Endress+Hauser Promag 300, Promass 300, Promass 500, Promag 500 Instructions Manual

Products Solutions Services

EA001164D/06/A2/01.16

71327830

Alteration Instructions

Promag 300, 500

Promass 300, 500

Activate the Software Licence Code

These Instructions are Alteration Instructions; they

do not replace the Operating Instructions included in

the scope of supply.

For detailed information, refer to the Operating

Instructions and other documentation or visit

"www.endress.com/deviceviewer".

2

Overview Registration key

3

1 Overview Registration key

Instruction is valid for the following order codes:

Order Code Application packages

DK8009– for Promass 300

DK8011– for Promass 500

DK5009– for Promag 300

DK5011– for Promag 500

Authorized personnel

4

2 Authorized personnel

NOTICE

‣ The person who carries out the alteration is responsible for safety during the work, the qual-

ity of work completed and safety of the device after alteration.

3 Authorized personnel to affix new nameplates

Approval of the measuring device Group of persons authorized to carry out alteration

without approval 1, 2, 3

with approval (for Ex. IECEx, ATEX, FM, CSA, TIIS, NEPSI) 1, 2, 3

1 = Trained customer technician

2 = Service technician authorized by Endress+Hauser

3 = Endress+Hauser (send measuring device back to manufacturer)

Approval of the measuring device Group of persons authorized to affix new nameplate

without approval 1, 2, 3

with approval Endress+Hauser*

1 = Trained customer technician

2 = Service technician authorized by Endress+Hauser

3 = Endress+Hauser (send measuring device back to manufacturer)

* Note: For the change of nameplates, some markets require field inpsection. Please follow your national legislation.

Safety instructions

5

4 Safety instructions

• Comply with national regulations governing mounting, electrical installation, commissioning,

maintenance and alteration procedures.

• Requirements with regard to specialized technical staff for the mounting, electrical

installation, commissioning, maintenance and alteration of the measuring devices:

– trained in instrument safety

– familiar with the individual operation conditions of the devices

– for Ex-certified measuring devices: also trained in explosion protection

• The measuring device is energized. Danger: Risk of electric shock! Open the measuring device

in a de-energized state only.

• In the case of Ex-certified measuring devices: Only open in a de-energized state (once a delay

of 10 minutes has elapsed after switching off the power supply) or in environments which do

not have a potentially explosive atmosphere.

• In the case of measuring devices in safety-related applications in accordance with IEC 61508

or IEC 61511: After alteration recommission in accordance with Operating Instructions.

Document the alteration procedure.

• Use genuine parts from Endress+Hauser only.

• Before removing the device: set the process in a safe condition and purge the pipe of

dangerous materials.

• Hot surfaces! Risk of injury! Before commencing work, allow the system and measuring device

to cool down to a touchable temperature.

• Follow the Operating Instructions for the device.

• Risk of damaging electronic components!

Ensure you have a working environment protected from electrostatic discharge.

• Only open housing for a brief period.

Avoid the penetration of foreign bodies, moisture or contaminants.

• Replace defective seal/gaskets with genuine parts from Endress+Hauser only.

• If threads are damaged or defective, the measuring device must be repaired.

• Threads (e.g. of the cover for the electronics and connection compartments) must be

lubricated. Use an acid-free, non-hardening grease if an abrasion resistant dry lubricant

is non-existent.

• If spacing is reduced or the dielectric strength of the measuring device cannot be guaranteed

during alteration work, perform a test on completion of the work (e.g. high-voltage test in

accordance with the manufacturer's instructions).

• Service connector:

– do not connect in potentially explosive atmospheres.

– only connect to Endress+Hauser service devices.

• Observe the instructions for transporting and returning the device outlined in the

Operating Instructions.

• If you have any questions, contact your Endess+Hauser service organization.

Tool List

6

5 Tool List

6 Safety symbols

7 Symbols for certain types of information

3 mm Crimp tool

A0011189-EN

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

A0011190-EN

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

A0011191-EN

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

A0011192-EN

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

A0011182

Allowed!

Indicates procedures, processes or actions that are allowed.

A0011184

Forbidden!

Indicates procedures, processes or actions that are forbidden.

A0011193

Tip

Indicates additional information.

Series of steps

DANGER

WARNING

CAUTION

NOTICE

1.

2.

3.

Activate the application package via Software Licence Code

7

8 Activate the application package via Software Licence Code

NOTICE

Notice for E+H service technician:

‣ Log into the device with the custom-password via access level "Maintenance".

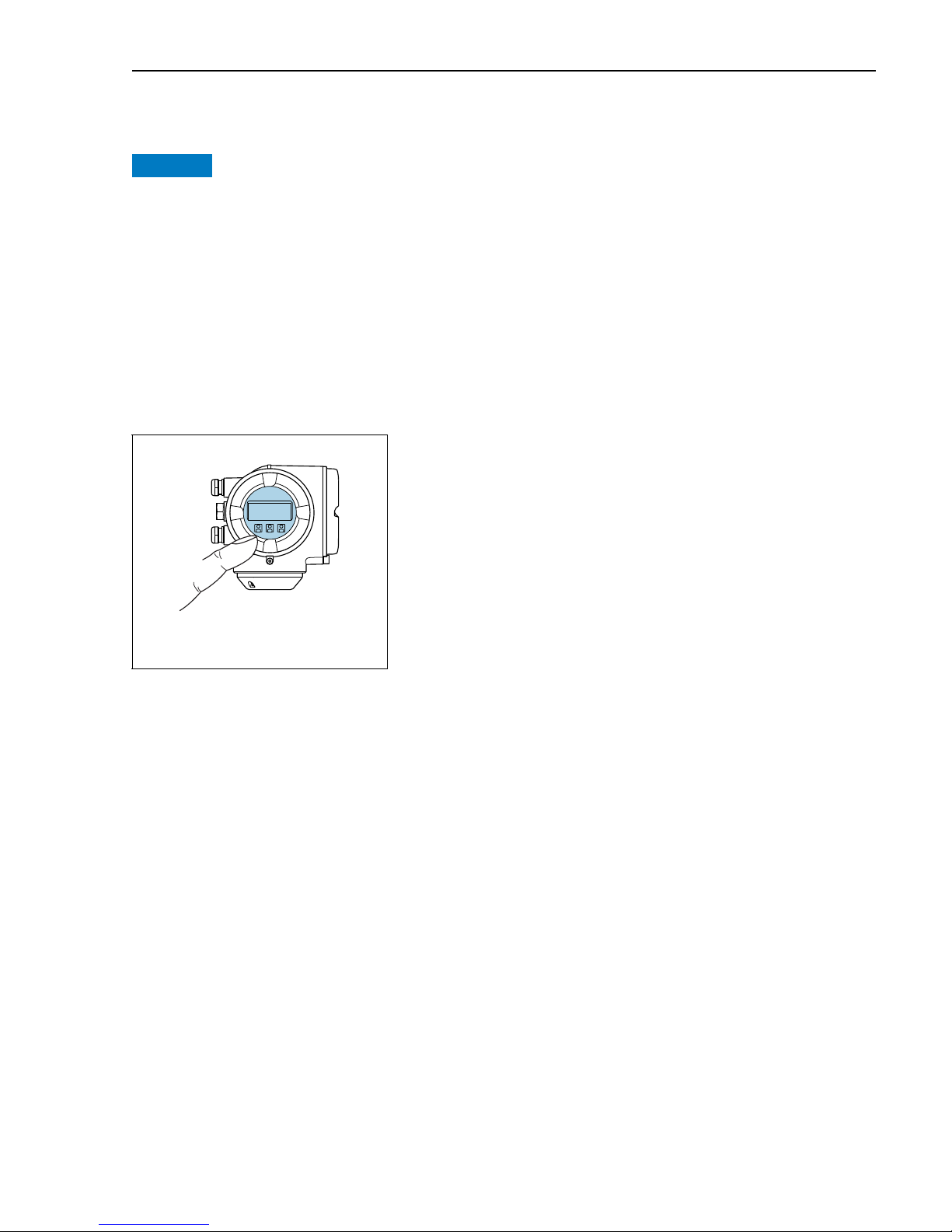

8.1 Enter the software option code: via display

Navigation: Select in the menu of the display:

Enter software-option(s):

1. Remove the keylock (2 sec)

2. Main menu → Display language: Select language

3. Main menu → Expert → Input code factory setting → 0000 or the changed code (customer

code)

4. Expert → System → Administration → Activate software option:

Enter software option code

5. Admininstration → Overview software options: Display of the activated softare option(s)

6. Main Menu → Expert → System → Administration → Overview software options

1.

A0026785

Activate the application package via Software Licence Code

8

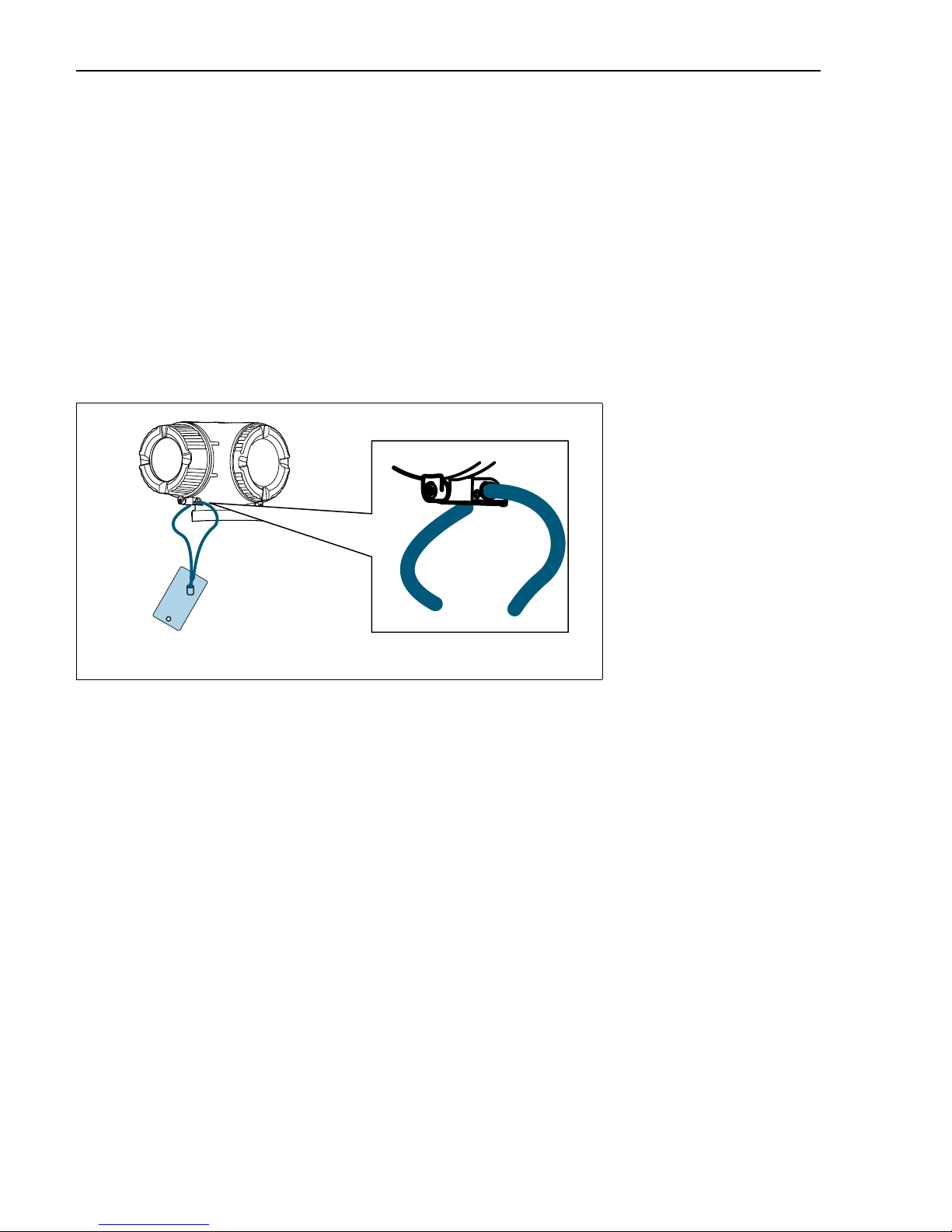

7. Check and note the date on the tag:

• Serial number of the device

• Order code new

• Entered activation code for the software-options (application package code)

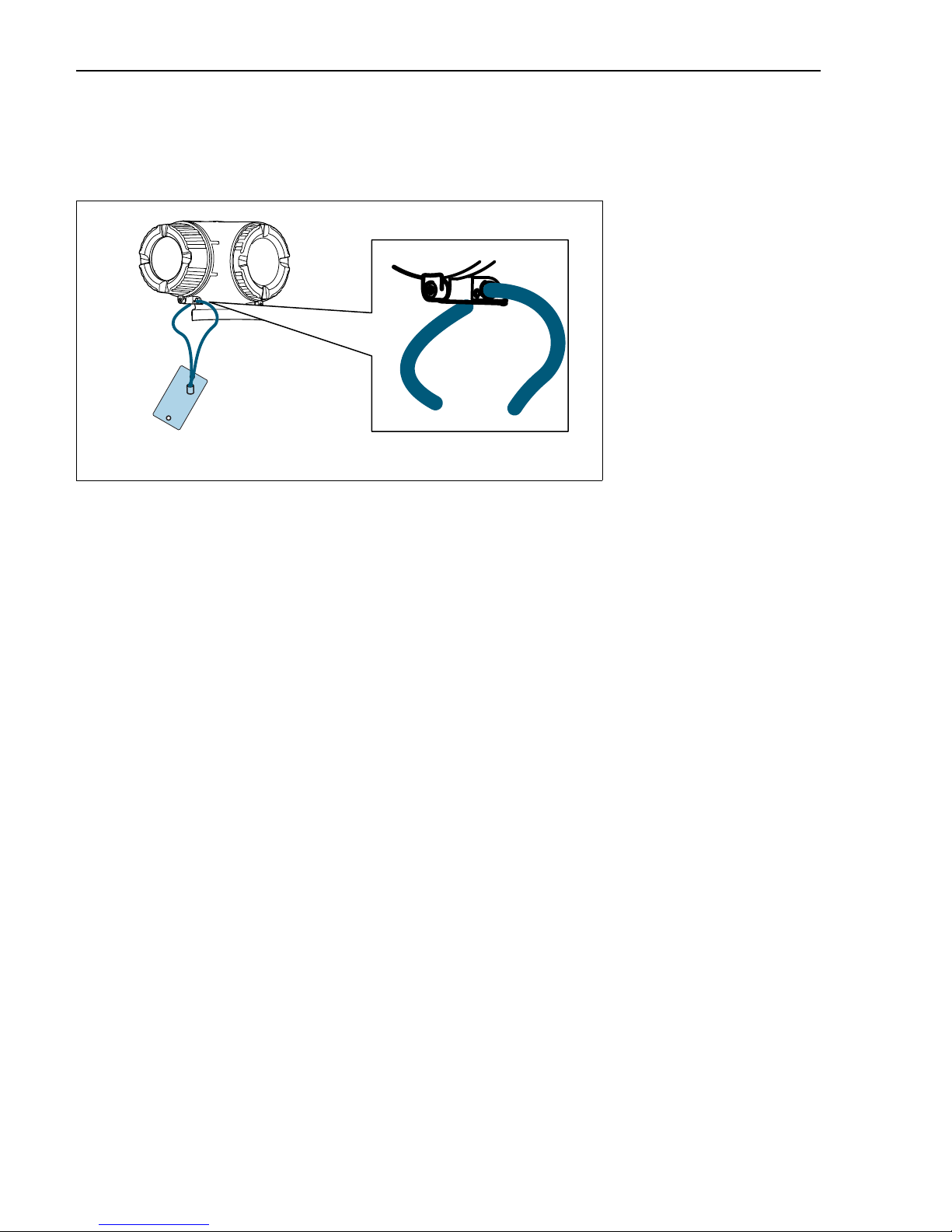

• Affix the tag with the enclosed stainless steel wire and crimp sleeve as indicated in the graphic:

• Affix the nameplate (optional) according to the device labeling (see chapter 3

"Authorized personnel").

1.

A0031061

Activate the application package via Software Licence Code

9

8.2 Enter the Software option code via Webserver

Open Webserver:

1. Select language

Login Webserver:

2. Webserver language: Select language

3. Login →

access status → Maintenance → Enter access code: Input code factory setting = 0000

or the changed code (customer code)

4. Menubar menu

5. Main menu

6. Expert

7. System

8. Administration

9. Activate software option: Enter software option code

10. Confirm software option code with "Enter"

11. Overview ot the software option: Display of the activated software option(s)

12.

Check of the date on the tag

:

• Serial number of the device

• Order code new

• Entered activation code for the software-options (application package code)

Activate the application package via Software Licence Code

10

13. Affix the tag with the enclosed stainless steel wire and crimp sleeve as indicated in

the graphic:

• Affix the nameplate (optional) according to the device labeling (see chapter 3

"Authorized personnel").

1.

A0031061

Loading...

Loading...