted cable with screening (DGND is connected to the

ground cable)

Topology Serial bus, electrically isolated, tree structure

Transmission distance Maximum 1,200 m including limbs or branches (negligible with

branches under 3 m)

Instrument address Accessed via touch control

Isolation Bus inputs are electrically isolated from the other electronics

Module name COM - 1

No. of units Maximum 10 instruments per loop

Baud rate 3,300 BPS

Cable Two wire (twisted pair) unscreened cable

Topology Serial bus, tree structure

Transmission distance Maximum 6,000 m

Instrument address Accessed via touch control

Isolation Serial communication circuit isolated from other circuits

Module name Commdule HART (2009), COM - 6 (2009~)

No. of units Maximum 15 instruments per loop

Baud rate 1,200 BPS

Cable Two wire, twisted pair screened cable Minimum core φ 0.15

(24AWG)

Transmission distance Maximum 1,200 m

Instrument address Accessed via touch control

Isolation Bus input are electrically isolated from the other electronics

Proservo

10 Endress+ Hauser

Whessoematic 550

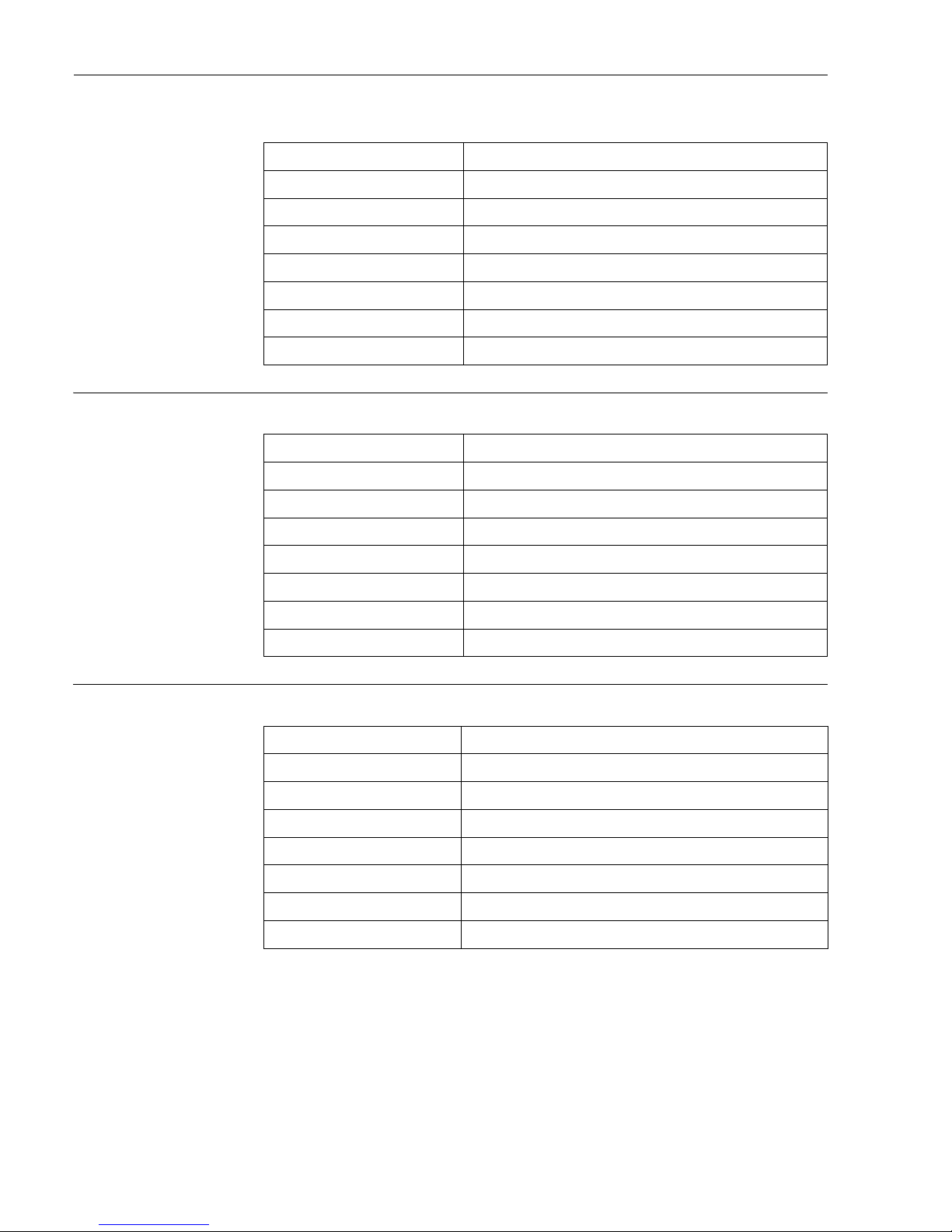

Mark / Space

Enraf Bi Phase Mark (BPM)

Module name WM550 communication module

No. of units 15 instruments per loop (connected to RTU)

Baud rate 1,200 / 2,400 bit/s

Cable Two wire, twisted cable with screening

Topology 20 mA current loop

Transmission distance Depending on specifications (ask your E+H engineer)

Instrument address Setting by DIP switches on communication board

Isolation Current loop circuit isolated from other circuits

Module name Mark/Space communication module

No. of units Depending on specification (ask to E+H engineer)

Baud rate 1,200 / 2,400 / 4,800 / 9,600 / 19,200 bit/s

Cable Four wire

Topology Serial bus, tree structure

Transmission distance Depending on specifications (ask your E+H engineer)

Instrument address Setting by DIP switches on communication board

Isolation Serial pulse isolated from other circuits

Module name COM - 3

No. of units Maximum 10 instruments per loop

Baud rate 1,200, 2,400 bit/s, selectable

Cable Two wire, twisted cable with screening

Topology Serial bus, electrically isolated, tree structure

Transmission distance Maximum 10 km

Instrument address Accessed via touch control

Isolation Serial communication circuit isolated from other circuits

Proservo

Endress+Hauser 11

Analogue output

Relay

Module name I/O - 5

Output 4...20 mA, two channeles freely assignable value

On alarm Switchable +110%, -10% or hold last measured value

Electrical isolation Analogue output isolated from other circuits

Adjustable damping 0 to 99 s

Maximum load 500 ohm

Load effect Negligible

Module name I/O - 3

Version 4 relays with potential free change-over contacts, freely assignable to

measured value

Hysteresis Switch points and switching hysteresis freely adjustable, residual

current fail-safe mode: minimum or maximum, selectable

Switching capacity AD max. 2 A, max. 250 V, max. 62.5 VA

DC max. 2 A, max. 220 V, max. 60 W

For FM / CSA: 5A250VAC, 8A250VAC

Proservo

12 Endress+ Hauser

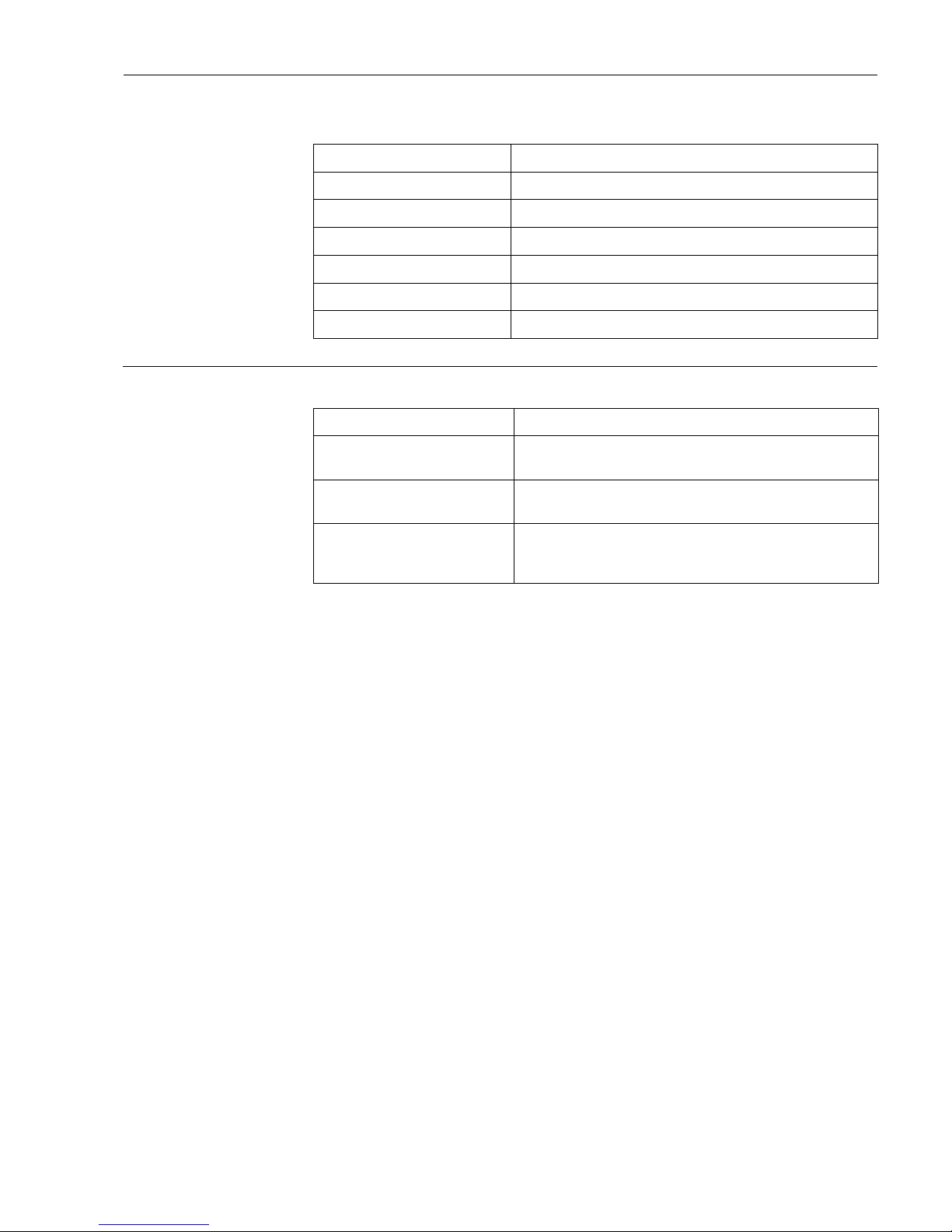

Power supply

Supply voltage High voltage type: 85 ... 264 VAC 50/60 Hz

Low voltage type: 20 ... 60 VDC / 20 ... 55 VAC 50/60Hz

Caution!

Allowable voltage supply is specifically stated depending on each Ex approvals. Refer to the designated

certification

Power consumption Maximum 50 VA, 50W (cos j=0.5)

Safe electrical isolation Between power supply and signal output, CPU, RS 485, relay and other electronics

Loading...

Loading...