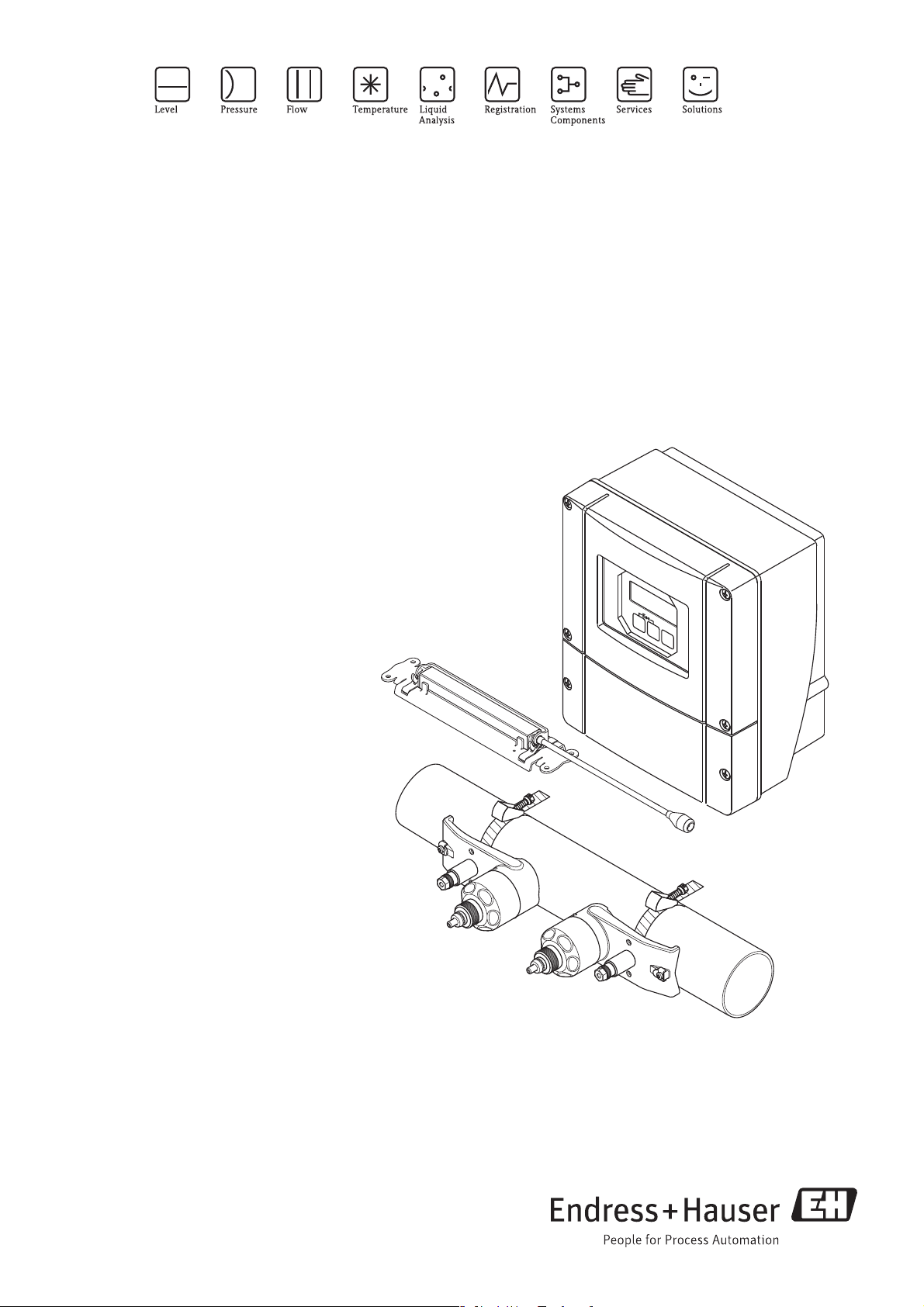

Page 1

Operating Instructions

Proline Prosonic Flow 93

HART

Ultrasonic flow measuring system

6

BA00070D/06/EN/13.11

71134382

Valid as of version

V 2.02.XX (Device software)

Page 2

Page 3

Proline Prosonic Flow 93 Table of contents

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and icons . . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Nameplate of the transmitter . . . . . . . . . . . . 7

2.1.2 Nameplate of the sensor . . . . . . . . . . . . . . . 8

2.1.3 Nameplate for the connections . . . . . . . . . . 9

2.2 Certificates and approvals . . . . . . . . . . . . . . . . . . . 10

2.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . 11

3.1 Incoming acceptance, transport and storage . . . . . . 11

3.1.1 Incoming acceptance . . . . . . . . . . . . . . . . . 11

3.1.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 Mounting location . . . . . . . . . . . . . . . . . . . 11

3.2.3 Orientation . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.4 Inlet and outlet run . . . . . . . . . . . . . . . . . . 12

3.2.5 Sensor selection and arrangement . . . . . . . 13

3.3 Two-channel operation . . . . . . . . . . . . . . . . . . . . . 14

3.3.1 Two-channel measurement . . . . . . . . . . . . 14

3.3.2 Two-path measurement . . . . . . . . . . . . . . . 15

3.4 Preparatory steps prior to installation . . . . . . . . . . . 16

3.5 Determining the necessary installation distances . . 16

3.5.1 Installation distances for Prosonic Flow

P or W clamp-on . . . . . . . . . . . . . . . . . . . 16

3.5.2 Installation distances for Prosonic Flow

W Insertion . . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 Determining values for installation distances . . . . . 17

3.6.1 Determining installation distances

via local operation . . . . . . . . . . . . . . . . . . . 17

3.6.2 Determining installation distances

via FieldCare . . . . . . . . . . . . . . . . . . . . . . . 22

3.6.3 Determining installation distances

via Applicator . . . . . . . . . . . . . . . . . . . . . . 28

3.7 Mechanical preparation . . . . . . . . . . . . . . . . . . . . . 30

3.7.1 Mounting the sensor holder with

U-shaped screws . . . . . . . . . . . . . . . . . . . . 30

3.7.2 Mounting the sensor holder

with strapping bands . . . . . . . . . . . . . . . . . 31

3.7.3 Premounting the strapping bands

(medium nominal diameters) . . . . . . . . . . . 32

3.7.4 Premounting the strapping bands

(large nominal diameters) . . . . . . . . . . . . . 33

3.7.5 Mounting the welded bolts . . . . . . . . . . . . 34

3.8 Installing Prosonic Flow W and P

(DN 15 to 65 / ½ to 2½") . . . . . . . . . . . . . . . . . . . 35

3.8.1 Mounting the sensor . . . . . . . . . . . . . . . . . 35

3.9 Installing Prosonic Flow P DN 50 to 4000

(2 to 160") (Clamp-on) . . . . . . . . . . . . . . . . . . . . . 37

3.9.1 Installation for measurement

via one traverse . . . . . . . . . . . . . . . . . . . . . 37

3.9.2 Installation for measurement

via two traverses . . . . . . . . . . . . . . . . . . . . 39

3.10 Installing Prosonic Flow W (Clamp-on) . . . . . . . . . 41

3.10.1 Installation for measurement

via one traverse . . . . . . . . . . . . . . . . . . . . . 41

3.10.2 Installation for measurement

via two traverses . . . . . . . . . . . . . . . . . . . . 43

3.11 Installing Prosonic Flow W (Insertion version) . . . . 45

3.11.1 Installation for measurement

as single-path insertion version . . . . . . . . . . 46

3.11.2 Installation for measurement

as dual-path insertion version . . . . . . . . . . . 49

3.12 Installing sensor DDU18 . . . . . . . . . . . . . . . . . . . . 53

3.13 Installing sensor DDU19 . . . . . . . . . . . . . . . . . . . . 54

3.13.1 Version 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.13.2 Version 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.14 Installing the wall-mount transmitter housing . . . . . 55

3.14.1 Direct wall mounting . . . . . . . . . . . . . . . . . 55

3.14.2 Panel mounting . . . . . . . . . . . . . . . . . . . . . 56

3.14.3 Pipe mounting . . . . . . . . . . . . . . . . . . . . . . 56

3.15 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 57

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.1 Sensor/transmitter connecting cable . . . . . . . . . . . 58

4.1.1 Connecting and grounding Prosonic Flow

W and P (DN 50 to 4000 / 2 to 160")

Two Single coaxial cables . . . . . . . . . . . . . . 58

4.1.2 Connecting and Grounding Prosonic Flow

W and Prosonic Flow P DN 15 to 65

(½ to 2½") Multicore cable . . . . . . . . . . . . 60

4.1.3 Cable specification for connecting cable . . . 61

4.2 Connecting the measuring unit . . . . . . . . . . . . . . . 61

4.2.1 Connecting the transmitter . . . . . . . . . . . . 61

4.2.2 Terminal assignment . . . . . . . . . . . . . . . . . 62

4.2.3 HART connection . . . . . . . . . . . . . . . . . . . 63

4.3 Potential equalization . . . . . . . . . . . . . . . . . . . . . . . 64

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 64

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 65

5 Operation . . . . . . . . . . . . . . . . . . . . . . 66

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . . 66

5.2 Display and operating elements . . . . . . . . . . . . . . . 66

5.3 Brief guide to the function matrix . . . . . . . . . . . . . . 69

5.3.1 General notes . . . . . . . . . . . . . . . . . . . . . . 70

5.3.2 Enabling the programming mode . . . . . . . . 70

5.3.3 Disabling the programming mode . . . . . . . . 70

5.4 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.4.1 Type of error . . . . . . . . . . . . . . . . . . . . . . . 71

5.4.2 Error message types . . . . . . . . . . . . . . . . . . 71

5.4.3 Confirming error messages . . . . . . . . . . . . . 72

Endress+Hauser 3

Page 4

Proline Prosonic Flow 93 Table of contents

5.5 Communication (HART) . . . . . . . . . . . . . . . . . . . . 72

5.5.1 Operating options . . . . . . . . . . . . . . . . . . . 73

5.5.2 Current device description files . . . . . . . . . 74

5.5.3 Device variables and process variables . . . . 74

5.5.4 Universal/common practice

HART commands . . . . . . . . . . . . . . . . . . . 75

5.5.5 Device status/error messages . . . . . . . . . . . 80

6 Commissioning . . . . . . . . . . . . . . . . . . 83

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2 Commissioning via onsite display . . . . . . . . . . . . . . 84

6.2.1 Quick Setup "Sensor Installation" . . . . . . . . 84

6.2.2 Quick Setup "Commissioning" . . . . . . . . . . 85

6.2.3 Quick Setup "Pulsating Flow" . . . . . . . . . . . 88

6.3 Application-specific commissioning . . . . . . . . . . . . 91

6.3.1 Zero point adjustment . . . . . . . . . . . . . . . . 91

6.3.2 Advanced diagnostic functions . . . . . . . . . 93

6.3.3 Data storage with "T-DAT SAVE/LOAD" . . 95

6.4 Hardware settings . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.4.1 Switching HART write protection on/off . . 96

6.4.2 Current output: active/passive . . . . . . . . . . 97

6.4.3 Relay contacts: NC contact/NO contact . . 98

6.5 Data storage device (HistoROM, F-CHIP) . . . . . . . . 99

6.5.1 HistoROM/T-DAT (transmitter-DAT) . . . . 99

6.5.2 F-CHIP (function chip) . . . . . . . . . . . . . . . 99

10.1.11 Human interface . . . . . . . . . . . . . . . . . . 129

10.1.12 Certificates and approvals . . . . . . . . . . . . 130

10.1.13 Accessories . . . . . . . . . . . . . . . . . . . . . . 130

10.1.14 Ordering information . . . . . . . . . . . . . . . 130

10.1.15 Documentation . . . . . . . . . . . . . . . . . . . 130

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

7 Maintenance . . . . . . . . . . . . . . . . . . . 100

8 Accessories . . . . . . . . . . . . . . . . . . . . 101

9 Troubleshooting . . . . . . . . . . . . . . . . 105

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . 105

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . 106

9.3 Process error messages . . . . . . . . . . . . . . . . . . . . . 110

9.4 Process errors without messages . . . . . . . . . . . . . 111

9.5 Response of outputs to errors . . . . . . . . . . . . . . . . 112

9.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.7 Installing and removing electronics boards . . . . . . 114

9.8 Installing and removing the W sensors . . . . . . . . . 116

9.9 Replacing the device fuse . . . . . . . . . . . . . . . . . . . 117

9.10 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9.11 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9.12 Software history . . . . . . . . . . . . . . . . . . . . . . . . . 118

10 Technical data . . . . . . . . . . . . . . . . . . 119

10.1 Quick technical data guide . . . . . . . . . . . . . . . . . . 119

10.1.1 Application . . . . . . . . . . . . . . . . . . . . . . . 119

10.1.2 Function and system design . . . . . . . . . . . 119

10.1.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.1.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . 120

10.1.5 Power supply . . . . . . . . . . . . . . . . . . . . . . 122

10.1.6 Performance characteristics . . . . . . . . . . . 123

10.1.7 Operating conditions: installation . . . . . . . 125

10.1.8 Operating conditions: environment . . . . . 125

10.1.9 Operating conditions: process . . . . . . . . . 126

10.1.10 Mechanical construction . . . . . . . . . . . . . 127

4 Endress+Hauser

Page 5

Proline Prosonic Flow 93 Safety instructions

1 Safety instructions

1.1 Designated use

The measuring device described in these Operating Instructions is to be used only for measuring the

flow rate of liquids in closed pipes.

Examples:

• Acids, alkalis, paints, oils

• Liquid gas

• Ultrapure water with low conductivity, water, wastewater

As well as measuring the volume flow, the sound velocity of the fluid is also always measured.

Different fluids can be distinguished or the fluid quality can be monitored.

Resulting from incorrect use or from use other than that designated the operational safety of the

measuring devices can be suspended. The manufacturer accepts no liability for damages being

produced from this.

1.2 Installation, commissioning and operation

Note the following points:

• Installation, connection to the electricity supply, commissioning and maintenance of the device

must be carried out by trained, qualified specialists authorized to perform such work by the

facility's owner-operator.

The specialist must have read and understood these Operating Instructions and must follow the

instructions they contain.

• The device must be operated by persons authorized and trained by the facility's owner-operator.

Strict compliance with the instructions in these Operating Instructions is mandatory.

• Endress+Hauser is willing to assist in clarifying the chemical resistance properties of parts wetted

by special fluids, including fluids used for cleaning.

However, small changes in temperature, concentration or the degree of contamination in the

process can result in changes to the corrosion resistance properties. Therefore, Endress+Hauser

cannot guarantee or accept liability for the corrosion resistance properties of wetted materials in

a specific application.

The user is responsible for choosing suitable wetted materials in the process.

• If carrying out welding work on the piping, the welding unit may not be grounded by means of

the measuring device.

• The installer must ensure that the measuring system is correctly wired in accordance with the

wiring diagrams. The transmitter must be grounded, except in cases where special protective

measures have been taken (e.g. galvanically isolated power supply SELV or PELV).

• Invariably, local regulations governing the opening and repair of electrical devices apply.

1.3 Operational safety

Note the following points:

• Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of these Operating Instructions. Strict compliance with

the installation instructions and ratings as stated in this supplementary documentation is

mandatory. The symbol on the front of this supplementary Ex documentation indicates the

approval and inspection authority (e.g. 0 Europe, 2 USA, 1 Canada).

• The measuring system complies with the general safety requirements in accordance with

EN 61010-1, the EMC requirements of IEC/EN 61326, and NAMUR Recommendation NE 21

and NE 43.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to this

Operating Instructions.

Endress+Hauser 5

Page 6

Safety instructions Proline Prosonic Flow 93

1.4 Return

The following procedures must be carried out before a flowmeter requiring repair or calibration, for

example, is returned to Endress+Hauser:

• Always enclose a duly completed "Declaration of Contamination" form. Only then can

Endress+Hauser transport, examine and repair a returned device.

Note!

!

You will find a preprinted "Declaration of Contamination" form at the back of this manual.

• Enclose special handling instructions if necessary, for example a safety data sheet as per

Regulation (EC) No 1907/2006 REACH.

• Remove all residues. Pay special attention to the grooves for seals and crevices which could

contain residues. This is particularly important if the substance is hazardous to health, e.g.

flammable, toxic, caustic, carcinogenic, etc.

#

Warning!

• Do not return a measuring device if you are not absolutely certain that all traces of hazardous

substances have been removed, e.g. substances which have penetrated crevices or diffused

through plastic.

• Costs incurred for waste disposal or injury (burns, etc.) due to inadequate cleaning will be charged

to the owner-operator.

#

"

!

1.5 Notes on safety conventions and icons

The devices are designed and tested to meet state-of-the-art safety requirements, and have left the

factory in a condition in which they are safe to operate. The devices comply with the applicable

standards and regulations in accordance with EN 61010 -1 "Protection Measures for Electrical

Equipment for Measurement, Control, Regulation and Laboratory Procedures". The devices can,

however, be a source of danger if used incorrectly or for other than the designated use.

For this reason, always pay particular attention to the safety instructions indicated in these

Operating Instructions by the following icons:

Warning!

"Warning" indicates an action or procedure which, if not performed correctly, can result in personal

injury or a safety hazard. Comply strictly with the instructions and proceed with care.

Caution!

"Caution" indicates an action or procedure which, if not performed correctly, can result in incorrect

operation or destruction of the device. Comply strictly with the instructions.

Note!

"Note" indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

6 Endress+Hauser

Page 7

Proline Prosonic Flow 93 Identification

PROSONIC FLOW 93

-20°C (-4°F) <Tamb<+60°C (+140°F)

IP67 / NEMA/Type 4XOrder Code:

Ser.No.:

TAG No.:

93PA1-XXXXXXXXXXXX

12345678901

ABCDEFGHJKLMNPQRST

16-62VDC/20-55VAC

50-60Hz

I-OUT (HART), f-OUT

15VA/W

i

Pat. US 5,479,007

Pat. UK EP 618 680

STATUS-OUT, STATUS-IN

2

3

4

5

76

1

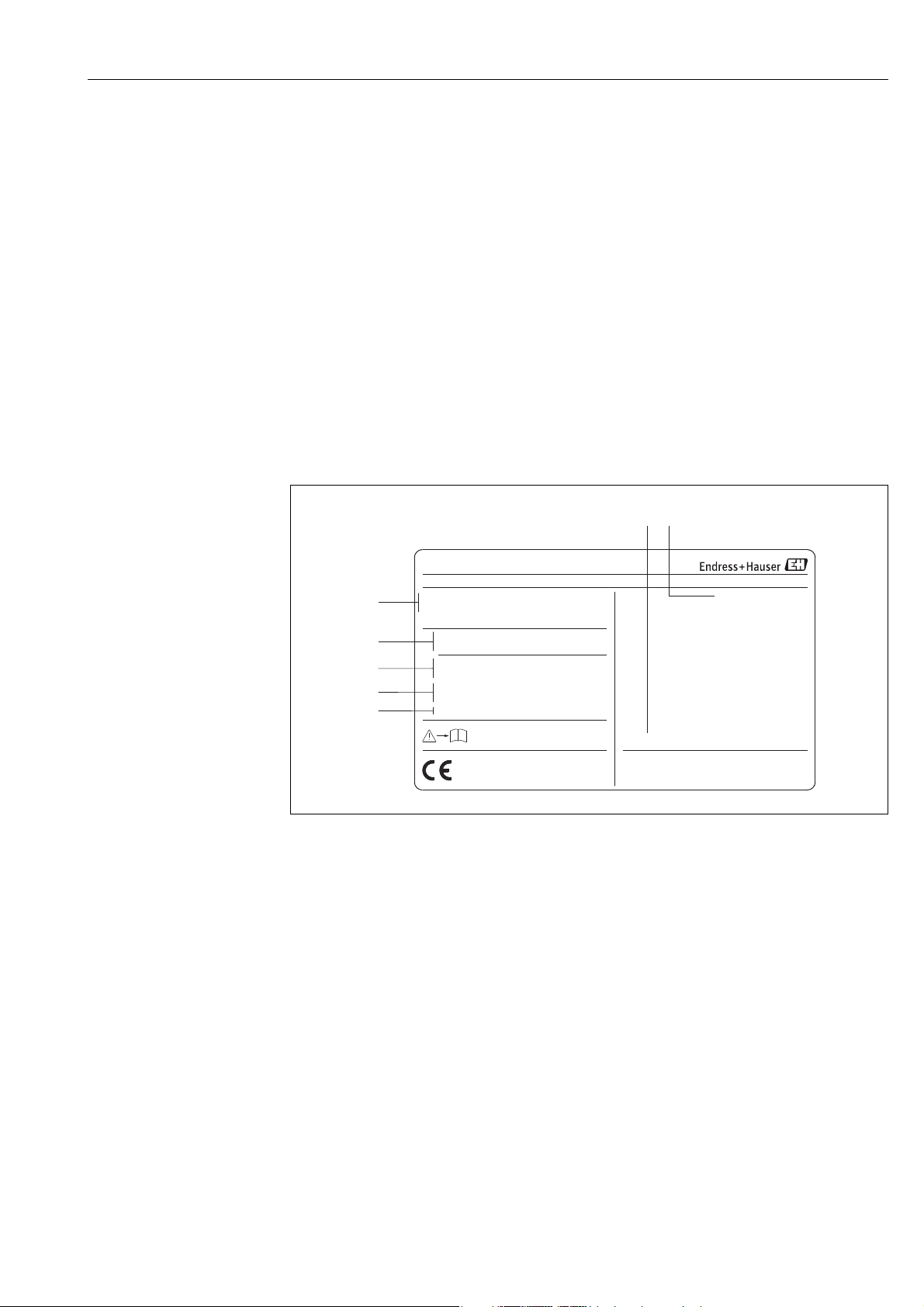

2 Identification

2.1 Device designation

The "Prosonic Flow 93" flowmeter system consists of the following components:

• Prosonic Flow 93 transmitter

•Sensor:

– Prosonic Flow P Clamp-on version (DN 15 to 65 / ½ to 2½")

– Prosonic Flow P Clamp-on version (DN 50 to 4000 / 2 to 160")

– Prosonic Flow W Clamp-on version (DN 15 to 65 / ½ to 2½")

– Prosonic Flow W Clamp-on version (DN 50 to 4000 / 2 to 160")

– Prosonic Flow W Insertion version

The transmitter and sensor are mounted separately from one another and connected by a

connecting cable.

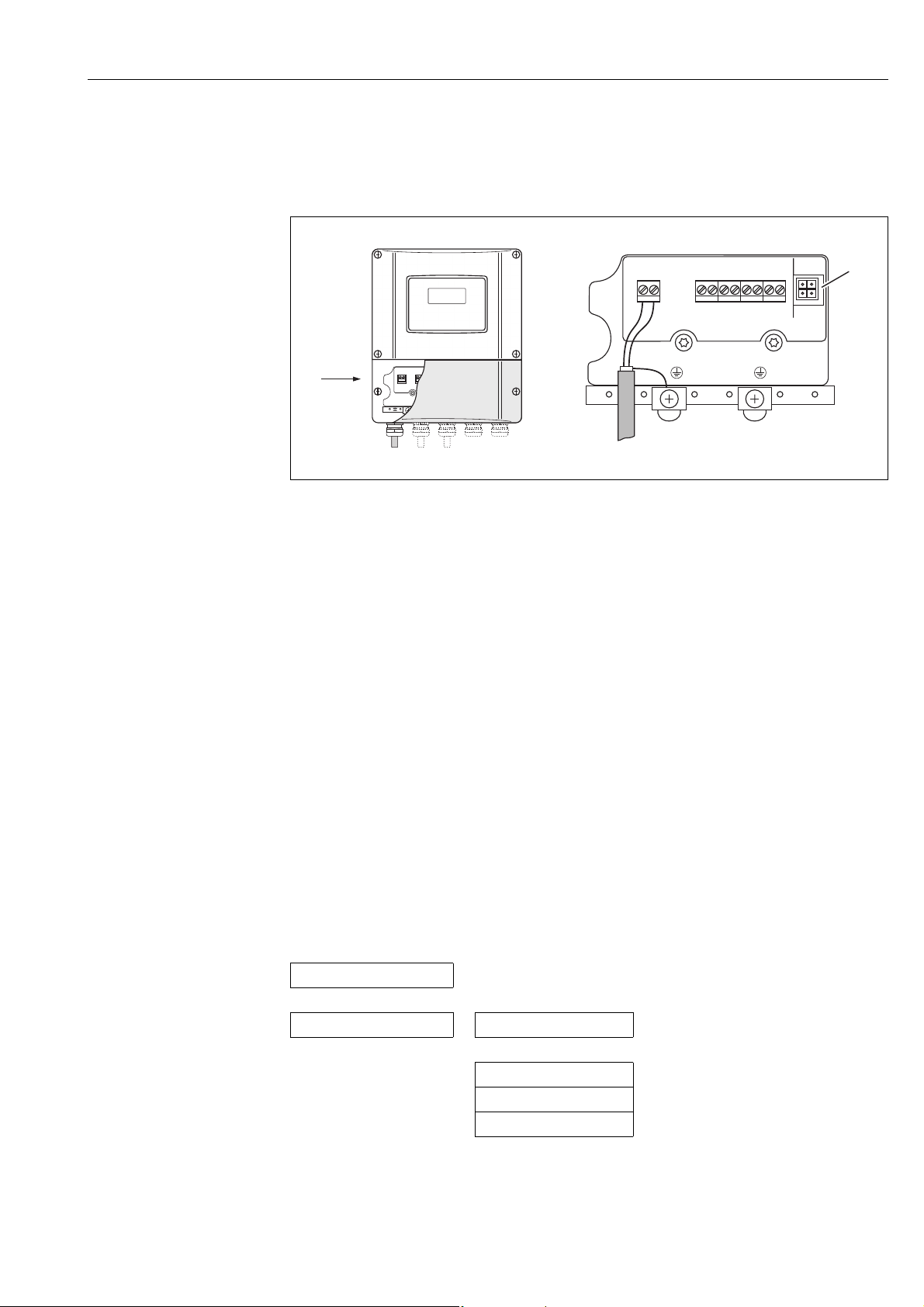

2.1.1 Nameplate of the transmitter

A0001157

Fig. 1: Nameplate specifications for the "Prosonic Flow 93" transmitter (example)

1 Order code/serial number: See the specifications on the order confirmation for the meanings of the individual

letters and digits

2 Power supply/frequency: 16 to 62 V DC / 20 to 55 V AC / 50 to 60 Hz

Power consumption: 15 VA / W

3 Reserved for additional information

4 Available inputs and outputs:

I-OUT (HART): with current output (HART)

f-OUT: with pulse/frequency output

RELAY: with relay output

STAT-IN: with status input (auxiliary input)

5Reserved for information on special products

6 Permitted ambient temperature range

7 Degree of protection

Endress+Hauser 7

Page 8

Identification Proline Prosonic Flow 93

N12895

4153 Reinach, Switzerland

II2G EEx ib IIC T6-T1

DMT 01 ATEX E 064 X

IECEx BVS 06.0... X

FEK0924

ENDRESS+HAUSER

TYPE 6P

NEMA

IP68

Tamb/Tumg:-40°C..+60°C

control dwg. of transmitter

For Installation refer to

CL.II, GP. EFG, CL.III

Dust-Ignitionproof for

CL.II, GP.EFG, CL.III

Intrinsically safe for CL.I, GP.ABCD

APPROVED

FM

0044

Warning: To maintain

Type/NEMA6p or IP68

protection the connector

must be fully engaged.

II2D Ex ibD 21 T6-T1

CH 1

XXXXX-XXXXXXXXXXXX

P-CL-1F-L-B

12345678901 RY

-40°C (-40°F) ... +80°C (+175°F)

Order Code:

DN100 - DN4000

Type:

Ser.No.:

i

2007

06/../....

XA059D/

OPEN CLOSE

PROSONIC FLOW P

4153 Reinach

Switzerland

8

7

1

2

3

4

5

6

9

2.1.2 Nameplate of the sensor

A0001158

Fig. 2: Nameplate specifications for the "Prosonic Flow P" sensor (example)

1 Order code/serial number: See the specifications on the order confirmation for the meanings of the individual

letters and digits.

2Sensor type

3 Range of nominal diameter: DN 100 to 4000 (4 to 160")

4 Max. fluid temperature range: –40 to +80 °C (–40 to +175 °F)

5Reserved for information on special products

6 Degree of protection

7 Permitted ambient temperature range

8 Data on explosion protection

Refer to the specific additional Ex documentation for detailed information.

Please do not hesitate to contact your Endress+Hauser sales office if you have any questions.

8 Endress+Hauser

Page 9

Proline Prosonic Flow 93 Identification

Communication:

Drivers:

Device SW:

ID xxxx (HEX)

XX.XX.XX (WEA)

XXXXXXXXXX

Date: DD.MMM.YYYY

Ex-works / ab-Werk/réglages usine

26(+) / 27(-)

NC:

Versorgung /

Tension d'alimentation

Observer manuel d'instruction

See operating manual

Betriebsanleitung beachten

Active: 0/4...20mA, RL max.=700 Ohm

Passive: 4...20mA, max. 30VDC

Passive: 30VDC, 250mA

Active: 24VDC/25mA (max. 250mA/20ms)

Passive: 30VDC, 250mA

(HART:RL.min.=250 OHM)

fmax = 1kHz

3...30VDC, Ri = 5kOhm

f-OUT

I-

OUT (HART)

12345678912Ser.No.:

Supply /

24(+) / 25(-)

22(+) / 23(-)

20(+) / 21(-)

N/LPE

A:

NO:

P:

L1/L+

12

319475-00XX

A

P

active

passive

normally open contact

normallyclosed contact

X

STATUS-OUT

STATUS-IN

X

Update 1 Update 2

2

3

1

4

5

6

7

8

9

10

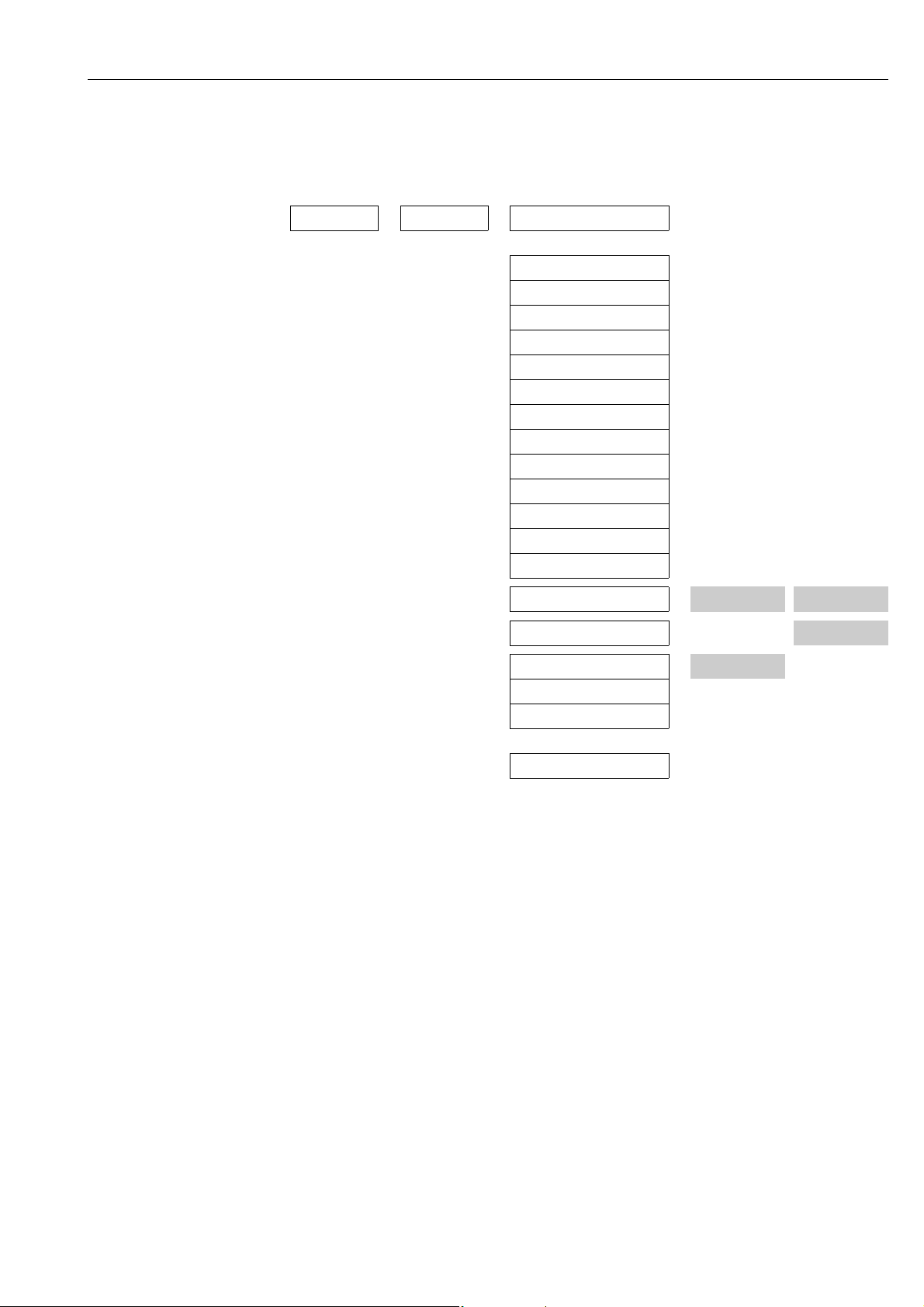

2.1.3 Nameplate for the connections

A0000963

Fig. 3: Nameplate specifications for Proline transmitter (example)

1 Serial number

2 Possible configuration of the current input

3 Possible configuration of the relay contacts

4 Terminal assignment, cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

Terminal No. 1: L1 for AC, L+ for DC

Terminal No. 2: N for AC, L- for DC

5 Signals present at the inputs and outputs, possible configurations and terminal assignment (20 to 27), see also

"Electrical values of the inputs/outputs"

6 Version of device software currently installed

7 Installed communication mode e.g.: HART, PROFIBUS PA, etc.

8 Information on current communication software (Device Revision and Device Description),

e.g.: Dev. 01 / DD 01 for HART

9 Date of installation

10 Current updates to the information listed in Points 6 to 9

Endress+Hauser 9

Page 10

Identification Proline Prosonic Flow 93

2.2 Certificates and approvals

The devices are designed in accordance with good engineering practice to meet state-of-the-art

safety requirements, have been tested, and left the factory in a condition in which they are safe to

operate.

The devices comply with the applicable standards and regulations in accordance with EN 61010-1

"Safety requirements for electrical equipment for measurement, control and laboratory use" and

with the EMC requirements of IEC/EN 61326.

The measuring system described in these Operating Instructions thus complies with the statutory

requirements of the EC Directives. Endress+Hauser confirms successful testing of the device by

affixing to it the CE mark.

The measuring system complies with the EMC requirements of the "Australian Communications

and Media Authority (ACMA)".

2.3 Registered trademarks

HART ®

Registered trademark of HART Communication Foundation, Austin, USA

®

HistoROM™, T-DAT™, F-CHIP

Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach, CH

, FieldCare®, Fieldcheck®, FieldXpert™, Applicator

®

10 Endress+Hauser

Page 11

Proline Prosonic Flow 93 Installation

3 Installation

3.1 Incoming acceptance, transport and storage

3.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches your

order.

3.1.2 Transport

The devices must be transported in the container supplied when transporting them to the measuring

point.

3.1.3 Storage

• Pack the measuring device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

• The storage temperature corresponds to the ambient temperature range of the transmitter, the

sensors and the corresponding sensor cables ( ä 119).

• The measuring device must be protected against direct sunlight during storage in order to avoid

unacceptably high surface temperatures.

3.2 Installation conditions

3.2.1 Dimensions

The dimensions and lengths of the sensor and transmitter are provided in the separate "Technical

Information" document on the device in question. This can be downloaded as a PDF file from

www.endress.com.

A list of the "Technical Information" documents available is provided on ä 130.

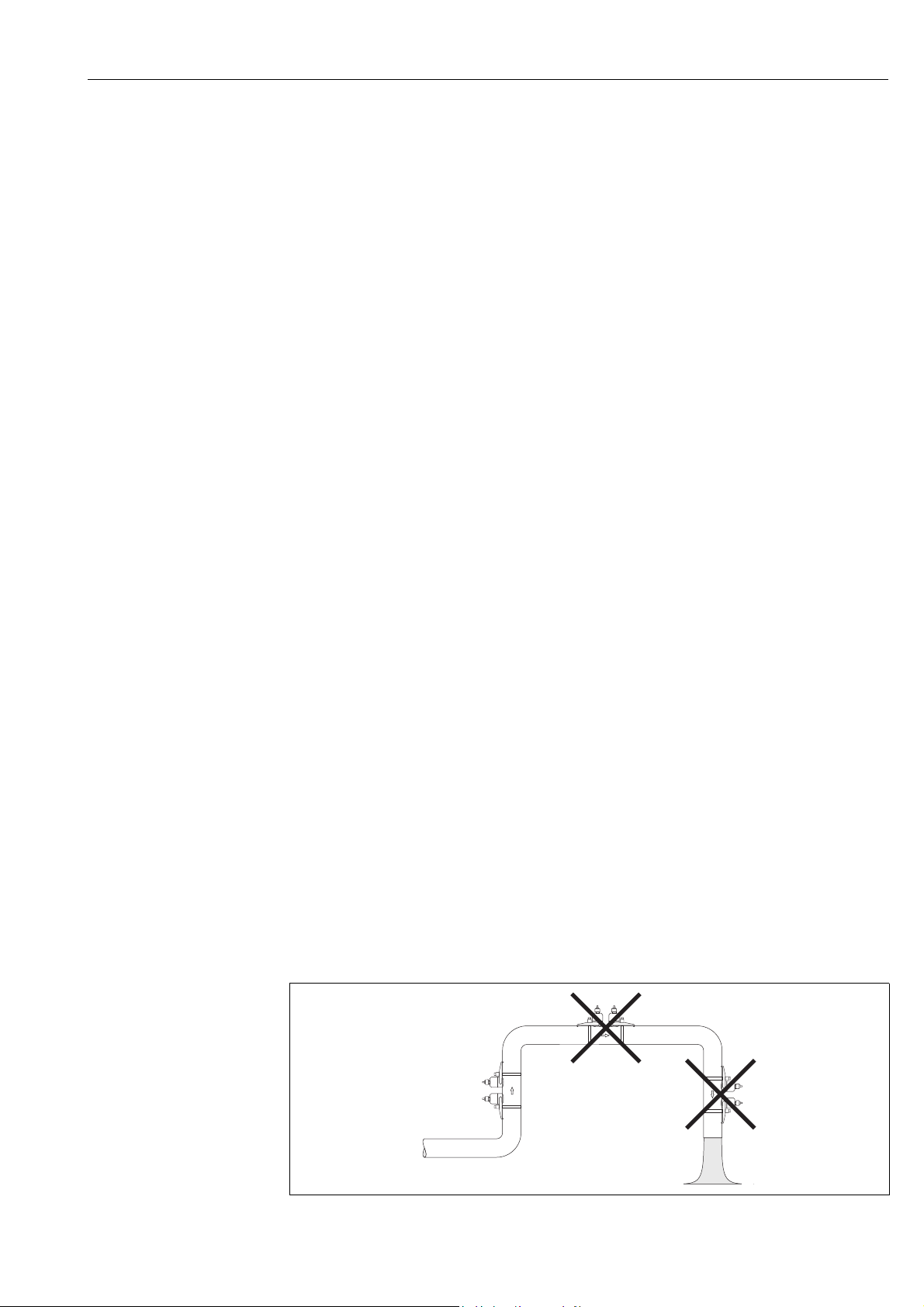

3.2.2 Mounting location

Correct flow measurement is possible only if a pipe is full. Entrained air or gas bubbles forming in

the pipe can result in an increase in measuring errors.

Avoid the following locations in the pipe installation:

• Highest point of a pipeline. Risk of air accumulating.

• Directly upstream of a free pipe outlet in a vertical pipeline.

A0001103

Fig. 4: Mounting location

Endress+Hauser 11

Page 12

Installation Proline Prosonic Flow 93

A

B

CC

15xDN

20xDN

20xDN

15xDN

3xDN

1

2

3

15xDN

10xDN

20xDN

20xDN

20xDN

15xDN

15xDN

10xDN

3xDN

3xDN

1

2

3

AB

11

22

1

2

1

2

1

2

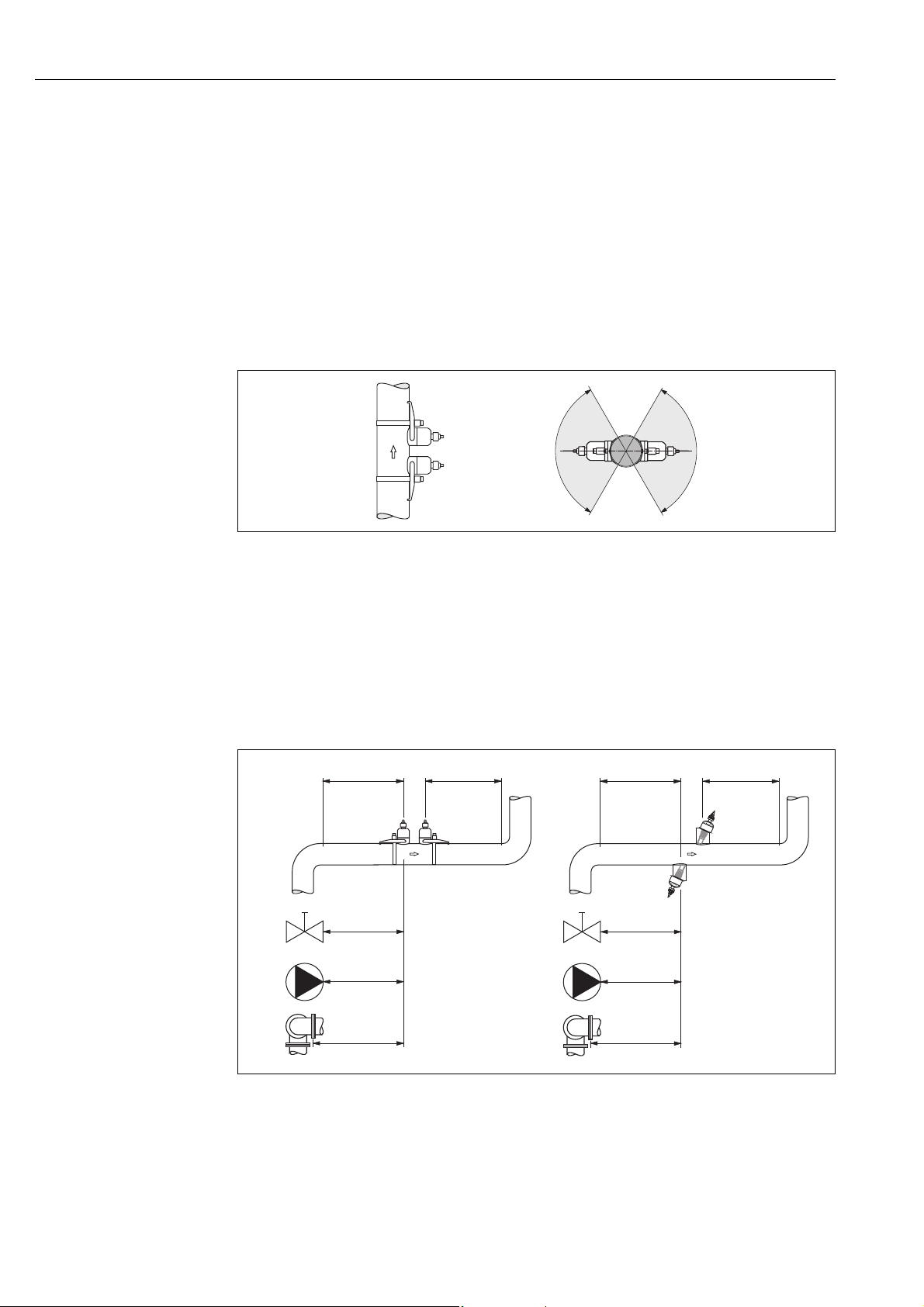

3.2.3 Orientation

Vertical orientation

We recommend the sensor be mounted where there is upward direction of flow. With this

orientation, entrained solids will sink down and gases will rise away from the sensor when the fluid

is stagnant.

Horizontal orientation

We recommend the sensors be mounted within an angle of ±60° to the horizontal (area shaded gray

in the graphic). With this orientation, flow measurement is less affected by any gas or air

accumulation in the upper area of the pipe or by buildup at the bottom of the pipe.

A0001105

Fig. 5: Recommended orientation and recommended installation range

A Vertical: Recommended installation with vertical/upward direction of flow

B Horizontal: Recommended installation range with horizontal orientation

C Recommended installation range max. 120°

3.2.4 Inlet and outlet run

If possible, install the sensor well clear of assemblies such as valves, T-pieces, elbows, etc. If several

flow obstructions are installed, the longest inlet or outlet run must be considered. Compliance with

the following inlet and outlet runs is required in order to ensure measuring accuracy.

Fig. 6: Recommended inlet and outlet runs to comply with measuring accuracy specifications

AClamp-on version

BInsertion version

1

= values for single-path version

2

= values for two-path version

1Valve (2/3 open)

2Pump

3 Two pipe bends in different directions

12 Endress+Hauser

A0013845

Page 13

Proline Prosonic Flow 93 Installation

BA

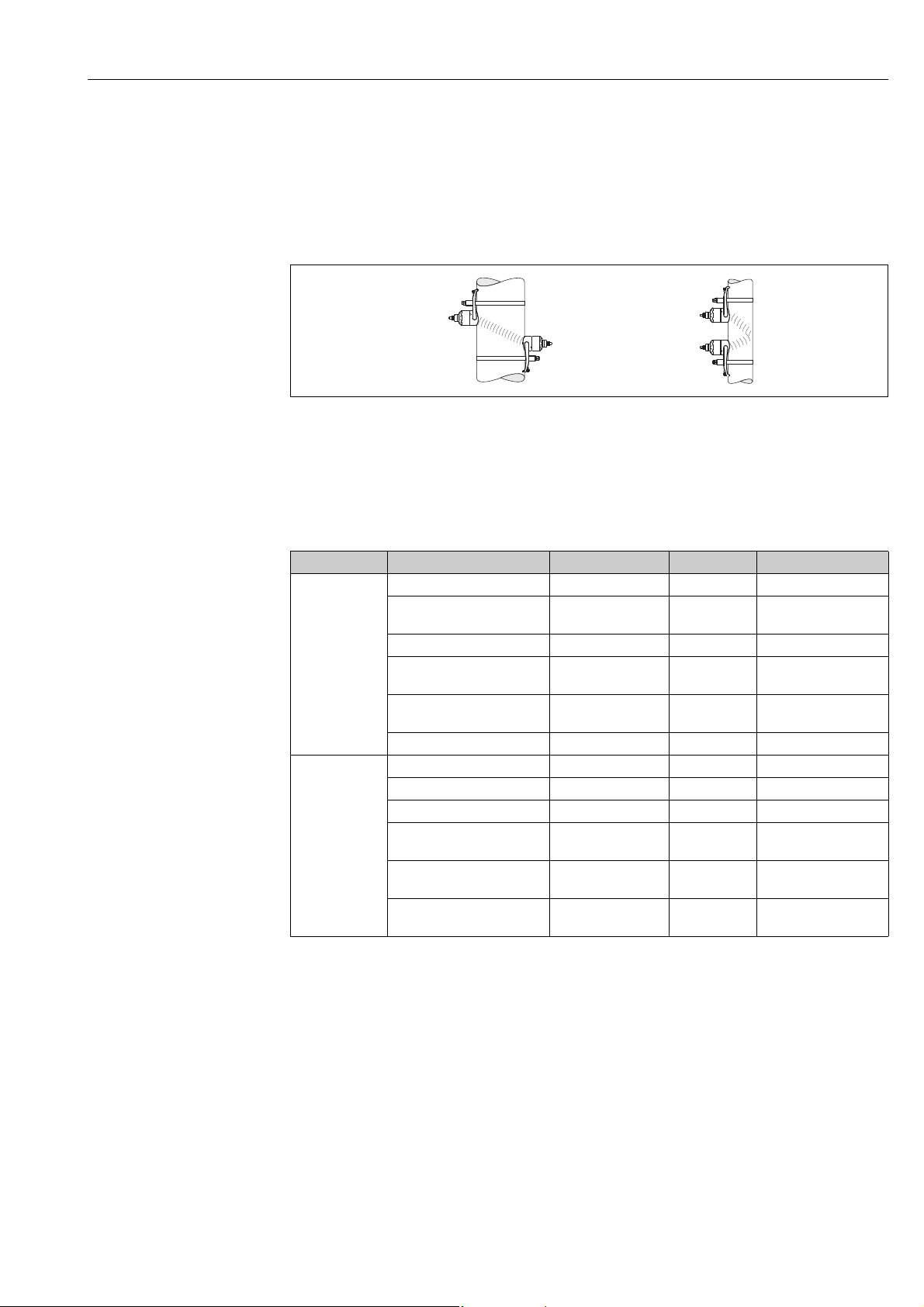

3.2.5 Sensor selection and arrangement

The sensors can be arranged in two ways:

• Mounting arrangement for measurement via one traverse: the sensors are located on opposite

sides of the pipe.

• Mounting arrangement for measurement via two traverses: the sensors are located on the same

side of the pipe.

A0001108

Fig. 7: Sensor mounting arrangement (top view)

A Mounting arrangement for measurement via one traverse

B Mounting arrangement for measurement via two traverses

The number of traverses required depends on the sensor type, the nominal diameter and the

thickness of the pipe wall. We recommend the following types of mounting:

Sensor Type Nominal Diameter Sensor Frequency Sensor ID Type of Mounting

DN 15 to 65 (½ to 2½") 6 MHz P-CL-6F* 2 traverses

DN 50 to 65 (2 to 2½") 2 MHz

P-CL-6F*

P-CL-2F*

2 (or 1) traverses

5)

DN 80 (3") 2 MHz P-CL-2F* 2 traverses

Prosonic Flow P

DN 100 to 300 (4 to 12") 2 MHz (or 1 MHz)

DN 300 to 600 (12 to 24") 1 MHz (or 2 MHz)

P-CL-2F*

P-CL-1F*

P-CL-1F*

P-CL-2F*

2 traverses

2 traverses

DN 650 to 4000 (26 to 160") 1 MHz P-CL-1F* 1 traverse

DN 15 to 65 (½ to 2½") 6 MHz W-CL-6F* 2 traverses

5)

DN 50 to 65 (2 to 2½") 2 MHz W-CL-2F* 2 (or 1) traverses

DN 80 (3") 2 MHz W-CL-2F* 2 traverses

Prosonic Flow W

DN 100 to 300 (4 to 12") 2 MHz (or 1 MHz)

DN 300 to 600 (12 to 24") 1 MHz (or 2 MHz)

DN 650 to 4000 (26 to 160") 1 MHz (or 0.5 MHz)

1)

The installation of clamp-on sensors is principally recommended in the 2 traverse type installation. This type of

W-CL-2F*

W-CL-1F*

W-CL-1F*

W-CL-2F*

W-CL-1F*

W-CL-05F*

2 traverses

2 traverses

1 traverse

3)

3)

3)

installation allows the easiest and most comfortable type of mounting and means that a system can also be mounted

even if the pipe can only be accessed from one side. However, in certain applications a 1 traverse installation may be

preferred. These include:

• Certain plastic pipes with wall thickness > 4 mm (0.16")

• Pipes made of composite materials such as GRP

• Lined pipes

• Applications with fluids with high acoustic damping

2)

If the pipe nominal diameter is small (DN 65 / 2½" and smaller), the sensor spacing with Prosonic Flow W can be too

small for two traverse installation. In this case, the 1 traverse type of installation must be used.

3)

0.5 MHz sensors are also recommended for applications with composite material pipes such as GRP and may be

recommended for certain lined pipes, pipes with wall thickness > 10 mm (0.4"), or applications with media with high

acoustic damping. In addition, for these applications we principally recommend mounting the W sensors in

a 1 traverse configuration.

4)

Insertion W sensors are mounted in a 1 traverse configuration ä 45.

5)

6 MHz sensors for applications where flow velocity10m/s (32.8Hz/s)

1)

2)

Endress+Hauser 13

Page 14

Installation Proline Prosonic Flow 93

BA

3.3 Two-channel operation

The transmitter is able to operate two independent measuring channels (measuring channel 1 and

measuring channel 2). A pair of sensors is connected per measuring channel. Both measuring

channels operate independently of one another and are supported by the transmitter to an equal

extent.

Two-channel operation can be used for the following measurements:

• Two-channel measurement = flow measurement at two separate measuring points

• Two-path measurement = redundant flow measurement at one measuring point

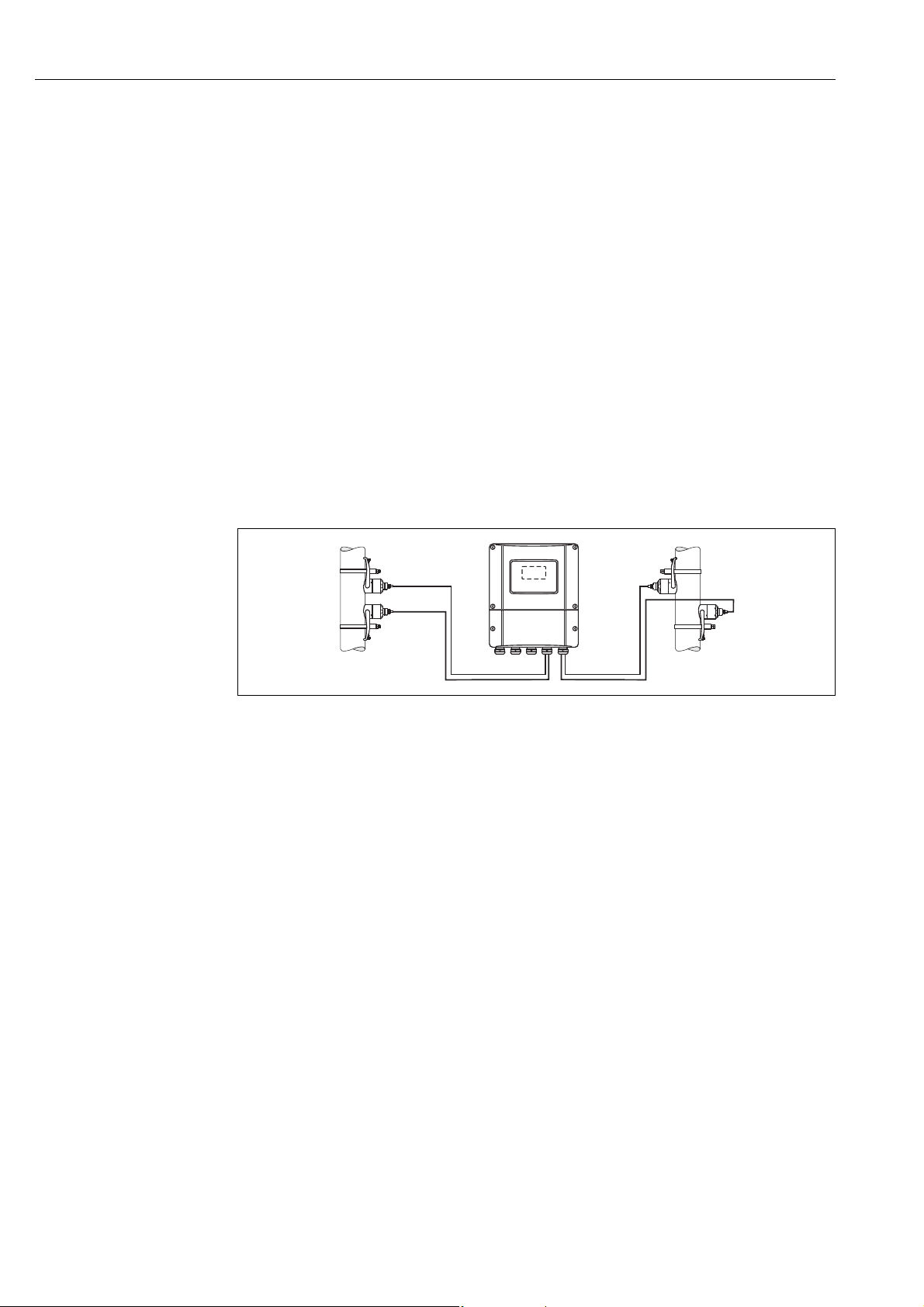

3.3.1 Two-channel measurement

The flow is measured at two separate measuring points in the case of two-channel measurement.

The measured values of the two measuring channels can be processed and displayed differently.

The following measured values can be output for two-channel measurement:

• Individual measured values per measuring channel (output independently of one another)

• The difference between the two measured values

• The sum of the two measured values

The two measuring channels can be configured individually. This makes it possible to independently

configure and select the display, outputs, sensor type and type of installation.

Fig. 8: Two-channel measurement: example of arranging sensor pairs at two separate measuring points

A Measuring channel 1: mounting the sensor pair for measurement via two traverses

B Measuring channel 2: mounting the sensor pair for measurement via one traverse

A0001159

14 Endress+Hauser

Page 15

Proline Prosonic Flow 93 Installation

BA

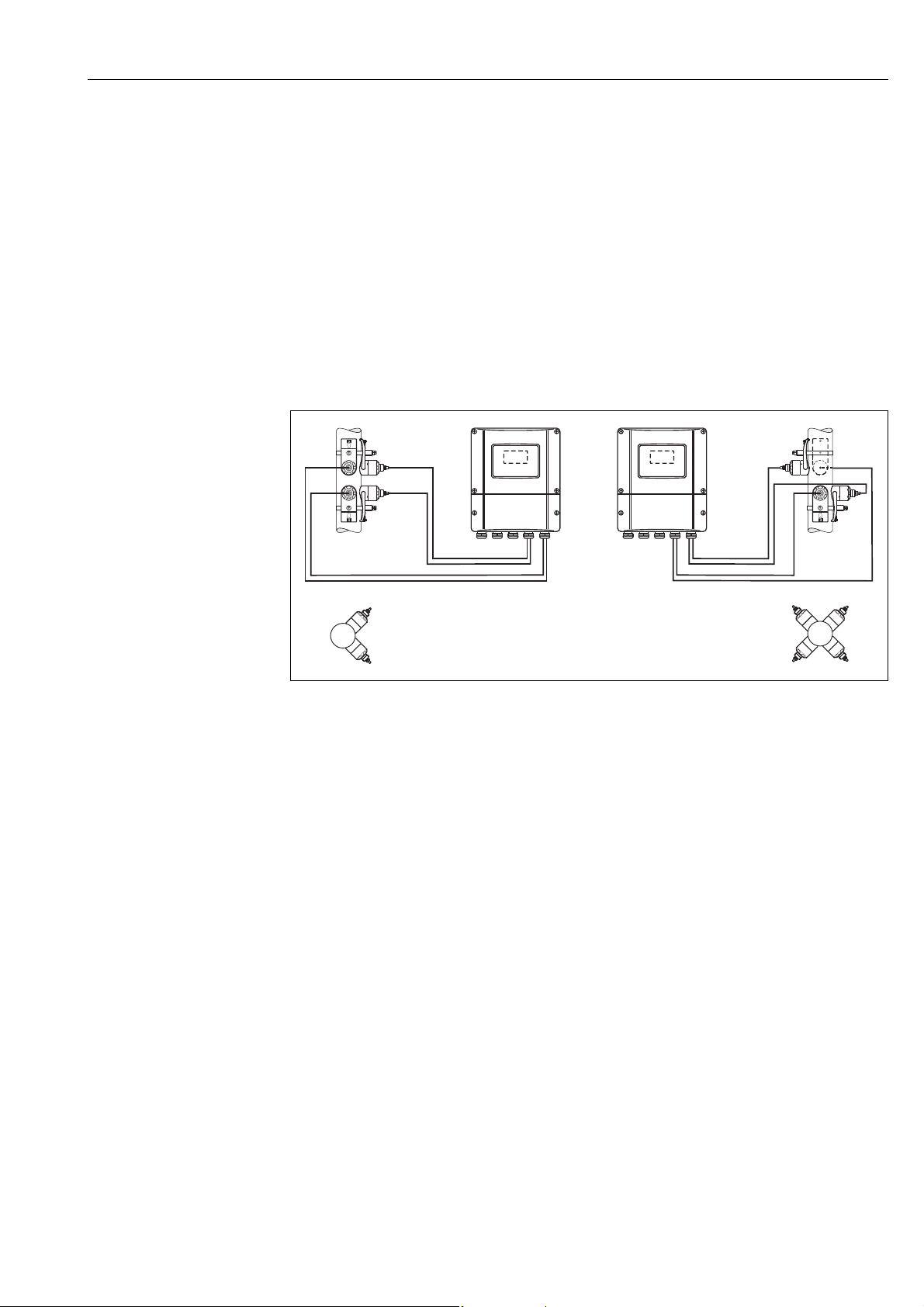

3.3.2 Two-path measurement

The flow is measured redundantly at one measuring point in the case of two-path measurement.

The measured values of the two measuring channels can be processed and displayed differently. The

following measured values can be output for two-path measurement:

• Individual measured values per measuring channel (output independently of one another)

• The average of the two measured values.

The "Averaging" function generally provides you with a more stable measured value. The function

is thus suitable for measurements under conditions that are not ideal (e.g. short inlet runs).

The two measuring channels can be configured individually. This makes it possible to independently

configure and select the display, outputs, sensor type and type of installation.

It is generally not necessary to individually configure the two measuring channels in the case of twopath measurement. However, in certain situations individual channel configuration can be used to

balance out application-specific asymmetries.

A0001160

Fig. 9: Two-path measurement: examples of arranging sensor pairs at one measuring point

A Measuring channel 1 and measuring channel 2: mounting the two sensor pairs for one measurement per pair via

two traverses

B Measuring channel 1 and measuring channel 2: mounting the two sensor pairs for one measurement per pair via

one traverse

Endress+Hauser 15

Page 16

Installation Proline Prosonic Flow 93

3.4 Preparatory steps prior to installation

Depending on the conditions specific to the measuring point (e.g. clamp-on, number of traverses,

fluid, etc.), a number of preparatory steps have to be taken before actually installing the sensors:

1. Determination of the values for the necessary installation distances based on the conditions

specific to the measuring point. A number of methods are available for determining the values:

– Local operation of the device

– FieldCare (operating program), connect a notebook to the transmitter

– Applicator (software), online on the Endress+Hauser Internet site

2. Mechanical preparation of the clamp-on retainers for the sensors:

– Premount the strapping bands (DN 50 to 200 / 2 to 8") or (DN 250 to 4000 / 10 to 160")

– Fix the welded bolts

3.5 Determining the necessary installation distances

The installation distances that have to be maintained depend on:

• The type of sensor: P or W (DN 50 to 4000 / 2 to 160"), P or W (DN 15 to 65 / ½ to 2½")

• Type of mounting:

– Clamp-on with strapping band or welded bolt

– Insertion version, installation in the pipe

• Number of traverses or single-path/dual-path version

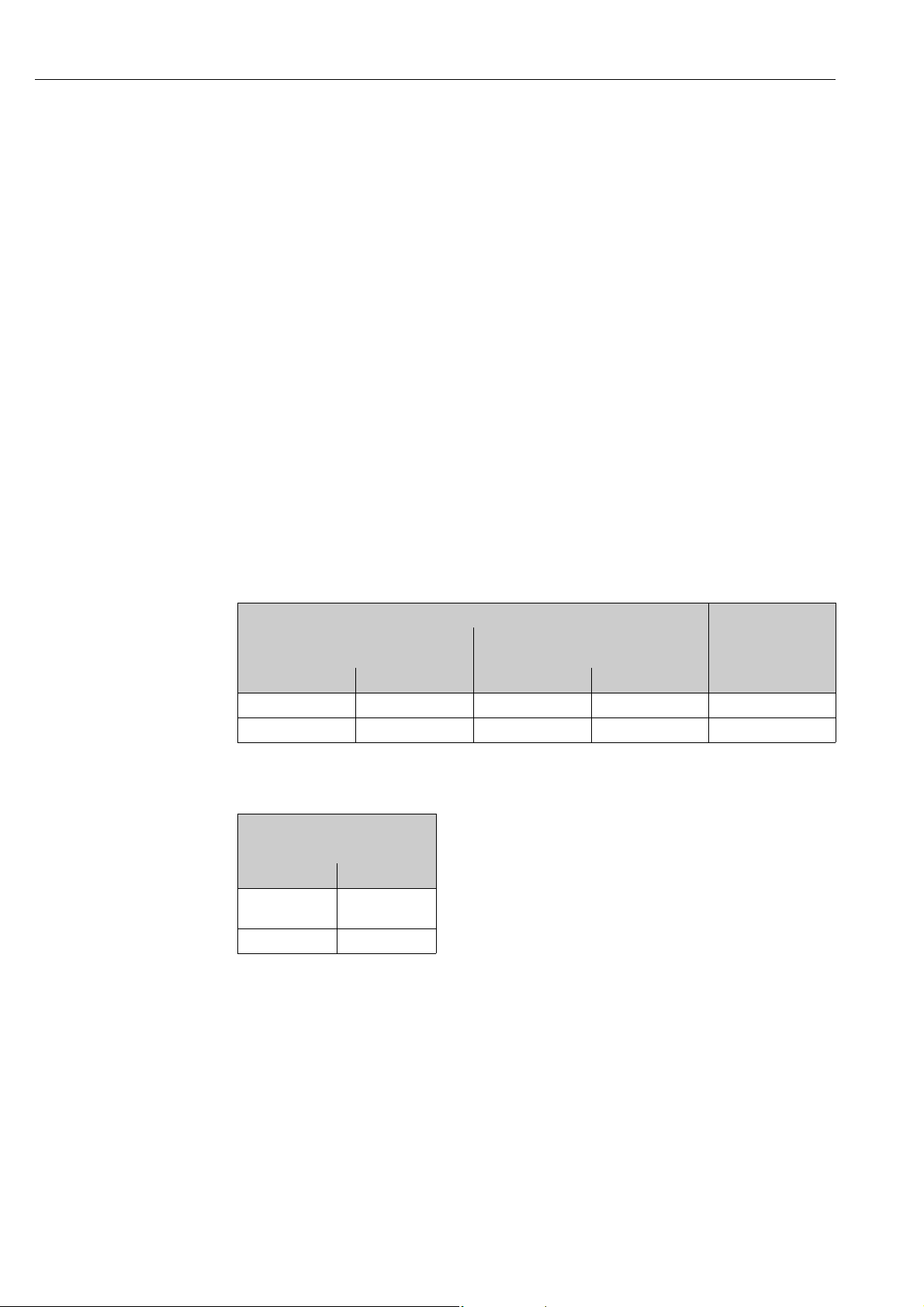

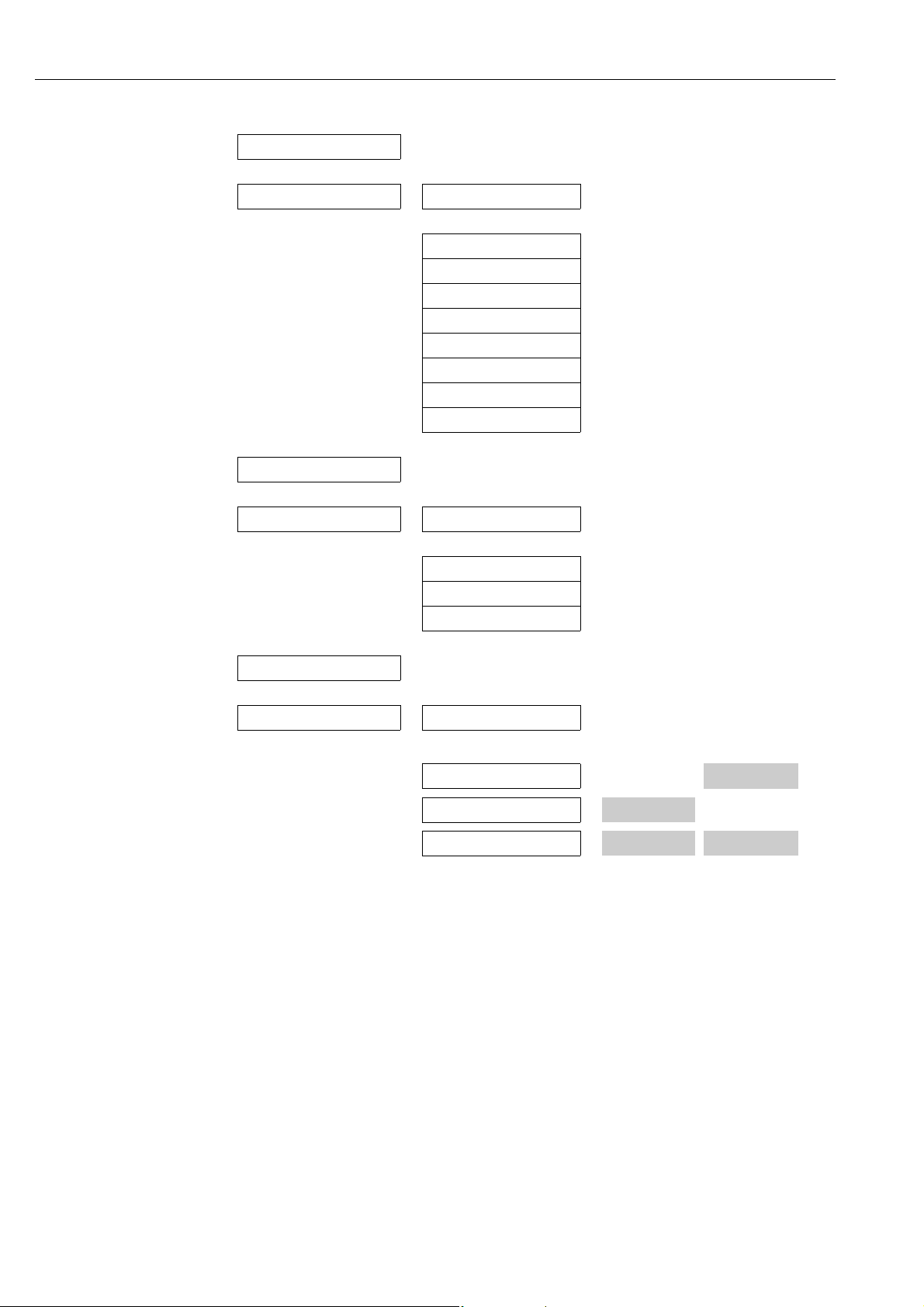

3.5.1 Installation distances for Prosonic Flow P or W clamp-on

DN 50 to 4000 (2 to 160") DN 15 to 65 (½ to 2½")

Clamp-on

Strapping band

1 traverse 2 traverses 1 traverse 2 traverses 2 traverses

SENSOR DISTANCE SENSOR DISTANCE SENSOR DISTANCE SENSOR DISTANCE SENSOR DISTANCE

WIRE LENGTH POSITION SENSOR WIRE LENGTH POSITION SENSOR –

Clamp-on

Welded bolts

Clamp-on

Strapping band

3.5.2 Installation distances for Prosonic Flow W Insertion

DN 200 to 4000 (8 to 160")

Insertion version

Single-path Dual-path

SENSOR

DISTANCE

PATH LENGTH ARC LENGTH

SENSOR

DISTANCE

16 Endress+Hauser

Page 17

Proline Prosonic Flow 93 Installation

a

b

c

c

90 (3.54)

35 (1.38)

192 (7.56)

81.5(3.2)

mm (inch)

3.6 Determining values for installation distances

3.6.1 Determining installation distances via local operation

Perform the following steps to determine the installation distances:

1. Mount the wall-mount housing.

2. Connect the power supply.

3. Switch on the measuring device.

4. Run the "Sensor Installation" Quick Setup menu.

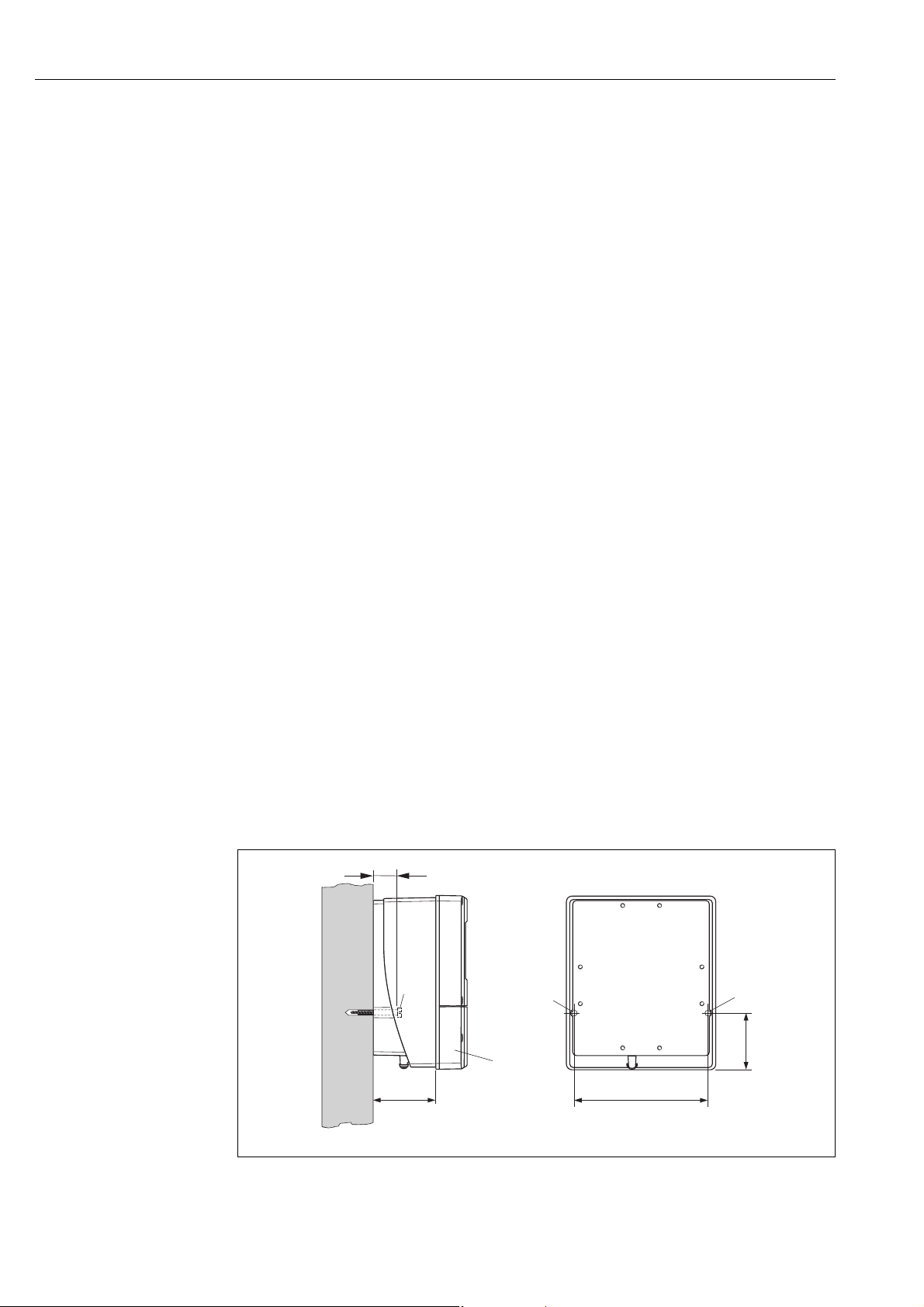

Installing the wall-mount transmitter housing

There are various ways of installing the wall-mount housing:

• Direct wall mounting

• Panel mounting (with separate mounting kit, accessories) ä 101

• Pipe mounting (with separate mounting kit, accessories) ä 101

Caution!

"

• Make sure that the permitted operating temperature range (-20 to +60 °C / –4 to +140 °F) is not

exceeded at the mounting location. Install the device in a shady location. Avoid direct sunlight.

• Always install the wall-mount housing in such a way that the cable entries are pointing down.

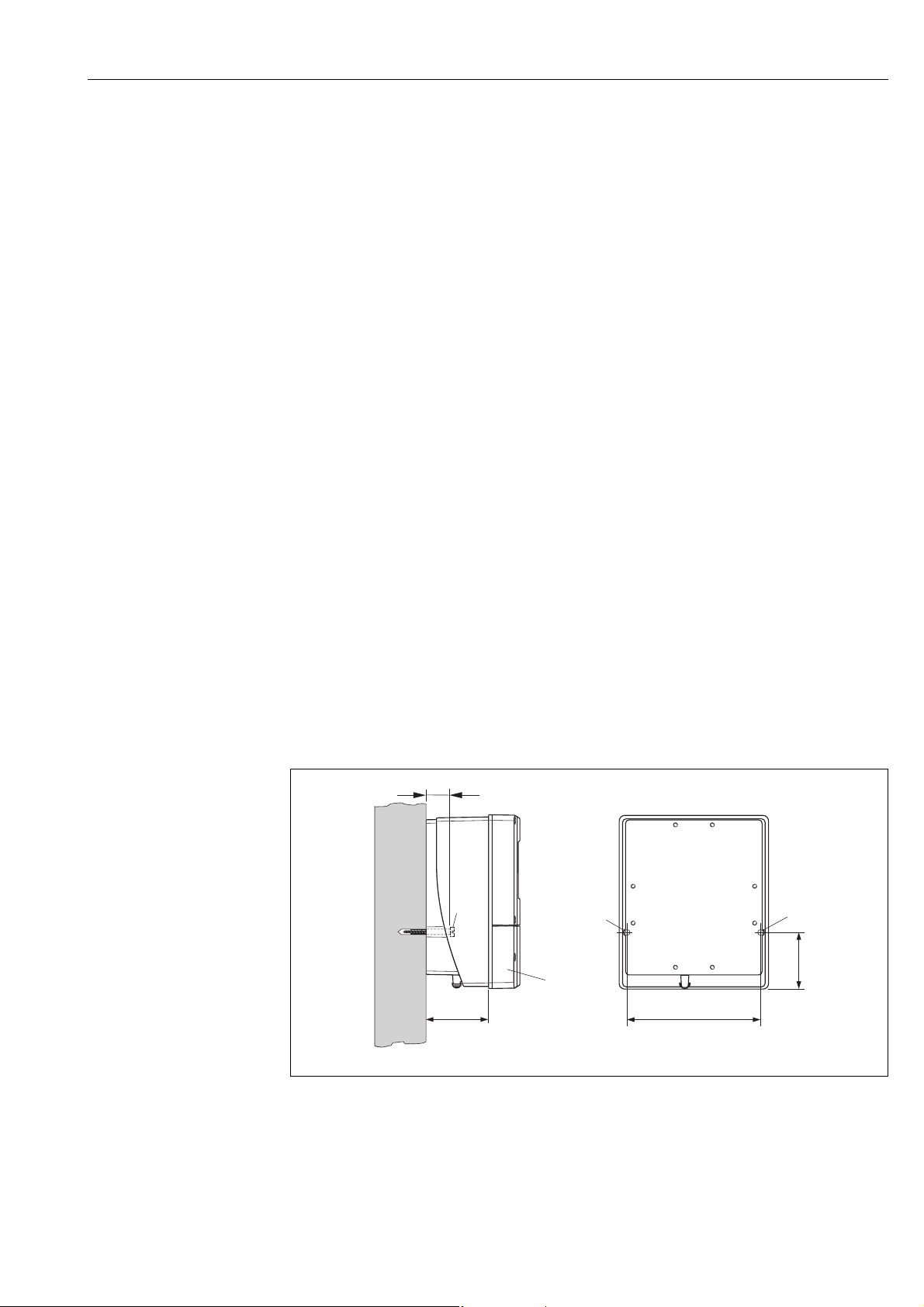

Direct wall mounting

1. Drill the holes ä 17.

2. Remove the cover of the connection compartment (a).

3. Push the two securing screws (b) through the appropriate bores (c) in the housing.

– Securing screws (M6): max. Ø 6.5 mm (0.26")

– Screw head: max. Ø 10.5 mm (0.41")

4. Secure the transmitter housing to the wall as indicated.

5. Screw the cover of the connection compartment (a) firmly onto the housing.

Fig. 10: Direct wall mounting

Endress+Hauser 17

A0001130

Page 18

Installation Proline Prosonic Flow 93

245(9.65)

~110 (~4.33)

210 (8.27)

+0.5 (+0.019)

–0.5(–0.019)

+0.5 (+0.019)

–0.5(–0.019)

mm (inch)

Ø 20…70

(Ø 0.79…2.75)

~~6.1)155 (

mm (inch)

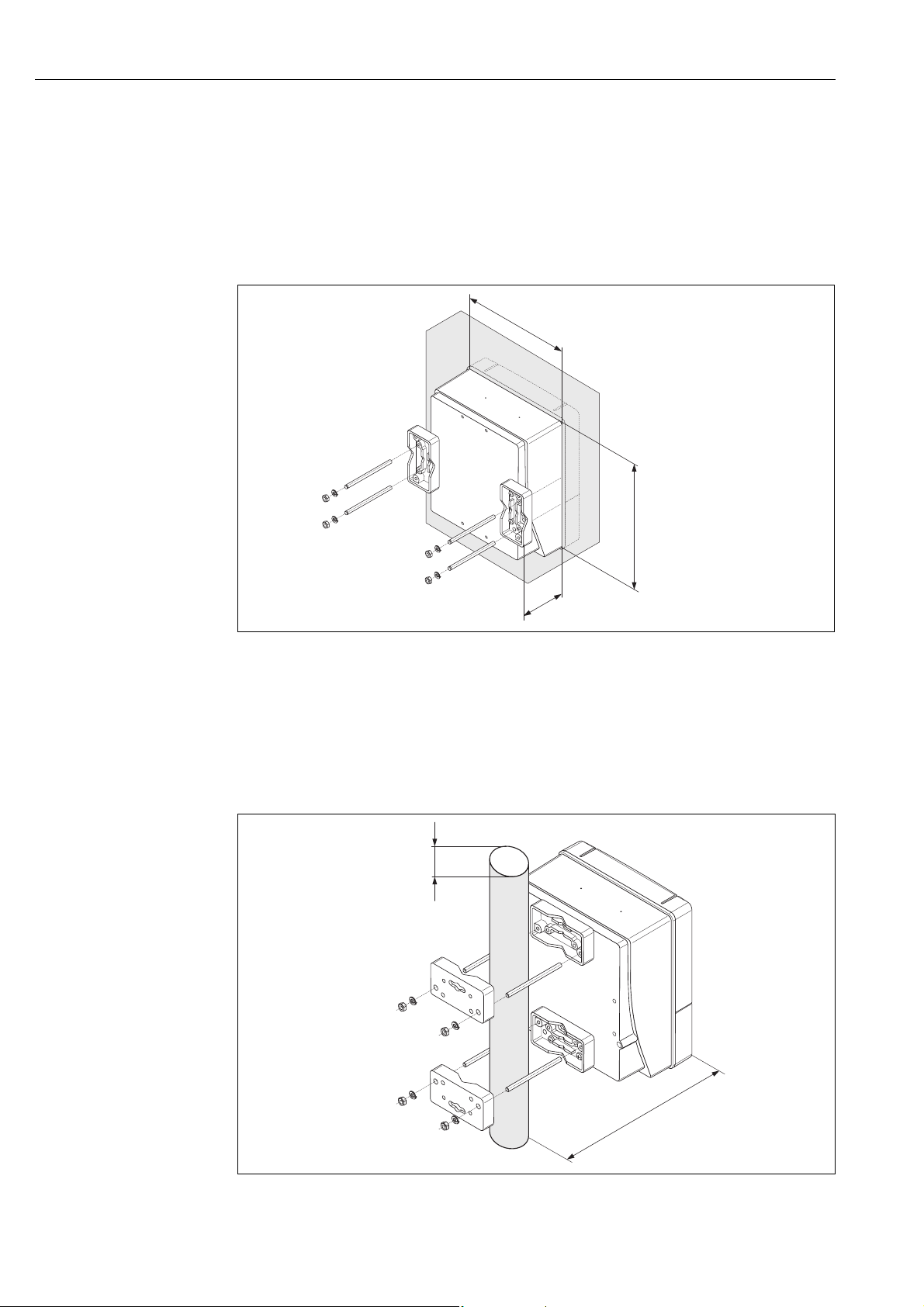

Panel mounting

1. Prepare the opening in the panel ä 18.

2. Slide the housing into the panel cutout from the front.

3. Screw the retainers onto the wall-mount housing.

4. Screw the threaded rods into the retainers and tighten until the housing is solidly seated on the

panel wall. Tighten the counter nuts. No further support is necessary.

Fig. 11: Panel mounting (wall-mount housing)

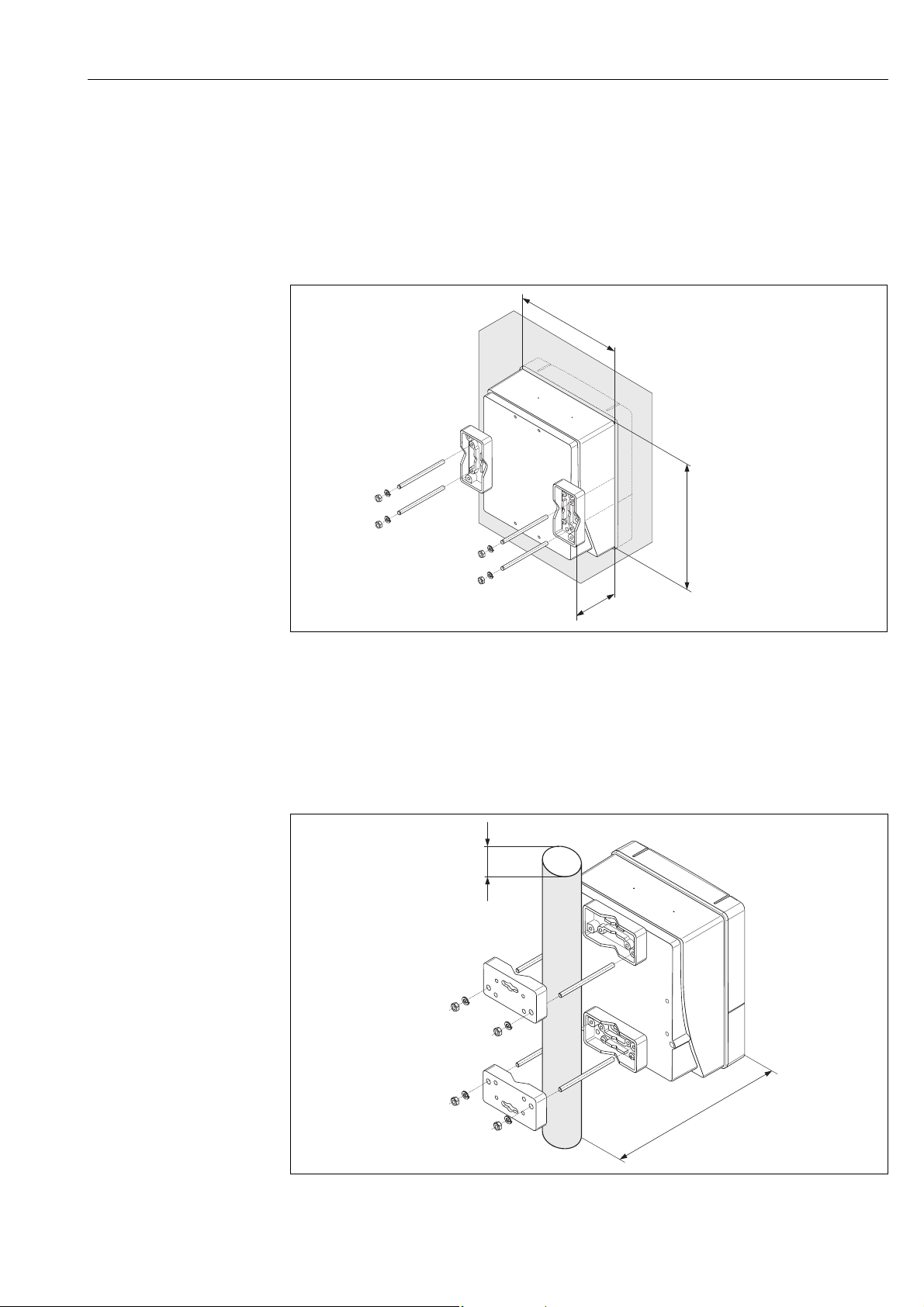

Pipe mounting

The assembly should be performed by following the instructions on ä 18.

Caution!

"

If a warm pipe is used for installation, make sure that the housing temperature does not exceed the

max. permitted value of +60 °C (+140 °F).

A0001131

Fig. 12: Pipe mounting (wall-mount housing)

18 Endress+Hauser

A0001132

Page 19

Proline Prosonic Flow 93 Installation

1

2

a1a

a

+

22

–

23

+

20

–

21

+

24

–

25

+

26

–

27

L1 (L+) N (L-)

A

A

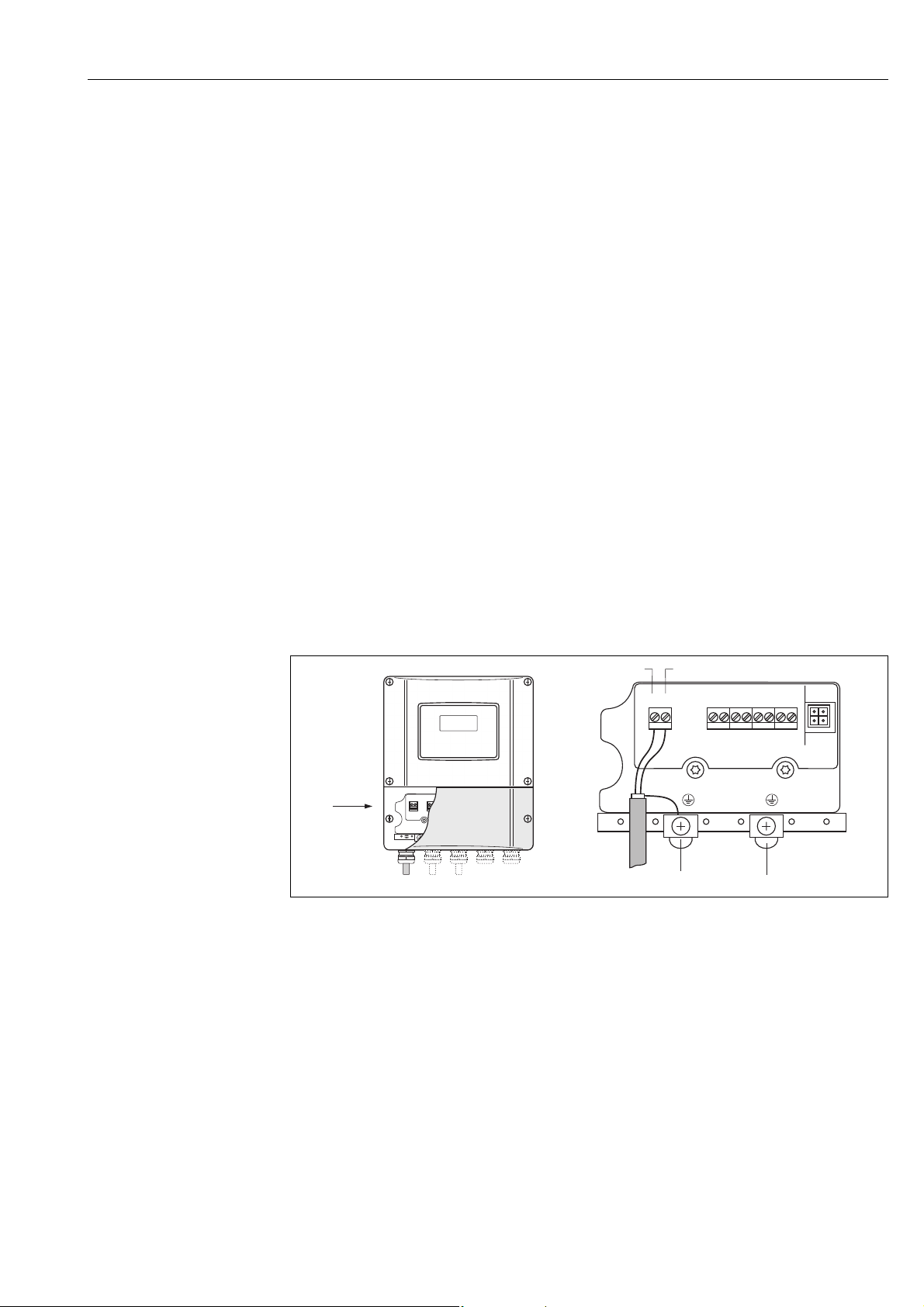

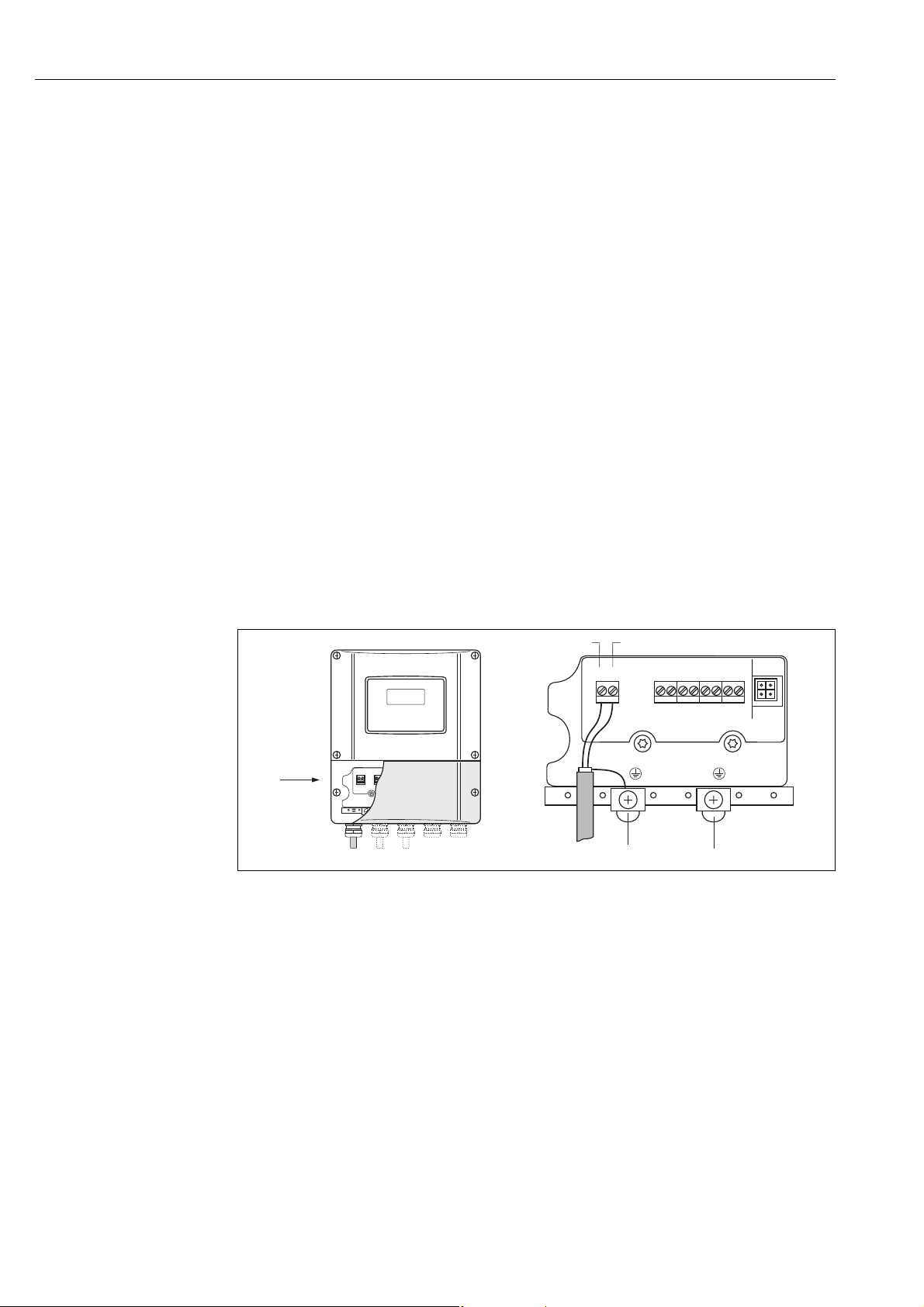

Connecting the power supply

#

!

#

Warning!

When connecting Ex-certified devices, please refer to the notes and diagrams in the Ex-specific

supplement to these Operating Instructions. Please do not hesitate to contact your Endress+Hauser

sales office if you have any questions.

Note!

The measuring device does not have an internal power switch. For this reason, assign the measuring

device a switch or power-circuit breaker which can be used to disconnect the power supply line

from the power grid.

Connecting the power supply

Warning!

• Risk of electric shock. Switch off the power supply before opening the device. Do not install or

wire the device while it is connected to the power supply. Failure to comply with this precaution

can result in irreparable damage to the electronics.

• Risk of electric shock. Connect the protective ground to the ground terminal on the housing

before the power supply is applied (not required for galvanically isolated power supply).

• Compare the specifications on the nameplate with the local supply voltage and frequency. The

national regulations governing the installation of electrical equipment also apply.

1. Remove the cover of the connection compartment from the transmitter housing.

2. Route the power supply cable through the cable entries.

3. Wire the power supply cable.

4. Tighten the cable gland.

5. Screw the connection compartment cover back onto the transmitter housing.

Fig. 13: Connecting the power supply; cable cross-section: max. 2.5 mm (14 AWG)

a Cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

Terminal No. 1: L1 for AC, L+ for DC

Terminal No. 2: N for AC, L- for DC

a1 Ground terminal for protective ground

Switching on the measuring device

1. Perform the post-connection check as specified in the checklist ä 65.

2. Switch on the supply voltage for the device. The device performs internal test functions.

!

Various messages appear on the display.

3. Normal measuring mode commences. Various measured value and/or status variables appear

on the display (HOME position).

Note!

If startup fails, an appropriate error message is displayed, depending on the cause ä 105.

Endress+Hauser 19

A0011363

Page 20

Installation Proline Prosonic Flow 93

Running the "Sensor Installation" Quick Setup menu

!

Note!

• If you are not familiar with the operation of the device ä 66.

• The following section only describes the steps necessary for clamp-on and insertion type of

mounting within the "Sensor Installation" Quick Setup.

Running the Quick Setup for clamp-on type of mounting

1. Enter or select installation-specific values or the values specified here.

2. Read off the installation distances necessary for mounting.

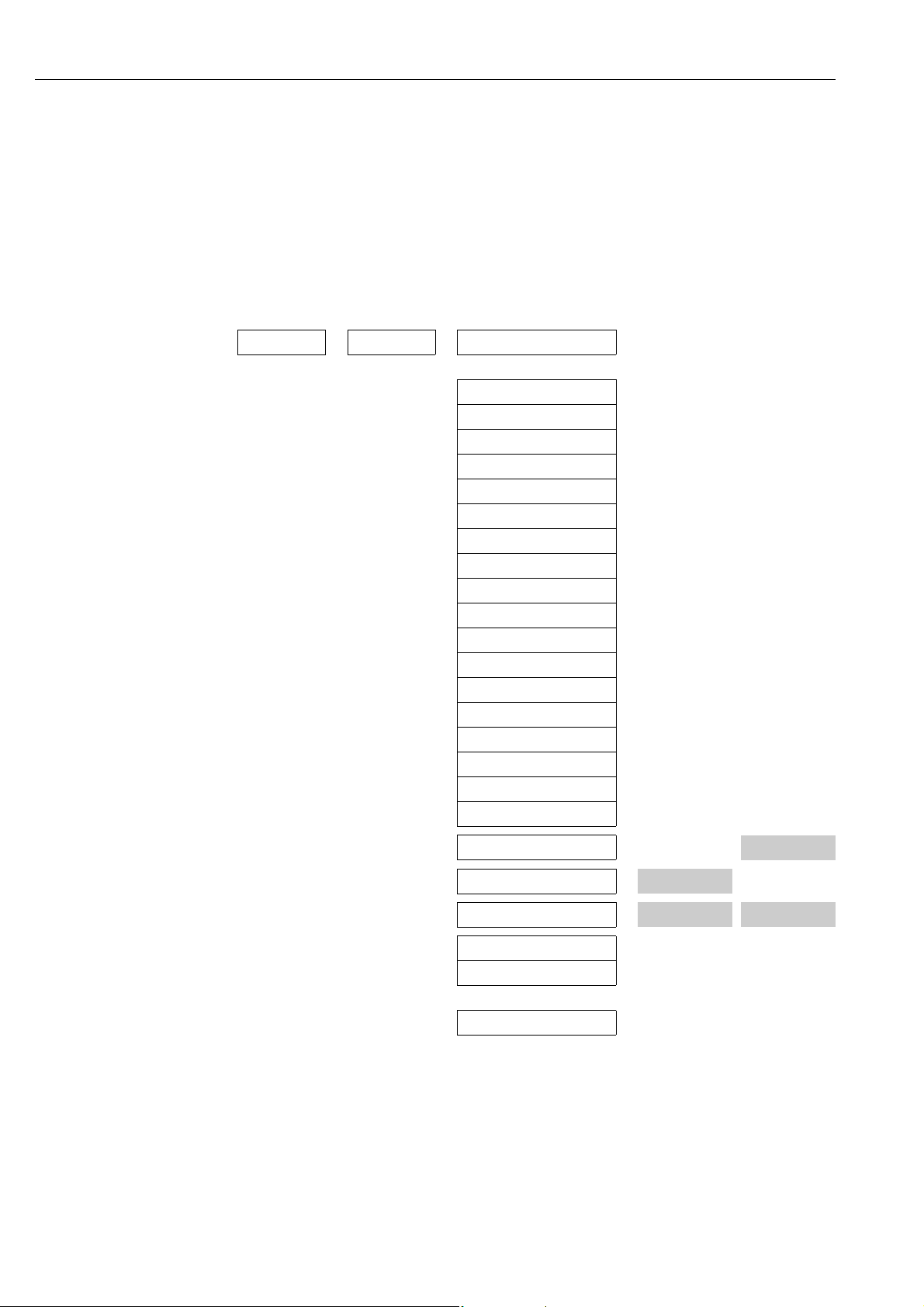

Home position Quick Setup Setup sensor

Language

CH1 Channel

Clamp-on Measurement

Sensor type

1 or 2 Sensor configuration = Number of traverses

Pipe standard

Nominal diameter

Pipe material

Sound velocity pipe

Pipe diameter

Circumference

Wall thickness

Liner Material

Sound Velocity Liner

Liner Thickness

Liquid

Temperature

Sound velocity liquid

Installation

distances for

measurement via

one traverse:

Installation

distances for

measurement via

two traverses:

Position sensor –

Wire length –

Sensor distance

No Other measurement?

No Other channel?

Setup sensor

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

• Prosonic Flow P or W (DN 15 to 65 / ½ to 2½) ä 37

• Prosonic Flow P (DN 50 to 4000 / 2 to 160") ä 37

•Prosonic Flow W ä 41

20 Endress+Hauser

Page 21

Proline Prosonic Flow 93 Installation

Running the Quick Setup for insertion type of mounting

1. Enter or select installation-specific values or the values specified here.

2. Read off the installation distances necessary for mounting.

Home position Quick Setup Setup sensor

Language

CH1 Channel

Insertion Measurement

Sensor type

1 or 2 Sensor configuration = Number of paths

Pipe standard

Nominal diameter

Pipe diameter

Circumference

Wall thickness

Liner Material

Sound Velocity Liner

Liner Thickness

Installation

distances for

measurement via

one path:

Installation

distances for

measurement via

two paths:

Sensor distance

Arc length –

Path length –

No Other measurement?

No Other channel?

Setup sensor

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

•Prosonic Flow W ä 45

Endress+Hauser 21

Page 22

Installation Proline Prosonic Flow 93

a

b

c

c

90 (3.54)

35 (1.38)

192 (7.56)

81.5(3.2)

mm (inch)

3.6.2 Determining installation distances via FieldCare

FieldCare is Endress+Hauser’s FDT-based plant asset management tool and allows the configuration

and diagnosis of intelligent field devices. The Proline flowmeters are accessed via a service interface

or via the service interface FXA193.

FieldCare and the FXA193 service interface can be ordered as accessories ä 101.

Perform the following steps to determine the installation distances:

1. Mount the wall-mount housing

2. Connecting the power supply

3. Connecting the PC to the plant asset management tool

4. Switch on the measuring device.

5. Read off the installation distances via FieldCare.

Installing the wall-mount transmitter housing

There are various ways of installing the wall-mount housing:

• Direct wall mounting

Panel mounting (with separate mounting kit, accessories) ä 101

Pipe mounting (with separate mounting kit, accessories) ä 101

Caution!

"

• Make sure that the permitted operating temperature range

(-20 to +60 °C / –4 to +140 °F) is not exceeded at the mounting location. Install the device in a

shady location. Avoid direct sunlight.

• Always install the wall-mount housing in such a way that the cable entries are pointing down.

Direct wall mounting

1. Drill the holes ä 22.

2. Remove the cover of the connection compartment (a).

3. Push the two securing screws (b) through the appropriate bores (c) in the housing.

– Securing screws (M6): max. Ø 6.5 mm (0.26")

– Screw head: max. Ø 10.5 mm (0.41")

4. Secure the transmitter housing to the wall as indicated.

5. Screw the cover of the connection compartment (a) firmly onto the housing.

22 Endress+Hauser

Fig. 14: Direct wall mounting

A0001130

Page 23

Proline Prosonic Flow 93 Installation

245(9.65)

~110 (~4.33)

210 (8.27)

+0.5 (+0.019)

–0.5(–0.019)

+0.5 (+0.019)

–0.5(–0.019)

mm (inch)

Ø 20…70

(Ø 0.79…2.75)

~~6.1)155 (

mm (inch)

Panel mounting

1. Prepare the opening in the panel ä 23.

2. Slide the housing into the panel cutout from the front.

3. Screw the retainers onto the wall-mount housing.

4. Screw the threaded rods into the retainers and tighten until the housing is solidly seated on the

panel wall. Tighten the counter nuts. No further support is necessary.

Fig. 15: Panel mounting (wall-mount housing)

Pipe mounting

The assembly should be performed by following the instructions on ä 23.

Caution!

"

If a warm pipe is used for installation, make sure that the housing temperature does not exceed the

max. permitted value of +60 °C (+140 °F).

A0001131

A0001132

Fig. 16: Pipe mounting (wall-mount housing)

Endress+Hauser 23

Page 24

Installation Proline Prosonic Flow 93

1

2

a1a

a

+

22

–

23

+

20

–

21

+

24

–

25

+

26

–

27

L1 (L+) N (L-)

A

A

Connecting the power supply

#

!

#

Warning!

When connecting Ex-certified devices, please refer to the notes and diagrams in the Ex-specific

supplement to these Operating Instructions. Please do not hesitate to contact your Endress+Hauser

sales office if you have any questions.

Note!

The measuring device does not have an internal power switch. For this reason, assign the measuring

device a switch or power-circuit breaker which can be used to disconnect the power supply line

from the power grid.

Connecting the power supply

Warning!

• Risk of electric shock. Switch off the power supply before opening the device. Do not install or

wire the device while it is connected to the power supply. Failure to comply with this precaution

can result in irreparable damage to the electronics.

• Risk of electric shock. Connect the protective ground to the ground terminal on the housing

before the power supply is applied (not required for galvanically isolated power supply).

• Compare the specifications on the nameplate with the local supply voltage and frequency. The

national regulations governing the installation of electrical equipment also apply.

1. Remove the cover of the connection compartment from the transmitter housing.

2. Route the power supply cable through the cable entries.

3. Wire the power supply cable.

4. Tighten the cable gland.

Fig. 17: Connecting the power supply; cable cross-section: max. 2.5 mm (14 AWG)

a Cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

Terminal No. 1: L1 for AC, L+ for DC

Terminal No. 2: N for AC, L- for DC

a1 Ground terminal for protective ground

24 Endress+Hauser

A0011363

Page 25

Proline Prosonic Flow 93 Installation

1

2

a

+

22

–

23

+

20

–

21

+

24

–

25

+

26

–

27

A

A

Connecting the PC to the plant asset management tool

A personal computer is connected to the FieldCare plant asset management tool via the service

interface FXA 193. The service interface FXA 193 is connected to the service connector of the

transmitter.

A0011365

Fig. 18: Connecting a PC with the FieldCare operating software

a Service adapter for connecting service interface FXA193

!

!

Switching on the measuring device

1. Perform the post-connection check as specified in the checklist ä 65.

2. Switch on the supply voltage for the device. The device performs internal test functions.

Various messages appear on the display.

3. Normal measuring mode commences. Various measured value and/or status variables appear

on the display (HOME position).

Note!

If startup fails, an appropriate error message is displayed, depending on the cause ä 105.

Reading off the installation distances via FieldCare

Note!

The following section only illustrates the functions necessary for clamp-on and insertion type of

mounting.

Reading off installation distances via FieldCare for clamp-on type of mounting

1. Enter or select installation-specific values or the values specified here.

2. Read off the installation distances necessary for mounting.

Basic function

Sensor data K1/K2 Sensor parameter

Clamp-on Measurement

Sensor type

1 or 2 Sensor configuration = Number of traverses

Endress+Hauser 25

Page 26

Installation Proline Prosonic Flow 93

Basic function

Process parameter K1/K2 Pipe data

Pipe standard

Nominal diameter

Pipe material

Sound velocity pipe

Circumference

Pipe diameter

Wall thickness

Liner material

Basic function

Process parameter K1/K2 Liquid data

Liquid

Temperature

Sound velocity liquid

Basic function

Process parameter K1/K2 Sensor parameter

Position sensor –

Wire length –

Sensor distance

Installation

distances for

measurement

via one traverse:

Installation

distances for

measurement via

two traverses:

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

• Prosonic Flow P or W (DN 15 to 65 / ½ to 2½") ä 35

• Prosonic Flow P (DN 50 to 4000 / 2 to 160") ä 37

• Prosonic Flow W (Clamp-on) ä 41

26 Endress+Hauser

Page 27

Proline Prosonic Flow 93 Installation

Reading off installation distances via FieldCare for insertion type of mounting

1. Enter or select installation-specific values or the values specified here.

2. Read off the installation distances necessary for mounting.

Basic function

Sensor data K1/K2 Sensor parameter

Insertion Measurement

Sensor type

Single-path or dual-path Sensor configuration = Number of paths

Basic function

Process parameter K1/K2 Pipe data

Pipe standard

Nominal diameter

Circumference

Pipe diameter

Wall thickness

Basic function

Process parameter K1/K2 Sensor parameter

Sensor distance

Arc length –

Path length –

Installation

distances for

measurement

via one traverse:

Installation

distances for

measurement via

two traverses:

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

•Prosonic Flow W ä 45.

Endress+Hauser 27

Page 28

Installation Proline Prosonic Flow 93

3.6.3 Determining installation distances via Applicator

Applicator is a software application for selecting and planning flowmeters. The installation distances

required for installation can be determined without having to commision the transmitter

beforehand.

Applicator is available:

• On a CD-ROM for installation on a local PC ä 104.

• Via the Internet for direct online entry www.endress.com select country.

On the Internet site, select Instruments Flow Tooling Applicator. In the "Applicator

Sizing Flow" field, select the "Start Applicator Sizing Flow online" link.

Determining installation distances for clamp-on, measuring via one traverse

Determine the installation distances required via Applicator:

• Select the fluid.

• Select the device (e.g. 93P Clamp-on).

• Enter or select measuring point-specific values.

• Select the number of traverses: 1

• Read off the necessary installation distances:

– Wire length: __________

– Sensor distance: __________

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

• Prosonic Flow P (DN 50 to 4000 / 2 to 160") ä 37

•Prosonic Flow W ä 41.

Determining installation distances for clamp-on, measuring via two traverses

Determine the installation distances required via Applicator:

• Select the fluid.

• Select the device (e.g. 93P Clamp-on).

• Enter or select measuring point-specific values.

• Select the number of traverses: 2

• Read off the necessary installation distances:

– Sensor position: __________

– Sensor distance: __________

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

• Prosonic Flow P or W (DN 15 to 65 / ½ to 2½") ä 39

• Prosonic Flow P (DN 50 to 4000 / 2 to 160") ä 39

•Prosonic Flow W ä 43.

Determining installation distances for insertion version, single-path measurement

Determine the installation distances required via Applicator:

• Select the fluid.

• Select the device (e.g. 93W Insert 1Ch).

• Enter or select measuring point-specific values.

• Read off the necessary installation distance:

– Sensor distance: __________

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

•Prosonic Flow W ä 46.

28 Endress+Hauser

Page 29

Proline Prosonic Flow 93 Installation

Determining installation distances for insertion version, dual-path measurement

Determine the installation distances required via Applicator:

• Select the fluid.

• Select the device (e.g. 93W Insert 2Ch).

• Enter or select measuring point-specific values.

• Read off the necessary installation distances:

– Sensor distance: __________

– Arc length: __________

Subsequent procedure

The sensors can be installed once the installation distances have been determined:

•Prosonic Flow W ä 41.

Endress+Hauser 29

Page 30

Installation Proline Prosonic Flow 93

A

3.7 Mechanical preparation

The way in which the sensors are secured differs on account of the pipe nominal diameter and the

sensor type. Depending on the type of sensor, users also have the option of securing the sensors with

strapping bands or screws such that they can be later removed, or permanently fixing the sensors in

place with welded bolts or welded retainers.

Overview of possible ways to secure the various sensors:

Prosonic Flow For the measuring range Pipe nominal

93W/93P DN 15 to 65

(½ to 2½")

93P DN 50 to 4000

(2 to 160")

93W DN 50 to 4000

(2 to 160")

diameter

DN 32 (1¼") Sensor holder with U-shaped screws ä 30

DN 32 (1¼") Sensor holder with strapping bands ä 31

DN 200 (8") Strapping bands (medium nominal diameters) ä 32

DN 200 (8") Strapping bands (large nominal diameters) ä 33

DN 200 (8") Strapping bands (medium nominal diameters) ä 32

DN 200 (8") Strapping bands (large nominal diameters) ä 33

Secured by

Welded bolts ä 34

Welded bolts ä 34

Welded bolts ä 34

Welded bolts ä 31

Insertion version ä 45

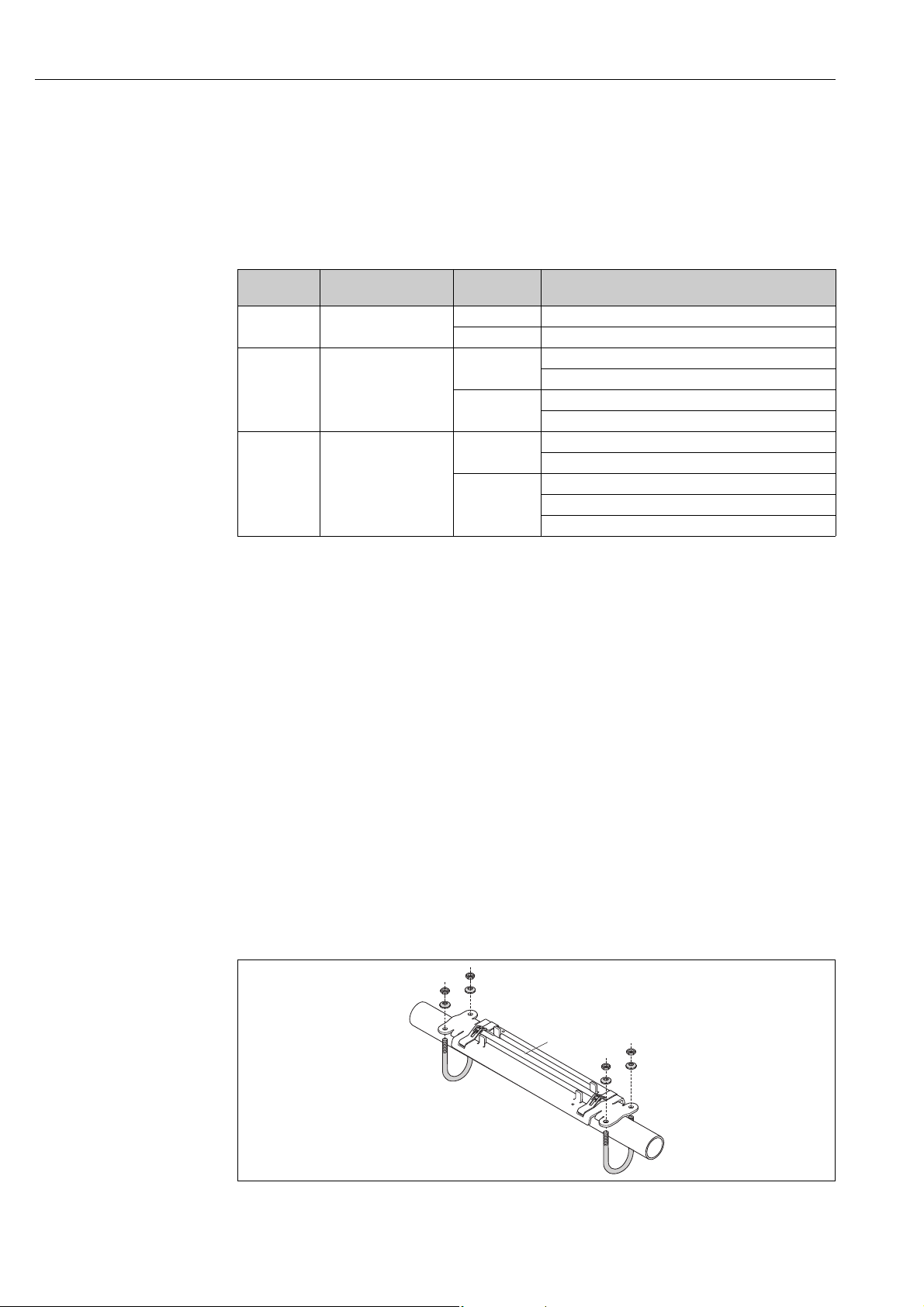

3.7.1 Mounting the sensor holder with U-shaped screws

For mounting on a pipe with a nominal diameter of DN 32 (1¼")

For sensors: Prosonic Flow 93W or P (DN 15 to 65 / ½ to 2½")

Procedure

1. Disconnect the sensor from the sensor holder.

2. Position the sensor holder on the pipe.

3. Put the U-shaped screws through the sensor holder and slightly lubricate the thread.

!

4. Screw nuts onto the U-shaped screws.

5. Set the holder to the exact position and tighten the nuts evenly.

Warning!

#

Risk of damaging plastic or glass pipes if the nuts of the U-shaped screws are tightened too

much! The use of a metal half-shell is recommended (on the opposite side of the sensor) when

working with plastic or glass pipes.

Note!

The visible pipe surface "A" must be smooth to ensure good accustic contact.

Fig. 19: Mounting the Prosonic Flow P or W sensor holder (DN 15 to 65 / ½ to 2½") with U-shaped screws

A0011XXXX

30 Endress+Hauser

Page 31

Proline Prosonic Flow 93 Installation

A

A

3.7.2 Mounting the sensor holder with strapping bands

For mounting on a pipe with a nominal diameter of DN 32 (1¼")

For sensors:

• Prosonic Flow 93W or P (DN 15 to 65 / ½ to 2½")

Procedure

1. Disconnect the sensor from the sensor holder.

2. Position the sensor holder on the pipe.

3. Wrap the strapping bands around the sensor holder and pipe without twisting them.

4. Guide the strapping bands through the strapping band locks (strapping screw is pushed up).

5. Tighten the strapping bands as tight as possible by hand.

6. Set the sensor holder to the correct position.

7. Push down the strapping screw and tighten the strapping bands so that they cannot slip.

8. Where necessary, shorten the strapping bands and trim the cut edges.

#

!

Warning!

Risk of injury. To avoid sharp edges, trim the cut edges after shortening the strapping bands.

A0011525

Fig. 20: Positioning the sensor holder and mounting the strapping bands

Note!

The visible pipe surface "A" must be smooth to ensure good accustic contact.

Endress+Hauser 31

A0011526

Fig. 21: Tightening the strapping screws of the strapping bands

Page 32

Installation Proline Prosonic Flow 93

1

2

3

3.7.3 Premounting the strapping bands (medium nominal diameters)

When mounting on a pipe with a nominal diameter of DN 200 (8")

For sensors:

• Prosonic Flow 93W or P (DN 50 to 4000 / 2 to 160")

Procedure

First strapping band

1. Fit the mounting bolt over the strapping band.

2. Wrap the strapping band around the pipe without twisting it.

3. Guide the end of the strapping band through the strapping band lock (strapping screw is

pushed up).

4. Tighten the strapping band as tight as possible by hand.

5. Set the strapping band to the desired position.

6. Push down the strapping screw and tighten the strapping band so that it cannot slip.

Second strapping band

7. Proceed as for the first strapping band (steps 1 to 7). Only slightly tighten the second strapping

band for final mounting. It must be possible to move the strapping band for final alignment.

#

Both strapping bands

8. Where necessary, shorten the strapping bands and trim the cut edges.

Warning!

Risk of injury. To avoid sharp edges, trim the cut edges after shortening the strapping bands.

A0001109

Fig. 22: Premounting strapping bands for pipe diameters DN 200 (8")

1 Mounting bolt

2 Strapping band

3 Strapping screw

32 Endress+Hauser

Page 33

Proline Prosonic Flow 93 Installation

3.

500 mm (20 in)

3.7.4 Premounting the strapping bands (large nominal diameters)

When mounting on a pipe with a nominal diameter in the range of

DN 600 (24")

For sensors:

• Prosonic Flow 93W or P (DN 50 to 4000 / 2 to 160")

Procedure

1. Measure the pipe circumference.

2. Shorten the strapping bands to one length (pipe circumference + 32 cm (12.6 in)) and trim the

cut edges.

Warning!

#

Risk of injury. To avoid sharp edges, trim the cut edges after shortening the strapping bands.

First strapping band

3. Fit the mounting bolt over the strapping band.

4. Wrap the strapping band around the pipe without twisting it.

5. Guide the end of the strapping band through the strapping band lock (strapping screw is

pushed up).

6. Tighten the strapping band as tight as possible by hand.

7. Set the strapping band to the desired position.

8. Push down the strapping screw and tighten the strapping band so that it cannot slip.

Second strapping band

9. Proceed as for the first strapping band (steps 3 to 8). Only slightly tighten the second strapping

band for final mounting. It must be possible to move the strapping band for final alignment.

A0015461

Fig. 23: Premounting strapping bands for pipe diameters DN > 600 (24")

1 Mounting bolt with guide*

2 Strapping band*

3 Strapping screw

* Distance between mounting bolt and strapping band lock min. 500 mm (20 in)

Endress+Hauser 33

Page 34

Installation Proline Prosonic Flow 93

M6

50

1

2

3

1

3.7.5 Mounting the welded bolts

When mounting on a pipe with a nominal diameter of DN 50 to 4000 (2 to 160")

For sensors:

• Prosonic Flow 93P (DN 50 to 4000 / 2 to 160")

• Prosonic Flow 93W

Procedure

The welded bolts must be fixed at the same installation distances as the mounting bolts with

strapping bands. The following sections explain how to the align the mounting bolts depending on

the type of mounting and the measurement method:

• Prosonic Flow P (DN 50 to 4000 / 2 to 160"), Clamp-on

– Installation for measurement via one traverse ä 37

– Installation for measurement via two traverses ä 39.

• Prosonic Flow W, Clamp-on

– Installation for measurement via one traverse ä 41

– Installation for measurement via two traverses ä 43.

The sensor holder is secured with a retaining nut with a metric ISO M6 thread as standard.

If you want to use another thread to secure the sensor holder, you must use a sensor holder with a

removable retaining nut (order number: 93WAx - xBxxxxxxxxxx).

A0001111

Fig. 24: Use of welded bolts

1 Welding seam

2 Retaining nut

3 Hole diameter max. 8.7 mm (0.34")

34 Endress+Hauser

Page 35

Proline Prosonic Flow 93 Installation

a

d

c

b

3.8 Installing Prosonic Flow W and P (DN 15 to 65 / ½ to 2½")

3.8.1 Mounting the sensor

Prerequisites

• The installation distance (sensor distance) is known ä 16.

• The sensor holder is already mounted ä 30.

Material

The following material is needed for mounting:

• Sensor incl. adapter cable

• Connecting cable for connecting to the transmitter

• Coupling fluid for an acoustic connection between the sensor and pipe

Procedure

1. Set the distance between the sensors as per the value determined for the sensor distance.

Press the movable sensor down slightly to move it.

!

A0011529

Fig. 25: Setting the distance between the sensors as per the value for the sensor distance

a Sensor distance (backside of sensor contact surface)

b Contact surfaces of the sensor

c Movable sensor

d Fixed sensor

2. Coat the contact surfaces of the sensors with an even layer of coupling fluid

(approx. 0.5 to 1 mm / 0.02 to 0.04") thick.

3. Fit the sensor housing on the sensor holder.

Note!

• Avoid to use a thick layer of the coupling fluid (less is more).

• Clean and reapply new coupling fluid when sensor is removed from the pipe.

• The sensor (DN 15 to 65 /½" to 2½") requires a smooth pipe surface.

Endress+Hauser 35

Page 36

Installation Proline Prosonic Flow 93

A0011527

Fig. 26: Fitting the sensor housing

4. Fix the sensor housing with the bracket.

Note!

!

– If necessary, the holder and sensor housing can be secured with a screw/nut or a

lead-seal (not part of the scope of supply).

– The bracket can only be released using an auxiliary tool.

A0011528

Fig. 27: Fixing the sensor housing

5. Connect the connecting cable to the adapter cable.

This completes the mounting process. The sensors can now be connected to the transmitter via the

connecting cables ä 61.

36 Endress+Hauser

Page 37

Proline Prosonic Flow 93 Installation

1234 567891011

SL

3.9 Installing Prosonic Flow P DN 50 to 4000 (2 to 160")

(Clamp-on)

3.9.1 Installation for measurement via one traverse

Prerequisites

• The installation distances (sensor distance and wire length) are known ä 16.

• The strapping bands are already mounted ä 30.

Material

The following material is needed for mounting:

• Two strapping bands incl. mounting bolts and centering plates where necessary

(already mounted ä 30)

• Two measuring wires, each with a cable lug and a fixer to position the strapping bands

•Two sensor holders

• Coupling fluid for an acoustic connection between the sensor and pipe

• Two sensors incl. connecting cables.

Procedure

1. Prepare the two measuring wires:

– Arrange the cable lugs and fixer such that the distance they are apart corresponds to the wire length (SL).

– Screw the fixer onto the measuring wire.

Fig. 28: Fixer (a) and cable lugs (b) at a distance that corresponds to the wire length (SL)

2. With the first measuring wire:

– Fit the fixer over the mounting bolt of the strapping band that is already securely mounted.

– Run the measuring wire clockwise around the pipe.

– Fit the cable lug over the mounting bolt of the strapping band that can still be moved.

3. With the second measuring wire:

– Fit the cable lug over the mounting bolt of the strapping band that is already securely

mounted.

– Run the measuring wire counterclockwise around the pipe.

– Fit the fixer over the mounting bolt of the strapping band that can still be moved.

4. Take the still movable strapping band, incl. the mounting bolt, and move it until both

measuring wires are evenly tensioned and tighten the strapping band so that it cannot slip.

A0001112

Endress+Hauser 37

A0001113

Fig. 29: Positioning the strapping bands (steps 2 to 4)

Page 38

Installation Proline Prosonic Flow 93

5. Loosen the screws of the fixers on the measuring wires and remove the measuring wires from

the mounting bolt.

6. Fit the sensor holders over the individual mounting bolts and tighten securely with the retaining nut.

A0001114

Fig. 30: Mounting the sensor holders

7. Coat the contact surfaces of the sensors with an even layer of coupling fluid approx. 1 mm

(0.04") thick, going from the groove through the center to the opposite edge.

!

Note!

• Avoid to use a thick layer of the coupling fluid (less is more).

• Clean and reapply new coupling fluid when the sensor is removed from the pipe.

•

On rough pipe surface e.g. GRP pipes ensure that the gaps crevices within the surface roughness

are filled. Apply sufficient coupling fluid

Fig. 31: Coating the contact surfaces of the sensor with coupling fluid

.

8. Insert the sensor into the sensor holder.

9. Fit the sensor cover on the sensor holder and turn until:

– The sensor cover engages with a click

– The arrows (Å / Æ "close") are pointing towards one another.

10. Screw the connecting cable into the individual sensor.

A0011373

A0001115

Fig. 32: Mounting the sensor and connecting the connecting cable

38 Endress+Hauser

Page 39

Proline Prosonic Flow 93 Installation

G

22

This completes the mounting process. The sensors can now be connected to the transmitter via the

connecting cables ä 61.

3.9.2 Installation for measurement via two traverses

Prerequisites

• The installation distance (position sensor) is known ä 16.

• The strapping bands are already mounted ä 30.

Material

The following material is needed for mounting:

• Two strapping bands incl. mounting bolts and centering plates where necessary

(already mounted ä 30)

• A mounting rail to position the strapping bands

• Two mounting rail retainers

•Two sensor holders

• Coupling fluid for an acoustic connection between the sensor and pipe

• Two sensors incl. connecting cables.

Mounting rail and POSITION SENSOR installation distance

The mounting rail has two rows with bores. The bores in one of the rows are indicated by letters

and the bores in the other row are indicated by numerical values. The value determined for the

POSITION SENSOR installation distance is made up of a letter and a numerical value.

The bores that are identified by the specific letter and numerical value are used to position the

strapping bands.

Procedure

1. Position the strapping bands with the aid of the mounting rail.

– Slide the mounting rail with the bore identified by the letter from POSITION SENSOR over

the mounting bolt of the strapping band that is permanently fixed in place.

– Position the movable strapping band and slide the mounting rail with the bore identified by

the numerical value from POSITION SENSOR over the mounting bolt.

Fig. 33: Determining the distance in accordance with the mounting rail (e.g. POSITION SENSOR G22)

2. Tighten the strapping band so that it cannot slip.

3. Remove the mounting rail from the mounting bolt.

4. Fit the sensor holders over the individual mounting bolts and tighten securely with the

retaining nut.

5. Screw the retainers of the mounting rail onto the sensor holder in question.

6. Screw the mounting rail onto the sensor holders.

Endress+Hauser 39

A0001116

Page 40

Installation Proline Prosonic Flow 93

A0001156

Fig. 34: Mounting the sensor holders and mounting rail

7. Coat the contact surfaces of the sensors with an even layer of coupling fluid approx. 1 mm

(0.04") thick, going from the groove through the center to the opposite edge.

!

Note!

• Avoid to use a thick layer of the coupling fluid (less is more).

• Clean and reapply new coupling fluid when sensor is removed from the pipe.

• On rough pipe surfaces e.g. GRP pipes ensure that the gaps

crevices within the surface roughness

are

filled. Apply sufficient coupling fluid.

Fig. 35: Coating the contact surfaces of the sensor with coupling fluid

8. Insert the sensor into the sensor holder.

9. Fit the sensor cover on the sensor holder and turn until:

– The sensor cover engages with a click

– The arrows (Å / Æ "close") are pointing towards one another.

10. Screw the connecting cable into the individual sensor.

Fig. 36: Mounting the sensor and connecting the connecting cable

A0011XXX

A0001112

This completes the mounting process. The sensors can now be connected to the transmitter via the

connecting cables ä 61.

40 Endress+Hauser

Page 41

Proline Prosonic Flow 93 Installation

1234 567891011

SL

3.10 Installing Prosonic Flow W (Clamp-on)

3.10.1 Installation for measurement via one traverse

Prerequisites

• The installation distances (sensor distance and wire length) are known ä 16.

• The strapping bands are already mounted ä 30.

Material

The following material is needed for mounting:

• Two strapping bands incl. mounting bolts and centering plates where necessary

(already mounted ä 30)

• Two measuring wires, each with a cable lug and a fixer to position the strapping bands

•Two sensor holders

• Coupling fluid for an acoustic connection between the sensor and pipe

• Two sensors incl. connecting cables.

Procedure

1. Prepare the two measuring wires:

– Arrange the cable lugs and fixer such that the distance they are apart corresponds to the wire

length (SL).

– Screw the fixer onto the measuring wire.

Fig. 37: Fixer (a) and cable lugs (b) at a distance that corresponds to the wire length (SL)

2. With the first measuring wire:

– Fit the fixer over the mounting bolt of the strapping band that is already securely mounted.

– Run the measuring wire clockwise around the pipe.

– Fit the cable lug over the mounting bolt of the strapping band that can still be moved.

3. With the second measuring wire:

– Fit the cable lug over the mounting bolt of the strapping band that is already securely

mounted.

– Run the measuring wire counterclockwise around the pipe.

– Fit the fixer over the mounting bolt of the strapping band that can still be moved.

4. Take the still movable strapping band, incl. the mounting bolt, and move it until both

measuring wires are evenly tensioned and tighten the strapping band so that it cannot slip.

A0001112

Endress+Hauser 41

A0001113

Fig. 38: Positioning the strapping bands (steps 2 to 4)

Page 42

Installation Proline Prosonic Flow 93

5. Loosen the screws of the fixers on the measuring wires and remove the measuring wires from

the mounting bolt.

6. Fit the sensor holders over the individual mounting bolts and tighten securely with the

retaining nut.

A0001114

Fig. 39: Mounting the sensor holders

7. Coat the contact surfaces of the sensors with an even layer of coupling fluid approx. 1 mm

(0.04") thick, going from the groove through the center to the opposite edge.

!

Note!

• Avoid to use a thick layer of the coupling fluid (less is more).

• Clean and reapply new coupling fluid when sensor is removed from the pipe.

• On rough pipe surfaces e.g. GRP pipes ensure that the gaps

crevices within the surface roughness

filled. Apply sufficient coupling fluid.

Fig. 40: Coating the contact surfaces of the sensor with coupling fluid

8. Insert the sensor into the sensor holder.

9. Fit the sensor cover on the sensor holder and turn until:

– The sensor cover engages with a click

– The arrows (Å / Æ "close") are pointing towards one another.

10. Screw the connecting cable into the individual sensor.

are

A0011373

A0001115

Fig. 41: Mounting the sensor and connecting the connecting cable

This completes the mounting process. The sensors can now be connected to the transmitter via the

connecting cables ä 61.

42 Endress+Hauser

Page 43

Proline Prosonic Flow 93 Installation

G

22

3.10.2 Installation for measurement via two traverses

Prerequisites

• The installation distance (position sensor) is known ä 16.

• The strapping bands are already mounted ä 30.

Material

The following material is needed for mounting:

• Two strapping bands incl. mounting bolts and centering plates where necessary

(already mounted ä 30)

• A mounting rail to position the strapping bands

• Two mounting rail retainers

•Two sensor holders

• Coupling fluid for an acoustic connection between the sensor and pipe

• Two sensors incl. connecting cables.

Mounting rail and POSITION SENSOR installation distance

The mounting rail has two rows with bores. The bores in one of the rows are indicated by letters

and the bores in the other row are indicated by numerical values. The value determined for the

POSITION SENSOR installation distance is made up of a letter and a numerical value.