Endress+Hauser Liquiphant M with FEL56, Liquiphant S with FEL56, Nivotester FTL325N-**** Series, Nivotester FTL325N Functional Safety Manual

Products Solutions Services

SD00188F/00/EN/13.13

71238762

Functional safety manual

Liquiphant M/S with FEL56

and Nivotester FTL325N

Level Limit Measuring System

[Ex ia]

CH1

CH1

FTL325N

T

[Ex ia]

CH1 CH2

CH3

CH1 CH2CH3

T

FTL325N

Application

Minimum detection (also dry running protection) of all

types of liquids in tanks to satisfy particular safety systems

requirements as per IEC 61508/IEC 61511-1.

The measuring device fulfils the requirements concerning

• Safety functions up to SIL 2

• Explosion protection by intrinsic safety or flameproof

enclosure

• EMC to EN 61326 and NAMUR Recommendation

NE 21.

Your benefits

• For minimum detection up to SIL 2

– Independently assessed (Functional Assessment) by

exida.com as per IEC 61508/IEC 61511-1

• Monitoring for corrosion on the tuning fork of the

sensor

• No calibration

• Fault message for circuit break and short-circuit

• Functional test of subsequent devices at the push

of a button

• Protected against outside vibration

• Easy commissioning

Liquiphant M/S with FEL56 and Nivotester FTL325N

2 Endress+Hauser

Table of contents

SIL declaration of conformity . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General depiction of a safety system (protection function) . . . 4

Structure of the measuring system . . . . . . . . . . . . . . . .5

Level limit measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Permitted device types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety function data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supplementary device documentation . . . . . . . . . . . . . . . . . . . . 7

Settings and installation instructions . . . . . . . . . . . . . .9

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Response in operation and failure . . . . . . . . . . . . . . . 10

Recurrent function tests of the measuring system . 10

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Specific values and wiring options for the

measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Exida Management Summary . . . . . . . . . . . . . . . . . . . 18

Supplementary Documentation . . . . . . . . . . . . . . . . . . . . . . . . . 20

Liquiphant M/S with FEL56 and Nivotester FTL325N

Endress+Hauser 3

SIL declaration of conformity

SIL-04001B-00-A2

Liquiphant M/S with FEL56 and Nivotester FTL325N

4 Endress+Hauser

Introduction

General depiction of a

safety system

(protection function)

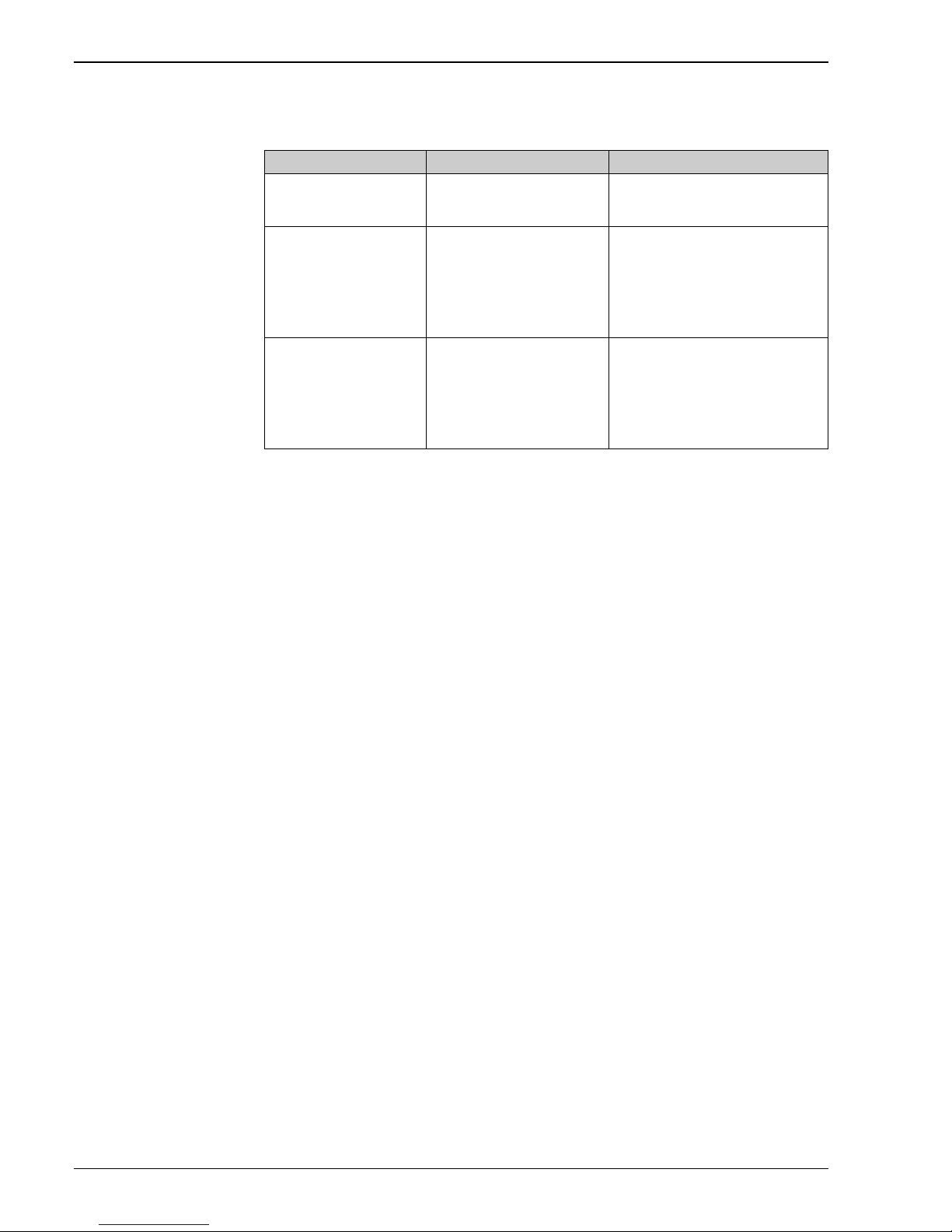

Parameter tables for determining Safety Integrity Level (SIL)

The following tables are used to define the reachable SIL or the requirements pertaining to the

“Average Probability of Dangerous Failure on Demand” (PFDav), the “Hardware Fault Tolerance” (HFT)

and the “Safe Failure Fraction” (SFF) of the safety system. The specific values for the Liquiphant M/S +

Nivotester FTL325N measuring system can be found in the Appendix.

Permitted probabilities of dangerous failures on demand of the complete safety related system

dependent on the SIL (e.g. exceeding a defined MIN level/switch point) (Source: IEC 61508, Part 1):

The following table shows the achievable Safety Integrity Level (SIL) as a function of the probability

fraction of safety-oriented failures and the "hardware fault tolerance" of the complete safety system for

type B systems (complex components, not all faults are known or can be described).

For general informationen about SIL please refer to: www.endress.com/sil

SIL PFD

av

4 10

5

to < 10

4

3 104 to < 10

3

2 103 to < 10

2

1 102 to < 10

1

SFF HFT

0 1 (0)

1)

1) In accordance with IEC 61511-1 (FDIS) (chapter 11.4.4), the HFT can be reduced by one (values in brackets)

if the devices used fulfil the following conditions:

- The device is proven in use,

- Only process-relevant parameters can be changed at the device (e.g. measuring range, ...),

- Changing the process-relevant parameters is protected (e.g. password, jumper, ...),

- The safety function requires less than SIL 4.

All conditions apply to Liquiphant M/S + Nivotester FTL325N.

2 (1)

1

< 60% not allowed SIL 1 SIL 2

60% to < 90% SIL 1 SIL 2 SIL 3

90% to < 99% SIL 2 SIL 3

99% SIL 3

Liquiphant M/S with FEL56 and Nivotester FTL325N

Endress+Hauser 5

Structure of the measuring system

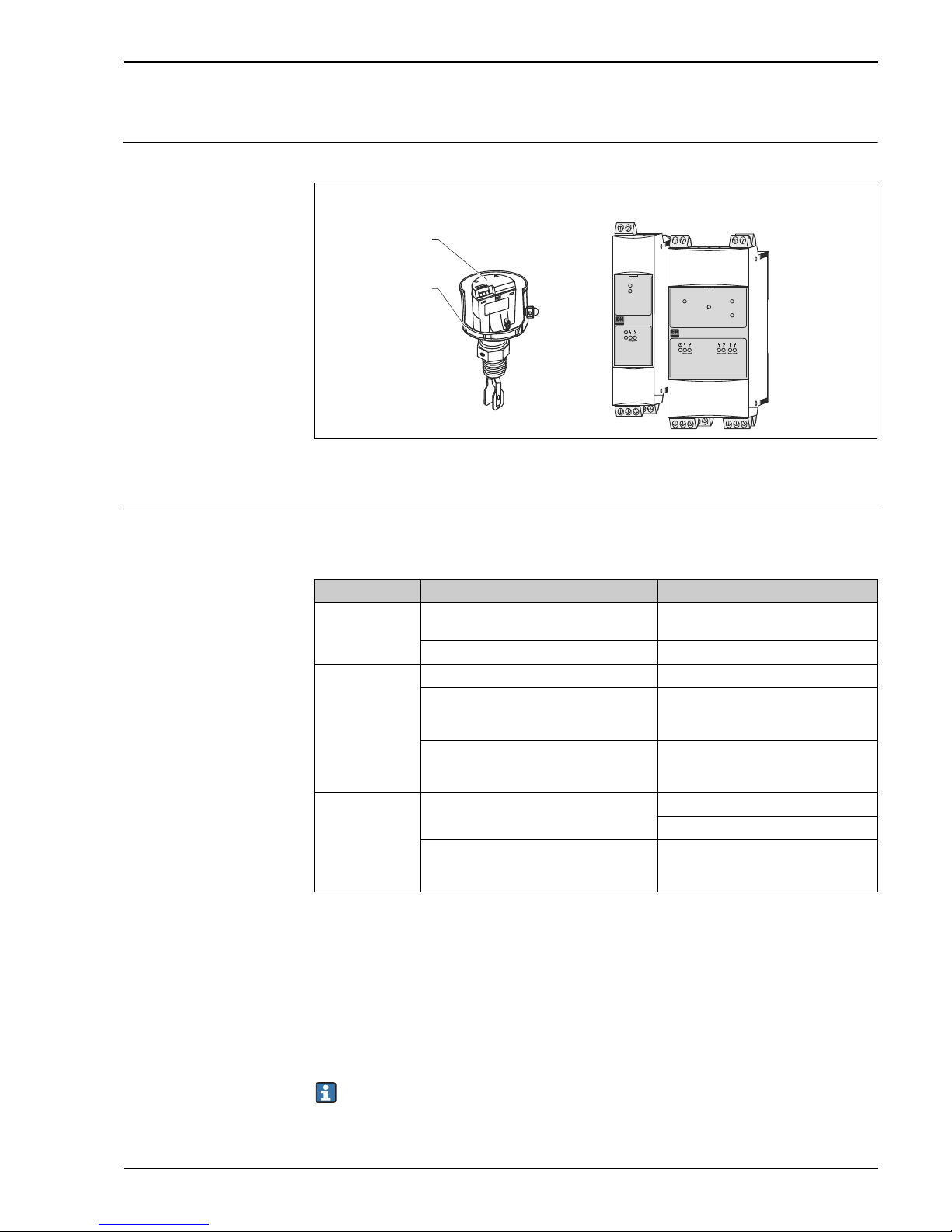

Level limit measuring system The measuring system's devices are displayed in the following diagram (example).

A0022173

1 FEL - Electronic insert A Nivotester FTL325N (one-channel)

2 Liquiphant M/S B Nivotester FTL325N (three-channel)

Safety function The safety function applies to all settings in MIN safety (monitoring of the covered state) and use of

the NO contacts of the level relays.

The following settings are permitted for the safety function:

The level relay always works in quiescent current safety; i.e. the relay releases when:

• The switch point is undershot (level falls below response height)

• A detected fault occurs

• The mains voltage fails

In addition to the level relay, the alarm relay works in quiescent current safety and releases when:

• One of the following faults occurs:

– the sensor connection is interrupted

– the sensor connection short circuits

• The mains voltage fails

[Ex ia]

CH1

CH1

FTL325

T

[Ex ia]

CH1 CH2

CH3

CH1 CH2 CH3

T

FTL325

AB

1

2

Device Setting As-delivered state

Liquiphant • Density switch setting: 0,5

• Density switch setting: 0,7

Density switch setting: 0,7

"MIN" safety "MAX" safety

Nivotester

FTL325N-#3#3

Error current signal > 2,1 mA Error current signal > 2,1 mA

All settings except

"S function" (see section "Settings and installation instructions")

Three-channel operation

The DIL switch for fault messaging

(short-circuit-, and circuit break-monitoring)

must be set to the ON position.

Failure switch "ON"

Nivotester

FTL325N-#1#1

Error current signal > 2,1 mA Error current signal > 2,1 mA

One-channel operation

The DIL switch for fault messaging

(short-circuit-, and circuit break-monitoring)

must be set to the ON position.

Failure switch "ON"

When the alarm relay releases, the level relay also releases.

Liquiphant M/S with FEL56 and Nivotester FTL325N

6 Endress+Hauser

Permitted device types The details pertaining to functional safety in this manual relate to the device versions listed below and

are valid as of the specified firmware and hardware version.

Unless otherwise specified, all subsequent versions can also be used for safety instrumented systems.

A modification process according to IEC 61508 is applied for device changes.

Valid device versions for safety-related use:

Valid firmware version: as of 01.00.00

Valid hardware version (electronics): as of 01.00

Valid device versions for safety-related use:

Valid firmware version: as of 01.00.00

Valid hardware version (electronics): as of 01.00

Valid device versions for safety-related use:

Liquiphant M FTL50, FTL50H, FTL51, FTL51C, FTL51H+ FEL56

Feature Designation Option model

010 Approval all

020 Process connection all

030 Probe length; Type all

040 Electronics; Output 6 FEL56; SIL NAMUR (L-H signal)

050 Housing; Cable Entry all

060 Additional options all

Liquiphant S FTL70, FTL71+ FEL56

Feature Designation Option model

010 Approval all

020 Process connection all

030 Probe length all

040 Electronics; Output 6 FEL56; SIL NAMUR (L-H signal)

050 Housing; Cable entry all

060 Additional option all

070 Application all

Nivotester FTL325N

Feature Designation Option model

010 Approval G

H

N

P

T

W

ATEX II 3(1)G Ex nC/A (ia) IIC T4, SIL, IECEx Zone 2

ATEX II (1)GD (Ex ia) IIC, WHG, SIL, IECEx (Ex ia) IIC

(Liquiphant M / Liquiphant S)

NEPSI (Ex ia) IIC, SIL (Liquiphant M / Liquiphant S)

FM IS Cl. I, II, III Div. 1 Gr. A-G, SIL (Liquiphant M / Liquiphant S)

CSA IS Cl. I, II, III Div. 1 Gr. A-G, SIL (Liquiphant M / Liquiphant S)

TIIS Ex ia IIC, SIL, labeling in Japan

020 Housing all

030 Power Supply all

040 Switch output all

Liquiphant M/S with FEL56 and Nivotester FTL325N

Endress+Hauser 7

Safety function data •The mandatory settings and data for the safety function can be found in chapter "Safety function",

ä 5 and chapter "Settings and installation instructions", ä 9.

• The measuring system reacts in 1,4 s.

Supplementary

device documentation

MTTR is set at eight hours.

Safety systems without a self-locking function must be monitored or set to an otherwise safe

state after carrying out the safety function within MTTR.

Liquiphant M FTL50, FTL50H, FTL51, FTL51H, FTL51C

Documentation Contents Comment

Technical Information

• FTL50, FTL50H, FTL51,

FTL51H:

TI00328F/00/EN

•FTL51C:

TI00347F/00/EN

–Technical data

– Accessories

– The documentation is available on the

Internet:

www.endress.com.

Operating Instructions

•FTL50, FTL51:

KA00143F/00/A6

KA00163F/00/A6

1)

• FTL50H, FTL51H:

KA00144F/00/A6

KA00164F/00/A6

)

•FTL51C:

KA00162F/00/A6

KA00165F/00/A6

)

1) with aluminium housing / separate terminal compartment.

– Installation

– Wiring

–Operation

– Commissioning

– Troubleshooting

– Repair

–Maintenance

– The documentation is supplied with the

device.

– The documentation is also available on

the Internet:

www.endress.com.

Safety instructions depending

on the selected version

"Approval"

Safety, installation and

operating instructions for devices,

which are suitable for use in

potentially explosive atmospheres

or as overfill

protection (WHG, German Water

Resources Act).

Additional safety instructions (XA, ZE) are

supplied with certified device versions.

Please refer to the nameplate for the relevant safety instructions.

Liquiphant S FTL70, FTL71

Documentation Contents Comment

Technical Information

TI00354F/00/EN

–Technical data

– Accessories

– The documentation is available on the

Internet:

www.endress.com.

Operating Instructions

KA00172F/00/A6

KA00173F/00/A6

1)

1) with aluminium housing / separate terminal compartment

– Installation

– Wiring

–Operation

– Commissioning

– Troubleshooting

– Repair

–Maintenance

– The documentation is supplied with the

device.

– The documentation is also available on

the Internet:

www.endress.com.

Safety instructions depending

on the selected version

"Approval"

Safety, installation and

operating instructions for devices,

which are suitable for use in

potentially explosive atmospheres

or as overfill

protection (WHG, German Water

Resources Act).

Additional safety instructions (XA, ZE) are

supplied with certified device versions.

Please refer to the nameplate for the relevant safety instructions.

Liquiphant M/S with FEL56 and Nivotester FTL325N

8 Endress+Hauser

Nivotester FTL325N

Documentation Contents Comment

Technical Information

TI00353F/00/EN

–Technical data

– Accessories

– The documentation is available on the

Internet:

www.endress.com.

Operating Instructions

• One-channel device:

KA00170F/00/A6

• Three-channel device:

KA00171F/00/A6

– Installation

– Wiring

–Operation

– Commissioning

– Troubleshooting

– Repair

–Maintenance

– The documentation is supplied with the

device.

– The documentation is also available on

the Internet:

www.endress.com.

Safety instructions depending

on the selected version

"Approval"

Safety, installation and

operating instructions for devices,

which are suitable for use in

potentially explosive atmospheres

or as overfill

protection (WHG, German Water

Resources Act).

Additional safety instructions (XA, ZE) are

supplied with certified device versions.

Please refer to the nameplate for the relevant safety instructions.

Loading...

Loading...