Endress+Hauser Proline Promass E 200 Operating Instructions Manual

BA01314D/06/EN/01.14

71258948

Valid as of version

01.00.zz (Device firmware)

Products Solutions Services

Operating Instructions

Proline Promass E 200

FOUNDATION Fieldbus

Coriolis flowmeter

Proline Promass E 200 FOUNDATION Fieldbus

• Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to

these Instructions.

2 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Table of contents

Table of contents

1 Document information .............. 6

1.1 Document function ..................... 6

1.2 Symbols used .......................... 6

1.2.1 Safety symbols .................. 6

1.2.2 Electrical symbols ................ 6

1.2.3 Tool symbols .................... 7

1.2.4 Symbols for certain types of

information .................... 7

1.2.5 Symbols in graphics ............... 7

1.3 Documentation ........................ 8

1.3.1 Standard documentation ........... 8

1.3.2 Supplementary device-dependent

documentation .................. 8

1.4 Registered trademarks ................... 8

2 Basic safety instructions ............ 9

2.1 Requirements for the personnel ............ 9

2.2 Designated use ........................ 9

2.3 Workplace safety ...................... 10

2.4 Operational safety ..................... 10

2.5 Product safety ........................ 10

2.6 IT security ........................... 11

3 Product description ................ 12

3.1 Product design ........................ 12

4 Incoming acceptance and product

identification ..................... 13

4.1 Incoming acceptance ................... 13

4.2 Product identification ................... 13

4.2.1 Transmitter nameplate ........... 14

4.2.2 Sensor nameplate ............... 15

4.2.3 Symbols on measuring device ...... 16

5 Storage and transport ............. 17

5.1 Storage conditions ..................... 17

5.2 Transporting the product ................ 17

5.3 Packaging disposal ..................... 18

6 Installation ....................... 19

6.1 Installation conditions .................. 19

6.1.1 Mounting position ............... 19

6.1.2 Requirements from environment and

process ....................... 21

6.1.3 Special mounting instructions ...... 22

6.2 Mounting the measuring device ........... 23

6.2.1 Required tools .................. 23

6.2.2 Preparing the measuring device ..... 23

6.2.3 Mounting the measuring device ..... 24

6.2.4 Turning the transmitter housing .... 24

6.2.5 Turning the display module ........ 24

6.3 Post-installation check .................. 25

7 Electrical connection .............. 26

7.1 Connection conditions .................. 26

7.1.1 Required tools .................. 26

7.1.2 Requirements for connecting cable ... 26

7.1.3 Terminal assignment ............. 27

7.1.4 Shielding and grounding .......... 27

7.1.5 Requirements for the supply unit .... 28

7.1.6 Preparing the measuring device ..... 28

7.2 Connecting the measuring device .......... 29

7.2.1 Connecting the transmitter ........ 29

7.3 Special connection instructions ............ 30

7.3.1 Connection examples ............. 30

7.4 Ensuring the degree of protection .......... 31

7.5 Post-connection check .................. 31

8 Operation options ................. 32

8.1 Overview of operation options ............ 32

8.2 Structure and function of the operating

menu .............................. 33

8.2.1 Structure of the operating menu .... 33

8.2.2 Operating philosophy ............ 34

8.3 Access to the operating menu via the local

display ............................. 34

8.3.1 Operational display .............. 34

8.3.2 Navigation view ................ 35

8.3.3 Editing view ................... 37

8.3.4 Operating elements .............. 39

8.3.5 Opening the context menu ......... 39

8.3.6 Navigating and selecting from list ... 41

8.3.7 Calling the parameter directly ...... 41

8.3.8 Calling up help text .............. 42

8.3.9 Changing the parameters ......... 43

8.3.10 User roles and related access

authorization .................. 44

8.3.11 Disabling write protection via access

code ......................... 44

8.3.12 Enabling and disabling the keypad

lock ......................... 44

8.4 Access to the operating menu via the

operating tool ........................ 45

8.4.1 Connecting the operating tool ...... 46

8.4.2 Field Xpert SFX350, SFX370 ....... 47

8.4.3 FieldCare ..................... 47

8.4.4 AMS Device Manager ............ 48

8.4.5 Field Communicator 475 .......... 48

9 System integration ................ 49

9.1 Overview of device description files ......... 49

9.1.1 Current version data for the device ... 49

9.1.2 Operating tools ................. 49

Endress+Hauser 3

Table of contents Proline Promass E 200 FOUNDATION Fieldbus

9.2 Integration into a FOUNDATION Fieldbus

network ............................ 50

9.2.1 Block model ................... 50

9.2.2 Assignment of the measured values

in the function blocks ............ 50

9.2.3 Index tables of Endress+Hauser

parameters .................... 51

9.2.4 Methods ...................... 52

10 Commissioning .................... 54

10.1 Function check ....................... 54

10.2 Switching on the measuring device ......... 54

10.3 Setting the operating language ............ 54

10.4 Configuring the measuring device .......... 54

10.4.1 Defining the tag name ............ 55

10.4.2 Setting the system units .......... 56

10.4.3 Selecting and setting the medium ... 58

10.4.4 Configuring the analog inputs ...... 60

10.4.5 Configuring the local display ....... 60

10.4.6 Configuring the low flow cut off ..... 63

10.4.7 Configuring the partial filled pipe

detection ..................... 64

10.5 Advanced settings ..................... 65

10.5.1 Carrying out a sensor adjustment .... 66

10.5.2 Configuring the pulse/frequency/

switch output .................. 66

10.5.3 Configuring the totalizer .......... 74

10.5.4 Carrying out additional display

configurations .................. 75

10.6 Configuration management .............. 77

10.6.1 Function scope of the ""Configuration

management" parameter"

parameter ..................... 78

10.7 Simulation ........................... 78

10.8 Protecting settings from unauthorized

access .............................. 80

10.8.1 Write protection via access code ..... 80

10.8.2 Write protection via write protection

switch ........................ 81

10.8.3 Write protection via block

operation ..................... 82

10.9 Configuring the measuring device via

FOUNDATION Fieldbus ................. 83

10.9.1 Block configuration .............. 83

10.9.2 Scaling the measured value in the

Analog Input Block .............. 84

11 Operation ......................... 86

11.1 Reading device locking status ............. 86

11.2 Adjusting the operating language .......... 86

11.3 Configuring the display ................. 86

11.4 Reading measured values ................ 86

11.4.1 Process variables ................ 86

11.4.2 Totalizer ...................... 87

11.4.3 Output values .................. 88

11.5 Adapting the measuring device to the process

conditions ........................... 88

11.6 Performing a totalizer reset .............. 88

11.7 Showing data logging ................... 89

12 Diagnostics and troubleshooting ... 92

12.1 General troubleshooting ................. 92

12.2 Diagnostic information on local display ...... 94

12.2.1 Diagnostic message .............. 94

12.2.2 Calling up remedial measures ...... 95

12.3 Diagnostic information in FieldCare ........ 96

12.3.1 Diagnostic options ............... 96

12.3.2 Calling up remedy information ...... 97

12.4 Adapting the diagnostic information ....... 97

12.4.1 Adapting the diagnostic behavior .... 97

12.4.2 Adapting the status signal ......... 97

12.5 Overview of diagnostic information ....... 101

12.6 Pending diagnostic events .............. 103

12.7 Diagnostic messages in the DIAGNOSTIC

Transducer Block ..................... 104

12.8 Diagnostic list ....................... 104

12.9 Event logbook ....................... 105

12.9.1 Event history .................. 105

12.9.2 Filtering the event logbook ....... 105

12.9.3 Overview of information events .... 105

12.10 Resetting the measuring device .......... 106

12.11 Device information ................... 107

12.12 Firmware history ..................... 108

13 Maintenance .................... 109

13.1 Maintenance tasks .................... 109

13.1.1 Exterior cleaning ............... 109

13.1.2 Interior cleaning ............... 109

13.2 Measuring and test equipment ........... 109

13.3 Endress+Hauser services ............... 109

14 Repair ........................... 110

14.1 General notes ....................... 110

14.2 Spare parts ......................... 110

14.3 Endress+Hauser services ............... 111

14.4 Return ............................. 111

14.5 Disposal ........................... 111

14.5.1 Removing the measuring device .... 111

14.5.2 Disposing of the measuring device .. 111

15 Accessories ...................... 112

15.1 Device-specific accessories .............. 112

15.1.1 For the transmitter ............. 112

15.1.2 For the sensor ................. 113

15.2 Communication-specific accessories ....... 113

15.3 Service-specific accessories .............. 113

15.4 System components ................... 114

16 Technical data ................... 115

16.1 Application ......................... 115

16.2 Function and system design ............. 115

16.3 Input .............................. 115

16.4 Output ............................ 117

16.5 Power supply ........................ 121

4 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Table of contents

16.6 Performance characteristics ............. 123

16.7 Installation ......................... 126

16.8 Environment ........................ 126

16.9 Process ............................ 127

16.10 Mechanical construction ............... 129

16.11 Operability ......................... 132

16.12 Certificates and approvals .............. 134

16.13 Application packages .................. 136

16.14 Accessories ......................... 136

16.15 Supplementary documentation ........... 136

17 Appendix ........................ 138

17.1 Endress+Hauser FOUNDATION Fieldbus

Parameter .......................... 138

17.1.1 Resource Block 2 .............. 138

17.1.2 Transducer Block Advanced Setup .. 142

17.1.3 Transducer Block Diagnostic ...... 146

17.1.4 Transducer Block Display ........ 155

17.1.5 Transducer Block Expert ......... 159

17.1.6 Transducer Block Expert Info ..... 162

17.1.7 Transducer Block Heartbeat ...... 164

17.1.8 Transducer Block Heartbeat Results

1 .......................... 166

17.1.9 Transducer Block Heartbeat Results

2 .......................... 173

17.1.10 Transducer Block Heartbeat Results

3 .......................... 180

17.1.11 Transducer Block Heartbeat Results

4 .......................... 187

17.1.12 Transducer Block HistoROM ...... 194

17.1.13 Transducer Block Service Info ..... 198

17.1.14 Transducer Block Service Sensor ... 201

17.1.15 Transducer Block Setup ......... 205

17.1.16 Transducer Block Total Inventory

Counter ..................... 208

17.2 Overview of the operating menu .......... 210

17.2.1 "Operation" menu ............... 211

17.2.2 "Setup" menu .................. 211

17.2.3 "Diagnostics" menu .............. 217

17.2.4 "Expert" menu ................. 221

Index ................................. 241

Endress+Hauser 5

Document information Proline Promass E 200 FOUNDATION Fieldbus

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols used

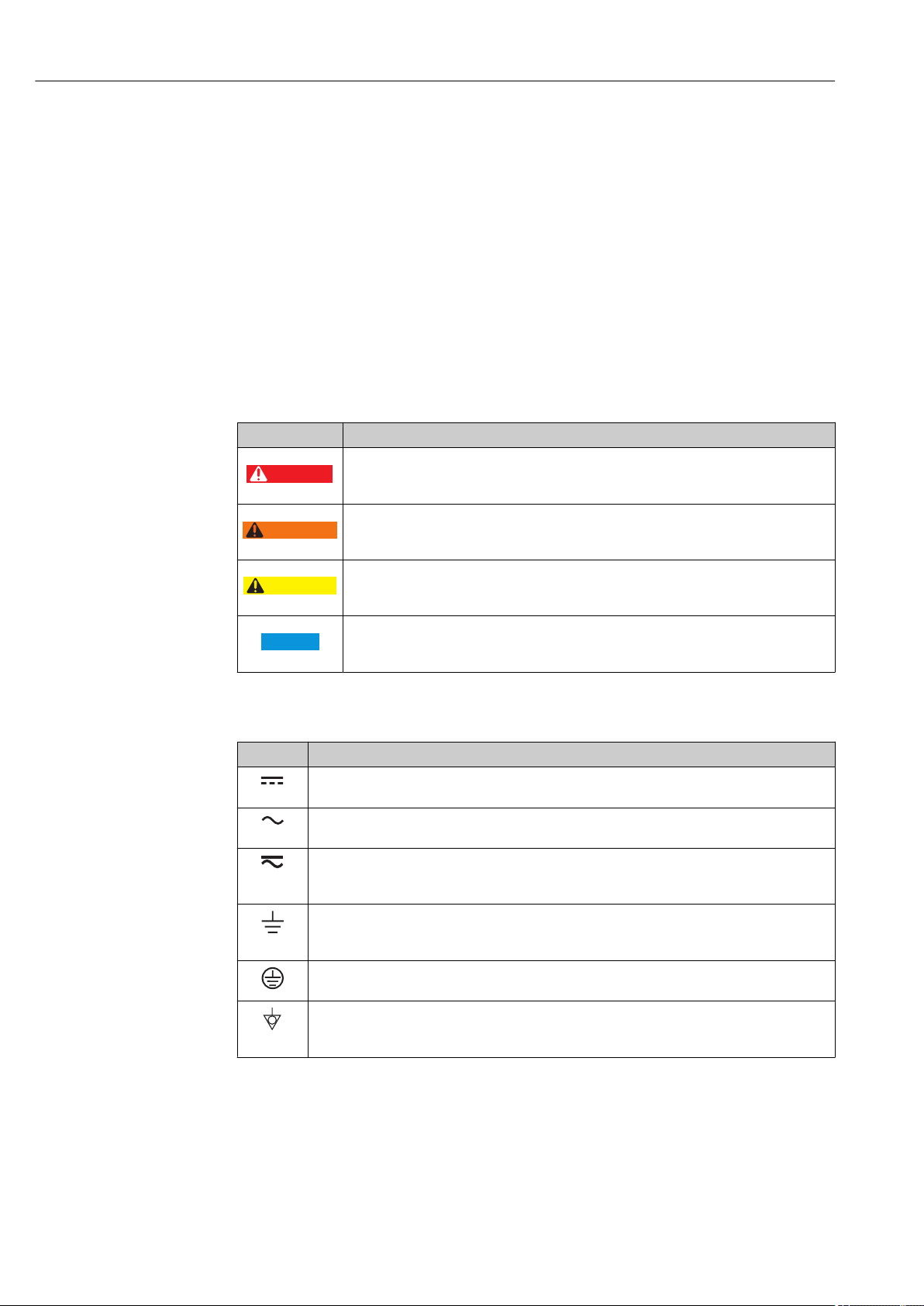

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

Direct current and alternating current

• A terminal to which alternating voltage or DC voltage is applied.

• A terminal through which alternating current or direct current flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a potential

equalization line or a star grounding system depending on national or company codes of practice.

6 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Document information

,…,

,…,

-

.

1.2.3 Tool symbols

Symbol Meaning

Flat blade screwdriver

Allen key

Open-ended wrench

1.2.4 Symbols for certain types of information

Symbol Meaning

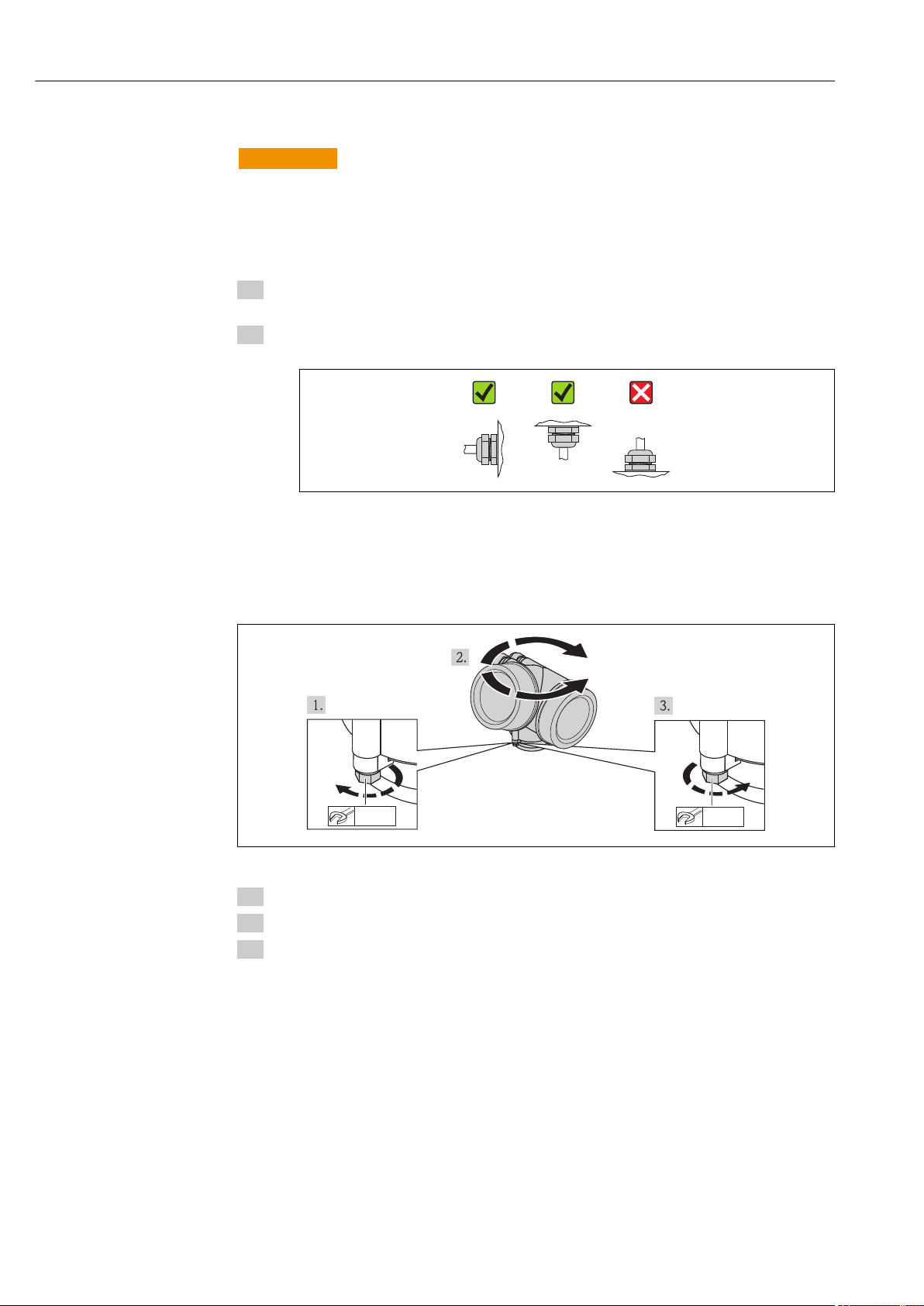

Permitted

Indicates procedures, processes or actions that are permitted.

Preferred

Indicates procedures, processes or actions that are preferred.

Forbidden

Indicates procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Refers to the corresponding device documentation.

Reference to page

Refers to the corresponding page number.

Reference to graphic

Refers to the corresponding graphic number and page number.

Series of steps

Result of a sequence of actions

Help in the event of a problem

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3,... Item numbers

Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Flow direction

A0013441

Hazardous area

Indicates a hazardous area.

A0011187

Safe area (non-hazardous area)

Indicates the non-hazardous area.

A0011188

Endress+Hauser 7

Document information Proline Promass E 200 FOUNDATION Fieldbus

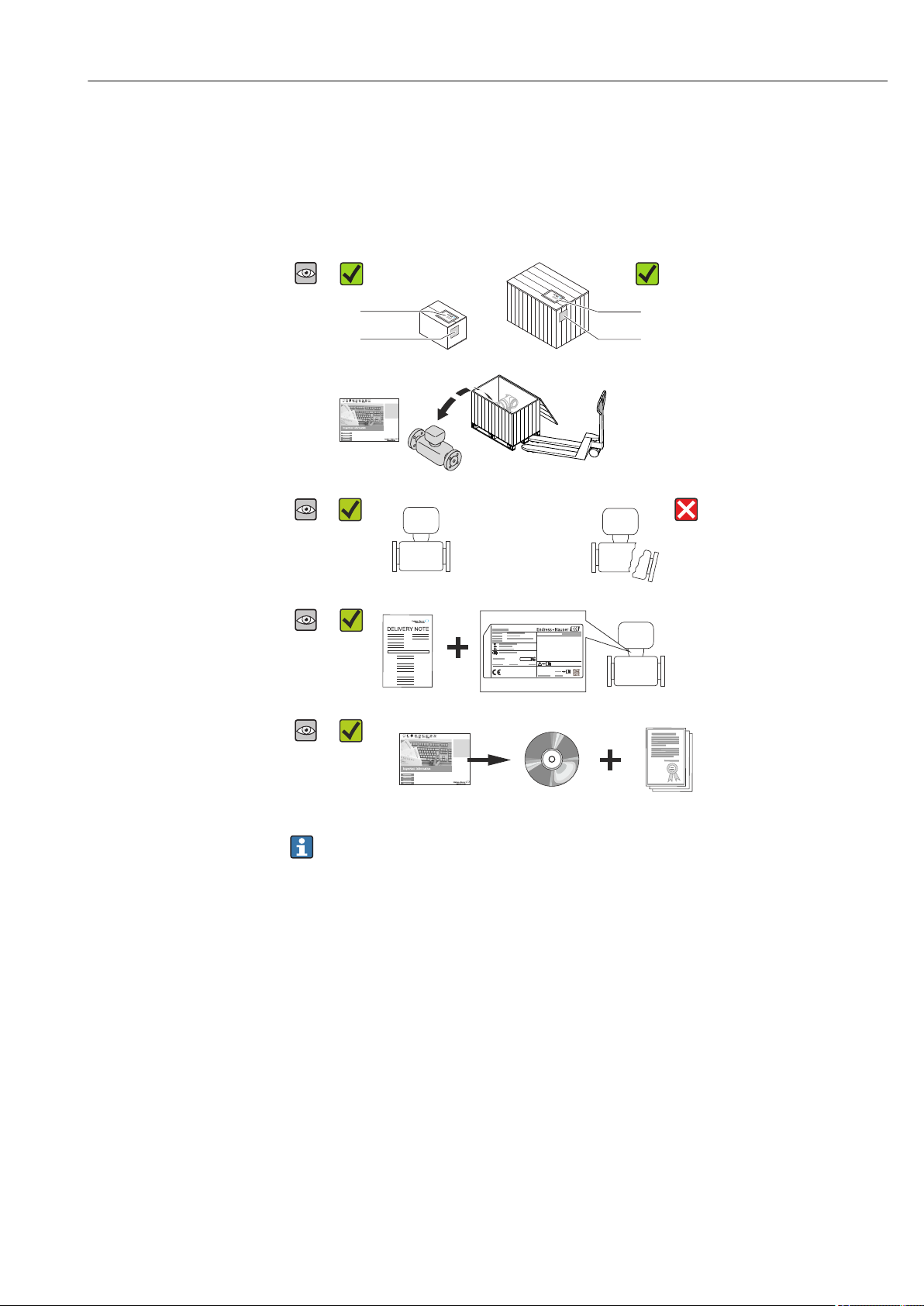

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The CD-ROM provided for the device (depending on the device version, the CD-ROM

might not be part of the delivery!)

• The W@M Device Viewer : Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate

or scan the 2-D matrix code (QR code) on the nameplate.

For a detailed list of the individual documents along with the documentation code

1.3.1 Standard documentation

Document type Purpose and content of the document

Technical Information Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Brief Operating Instructions Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information

from incoming acceptance to initial commissioning.

Description of Device Parameters Reference for your parameters

The document provides a detailed explanation of each individual

parameter in the operating menu. The description is aimed at those who

work with the device over the entire life cycle and perform specific

configurations.

1.3.2 Supplementary device-dependent documentation

Additional documents are supplied depending on the device version ordered: Always

comply strictly with the instructions in the supplementary documentation. The

supplementary documentation is an integral part of the device documentation.

1.4 Registered trademarks

FOUNDATIONTM Fieldbus

Registration-pending trademark of the Fieldbus Foundation, Austin, Texas, USA

TRI-CLAMP

Registered trademark of Ladish & Co., Inc., Kenosha, USA

Applicator®, FieldCare®, Field XpertTM, HistoROM®, Heartbeat Technology

Registered or registration-pending trademarks of the Endress+Hauser Group

®

TM

8 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

Application and media

The measuring device described in these Instructions is intended only for flow

measurement of liquids and gases.

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or in applications

where there is an increased risk due to process pressure, are labeled accordingly on the

nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and

‣

the general conditions listed in the Operating Instructions and supplementary

documentation.

Based on the nameplate, check whether the ordered device is permitted for the

‣

intended use in the hazardous area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials

‣

are adequately resistant.

If the measuring device is not operated at atmospheric temperature, compliance with

‣

the relevant basic conditions specified in the associated device documentation is

absolutely essential: "Documentation" section (→ 8).

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage

caused by improper or non-designated use.

WARNING

!

Danger of breakage of the measuring tube due to corrosive or abrasive fluids.

Housing breakage due to mechanical overload possible!

Verify the compatibility of the process fluid with the measuring tube material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Observe the specified pressure and temperature range.

‣

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance

‣

in verifying the corrosion resistance of fluid-wetted materials, but does not accept any

Endress+Hauser 9

Basic safety instructions Proline Promass E 200 FOUNDATION Fieldbus

warranty or liability as minute changes in the temperature, concentration or level of

contamination in the process can alter the corrosion resistance properties.

Residual risks

WARNING

!

Danger of housing breaking due to measuring tube breakage!

In the event of a measuring tube breakage for a device version without rupture disk it is

‣

possible for the pressure loading capacity of the sensor housing to be exceeded. This

can lead to rupture or failure of the sensor housing.

The external surface temperature of the housing can increase by max. 20 K due to the

power consumption of the electronic components. Hot process fluids passing through the

measuring device will further increase the surface temperature of the housing. The surface

of the sensor, in particular, can reach temperatures which are close to the fluid

temperature.

Possible burn hazard due to fluid temperatures!

For elevated fluid temperature, ensure protection against contact to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

For welding work on the piping:

Do not ground the welding unit via the measuring device.

‣

If working on and with the device with wet hands:

It is recommended to wear gloves on account of the higher risk of electric shock.

‣

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

‣

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

10 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Basic safety instructions

2.6 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser 11

Product description Proline Promass E 200 FOUNDATION Fieldbus

1 2

3

4

5 6

7

8

9

+

E

–

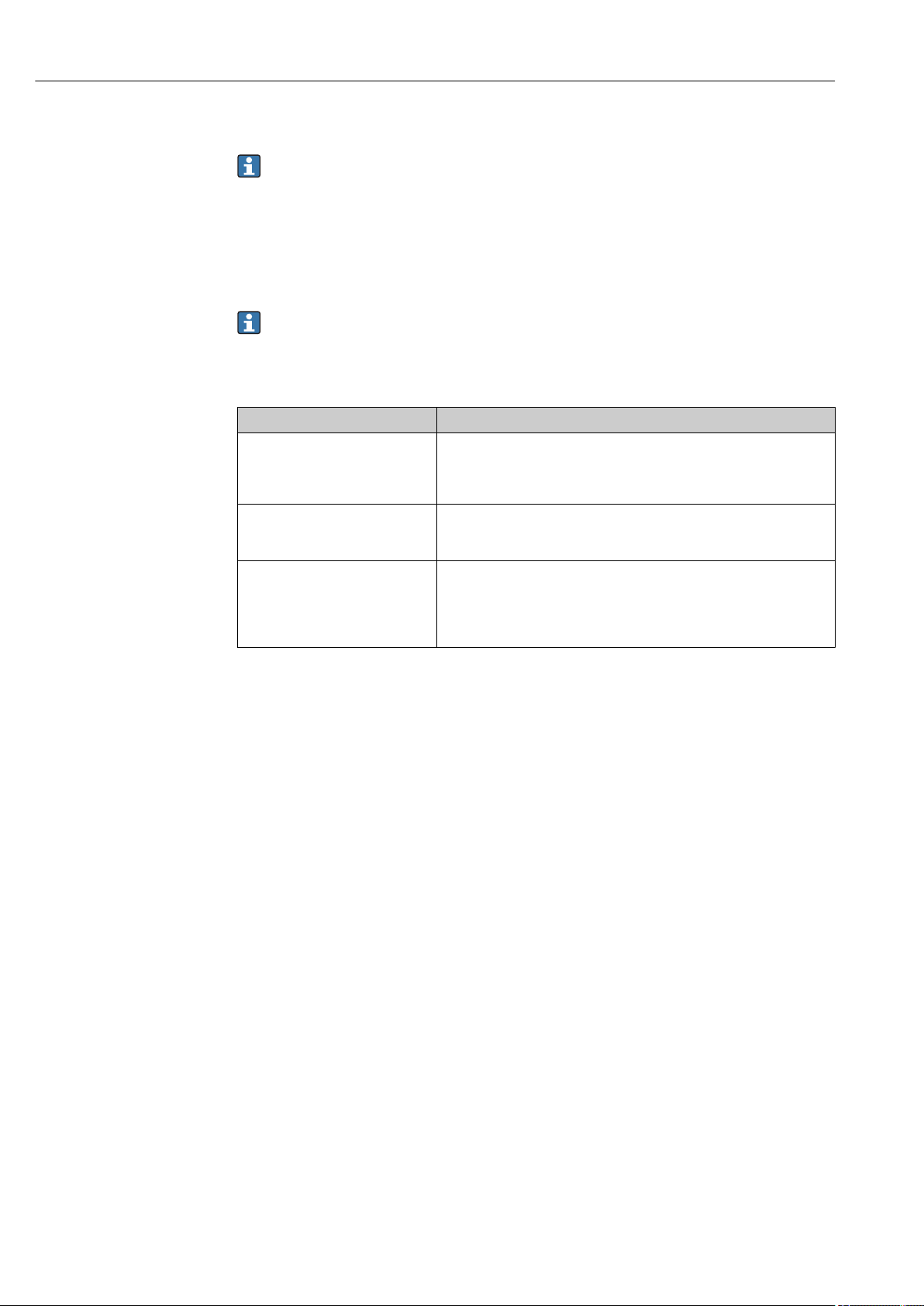

3 Product description

3.1 Product design

A0014056

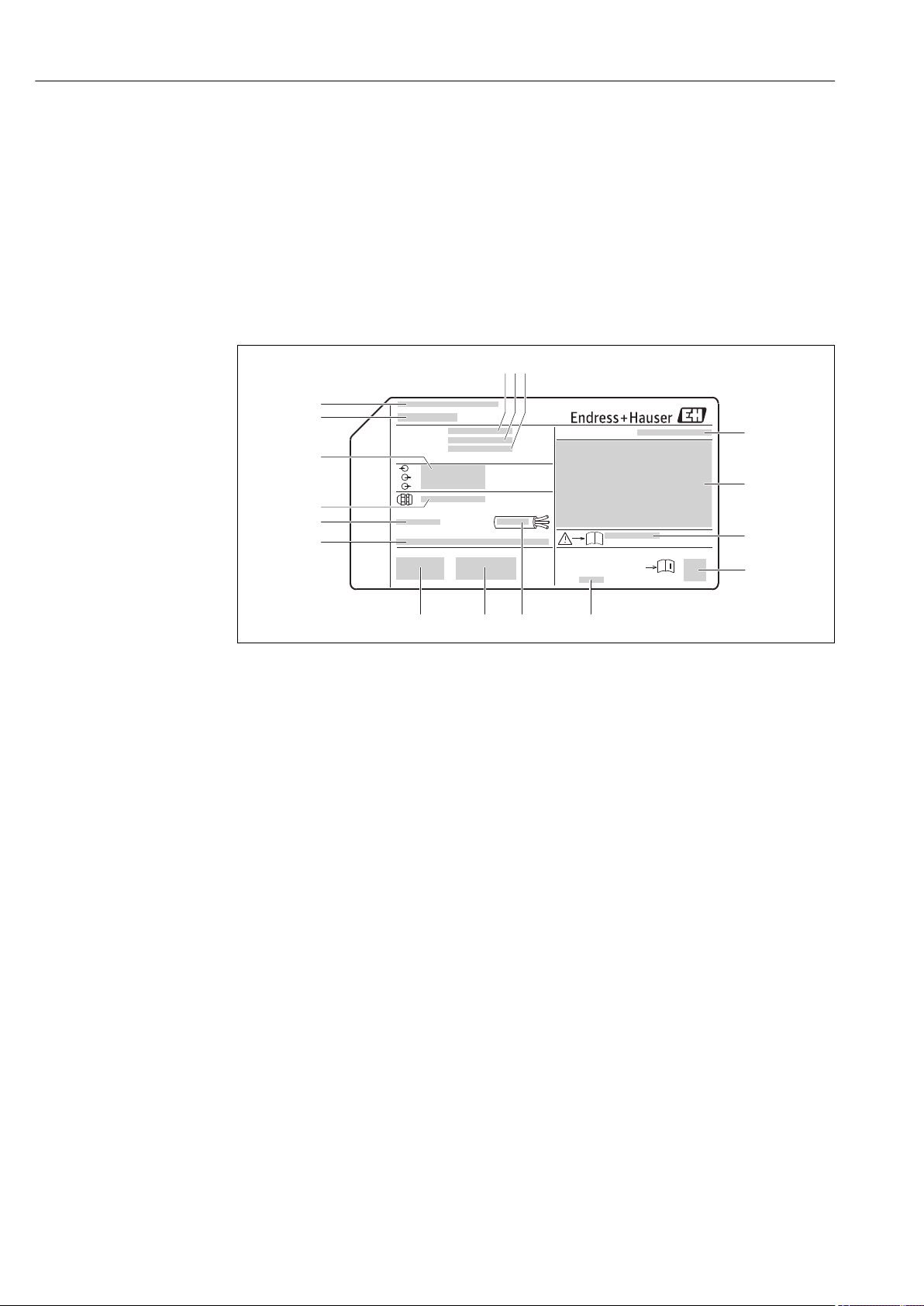

1 Important components of a measuring device

1 Electronics compartment cover

2 Display module

3 Main electronics module

4 Cable glands

5 Transmitter housing (incl. integrated HistoROM)

6 I/O electronics module

7 Terminals (spring loaded terminals, pluggable)

8 Connection compartment cover

9 Sensor (incl. HistoROM S-DAT)

12 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Incoming acceptance and product identification

1

+

2

1

+

2

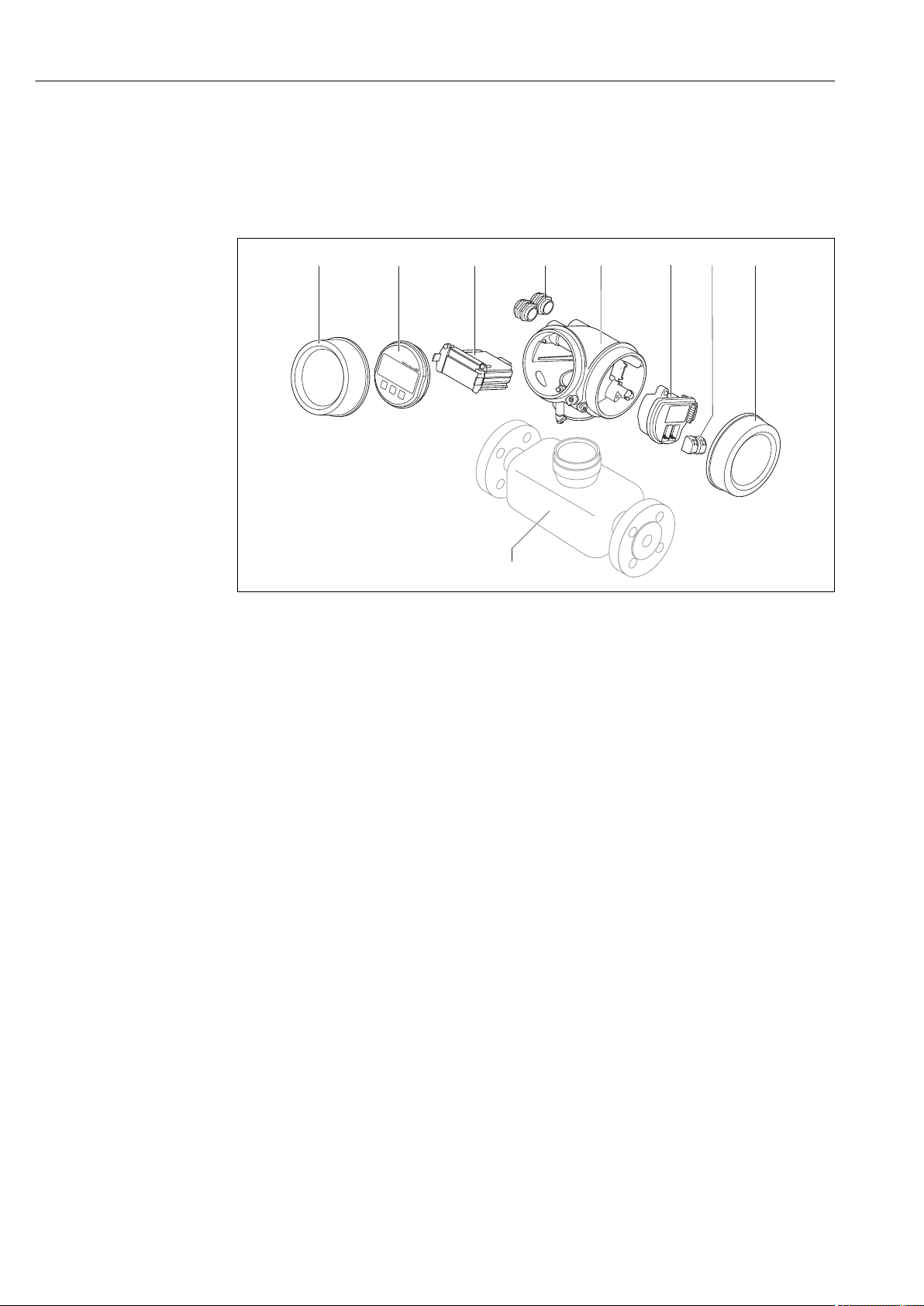

4 Incoming acceptance and product

identification

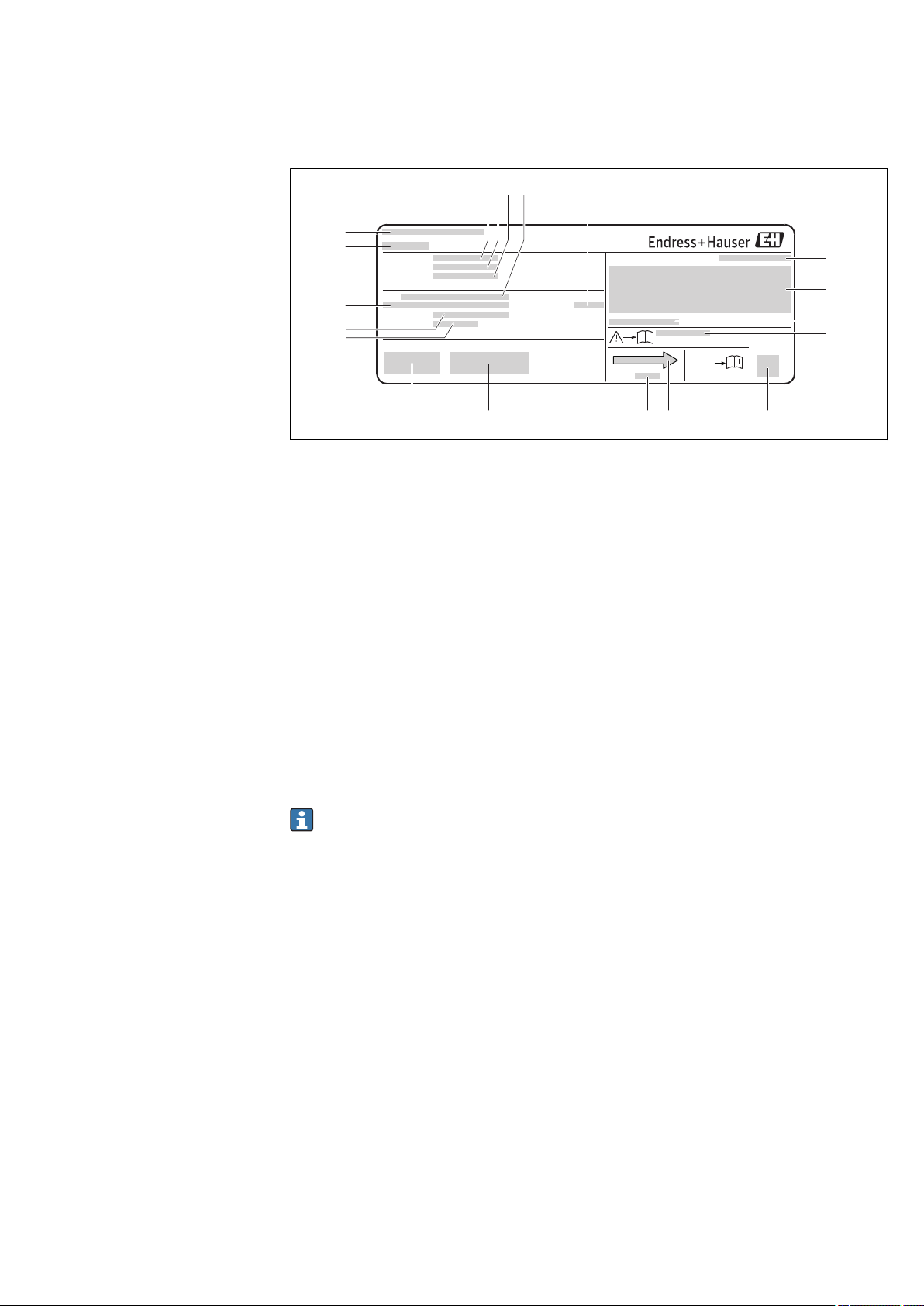

4.1 Incoming acceptance

Are the order codes on the

delivery note (1) and the

product sticker (2)

identical?

Are the goods undamaged?

Do the nameplate data

match the ordering

information on the delivery

note?

Is the CD-ROM with the

Technical Documentation

(depends on device

version) and documents

present?

• If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

• Depending on the device version, the CD-ROM might not be part of the delivery! In

such cases, the technical documentation is available via the Internet or via the

Endress+Hauser Operations App, see the "Product identification" section

(→ 14).

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App

or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information for the measuring device is displayed.

Endress+Hauser 13

Incoming acceptance and product identification Proline Promass E 200 FOUNDATION Fieldbus

Ordercode:

Ext.ord.cd.:

Ser.no.:

Date:

i

i

Patents

322540-0001

1

2

3 4 5

6

7

8

9

10 11

12

14

15

16

17

13

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The chapters "Additional standard documentation on the device" (→ 8) and

"Supplementary device-dependent documentation" (→ 8)

• The W@M Device Viewer: Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2-D matrix code (QR code) on the nameplate.

4.2.1 Transmitter nameplate

A0013906

2 Example of a transmitter nameplate

1 Manufacturing location

2 Name of the transmitter

3 Order code

4 Serial number (Ser. no.)

5 Extended order code (Ext. ord. cd.)

6 Electrical connection data, e.g. available inputs and outputs, supply voltage

7 Type of cable glands

8 Permitted ambient temperature (Ta)

9 Firmware version (FW) from the factory

10 CE mark, C-Tick

11 Additional information on version: certificates, approvals

12 Permitted temperature range for cable

13 Manufacturing date: year-month

14 Degree of protection

15 Approval information for explosion protection

16 Document number of safety-related supplementary documentation

17 2-D matrix code

14 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Incoming acceptance and product identification

Date:

Size:

Material:

Tm:

Patents

i

Ptest =

i

Order code:

Ext. ord. cd.:

Ser. no.:

322541-0000

0044

11

1

2

3 4 5

6 7

12

8

9

13 14 15

16

17

19

18

10

4.2.2 Sensor nameplate

A0013907

3 Example of a sensor nameplate

1 Manufacturing location

2 Name of the sensor

3 Order code

4 Serial number (Ser. no.)

5 Extended order code (Ext. ord. cd.)

6 Nominal diameter of the sensor

7 Test pressure of the sensor

8 Flange nominal diameter/nominal pressure

9 Material of measuring tube and manifold

10 Medium temperature range

11 CE mark, C-Tick

12 Additional information on version: certificates, approvals

13 Manufacturing date: year-month

14 Flow direction

15 2-D matrix code

16 Degree of protection

17 Approval information for explosion protection and Pressure Equipment Directive

18 Permitted ambient temperature (Ta)

19 Document number of safety-related supplementary documentation

Order code

The measuring device is reordered using the order code.

Extended order code

• The device type (product root) and basic specifications (mandatory features) are

always listed.

• Of the optional specifications (optional features), only the safety and approvalrelated specifications are listed (e.g. LA). If other optional specifications are also

ordered, these are indicated collectively using the # placeholder symbol (e.g. #LA#).

• If the ordered optional specifications do not include any safety and approval-related

specifications, they are indicated by the + placeholder symbol (e.g. XXXXXX-ABCDE

+).

Endress+Hauser 15

Incoming acceptance and product identification Proline Promass E 200 FOUNDATION Fieldbus

4.2.3 Symbols on measuring device

Symbol Meaning

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious

or fatal injury.

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

16 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Storage and transport

5 Storage and transport

5.1 Storage conditions

Observe the following notes for storage:

• Store in the original packaging to ensure protection from shock.

• Do not remove protective covers or protective caps installed on process connections.

They prevent mechanical damage to the sealing surfaces and fouling in the measuring

tube.

• Protect from direct sunlight to avoid unacceptably high surface temperatures.

• Storage temperature: –40 to +80 °C (–40 to +176 °F), preferable for +20 °C (+68 °F)

• Store in a dry and dust-free place.

• Do not store outdoors.

5.2 Transporting the product

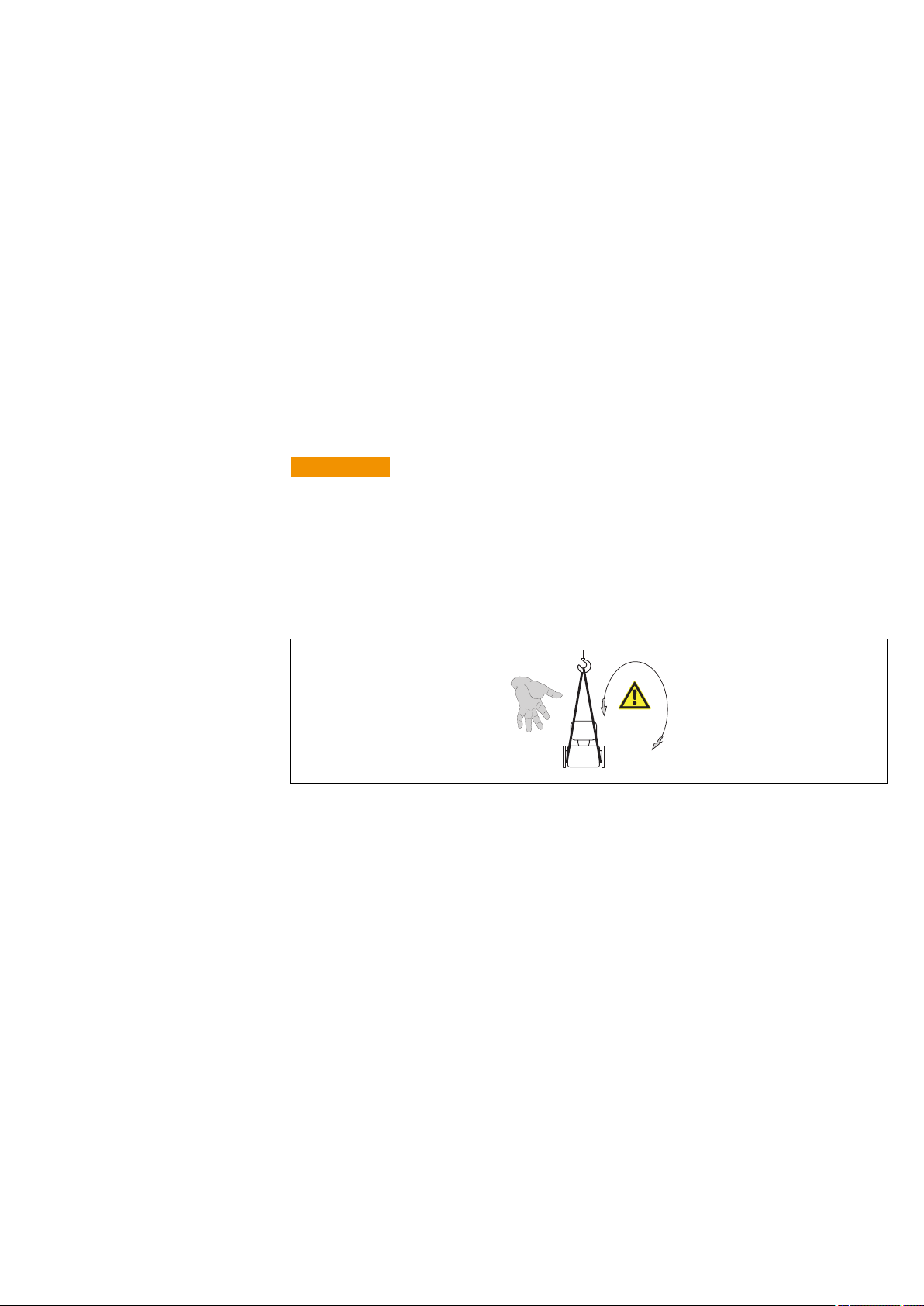

WARNING

!

Center of gravity of the measuring device is higher than the suspension points of the

webbing slings.

Risk of injury if the measuring device slips.

Secure the measuring device from rotating or slipping.

‣

Observe the weight specified on the packaging (stick-on label).

‣

Observe the transport instructions on the stick-on label on the electronics compartment

‣

cover.

Observe the following notes during transport:

• Transport the measuring device to the measuring point in the original packaging.

• Lifting gear

– Webbing slings: Do not use chains, as they could damage the housing.

– For wood crates, the floor structure enables these to be loaded lengthwise or broadside

using a forklift.

• For measuring device > DN 40 (1½ in): lift the measuring device using the webbing

slings at the process connections; do not lift at the transmitter housing.

• Do not remove protective covers or protective caps installed on process connections.

They prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

A0015606

Endress+Hauser 17

Storage and transport Proline Promass E 200 FOUNDATION Fieldbus

5.3 Packaging disposal

All packaging materials are environmentally friendly and 100% recyclable:

• Measuring device secondary packaging: polymer stretch film that conforms to EC

Directive 2002/95/EC (RoHS).

• Packaging:

– Wood crate, treated in accordance with ISPM 15 standard, which is confirmed by the

affixed IPPC logo.

or

– Carton in accordance with European Packaging Directive 94/62EC; recyclability is

confirmed by the affixed RESY symbol.

• Seaworthy packaging (optional): Wood crate, treated in accordance with ISPM 15

standard, which is confirmed by the affixed IPPC logo.

• Carrying and mounting hardware:

– Disposable plastic pallet

– Plastic straps

– Plastic adhesive strips

• Dunnage: Paper cushion

18 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Installation

1

2

3

4

5

6 Installation

6.1 Installation conditions

No special measures such as supports are necessary. External forces are absorbed by the

construction of the device.

6.1.1 Mounting position

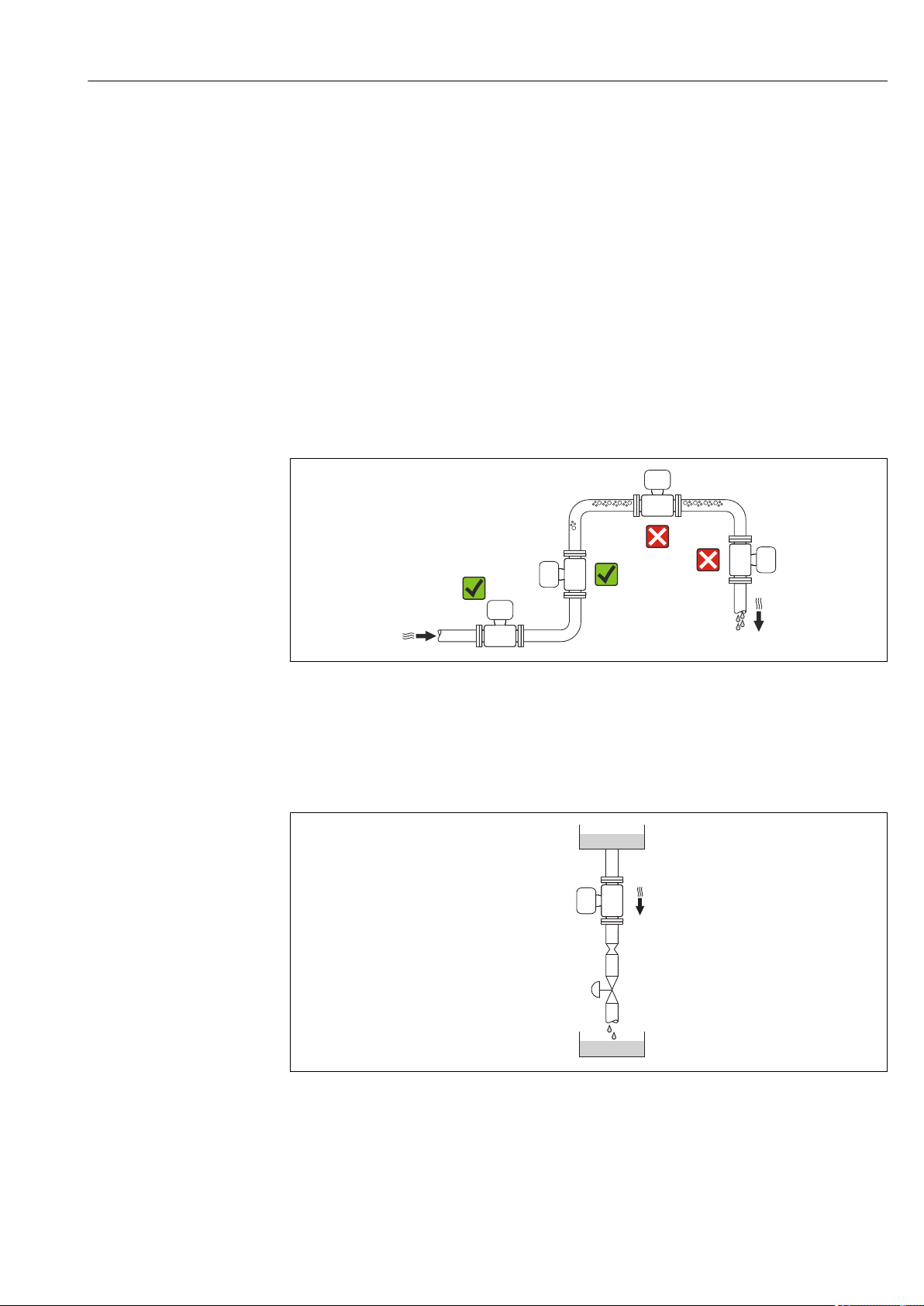

Mounting location

To prevent measuring errors arising from accumulation of gas bubbles in the measuring

tube, avoid the following mounting locations in the pipe:

• Highest point of a pipeline.

• Directly upstream of a free pipe outlet in a down pipe.

A0023344

Installation in down pipes

However, the following installation suggestion allows for installation in an open vertical

pipeline. Pipe restrictions or the use of an orifice with a smaller cross-section than the

nominal diameter prevent the sensor running empty while measurement is in progress.

4 Installation in a down pipe (e.g. for batching applications)

1 Supply tank

2 Sensor

3 Orifice plate, pipe restriction

4 Valve

5 Batching tank

A0015596

Endress+Hauser 19

Installation Proline Promass E 200 FOUNDATION Fieldbus

1 2

DN Ø orifice plate, pipe restriction

[mm] [in] [mm] [in]

8 ³⁄₈ 6 0.24

15 ½ 10 0.40

25 1 14 0.55

40 1½ 22 0.87

50 2 28 1.10

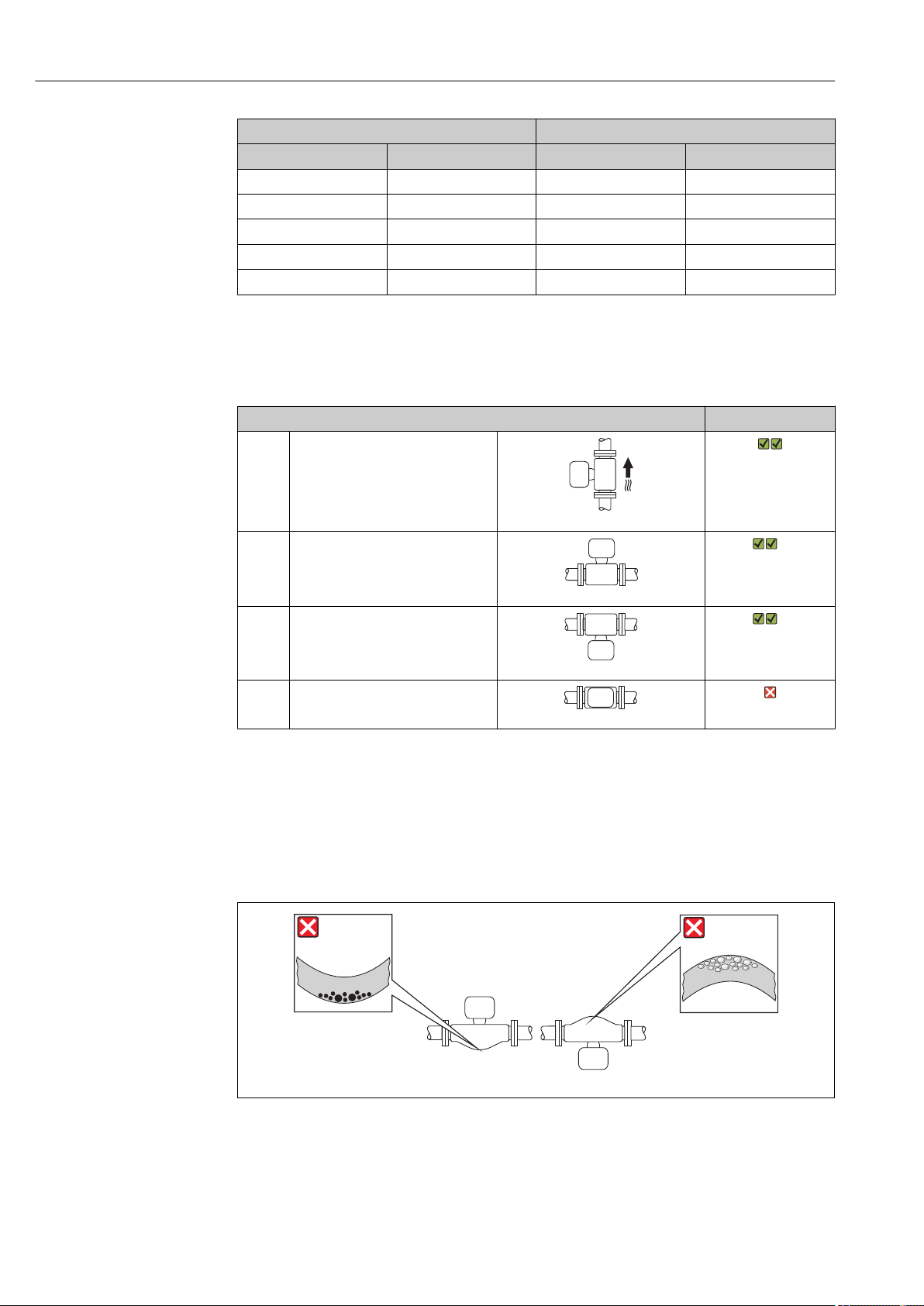

Orientation

The direction of the arrow on the sensor nameplate helps you to install the sensor

according to the flow direction (direction of medium flow through the piping).

Orientation Recommendation

A Vertical orientation

A0015591

B Horizontal orientation, transmitter

head up

1)

Exception:

(→ 5, 20)

A0015589

C Horizontal orientation, transmitter

head down

2)

Exception:

(→ 5, 20)

A0015590

D Horizontal orientation, transmitter

head at side

A0015592

1) Applications with low process temperatures may reduce the ambient temperature. To maintain the

minimum ambient temperature for the transmitter, this orientation is recommended.

2) Applications with high process temperatures may increase the ambient temperature. To maintain the

maximum ambient temperature for the transmitter, this orientation is recommended.

If a sensor is installed horizontally with a curved measuring tube, match the position of the

sensor to the fluid properties.

A0014057

5 Orientation of sensor with curved measuring tube

1 Avoid this orientation for fluids with entrained solids: Risk of solids accumulating.

2 Avoid this orientation for outgassing fluids: Risk of gas accumulating.

20 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Installation

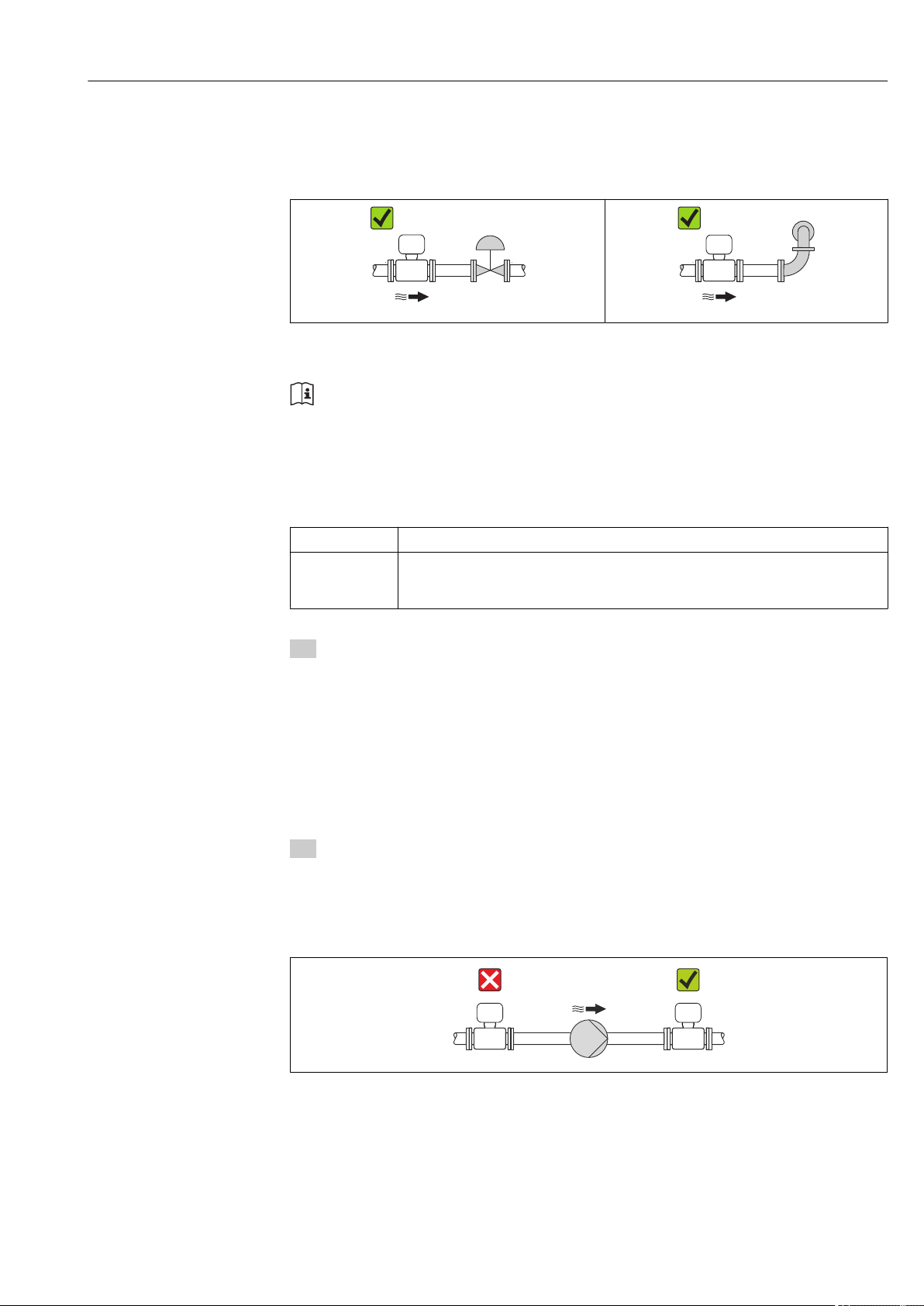

Inlet and outlet runs

No special precautions need to be taken for fittings which create turbulence, such as

valves, elbows or T-pieces, as long as no cavitation occurs (→ 21).

A0015597 A0015598

Installation dimensions

For the dimensions and installation lengths of the device, see the "Technical

Information" document, "Mechanical construction" section

6.1.2 Requirements from environment and process

Ambient temperature range

Measuring device –40 to +60 °C (–40 to +140 °F)

Local display –20 to +60 °C (–4 to +140 °F)

The readability of the display may be impaired at temperatures outside the temperature

range.

If operating outdoors:

‣

Avoid direct sunlight, particularly in warm climatic regions.

System pressure

It is important that cavitation does not occur, or that gases entrained in the liquids do not

outgas.

Cavitation is caused if the pressure drops below the vapor pressure:

• In liquids that have a low boiling point (e.g. hydrocarbons, solvents, liquefied gases)

• In suction lines

Ensure the system pressure is sufficiently high to prevent cavitation and outgassing.

‣

For this reason, the following mounting locations are recommended:

• At the lowest point in a vertical pipe

• Downstream from pumps (no danger of vacuum)

A0015594

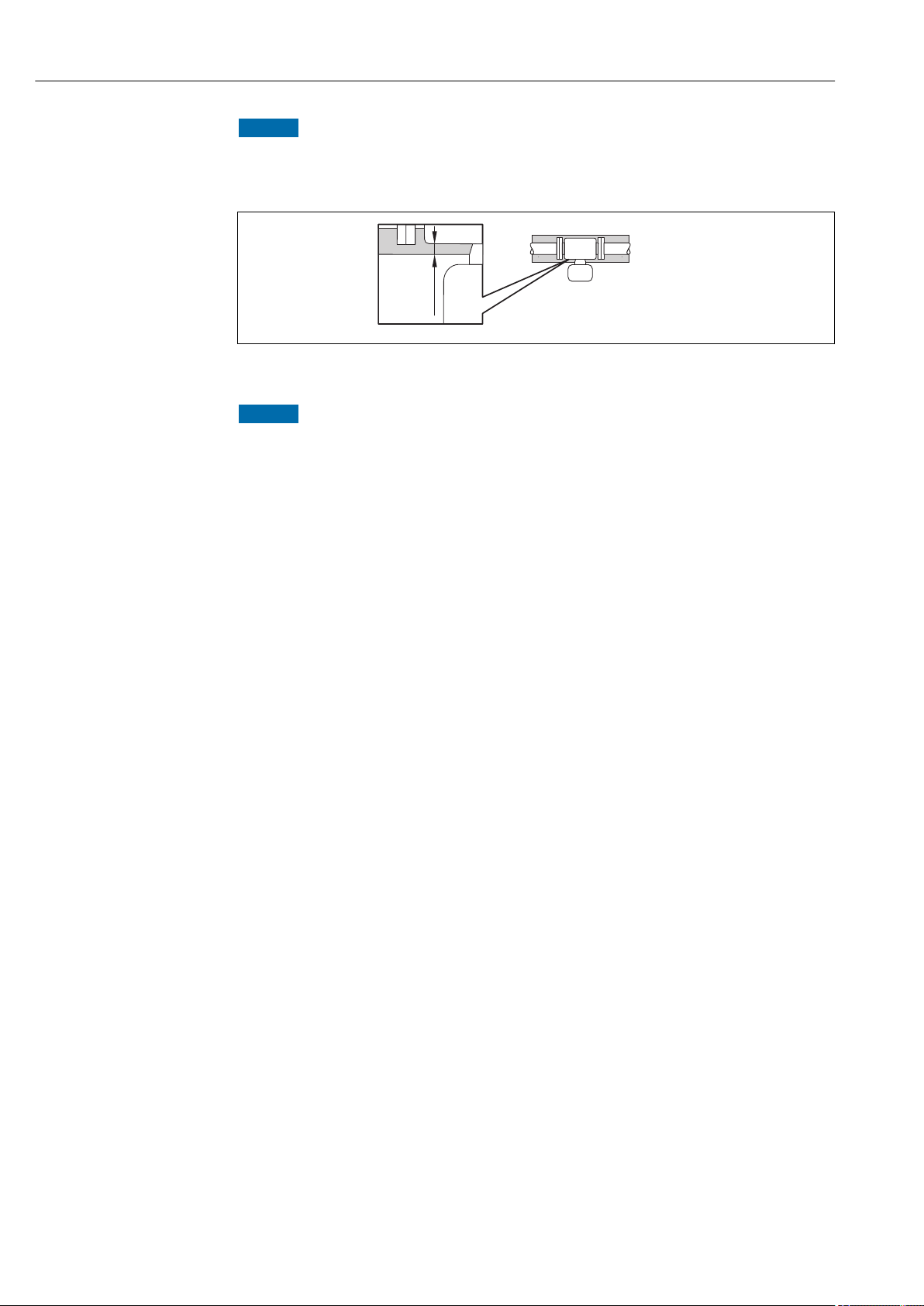

Thermal insulation

In the case of some fluids, it is important that the heat radiated from the sensor to the

transmitter is kept to a minimum. A wide range of materials can be used for the required

insulation.

Endress+Hauser 21

Installation Proline Promass E 200 FOUNDATION Fieldbus

mm (in)

£ 20 (0.79)

NOTICE

Electronics overheating on account of thermal insulation!

Observe maximum permitted insulation height of the transmitter neck so that the

‣

transmitter head is completely free.

A0016749

Heating

NOTICE

Electronics can overheat due to elevated ambient temperature!

Observe maximum permitted ambient temperature for the transmitter (→ 21).

‣

Depending on the fluid temperature, take the device orientation requirements into

‣

account .

Heating options

If a fluid requires that no heat loss should occur at the sensor, users can avail of the

following heating options:

• Electrical heating, e.g. with electric band heaters

• Via pipes carrying hot water or steam

• Via heating jackets

Using an electrical trace heating system

If heating is regulated via phase angle control or pulse packages, magnetic fields can affect

the measured values (= for values that are greater than the values approved by the EN

standard (sine 30 A/m)).

For this reason, the sensor must be magnetically shielded: the housing can be shielded

with tin plates or electric sheets without a privileged direction (e.g. V330-35A).

The sheet must have the following properties:

• Relative magnetic permeability µr ≥ 300

• Plate thickness d ≥ 0.35 mm (d ≥ 0.014 in)

Vibrations

The high oscillation frequency of the measuring tubes ensures that the correct operation of

the measuring system is not influenced by plant vibrations.

6.1.3 Special mounting instructions

Rupture disk

Make sure that the function and operation of the rupture disk is not impeded through the

installation of the device. The position of the rupture disk is indicated on a sticker applied

over it. If the rupture disk is triggered, the sticker is destroyed. The disk can therefore be

visually monitored. For additional information that is relevant to the process (→ 127).

22 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Installation

RUPTURE DISK

i

A0007823

6 Rupture disk label

After the rupture disk is actuated, do not operate the measuring device any more.

‣

WARNING

!

Limited functional reliability of the rupture disk.

Danger to persons from escaping fluids!

Do not remove the rupture disk.

‣

When using a rupture disk, do not use a heating jacket.

‣

Make sure that the function and operation of the rupture disk is not impeded through

‣

the installation of the device.

Take precautions to prevent damage and danger to persons if the rupture disk is

‣

actuated.

Observe information on the rupture disk sticker.

‣

Zero point adjustment

All measuring devices are calibrated in accordance with state-of-the-art technology.

Calibration takes place under reference conditions (→ 123). Therefore, a zero point

adjustment in the field is generally not required.

Experience shows that zero point adjustment is advisable only in special cases:

• To achieve maximum measuring accuracy even with low flow rates

• Under extreme process or operating conditions (e.g. very high process temperatures or

very high-viscosity fluids).

Zero point adjustment is performed via the Zero point adjustment control parameter

(→ 66).

6.2 Mounting the measuring device

6.2.1 Required tools

For transmitter

• For turning the transmitter housing: Open-ended wrench8 mm

• For opening the securing clamps: Allen key3 mm

For sensor

For flanges and other process connections: Corresponding mounting tools

6.2.2 Preparing the measuring device

1. Remove all remaining transport packaging.

2. Remove any protective covers or protective caps present from the sensor.

3. If present, remove transport protection of the rupture disk.

4. Remove stick-on label on the electronics compartment cover.

Endress+Hauser 23

Installation Proline Promass E 200 FOUNDATION Fieldbus

max.350°

8mm

8mm

6.2.3 Mounting the measuring device

WARNING

!

Danger due to improper process sealing!

Ensure that the inside diameters of the gaskets are greater than or equal to that of the

‣

process connections and piping.

Ensure that the gaskets are clean and undamaged.

‣

Install the gaskets correctly.

‣

1. Ensure that the direction of the arrow on the nameplate of the sensor matches the

flow direction of the fluid.

2. Install the measuring device or turn the transmitter housing so that the cable entries

do not point upwards.

A0013964

6.2.4 Turning the transmitter housing

To provide easier access to the connection compartment or display module, the transmitter

housing can be turned.

A0013713

1. Release the fixing screw.

2. Turn the housing to the desired position.

3. Firmly tighten the securing screw.

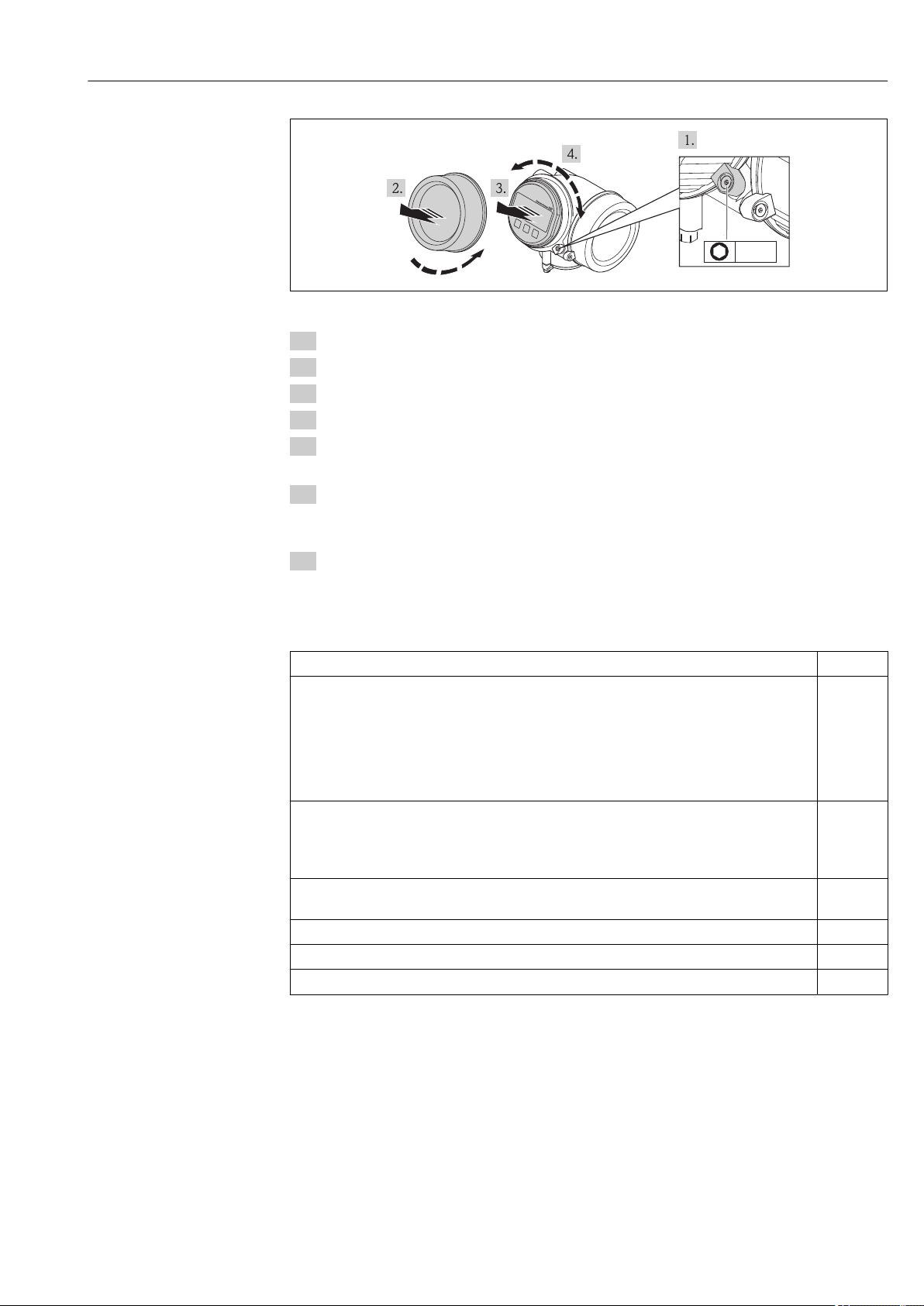

6.2.5 Turning the display module

The display module can be turned to optimize display readability and operability.

24 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Installation

+

E

–

1

3mm

A0013905

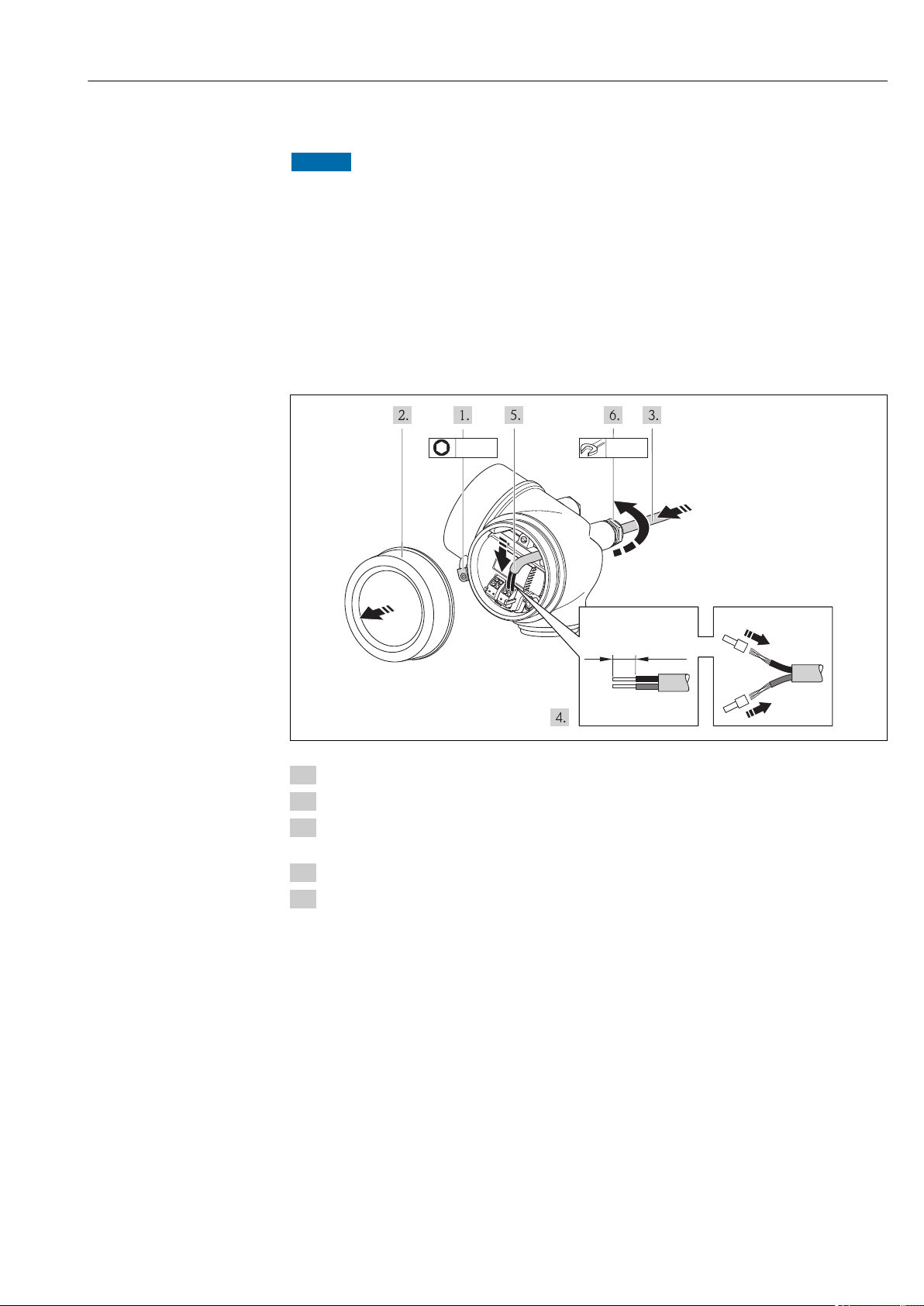

1. Loosen the securing clamp of the electronics compartment cover using an Allen key.

2. Unscrew cover of the electronics compartment from the transmitter housing.

3. Optional: pull out the display module with a gentle rotational movement.

4. Rotate the display module into the desired position: Max. 8 × 45° in each direction.

5. Without display module pulled out:

Allow display module to engage at desired position.

6. With display module pulled out:

Feed the cable into the gap between the housing and main electronics module and

plug the display module into the electronics compartment until it engages.

7. Reverse the removal procedure to reassemble the transmitter.

6.3 Post-installation check

Is the device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature (→ 127)

• Process pressure (refer to the chapter on "Pressure-temperature ratings" of the "Technical

Information" document)

• Ambient temperature (→ 21)

• Measuring range (→ 115)

Has the correct orientation for the sensor been selected ?

• According to sensor type

• According to medium temperature

• According to medium properties (outgassing, with entrained solids)

Does the arrow on the sensor nameplate match the direction of flow of the fluid through the

piping (→ 20)?

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected from precipitation and direct sunlight?

Are the securing screw and securing clamp tightened securely?

Endress+Hauser 25

Electrical connection Proline Promass E 200 FOUNDATION Fieldbus

7 Electrical connection

The measuring device does not have an internal circuit breaker. For this reason,

assign the measuring device a switch or power-circuit breaker so that the power

supply line can be easily disconnected from the mains.

7.1 Connection conditions

7.1.1 Required tools

• For cable entries: Use corresponding tools

• For securing clamp: Allen key 3 mm

• Wire stripper

• When using stranded cables: crimping tool for ferrule

• For removing cables from terminal: flat blade screwdriver ≤3 mm (0.12 in)

7.1.2 Requirements for connecting cable

The connecting cables provided by the customer must fulfill the following requirements.

Electrical safety

In accordance with applicable federal/national regulations.

Permitted temperature range

• –40 °C (–40 °F) to +80 °C (+176 °F)

• Minimum requirement: cable temperature range ≥ ambient temperature +20 K

Signal cable

FOUNDATION Fieldbus

Twisted, shielded two-wire cable.

For further information on planning and installing FOUNDATION Fieldbus networks

see:

• Operating Instructions for "FOUNDATION Fieldbus Overview" (BA00013S)

• FOUNDATION Fieldbus Guideline

• IEC 61158-2 (MBP)

Pulse/frequency/switch output

Standard installation cable is sufficient.

Cable diameter

• Cable glands supplied:

M20 × 1.5 with cable 6 to 12 mm (0.24 to 0.47 in)

• Plug-in spring terminals for device version without integrated overvoltage protection:

wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Screw terminals for device version with integrated overvoltage protection: wire crosssections 0.2 to 2.5 mm2 (24 to 14 AWG)

26 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Electrical connection

–

4

+

1

–

2

+

3

1

2

3

+

1

–

2

–

4

+

3

1

2

3

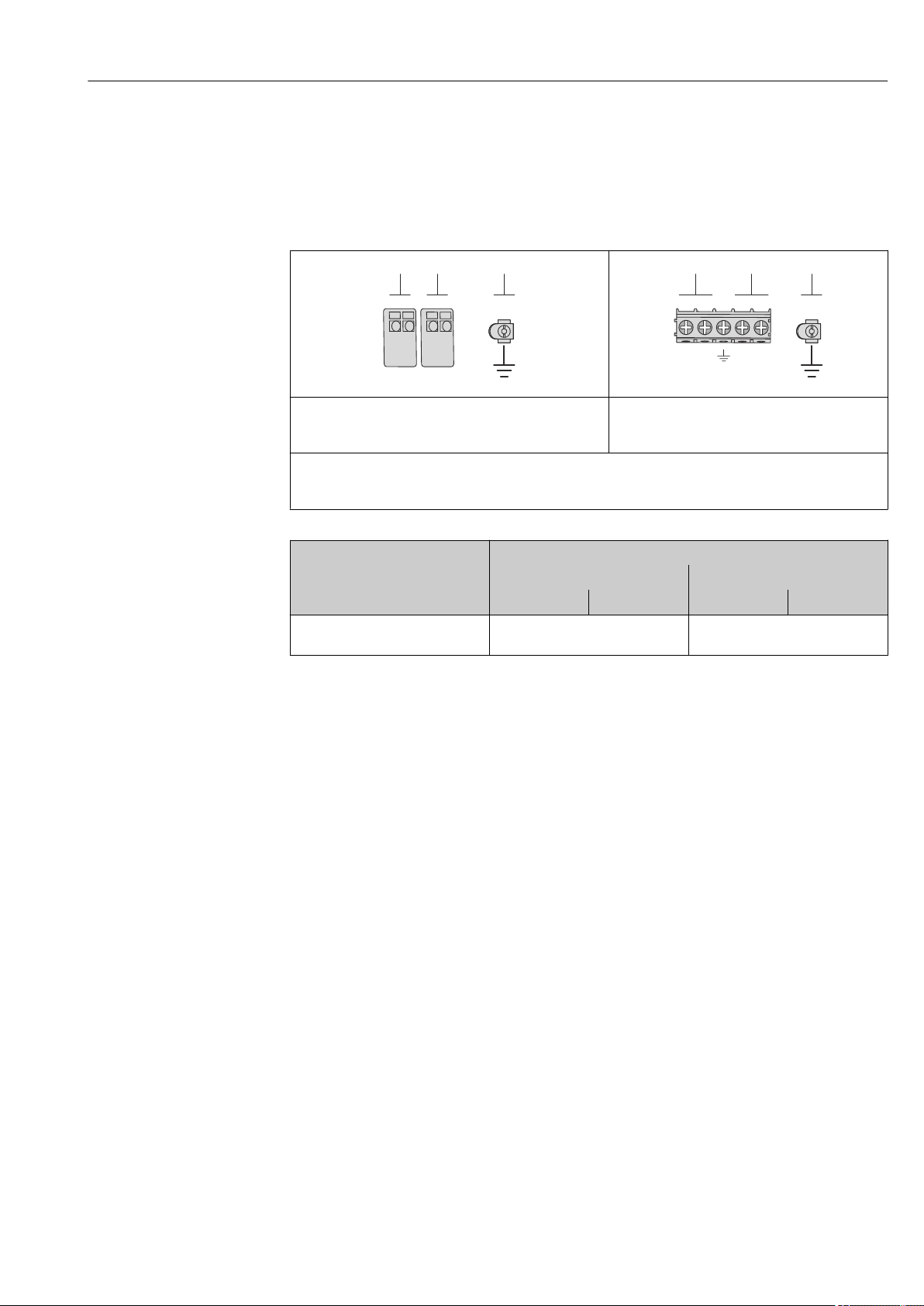

7.1.3 Terminal assignment

Transmitter

Connection version for FOUNDATION Fieldbus, pulse/frequency/switch output

A0013570

Maximum number of terminals Maximum number of terminals for order code for

"Accessory mounted", option NA "Overvoltage

protection"

1

Output 1: FOUNDATION Fieldbus

2

Output 2 (passive: pulse/frequency/switch output

3

Ground terminal for cable shield

Order code for "Output" Terminal numbers

Output 1 Output 2

1 (+) 2 (-) 3 (+) 4 (-)

1) 2)

Option E

1) Output 1 must always be used; output 2 is optional.

2) FOUNDATION Fieldbus with integrated reverse polarity protection.

FOUNDATION Fieldbus

Pulse/frequency/switch output

(passive)

A0018161

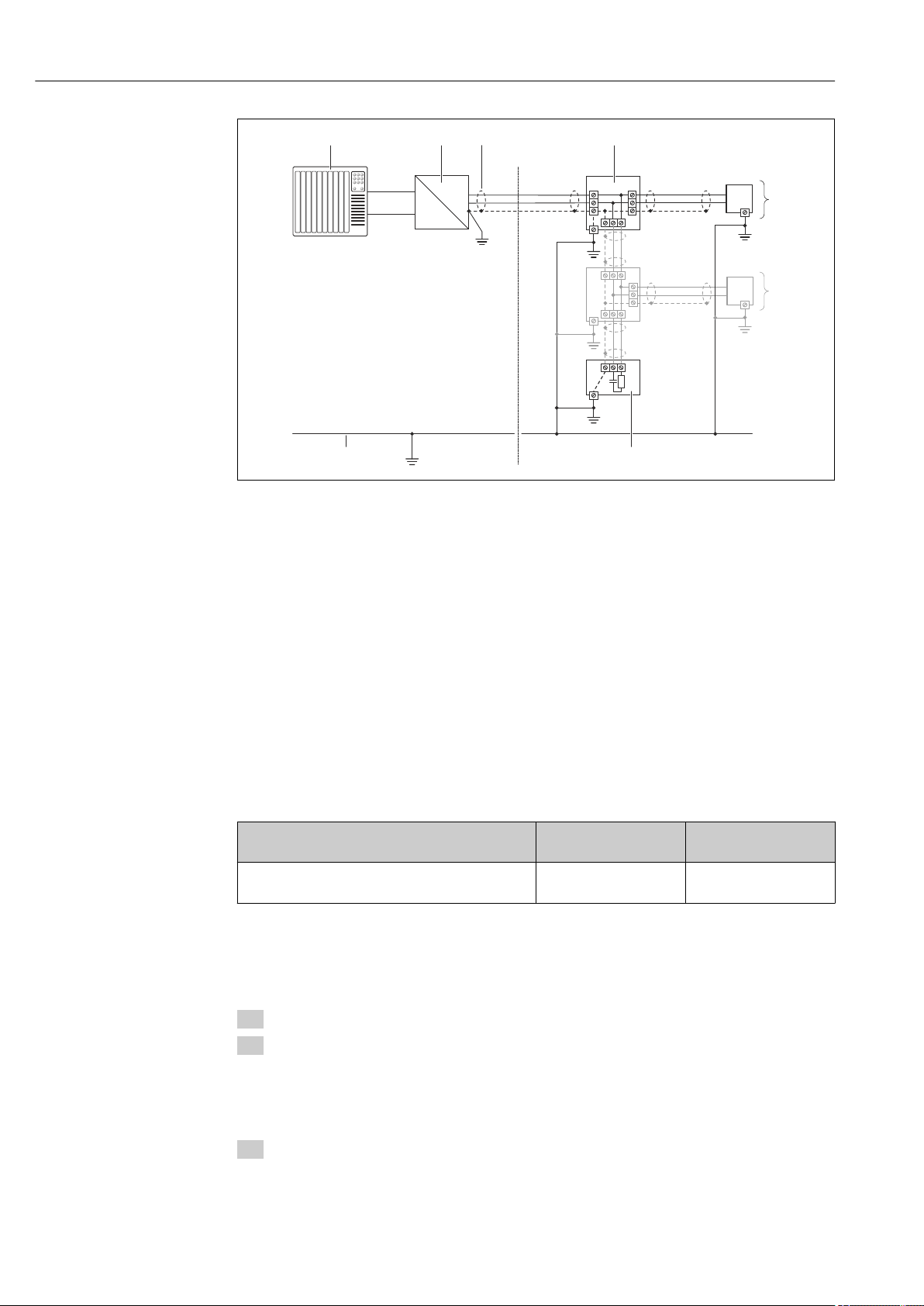

7.1.4 Shielding and grounding

Optimum electromagnetic compatibility (EMC) of the fieldbus system can only be

guaranteed if the system components and, in particular, the lines are shielded and the

shield forms as complete a cover as possible. A shield coverage of 90% is ideal.

• To ensure an optimum EMC protective effect, connect the shield as often as possible to

the reference ground.

• For reasons of explosion protection, you should refrain from grounding however.

To comply with both requirements, the fieldbus system allows three different types of

shielding:

• Shielding at both ends.

• Shielding at one end on the feed side with capacitance termination at the field device.

• Shielding at one end on the feed side.

Experience shows that the best results with regard to EMC are achieved in most cases in

installations with one-sided shielding on the feed side (without capacitance termination at

the field device). Appropriate measures with regard to input wiring must be taken to allow

unrestricted operation when EMC interference is present. These measures have been

taken into account for this device. Operation in the event of disturbance variables as per

NAMUR NE21 is thus guaranteed.

Where there are large differences in potential between the individual grounding points,

only one point of the shielding is connected directly with the reference ground. In systems

without potential equalization, therefore, cable shielding of fieldbus systems should only

be grounded on one side, for example at the fieldbus supply unit or at safety barriers.

Endress+Hauser 27

Electrical connection Proline Promass E 200 FOUNDATION Fieldbus

21 3

+

-

+

-

+

-

4

5

5

78

6

6

6

6

6

6

.

-

A0019004

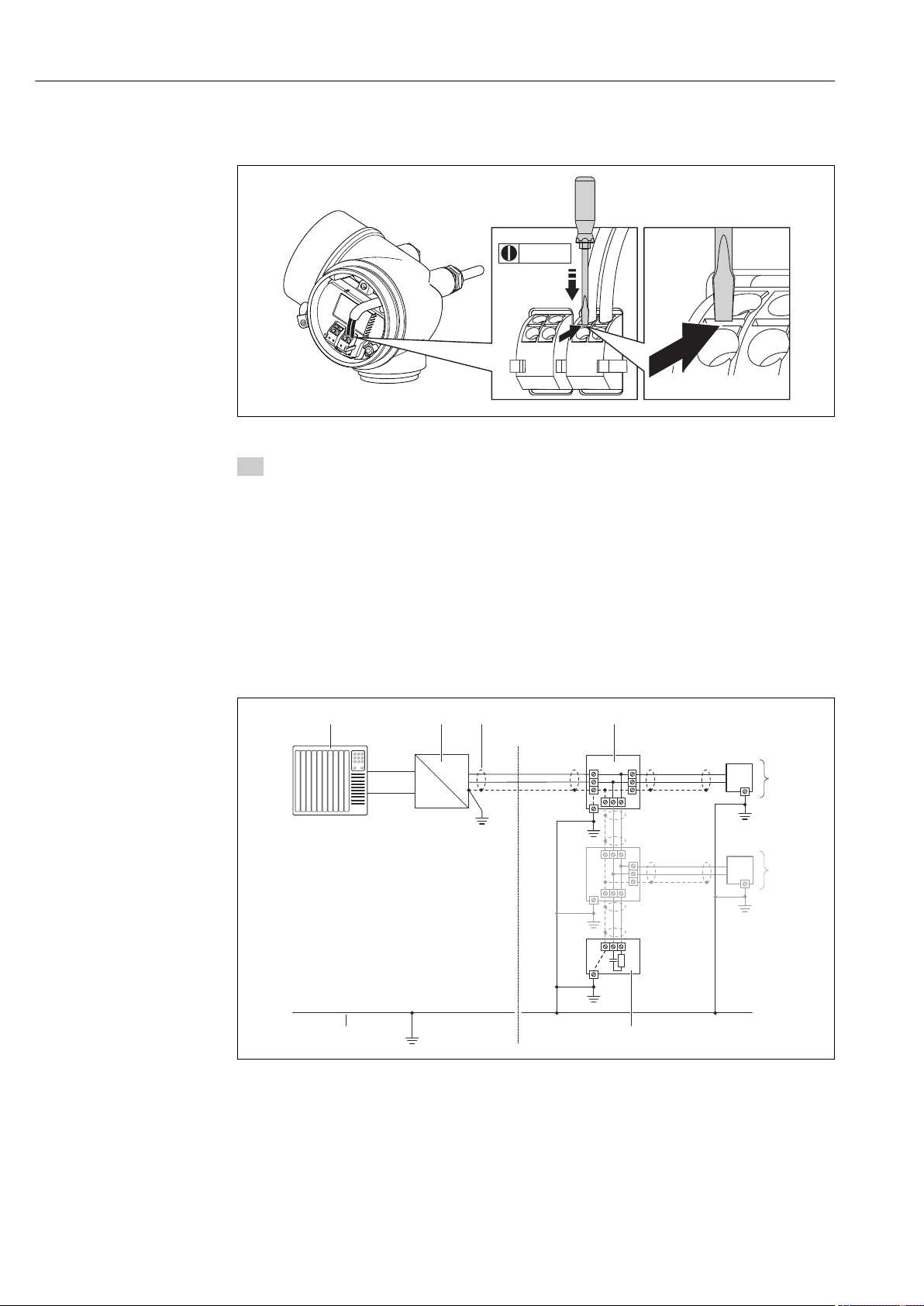

1 Controller (e.g. PLC)

2 Power Conditioner (FOUNDATION Fieldbus)

3 Cable shield

4 T-box

5 Measuring device

6 Local grounding

7 Bus terminator

8 Potential matching line

7.1.5 Requirements for the supply unit

Supply voltage

Transmitter

An external power supply is required for each output. The following supply voltage values

apply for FOUNDATION Fieldbus and the pulse/frequency/switch output:

Order code for "Output"

1)

Option E

switch output

1) For device versions with local display SD03: The terminal voltage must be increased by DC 0.5 V if

: FOUNDATION Fieldbus, pulse/frequency/

backlighting is used.

Minimum terminal

voltage

≥DC 9 V DC 32 V

Maximum terminal

voltage

7.1.6 Preparing the measuring device

1. Remove dummy plug if present.

2. NOTICE! Insufficient sealing of the housing! Operational reliability of the measuring

device could be compromised. Use suitable cable glands corresponding to the degree

of protection.

If measuring device is delivered without cable glands:

Provide suitable cable gland for corresponding connecting cable (→ 26).

3. If measuring device is delivered with cable glands:

Observe cable specification (→ 26).

28 Endress+Hauser

Proline Promass E 200 FOUNDATION Fieldbus Electrical connection

10(0.4)

mm(in)

20 mm3mm

7.2 Connecting the measuring device

NOTICE

Limitation of electrical safety due to incorrect connection!

Have electrical connection work carried out by correspondingly trained specialists only.

‣

Observe applicable federal/national installation codes and regulations.

‣

Comply with local workplace safety regulations.

‣

For use in potentially explosive atmospheres, observe the information in the device-

‣

specific Ex documentation.

7.2.1 Connecting the transmitter

Connection via terminals

1. Loosen the securing clamp of the connection compartment cover.

2. Unscrew the connection compartment cover.

3. Push the cable through the cable entry . To ensure tight sealing, do not remove the

sealing ring from the cable entry.

4. Strip the cable and cable ends. In the case of stranded cables, also fit ferrules.

5. WARNING! Housing degree of protection may be voided due to insufficient sealing of

the housing. Screw in the screw without using any lubricant. The threads on the

cover are coated with a dry lubricant.

Reverse the removal procedure to reassemble the transmitter.

A0013836

Endress+Hauser 29

Electrical connection Proline Promass E 200 FOUNDATION Fieldbus

mm (in)

213 4

3 (0.12)

21 3

+

-

+

-

+

-

4

5

5

78

6

6

6

6

6

6

.

-

Removing a cable

A0013835

To remove a cable from the terminal, use a flat-blade screwdriver to push the slot

‣

between the two terminal holes while simultaneously pulling the cable end out of the

terminal.

7.3 Special connection instructions

7.3.1 Connection examples

FOUNDATION Fieldbus

7 Connection example for FOUNDATION Fieldbus

30 Endress+Hauser

1 Control system (e.g. PLC)

2 Power Conditioner (FOUNDATION Fieldbus)

3 Cable shield

4 T-box

5 Measuring device

6 Local grounding

7 Bus terminator

8 Potential matching line

A0019004

Loading...

Loading...