Page 1

Technical Information

Proline Prosonic Flow 92F

Ultrasonic Flow Measuring System

2-Wire loop powered inline flowmeter

Application

The flowmeter is ideally suited for applications in process

control and utility measurement in practically all sectors

of industry such as the chemical and petrochemical

industry, energy production and district heating.

• Loop powered transmitter (2-Wire)

• Accuracy up to ±0.3%

• Fluid temperatures up to 200 °C (392 °F)

• Process pressures up to 40 bar (ASME Cl. 300)

• Galvanically isolated pulse output available

Approvals for hazardous area:

• ATEX, FM, CSA, TIIS, IECEx, NEPSI

Connection to common process control systems:

• HART, PROFIBUS PA, FOUNDATION Fieldbus

Relevant safety aspects:

• Pressure Equipment Directive (PED)

• Process sealing accoring to ISA 12.27.01

Your benefits

The Prosonic Flow 92F is a calibrated meter capable of

measuring flow of conductive and especially nonconductive liquids such as solvents, hydrocarbons and

non-conductive water.

The Proline transmitter concept comprises of:

• Diagnostic ability and data back-up capability for

increased process quality

• Permanent self-monitoring and diagnosis of

transmitter and sensor

The Proline Prosonic Flow sensors comprises:

• Available as a 2, 3 or 4 beam version

• Innovative 3 and 4 fourbeam design facilitates

a reduced requirement for upstream pipework

( 5 pipe diameter)

• Calibration traceable to international standards

• No pressure drop

• Maintenance free due to no moving parts

TI00073D/06/EN/13.10

71124142

Page 2

Table of contents

Proline Prosonic Flow 92F

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Outputs in general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Low flow cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical connection measuring unit . . . . . . . . . . . . . . . . . . . . . . . 7

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical connection remote version . . . . . . . . . . . . . . . . . . . . . . . 7

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote version cable specifications . . . . . . . . . . . . . . . . . . . . . . . . 8

Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating elements (HART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 18

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

C-tick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Certification PROFIBUS PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FOUNDATION Fieldbus certification . . . . . . . . . . . . . . . . . . . . . 19

Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 20

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . 20

Performance characteristics. . . . . . . . . . . . . . . . . . . . . 9

Reference calibration conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating conditions: Installation . . . . . . . . . . . . . . . . 9

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inlet and outlet runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating conditions: Environment . . . . . . . . . . . . . . 12

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . 12

Operating conditions: Process . . . . . . . . . . . . . . . . . . 13

Fluid temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Medium pressure range (nominal pressure) . . . . . . . . . . . . . . . . . 13

Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 13

Design, dimensions, weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Material load diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Endress+Hauser

Page 3

Proline Prosonic Flow 92F

T'

1

T'

1

T

1

D»T e

Function and system design

Measuring principle A Prosonic Flow inline flowmeter measures the flow rate of the passing fluid by using sensor pairs located on

opposite sides of the meter body and at an angle so that one of the sensors in the pair is slightly downstream.

The flow signal is established by alternating an acoustic signal between the sensor pairs and measuring the time

of flight of each transmission. Then utilizing the fact that sound travels faster with the flow versus against the

flow, this differential time ( T) can be used to determine the fluids velocity between the sensors.

The volume flow rate is established by combining all the flow velocities determined by the sensor pairs with

the cross sectional area of the meter body and extensive knowledge about fluid flow dynamics. The design of

the sensors and their position ensures that only a short straight run of pipe upstream of the meter is required

after typical flow obstructions such as bends in one or two planes. Advance digital signal processing facilitates

constant validation of the flow measurement reducing susceptibility to multiphase flow conditions and

increases the reliability of the measurement.

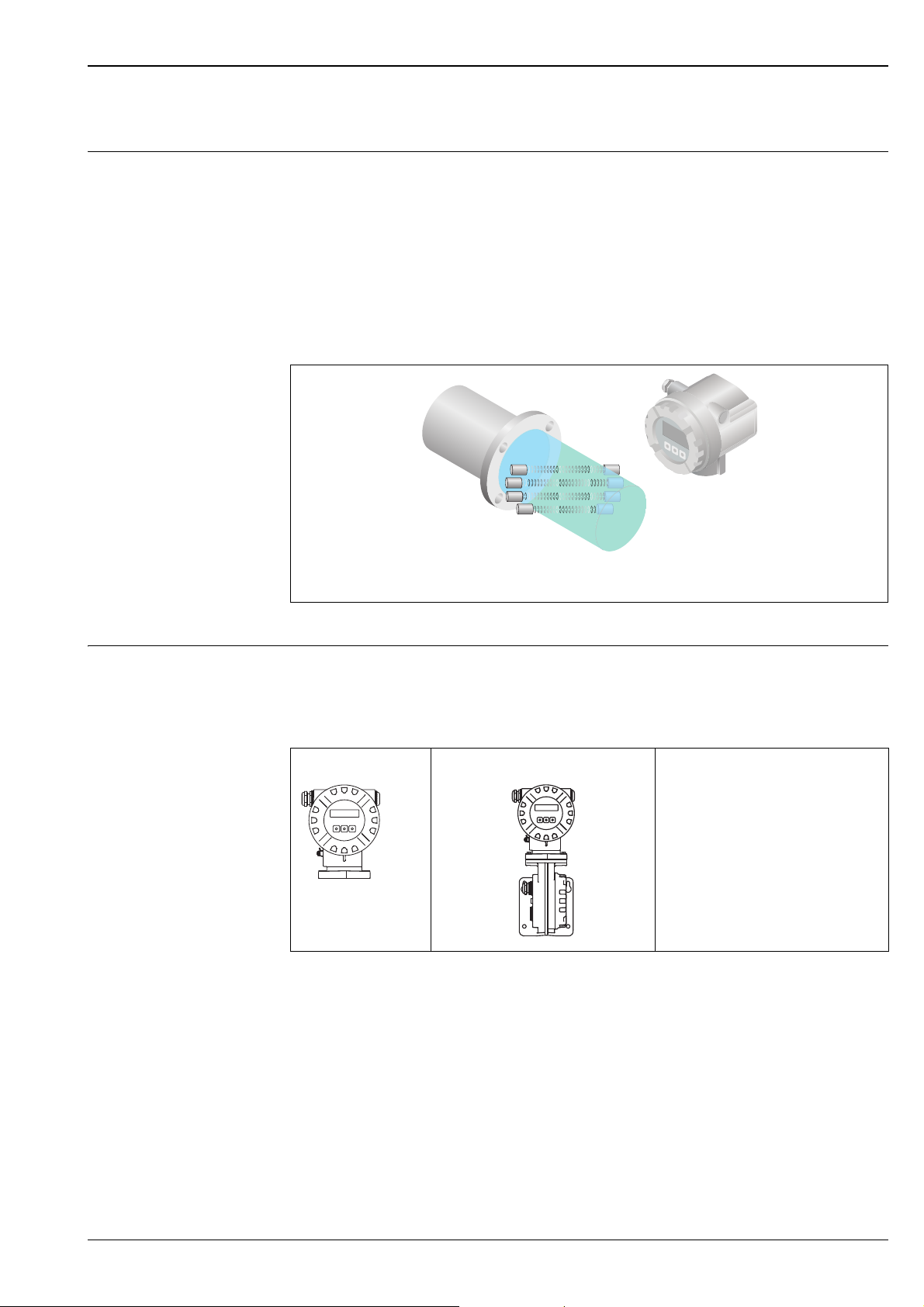

Measuring system The measuring system consists of a transmitter and a sensor. Two versions are available:

• Compact version: transmitter and sensor form a mechanical unit

• Remote version: transmitter and sensor are mounted physically separate from one another

Transmitter

Prosonic Flow 92

Prosonic Flow 92 remote version

a0005962

• Two line liquid crystal display

• Operation with push buttons

• 2-Wire loop powered

• Optional explosion proof housing

a0005963

a0006215

Endress+Hauser 3

Page 4

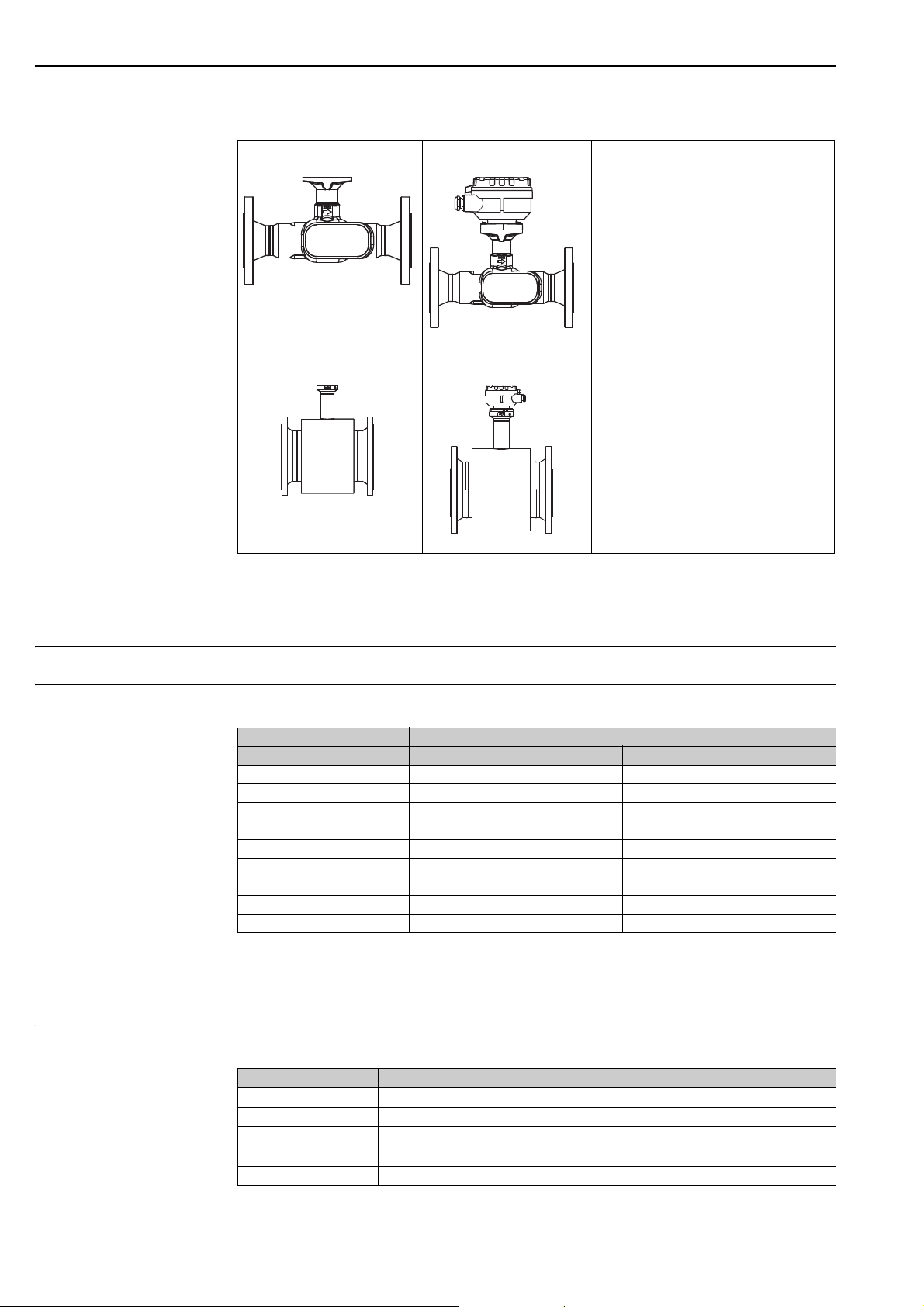

Sensor

Proline Prosonic Flow 92F

F

F (remote Version)

• Nominal diameters DN 25 to 100 (1 to 4")

• Process sensor for fluid temperatures up to

150 °C /302 °F

(optional 200 °C /392 °F)

• Tube material: stainless steel

• Process pressures up to 40 bar

Remote version:

• IP67 housing (Optional IP68)

a0005966

• Standard remote cable length of 10 and 30 m

(30 and 90 ft)

• Optional remote cable length up to

a0005967

F

F (remote Version)

a maximum 50 m (150 ft)

• Nominal diameters DN 150 to 300 (6 to 12")

• Process sensor for fluid temperatures up to

150 °C /302 °F

(optional 200 °C /392 °F)

• Tube material: stainless steel, carbon steel

• Process pressures up to 40 bar

Remote version:

• IP67 housing (Optional IP68)

• Standard remote cable length of 10 and 30 m

a0014351

(30 and 90 ft)

• Optional remote cable length up to

a0014352

a maximum 50 m (150 ft)

Input

Measured variable Flow velocity (transit time difference proportional to flow velocity)

Measuring range Typically v = –10 to 10 m/s with the specified accuracy

Nominal diameter Range for full scale values (liquids) m

mm inch SI-Unit US-Unit

25 1" 0 to 300 dm

40 1½" 0 to 750 dm

50 2" 0 to 1100 dm

80 3" 0 to 3000 dm

100 4" 0 to 4700 dm

150 6" 0 to 10 m

200 8" 0 to 20 m³/min 0 to 5280 gal/min

250 10" 0 to 30 m³/min 0 to 7930 gal/min

300 12" 0 to 40 m³/min 0 to 10570 gal/min

3

/min 0 to 80 gal/min

3

/min 0 to 200 gal/min

3

/min 0 to 300 gal/min

3

/min 0 to 800 gal/min

3

/min 0 to 1250 gal/min

3

/min 0 to 2800 gal/min

Output

Outputs in general The following measured variables can generally be output via the outputs:

min(F)…mmax(F)

Current output Freq. output Pulse output Status output

Volume flow X X X Limit value

Calculated Mass flow X X X Limit value

Sound velocity X X – Limit value

Flow velocity X X – Limit value

Signal strength X X – Limit value

4 Endress+Hauser

Page 5

Proline Prosonic Flow 92F

Output signal Current output:

Current output:

• 4 to 20 mA with HART

• Full scale value and time constant (0 to 100 s) can be set

Pulse/status output/Frequency output:

Open collector, passive, galvanically isolated

• Non-Ex, Ex d - version:

= 35 V, with 15 mA current limiting, Ri = 500

U

max

• Ex i version:

= 30 V, with 15 mA current limiting, Ri = 500

U

max

The pulse/status output can be configured as:

• Pulse output:

– Pulse value and pulse polarity can be selected,

– Pulse width can be configured (0.005 to 2s)

– Pulse frequency max. 100 Hz

• Status output:

Can be configured for diagnosis code messages or flow limit values

• Frequency output:

End frequency 0 to 1000 Hz (f

= 1250 Hz)

max

PROFIBUS PA interface

• PROFIBUS PA in accordance with IEC 61158 (MBP), galvanically isolated

• Profile Version 3.01

• Data transmission rate: 31.25 kBaud

• Current consumption: 16 mA

• Permitted supply voltage: 9 to 32 V; 0.5 W

• Bus connection with integrated reverse polarity protection

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Signal coding: Manchester II

• Bus address can be configured via miniature switches at the device or operating program

FOUNDATION Fieldbus interface:

• FOUNDATION Fieldbus H1, IEC 61158-2, galvanically isolated

• Data transmission rate: 31.25 kBit/s

• Current consumption: 16 mA

• Permitted supply voltage: 9 to 32 V

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Bus connection with integrated reverse polarity protection

• Signal encoding: Manchester II

• ITK Version 5.0

• Function blocks: 4 × Analog Input, 1 × Analog Output, 1 × Digital Input, 1 × Digital Output, 1 × PID

• Output data: Volume flow, Sound velocity, Flow velocity, Signal strength, Totalizers 1 to 2

• Input data: Positive zero return (ON/OFF), Zero point adjustment, Reset totalizer

• Link Master (LM) function is supported

Signal on alarm Current output:

Failsafe mode selectable (e.g. in accordance with NAMUR Recommendation NE 43)

Status output:

"Non conductive" in the event of fault or power supply failure.

Endress+Hauser 5

Page 6

Load

00

100 100

200 200

300 300

400 400

500 500

600 600

700 700

800 800

900 900

1000 1000

1100 1100

BB

RR

[] []

10 1020 2025 2530 3036 3615 15

18

21

W

0

100

200

300

400

500

600

700

800

900

1000

1100

B

S

R

U

V

[]

[

10

20 25 30

15

18

W

Ex i

Exi/Exn

W

Ex d

Ex

RB=

(U

SKl

–U )

(I )

max

-3

– 10 0.022

=

(U

SKl

–U )

Proline Prosonic Flow 92F

a0001921

Behavior of load and supply voltage

The area marked in gray indicates the permissible load (with HART: min. 250 .)

The load is calculated as follows:

Load, load resistance

R

B

Supply voltage:

U

S

- Non-Ex = 12 to 35 V DC

- Ex d = 15 to 35 V DC

- Ex i = 12 to 30 V DC

Terminal voltage:

U

KL

- Non-Ex = min. 12 V DC

- Ex d = min. 15 V DC

- Ex i = min. 12 V DC

Output current (22.6 mA)

I

max.

Low flow cutoff Switch points for low flow cutoff can be selected as required.

Galvanic isolation All circuits for inputs, outputs, and power supply are galvanically isolated from each other.

6 Endress+Hauser

Page 7

Proline Prosonic Flow 92F

12 34

A

C

++

–

B

–

a

c

b

d

1

G

1

GROUND

2

GROUND

2

G

1G2

G

1

GROUND

2

GROUND

3G

3

GROUND

4

GROUND

4 G

3

GROUND

4

GROUND

5G

5

GROUND

6

GROUND

6G

5

GROUND

6

GROUND

7

G

7

GROUND

8

GROUND

8G

7

GROUND

8

GROUND

3G

4

G5G6G7G8G

1

2

3

4

5

6 7

8

e

f

Electrical connection measuring unit

Power supply

A0010962

A – HART: power supply, current output

– PROFIBUS PA: 1 = PA+, 2 = PA–

– FOUNDATION Fieldbus: 1 = FF+, 2 = FF–

B Optional frequency output (not for PROFIBUS PA , FOUNDATION Fieldbus),

can also be operated as Pulse or status output

C Ground terminal (relevant for remote version)

Terminal assignment

Electrical connection remote version

Terminal No. (inputs/outputs)

Order version 1 2 3 4

92***-***********W HART current output –

92***-***********A HART current output Pulse/status output/frequency output

92F**-***********H PA+ PA– –

92F**-***********K FF+ FF– –

Endress+Hauser 7

a0005764

Connecting the remote version

a Cover of the connection compartment (transmitter)

b Cover of the connection compartment (sensor)

c Connecting cable (signal cable)

d Identical potential matching for sensor and transmitter

e Connect the shielding to the ground terminal in the transmitter housing and keep it as short as possible

f Connect the shielding to the ground terminal in the connection housing

Page 8

Supply voltage HART:

Non-Ex: 12 to 35 V DC (with HART: 18 to 35 V DC)

Ex i: 12 to 30 V DC (with HART 18 to 30 V DC)

Ex d: 15 to 35 V DC (with HART: 21 to 35 V DC)

PROFIBUS PA and FOUNDATION Fieldbus:

• Non-Ex: 9 to 32 V DC

• Ex i/IS and Ex n: 9 to 30 V DC

• Ex d/XP: 9 to 35 V DC

• Current consumption PROFIBUS PA: 16 mA, FOUNDATION Fieldbus: 16 mA

Cable entries Power supply and signal cables (inputs/outputs):

• Cable entry M20 × 1.5

• Thread for cable entries, ½" NPT, G ½" (not for threaded version)

• Optional processing sealing according ISA 12.27.01

Proline Prosonic Flow 92F

Remote version cable specifications

Power supply failure • Totalizer stops at the last value determined (can be configured).

• Use a connecting cable with a continuous service temperature range of at least:

–40 °C /–40 °F (permitted max. ambient temperature plus 10 °C /18 °F)

• The cables are available with a fixed length of 10 m and 30 m and optionally available with variable lengths

ranging from 1 m (3.3 ft) to max. 50 m (164 ft).

• All settings are kept in the HISTO-RAM, T-DAT.

• Diagnosis code messages (incl. value of operated hours counter) are stored.

8 Endress+Hauser

Page 9

Proline Prosonic Flow 92F

Performance characteristics

Reference calibration conditions

Maximum measured error

Repeatability ±0.2% of reading

Error limits following ISO/DIN 11631:

• 20 to 30 °C (68 to 86 °F); 2 to 4 bar

• Calibration systems as per national norms

• Zero point calibrated under operating conditions

DN 25 to DN 300 (1 to 12")

0.5 to 10 m/s (1.6 ft to 33 ft/s) ±0.5% of reading *

Optional for DN 80 to DN 300 (3 to 12")

0.5 to 10 m/s (1.6 ft to 33 ft/s) ±0.3% of reading *

* For a Reynolds number > 10000

Operating conditions: Installation

Note the following points:

• No special measures such as supports are necessary. External forces are absorbed by the construction of the

instrument.

• The flowmeter flanges must be coplanar with connecting flanges and free from tension.

• The maximum permitted ambient temperatures ( ä 12) and fluid temperatures ( ä 13) must be

observed.

• Pay particular attention to the notes on orientation and piping insulation on the following pages.

• The correct operation of the measuring system is not influenced by pipe vibrations.

Installation instructions Mounting location

Entrained air or gas bubbles in the measuring tube can result in an increase in measuring errors or loss of

measurment.

Avoid the following mounting locations in the pipe:

• Highest point of a pipeline. Risk of air accumulating.

• Directly upstream from a free pipe outlet in a vertical pipeline.

Mounting location

a0006081

Endress+Hauser 9

Page 10

Proline Prosonic Flow 92F

1

2

3

4

5

A BC D

Notwithstanding the above, the installation proposal below permits installation in an open vertical pipeline.

Pipe restrictions or the use of an orifice with a smaller cross section than the nominal diameter prevent the

sensor running empty while measurement is in progress.

a0006082

Installation in a down pipe (e.g. for batching applications)

1 = Supply tank , 2 = Sensor, 3 = Orifice plate, pipe restriction , 4 = Valve, 5 = Batching tank

Orientation

Make sure that the direction of the arrow on the nameplate of the sensor matches the direction of flow

(direction of fluid flow through the pipe).

Orientations A, B and C recommended, orientation D only recommended under certain circumstances

Heating

Some fluids require heat to be transfered at the sensor. Heating can be electrical, such as electrical heat tracing

or by heat jacketing, the meter.

Caution!

"

• Risk of electronics overheating! Consequently, make sure that the adapter between the sensor and

transmitter and the connection housing of the remote version always remain free of insulating material. Note

that the orientation of the meter could significantly reduce the temperature at the electronics.

• If using an electric trace heating system whose heating is regulated via phase angle control or pulse packages,

influence on the measured values cannot be ruled out due to magnetic fields (i.e. for values that are greater

than the values approved by the EN standard (sine 30 A/m)). In such instances, it is necessary to

magnetically shield the sensor

a0005971

10 Endress+Hauser

Page 11

Proline Prosonic Flow 92F

max. 20

max. 20

2

A

1

3

A

A

4

A

5 DN×

10 DN×

B

3 DN×

15 DN×

5 × DN

B

3 DN×

B

3 DN×

B

3 DN×

Thermal insulation

Some fluids require suitable measures to avoid heat transfer at the sensor. A wide range of materials can be

used to provide the required thermal insulation.

a0005763-en

A maximum insulation thickness of 20 mm must be observed in the area of the electronics/neck..

If the device is installed horizontally (with transmitter head pointing upwards), an insulation thickness of min.

10 mm is recommended to reduce convection. The maximum insulation thickness of 20 mm must not be

exceeded.

Limiting flow

Information on limiting flow is provided under "Measuring range" in the technical data section.

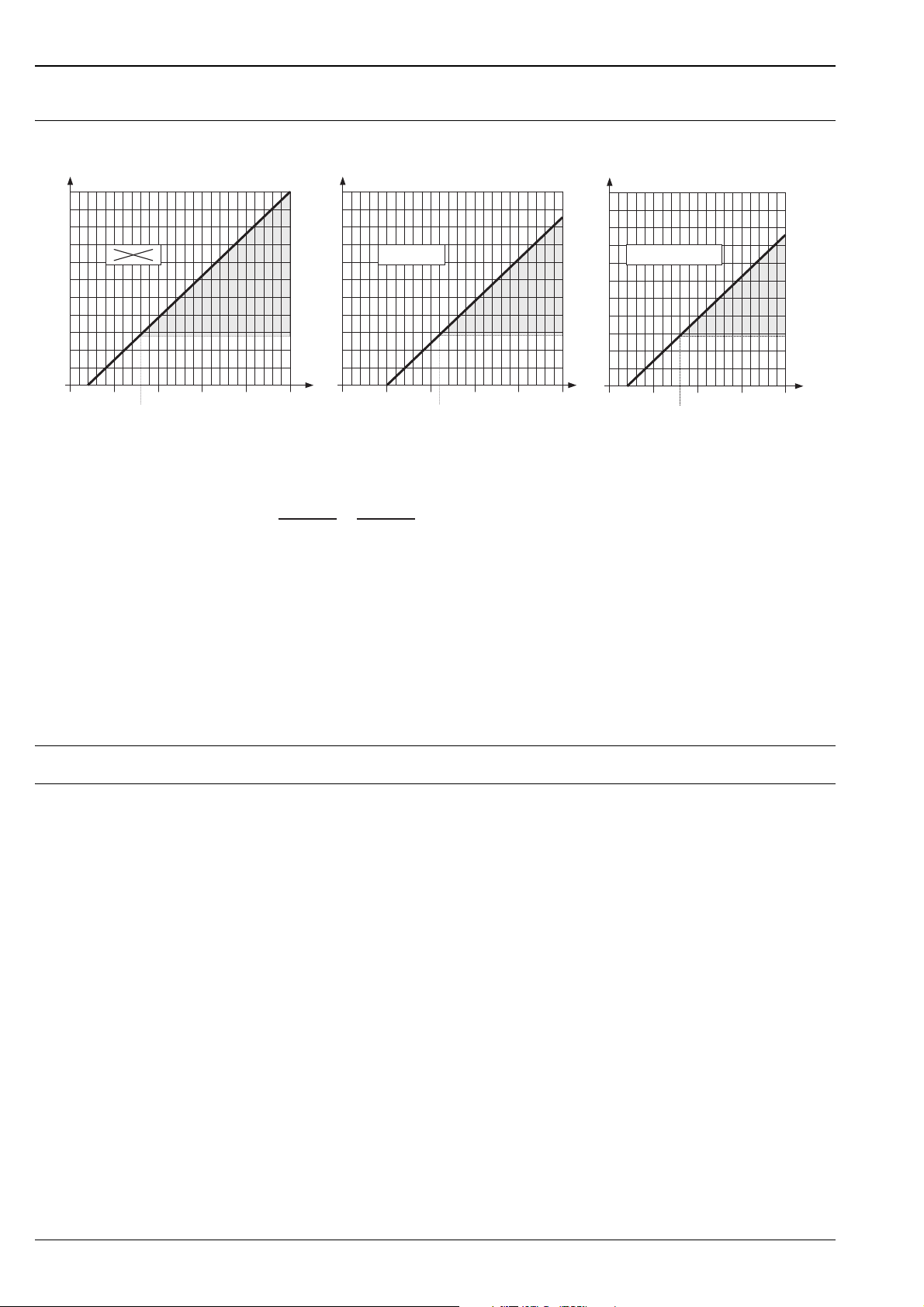

Inlet and outlet runs If possible, install the sensor well clear of fittings such as valves, T-pieces, elbows, etc. As a minimum, the inlet

and outlet runs shown below must be observed to achieve the specified accuracy of the device. The longest

inlet run shown must be observed if two or more flow disturbances are present.

A0006267

Minimum inlet and outlet runs with various flow obstructions (values given for 3 and 4 path versions)

A = Inlet run, B = Outlet run, 1 = 90° elbow or T-piece, 2 = Pump, 3 = 2 × 90° elbow, out of plane,

4 = Control valve

Endress+Hauser 11

Page 12

Operating conditions: Environment

Ambient temperature range Compact version

• Standard: –40 to +60 °C (–40 to 140 °F)

• EEx-d / EEx-i version: –40 to +60 °C (–40 to 140 °F)

Display can be read between –20 to +70 °C (–4 to 158 °F)

Remote version

•Sensor:

– Standard: –40 to +80 °C (–40 to 176 °F)

– EEx-d / EEx-i version: –40 to +80 °C (–40 to 176 °F)

• Transmitter:

– Standard: –40 to +60 °C (–40 to 140 °F)

– EEx-i version: –40 to +60 °C (–40 to 140 °F)

– EEx-d version: –40 to +60 °C (–40 to 140 °F)

Display can be read between –20 to +70 °C (–40 to 158 °F)

!

Storage temperature Standard: –40 to +80 °C (–40 to 176 °F)

Note!

When mounting outside, protect from direct sunlight with a protective cover (order number 543199),

especially in warmer climates with high ambient temperatures.

EEx-d / EEx-i version: –40 to +80 °C (–40 to 176 °F)

Proline Prosonic Flow 92F

Degree of protection • Transmitter Prosonic Flow 92: IP67 (NEMA 4X)

• Sensor Prosonic Flow F Inline: IP67 (NEMA 4X)

Optional: IP 68 (NEMA 6P)

!

Shock resistance In accordance with IEC 68-2-31

Vibration resistance Acceleration up to 1 g, 10 to 150 Hz, following IEC 68-2-6

Electromagnetic compatibility (EMC)

Note!

The Prosonic Flow 92 F can be supplied with IP 68 rating (permanent immersion in water to a depth of

3 meters /98 ft). In this case the transmitter must be installed remote from the sensor.

To IEC/EN 61326 and NAMUR recommendation NE 21

12 Endress+Hauser

Page 13

Proline Prosonic Flow 92F

Esc

E

-

+

D

G

H J*

K*

C

E

F

B

A*

Operating conditions: Process

Fluid temperature range

Medium pressure range

Size Range DN 25 to 100

(1 to 4")

Standard ASME & AD2000 ASME & AD2000 ASME AD2000

Version Stainless Steel Stainless Steel Carbon Steel Carbon Steel

Standard –40 to 150 °C

(–40 to 302 °F)

Optional –40 to 200 °C

(–40 to 392 °F)

*For PED device minimum temperature is –10 °C (14 °F)

–40 to 150 °C

(–40 to 302 °F)

–40 to 200 °C

(–40 to 392 °F)

DN 150 to 300

(6 to 12")

–29 to 130 °C*

(–84 to 266 °F)

–29 to 200 °C*

(–20 to 392 °F)

EN PN 16 to 40 / ASME Cl 150, Cl 300 / JIS 10K, 20K

(nominal pressure)

Pressure loss Pressure loss is negligible if the sensor is installed in a pipe of the same nominal diameter.

Mechanical construction

Design, dimensions, weights Dimensions of transmitter, remote version

–10 to 130 °C

(–14 to 266 °F)

–10 to 200 °C

(–14 to 392 °F)

Endress+Hauser 13

A B C D E F G H J K

[mm]

(inch)

232

9.13

* The following dimensions differ depending on the version:

– The dimension 232 mm (9.13 inch) changes to 226 mm (8.9 inch) in the blind version (without local operation).

– The dimension 170 mm (6.9 inch) changes to 183 mm (7.2 inch) in the Ex d/XP version.

– The dimension 340 mm (13.4 inch) changes to 353 mm (13.9 inch) in the Ex d/XP version.

!

The transmitter housing has one cable gland or cable entry. Measuring devices with a pulse, frequency or status output

have two cable glands or cable entries (devices with TIIS approval only have one cable gland).

Note!

[mm]

(inch)

8.6 (M8)

0.3

[mm]

(inch)

100

3.9

[mm]

(inch)

123

4.8

[mm]

(inch)

100

3.9

[mm]

(inch)

23

0.9

[mm]

(inch)

144

5,7

[mm]

(inch)

170

6.7

[mm]

(inch)

170

6.7

A0003594

[mm]

(inch)

340

13.4

Page 14

Proline Prosonic Flow 92F

A*

F*

E

H

L

X

D

H + 7 (0.28)

mm (inch)

H

–

42 (1.65)

d

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

K

E

E

P

H

T

I

G

H

T

W

E

N

C

I

R

C

U

I

T

A

L

I

V

E

WARNING

N

I

C

H

T

U

N

T

E

R

S

P

A

N

N

U

N

G

Ö

F

F

N

E

N

AVERTISSEMENT

N

E

S

P

A

S

O

U

V

R

I

R

O

U

S

T

E

N

S

I

O

N

WARNUNG

E

+

Esc

B1**

B2**

C

G

1

2

3

4

E

E

N25 – 100 (1…4")D

N150 – 300 (6…12")D

161

…

181**

141

…

151**

H42 (1.65)

Dimensions of Prosonic Flow 92F

Flanged version to:

• EN 1092-1 (DIN 2501), Ra = 6.3 to 12.5 μm

Raised face to: EN 1092-1 Form B1 (DIN 2526 Form C), PN 10 to 40, Ra = 6.3 to 12.5 μm

• ASME B16.5, Class 150 to 300, Ra = 125 to 250 μin

• AARH/Ra = 125 to 250 μin

• JIS B2220, 10 to 40K, Ra = 125 to 250 μin

A0006033

1 Standard- and Ex -i version

2 Ex d version (Transmitter)

3 Remote version DN 25 to 100 (1 to 4")

4 Remote version DN 150 to 300 (6 to 12")

Dimensions of Prosonic Flow 92F

mm 149 – – 121 105 151 161

inch 5.87 6.34…7.13 5.55…5.94 4.76 4.13 5.94 6.34

* The following dimensions change as follows in the blind version (without local operation):

– Standard, and Ex i version: the dimension 149 mm (5.87 inch) changes to 142 mm (5.60 inch) in the blind version.

–Ex d version: the dimension 151 mm (5.94 inch) changes to 144 mm (5.67 inch) in the blind version.

** The dimension depends on the cable gland used.

A B1** B2** C E F* G

14 Endress+Hauser

Page 15

Proline Prosonic Flow 92F

!

Note!

The weight data refer to the compact version.

The weight of the remote version is approx. 0.9 kg (1.98 lbs) greater.

Flange according to EN 1092-1

DN Pressure rating d [mm] D [mm] H [mm] L [mm]* X [mm]* Weight [kg]

25 PN 40 28.5 115.0 284.5 300 18 10

40 PN 40 43.1 150.0 287.0 315 18 12

50 PN 40 54.5 165.0 291.5 325 20 14

80 PN 40 82.5 200.0 310.5 390 24 24

100

150

200

250

300

*including raised face

PN 16 107.1 220.0

PN 40 107.1 235.0 24 35

PN 16 159.3 285.0

PN 40 159.3 300.0 400 33 53.9

PN 16 207.3 340.0

PN 40 206.5 375.0 400 41 92.0

PN 16 260.4 405.0

PN 40 258.8 450.0 450 47 130.9

PN 16 309.7 460.0

PN 40 307.9 515.0 500 55 174.3

323.5 460

439.2

464.6

491.6

517.0

400 23 33.0

400 25 44.2

400 28 62.7

500 32 82.1

20 32

Flange according to ASME B16.5 (SI-Units)

Size Pressure rating d [mm] D [mm] H [mm] L [mm]* X [mm]* Weight [kg]

Schedule 40

25

Schedule 80

Schedule 40

40

Schedule 80

Schedule 40

50

Schedule 80

Schedule 40

80

Schedule 80

Schedule 40

100

Schedule 80

150 Schedule 40

200 Schedule 40

250 Schedule 40

300 Schedule 40

*including raised face

Cl. 150 26.7 107.9

Cl. 300 26.7 123.8 19.1 10

Cl. 150 24.3 107.9 15.7 9

Cl. 300 24.3 123.8 19.1 10

Cl. 150 40.9 127.0

Cl. 300 40.9 155.6 20.6 13

Cl. 150 38.1 127.0 17.5 11

Cl. 300 38.1 155.6 20.6 13

Cl. 150 52.6 152.4

Cl. 300 52.6 165.0 22.4 14

Cl. 150 49.2 152.4 19.1 13

Cl. 300 49.2 165.0 22.4 15

Cl. 150 78.0 190.5

Cl. 300 78.0 210.0 28.4 28

Cl. 150 73.7 190.5 23.9 25

Cl. 300 73.7 210.0 28.4 28

Cl. 150 102.4 228.6

Cl. 300 102.4 254.0 31.8 44

Cl. 150 97.0 228.6 24.4 36

Cl. 300 97.0 254.0 31.8 44

Cl. 150 154.1 279.4

Cl. 300 154.1 317.5 450 36.7 56.5

Cl. 150 202.7 342.9

Cl. 300 202.7 381.0 450 41.1 82.6

Cl. 150 254.5 406.4

Cl. 300 254.5 444.5 500 47.8 118.3

Cl. 150 303.2 482.5

Cl. 300 303.2 520.7 550 50.8 164.5

284.5 300

287.0 315

291.5 325

310.5 390

330.0 460

439.2

464.6

491.6

517.0

400 25.4 38.9

400 28.4 57.6

450 30.2 79.9

500 31.8 113.5

15.7 9

17.5 11

19.1 13

23.9 24

24.4 36

Endress+Hauser 15

Page 16

Proline Prosonic Flow 92F

Flange according to ASME B16.5 (US-Units)

DN Druckstufe d [inch] D [inch] H [inch] L [inch]* X [inch]* Gewicht [lbs]

Schedule 40

1 "

Schedule 80

Schedule 40

1½"

Schedule 80

Schedule 40

2"

Schedule 80

Schedule 40

3"

Schedule 80

Schedule 40

4"

Schedule 80

6" Schedule 40

8" Schedule 40

10" Schedule 40

12" Schedule 40

*including raised face

Cl. 150 1.05 4.25

Cl. 300 1.05 4.87 0.75 22.1

Cl. 150 0.96 4.25 0.62 19.9

Cl. 300 0.96 4.87 0.75 22.1

Cl. 150 1.61 5.00

Cl. 300 1.61 6.13 0.81 28.7

Cl. 150 1.50 5.00 17.5 24.3

Cl. 300 1.50 6.13 0.81 28.7

Cl. 150 2.07 6.00

Cl. 300 2.07 6.50 0.88 14.0

Cl. 150 1.94 6.00 0.75 28.7

Cl. 300 1.94 6.50 0.88 33.1

Cl. 150 3.07 7.50

Cl. 300 3.07 8.27 1.12 61.8

Cl. 150 2.90 7.50 0.94 55.1

Cl. 300 2.90 8.27 1.12 61.8

Cl. 150 4.03 9.00

Cl. 300 4.03 10.0 1.25 97.0

Cl. 150 3.82 9.00 0.96 79.4

Cl. 300 3.82 10.0 1.25 79.4

Cl. 150 6.07 11.0

Cl. 300 6.07 12.5 17.7 1.44 124.6

Cl. 150 7.98 13.5

Cl. 300 7.98 15.0 17.7 1.62 182.1

Cl. 150 10.0 16.0

Cl. 300 10.0 17.5 19.7 1.88 260.8

Cl. 150 11.9 19.0

Cl. 300 11.9 20.5 21.7 2.00 362.7

11.2 11.8

11.3 12.4

11.5 12.8

12.2 15.40

13.0 18.1

17.3

18.3

19.4

20.4

15.8 1.00 85.8

15.8 1.12 127.0

17.7 1.19 176.1

19.7 1.25 250.2

0.62 19.9

17.5 24.3

0.75 28.7

0.94 52.9

0,96 79.4

Flange according to JIS B2220

DN Pressure rating d [mm] D [mm] H [mm] L [mm] X [mm] Weight [kg]

Schedule 40 20K 27.2 125.0

25

Schedule 80 20K 24.3 125.0 16

Schedule 40 20K 41.2 140.0

40

Schedule 80 20K 38.1 140.0 18

Schedule 40

50

Schedule 80

Schedule 40

80

Schedule 80

Schedule 40

100

Schedule 80

10K 52.7 155.0

20K 52.7 155.0 18

10K 49.2 155.0 16

20K 49.2 155.0 18

10K 78.1 185.0

20K 78.1 200.0 22 28

10K 73.7 185.0 18 25

20K 73.7 200.0 22 28

10K 102.3 210.0

20K 102.3 225.0 24 44

10K 97.0 210.0 18 36

20K 97.0 225.0 24 44

284.5 300

287.0 315

291.5 325

310.5 390

323.5 460

Weight See dimension tables ä 14 ff.

Material Transmitter housing and connection housing, sensor (remote version):

Compact housing: powder coated die cast aluminium

DN25 to 100 DN150 to 300

Standard ASME & AD2000 ASME & AD2000 ASME AD2000

Meter body A351-CF3M 1.4404+TP316+TP316L A106 Grd. B A106 Grd. B

1.4462

Sensor 1.4404+316L+316

Flanges 1.4404+F316+F316L 1.4404+F316+F316L A105+1.0432 1.0426

Designed for NACE MR0175/ISO 15156 and NACE MR0103

It is the equipment user‘s responsibility to select the materials suitable for the intended services.

Carbon steel with outer protective painting to 130 °C (266 °F) or optional 200 °C (392 °F)

1.4404+316L+316

1.4462

1.4404+316L+316

16

18

16

18 24

18 36

1.4404+316L+316

10

12

13

1.4462

16 Endress+Hauser

Page 17

Proline Prosonic Flow 92F

0

10

20

30

40

50

[bar]

300

400

500

700

600

200

100

0

800

[psi]

-60

-40

-20

020

40 60 80 100 120 140

180

200

160

[°C]

-40

0

-80

40 80 120 160 200 240 280 320 360 400

[°F]

PN40

PN16

PN

25

-60

-40

-20

020

40 60 80 100 120 140

180

200

160

[°C]

-40

0

-80

40 80 120 160 200 240 280 320 360 400

[°F]

Cl.150

Cl.300

0

10

20

30

40

50

[bar]

300

400

500

700

600

200

100

0

800

[psi]

-60

-40

-20

020

40 60 80 100 120 140

180

200

160

[°C]

0

10

20

30

[bar]

10K

20K

Material load diagram Pressure-temperature curve to EN 1092-1, stainless steel

Pressure-temperature curve to ASME B16.5, stainless steel

Class 150 to 300

A0010911

A0010909

Pressure-temperature curve to JIS B2220, stainless steel

10 to 40 K

A0010910

Endress+Hauser 17

Page 18

Pressure-temperature curve to EN 1092-1, carbon steel

-40

-20

020

40 60 80 100 120 140

180

200

160

[°C]

-40

0

40 80 120 160 200 240 280 320 360 400

[°F]

40

[bar]

[psi]

600

500

400

300

200

100

00

30

20

10

N40P

N16P

0

10

20

30

40

50

[bar]

300

400

500

700

600

200

100

0

800

[psi]

-60

-40

-20

020

40 60 80 100 120 140

180

200

160

[°C]

-40

0

-80

40 80 120 160 200 240 280 320 360 400

[°F]

Cl.150

Cl.300

Pressure-temperature curve to ASME B16.5, carbon steel

Proline Prosonic Flow 92F

A0014656

Human interface

Display elements • Liquid crystal display: double spaced with 16 characters per line

• Selectable display of different measured values and status variables

• At ambient temperatures below –20 °C (–4 °F) the readability of the display may be impaired.

Operating elements (HART) • Local operation with three keys (–, +, E)

• Application specific Quick Setup menus for straightforward commissioning

• Operating elements accessible also in Ex-zones

Remote operation Remote operation possible via:

•HART

• PROFIBUS PA

• FOUNDATION Fieldbus

• FieldCare

CE mark The device is in conformity with the statutory requirements of the EC Directives.

18 Endress+Hauser

Certificates and approvals

Endress+Hauser confirms successful testing of the device by affixing the CE mark.

A0014674

Page 19

Proline Prosonic Flow 92F

C-tick The measuring system meets the EMC requirements of the Australian Communications and Media Authority

(ACMA).

Ex approval Information about currently available Ex versions (ATEX, FM, CSA) can be supplied by your Endress+Hauser

sales organization. All explosion protection data are given in a separate documentation which is available upon

request.

Certification PROFIBUS PA The flowmeter has successfully passed all test procedures and is certified and registered by the PNO (PROFIBUS

User Organization). The device thus meets all the requirements of the specifications following:

• Certified to PROFIBUS PA Profile Version 3.0 (device certification number: on request)

• The device can also be operated with certified devices of other manufacturers (interoperability)

FOUNDATION Fieldbus certification

Other standards and guidelines

The flowmeter has passed all the test procedures implemented and has been certified and registered by the

Fieldbus Foundation. The flowmeter thus meets all the requirements of the specifications listed below:

• Certified to FOUNDATION Fieldbus specification

• The flowmeter meets all the specifications of the FOUNDATION Fieldbus-H1.

• Interoperability Test Kit (ITK), revision status 5.0:

The device can also be operated in conjunction with other-make certified devices

• Physical Layer Conformance Test of the Fieldbus Foundation

• EN 60529

Degrees of protection by housing (IP code).

• EN 61010-1

Protection Measures for Electrical Equipment for Measurement, Control, Regulation and Laboratory

Procedures.

• IEC/EN 61326

"Emission in accordance with Class A requirements".

Electromagnetic compatibility (EMC- requirements).

• NAMUR NE 21

Electromagnetic compatibility (EMC) of industrial process and laboratory control equipment.

• NAMUR NE 43

Standardization of the signal level for the breakdown information of digital transmitters with analogue output

signal.

• NAMUR NE 53

Software of field devices and signal processing devices with digital electronics.

• ASME/ISA-S.61010-1(82.02.01) CSA-C22.2 No. 1010.1 ASME/UL 61010-1

Safety requirements for Electrical Equipment for Measurement and Control and Laboratory Use.

Pollution degree 2

• NACE Standard MR0103

Standard Material Requirements - Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum

Refining Environments

• NACE Standard MR0175

Standard Material Requirements - Sulfide Stress Cracking Resistant Metallic Materials for Oilfield Equipment

Pressure Equipment Directive The measuring devices can be ordered with or without PED (Pressure Equipment Directive). If a device with

PED is required, this must be ordered explicitly. For devices with nominal diameters less than or equal to DN

25 (1"), this is neither possible nor necessary.

• With the identification PED/G1/III on the sensor nameplate, Endress+Hauser confirms conformity with the

"Basic safety requirements" of Appendix I of the Pressure Equipment Directive 97/23/EC.

• Devices with this identification (with PED) are suitable for the following types of fluid:

- Fluids of Group 1 and 2 with a steam pressure of greater or less than 0.5 bar (7.3 psi)

- Unstable gases

• Devices without this identification (without PED) are designed and manufactured according to good

engineering practice. They correspond to the requirements of Art. 3, Section 3 of the Pressure Equipment

Directive 97/23/EC. Their application is illustrated in Diagrams 6 to 9 in Appendix II of the Pressure

Equipment Directive 97/23/EC.

Endress+Hauser 19

Page 20

Ordering information

Instruments International

Endress+Hauser

Instruments International AG

Kaegenstrasse 2

4153 Reinach

Switzerland

Tel.+41 61 715 81 00

Fax +41 61 715 25 00

www.endress.com

info@ii.endress.com

The Endress+Hauser service organization can provide detailed ordering information and information on the

order codes on request.

Accessories

Various accessories, which can be ordered separately from Endress+Hauser, are available for the transmitter

and the sensor.

Documentation

• Flow measuring technology (FA005D/06)

• Supplementary documentation on Ex-ratings: ATEX, FM, CSA

• Operating Instructions Prosonic Flow 92 (BA00121D/06)

• Operating Instructions Prosonic Flow 92 PROFIBUS PA (BA00122D/06)

Registered trademarks

HART®

Registered trademark of HART Communication Foundation, Austin, USA

PROFIBUS

Registered trademark of the PROFIBUS User Organization, Karlsruhe, Germany

FOUNDATION™ Fieldbus

Registered trademark of the Fieldbus FOUNDATION, Austin, USA

HistoROM™ T-DAT

Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach, CH

®

®

, FieldCare ®, Fieldcheck®, FieldXpert™, Applicator

®

TI00073D/06/EN/13.10

71124142

FM+SGML6.0/ProMoDo

Loading...

Loading...