Page 1

TI01333D/06/EN/03.19

71439415

2019-07-01

Products Solutions Services

Technical Information

Proline Prowirl F 200

Vortex flowmeter

Versatile flowmeter with wet steam detection and first-rate accuracy

Application

• Preferred measuring principle for wet/saturated/

superheated steam, gases & liquids (also cryogenic)

• Suitable for a wide range of applications; optimized for

steam applications

Device properties

• Wet steam capabilities for DN 25 to 300 (1 bis 12")

• Flexible positioning of pressure cell

• Industrial siphon design for pressure measurement

• Display module with data transfer function

• Robust dual-compartment housing

• Plant safety: worldwide approvals (SIL, Haz. area)

Your benefits

• Easy energy management – integrated temperature and

pressure measurement for steam and gases

• Space-saving engineering – inlet run compensation

• Same accuracy down to Re 10 000 –

most linear Vortex meter body

• Long-term stability – robust drift-free capacitive sensor

• Convenient device wiring – separate connection

compartment

• Safe operation – no need to open the device due to display

with touch control, background lighting

• Integrated verification – Heartbeat Technology

Page 2

Table of contents

Proline Prowirl F 200

About this document ........................ 3

Symbols .................................... 3

Function and system design ................... 4

Measuring principle ............................ 4

Measuring system ............................. 8

Input ..................................... 9

Measured variable ............................. 9

Measuring range ............................. 10

Operable flow range ........................... 14

Input signal ................................ 15

Output .................................. 16

Output signal ............................... 16

Signal on alarm .............................. 17

Load ..................................... 18

Ex connection data ........................... 19

Low flow cut off ............................. 24

Galvanic isolation ............................ 24

Protocol-specific data .......................... 24

Power supply ............................. 26

Terminal assignment .......................... 26

Pin assignment, device plug ...................... 28

Supply voltage .............................. 29

Power consumption ........................... 30

Current consumption .......................... 30

Power supply failure .......................... 30

Electrical connection .......................... 30

Potential equalization ......................... 35

Terminals ................................. 35

Cable entries ............................... 35

Cable specification ............................ 35

Overvoltage protection ......................... 37

Electromagnetic compatibility (EMC) ............... 50

Process .................................. 50

Medium temperature range ...................... 50

Pressure-temperature ratings .................... 51

Nominal pressure of sensor ...................... 54

Pressure specifications ......................... 54

Pressure loss ............................... 54

Thermal insulation ........................... 54

Mechanical construction .................... 55

Dimensions in SI units ......................... 55

Dimensions in US units ......................... 68

Weight ................................... 75

Materials .................................. 79

Flange connections ........................... 83

Operability ............................... 83

Operating concept ............................ 83

Languages ................................. 83

Local operation .............................. 84

Remote operation ............................ 85

Service interface ............................. 87

Certificates and approvals ................... 87

CE mark ................................... 87

RCM-tick symbol ............................. 87

Ex approval ................................ 87

Functional safety ............................. 89

HART certification ............................ 90

FOUNDATION Fieldbus certification ................ 90

Certification PROFIBUS ......................... 90

Pressure Equipment Directive .................... 90

Experience ................................. 90

Other standards and guidelines ................... 90

Performance characteristics .................. 38

Reference operating conditions ................... 38

Maximum measured error ....................... 38

Repeatability ............................... 41

Response time .............................. 42

Influence of ambient temperature ................. 42

Installation ............................... 42

Mounting location ............................ 42

Orientation ................................ 42

Inlet and outlet runs .......................... 44

Length of connecting cable ...................... 46

Mounting the transmitter housing ................. 47

Special mounting instructions .................... 47

Environment .............................. 48

Ambient temperature range ..................... 48

Storage temperature .......................... 49

Climate class ............................... 49

Degree of protection .......................... 49

Vibration- and shock-resistance ................... 49

Ordering information ....................... 91

Product generation index ....................... 91

Application packages ....................... 91

Diagnostics functions .......................... 91

Heartbeat Technology ......................... 92

Wet steam detection .......................... 92

Wet steam measurement ....................... 92

Accessories ............................... 92

Device-specific accessories ...................... 93

Communication-specific accessories ................ 94

Service-specific accessories ...................... 95

System components ........................... 95

Supplementary documentation ............... 95

Standard documentation ........................ 96

Supplementary device-dependent documentation ....... 96

Registered trademarks ...................... 97

2 Endress+Hauser

Page 3

Proline Prowirl F 200

A

1.

About this document

Symbols Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

Communication symbols

Symbol Meaning

Wireless Local Area Network (WLAN)

Communication via a wireless, local network.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

Reference to page.

Reference to graphic.

Visual inspection.

Symbols in graphics

Symbol Meaning

1, 2, 3, ... Item numbers

, 2., 3., … Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Endress+Hauser 3

Page 4

Symbol Meaning

-

.

K-Factor =

Pulses

Unit Volume [m³]

Hazardous area

Safe area (non-hazardous area)

Flow direction

Function and system design

Proline Prowirl F 200

Measuring principle

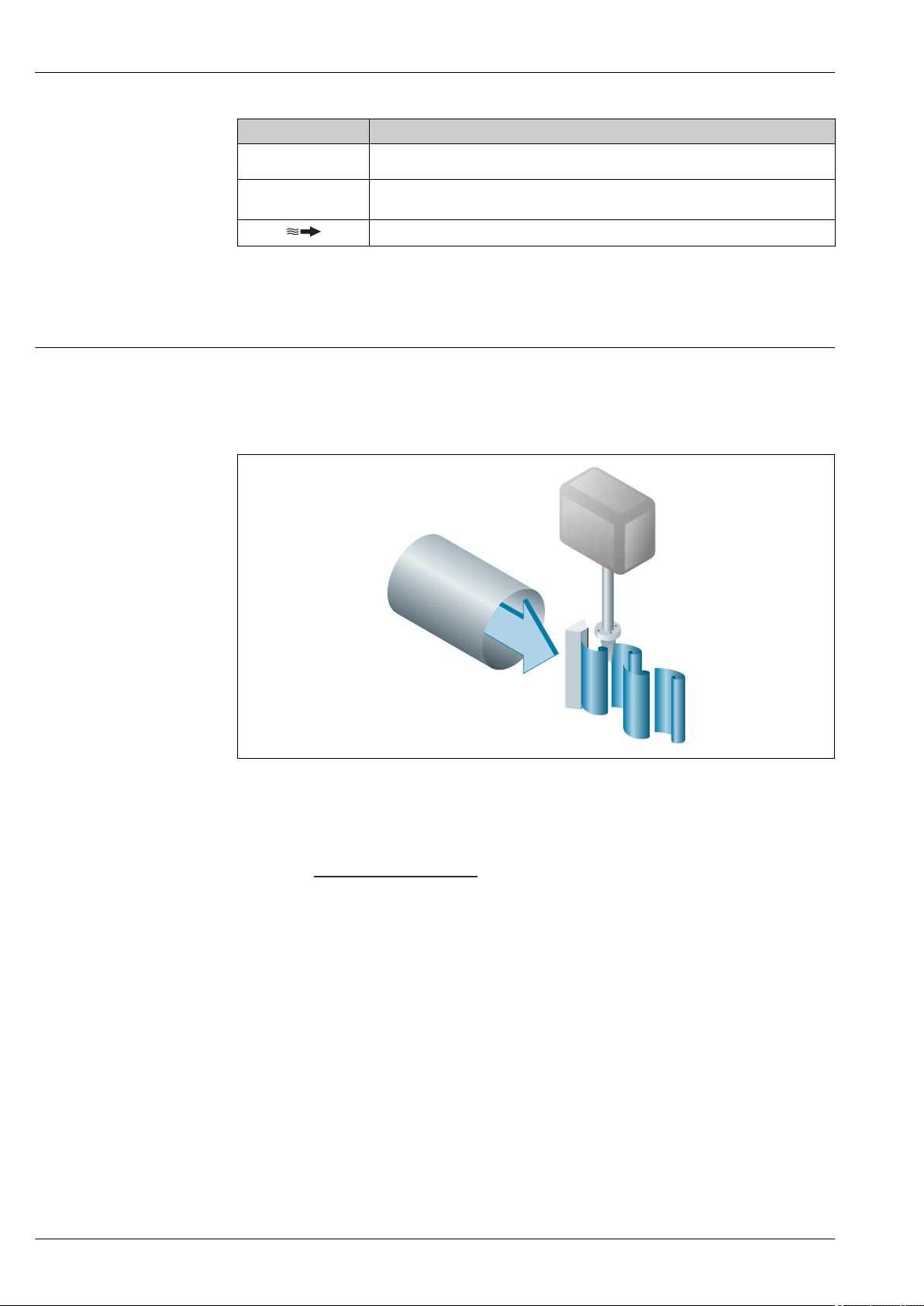

Vortex meters work on the principle of the Karman vortex street. When fluid flows past a bluff body,

vortices are alternately formed on both sides with opposite directions of rotation. These vortices each

generate a local low pressure. The pressure fluctuations are recorded by the sensor and converted to

electrical pulses. The vortices develop very regularly within the permitted application limits of the

device. Therefore, the frequency of vortex shedding is proportional to the volume flow.

A0033465

1 Sample graphic

The calibration factor (K-factor) is used as the proportional constant:

Within the application limits of the device, the K-factor only depends on the geometry of the device.

It is for Re > 10 000:

• Independent of the flow velocity and the fluid properties viscosity and density

• Independent of the type of substance under measurement: steam, gas or liquid

The primary measuring signal is linear to the flow. After production, the K-factor is determined in

the factory by means of calibration. It is not subject to long-time drift or zero-point drift.

The device does not contain any moving parts and does not require any maintenance.

The capacitance sensor

The sensor of a vortex flowmeter has a major influence on the performance, robustness and

reliability of the entire measuring system.

4 Endress+Hauser

A0003939-EN

Page 5

Proline Prowirl F 200

1 2

The robust DSC sensor is:

• burst-tested

• tested against vibrations

• tested against thermal shock (thermal shocks of 150 K/s)

The measuring device uses the tried-and-tested, capacitance measuring technology from

Endress+Hauser, which is already in use in over 450 000 measuring points worldwide. Thanks to its

design, the capacitance sensor is also particularly mechanically resistant to temperature shocks and

pressure shocks in steam pipelines.

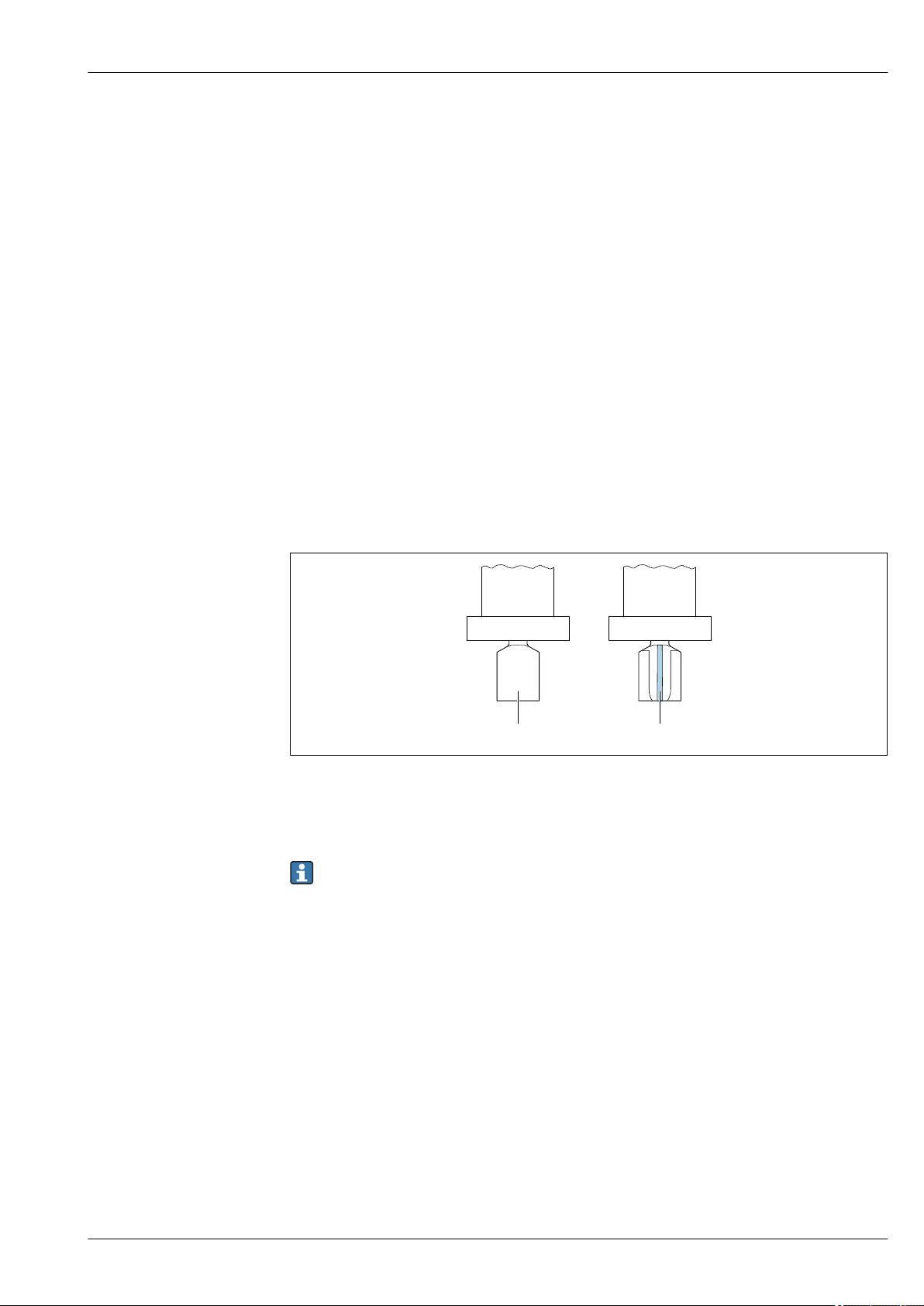

Temperature measurement

The "mass" option is available under the order code for "Sensor version". With this option the

measuring device can also measure the temperature of the medium.

The temperature is measured via Pt 1000 temperature sensors. These are located in the paddle of

the DSC sensor and are therefore in the direct vicinity of the fluid.

Order code for "Sensor version; DSC sensor; measuring tube":

• Option AA "volume; 316L; 316L"

• Option AB "volume; Alloy C22; 316L"

• Option AC "volume; Alloy C22; Alloy C22"

• Option BA "volume high-temperature; 316L; 316L"

• Option BB "volume high-temperature; Alloy C22; 316L"

• Option CA "Mass; 316L; 316L (integrated temperature measurement)"

• Option CB "Mass; Alloy C22; 316L (integrated temperature measurement)"

• Option CC "Mass; Alloy C22; Alloy C22 (integrated temperature measurement)"

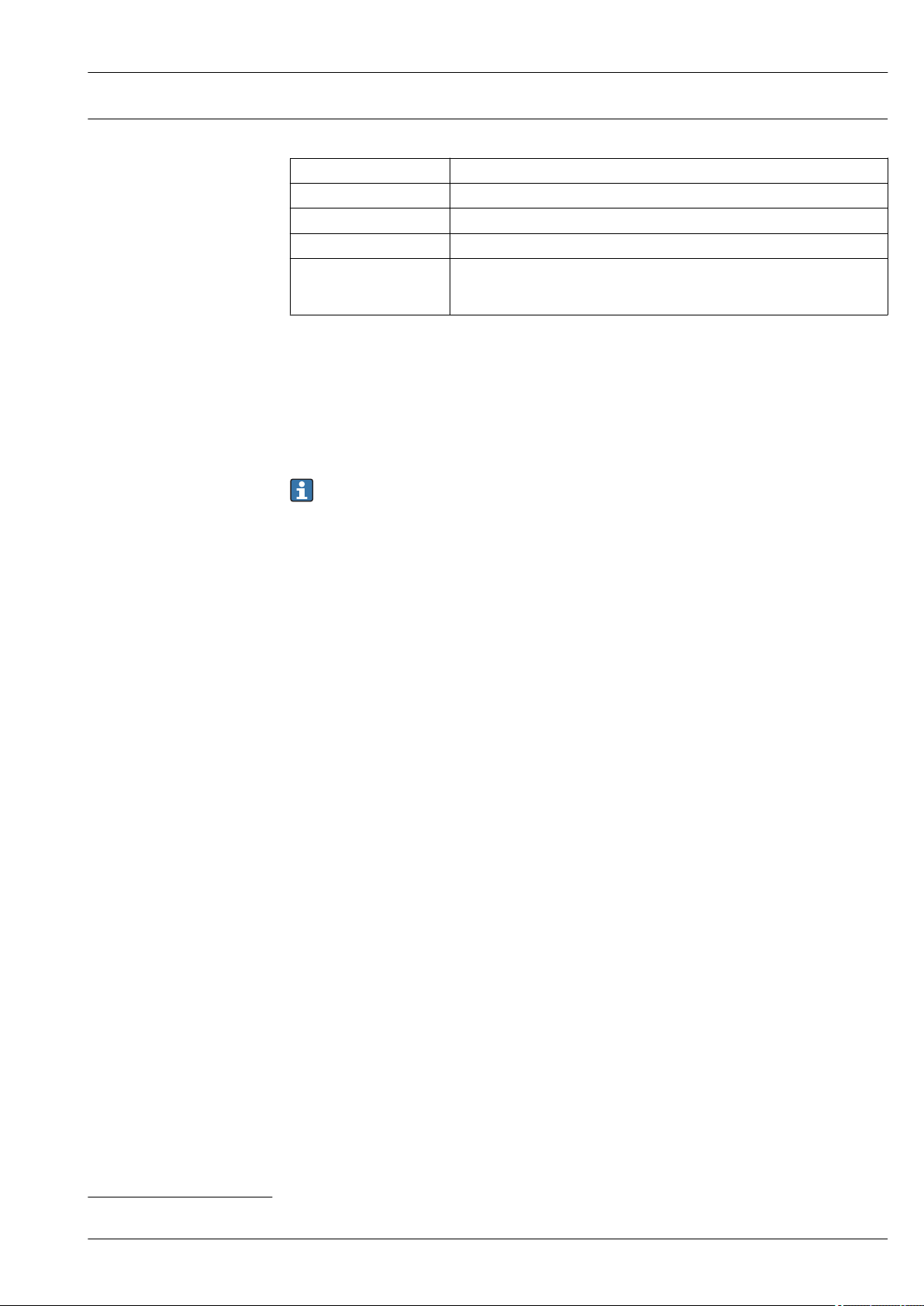

A0034068

1 Order code for "Sensor version", option "volume" or "volume high-temperature"

2 Order code for "Sensor version", option "mass"

Pressure and temperature measurement

The "mass" sensor version (integrated pressure/temperature measurement) is available only for

measuring devices in the HART communication mode.

The "mass steam" or "mass gas/liquid" options are available under the order code for "Sensor version;

DSC sensor; measuring tube". With these options, the measuring device can also measure the

pressure and temperature of the fluid.

The temperature is measured via Pt 1000 temperature sensors. These are located in the paddle of

the DSC sensor and are therefore in the direct vicinity of the fluid. Pressure measurement is located

directly on the meter body at the level of the bluff body. The position of the pressure tapping was

chosen so that pressure and temperature could be measured at the same point. This enables accurate

density and/or energy compensation of the fluid using pressure and temperature. The measured

pressure tends to be somewhat lower than the line pressure. For this reason, Endress+Hauser offers

a correction to the line pressure (integrated in the device).

Order code for "Sensor version; DSC sensor; measuring tube":

• Option DA "Mass steam; 316L; 316L (integrated pressure/temperature measurement)"

• Option DB "Mass gas/liquid; 316L; 316L (integrated pressure/temperature measurement)"

Lifelong calibration

Experience has shown that recalibrated measuring devices demonstrate a very high degree of

stability compared to their original calibration: The recalibration values were all within the original

Endress+Hauser 5

Page 6

Proline Prowirl F 200

measuring accuracy specifications of the devices. This applies to the measured volume flow, the

device's primary measured variable.

Various tests and simulation have shown that once the radii of the edges on the bluff body are less

than 1 mm (0.04 in), the resulting effect does not have a negative impact on accuracy.

If the radii of the edges on the bluff body do not exceed 1 mm (0.04 in), the following general

statements apply (in the case of non-abrasive and non-corrosive media, such as in most water and

steam applications):

• The measuring device does not display an offset in the calibration and the accuracy is still

guaranteed.

• All the edges on the bluff body have a radius that is typically smaller in size. As the measuring

devices are naturally also calibrated with these radii, the measuring device remains within the

specified accuracy rating provided that the additional radius that is produced as a result of wear

and tear does not exceed 1 mm (0.04 in).

Consequently, it can be said that the product line offers lifelong calibration if the measuring device is

used in non-abrasive and non-corrosive media.

Inlet run correction

Inlet run correction makes it possible to shorten the necessary inlet run before the measuring device

to a minimum length of 10 × DN. If the inlet run available is too short, the measuring device can

correct the measured error depending on the preceding disruption in the flow profile. This results in

an additional measured error of ±0.5 %o.r.

The Inlet Run Correction function can be used for the following pressure ratings and nominal

diameters:

DN 15 to 150 (1 to 6")

• EN (DIN)

• ASME B16.5, Sch. 40/80

Inlet run correction is possible for the following flow obstructions:

• Single elbow (90° elbow)

• Double elbow (2 × 90° elbows, opposite)

• Double elbow 3D (2 × 90° elbows, opposite, not on one plane)

• Reduction by one nominal diameter size

Inlet and outlet runs to be considered → 44

1)

For detailed information about inlet run correction, see the Special Documentation for the

device

Air and industrial gases

The measuring device enables users to calculate the density and energy of air and industrial gases.

The calculations are based on time-tested standard calculation methods. It is possible to

automatically compensate for the effect of pressure and temperature via an external or constant

value.

This makes it possible to output the energy flow, standard volume flow and mass flow of the

following gases:

• Single gas

• Gas mixture

• Air

• User-specific gas

For detailed information on the parameters, see the Operating Instructions.→ 96

Natural gas

The device enables users to calculate the chemical properties (gross calorific value, net calorific

value) of natural gases. The calculations are based on time-tested standard calculation methods. It is

possible to automatically compensate for the effect of pressure and temperature via an external or

constant value.

This makes it possible to output the energy flow, standard volume flow and mass flow in accordance

with the following standard methods:

1) = of reading

6 Endress+Hauser

Page 7

Proline Prowirl F 200

Energy can be calculated based on the following standards:

• AGA5

• ISO 6976

• GPA 2172

Density can be calculated based on the following standards:

• ISO 12213-2 (AGA8-DC92)

• ISO 12213-3

• AGA NX19

• AGA8 Gross 1

• SGERG 88

For detailed information on the parameters, see the Operating Instructions.→ 96

Endress+Hauser 7

Page 8

Proline Prowirl F 200

1 2

Measuring system

The device consists of a transmitter and a sensor.

Two device versions are available:

• Compact version – transmitter and sensor form a mechanical unit.

• Remote version - transmitter and sensor are mounted in separate locations.

Transmitter

Prowirl 200 Device versions and materials:

• Compact or remote version, aluminum coated:

Aluminum, AlSi10Mg, coated

• Compact or remote version, stainless:

For maximum corrosion resistance: stainless steel CF3M

Configuration:

• Via four-line local display with key operation or via four-line,

illuminated local display with touch control and guided menus ("Make-

A0013471

it-run" wizards) for applications

• Via operating tools (e.g. FieldCare)

Sensor

ProwirlF Flanged version:

• Nominal diameter range: DN 15 to 300 (½ to 12")

• Materials:

• Measuring tubes

DN 15 to 300 (½ to 12"): stainless cast steel, CF3M/1.4408

DN 15 to 150 (½ to 6"): cast, CX2MW similar to Alloy C22/2.4602

• Flange connections

DN 15 to 300 (½ to 12"): stainless steel, triple-certified material,

1.4404/F316/F316L

• DN 15 to 150 (½ to 6"), pressure ratings up to PN40/Class 300: cast,

CX2MW similar to Alloy C22/2.4602

A0034075

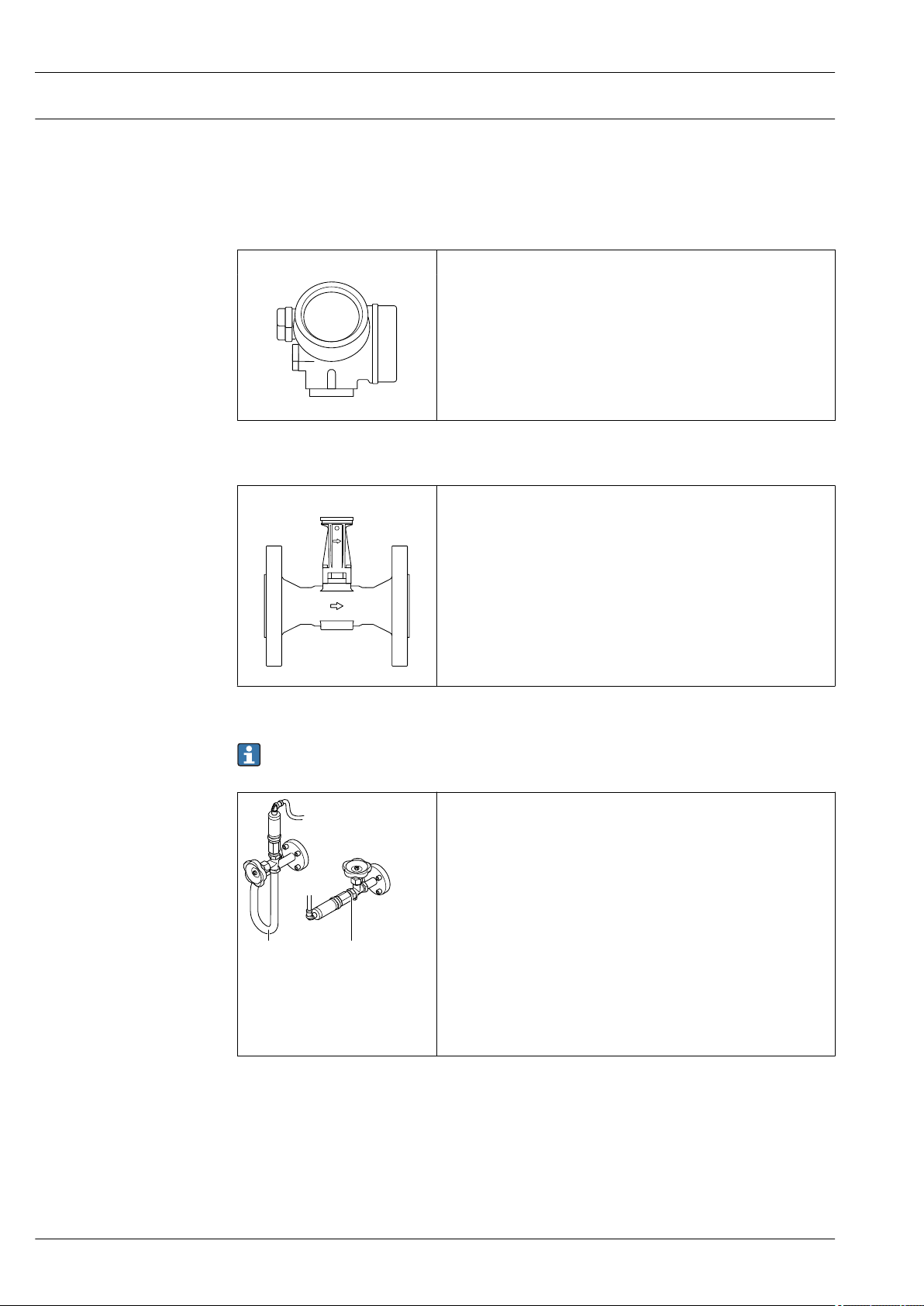

Pressure measuring cell

The "mass" sensor version (integrated pressure/temperature measurement) is available only for

measuring devices in the HART communication mode.

Versions:

Pressure components

• Pressure measuring cell 2 bar_a

• Pressure measuring cell 4 bar_a

• Pressure measuring cell 10 bar_a

• Pressure measuring cell 40 bar_a

• Pressure measuring cell 100 bar_a

Material

• Wetted parts:

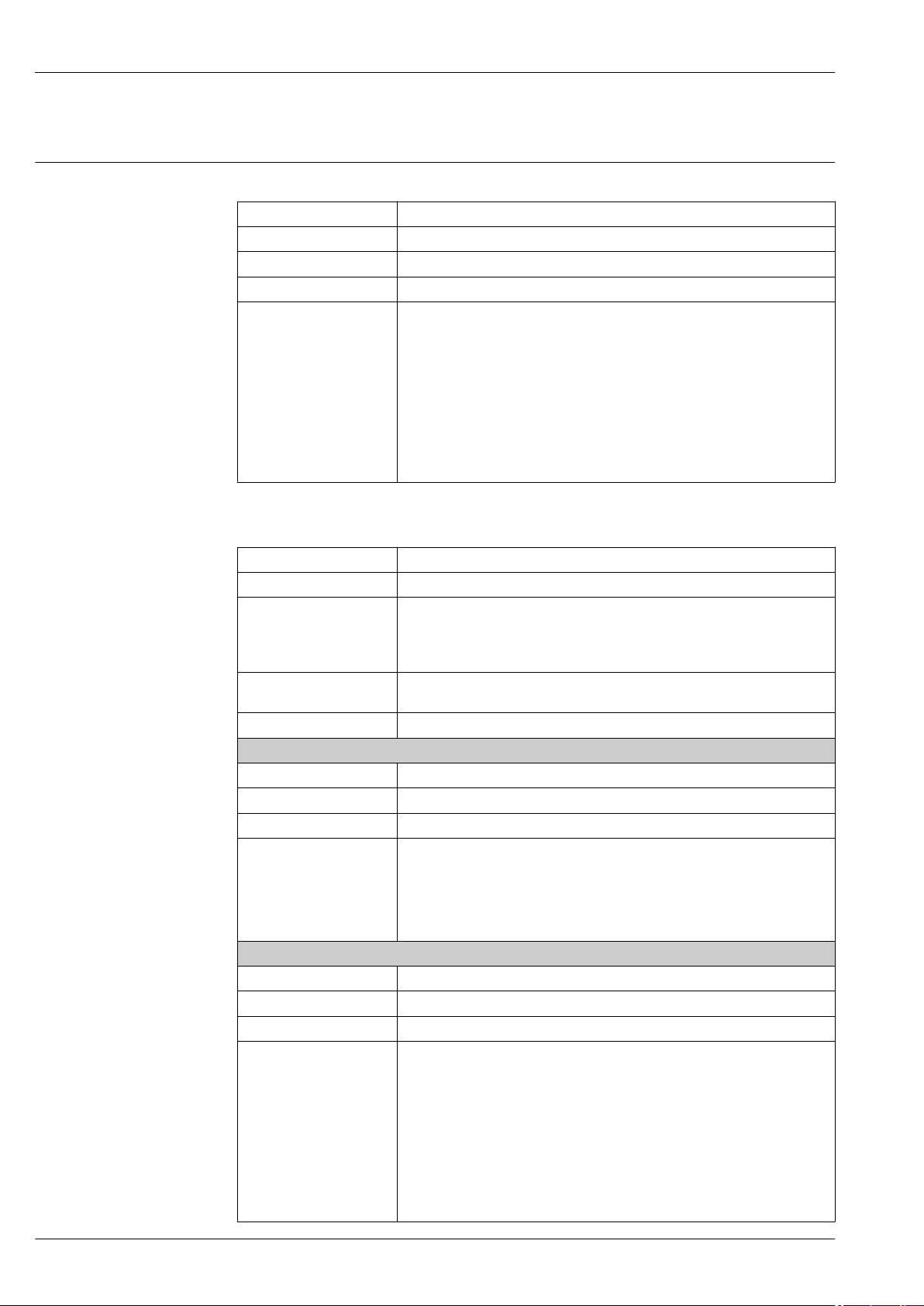

A0034080

1 Option DA "mass steam"

2 Option DB "mass gas/liquid"

• Process connection

Stainless steel, 1.4404/316L

• Membrane

Stainless steel, 1.4435/316L

• Non-wetted parts:

Housing

Stainless steel ,1.4404

8 Endress+Hauser

Page 9

Proline Prowirl F 200

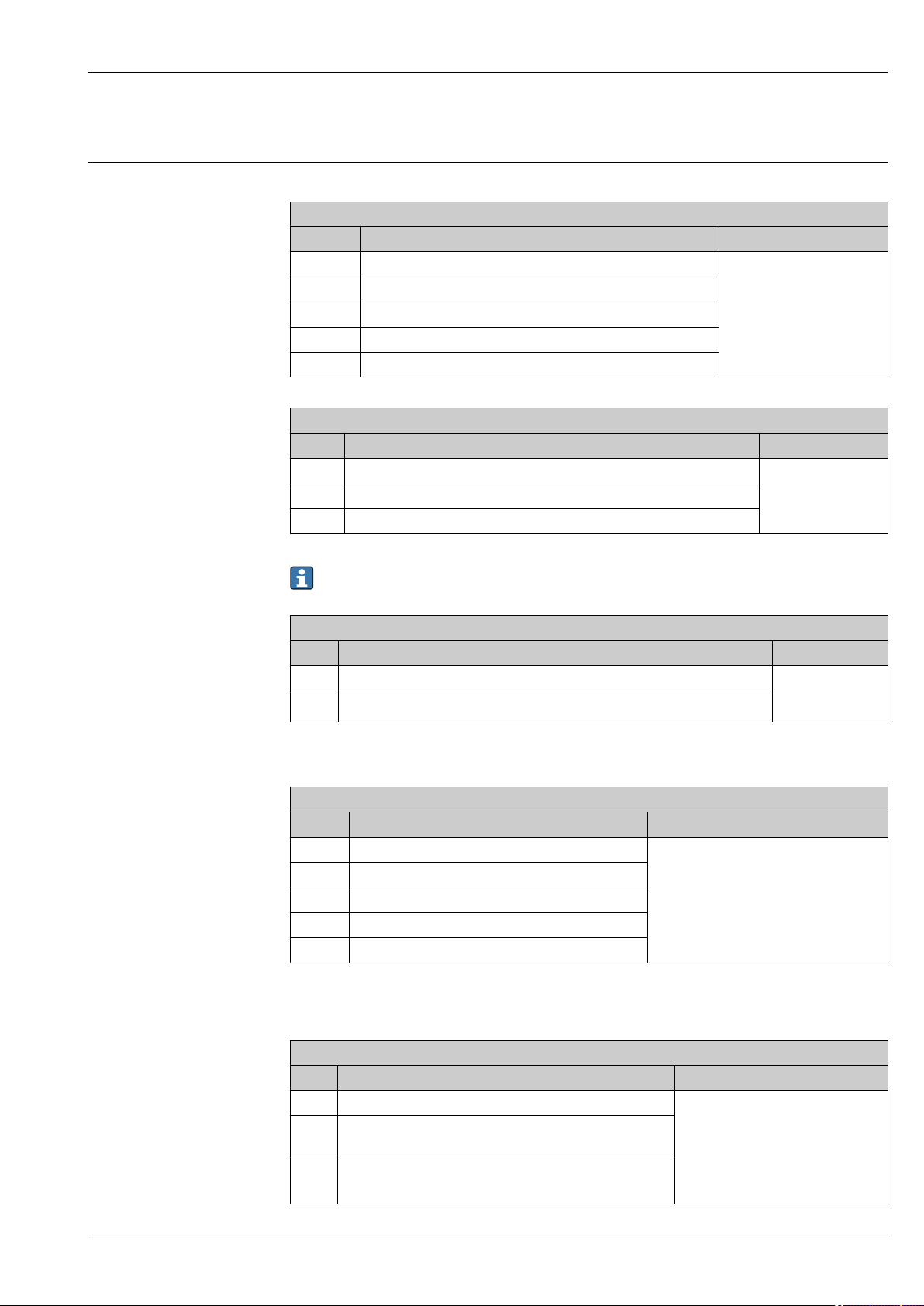

Input

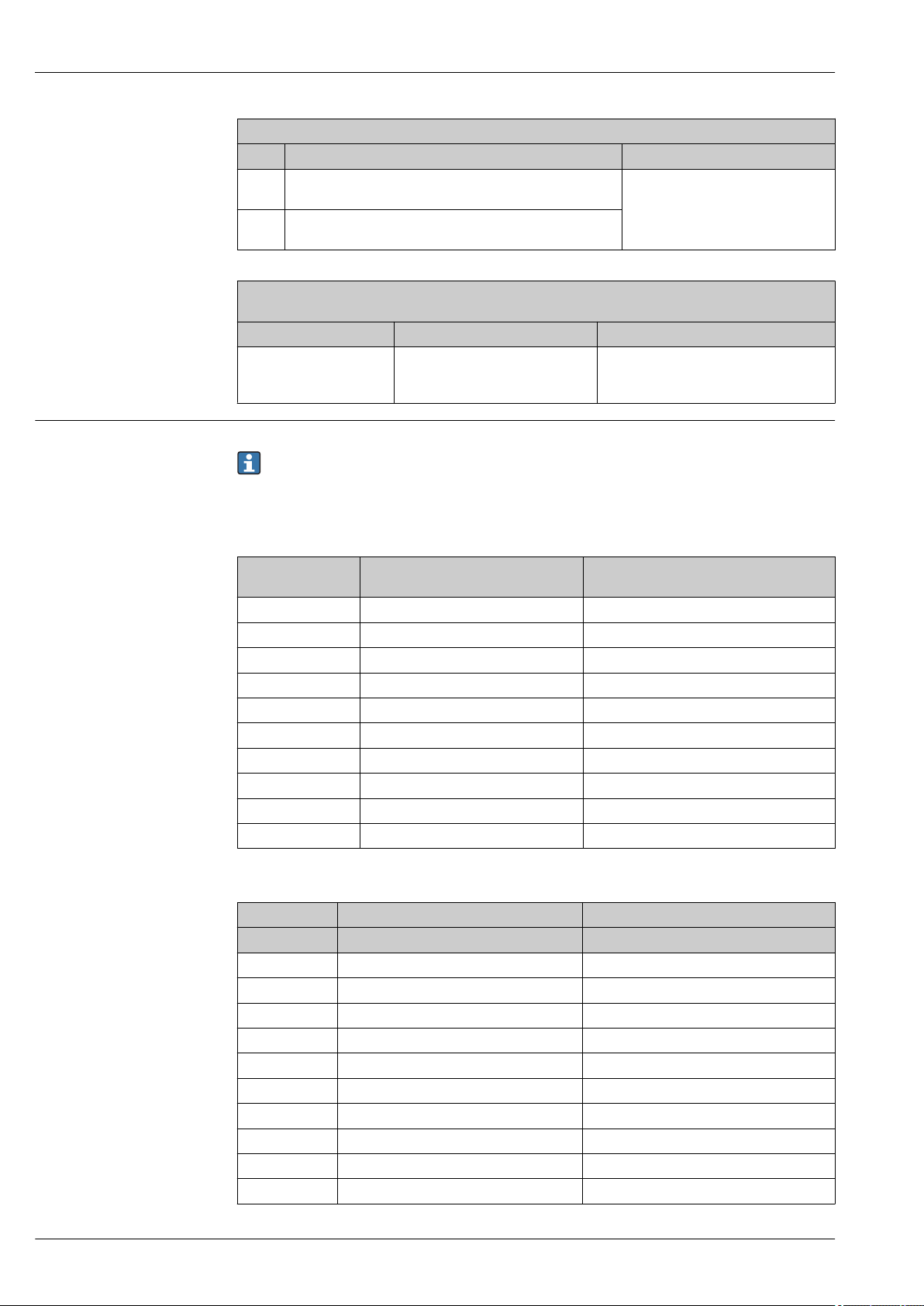

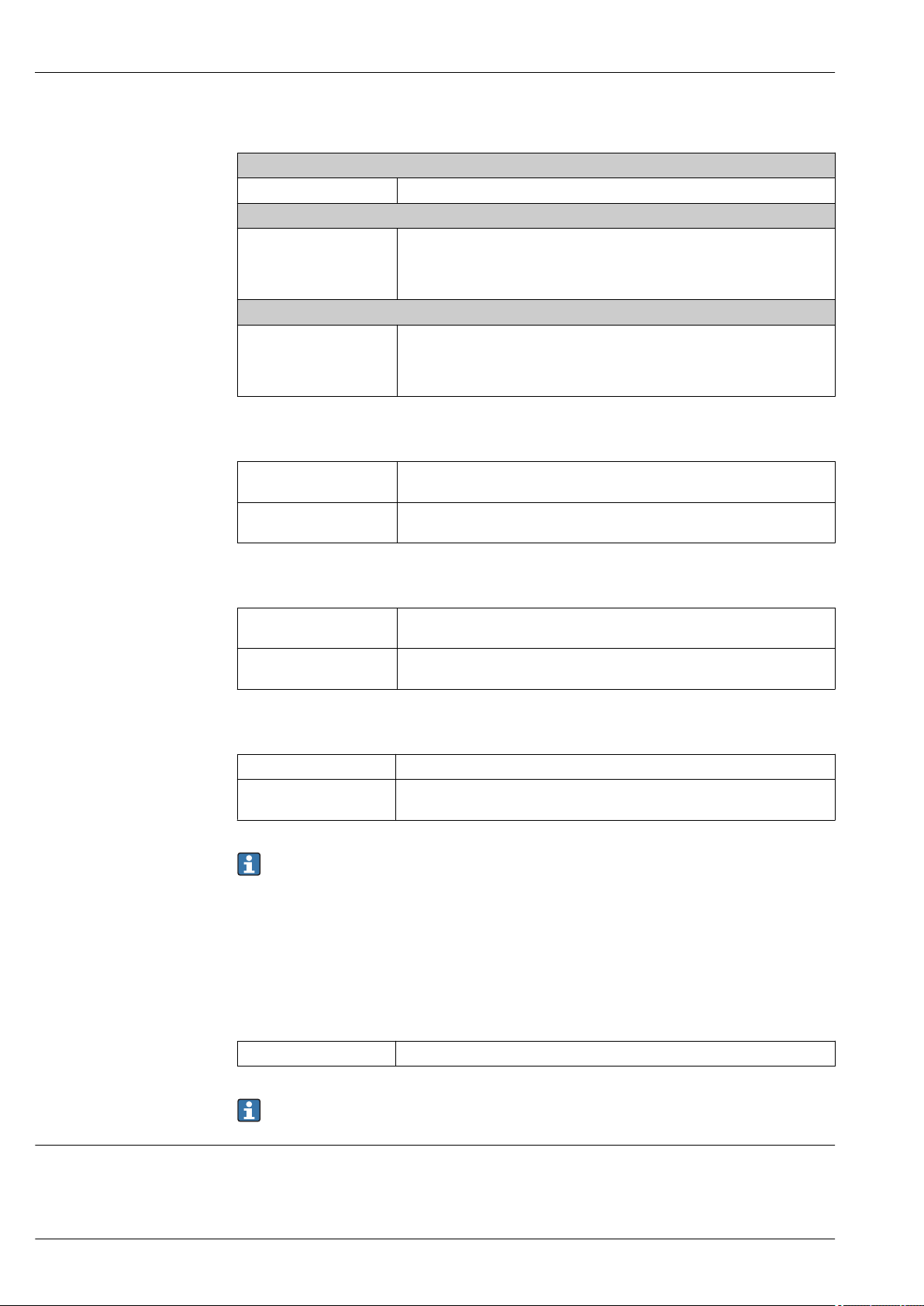

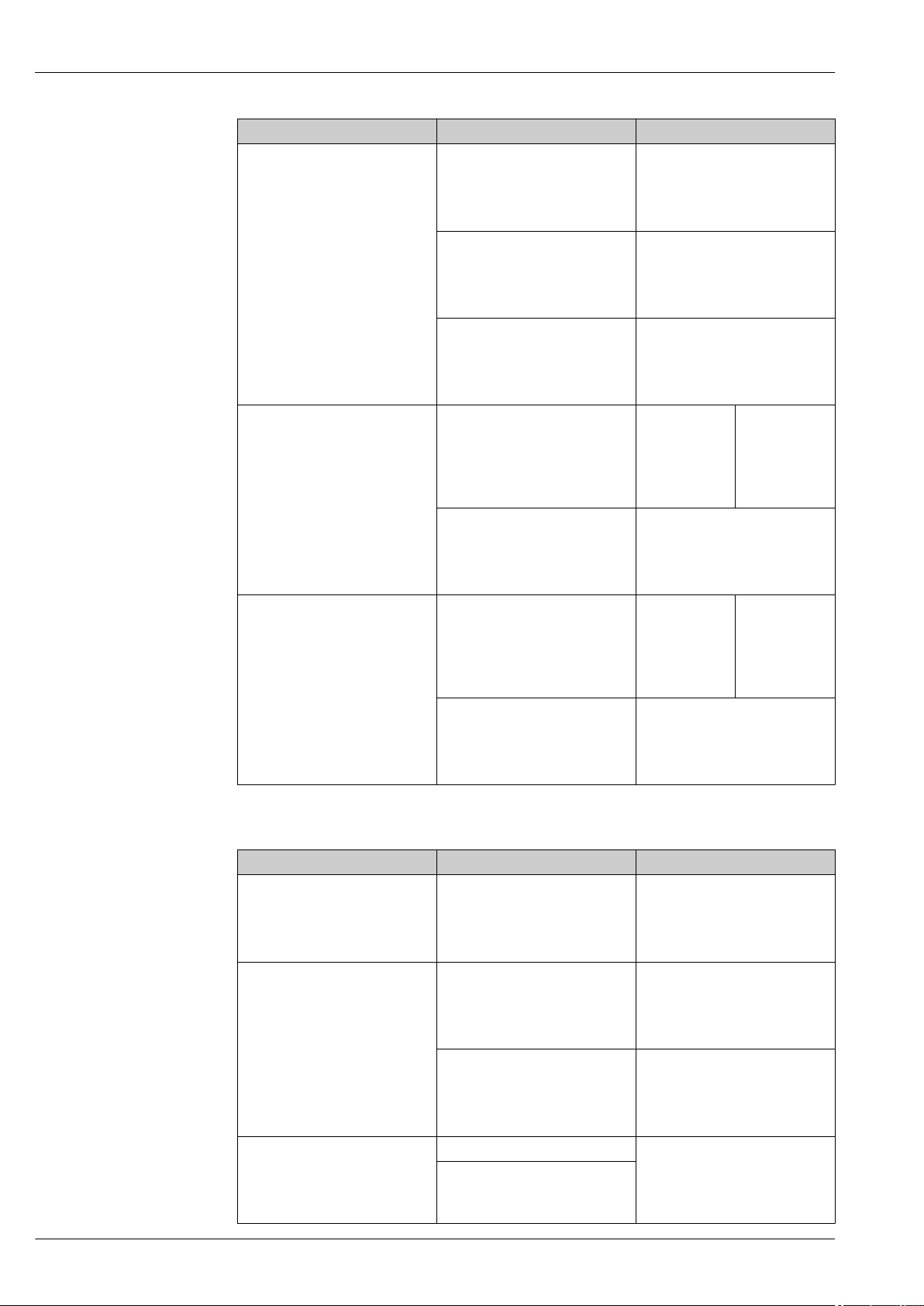

Measured variable Direct measured variables

Order code for "Sensor version; DSC sensor; measuring tube"

Option Description Measured variable

AA Volume; 316L; 316L Volume flow

AB Volume; Alloy C22; 316L

AC Volume; Alloy C22; Alloy C22

BA Volume high-temperature; 316L; 316L

BB Volume high-temperature; Alloy C22; 316L

Order code for "Sensor version; DSC sensor; measuring tube"

Option Description Measured variable

CA Mass; 316L; 316L (integrated temperature measurement) • Volume flow

CB Mass; Alloy ; C22; 316L (integrated temperature measurement)

CC Mass; Alloy C22; Alloy C22 (integrated temperature measurement)

• Temperature

The "mass" sensor version (integrated pressure/temperature measurement) is available only for

measuring devices in the HART communication mode.

Order code for "Sensor version; DSC sensor; measuring tube"

Option Description Measured variable

DA Mass steam; 316L; 316L (integrated pressure/temperature measurement) • Volume flow

DB Mass gas/liquid; 316L; 316L (integrated pressure/temperature measurement),

• Temperature

• Pressure

Calculated measured variables

Order code for "Sensor version; DSC sensor; measuring tube"

Option Description Measured variable

AA Volume; 316L; 316L Under constant process conditions:

AB Volume; Alloy C22; 316L

AC Volume; Alloy C22; Alloy C22

BA Volume high-temperature; 316L; 316L

BB Volume high-temperature; Alloy C22; 316L

1) A fixed density must be entered for calculating the mass flow (Setup menu → Advanced setup submenu →

External compensation submenu → Fixed density parameter).

• Mass flow

• Corrected volume flow

The totalized values for:

• Volume flow

• Mass flow

• Corrected volume flow

1)

Order code for "Sensor version; DSC sensor; measuring tube"

Option Description Measured variable

CA Mass; 316L; 316L (integrated temperature measurement) • Corrected volume flow

CB Mass; Alloy C22; 316L (integrated temperature

measurement)

CC Mass; Alloy C22; Alloy C22 (integrated temperature

measurement)

• Mass flow

• Calculated saturated steam pressure

• Energy flow

• Heat flow difference

• Specific volume

• Degrees of superheat

Endress+Hauser 9

Page 10

Proline Prowirl F 200

Order code for "Sensor version; DSC sensor; measuring tube"

Option Description Measured variable

DA Mass steam; 316L; 316L (integrated pressure/temperature

measurement)

DB Mass gas/liquid; 316L; 316L (integrated pressure/

temperature measurement)

Order code for "Sensor version", option "mass flow (integrated temperature measurement)" combined

with order code for "Application package"

Option Description Measured variable

EU Wet steam measurement • Steam quality

• Total mass flow

• Condensate mass flow

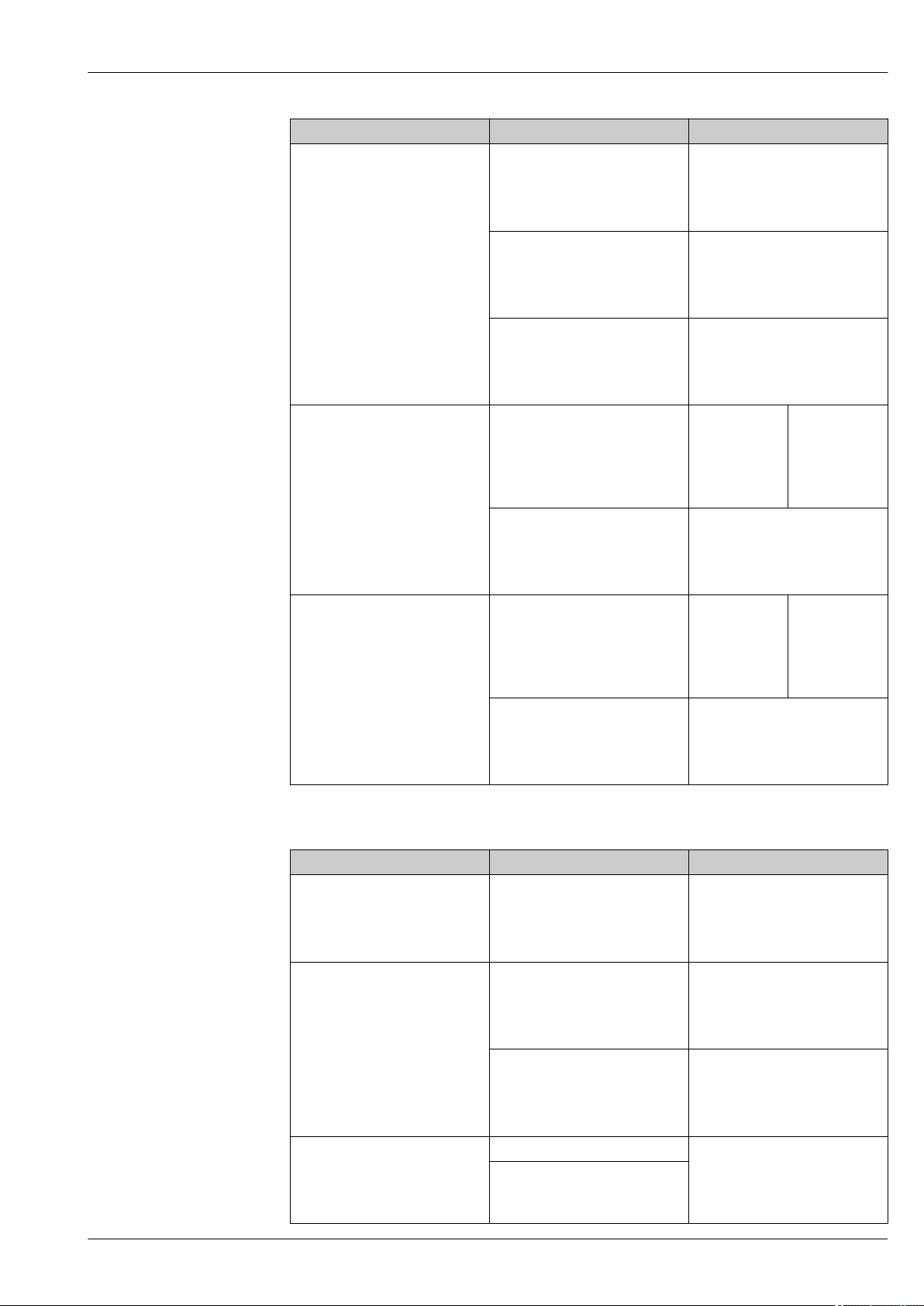

Measuring range

The measuring range is dependent on the nominal diameter, the fluid and environmental influences.

The following specified values are the largest possible flow measuring ranges (Q

min

to Q

max

) for

each nominal diameter. Depending on the fluid properties and environmental influences, the

measuring range may be subject to additional restrictions. Additional restrictions apply to both

the lower range value and the upper range value.

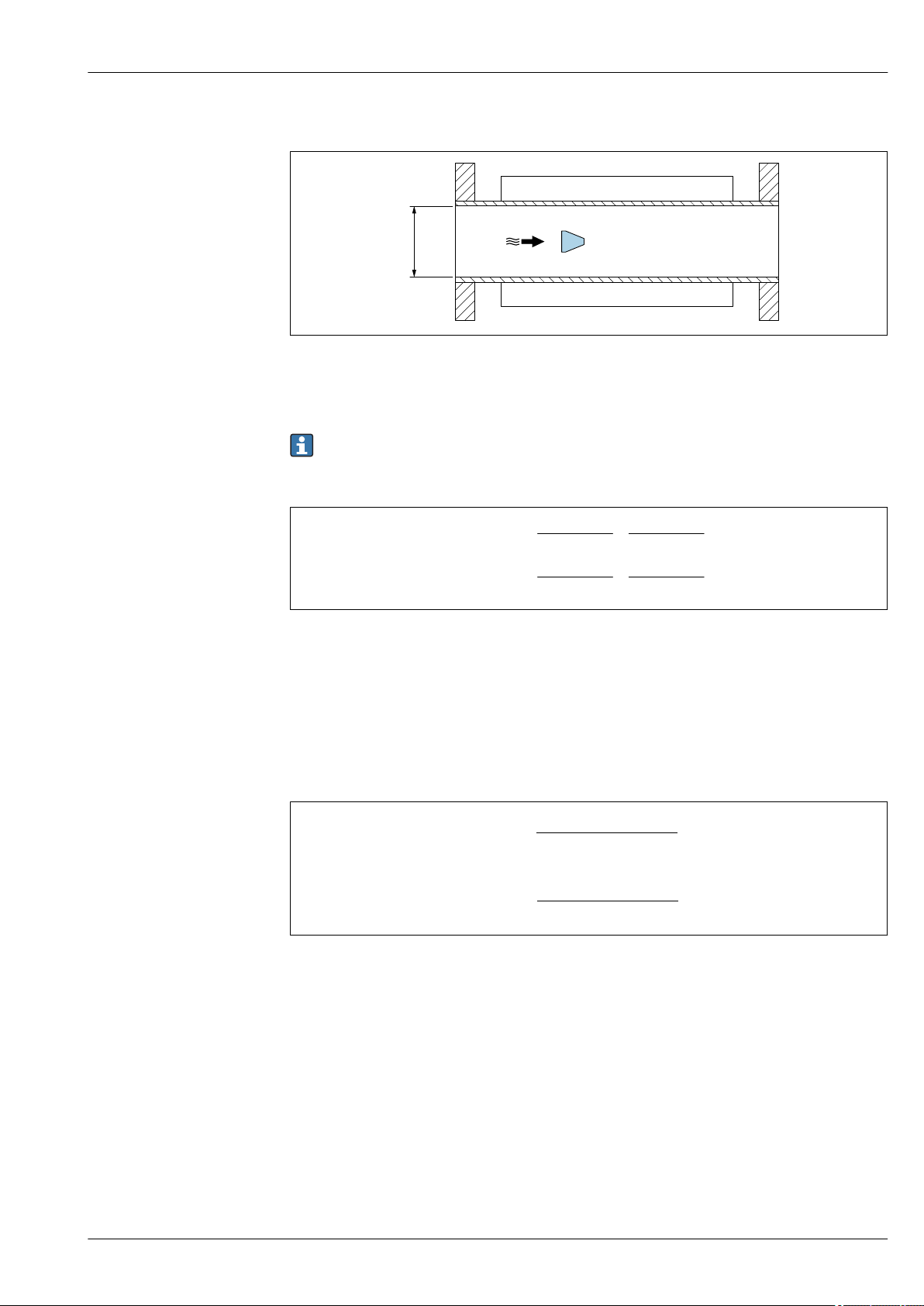

Flow measuring ranges in SI units

DN

[mm]

15 0.076 to 4.9 0.39 to 25

25 0.23 to 15 1.2 to 130

40 0.57 to 37 2.9 to 310

50 0.96 to 62 4.9 to 820

80 2.2 to 140 11 to 1 800

100 3.7 to 240 19 to 3 200

150 8.5 to 540 43 to 7 300

200 15 to 950 75 to 13 000

250 23 to 1 500 120 to 20 000

300 33 to 2 100 170 to 28 000

Liquids

[m³/h]

Gas/steam

[m³/h]

Flow measuring ranges in US units

DN Liquids Gas/steam

[in] [ft³/min] [ft³/min]

½ 0.045 to 2.9 0.23 to 15

1 0.14 to 8.8 0.7 to 74

1½ 0.34 to 22 1.7 to 180

2 0.56 to 36 2.9 to 480

3 1.3 to 81 6.4 to 1 100

4 2.2 to 140 11 to 1 900

6 5 to 320 25 to 4 300

8 8.7 to 560 44 to 7 500

10 14 to 880 70 to 12 000

12 19 to 1 300 99 to 17 000

10 Endress+Hauser

Page 11

Proline Prowirl F 200

D

i

v,Q

v [m/s] =

4 · Q [m /h]³

π · D [m]i²

·

1

3600 [s/h]

v [!/s] =

4 · Q [ /min]ft³

π · D [ft]i²

·

1

60 [s/min]

Re

=

4 · Q [m³/s] · [kg/m³]ρ

· D [m] · µ [Pa · s]π

i

Re

=

4 · Q [ft³/s] · [lbm/ft³]ρ

· D [ft] · µ [lbf · s/ft ]π

i

²

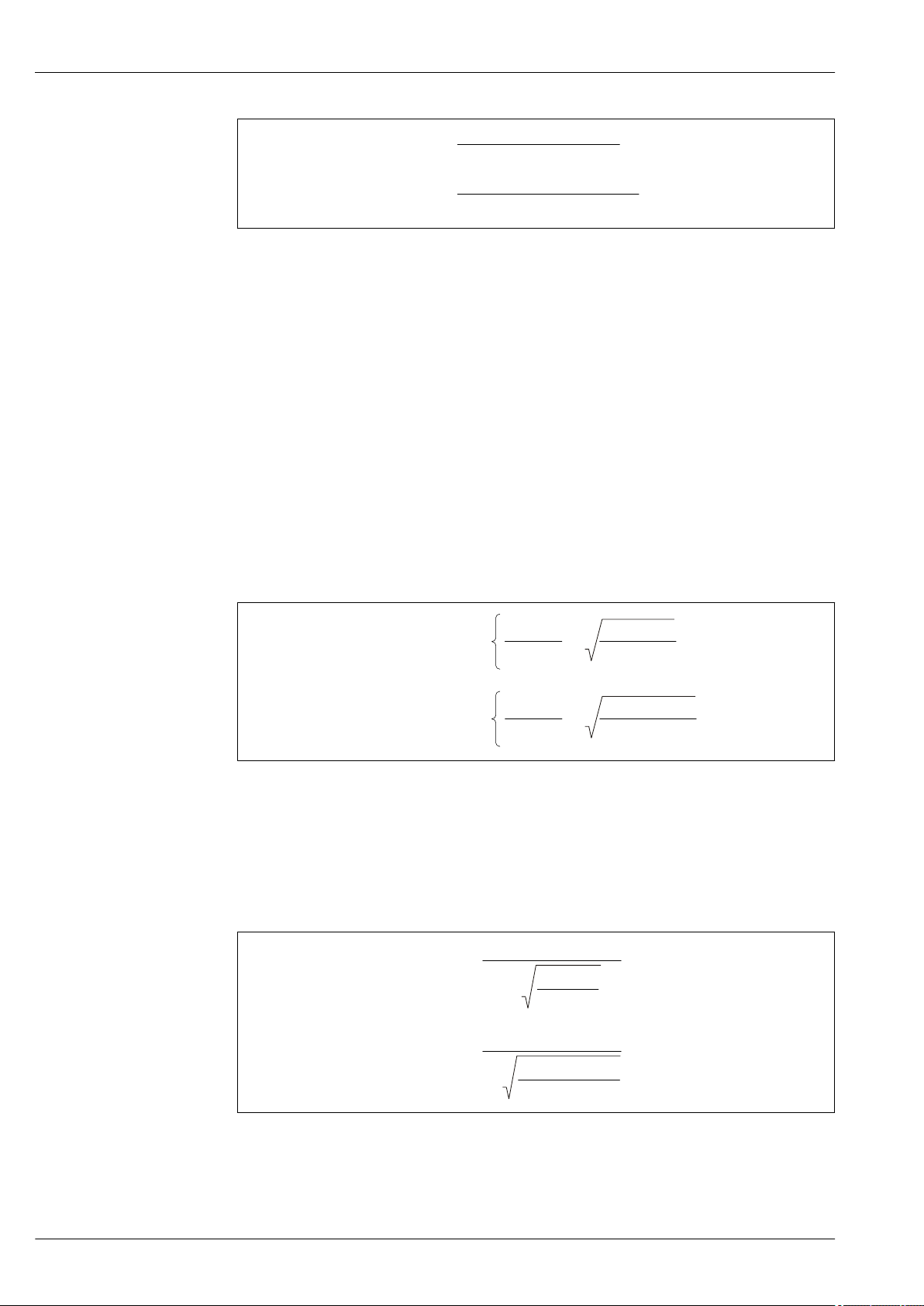

Flow velocity

A0033468

DiInternal diameter of measuring tube (corresponds to dimension K→ 55)

v Velocity in measuring tube

Q Flow

The internal diameter of measuring tube Di is denoted in the dimensions as dimension

K.→ 55.

Calculation of flow velocity:

A0034301

Lower range value

A restriction applies to the lower range value due to the turbulent flow profile, which only occurs

with Reynolds numbers greater than 5 000. The Reynolds number is dimensionless and indicates the

ratio of the inertia force of a fluid to its viscous force when flowing and is used as a characteristic

variable for pipe flows. In the case of pipe flows with Reynolds numbers less than 5 000, periodic

vortices are no longer generated and flow rate measurement is no longer possible.

The Reynolds number is calculated as follows:

A0034291

Re Reynolds number

Q Flow

D

i

µ Dynamic viscosity

ρ Density

Internal diameter of measuring tube (corresponds to dimension K→ 55)

The Reynolds number, 5 000 together with the density and viscosity of the fluid and the nominal

diameter, is used to calculate the corresponding flow rate.

Endress+Hauser 11

Page 12

Proline Prowirl F 200

Q [m /h] =

Re = 5000

³

5000 [Pa· · D [m] · · s]

i

π μ

· 3600 [s/h]

4 [kg/m ]· ³ρ

Q [ /h] =

Re = 5000

!³

5000 [lbf· · D [ft] · · s/ft ]i²π μ

· 60 [s/min]

4 [lbm/ ]· !³ρ

v [m/s] = max

AmpMin

mf [m/s]

x²

v [!/s] = max

AmpMin

mf [!/s]

x²

0.062 [lb/! ]³

ρ [lb/!]³

1 [kg/ ]m³

ρ [kg/ ]m³

⋅

⋅

Q [m /h] =

AmpMin

³

v [m/s]

AmpMin

· · D [m]i²π

· 3600 [s/h]

4 ·

ρ [kg/m ]³

1 [kg/m ]³

Q [ /min] =

AmpMin

!³

v [!/s]

AmpMin

· · D [ft]i²π

· 60 [s/min]

4 ·

ρ [lbm/ ]#³

0.0624 [lbm/ ]!³

A0034302

Q

Re = 5000

D

i

µ Dynamic viscosity

ρ Density

Flow rate is dependent on the Reynolds number

Internal diameter of measuring tube (corresponds to dimension K→ 55)

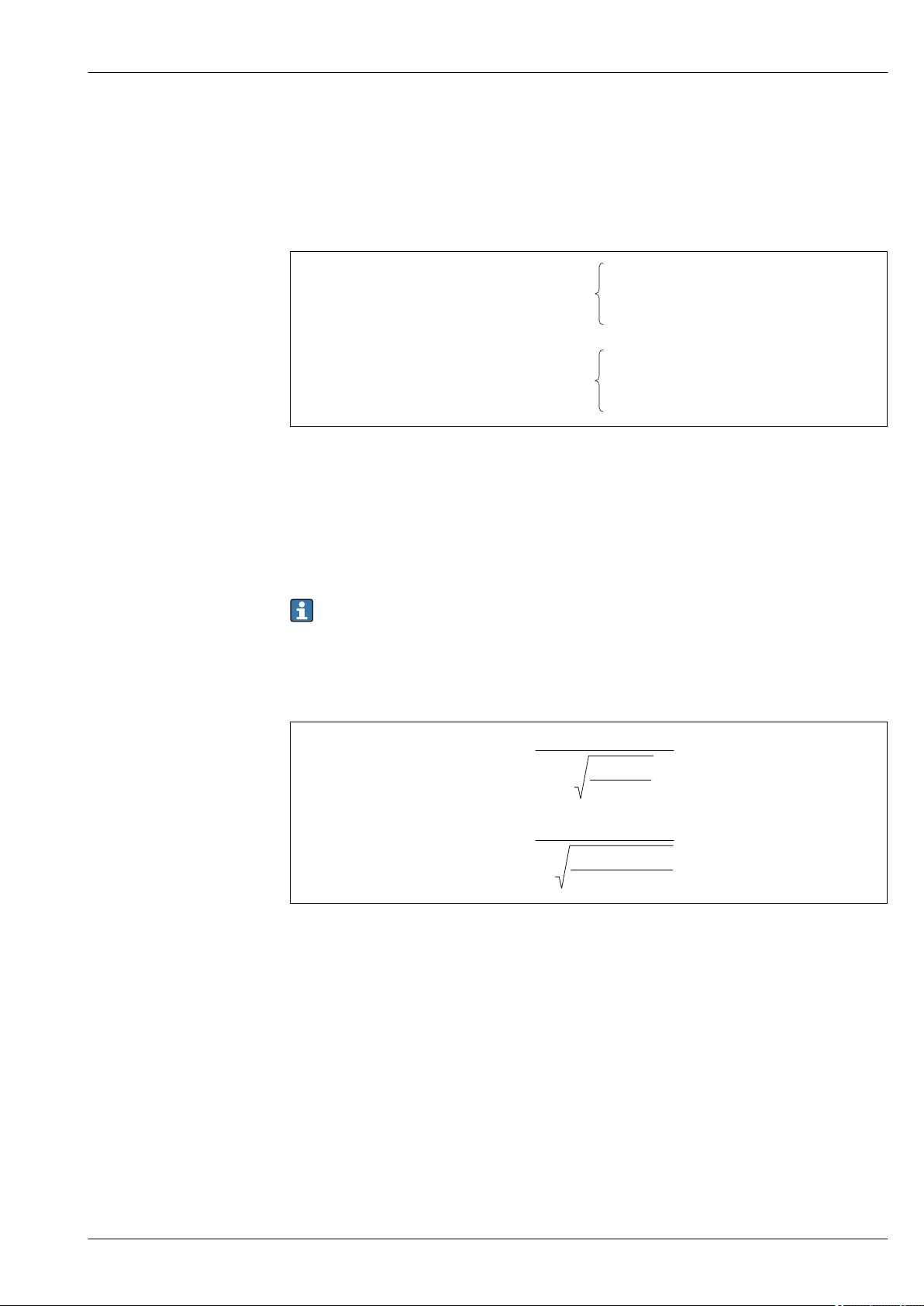

The measuring signal must have a certain minimum signal amplitude so that the signals can be

evaluated without any errors. Using the nominal diameter, the corresponding flow can also be

derived from this amplitude. The minimum signal amplitude depends on the setting for the

sensitivity of the DSC sensor (s), the steam quality (x) and the force of the vibrations present (a). The

value mf corresponds to the lowest measurable flow velocity without vibration (no wet steam) at a

density of 1 kg/m3 (0.0624 lbm/ft^3). The value mf can be set in the range from

6 to 20 m/s (1.8 to 6 ft/s) (factory setting 12 m/s (3.7 ft/s)) with the Sensitivity parameter (value

range 1 to 9, factory setting 5).

The lowest flow velocity that can be measured on account of the signal amplitude v

AmpMin

is derived

from the Sensitivity parameter and the steam quality (x) or from the force of vibrations present (a).

v

AmpMin

mf Sensitivity

x Steam quality

ρ Density

12 Endress+Hauser

Q

AmpMin

v

AmpMin

Minimum measurable flow velocity based on signal amplitude

Minimum measurable flow rate based on signal amplitude

Minimum measurable flow velocity based on signal amplitude

A0034303

A0034304

Page 13

Proline Prowirl F 200

Q [m /h] = max

Low

³

Q [m /h]

min

³

Q [m /h]

Re = 5000

³

Q [m /h]

AmpMin

³

Q [! /min] = max

Low

³

Q [ /min]

min

!³

Q [ /min]

Re = 5000

!³

Q [ /min]

AmpMin

!³

Q [m /h] =

AmpMax

³

350[m/s] · · D [m]i²π

· 3600 [s/h]

4 ·

ρ [kg/m ]³

1 [kg/m ]³

Q [ /min] =

AmpMax

!³

1148[!/s] · · D [ft]i²π

· 60 [s/min]

4 ·

ρ [lbm/ ]#³

0.0624 [lbm/ ]!³

D

i

Internal diameter of measuring tube (corresponds to dimension K→ 55)

ρ Density

The effective lower range value Q

5000

Q

Low

Q

min

Q

Re = 5000

Q

AmpMin

and Q

.

AmpMin

Effective lower range value

Minimum measurable flow rate

Flow rate is dependent on the Reynolds number

Minimum measurable flow rate based on signal amplitude

is determined using the largest of the three values Q

Low

min

, Q

Re =

A0034313

The Applicator is available for calculation purposes.

Upper range value

The measuring signal amplitude must be below a certain limit value to ensure that the signals can be

evaluated without error. This results in a maximum permitted flow rate Q

Q

AmpMax

D

i

ρ Density

Maximum measurable flow rate based on signal amplitude

Internal diameter of measuring tube (corresponds to dimension K→ 55)

AmpMax

:

A0034316

Endress+Hauser 13

For gas applications, an additional restriction applies to the upper range value with regard to the

Mach number in the measuring device, which must be less than 0.3. The Mach number Ma describes

the ratio of the flow velocity v to the sound velocity c in the fluid.

Page 14

Ma =

v [m/s]

c [m/s]

Ma =

v [!/s]

c [!/s]

Ma Mach number

Q [m /h] =

Ma = 0.3

³

0.3 · c [m/s] · · D [m]i²

π

4

· 3600 [s/h]

Q [ /min] =

Ma = 0.3

!³

0.3 · c [ft/s] · · D [ft]i²

π

4

· 60 [s/min]

Q [m /h] = min

High

³

Q [m /h]

max

³

Q [m /h]

AmpMax

³

Q [m /h]

Ma = 0.3

³

Q [! /min] = min

High

³

Q [ /min]

max

!³

Q [ /min]

AmpMax

!³

Q [ /min]

Ma = 0.3

!³

v

Flow velocity

c Sound velocity

The corresponding flow rate can be derived using the nominal diameter.

Proline Prowirl F 200

A0034321

Q

Ma = 0.3

Restricted upper range value is dependent on Mach number

c Sound velocity

D

i

Internal diameter of measuring tube (corresponds to dimension K→ 55)

ρ Density

The effective upper range value Q

Q

AmpMax

Q

High

Q

max

Q

AmpMax

Q

Ma = 0.3

and Q

Ma=0.3

.

Effective upper range value

Maximum measurable flow rate

Maximum measurable flow rate based on signal amplitude

Restricted upper range value is dependent on Mach number

is determined using the smallest of the three values Q

High

max

A0034337

,

A0034338

For liquids, the occurrence of cavitation may also restrict the upper range value.

The Applicator is available for calculation purposes.

Operable flow range

14 Endress+Hauser

The value, which is typically up to 49: 1, may vary depending on the operating conditions (ratio

between upper range value and lower range value)

Page 15

Proline Prowirl F 200

Input signal Current input

Current input 4-20 mA (passive)

Resolution 1 µA

Voltage drop Typically: 2.2 to 3 V for 3.6 to 22 mA

Maximum voltage ≤ 35 V

Possible input variables • Pressure

External measured values

To increase the accuracy of certain measured variables or to calculate the corrected volume flow, the

automation system can continuously write different measured values to the measuring device:

• Operating pressure to increase accuracy (Endress+Hauser recommends the use of a pressure

measuring device for absolute pressure, e.g. Cerabar M or Cerabar S)

• Medium temperature to increase accuracy (e.g. iTEMP)

• Reference density for calculating the corrected volume flow

• Various pressure measuring devices can be ordered as accessories from Endress+Hauser.

• If using pressure measuring devices, pay attention to outlet runs when installing external

devices→ 46.

If the measuring device does not have pressure or temperature compensation

that external pressure measurement values be read in so that the following measured variables can

be calculated:

• Energy flow

• Mass flow

• Corrected volume flow

• Temperature

• Density

2)

, it is recommended

Integrated pressure and temperature measurement

The measuring device can also directly record external variables for density and energy

compensation.

This product version offers the following benefits:

• Measurement of pressure, temperature and flow in a true 2-wire version

• Recording of pressure and temperature at the same point, thus ensuring maximum accuracy of

density and energy compensation.

• Continuous monitoring of pressure and temperature, thus enabling complete integration in

Heartbeat.

• Easy testing of pressure measurement accuracy:

• Application of pressure by pressure calibration unit, followed by input into measuring device

• Automatic error correction performed by device in the event of a deviation

• Availability of calculated line pressure.

Current input

The measured values are written from the automation system to the measuring device via the

current input → 15.

HART protocol

The measured values are written from the automation system to the measuring device via the HART

protocol. The pressure transmitter must support the following protocol-specific functions:

• HART protocol

• Burst mode

Digital communication

The measured values can be written from the automation system to the measuring via:

• FOUNDATION Fieldbus

• PROFIBUS PA

2) Order code for "Sensor option", option DA, DB

Endress+Hauser 15

Page 16

Output

Output signal Current output

Current output 1 4-20 mA HART (passive)

Current output 2 4-20 mA (passive)

Resolution < 1 µA

Damping Adjustable: 0.0 to 999.9 s

Assignable measured

variables

Proline Prowirl F 200

• Volume flow

• Corrected volume flow

• Mass flow

• Flow velocity

• Temperature

• Pressure

• Calculated saturated steam pressure

• Steam quality

• Total mass flow

• Energy flow

• Heat flow difference

Pulse/frequency/switch output

Function Can be set to pulse, frequency or switch output

Version Passive, open collector

Maximum input values • DC 35 V

• 50 mA

For information on the Ex connection values → 19

Voltage drop • For ≤ 2 mA: 2 V

• For 10 mA: 8 V

Residual current ≤ 0.05 mA

Pulse output

Pulse width Adjustable: 5 to 2 000 ms

Maximum pulse rate 100 Impulse/s

Pulse value Adjustable

Assignable measured

variables

Frequency output

Output frequency Adjustable: 0 to 1 000 Hz

Damping Adjustable: 0 to 999 s

Pulse/pause ratio 1:1

Assignable measured

variables

• Mass flow

• Volume flow

• Corrected volume flow

• Total mass flow

• Energy flow

• Heat flow difference

• Volume flow

• Corrected volume flow

• Mass flow

• Flow velocity

• Temperature

• Calculated saturated steam pressure

• Steam quality

• Total mass flow

• Energy flow

• Heat flow difference

• Pressure

16 Endress+Hauser

Page 17

Proline Prowirl F 200

Switch output

Switching behavior Binary, conductive or non-conductive

Switching delay Adjustable: 0 to 100 s

Number of switching

cycles

Assignable functions • Off

Unlimited

• On

• Diagnostic behavior

• Limit value

• Volume flow

• Corrected volume flow

• Mass flow

• Flow velocity

• Temperature

• Calculated saturated steam pressure

• Steam quality

• Total mass flow

• Energy flow

• Heat flow difference

• Pressure

• Reynolds number

• Totalizer 1-3

• Status

• Status of low flow cut off

Signal on alarm

FOUNDATION Fieldbus

FOUNDATION Fieldbus H1, IEC 61158-2, galvanically isolated

Data transfer 31.25 kbit/s

Current consumption 15 mA

Permitted supply voltage 9 to 32 V

Bus connection With integrated reverse polarity protection

PROFIBUS PA

PROFIBUS PA In accordance with EN 50170 Volume 2, IEC 61158-2 (MBP), galvanically

isolated

Data transmission 31.25 kbit/s

Current consumption 16 mA

Permitted supply voltage 9 to 32 V

Bus connection With integrated reverse polarity protection

Depending on the interface, failure information is displayed as follows:

Current output 4 to 20 mA

4 to 20 mA

Failure mode Choose from:

• 4 to 20 mA in accordance with NAMUR recommendation NE 43

• 4 to 20 mA in accordance with US

• Min. value: 3.59 mA

• Max. value: 22.5 mA

• Freely definable value between: 3.59 to 22.5 mA

• Actual value

• Last valid value

Endress+Hauser 17

Page 18

Pulse/frequency/switch output

Pulse output

Failure mode No pulses

Frequency output

Failure mode Choose from:

• Actual value

• 0 Hz

• Defined value: 0 to 1 250 Hz

Switch output

Failure mode Choose from:

• Current status

• Open

• Closed

FOUNDATION Fieldbus

Proline Prowirl F 200

Status and alarm

messages

Failure current FDE (Fault

Disconnection Electronic)

Diagnostics in accordance with FF-891

0 mA

PROFIBUS PA

Status and alarm

messages

Failure current FDE (Fault

Disconnection Electronic)

Diagnostics in accordance with PROFIBUS PA Profile 3.02

0 mA

Local display

Plain text display With information on cause and remedial measures

Backlight Additionally for device version with SD03 local display: red lighting indicates a

device error.

Status signal as per NAMUR recommendation NE 107

Interface/protocol

• Via digital communication:

• HART protocol

• FOUNDATION Fieldbus

• PROFIBUS PA

• Via service interface

CDI service interface

Plain text display With information on cause and remedial measures

Additional information on remote operation → 85

Load

Load for current output: 0 to 500 Ω, depending on the external supply voltage of the power supply

unit

18 Endress+Hauser

Page 19

Proline Prowirl F 200

0

100

200

300

400

500

16 18 20

22 24

26 28 30 32

U [V]

S

RB[Ω]

34 36

A B

Calculation of the maximum load

Depending on the supply voltage of the power supply unit (US), the maximum load (RB) including

line resistance must be observed to ensure adequate terminal voltage at the device. In doing so,

observe the minimum terminal voltage

• For US = 17.9 to 18.9 V: RB ≤ (US - 17.9 V): 0.0036 A

• For US = 18.9 to 24 V: RB ≤ (US - 13 V): 0.022 A

• For US = ≥ 24 V: RB ≤ 500 Ω

A Operating range for order code for "Output", option A "4-20 mA HART"/option B "4-20 mA HART, pulse/

frequency/switch output" with Ex i and option C "4-20 mA HART + 4-20 mA analog"

B Operating range for order code for "Output", option A "4-20 mA HART"/option B "4-20 mA HART, pulse/

frequency/switch output" with non-Ex and Ex d

Sample calculation

Supply voltage of power supply unit: US =19 V

Maximum load: RB ≤ (19 V - 13 V): 0.022 A = 273 Ω

Ex connection data Safety-related values

Type of protection Ex d

Order code for "Output" Output type Safety-related values

Option A 4-20mA HART U

Option B 4-20mA HART U

Option C 4-20mA HART

Option D 4-20mA HART U

Option E FOUNDATION Fieldbus U

Pulse/frequency/switch output U

4-20mA analog

Pulse/frequency/switch output U

4 to 20 mA current input U

Pulse/frequency/switch output U

nom

U

max

nom

U

max

nom

U

max

P

max

U

nom

U

max

nom

U

max

nom

U

max

P

max

nom

U

max

nom

U

max

P

max

nom

U

max

P

max

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 30 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 35 V

= 250 V

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

A0013563

Endress+Hauser 19

Page 20

Proline Prowirl F 200

Order code for "Output" Output type Safety-related values

Option G PROFIBUS PA U

Pulse/frequency/switch output U

1) Internal circuit limited by Ri = 760.5 Ω

Type of protection Ex ec Ex nA

Order code for "Output" Output type Safety-related values

Option A 4-20mA HART U

Option B 4-20mA HART U

Pulse/frequency/switch output U

Option C 4-20mA HART

4-20mA analog

Option D 4-20mA HART U

Pulse/frequency/switch output U

4 to 20 mA current input U

Option E FOUNDATION Fieldbus U

Pulse/frequency/switch output U

Option G PROFIBUS PA U

Pulse/frequency/switch output U

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

nom

U

max

nom

U

max

P

max

U

nom

U

max

nom

U

max

nom

U

max

P

max

nom

U

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 30 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= 1 W

= DC 35 V

= 250 V

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

= 1 W

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

= 1 W

1) Internal circuit limited by Ri = 760.5 Ω

Type of protection XP

Order code for "Output" Output type Safety-related values

Option A 4-20mA HART U

Option B 4-20mA HART U

Pulse/frequency/switch output U

Option C 4-20mA HART U

nom

U

max

nom

U

max

nom

U

max

P

max

nom

U

max

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 30 V

= 250 V

20 Endress+Hauser

Page 21

Proline Prowirl F 200

Order code for "Output" Output type Safety-related values

4-20mA analog

Option D 4-20mA HART U

Pulse/frequency/switch output U

4 to 20 mA current input U

Option E FOUNDATION Fieldbus U

Pulse/frequency/switch output U

Option G PROFIBUS PA U

Pulse/frequency/switch output U

nom

U

max

nom

U

max

P

max

nom

U

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 35 V

= 250 V

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

1) Internal circuit limited by Ri = 760.5 Ω

Intrinsically safe values

Type of protection Ex ia

Order code for "Output" Output type Intrinsically safe values

Option A 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option B 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 6 nF

Option C 4-20mA HART Ui = DC 30 V

4-20mA analog

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 30 nF

Endress+Hauser 21

Page 22

Proline Prowirl F 200

Order code for "Output" Output type Intrinsically safe values

Option D 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 6 nF

4 to 20 mA current input Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option E FOUNDATION Fieldbus STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

Option G PROFIBUS PA STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

Type of protection Ex ic

Order code for "Output" Output type Intrinsically safe values

Option A 4-20mA HART Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option B 4-20mA HART Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 6 nF

Option C 4-20mA HART Ui = DC 30 V

4-20mA analog

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 30 nF

22 Endress+Hauser

Page 23

Proline Prowirl F 200

Order code for "Output" Output type Intrinsically safe values

Option D 4-20mA HART Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 6 nF

4 to 20 mA current input Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option E FOUNDATION Fieldbus STANDARD

Ui = 32 V

li = 300 mA

Pi = n.a.

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 35 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

Option G PROFIBUS PA STANDARD

Ui = 32 V

li = 300 mA

Pi = n.a.

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 35 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

FISCO

Ui = 17.5 V

li = n.a.

Pi = n.a.

Li = 10 µH

Ci = 5 nF

FISCO

Ui = 17.5 V

li = n.a.

Pi = n.a.

Li = 10 µH

Ci = 5 nF

Type of protection IS

Order code for "Output" Output type Intrinsically safe values

Option A 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option B 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 6 nF

Option C 4-20mA HART Ui = DC 30 V

4-20mA analog

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 30 nF

Endress+Hauser 23

Page 24

Proline Prowirl F 200

Order code for "Output" Output type Intrinsically safe values

Option D 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 6 nF

4 to 20 mA current input Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option E FOUNDATION Fieldbus STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

Option G PROFIBUS PA STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

Low flow cut off

Galvanic isolation

The switch points for low flow cut off are preset and can be configured.

All inputs and outputs are galvanically isolated from one another.

Protocol-specific data HART

Manufacturer ID 0x11

Device type ID 0x0038

HART protocol revision 7

Device description files

(DTM, DD)

HART load • Min. 250 Ω

System integration For information on system integration, see Operating Instructions.→ 96

Information and files under:

www.endress.com

• Max. 500 Ω

• Measured variables via HART protocol

• Burst Mode functionality

24 Endress+Hauser

Page 25

Proline Prowirl F 200

FOUNDATION Fieldbus

Manufacturer ID 0x452B48

Ident number 0x1038

Device revision 2

DD revision Information and files under:

CFF revision

Device Tester Version (ITK

version)

ITK Test Campaign Number Information:

Link Master capability (LAS) Yes

Choice of "Link Master" and

"Basic Device"

Node address Factory setting: 247 (0xF7)

Supported functions The following methods are supported:

Virtual Communication Relationships (VCRs)

Number of VCRs 44

Number of link objects in VFD 50

Permanent entries 1

Client VCRs 0

Server VCRs 10

Source VCRs 43

Sink VCRs 0

Subscriber VCRs 43

Publisher VCRs 43

Device Link Capabilities

Slot time 4

Min. delay between PDU 8

Max. response delay Min. 5

System integration For information on system integration, see Operating Instructions.→ 96

• www.endress.com

• www.fieldbus.org

6.2.0

• www.endress.com

• www.fieldbus.org

Yes

Factory setting: Basic Device

• Restart

• ENP Restart

• Diagnostic

• Read events

• Read trend data

• Cyclic data transmission

• Description of the modules

• Execution times

• Methods

PROFIBUS PA

Manufacturer ID 0x11

Ident number 0x1564

Profile version 3.02

Device description files (GSD,

DTM, DD)

Information and files under:

• www.endress.com

• www.profibus.org

Endress+Hauser 25

Page 26

Supported functions • Identification & Maintenance

3 4 1 2

4

5 6

+ – + –+ –

123

Configuration of the device

address

System integration For information on system integration, see Operating Instructions.→ 96

Power supply

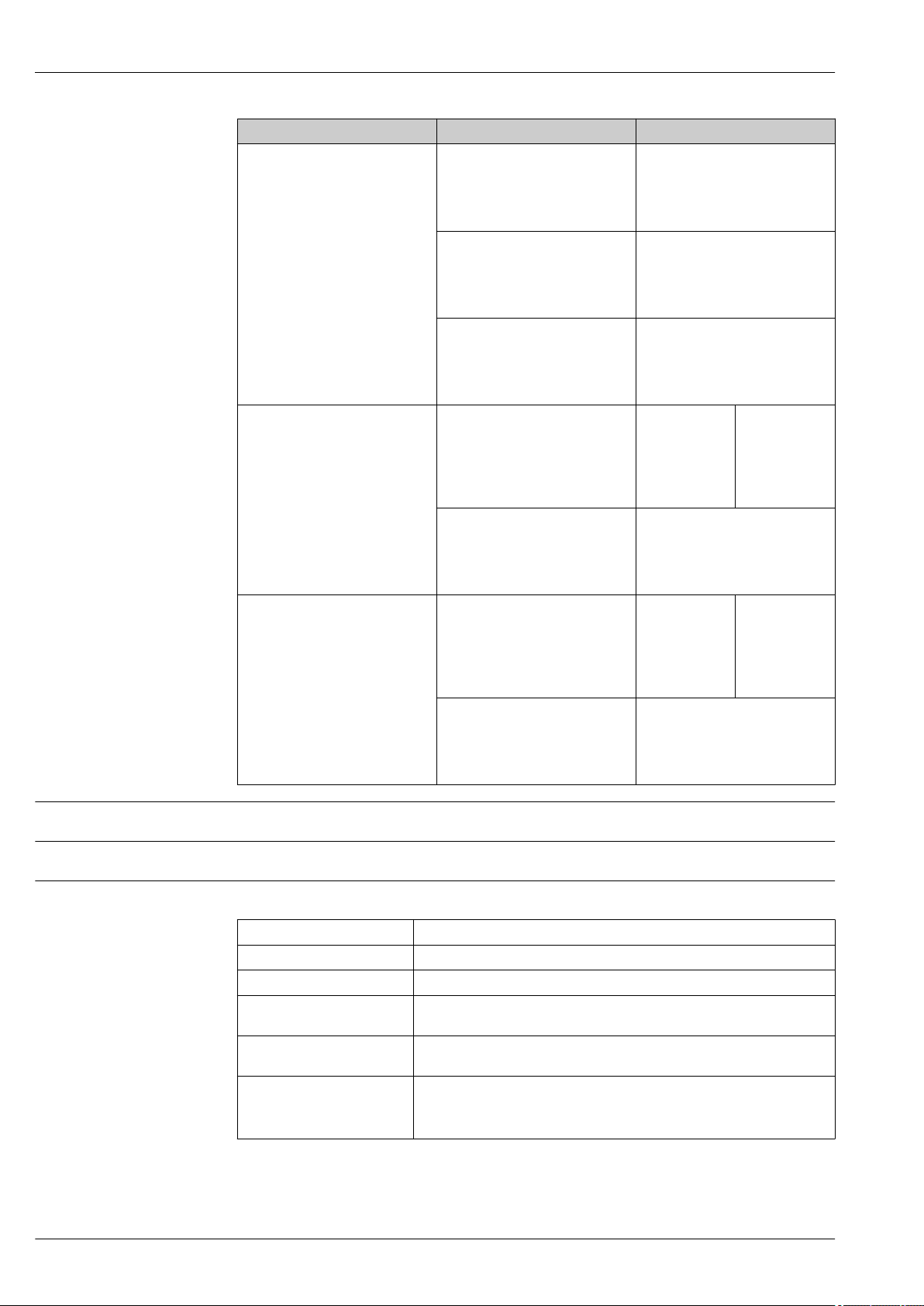

Terminal assignment Transmitter

Proline Prowirl F 200

Simple device identification via control system and nameplate

• PROFIBUS upload/download

Reading and writing parameters is up to ten times faster with PROFIBUS

upload/download

• Condensed status

Simplest and self-explanatory diagnostic information by categorizing

diagnostic messages that occur

• DIP switches on the I/O electronics module

• Local display

• Via operating tools (e. g. FieldCare)

• Cyclic data transmission

• Block model

• Description of the modules

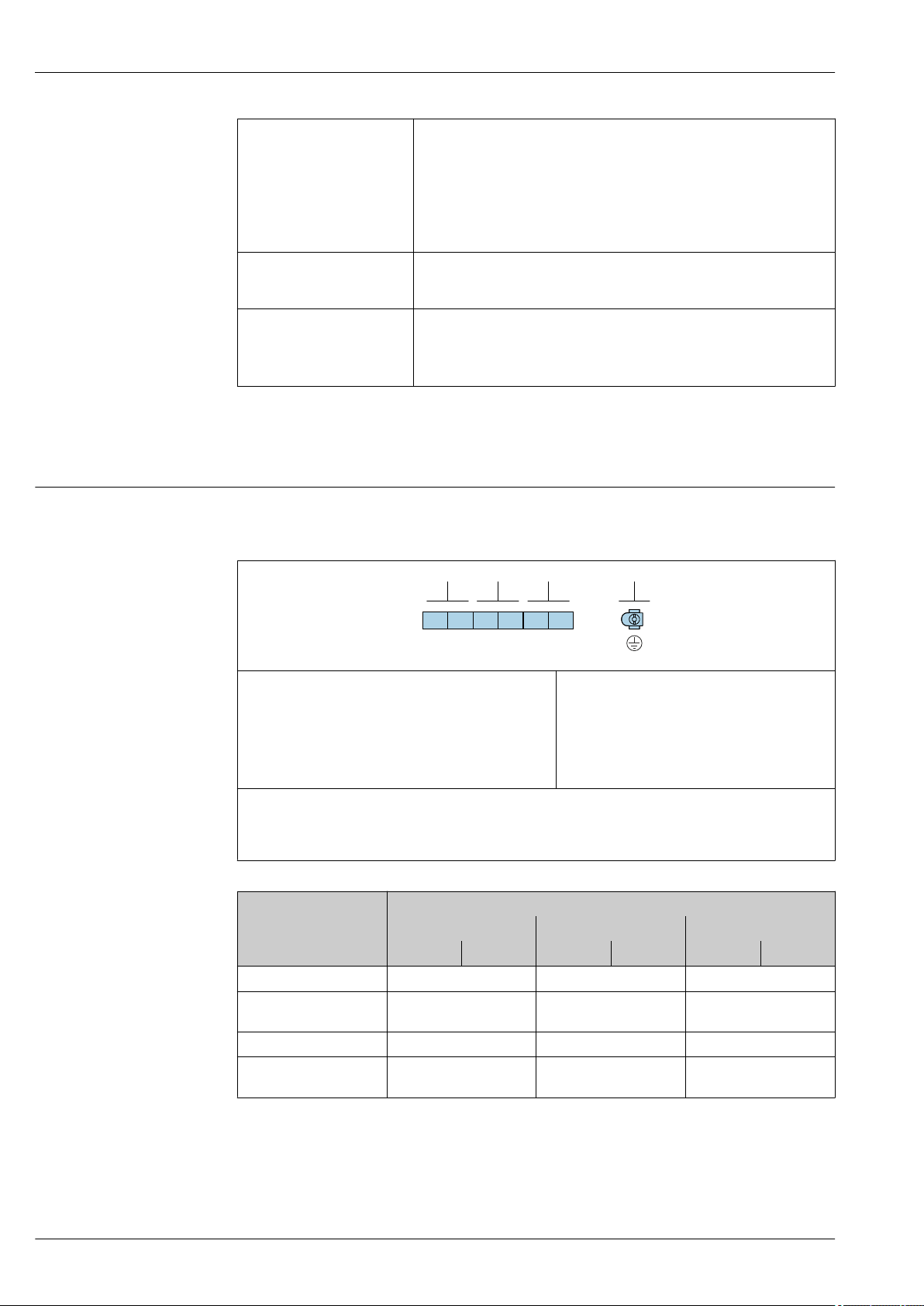

Connection versions

Maximum number of terminals

Terminals 1 to 6:

Without integrated overvoltage protection

1

Output 1 (passive): supply voltage and signal transmission

2

Output 2 (passive): supply voltage and signal transmission

3

Input (passive): supply voltage and signal transmission

4

Ground terminal for cable shield

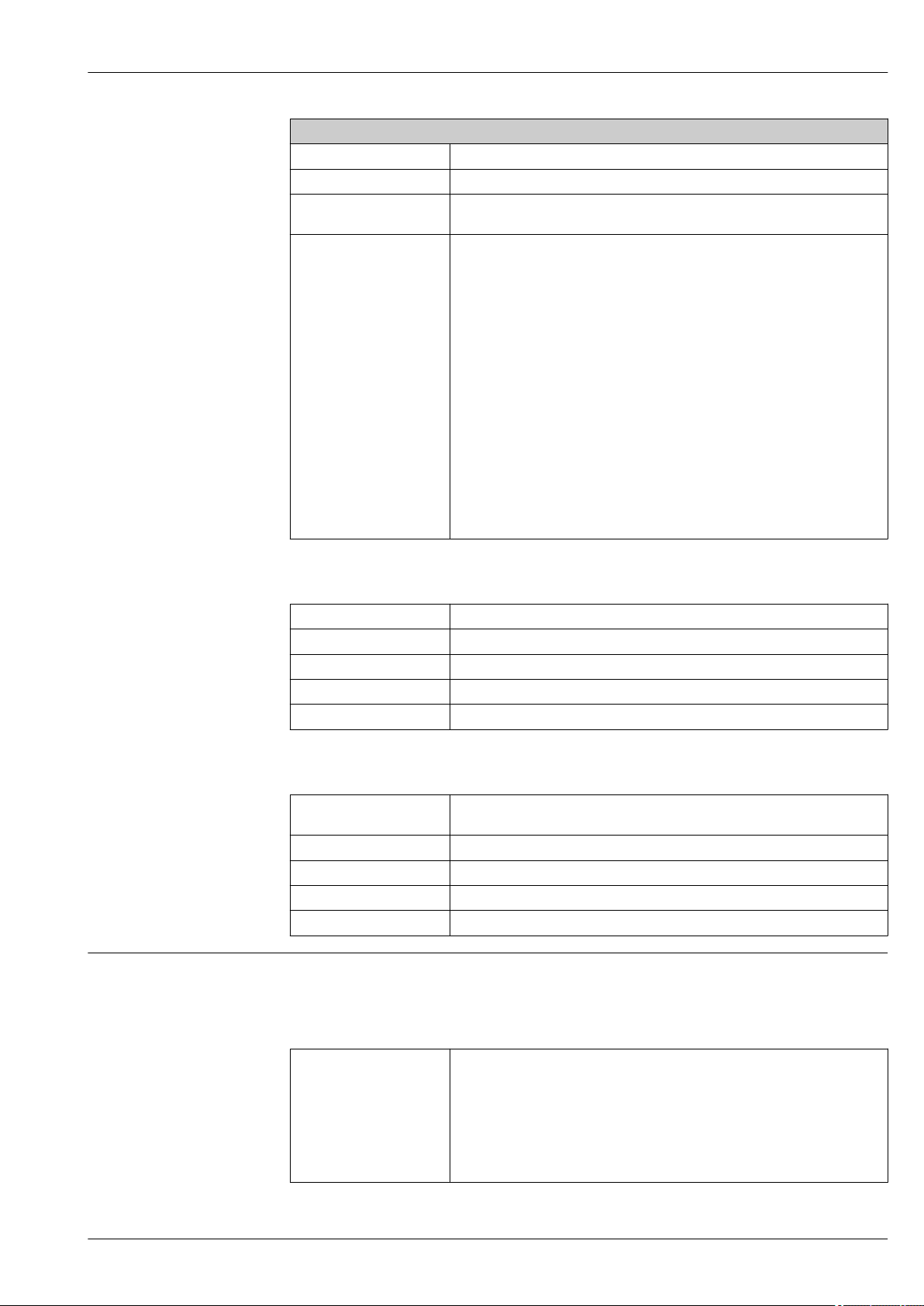

Order code for "Output" Terminal numbers

Output 1 Output 2 Input

1 (+) 2 (-) 3 (+) 4 (-) 5 (+) 6 (-)

Option A 4-20 mA HART (passive) - -

Option B

Option C

Option D

1)

1)

1) 2)

4-20 mA HART (passive)

4-20 mA HART (passive) 4-20 mA analog (passive) -

4-20 mA HART (passive)

Maximum number of terminals for order code for

"Accessory mounted", option NA "Overvoltage

protection"

• Terminals 1 to 4:

With integrated overvoltage protection

• Terminals 5 to 6:

Without integrated overvoltage protection

Pulse/frequency/switch

output (passive)

Pulse/frequency/switch

output (passive)

A0033475

-

4-20 mA current input

(passive)

26 Endress+Hauser

Page 27

Proline Prowirl F 200

+ –

+ –

2

1

1

2

1 2 3 4

1 2 3 4

GNYEWHBN

Order code for "Output" Terminal numbers

Output 1 Output 2 Input

1 (+) 2 (-) 3 (+) 4 (-) 5 (+) 6 (-)

Option E

Option G

1) Output 1 must always be used; output 2 is optional.

2) The integrated overvoltage protection is not used with option D: Terminals 5 and 6 (current input) are not

protected against overvoltage.

3) FOUNDATION Fieldbus with integrated reverse polarity protection.

4) PROFIBUS PA with integrated reverse polarity protection.

1) 3)

1) 4)

FOUNDATION Fieldbus

PROFIBUS PA

Pulse/frequency/switch

output (passive)

Pulse/frequency/switch

output (passive)

-

-

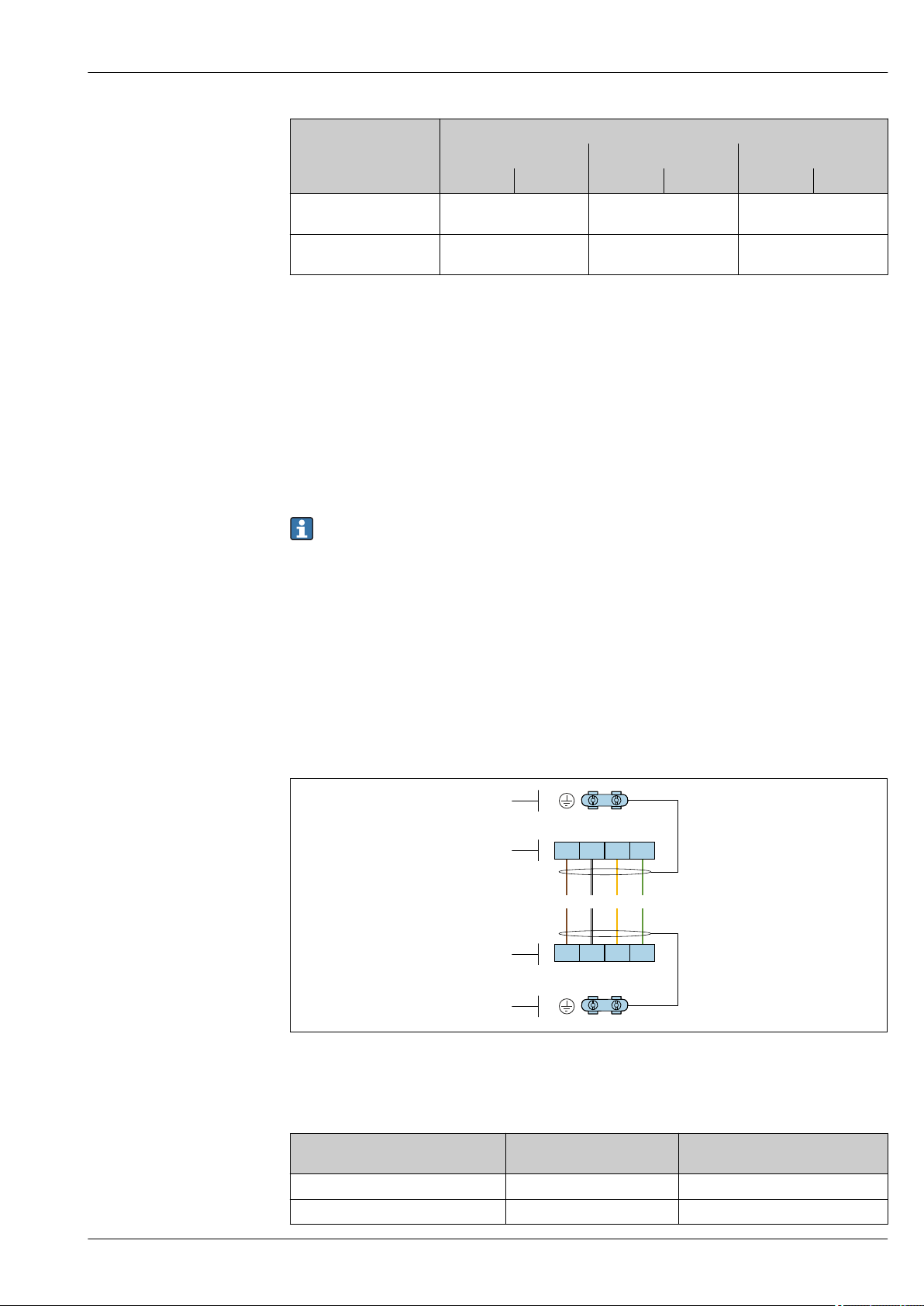

Connecting cable for remote version

Transmitter and sensor connection housing

In the case of the remote version, the sensor and transmitter are mounted separately from on

another and connected by a connecting cable. Connection is performed via the sensor connection

housing and the transmitter housing.

How the connecting cable is connected in the transmitter housing depends on the measuring

device approval and the version of the connecting cable used.

In the following versions, only terminals can be used for connection in the transmitter housing:

• Certain approvals: Ex nA, Ex ec, Ex tb and Division 1

• Use of reinforced connecting cable

• Order code for "Sensor version; DSC sensor; measuring tube", option DA, DB

In the following versions, an M12 device connector is used for connection in the transmitter

housing:

• All other approvals

• Use of connecting cable (standard)

Terminals are always used to connect the connecting cable in the sensor connection housing

(tightening torques for screws for cable strain relief: 1.2 to 1.7 Nm).

Connecting cable (standard, reinforced)

A0033476

2 Terminals for connection compartment in the transmitter wall holder and the sensor connection housing

1 Terminals for connecting cable

2 Grounding via the cable strain relief

Terminal number Assignment Cable color

Connecting cable

1 Supply voltage Brown

2 Grounding White

Endress+Hauser 27

Page 28

Terminal number Assignment Cable color

+–

+ –

2

1

1

2

1 2 3 4

1 2 3 4556677

RDGNWHBN BK YE BU

+–

+ –

RES

VCC

GND

RES

VCC

GND

1

2

4

3

1

2

4

3

3 RS485 (+) Yellow

4 RS485 (–) Green

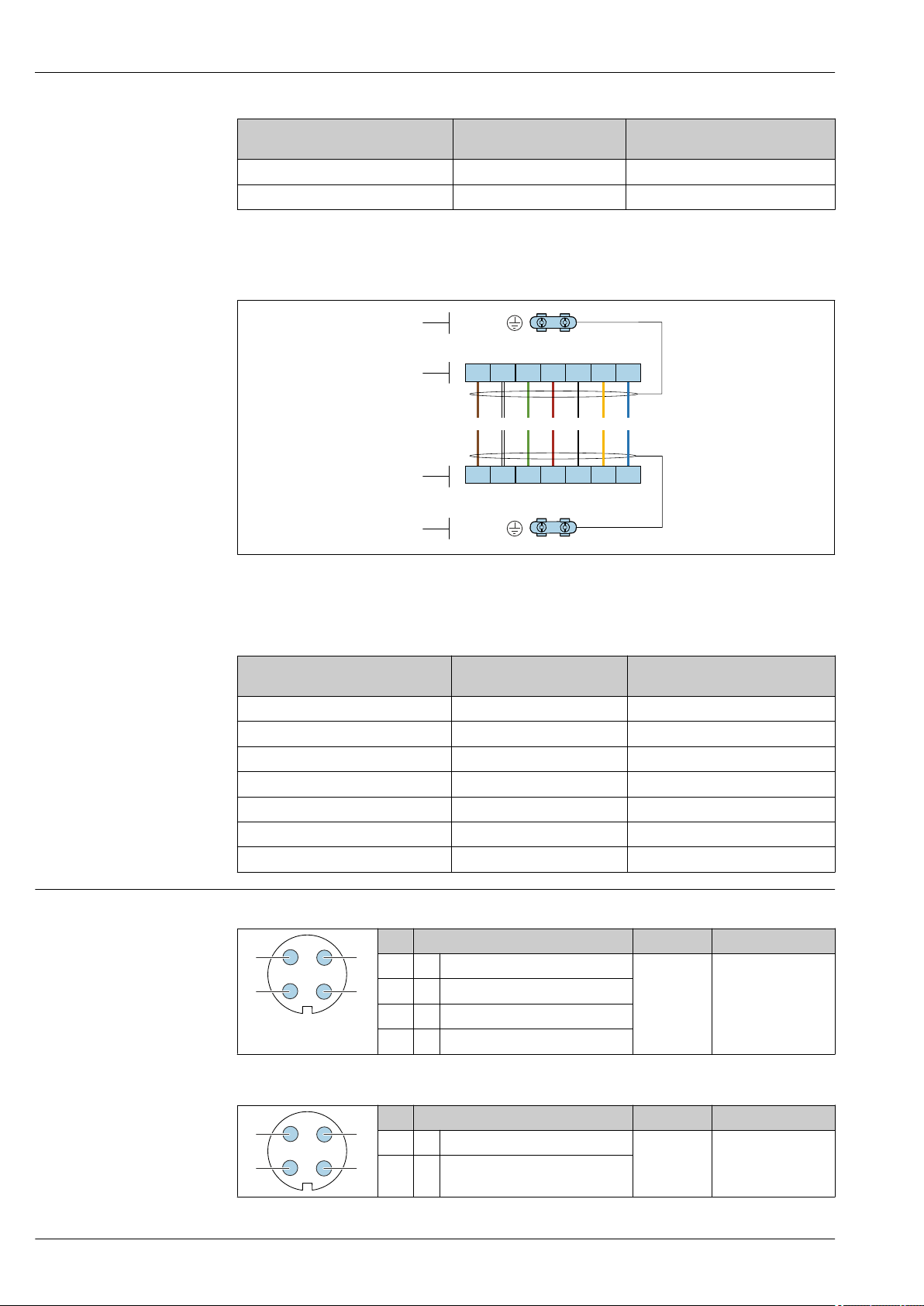

Connecting cable (option "mass pressure-/temperature-compensated")

Order code for "Sensor version; DSC sensor; measuring tube", option DA, DB

Proline Prowirl F 200

Connecting cable

3 Terminals for connection compartment in the transmitter wall holder and the sensor connection housing

1 Terminals for connecting cable

2 Grounding via the cable strain relief

Terminal number Assignment Cable color

Pin assignment, device plug PROFIBUS PA

A0034571

Connecting cable

1 RS485 (-) DPC Brown

2 RS485 (+) DPC White

3 Reset Green

4 Supply voltage red

5 Grounding Black

6 RS485 (+) Yellow

7 RS485 (–) Blue

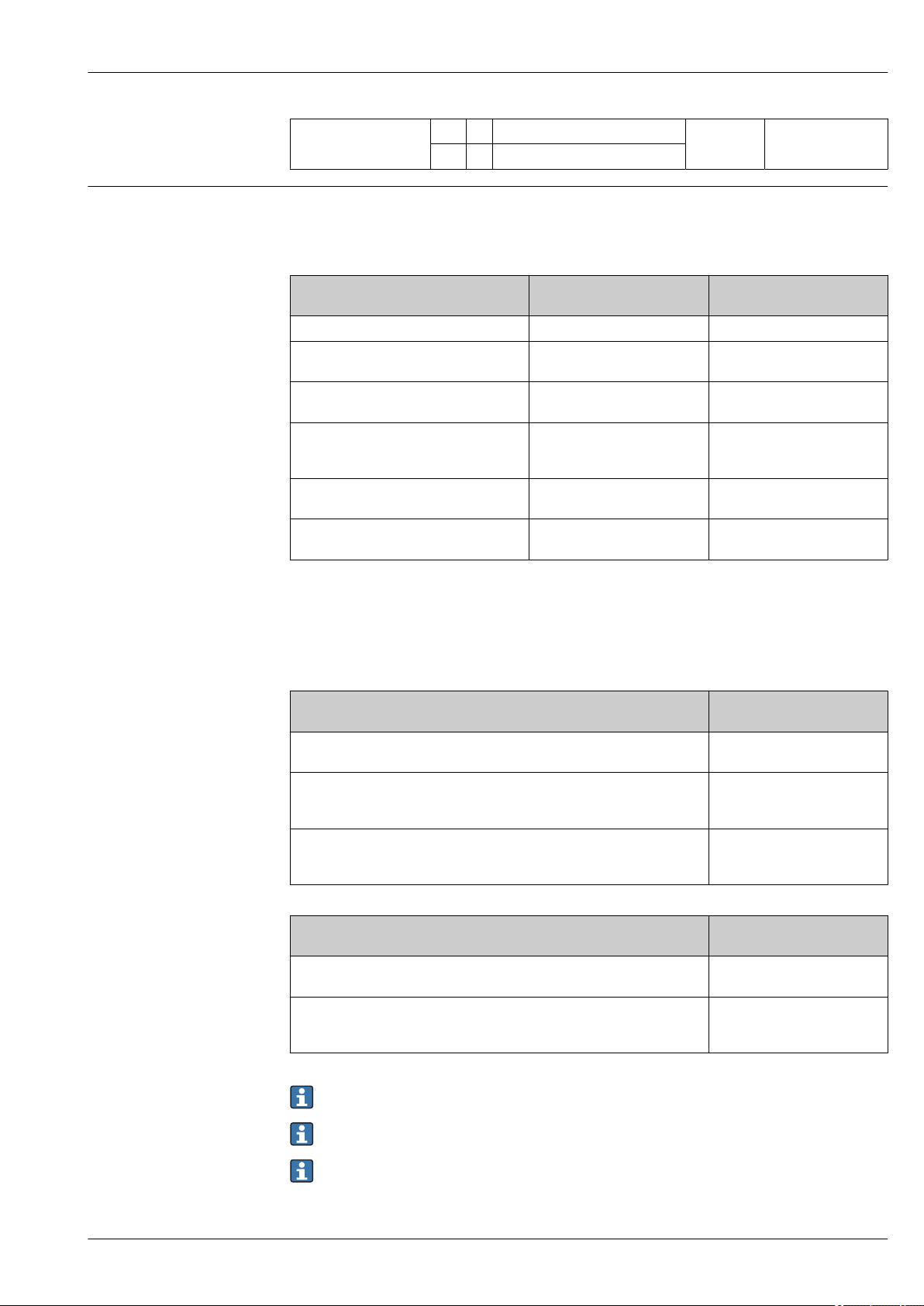

Pin Assignment Coding Plug/socket

1 + PROFIBUS PA + A Plug

2 Grounding

3 - PROFIBUS PA –

4 Not assigned

28 Endress+Hauser

FOUNDATION Fieldbus

Pin Assignment Coding Plug/socket

1 + Signal + A Plug

2 - Signal –

Page 29

Proline Prowirl F 200

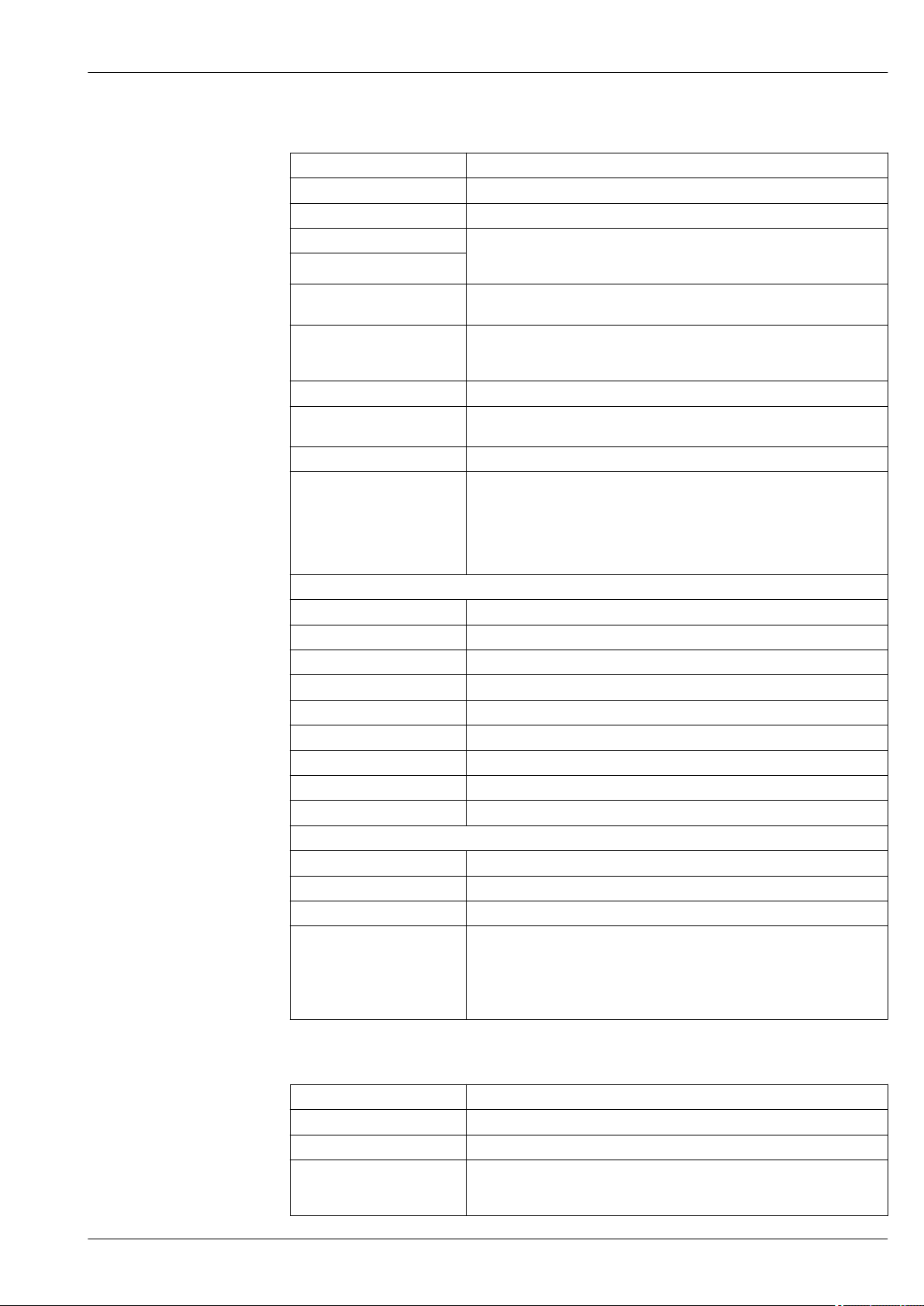

Supply voltage Transmitter

An external power supply is required for each output.

3 Grounding

4 Not assigned

Supply voltage for a compact version without a local display

Order code for "Output; input" Minimum

terminal voltage

Option A: 4-20 mA HART ≥ DC 12 V DC 35 V

Option B: 4-20 mA HART, pulse/

frequency/switch output

Option C: 4-20 mA HART + 4-20 mA

analog

Option D: 4-20 mA HART, pulse/

frequency/switch output, 4-20 mA current

3)

input

Option E: FOUNDATION Fieldbus, pulse/

frequency/switch output

Option G: PROFIBUS PA, pulse/frequency/

switch output

1) In event of external supply voltage of the power supply unit with load, the PROFIBUS DP/PA coupler or

FOUNDATION Fieldbus power conditioners

2) The minimum terminal voltage increases if local operation is used: see the following table

3) Voltage drop 2.2 to 3 V for 3.59 to 22 mA

1)

2)

≥ DC 12 V DC 35 V

≥ DC 12 V DC 30 V

≥ DC 12 V DC 35 V

≥ DC 9 V DC 32 V

≥ DC 9 V DC 32 V

Maximum

terminal voltage

Increase in minimum terminal voltage

Order code for "Display; operation"

Option C:

Local operation SD02

Option E:

Local operation SD03 with lighting

(backlighting not used)

Option E:

Local operation SD03 with lighting

(backlighting used)

Increase in minimum

terminal voltage

+ DC 1 V

+ DC 1 V

+ DC 3 V

Order code for "Sensor version; DSC sensor; measuring tube"

Option DA:

Mass steam; 316L; 316L (integrated pressure/temperature measurement)

Option DB:

Mass gas/liquid; 316L; 316L (integrated pressure/temperature

measurement)

Increase in minimum

terminal voltage

+ DC 1 V

+ DC 1 V

For information about the load see → 18

Various power supply units can be ordered from Endress+Hauser: → 95

For information on the Ex connection values → 19

Endress+Hauser 29

Page 30

Power consumption Transmitter

Order code for "Output; input" Maximum power consumption

Option A: 4-20 mA HART 770 mW

Option B: 4-20 mA HART, pulse/

frequency/switch output

Option C: 4-20 mA HART + 4-20 mA

analog

Option D: 4-20 mA HART, pulse/

frequency/switch output, 4-20 mA current

input

Option E: FOUNDATION Fieldbus, pulse/

frequency/switch output

Option G: PROFIBUS PA, pulse/frequency/

switch output

For information on the Ex connection values → 19

Proline Prowirl F 200

• Operation with output 1: 770 mW

• Operation with output 1 and 2: 2 770 mW

• Operation with output 1: 660 mW

• Operation with output 1 and 2: 1 320 mW

• Operation with output 1: 770 mW

• Operation with output 1 and 2: 2770 mW

• Operation with output 1 and input: 840 mW

• Operation with output 1, 2 and input: 2840 mW

• Operation with output 1: 512 mW

• Operation with output 1 and 2: 2 512 mW

• Operation with output 1: 512 mW

• Operation with output 1 and 2: 2 512 mW

Current consumption Current output

For every 4-20 mA or 4-20 mA HART current output: 3.6 to 22.5 mA

If the option Defined value is selected in the Failure mode parameter : 3.59 to 22.5 mA

Current input

3.59 to 22.5 mA

Internal current limiting: max. 26 mA

FOUNDATION Fieldbus

15 mA

PROFIBUS PA

15 mA

Power supply failure

• Totalizers stop at the last value measured.

• Depending on the device version, the configuration is retained in the device memoryor in the

pluggable data memory (HistoROM DAT).

• Error messages (incl. total operated hours) are stored.

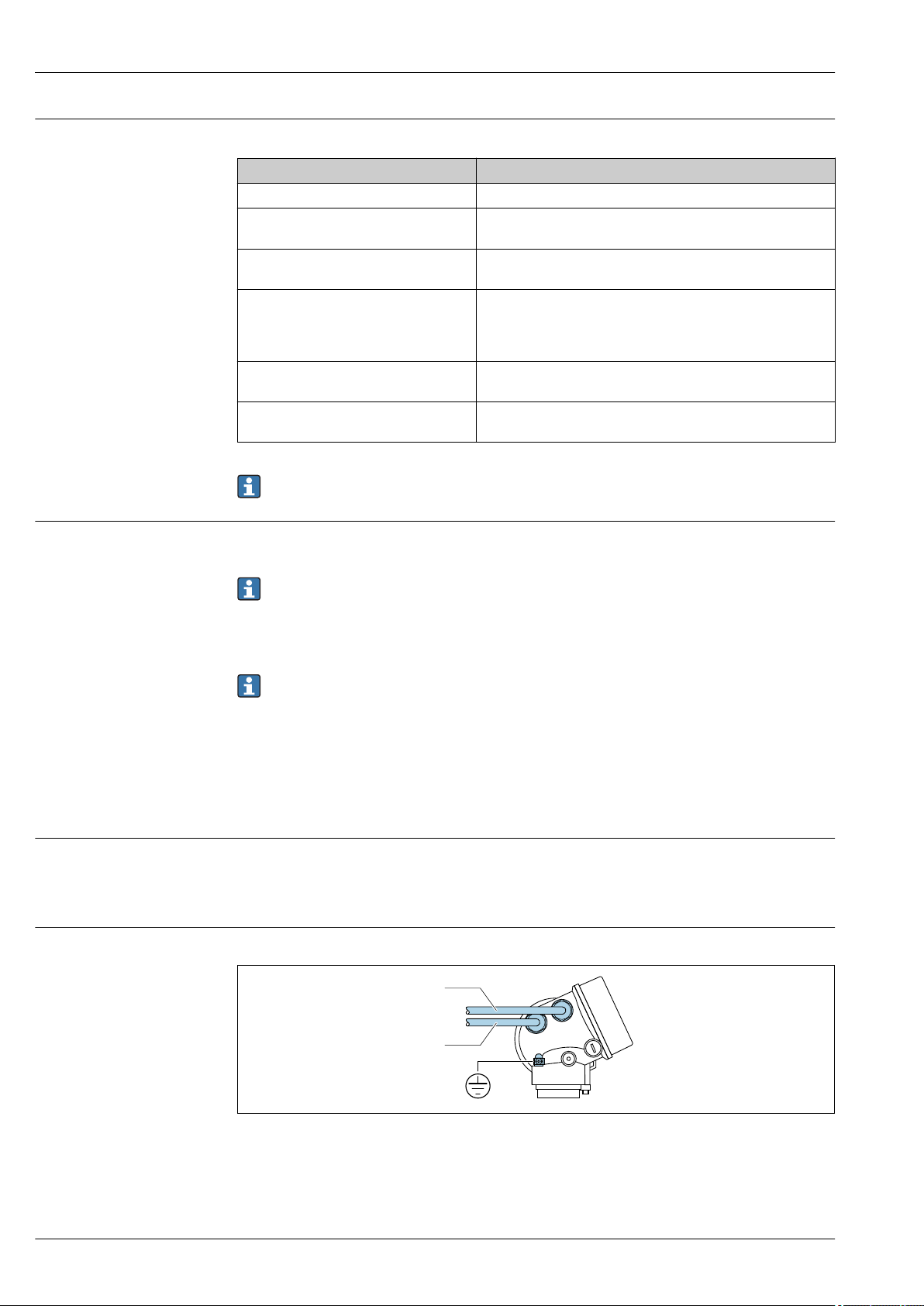

Electrical connection Connecting the transmitter

A0033480

1 Cable entries for inputs/outputs

30 Endress+Hauser

Page 31

Proline Prowirl F 200

3

1

2

2

3

4...20 mA

41

5

Remote version connection

Connecting cable

A0033481

4 Connecting cable connection

1 Wall holder with connection compartment (transmitter)

2 Connecting cable

3 Sensor connection housing

How the connecting cable is connected in the transmitter housing depends on the measuring

device approval and the version of the connecting cable used.

In the following versions, only terminals can be used for connection in the transmitter housing:

• Certain approvals: Ex nA, Ex ec, Ex tb and Division 1

• Use of reinforced connecting cable

• Order code for "Sensor version; DSC sensor; measuring tube", option DA, DB

In the following versions, an M12 device connector is used for connection in the transmitter

housing:

• All other approvals

• Use of connecting cable (standard)

Terminals are always used to connect the connecting cable in the sensor connection housing

(tightening torques for screws for cable strain relief: 1.2 to 1.7 Nm).

Connection examples

Current output 4-20 mA HART

A0028762

5 Connection example for 4 to 20 mA HART current output (passive)

1 Automation system with current input (e.g. PLC)

2 Power supply

3 Cable shield provided at one end. The cable shield must be grounded at both ends to comply with EMC

requirements; observe cable specifications

4 Analog display unit: observe maximum load

5 Transmitter

Endress+Hauser 31

Page 32

Pulse/frequency output

1

2

3

12345

1

2

3

6 Connection example for pulse/frequency output (passive)

1 Automation system with pulse/frequency input (e.g. PLC)

2 Power supply

3 Transmitter: Observe input values

Switch output

Proline Prowirl F 200

A0028761

7 Connection example for switch output (passive)

1 Automation system with switch input (e.g. PLC)

2 Power supply

3 Transmitter: Observe input values

A0028760

32 Endress+Hauser

Page 33

Proline Prowirl F 200

21 3 4

78

6 6

6

6

5

6

6

5

FOUNDATION Fieldbus

8 Connection example for FOUNDATION Fieldbus

1 Control system (e.g. PLC)

2 Power Conditioner (FOUNDATION Fieldbus)

3 Cable shield provided at one end. The cable shield must be grounded at both ends to comply with EMC

requirements; observe cable specifications

4 T-box

5 Measuring device

6 Local grounding

7 Bus terminator

8 Potential matching line

A0028768

Endress+Hauser 33

Page 34

PROFIBUS PA

21 3 4

78

6 6

6

6

5

6

6

5

31

4

2

Proline Prowirl F 200

9 Connection example for PROFIBUS PA

1 Control system (e.g. PLC)

2 PROFIBUS PA segment coupler

3 Cable shield provided at one end. The cable shield must be grounded at both ends to comply with EMC

requirements; observe cable specifications

4 T-box

5 Measuring device

6 Local grounding

7 Bus terminator

8 Potential matching line

Current input

10 Connection example for 4-20 mA current input

1 Active barrier for power supply (e.g. RN221N)

2 Terminal box

3 External measuring device (to read in pressure or temperature, for instance)

4 Transmitter

A0028768

A0028915

34 Endress+Hauser

Page 35

Proline Prowirl F 200

2

4...20 mA

4

1

2

3

3

6

5

HART input

A0028763

11 Connection example for HART input with a common negative (passive)

1 Automation system with HART output (e.g. PLC)

2 Active barrier for power supply (e.g. RN221N)

3 Cable shield provided at one end. The cable shield must be grounded at both ends to comply with EMC

requirements; observe cable specifications

4 Analog display unit: observe maximum load

5 Pressure measuring device (e.g. Cerabar M, Cerabar S): see requirements

6 Transmitter

Potential equalization Requirements

Please consider the following to ensure correct measurement:

• Same electrical potential for the fluid and sensor

• Remote version: same electrical potential for the sensor and transmitter

• Company-internal grounding concepts

• Pipe material and grounding

Terminals

• For device version without integrated overvoltage protection: plug-in spring terminals for wire

cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• For device version with integrated overvoltage protection: screw terminals for wire cross-sections

0.2 to 2.5 mm2 (24 to 14 AWG)

Cable entries

• Cable gland (not for Ex d): M20 × 1.5 with cable ⌀ 6 to 12 mm (0.24 to 0.47 in)

• Thread for cable entry:

• For non-hazardous and hazardous areas: NPT ½"

• For non-hazardous and hazardous areas (not for XP): G ½"

• For Ex d: M20 × 1.5

Cable specification Permitted temperature range

• The installation guidelines that apply in the country of installation must be observed.

• The cables must be suitable for the minimum and maximum temperatures to be expected.

Signal cable

Current output 4 to 20 mA HART

A shielded cable is recommended. Observe grounding concept of the plant.

Current output 4 to 20 mA

Standard installation cable is sufficient.

Pulse/frequency/switch output

Standard installation cable is sufficient.

Endress+Hauser 35

Page 36

Proline Prowirl F 200

Current input

Standard installation cable is sufficient.

FOUNDATION Fieldbus

Twisted, shielded two-wire cable.

For further information on planning and installing FOUNDATION Fieldbus networks see:

• Operating Instructions for "FOUNDATION Fieldbus Overview" (BA00013S)

• FOUNDATION Fieldbus Guideline

• IEC 61158-2 (MBP)

PROFIBUS PA

Twisted, shielded two-wire cable. Cable type A is recommended .

For further information on planning and installing PROFIBUS networks see:

• Operating Instructions "PROFIBUS DP/PA: Guidelines for planning and commissioning"

(BA00034S)

• PNO Directive 2.092 "PROFIBUS PA User and Installation Guideline"

• IEC 61158-2 (MBP)

Connecting cable for remote version

Connecting cable (standard)

Standard cable

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx.85 %

Cable length 5 m (16 ft), 10 m (32 ft), 20 m (65 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

2 × 2 × 0.5 mm2 (22 AWG) PVC cable with common shield (2 pairs, pairstranded)

can move freely: –25 to +105 °C (–13 to +221 °F)

1)

Connecting cable (reinforced)

Cable, reinforced

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx. 85%

Strain relief and

reinforcement

Cable length 5 m (16 ft), 10 m (32 ft), 20 m (65 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

2 × 2 × 0.34 mm2 (22 AWG) PVC cable with common shield (2 pairs, pairstranded) and additional steel-wire braided sheath

Steel-wire braid, galvanized

can move freely: –25 to +105 °C (–13 to +221 °F)

1)

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

Connecting cable (option "mass pressure-/temperature-compensated")

Order code for "Sensor version; DSC sensor; measuring tube", option DA, DB

36 Endress+Hauser

Page 37

Proline Prowirl F 200

Standard cable

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx. 85%

Cable length 10 m (32 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

[(3 × 2) + 1] × 0.34 mm2 (22 AWG)PVC cable with common shield (3 pairs, pairstranded)

can move freely: –25 to +105 °C (–13 to +221 °F)

1)

Connecting cable (option "mass pressure-/temperature-compensated")

Order code for "Sensor version; DSC sensor; measuring tube", option DA, DB

Standard cable

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx. 85%

Cable length 10 m (32 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

[(3 × 2) + 1] × 0.34 mm2 (22 AWG)PVC cable with common shield (3 pairs, pairstranded)

can move freely: –25 to +105 °C (–13 to +221 °F)

1)

Overvoltage protection

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

The device can be ordered with integrated overvoltage protection for diverse approvals:

Order code for "Accessory mounted", option NA "Overvoltage protection"

Input voltage range Values correspond to supply voltage specifications → 29

Resistance per channel 2 ⋅ 0.5 Ω max.

DC sparkover voltage 400 to 700 V

Trip surge voltage < 800 V

Capacitance at 1 MHz < 1.5 pF

Nominal discharge current

(8/20 μs)

Temperature range –40 to +85 °C (–40 to +185 °F)

1) The voltage is reduced by the amount of the internal resistance I

10 kA

min

⋅ R

i

1)

Depending on the temperature class, restrictions apply to the ambient temperature for device

versions with overvoltage protection .

For detailed information on the temperature tables, see the "Safety Instructions" (XA) for the

device.

Endress+Hauser 37

Page 38

Performance characteristics

Re

min

Re

max

Re

Re

max

A2

A1

-A2

Re

1

Re

2

Q [m /h] =

AmpMin

³

v [m/s]

AmpMin

· · D [m]i²π

· 3600 [s/h]

4 ·

ρ [kg/m ]³

1 [kg/m ]³

AmpMin

!³

v [!/s]

AmpMin

· · D [ft]i²π

· 60 [s/min]

4 ·

ρ [lbm/ ]#³

0.0624 [lbm/ ]!³

Re =

max

ρ · 4 · Q

Heigh

· · K

μ π

Proline Prowirl F 200

Reference operating conditions

• Error limits following ISO/DIN 11631

• +20 to +30 °C (+68 to +86 °F)

• 2 to 4 bar (29 to 58 psi)

• Calibration system traceable to national standards

• Calibration with the process connection corresponding to the particular standard

To obtain measured errors, use the Applicator sizing tool → 95

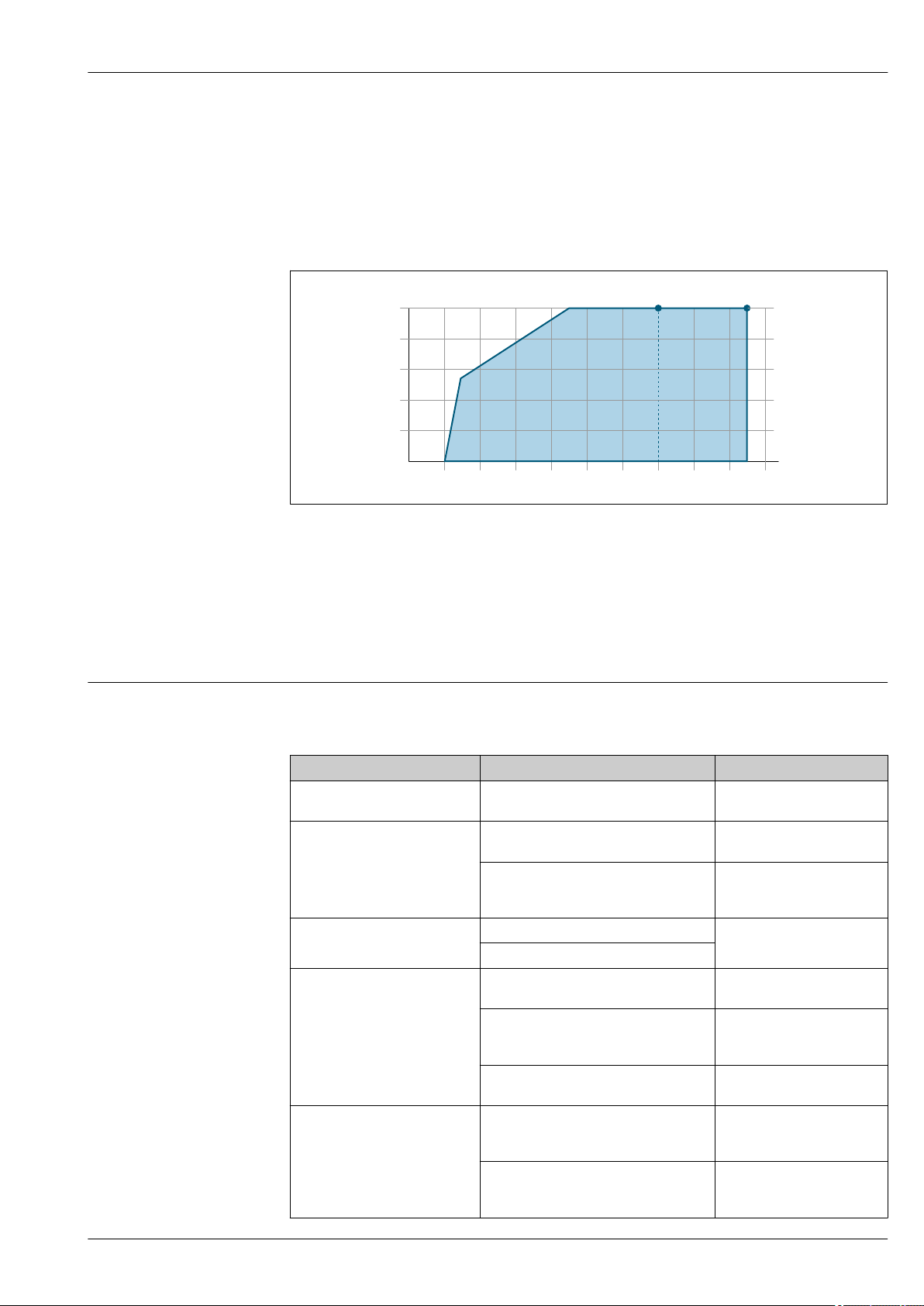

Maximum measured error Base accuracy

o.r. = of reading

Reynolds number

Re

Re

Re

5 000

1

10 000

2

Reynolds number for minimum permitted volume flow in measuring tube

min

• Standard

• Option N "0.65% volume PremiumCal 5-point

Re

Defined by internal diameter of measuring tube, Mach number and maximum permitted velocity in

max

measuring tube

Further information on effective upper range value Q

→ 13

High

A0034077

A0034304

A0034339

38 Endress+Hauser

Page 39

Proline Prowirl F 200

Volume flow

Medium type Incompressible Compressible

Reynolds number

Measured value deviation PremiumCal

1)

Standard PremiumCal

range

Re2 to Re

Re1 to Re

max

2

A1 < 0.65 % < 0.75 % < 0.9 % < 1.0 %

A2 < 2.5 % < 5.0 % < 2.5 % < 5.0 %

1) Order code for "Calibration flow", option N "0.65% volume PremiumCal 5-point"

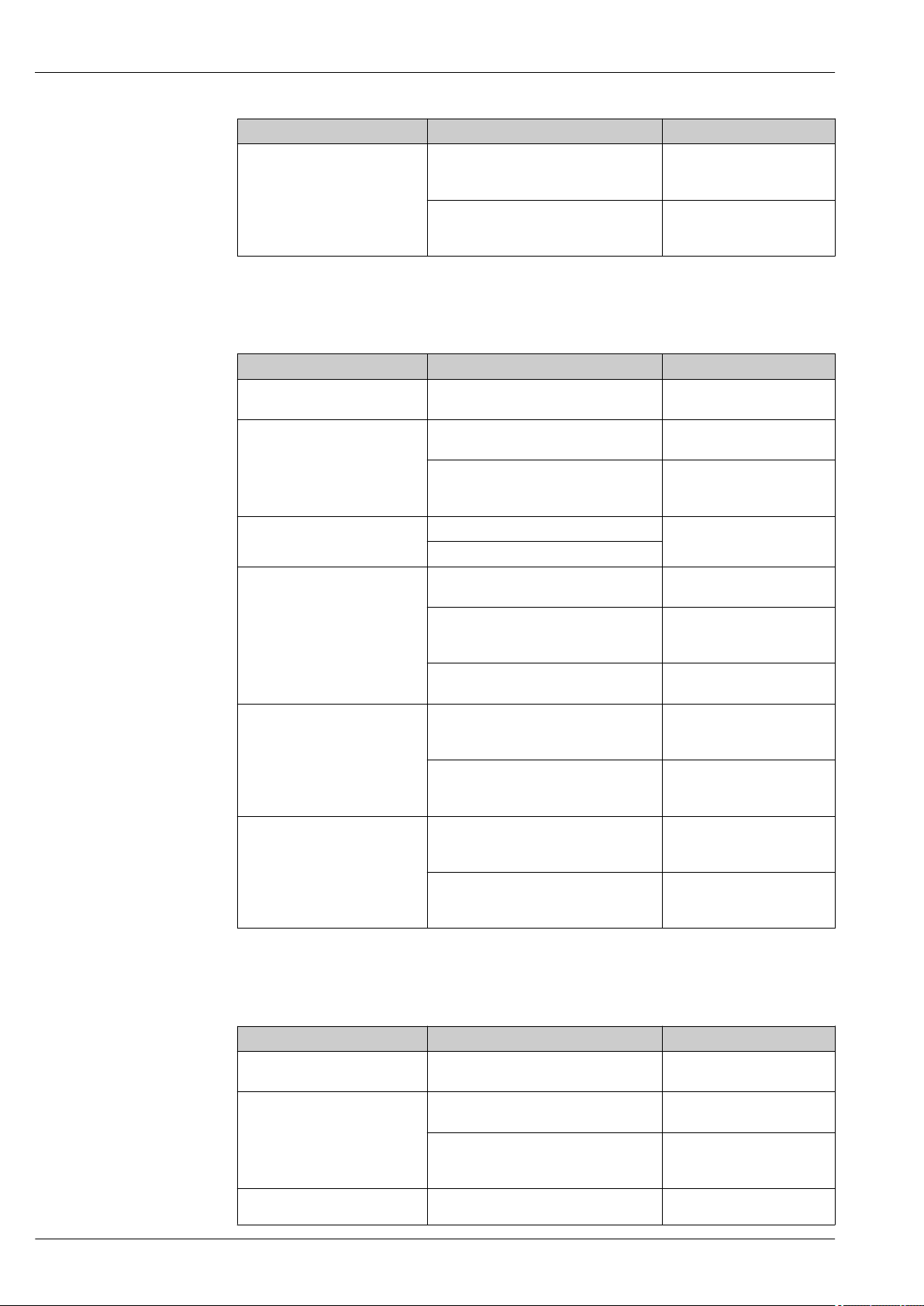

Temperature

• Saturated steam and liquids at room temperature, if T > 100 °C (212 °F):

< 1 °C (1.8 °F)

• Gas: < 1 % o.r. [K]

• Volume flow: 70 m/s (230 ft/s): 2 % o.r.

• Rise time 50 % (stirred under water, following IEC 60751): 8 s

Pressure

1)

Standard

Order code for "Pressure component"

1)

Nominal value

[bar abs.]

Pressure ranges and measured errors

Pressure range

Maximum measured error

2)

[bar abs.]

Option B

Pressure measuring cell 2 bar_a

Option C

Pressure measuring cell 4 bar_a

Option D

Pressure measuring cell 10 bar_a

Option E

Pressure measuring cell 40 bar_a

2 0.01 ≤ p ≤ 0.4

0.4 ≤ p ≤ 2

4 0.01 ≤ p ≤ 0.8

0.8 ≤ p ≤ 4

10 0.01 ≤ p ≤ 2

2 ≤ p ≤ 10

40 0.01 ≤ p ≤ 8

8 ≤ p ≤ 40

0.5 % of 0.4 abs.

0.5 % o.r.

0.5 % of 0.8 bar abs.

0.5 % o.r.

0.5 % of 2 bar abs.

0.5 % o.r.

0.5 % of

8 bar abs.

0.5 % o.r.

Option F

Pressure measuring cell 100 bar_a

100 0.01 ≤ p ≤ 20

20 ≤ p ≤ 100

0.5 % of 20 bar abs.

0.5 % o.r.

1) The "mass" sensor version (integrated pressure/temperature measurement) is available only for measuring

devices in HART communication mode.

2) The specific measured errors refer to the position of the measurement in the measuring tube and do not

correspond to the pressure in the pipe connection line upstream or downstream from the measuring

device. No measured error is specified for the measured error for the "pressure" measured variable that can

be assigned to the outputs.

Mass flow saturated steam

Sensor version Mass (integrated temperature

measurement)

Process

pressure

Flow velocity

[m/s (ft/s)]

[bar abs.]

> 4.76 20 to 50

Reynolds

number

range

Re2 to Re

max

Measured

PremiumCal

value

deviation

A1 < 1.6 % < 1.7 % < 1.4 % < 1.5 %

2)

Standard PremiumCal

Mass (integrated pressure/

temperature measurement)

2)

Standard

1)

(66 to 164)

> 3.62 10 to 70

Re2 to Re

max

A1 < 1.9 % < 2.0 % < 1.7 % < 1.8 %

(33 to 230)

In all cases not specified here, the following applies: < 5.7 %

1) Sensor version available only for measuring devices in HART communication mode.

2) Order code for "Calibration flow", option N "0.65% volume PremiumCal 5-point"

Endress+Hauser 39

Page 40

Proline Prowirl F 200

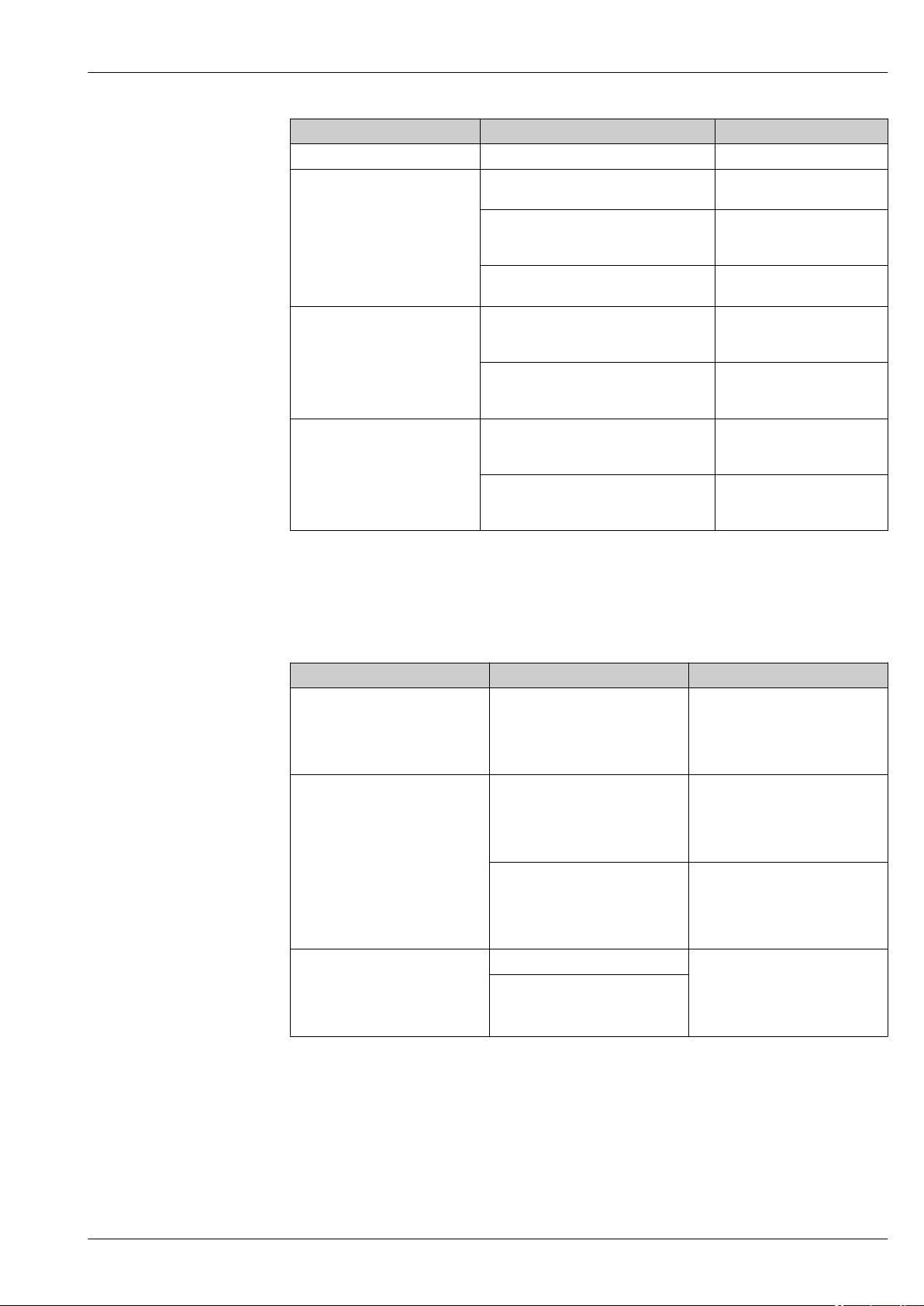

Mass flow of superheated steam/gases

Sensor version Mass (integrated pressure/

temperature measurement)

Process

pressure

[bar abs.]

< 40 All velocities Re2 to Re

< 120 Re2 to Re

In all cases not specified here, the following applies: < 6.6 %

1) Sensor version available only for measuring devices in HART communication mode.

2) The use of a Cerabar S is required for the measured errors listed in the following section. The measured error used to calculate the error in the

measured pressure is 0.15 %.

3) Order code for "Calibration flow", option N "0.65% volume PremiumCal 5-point"

Flow velocity

[m/s (ft/s)]

Reynolds

number

range

max

max

Measured

value

deviation

A1 < 1.4 % < 1.5 % < 1.6 % < 1.7 %

A1 < 2.3 % < 2.4 % < 2.5 % < 2.6 %