Endress+Hauser Proline Prowirl 72W, Proline Prowirl 73F, Proline Prowirl 72F, Proline Prowirl 73W Technical Information

TI00070D/06/EN/01.11

71128149

Technical Information

Proline Prowirl 72F, 72W, 73F, 73W

Vortex flow measuring system

Reliable flow measurement of gas, steam and liquids

Application

For the universal measurement of the volume flow

of gases, steam and liquids.

The mass flow of steam, water (as per IAPWS-IF97

ASME), natural gas (as per AGA NX-19/AGA8-DC92

detailed method/AGA8 Gross Method 1/SGERG-88),

compressed air, other gases and liquids can also be

calculated with the aid of integrated temperature

measurement and by reading in external pressure values

(Prowirl 73).

Maximum range of applications thanks to:

• Fluid temperature range from –200 to +400 °C

(–328 to +752 °F)

• Pressure ratings up to PN 250/Class 1500

• Sensor with integrated (optional) diameter reduction

by one line size (R Style) or two line sizes (S Style)

• Dualsens version (optional) for redundant

measurements with two sensors and electronics

Approvals for:

• ATEX, FM, CSA, TIIS, NEPSI, IEC

• HART, PROFIBUS PA, FOUNDATION Fieldbus

• Pressure Equipment Directive, SIL 2

Your benefits

The robust Prowirl sensor, tried and tested in over

200 000 applications, offers:

• High resistance to vibrations, temperature shocks,

contaminated fluids and water hammer

• No maintenance, no moving parts, no zero-point drift

("lifetime" calibration)

• Software initial settings save time and costs

Additional possibilities:

• Complete saturated steam or liquid-mass measuring

point in one single device

• Calculation of the mass flow from the measured

variables volume flow and temperature in the

integrated flow computer

• External pressure value read-in for superheated steam

and gas applications

• External temperature value read-in for delta heat

measurement

Proline Prowirl 72F, 72W, 73F, 73W

2 Endress+Hauser

Table of contents

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Low flow cut off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring HART input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring remote version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance characteristics. . . . . . . . . . . . . . . . . . . . 20

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Reaction time/step response time . . . . . . . . . . . . . . . . . . . . . . . . 21

Influence of ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . 21

Operating conditions: installation . . . . . . . . . . . . . . . 22

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inlet and outlet run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating conditions: environment . . . . . . . . . . . . . . 27

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . 27

Operating conditions: process . . . . . . . . . . . . . . . . . . 28

Medium temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Medium pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 32

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operating elements (HART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 53

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

C-tick mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ex-approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Pressure measuring device approval . . . . . . . . . . . . . . . . . . . . . . 54

Certification FOUNDATION Fieldbus . . . . . . . . . . . . . . . . . . . . . 54

Certification PROFIBUS PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Functional safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 56

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Device-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Measuring principle-specific accessories . . . . . . . . . . . . . . . . . . . 58

Communication-specific accessories . . . . . . . . . . . . . . . . . . . . . . 60

Service-specific accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . 62

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 3

Function and system design

Measuring principle Vortex meters work on the principle of the Kármán vortex street. When fluid flows past a bluff body, vortices

are alternately formed on both sides with opposite directions of rotation. These vortices each generate a local

low pressure. The pressure fluctuations are recorded by the sensor and converted to electrical pulses. The

vortices develop very regularly within the permitted application limits of the device. Therefore, the frequency

of vortex shedding is proportional to the volume flow.

A0003938

The calibration factor (K-factor) is used as the proportional constant:

A0003939-en

• Within the application limits of the device, the K-factor only depends on the geometry of the device. It is

independent of the fluid velocity and the fluid properties viscosity and density. In this way, the K-factor is

also independent of the type of matter that is to be measured, regardless of whether this is steam, gas or

liquid.

• The primary measuring signal is already digital (frequency signal) and linear to the flow.

After production, the K-factor is determined in the factory by means of calibration and is not subject to longterm or zero-point drift.

• The device does not contain any moving parts and does not require maintenance.

v

K-Factor =

Pulses

Unit Volume [dm³]

Proline Prowirl 72F, 72W, 73F, 73W

4 Endress+Hauser

The capacitive sensor

The sensor of a vortex flowmeter has a major influence on the performance, robustness and reliability of the

whole measuring system.

The robust DSC sensor – with an integrated temperature measurement (Pt 1000) with Prowirl 73 –

is burst-tested and vibration and temperature-shock-tested (temperature shocks of 150 K/s). The Prowirl uses

the tried-and-tested capacitive measuring technology of Endress+Hauser applied in over 200 000 measuring

points worldwide.

The DSC (differential switched capacitance) sensor patented by Endress+Hauser has complete mechanical

balancing. It only reacts to the measured variable (vortex), not to vibrations. Even in the event of pipe

vibrations, the smallest of flows can be reliably measured at low density thanks to the unimpaired sensitivity of

the sensor. Thus, the wide turndown is also maintained even in the event of harsh operating conditions.

Vibrations up to 1 g, in frequencies up to 500 Hz in every axis (X, Y, Z), do not affect the flow measurement.

Due to its design, the capacitive sensor is also particularly mechanically resistant to temperature shocks and

water hammers in steam lines.

"Lifetime" calibration

Experience has shown that recalibrated Prowirl devices exhibit a very high degree of stability compared to their

original calibration: The recalibration values were all within the original measuring accuracy specifications of

the devices.

Various tests and simulation procedures carried out on devices by filing away the edges of Prowirl's bluff body

found that there was no negative impact on the accuracy up to a rounding diameter of 1 mm (0.04").

Generally the following statements are true:

• Experience has shown that if the fluid is non-abrasive and non-corrosive (e.g. most water and steam

applications), the meter's edges will never show rounding at the edges that is 1 mm (0.04") or more.

• If the rounding of the meter's edges is always 1 mm (0.04") or less, the meter will never show a calibration

shift that is out of the meter's original specifications.

• Typically, the bluff body's edges exhibit a small rounding that is less than 1 mm (0.04"). The meter, however,

is calibrated with this rounded edge. Therefore, the meter will stay within the tolerance specifications as long

as the additional wear and tear of the edge does not exceed an additional 1 mm (0.04").

Thus, the Prowirl product line offers calibration for life if the measuring device is used in non-abrasive and noncorrosive fluids.

A0003940-en

DSC sensor, Prowirl 72

A0004056-en

DSC sensor, Prowirl 73 with in tegrated temperature sensor

(Pt 1000)

Sensor

Seal

Y-Axis

X-Axis

Z-Axis

Sensor

Y-Axis

X-Axis

Z-Axis

Pt 1000

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 5

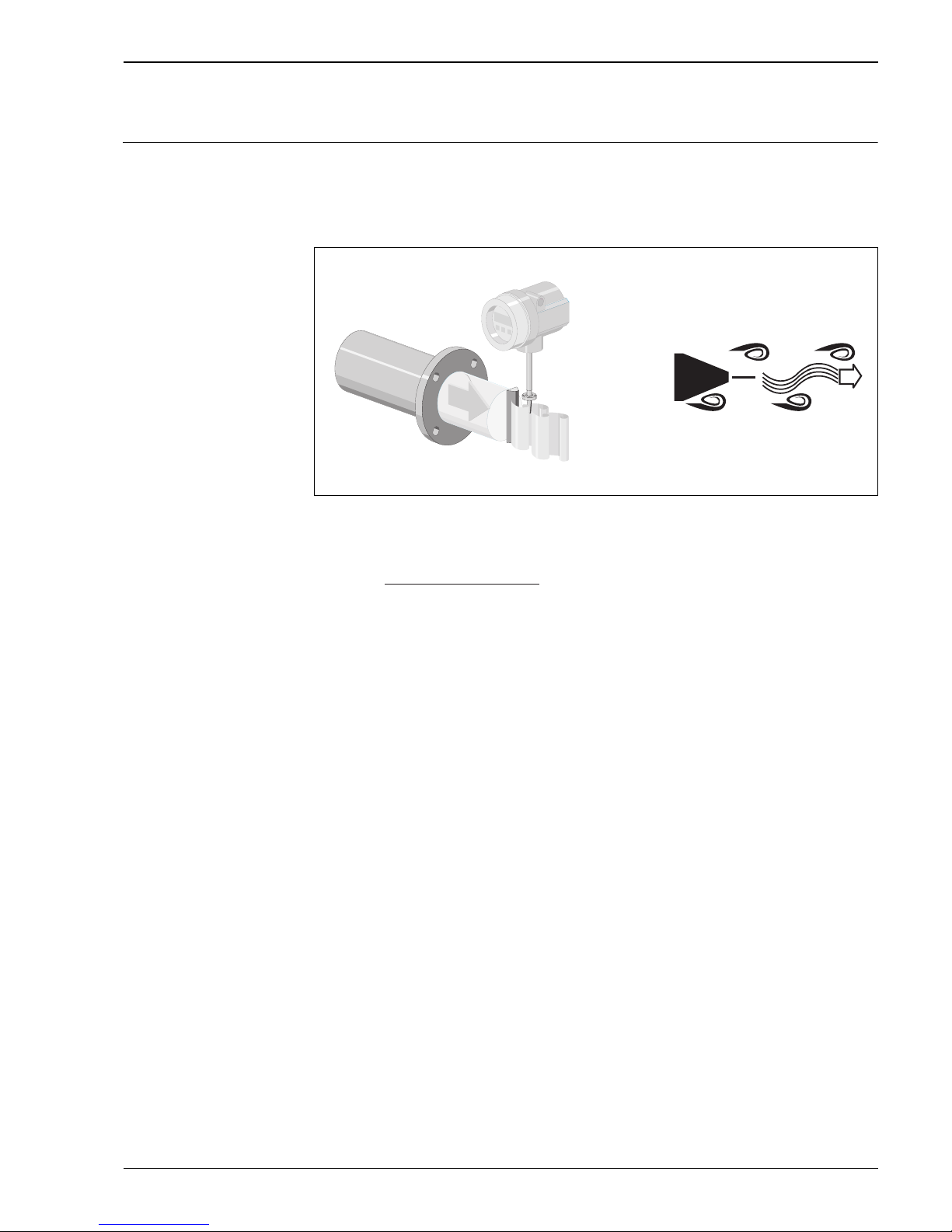

Sensor with integrated nominal diameter reduction

In many applications, the nominal diameter of the customer's pipe does not correspond to the nominal diameter

that is optimum for a vortex meter as the flow velocity is too low for vortex formation after the bluff body. This

is expressed in a signal loss in the lower flow range. To reduce the nominal diameter by one or two steps, and

thus increase the flow velocity, it is common practice nowadays to fit such measuring points with the following

adapters:

• Reducer (a)

• Straight pipe segment (b) as the inlet run (min. 15 × DN) in front of the vortex meter

• Straight pipe segment (c) as the outlet run (min. 5 × DN) after the vortex meter

• Expansion (d)

Endress+Hauser is now offering the Prowirl 72/73 vortex meter with integrated nominal diameter reduction

for such applications.

A0007142

Left: Traditional means for reducing pipeline section

Right: Nominal diameter reduction by using Prowirl with integrated line size reduction

Nomenclature for Prowirl vortex meters (flanged devices) with integrated nominal diameter reduction:

• Prowirl 72F/73F "R Style": single reduction of line size, e.g. from DN 80 (3") to DN 50 (2")

• Prowirl 72F/73F "S Style": double reduction of line size, e.g. from DN 80 (3") to DN 40 (1½")

(S = "super" reduced)

These models offer the following benefits:

• Cost and time saving as the adapter pieces with inlet and outlet runs are completely replaced by one single

device (additional inlet and outlet runs to be considered ä 25)

• Measuring range extended for lower flow rates

• Lower risk (of incorrect measuring device layout) in the planning phase as R Style and S Style measuring

devices have the same lengths as standard flanged devices. Each device type can be used alternatively

without making complicated changes to the layout.

• Accuracy specifications identical to those for standard devices

Temperature measurement (Prowirl 73)

In addition to the volume flow, the Prowirl 73 also measures the fluid temperature. The temperature is

measured by means of a temperature sensor Pt 1000 which is located in the paddle of the DSC sensor,

i.e. directly in the fluid ( ä 4).

Flow computer (Prowirl 73)

The electronics of the Prowirl 73 have an integral flow computer. With the aid of this flow computer other

process variables can be calculated from the primary measured variables (volume flow and temperature), e.g.:

• The mass flow and heat flow of saturated steam and water in accordance with IAPWS-IF97/ASME

• The mass flow and heat flow of superheated steam (at constant pressure or pressure read in via HART/

PROFIBUS PA/FOUNDATION Fieldbus) in accordance with IAPWS-IF97/ASME

• The mass flow and corrected volume flow of gases (at constant pressure or pressure read in via HART/

PROFIBUS PA/FOUNDATION Fieldbus), e.g. compressed air and natural gas AGA NX-19, AGA8-DC92,

ISO12213-2, AGA8 Gross Method 1 and SGERG-88 (see below). Additional gases can be programmed using

the real gas equation.

a

b

c d

Proline Prowirl 72F, 72W, 73F, 73W

6 Endress+Hauser

In the case of 4 to 20mA HART devices, the following gases are preprogrammed:

The heat flow (energy) of these gases is calculated as per ISO 6976 - based on the net calorific value or gross

calorific value.

• Optional with PROFIBUS PA and FOUNDATION Fieldbus: natural gas AGA NX-19 (corrected volume flow

and mass flow);

Optional for 4 to 20 mA HART: natural gas AGA NX-19, AGA8-DC92, ISO 12213-2, AGA8 Gross Method1,

SGERG-88 (corrected volume flow, mass flow, heat flow).

For natural gas AGA NX-19, AGA8 Gross Method 1 and SGERG-88, the gross calorific value or the net

calorific value can be entered to calculate the heat flow (energy). For AGA8-DC92 and ISO 12213-2, the

data for the gross calorific value and net calorific value are stored in the device according ISO 6976.

• The mass flow of any liquid (linear equation). The gross calorific value or the net calorific value can be

entered to calculate the heat flow (energy).

• Delta heat between saturated steam and condensate (second temperature value read in via HART) in

accordance with IAPWS-IF97/ASME.

• Delta heat between warm water and cold water (second temperature value read in via HART) in accordance

with IAPWS-IF97/ASME.

• In saturated steam measurements, the pressure of the steam can also be calculated from the measured

temperature and output in accordance with IAPWS-IF97/ASME.

The mass flow is calculated as the product of (volume flow × operating density). In the case of saturated steam,

water and other liquids, the operating density is a function of the temperature. In the case of superheated steam

and all other gases, the operating density is a function of the temperature and pressure.

The corrected volume flow is calculated as the product of (volume flow × operating density), divided by the

reference density. In the case of water and other liquids, the operating density is a function of the temperature.

In the case of all other gases, the operating density is a function of the temperature and pressure.

The heat flow is calculated as the product of (volume flow × operating density × specific enthalpy). In the case

of saturated steam and water, the operating density is a function of the temperature. In the case of superheated

steam, natural gas NX-19, natural gas AGA8-DC92, natural gas ISO 12213-2, natural gas AGA8 Gross Method

1 and natural gas SGERG-88, the operating density is a function of the temperature and pressure.

Diagnostic functions (Prowirl 73)

Extensive diagnostic options, such as retracing fluid and ambient temperatures, extreme flows etc., are also

optionally available for the measuring device.

Ammonia Helium 4 Nitrogen

Argon Hydrogen (normal) Oxygen

Butane Hydrogen chloride Propane

Carbon dioxide Hydrogen sulfide Xenon

Chlorine Krypton Mixtures of up to 8 components of

these gases

Ethane Methane

Ethylene (ethene) Neon

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 7

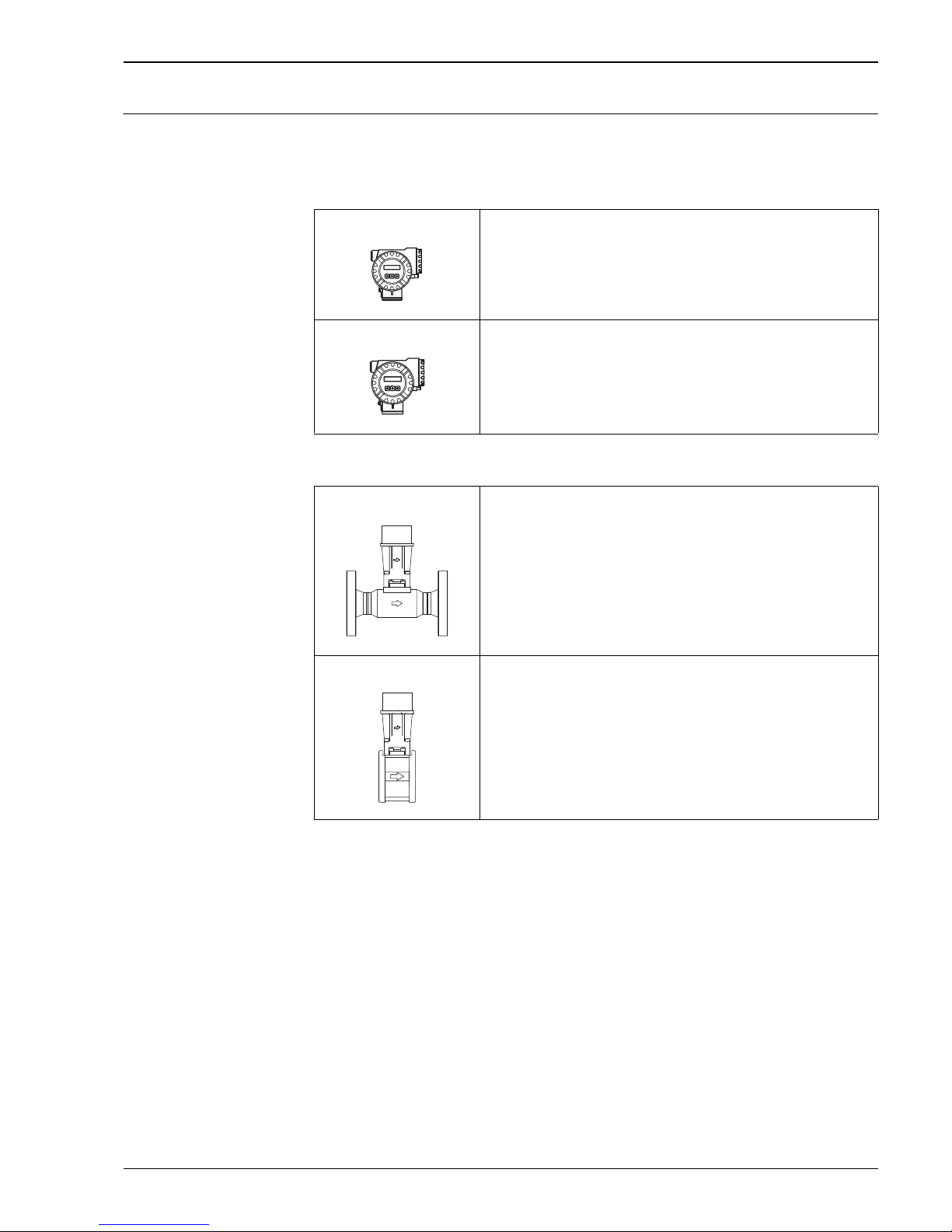

Measuring system The measuring system comprises a sensor and a transmitter. Two versions are available:

• Compact version: sensor and transmitter form a mechanical unit.

• Remote version: sensor is mounted separate from the transmitter (up to max. 30 m / 98 ft).

Transmitter

Sensor

Prowirl 72

A0009906

• Two-line liquid crystal display

• Configuration using pushbuttons

• Quick Setup for rapid commissioning

• Volume flow and calculated variables (mass flow or corrected volume flow)

Prowirl 73

A0009906

• Two-line liquid crystal display

• Configuration using pushbuttons

• Quick Setup for rapid commissioning

• Volume flow and temperature as well as calculated variables (mass flow, heat flow

or corrected volume flow)

F

A0009921

• Flanged version

• Range of nominal diameters DN 15 to 300 (½ to 12")

• Material of measuring tube: e.g.

– Stainless steel, A351-CF3M

– Alloy C-22 (only for Prowirl 72)

W

A0009922

• Wafer version (flangeless version)

• Range of nominal diameters DN 15 to 150 (½ to 6")

• Material of measuring tube: e.g. stainless steel, A351-CF3M

Esc

E

-

+

Esc

E

-

+

Proline Prowirl 72F, 72W, 73F, 73W

8 Endress+Hauser

Input

Measured variable Prowirl 72

• Volumetric flow (volume flow) is proportional to the frequency of vortex shedding after the bluff body.

• The following can be output as the output variable:

– Volume flow

– Mass flow or corrected volume flow (if process conditions are constant)

Prowirl 73

• Volumetric flow (volume flow) is proportional to the frequency of vortex shedding after the bluff body.

• The temperature can be output directly and is used to calculate the mass flow for example.

• The following can be output as the output variable:

– The measured process variables volume flow and temperature

– The calculated process variables mass flow, heat flow or corrected volume flow

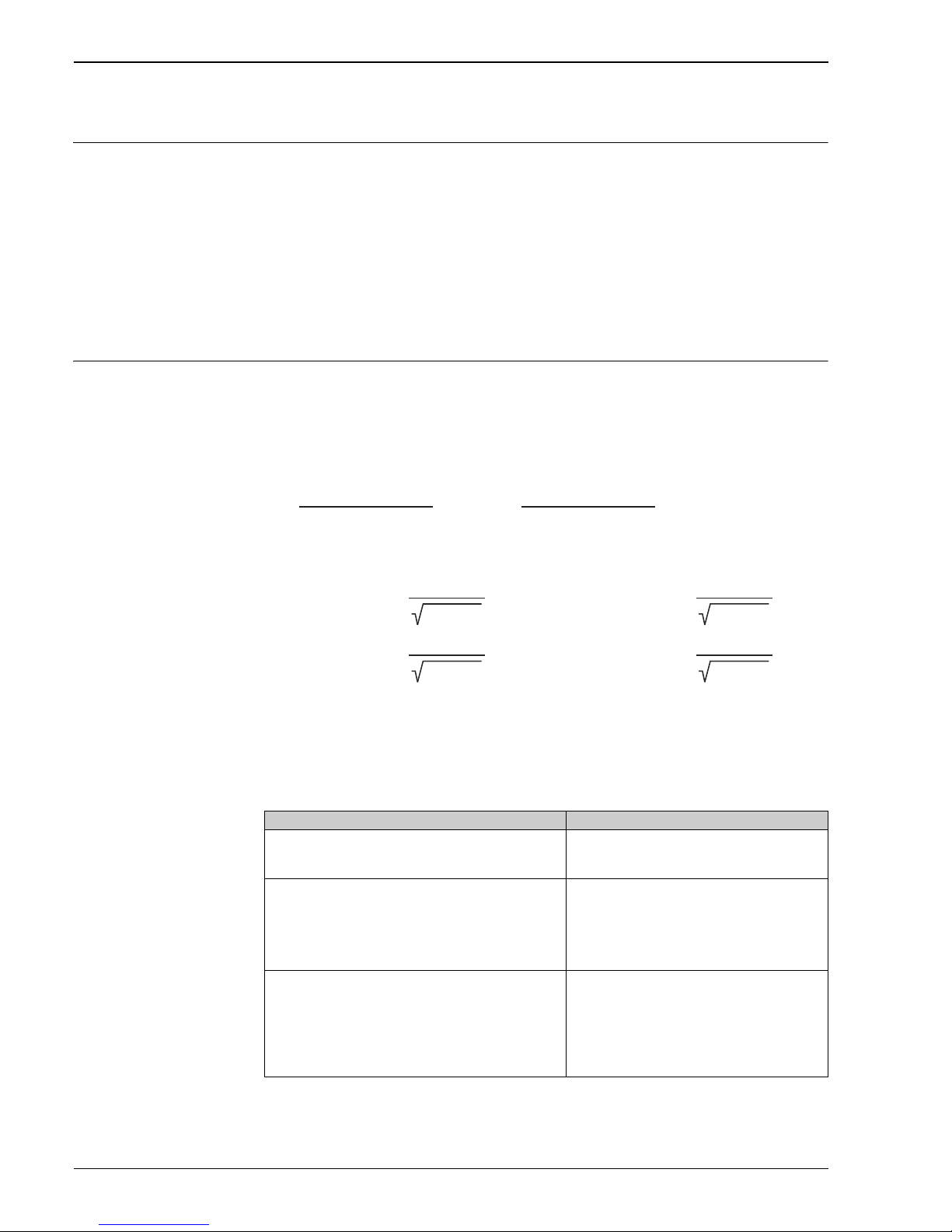

Measuring range The measuring range depends on the fluid and the nominal diameter.

Start of measuring range

Depends on the density and the Reynolds number (Re

min

= 4000, Re

linear

= 20 000).

The Reynolds number is dimensionless and is the ratio of inertial forces to viscous forces of the fluid. It is used

for characterizing the flow. The Reynolds number is calculated as follows:

A0003794

Re = Reynolds number; Q = flow; di = internal diameter; = dynamic viscosity, = density

A0003239

* with amplification 5

Full scale value

Liquids: v

max

= 9 m/s (30 ft/s)

Gas/steam: see table

!

Note!

By using the selection and planning program "Applicator", you can determine the exact values for the fluid you

use. You can obtain the Applicator from your Endress+Hauser sales center or on the Internet under

www.endress.com.

Re

=

4·Q · m³[m³/s] [kg/ ]r

di [m] · µp · [Pa·s]

Re

=

4·Q · ³[ft³/s] [lb/ft ]r

di [ft] · µp · [0.001 cP]

Re

=

4·Q · m³[m³/s] [kg/ ]r

di [m] · µp · [Pa·s]

v

½…1"

®

=

min.

4.92

r [lb/ft³]

v

1½…12"

® =

min.

5.74

r [lb/ft³]

[ft/s] [ft/s]

v

DN 15…25

®

=

min.

6

r [kg/m³]

v

DN 40…300

® =

min.

7

r [kg/m³]

[m/s] [m/s]

*

*

*

*

Nominal diameter v

max

Standard version: DN 15 (½")

R Style: DN 25 (1") > DN 15 (½")

S Style: DN 40 (1½") >> DN 15 (½")

46 m/s (151 ft/s) or Mach 0.3

(depending on which value is smaller)

Standard version: DN 25 (1"), DN 40 (1½")

R Style:

– DN 40 (1½") > DN 25 (1")

– DN 50 (2") > DN 40 (1½")

S Style:

– DN 80 (3") >> DN 40 (1½")

75 m/s (246 ft/s) or Mach 0.3

(depending on which value is smaller)

Standard version: DN 50 to 300 (2 to 12")

R Style:

– DN 80 (3") > DN 50 (2")

– Nominal diameters larger than DN 80 (3")

S Style:

– DN 100 (4") >> DN 50 (2")

– Nominal diameters larger than DN 100 (4")

120 m/s (394 ft/s) or Mach 0.3

(depending on which value is smaller)

Calibrated range: up to 75 m/s (246 ft/s)

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 9

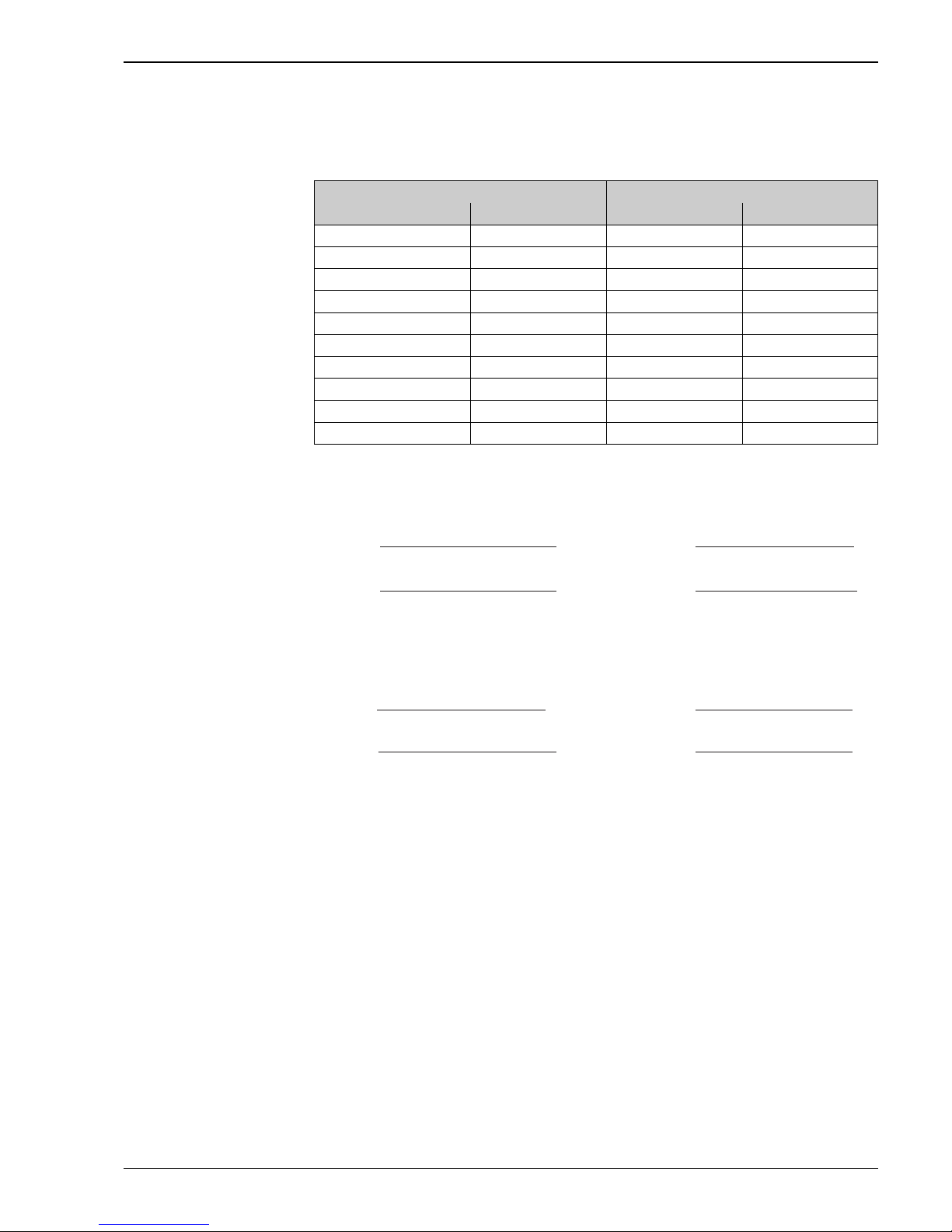

K-factor range

The table is used for orientation purposes. The range in which the K-factor can be is indicated for individual

nominal diameters and designs.

Measuring range for gases [m³/h or Nm³/h]

In the case of gases, the start of the measuring range depends on the density. With ideal gases, the density []

or corrected density [

N

] can be calculated using the following formulae:

A0003946

The following formulae can be used to calculate the volume [Q ] or corrected volume [ QN] in the case of ideal

gases:

A0003941

T = Operating temperature, P = operating pressure

Nominal diameter K-factor range (pulses/dm)

DIN/JIS ANSI 72F / 73F 72W / 73W

DN 15 ½" 390 to 450 245 to 280

DN 25 1" 70 to 85 48 to 55

DN 40 1½" 18 to 22 14 to 17

DN 50 2" 8 to 11 6 to 8

DN 80 3" 2.5 to 3.2 1.9 to 2.4

DN 100 4" 1.1 to 1.4 0.9 to 1.1

DN 150 6" 0.3 to 0.4 0.27 to 0.32

DN 200 8" 0.1266 to 0.1400 –

DN 250 10" 0.0677 to 0.0748 –

DN 300 12" 0.0364 to 0.0402 –

r [kg/m³] =

[kg/Nm³] · P [bar abs] · 273.15 [K]

N

r

T [K] · 1.013 [bar abs]

[kg/Nm³] =

[kg/m³] · T [K] · 1.013 [bar abs]

N

r

r

P [bar abs] · 273.15 [K]

r [kg/m³] =

[kg/Nm³] · P [bar abs] · 273.15 [K]

N

r

T [K] · 1.013 [bar abs]

[kg/Nm³] =

[kg/m³] · T [K] · 1.013 [bar abs]

N

r

r

P [bar abs] · 273.15 [K]

r [lb/ft³] =

[lb/SCF] · P [psia] · 530 [°R]

N

r

T [°F + 460] · 14.7 [psia]

[lb/SCF] =

[lb/ft³] · T [°F + 460] · 14.7 [psia]

N

r

r

P [psia] · 530 [°R]

[Nm³/h] =

N

Q

[m³/h] · P [bar abs] · 273.15 [K]Q

T [K] · 1.013 [bar abs]

Q [m³/h] =

N

[Nm³/h] · T [K] · 1.013 [bar abs]

Q

P [bar abs] · 273.15 [K]

[Nm³/h] =

N

Q

[m³/h] · P [bar abs] · 273.15 [K]Q

T [K] · 1.013 [bar abs]

Q [m³/h] =

N

[Nm³/h] · T [K] · 1.013 [bar abs]

Q

P [bar abs] · 273.15 [K]

[SCF/h] =

N

Q

[ft³/h] · P [psia] · 530 [°R]Q

T [°F + 460] · 14.7 [psia]

Q [ft³/h] =

N

[SCF/h] · T [°F + 460] · 14.7 [psia]

Q

P [psia] · 530 [°R]

Proline Prowirl 72F, 72W, 73F, 73W

10 Endress+Hauser

Input signal HART input functionality (Prowirl 73)

Prowirl 73 (4 to 20 mA HART) is able to read in an external pressure, temperature or density value. The

following order options are required for this purpose:

• Prowirl 73: output/input option W (4–20 mA HART) or A (4–20 mA HART + frequency)

•2 active barrier RN221N–x1 (for x: A = for non-hazardous areas, B = ATEX, C = FM, D = CSA)

• If reading in pressure: 1 Cerabar M or Cerabar S in burst mode (Activated burst mode must be noted with

the order of the Cerabar M or S. Otherwise the burst mode must be activated locally either with FieldCare

or with a HART handheld (FieldXpert).)

When this functionality is used, the following signals can be made available to the control system, e.g. in an

application with superheated steam:

• Pressure as 4 to 20 mA signal

•Temperature

• Mass flow

Pressure input (PROFIBUS PA, FOUNDATION Fieldbus)

An external pressure value function block can be read in with Prowirl 73 (bus version). The following order

options are required for this purpose:

PROFIBUS PA:

• Prowirl 73 output/input option H (PROFIBUS PA)

• Cerabar M electronics/display option P or R; ceramic sensor option 2F, 2H, 2M, 2P or 2S

Cerabar S Evolution output/operation option M, N or O; d:sensor range option 2C, 2E, 2F, 2H,

2K, 2M, 2P or 2S

FOUNDATION Fieldbus (FF):

• Prowirl 73 output/input option K (FOUNDATION Fieldbus)

• Cerabar S Evolution output/operation option P, Q or R; d:sensor range option 2C, 2E, 2F, 2H,

2K, 2M, 2P or 2S

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 11

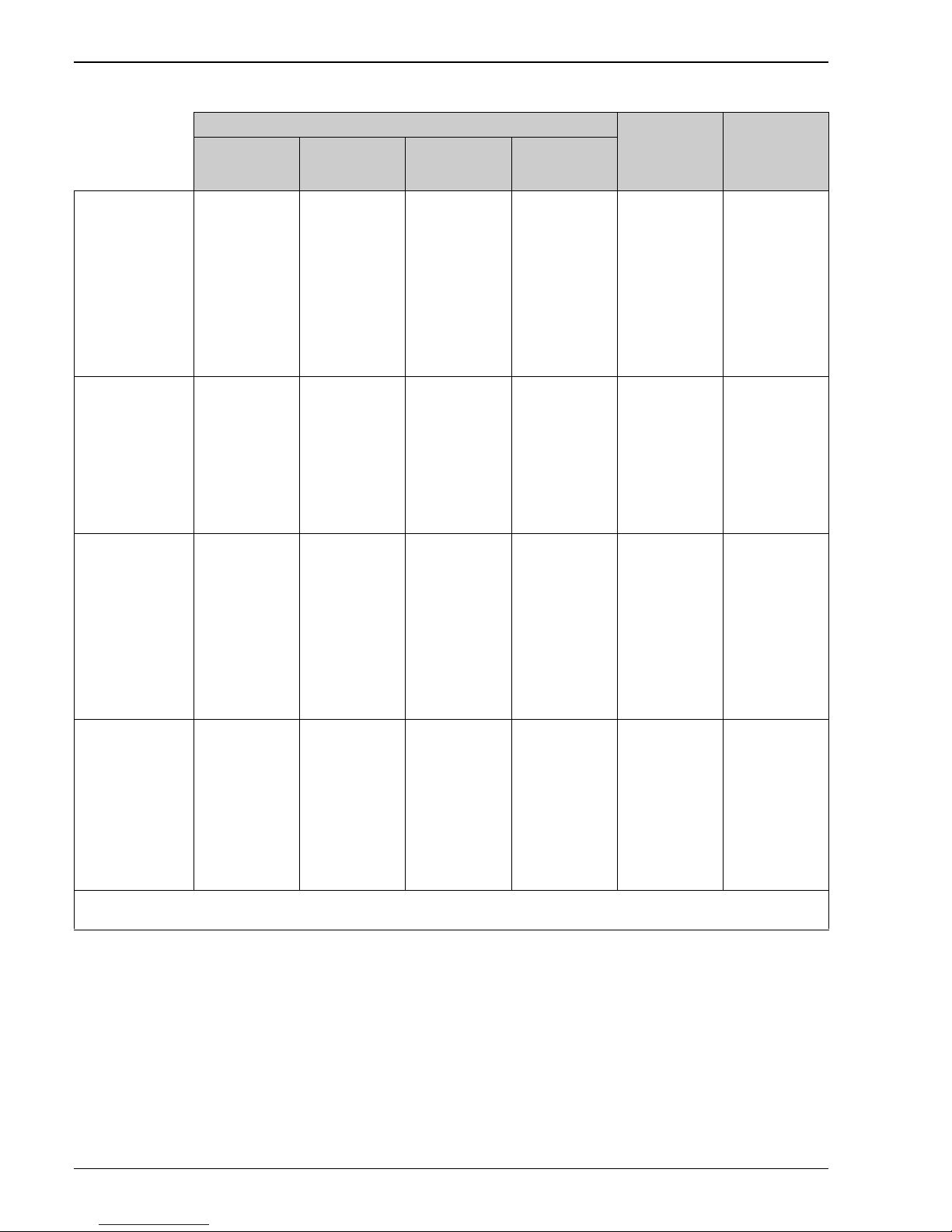

Output

Prowirl 72

By means of the outputs in the 4 to 20 mA/HART version of Prowirl 72, the volume flow and, if process

conditions are constant, the calculated mass flow and corrected volume flow can be output via the current

output and optionally via the pulse output or as a limit value via the status output.

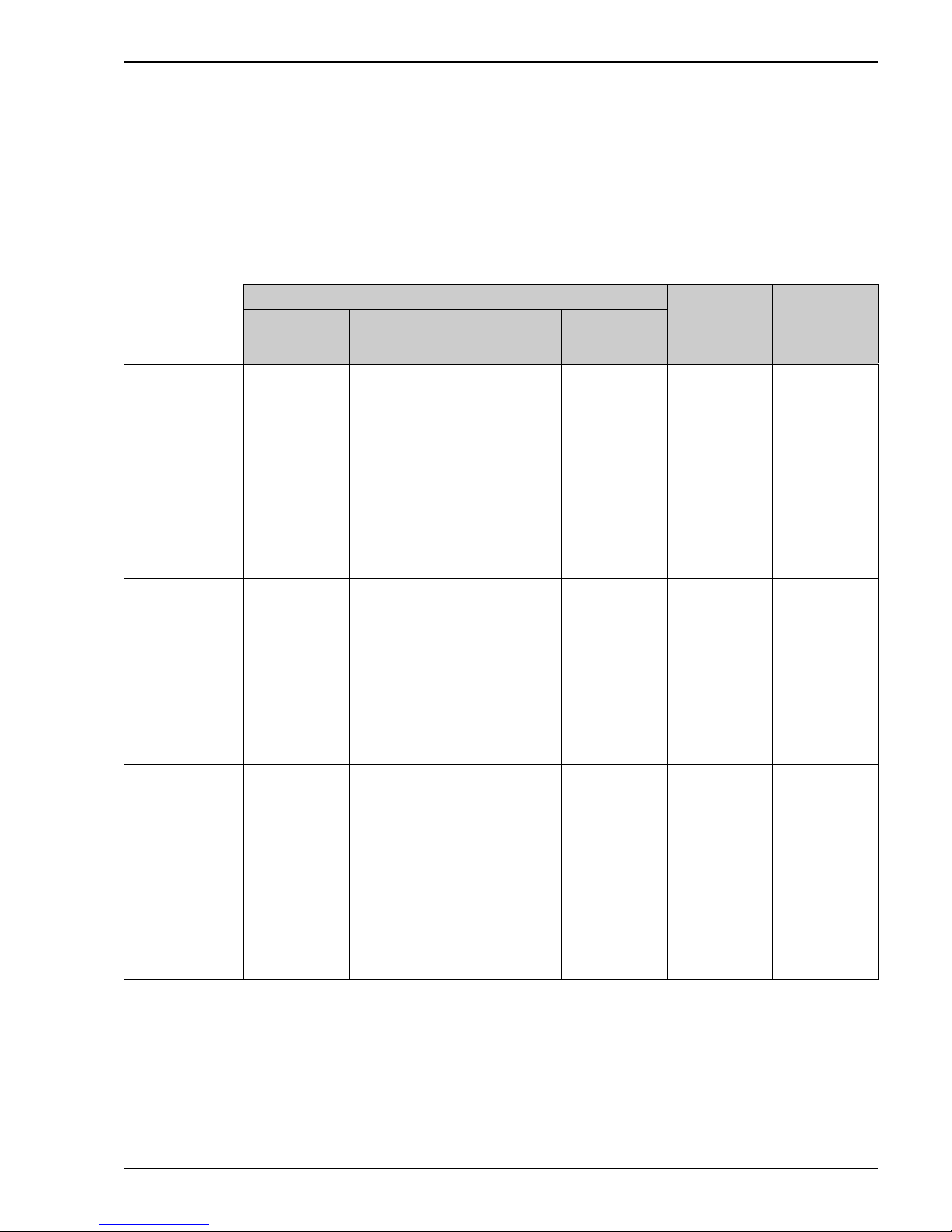

Prowirl 73

By means of the outputs in the 4 to 20 mA/HART version of Prowirl 73, the following measured variables can

generally be output:

4 to 20 mA HART measuring devices

PROFIBUS - PA

(4 AI Blocks)

FOUNDATION

Fieldbus FF

(7 AI Blocks)

Current output

Frequency output

(only for output

option A)

Pulse output

(only for output

option A)

Status output

(only for output

option A)

Saturated steam

• Volume flow/mass

flow/heat flow

• Temperature

• Saturation steam

pressure

• Volume flow/mass

flow/heat flow

• Temperature

• Saturation steam

pressure

•Volume

•Mass

•Heat

• Volume flow/mass

flow/heat flow

limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

•Calculated

saturated steam

pressure limit value

• Volume flow/mass

flow/heat flow

• Temperature

• Saturation steam

pressure

• Specific enthalpy

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

• Volume flow/mass

flow/heat flow

• Temperature

• Saturation steam

pressure

• Specific enthalpy

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

Superheated steam

• Volume flow/mass

flow/heat flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

• Volume flow/mass

flow/heat flow

limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

• Volume flow/mass

flow/heat flow

• Temperature

• Specific enthalpy

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

• Volume flow/mass

flow/heat flow

• Temperature

• Specific enthalpy

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

Water

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

•

Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• Specific enthalpy

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• Specific enthalpy

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

Proline Prowirl 72F, 72W, 73F, 73W

12 Endress+Hauser

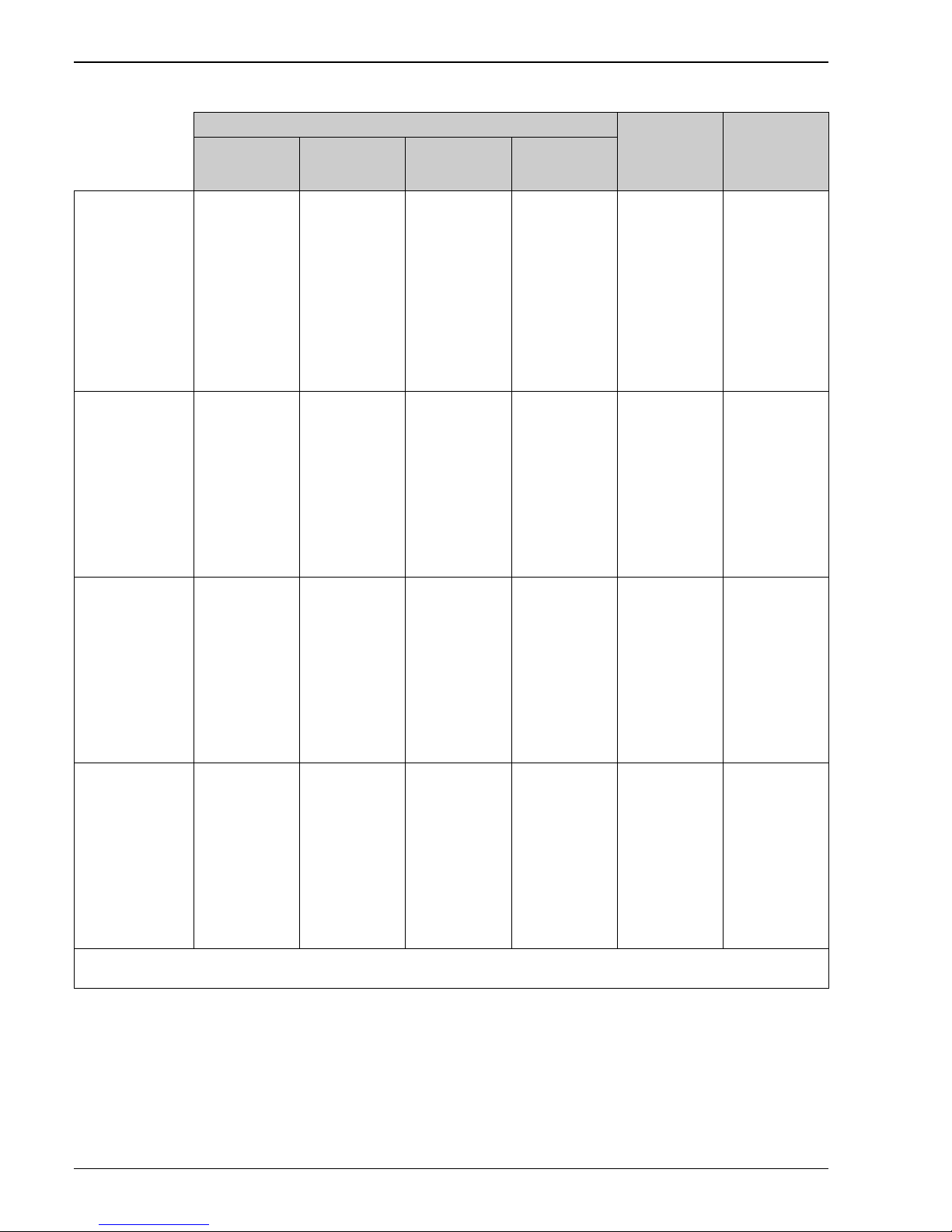

Compressed air

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

• Volume flow/mass

flow/corrected

volume flow

• Temperature

• Compressibility

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

• Volume flow/mass

flow/corrected

volume flow

• Temperature

• Compressibility

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

Ar, NH3, C4H10,

CO2, CO, Cl2, C2H6,

C2H4, He 4, H2

(normal), HCl, H2S,

Kr, CH4, Ne, N2, O2,

C3H8, Xe*

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/corrected

volume flow limit

value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

No data

Use real gas

equation

No data

Use real gas

equation

Mixtures of up to 8 of

the components above

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•H

eat

•Corrected volume

• Volume flow/mass

flow/corrected

volume flow limit

value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

No data

Use real gas

equation

No data

Use real gas

equation

Real gas equation

• Volume flow/mass

flow/corrected

volume flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/corrected

volume flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Corrected volume

• Volume flow/mass

flow/corrected

volume flow limit

value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

• Volume flow/mass

flow/corrected

volume flow

• Temperature

•Frequency

• Flow velocity

• Totalizer

• Optional:

electronics

temperature

• Volume flow/mass

flow/corrected

volume flow

• Temperature

•Frequency

• Flow velocity

• Totalizer

• Optional:

electronics

temperature

* Argon, ammonia, butane, carbon dioxide, carbon monoxide, chlorine, ethane, ethylene (ethene), helium 4, hydrogen (normal), hydrogen chloride, hydrogen

sulfide, krypton, methane, neon, nitrogen, oxygen, propane, xenon

4 to 20 mA HART measuring devices

PROFIBUS - PA

(4 AI Blocks)

FOUNDATION

Fieldbus FF

(7 AI Blocks)

Current output

Frequency output

(only for output

option A)

Pulse output

(only for output

option A)

Status output

(only for output

option A)

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 13

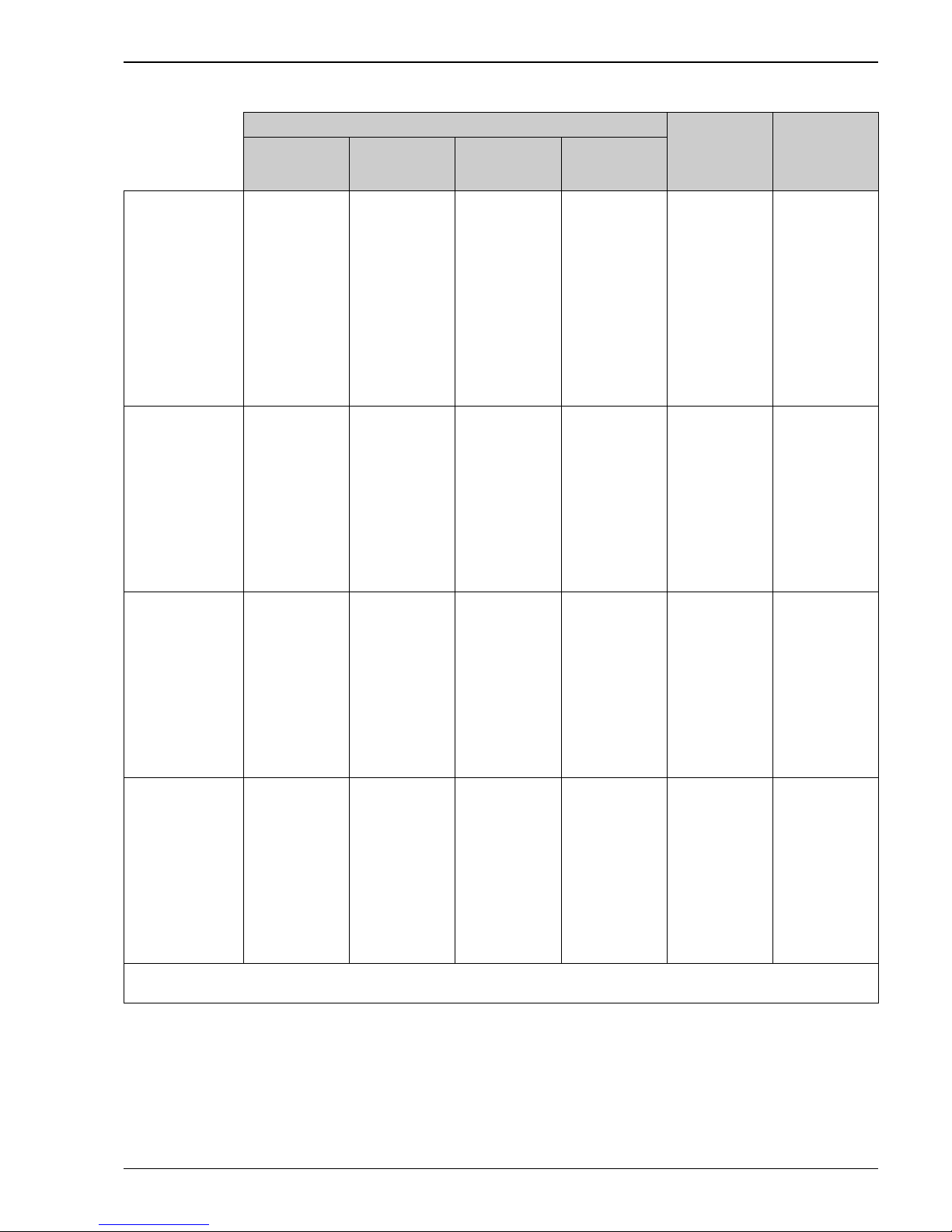

Natural gas AGA NX19

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/corrected

volume flow limit

value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

• Volume flow/mass

flow/corrected

volume flow

• Temperature

• Supercompressibility

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

• Volume flow/mass

flow/corrected

volume flow

• Temperature

• Supercompressibility

•Frequency

• Flow velocity

• Totalizer

• Optional:

–Reynolds

number

– Electronics

temperature

Natural gas

AGA8-DC92 detailed

method

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

No data

Use natural gas

AGA NX-19 or real

gas equation

No data

Use natural gas

AGA NX-19 or real

gas equation

Natural gas

ISO 12213-2

• Volume flow/mass

flow/heat flow/

corrected volume

flow

•

Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

No data

Use natural gas

AGA NX-19 or real

gas equation

No data

Use natural gas

AGA NX-19 or real

gas equation

Natural gas AGA8

Gross Method 1

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

No data

Use natural gas

AGA NX-19 or real

gas equation

No data

Use natural gas

AGA NX-19 or real

gas equation

* Argon, ammonia, butane, carbon dioxide, carbon monoxide, chlorine, ethane, ethylene (ethene), helium 4, hydrogen (normal), hydrogen chloride, hydrogen

sulfide, krypton, methane, neon, nitrogen, oxygen, propane, xenon

4 to 20 mA HART measuring devices

PROFIBUS - PA

(4 AI Blocks)

FOUNDATION

Fieldbus FF

(7 AI Blocks)

Current output

Frequency output

(only for output

option A)

Pulse output

(only for output

option A)

Status output

(only for output

option A)

Proline Prowirl 72F, 72W, 73F, 73W

14 Endress+Hauser

If configured, the following calculated measured variables can also be displayed via the local display in

Prowirl 73:

•Density

• Specific enthalpy

• Saturation steam pressure (for saturated steam)

•Z-factor

• Flow velocity

Natural gas SGERG-88

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• External pressure

(if it can be read in)

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• External pressure

limit value (if it can

be read in)

No data

Use natural gas

AGA NX-19 or real

gas equation

No data

Use natural gas

AGA NX-19 or real

gas equation

User-defined liquid

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/corrected

volume flow limit

value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

• Volume flow/mass

flow/corrected

volume flow

• Temperature

•Frequency

• Flow velocity

• Totalizer

• Optional:

electronics

temperature

• Volume flow/mass

flow/corrected

volume flow

• Temperature

•Frequency

• Flow velocity

• Totalizer

• Optional:

electronics

temperature

Water delta heat

application

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

•External

temperature

• Volume flow/mass

flow/heat flow/

corrected volume

flow

• Temperature

•External

temperature

•Volume

•Mass

•Heat

•Corrected volume

• Volume flow/mass

flow/heat flow/

corrected volume

flow limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

•External

temperature limit

va

lue

No data No data

Saturated steam delta

heat application

• Volume flow/mass

flow/heat flow

• Temperature

•External

temperature

• Volume flow/mass

flow/heat flow

• Temperature

•External

temperature

•Volume

•Mass

•Heat

• Volume flow/mass

flow/heat flow

limit value

• Temperature limit

value

• Totalizer limit

value

• Velocity limit value

•External

temperature limit

value

No data No data

* Argon, ammonia, butane, carbon dioxide, carbon monoxide, chlorine, ethane, ethylene (ethene), helium 4, hydrogen (normal), hydrogen chloride, hydrogen

sulfide, krypton, methane, neon, nitrogen, oxygen, propane, xenon

4 to 20 mA HART measuring devices

PROFIBUS - PA

(4 AI Blocks)

FOUNDATION

Fieldbus FF

(7 AI Blocks)

Current output

Frequency output

(only for output

option A)

Pulse output

(only for output

option A)

Status output

(only for output

option A)

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 15

Output signal Prowirl 72

Current output:

• 4 to 20 mA with HART,

• Full scale value and time constant (0 to 100 s) can be set

Pulse/status output:

• Open collector, passive, galvanically isolated

– Non-Ex, Ex d/XP version: U

max

= 36 V, with 15 mA current limiting, Ri = 500

– Ex i/IS and Ex n version: U

max

= 30 V, with 15 mA current limiting, Ri = 500

The pulse/status output can be configured as:

• Pulse output:

– Pulse value and polarity can be selected

– Pulse width can be configured (0.005 to 2 s)

– Pulse frequency max. 100 Hz

• Status output:

Can be configured for error messages or flow limit values

• Vortex frequency:

– Direct output of unscaled vortex pulses 0.5 to 2850 Hz

(e.g. for connecting to an RMC621 flow computer)

– Pulse ratio 1:1

• PFM signal (pulse/frequency modulation):

With external connection via flow computer RMC621 or RMS621

PROFIBUS PA interface:

• PROFIBUS PA in accordance with EN 50170 Volume 2, IEC 61158-2 (MBP), galvanically isolated

• Current consumption = 16 mA

• Error current FDE (fault disconnection electronic) = 0 mA

• Data transmission rate: supported baudrate = 31.25 kBit/s

• Signal encoding = Manchester II

• Function blocks: 1 Analog Input, 1 totalizer

• Output data: volume flow, calculated mass flow, corrected volume flow, totalizer

• Input data: positive zero return (ON/OFF), totalizer control

• Bus address can be set at the device via DIP switches

FOUNDATION Fieldbus interface:

• FOUNDATION Fieldbus H1, IEC 61158-2, galvanically isolated

• Current consumption = 16 mA

• Error current FDE (fault disconnection electronic) = 0 mA

• Data transmission rate: supported baudrate = 31.25 kBit/s

• Signal encoding = Manchester II

• Function blocks: 2 Analog Input, 1 Discrete Output

• Output data: volume flow, calculated mass flow, corrected volume flow, totalizer

• Input data: positive zero return (ON/OFF), totalizer reset

• Link Master (LM) functionality is supported

Proline Prowirl 72F, 72W, 73F, 73W

16 Endress+Hauser

Prowirl 73

Current output:

• 4 to 20 mA with HART,

• Full scale value and time constant (0 to 100 s) can be set

Frequency output, pulse/status output:

• Frequency output (optional): open collector, passive, galvanically isolated

– Non-Ex, Ex d/XP version: U

max

= 36 V, with 15 mA current limiting, Ri = 500

– Ex i/IS and Ex n version: U

max

= 30 V, with 15 mA current limiting, Ri = 500

The pulse/status output can be configured as:

• Frequency output:

– End frequency 0 to 1000 Hz (fmax = 1250 Hz)

• Pulse output:

– Pulse value and polarity can be selected

– Pulse width can be configured (0.005 to 2 s)

– Pulse frequency max. 100 Hz

• Status output:

Can be configured for error messages or flow values, temperature values, pressure limit values

• Vortex frequency:

– Direct output of unscaled vortex pulses 0.5 to 2850 Hz

(e.g. for connecting to an RMC621 flow computer)

– Pulse ratio 1:1

PROFIBUS PA interface:

• PROFIBUS PA in accordance with EN 50170 Volume 2, IEC 61158-2 (MBP), galvanically isolated

• Current consumption = 16 mA

• Error current FDE (fault disconnection electronic) = 0 mA

• Data transmission rate: supported baudrate = 31.25 kBit/s

• Signal encoding = Manchester II

• Function blocks: 4 Analog Input, 2 totalizer

• Output data: volume flow, mass flow, corrected volume flow, heat flow, temperature, density, specific

enthalpy, calculated steam pressure (saturated steam), operating Z-factor, vortex frequency, electronics

temperature, Reynolds number, velocity, totalizer

• Input data: positive zero return (ON/OFF), totalizer control, absolute pressure, display value

• Bus address can be set at the device via DIP switches

FOUNDATION Fieldbus interface:

• FOUNDATION Fieldbus H1, IEC 61158-2, galvanically isolated

• Current consumption = 16 mA

• Error current FDE (fault disconnection electronic) = 0 mA

• Data transmission rate: supported baudrate = 31.25 kBit/s

• Signal encoding = Manchester II

• Function blocks: 6 Analog Input, 1 Discrete Output, 1 Analog Output

• Output data: volume flow, mass flow, corrected volume flow, heat flow, temperature, density, specific

enthalpy, calculated steam pressure (saturated steam), operating Z-factor, vortex frequency, electronics

temperature, Reynolds number, velocity, totalizer 1 + 2

• Input data: positive zero return (ON/OFF), totalizer reset, absolute pressure

• Link Master (LM) functionality is supported

Signal on alarm • Current output: error response can be selected (e.g. in accordance with NAMUR Recommendation NE 43)

• Pulse output: error response can be selected

• Status output: "not conducting" in event of fault

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 17

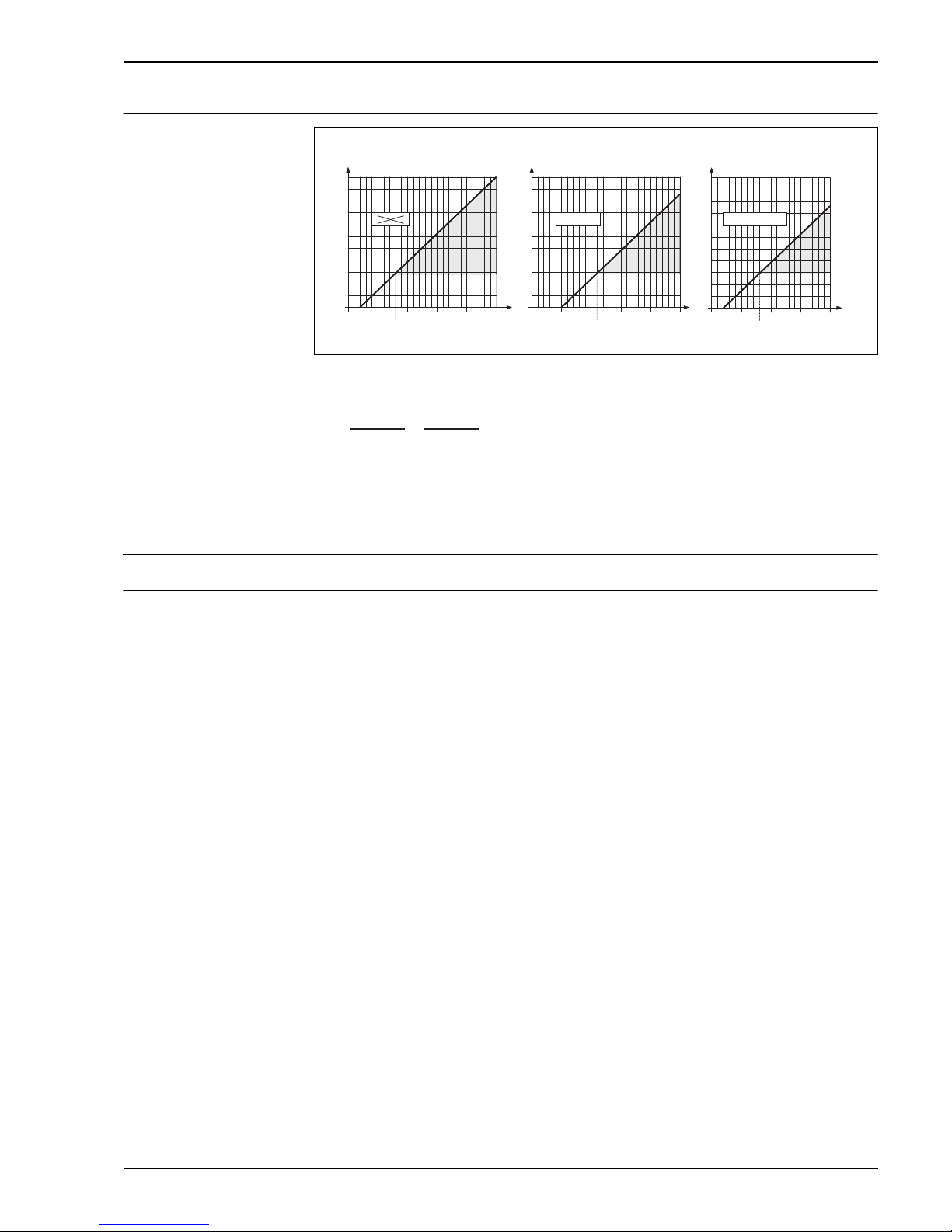

Load

A0001921

The area shaded gray refers to the permitted load (for HART: min. 250 )

The load is calculated as follows:

R

B

Load, load resistance

U

S

Supply voltage: non-Ex = 12 to 36 V DC; Ex d /XP= 15 to 36 V DC; Ex i /IS and Ex n = 12 to 30 V DC

U

Kl

Terminal voltage: non-Ex = min. 12 V DC; Ex d/XP = min. 15 V DC; Ex i/IS and Ex n = min. 12 V DC

I

max

Output current (22.6 mA)

Low flow cut off Switch points for low flow cut off can be selected as required.

Galvanic isolation All electrical connections are galvanically isolated from one another.

00

100 100

200 200

300 300

400 400

500 500

600 600

700 700

800 800

900 900

1000 1000

1100 1100

BB

RR

[] []

10 1020 2025 2530 3036 3615 15

18

21

W

0

100

200

300

400

500

600

700

800

900

1000

1100

B

S

R

U

V

[]

[]

10

20 25 30

15

18

W

Ex i

Exi/Exn

W

Ex d

Ex

RB=

(U

SKl

– U )

(I )

max

-3

– 10 0.022

=

(U

SKl

– U )

Proline Prowirl 72F, 72W, 73F, 73W

18 Endress+Hauser

Power supply

Electrical connection

A0003392

A – HART: power supply, current output

– PROFIBUS PA: 1 = PA+, 2 = PA–

– FOUNDATION Fieldbus: 1 = FF+, 2 = FF–

B Optional pulse output (not for PROFIBUS PA and FOUNDATION Fieldbus), can also be operated as:

– Status output

– Only Prowirl 73: frequency output

– Only Prowirl 73: as a PFM output (pulse/frequency modulation) together with an RMC621 or

RMS621 flow computer

C Ground terminal (relevant for remote version)

D Only Prowirl 72: PFM (pulse/frequency modulation) wiring for connecting to flow computer RMC621 or RMS621

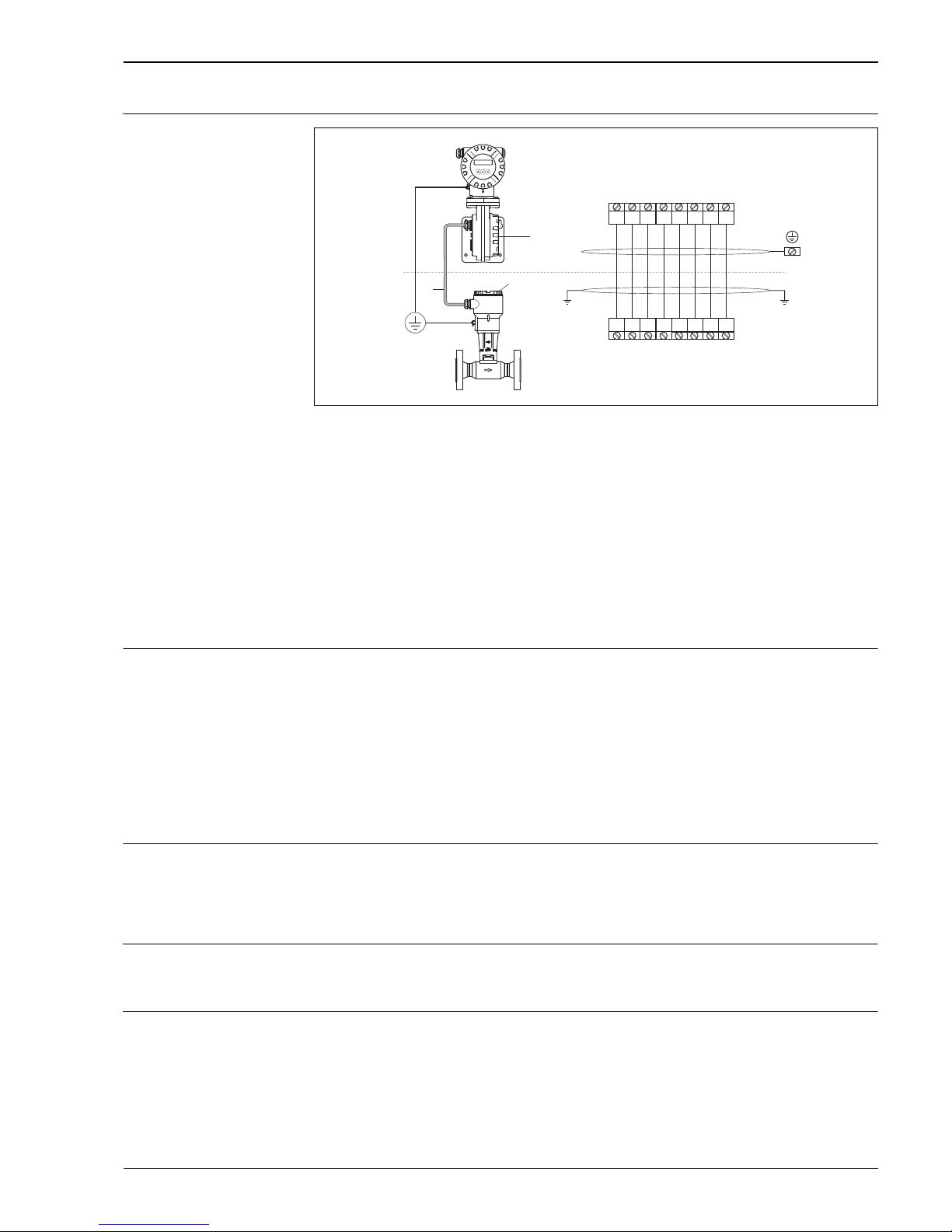

Wiring HART input

A0004215

1 Connection diagram for PLC with common "plus"

Dotted line = alternative wiring when only the signal of the Prowirl 73 is fed to the PLC.

2 Connection diagram for PLC with common "minus"

Dotted line = alternative wiring when only the signal of the Prowirl 73 is fed to the PLC.

3 Connection diagram without PLC

Dotted line = wiring without connection to external components (e.g. recorder, displays, Fieldgate, etc.)

A = Prowirl 73, B = pressure sensor (Cerabar M), C = temperature sensor (Omnigrad TR10) or other external measuring

devices (HART-enabled and burst-enabled), D = active barrier RN221N

12 1234 34

A

D

C

++++

----

C

B

1

2

3

C

1

2

AB

DD

1

1

2

2

1

2

I+ I–

I+

I–

D D

AB

C

1

2

1

2

I+ I–

I+

I–

250W

0+H

0–

0– 0+H0+0+

PLC+PLC (73) in PLC (p/T) in

PLC+

250W

0+

0+H

0– 0+

0+H

0–

PLC– PLC (73) in

PLC (p/T) inPLC–

250 W

0+

0+H

0– 0+

0+H

0–

–

+

–

+

Proline Prowirl 72F, 72W, 73F, 73W

Endress+Hauser 19

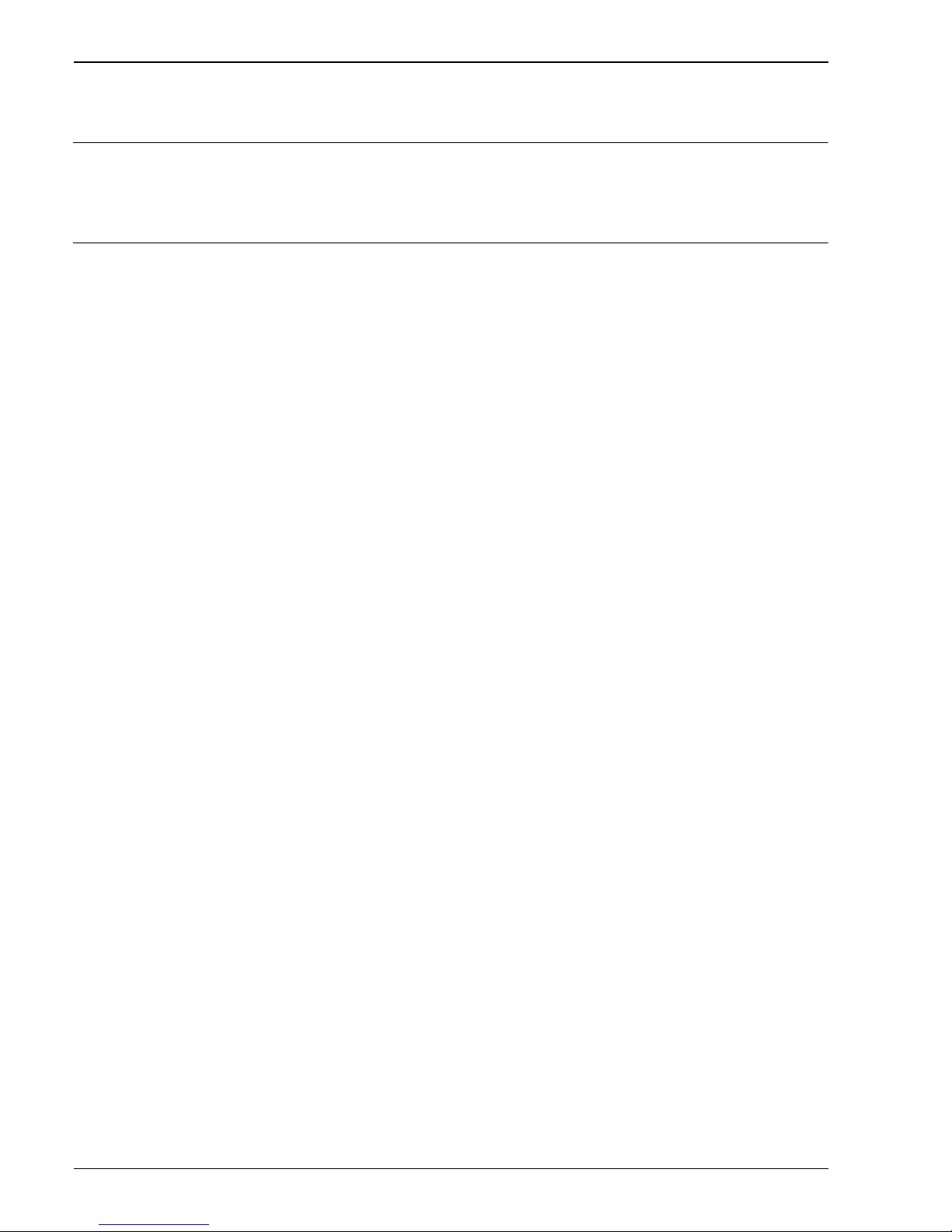

Wiring remote version

A0001893

Connecting the remote version

a = Connection compartment cover (transmitter)

b = Connection compartment cover (sensor)

c = Connecting cable (signal cable)

d = Identical potential matching for sensor and transmitter

e = Connect shielding to ground terminal in transmitter housing and keep as short as possible

f = Connect shielding to cable strain relief clamp in connection housing

Wire colors (color code according to DIN 47100):

Terminal number: 1 = white; 2 = brown; 3 = green; 4 = yellow, 5 = gray; 6 = pink; 7 = blue; 8 = red

Optionally available with armored signal cable. Been suitable for static laying and flexible applications with free movement

without tensile load and without obligatory guidance. For layings in dry and damp areas, in the soil as well as in the external

area.

Supply voltage HART:

• Non-Ex: 12 to 36 V DC (with HART: 18 to 36 V DC)

• Ex i/IS and Ex n: 12 to 30 V DC (with HART: 18 to 30 V DC)

• Ex d/XP: 15 to 36 V DC (with HART: 21 to 36 V DC)

PROFIBUS PA and FOUNDATION Fieldbus:

• Non-Ex: 9 to 32 V DC

• Ex i/IS and Ex n: 9 to 24 V DC

• Ex d/XP: 9 to 32 V DC

• Current consumption PROFIBUS PA: 16 mA, FOUNDATION Fieldbus: 16 mA

Cable entries Power supply and signal cables (outputs):

• Cable entry M20 1.5 (6 to 12 mm / 0.24 to 0.47")

• Cable entry M20 1.5 for armored signal cable (9.5 to 16 mm / 0.37 to 0.63")

• Thread for cable entry: ½" NPT, G ½", G ½" Shimada

• Fieldbus connector

Cable specifications Permitted temperature range:

• Standard cable: –40 °C (–40 °F) to maximum permissible ambient temperature plus 10 °C (18 °F)

• Armored cable: –30 to +70 °C (–22 to +158 °F)

Power supply failure • Totalizer stops at the last value determined.

• All settings are kept in the EEPROM.

• Error messages (incl. value of operated hours counter) are stored.

a

c

b

d

3

3

1

1

4

4

2

2

55667

7

8

8

DIFF +

DIFF +

DIFF –

DIFF –

GROUND

GROUND

+5VA

+5VA

–5VA

–5VA

TEMP 1

TEMP 1

TEMP 2

TEMP 2

TEMP 3

TEMP 3

e

f

Proline Prowirl 72F, 72W, 73F, 73W

20 Endress+Hauser

Performance characteristics

Reference operating

conditions

Error limits following ISO/DIN 11631:

• +20 to +30 °C (+68 to +86 °F)

• 2 to 4 bar (29 to 58 psi)

• Calibration rig traceable to national calibration standards

• Calibration with the process connection corresponding to the standard in question

Maximum measured error Prowirl 72

• Liquid:

< 0.75% o.r. for Re > 20000

< 0.75% o.f.s for Re between 4000 and 20000

• Gas/steam:

< 1% o.r. for Re > 20000 and v < 75 m/s (246 ft/s)

< 1% o.f.s for Re between 4000 and 20000

o.r. = of reading, o.f.s = of full scale value, Re = Reynolds number

Prowirl 73

• Volume flow (liquid):

< 0.75% o.r. for Re > 20000

< 0.75% o.f.s for Re between 4000 and 20000

• Volume flow (gas/steam):

< 1% o.r. for Re > 20000 and v < 75 m/s (246 ft/s)

< 1% o.f.s for Re between 4000 and 20000

•Temperature:

< 1°C / 1.8 °F (T > 100 °C / 212 °F, saturated steam and for liquids at ambient temperature);

< 1% o.r. [K] (gas)

Rise time 50% (agitated under water, following IEC 60751): 8 s

• Mass flow (saturated steam):

– For flow velocities 20 to 50 m/s (66 to 164 ft/s), T > 150 °C / 302 °F (423 K)

< 1.7% o.r. (2% o.r. for remote version) for Re > 20000

< 1.7% o.f.s (2% o.f.s for remote version) for Re between 4000 and 20000

– For flow velocities 10 to 70 m/s (33 to 230 ft/s), T > 140 °C / 284 °F (413 K)

< 2% o.r. (2.3% o.r. for remote version) for Re > 20000

< 2% o.f.s (2.3% o.f.s for remote version) for Re between 4000 and 20000

• Mass flow of superheated steam and gas (air, natural gas AGA NX-19, AGA8-DC92, ISO 12213-2, AGA8

Gross Method 1, SGERG-88, preprogrammed gases – does not apply to the real gas equation):

!

Note!

A Cerabar S device has to be used for the measuring errors listed below. The measured error used to calculate

the error in the measured pressure is 0.15%.

< 1.7% o.r. (2.0% o.r. for remote version) for Re > 20000 and process pressure < 40 bar abs (580 psi abs)

< 1.7% o.f.s. (2.0% for remote version) for Re between 4000 and 20000 and

process pressure < 40 bar abs (580 psi abs)

< 2.6% o.r. (2.9% o.r. for remote version) for Re > 20000 and process pressure < 120 bar abs (1740 psi abs)

< 2.6% o.f.s. (2.9% o.r. for remote version) for Re between 4000 and 20000 and

process pressure < 120 bar abs (1740 psi abs)

• Mass flow (water):

< 0.85% o.r. (1.15% o.r. for remote version) for Re > 20000

< 0.85% o.f.s (1.15% o.f.s for remote version) for Re between 4000 and 20000

• Mass flow (customer-defined liquids):

To specify the system accuracy, Endress+Hauser requires information on the type of liquid and its operating

temperature, or information in tabular form on the dependency between the liquid density and temperature.

Example: Acetone is to be measured at fluid temperatures between 70 and 90 °C (158 and 194 °F). The

parameters TEMPERATURE VALUE (here 80 °C / 176 °F), DENSITY VALUE (here 720.00 kg/m

) and

EXPANSION COEFFICIENT (here 18.0298 × 10E-4 1/°C) have to be entered in the transmitter for this

purpose. The overall system uncertainty, which is smaller than 0.9% for the example cited above, is made

up of the following measuring uncertainties: Uncertainty of volume flow measurement, uncertainty of

temperature measurement, uncertainty of the density-temperature correlation used (incl. the resulting

uncertainty of density).

Loading...

Loading...