Page 1

Operating Instructions

Esc

Esc

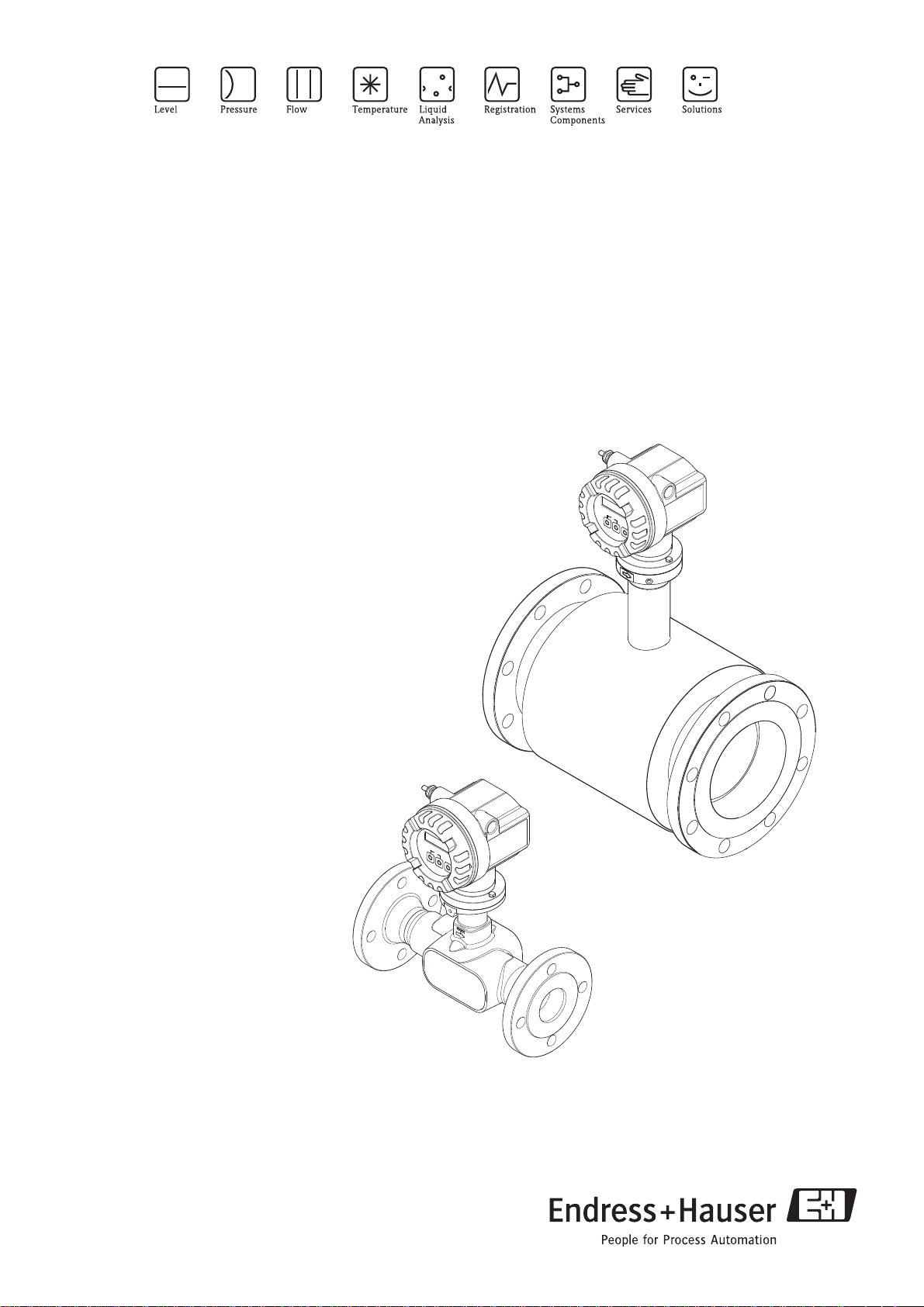

Proline Prosonic Flow 92F HART

Ultrasonic Flow Measuring System

6

BA00121D/06/EN/13.10

71124139

Valid as of version

V1.01.XX (device software)

Page 2

Page 3

Proline Prosonic Flow 92F Table of contents

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and icons . . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Nameplate of the transmitter . . . . . . . . . . . . 7

2.1.2 Nameplate of the sensor . . . . . . . . . . . . . . . 8

2.1.3 Nameplate for connections . . . . . . . . . . . . . 8

2.2 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

2.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . 10

3.1 Incoming acceptance, transport, storage . . . . . . . . . 10

3.1.1 Incoming acceptance . . . . . . . . . . . . . . . . . 10

3.1.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 Mounting location . . . . . . . . . . . . . . . . . . . 11

3.2.3 Orientation . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.4 Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.5 Thermal insulation . . . . . . . . . . . . . . . . . . 13

3.2.6 Inlet and outlet run . . . . . . . . . . . . . . . . . . 13

3.2.7 Limiting flow . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . 14

3.3.1 Mounting the sensor . . . . . . . . . . . . . . . . . 14

3.3.2 Turning the transmitter housing . . . . . . . . 14

3.3.3 Turning the local display . . . . . . . . . . . . . . 14

3.3.4 Mounting the remote version . . . . . . . . . . 15

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 15

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 16

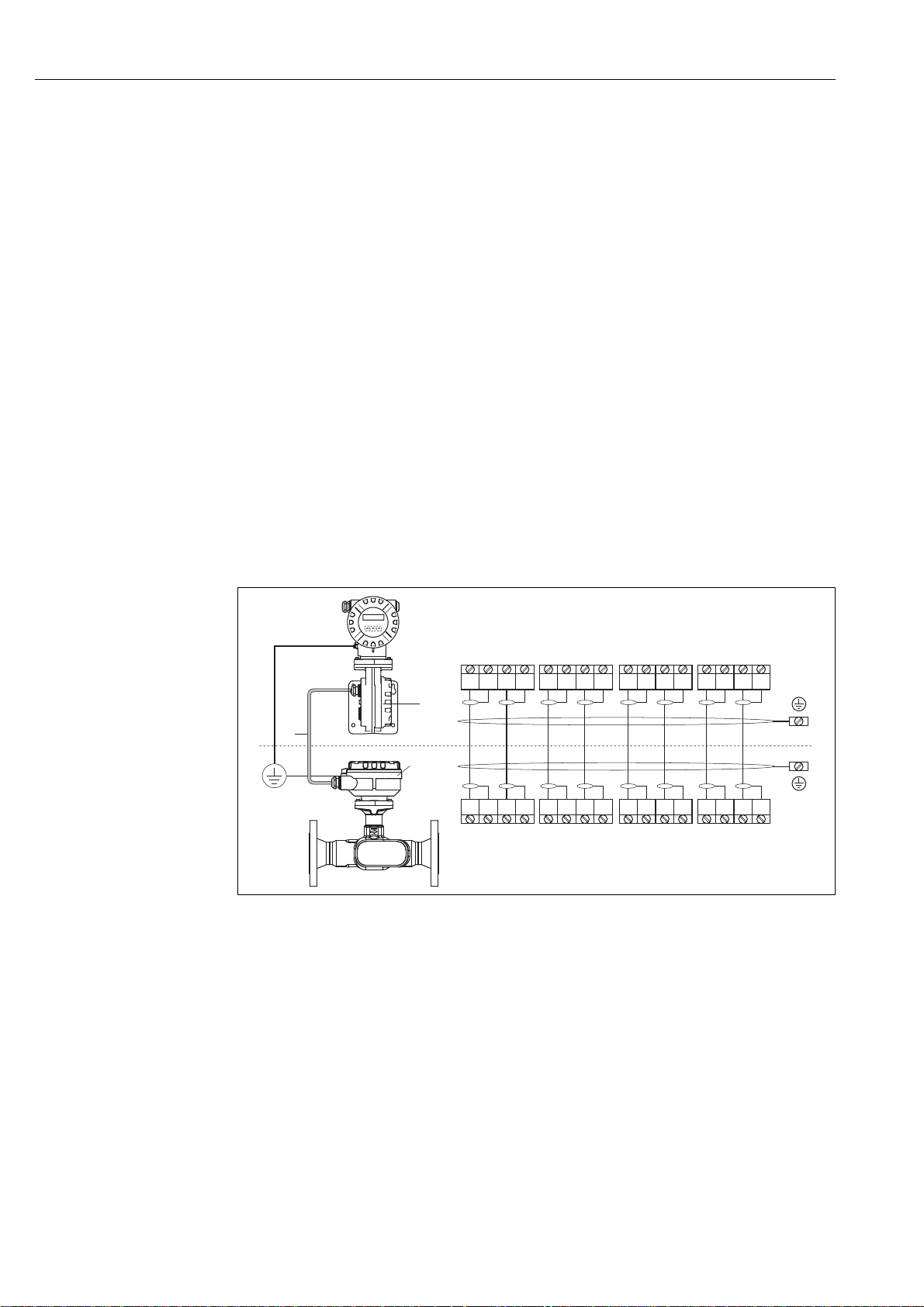

4.1 Connecting the remote version . . . . . . . . . . . . . . . 16

4.1.1 Connecting cable for sensor/transmitter . . 16

4.1.2 Cable specification for connecting cable . . . 16

4.2 Connecting the measuring unit . . . . . . . . . . . . . . . 17

4.2.1 Connecting the transmitter . . . . . . . . . . . . 17

4.2.2 Terminal assignment . . . . . . . . . . . . . . . . . 19

4.2.3 HART connection . . . . . . . . . . . . . . . . . . . 20

4.3 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 22

5 Operation . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Display and operating elements . . . . . . . . . . . . . . . 23

5.2 Operation via the function matrix . . . . . . . . . . . . . 24

5.2.1 General notes . . . . . . . . . . . . . . . . . . . . . . 25

5.2.2 Enabling the programming mode . . . . . . . . 25

5.2.3 Disabling the programming mode . . . . . . . 25

5.3 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.1 Operating options . . . . . . . . . . . . . . . . . . . 27

5.3.2 Current device description files . . . . . . . . . 28

5.3.3 Device variables and process variables . . . . 29

5.3.4 Universal/common practice HART commands . . 30

5.3.5 Device status/diagnosis code messages . . . . 35

5.3.6 Switching HART write protection on/off . . 37

6 Commissioning . . . . . . . . . . . . . . . . . . 38

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2 Switching on the measuring device . . . . . . . . . . . . 38

6.3 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.1 "Commissioning" Quick Setup . . . . . . . . . . 39

6.3.2 Data backup with the T–DAT SAVE/LOAD

function . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4 Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.1 Zero point adjustment . . . . . . . . . . . . . . . . 42

6.5 Data storage device (HistoROM) . . . . . . . . . . . . . . 43

6.5.1 HistoROM/T-DAT (transmitter–DAT) . . . . 43

7 Maintenance . . . . . . . . . . . . . . . . . . . . 44

7.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Cleaning with pigs . . . . . . . . . . . . . . . . . . . . . . . . . 44

8 Accessories . . . . . . . . . . . . . . . . . . . . . 45

8.1 Device-specific accessories . . . . . . . . . . . . . . . . . . . 45

8.2 Measuring principle-specific accessories . . . . . . . . . 45

8.3 Communication-specific accessories . . . . . . . . . . . . 45

8.4 Service-specific accessories . . . . . . . . . . . . . . . . . . . 46

9 Troubleshooting . . . . . . . . . . . . . . . . . 47

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . . 47

9.2 Diagnosis code messages . . . . . . . . . . . . . . . . . . . . 48

9.2.1 Category F diagnosis code messages . . . . . . 48

9.2.2 Category C diagnosis code messages . . . . . 49

9.2.3 Category S diagnosis code messages . . . . . . 50

9.3 Process errors without messages . . . . . . . . . . . . . . 51

9.4 Response of outputs to errors . . . . . . . . . . . . . . . . . 52

9.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.5.1 Installing and removing electronics boards . 54

9.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.8 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10 Technical data . . . . . . . . . . . . . . . . . . . 59

10.1 Technical data at a glance . . . . . . . . . . . . . . . . . . . 59

10.1.1 Application . . . . . . . . . . . . . . . . . . . . . . . . 59

10.1.2 Function and system design . . . . . . . . . . . . 59

10.1.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.1.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.1.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . 62

10.1.6 Performance characteristics . . . . . . . . . . . . 62

10.1.7 Operating conditions: Installation . . . . . . . . 62

10.1.8 Operating conditions: Environment . . . . . . 63

Endress+Hauser 3

Page 4

Proline Prosonic Flow 92F Table of contents

10.1.9 Operating conditions: Process . . . . . . . . . . 64

10.1.10 Mechanical construction . . . . . . . . . . . . . . 64

10.1.11 Human interface . . . . . . . . . . . . . . . . . . . . 66

10.1.12 Certificates and approvals . . . . . . . . . . . . . 66

10.1.13 Ordering information . . . . . . . . . . . . . . . . 67

10.1.14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . 67

10.1.15 Documentation . . . . . . . . . . . . . . . . . . . . 67

11 Description of device functions . . . . . . 68

11.1 Illustration of the function matrix . . . . . . . . . . . . . . 68

11.2 Group MEASURING VALUES . . . . . . . . . . . . . . . . 70

11.3 Group . . . . . . . . . . . . . . . . . . . . . SYSTEM UNITS 71

11.4 Group QUICK SETUP . . . . . . . . . . . . . . . . . . . . . . 75

11.5 Group OPERATION . . . . . . . . . . . . . . . . . . . . . . . 76

11.6 Group USER INTERFACE . . . . . . . . . . . . . . . . . . . 77

11.7 Group TOTALIZER . . . . . . . . . . . . . . . . . . . . . . . . 79

11.7.1 Function group TOTALIZER 1 (TOTALIZER 2) . 79

11.7.2 Group HANDLING TOTALIZER . . . . . . . . 81

11.8 Group CURRENT OUTPUT . . . . . . . . . . . . . . . . . . 82

11.9 Group PULSE, FREQUENCY, STATUS . . . . . . . . . . 85

11.10 Information on the response of the status output . . 98

11.11 Group COMMUNICATION . . . . . . . . . . . . . . . . . 100

11.12 Group PROCESS PARAMETER . . . . . . . . . . . . . . 101

11.13 Group SYSTEM PARAMETER . . . . . . . . . . . . . . . 103

11.14 Group SENSOR DATA . . . . . . . . . . . . . . . . . . . . . 104

11.15 Group SUPERVISION . . . . . . . . . . . . . . . . . . . . . 106

11.16 Group SIMULATION SYSTEM . . . . . . . . . . . . . . 108

11.17 Group SENSOR VERSION . . . . . . . . . . . . . . . . . . 108

11.18 Group AMPLIFIER VERSION . . . . . . . . . . . . . . . . 108

12 Factory settings . . . . . . . . . . . . . . . . . 109

12.1 Metric system units (not for USA and Canada) . . . 109

12.1.1 Low flow cut off, fullscale value, pulse value,

totalizer → Page 71 . . . . . . . . . . . . . . . . 109

12.1.2 Language → Page 76 . . . . . . . . . . . . . . . 109

12.1.3 Unit totalizer 1 + 2 → ä 79 . . . . . . . . . . 109

12.2 US units (only for USA and Canada) . . . . . . . . . . . 110

12.2.1 low flow cut off, full scale value, pulse value,

totalizer → ä 71 . . . . . . . . . . . . . . . . . . 110

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4 Endress+Hauser

Page 5

Proline Prosonic Flow 92F Safety instructions

1 Safety instructions

1.1 Designated use

The measuring device described in these Operating Instructions is to be used only for measuring the

flow rate of liquids in closed pipes, e.g.:

• Acids, alkalis, paints, oils

• Liquefied gas

• Ultrapure water with a low conductivity, water, wastewater

In addition to measuring the volume flow, the measuring device also always measures the sound

velocity of the fluid. In this way, different fluids can be distinguished or the fluid quality can be

monitored.

Resulting from incorrect use or from use other than that designated the operational safety of the

measuring devices can be suspended. The manufacturer accepts no liability for damages being

produced from this.

1.2 Installation, commissioning and operation

Note the following points:

• Installation, connection to the electricity supply, commissioning and maintenance of the device

must be carried out by trained, qualified specialists authorized to perform such work by the

facility's owner operator. The specialist must have read and understood these Operating

Instructions and must follow the instructions they contain.

• The device must be operated by persons authorized and trained by the facility's owner-operator.

Strict compliance with the instructions in these Operating Instructions is mandatory.

• In the case of special fluids (incl. fluids for cleaning), Endress+Hauser will be happy to assist in

clarifying the corrosion resistance properties of wetted materials. Slight changes to the

temperature, concentration or degree of contamination in the process can, however, alter the

corrosion resistance. Consequently, Endress+Hauser does not accept any guarantee or liability

with regard to the corrosion resistance of wetted materials in a specific application. The user is

responsible for the choice of suitable wetted materials in the process.

• If carrying out welding work on the piping, the welding unit may not be grounded by means of

the measuring device.

• The installer must ensure that the measuring system is correctly wired in accordance with the

wiring diagrams. The transmitter must be grounded, unless the power supply is galvanically

isolated.

• Invariably, local regulations governing the opening and repair of electrical devices apply.

1.3 Operational safety

• Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of these Operating Instructions. Strict compliance with

the installation instructions and ratings as listed in this supplementary documentation is

mandatory. The symbol on the front of this supplementary Ex documentation indicates the

approval and the inspection authority (0 Europe, 2 USA, 1 Canada).

• The measuring device complies with the general safety requirements in accordance with EN 61010,

the EMC requirements of IEC/EN 61326 and NAMUR recommendations NE 21 and NE 43.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to these

Operating Instructions.

Endress+Hauser 5

Page 6

Safety instructions Proline Prosonic Flow 92F

1.4 Return

• Do not return a measuring device if you are not absolutely certain that all traces of hazardous

substances have been removed, e.g. substances which have penetrated crevices or diffused

through plastic.

• Costs incurred for waste disposal and injury (burns, etc.) due to inadequate cleaning will be

charged to the owner-operator.

• Please note the measures on → ä 58

1.5 Notes on safety conventions and icons

The devices are designed to meet state-of-the-art safety requirements, have been tested, and left the

factory in a condition in which they are safe to operate. The devices comply with the applicable

standards and regulations in accordance with EN 61010 "Protection Measures for Electrical

Equipment for Measurement, Control, Regulation and Laboratory Procedures". The devices can,

however, be a source of danger if used incorrectly or for anything other than the designated use.

Consequently, always pay particular attention to the safety instructions indicated in these Operating

Instructions by the following symbols:

#

Warning!

"Warning" indicates an action or procedure which, if not performed correctly, can result in injury

or a safety hazard. Comply strictly with the instructions and proceed with care.

"

!

Caution!

"Caution" indicates an action or procedure which, if not performed correctly, can result in incorrect

operation or destruction of the device. Comply strictly with the instructions.

Note!

"Note" indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

6 Endress+Hauser

Page 7

Proline Prosonic Flow 92F Identification

N12895

Prosonic Flow 92

ABCDEFGHJKLMNPQRST

TAGNo.:

Ser.No.:

12345678901

Order Code:

i

IP67 / NEMA/Type4X

-40°F<Ta<+140°F

Ta+10°C/18°F

92FXX-XXXXXXXXXXX

12-35VDC

4...20mA, HART

1.2W

-40°C<Ta<+60°C

1

2

4

5

3

2 Identification

2.1 Device designation

The "Prosonic Flow 92" flowmeter system consists of the following components:

• Prosonic Flow 92 transmitter

• Prosonic Flow F Inline sensor

Two versions are available:

• Compact version: transmitter and sensor form a single mechanical unit.

• Remote version: transmitter and sensor are installed separately.

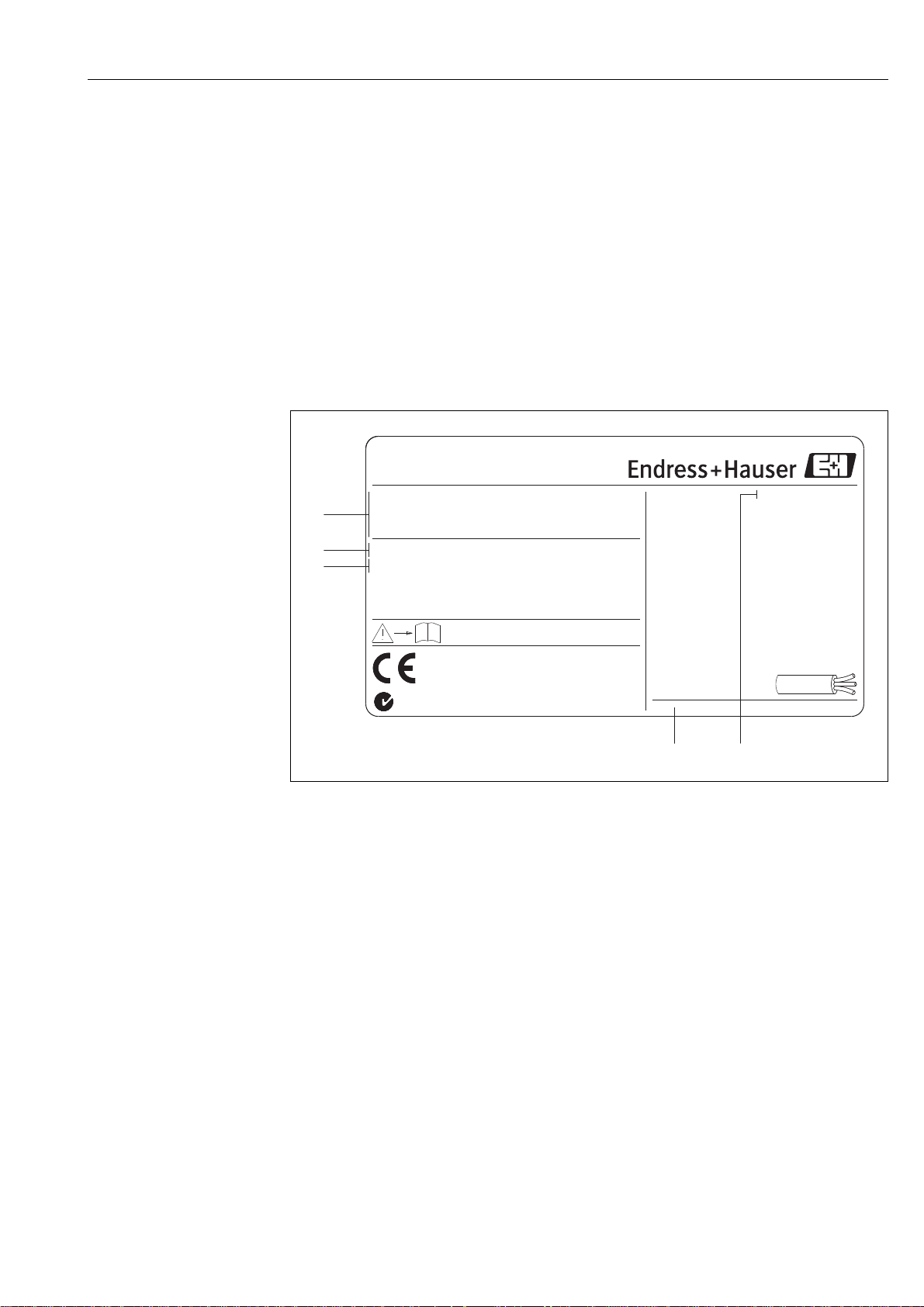

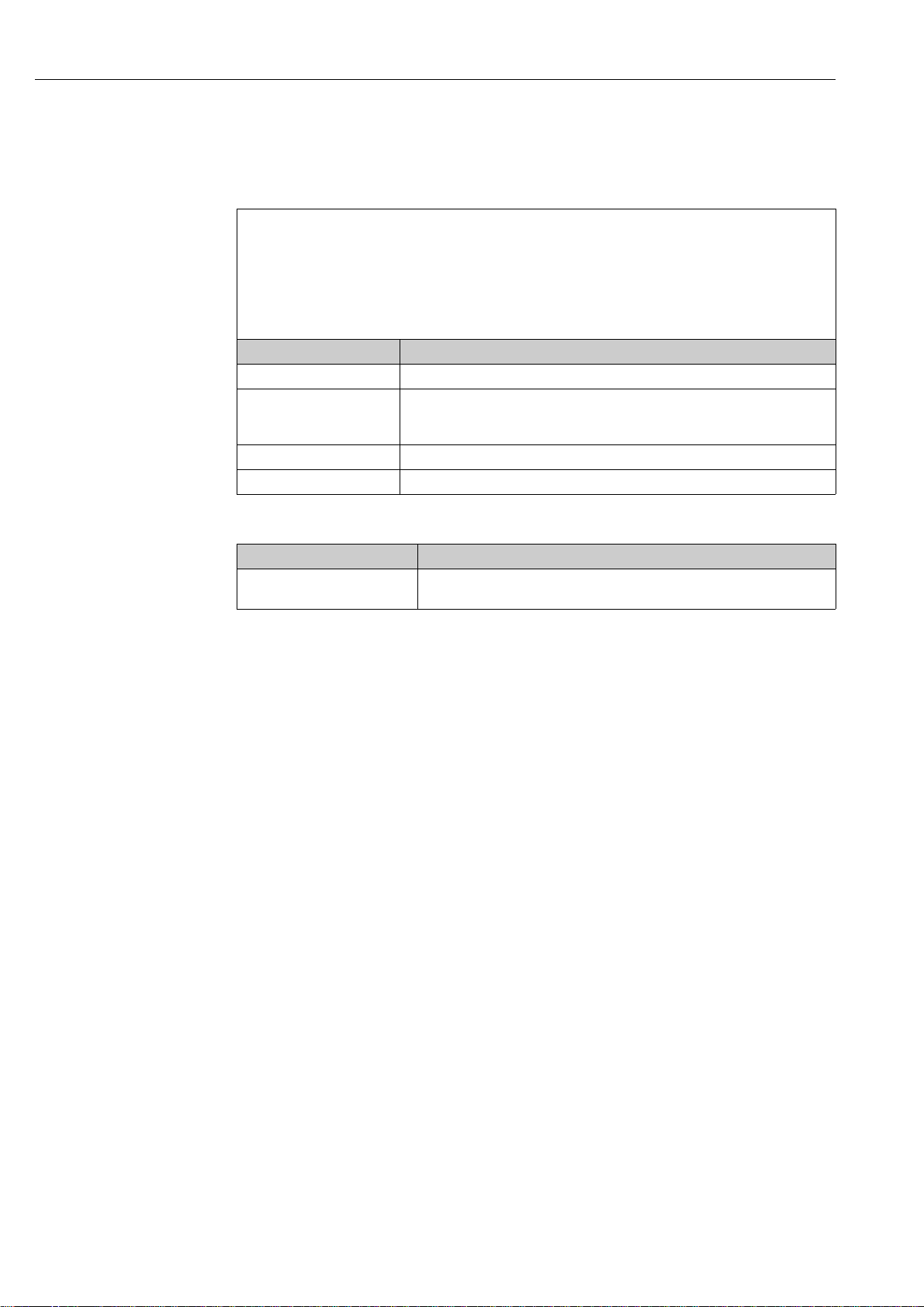

2.1.1 Nameplate of the transmitter

a0006111

Fig. 1: Nameplate specifications for the "Prosonic Flow" transmitter (example)

1 Order code / serial number: See the specifications on the order confirmation for the meanings of the individual

letters and digits

2 Power supply: 12 to 35 V DC

Power consumption: 1.2 W

3 Available outputs

4 Permitted ambient temperature range

5 Degree of protection

Endress+Hauser 7

Page 8

Identification Proline Prosonic Flow 92F

2

3

4

5

1

7

6

Switzerland

4153 Reinach

-40°C <Tamb< +80°C

-40° <TambF < +176°F

IP67 / NEMA/Type4X

5P-CAL

TM:

-40°C(-40°F)...+150°C(+302°F)

CF3M / 1.4404 / F316L / F316

Materials:

DN100/4" DIN/EN PN16

1.000/0000

K-factor:

XXXXXXXXXXX

Ser.No.:

Order Code:

Prosonic Flow F

92FXX-XXXXXXXXXXXXX

N12895

i

8

Connector

Plug

Observer manuel d'Instruction.

4..20mA

max. 36VDC

max. 36VDC

max. 15mA

Optional

Betriebsanleitung beachten.

See operating manual.

1

3

4

2

Do not sep rate when energized!a

ATEXII3G / Zone 2:

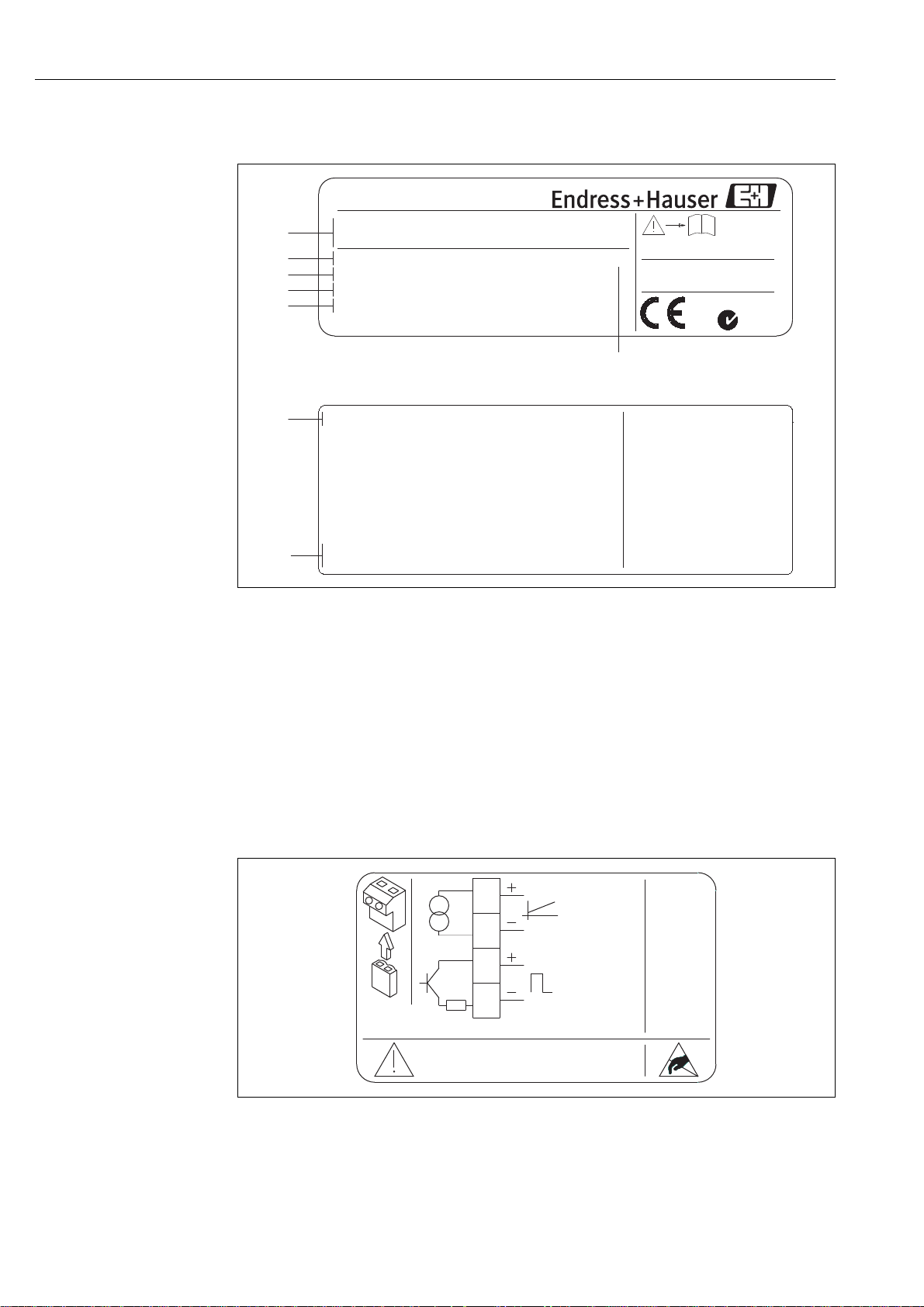

2.1.2 Nameplate of the sensor

a0006107

Fig. 2: Nameplate specifications for the Prosonic Flow F sensor (example)

1 Order code/serial number: See the specifications on the order confirmation for the meanings of the individual

letters and digits

2 Calibration factor with zero point

3 Device nominal diameter/nominal pressure

4 Measuring tube material

5 Medium temperature range

6 Degree of protection

7 Permitted ambient temperature range

8 Additional information (examples):

– 5P-CAL: with 5-point calibration

2.1.3 Nameplate for connections

Fig. 3: Nameplate specifications for Proline transmitter (example)

8 Endress+Hauser

a0006110

Page 9

Proline Prosonic Flow 92F Identification

2.2 Certificates and approvals

The devices are designed in accordance with good engineering practice to meet state-of-the-art

safety requirements, have been tested, and left the factory in a condition in which they are safe to

operate.

The measuring device complies with the general safety requirements in accordance with EN 61010,

the EMC requirements of IEC/EN 61326 and NAMUR recommendations NE 21 and NE 43.

The measuring system described in these Operating Instructions thus complies with the statutory

requirements of the EC Directives. Endress+Hauser confirms successful testing of the device by

affixing to it the CE mark.

The measuring system complies with the EMC requirements of the Australian Communications and

Media Authority (ACMA).

!

Note!

A detailed list of all the certificates and approvals is provided in the technical data on Page 66.

2.3 Registered trademarks

HART®

Registered trademark of the HART Communication Foundation, Austin, USA

®

HistoROM™ T-DAT

Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach, CH

, FieldCare ®, Fieldcheck®, FieldXpert™, Applicator

®

Endress+Hauser 9

Page 10

Installation Proline Prosonic Flow 92F

3 Installation

3.1 Incoming acceptance, transport, storage

3.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches your

order.

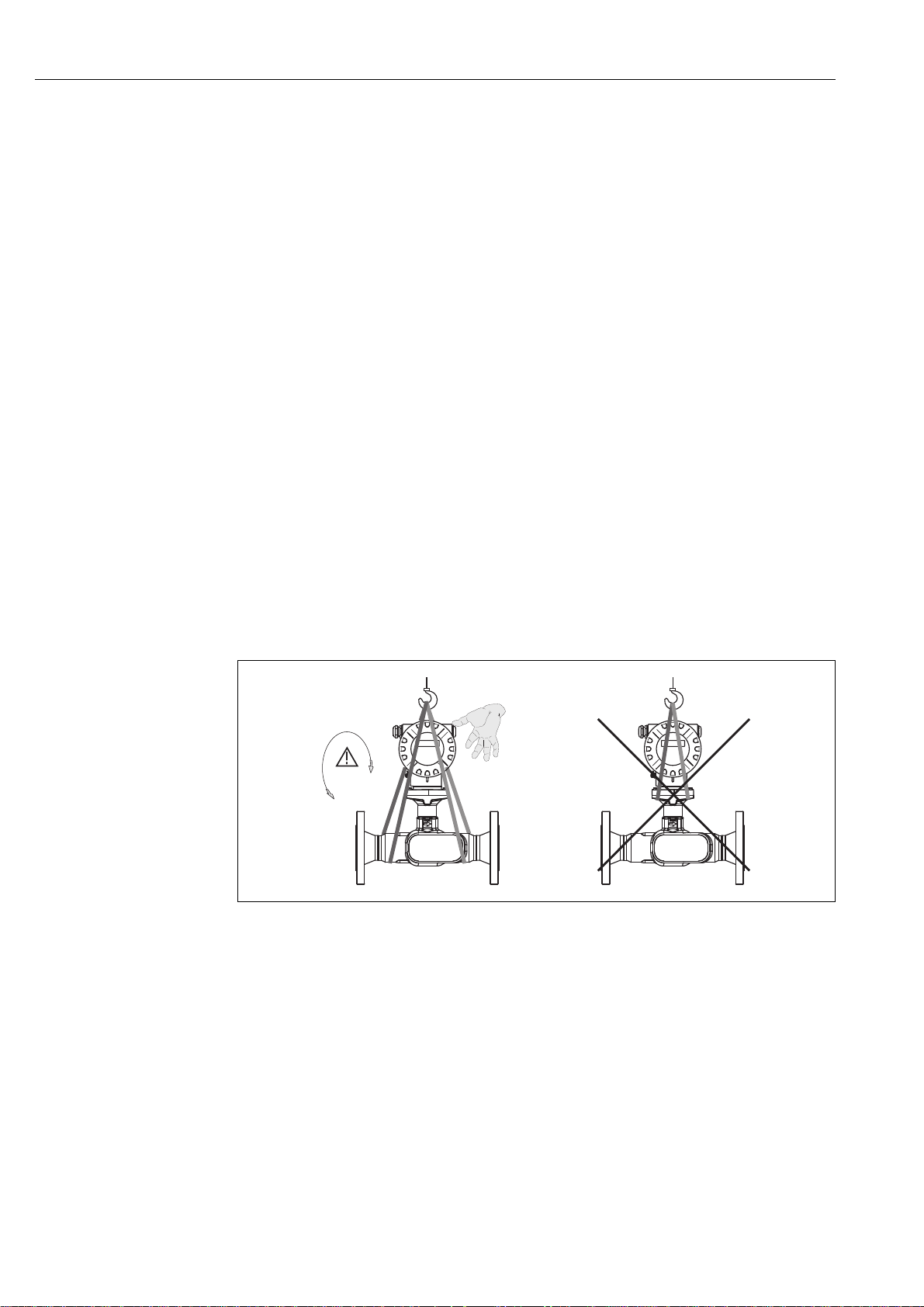

3.1.2 Transport

Please note the following when unpacking or transporting to the measuring point:

• The devices must be transported in the container supplied.

• The covers or caps fitted to the process connections prevent mechanical damage to the sealing

faces and the ingress of foreign matter to the measuring tube during transportation and storage.

Consequently, do not remove these covers or caps until immediately before installation.

• Devices with nominal diameters > DN 40 (> 1½") may not be lifted at the transmitter housing or

at the connection housing of the remote version when transporting. Use carrier slings when

transporting and put the slings around both process connections. Avoid chains as these could

damage the housing.

#

Warning!

Risk of injury if the measuring device slips. The center of gravity of the entire measuring device

might be higher than the points around which the slings are slung.

Therefore, when transporting, make sure that the device does not unintentionally turn or slip.

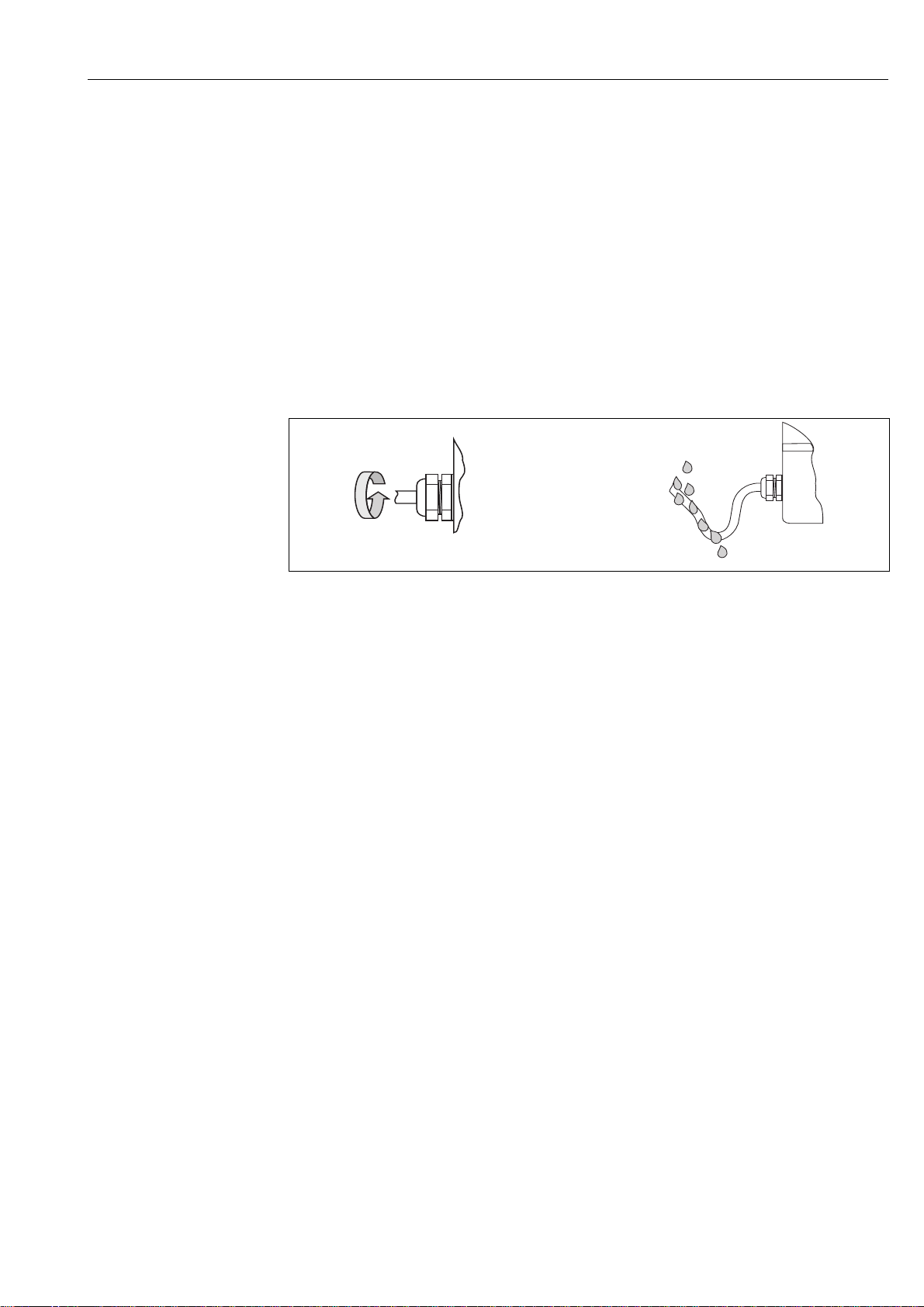

a0005765

Fig. 4: Instructions for transporting sensors with a nominal diameter > DN 40 (> 1½")

3.1.3 Storage

Note the following points:

• Pack the measuring device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

• The permissible storage temperature is –40 to +80 °C (–40 °F to 176 °F),

preferably +20 °C (68 °F).

• Do not remove the protective covers or caps on the process connections until you are ready to

install the device.

• The measuring device must be protected against direct sunlight during storage in order to avoid

unacceptably high surface temperatures.

10 Endress+Hauser

Page 11

Proline Prosonic Flow 92F Installation

1

2

3

4

5

3.2 Installation conditions

Note the following points:

• No special measures such as supports are necessary. External forces are absorbed by the

construction of the instrument.

• The flowmeter flanges must be coplanar with connecting flanges and free from tension.

• The maximum permitted ambient temperatures (→ ä 63) and fluid temperatures (→ ä 63)

must be observed.

• Pay particular attention to the notes on orientation and piping insulation on the following pages.

• The correct operation of the measuring system is not influenced by pipe vibrations.

3.2.1 Dimensions

All the dimensions and lengths of the sensor and transmitter are provided in the separate

documentation "Technical Information". → ä 67

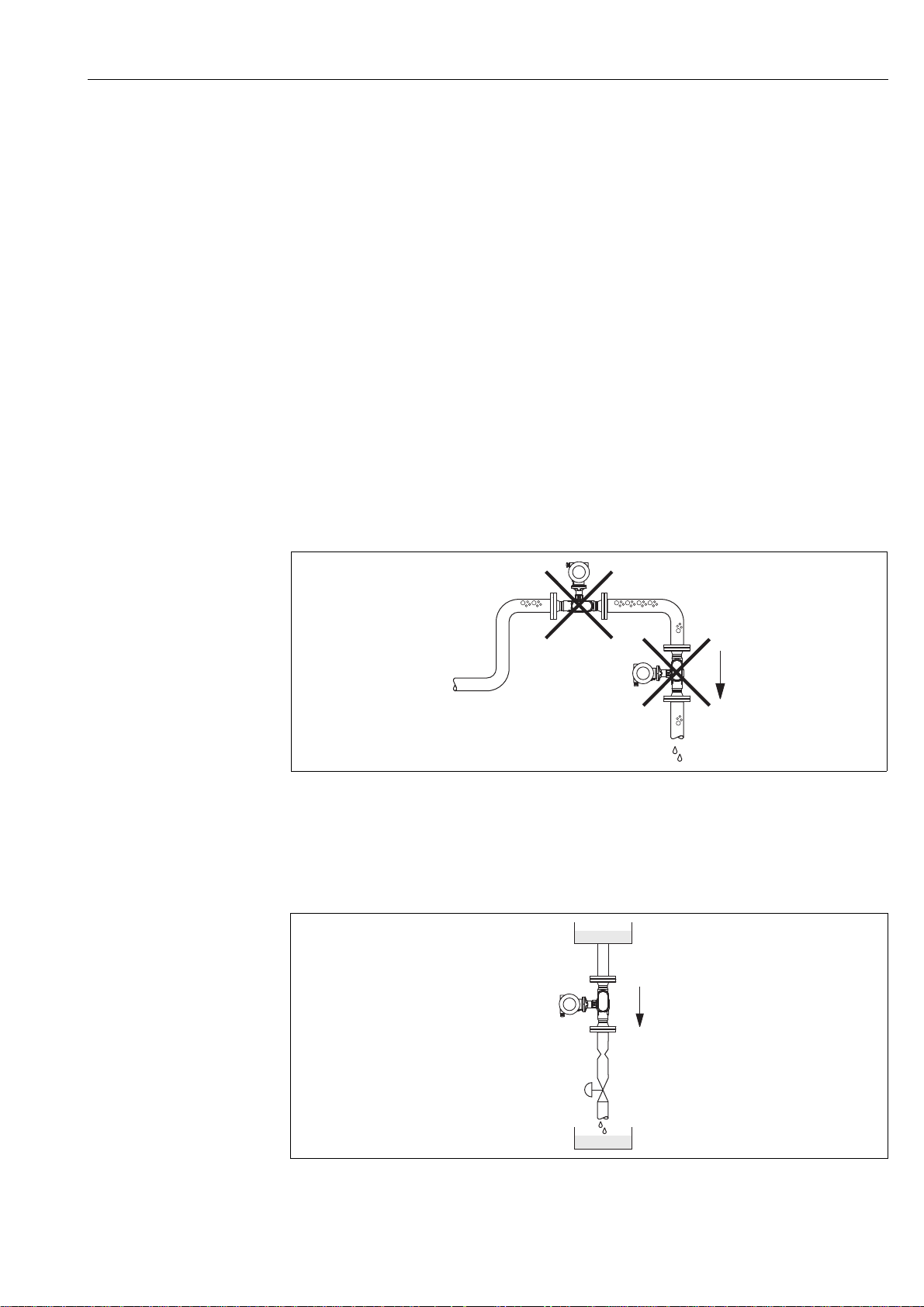

3.2.2 Mounting location

Accumulated gas bubbles in the measuring tube can result in measuring errors.

Avoid the following locations:

• Highest point of a pipeline. Risk of gas accumulating.

• Directly upstream of a free pipe outlet in a vertical pipeline.

a0006081

Fig. 5: Mounting location

The proposed configuration in the following diagram, however, permits installation in a vertical

pipeline. Pipe restrictors or the use of an orifice plate with a smaller cross section than the nominal

diameter prevent the sensor from running empty during measurement.

Fig. 6: Installation in a vertical pipe (e.g. for batching applications)

1 = Supply tank , 2 = Sensor, 3 = Orifice plate, pipe restriction , 4 = Valve, 5 = Batching tank

a0006082

Endress+Hauser 11

Page 12

Installation Proline Prosonic Flow 92F

A BC D

System pressure

No additional pressure loss results from installing the device. It is important to ensure that cavitation

or degassing does not occur at fittings upstream from the measuring device as this can affect sound

transmission in the fluid.

No special measures need to be taken for fluids which have properties similar to water under normal

conditions.

In the case of liquids with a low boiling point (hydrocarbons, solvents, liquefied gases) or in suction

lines, it is important to ensure that pressure does not drop below the vapor pressure and that the

liquid does not start to boil. It is also important to ensure that the gases that occur naturally in many

liquids do not outgas. Such effects can be prevented when system pressure is sufficiently high.

For this reason, preference should be given to the following mounting locations:

• Downstream from pumps (no danger of vacuum)

• At the lowest point in a vertical pipe

3.2.3 Orientation

Make sure that the direction of the arrow on the nameplate of the sensor matches the direction of

flow (direction in which the fluid flows through the pipe).

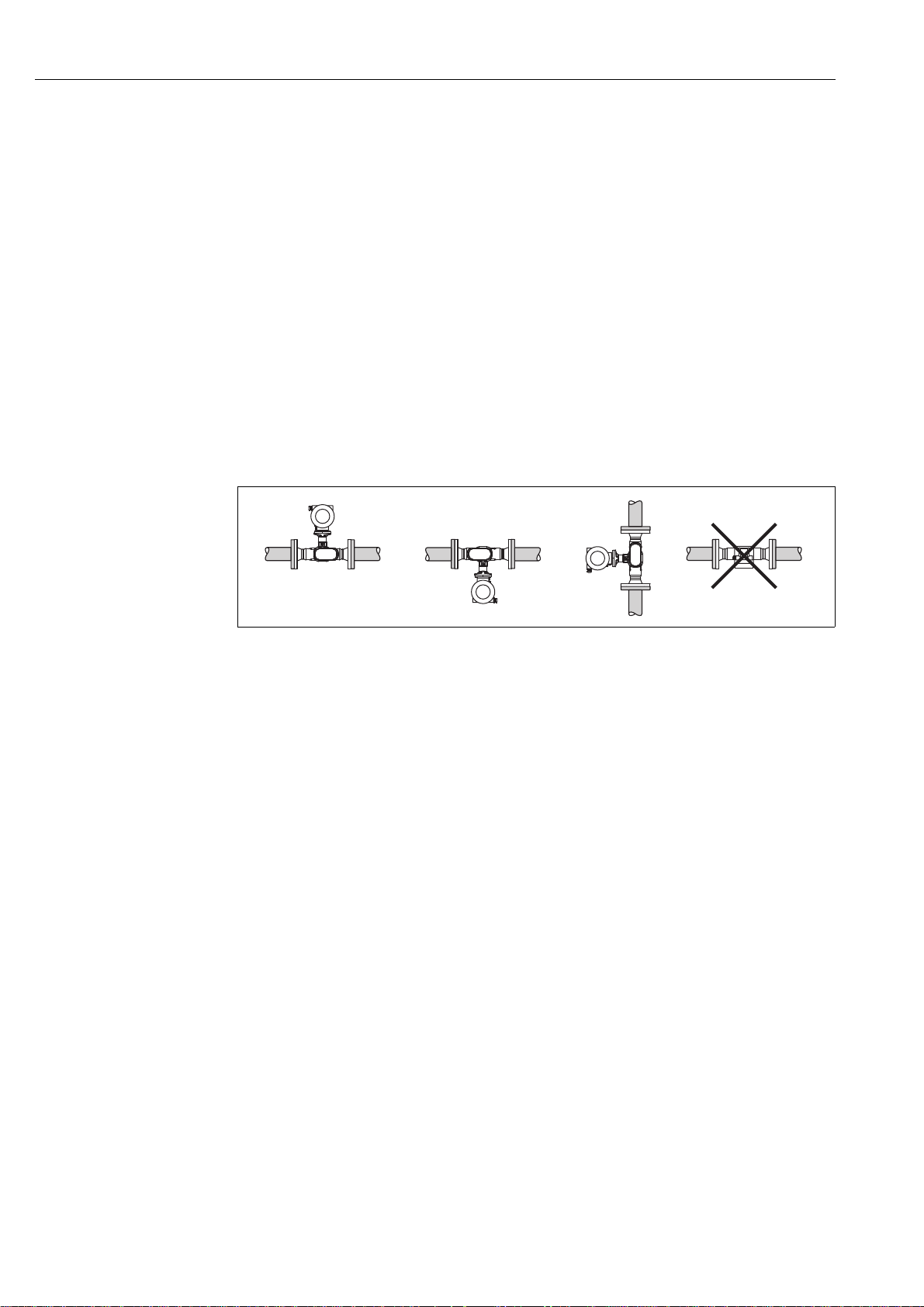

Fig. 7: Orientations A, B and C recommended, orientation D only recommended under certain circumstances

3.2.4 Heating

Some fluids require heat to be transfered at the sensor. Heating can be electric, e.g. with heated

elements, or by hot water or steam.

Caution!

"

• Danger of electronics overheating!

Make sure that the adapter between the sensor and transmitter and the connection housing of

the remote version always remain free of insulating material.

• When using electrical heat tracing whose heat is regulated using phase control or by pulse packs,

it cannot be ruled out that the measured values are influenced by magnetic fields which may

occur, (i.e. at values greater than those permitted by the EC standard (Sinus 30 A/m)). In such

cases, the sensor must be magnetically shielded.

a0005971

12 Endress+Hauser

Page 13

Proline Prosonic Flow 92F Installation

max. 20 (0.8)

max. 20 (0.8)

mm (inch)

2

A

1

3

A

A

4

A

5DN×

10 DN×

B

3 DN×

15 DN×

5 × DN

B

3 DN×

B

3 DN×

B

3 DN×

3.2.5 Thermal insulation

Some fluids require suitable measures to avoid loss of heat at the sensor. A wide range of materials

can be used to provide the required thermal insulation.

a0005763-ae

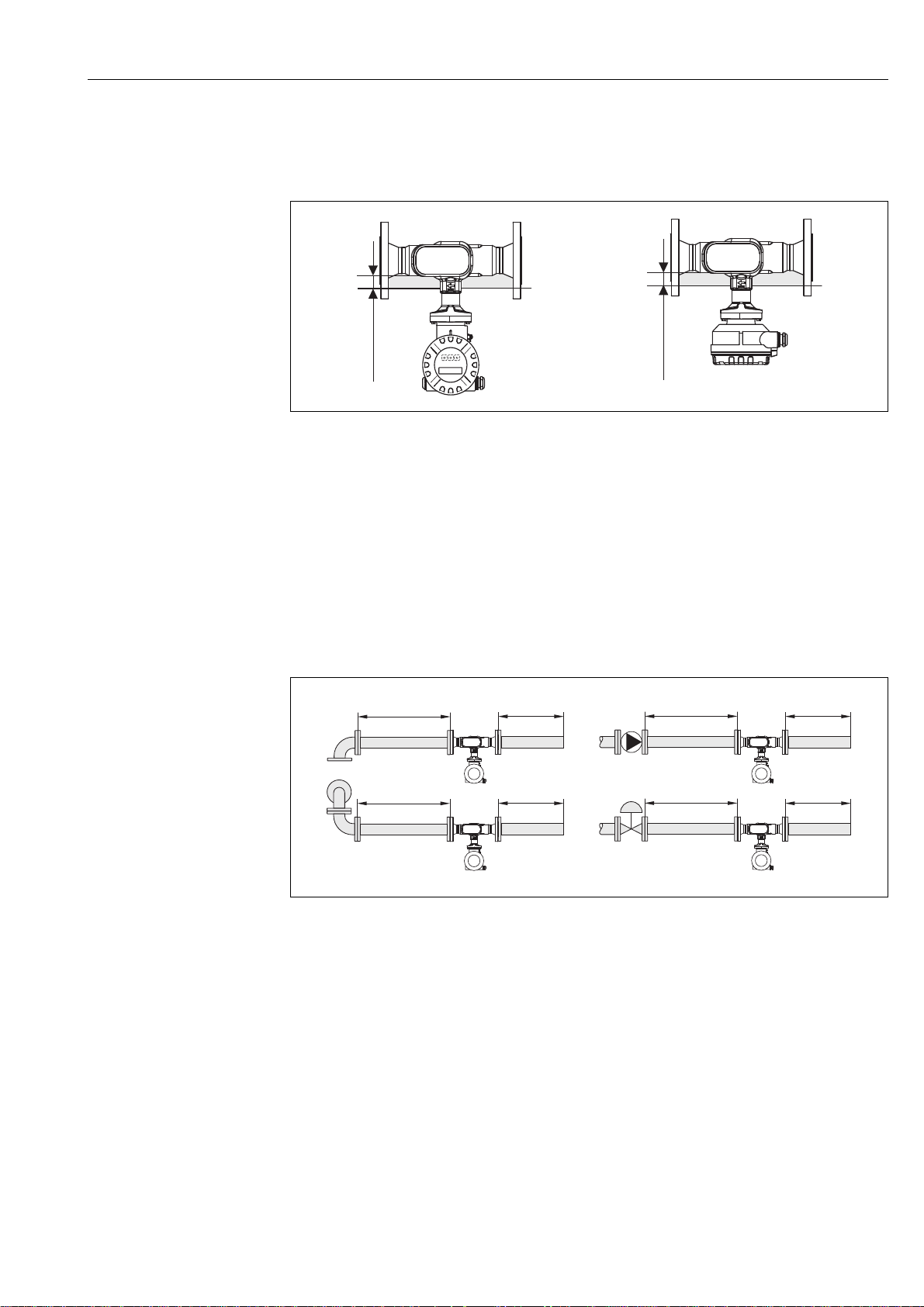

Fig. 8: A maximum insulation thickness of 20 mm (0.8 inch) must be observed in the area of the electronics/neck.

If the device is installed horizontally (with transmitter head pointing upwards), an insulation

thickness of min. 10 mm (0.4") is recommended to reduce convection. The maximum insulation

thickness of 20 mm (0.8") must not be exceeded.

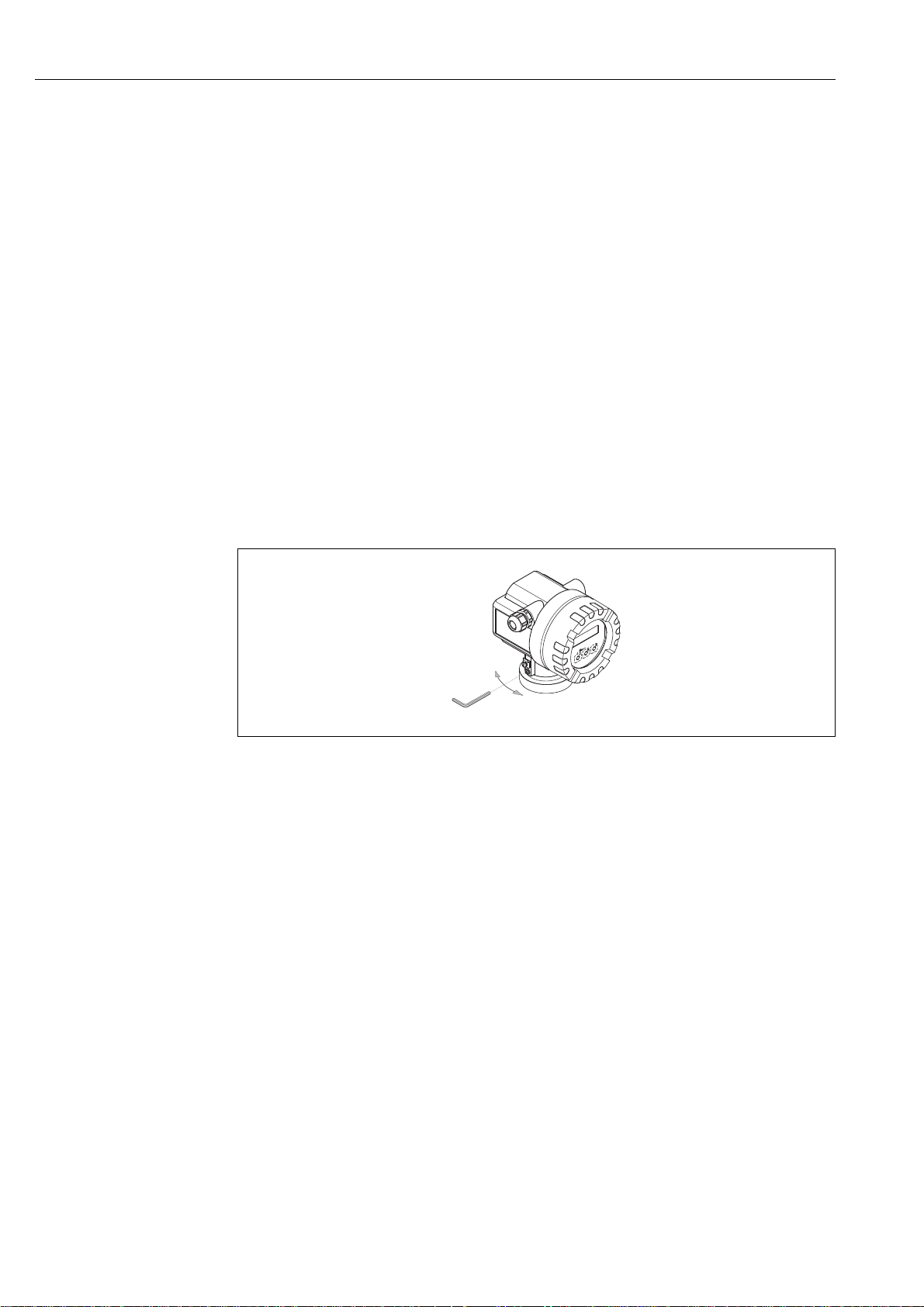

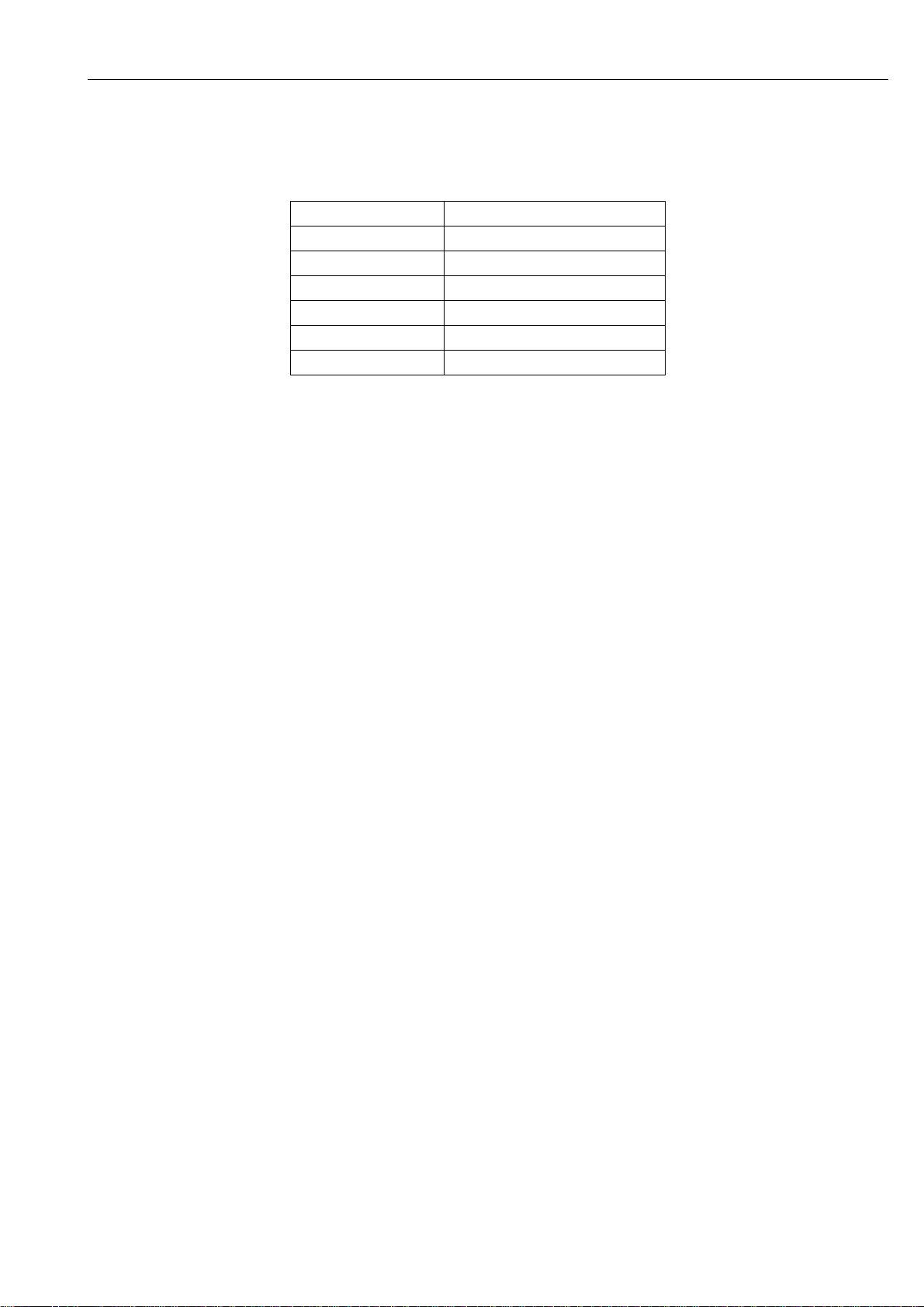

3.2.6 Inlet and outlet run

If possible, install the sensor well clear of fittings such as valves, T-pieces, elbows, etc. As a

minimum, the inlet and outlet runs shown below must be observed to achieve the specified

accuracy of the device. The longest inlet run shown must be observed if two or more flow

disturbances are present.

A0006267

Fig. 9: Minimum inlet and outlet runs with various flow obstructions (values given for 3 and 4 path versions)

A = Inlet run, B = Outlet run, 1 = 90° elbow or T-piece, 2 = Pump, 3 = 2 × 90° elbow, 3-dimensional, 4 = Control valve

3.2.7 Limiting flow

Information on limiting flow is provided under "Measuring range" in the technical data section.

Endress+Hauser 13

Page 14

Installation Proline Prosonic Flow 92F

180°

180°

3.3 Installation instructions

3.3.1 Mounting the sensor

• Prior to installing the measuring device in the piping, remove all traces of transport packaging and

any protective covers from the sensor.

• Make sure that the internal diameters of seals are the same as, or greater than, those of the

measuring device and piping. If seals with a smaller internal diameter are used, this affects the

flow and results in inaccurate measurement.

• Ensure that the arrow on the measuring tube matches the direction of flow in the piping.

• For Carbon steel option remove transport protection coating using mineral spirit (optional).

3.3.2 Turning the transmitter housing

1. Loosen the safety screw.

2. Turn the transmitter housing to the desired position (max. 180° in each direction to the stop).

Note!

!

There are recesses in the rotating groove at 90° stages (only compact version).

These help you align the transmitter easier.

3. Retighten the securing screw.

Fig. 10: Turning the transmitter housing

3.3.3 Turning the local display

1. Unscrew the cover of the electronics compartment from the transmitter housing.

2. Remove the display module from the transmitter retainer rails.

3. Turn the display to the desired position (max. 4 x 45° in each direction) and

reset it onto the retaining rails.

4. Screw the cover of the electronics compartment firmly back onto the transmitter housing.

a0005766

14 Endress+Hauser

Page 15

Proline Prosonic Flow 92F Installation

ANSCHLUSSKLEMMEN - FIELD TERMINALS

ANSCHLUSSKLEMMEN - FIELD TERMINALS

AB

232 (9.13)

227 (8.94)

mm (inch)

*226 (*8.90)

*221 (*8.70)

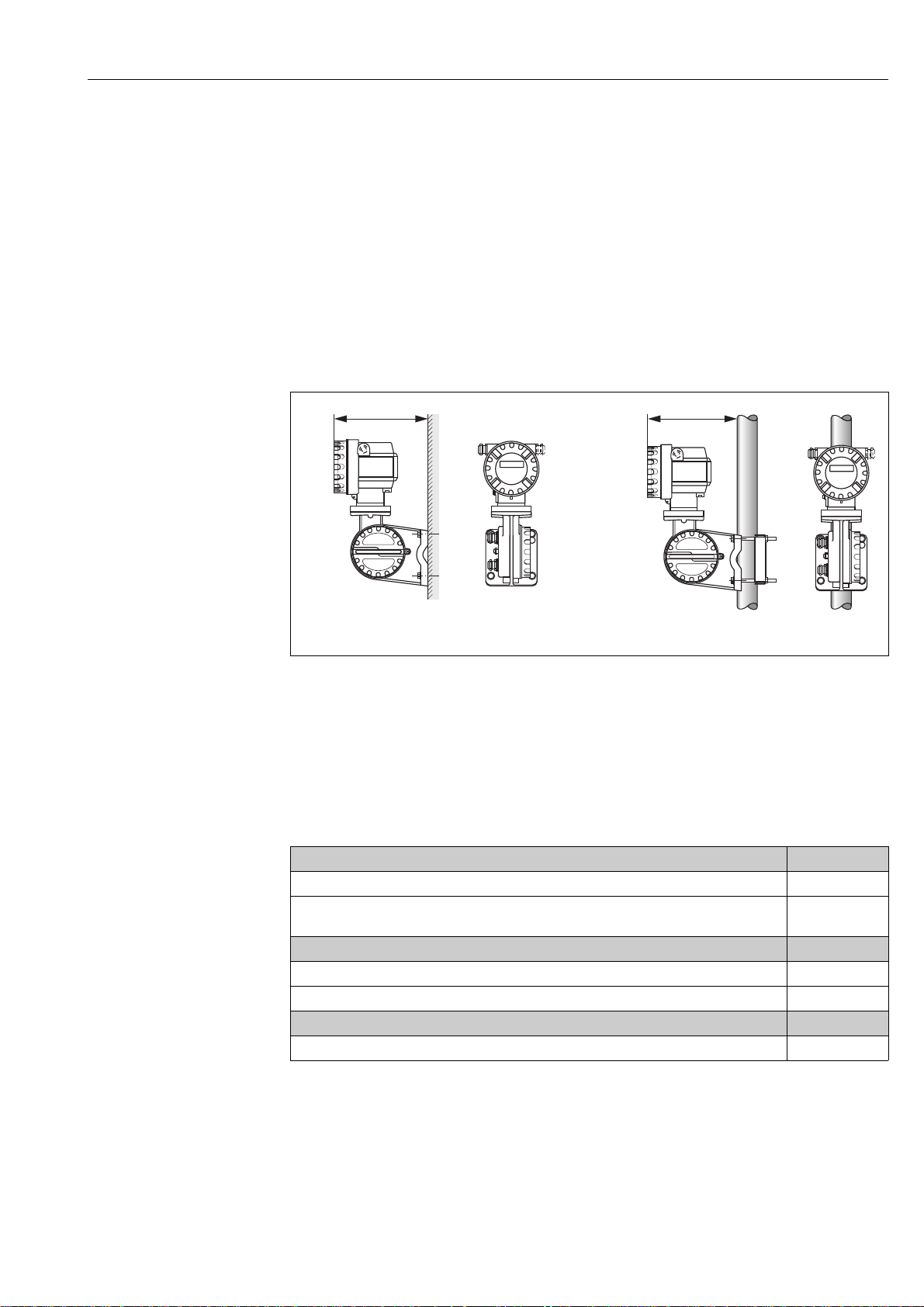

3.3.4 Mounting the remote version

The transmitter can be mounted in the following ways:

• Wall mounting

• Pipe mounting (with separate mounting kit, accessories) → ä 45

Caution!

"

When mounting on a pipe, the ambient temperature range may not be exceeded.

→ ä 63

The transmitter and the sensor must be mounted separate in the following circumstances:

• Poor accessibility

• Lack of space

• Extreme ambient temperatures

Mount the transmitter as illustrated in the diagram.

Fig. 11: Mounting the transmitter (remote version)

A Direct wall mounting

B Pipe mounting

* Dimensions for version without local display

3.4 Post-installation check

Perform the following checks after installing the measuring device:

Device condition and specifications Notes

Is the device damaged (visual inspection)? -

Do the process temperature/pressure, ambient temperature, measuring range etc. correspond to the

specifications of the device?

Installation Notes

Does the arrow on the sensor or sensor neck match the direction of flow through the pipe? -

Are the measuring point number and labeling correct (visual inspection)? –

Process environment / process conditions Notes

Is the measuring device protected against direct sunlight? -→ ä 63

→ ä 5

a0005947-ae

Endress+Hauser 15

Page 16

Wiring Proline Prosonic Flow 92F

a

c

b

d

1

G

1

GROUND

2

GROUND

2

G

1G2

G

1

GROUND

2

GROUND

3G

3

GROUND

4

GROUND

4 G

3

GROUND

4

GROUND

5G

5

GROUND

6

GROUND

6G

5

GROUND

6

GROUND

7

G

7

GROUND

8

GROUND

8G

7

GROUND

8

GROUND

3G

4

G5G6G7G8G

1

2

3

4

5

6 7

8

e

f

4 Wiring

4.1 Connecting the remote version

4.1.1 Connecting cable for sensor/transmitter

!

Note!

• The remote version must be grounded. In doing so, the sensor and transmitter must be connected

to the same potential matching (see Fig. 12, d).

• You may only connect the sensor to the transmitter with the same serial number (see nameplate).

Communication errors can occur if this is not observed when connecting the devices.

Procedure

1. Remove the covers of the connection compartments (a/b).

2. Feed the connecting cable (c) through the appropriate cable entries.

3. Wire the sensor and transmitter in accordance with the electrical connection diagram:

see Fig. 12 or the wiring diagram in the cover of the connection compartment.

4. Connect the appropriate cable shield (e/f).

5. Firmly tighten the glands of the cable entries.

6. Screw the covers of the connection compartments (a/b) back on.

Fig. 12: Connecting the remote version

a Cover of the connection compartment (transmitter)

b Cover of the connection compartment (sensor)

c Connecting cable (signal cable)

d Identical potential matching for sensor and transmitter

e Connect the shielding to the ground terminal in the transmitter housing and keep it as short as possible

f Connect the shielding to the ground terminal in the connection housing

4.1.2 Cable specification for connecting cable

Only use the cables supplied by Endress+Hauser and pre-terminated at the factory. The cables are

16 Endress+Hauser

available with a fixed length of 10 m (30 feet) and 30 m (90 feet) and optionally available with

variable lengths ranging from 1 m (3 feet) to max. 50 m (150 feet). The cable sheathing is made of

PVC.

a0005764

Page 17

Proline Prosonic Flow 92F Wiring

4.2 Connecting the measuring unit

4.2.1 Connecting the transmitter

#

!

Warning!

When connecting Ex-certified devices, see the notes and diagrams in the Ex-specific supplement to

these Operating Instructions. Please do not hesitate to contact your Endress+Hauser representative

if you have any questions.

Note!

• Observe national regulations governing the installation of electrical equipment.

• The remote version must be grounded. In doing so, the sensor and transmitter must be connected

to the same potential matching.

• When connecting the transmitter, use a connecting cable with a continuous service temperature

range between –40 °C (–40 °F) and the permitted max. ambient temperature plus 10 °C (plus 18 °F)

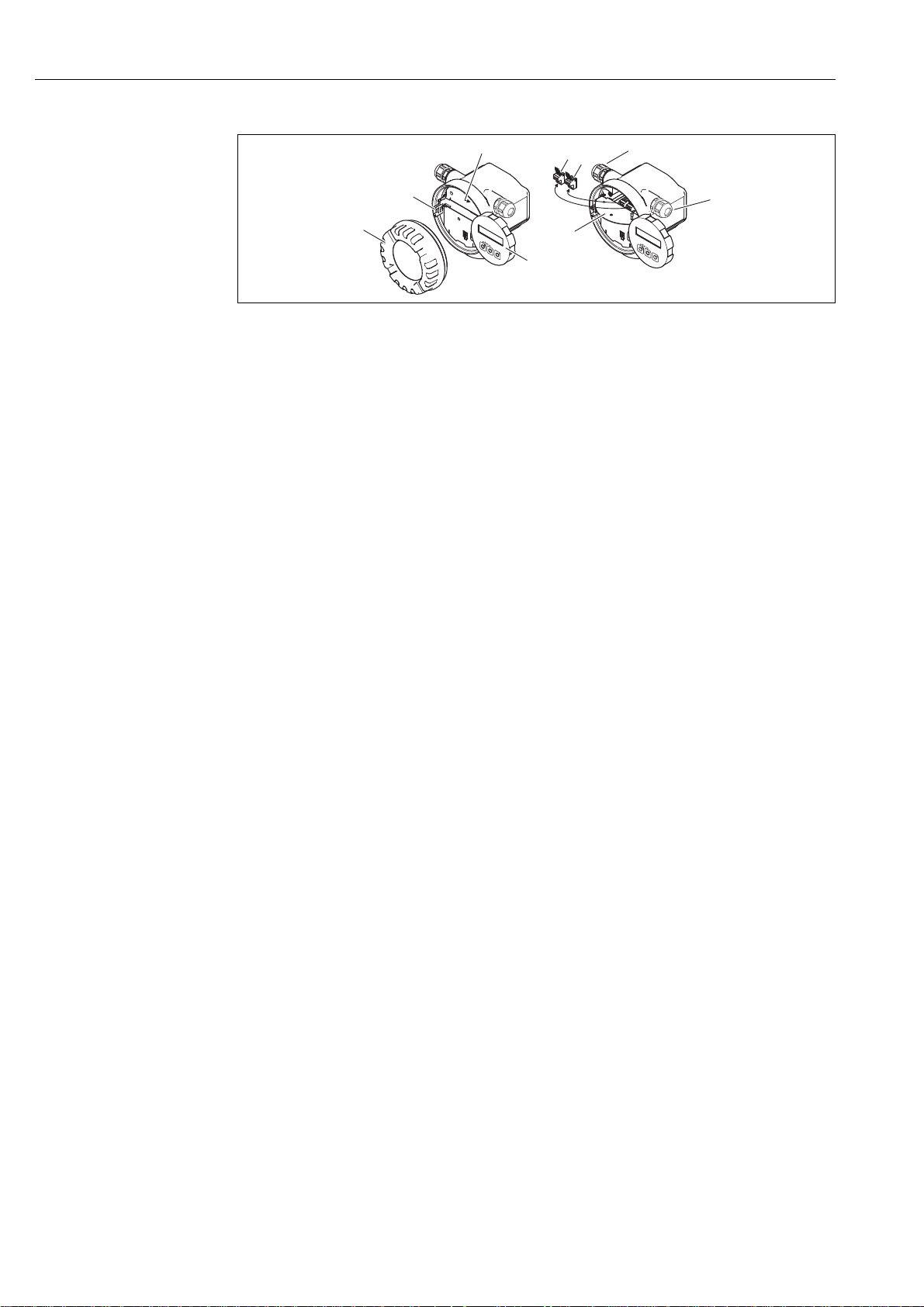

Connecting the transmitter, non-Ex/Ex-i version (→ å 13)

1. Unscrew the cover (a) of the electronics compartment from the transmitter housing.

2. Remove the display module (b) from the retaining rails (c) and refit onto the right retaining rail

with the left side of the display (this secures the display module).

3. Loosen screw (d) of the cover of the connection compartment and fold the cover down.

4. Push the cable for the power supply current output through the cable gland (e).

Optional: push the cable for the pulse output/frequency output through the cable gland (f).

5. Pull the terminal connector (g) out of the transmitter housing and connect the cable for the

power supply/current output. (→ Fig. 14, A)

Optional: pull terminal connector (h) out of the transmitter housing and connect the cable for

the pulse output/frequency output. (→ Fig. 14, B)

Note!

!

The terminal connectors (g / h) are pluggable, i.e. they can be plugged out of the transmitter

housing to connect the cables.

6. Plug the terminal connectors (g / h) into the transmitter housing.

Note!

!

The connectors are coded so you cannot mix them up.

7. Only remote version:

secure the ground cable to the ground terminal (→ Fig. 14, C).

8. Tighten the cable glands (e / f) (see alsoPage 21).

9. Fold up the cover of the connection compartment and tighten the screws (d).

10. Remove the display module (b) and fit on the retaining rails (c).

11. Screw the cover of the electronics compartment (a) onto the transmitter housing.

Endress+Hauser 17

Page 18

Wiring Proline Prosonic Flow 92F

e

f

g

h

d

a

c

b

d

a0001895

Fig. 13: Connecting the transmitter, non-Ex/Ex i version

a Cover of electronics compartment

b Display module

c Retaining rail for display module

d Connection compartment cover

e Cable gland for power supply/current output cable

f Cable gland for pulse output/frequency output cable (optional)

g Terminal connector for power supply/current output

h Terminal connector for pulse output/frequency output (optional)

Connecting the transmitter, Ex-d → å 14

1. Open the clamp (a) securing the cover of the connection compartment.

2. Unscrew the cover (b) of the connection compartment from the transmitter housing.

3. Push the cable for the power supply/current output through the cable gland (c).

Optional: push the cable for the pulse output/frequency output through the cable gland (d).

4. Pull the terminal connector (e) out of the transmitter housing and connect the cable for the

power supply/current output. (→ Fig. 14, A)

Optional: pull terminal connector (f) out of the transmitter housing and connect the cable for

the pulse output/frequency output. (→ Fig. 14, B)

Note!

!

The terminal connectors (e/f) are pluggable, i.e. they can be plugged out of the transmitter

housing to connect the cables.

5. Plug the terminal connectors (e / f) into the transmitter housing.

Note!

!

The connectors are coded so you cannot mix them up.

6. Only remote version:

secure the ground cable to the ground terminal (→ Fig. 14, C).

7. Tighten the cable glands (c / d) (see alsoPage 21).

8. Secure the ground cable to the ground terminal (only remote version)

9. Screw the cover (b) of the connection compartment onto the transmitter housing.

10. Tighten the clamp (a) securing the cover of the connection compartment.

18 Endress+Hauser

Page 19

Proline Prosonic Flow 92F Wiring

f

e

b

a

c

d

12 34

A

C

++

--

B

a0001896

Fig. 14: Connecting the transmitter, Ex d version

a Clamp securing cover of connection compartment

b Cover of connection compartment

c Cable gland for power supply/current output cable

d Cable gland for pulse output/frequency output cable (optional)

e Terminal connector for power supply/current output

f Terminal connector for pulse output/frequency output (optional)

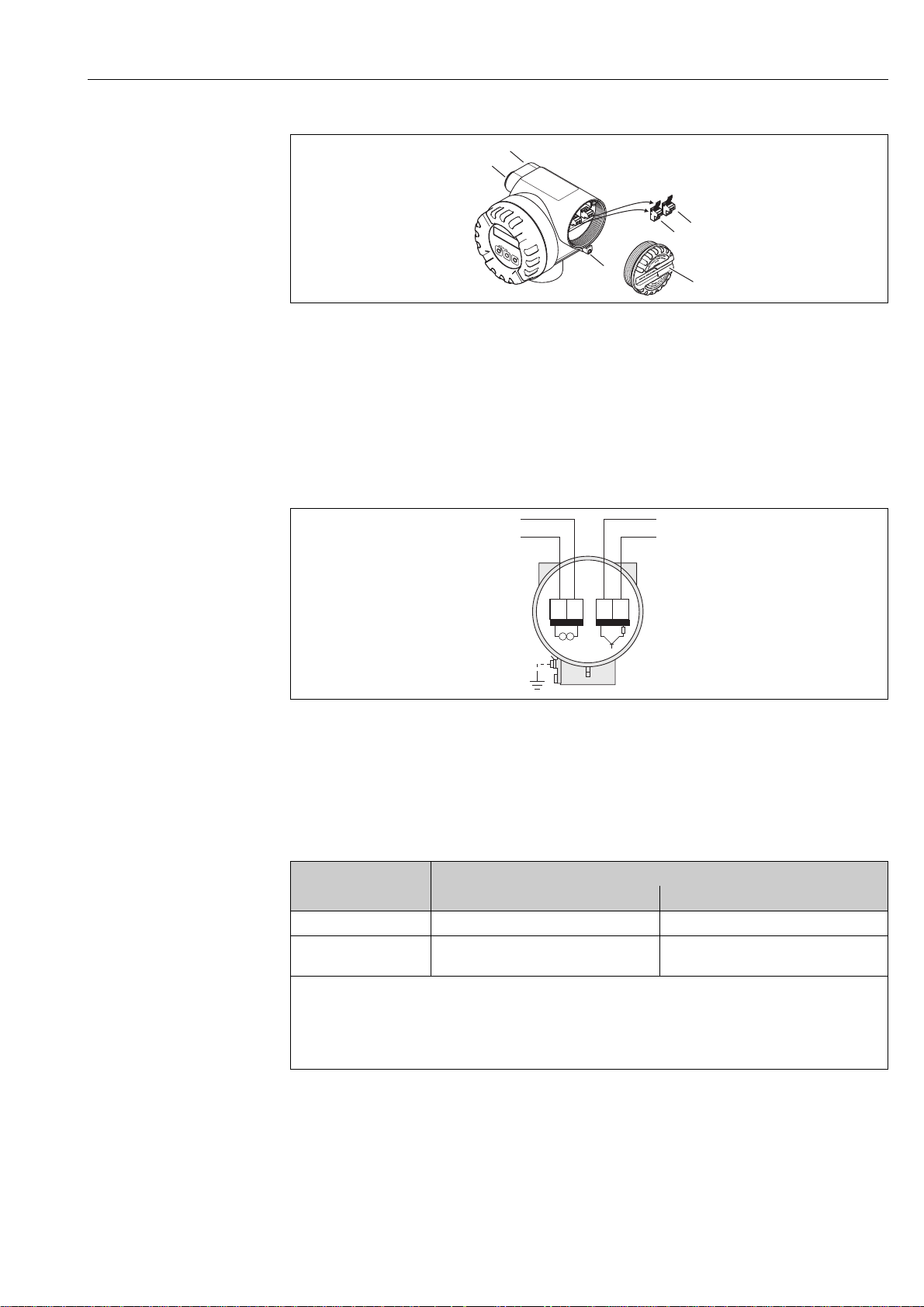

Wiring diagram

A0014635

Fig. 15: Assignment of terminals

A Power supply/current output

B Optional pulse output/status output

C Ground terminal (only relevant for remote version)

4.2.2 Terminal assignment

Terminal No. (inputs/outputs)

Order version 1 – 2 3 – 4

92***-***********W HART current output –

92***-***********A HART current output

HART current output

Galvanically isolated, 4 to 20 mA with HART

Pulse/status output

Open collector, passive, galvanically isolated, Umax = 30 V, with 15 mA current limiting, Ri = 500 Ω, can be configured

as pulse output or status output

Pulse/status output/

frequency output

Endress+Hauser 19

Page 20

Wiring Proline Prosonic Flow 92F

+1

–2

1

3

4

1

# % &

Copy

G H I

PQ R S

, ( )‘

AB C

Paste

Page

On

Page

Up

DeleteBksp

Insert

J K L

TU V

_ < >

D E F

Hot Key

+ Hot Key

M N O

W XYZ

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

³W250

12 34

++

--

2

+26

-27

RS 232

1

3

5

4

³W250

12 34

++

--

2

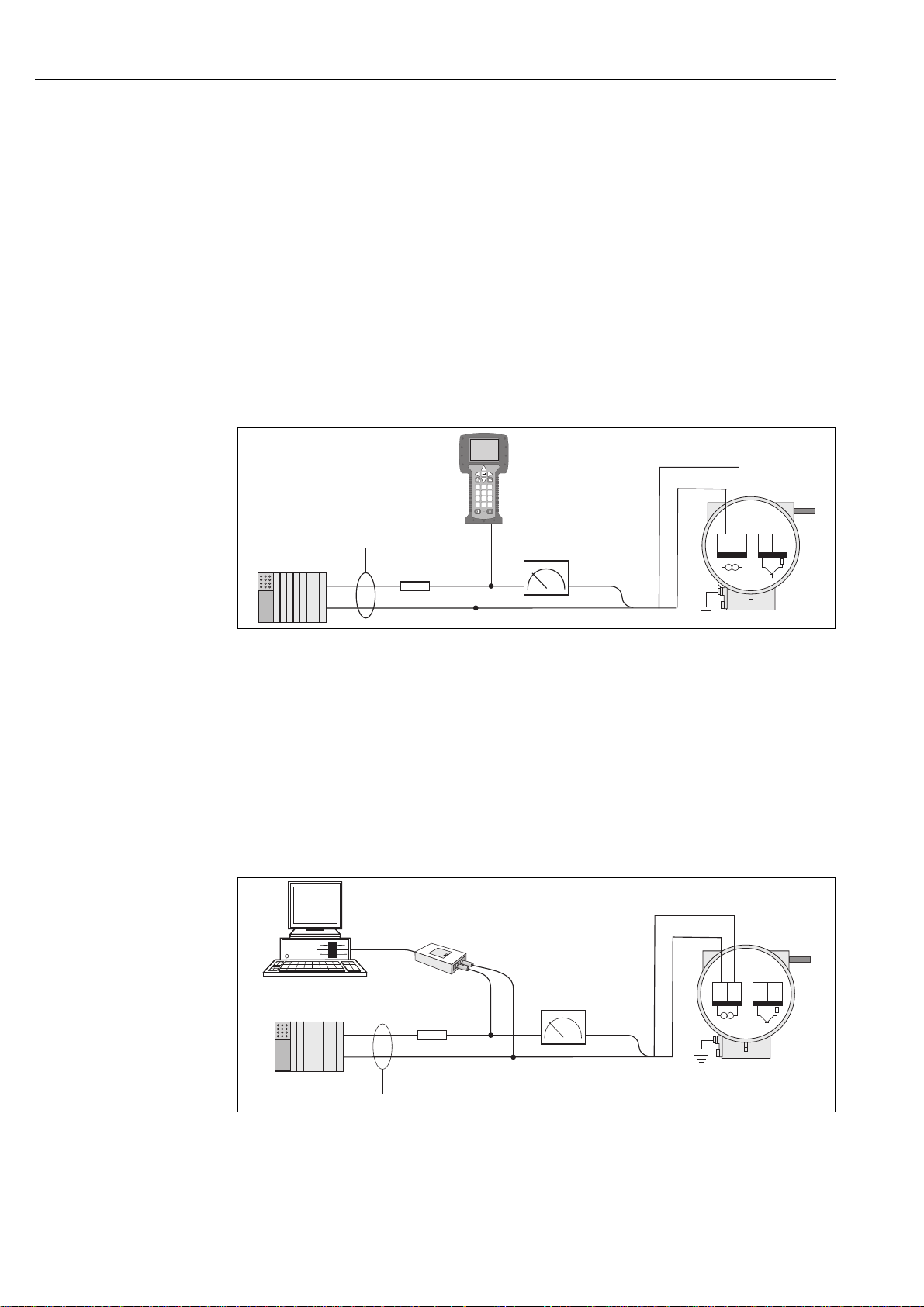

4.2.3 HART connection

Users have the following connection options at their disposal:

• Direct connection to transmitter by means of terminals 1 (+) / 2 (−)

• Connection by means of the 4 to 20 mA circuit

!

Note!

• The measuring circuit's minimum load must be at least 250 Ω .

• After commissioning, make the following setting:

Switch HART write protection on or off (see Page 38)→ Page 37

• For connecting, please refer also to the documentation issued by the HART Communication

Foundation, in particular HCF LIT 20: "HART, a technical summary".

Connecting the HART handheld terminal

For the connection, also refer to the documentation issued by the HART Communication

Foundation, and in particular HCF LIT 20: "HART, a technical summary".

A0014632

Fig. 16: Electrical connection to the HART operating terminal

1HART operating terminal

2Power supply

3 Shielding

4 Additional switching units or PLC with passive input

Connecting a PC with operating software

A HART modem (e.g. "Commubox FXA195") is required for connecting a PC with operating

software (e.g. "FieldCare").

For the connection, also refer to the documentat

ion issued by the HART Communication

Foundation, and in particular HCF LIT 20: "HART, a technical summary".

20 Endress+Hauser

Fig. 17: Electrical connection of a PC with operating software

1 PC with operating software

2Power supply

3 Shielding

4 Additional switching units or PLC with passive input

5 HART modem e.g. Commubox FXA195

A0014633

Page 21

Proline Prosonic Flow 92F Wiring

a b

4.3 Degree of protection

The devices fulfill all the requirements for IP 67 (optional IP 68) degree of protection. Compliance

with the following points is mandatory following installation in the field or servicing in order to

ensure that IP 67 protection is maintained:

• The housing seals must be clean and undamaged when inserted into their grooves. The seals must

be dried, cleaned or replaced if necessary.

• All housing screws and screw caps must be firmly tightened.

• The cables used for connection must be of the specified outside diameter.

• Firmly tighten the cable entries.

• The cables must loop down before they enter the cable entries ("water trap").

This arrangement prevents moisture penetrating the entry. Always install the measuring device

in such a way that the cable entries do not point up.

• Replace all unused cable entries with dummy plugs.

• Do not remove the grommet from the cable entry.

"

!

a0001914

Fig. 18: Installation instructions for cable entries

Caution!

The cable glands of the sensor housing must not be released as the degree of protection guaranteed

by Endress+Hauser would no longer apply.

Note!

The Prosonic Flow 92F can be supplied with IP 68 rating (permanent immersion in water to a depth

ot 3 meters /10 ft). In this case the transmitter must be installed remote from the sensor.

Endress+Hauser 21

Page 22

Wiring Proline Prosonic Flow 92F

4.4 Post-connection check

Perform the following checks after completing electrical installation of the measuring device:

Device condition and specifications Notes

Are cables or the device damaged (visual inspection)? −

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate?

• Non-Ex: 12 to 35 V DC (with HART: 18 to 35 V DC)

• Ex i and Ex n: 12 to 30 V DC (with HART 18 to 30 V DC)

• Ex d: 15 to 35 V DC (with HART 21 to 35 V DC)

Do the cables used comply with the specifications? → ä 16, → ä 62

Do the cables have adequate strain relief? −

Are the cables for power supply/current output, frequency output (optional) and

grounding connected correctly?

Remote version only:

Is the connecting cable between the sensor and transmitter connected correctly?

Remote version only:

Are the sensor and transmitter connected to the same potential matching?

Are all screw terminals firmly tightened? −

Are all the cable entries installed, tightened and sealed?

Cable run with "water trap"?

Are all the housing covers installed and tightened? −

−

→ ä 17

→ ä 16

→ ä 16

→ ä 21

22 Endress+Hauser

Page 23

Proline Prosonic Flow 92F Operation

Esc

E

+

-

1

32

+48.25 xx/yy

+3702.6 x

5Operation

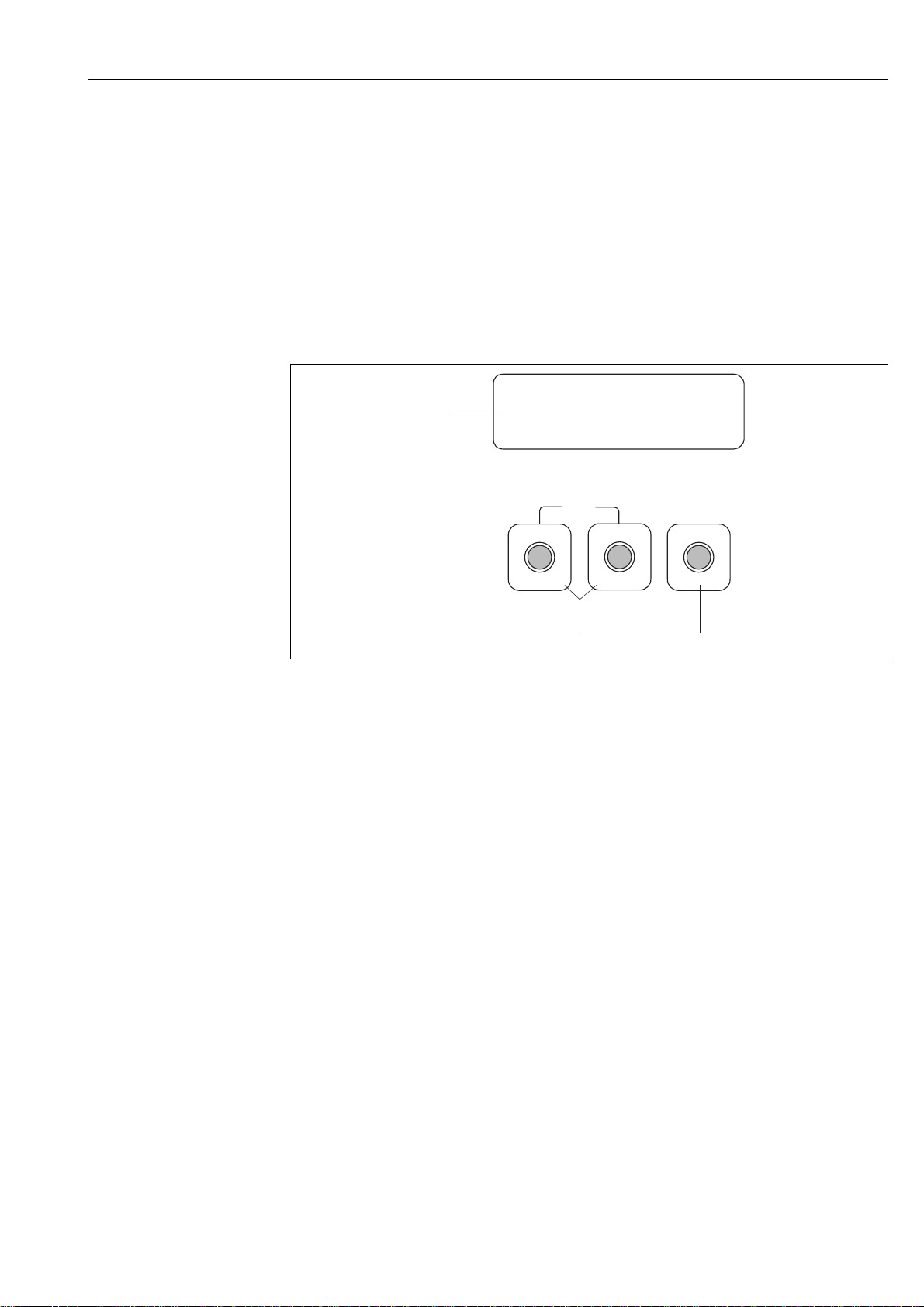

5.1 Display and operating elements

The local display enables you to read important parameters directly at the measuring point and

configure the device using the "Quick Setup" or the function matrix.

The display consists of two lines; this is where measured values and/or status variables (e.g. bar

graph) are displayed.

By means of local operation, you can change the assignment of the display lines to different variables

to suit your needs and preferences. See Device Functions in the Appendix → ä 68

a0001141

Fig. 19: Display and operating elements

1 Liquid crystal display

The two-line liquid-crystal display shows measured values and diagnosis messages.

– Top line: shows main measured values, e.g. volume flow in [dm/h] or in [%].

– Bottom line: shows additional measured variables and status variables, e.g. totalizer reading in [dm], bar graph,

tag name.

– During commissioning or in the event of a fault in normal measuring operation, a diagnosis message flashes on

the screen.

The first line shows the diagnosis code beginning with the letters F, C, S or M and a short text containing the

2Plus/minus keys

3Enter key

diagnosis message appears on the second line.

– Enter numerical values, select parameters

– Select different function groups within the function matrix

Press the +/- keys simultaneously to trigger the following functions:

– Exit the function matrix step by step → HOME position

– Press and hold down +/- keys for longer than 3 seconds → return directly to the HOME position

–Cancel data entry

–HOME position→ enter the function matrix

– Save the numerical values you input or settings you changed

Endress+Hauser 23

Page 24

Operation Proline Prosonic Flow 92F

>3s

-

+

E

Esc

E

E

E

E

E E E E E

–

+

+

Esc

–

+

Esc

–

+

Esc

–

E

m

n

o

p

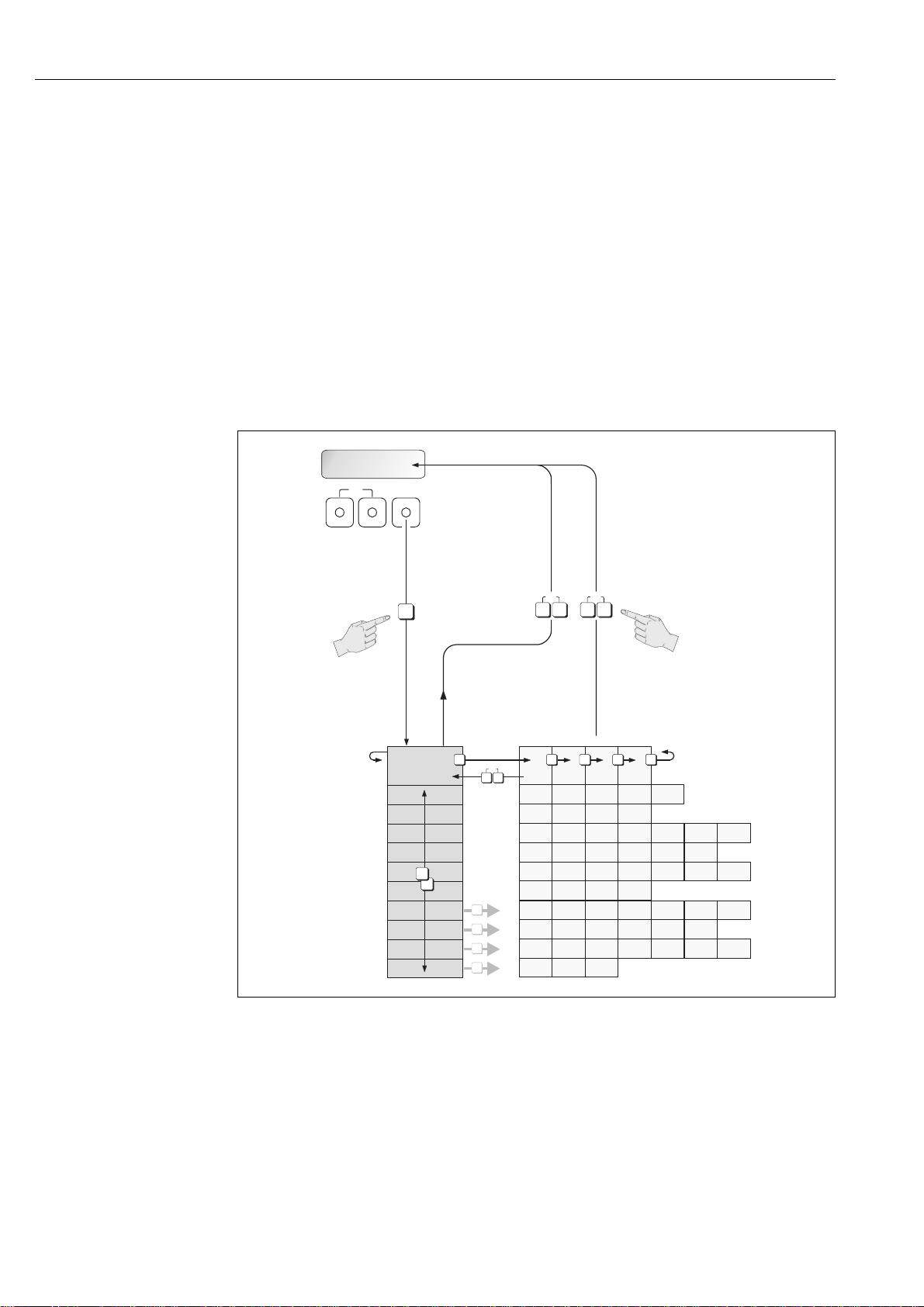

5.2 Operation via the function matrix

!

Note!

• Please refer to the general notes → ä 25

• Function descriptions → see the "Description of Device Functions" manual

1. HOME position → F → enter the function matrix

2. Select a function group e.g. CURRENT OUTPUT

3. Select a function (e.g. TIME CONSTANT)

Change parameter/enter numerical values:

P → select or enter enable code, parameters, numerical values

F → save your entries

4. Exit the function matrix:

– Press and hold down the Esc key (X) for more than 3 seconds → HOME position

– Repeatedly press Esc key (X) → return step by step to HOME position

Fig. 20: Selecting and configuring functions (function matrix)

24 Endress+Hauser

a0001142

Page 25

Proline Prosonic Flow 92F Operation

5.2.1 General notes

The Quick Setup menu is adequate for commissioning with the necessary standard settings.

Complex measuring operations on the other hand necessitate additional functions that you can

configure as necessary and customize to suit your process conditions. The function matrix,

therefore, comprises a multiplicity of additional functions which, for the sake of clarity, are arranged

in a number of function groups.

Comply with the following instructions when configuring functions:

• You select functions as described already.

• You can switch off certain functions (OFF). If you do so, related functions in other function groups

will no longer be displayed.

• Certain functions prompt you to confirm your data entries. Press P to select "SURE [ YES ]" and

press F to confirm. This saves your setting or starts a function, as applicable.

• Return to the HOME position is automatic if no key is pressed for 5 minutes.

• Programming mode is automatically disabled if you do not press a key within 60 seconds

following return to the HOME position.

!

!

"

Note!

A detailed description of all the functions required for commissioning is provided in Section 11.1

"Description of device functions".

Note!

• The transmitter continues to measure while data entry is in progress, i.e. the current measured

values are output via the signal outputs in the normal way.

• If the power supply fails, all preset and configured values remain safely stored in the EEPROM.

5.2.2 Enabling the programming mode

The function matrix can be disabled. Disabling the function matrix rules out the possibility of

inadvertent changes to device functions, numerical values or factory settings. A numerical code

(factory setting = 92) has to be entered before settings can be changed.

If you use a code number of your choice, you exclude the possibility of unauthorized persons

accessing data ( → see "Description of Device Functions" manual).

Comply with the following instructions when entering codes:

• If programming is disabled and the P operating elements are pressed in any function, a prompt

for the code automatically appears on the display.

• If "0" is entered as the private code, programming is always enabled.

• Your Endress+Hauser service organization can be of assistance if you are locked out of the device.

Caution!

Changing certain parameters influences numerous functions of the entire measuring device, and

may effect measuring accuracy!

There is no need to change these parameters under normal circumstances and consequently, they

are protected by a special service code known only to the Endress+Hauser service organization.

Please contact Endress+Hauser if you have any questions.

5.2.3 Disabling the programming mode

Programming mode is disabled if you do not press an operating element within 60 seconds following

automatic return to the HOME position.

You can also disable programming by entering any number (other than the private code) in the

ACCESS CODE function.

Endress+Hauser 25

Page 26

Operation Proline Prosonic Flow 92F

5.3 Communication

In addition to via local operation, the measuring device can also be configured and measured values

obtained by means of the HART protocol. Digital communication takes place using the 4–20 mA

current output HART.

The HART protocol allows the transfer of measuring and device data between the HART master and

the field devices for configuration and diagnostics purposes. HART masters, such as a handheld

terminal or PC-based operating programs (such as FieldCare), require device description (DD) files.

They are used to access all the information in a HART device. Such information is transferred solely

via "commands". There are three different command classes:

There are three different command classes:

• Universal commands

All HART devices support and use universal commands. The following functionalities are linked

to them:

– Recognizing HART devices

– Reading off digital measured values (volume flow, totalizer, etc.)

• Common practice commands:

Common practice commands offer functions which are supported and can be executed by many

but not all field devices.

• Device-specific commands:

These commands allow access to device-specific functions which are not HART standard. Such

commands access individual field device information, (among other things), such as empty-pipe/

full-pipe adjustment values, low flow cutoff settings etc.

!

Note!

The measuring device has all three command classes.

List of all "Universal Commands" and "Common Practice Commands": → ä 30

26 Endress+Hauser

Page 27

Proline Prosonic Flow 92F Operation

5.3.1 Operating options

For the complete operation of the measuring device, including device-specific commands, there are

device description (DD) files available to the user to provide the following operating aids and

programs:

!

Note!

• The HART protocol requires the "4 to 20 mA HART" setting (individual options see device

function) in the CURRENT SPAN function (current output 1).

HART Field Communicator Field Xpert

Selecting device functions with a HART Communicator is a process involving a number of menu

levels and a special HART function matrix.

The HART operating instructions in the carrying case of the HART handheld terminal contain more

detailed information on the device.

Operating program "FieldCare"

FieldCare is Endress+Hauser’s FDT-based plant asset management tool and allows the configuration

and diagnosis of intelligent field devices. By using status information, you also have a simple but

effective tool for monitoring devices.

Operating program "SIMATIC PDM" (Siemens)

SIMATIC PDM is a standardized, manufacturer independent tool for the operation, configuration,

maintenance and diagnosis of intelligent field devices.

Operating program "AMS" (Emerson Process Management)

AMS (Asset Management Solutions): program for operating and configuring devices.

Endress+Hauser 27

Page 28

Operation Proline Prosonic Flow 92F

5.3.2 Current device description files

The following table illustrates the suitable device description file for the operating tool in question

and then indicates where these can be obtained.

HART protocol:

Valid for software: 1.01.XX → Function "Device software"

Device data HART

Manufacturer ID:

Device ID:

HART version data: Device Revision 6/ DD Revision 1

Software release: 12.2010

Operating program: Sources for obtaining device descriptions:

Handheld terminal Field Xpert • Use update function of handheld terminal

FieldCare / DTM • www.endress.com → Download

AMS • www.endress.com → Download

SIMATIC PDM • www.endress.com → Download

(ENDRESS+HAUSER)

11

hex

61

hex

• CD-ROM (Endress+Hauser order number 56004088)

• DVD (Endress+Hauser order number 70100690)

→ Function "Manufact ID"

→ Function "Device ID"

!

Tester/simulator: Sources for obtaining device descriptions:

Fieldcheck • Update by means of FieldCare via the Flow Device FXA193/291 DTM

in the Fieldflash module

Note!

The "Fieldcheck" tester/simulator is used for testing flowmeters in the field. When used in

conjunction with the "FieldCare" software package, test results can be imported into a database,

printed out and used for official certification. Contact your Endress+Hauser representative for more

information.

28 Endress+Hauser

Page 29

Proline Prosonic Flow 92F Operation

5.3.3 Device variables and process variables

Device variables:

The following device variables are available via the HART protocol:

ID (decimal) Device variable

30 Volume flow

40 Sound velocity

43 Signal strength

49 Flow velocity

240 Totalizer 1

241 Totalizer 2

Process variables:

At the factory, the process variables are assigned to the following device variables:

• Primary process variable (PV) → volume flow

• Secondary process variable (SV) → totalizer

• Third process variable (TV) → sound velocity

• Fourth process variable (FV) → flow velocity

!

Note!

You can set or change the assignment of device variables to process variables using Command 51

→ ä 33.

Endress+Hauser 29

Page 30

Operation Proline Prosonic Flow 92F

5.3.4 Universal/common practice HART commands

The following table contains all the universal commands supported by the device.

Command No.

HART command/access type

Universal commands

0 Read the unique device identifier

Access type = Read

1 Read the primary process variable

Access type = Read

2 Read the primary process variable as

current in mA and percentage of the

set measuring range

Access type = Read

3 Read the primary process variable as

current in mA and four (preset

using command 51) dynamic

process variables

Access type = Read

Command data

(numeric data in decimal form)

None The device identifier provides information on the device

None – Byte 0: HART unit ID of the primary process variable

None – Byte 0-3: current current of the primary process

None 24 bytes are sent as a response:

Response data

(numeric data in decimal form)

and manufacturer; it cannot be altered.

The response consists of a 12-byte device ID:

– Byte 0: fixed value 254

– Byte 1: manufacturer ID, 17 = E+H

– Byte 2: device type ID, e.g. 0x61 = Prosonic 92

– Byte 3: number of preambles

– Byte 4: rev. no. universal commands

– Byte 5: rev. no. device-spec. Commands

– Byte 6: software revision

– Byte 7: hardware revision

– Byte 8: additional device information

– Byte 9-11: device identification

– Byte 1-4: primary process variable

Factory setting:

Primary process variable = volume flow

Note!

!

• You can set the assignment of device variables to

process variables using Command 51.

• Manufacturer-specific units are represented using the

HART unit ID "240".

variable in mA

– Byte 4-7: percentage of the set measuring range

Factory setting:

Primary process variable = volume flow

Note!

!

You can set the assignment of device variables to process

variables using Command 51.

– Byte 0-3: current of the primary process variable in

mA

– Byte 4: HART unit ID of the primary process variable

– Byte 5-8: primary process variable

– Byte 9: HART unit ID of the secondary process

variable

– Byte 10-13: secondary process variable

– Byte 14: HART unit ID of the third process variable

– Byte 15-18: third process variable

– Byte 19: HART unit ID of the fourth process variable

– Byte 20-23: fourth process variable

Factory setting:

• Primary process variable = volume flow

• Secondary process variable = totalizer 1

• Third process variable = sound velocity

• Fourth process variable = flow velocity

Note!

!

• You can set the assignment of device variables to

process variables using Command 51.

• Manufacturer-specific units are represented using the

HART unit ID "240".

30 Endress+Hauser

Page 31

Proline Prosonic Flow 92F Operation

Command No.

HART command/access type

6 Set HART short-form address

Access type = Write

11 Read the unique device identifier

using the TAG

Access type = Read

12 Read user message

Access type = Read

13 Read TAG, TAG description and

date

Access type = Read

14 Read sensor information on the

primary process variable

15 Read output information of the

primary process variable

Access type = Read

16 Read the device production number

Access type = Read

Command data

(numeric data in decimal form)

Byte 0: desired address (0 to 15)

Factory setting:

0

Note!

!

With an address >0 (multidrop mode), the current

output of the primary process variable is fixed to 4 mA.

Byte 0-5: TAG The device identifier provides information on the device

None Byte 0-24: user message

None – Byte 0-5: TAG

None – Byte 0-2: serial number of the sensor

None – Byte 0: alarm selection ID

None Byte 0-2: production number

Response data

(numeric data in decimal form)

Byte 0: active address

and manufacturer; it cannot be altered.

The response consists of a 12-byte device ID if the given

TAG matches the one saved in the device:

– Byte 0: fixed value 254

– Byte 1: manufacturer ID, 17 = E+H

– Byte 2: device type ID, 0x61 = Prosonic 92

– Byte 3: number of preambles

– Byte 4: rev. no. universal commands

– Byte 5: rev. no. device-spec. Commands

– Byte 6: software revision

– Byte 7: hardware revision

– Byte 8: additional device information

– Byte 9-11: device identification

Note!

!

You can write the user message using command 17.

– Byte 6-17: TAG description

– Byte 18-20: date

Note!

!

You can write the TAG, TAG description and date using

command 18.

– Byte 3: HART unit ID of the sensor limits and

measuring range of the primary process variable

– Byte 4-7: upper sensor limit

– Byte 8-11: lower sensor limit

– Byte 12-15: minimum span

Note!

!

• The data relate to the primary process variable (=

volume flow).

• Manufacturer-specific units are represented using the

HART unit ID "240".

– Byte 1: ID for transfer function

– Byte 2: HART unit ID for the set measuring range of

the primary process variable

– Byte 3-6: end of measuring range, value for 20 mA

– Byte 7-10: start of measuring range, value for 4 mA

– Byte 11-14: attenuation constant in [s]

– Byte 15: ID for write protection

– Byte 16: ID for OEM dealer, 17 = E+H

Factory setting:

Primary process variable = volume flow

Note!

!

• You can set the assignment of device variables to

process variables using Command 51.

• Manufacturer-specific units are represented using the

HART unit ID "240".

Endress+Hauser 31

Page 32

Operation Proline Prosonic Flow 92F

Command No.

HART command/access type

17 Write user message

Access = Write

18 Write TAG, TAG description and

date

Access = Write

Command data

(numeric data in decimal form)

You can save any 32-character long text in the device

with this parameter:

Byte 0-23: desired user message

You can save an 8-character TAG, a 16-character TAG

description and a date with this parameter:

–Byte 0-5: TAG

– Byte 6-17: TAG description

–Byte 18-20: date

Response data

(numeric data in decimal form)

Displays the current user message in the device:

Byte 0-23: current user message in the device

Displays the current information in the device:

–Byte 0-5: TAG

–Byte 6-17: TAG description

– Byte 18-20: date

The following table contains all the common practice commands supported by the device.

Command No.

HART command/access type

Common practice commands

33 Read measured values Byte 0: device variable ID for channel 0

34 Write attenuation constant for

primary process variable

Access = Write

35 Write measuring range of the

primary process variable

Access = Write

36 Set full scale value None None

37 Set lower range value None None

38 Device status reset "configuration

changed"

Access = Write

40 Simulate output current of the

primary process variable

Access = Write

42 Perform device reset

Access = Write

Command data

(numeric data in decimal form)

Byte 1: device variable ID for channel 1

Byte 2: device variable ID for channel 2

Byte 3: device variable ID for channel 3

Byte 0-3: attenuation constant of the primary process

variable in seconds

Factory setting:

Primary process variable = flow

Write the desired measuring range:

– Byte 0: HART unit ID for the primary process variable

– Byte 1-4: end of measuring range, value for 20 mA

– Byte 5-8: start of measuring range, value for 4 mA

Factory setting:

Primary process variable = flow

Note!

!

• You can set the assignment of device variables to

process variables using Command 51.

• If the HART unit ID does not suit the process variable,

the device will continue with the last valid unit.

None None

Simulation of the desired output current of the primary

process variable.

An entry value of 0 exits the simulation mode:

Byte 0-3: output current in mA

Factory setting:

Primary process variable = flow

Note!

!

You can set the assignment of device variables to process

variables with Command 51.

None None

Response data

(numeric data in decimal form)

Byte 0: device variable ID for channel 0

Byte 1: unit ID for channel 0

Byte 2-5: value of channel 0

Byte 6: device variable ID for channel 1

Byte 7: unit ID for channel 1

Byte 8-11: value of channel 1

Byte 12: device variable ID for channel 2

Byte 13: unit ID for channel 2

Byte 14-17: value of channel 2

Byte 18: device variable ID for channel 3

Byte 19: unit ID for channel 3

Byte 20-23: value of channel 3

Displays the current attenuation constant in the device:

Byte 0-3: attenuation constant in seconds

The measuring range currently set is shown as the

response:

– Byte 0: HART unit ID for the set measuring range of

the primary process variable

– Byte 1-4: end of measuring range, value for 20 mA

– Byte 5-8: start of measuring range, value for 4 mA

(is always at "0")

!

Manufacturer-specific units are represented using the

HART unit ID "240".

The current output current of the primary process

variable is displayed as a response:

Byte 0-3: output current in mA

Note!

32 Endress+Hauser

Page 33

Proline Prosonic Flow 92F Operation

Command No.

HART command/access type

44 Write unit of the primary process

variable

Access = Write

45 Zero point adjustment at the

current output

46 Span adjustment (adjustment of the

measuring range) at the current

output

48 Read extended device status

Access = Read

50 Read assignment of the device

variables to the four process

variables

Access = Read

51 Write assignments of the device

variables to the four process

variables

Access = Write

Command data

(numeric data in decimal form)

Specify the unit of the primary process variable.

Only units which are suitable for the process variable are

accepted by the device:

Byte 0: HART unit ID

Factory setting:

Primary process variable = flow

Note!

!

• If the written HART unit ID does not suit the process

variable, the device will continue with the last valid

unit.

• If you change the unit of the primary process variable,

this does not affect the system units.

Byte 0-3: measured current in mA The current output current of the primary process

Byte 0-3: measured current in mA The current output current of the primary process

None The current device status is displayed in extended form

None Display of the current variable assignment of the process

Specify device variables for the four process variables:

– Byte 0: device variable ID to the primary process

variable

– Byte 1: device variable ID to the secondary process

variable

– Byte 2: device variable ID to the third process variable

– Byte 3: device variable ID to the fourth process

variable

ID of the supported device variables:

See data → ä 29

Factory setting:

• Primary process variable = flow

• Secondary process variable = totalizer 1

• Third process variable = sound velocity

• Fourth process variable = flow velocity

Response data

(numeric data in decimal form)

The current unit code of the primary process variable is

displayed as a response:

Byte 0: HART unit ID

Note!

!

Manufacturer-specific units are represented using the

HART unit ID "240".

variable is displayed as a response:

Byte 0-3: output current in mA

variable is displayed as a response:

Byte 0-3: output current in mA

as the response:

Coding: see Table → Page 35

variables:

– Byte 0: device variable ID to the primary process

variable

– Byte 1: device variable ID to the secondary process

variable

– Byte 2: device variable ID to the third process variable

– Byte 3: device variable ID to the fourth process

variable

Factory setting:

• Primary process variable: ID 1 for flow

• Second process variable: code 250 for totalizer 1

• Third process variable: code 7 for sound velocity

• Fourth process variable: code 9 for flow velocity

Note!

!

You can set the assignment of device variables to process

variables with Command 51.

The variable assignment of the process variables is

displayed as a response:

– Byte 0: device variable ID to the primary process

variable

– Byte 1: device variable ID to the secondary process

variable

– Byte 2: device variable ID to the third process variable

– Byte 3: device variable ID to the fourth process

variable

Endress+Hauser 33

Page 34

Operation Proline Prosonic Flow 92F

Command No.

HART command/access type

53 Write device variable unit

Access = Write

54 Read information on the device

variables

Access = Read

59 Specify number of preambles in

message responses

Access = Write

Command data

(numeric data in decimal form)

This command sets the unit of the given device variables.

Only those units which suit the device variable are

transferred:

– Byte 0: device variable ID

– Byte 1: HART unit ID

ID of the supported device variables:

See data → ä 29

Note!

!

• If the written unit does not suit the device variable,

the device will continue with the last valid unit.

• If you change the unit of the device variable, this does

not affect the system units.

Byte 0: device variable ID Byte 0: device variable ID

This parameter specifies the number of preambles which

are inserted in the message responses:

Byte 0: number of preambles (2 to 20)

Response data

(numeric data in decimal form)

The current unit of the device variables is displayed in

the device as a response:

– Byte 0: device variable ID

– Byte 1: HART unit ID

Note!

!

Manufacturer-specific units are represented using the

HART unit ID "240".

Byte 1-3: serial number of the associated sensor

Byte 4: unit ID for device variable

Byte 5-8: upper limit of the device variable

Byte 9-12: lower limit of the device variable

Byte 13-16: time constant of device variable (unit: s)

As a response, the current number of the preambles is

displayed in the response message:

Byte 0: number of preambles

34 Endress+Hauser

Page 35

Proline Prosonic Flow 92F Operation

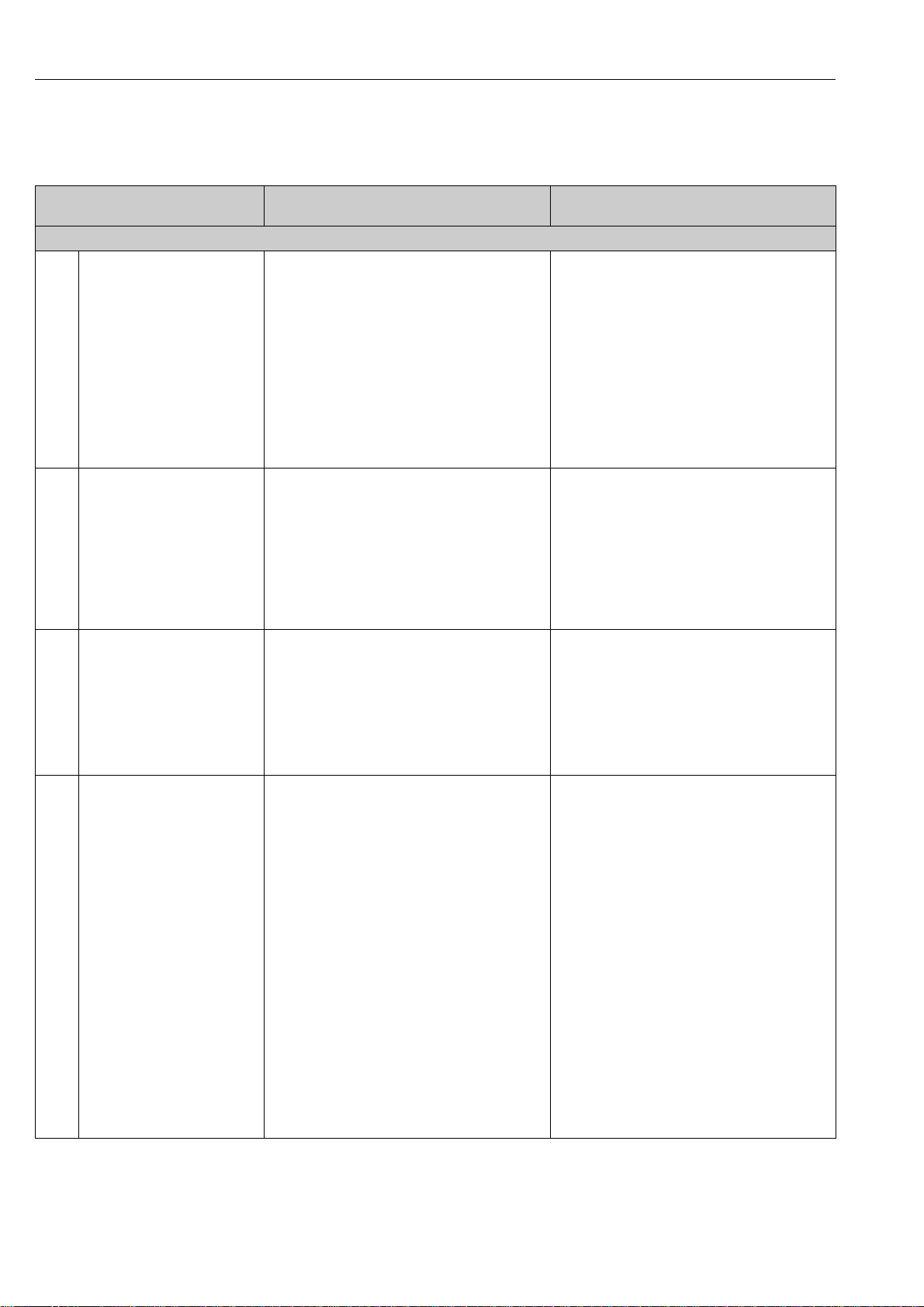

5.3.5 Device status/diagnosis code messages

You can read the extended device status, in this case, current diagnosis code messages, via

command "48". The command delivers bit-encoded information (see table below).

!

Note!

Detailed information on the device status messages and diagnosis code messages, and how they are

rectified, can be found in the Troubleshooting section on → ä 47

Byte Bit Diagnosis

code

0 0 284 Software update Loading new amplifier software version. No other commands

1 481 Diagnostic active

2 281 Initialization Initialization in progress. All outputs are set to 0.

3 411 Upload/download Uploading and downloading device files. No other commands

4 1 Device fault Serious device error

5 282-1 Data storage Error when accessing the amplifier EEPROM

6 282-2 Data storage Error when accessing the I/O module EEPROM

7 282-3 Data storage Error when accessing the T-DAT

1 0 283-1 Checksum error Data in the amplifier EEPROM faulty

1 283-2 Checksum error Data in the I/O module EEPROM faulty

2 283-3 Checksum error Data in the T-DAT EEPROM faulty

3 242 Incompatible SW The I/O board and the amplifier board are not compatible

4 62-1 Sensor connection Connection (down) sensor K1 / transmitter interrupted

5 62-2 Sensor connection Connection (up) sensor K1 / transmitter interrupted

6 62-3 Sensor connection Connection (down) sensor K2 / transmitter interrupted

7 62-5 Sensor connection Connection (up) sensor K2 / transmitter interrupted

2 0 62-5 Sensor connection Connection (down) sensor K3 / transmitter interrupted

1 62-6 Sensor connection Connection (up) sensor K3 / transmitter interrupted

2 62-7 Sensor connection Connection (down) sensor K4 / transmitter interrupted

3 62-8 Sensor connection Connection (up) sensor K4 / transmitter interrupted

4 283-4 Checksum error Totalizer checksum error

5 262 Module connection Internal communication error on the amplifier board

6 823-1 Ambient temp. The lower medium temperature limit for the thermosensor was

7 823-2 Ambient temp. The upper medium temperature limit for the thermosensor was

3 0 881-1 Sensor signal Channel 1: signal strength of the sensor too low

1 881-2 Sensor signal Channel 2: signal strength of the sensor too low

2 881-3 Sensor signal Channel 3: signal strength of the sensor too low

3 881-4 Sensor signal Channel 4: signal strength of the sensor too low

4 431-1 Adjust Zero point adjustment faulty

5 431-2 Adjust Channel 1: zero point adjustment faulty

6 431-3 Adjust Channel 2: zero point adjustment faulty

7 431-4 Adjust Channel 3: zero point adjustment faulty

Brief description of the message → ä 48

possible at this point.

possible at this point.

undershot

overshot

Endress+Hauser 35

Page 36

Operation Proline Prosonic Flow 92F

Byte Bit Diagnosis

code

4 0 431-5 Adjust Channel 4: zero point adjustment faulty

1 861-1 Medium Volume flow outside specified range.

2 861-2 Medium Flow velocity outside specified range.

3 861-3 Medium Signal strength outside specified range.

4 861-4 Medium Sound velocity outside specified range.

5 861-5 Medium Acceptance rate outside specified range.

6 861-6 Medium Profile factor outside specified range.

7 861-7 Medium Symmetry outside specified range.

5 0 412 Write backup Data backup to T-DAT failed

1 413 Read backup Error when accessing the T-DAT

2 461-1 Signal output Current adjustment active

3 453 Value suppression Positive zero return active

4 484 Simulation error Simulation of failsafe mode (outputs) active

5 485 Simulation value Measured variable simulation active

6 482-1 Simulation outp. Current output simulation active

7 482-2 Simulation outp. Simulation frequency output active

14 0 482-3 Simulation outp. Pulse output simulation active

1 482-4 Simulation outp. Status output simulation active

2 461-2 Signal output Current output: flow outside range

3 461-3 Signal output Frequency output: flow outside range

4 461-4 Signal output Pulse output: flow outside range

5 431-6 Adjust Zero point adjustment in progress

Brief description of the message → ä 48

36 Endress+Hauser

Page 37

Proline Prosonic Flow 92F Operation

a

b

c

A

ON

OFF

21 163264

4

8

d

ON

1 2 3 4 5 6 7 8

S

A

ON

1 2

4

0

B CD

e

ON

2345678

S

A

ON

12

4

0

1

5.3.6 Switching HART write protection on/off

Write protection can be activated or deactivated via switch block 2 (e/D).

The current status is displayed in the WRITE PROTECT function (see → ä 100).

1. Unscrew the cover of the electronics compartment from the transmitter housing.

2. Remove the display module (a) from the retaining rails (b) and refit onto right retaining rail with

the left side (this secures the display module).

3. Fold up the plastic cover (c).

4. At switch block 2 (e), move miniature switch 2 (D) to the desired position:

OFF position, miniature switch moved up = write protection deactivated ON position,

miniature switch moved down = write protection activated

5. Installation is the reverse of the removal procedure.

a0005949

Fig. 21: Switching HART write protection on/off

a Display module

b Retaining rails for the display module

cPlastic cover

dSwitch block 1:

– A (Miniature switches 1 to 7): not assigned/no function

– B (Miniature switch 8): not assigned/no function

eSwitch block 2:

– C (Miniature switch 1): not assigned/no function

– D (Miniature switch 2):

Switch write protection on/off

OFF = deactivated, write protection deactivated (miniature switch moved up)

ON = activated, write protection activated (miniature switch moved down)

(the current status of the write protection is displayed in the WRITE PROTECT function →→ä 100)

Endress+Hauser 37

Page 38

Commissioning Proline Prosonic Flow 92F

6 Commissioning

6.1 Function check

Make sure that the following function checks have been performed successfully before switching on

the supply voltage for the measuring device:

• "Post-installation check" checklist → ä 15

• "Post-connection check" checklist → ä 22

6.2 Switching on the measuring device

Once the function check has been performed successfully, the device is operational and can be

switched on via the supply voltage. The device then performs internal test functions and the

following messages are shown on the local display:

!

PROSONIC FLOW 92

V XX.XX.XX