Page 1

BA01449D/06/EN/03.16

Power

Error

ESC

E

+

-

71311429

Valid as of version

V 3.00.9 (device software)

V 3.01.3 (Nanomass Communication)

Products Solutions Services

Operating Instructions

Nanomass Gas Density

MEMS Coriolis density meter

Page 2

Nanomass Gas Density

• Make sure the Operating Instructions are stored in a safe place such that they are always

available when working on or with the measuring device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the Operating Instructions that are

specific to working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to

these Operating Instructions.

2 Endress+Hauser

Page 3

Nanomass Gas Density

Table of contents

1 Notes on the Operating Instructions. . . 5

1.1 Document function . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Technical documentation . . . . . . . . . . . . . . . . . . . . . 6

1.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 7

2 Basic safety instructions . . . . . . . . . . . . . 8

2.1 Requirements for personnel . . . . . . . . . . . . . . . . . . 8

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Occupational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Product description . . . . . . . . . . . . . . . . 10

3.1 Product design . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . 11

4.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Product identification . . . . . . . . . . . . . . . . . . . . . . 11

5 Storage, transportation, disposal of

packaging . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Transporting the product . . . . . . . . . . . . . . . . . . . 14

5.3 Disposal of packaging . . . . . . . . . . . . . . . . . . . . . . 14

6 Installation . . . . . . . . . . . . . . . . . . . . . . . 15

10 Commissioning . . . . . . . . . . . . . . . . . . . 36

10.1 Installation and function check . . . . . . . . . . . . . . . 36

10.2 Switching on the measuring device . . . . . . . . . . . 36

10.3 Setting the operating language . . . . . . . . . . . . . . 36

10.4 Configuring the measuring device . . . . . . . . . . . . 36

10.5 Advanced settings . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.6 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10.7 "Datalog Function" application package . . . . . . . . 43

10.8 "Concentration Measurement" application package

44

11 Operation . . . . . . . . . . . . . . . . . . . . . . . . 47

11.1 Changing the operating language . . . . . . . . . . . . 47

11.2 Configuring the local display . . . . . . . . . . . . . . . . . 47

11.3 Reading measured values on the local display . . 47

11.4 Accessing real-time measuring data . . . . . . . . . . 48

11.5 Retrieving measuring data . . . . . . . . . . . . . . . . . . 51

11.6 Adapting the measuring device to the process

conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.7 Updating the firmware . . . . . . . . . . . . . . . . . . . . . 53

12 Diagnostics and troubleshooting . . . . 54

12.1 General troubleshooting . . . . . . . . . . . . . . . . . . . . 54

12.2 Diagnostic information via light emitting diodes . .

55

12.3 Diagnostic information on local display . . . . . . . . 55

12.4 Diagnostic information in the operating tool . . . 56

12.5 Resetting the measuring device to factory default

settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

12.6 Performing density adjustment with air . . . . . . . 57

12.7 Device information . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . 15

6.2 Mounting the measuring device . . . . . . . . . . . . . 18

6.3 Post-installation check . . . . . . . . . . . . . . . . . . . . . 19

7 Electrical connection . . . . . . . . . . . . . . . 20

7.1 Connection conditions . . . . . . . . . . . . . . . . . . . . . 20

7.2 Connecting the measuring device . . . . . . . . . . . . 22

7.3 Special connection instructions . . . . . . . . . . . . . . 24

7.4 Guaranteeing the degree of protection . . . . . . . 24

7.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 25

8 Operating options . . . . . . . . . . . . . . . . .26

8.1 Overview of operating options . . . . . . . . . . . . . . 26

8.2 Access to the measuring device via the local display

26

8.3 Access to the measuring device via the

"Nanomass Communication" operating tool . . . . 28

9 System integration. . . . . . . . . . . . . . . . . 34

9.1 Overview of device description files . . . . . . . . . . 34

9.2 Measured variables via serial interface . . . . . . . 34

13 Maintenance . . . . . . . . . . . . . . . . . . . . . 59

13.1 Maintenance tasks . . . . . . . . . . . . . . . . . . . . . . . . . 59

13.2 Measuring and test equipment . . . . . . . . . . . . . . . 59

13.3 Endress+Hauser services . . . . . . . . . . . . . . . . . . . . 60

14 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

14.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

14.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

14.3 Endress+Hauser services . . . . . . . . . . . . . . . . . . . . 61

14.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

14.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

15 Accessories. . . . . . . . . . . . . . . . . . . . . . . 63

15.1 Device-specific accessories . . . . . . . . . . . . . . . . . . 63

15.2 Service-specific accessories . . . . . . . . . . . . . . . . . 63

15.3 System components . . . . . . . . . . . . . . . . . . . . . . . . 64

16 Technical data . . . . . . . . . . . . . . . . . . . . 65

16.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

16.2 Function and system design . . . . . . . . . . . . . . . . . 65

Endress+Hauser 3

Page 4

Nanomass Gas Density

16.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

16.4 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

16.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

16.6 Performance characteristics . . . . . . . . . . . . . . . . . 67

16.7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

16.8 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

16.9 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

16.10 Mechanical construction . . . . . . . . . . . . . . . . . . . . 71

16.11 Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

16.12 Certificates and approvals . . . . . . . . . . . . . . . . . . . 73

16.13 Application packages . . . . . . . . . . . . . . . . . . . . . . . 73

16.14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

16.15 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

17 Appendix . . . . . . . . . . . . . . . . . . . . . . . . .75

17.1 Overview of the device parameters . . . . . . . . . . . 75

17.2 Menu "Measuring variables" "Main values" . . . 76

17.3 Menu "Measuring variables" "System units" . . . 77

17.4 Menu "Measuring variables" "Special units" . . . 78

17.5 Menu "User interface" "Display" . . . . . . . . . . . . . 79

17.6 Menu "User interface" "Assign" . . . . . . . . . . . . . 79

17.7 Menu "Output 4-20 mA" "Output channel 1" . . 81

17.8 Menu "Output 4-20 mA" "Output channel 2" . . 82

17.9 Menu "Output 4-20 mA"

"Response channel 1/2" . . . . . . . . . . . . . . . . . . . . . 83

17.10 Menu "Output 4-20 mA" "Simulation" . . . . . . . . 83

17.11 Menu "Basic function" "System parameter" . . . 84

17.12 Menu "Special function" "Density function" . . . 84

17.13 Menu "Supervision"

"Assign error prompt for channel 2" . . . . . . . . . . . 86

17.14 Menu "Device settings"

"Advanced configuration" . . . . . . . . . . . . . . . . . . . . 86

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

4 Endress+Hauser

Page 5

Nanomass Gas Density Notes on the Operating Instructions

DANGER

WARNING

CAUTION

NOTICE

1 Notes on the Operating Instructions

1.1 Document function

These Operating Instructions contain all the information that is required in the various

phases of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

A0011189-EN

A0011190-EN

A0011191-EN

A0011192-EN

result in serious or fatal injury.

WARNING

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium personal injury.

NOTE

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011197

Alternating current

A terminal to which alternating voltage is applied or through which alternating current

A0011198

A0017381

A0011200

flows.

Direct current and alternating current

• A terminal to which alternating voltage or DC voltage is applied.

• A terminal through which alternating current or direct current flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

1.2.3 Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Preferred

Indicates procedures, processes or actions that are preferred.

A0011183

Endress+Hauser 5

Page 6

Notes on the Operating Instructions Nanomass Gas Density

-

.

Symbol Meaning

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding measuring device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

1., 2., 3.,... Series of steps

Result of a sequence of actions

Help in the event of a problem

A0013562

Visual inspection

A0015502

1.2.4 Symbols in graphics

Symbol Meaning

1, 2, 3,... Item numbers

A, B, C, ... Views

A-A, B-B, C-C,.. Sections

Flow direction

A0013441

Hazardous area

Indicates the hazardous area.

A0011187

Safe area (non-hazardous area)

Indicates the non-hazardous area.

A0011188

1.2.5 Abbreviations

Abbreviation Meaning

MEMS Micro-Electro Mechanical System

1.3 Technical documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• CD-ROM provided.

• W@M Device Viewer: enter the serial number indicated on the nameplate

(www.endress.com/deviceviewer).

• The Endress+Hauser Operations App: enter the serial number indicated on the nameplate

or scan the 2-D matrix code (QR code) provided on the nameplate.

For a detailed list of the individual documents along with the documentation code (

74).

6 Endress+Hauser

Page 7

Nanomass Gas Density Notes on the Operating Instructions

1.3.1 Standard documentation

Document type Purpose and content of the document

Technical Information Planning aid for your measuring device

This document contains all the technical data for the measuring device and

provides an overview of the specific accessories and spare parts that can be

ordered.

Brief Operating Instructions Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information from

incoming acceptance to initial commissioning.

1.3.2 Supplementary device-dependent documentation

Additional documents are supplied depending on the device version ordered. The

instructions in the supplementary documentation must also be followed when

commissioning and operating the device. The supplementary documentation is an integral

part of the device documentation.

1.4 Registered trademarks

Applicator®, Nanomass

Registered or registration-pending trademarks of the Endress+Hauser Group

BOROFLOAT

®

Registered trademark of Schott AG, Jena, Germany

Microsoft

®

Registered trademark of the Microsoft Corporation, Redmond, Washington, USA

Swagelok

®

Registered trademark of Swagelok & Co., Solon, USA

®

Endress+Hauser 7

Page 8

Basic safety instructions Nanomass Gas Density

2 Basic safety instructions

2.1 Requirements for personnel

Personnel involved in installation, commissioning, diagnostics and maintenance must meet

the following requirements:

• Are trained specialists with relevant qualifications for the specific functions and tasks.

• Are authorized by the plant owner/operator.

• Are familiar with federal/national regulations.

• Before starting work, personnel must read and understand the instructions in the manual

and supplementary documentation as well as the certificates (depending on the

application).

• Follow instructions and comply with basic conditions.

Operating personnel must meet the following requirements:

• Are instructed and authorized according to the requirements of the task by the facility's

owner-operator.

• Follow the instructions in the manual.

2.2 Designated use

Application and media

The measuring device described in this manual is intended for the density and concentration

measurement of non-corrosive gases only. Only permitted media are allowed. See the

"Media" section ( 69).

Depending on the version ordered, the measuring device can also measure explosive and

flammable media.

Measuring devices designed for use in hazardous areas or in applications where the process

pressure poses a high risk are specially labeled as such on the nameplate.

To ensure that the measuring device remains in perfect condition during the operating time,

compliance with the following conditions is mandatory:

Only use the measuring device in full compliance with the data on the nameplate and the

general conditions in the Operating Instructions and supplementary documentation.

Based on the nameplate, check whether the ordered measuring device is permitted for

the intended use in the hazardous area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials are

adequately resistant. See the "Media" section ( 69).

If the measuring device is not operated at atmospheric temperature, compliance with

relevant basic conditions specified in the device documentation provided is absolutely

essential. See also the "Technical Documentation" ( 65).

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage

caused by improper or non-designated use.

Clarification of borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability as even minute changes in the temperature, concentration or level

of contamination in the process can alter the corrosion resistance properties.

Residual risks

Possible burn hazard due to fluid temperatures!

If fluid temperatures are high, ensure protection against contact to prevent burns.

8 Endress+Hauser

Page 9

Nanomass Gas Density Basic safety instructions

2.3 Occupational safety

If working on and with the measuring device:

Wear the required personal protective equipment according to federal/national

regulations.

2.4 Operational safety

Risk of injury!

Only operate the measuring device in proper technical condition, free from errors and

faults.

The operator is responsible for the interference-free operation of the device.

Modifications to the measuring device

Unauthorized modifications to the measuring device are not permitted and can lead to

unforeseeable dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

Repairs

To ensure continued operational safety and reliability:

Carry out repairs on the measuring device only if they are expressly permitted.

Observe federal/national regulations pertaining to repair of an electrical device.

Use original spare parts and accessories from Endress+Hauser only.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate. It meets general safety standards and legal requirements. It also

complies with the EC directives listed in the device-specific EC Declaration of Conformity.

Endress+Hauser confirms this by affixing the CE mark to the device.

2.6 IT security

We only provide a warranty if the measuring device is installed and used as described in the

Operating Instructions. The measuring device is equipped with security mechanisms to

protect it against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the measuring device and device data transfer must be

implemented by the operators themselves.

Endress+Hauser 9

Page 10

Product description Nanomass Gas Density

1

2 (3)

4

5

6

8

9

7

8

3 Product description

3.1 Product design

A0026432

Fig. 1: Important components of the measuring device (device version with RS232 interface)

1 Connection for 4-20mA analog outputs

2 RS232 interface for digital signal transmission (optional)

3 USB port for digital signal transmission and supply voltage (optional, not illustrated in graphic)

4Grounding clamp

5 Connection for supply voltage

6 Connection for pressure sensor

7 Pressure sensor

8 Connections for inlet and outlet

9 Local operation with display, operating elements and LED status indication

10 Endress+Hauser

Page 11

Nanomass Gas Density Incoming acceptance and product identification

1

2

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Is the order code on the delivery note (1) identical to the order code

on the product sticker (2)?

A0027449

Is the measuring device undamaged?

Do the nameplate data match the ordering information on the delivery note?

If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note.

• Enter the serial number indicated on the nameplate in W@M Device Viewer

(www.endress.com/deviceviewer): all the information about the measuring device is

displayed.

• Enter the serial number indicated on the nameplate into the Endress+Hauser Operations

App or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information about the measuring device is displayed.

For an overview of the scope of the Technical Documentation provided, refer to the

following:

• "Additional standard device documentation" section ( 7) and

"Supplementary device-dependent documentation" section ( 7)

• W@M Device Viewer: serial number indicated on the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: enter the serial number indicated on the nameplate

or scan the 2-D matrix code (QR code) provided on the nameplate.

Endress+Hauser 11

Page 12

Incoming acceptance and product identification Nanomass Gas Density

1

Order code:

Ext. ord. cd.:

Ser. no.:

Date:

FW: Dev.Rev.:

p max:

Tm/Ta:

Density range:

Suitable medium:

i

CRN no.:

2

3

4

5

6

7

8

9

10

11

12

14 15 19 20

21

22

23

161317

18

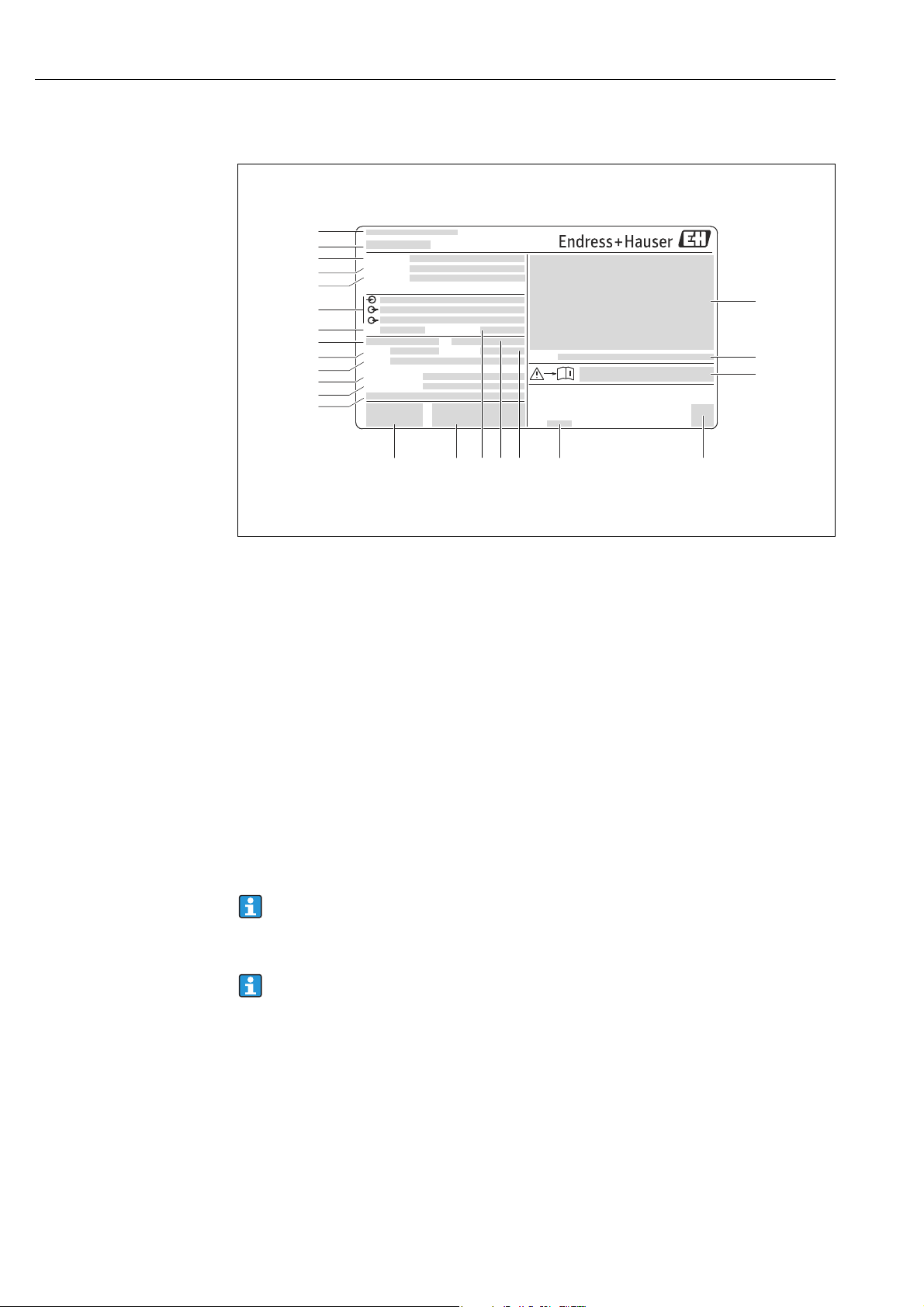

4.2.1 Nameplate

Fig. 2: Example of a nameplate

1 Place of manufacture

2 Name of the measuring device

3Order code

4 Serial number (ser. no.)

5 Extended order code (ext. ord. co.)

6 Electrical connection data, e.g. available inputs and outputs, supply voltage

7 Firmware version (FW)

8 Nominal diameter of the micro-channel

9 Maximum permitted system pressure

10 Permitted ambient temperature range (T

11 Permitted medium density range

12 Permitted media

13 Additional information on the device version: special product

14 CE mark, C-tick

15 Additional information on the device version: certificates, approvals

16 Device version (Dev.Rev.)

17 Nominal diameter of the process connection

18 IP protection class

19 Date of manufacture: year-month

20 2-D matrix code

21 Document number of safety-related supplementary documentation

22 Approval information for CRN

23 Approval information for explosion protection

) and medium temperature range (Tm)

a

Order code

The measuring device is reordered using the order code.

A0026851

Extended order code

• The device type (product root) and basic specifications (mandatory features) are always

12 Endress+Hauser

listed.

• With regard to optional specifications (optional features), only the safety and approvalrelated specifications are listed (e.g. LD). If other optional specifications have also been

ordered, they are indicated by the placeholder symbol "#" (e.g. #LD#).

• If ordered optional specifications do not include any safety and approval-related

specifications, they are indicated by the placeholder symbol (+).

(e.g. DCEBN7-AAACAA01AA11+).

Page 13

Nanomass Gas Density Incoming acceptance and product identification

4.2.2 Symbols on measuring device

Symbol Meaning

WARNING

#

A0011199

A0011194

This symbol alerts you to a life-threatening situation. Failure to avoid this situation

can result in serious or fatal injury.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Reference to documentation

Refers to the corresponding measuring device documentation.

Endress+Hauser 13

Page 14

Storage, transportation, disposal of packaging Nanomass Gas Density

5 Storage, transportation, disposal of packaging

5.1 Storage conditions

Observe the following notes for storage:

• Store in the original packaging to ensure protection from shock.

• Do not remove protection caps mounted on connections.

They prevent any dirt from entering the micro-electro mechanical system (MEMS).

• Protect from direct sunlight to avoid unacceptably high surface temperatures.

• Select a storage location where moisture cannot collect in the measuring device as fungus

and bacteria infestation can damage the MEMS.

• Store in a dry and dust-free place.

• Do not store outdoors.

• Storage temperature 68.

5.2 Transporting the product

Observe the following during transport:

• Transport the measuring device to the measuring point in the original packaging.

• Do not remove protection caps mounted on connections. They prevent contamination of

the MEMS.

• Observe the transport instructions on the adhesive label on the packaging.

5.3 Disposal of packaging

All packaging materials are environmentally friendly and 100% recyclable:

• Measuring device secondary packaging:

– Polymer stretch wrap

–PE foam

• Protection caps on process connections: polymer LDPE

• Packaging: box in accordance with European Packaging Directive 94/62EC;

recyclability is confirmed by the affixed recycling symbol.

• Carrying and mounting hardware:

– Disposable plastic pallet

– Plastic straps

– Plastic adhesive strips

• Dunnage: paper cushion

14 Endress+Hauser

Page 15

Nanomass Gas Density Installation

6Installation

6.1 Installation conditions

No special measures such as supports are necessary. External forces are absorbed by the

construction of the device.

6.1.1 Mounting position

Mounting location

The measuring device is usually installed in a bypass line. If flow rates are low, the device can

also be installed in the main pipe.

Installation in a bypass line is recommended in the following cases:

• Flow rate >1 l/min (0.26 gal/min.)

• Pipeline diameter >6 mm (0.24 in)

Orientation

The orientation of the device does not affect the measuring accuracy.

Flow direction

The flow direction does not affect the measuring accuracy.

Inlet and outlet runs

Inlet and outlet runs do not affect the measuring accuracy.

6.1.2 Requirements from environment and process

Ambient temperature range

Non-Ex version –20 to +60 °C (–4 to +140 °F)

Ex ia IIC T4 version –20 to +60 °C (–4 to +140 °F)

• If operating via USB port: operating temperature is limited to 0 to 60 °C (32 to 140 °F).

• If operating outdoors: avoid direct sunlight, particularly in warm climatic regions.

System pressure

Permitted absolute system

pressure

Max. 20 bar (290 psi)

The relative accuracy of the density measurement increases with increasing system

pressure.

Filter

To prevent the micro-channel from clogging, it is advisable to install a filter upstream from

the measuring device. The filter is included in the delivery.

• Recommended filter pore size: 15 m

Endress+Hauser 15

Page 16

Installation Nanomass Gas Density

1

2

2

34

ΔP < 0.1 bar (1.45 psi)

P2 < P1

P1 < 20 bar (290 psi)

Thermal insulation

Due to a low thermal capacity of the medium, the medium temperature can be greatly

affected by the ambient temperature through the supply line and the measuring device. The

influence of the ambient temperature on the medium temperature can be reduced by

insulating the supply line.

Vibrations

Due to the high operating frequency of the micro-channel, vibrations (<20 kHz) do not affect

measuring accuracy.

6.1.3 Special mounting instructions

Wall mounting

Use drill holes and M6 screws to secure the filter to a wall or a secure base.

A0026012

Pipe mounting

Use the "pipe mounting kit" accessory to secure to a pipe or post.

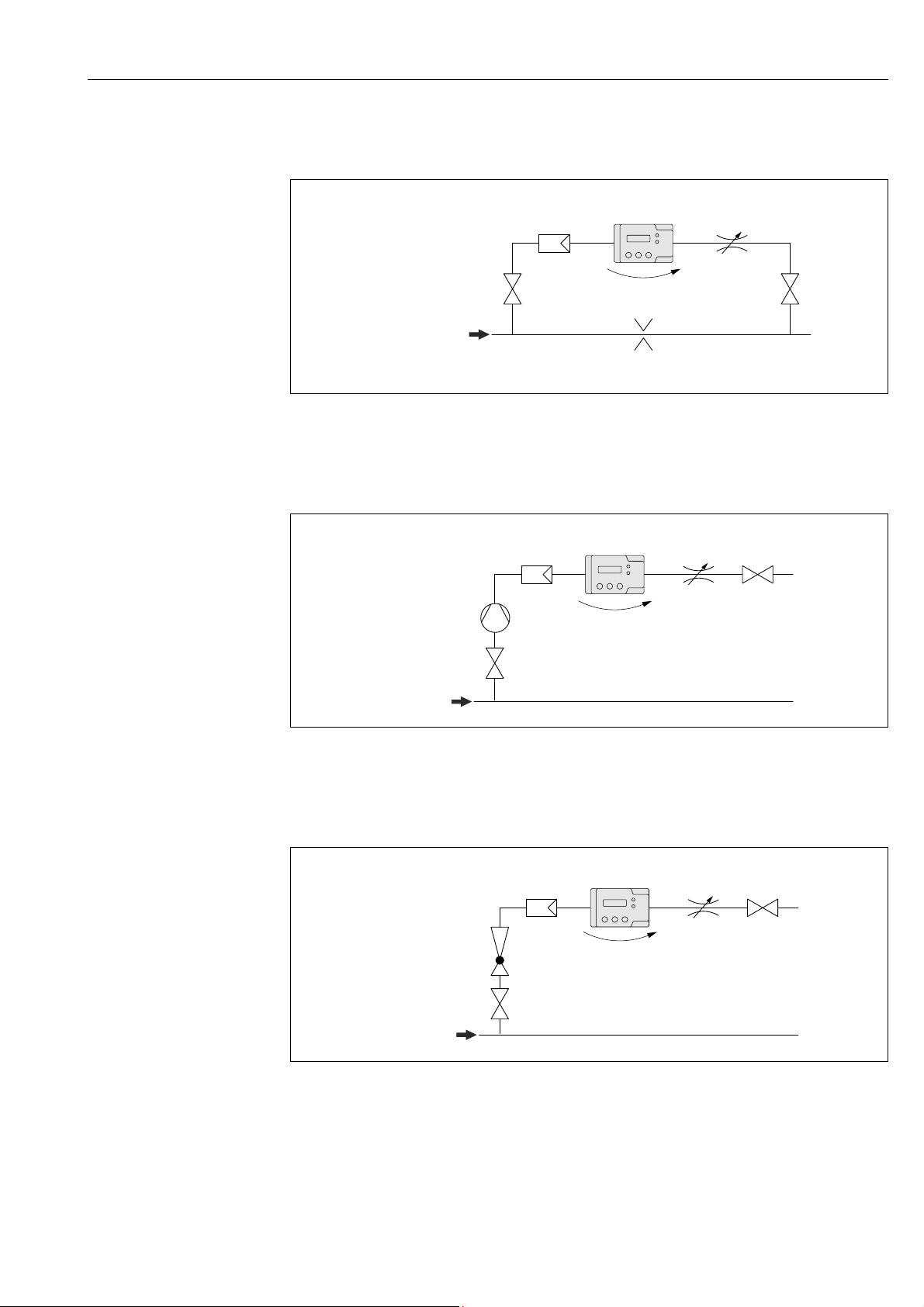

Installation in a bypass line

Note the following when installing in a bypass line:

• A pressure drop must be created for the medium to flow through the measuring device.

• The maximum permissible pressure drop of 0.1 bar (1.45 psi) across the measuring device

may not be exceeded.

• The bypass line can be routed to the atmosphere or back to the process pipe.

Examples:

• Create necessary pressure drop with throttle (or flow monitor) downstream from the

measuring device.

Fig. 3: 1 = Nanomass; 2 = Valve; 3 = Filter; 4 = Throttle

16 Endress+Hauser

A0026152

Page 17

Nanomass Gas Density Installation

1

22

34

ΔP < 0.1 bar (1.45 psi)

P1 < 20 bar (290 psi)

P2 < P1

5

1

2

2

34

ΔP < 0.1 bar (1.45 psi)

P3 < P2

P1

5

20 bar (290 psi) > P2 > P1

1

2

2

34

ΔP < 0.1 bar (1.45 psi)

P3 < P2

P1 > 20 bar (290 psi)

5

P2 < 20 bar (290 psi) < P1

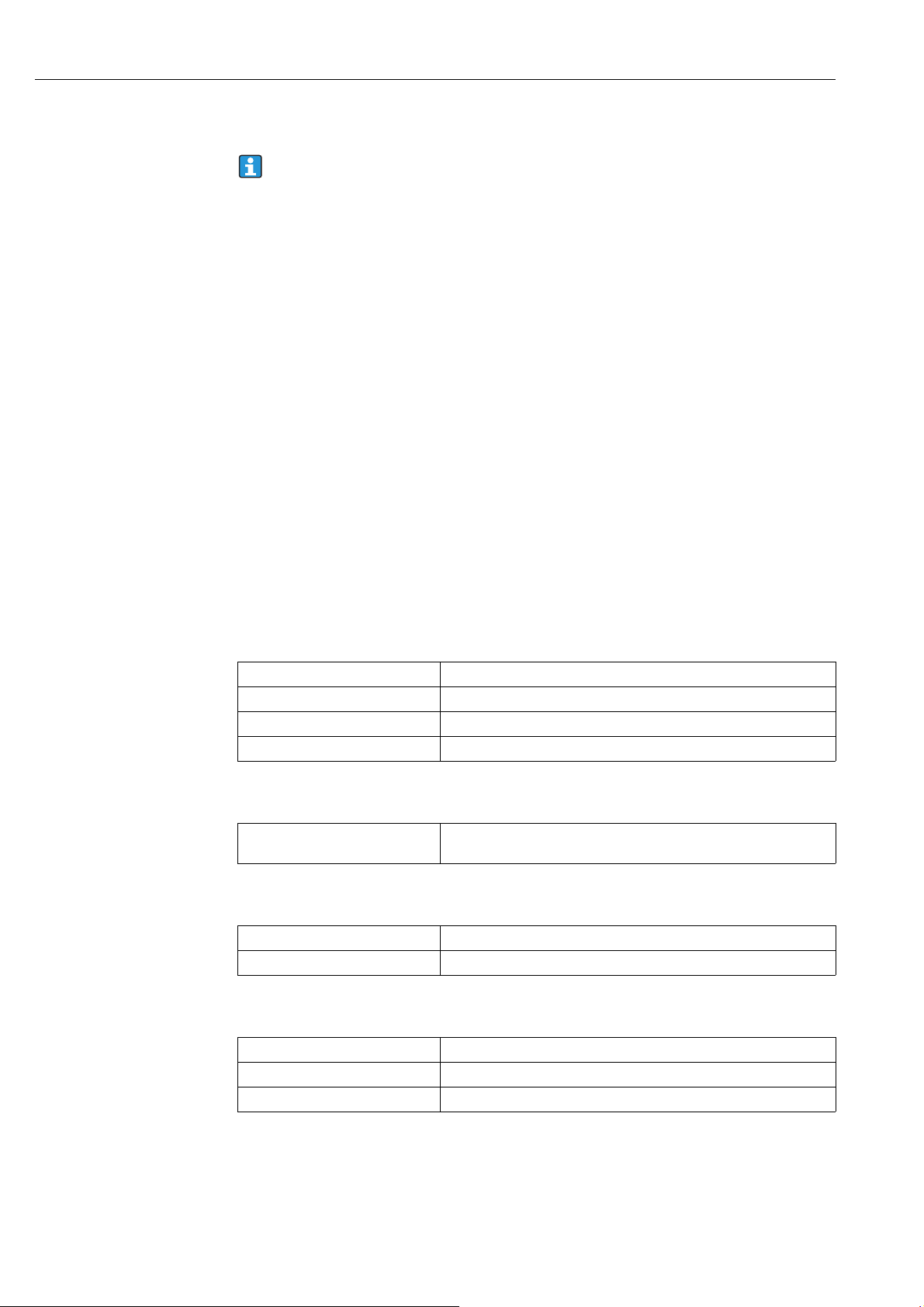

• Create necessary pressure drop with orifice plate in process pipe and with throttle (or flow

monitor) downstream from the measuring device.

A0026153

Fig. 4: 1 = Nanomass; 2 = Valve; 3 = Filter; 4 = Throttle; 5 = Orifice plate

• Create necessary pressure drop with compressor upstream and throttle (or flow monitor)

downstream from the measuring device.

Fig. 5: 1 = Nanomass; 2 = Valve; 3 = Filter; 4 = Throttle; 5 = Compressor

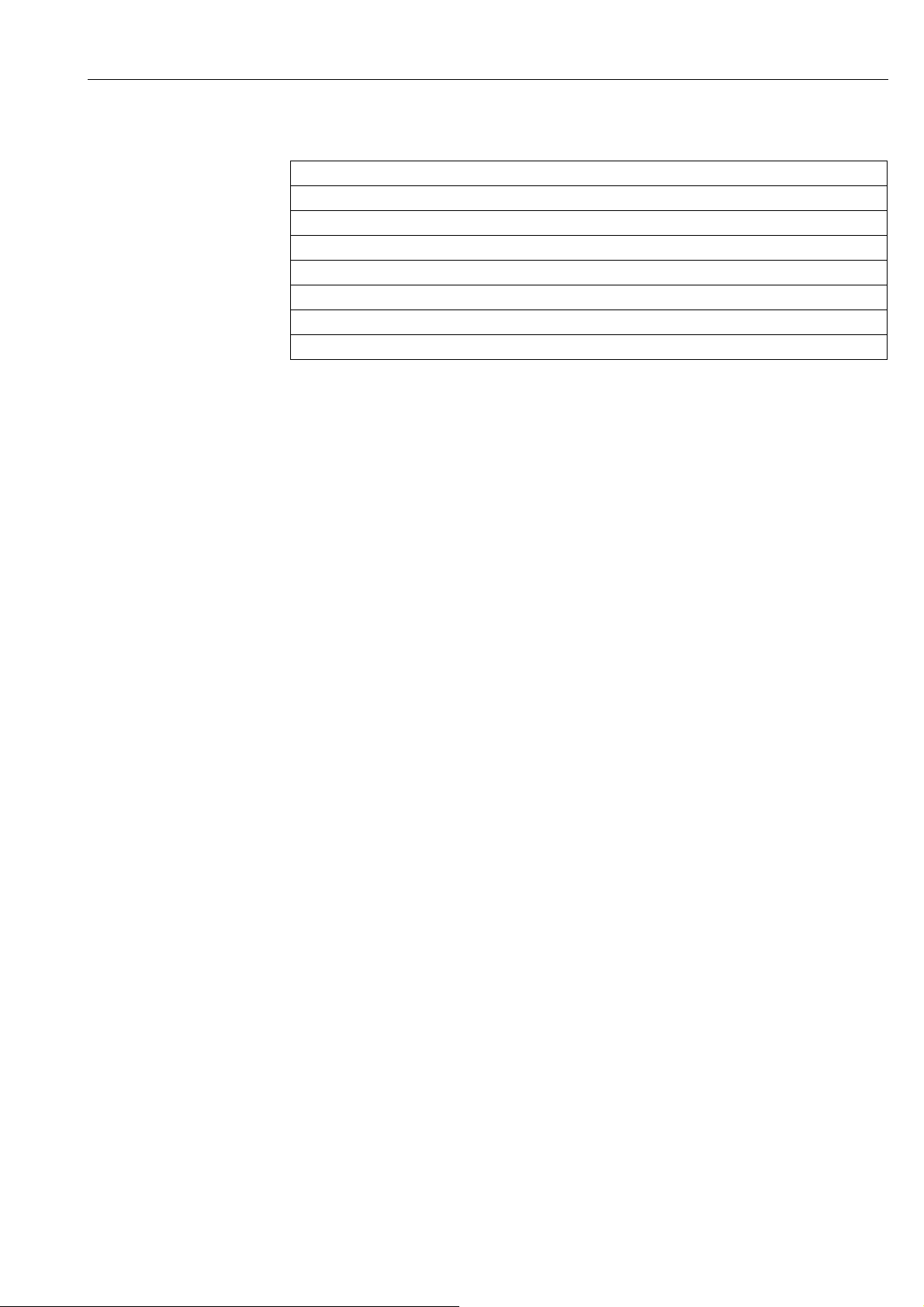

• If process pressure > 20 bar: create necessary pressure drop with pressure reduction valve

upstream and throttle (or flow monitor) downstream from the measuring device.

Fig. 6: 1 = Nanomass; 2 = Valve; 3 = Filter; 4 = Throttle; 5 = Pressure reduction valve

A0026154

A0026155

Endress+Hauser 17

Page 18

Installation Nanomass Gas Density

WARNING

NOTICE

NOTICE

Swagelok pipe fitting

The measuring device and the filter supplied are mounted in the pipe using a ¹⁄" Swagelok

pipe fitting.

1. Cut the pipe at a right-angle and deburr it.

2. Push the pipe into the fitting as far as it will go.

3. Tighten the nut finger-tight.

4. Mark the nut at the 6-o'clock position.

5. Tighten the nut. In doing so, observe the following options:

– When mounting for the first time, tighten with 1 ¹⁄₄ rotations.

– When mounting a second time, tighten with a ¹⁄₄ rotation.

For more information, see the installation instructions for pipe fittings provided by

Swagelok.

Pressure sensor

The measuring device only provides correct measured values when the pressure sensor is

connected. The pressure sensor is already connected when the device is delivered.

Make sure that the pressure sensor is connected correctly.

6.2 Mounting the measuring device

6.2.1 Required tools

For process connections: use an appropriate tool for mounting with Swagelok pipe fittings.

6.2.2 Preparing the measuring device

1. Remove all remaining transport packaging.

2. Remove the protection caps on the inlet and outlet.

6.2.3 Mounting the measuring device

Incorrect device mounting

Burst pipes can cause injury.

Never install the device in the pipe in such a way that it is suspended freely without

additional support.

Mechanical load on the process connections

Pipe forces can affect the vibrations of the micro-channel and thereby impact the accuracy

of measurement.

Avoid high mechanical load on the pipes at process connections.

If mounting on the process pipe, use a wrench to cushion the torque. Do not allow torques

to act on the measuring device.

Blockage of the micro-channel

Install a filter upstream from the measuring device ( 15).

1. To ensure compliance with the maximum flow specifications in the measuring device

and the recommended pressure drop across the measuring device, use a bypass line

with appropriate assemblies where necessary ( 16).

18 Endress+Hauser

Page 19

Nanomass Gas Density Installation

2. Connect the filter to the pipe ( 15) and secure with a Swagelok pipe fitting (

18).

3. Mount the measuring device on a wall or ceiling using drill holes ( 16).

4. Connect the measuring device to the pipe and secure with a Swagelok pipe fitting (

18).

6.3 Post-installation check

Is the device undamaged (visual inspection)?

If assemblies are installed, are they undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

•Medium 69

• Medium temperature range 69

• Process pressure (refer to the section on "Pressure-temperature ratings" in the "Technical

Information" document )

• Ambient temperature range 15

• Measuring range 65

Are the measuring point identification and labeling correct (visual inspection)?

Is the measuring device adequately protected from precipitation and direct sunlight?

Are the securing screws tightened securely?

Is the pressure sensor connected?

Endress+Hauser 19

Page 20

Electrical connection Nanomass Gas Density

7 Electrical connection

The measuring device does not have an internal circuit breaker. For this reason, assign

the measuring device a switch or power-circuit breaker so that the power supply line can

be easily disconnected from the mains.

7.1 Connection conditions

7.1.1 Required tools

• For cable entries: use an appropriate tool.

• When using stranded cables: use a crimper for wire end ferrule.

7.1.2 Connecting cable requirements

The connecting cables provided by the customer must fulfill the following requirements:

Electrical safety

In accordance with applicable national regulations.

Permitted temperature range

• –40 to 80 °C (–40 to 176 °F)

• Minimum requirement: cable temperature range ambient temperature + 20 K

Power supply cable

Outer diameter 3.5 to 5 mm

Number of cores Min. 2

Cable resistance 77.8 /km at 20 °C

Shielding Single shielding

Signal cable

Shielding A shielded cable is recommended. Observe grounding concept of the

plant.

USB cable

Cable type Mini USB, type B, Buccaneer; standard USB, type A

Cable length Max. 5 m

RS232 cable

Cable type M12, 4-pin; D-Sub, 9-pin

Cable length Max. 5 m

Transmission rate 57600 Bd

20 Endress+Hauser

Page 21

Nanomass Gas Density Electrical connection

2

1

1

4

2

3

2

3

1

4

NOTICE

7.1.3 Pin assignment of connector

Connector for supply voltage

Pin Assignment Coding,

1 L- DC 8 to 30 V A Connector

A0026825

2L+

Connector for signal transmission

4-20 mA connector

Pin Assignment Coding,

1 +/- Current output 1, 4-20 mA

(passive)

A0026826

2 -/+ Current output 1, 4-20 mA

3 +/- Current output 2, 4-20 mA

4 -/+ Current output 2, 4-20 mA

(passive)

(passive)

(passive)

RS232 device socket

Pin Assignment Coding,

1Shield A Socket

2 Txout (transmitted data)

A0026827

3Rxin (received da)

4 Common ground

connector

face

connector

face

A Connector

connector

face

Connector/

socket

Connector/

socket

Connector/

socket

USB device socket

Assignment Connector/socket

Mini-USB, type B, Buccaneer Socket

A0026828

7.1.4 Preparing the measuring device

Remove the protection caps from the connections.

Measuring device not leak tight

If the measuring device is not leak tight, this can impair the operational reliability of the

measuring device.

Only remove the protection caps if connections are used.

Endress+Hauser 21

Page 22

Electrical connection Nanomass Gas Density

WARNING

1

1

2

3

5

5

66

4 4

7.2 Connecting the measuring device

Improper connection can cause serious injury or death

Have electrical connection work carried out by correspondingly trained specialists only.

Observe applicable federal/national installation codes and regulations.

Comply with local workplace safety regulations.

If using in hazardous areas, observe the explosion protection documentation.

A0026017

Fig. 7: Measuring device versions and connection versions

1 Connector for 4-20 mA

2 RS232 interface (optional)

3 USB port (optional)

4Grounding clamp

5 Connector for supply voltage

6 Connector for pressure sensor (connected on delivery)

7.2.1 Connecting the supply voltage cable

The supply voltage can be connected via the supply voltage connection or in an area without

explosion hazards optionally via the USB port. If the supply voltage connection is to be used

for the supply voltage, perform the following steps:

1. Measuring device with USB port: make sure that the measuring device is disconnected

from the USB port.

2. If necessary, strip 10 mm (0.4 in) of the supply voltage cable and cable ends. In the case

of stranded cables, also fit ferrules.

3. Where applicable, connect the cable to the connector for supply voltage in accordance

with the pin assignment 21.

4. Insert the connector into the supply voltage connection of the measuring device and

screw tight.

5. If using in hazardous areas: fit the USB protection cap and tighten securely.

22 Endress+Hauser

Page 23

Nanomass Gas Density Electrical connection

7.2.2 Connecting the signal cables

Signals can be transmitted digitally via a USB port or RS232 interface or by analog

communication via the passive 4-20 mA connection.

Connect the 4-20 mA cable

1. Strip 10 mm (0.4 in) of the cable and cable ends. In the case of stranded cables, also fit

ferrules.

2. Connect the cable to the 4-20 mA connector in accordance with the pin assignment

21.

3. Insert the connector into the 4-20 mA connection of the measuring device and screw

tight.

4. Connect the signal cable to the 12-24 V power supply 24.

Connect the RS232 cable (optional)

1. If necessary, strip 10 mm (0.4 in) of the cable and cable ends. In the case of stranded

cables, also fit ferrules.

2. Where applicable, connect the cable to the RS232 connector in accordance with the pin

assignment 21.

3. Connect the RS232 cable to the RS232 socket of the measuring device and the COM port

(RS232) of the PC and screw tight.

Connect the USB cable (optional)

1. Make sure that the measuring device is disconnected from the supply voltage.

2. Connect the USB cable to the USB port of the measuring device and the USB port of the

PC.

3. Secure the cable to the device with a protection cap and cable clamp.

Endress+Hauser 23

Page 24

Electrical connection Nanomass Gas Density

4...20 mA

421

+

5

4...20 mA

+

6

4

2

+

+

_

3

+

_

3

_

+

_

_

_

7.3 Special connection instructions

7.3.1 Connection examples

Current output 4-20 mA

A0026824

Fig. 8: Connection example for 4-20 mA current output

1 Automation system with current input (e.g. PLC)

2 Cable shield, comply with connecting cable requirements (→ 20)

3 Power supply 12-24 V

4 Analog display unit: observe maximum load (→ 65)

5 Measuring device, current output 1 (pin 1 and 2, protected against reverse polarity)

6 Measuring device, current output 2 (pin 3 and 4, protected against reverse polarity)

7.4 Guaranteeing the degree of protection

The measuring device meets all the requirements of IP65/67 protection.

To guarantee IP65/67 protection, carry out the following steps after the electrical

connection:

For USB port:

1. Check whether the seals of protection caps are clean and inserted correctly.

2. Fit the protection caps and tighten securely.

24 Endress+Hauser

Page 25

Nanomass Gas Density Electrical connection

7.5 Post-connection check

Are cables and the device undamaged (visual inspection)?

Do the cables comply with the requirements ( 20)?

Do the cables have adequate strain relief?

Does the supply voltage match the specifications on the nameplate?

Are all connectors installed and protection caps securely tightened?

Is the pin assignment of the connectors correct?

Depending on the device option and the use of the device: is the USB connector secure?

If supply voltage is provided, is the power LED on the measuring device lit?

Endress+Hauser 25

Page 26

Operating options Nanomass Gas Density

NOTICE

ESC

E

+

-

1

.00145 kg/ccρ= 0

Temp= 23.21°C

2

Power

Error

3

8 Operating options

8.1 Overview of operating options

The measuring device offers users the following operating options:

• Local operation

• "Nanomass Communication" operating tool (via USB port or RS232 interface)

The operating language of the measuring device is English. Other language options are

not supported.

Errors during measurement values transmission

Errors may occur at the current output during the measurement values transmission with

the local operation or the "Nanomass Communication" operating tool.

Complete operation for correct measurement value.

8.2 Access to the measuring device via the local display

8.2.1 Operational display

The operational display is used to display measured variables, parameters, dialog texts and

error messages.

A0027442

Fig. 9: Operational display

1 Measured value display and parameterization view (2-lines)

2 Operating elements

3 LED status indicator

Measured value display

A measured variable is displayed on every line. A maximum of four measured variables in

total can be displayed in multiplex mode. In multiplex mode, the measured variables

alternate on the screen every 5 seconds.

Measured variables

Abbreviation Description

ρ Density

ρr Reference density

26 Endress+Hauser

Temp Temperature

Conc Concentration

Press Pressure

Page 27

Nanomass Gas Density Operating options

1

Measure variables

User interface

2

1

System units

Special units

2

1

Density

g/cc

2

-

+

E

E

+

E

-

+

+

+

-

+

The number and display format of the measured values can be configured in the "User

interface" "Assign" menu.

Parameterization views

The user is in the operational display mode: press Enter to enter the parameterization

mode.

Menu Submenu Parameter

1 2Selected menu item

Next menu item

Operating elements

Key Description

Minus key

A0027444

A0027443

A0027445

In a menu or submenu

Navigate between the menus or submenus

In a parameter

Change a parameter value

Plus key

In a menu or submenu

Navigate between the menus or submenus

In a parameter

Change the parameter value

Enter key

In a menu or submenu

Call a submenu or parameter

In a parameter

Confirm an entry or navigate to the next parameter

A0027439

1 2Selected submenu item

Next submenu item

A0027446

A0027441

1 2Parameter name

Parameter value

Back/Forwards key combination (press keys simultaneously)

In a parameter

Navigate within a parameter value to the next or previous number or digit.

A0027447

Escape key combination (press keys simultaneously)

In a menu

A0027440

Exit the parameterization view and go to the measured value display

In a submenu

Exit the submenu and go to the menu

In a parameter

Exit the parameter and go to the submenu

LED status indicators

For a description, see "Diagnostic information via light emitting diodes" 55.

Endress+Hauser 27

Page 28

Operating options Nanomass Gas Density

8.2.2 Functions

Function Operation

Display measured values Once the measuring device has been connected to

Enter parameterization The user is in the operational display mode.

the supply voltage and the measuring device is

ready for operation, the measured values appear

on the operational display.

Press Enter.

Disable write protection via access code Parameterization is protected by an access code.

This code cannot be configured.

Enter the access code 0074 using the plus and

minus keys. Press Enter to confirm each digit.

Navigate between the menus or submenus The user is in the parameterization view in a

menu or submenu.

Press the Plus or Minus key.

Call submenus or parameters The user is in the parameterization view in a

menu or submenu.

Press Enter.

Change parameter values The user has called up a parameter.

Press the Plus or Minus key.

Navigate within the parameter value to the next

number or digit

The user has called up a parameter and makes

changes to a parameter value.

Press the Plus and Enter key or the Minus and

Enter key simultaneously.

Confirm entries The user has called up a parameter and makes

changes to a parameter value.

Press Enter.

Navigate to the next parameter The user has called up a parameter.

Press Enter.

Return to the previous menu or submenu

Press the Plus and Minus key simultaneously.

8.3 Access to the measuring device via the "Nanomass Communication" operating tool

8.3.1 Function scope

The measuring device can be operated and configured via the "Nanomass Communication"

operating tool. The parameter structure is the same as with the local display ( 75). In

addition to the measured values and the parameters, status information on the measuring

device is also displayed and allows the user to monitor the status of the device. Furthermore

the measuring device data can be managed and visualized and basic device parameters (e.g.

calibration factors or device clock) can be configured.

8.3.2 Prerequisites

Hardware

Connecting cable Depends on the device interface:

• USB cable: mini USB, type B, Buccaneer; standard USB, type A or

• RS232 cable: M12, 4-pin, gold contact; D-Sub, 9-pin

28 Endress+Hauser

Page 29

Nanomass Gas Density Operating options

NOTICE

Computer Depends on the device interface:

•USB port or

•RS232 interface

Disk drives (in the case of installation the "Nanomass Communication" operating

tool via CD-ROM):

•CD-ROM drive

Computer software

Recommended

operating system

Drivers •USB driver

Computer

configuration

PC:

• Windows 8.1 (32bit or 64bit)

• Windows 7 (32bit or 64bit)

•Windows XP

For installing on Windows XP, Windows 7 and Windows 8.1 administrator

rights are required.

The following components must be installed on the PC to be able to install the

"Nanomass Communication" operating tool. If the components are not already

installed, they will be installed automatically when the setup file is run.

• National Instruments VISA Runtime, Version 5.4 or higher

• For USB port: virtual serial interface according to RS232 (virtual com port)

8.3.3 Installing the "Nanomass Communication" operating tool

Upgrading from an earlier version

If an earlier version of the tool is installed, installing a new version can cause problems.

Uninstall the earlier version before installing the new "Nanomass Communication"

operating tool.

Installing the "Nanomass Communication" operating tool

1. Close all applications.

2. Insert the CD-ROM supplied in the drive.

3. Start the installation by double clicking on "setup.exe" in the CD directory "software/

Nanomass Communication".

4. Follow the instructions in the installation window.

8.3.4 Connecting the measuring device to the PC

For information on connecting the device via an RS232 or USB cable 23.

8.3.5 Establishing a connection

The "Nanomass Communication" operating tool automatically detects the measuring device

connected to the PC. Several devices can be connected simultaneously. Only one measuring

device can be selected in the operating tool, however.

1. Start Nanomass Communication.

The PC assigns the COM port automatically for the connected measuring device.

2. In the "COM-Port" selection box, select the COM port assigned by the PC for the

connected measuring device.

Endress+Hauser 29

Page 30

Operating options Nanomass Gas Density

First connection of the device

If the device is connected the first time on the computer, it will incorrectly recognized.

In case of first device connection install USB driver.

Install USB driver:

1. Depending on the version, connect the device to your computer via the USB- or the

RS232-interface.

2. Open the Device Manager.

3. Update the driver software by right click on the device.

4. Select the manual search and the installation of the driver software in the installation

window. The driver software is located in the directory "drivers/USB_driver_F".

5. Follow the instructions in the following installation windows.

No COM port is displayed

1. Select "Refresh" in the "COM-Port" selection box.

The PC updates the picklist.

2. In the "COM-Port" selection box, select the COM port assigned by the PC for the

connected measuring device.

30 Endress+Hauser

Page 31

Nanomass Gas Density Operating options

123 4 5

8.3.6 User interface

Fig. 10: User interface

1 Exit Nanomass Communication

2 Nanomass Communication software version

3 Establish a connection

4 Device configuration and device functions

5 Measured value display and status indication

Establishing a connection

Selection/display Description

COM port Communication interface

Select the communication interface for communicating with the measuring device. The

list displayed contains all the COM ports available. A "Refresh" function is also provided

to update the list.

Device type Device type

Displays the type of device that is connected ("Nanomass Gas Density").

A0027438

Endress+Hauser 31

Page 32

Operating options Nanomass Gas Density

Device configuration and device functions

Function area Description

Parameter Parameter

Access to the device's operating menu structure; same as local display:

• Configuration of parameters

Real-time

measuring data

Measuring data

retrieval

Device settings Device settings

Real-time measuring data

Access to current measured values:

• Graphic display of current measured values

• Recording of current measured values (in text file)

Measuring data retrieval

Access to the internal data memory:

• Settings for saving measured values

• Export saved measured values (to text file)

Access to device information and device settings:

• Display device information

• Configure the communication port (COM port)

• Configure the display delay

• Configure the device clock

• Configure the calibration parameters

•Service functions (protected by a code)

To access the "Device settings" function area, you must enter the access code 0074

in the "Access code for technician mode" field and then press "OK" to confirm.

Measured value display

The measuring variables listed below are displayed along with their unit in the measured

value display area. The display format can be changed via the parameter settings. A red

signal to the right of the measured value indicates whether this value is being saved to a file.

Measuring variables

Measuring variable Description

Density Density

Displays the measured density.

Reference Density Reference density

Displays the calculated reference density. The measuring variable is only displayed if

the "Fixed" parameter value is selected in the "Density function" parameter.

Temperature Temperature

Concentration Concentration

Pressure Pressure

Displays the medium temperature measured during density measurement.

Displays the calculated concentration of a substance. The measuring variable is only

displayed if the "Concentration Measurement" application package is used and the

"Flexible" parameter value is selected in the "Density function" parameter.

Displays the pressure measured by the sensor during density measurement.

32 Endress+Hauser

Page 33

Nanomass Gas Density Operating options

1

2

3

8.3.7 Parameter

Users can access the operating menu structure of the device in the "Parameter" function area.

This menu structure can also be called via local operation.

Screen layout

Fig. 11: Parameter

1 Navigation area

2 Displays the configured parameter value

3 Configuration area

A0027435

Choosing parameters

It is not possible to directly select an individual parameter in the navigation area.

To select a parameter, select the menu or submenu in question e.g. "Measuring variables"

or "System units".

Parameters pertaining to the menu are displayed in the configuration area to the

right of the navigation area.

Changing parameter values

Enter or select the parameter value in the input box.

The measuring device adopts the new parameter value and "Refreshing" is displayed

on the screen.

Endress+Hauser 33

Page 34

System integration Nanomass Gas Density

9 System integration

9.1 Overview of device description files

9.1.1 Current version data for the device

Firmware version • On the title page of the Operating instructions

Release date of firmware version 31.08.2015

Device type ID • In Nanomass Communication: Header "Device type"

Device version On the nameplate ( 12)

• On the nameplate ( 12)

• In Nanomass Communication: function area "Device settings"

"Device information" "Firmware Version"

• On the local display during device start-up.

• On the local display during device start-up.

9.1.2 Operating tools

Operating tools via serial interface Sources for obtaining device descriptions

Nanomass Communication • www.endress.com Download Area

• CD–ROM (contact Endress+Hauser)

9.2 Measured variables via serial interface

9.2.1 General settings for the serial interface

Baud rate 19200

Data bits 8

Stop bits 1

Parity bit None (0)

FlowControl None (0)

Transmission mode By packet (char = 8 bit or 1 byte)

34 Endress+Hauser

Page 35

Nanomass Gas Density System integration

@!000820.55 !00050.00062@!00060.00000@!00091.02@!@

1

23123123123

1

9.2.2 Data structure and commands

The commands which can be used to read measured variables and device information out of

the measuring device are listed below. The data are transmitted in packets. The data are

divided into seven packets. Only packet 5 is variable and can be used. For data interrogation,

the bytes must be specified in hexadecimal format.

Packet Byte (hex) Description String output

String

name

10x01No access possible --

20x00No access possible --

30x00No access possible --

40x00No access possible --

5 0x05 Device information pcb No function

mtf No function

den No function

de No function

fid No function

Description

pip No function

cus Tag name

(defined by customer)

ser Serial number

0x08 Measured data 0008 Temperature in °C

0005 Density in kg/m

0006 Reference density

0011 Concentration

0009 Pressure in bar absolute

60x02No access possible --

70x03No access possible --

3

Example

String entry to call up measured data: 0x01 0x00 0x00 0x00 0x08 0x02 0x03.

The device returns the following data. Please note that the string values used are only

sample values:

Fig. 12: String entry

1Separator

2String name

3 String value

Endress+Hauser 35

A0027448

Page 36

Commissioning Nanomass Gas Density

10 Commissioning

10.1 Installation and function check

Before commissioning the device, make sure that the post-installation and post-connection

checks have been performed.

• "Post-installation check" checklist 19.

• "Post-connection check" checklist 25.

10.2 Switching on the measuring device

After a successful function check, switch on the measuring device. If power is supplied via

the USB port, the measuring device starts automatically as soon as the USB cable is

connected.

After a successful startup, the local display switches automatically from the startup display

to the operational display.

If nothing appears on the local display or an error message is displayed, refer to the

section on "Diagnostics and troubleshooting" 54.

10.3 Setting the operating language

The operating language of the measuring device is English. Other language options are not

available.

10.4 Configuring the measuring device

An overview of all the device parameters and a description of the parameters is provided

in the appendix 75.

10.4.1 Defining the tag name

The tag name must be defined via the "Nanomass Communication" operating tool.

Navigation

Function area "Device settings" "Device information" "Tag name"

To access the "Device settings" function area, you must enter the access code 0074 in the

"Access code for technician mode" window and then press "OK" to confirm.

Defining the tag name

1. Call up the "Device settings" function area.

2. Enter the new tag name under "Tag name" in the "Device information" area.

3. Click "Send" to confirm the name.

The message "Tag name changed" appears.

The name is saved in the device.

4. Click "OK" to confirm the message.

10.4.2 Setting the serial port delay time

The delay time for sending and receiving data via the serial port must be defined via the

"Nanomass Communication" operating tool.

36 Endress+Hauser

Page 37

Nanomass Gas Density Commissioning

Navigation

Function area "Device settings" "COM-Port "Data retrieval delay"

To access the "Device settings" function area, you must enter the access code 0074 in the

"Access code for technician mode" field and then press "OK" to confirm.

Setting the delay time

1. Call up the "Device settings" function area.

2. Under "Data retrieval delay" in the "COM-Port" area, enter a delay time of between 200

and 500 ms for the serial port.

The delay time is saved in the device.

10.4.3 Setting the sampling rate

The frequency at which data are saved in the internal data memory must be defined via the

"Nanomass Communication" operating tool.

Navigation

Function area "Device settings" "Internal data logger" "Sampling rate"

To access the "Device settings" function area, you must enter the access code 0074 in the

"Access code for technician mode" field and then press "OK" to confirm.

Setting the sampling rate

1. Call up the "Device settings" function area.

2. Under "Sampling rate" in the "Internal data logger" section, enter the sampling rate at

which data are saved in the internal data memory. The sampling rate can be between

1 and 3600 seconds.

3. Click the "Set sampling rate" button to confirm the sampling rate.

The sampling rate is saved in the device.

10.4.4 Setting the date and time

The date and time in the measuring device must be defined via the "Nanomass

Communication" operating tool.

Navigation

Function area "Device settings" "Device settings"

To access the "Device settings" function area, you must enter the access code 0074 in the

"Access code for technician mode" field and then press "OK" to confirm.

Setting the date and time

1. Call up the "Device settings" function area.

2. Click the "Set clock" button in the "Device settings" area.

An input box and a calendar function appear.

3. Enter the time and date, or select them from the calendar, and click the "Send date and

time" button to confirm your settings.

The message "Data and time changed" appears.

The date and time are saved in the measuring device.

4. Click "OK" to confirm the message.

Endress+Hauser 37

Page 38

Commissioning Nanomass Gas Density

10.4.5 Configuring the current output

Various parameters are used to configure the current output. In addition, there are

differences depending on which current output is being configured.

Navigation

1. Menu "Measuring variables" "System units"

2. Menu "Output 4-20 mA" "Output channel 1" and "Output channel 2"

3. Menu "Output 4-20 mA" "Response channel 1/2"

4. Menu "Supervision" "Assign error prompt for channel 2"

Parameter overview with brief description

Menu "Measuring variables" → "System units"

Parameter Procedure Selection/input Factory setting

Density Select the unit for density.

Result

The selected unit applies for:

• The "Density" process variable

• The "4mA Ch1" parameter

• The "20mA Ch1" parameter

• The "4mA Ch2" parameter

• The "20mA Ch2" parameter

Note

If the unit is changed, configured current

output values are automatically adapted

to the new unit.

Specific Gravity = measured density/

density of air;

Molecular weight = average molar mass

according to the ideal gas law

Reference density Select the unit for reference density.

Result

The selected unit applies for: the

"Reference Density" process variable

Note

If the unit is changed, configured current

output values are automatically adapted

to the new unit.

Temperature Select the unit for temperature.

Result

The selected unit applies for:

• The "Temperature" process variable

• The "4mA Ch1" parameter

• The "20mA Ch1" parameter

• The "4mA Ch2" parameter

• The "20mA Ch2" parameter

Note

If the unit is changed, configured current

output values are automatically adapted

to the new unit.

•g/cm³

•g/cc

•kg/L

•kg/m³

•Lb/ft³

•Lb/gal

• Unit defined under "Text arb.

density"

•Specific gravity

•Molecular weight

•g/cm³

•g/cc

•kg/L

•kg/m³

•Lb/ft³

•Lb/gal

•°C

•K

•°F

•°R

kg/m³

kg/m³

Country-specific:

•°C

•°F

38 Endress+Hauser

Page 39

Nanomass Gas Density Commissioning

Parameter Procedure Selection/input Factory setting

Pressure Select the unit for pressure.

Result

The selected unit applies for:

• The "Pressure" process variable

• The "4mA Ch1" parameter

• The "20mA Ch1" parameter

• The "4mA Ch2" parameter

• The "20mA Ch2" parameter

Note

If the unit is changed, configured current

output values are automatically adapted

to the new unit.

• bar absolute

•bar gauge

• psi absolute

• psi gauge

•kPa absolute

•kPa gauge

Country-specific:

•kPa absolute

• psi absolute

Menu "Output 4-20mA" → "Output channel 1

Parameter Description Selection/input Factory setting

Assign Select process variable for current output 1.•Off

•Density

•Ref. density

• Concentration (optional)

•Temperature

• Pressure

Span Select current span for current output 1. • Namur 4-20mA

• Non Namur 4-20mA

4mA Ch1 Enter the lower limit for 4 mA current. Decimal. 0 (kg/m

20mA Ch1 Enter the upper limit for 20 mA current. Decimal. 1 (kg/m

Density

Non Namur 4-20mA

3

)

3

)

Menu "Output 4-20mA" → "Output channel 2"

Parameter Description Selection/input Factory setting

Assign Select process variable for current output 2.•Off

•Density

•Ref. density

• Concentration (optional)

•Temperature

• Pressure

Span Select current span for current output 2. • Namur 4-20mA

• Non Namur 4-20mA

4mA Ch2 Enter the lower limit for 4 mA current. Decimal. 0 (°C)

20mA Ch2 Enter the upper limit for 20 mA current. Decimal. 20 (°C)

Temperature

Non Namur 4-20mA

Menu "Output 4-20mA" → "Response channel 1/2"

Parameter Description Selection/input Factory setting

Failsafe mode channel 1 Specify the output behavior of current

output 1 in the event of a device alarm.

Note

In the event of a breakdown of the power

supply the value of the current output is

<1 mA. The failure mode in accordance

with NAMUR Recommendation NE 43 is

ensured.

• Min current

•Max current

•Hold value

•Actual value

Min current

Endress+Hauser 39

Page 40

Commissioning Nanomass Gas Density

Parameter Description Selection/input Factory setting

Failsafe mode channel 2 Specify the output behavior of current

output 2 in the event of a device alarm.

Note

In the event of a breakdown of the power

supply the value of the current output is

<1 mA. The failure mode in accordance

with NAMUR Recommendation NE 43 is

ensured.

•Min current

• Max current

•Hold value

•Actual value

Min current

Menu "Supervision" → "Assign error prompt for channel 2"

Parameter Description Selection/input Factory setting

Tube not oscillating Select whether an error message should

be displayed at current output 2 if the

measuring channel is not oscillating or is

oscillating in the wrong frequency range.

Density range Select whether an error message should

be displayed at current output 2 if the

density value is outside the permitted

range.

•On

•Off

•On

•Off

Off

Off

10.4.6 Configuring the local display

Various parameters are used to configure the local display.

Navigation

1. Menu "User interface" "Assign" "Top line display"

2. Menu "User interface" "Assign" "Top line display multiplex"

3. Menu "User interface" "Assign" "Bottom line display"

4. Menu "User interface" "Assign" "Bottom line display multiplex"

Parameter overview with brief description

Menu "User interface" → "Assign" → "Top line display"

Parameter Description Selection/input Factory setting

Top line display Select the measured value that is shown

on the top line of the local display.

•Off

•Density

• Concentration (optional)

•Ref. density

• Temperature

• Pressure

Density

Menu "User interface" → "Assign" → "Top line display multiplex"

Parameter Description Selection/input Factory setting

Top line display multiplex Select the measured value that is shown

on the top line of the local display when

the display changes.

•Off

•Density

• Concentration (optional)

•Ref. density

• Temperature

• Pressure

Off

40 Endress+Hauser

Page 41

Nanomass Gas Density Commissioning

Menu "User interface" → "Assign" → "Bottom line display"

Parameter Description Selection/input Factory setting

Bottom line display Select the measured value that is shown

on the second line of the local display.

•Off

•Density

• Concentration (optional)

•Ref. density

•Temperature

• Pressure

Temperature

Menu "User Interface" → "Assign" → "Bottom line display multiplex""

Parameter Description Selection/input Factory setting

Bottom line display multiplex Select the measured value that is shown

on the second line of the local display

when the display changes.

•Off

•Density

• Concentration (optional)

• Ref. density

• Temperature

• Pressure

Pressure

10.4.7 Configuring the output behavior

Various parameters are used to configure the output behavior.

Navigation

1. Menu "Output 4-20mA" "Response channel 1/2" "Time constant output"

2. Menu "Basic function" "System parameter" "Time constant input"

Parameter overview with brief description

Menu "Output 4-20mA" → "Response channel 1/2" → "Time constant output"

Parameter Description Selection/input Factory setting

Time constant output Set the response time of the output signal

to variations in the measured value.

Menu "Basic function" → "System parameter" → "Time constant input"

Parameter Description Selection/input Factory setting

Time constant input Set the response time of the local display

to variations in the measured value.

Positive integer 0 to 120 s 0 s

Positive integer 0 to 120 s 0 s

10.5 Advanced settings

The measuring device supports the entry of user-defined units. Furthermore, it is possible to

configure reference density measurement and concentration measurement as well as

density adjustment.

10.5.1 Entering user-defined density units

A user-defined unit can be entered for the "Density" measuring variable in the "Special Units"

menu. The unit is then available for selection in the "Density" parameter in the menu

"Measuring variables" "System units".

Endress+Hauser 41

Page 42

Commissioning Nanomass Gas Density

Navigation

Menu "Measuring variables" "Special units"

Parameter overview with brief description

Menu "Measuring variables" → "Special units"

Parameter Description Selection/input Factory setting

Text arb. density (4 char.) Enter the text string for the arbitrary

density unit. The unit is then available

for selection in the "Density" parameter in

the "System unit" menu.

Factor arbitrary density Enter the quantity factor for the arbitrary

density unit. The factor converts the

original measured value into the

arbitrary unit.

XXXX (max. 4 characters) "___" (no text)

6-digit floating point number and

a 1-digit exponent

1.00000E+0

10.5.2 Configuring reference density measurement

Settings for calculating the reference density can be made in the "Special Function" menu.

Navigation

Menu "Special function" "Density function"

Parameter overview with brief description

Menu "Special function" → "Density function"

Parameter Description Selection/input Factory setting

Density type Select the density function for calculating

special density values or the percentage

of components in binary mixtures.

Reference pressure Enter the reference pressure for

calculating the reference density.

Reference temperature Enter the reference temperature for

calculating the reference density.

•Fixed Off

Decimal number with sign 14.7 psi a

Decimal number with sign 20 °C

10.5.3 Configuring the concentration measurement

Information on concentration measurement 44

10.5.4 Performing density adjustment with medium

A density adjustment can be performed under process conditions to achieve optimum

accuracy. The density adjustment must be performed using the "Nanomass Communication"

operating tool.

Navigation

Function area "Device settings" Menu "Calibrate density" "Single point density calibration"

To access the "Device settings" function area, you must enter the access code 0074 in the

"Access code for technician mode" field and then press "OK" to confirm.

42 Endress+Hauser

Page 43

Nanomass Gas Density Commissioning

Performing density adjustment with medium

The measuring device must be filled with the medium to perform density adjustment.

Furthermore, the exact density of the medium at the indicated temperature and

pressure must be known.

1. Call up the "Device settings" function area.

2. In the "Calibrate density" section, click the "Enter actual density" button to enter the

current density.

The "Prompt" window opens.

3. Enter the value of the current density in the "Density" field and click "OK" to confirm.

The message "Are you sure you want to continue?" appears.

4. Click "Yes, calibrate" to perform the density adjustment.

Density adjustment commences.

Density adjustment has failed

If the density adjustment does not go to plan, the default factory density coefficients

can be restored with the "Reset field calibration" function.

1. Call up the "Device settings" function area.

2. In the "Calibrate density" section, click the "Perform reset" button to reset the density

calibration to the factory default setting.

The "Reset field calibration density offset value" message appears on the display.

3. Click "Continue" to continue the reset process.

The density calibration is reset to the factory default.

10.6 Simulation

The "Simulation" function allows users to simulate different process variables and the device

alarm behavior without a real measuring situation.

Navigation

Menu "Output 4-20mA" "Simulation"

Parameter overview with brief description

Menu "Output 4-20mA" → "Simulation"

Parameter Description Selection/input Factory setting

Activate simulation Switch simulation of the current outputs

on and off.

Current value Enter the current value for simulation. 2.00 to 23.00 mA 2.00 mA

•On

•Off

Off

10.7 "Datalog Function" application package

10.7.1 Availability

If the "Datalog Function" application package was ordered for the measuring device ex works,

the function is available when the measuring device is delivered from the factory. The

function is accessed via Nanomass Communication. No particular measures are required to

be able to put the function into operation.

Endress+Hauser 43

Page 44

Commissioning Nanomass Gas Density

Ways to check function availability:

• Using the serial number on the device:

W@M Device viewer order code option EB "Datalog function"

• In the operating menu of Nanomass Communication:

Check, whether the function appears in Nanomass Communication. If it is possible to open

the "Measuring data retrieval" function area, the function is activated.

If the function cannot be accessed, the application package was not selected when the device

was ordered. It is possible to subsequently activate the function.

10.7.2 Activation

For activation, a conversion kit from Endress+Hauser is required. Among other things, this

kit contains an activation code which must be entered via Nanomass Communication to

activate the "Concentration Measurement" function.

The activation function is available under "Device Settings" "Service mode" "Activate

software options". Once activated the "Datalog function" application package is permanently