Endress+Hauser Proline T-Mass 65I Operating Manual

BA00111D/06/EN/13.14

71261899

Valid as of version

V 1.01.00 (Device software)

Products Solutions Services

Operating Instructions

Proline t-mass 65

Thermal mass flowmeter

6

Proline t-mass 65

Table of contents

1 Document information . . . . . . . . . . . . . . 3

1.1 Document conventions . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety instructions . . . . . . . . . . . . . . . . . 5

2.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Installation, commissioning and operation . . . . . . 5

2.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Identification . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Certificates and approvals . . . . . . . . . . . . . . . . . . 10

3.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . 10

4 Installation . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Incoming acceptance, transport and storage . . . 11

4.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . 12

4.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 27

5 Electrical connection. . . . . . . . . . . . . . . 28

5.1 Connecting the remote version . . . . . . . . . . . . . . 28

5.2 Connecting the measuring unit . . . . . . . . . . . . . . 30

5.3 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 33

5.4 Post-connection check . . . . . . . . . . . . . . . . . . . . . 34

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Display and operating elements . . . . . . . . . . . . . 35

6.2 Brief operating instructions for the function matrix

36

6.3 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9 Accessories . . . . . . . . . . . . . . . . . . . . . . .69

9.1 Device-specific accessories . . . . . . . . . . . . . . . . . . 69

9.2 Communication-specific accessories . . . . . . . . . . 69

9.3 Service-specific accessories . . . . . . . . . . . . . . . . . . 70

10 Trouble-shooting . . . . . . . . . . . . . . . . . .71

10.1 Trouble-shooting instructions . . . . . . . . . . . . . . . 71

10.2 System error messages . . . . . . . . . . . . . . . . . . . . . 72

10.3 Process error messages . . . . . . . . . . . . . . . . . . . . . 76

10.4 Process errors without messages . . . . . . . . . . . . . 76

10.5 Response of outputs to errors . . . . . . . . . . . . . . . . 78

10.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.7 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.9 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11 Technical data. . . . . . . . . . . . . . . . . . . . .88

11.1 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.2 Function and system design . . . . . . . . . . . . . . . . . 88

11.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.6 Performance characteristics . . . . . . . . . . . . . . . . . 90

11.7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.8 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.9 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.10 Mechanical construction . . . . . . . . . . . . . . . . . . . . 95

11.11 Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.12 Certificates and approvals . . . . . . . . . . . . . . . . . . . 97

11.13 Ordering information . . . . . . . . . . . . . . . . . . . . . . . 99

11.14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

11.15 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7 Commissioning . . . . . . . . . . . . . . . . . . . 50

7.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2 Switching on the measuring device . . . . . . . . . . 50

7.3 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.5 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.6 Data storage device (HistoROM) . . . . . . . . . . . . . 66

8 Maintenance . . . . . . . . . . . . . . . . . . . . . 67

8.1 External cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.2 Pipe cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.3 Sensor cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.4 Replacing seals . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.5 In-situ calibration . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.6 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2 Endress+Hauser

Proline t-mass 65 Document information

1 Document information

1.1 Document conventions

1.1.1 Safety symbols

Symbol Device particularities and document content

“Caution” indicates an action or procedure which, if not performed correctly, can result

"

#

!

Caution!

Warning!

Note!

in incorrect operation or destruction of the device. Comply strictly with the instructions.

"Warning" indicates an action or procedure which, if not performed correctly, can result

in injury or a safety hazard. Comply strictly with the instructions and proceed with care.

"Note" indicates an action or procedure which, if not performed correctly, can have an

indirect effect on operation or trigger an unexpected response on the part of the device.

1.1.2 Electrical symbols

Symbol Meaning

Direct current

A terminal at which DC voltage is present or through which direct current flows.

A0011197

Alternating current

A terminal at which alternating voltage (sinusoidal) is present or through which alternating

A0011198

A0011200

A0011199

A0011201

current flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Equipotential connection

A connection that must be connected to the plant grounding system: This may be a potential

equalization line or a star grounding system depending on national or company codes of practice.

Endress+Hauser 3

Document information Proline t-mass 65

-

.

1.1.3 Symbols for types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Preferred

Indicates procedures, processes or actions that are preferred.

A0011183

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011200

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

1., 2., 3. etc. Series of steps

Ã

Result of a sequence of actions

Help in the event of a problem

A0013562

1.1.4 Symbols for graphics

Symbol Meaning

1, 2, 3 etc. Item numbers

A, B, C etc. Views

A-A, B-B, C-C etc. Item numbers

Flow direction

A0013441

Hazardous area

Indicates the hazardous area.

A0011187

Safe area (non-hazardous area)

Indicates the non-hazardous area.

A0011187

4 Endress+Hauser

Proline t-mass 65 Safety instructions

2 Safety instructions

2.1 Designated use

The measuring device described in these Operating Instructions is to be used only for

measuring the mass flow rate of gases (e. g. kg, Nm

gas temperature. The measuring device can be configured to measure a standard range of

pure gases or gas mixtures.

Examples:

•Air

•Oxygen

•Nitrogen

• Carbon Dioxide

• Argon, etc.

The use with corrosive, saturated or unclean gases should be treated with caution In such

cases, please contact your Endress+Hauser sales center for clarification. The use with

unstable gases or gases not deemed to be suitable by Endress+Hauser must be avoided. The

measuring device is not designed to be used with liquids or fluids in the liquid phase.

Resulting from incorrect use or from use other than that designated, the operational safety

of the measuring devices can be jeopardized. The manufacturer accepts no liability for

damages being produced from this.

3

Sft3). A t th e same tim e, it also meas ures

2.2 Installation, commissioning and operation

Note the following points:

• Installation, connection to the electricity supply, commissioning, operation and

maintenance of the measuring device must be carried out by trained, qualified specialists

authorized to perform such work by the facility's owner operator. The specialist must have

read and understood these Operating Instructions and must follow the instructions they

contain.

• Endress+Hauser is willing to assist in clarifying the chemical resistance properties of parts

wetted by special fluids, including fluids used for cleaning. However small changes in

temperature, concentration or the degree of contamination in the process can result in

changes of the chemical resistance properties. Therefore, Endress+Hauser can not

guarantee or accept liability for the chemical resistance properties of the fluid wetted

materials in a specific application. The operator is responsible for the choice of fluid wetted

materials in regards to their in-process resistance to corrosion.

• If carrying out welding work on the piping, the welding unit should not be grounded by

means of the measuring device.

• The installer must ensure that the measuring device is correctly wired in accordance with

the wiring diagrams. The transmitter must be grounded unless special protection

measures have been taken e.g. galvanically isolated power supply SELV or PELV! (SELV =

Safe Extra Low Voltage; PELV = Protective Extra Low Voltage)

• Invariably, local regulations governing the opening and repair of electrical devices apply.

Endress+Hauser 5

Safety instructions Proline t-mass 65

2.3 Operational safety

Note the following points:

• Measuring devices for use in hazardous environments are accompanied by separate

"Ex documentation", which is an integral part of these Operating Instructions. Strict

compliance with the installation instructions and ratings as stated in this supplementary

documentation is mandatory.

The symbol on the front of this supplementary Ex documentation indicates the approval

and the certification body (e.g. 0Europe, 2 USA, 1 Canada).

• Burn hazard! When hot fluid passes through the measuring tube, the surface temperature

of the housing increases. In the case of the sensor, in particular, users should expect

temperatures that can be close to the fluid temperature. If the temperature of the fluid is

high, implement sufficient measures to prevent burning or scalding.

• The measuring device complies with the general safety requirements in accordance with

EN 61010-1, the EMC requirements of IEC/EN 61326, and NAMUR recommendation

NE 21, NE 43 and NE 53.

• The separate document on the Pressure Equipment Directive must be observed for

measuring devices used in Category II or III installations in accordance with the Pressure

Equipment Directive.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser sales center will supply you with current information and updates to

these Operating Instructions.

2.4 Return

• Do not return a measuring device if it is not absolutely certain that it has been fully cleaned

of all traces of hazardous substances, e.g. substances which have penetrated crevices or

diffused through plastic.

• Costs incurred for waste disposal and injury (burns, etc.) due to inadequate cleaning of the

measuring device will be charged to the owner-operator.

• Refer to the measures on →86.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate. It complies with the applicable standards and regulations in

accordance with EN 61010-1 "Safety requirements for electrical equipment for

measurement, control and laboratory use". It can, however, be a source of danger if used

incorrectly or for other than the designated use.

6 Endress+Hauser

Proline t-mass 65 Identification

Order Code:

Ser.No.:

TAG No.:

20-55VAC/16-62VDC

50-60Hz

14VA/8W

IP67/NEMA/Type4X65F25-XXXXXXXXXXXX

12345678901

ABCDEFGHJKLMNPQRST

–20°C (–4°F) < Tamb < +60°C (+140°F)

I-OUT ( HART), f-OUT

Proline t-mass 65

RELAY, RELAY

i

1

2

3

4

7

8

5

6

N12895

3 Identification

3.1 Device designation

The "t-mass 65" measuring device consists of the following components:

• t-mass 65 transmitter

• t-mass F, t-mass I sensors

Two versions are available:

• Compact version: transmitter and sensor form a single mechanical unit.

• Remote version: transmitter and sensor are installed separately.

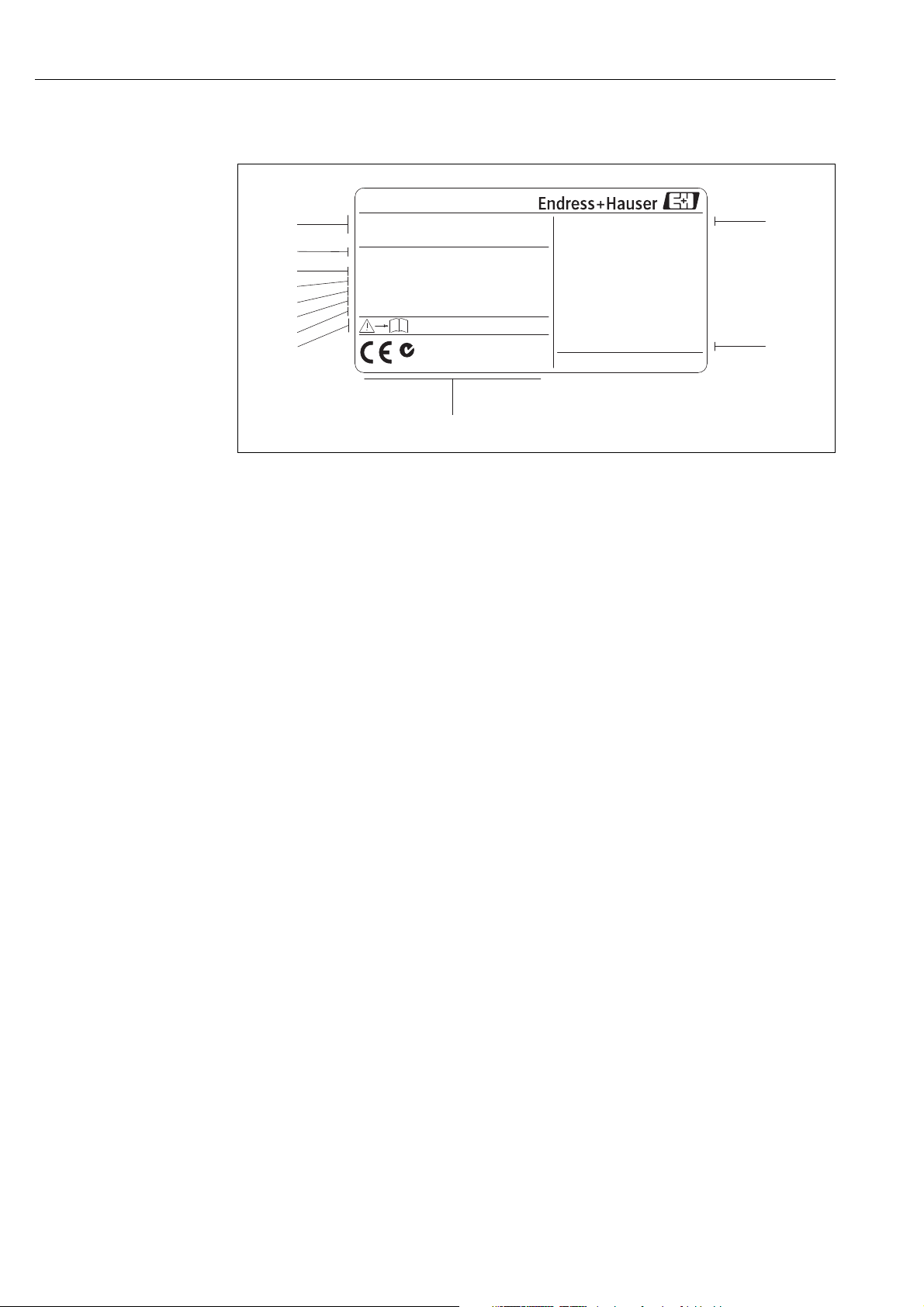

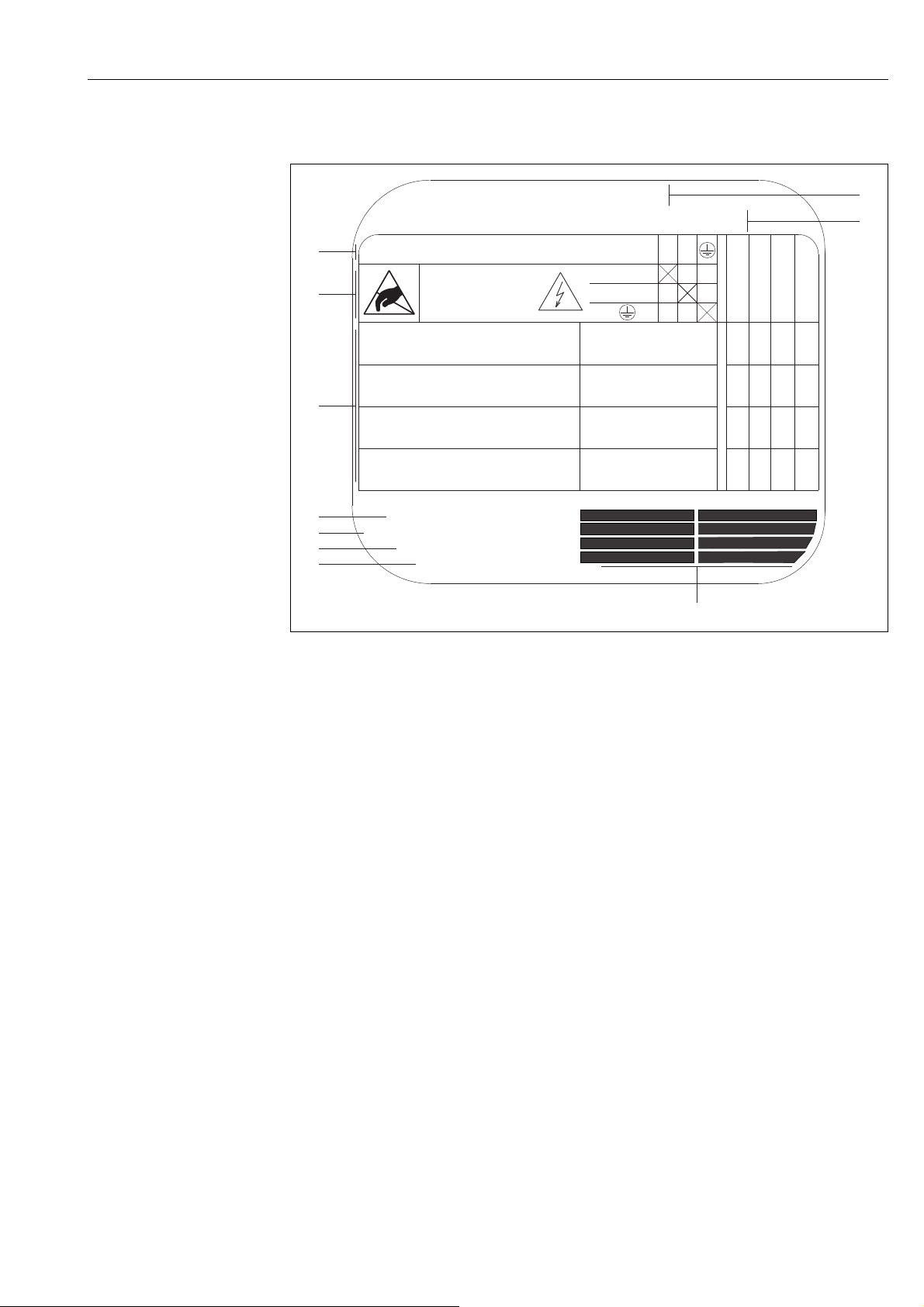

3.1.1 Nameplate of the transmitter

A0005101

Fig. 1: Nameplate specifications for the "t-mass 65" transmitter (example)

1 Order code, serial number: See the specifications on the order confirmation for the meanings of the individual letters and

digits.

2 Power supply, frequency, power consumption

3 Available inputs/outputs:

4 Reserved for information on special products

5 Please refer to operating instructions / documentation

6 Reserved for certificates, approvals and for additional information on device version

7 Ambient temperature range

8 Degree of protection

Endress+Hauser 7

Identification Proline t-mass 65

1

2

4

5

6

7

9

11

10

3

Proline t-mass F

ABCDEFGHIJKLMNOPQRST

TAG-No.:

Ser.No.:

12345678901

Order Code:

IP67 / NEMA/Type 4X

65F50-XXXXXXXXXXXX

P:

T:

Materials:

Seal:

3.1

-0.5...40bar / -7.25...+580 psi gauge

EPDM / PEEK

316/316L/1.4404/Alloy C 22- (2.4602)

-40°C...+100°C / -40°F...+212°F

-20°C(-4°F) <Tamb< +60°C(+140°F)

i

DN50 DIN/EN PN40

N12895

8

3.1.2 Nameplate of the sensor

A0005512

Fig. 2: Nameplate specifications for the "t-mass F" sensor (example)

1 Order code, serial number: See the specifications on the order confirmation for the meanings of the individual letters and

digits.

2 Nominal diameter device

3 Pressure range

4 Temperature range

5 Material of measuring tubes

6Seal material

7 Reserved for information on special products

8 Please refer to operating instructions / documentation

9 Ambient temperature range

10 Degree of protection

11 Reserved for additional information on device version (approvals, certificates)

8 Endress+Hauser

Proline t-mass 65 Identification

Active: 0/4...20mA, RL max. = 700 Ohm

Passive: 4...20mA, max. 30VDC, Ri < 150 Ohm

Passive: 30VDC, 250mA

(HART: RL.min. = 250 OHM)

fmax = 1kHz

3...30VDC, Ri = 5kOhm

f-OUT

I-OUT (HART)

A

P

STATUS-IN

X

f-OUT

Passive: 30VDC, 250mA

fmax = 1kHz

P

Communication:

Drivers:

Device SW: XX.XX.XX

XXXXXXXXXXXXXXXX

Date: 01. MAI 2009

Ex-works / ab-Werk / réglages usine

26(+) / 27(-)

NC:

Versorgung /

Tension d'alimentation

Observer manuel d'instruction

See operating manual

Betriebsanleitung beachten

XXXXXXXXXXXSer.No.:

Supply /

24(+) / 25(-)

22(+) / 23(-)

20(+) / 21(-)

N/L-

PE

A:

NO:

P:

L1/L+

12

319475-00XX

active

passive

normally open contact

normally closed contact

Update 1 Update 2

2

3

1

4

5

6

7

8

9

10

3.1.3 Nameplate for connections

a0013819

Fig. 3: Nameplate specifications for transmitter connections (example)

1 Serial number

2 Possible configuration of current output

3 Possible configuration of relay contacts

4 Terminal assignment, cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

Terminal No. 1: L1 for AC, L+ for DC

Terminal No. 2: N for AC, L– for DC

5 Signals present at inputs and outputs, possible configuration and terminal assignment (20 to 27),

see also "Electrical values of inputs/outputs", →88

6 Version of device software currently installed

7 Installed communication type, e.g.: HART, PROFIBUS DP, etc.

8 Information on current communication software (Device Revision and Device Description),

e.g.: Dev. 01 / DD 01 for HART

9Date of manufacture

10 Current updates to data specified in points 6 to 9

Endress+Hauser 9

Identification Proline t-mass 65

3.2 Certificates and approvals

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate. The measuring device complies with the applicable standards and

regulations in accordance with EN 61010-1 "Safety requirements for electrical equipment

for measurement, control and laboratory use" and with the EMC requirements of IEC/EN

61326.

The measuring device described in these Operating Instructions thus complies with the

statutory requirements of the EC Directives. Endress+Hauser confirms successful testing of

the measuring device by affixing to it the CE mark.

The measuring device meets the EMC requirements of the Australian Communications and

Media Authority (ACMA).

3.3 Registered trademarks

KALREZ® and VITON

Registered trademarks of DuPont Performance Elastomers L.L.C., Wilmington, USA

™

AMS

Registered trademark of Emmerson Process Management, St. Louis, USA

®

HART

Registered trademark of HART Communication Foundation, Austin, USA

HistoROM™, S-DAT

Applicator

®

, t-mass

Registered or registration-pending trademarks of businesses in the Endress+Hauser Group

®

®

, T-DAT™, F-CHIP®, FieldCare®, Field XpertTM, FieldCheck®,

®

10 Endress+Hauser

Proline t-mass 65 Installation

4Installation

4.1 Incoming acceptance, transport and storage

4.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Is the packaging or content undamaged?

• Is the delivery complete and do the delivered goods match your order?

4.1.2 Transport

Observe the following instructions when unpacking and transporting the device to its final

location:

• Transport the measuring device in the container in which it is delivered.

• The covers or caps fitted to the process connections prevent mechanical damage to the

sealing surfaces and contamination in the measuring tube when the unit is being

transported or in storage. Do not remove these covers or caps until immediately before

installation.

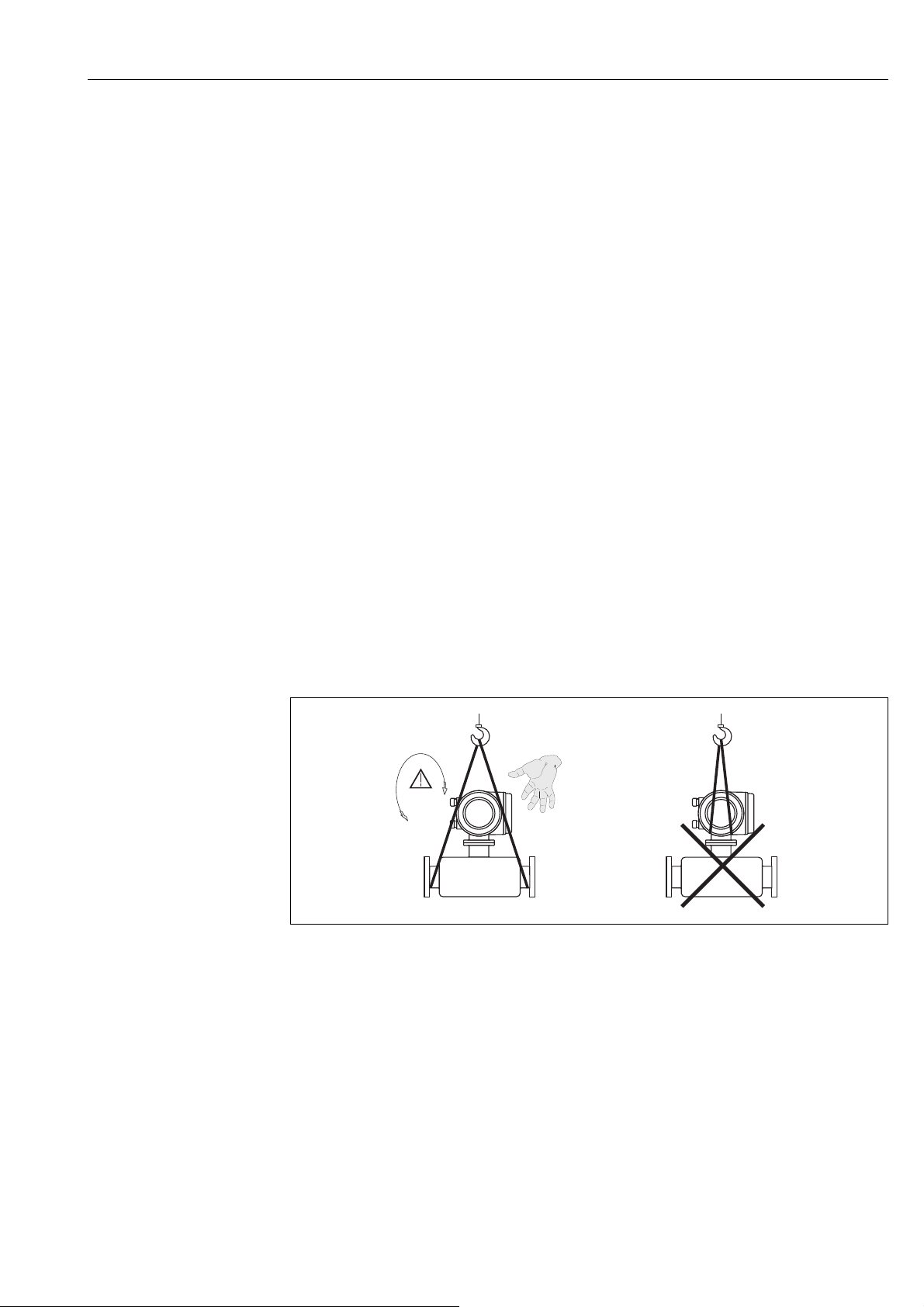

• Do not lift measuring devices of nominal diameters > DN 40 (1½") by the transmitter

housing or the connection housing in the case of the remote version →4. For

transportation purposes, use webbing slings slung round the two process connections. Do

not use chains, as they could damage the housing.

#

Warning!

Risk of injury if the measuring device slips. The center of gravity of the assembled measuring

device might be higher than the points around which the slings are slung.

When transporting, make sure that the measuring device does not unexpectedly turn

around its axis or slip.

A0004294

Fig. 4: Instructions for transporting sensors with > DN 40 (> 1½")

4.1.3 Storage

Note the following points:

• Pack the measuring device in such a way as to protect it reliably against impact for storage

(and transportation). The original packaging provides optimum protection.

• The permissible storage temperature is: –40 to +80 °C (–40 to +176 °F),

preferably +20 °C (+68 °F).

• Do not remove the protective covers or caps on the process connections until you are ready

to install the device.

• The measuring device must be protected against direct sunlight during storage in order to

avoid unacceptably high surface temperatures.

• Devices delivered with special sealing or bagging for oxygen service must remain sealed or

bagged until ready for installation.

Endress+Hauser 11

Installation Proline t-mass 65

4.2 Installation conditions

Note the following points:

• The thermal dispersion principle is very sensitive to disturbed flow conditions.

• Observe the recommended inlet and outlet requirements.

• Good engineering practice is necessary for the associated pipe work and installation.

• Ensure correct alignment and orientation of the sensor.

• Take measures to reduce or avoid condensation (e.g. install a condensation trap, thermal

insulation, etc.).

• The maximum permitted ambient temperatures →92 and the medium temperature

range →93 must be observed.

• Install the transmitter in a shaded location or use a protective sun shield.

• For mechanical reasons, and in order to protect the pipe, it is advisable to support heavy

sensors.

4.2.1 Dimensions

The dimensions and installation lengths of the sensor and transmitter can be found in the

"Technical Information" for the device in question. This document can be downloaded as a

PDF file from www.endress.com. A list of the "Technical Information" documents available

can be found in the "Documentation" section on →99.

4.2.2 System pressure and pulsating flow

Reciprocating pumps and some compressor systems can create strong changes in process

pressure that can induce spurious internal flow patterns and therefore cause additional

measurement error. These pressure pulses must be reduced by the appropriate measures:

• Use of expansion tanks

• Use of inlet expanders

• Relocate the flowmeter further downstream

In compressed air systems, it is recommended to mount the flowmeter after the filter, dryer

and buffer devices to avoid pulsations and oil/dirt contamination.

Do not mount the flowmeter directly after the compressor outlet.

12 Endress+Hauser

Proline t-mass 65 Installation

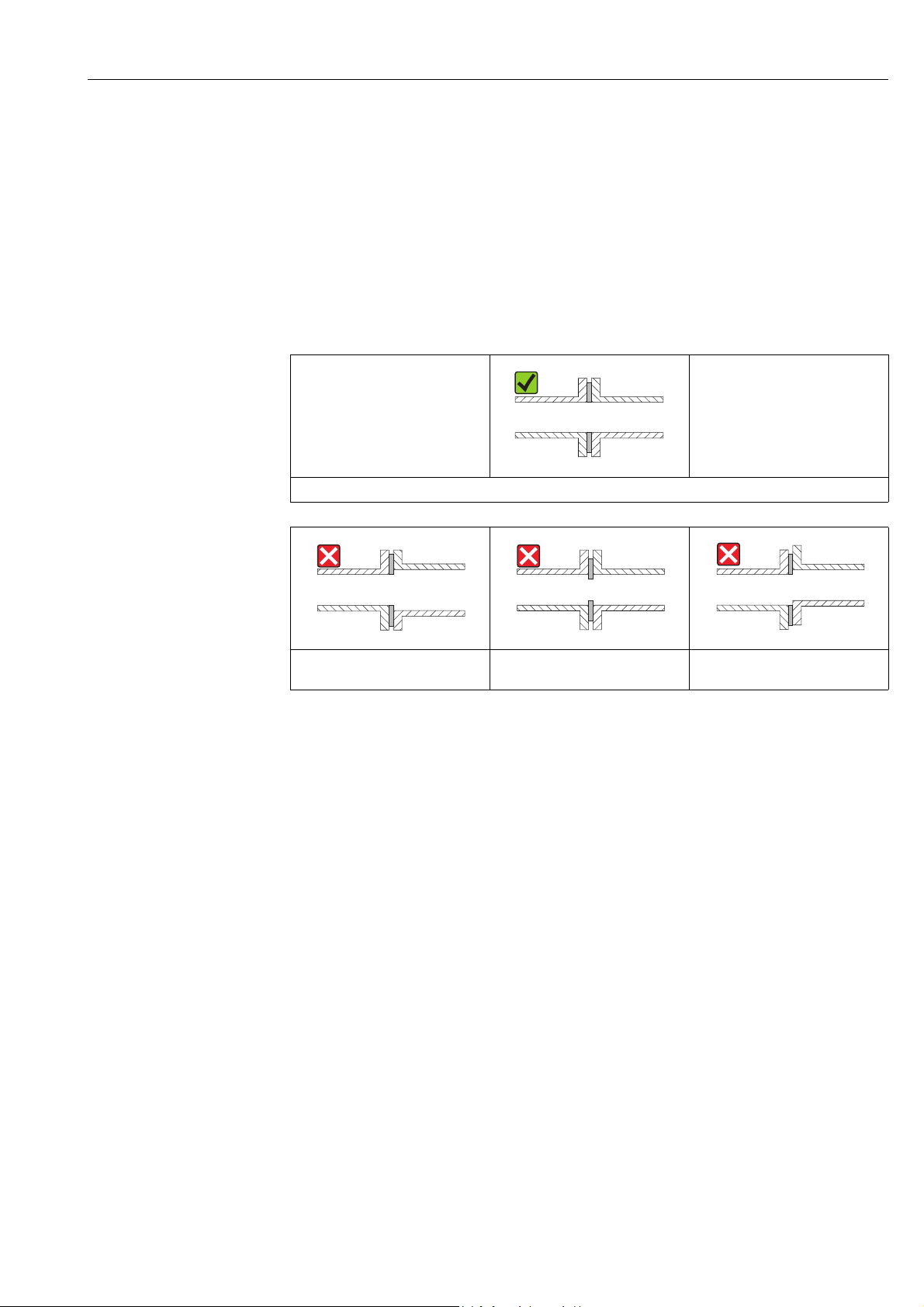

4.2.3 Pipework requirements

Good engineering practice should be followed at all times:

• Correct preparation, welding and finishing techniques

• Correctly sized gaskets

• Correctly aligned flanges and gaskets

• Connecting pipe work should match the internal diameter of the flowmeter. Maximum

pipe diameter mismatch should not exceed:

– 1 mm (0.04 in) for diameters < DN 200 (8")

– 3 mm (0.12 in) for diameters DN 200 (8")

Further information is provided in ISO Standard 14511.

A0005103

Correctly aligned flanges and gaskets

A0005104 A0005105 A0005106

Pipe diameter one is not equal pipe

diameter two

Caution!

"

New installations should be free of metallic and abrasive particles to prevent damage to the

Incorrectly sized gaskets Incorrectly aligned flanges and

gaskets

sensing elements on start-up.

Endress+Hauser 13

Installation Proline t-mass 65

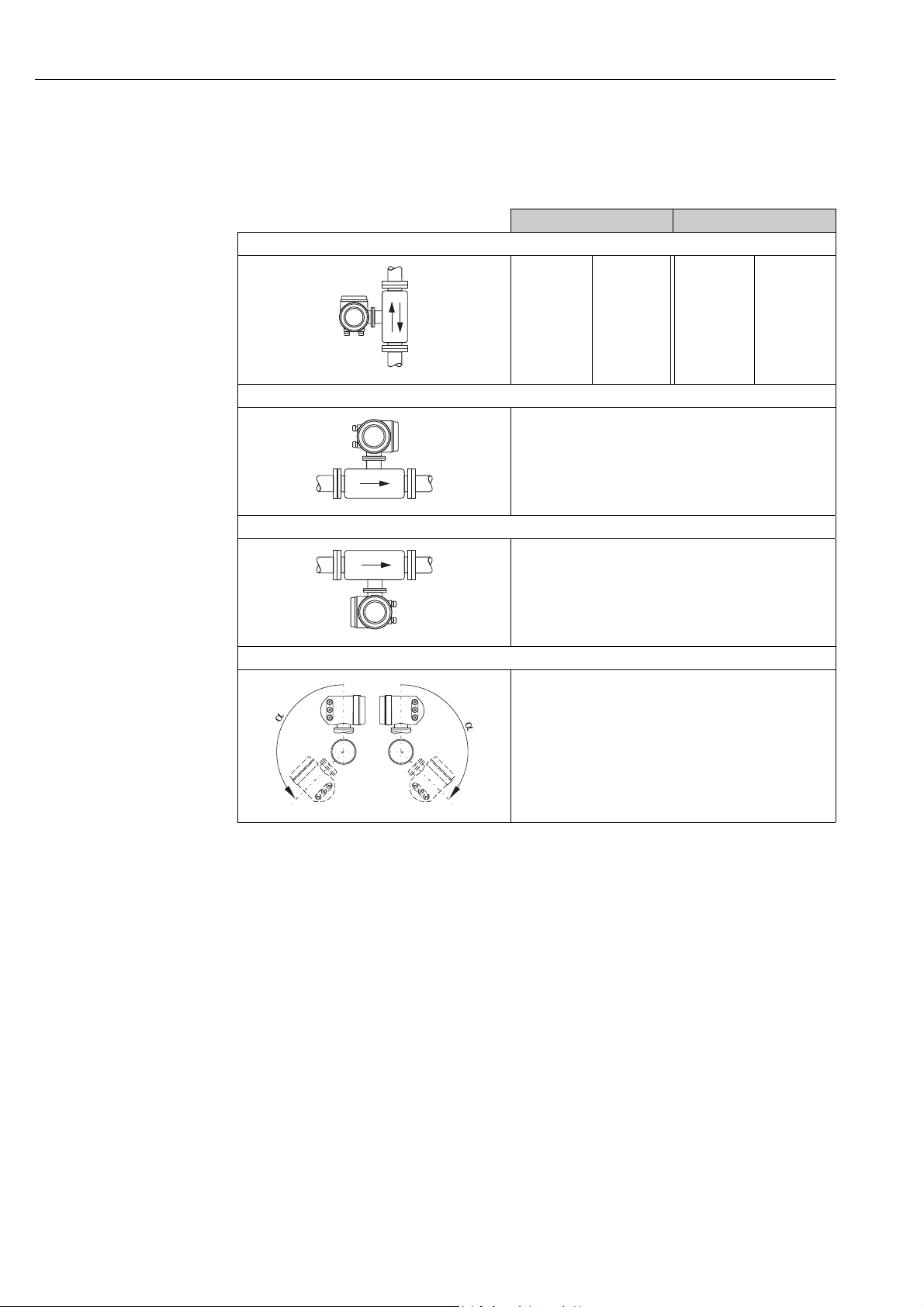

4.2.4 Orientation

Make sure that the direction arrow on the sensor matches the direction of flow through the

pipe.

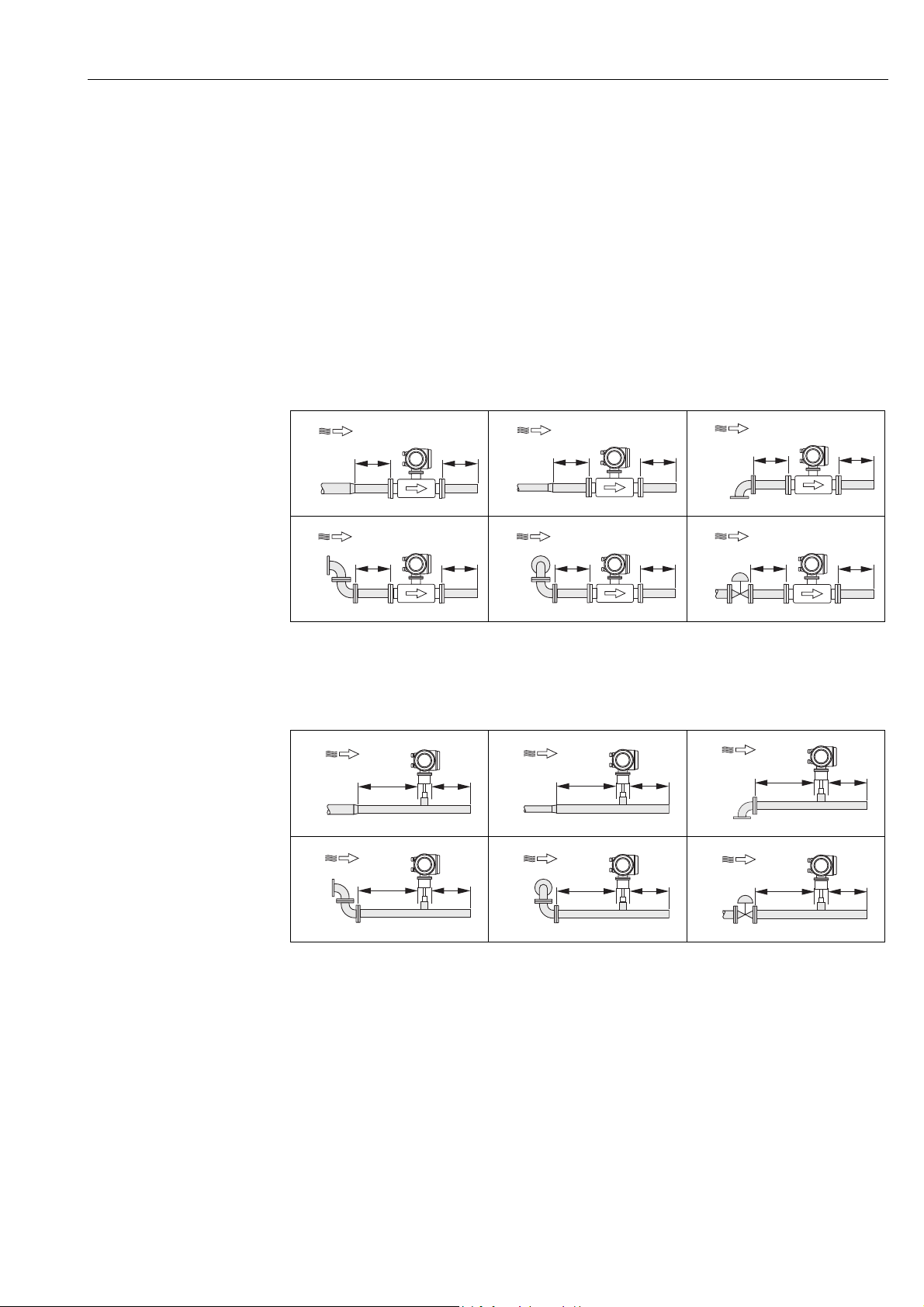

Flanged sensor Insertion sensor

Vertical orientation

compact

remote

compact

remote

A0013785

Horizontal orientation, transmitter head up

A0013786

Horizontal orientation, transmitter head down

A0013787

Inclined orientation, transmitter head down

m

m

compact/remote

n

compact/remote

o

compact/remote

p

m, n

m

A0009897

= Recommended orientation

= Orientation recommended in certain situations

In the case of saturated or unclean gases, upward flow in a vertical pipe section is preferred

m

to minimize condensation/contamination.

Not recommended if the vibrations are too high or if the installation is unstable.

n

Only suitable for clean/dry gases. Do not mount the sensor from the bottom, on horizontal pipes, if build-up

o

or condensate are likely to be present. Mount the sensor in a position as indicated below

If the gas is very wet or saturated with water (e. g. biogas, undried compressed air), mount in inclined

p

orientation (approx. 135° ±10°).

14 Endress+Hauser

Proline t-mass 65 Installation

15xDN 2xDN

15xDN

2xDN

15xDN

2xDN

20xDN

2xDN

35xDN

2xDN

50xDN

2xDN

20xDN 5xDN

20xDN 5xDN

20xDN 5xDN

25xDN 5xDN

40xDN 5xDN

50xDN 5xDN

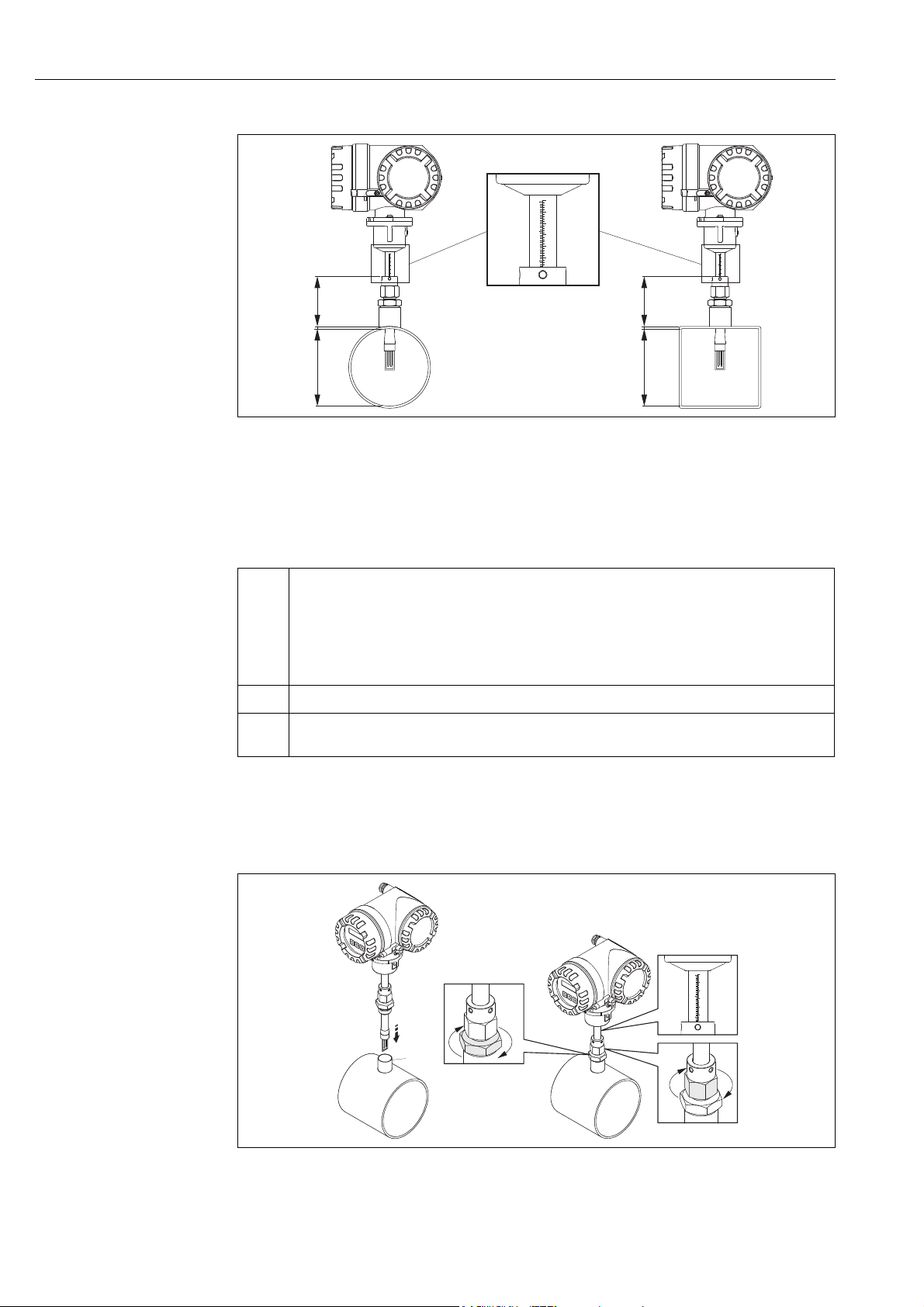

4.2.5 Inlet and outlet runs

The thermal dispersion principle is sensitive to disturbed flow conditions.

As a general rule, the thermal flowmeter should always be installed as far away as possible

from any flow disturbances. For further information ISO Standard 14511.

!

Note!

• Where two or more flow disturbances are located upstream of the meter, the longest

indicated inlet length should prevail. For example if a control valve is additionally mounted

upstream from the measuring device and an elbow on the inlet side, select the

recommended inlet length for control valves: 50 × DN

• For very light gases such as Helium and Hydrogen all upstream distances should be

doubled.

The minimum recommendations for inlet and outlet runs (without flow conditioner) are:

Flanged sensor

1

4

1 = Reduction, 2 = Expansion, 3 = 90° elbow or T-piece, 4 = 2 × 90° elbow,

5 = 2 × 90° elbow (3-dimensional), 6 = Control valve

A0007523

A0007526

2

A0007524

5

A0007527

Insertion sensor

1

4

A0007529

2

A0007530

5

3

A0007525

6

A0007528

3

A0007531

6

Endress+Hauser 15

!

A0007532

1 = Reduction, 2 = Expansion, 3 = 90° elbow or T-piece, 4 = 2 × 90° elbow,

5 = 2 × 90° elbow (3-dimensional), 6 = Control valve or pressure regulator

A0007564

A0007534

Note!

A specially designed perforated plate flow conditioner can be installed if it is not possible to

observe the inlet runs required (→16).

Installation Proline t-mass 65

PT

2...5 x DN

2 × DN5 - 10 × DN

>8 × DN 5 × DN

5 - 10 × DN

2

1

Outlet runs with pressure measuring points

The pressure measuring point should be installed downstream of the measuring device, so

that there is no potential influence of the pressure transmitter process connection on the

flow entering the measuring point.

A0005114

Fig. 5: Installing a pressure measuring point (PT = pressure transmitter)

Perforated plate flow conditioner

It is recommended to install a perforated plate flow conditioner if the recommended inlet

runs are not available.

!

A0005115

Fig. 6: The figure above illustrates the minimum recommended inlet and outlet runs expressed in multiples of the pipe diameter

1 = Flow conditioner with the flanged sensor, 2 = Flow conditioner with the insertion sensor

using a flow conditioner.

Flow conditioner for use with insertion sensors 65I →69

The well known "Mitsubishi" design is recommended for this application DN 80 mm to

DN 300 mm (3" to 12"). The flow conditioner must be installed at a distance of 8 × DN

upstream of the sensor. A further 5 pipe diameters minimum inlet run is required upstream

of the actual conditioner itself.

Measured errors can occur depending on disturbances in the inlet run. Therefore it is

advisable to choose inlet runs that are as long as possible.

Note!

In the case of insertion devices, the inlet run selected downstream of the conditioner should

be as long as possible.

16 Endress+Hauser

Proline t-mass 65 Installation

1

2

2

3

4

1

1

1

Perforated plate flow conditioners (19 hole) for use with flanged sensor 65F →69

This is a special Endress+Hauser version designed especially for use with the t-mass F sensor

(sizes DN 25 to 100 / 1" to 4"). The mounting hole patterns and sizing are of a multi-variant

design which means that one plate will fit different flange pressure classes e.g. Cl. 150 and

Cl. 300.

The flow conditioner and gaskets are fitted between the pipe flange and the measuring

device →7. Use only standard bolts which match the flange bolt hole to guarantee that

the flow conditioner is centered correctly.

The alignment notch must also be pointing in the same plane as the transmitter. Incorrect

installation of the flow conditioner will have a small effect on the measurement accuracy.

A0005116

Fig. 7: Flow conditioner mounting arrangement (example)

1=perforated plate flow conditioner, 2= seal/gasket, 3= alignment notch, 4 = alignment in the same plane as the transmitter

Note

• Order the t-mass F sensor and the flow conditioner together to ensure that they are

calibrated together. Joint calibration guarantees optimum performance. Ordering the flow

conditioner separately and using it with the measuring device will further increase

measurement uncertainty.

• The use of conditioners from other suppliers will affect the flow profile and pressure drop

and will have an adverse effect on performance.

• Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the

customer.

Endress+Hauser 17

Installation Proline t-mass 65

aa

bb

4.2.6 Heating

Some applications require suitable measures to avoid heat loss (condensation). Heating can

be electric, e. g. with heated elements, or by means of copper pipes carrying hot water or

steam.

Caution!

"

Risk of electronics overheating! Consequently, make sure that the adapter between sensor

and transmitter and the connection housing of the remote version always remain free of

insulating material.

4.2.7 Thermal insulation

If the gas is very wet or saturated with water (e.g. biogas), the piping and sensor housing

should be insulated to prevent water droplets from condensing on the transducer.

Fig. 8: Maximum thermal insulation for t-mass 65F and 65I

a Maximum insulation height for the flanged sensor

b Maximum insulation height for the insertion sensor

4.2.8 Vibrations

Caution!

"

Excessive vibration can result in mechanical damage to the measuring device and its

mounting.

Observe the vibration specification in the technical data section →93

A0005122

18 Endress+Hauser

Proline t-mass 65 Installation

90°

90°

4.3 Installation

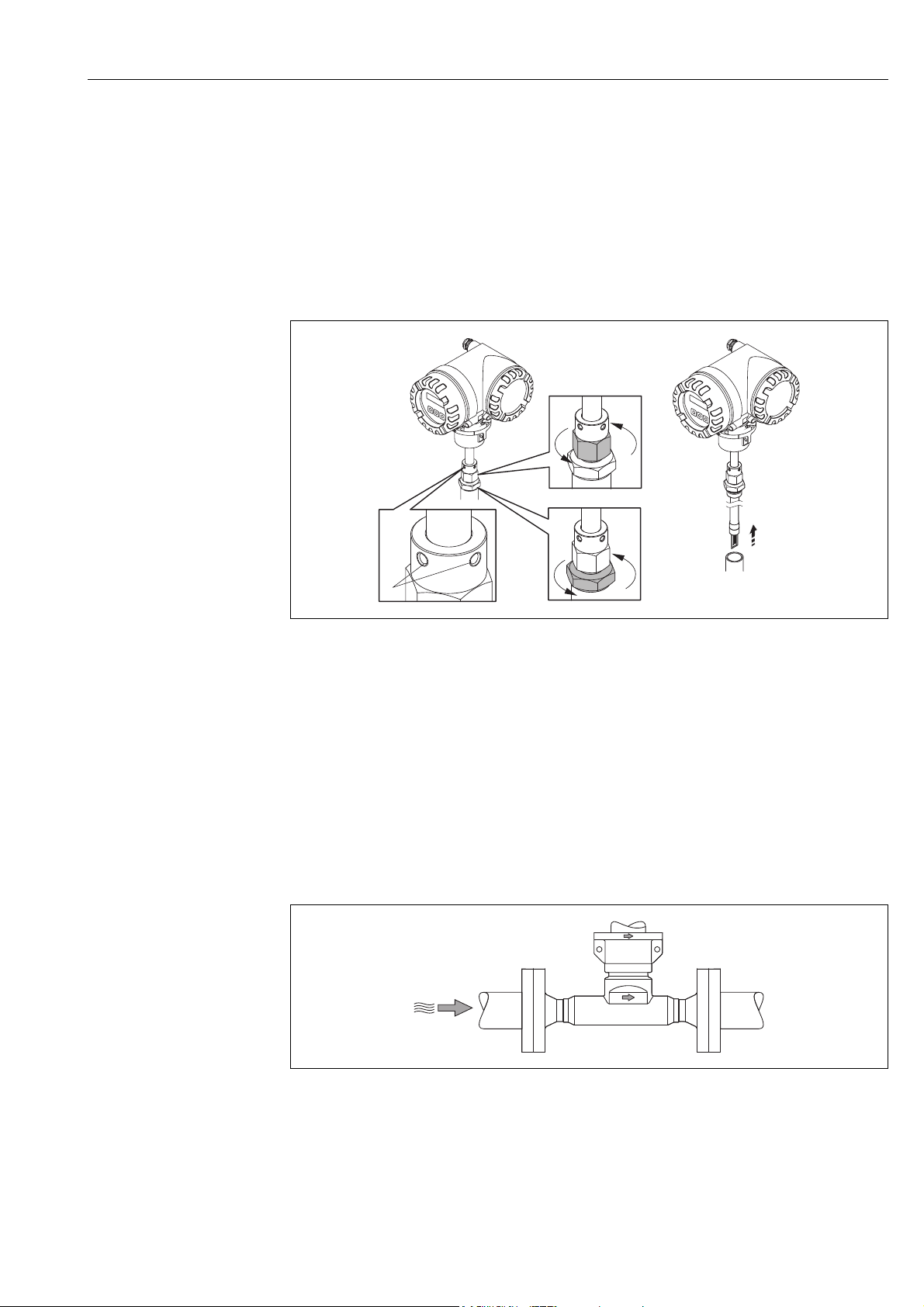

4.3.1 Mounting the insertion sensor

The sensor can be mounted into a welding boss or a retractable mounting set. If a retractable

mounting set is being used, then refer to the supplementary documentation delivered with

the mounting set.

Mounting the welding boss

This instruction describes mounting of the Endress+Hauser welding boss. If a welding boss

is already available or a customer-specific one is being used, then go to the next section

"Insertion depth calculation and adjustment."

!

"

#

Note!

• Take the orientation and inlet and outlet runs into account before mounting the welding

socket →14 ff.

• The welding boss is made of stainless steel 1.4404 (316/316L). Use appropriate welding

technique.

Caution!

• When mounting the fitting to a thin wall duct, use a suitable support bracket for the sensor

and weld the welding boss to a base plate to spread the load. Otherwise, the mounting may

be unstable and the duct wall can be damaged.

Warning!

• These instructions are only applicable to installation in an un-pressurized line, without gas

present and at safe temperatures.

1. Drill or a cut hole of Ø 31.0 mm ± 0.5 mm (1.22 ± 0.019") in the pipe.

2. Deburr the hole.

3. Fit the edge of the welding boss into the hole, align it vertically and weld it on →9.

A0010098

Fig. 9: Positioning the welding socket on the pipe (or duct)

Insertion depth calculation and adjustment

To ensure optimum measurement performance, the insertion sensor must be installed in the

correct position in the pipe or duct (30% of the internal diameter).

A millimeter and inch scale is provided along the entire length of the sensor tube. This

makes it possible to align the sensor at the right depth.

4. Calculate the insertion depth:

– with the help of the Quick Setup "Sensor" →53 or

Endress+Hauser 19

– using the following dimensions and formulae

Installation Proline t-mass 65

A

B

C

A

B

C

230

220

210

200

190

180

9

8

7

230

220

210

200

190

180

9

8

7

230

220

210

200

190

180

9

8

7

1

3

4

2

230

220

210

200

190

180

9

8

7

A0005118

Fig. 10: Dimensions needed to calculate the insertion depth

A Pipes: internal diameter

Ducts: internal dimension

B Wall thickness

C Dimension from pipe/duct to the compression fitting

!

The following dimensions are required to calculate the insertion depth:

A • For circular pipes: the internal diameter (DN)

B Pipe / duct wall thickness

C Height of the welding nozzle at the pipe/duct including the sensor compression fitting or low pressure

• For rectangular ducts:

– The internal duct height if the sensor is installed vertically

– The internal duct width if the sensor is installed horizontally

Note!

!

Minimum length of dimension A = 80 mm (3.15 in)

mounting set (if used).

Note!

For detailed remarks on calculation refer to Technical Information TI00069D.

• Calculated insertion depth = (0.3 × A) + B + C + 2 mm (0.08 in)

Note down the calculated value.

Fig. 11: Aligning the sensor to the calculated insertion depth

20 Endress+Hauser

A0010001

Proline t-mass 65 Installation

90°±7°

90°±3°

B

A

1

2

5. Insert the sensor in the nozzle (1) and tighten the lower nut of the compression fitting

(2) finger-tight.

Caution!

"

– NPT thread: use a thread sealing tape or paste

– G 1 A thread: the sealing ring supplied must be installed

6. Tighten the upper nut of compression fitting (3) such that the sensor can still be

adjusted.

7. Read off the calculated insertion depth from the scale and adjust the sensor so that the

value aligns with the upper end of the compression fitting (4).

8. Tighten the lower nut of the compression fitting 1¼ revolutions using a wrench

(42 mm).

Aligning the sensor with the flow direction

A0005117

Fig. 12: Aligning the sensor with the flow direction

9. Check and ensure that the sensor is aligned vertically at a 90° angle on the pipe/duct.

Turn the sensor so that the arrow marking matches the direction of flow.

!

Note!

To ensure optimum exposure of the measuring transducer to the flowing gas stream, the

sensor must not be rotated more than 7° from this alignment.

Fig. 13: Securing the position of the sensor

A0010114

Endress+Hauser 21

Installation Proline t-mass 65

10. Tighten the compression fitting (1) by hand to secure the position of the sensor. Then,

using an open-ended wrench, tighten another 1¼ revolutions in a clockwise direction.

11. Fix the two securing screws (2) (Allen key 3 mm; (1/8")).

Warning!

#

Observe torque: 4 Nm (2.95 lbf ft)

12. Check that the sensor and transmitter do not turn.

13. Check the measuring point for leaks at the maximum operating pressure.

22 Endress+Hauser

Proline t-mass 65 Installation

1

2

3

4.3.2 Removing the insertion sensor

#

Warning!

• Do not remove the measuring device when it is pressurized! Stop the gas flow and

unpressurize the process pipe.

• In the case of toxic, explosive or flammable gases, the pipe in which the measuring device

is installed must be purged with an inert gas to remove all traces of the gas used.

• Make sure that the process cannot be resumed while removal work is in progress.

• Allow the system and measuring device to cool to a safe temperature

(e.g. <50 °C, (<120 ° F)).

Fig. 14: Removing the insertion sensor

1. Release the securing screws (1).

2. Release the upper nut of compression fitting using a wrench, turning in a

counterclockwise direction (2).

Caution!

"

In the case of vertical installation, do not drop the measuring device into the pipe.

3. Unscrew the lower nut of compression fitting (3) and remove the sensor.

4.3.3 Mounting the flanged sensor

The arrow on the sensor must match with the actual direction of flow through the pipe.

Fig. 15: Mounting in direction of flow

A0011016

A0013663

Endress+Hauser 23

Installation Proline t-mass 65

3

5

6

1

2

4

4 x 45°

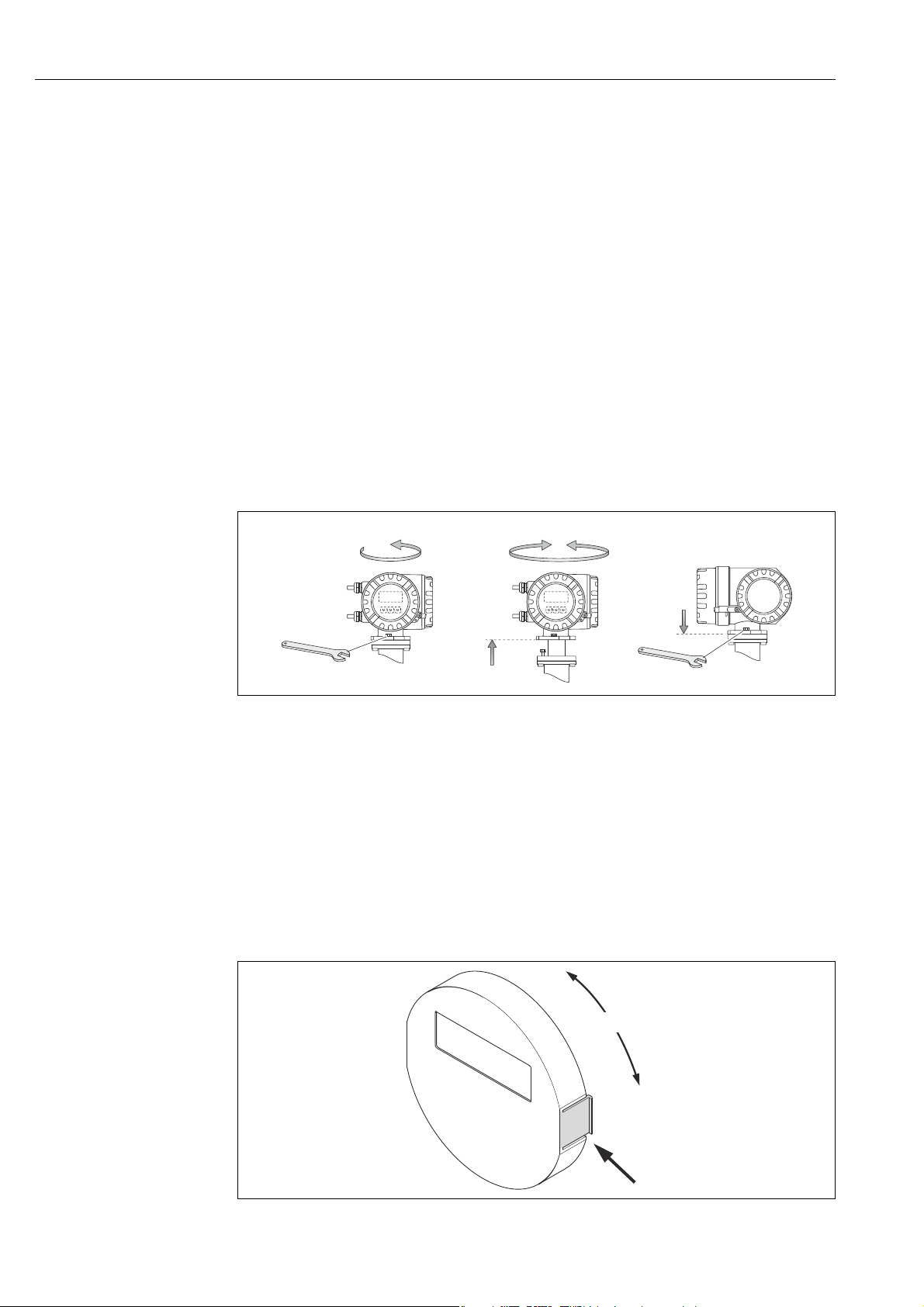

4.3.4 Turning the transmitter housing

Turning the aluminum field housing

#

Warning!

The rotating mechanism for measuring devices for hazardous areas Zone 1 (ATEX/IEC Ex)

or Clas s I Div . 1 ( FM/C SA) is dif fere nt to that described here. The procedure for turning these

housings is described in the Ex-specific documentation →99.

1. Loosen the two securing screws.

Caution!

"

Special screw! Do not loosen screw completely or replace with another screw.

Use only original Endress+Hauser parts.

1. Turn the bayonet catch as far as it will go.

2. Carefully lift the transmitter housing as far as it will go.

3. Turn the transmitter housing to the desired position (max. 2 × 90° in either direction).

4. Lower the housing into position and re-engage the bayonet catch.

5. Retighten the two securing screws.

A0004302

Fig. 16: Turning the transmitter housing (aluminum field housing)

4.3.5 Turning the local display

1. Unscrew cover of the electronics compartment from the transmitter housing.

2. Press the side latches on the display module and remove the module from the

electronics compartment cover plate.

3. Rotate the display to the desired position (4 × 45 ° in both directions), and reset it onto

the electronics compartment cover plate.

4. Screw the cover of the electronics compartment firmly back onto the transmitter

housing.

Fig. 17: Turning the local display (field housing)

24 Endress+Hauser

A0003236

Proline t-mass 65 Installation

a

b

c

90 (3.54)

35 (1.38)

192 (7.56)

81.5 (3.2)

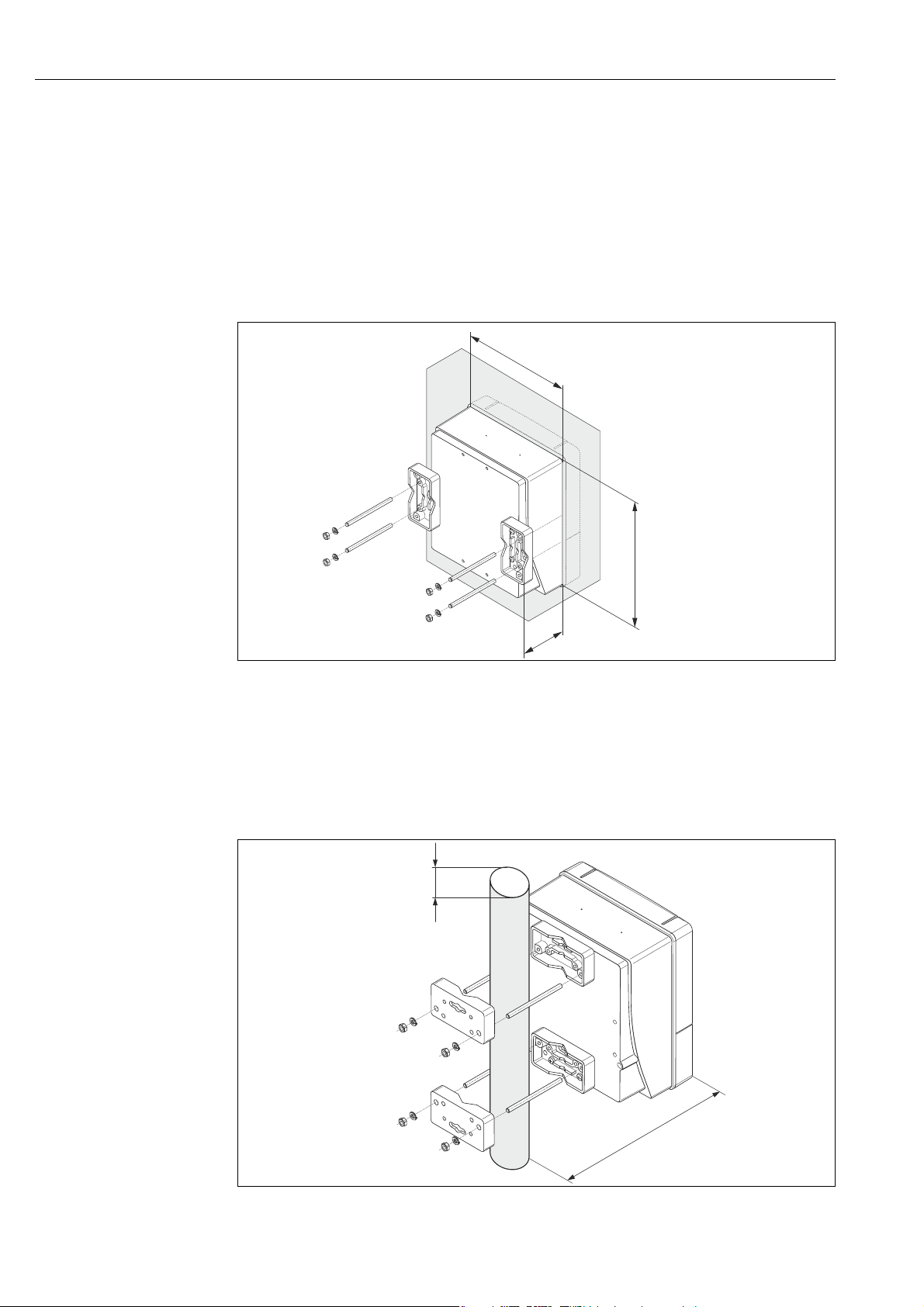

4.3.6 Installing the wall-mount transmitter housing

There are various ways of installing the wall-mount transmitter housing:

• Mounted directly on the wall

• Installation in control panel →26 (separate mounting set, accessories) →69

•Pipe mounting →26 (separate mounting set, accessories →69)

Caution!

"

• The ambient temperature may not exceed the permissible range of –20 to +60 °C

(-4 to +140 °F), optionally –40 to +60 °C (–40 to +140 °F), at the mounting location.

• Install the device in a shady location. Avoid direct sunlight on the display.

• Always install the wall-mount housing in such a way that the cable entries are pointing

down.

Mounted directly on the wall

1. Drill the holes as illustrated in the diagram.

2. Remove the cover of the connection compartment (a).

3. Push the two securing screws (b) through the appropriate bores (c) in the housing.

– Securing screws (M6): max. Ø 6.5 mm (0.26 inch)

– Screw head: max. Ø 10.5 mm (0.41 inch)

4. Secure the transmitter housing to the wall as indicated.

5. Screw the cover of the connection compartment (a) firmly onto the housing.

Fig. 18: Engineering unit mm (in)

A0001130

Endress+Hauser 25

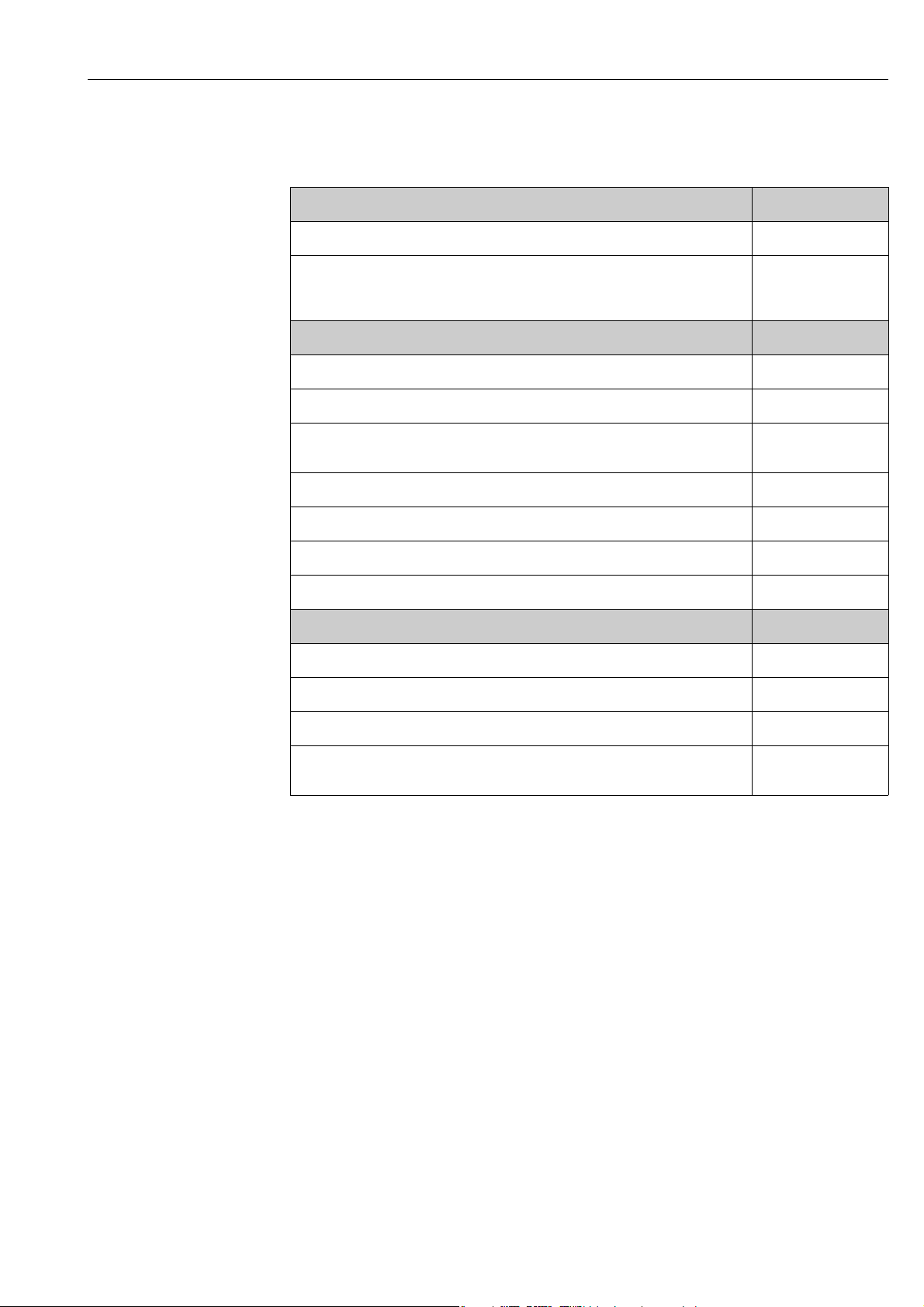

Installation Proline t-mass 65

245 (9.65)

~110 (~4.33)

210 (8.27)

+0.5 (+0.019)

–0.5 (–0.019)

+0.5 (+0.019)

–0.5 (–0.019)

Ø 20…70

(Ø 0.79…2.75)

~ ~ 6.1)155 (

Installation in control panel

1. Prepare the opening in the panel as illustrated in the diagram.

2. Slide the housing into the opening in the panel from the front.

3. Screw the fasteners onto the wall-mount housing.

4. Screw threaded rods into holders and tighten

until the housing is solidly seated on the panel wall. Afterwards, tighten the locking

nuts.

Additional support is not necessary.

Fig. 19: Engineering unit mm (in)

Pipe mounting

The assembly should be performed by following the instructions in the diagram.

Caution!

"

If a warm pipe is used for installation, make sure

that the housing temperature does not exceed the max. permitted value of +60 °C (+140 °F).

A0001131

Fig. 20: Engineering unit mm (in)

26 Endress+Hauser

A0001132

Proline t-mass 65 Installation

4.4 Post-installation check

Perform the following checks after installing the measuring device in the pipe:

Device condition and specifications Notes

Is the measuring device undamaged (visual inspection)? –

Does the device correspond to specifications at the measurement point, including

process temperature and pressure, ambient temperature, measuring range, etc.?

Check the name plate.

Installation Notes

Correct alignment of pipe/gasket/flowmeter body? →13

Professional installation, e.g. correct pipe internal diameter, correctly sized gaskets? →13

Is the position chosen for the sensor correct, in other words suitable for sensor type,

fluid properties and fluid temperature?

Is there sufficient upstream and downstream pipe sensor? →15

Correct installation of flow conditioner (if fitted)? →16

Does the arrow on the sensor match the direction of flow through the pipe? →14

Correct sensor depth (insertion sensor only)? →19

Process environment/process conditions Notes

Is the measuring device protected against moisture and direct sunlight? –

Is the measuring device protected against overheating? →18

→7

→14

Is the measuring device protected against excessive vibration? →18, →93

Check gas conditions (e. g. purity, dryness, cleanliness) Select suitable

orientation →14

Endress+Hauser 27

Electrical connection Proline t-mass 65

N

i

c

h

t

u

n

t

e

r

S

p

a

n

n

u

n

g

ö

f

f

n

e

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

N

e

p

a

s

o

u

v

r

i

r

l

’

a

p

p

a

r

e

i

l

s

o

u

s

t

e

n

s

i

o

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

AB

C

D

41 42 43 44

GND

6…

10V

COMMS

+

-

+

-

GND

COMMS

--

++

41 42 43 44

6…

10V

5 Electrical connection

#

!

!

#

Warning!

When connecting Ex-certified measuring devices, see the notes and diagrams in the Exspecific supplement to these Operating Instructions. Please do not hesitate to contact your

Endress+Hauser sales center if you have any questions.

Note!

The measuring device does not have an internal power isolation switch. Therefore provide

an isolation switch or circuit breaker which can be used to disconnect the power supply to

the measuring device.

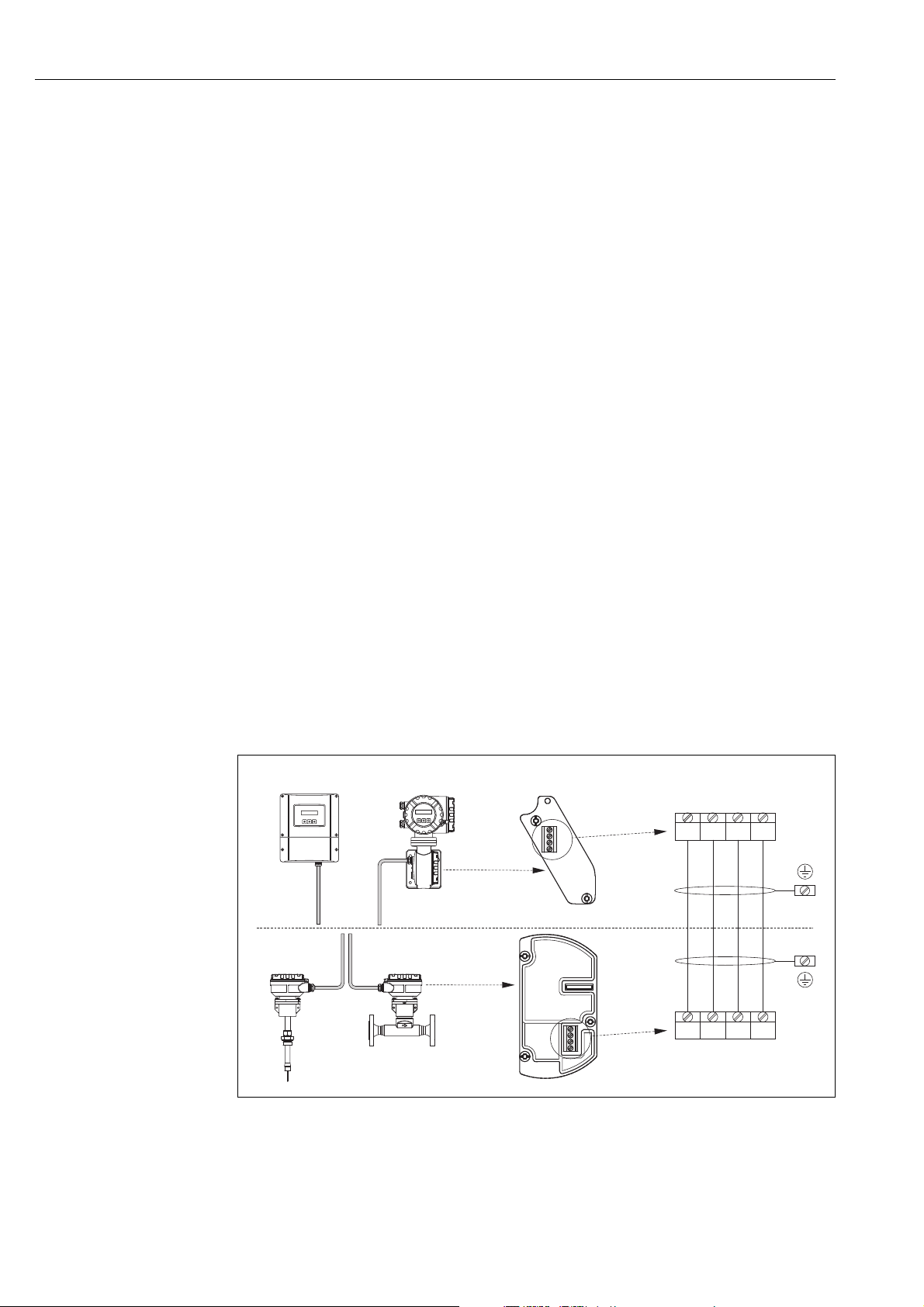

5.1 Connecting the remote version

Note!

A cable is not supplied for the remote version.

5.1.1 Connecting the connecting cable for sensor/transmitter

Warning!

• After removing the electronics cover, there is a risk of electric shock as shock protection is

removed! Switch off the measuring device before removing internal covers.

• Risk of electric shock. Connect the protective earth to the ground terminal on the housing

before the power is supplied.

1. Remove the connection compartment cover by loosening the fixing screws on the

transmitter and sensor housing.

2. Feed the connecting cable through the appropriate cable entry.

3. Establish the connections between sensor and transmitter in accordance with the

wiring diagram (→21 or see wiring diagram in screw cap; wire cross-section:

max. 2.5 mm² (14 AWG)).

4. Screw the connection compartment cover back onto the sensor or transmitter housing.

Fig. 21: Connecting the remote version

A Wallmount housing; Non-hazardous area and zone 2 (ATEX II3G, FM/CSA)

B Field housing; Zone 1 (ATEX II2GD, IECEx, FM/CSA)

C Remote sensor insertion

D Remote sensor flanged

Wire colors (when supplied by Endress+Hauser):

Terminal no. 41 = white; 42 = brown; 43 = green; 44 = yellow

see separate "Ex documentation"

see separate "Ex documentation"

A0005123

28 Endress+Hauser

Proline t-mass 65 Electrical connection

5.1.2 Cable specification, connecting cable

A cable with the following specifications must be used for the remote version:

• 2 × 2 × 0.5 mm² (AWG 20) PVC cable with common shield (2 twisted pairs)

• Conductor resistance: 40 /km ( 131.2 /1000 ft)

•Operating voltage: 250 V

• Temperature range: –40 to +105 °C (–40 to +221 °F)

• Overall nominal diameter: 8.5 mm (0.335")

• Maximum cable length: 100 m (328 feet)

!

Note!

• The cable must be installed securely to prevent movement

• The cable should be of sufficient diameter to provide adequate sealing of the compression

fitting →90.

Endress+Hauser 29

Electrical connection Proline t-mass 65

5.2 Connecting the measuring unit

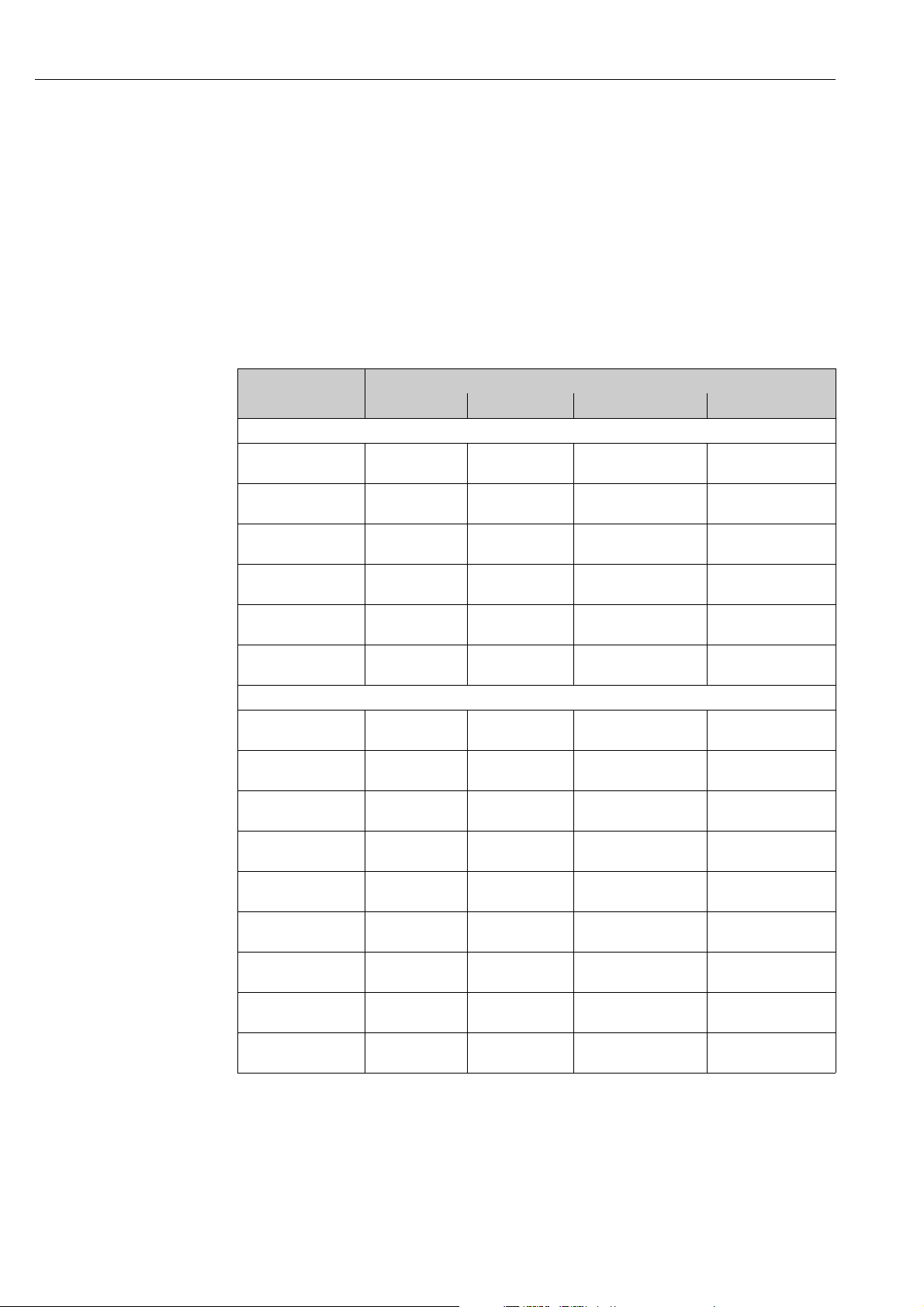

5.2.1 Terminal assignment

Electrical values for inputs

→88

Electrical values for outputs

→89

Terminal No. (inputs/outputs)

Order variant 20 (+) / 21 (–) 22 (+) / 23 (–) 24 (+) / 25 (–) 26 (+) / 27 (–)

Fixed communication boards (permanent assignment)

65F**-***********A

65I-*************A

65F**-***********B

65I-*************B

65F**-***********R

65I-*************R

65F**-***********S

65I-*************S

65F**-***********T

65I-*************T

65F**-***********U

65I-*************U

Flexible communication boards

65F**-***********C

65I-*************C

65F**-***********D

65I-*************D

65F**-***********E

65I-*************E

65F**-***********L

65I-*************L

65F**-***********2

65I-*************2

65F**-***********4

65I-*************4

65F**-***********5

65I-*************5

65F**-***********6

65I-*************6

65F**-***********8

65I-*************8

Relay output Relay output Frequency output

Relay output 2 Relay output 1 Frequency output Current output, HART

Status input Relay output Frequency output Current output, HART

Status input Relay output Current output 2

Status input Relay output 2 Relay output 1 Current output, HART

Relay output Current output 2 Frequency output

Current input Relay output Frequency output Current output, HART

Status input Current input Frequency output Current output, HART

Status input Current input Current output 2 Current output, HART

Status input Frequency output Current output 2 Current output, HART

- - Frequency output

--

--

--

--

Current output 2

Ex i, active

Frequency output

Ex i, passive

Frequency output

Ex i, passive

Current output 2

Ex i, passive

Current output

HART

Current output

HART

Current output 1,

Ex i, active, HART

Current output, Ex i,

active, HART

Current output, Ex i,

passive, HART

Current output 1,

Ex i, passive, HART

Current output 1,

HART

Current output 1,

HART

30 Endress+Hauser

Loading...

Loading...