Page 1

TI00069D/06/EN/13.14

71261937

Products Solutions Services

Technical Information

Proline t-mass 65F, 65I

Thermal mass flowmeter

The high performing flowmeter with intelligent and dynamic adaptation to

changing process conditions

F: Inline version, I: Insertion version

Application

• Measuring principle is characterized by a high operable flow

range and direct mass flow measurement

• F: Measurement of gases and gas mixtures in small line sizes

• I: Measurement of gases and gas mixtures in circular piping or

rectangular ducts

Device properties F

• Inline version: nominal diameter DN 15 to 100 (½ to 4")

• Process pressure up to PN 40, Class 300

• High accuracy: ±1.5 % o.r. (10 to 100 % o.f.s.)

Device properties I

• Insertion version for nominal diameter DN 80 to 1500

(3 to 60")

• Medium temperature up to +130 °C (266 °F)

• High accuracy: ±1.5 % o.r. (10 to 100 % o.f.s.)

Device properties 65

• Device in compact or remote version

• 4-20 mA HART, PROFIBUS PA/DP, Modbus RS485, FF

• Worldwide approvals (Hazardous area)

Your benefits

• Plant safety – high accuracy and repeatability for a wide range

of utility and process gases

• Cost-effective measurement – easy installation, negligible

pressure loss and maintenance-free

• Reliable flow trending – multivariable measurement

• Flexible device configuration to suit the application –

integrated "Gas Engine" functionality

• For demanding applications – user-definable gas mixtures,

high repeatability and accuracy

• Automatic recovery of data for servicing

Page 2

Table of contents

Proline t-mass 65F, 65I

Document information . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Function and system design . . . . . . . . . . . . . . . . . . . . . .4

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Low flow cut off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Device plug connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Remote version

cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pressure-temperature ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Limiting flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Thermal insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hot tap, process pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cold tap, atmospheric pressure . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 27

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Process connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 47

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

C-Tick mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

FOUNDATION Fieldbus certification . . . . . . . . . . . . . . . . . . . . . 47

PROFIBUS DP/PA certification . . . . . . . . . . . . . . . . . . . . . . . . . 48

Modbus RS485 certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pressure measuring device approval . . . . . . . . . . . . . . . . . . . . . 48

Oxygen service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 48

Performance characteristics . . . . . . . . . . . . . . . . . . . . 14

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reaction time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Influence of medium pressure

(Pressure co-efficient) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inlet and outlet runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mounting conditions for the insertion version . . . . . . . . . . . . 20

Length of connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting wall-mount housing . . . . . . . . . . . . . . . . . . . . . . . . . 22

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Medium temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Device-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Communication-specific accessories . . . . . . . . . . . . . . . . . . . . . 49

Service-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . 50

2 Endress+Hauser

Page 3

Proline t-mass 65F, 65I

Document information

Symbols used Electrical symbols

Symbol Meaning

A0011197

A0011198

A0011200

A0011199

A0011201

Direct current

A terminal at which DC voltage is present or through which direct current flows.

Alternating current

A terminal at which alternating voltage (sinusoidal) is present or through which

alternating current flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that must be connected to the plant grounding system:

This may be a potential equalization line or a star grounding system depending on

national or company codes of practice.

Symbols for types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Preferred

Indicates procedures, processes or actions that are preferred.

A0011183

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011200

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

Reference to graphic

Refers to the corresponding graphic number and page number.

A0011196

Symbols in graphics

Symbol Meaning

1, 2, 3 etc. Item numbers

A, B, C etc. Views

A-A, B-B, C-C

Sections

etc.

Flow direction

A0013441

Endress+Hauser 3

Page 4

Proline t-mass 65F, 65I

Esc

E

-

+

Function and system design

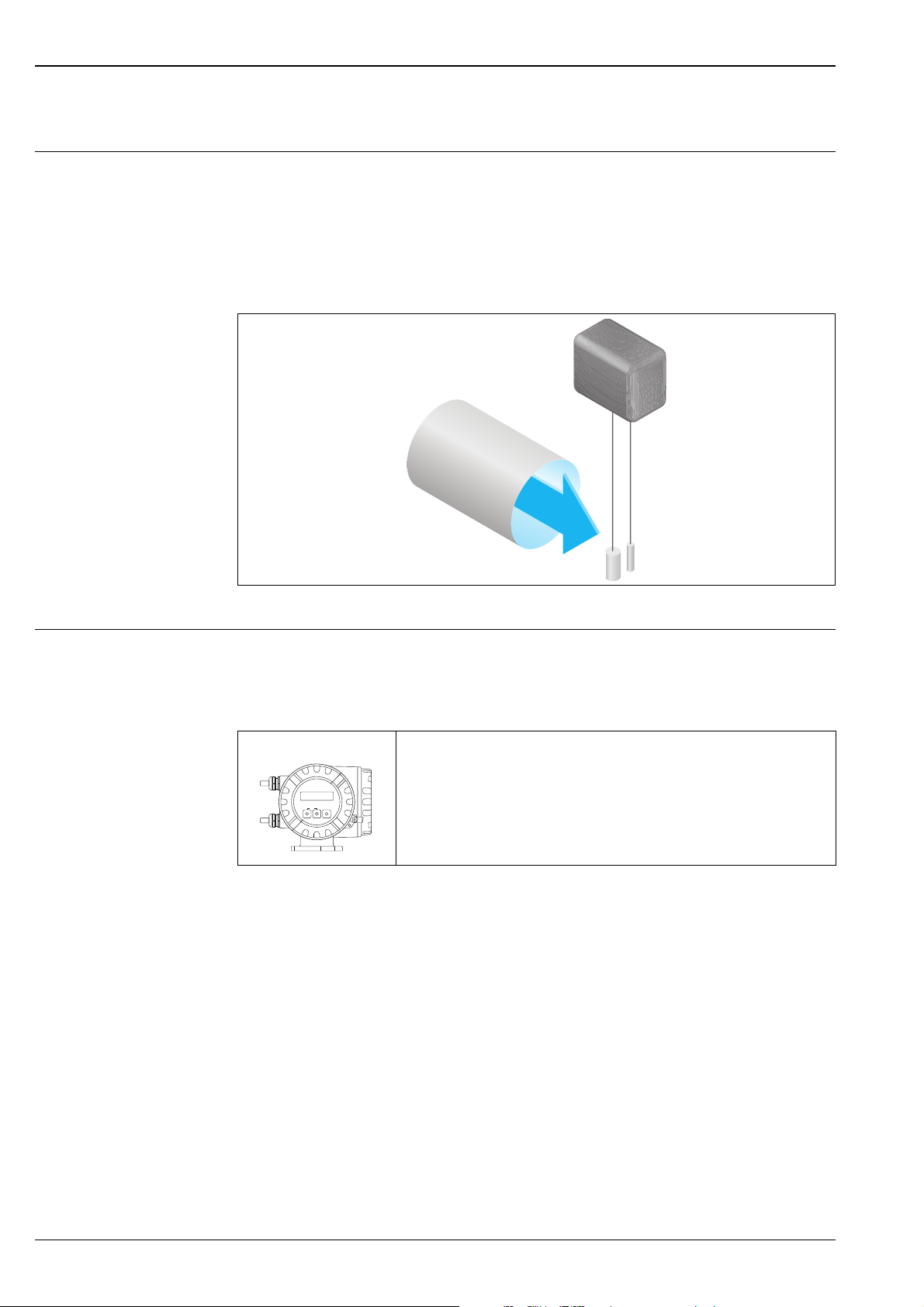

Measuring principle The thermal principle operates by monitoring the cooling effect of a gas stream as it passes over a

heated transducer (PT100).

Gas flowing through the sensing section passes over two PT 100 RTD transducers one of which is used

conventionally as a temperature sensing device, whilst the other is used as a heater. The temperature

sensor monitors the actual process values whilst the heater is maintained at a constant differential

temperature above this by varying the power consumed by the sensor. The greater the mass flow, the

greater the cooling effect and power required to maintain the differential temperature. The measured

heater power is therefore a measure of the gas mass flowrate.

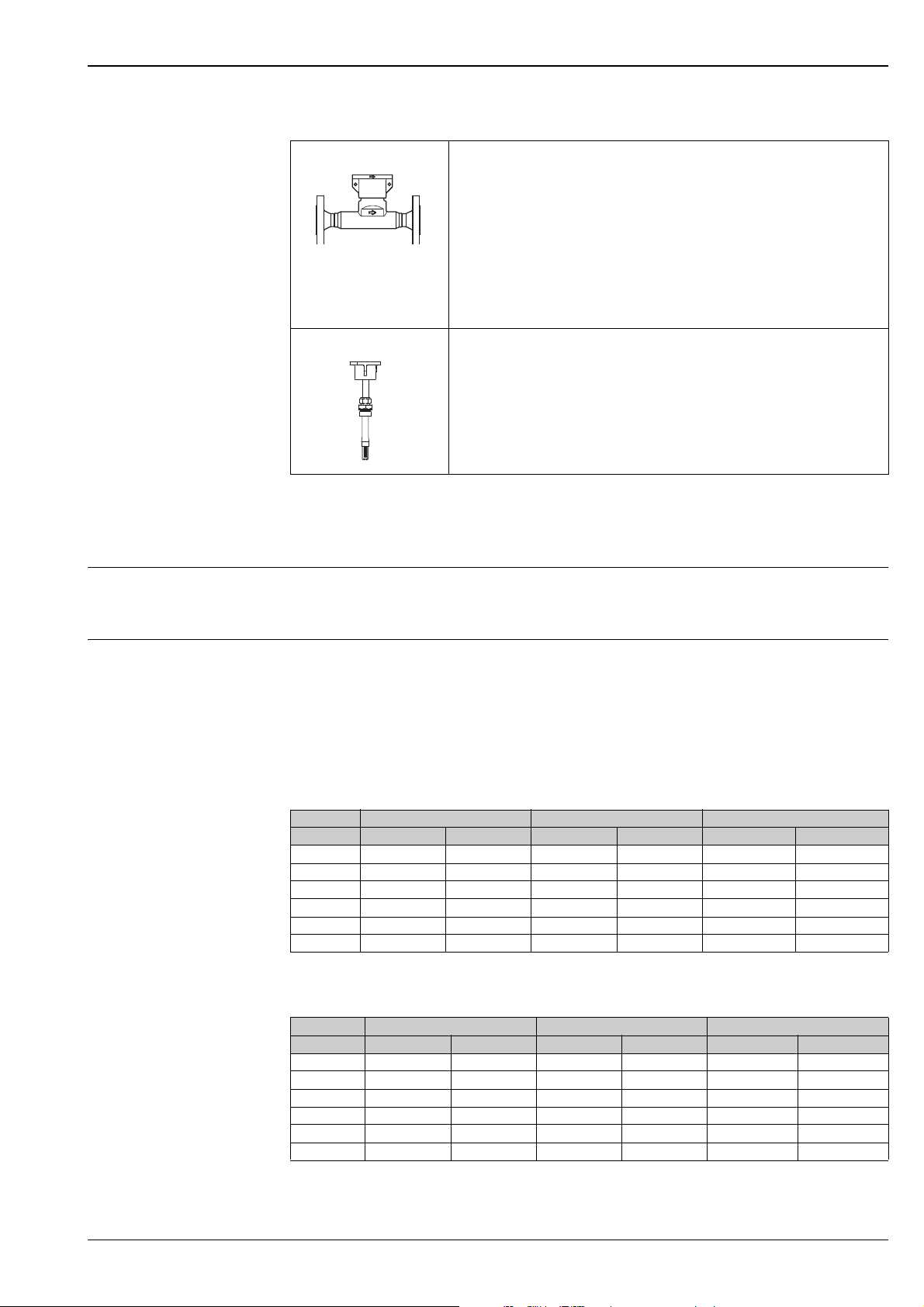

Measuring system The measuring device consists of a transmitter and a sensor. Two versions are available:

• Compact version: transmitter and sensor form a mechanical unit.

• Remote version: transmitter and sensor are mounted separately from one another.

Transmitter

t-mass 65

• Two-line liquid-crystal display

• Configuration using push button operation

A0003671

A0016823

4 Endress+Hauser

Page 5

Proline t-mass 65F, 65I

Sensor

F

I

•Inline version

• Nominal diameter DN 15 to 100 (½ to 4")

Measuring tube materials:

• Wetted parts:

- 1.4404 (316L)

A0005137

A0005138

- CF3M

• Non-wetted parts:

- 1.4301 (304)

Transducer materials

• 1.4404 (316L)

• Alloy C22 (optional)

•Insertion version

• Sensor length 235/335/435/608 for DN 80 to 1500 (9.25"/13.2"/17.1"/24" for

3 to 60")

Insertion tube materials:

• 1.4404 (316/316L)

Transducer materials:

• 1.4404 (316L)

• Alloy C22 (optional)

Input

Measured variable • Mass flow

• Gas temperature

• Gas heat flow

Measuring range Air under ambient conditions

The measuring range is dependant on the gas selection, line size and use of flow conditioner. Each

measuring device is calibrated individually with air. A mathematical conversion is performed in the

device to adapt to customized gases.

The table below defines the ranges available for air without a flow conditioner. To obtain information

on other gases and process conditions, please contact your Endress+Hauser sales center, or use the

Applicator selection software.

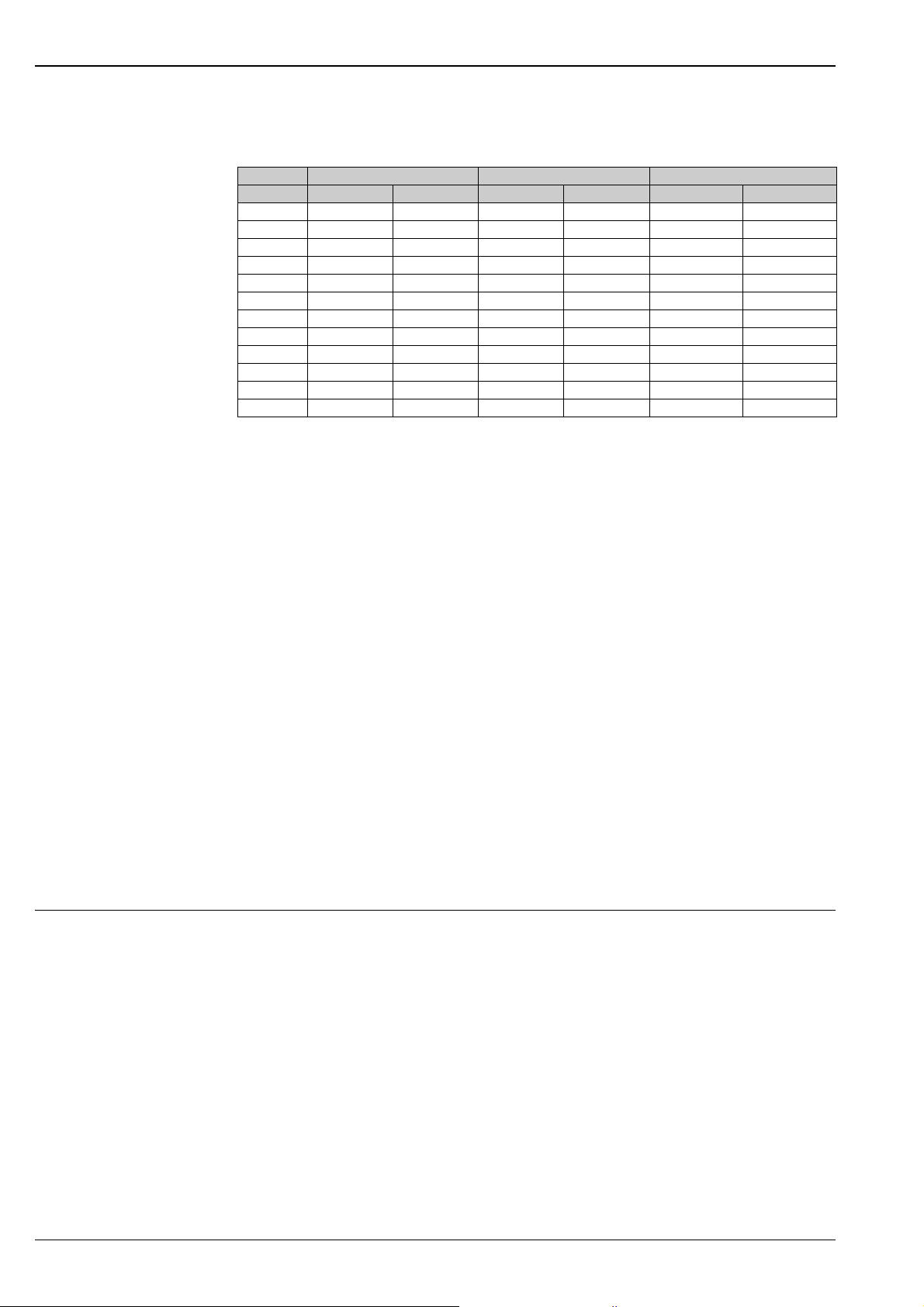

Measuring range for the EN (DIN)/JIS flanged versions, metric units:

DN kg/h Nm3/h at 0°C, 1.013 bar a sft3/min. at 15°C, 1.013 bar a

min. max. min. max. min. max.

15 0.5 53 0.38 41 0.23 25

25 2 200 1.5 155 1.0 96

40 6 555 4.6 429 3.0 266

50 10 910 7.7 704 5.0 436

80 20 2030 15.5 1570 10 974

100 38 3750 29 2900 18 1800

Measuring range for the ASME flanged version, US units:

DN lb/h Sm3/h at 59 °F, 14.7 psi a sft3/min. at 59 °F, 14.7 psi a

min. max. min. max. min. max.

½" 1.1 116 0.4 42 0.23 25

1" 4.4 440 1.6 160 1.0 96

1 ½" 13.2 1220 4.8 450 3.0 266

2" 22 2002 8 740 5.0 436

3" 44 4466 16 1656 10 974

4" 84 8250 30 3060 18 1800

Endress+Hauser 5

Page 6

Proline t-mass 65F, 65I

Measuring range for the insertion version, metric units:

DN kg/h Nm3/h at 0°C, 1.013 bar a sft3/min. at 15°C, 1.013 bar a

min. max. min. max. min. max.

80 20 2030 15.5 1570 9.6 974

100 38 3750 29.0 2900 18 1800

150 50 7500 38 5800 24 3600

200 80 12500 62 9666 38 6000

250 120 20000 93 15468 58 9600

300 180 28000 139 21655 86 13440

400 300 50000 232 38670 144 24000

500 500 80000 386 61870 240 38400

600 700 115000 540 88 940 336 55200

700 900 159000 696 122 970 432 76300

1000 2000 320000 1546 247846 960 153 600

1500 2500 720000 1933 556844 1200 345600

The flow rates shown are representative of the calibrated conditions only and do not necessarily reflect

what the meter can measure under operating conditions and actual internal pipe dimensions found on

site. To correctly size and select a meter, it is recommended that you either contact your local

Endress+Hauser sales center or use Endress+Hauser's "Applicator" software package.

Special applications

High gas velocities (>70 m/s)

In the event of high gas velocities, it is advisable to read in the process pressure dynamically or to enter

the pressure very precisely as a velocity-dependent correction is performed.

Light gases

• Due to the very high thermal conductivity of hydrogen (H

hydrogen is the lightest of all gases, it can prove very difficult to reliably measure this gas. Depending

on the application, the flow rates of hydrogen are often particularly slow and the flow profiles are

not sufficiently developed. It is not unusual for the flows to be in the laminar range, whereas a

turbulent flow regime would be required for optimum measurement.

• Despite loss of accuracy and linearity in hydrogen applications with low flow rates, the t-mass 65

measures with good repeatability and is therefore suitable for monitoring flow conditions (e.g. leak

detection).

• A linear, reliable measured value is difficult to obtain in applications with light gases with a Reynolds

number below RE 4000. While this can be improved by making a special adjustment in the lower

flow range, a loss of accuracy and linearity should be expected. It is advisable to contact your

Endress+Hauser sales center if your application involves media with Reynolds numbers below

RE 4000.

• When mounting, please note that the recommended upstream distances should be doubled for very

light gases such as helium and hydrogen. ä 17

Input signal Current input:

Active/passive selectable, galvanically isolated, resolution: 2 μA

• Active: 4 to 20 mA, R

• Passive: 0/4 to 20 mA, Ri 150 , U

!

Note!

The current input can be configured for pressure, gas analyzer:

The measuring device can read out the composition of the gas from the gas analyzer and automatically

update the first two components (e.g. GAS TYPE 1 and 2) in the programmed gas mixture. This makes

a more accurate measurement available even in the case of variable gas compositions, e.g. variable

methane and carbon dioxide components in a biogas application.

150 , U

i

) (9 times that of air) and the fact that

= 24 V DC, short-circuit proof

out

= 30 V DC

max

6 Endress+Hauser

Page 7

Proline t-mass 65F, 65I

Status input (auxiliary input) for HART version

U = 3 to 30 V DC, Ri = 5 k, galvanically isolated; switch level ±3 to ±30 V DC;

Configurable for: gas group, totalizer reset, positive zero return

Status input (auxiliary input) for PROFIBUS DP

U = 3 to 30 V DC, Ri = 3 k, galvanically isolated; switch level: ±3 to ±30 V DC, independent of polarity.

Configurable for: positive zero return, error message reset

Status input (auxiliary input) for MODBUS RS485

U = 3 to 30 V DC, R

Configurable for: totalizer reset, positive zero return, error message reset

Output

Output signal Current output

Active/passive selectable, galvanically isolated, time constant selectable (0.0 to 100.0 s), full scale

value selectable, temperature coefficient: typically 0.005% o.f.s./°C, resolution: 0.5 μA

• Active: 0/4 to 20 mA, RL < 700 (for HART: RL 250 )

• Passive: 4 to 20 mA; supply voltage VS 18 to 30 V DC; Ri 150

If the current output is used as a temperature output, please observe the following information:

Class B according to EN 60751

= 3 k, galvanically isolated; switch level: ±3 to ±30 V DC, independent of polarity.

i

Pulse-frequency output

Active/passive selectable, galvanically isolated

• Active: 24 V DC, 25 mA (max. 250 mA during 20 ms), RL 100 (Flexible I/O boards, see terminal

assignment ä 11)

• Passive: Open Collector, 30 V DC, 250 mA

• Frequency output: full scale frequency 2 to 1000 Hz (f

pulse width max. 2 s, time constant selectable (0.0 to 100.0 s)

• Pulse output: pulse value and pulse polarity can be selected, pulse width adjustable (0.5 to 2000 ms;

factory setting 20 ms)

FOUNDATION Fieldbus

• FOUNDATION Fieldbus H1, IEC 61158-2, galvanically isolated

• Data transmission rate: 31.25 kBit/s

• Current consumption: 12 mA

• Permitted supply voltage: 9 to 32 V

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Bus connection with integrated reverse polarity protection

• Signal encoding: Manchester II

•ITK Version 5.01

•Function blocks:

– 7 × Analog Input (Execution time: each 18 ms)

– 1 × Analog Output (Execution time: 18 ms)

– 1 × Digital Output (18 ms)

– 1 × PID (25 ms)

– 1 × Arithmetic (20 ms)

– 1 × Input Selector (20 ms)

– 1 × Signal Characterizer (20 ms)

–1 × Integrator (18 ms)

•Number of VCRs: 38

• Number of link objects in VFD: 40

• Output data: Mass flow, Corrected volume flow, Temperature, Totalizers 1 to 3

• Input data: Positive zero return (ON/OFF), Zero point adjustment, Measuring mode,

Reset totalizer

• Link Master (LM) function is supported

• Available output combination ä 11

= 1250 Hz), on/off ratio 1:1,

max

Endress+Hauser 7

Page 8

Proline t-mass 65F, 65I

PROFIBUS DP

• PROFIBUS DP in accordance with EN 50170 Volume 2

• Profile Version 3.0

• Data transmission rate: 9.6 kBaud to 12 MBaud

• Automatic data transmission rate recognition

• Signal encoding: NRZ-Code

• Function blocks: 3 × Analog Input, 2 × Totalizer, 1 × Analog Output,

• Output data: Mass flow, Corrected volume flow, Temperature, Totalizers 1 to 2

• Input data: Positive zero return (ON/OFF), Zero point adjustment, Measuring mode, Totalizer

control

• Bus address can be configured via miniature switches or via the local display (optional)

• Available output combination ä 11

PROFIBUS PA

• PROFIBUS PA in accordance with EN 50170 Volume 2, IEC 61158-2 (MBP), galvanically isolated

• Data transmission rate: 31.25 kBit/s

• Current consumption: 11 mA

• Permitted supply voltage: 9 to 32 V

• Bus connection with integrated reverse polarity protection

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Signal encoding: Manchester II

• Function blocks: 3 × Analog Input, 2 × Totalizer, 1 × Analog Output,

• Output data: Mass flow, Corrected volume flow, Temperature, Totalizers 1 to 2

• Input data: Positive zero return (ON/OFF), Zero point adjustment, Measuring mode, Totalizer

control

• Bus address can be configured via miniature switches or via the local display (optional)

• Available output combination ä 11

Modbus RS485

• Modbus device type: slave

• Address range: 1 to 247

• Supported function codes: 03, 04, 06, 08, 16, 23

• Broadcast: supported with the function codes 06, 16, 23

• Physical interface: RS485 in accordance with EIA/TIA-485 standard

• Supported baud rate: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 Baud

• Transmission mode: RTU or ASCII

•Response times:

Direct data access = typically 25 to 50 ms

Auto-scan buffer (data range) = typically 3 to 5 ms

• Available output combination ä 11

Signal on alarm Current output

Failsafe mode selectable (e.g. in accordance with NAMUR Recommendation NE 43)

Current input

Failsafe value selectable

Pulse/frequency output

Failsafe mode selectable

Status output:

"Non conductive" in the event of fault or power supply failure.

Relay output

"De-energized" in the event of fault or power supply failure.

FOUNDATION Fieldbus

Status message in accordance with the specifications of FOUNDATION Fieldbus

PROFIBUS DP/PA

Status and alarm messages in accordance with PROFIBUS Profile Version 3.0.

Modbus RS485

If an error occurs, the value "NaN" (not a number) is output for the measured values.

8 Endress+Hauser

Page 9

Proline t-mass 65F, 65I

Load See "Output signal"

Low flow cut off Switch points for low flow cut off are programmable

Galvanic isolation All circuits for inputs, outputs, and power supply are galvanically isolated from each other.

Switching output Relay output: Normally closed (NC) or normally open (NO) contacts available

(factory setting: relay 1 = NO, relay 2 = NC), max. 30 V / 0.5 A AC; 60 V / 0.1 A DC, galvanically

isolated.

Configurable for: error messages, limit values

Factory setting: closed

Endress+Hauser 9

Page 10

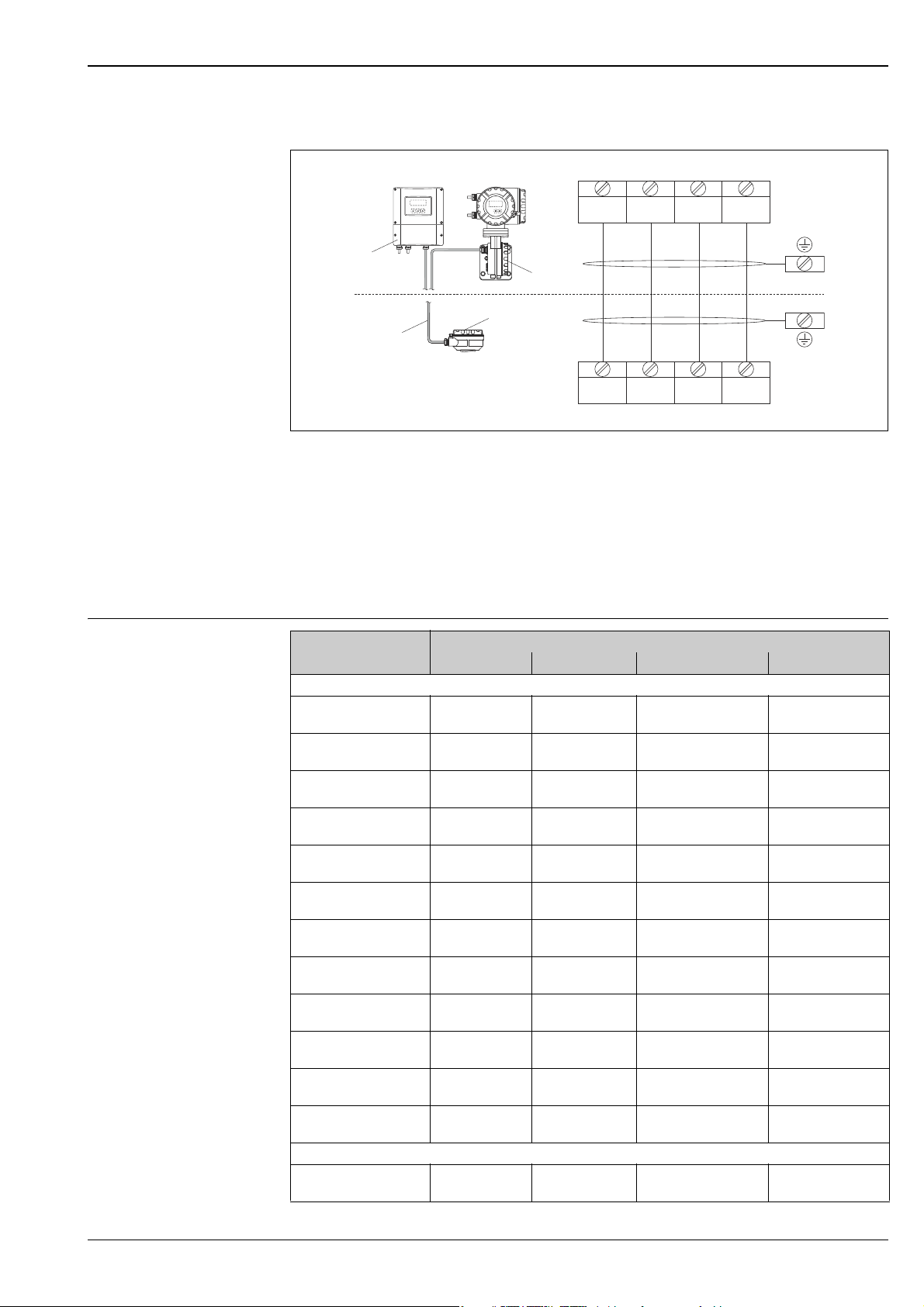

Terminal assignment

PROFIBUS PA*

FOUNDATION Fieldbus*

HART*

HART**

27

25

23

21

2

1

26

24

22

20

L1 (L+)

N (L-)

–

–

–

+

+

+

PA(–)/FF(–)

27

25

23

21

2

1

26

24

22

20

L1 (L+)

N (L-)

–

–

–

+

+

+

A (RxD/TxD-N)

B (RxD/TxD-P)

PA(+)/FF(+)

d

c

e

b

–27

–25

–23

–21

+ 26

+ 24

+ 22

+ 20

N (L-) 2

L1 (L+)1

a

A

d

b

g

d

c

e

b

d

c

e

b

g

PROFIBUS DP*

f f

f

a

B

(d)

b

d/(g)

27

25

23

21

2

1

26

24

22

20

L1 (L+)

N (L-)

–

–

–

+

+

+

A (RxD/TxD-N)

B (RxD/TxD-P)

d

c

e

b

g

Modbus RS485*

f

Proline t-mass 65F, 65I

Power supply

Connecting the transmitter, cable cross-section max. 2.5 mm² (14 AWG)

A View A (field housing)

B View C (wall-mount housing)

*) fixed communication board

**) flexible communication board

a Connection compartment cover

b Cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

c Ground terminal for protective ground

d Signal cable: see Terminal assignment

e Ground terminal for signal cable shield / fieldbus cable / RS485 line

f Service adapter for connecting service interface FXA 193 (Fieldcheck, FieldCare)

g Signal cable: see Terminal assignment

ä

ä

11

11

Terminal No. 1: L1 for AC, L+ for DC

Terminal No. 2: N for AC, L- for DC

Fieldbus cable:

Terminal No. 26: DP (B) / PA (+) / FF (+) / MODBUS RS485 (B) / (PA, FF: with reverse polarity protection)

Terminal No. 27: DP (A) / PA (–) / FF (–) / MODBUS RS485 (A) / (PA, FF: with reverse polarity protection)

Cable for external termination (only for PROFIBUS DP with permanent assignment communication board):

Terminal No. 24: +5 V

Terminal No. 25: DGND

A0005135

10 Endress+Hauser

Page 11

Proline t-mass 65F, 65I

a

b

c

d

d

d

e

GND

COM

6 …10V

+

-

+

-

41

42 43

44

GND COM

6 …10V

+

-

+

-

41

42 43

44

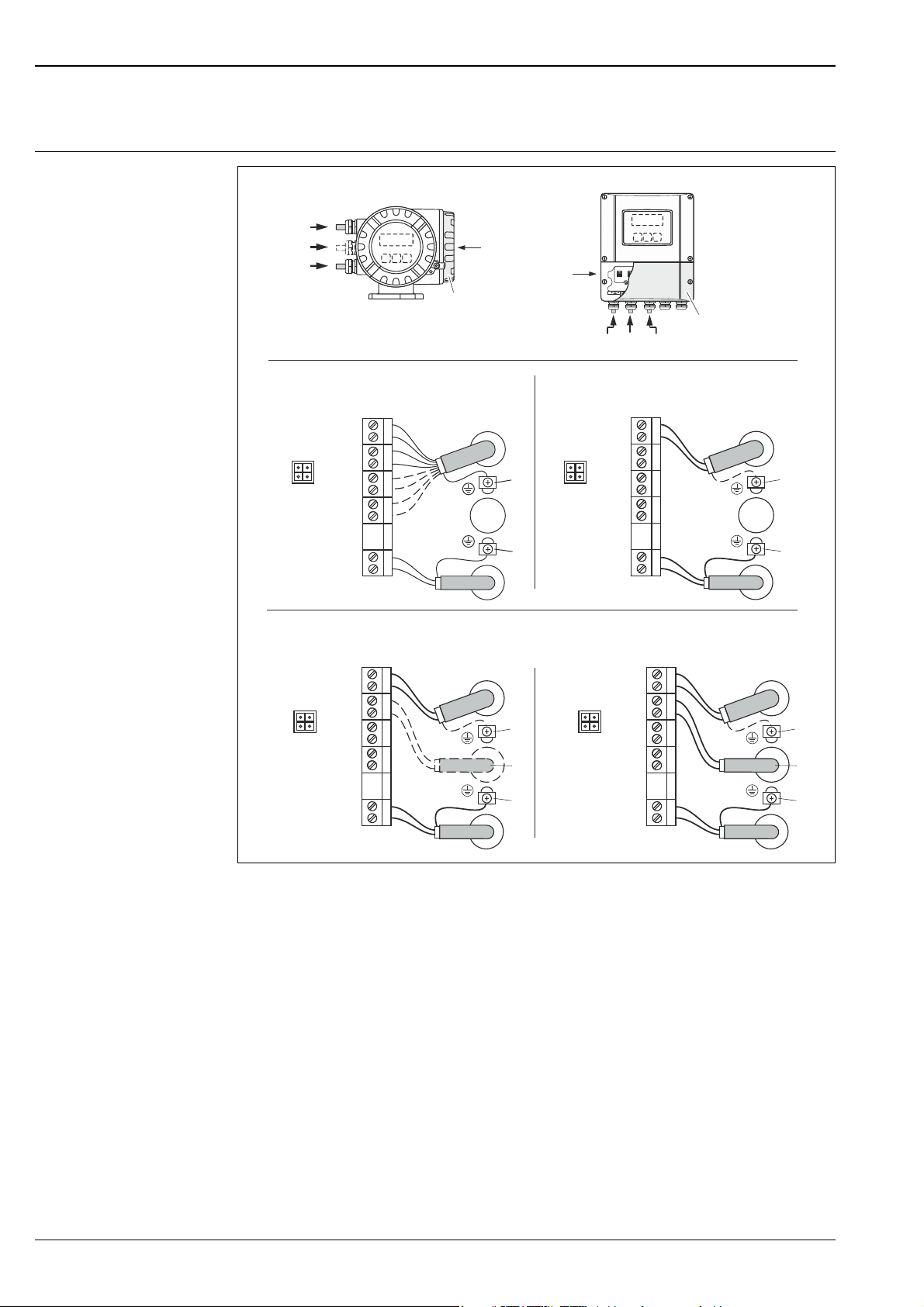

Remote version

Connecting the remote version

a Wall-mount housing transmitter: non-hazardous area and ATEX II3G / zone 2

b Wall-mount housing transmitter: ATEX II2G / Zone 1; FM/CSA

c Connection housing sensor

d Cover for connection compartment or connection housing

e Connecting cable

GND Ground connection

COM Communication connection

Terminal No.:

41 = white; 42 = brown; 43 = green; 44 = yellow

see separate "Ex documentation"

see separate "Ex documentation"

A0013669

Device plug connectors

Order version 20 (+) / 21 (–) 22 (+) / 23 (–) 24 (+) / 25 (–) 26 (+) / 27 (–)

Fixed communication boards (permanent assignment)

65F**-***********A

65I-*************A

65F**-***********B

65I-*************B

65***-***********F

65I-*************F

65***-***********G

65I-*************G

65***-***********H

65I-*************H

65***-***********J

65I-*************J

65***-***********K

65I-*************K

65***-***********Q

65I-*************Q

65F**-***********R

65I-*************R

65F**-***********S

65I-*************S

65F**-***********T

65I-*************T

65F**-***********U

65I-*************U

Flexible communication boards

65F**-***********C

65I-*************C

- - Frequency output

Relay output Relay output Frequency output

-- -PROFIBUS PA, Ex i

-- -

-- -PROFIBUS PA

- - +5V (ext. termination) PROFIBUS DP

-- -

- - Status input Modbus RS485

--

--

--

--

Relay output 2 Relay output 1 Frequency output

Terminal No. (inputs/outputs)

Current output 2

Ex i, active

Frequency output

Ex i, passive

Frequency output

Ex i, passive

Current output 2

Ex i, passive

Current output

HART

Current output

HART

FOUNDATION

Fieldbus Ex i

FOUNDATION

Fieldbus

Current output 1

Ex i active, HART

Current output Ex i

Active, HART

Current output Ex i

Passive, HART

Current output 1

Ex i passive, HART

Current output

HART

Endress+Hauser 11

Page 12

Proline t-mass 65F, 65I

Terminal No. (inputs/outputs)

Order version 20 (+) / 21 (–) 22 (+) / 23 (–) 24 (+) / 25 (–) 26 (+) / 27 (–)

65F**-***********D

65I-*************D

65F**-***********E

65I-*************E

65F**-***********L

65I-*************L

65F**-***********2

65I-*************2

65F**-***********4

65I-*************4

65F**-***********5

65I-*************5

65F**-***********6

65I-*************6

65F**-***********8

65I-*************8

Status input Relay output Frequency output

Status input Relay output Current output 2

Status input Relay output 2 Relay output 1

Relay output Current output 2 Frequency output

Current input Relay output Frequency output

Status input Current input Frequency output

Status input Current input Current output 2

Status input Frequency output Current output 2

Current output

Current output 1

Current output

Current output 1

Current output

Current output

Current output

Current output

HART

HART

HART

HART

HART

HART

HART

HART

Supply voltage 85 to 260 V AC, 45 to 65 Hz

20 to 55 V AC, 45 to 65 Hz

16 to 62 V DC

Power consumption • AC: 85 to 260 V = 18.2 VA; 20 to 55 V = 14 VA ; (including sensor)

• DC: 8 W (including sensor)

Switch-on current:

• Max. 8 A (<5 ms) at 24 V DC

• Max. 4 A (<5 ms) at 260 V AC

Power supply failure Lasting minimum 1 power cycle

• EEPROM/HistoROM/T-DAT saves measuring device data if the power supply fails.

• HistoROM S-DAT is on exchangeable data storage chip with sensor specific data (pipe type, nominal

diameter, serial number, flow conditioner, zero point, etc.).

• Totalizer stops at the last value determined

Potential equalization No special measures for potential equalization are required.

For instruments for use in hazardous areas, observe the corresponding guidelines in the specific

Ex documentation.

Cable entries Power supply and signal cables (inputs/outputs):

• Cable entry M20 × 1.5 (8 to 12 mm (0.31 to 0.47 in))

• Thread for cable entries, ½" NPT, G ½"

Connecting cable for remote version:

• Cable entry M20 × 1.5 (8 to 12 mm (0.31 to 0.47 in))

• Thread for cable entries, ½" NPT, G ½"

12 Endress+Hauser

Page 13

Proline t-mass 65F, 65I

Remote version cable specifications

• 2 × 2 × 0.5 mm² (AWG 20) PVC cable with common shield (2 twisted pairs)

• Conductor resistance: £ 40 /km [£ 131.2 / 1000 ft]

• Capacitance, core/shield: 0.001 F/m

• Inductance: £ 0.9 mH/m [ £ 2.952 mH/ft]

• Operating voltage: 250 V

• Temperature range: –40 to +105 °C [–40 to +221 °F]

• Overall nominal diameter: 8.5 mm [0.335"]

• Maximum cable length: 100 m [328 feet]

Use in environments with strong electrical interference:

The measuring device complies with the general safety requirements in accordance with EN 61010,

the EMC requirements of IEC/EN 61326, and NAMUR recommendation NE 21/43.

The Ex documentation contains the cable specifications for the measuring devices that are used in

hazardous areas.

Note

• The cable must be ordered separately.

Endress+Hauser 13

Page 14

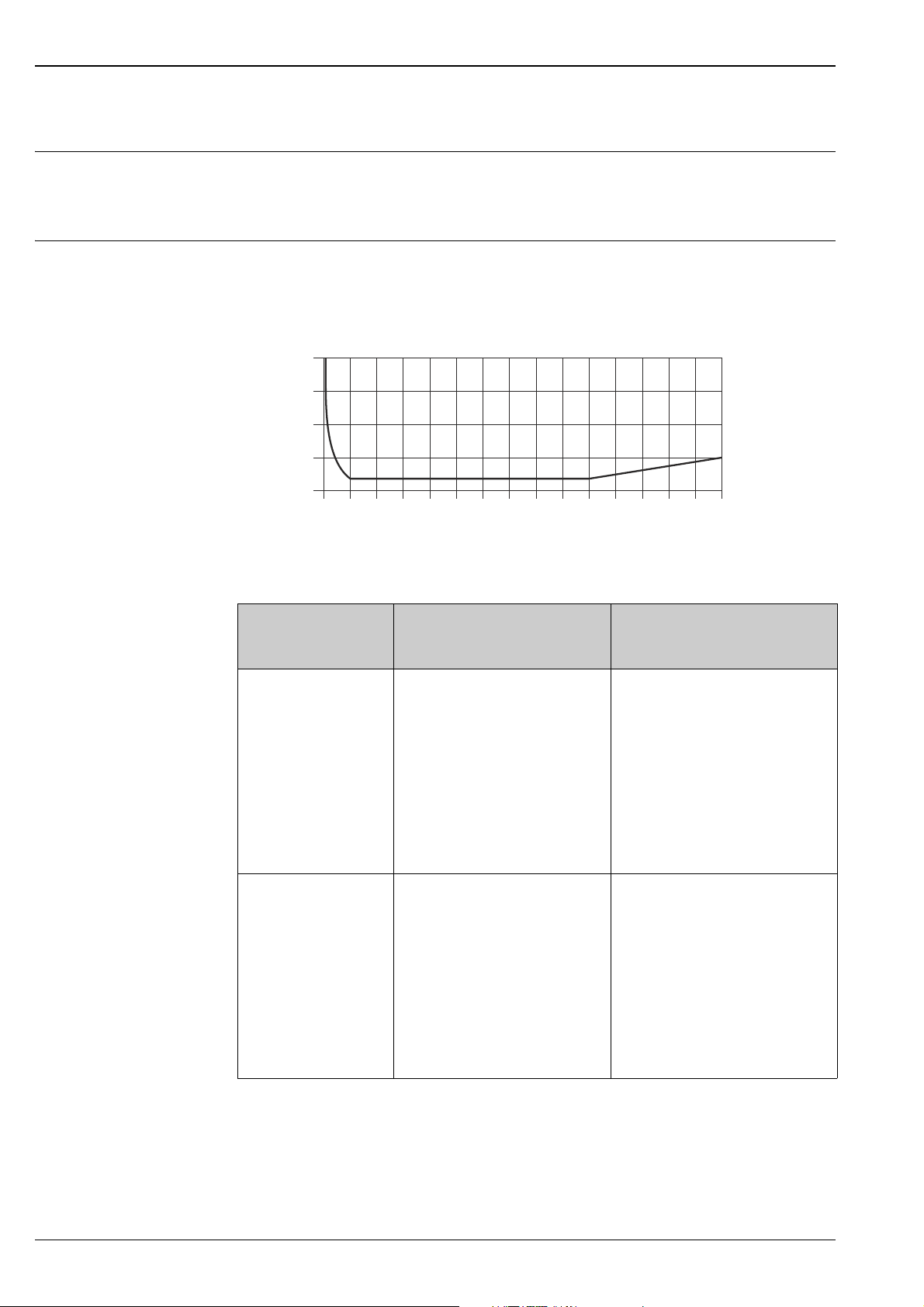

Performance characteristics

010

[% kg/h]

±10

0

50 80

[%]

90 100

±5

±15

20 30 40 60 70

±20

110 120 130 140 150

[% lb/h]

Proline t-mass 65F, 65I

Reference operating conditions

• Traceable to National Standards

• Accredited according to ISO/IEC 17025

• Air-controlled to 24 °C ± 0.5 °C (75.2 °F ± 0.9 °F) at atmospheric pressure

• Humidity-controlled < 40% RH

Maximum measured error t-mass 65F and t-mass 65I

±1.5 % of reading for 100 % to 10 % of range (at reference conditions)

±0.15 % of full scale for 10 % to 1 % of range (at reference conditions)

Maximum measured error (% mass flow (Q)) as % of full scale value, see next table.

A0024121

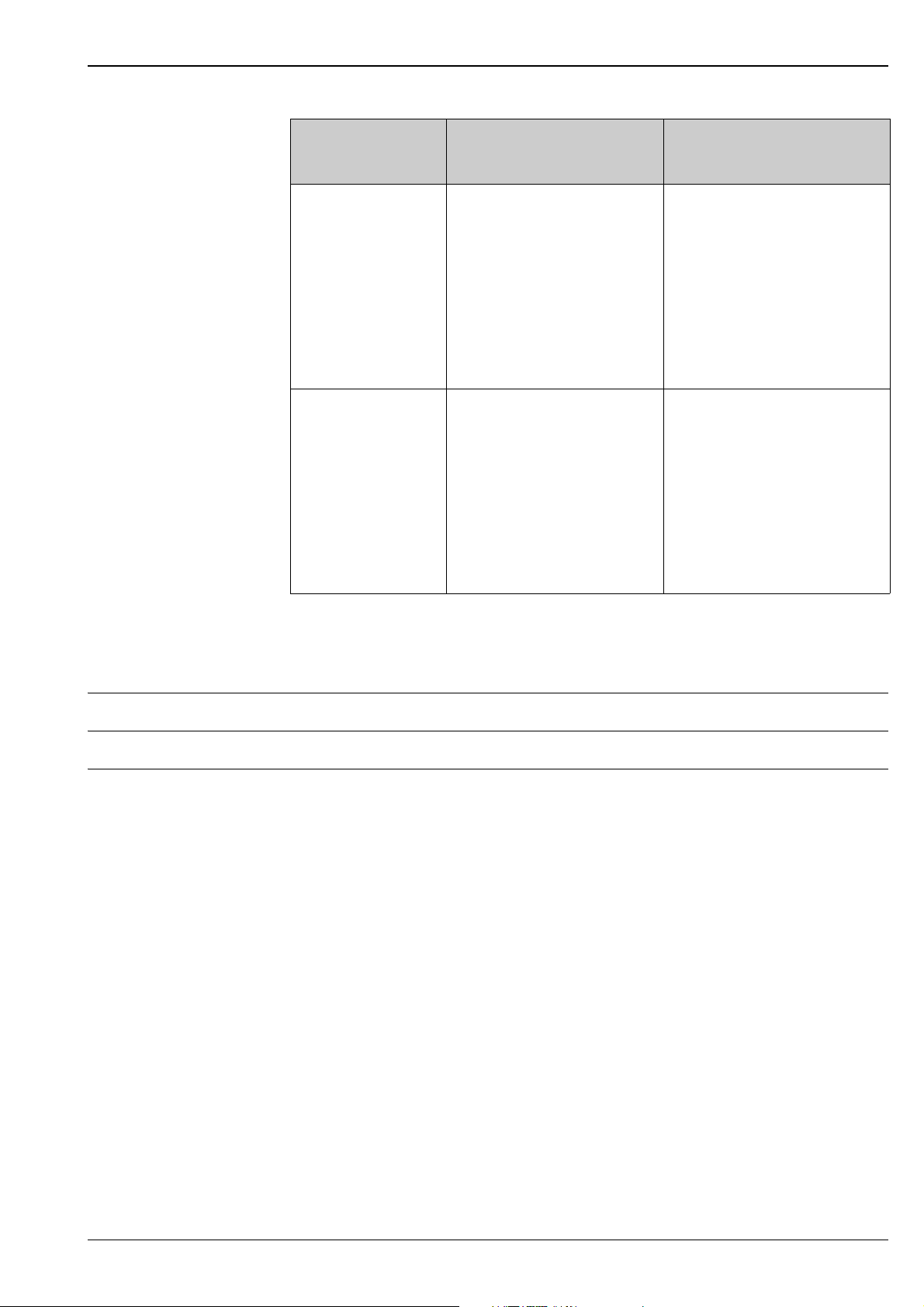

Order code for

"Calibration flow"

(not verified

G Q = 100 to 150 %:

H Q = 100 to 150 %:

Performance characteristics Description

±1.5 to ±5 % of the current measured

value increasing linearly as expressed

in the following equation:

±1.5 ± (X

(100 % < X

flow in % o.f.s.)

Q = 10 to 100 % of full scale value

±1.5 % o.r.

Q = 1 to 10 % of full scale value

±0.15 % o.f.s.

(all data under reference conditions)

±1.5 to ±5 % of the current measured

value increasing linearly as expressed

in the following equation:

±1.5 ± (X

(100 % < X

flow in % o.f.s.)

Q = 10 to 100 % of full scale value

±1.5 % o.r.

Q = 1 to 10 % of full scale value

±0.15 % o.f.s.

(all data under reference conditions)

-100) × 0.07[% o.r.]

n

≤ 150 %; Xn = current

n

-100) × 0.07[% o.r.]

n

≤ 150 %; Xn = current

n

Factory calibration:

The measuring device is calibrated and

adjusted on an accredited and traceable

calibration rig and its accuracy is

certified in a calibration report

(3 control points).

Factory calibration + flow conditioner

The measuring device is calibrated and

adjusted on an accredited and traceable

calibration rig with a flow conditioner

and its accuracy is certified in a

calibration report (3 control points).

:

14 Endress+Hauser

Page 15

Proline t-mass 65F, 65I

Order code for

Performance characteristics Description

"Calibration flow"

(not verified

K Q = 100 to 150 %:

±1.5 to ±5 % of the current measured

value increasing linearly as expressed

in the following equation:

±1.5 ± (X

(100 % < X

flow in % o.f.s.)

-100) × 0.07[% o.r.]

n

≤ 150 %; Xn = current

n

Q = 10 to 100 % of full scale value

±1.5 % o.r.

Q = 1 to 10 % of full scale value

±0.15 % o.f.s.

(all data under reference conditions)

L Q = 100 to 150 %:

±1.5 to ±5 % of the current measured

value increasing linearly as expressed

in the following equation:

±1.5 ± (X

(100 % < X

flow in % o.f.s.)

-100) × 0.07[% o.r.]

n

≤ 150 %; Xn = current

n

Q = 10 to 100 % of full scale value

±1.5 % o.r.

Q = 1 to 10 % of full scale value

±0.15 % o.f.s.

(all data under reference conditions)

5-point, traceable ISO/IEC17025:

The measuring device is calibrated and

adjusted on an accredited and traceable

calibration rig and its accuracy is

certified in a Swiss Calibration Services

(SCS) calibration report (5 control

points), which confirms traceability to

the national calibration standard.

5-point, traceable ISO/IEC17025 + flow

conditioner

:

The measuring device is calibrated and

adjusted on an accredited and traceable

calibration rig with a flow conditioner

and its accuracy is certified in a Swiss

Calibration Services (SCS) calibration

report (5 control points), which

confirms traceability to the national

calibration standard.

1. The full scale value depends on the nominal diameter of the device and the maximum flow

capacity of the calibration rig. The full scale values are listed in the following section.

2. A flow conditioner is also supplied.

Repeatability ±0.5 % of reading for velocities above 1.0 m/s (3.3 ft/s)

Reaction time Typically less than 2 seconds for 63 % of a given step change (in either direction).

Influence of medium pressure

Air: 0.35% per bar (0.02% per psi) of process pressure change (of set process pressure)

(Pressure co-efficient)

Endress+Hauser 15

Page 16

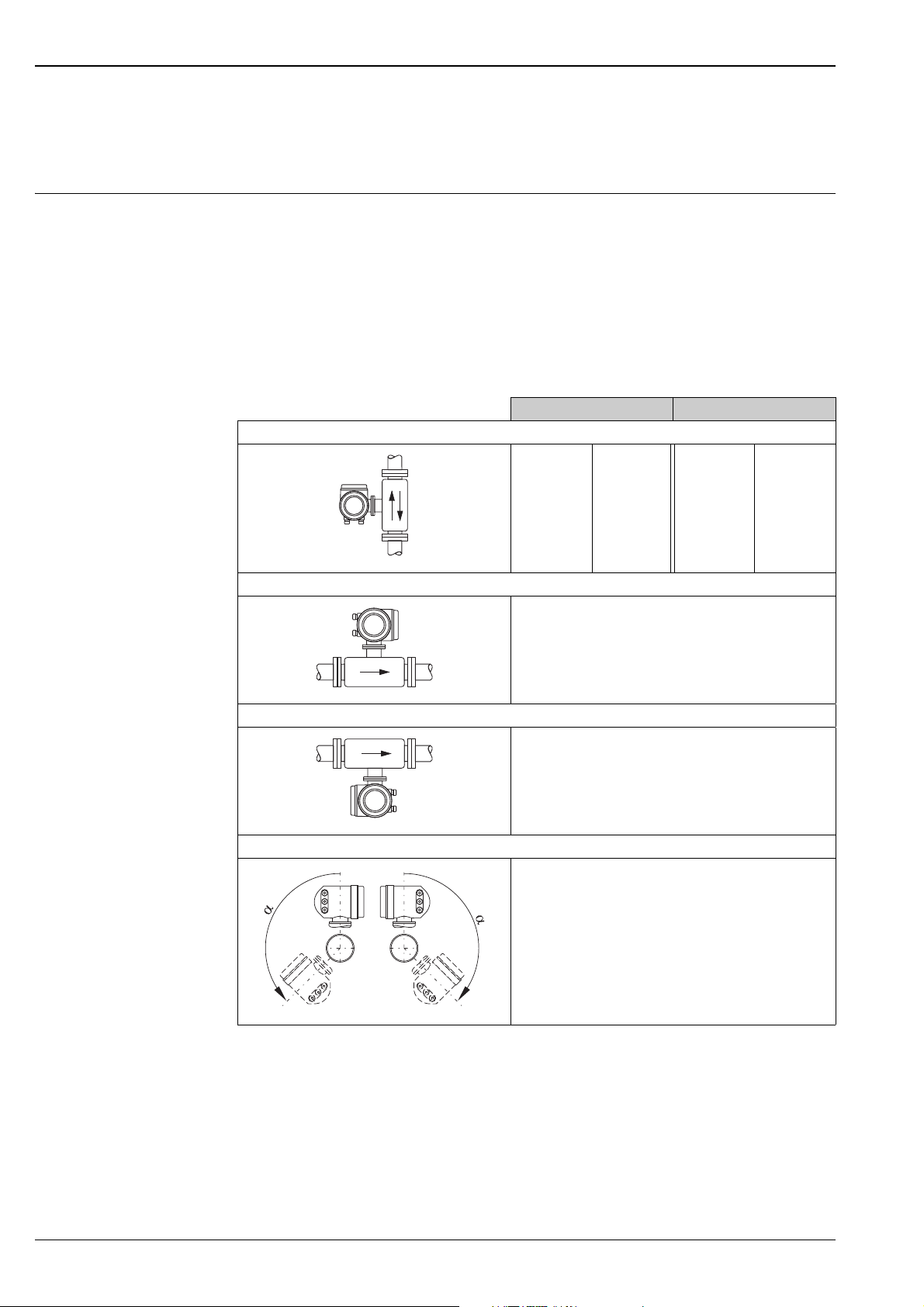

Installation

Thermal meters require a fully developed flow profile as a prerequisite for correct flow measurement.

For this reason, please note the following points when installing the device.

Orientation • The thermal dispersion principle is sensitive to disturbed flow conditions.

• Observe the recommended inlet and outlet requirements.

• Good engineering practice is necessary for the associated pipe work and installation.

• Ensure correct alignment and orientation of the sensor.

• Take measures to reduce or avoid condensation (e.g. install a condensation trap, thermal insulation,

trace heating system etc.).

• The maximum permitted ambient temperatures and the medium temperature range ( ä 23) must

be observed.

• Install the transmitter in a shaded location or use a protective sun shield.

• For mechanical reasons, and in order to protect the pipe, it is advisable to support heavy sensors.

Flanged sensor Insertion sensor

Vertical orientation

compact

remote

Proline t-mass 65F, 65I

compact

remote

A0013785

Horizontal orientation, transmitter head up

A0013786

Horizontal orientation, transmitter head down

A0013787

Inclined orientation, transmitter head down

m

m

compact/remote

n

compact/remote

o

compact/remote

p

m, n

m

A0009897

= Recommended orientation

= Orientation recommended in certain situations

In the case of saturated or unclean gases, upward flow in a vertical pipe section is preferred to minimize

m

condensation/contamination.

Not recommended if the vibrations are high or if the installation is unstable.

n

Only suitable for clean/dry gases. Do not mount the sensor from the bottom, on horizontal pipes, if build-

o

ups or condensate are likely to be present. Mount the sensor in a position as indicated below

If the gas is very wet or saturated with water (e. g. biogas, undried compressed air), mount in inclined

p

orientation (approx. 135° ±10°).

16 Endress+Hauser

Page 17

Proline t-mass 65F, 65I

15xDN 2xDN

15xDN

2xDN

15xDN

2xDN

20xDN

2xDN

35xDN

2xDN

50xDN

2xDN

20xDN 5xDN

20xDN 5xDN

20xDN 5xDN

25xDN 5xDN

40xDN 5xDN

50xDN 5xDN

PT

2...5 x DN

Inlet and outlet runs The thermal dispersion principle is sensitive to disturbed flow conditions.

As a general rule, the thermal flowmeter should always be installed as far away as possible from any

flow disturbances. For further information ISO Standard 14511.

• Where two or more flow disturbances are located upstream of the meter, the recommended inlet

length for the flow disturbance causing strongest disturbance must be used. For example if a control

valve is additionally mounted upstream from the measuring device and an elbow on the inlet side,

select the recommended inlet length for control valves: 50 × DN

• For very light gases such as Helium and Hydrogen all upstream distances should be doubled.

The minimum recommendations for inlet and outlet runs (without flow conditioner) are:

Flanged sensor

1

4

A0007523

A0007526

2

A0007524

5

A0007527

1 = Reduction, 2 = Expansion, 3 = 90° elbow or T-piece, 4 = 2 × 90° elbow,

5 = 2 × 90° elbow (3-dimensional), 6 = Control valve

Insertion sensor

A0007529

2

A0007530

5

1

4

3

A0007525

6

A0007528

3

A0007531

6

Endress+Hauser 17

A0007532

A0007564

A0007534

1 = Reduction, 2 = Expansion, 3 = 90° elbow or T-piece, 4 = 2 × 90° elbow,

5 = 2 × 90° elbow (3-dimensional), 6 = Control valve or pressure regulator

A specially designed perforated plate flow conditioner can be installed if it is not possible to observe

the inlet runs required ( ä 17).

Outlet runs with pressure measuring points

The pressure measuring point should be installed downstream of the measuring device, so that there

is no potential influence of the pressure transmitter process connection on the flow entering the

measuring point.

A0005114

Installing a pressure measuring point (PT = pressure transmitter)

Page 18

Proline t-mass 65F, 65I

2 × DN5 - 10 × DN

>8 × DN 5 × DN

5 - 10 × DN

2

1

Perforated plate flow conditioner

It is recommended to install a perforated plate flow conditioner if the recommended inlet runs are not

available.

A0005115

The figure above illustrates the minimum recommended inlet and outlet runs expressed in multiples of the pipe diameter using a flow

conditioner.

1 = Flow conditioner with the flanged sensor, 2 = Flow conditioner with the insertion sensor

!

Flow conditioner for use with insertion sensors 65I

The well known "Mitsubishi" design is recommended for this application DN 80 mm to DN 300 mm

(3" to 12"). The flow conditioner must be installed at a minimum distance of 8 × DN upstream of the

sensor. A further 5 pipe diameters minimum inlet run is required upstream of the actual conditioner

itself.

Measured errors can occur depending on disturbances in the inlet run. Therefore it is advisable to

choose inlet runs that are as long as possible.

Note!

In the case of insertion devices, the inlet run selected downstream of the conditioner should be as long

as possible.

Perforated plate flow conditioners (19 hole) for use with flanged sensor 65F

This is a special Endress+Hauser version designed especially for use with the t-mass F sensor (sizes DN

25 to 100 (1 to 4")). The mounting hole patterns and sizing are of a multi-variant design which means

that one plate will fit different flange pressure classes e.g. Cl. 150 and Cl. 300.

The flow conditioner and gaskets are fitted between the pipe flange and the measuring device. Use only

standard bolts which match the flange bolt hole to guarantee that the flow conditioner is centered

correctly.

The alignment notch must also be pointing in the same plane as the transmitter. Incorrect installation

of the flow conditioner will have a small effect on the measurement accuracy.

ä

49

ä

49

18 Endress+Hauser

Page 19

Proline t-mass 65F, 65I

1

2

2

3

4

1

1

1

Dp = K

g

2

r

D

4

1

Δp = 1876

1

148

2

5.94

28.5

4

= 10.5 mbar

Δp = 8.4

1

326

2

0.371

1.05

4

= 0.198 psi10

-7

A0005116

Flow conditioner mounting arrangement (example)

1 = Perforated plate flow conditioner, 2 = Seal/gasket, 3 = Notch, 4 = Correct pointing of alignment notch in the same plane as the

transmitter

Note

• Order the t-mass F sensor and the flow conditioner together to ensure that they are calibrated

together. Joint calibration guarantees optimum performance. Ordering the flow conditioner

separately and using it with the device will further increase measurement uncertainty.

• The use of conditioners from other suppliers will affect the flow profile and pressure drop and will

have an adverse effect on performance.

• Bolts, nuts, seals, etc. are not included in the scope of supply and must be supplied by the customer.

Pressure loss calculation

Pressure loss: p in mbar or psi

Mass flow :

Density: in kg/m

Diameter: D in mm or inch

K (constant) = 1876 (SI units) or 8.4 · 10

in kg/h or lbm/h

g

3 or lbm/ft3

–7

(US units)

Calculation examples:

= 148 kg/h or 326 lbm/h

g

5.94 kg/m3 (at 5 bar abs at 20 °C) or 0.37 lbm/ft (at 72.5 psi abs at 68 °F)

D = 28.5 mm (for a DN 25, PN 40) or 1.05 in (for a 1" Class 150 Sched 40)

SI units US units

Pipework requirements

Good engineering practice should be followed at all times:

• Correct preparation, welding and finishing techniques

• Correctly sized gaskets

• Correctly aligned flanges and gaskets

Endress+Hauser 19

Page 20

Proline t-mass 65F, 65I

A

B

C2

230

220

210

200

190

180

9

8

7

230

220

210

200

190

180

9

8

7

230

220

210

200

190

180

9

8

7

C1

A

B

C2

C1

• Connecting pipe work should match the internal diameter of the flowmeter. Maximum pipe

diameter mismatch should not exceed:

– 1 mm (0.04 in) for diameters < DN 200 (8")

– 3 mm (0.12 in) for diameters DN 200 (8")

• New installations should be free of metallic and abrasive particles to prevent damage to the sensing

elements on start-up

Further information is provided in ISO Standard 14511.

Correctly aligned flanges and gaskets

A0005103

Mounting conditions for the insertion version

A0005104 A0005105 A0005106

Pipe diameter one is not equal pipe

diameter two

Incorrectly sized gaskets Incorrectly aligned flanges and

gaskets

Selecting the length of the insertion sensor

The minimum required length of the insertion sensor can be determined by using Endress+Hauser's

sizing tool, Applicator (version 10.02 or later "Accessories") or according to the following calculation

steps.

The minimum required length of the insertion sensor is determined by the necessary insertion depth.

The calculated insertion depth must lie within the adjustable range of the selected insertion sensor.

1. Determine the dimensions A, B, C1 and C2

A = For circular pipes: the internal pipe diameter (DN)

For rectangular pipes/ducts: the inner dimension

B = Wall thickness of pipe or duct

C1+C2 = Length of mounting set and insertion tube's compression fitting

20 Endress+Hauser

A0014024

Page 21

Proline t-mass 65F, 65I

90° (± 3°)

D

90° (± 3°)

90° (±3°)

90°(±7°)

Determine the dimensions C1 and C2

If only Endress+Hauser accessories are used

DK6MB-BXA Mounting boss G1A: C1 + C2 = 106 mm (4.17 in)

DK6MB-AXA Mounting boss 1" NPT: C1 + C2 = 112 mm (4.41 in)

If it is intended not to solely use Endress+Hauser accessories

C1 Height of pipe connection (mounting boss) used

C2 Process connection with G1A thread: 46mm (1.81 in)

Process connection with NPT thread: 52mm (2.05 in)

2. Calculate the insertion depth

Insertion depth = (0.3 × A) + B + (C1 + C2) + 2 mm (0.08 in)

3. A suitable insertion sensor length can be determined by comparing the calculated insertion depth

with the following table.

The calculated insertion depth must be within the adjusting range of the corresponding insertion

sensor length!

Insertion length Adjusting range (insertion depth)

G1A Thread NPT Thread

mm in mm in mm in

235 9 120 to 230 4.7 to 9.0 126 to 230 4.96 to 9.0

335 13 120 to 330 4.7 to 13.0 126 to 330 4.96 to 13.0

435 17 120 to 430 4.7 to 17.0 126 to 430 4.96 to 17.0

608 24 120 to 604 4.7 to 23.8 126 to 604 4.96 to 23.8

Mounting conditions for welding sockets

When mounting the fitting to a thin wall duct, use a

suitable support bracket for the sensor.

D = Ø 31.0 ± 0.5 mm (1.22 ± 0.019 in)

A0011843

Aligning the insertion version to flow direction

Check and ensure that the sensor is aligned vertically at a 90° angle on the pipe/duct.

Turn the sensor so that the arrow marking matches the direction of flow.

A0007536 A0007537

Endress+Hauser 21

Page 22

Length of connecting cable Max. 100 m (328 ft), remote version (order separately)

a

b

c

90 (3.54)

35 (1.38)

192 (7.56)

81.5 (3.2)

AB

245 (9.65)

+0.5 (0.02)

-0.5 (0.02)

210 (8.27)

+0.5 (0.02)

-0.5 (0.02)

Ø 20...70

(0.78 to 2.75)

~110 (4.3)

~155 (6.1)

Proline t-mass 65F, 65I

Mounting wall-mount housing

• Make sure that ambient temperature does not go beyond the permissible range

–20 to +60 °C (–4 to + °140 F), optional –40 to +60 °C (–40 to +140 °F).

• Install the device in a shady location. Avoid direct sunlight.

• Always install the wall-mount housing in such a way that the cable entries are pointing down.

Wall mounting

Engineering unit mm (in)

a = Cover of the connection compartment

b = Securing screws (M6): max. Ø 6.5 mm (0.26"); screw head: max. Ø 10.5 mm (0.41")

c = Appropriate bores in the housing.

A0001130

Pipe mounting and installation in control panel

If a warm pipe is used for installation, make sure

that the housing temperature does not exceed the maximum permitted value of +60 °C. (+140 °F).

Engineering unit mm (in)

A = Pipe mounting of wallmount housing

B = Installation in control panel of wallmount housing

A0005256

22 Endress+Hauser

Page 23

Proline t-mass 65F, 65I

Environment

Ambient temperature range Standard: –20 to +60 °C (–4 to +140 °F)

Optional: –40 to +60 °C (–40 to +140 °F)

• Install the device in a shady location. Avoid direct sunlight, particularly in warm climatic regions.

(A protective sun cover is available on request)

• At ambient temperatures below –20 °C (–4 °F) the readability of the display may be impaired.

Storage temperature –40 to +80 °C (–40 to +176 °F), recommended: +20 °C (+68 °F)

Degree of protection Standard: IP 67 (NEMA 4X) for transmitter and sensor

Shock resistance According to IEC 60068-2-31

Vibration resistance Acceleration up to 1 g, 10 to 150 Hz, following IEC 60068-2-6

Electromagnetic compatibility

To IEC/EN 61326 and NAMUR recommendation NE 21

Endress+Hauser 23

Page 24

Process

Medium temperature range Sensor

t-mass F:

–40 to +100 °C (–40 to +212 °F)

t-mass I:

–40 to +130 °C (–40 to +266 °F)

Seals t-mass F

O-rings:

Viton FKM –20 to +100 °C (–4 to +212 °F)

Kalrez –20 to +100 °C (–4 to +212 °F)

EPDM –40 to +100 °C (–40 to +212 °F)

Bushing:

PEEK –40 to +100 °C (–40 to +212 °F)

Seals t-mass I

Bonded seals:

Kalrez –20 to +130 °C (–4 to +266 °F)

EPDM –40 to +130 °C (–40 to +266 °F)

Nitrile –35 to +130 °C (–31 to +266 °F)

Ferrule:

PEEK –40 to +130 °C (–40 to +266 °F)

Note

We recommend special materials (Alloy and PVDF) for aggressive media (e.g. chlorine or ozone).

Please contact your Endress+Hauser sales center for clarification.

Proline t-mass 65F, 65I

Media The following media and media mixtures can be measured. A mixture can consist of up to

8 components from the following list.

AIR

AMMONIA

ARGON

BUTANE

CARBON DIOXIDE

CARBON MONOXIDE

CHLORINE

ETHANE

ETHYLENE

HELIUM 4

HYDROGEN NORMAL

HYDROGEN CHLORIDE

HYDROGEN SULFIDE

KRYPTON

METHANE

NEON

NITROGEN

OXYGEN

PROPANE

XENON

Note

Other media (e.g. ozone) available on request. Contact your Endress+Hauser sales center for

clarification.

24 Endress+Hauser

Page 25

Proline t-mass 65F, 65I

0

10

20

[bar]

-40

-30

-20

-10 0

10 20 30 40

[°C]

-20

0

-40

20 40

60

80 100 120

[°F]

300

400

500

600

200

100

0

[psi]

50

60 70 80 90

30

40

PN40

PN16

140 160 180

200

100

220

5

15

25

35

0

10

20

[bar]

-40

-30

-20

-10 0

10 20 30 40

[°C]

-20

0

-40

20 40

60

80 100 120

[°F]

300

200

100

0

[psi]

50

60 70 80 90

20K

10K

140 160 180

200

100

220

5

15

25

400

0

10

20

[bar]

-40

-30

-20

-10 0

10 20 30 40

[°C]

-20

0

-40

20 40

60

80 100 120

[°F]

300

400

500

600

200

100

0

[psi]

50

60 70 80 90

30

40

Cl. 300

Cl. 150

140 160 180

200

100

220

5

15

25

35

Pressure-temperature ratings

Flange connections to EN 1092-1 (DIN 2501/DIN 2512N)

Flange material: stainless steel 1.4404/316L/316

A0005240

Flange connections to JIS B2220

Flange material: stainless steel 1.4404/316L/316

A0005241

Flange connection as per ASME B16.5

Flange material: stainless steel 1.4404/316L/316

Endress+Hauser 25

A0013825

Page 26

Proline t-mass 65F, 65I

aa

bb

Limiting flow See "Measuring range" section ä 5.

The velocity in the measuring tube should not exceed 130 m/s (427 ft/s), (in air).

Pressure loss Negligible (without flow conditioner).

Refer to Applicator for the precise calculation

System pressure t-mass F:

–0.5 to 40 bar gauge (–7.25 to 580 psi gauge)

t-mass I:

–0.5 to 20 bar gauge (–7.25 to 290 psi gauge)

Thermal insulation If the gas is very wet or saturated with water (e.g. biogas), the piping and sensor housing should be

insulated, and heated where necessary, to prevent water droplets from condensing on the transducer.

A0005122

Maximum thermal insulation for t-mass 65F and 65I

a Maximum insulation height for the flanged sensor

b Maximum insulation height for the insertion sensor

Hot tap, process pressure The Hot tap for mounting and removal at process pressure may only be used with non-toxic, innocuous

gases classified as "Group II" in accordance with European Directive 67/548/EEC Art. 2.

Medium pressure version

Max. process pressure: 20 barg (290 psig)

Max. extraction pressure: 16 barg (230 psig)

Max. extraction temperature: +50 °C (+122 °F)

Min. sensor length: 435 mm (17 in)

Low pressure version

Max. process pressure: 20 barg (290 psig)

Max. extraction pressure: 4.5 barg (65 psig)

Max. extraction temperature: +50 °C (+122 °F)

Min. sensor length: 335 mm (13 in)

Cold tap, atmospheric pressure

Cold tap for mounting and removal at atmospheric pressure

Max. process pressure: 20 barg (290 psig)

Max. extraction pressure: 1 bar(a) (14.5 psia)

Max. extraction temperature: +50 °C (+122 °F)

Min. sensor length: 335 mm (13 in)

26 Endress+Hauser

Page 27

Proline t-mass 65F, 65I

V

102 (4.0)

Ø 129 (5.1)

52 (2.0)

79 (3.1)

50 (1.96)

Mechanical construction

Design, dimensions

Dimensions:

Transmitter remote version, connection housing (II2G/Zone 1), flange version ä 27

Transmitter remote version, connection housing (II2G/Zone 1) ä 28

Transmitter remote version, wall-mount housing (non Ex-zone and II3G/Zone 2) ä 30

Mounting wall-mount housing ä 22

Process connections in SI units

t-mass 65F: Flange connections EN (DIN), JIS ä 31

t-mass 65F: Flange connections as per ASME ä 33

t-mass 65I: Compact insertion version ä 35

t-mass 65I: Remote sensor housing insertion version ä 35

Flow conditioner (as per EN (DIN) / JIS / ASME) ä 36

Hot tap, process pressure ä 37

Cold tap, atmospheric pressure ä 38

Process connections in US units

t-mass 65F: Flange connections as per ASME ä 39

t-mass 65I: Compact insertion version ä 41

t-mass 65I: Remote sensor housing insertion version ä 41

Flow conditioner according to ASME ä 42

Hot tap, process pressure ä 43

Cold tap, atmospheric pressure ä 44

Transmitter remote version, connection housing (II2G/Zone 1), flange version

Engineering unit mm (in); dimensions "V":

ä

31 and

ä

33

A0005158

Endress+Hauser 27

Page 28

Transmitter remote version, connection housing (II2G/Zone 1)

N

i

c

h

t

u

n

t

e

r

S

p

a

n

n

u

n

g

ö

f

f

n

e

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

N

e

p

a

s

o

u

v

r

i

r

l

’

a

p

p

a

r

e

i

l

s

o

u

s

t

e

n

s

i

o

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

Nicht-eigensichere

Stromkreise durch

IP40-Abdeckung geschützt

Non-intrinsically safe

circuits Ip40 protected

Boucles de courant

sans sécurité intrinsèque

protégées par Ip40

B*

B

A*

A

F

G

D

C

H

J

K

L

M

E

Esc

E

+

–

Proline t-mass 65F, 65I

Dimensions in SI units

A A* B B* C D E F G H J K L M

8.6

265 242 240 217 206 186 178

(M8)

100 130 100 144 170 348

* Blind version (without display)

All dimensions in [mm]

Dimensions in US units

A A* B B* C D E F G H J K L M

10.4 9.53 9.45 8.54 8.11 7.32 7.01

* Blind version (without display)

All dimensions in [in]

0.34

(M8)

3.94 5.12 3.94 5.67 6.69 13.7

A0006999

28 Endress+Hauser

Page 29

Proline t-mass 65F, 65I

Nicht-eigensichere

Stromkreise durch

IP40-Abdeckung geschützt

Non-intrinsically safe

circuits Ip40 protected

Boucles de courant

sans sécurité intrinsèque

protégées par Ip40

a

240 (9.45)

N

i

c

h

t

u

n

t

e

r

S

p

a

n

n

u

n

g

ö

f

f

n

e

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

N

e

p

a

s

o

u

v

r

i

r

l

’

a

p

p

a

r

e

i

l

s

o

u

s

t

e

n

s

i

o

n

K

e

e

p

c

o

v

e

r

t

i

g

h

t

w

h

i

l

e

c

i

r

c

u

i

t

s

a

r

e

a

l

i

v

e

Esc

E

+

–

Pipe mounting of the remote field housing

If a warm pipe is used for installation, make sure that the housing temperature does not exceed the

max. permitted value of +60 °C (+140 °F).

A0005157

Engineering unit mm (in); a = pipe mounting (separate mounting set, see accessories)

Endress+Hauser 29

Page 30

Proline t-mass 65F, 65I

Esc

E

-

+

D

C

B

A

F

E

G

K

J

Q

N

L

O

R

H J

M

PP

SS

T

Transmitter remote version, wall-mount housing (non Ex-zone and II3G/Zone 2)

Dimensions in SI units

A B C D E F G H J K

215 250 90.5 159.5 135 90 45 >50 81 53

L M N O P Q R S T

95 53 102 81.5 11.5 192 8 × M5 20 2 × 6.5

1)

Fixing bolt for wall assembly: M6 (screw head max. 10.5 mm)

All dimensions in [mm]

Dimensions in US units

A B C D E F G H J K

8.46 9.84 3.56 6.27 5.31 3.54 1.77 >1.97 3.18 2.08

L M N O P Q R S T

3.74 2.08 4.01 3.20 0.45 7.55 8 × M5 0.79 2 × 0.26

1)

Fixing bolt for wall assembly: M6 (screw head max. 0.41 in)

All dimensions in [in]

A0001150

1)

1)

30 Endress+Hauser

Page 31

Proline t-mass 65F, 65I

G

LK

U

N

S

L

P T

B

V

di

227 (8.94)

207 (8.15)

168 (6.61)

160 (6.3)

+1.5 (0.06)

- 2.0 (0.08)

Process connections in SI units

t-mass 65F: Flange connections EN (DIN), JIS

A0005162

Engineering unit mm (in)

Flange EN 1092-1 (DIN 2501 / DIN 2512N 1)) / PN 16: 1.4404/316L/316

Surface roughness (flange): EN 1092-1 Form B1 (DIN 2526 Form C), Ra 6.3 to 12.5 μm

DN di B G L LK N P S T U V

100 97 303 220 800 180 8 × Ø18 500.5 20 299.5 107.1 143

1)

Flange with groove to EN 1092-1 Form D (DIN 2512N) available

All dimensions in [mm]

Flange EN 1092-1 (DIN 2501 / DIN 2512N 1)) / PN 40: 1.4404/316L/316

Surface roughness (flange): EN 1092-1 Form B1 (DIN 2526 Form C), Ra 6.3 to 12.5 μm

DN di B G L LK N P S T U V

15 13.9 276.5 95 245 65 4 × Ø14 132.5 16 112.5 17.3 116.5

25 24.3 276.5 115 245 85 4 × Ø14 132.5 18 112.5 28.5 116.5

40 38.1 273.5 150 320 110 4 × Ø18 200 18 120 43.1 113.5

50 49.2 278.5 165 400 125 4 × Ø18 250 20 150 54.5 118.5

80 73.7 291 200 640 160 8 × Ø18 400 24 240 82.5 131

100 97 303 235 800 190 8 × Ø22 500.5 24 299.5 107.1 143

1)

Flange with groove to EN 1092-1 Form D (DIN 2512N) available

All dimensions in [mm]

Flange JIS B2220/ 10K / Sched 40: 1.4404/316L/316

Surface roughness (flange): Ra 3.2 to 6.3 μm

DN di B G L LK N P S T U V

50 49.2 278.5 155 400 120 4 × Ø19 250.0 17.5 150.0 52.7 118.5

80 73.7 291.0 185 640 150 8 × Ø19 400.0 20 240.0 78.1 131.0

100 97.0 303.0 210 800 175 8 × Ø19 500.5 20 299.5 102.3 143.0

All dimensions in [mm]

Endress+Hauser 31

Page 32

Proline t-mass 65F, 65I

Flange JIS B2220/ 10K / Sched 80: 1.4404/316L/316

Surface roughness (flange): Ra 3.2 to 6.3 μm

DN di B G L LK N P S T U V

50 49.2 278.5 155 400 120 4 × Ø19 250.0 17.5 150.0 49.2 118.5

80 73.7 291.0 185 640 150 8 × Ø19 400.0 20 240.0 73.7 131.0

100 97.0 303.0 210 800 175 8 × Ø19 500.5 20 299.5 97.0 143.0

All dimensions in [mm]

Flange JIS B2220/ 20K / Sched 40: 1.4404/316L/316

Surface roughness (flange): Ra 3.2 to 6.3 μm

DN di B G L LK N P S T U V

15 13.9 276.5 95 245 70 4 × Ø15 132.5 15 112.5 16.1 116.5

25 24.3 276.5 125 245 90 4 × Ø19 132.5 17 112.5 27.2 116.5

40 38.1 273.5 140 320 105 4 × Ø19 200 19 120 41.2 113.5

50 49.2 278.5 155 400 120 8 × Ø19 250 20 150 52.7 118.5

80 73.7 291.0 200 640 160 8 × Ø23 400 22 240 78.1 131.0

100 97 303.0 225 800 185 8 × Ø23 500.5 24 299.5 102.3 143.0

All dimensions in [mm]

Flange JIS B2220/ 20K / Sched 80: 1.4404/316L/316

Surface roughness (flange): Ra 3.2 to 6.3 μm

DN di B G L LK N P S T U V

15 13.9 276.5 95 245 70 4 × Ø15 132.5 15 112.5 13.9 116.5

25 24.3 276.5 125 245 90 4 × Ø19 132.5 17 112.5 24.3 116.5

40 38.1 273.5 140 320 105 4 × Ø19 200 19 120 38.1 113.5

50 49.2 278.5 155 400 120 8 × Ø19 250 20 150 49.2 118.5

80 73.7 291.0 200 640 160 8 × Ø23 400 22 240 73.7 131.0

100 97 303.0 225 800 185 8 × Ø23 500.5 24 299.5 97 143.0

All dimensions in [mm]

32 Endress+Hauser

Page 33

Proline t-mass 65F, 65I

G

LK

U

N

S

L

P T

B

V

di

227 (8.94)

207 (8.15)

168 (6.61)

160 (6.3)

+1.5 (0.06)

- 2.0 (0.08)

t-mass 65F: Flange connections as per ASME

A0005162

Engineering unit mm (in)

Flange ASME B16.5 / Cl 150 / Sched 40: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

15 ½" 13.9 276.4 88.9 245 60.5 4 × Ø 15.7 132.5 11.2 112.5 15.7 112

25 1" 24.3 276.4 108.0 245 79.2 4 × Ø 15.7 132.5 14.2 112.5 26.7 112

40 1 ½" 38.1 273.6 127.0 320 98.6 4 × Ø 15.7 200 17.5 120 40.9 109

50 2" 49.2 278 152.4 400 120.7 4 × Ø 19.1 250 19.1 150 52.6 118

80 3" 73.7 291.1 190.5 640 152.4 4 × Ø 19.1 400 23.9 240 78.0 127

100 4" 97 303.0 228.6 800 190.5 8 × Ø 19.1 500.5 24.5 299.5 102.4 139

All dimensions in [mm]

Flange ASME B16.5 / Cl 150 / Sched 80: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

15 ½" 13.9 276.4 88.9 245 60.5 4 × Ø 15.7 132.5 11.2 112.5 13.9 112

25 1" 24.3 276.4 108.0 245 79.2 4 × Ø 15.7 132.5 14.2 112.5 24.3 112

40 1 ½" 38.1 273.6 127.0 320 98.6 4 × Ø 15.7 200 17.5 120 38.1 109

50 2" 49.2 278 152.4 400 120.7 4 × Ø 19.1 250 19.1 150 49.2 118

80 3" 73.7 291.1 190.5 640 152.4 4 × Ø 19.1 400 23.9 240 73.7 127

100 4" 97 303.0 228.6 800 190.5 8 × Ø 19.1 500.5 24.5 299.5 97.0 139

All dimensions in [mm]

Endress+Hauser 33

Page 34

Proline t-mass 65F, 65I

Flange ASME B16.5 / Cl 300 / Sched 40: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

15 ½" 13.9 276.4 95.2 245 66.5 4 × Ø 15.7 132.5 14.2 112.5 15.7 112

25 1" 24.3 276.4 124.0 245 88.9 4 × Ø 19.1 132.5 17.5 112.5 26.7 112

40 1 ½" 38.1 273.6 155.4 320 114.3 4 × Ø 22.4 200 20.6 120 40.9 109

50 2" 49.2 278 165.1 400 127.0 8 × Ø 19.1 250 22.4 150 52.6 118

80 3" 73.7 291.1 209.6 640 168.1 8 × Ø 22.4 400 28.4 240 78.0 127

100 4" 97 303.0 254.0 800 200.2 8 × Ø 22.4 500.5 31.8 299.5 102.4 139

All dimensions in [mm]

Flange ASME B16.5 / Cl 300 / Sched 80: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

15 ½" 13.9 276.4 95.2 245 66.5 4 × Ø 15.7 132.5 14.2 112.5 13.9 112

25 1" 24.3 276.4 124.0 245 88.9 4 × Ø 19.1 132.5 17.5 112.5 24.3 112

40 1 ½" 38.1 273.6 155.4 320 114.3 4 × Ø 22.4 200 20.6 120 38.1 109

50 2" 49.2 278 165.1 400 127.0 8 × Ø 19.1 250 22.4 150 49.2 118

80 3" 73.7 291.1 209.6 640 168.1 8 × Ø 22.4 400 28.4 240 73.7 127

100 4" 97 303.0 254.0 800 200.2 8 × Ø 22.4 500.5 31.8 299.5 97.0 139

All dimensions in [mm]

34 Endress+Hauser

Page 35

Proline t-mass 65F, 65I

G 1 A / 1" MNPT

L

W

V

227 (8.94)

207 (8.15)

168 (6.61)

160 (6.3)

55 (2.2)

63 (2.5)

G 1 A / 1" MNPT

L

R

W

V

Ø 129 (5.1)

52 (2.0)

79 (3.1)

50 (1.96)

102(4.0)

55 (2.2)

63(2.5)

t-mass 65I: Compact insertion version

Engineering unit mm (in)

t-mass 65I: Remote sensor housing insertion version

Engineering unit mm (in)

A0005163

A0005159

Length tmass 65I V W L L

235 235.1 252.6 475.6 417.6

335 335.1 352.6 575.6 517.6

R

435 435.1 452.6 675.6 617.6

608 608.1 625.6 848.6 790.6

All dimensions in [mm].

Endress+Hauser 35

Page 36

Flow conditioner (as per EN (DIN) / JIS / ASME)

D1

D2

ØF

S

A

B

C

R

Q

D

D2

D3

D1

ØF2

ØF1

Proline t-mass 65F, 65I

A0005166

EN (DIN)

PN 16 PN 40

DN Type D1 D2 F Q R S [kg] S [kg]

25 A 83 105 13 5 2.5 – – 4.5 0.3

40 A 108 135 17 5 2.5 – – 7.0 0.7

50 A 123 150 17 5 2.5 – – 8.5 1.0

80 C 158 185 17 5 2.5 – – 13.0 2.3

100 C 187 220 22 5 2.5 17.0 4.1 17.0 4.1

All dimensions in [mm]

JIS 10K/20K

Sched 40 Sched 80

DN Type D1 D2 F Q R S [kg] S [kg]

25 A 87 115 17 5 2.5 4.5 0.4 4.0 0.4

40 A 102 130 17 5 2.5 6.5 0.7 6.0 0.7

50 B 117 145 17 5 2.5 8.5 1.2 8.0 1.1

80 C 157 188 21 5 2.5 12.5 3.0 12.0 2.8

100 C 182 214 21 5 2.5 16.5 5.1 15.5 4.8

All dimensions in [mm]

ASME Cl. 150/300

Sched 40 Sched 80

DN Type D1 D2 D3 F F1 F2 Q R S [kg] S [kg]

25 1" A 85.5 110 – 19.0 – – 5 2.5 4.5 0.4 4 0.4

36 Endress+Hauser

40 1 ½" A 109.5 142 – 23.5 – – 5 2.5 6.5 0.9 6 0.9

50 2" D 127 150 120.7 17.0 – – 5 2.5 8.5 1.3 8 1.3

80 3" D 168.3 200 152.4 – 20.0 17 5 2.5 12.5 3.2 12 3.2

100 4" C 197 230 – 23.5 – – 5 2.5 16.5 5.3 15.5 5.3

All dimensions in [mm]

Page 37

Proline t-mass 65F, 65I

V3

V1

V2

5

F

E

6

7

H

G

I

R

3

4

2

L

B

C

Y

A

D

1

Hot tap, process pressure

Low-pressure and medium-pressure version

A0024284

1 Safety chain for low-pressure version

2 Sensor connection

3 Ball valve

4 Retrofit adapter

5 Weld boss process connection

6 Flange adapter

7 Flange process connection

V1 Version with retrofit adapter

V2 Version with weld boss

V3 Version with flange

L A B C D E F G H I R Y

252.5 42.2

All dimensions in [mm]

V1 V2 V3

2.8 2.4 4.9

Weight in [kg]

~85 88 60 123 33.4 33.4 54 123.9 165 620

Endress+Hauser 37

Page 38

Extractor assemblies for medium-pressure version

A

E

C

B

D

L

201 (7.9)

165 (6.5)

G1"/NPT1"

90 (3.5)

86 (3.4)

25 (1)

30 (1.2)

4 (0.2)

38.1 (1.5)

38.1 (1.5)

Proline t-mass 65F, 65I

A0022055

L A B C D E Weight

740 740 40 700 120 180 8.4

All dimensions in [mm], weight in [kg]

Cold tap, atmospheric pressure

Engineering unit mm (in)

A0024413

38 Endress+Hauser

Page 39

Proline t-mass 65F, 65I

G

LK

U

N

S

L

P T

B

V

di

227 (8.94)

207 (8.15)

168 (6.61)

160 (6.3)

+1.5 (0.06)

- 2.0 (0.08)

Process connections in US units

t-mass 65F: Flange connections as per ASME

A0005162

Engineering unit mm (in)

Flange ASME B16.5 / Cl 150 / Sched 40: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

½" 0.55 10.9 3.50 9.65 2.38 4 × 0.62 5.22 0.44 4.43 0.62 4.41

1" 0.96 10.9 4.25 9.65 3.12 4 × 0.62 5.22 0.56 4.43 1.05 4.41

1 ½" 1.50 10.8 5.00 12.60 3.88 4 × 0.62 7.87 0.69 4.72 1.61 4.29

2" 1.94 10.9 6.00 15.75 4.75 4 × 0.75 9.84 0.75 5.91 2.07 4.65

3" 2.90 11.5 7.50 25.20 6.00 4 × 0.75 15.75 0.94 9.45 3.07 5.00

4" 3.82 11.9 9.00 31.50 7.50 8 × 0.75 19.70 0.96 11.79 4.03 5.47

All dimensions in [in]

Flange ASME B16.5 / Cl 150 / Sched 80: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

½" 0.55 10.9 3.50 9.65 2.38 4 × 0.62 5.22 0.44 4.43 0.55 4.41

1" 0.96 10.9 4.25 9.65 3.12 4 × 0.62 5.22 0.56 4.43 0.96 4.41

1 ½" 1.50 10.8 5.00 12.6 3.88 4 × 0.62 7.87 0.69 4.72 1.50 4.29

2" 1.94 10.9 6.00 15.7 4.75 4 × 0.75 9.84 0.75 5.91 1.94 4.65

3" 2.90 11.5 7.50 25.2 6.00 4 × 0.75 15.75 0.94 9.45 2.90 5.00

4" 3.82 11.9 9.00 31.5 7.50 8 × 0.75 19.70 0.96 11.79 3.82 5.47

All dimensions in [in]

Endress+Hauser 39

Page 40

Proline t-mass 65F, 65I

Flange ASME B16.5 / Cl 300 / Sched 40: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

½" 0.55 10.9 3.75 9.65 2.62 4 × 0.62 5.22 0.56 4.43 0.62 4.41

1" 0.96 10.9 4.88 9.65 3.50 4 × 0.75 5.22 0.69 4.43 1.05 4.41

1 ½" 1.50 10.8 6.12 12.6 4.50 4 × 0.88 7.87 0.81 4.72 1.61 4.29

2" 1.94 10.9 6.50 15.7 5.00 8 × 0.75 9.84 0.88 5.91 2.07 4.65

3" 2.90 11.5 8.25 25.2 6.62 8 × 0.88 15.75 1.12 9.45 3.07 5.00

4" 3.82 11.9 10.00 31.5 7.88 8 × 0.88 19.70 1.25 11.79 4.03 5.47

All dimensions in [in]

Flange ASME B16.5 / Cl 300 / Sched 80: 1.4404/316L/316

Surface roughness (flange): N9 / 250 μin

DN di B G L LK N P S T U V

½" 0.55 10.9 3.75 9.65 2.62 4 × 0.62 5.22 0.56 4.43 0.55 4.41

1" 0.96 10.9 4.88 9.65 3.50 4 × 0.75 5.22 0.69 4.43 0.96 4.41

1 ½" 1.50 10.8 6.12 12.6 4.50 4 × 0.88 7.87 0.81 4.72 1.50 4.29

2" 1.94 10.9 6.50 15.7 5.00 8 × 0.75 9.84 0.88 5.91 1.94 4.65

3" 2.90 11.5 8.25 25.2 6.62 8 × 0.88 15.75 1.12 9.45 2.90 5.00

4" 3.82 11.9 10.00 31.5 7.88 8 × 0.88 19.70 1.25 11.79 3.82 5.47

All dimensions in [in]

40 Endress+Hauser

Page 41

Proline t-mass 65F, 65I

G 1 A / 1" MNPT

L

W

V

227 (8.94)

207 (8.15)

168 (6.61)

160 (6.3)

55 (2.2)

63 (2.5)

G 1 A / 1" MNPT

L

R

W

V

Ø 129 (5.1)

52 (2.0)

79 (3.1)

50 (1.96)

102(4.0)

55 (2.2)

63(2.5)

t-mass 65I: Compact insertion version

Engineering unit mm (in)

t-mass 65I: Remote sensor housing insertion version

Engineering unit mm (in)

A0005163

A0005159

Length tmass 65I V W L L

9" 9.26 9.94 18.72 16.44

13" 13.19 13.88 22.66 20.38

R

17" 17.13 17.82 26.60 24.31

24" 23.94 24.63 33.41 31.13

All dimensions in [in]

Endress+Hauser 41

Page 42

Flow conditioner according to ASME

D1

D2

ØF

S

A

B

C

R

Q

D

D2

D3

D1

ØF2

ØF1

Proline t-mass 65F, 65I

A0005166

ASME Cl. 150/300

Sched 40 Sched 80

DN Type D1 D2 D3 F F1 F2 Q R S [lbs] S [lbs]

1" A 3.37 4.33 – 0.75 – – 0.20 0.10 0.18 0.88 0.16 0.88

1 ½" A 4.31 5.59 – 0.93 – – 0.20 0.10 0.26 1.98 0.24 1.98

2" D 5 5.91 4.75 0.67 – – 0.20 0.10 0.33 2.86 0.31 2.86

3" D 6.63 7.87 6 – 0.79 0.67 0.20 0.10 0.49 7.05 0.47 7.05

4" C 7.76 9.06 – 0.93 – – 0.20 0.10 0.65 11.68 0.61 11.68

All dimensions in [in]

42 Endress+Hauser

Page 43

Proline t-mass 65F, 65I

V3

V1

V2

5

F

E

6

7

H

G

I

R

3

4

2

L

B

C

Y

A

D

1

Hot tap, process pressure

Low-pressure and medium-pressure version

A0024284

1 Safety chain for low-pressure version

2 Sensor connection

3 Ball valve

4 Retrofit adapter

5 Weld boss process connection

6 Flange adapter

7 Flange process connection

V1 Version with retrofit adapter

V2 Version with weld boss

V3 Version with flange

L A B C D E F G H I R Y

9.94 1.66

All dimensions in [in]

V1 V2 V3

6.17 5.29 10.80

Weight in [lbs]

~3.35 3.46 2.36 4.84 1.31 1.31 2.13 4.88 6.50 24.41

Endress+Hauser 43

Page 44

Extractor assemblies for medium-pressure version

A

E

C

B

D

L

201 (7.9)

165 (6.5)

G1"/NPT1"

90 (3.5)

86 (3.4)

25 (1)

30 (1.2)

4 (0.2)

38.1 (1.5)

38.1 (1.5)

Proline t-mass 65F, 65I

A0022055

L A B C D E Weight

29.13 29.13 1.57 27.56 4.72 7.09 18.52