Endress+Hauser Deltabar S PMD70, Deltabar S PMD75, Deltabar S PMD76, Deltabar S PMD77, Deltabar S PMD78 Operating Instructions Manual

Page 1

Brief Operating Instructions

Deltabar S

PMD70, PMD75, FMD76, FMD77, FMD78

Differential pressure measurement

These Instructions are Brief Operating Instructions; they do not replace the

Operating Instructions included in the scope of supply.

For detailed information, refer to the Operating Instructions and other

documentation on the CD-ROM provided or visit

"www.endress.com/deviceviewer".

KA01024P/00/EN/15.14

71254469

Page 2

Table of contents Deltabar S FOUNDATION Fieldbus

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Installation, commissioning and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Operational safety and process safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Safety icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 General installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Measuring arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Installation instructions for devices with diaphragm seals (FMD78) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Assembling and mounting the "separate housing" version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Connecting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Connecting the measuring unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Onsite display (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Onsite operation via onsite display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Locking/unlocking operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Commissioning via an FF configuration program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Selecting the language and measuring mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 Position adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4 Flow measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5 Level measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.6 Differential pressure measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.7 Scaling the OUT parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2 Endress+Hauser

Page 3

Deltabar S FOUNDATION Fieldbus Safety instructions

1 Safety instructions

1.1 Designated use

The Deltabar S is a differential pressure transmitter for measuring differential pressure, level and

flow.

The manufacturer accepts no liability for damages resulting from incorrect use or use other than

that designated.

1.2 Installation, commissioning and operation

• The device must only be installed, connected, commissioned and maintained by qualified and

authorized specialists (e.g. electrical technicians) in full compliance with the instructions in

this manual, the applicable norms, legal regulations and certificates (depending on the

application).

• The specialist must have read and understood this manual and must follow the instructions it

contains. If you are unclear on anything in these Brief Operating Instructions, you must read

the Operating Instructions (on the CD-ROM). The Operating Instructions provide detailed

information on the device/measuring system.

• The device may only be modified or repaired if such work is expressly permitted in the

Operating Instructions (see CD-ROM).

• If faults cannot be rectified, the device must be taken out of service and secured against

unintentional commissioning.

• Do not operate damaged devices. Mark them as defective.

1.3 Operational safety and process safety

• Alternative monitoring measures must be taken to ensure operational safety and process safety

during configuration, testing and maintenance work on the device.

• The device is safely built and tested according to state-of-the-art technology and has left the

factory in perfect condition as regards technical safety. The applicable regulations and

European standards have been taken into account.

• Pay particular attention to the technical data on the nameplate.

• Devices for use in hazardous areas are fitted with an additional nameplate. If the device is to

be installed in an explosion hazardous area, then the specifications in the certificate as well as

all national and local regulations must be observed. The device is accompanied by separate

"Ex documentation", which is an integral part of this Operating Instructions. The installation

regulations, connection values and Safety Instructions listed in this Ex document must be

observed. The documentation number of the related Safety Instructions is also indicated on

the additional nameplate.

1.4 Return

Follow the instructions on returning the device as outlined in the Operating Instructions on the

CD-ROM provided.

Endress+Hauser 3

Page 4

Product identification Deltabar S FOUNDATION Fieldbus

1.5 Safety icons

Symbol Meaning

Warning!

#

!

A warning highlights actions or procedures which, if not performed correctly, will lead to personal injury,

a safety hazard or destruction of the instrument.

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal injury or

"

incorrect functioning of the instrument.

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect operation

or may lead to an instrument response which is not planned.

2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is displayed.

For an overview of the technical documentation provided, enter the serial number from the

nameplates in the W@M Device Viewer (www.endress.com/deviceviewer).

3 Installation

3.1 General installation instructions

Warning!

#

The seal is not allowed to press on the process isolating diaphragm as this could affect the

measurement result.

Note!

!

• Due to the orientation of the Deltabar S, there may be a shift in the measured value, i.e. when

the container is empty, the measured value does not display zero. You can correct this zero

point shift either via the "zero" key on the electronic insert, or on the outside of the device or

via the onsite display. See Page 15, Section 5.2.1 "Position of operating elements", Page 16,

Section 5.2.2 "Function of the operating elements – onsite display not connected" and Page

25, Section 6.3 "Position adjustment".

• For FMD77 and FMD78, please refer to Section 3.3 "Installation instructions for devices with

diaphragm seals (FMD78)", Page 7.

• The FMD77 must only be insulated up to a certain height.

4 Endress+Hauser

Page 5

Deltabar S FOUNDATION Fieldbus Installation

• General recommendations for routing the impulse piping can be found in DIN 19210

"Methods for measurement of fluid flow; differential piping for flow measurement devices" or

the corresponding national or international standards.

• Using a three-valve or five-valve manifold allows for easy commissioning, installation and

maintenance without interrupting the process.

• When routing the impulse piping outdoors, ensure that sufficient anti-freeze protection is

used, e.g. by using pipe heat tracing.

• Do not clean or touch diaphragm seals with hard or pointed objects.

• Install the impulse piping with a monotonic gradient of at least 10%.

• To ensure optimal readability of the onsite display, it is possible to rotate the housing up to

380°.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls.

3.2 Measuring arrangement

3.2.1 Pressure measurement

• The PMD70, PMD75 and FMD78 are best suited for differential pressure measurement.

• Measuring arrangement for gases: Mount device above the measuring point.

• Measuring arrangement for liquids and steams: Mount device below tapping point.

• For differential pressure measurement in vapor, mount the condensate traps at the same level

as the same the tapping point and at the same distance from Deltabar S.

3.2.2 Level measurement

• All Deltabar S devices are best suited for level measurement in closed tanks.

• PMD70, PMD75, FMD76 and FMD77 are suitable to level measurement in open tanks.

Measuring arrangement level measurement in closed tanks and closed tanks with

superimposed vapor

• PMD70, PMD75: Mount device below the lower measuring connection. Always connect the

negative side above the maximum level via an impulse piping.

• FMD76, FMD77: Mount device direct on the tank. Always connect the negative side above

the maximum level via an impulse piping.

• FMD78 ä 7, Section 3.3 and Section 3.4.

• In the case of level measurement in closed tanks with superimposed vapor, a condensate trap

ensures pressure which remains constant on the minus side.

Measuring arrangement level measurement in open tanks

• PMD70, PMD75: Mount device below the lower measuring connection. The negative side is

open to atmosphere pressure.

• FMD76, FMD77: Mount device direct on the tank. The negative side is open to atmosphere

pressure.

3.2.3 Flow measurement

• The PMD70 and PMD75 are best suited for flow measurement.

• Measuring arrangement for gases: Mount device above the measuring point.

Endress+Hauser 5

Page 6

Installation Deltabar S FOUNDATION Fieldbus

• Measuring arrangement for liquids and steams: Mount device below tapping point.

• For flow measurement in vapors, mount the condensate traps at the same level as the same

the tapping point and at the same distance from Deltabar S.

6 Endress+Hauser

Page 7

Deltabar S FOUNDATION Fieldbus Installation

3.3 Installation instructions for devices with diaphragm seals (FMD78)

Note!

!

• The diaphragm seal, together with the pressure transmitter, forms a closed, calibrated system,

which is filled through openings in the diaphragm seal and in the measurement system of the

pressure transmitter. These openings are sealed and must not be opened.

• Do not remove the protection of the process isolating diaphragm until shortly before

installation.

• When using a mounting bracket, sufficient strain relief must be ensured for the capillaries in

order to prevent the capillary bending down (bending radius 100 mm).

• Please note that the hydrostatic pressure of the liquid columns in the capillaries can cause zero

point shift. You can correct this zero point shift either via the "zero" key on the electronic

insert, or on the outside of the device or via the onsite display. See Page 15, Section 5.2.1

"Position of operating elements", Page 16, Section 5.2.2 "Function of the operating elements

– onsite display not connected" and Page 25, Section 6.3 "Position adjustment".

• Please note the application limits of the diaphragm seal filling oil as detailed in the Technical

Information for Deltabar S TI00382P, Section "Planning instructions for diaphragm seal

systems" or at "www.endress.com/applicator".

In order to obtain more precise measurement results and to avoid a defect in the device, mount

the capillaries as follows:

• vibration-free (in order to avoid additional pressure fluctuations)

• not in the vicinity of heating or cooling lines

• insulate if the ambient temperature is below ore above the reference temperature

• with a bending radius of 100 mm.

• The ambient temperature and length of both capillaries should be the same when using

two-sided diaphragm seal systems.

• Two diaphragm seals which are the same (e.g. with regard to diameter, material, etc.) should

always be used for the negative and positive side (standard delivery).

Endress+Hauser 7

Page 8

Installation Deltabar S FOUNDATION Fieldbus

+ –

+

–

≥ 100 mm

+ –

+

–

H1

–

+

0.0

2.0

4.0

6.0

8.0

10.0

12.0

50 100 300 400 500 600 700 800 900 1000

200

Inert oil

High temperature

oil

Vegetable oil

Silicone oil

Pressure, diaphragm seal positive side [mbar

abs

]

Height difference H1 [m]

Low temperature oil

Fig. 1: Mounting Deltabar S, FMD78 with diaphragm seals and capillary, recommended mounting for vacuum

applications: mount pressure transmitter below the lowest diaphragm seal!

P01-FMD78xxx-11-xx-xx-xx-005

3.3.1 Vacuum application (FMD78)

For applications under vacuum, Endress+Hauser recommends mounting the pressure

transmitter underneath the lower diaphragm seal. A vacuum load of the diaphragm seal caused

by the presence of filling oil in the capillaries is hereby prevented.

When the pressure transmitter is mounted above the lower diaphragm seal, the maximum

height difference H1 in accordance with the illustration below on the left must not be exceeded.

The maximum height difference is dependent on the density of the filling oil and the smallest

ever pressure that is permitted to occur at the diaphragm seal on the positive side (empty

container), see illustration below, on the right.

Fig. 2: Installation above the lower diaphragm

seal

P01-FMD7xxxx-11-xx-xx-xx-001

Fig. 3: Diagram of maximum installation height above the lower

diaphragm seal for vacuum applications dependent on the

pressure at the diaphragm seal on the positive side

P01-FMD78xxx-05-xx-xx-xx-016

8 Endress+Hauser

Page 9

Deltabar S FOUNDATION Fieldbus Installation

r ³ 120 mm

1

2

4

5

6

7

3.4 Assembling and mounting the "separate housing" version

Fig. 4: "Separate housing" version

1 In the "separate housing" version, the sensor is supplied with process connection and cable fitted.

2 Cable with connection jack

4Plug

5Locking screw

6 Housing fitted with housing adapter, included

7 Mounting bracket suitable for wall and pipe mounting, included

P01-xMD7xxxx-11-xx-xx-xx-011

Assembly and mounting

1. Connect plug (item 4) into the corresponding connection jack of the cable (item 2).

2. Plug the cable into the housing adapter (item 6).

3. Tighten the locking screw (item 5).

4. Mount the housing on a wall or pipe using the mounting bracket (item 7).

When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at

least 5 Nm.

Mount the cable with a bending radius (r) 120 mm.

Endress+Hauser 9

Page 10

Wiring Deltabar S FOUNDATION Fieldbus

4 Wiring

Warning!

#

• If the operating voltage is > 35 VDC: Dangerous contact voltage at terminals.

Risk of electric shock!

In a wet environment, do not open the cover if voltage is present.

• Risk of electric shock and/or explosion! Switch off the supply voltage before connecting the

device.

• When using the measuring device in hazardous areas, installation must comply with the

corresponding national standards and regulations and the Safety Instructions or Installation or

Control Drawings.

4.1 Connecting the device

Note!

!

• Devices with integrated overvoltage protection must be grounded.

• Protective circuits against reverse polarity, HF influences and overvoltage peaks are installed.

• The supply voltage must match the supply voltage on the nameplate.

• Switch off the supply voltage before connecting the device.

• Remove housing cover of the terminal compartment.

• Guide cable through the gland. Preferably use twisted, shielded two-wire cable.

• Connect device in accordance with the following diagram.

• Screw down housing cover.

• Switch on supply voltage.

10 Endress+Hauser

Page 11

Deltabar S FOUNDATION Fieldbus Wiring

➀

➁

➂

➃

➄

FF FF

FF FF

Fig. 5: Electrical connection FOUNDATION Fieldbus, observe also the following section.

For devices with 7/8" plug see Operating Instructions.

1Housing

2 Internal ground terminal

3 External ground terminal

4 Supply voltage, for version in non-hazardous area = 9...32 V DC

5 Devices with integrated overvoltage protection are labeled OVP (overvoltage protection) here.

4.2 Connecting the measuring unit

Note!

!

For further information on the network structure and grounding and for further bus system

components such as bus cables, see the relevant documentation, e.g. Operating Instructions

BA00013S "FOUNDATION Fieldbus Overview" and the FOUNDATION Fieldbus Guideline.

4.2.1 Supply voltage

• Version for non-hazardous area: 9...32 V DC

4.2.2 Current consumption

15.5 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause 21.

4.2.3 Cable specification

• Use a twisted, shielded two-wire cable, preferably cable type A.

• Terminals for wire cross-Sections: 0.5...2.5 mm

• Outer cable diameter: 5...9 mm

2

P01-xMx7xxxx-04-xx-xx-xx-009

Endress+Hauser 11

Page 12

Wiring Deltabar S FOUNDATION Fieldbus

Note!

!

For further information on the cable specifications, see Operating Instructions BA00013S

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2

(MBP).

4.2.4 Grounding and shielding

Deltabar S must be grounded, for example by means of the external ground terminal.

Different grounding and shielding installation methods are available for FOUNDATION Fieldbus

networks such as:

• Isolated installation (see also IEC 61158-2)

• Installation with multiple grounding

• Capacitive installation

12 Endress+Hauser

Page 13

Deltabar S FOUNDATION Fieldbus Operation

E

+

–

Bargraph

Operating keys

Symbol

Bargraph

ValueFunction name

Measured value display

Unit

Header line

Information

line

Main line

Parameter

Identification

number

Editing modes

Selection

options

Value that

can be edited

Current measured value

5 Operation

5.1 Onsite display (optional)

A 4-line liquid crystal display (LCD) is used for display and operation. The onsite display shows

measured values, dialog texts, fault messages and notice messages.

The display of the device can be turned in 90° steps.

Depending on the installation position of the device, this makes it easy to operate the device and

read the measured values.

The onsite display is available in English. The assignment of the English parameter names to the

German parameter names is provided in the Operating Instructions. Needless to say, the device

can also be operated in 6 languages (de, en, fr, es, jp, ch) via the DTM or EDD. The FieldCare

program is an E+H DTM operating tool and can be acquired from endress.com.

P01-xxxxxxxx-07-xx-xx-xx-011

Endress+Hauser 13

Page 14

Operation Deltabar S FOUNDATION Fieldbus

The following table illustrates the symbols that can appear on the onsite display. Four symbols

can occur at one time.

Symbol Meaning

Alarm symbol

– Symbol flashing: warning, device continues measuring.

– Symbol permanently lit: error, device does not continue measuring.

Note: The alarm symbol may overlie the tendency symbol.

Lock symbol

The operation of the device is locked. Unlock device, see Page 21, Section 5.4.

Communication symbol

Data transfer via communication

Simulation symbol

Simulation mode is activated. DIP switch 2 for simulation is set to "On".

See Page 15, Section 5.2.1 "Position of operating elements".

Tendency symbol (increasing)

The primary value of the Transducer Block is increasing.

Tendency symbol (decreasing)

The primary value of the Transducer Block is decreasing.

Tendency symbol (constant)

The primary value of the Transducer Block has remained constant over the past few minutes.

14 Endress+Hauser

Page 15

Deltabar S FOUNDATION Fieldbus Operation

➀

0%

Zero

HW

21

PC

1

2

➀➁

➃

on

off

➂

➄

➅

Sim.

Sensor

on

off

Simulation

0%

Zero

Display

Histo

ROM

5.2 Operating elements

5.2.1 Position of operating elements

With regard to aluminum housings and stainless steel housing (T14/T15), the operating key is

located either outside the device under the protection cap or inside on the electronic insert. In

hygienic stainless housings (T17), the operating key is always located inside on the electronic

insert. Additionally, three operating keys are located on the optional onsite display.

Fig. 6: Operating key, external under the protective flap

1 Operating key or position adjustment (zero

point-correction) or total reset

P01-PMx7xxxx-19-xx-xx-xx-075

Fig. 7: Operating key and operating elements, internal

1 Green LED to indicate value is accepted

2 Operating key for position adjustment (zero

point-correction)

3 Slot for optional display

4 Slot for optional HistoROM

5 DIP-switch for locking/unlocking

measured-value-relevant parameters

6 DIP switch for simulation mode

P01-xxxxxxxx-19-xx-xx-xx-106

®

/M-DAT

Endress+Hauser 15

Page 16

Operation Deltabar S FOUNDATION Fieldbus

0%

Zero

1

2

on

Sim.

5.2.2 Function of the operating elements – onsite display not connected

Operating key(s) Meaning

– Position adjustment (zero point correction): Press key for at least 3 seconds. The

LED on the electronic insert lights up briefly if the pressure applied has been

accepted for position adjustment.

See also Page 37 ("Level" measuring mode) or Page 41 ("Pressure" measuring

mode).

P02-xxxxxxxx-19-xx-xx-xx-107

P01-xxxxxxxx-19-xx-xx-xx-134

– Total reset: Press key for at least 12 seconds. If the LED on the electronic insert

lights up briefly, the reset is being carried out.

– DIP-switch 1: for locking/unlocking measured-value-relevant parameters

Factory setting: off (unlocked)

– DIP switch 2: for simulation mode

Factory setting: off (simulation mode off)

To carry out a simulation the DIP switch has to be set in the "on" position. See

also Operating Instructions BA00301P, Section "Simulation".

5.2.3 Function of the operating elements – onsite display connected

Operating key(s) Meaning

– Navigate upwards in the picklist

– Edit the numerical values and characters within a function

– Navigate downwards in the picklist

– Edit the numerical values and characters within a function

–Confirm entry

– Jump to the next item

Contrast setting of onsite display: darker

O

O

S

F

and

F

and

S

F

and

O

16 Endress+Hauser

S

Contrast setting of onsite display: brighter

ESC functions:

– Exit edit mode without saving the changed value.

– You are in a menu within a function group. The first time you press the keys

simultaneously, you go back a parameter within the function group. Each time you

press the keys simultaneously after that, you go up a level in the menu.

– You are in a menu at a selection level. Each time you press the keys simultaneously,

you go up a level in the menu.

Note: The terms function group, level and selection level are explained in

Section 5.3.1, Page 17.

Page 17

Deltabar S FOUNDATION Fieldbus Operation

➀

➂

➁

➃

Measured value

GROUP SELECTION

DISPLAYSETTINGS

EXTENDED SETUP

POS. ZERO ADJUST

POS. INPUT VALUE

CALIB. OFFSET

POSITION ADJUSTMENT BASIC SETUP

OPERATING MENU

QUICK SETUP

MEASURING MODELANGUAGE

5.3 Onsite operation via onsite display

5.3.1 Structure of the operating menu

The menu is split into four levels. The three upper levels are used to navigate while you use the

bottom level to enter numerical values, select options and save settings. For the entire menu

see CD-ROM, Operating Instructions BA00301P.

The structure of the OPERATING MENU depends on the measuring mode selected, e.g. if the

"Pressure" measuring mode is selected, only the functions necessary for this mode are displayed.

Fig. 8: Structure of the operating menu

1 1. Selection level

2 2. Selection level

3Function groups

4 Parameter

Endress+Hauser 17

P01-xxxxxxxx-19-xx-xx-xx-145

Page 18

Operation Deltabar S FOUNDATION Fieldbus

5.3.2 Selecting an option

Example: Selecting the "Pressure" measuring mode.

Onsite display Operation

"Flow" has been selected as the measuring mode. A ✓ in

front of the menu text indicates the active option.

P01-xxxxxxxx-19-xx-xx-en-017

Use "+" or "–" to select "Pressure" as the operating mode.

P01-xxxxxxxx-19-xx-xx-en-033

1. Confirm your choice with "E". A ✓ in front of the

menu text indicates the active option.(The "Pressure"

measuring mode is selected.)

2. Jump to the next item with "E".

P01-xxxxxxxx-19-xx-xx-en-034

5.3.3 Editing a value

Example: adjusting DAMPING VALUE function from 2.0 s to 30.0 s. ä 16, Section 5.2.3

"Function of the operating elements – onsite display connected".

Onsite display Operation

The onsite display shows the parameter to be changed. The

value highlighted in black can be changed. The "s" unit is

fixed and cannot be changed.

P01-xxxxxxxx-19-xx-xx-en-023

18 Endress+Hauser

Page 19

Deltabar S FOUNDATION Fieldbus Operation

Onsite display Operation

1. Press "+" or "–" to get to the editing mode.

2. The first digit is highlighted in black.

P01-xxxxxxxx-19-xx-xx-en-027

1. Use "+" to change "2" to "3".

2. Confirm "3" with "E". The cursor jumps to the next

position (highlighted in black).

P01-xxxxxxxx-19-xx-xx-en-028

The decimal point is highlighted in black, i.e. you can now

edit it.

P01-xxxxxxxx-19-xx-xx-en-029

1. Keep pressing "+" or "–" until "0" is displayed.

2. Confirm "0" with "E".

The cursor jumps to the next position. is displayed

and is highlighted in black. See next graphic.

P01-xxxxxxxx-19-xx-xx-en-030

Use "E" to save the new value and exit the editing mode.

See next graphic.

P01-xxxxxxxx-19-xx-xx-en-031

The new value for the damping is now 30.0 s.

– Jump to the next parameter with "E".

– You can get back to the editing mode with "+" or "–".

P01-xxxxxxxx-19-xx-xx-en-032

Endress+Hauser 19

Page 20

Operation Deltabar S FOUNDATION Fieldbus

5.3.4 Taking pressure applied at device as value

Example: performing position adjustment.

Onsite display Operation

The bottom line on the onsite display displays the pressure

present, here 3.9 mbar.

P01-xxxxxxxx-19-xx-xx-en-158

Use "+" or "–" to switch to the "Confirm" option. The

active selection is highlighted in black.

P01-xxxxxxxx-19-xx-xx-en-159

Use "E" to assign the value (3.9 mbar) to the POS. ZERO

ADJUST parameter. The device confirms the calibration

and jumps back to the parameter, here POS. ZERO

ADJUST (see next graphic).

P01-xxxxxxxx-19-xx-xx-en-037

Switch to the next parameter with "E".

P01-xxxxxxxx-19-xx-xx-en-160

20 Endress+Hauser

Page 21

Deltabar S FOUNDATION Fieldbus Operation

5.4 Locking/unlocking operation

Once you have entered all the parameters, you can lock your entries against unauthorized and

undesired access.

You have the following possibilities for locking/unlocking the operation:

• Via a DIP switch on the electronic insert, locally at the device (see Page 15).

• Via the onsite display (optional)

• Via digital communication.

The -symbol on the onsite display indicates that operation is locked. Parameters which refer

to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST can still be altered.

Note!

!

• If operation is locked by means of the DIP-switch, you can only unlock operation again by

means of the DIP-switch. If operation is locked by means of remote operation e.g. FieldCare,

you can only unlock operation again by means of remote operation.

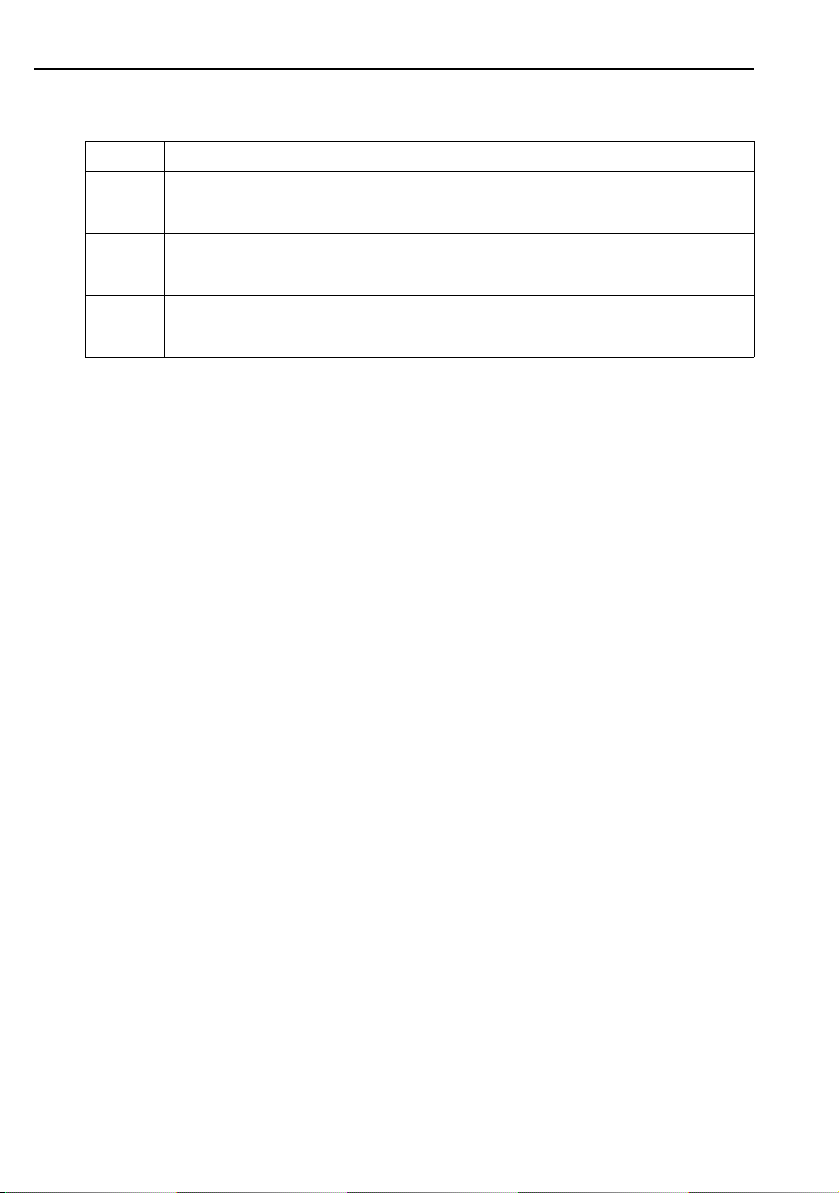

The table provides an overview of the locking functions:

Locking

via

DIP-Switch yes no no yes no no

Onsite display yes no no no yes yes

Remote operation yes no no no yes yes

1) Parameters which refer to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST can still be

altered.

Locking operation 1. Operation via FF configuration program: select SWLOCK parameter in the Resource

Unlocking operation 1. Operation via FF configuration program: select SWLOCK parameter in the Resource

View/read

parameter

Modify/write via

Onsite

display

Locking/Unlocking operation via onsite display or remote operation

Block.

Operation via FieldCare: select INSERT PIN No. parameter.

Menu path: OPERATING MENU OPERATION INSERT PIN No.

2. To lock operation, enter "0" for the parameter.

Block.

Operation via FieldCare: select INSERT PIN No. parameter.

2. To unlock operation, enter "100" for the parameter.

1)

Remote

operation

Unlocking via

DIP-Switch Onsite

display

Remote

operation

Endress+Hauser 21

Page 22

Commissioning Deltabar S FOUNDATION Fieldbus

6 Commissioning

Warning!

#

• If a pressure that is lower than the minimum permitted pressure is present at the device,

messages "E120 sensor low pressure" and "E727 sensor pressure error - overrange" are output

in succession.

• If a pressure that is greater than the maximum permitted pressure is present at the device,

messages "E115 sensor overpressure" and "E727 sensor pressure error - overrange" are output

in succession.

• The messages E727, E115 and E120 are "Error"-type messages and can be configured as a

"Warning" or an "Alarm". The factory setting for these messages is "Warning". This setting

prevents the BAD status from being transmitted in applications (e.g. cascade measurement)

where the user is aware of the risk of the sensor range being overshot.

• We recommend setting messages E727, E115 and E120 to "Alarm" in the following instances:

– It is not necessary to violate the sensor range for the measuring application.

– A position adjustment must be carried out that has to correct a large measured error as a

result of the orientation of the device.

6.1 Commissioning via an FF configuration program

Note!

!

• The device is configured for the Pressure measuring mode as standard. The measuring range

and the unit in which the measured value is transmitted, as well as the digital output value of

the Analog Input Block OUT, correspond to the data on the nameplate. Following a reset with

code 7864, the OUT parameter may have to be rescaled (see also Page 42, Section 6.7

"Scaling the OUT parameter").

1. Switch on the device.

2. Note the DEVICE_ID.

3. Open the configuration program.

4. Load Cff and device description files into the host system or the configuration program.

Make sure you are using the right system files.

5. Identify the device using the DEVICE_ID. Assign the desired tag name to the device by

means of the PD_TAG parameter.

22 Endress+Hauser

Page 23

Deltabar S FOUNDATION Fieldbus Commissioning

Configuring the Resource Block

1. Open the Resource Block.

2. If necessary, disable the lock for device operation. See Page 21, Section 5.4

"Locking/unlocking operation". Operating is unlocked as standard.

3. If necessary, change the block name. Factory setting: RS_452B481009-xxxxxxxxxxx

4. If necessary, assign a description to the block by means of the TAG_DESC parameter.

5. If necessary, change other parameters as per the requirements.

Configuring the Transducer Blocks

Deltabar S has the following Transducer Blocks:

• Pressure Transducer Block

• Service Transducer Block

• DP Flow Block

• Display Transducer Block

• Diagnostic Transducer Block

The explanation that follows is an example for the Pressure Transducer Block.

1. If necessary, change the block name. Factory setting: RS_452B481009-xxxxxxxxxxx

2. Set the block mode to OOS using the MODE_BLK parameter, TARGET element.

3. Configure the device in accordance with the measuring task. See also these Brief

Operating Instructions Section 6.2 to Section 6.7.

4. Set the block mode to Auto using the MODE_BLK parameter, TARGET element.

Note!

!

The block mode must be set to "Auto" for the Pressure, Service and DP Flow Block for the

measuring device to function correctly.

Configuring the Analog Input Blocks

Deltabar S has 3 Analog Input Blocks that can be assigned as required to the various process

variables.

1. If necessary, change the block name. Factory setting: RS_452B481009-xxxxxxxxxxx

2. Set the block mode to OOS using the MODE_BLK parameter, TARGET element.

3. Use the CHANNEL parameter to select the process variable which should be used as the

input value for the Analog Input Block. The following settings are possible:

– CHANNEL = 1: Primary value, a pressure, level or flow value depending on the

measuring mode selected

– CHANNEL = 2: Secondary value, here the sensor temperature

– CHANNEL = 6: Totalizer 1

Factory setting:

– Analog Input Block 1: CHANNEL = 1: Primary Value (pressure measured value)

– Analog Input Block 2: CHANNEL = 2: Secondary Value (sensor temperature)

– Analog Input Block 3: CHANNEL = 3: Totalizer 1

Endress+Hauser 23

Page 24

Commissioning Deltabar S FOUNDATION Fieldbus

4. Use the XD_SCALE parameter to select the desired unit and the block input range for the

process variable. See also Page 42, Section 6.7 "Scaling the OUT parameter".

Make sure that the unit selected suits the process variable selected. If the process variable

does not suit the unit, the BLOCK_ERROR parameter reports "Block Configuration Error"

and the block mode cannot be set to "Auto".

5. Use the L_TYPE parameter to select the type of linearization for the input variable (factory

setting: Direct).

Make sure that the settings for the XD_SCALE and OUT_SCALE parameters are the same

for the "Direct" linearization type. If the process values and units do not match, the

BLOCK_ERROR parameter reports "Block Configuration Error" and the block mode cannot

be set to "Auto".

6. Enter the alarm and critical alarm messages by means of the HI_HI_LIM, HI_LIM,

LO_LO_LIM and LO_LO_LIM parameters. The limit values entered have to be within the

value range specified for the OUT_SCALE parameter.

7. Specify the alarm priorities by means of the HI_HI_PRI, HI_PRI, LO_LO_PRI and LO_PRI

parameters. Reporting to the field host system only takes place with alarms with a priority

greater than 2.

8. Set the block mode to Auto using the MODE_BLK parameter, TARGET element. For this

purpose, the Resource Block must also be set to the "Auto" block mode.

Additional configuration

1. Depending on the control or automation task, configure additional function blocks and

output blocks. See also Operating Instructions BA00303P "Description of Device

Functions Cerabar S/Deltabar S/Deltapilot S".

2. Link the function blocks and output blocks.

3. After specifying the active LAS, download all the data and parameters to the field device.

6.2 Selecting the language and measuring mode

6.2.1 Local operation

The MEASURING MODE parameter is on the 1st selection level. See also Page 17,

Section 5.3.1 "Structure of the operating menu".

The following measuring modes are available:

• Pressure

• Level

• Flow

6.2.2 Selecting the language and measuring mode via FieldCare

The parameters for setting the measuring mode are displayed in the FieldCare "Measuring mode"

menu.

24 Endress+Hauser

Page 25

Deltabar S FOUNDATION Fieldbus Commissioning

The following measuring modes are available:

• Pressure

• Level

• Flow

The LANGUAGE parameter is arranged in the DISPLAY group.

• Select the menu language for FieldCare using the "Language Button" in the configuration

window. Select the menu language for the FieldCare frame by means of the "Extra" menu

"Options" "Display"

"Language".

The following languages are available:

•Deutsch

• English

• Français

•Español

• Chinese

• Japanese

6.3 Position adjustment

Due to the orientation of the device, there may be a shift in the measured value, i.e. when the

container is empty or partly filled, the measured value parameter does not display zero. There

are two options to choose from when performing position adjustment.

• Onsite display menu path: GROUP SELECTION OPERATING MENU SETTINGS

POSITION ADJUSTMENT

• FieldCare menu path: OPERATING MENU SETTINGS POSITION ADJUSTMENT

6.3.1 Performing position adjustment via the onsite display or FieldCare

The parameters listed in the following table can be found in the POSITION ADJUSTMENT

group (menu path: OPERATING MENU SETTINGS POSITION ADJUSTMENT).

Parameter name Description

POS. ZERO ADJUST

Entry

Endress+Hauser 25

Position adjustment – the pressure difference between zero (set point) and the measured pressure

need not be known.

Example:

– MEASURED VALUE = 2.2 mbar

– Correct the MEASURED VALUE via the POS. ZERO ADJUST parameter with the "Confirm"

option. This means that you are assigning the value 0.0 to the pressure present.

– MEASURED VALUE (after pos. zero adjust) = 0.0 mbar

The CALIB. OFFSET parameter displays the resulting pressure difference (offset) by which the

MEASURED VALUE was corrected.

Factory setting:

0.0

Page 26

Commissioning Deltabar S FOUNDATION Fieldbus

Parameter name Description

POS. INPUT VALUE

Input

CALIB. OFFSET

Entry

Position adjustment – the pressure difference between zero (set point) and the measured pressure

need not be known. To correct the pressure difference, you need a reference measurement value (e. g.

from a reference device).

Example:

– MEASURED VALUE = 0.5 mbar

– For the POS. INPUT VALUE parameter, specify the desired set point for the MEASURED VALUE,

e.g. 2 mbar. (The following applies: MEASURED VALUE

– MEASURED VALUE (after entry for POS. INPUT VALUE) = 2.0 mbar

– The CALIB. OFFSET parameter displays the resulting pressure difference (offset) by which the

MEASURED VALUE was corrected.

The following applies: CALIB. OFFSET = MEASURED VALUE

here: CALIB. OFFSET = 0.5 mbar – 2.0 mbar = – 1.5 mbar)

Factory setting:

0.0

Position adjustment – the pressure difference between zero (set point) and the measured pressure is

known. (A reference pressure is not present at the device.)

Example:

– MEASURED VALUE = 2.2 mbar

– Via the CALIB. OFFSET parameter, enter the value by which the MEASURED VALUE should be

corrected. To correct the MEASURED VALUE to 0.0 mbar, you must enter the value 2.2 here.

(The following applies: MEASURED VALUE

– MEASURED VALUE (after entry for calib. offset) = 0.0 mbar

Factory setting:

0.0

= MEASURED VALUE

new

= POS. INPUT VALUE)

new

– POS. INPUT VALUE,

old

– CALIB. OFFSET)

old

6.4 Flow measurement

6.4.1 Preparatory steps

Note!

!

• The Deltabar S PMD70 or PMD75 is usually used for flow measurement.

• Before calibrating the Deltabar S, the impulse piping must be cleaned and filled with fluid.

See the following table.

26 Endress+Hauser

Page 27

Deltabar S FOUNDATION Fieldbus Commissioning

I

II

+–

–+

6

6

7

7

–+

3

24

A B

A

B

+

1

5

24

3

II

I

IIIIII

Valves Meaning Preferred installation

1 Close 3.

2 Fill measuring system with fluid.

Open A, B, 2, 4. Fluid flows in.

1)

3 Clean impulse piping if necessary

– by blowing out with compressed air in the case of gases

– by rinsing out in the case of liquids.

Close 2 and 4. Block off device.

Open 1 and 5.

Close 1 and 5.

4Vent device.

Open 2 and 4. Introduce fluid.

Close 4. Close negative side.

Open 3. Balance positive and negative

Open 6 and 7 briefly, then

close them again.

5 Carry out pos. zero adjustment if the following conditions are

met. If the conditions are not met, then do not carry out the

pos. zero adjustment until after step 6. See Page 29,

Section 6.4.3 and 25, Section 6.3.

Conditions:

– The process cannot be blocked off.

– The tapping points (A and B) are at the same geodetic

height.

6 Set measuring point in operation.

Close 3. Shut off positive side from

Open 4. Connect negative side.

Now

–1

– 2 and 4 are open.

– A and B open (if present).

7 Carry out pos. zero adjustment if the flow can be blocked off.

In this case, step 5 is not applicable. See Page 29,

Section 6.4.3 and 25, Section 6.3.

8 Carry out calibration. See Page 28, Section 6.4.2.

1) for arrangement with 5 valves

, 3, 5, 6 and 7 are closed.

:

Blow out/rinse out impulse

piping.

Close valves after cleaning.

side.

Fill device completely with

fluid and remove air.

negative side.

Fig. 9: Above: preferred installation for gases

Below: preferred installation for liquids

I Deltabar S, PMD70 or PMD75

II Three-valve manifold

III Separator

1, 5 Drain valves

2, 4 Inlet valves

3 Equalizing valve

6, 7 Vent valves on Deltabar S

A, B Shutoff valves

P01-xMD7xxxx-11-xx-xx-xx-002

Endress+Hauser 27

Page 28

Commissioning Deltabar S FOUNDATION Fieldbus

6.4.2 Information on flow measurement

In the "Flow" measuring mode, the device determines a volume or mass flow value from the

differential pressure measured. The differential pressure is generated by means of primary

devices such as pitot tubes or orifice plates and depends on the volume or mass flow. Four flow

measuring modes are available: volume flow, norm volume flow (European norm conditions),

standard volume flow (American standard conditions) and mass flow.

In addition, the Deltabar S software is equipped with two totalizers as standard. The totalizers

add up the volume or the mass flow. The counting function and the unit can be set separately

for both totalizers. The first totalizer (totalizer 1) can be reset to zero at any time while the

second (totalizer 2) totalizes the flow from commissioning onwards and cannot be reset.

Note!

!

• There is a Quick Setup menu for each of the measuring modes Pressure, Level and Flow which

guides you through the most important basic functions. With the setting in the MEASURING

MODE parameter, you specify which Quick Setup menu should be displayed. See also

Page 24, Section 6.2 "Selecting the language and measuring mode". No Quick Setup menus

are available for the FF configuration programs.

• For a detailed description of the parameters see the Operating Instructions BA00303P

"Cerabar S/Deltabar S/Deltapilot S, Description of device functions"

– FF, Table Pressure Transducer Block

– FF, Table DP Flow Block

– FieldCare, Table POSITION ADJUSTMENT

– FieldCare, Table BASIC SETUP

– FieldCare, Table EXTENDED SETUP

– FieldCare, Table TOTALIZER SETUP

28 Endress+Hauser

Page 29

Deltabar S FOUNDATION Fieldbus Commissioning

1) 1)2) 2)

1)

1) On-site display only

2) FieldCare only

PROFILE VIEW

MAX FLOW

MAX. PRESS. FLOW

POS. ZERO ADJUST

DAMPING VALUE

MEASURED VALUE

QUICK SETUP

GROUPSELECTION

MEASURING MODE MEASURING MODELANGUAGE

FlowPressure Level

QUICK SETUP OPERATING MENU

6.4.3 Quick Setup menu for the Flow measuring mode

Fig. 10: Quick Setup menu for the Flow measuring mode

P01-xxxxxxxx-19-xx-xx-xx-166

Onsite operation FieldCare

Measured value display

Switch from the measured value display to GROUP

SELECTION with F.

GROUP SELECTION

Select MEASURING MODE.

Measured value display

Select QUICK SETUP menu.

Measuring Mode

Select the Primary Value Type parameter.

MEASURING MODE

Select "Flow" option.

GROUP SELECTION

Select QUICK SETUP menu.

POS. ZERO ADJUST

Due to orientation of the device, there may be a shift in the

measured value. You correct the MEASURED VALUE via the

POS. ZERO ADJUST parameter with the "Confirm" option,

i. e. you assign the value 0.0 to the pressure present.

MAX. FLOW

Enter maximum flow of primary device.

(See also layout sheet of primary device).

MAX. PRESS FLOW

Enter maximum pressure of primary device.

(See also layout sheet of primary device).

Primary Value Type

Select "Flow" option.

POS. ZERO ADJUST

Due to orientation of the device, there may be a shift in the

measured value. You correct the MEASURED VALUE via the

POS. ZERO ADJUST parameter with the "Confirm" option,

i. e. you assign the value 0.0 to the pressure present.

MAX. FLOW

Enter maximum flow of primary device.

(See also layout sheet of primary device).

MAX. PRESS FLOW

Enter maximum pressure of primary device.

(See also layout sheet of primary device).

Endress+Hauser 29

Page 30

Commissioning Deltabar S FOUNDATION Fieldbus

Onsite operation FieldCare

DAMPING TIME

Enter damping time (time constant ). The damping affects

the speed at which all subsequent elements, such as the

onsite display, measured value and OUT value of the Analog

Input Block react to a change in the pressure.

Note!

!

For onsite operation, see also Page 16, Section 5.2.3 "Function of the operating elements –

DAMPING TIME

Enter damping time (time constant ). The damping affects

the speed at which all subsequent elements, such as the

onsite display, measured value and OUT value of the Analog

Input Block react to a change in the pressure.

onsite display connected" and Page 17, Section 5.3 "Onsite operation via onsite display".

30 Endress+Hauser

Page 31

Deltabar S FOUNDATION Fieldbus Commissioning

+

A

B

6

II

I

+

–

p

atm

6.5 Level measurement

6.5.1 Preparatory steps

Open container

Note!

!

• The Deltabar S PMD70, PMD75, FMD76 and FMD77 are suitable for level measurement in

an open container.

• FMD76 and FMD77: the device is ready for calibration immediately after opening the shutoff

valves (may or may not be present).

• PMD70 and PMD75: before calibrating the device, the impulse piping must be cleaned and

filled with fluid. See the following table.

Valves Meaning Installation

1 Fill container to a level above the lower tap.

2 Fill measuring system with fluid.

Open A. Open shutoff valve.

3Vent device.

Open 6 briefly, then close it

again.

4 Set measuring point in operation.

Now

– B and 6 are closed.

– A is open.

5 Carry out calibration.

See Page 34, Section 6.5.2.

Fill device completely with

fluid and remove air.

Fig. 11: Open container

I Deltabar S, PMD70 or PMD75

II Separator

6 Vent valves on Deltabar S

A Shutoff valve

B Drain valve

P01-xMD7xxxx-11-xx-xx-xx-003

Endress+Hauser 31

Page 32

Commissioning Deltabar S FOUNDATION Fieldbus

+

A

B

6

7

3

2

4

1

5

+

–

II

I

IIIIII

Closed container

Note!

!

• All Deltabar S versions are suitable for level measurement in closed containers.

• FMD76 and FMD77: the device is ready for calibration immediately after opening the shutoff

valves (may or may not be present).

• FMD78: the device is ready for calibration immediately.

• PMD70 and PMD75: before calibrating the device, the impulse piping must be cleaned and

filled with fluid. See the following table.

Valves Meaning Installation

1 Fill container to a level above the lower tap.

2 Fill measuring system with fluid.

Close 3. Shut off positive side from

Open A and B. Open shutoff valves.

3 Vent positive side (empty negative side if necessary).

Open 2 and 4. Introduce fluid on positive

Open 6 and 7 briefly, then

close them again.

4 Set measuring point in operation.

Now

– 3, 6 and 7 are closed.

– 2, 4, A and B are open.

5 Carry out calibration.

See Page 34, Section 6.5.2.

negative side.

side.

Fill positive side completely

with fluid and remove air.

Fig. 12: Closed container

I Deltabar S, PMD70 and PMD75

II Three-valve manifold

III Separator

1, 2 Drain valves

2, 4 Inlet valves

3 Equalizing valve

6, 7 Vent valve on Deltabar S

A, B Shutoff valve

P01-xMD7xxxx-11-xx-xx-xx-004

32 Endress+Hauser

Page 33

Deltabar S FOUNDATION Fieldbus Commissioning

6

7

+

–

+

A

B

3

2

4

1

5

II

I

IIIIII

Closed containers with superimposed steam

Note!

!

• All Deltabar S versions are suitable for level measurement in containers with superimposed

steam.

• FMD76 and FMD77: the device is ready for calibration immediately after opening a shutoff

valve (may or may not be present).

• FMD78: the device is ready for calibration immediately.

• PMD70 and PMD75: before calibrating the device, the impulse piping must be cleaned and

filled with fluid. See the following table.

Valves Meaning Installation

1 Fill container to a level above the lower tap.

2 Fill measuring system with fluid.

Open A and B. Open shutoff valves.

Fill the negative impulse piping to the level of the condensate

trap.

3Vent device.

Open 2 and 4. Introduce fluid.

Close 4. Close negative side.

Open 3. Balance positive and negative

Open 6 and 7 briefly, then

close them again.

4 Set measuring point in operation.

Close 3. Shut off positive side from

Open 4. Connect negative side.

Now

– 3, 6 and 7 are closed.

– 2, 4, A and B are open.

5 Carry out calibration.

See Page 34, Section 6.5.2.

side.

Fill device completely with

fluid and remove air.

negative side.

Fig. 13: Closed container with superimposed steam

I Deltabar S, PMD70 and PMD75

II Three-valve manifold

III Separator

1, 5 Drain valves

2, 4 Inlet valves

3 Equalizing valve

6, 7 Vent valves on Deltabar S

A, B Shutoff valves

P01-xMD7xxxx-11-xx-xx-xx-005

Endress+Hauser 33

Page 34

Commissioning Deltabar S FOUNDATION Fieldbus

6.5.2 Information on level measurement

Note!

!

• The Flow, Level and Pressure operating modes each have a quick setup menu which guides

you through the most important basic functions. See Page 37 for the "Level" quick setup

menu.

• Furthermore, the three level modes "Level Easy Pressure", "Level Easy Height" and "Level

Standard" are available to you for level measurement. You can select from the "Linear",

"Pressure linearized" and "Height linearized" level types for the "Level Standard" level mode.

The table in the "Overview of level measurement" section below provides an overview of the

various measuring tasks.

– In the "Level Easy Pressure" and "Level Easy Height" level modes, the values entered are

not tested as extensively as in the "Level Standard" level mode. The values entered for

EMPTY CALIB./FULL CALIB., EMPTY PRESSURE/FULL PRESSURE and EMPTY

HEIGHT/FULL must have a minimum interval of 1% for the "Level Easy Pressure" and

"Level Easy Height" level modes. The value will be rejected with a warning message if the

values are too close together. Further limit values are not checked; i.e. the values entered

must be appropriate for the sensor and the measuring task so that the measuring device can

measure correctly.

– The "Level Easy Pressure" and "Level Easy Height" level modes encompass fewer

parameters than the "Level Standard" mode and are used for quick and easy configuration

of a level application.

– Customer-specific units of fill level, volume and mass or a linearization table may only be

entered in the "Level Standard" level mode.

• For a detailed description of the parameters and configuration examples, see Operating

Instructions BA00303P "Cerabar S/Deltabar S/ Deltapilot S, Description of Device

Functions".

34 Endress+Hauser

Page 35

Deltabar S FOUNDATION Fieldbus Commissioning

6.5.3 Overview of level measurement

Measuring task LEVEL

The measured

variable is in direct

proportion to the

measured pressure.

Calibration is

performed by

entering two

pressure-level

value pairs.

The measured

variable is in direct

proportion to the

measured pressure.

Calibration is

performed by

entering the

density and two

height-level value

pairs.

The measured

variable is in direct

proportion to the

measured pressure.

SELECTION/LE

VEL MODE

LEVEL

SELECTION: Level

Easy Pressure

LEVEL

SELECTION: Level

Easy Height

LEVEL

SELECTION: Level

standard/

LEVEL MODE:

Linear

Measured

variable options

Via OUTPUT UNIT

parameter: %, level,

volume or mass

units.

Via OUTPUT UNIT

parameter: %, level,

volume or mass

units.

Via LIN.

MEASURAND

parameter:

– % (level)

– Level

– Volume

–Mass

Description Comment Measured value

– Calibration with

reference

pressure – wet

calibration, see

Operating

Instructions

BA00303P.

–Calibration

without

reference

pressure – dry

calibration, see

Operating

Instructions

BA00303P.

– Calibration with

reference

pressure – wet

calibration, see

Operating

Instructions

BA00303P.

–Calibration

without

reference

pressure – dry

calibration, see

Operating

Instructions

BA00303P.

– Calibration with

reference

pressure – wet

calibration, see

Operating

Instructions

BA00303P.

–Calibration

without

reference

pressure – dry

calibration, see

Operating

Instructions

BA00303P.

– Incorrect entries

are possible

– Customized

units are not

possible

– Incorrect entries

are possible

– Customized

units are not

possible

– Incorrect entries

are rejected by

the device

– Customized

level, volume

and mass units

are possible

display

The measured

value display and

the LEVEL

BEFORE LIN.

parameter show

the measured

value.

The measured

value display and

the LEVEL

BEFORE LIN.

parameter show

the measured

value.

The measured

value display and

the LEVEL

BEFORE LIN.

parameter show

the measured

value.

Endress+Hauser 35

Page 36

Commissioning Deltabar S FOUNDATION Fieldbus

Measuring task LEVEL

The measured

variable is not in

direct proportion to

the measured

pressure as, for

example, with

containers with a

conical outlet. A

linearization table

must be entered for

the calibration.

–Two measured

variables are

required or

– The container

shape is given

by value pairs,

such as height

and volume.

The 1st measured

variable %-height

or height must be

in direct proportion

to the measured

pressure. The 2nd

measured variable

volume, mass or %

must not be in

direct proportion to

the measured

pressure. A

linearization table

must be entered for

the 2nd measured

variable. The 2nd

measured variable

is assigned to the

1st measured

variable by means

of this table.

SELECTION/LE

VEL MODE

LEVEL

SELECTION: Level

standard/

LEVEL MODE:

Pressure linearized

LEVEL

SELECTION: Level

standard/

LEVEL MODE:

Height linearized

Measured

variable options

Via LINd.

MEASURAND

parameter:

– Pressure + %

– Pressure +

volume

– Pressure + mass

Via COMB.

MEASURAND

parameter:

–Height +

volume

–Height + mass

–Height + %

–%-Height +

volume

–%-Height +

mass

–%-Height + %

Description Comment Measured value

– Calibration with

reference

pressure:

semiautomatic

entry of

linearization

table, see

Operating

Instructions

BA00303P.

– Calibration

without

reference

pressure:

manual entry of

linearization

table, see

Operating

Instructions

BA00303P.

– Calibration with

reference

pressure: wet

calibration and

semiautomatic

entry of

linearization

table, see

Operating

Instructions

BA00303P.

– Calibration

without

reference

pressure: dry

calibration and

manual entry of

linearization

table, see

Operating

Instructions

BA00303P.

– I ncorrect entries

are rejected by

the device

– Customized

level, volume

and mass units

are possible

– I ncorrect entries

are rejected by

the device

– Customized

level, volume

and mass units

are possible

display

The measured

value display and

the TANK

CONTENT

parameter show

the measured

value.

The measured

value display and

the TANK

CONTENT

parameter show

the 2nd measured

value (volume,

mass or %).

The LEVEL

BEFORE LIN

parameter displays

the 1st measured

value

(%-height or

height).

36 Endress+Hauser

Page 37

Deltabar S FOUNDATION Fieldbus Commissioning

1)2)1)

1)

2)

1)

2)

2)

3)

3)

EMPTY CALIB.

FULL CALIB.

LEVELSELECTION

1) On-site display only

2) FieldCare only

3) – LEVELSELECTION "Level Easy Pressure"

and CALIBRATION MODE "Wet"

– LEVELSELECTION = "Level Standard",

LEVEL MODE = "Linear" and

CALIBRATION MODE = "Wet"

PROFILE VIEW

POS. ZERO ADJUST

DAMPING VALUE

MEASURED VALUE

QUICK SETUP

MEASURING MODE

GROUPSELECTION

MEASURING MODEMEASURING MODELANGUAGE

FlowPressure Level

LEVELSELECTION

OPERATING MENU

6.5.4 Quick Setup menu for the Level measuring mode

Note!

!

• Some parameters are only displayed if other parameters are appropriately configured. For

example, the EMPTY CALIB. parameter is only displayed in the following cases:

– LEVEL SELECTION "Level Easy Pressure" and CALIBRATION MODE "Wet"

– LEVEL SELECTION "Level Standard", LEVEL MODE "Linear" and CALIBRATION MODE

"Wet"

You can find the LEVEL MODE and the CALIBRATION MODE parameters in the BASIC

SETTINGS function group.

• The following parameters are set to the following values in the factory:

– LEVEL SELECTION: Level Easy Pressure

– CALIBRATION MODE: Wet

– OUTPUT UNIT or LIN. MEASURAND: %

– EMPTY CALIB.: 0.0

– FULL CALIB.: 100.0

• The quick setup is suitable for simple and quick commissioning. If you wish to make more

complex settings, e.g. change the unit from "%" to "m", you will have to calibrate using the

BASIC SETTINGS group. See Operating Instructions BA00303P.

Fig. 14: Quick Setup menu for the "Level" measuring mode"

Endress+Hauser 37

P01-xMD7xxxx-19-xx-xx-xx-079

Page 38

Commissioning Deltabar S FOUNDATION Fieldbus

Onsite operation FieldCare

Measured value display

Switch from the measured value display to GROUP

SELECTION with F.

GROUP SELECTION

Select MEASURING MODE.

MEASURING MODE

Select "Level" option.

LEVEL SELECTION

Select level mode. For an overview see Page 35.

GROUP SELECTION

Select QUICK SETUP menu.

POS. ZERO ADJUST

Due to orientation of the device, there may be a shift in the

measured value. You correct the MEASURED VALUE via the

POS. ZERO ADJUST parameter with the "Confirm" option, i.

e. you assign the value 0.0 to the pressure present.

EMPTY CALIB.

Enter level for the lower calibration point.

For this parameter, enter a level value which is assigned to

the pressure present at the device.

FULL CALIB.

Enter level for the upper calibration point.

For this parameter, enter a level value which is assigned to

the pressure present at the device.

DAMPING TIME

Enter damping time (time constant ). The damping affects

the speed at which all subsequent elements, such as the

onsite display, measured value and OUT value of the Analog

Input Block react to a change in the pressure.

1)

1

Measured value display

Select QUICK SETUP menu.

Measuring Mode

Select the Primary Value Type parameter.

Primary Value Type

Select "Level" option.

LEVEL SELECTION / Level Selection

Select level mode. For an overview see Page 35.

POS. ZERO ADJUST

Due to orientation of the device, there may be a shift in the

measured value. You correct the MEASURED VALUE via the

POS. ZERO ADJUST parameter with the "Confirm" option, i.

e. you assign the value 0.0 to the pressure present.

EMPTY CALIB.

Enter level for the lower calibration point.

For this parameter, enter a level value which is assigned to

the pressure present at the device.

FULL CALIB.

Enter level for the upper calibration point.

For this parameter, enter a level value which is assigned to

the pressure present at the device.

DAMPING TIME

Enter damping time (time constant ). The damping affects

the speed at which all subsequent elements, such as the

onsite display, measured value and OUT value of the Analog

Input Block react to a change in the pressure.

1

1

1) – LEVEL SELECTION "Level Easy Pressure" and CALIBRATION MODE "Wet"

– LEVEL SELECTION "Level Standard", LEVEL MODE "Linear" and CALIBRATION MODE "Wet"

Note!

!

For onsite operation, see also Page 16, Section 5.2.3 "Function of the operating elements –

onsite display connected" and Page 17, Section 5.3 "Onsite operation via onsite display".

38 Endress+Hauser

Page 39

Deltabar S FOUNDATION Fieldbus Commissioning

6.6 Differential pressure measurement

6.6.1 Preparatory steps

Note!

!

• The Deltabar S PMD70, PMD75 and FMD78 are usually used for differential pressure

measurement.

• FMD78: the device is ready for calibration immediately.

• PMD70 and PMD75: before calibrating the device, the impulse piping must be cleaned and

filled with fluid. See the following table.

Endress+Hauser 39

Page 40

Commissioning Deltabar S FOUNDATION Fieldbus

I

II

+–

–+

6

6

7

7

–+

3

24

A B

A

B

+

1

5

24

3

II

I

IIIIII

Valves Meaning Preferred installation

1 Close 3.

2 Fill measuring system with fluid.

Open A, B, 2, 4. Fluid flows in.

3 Clean impulse piping if necessary:

– by blowing out with compressed air in the case of gases

– by rinsing out in the case of liquids.

Close 2 and 4. Block off device.

Open 1 and 5.

Close 1 and 5.

4 Vent device.

Open 2 and 4. Introduce fluid.

Close 4. Close negative side.

Open 3. Balance positive and negative

Open 6 and 7 briefly, then

close them again.

5 Set measuring point in operation.

Close 3. Shut off positive side from

Open 4. Connect negative side.

Now

–1

– 2 and 4 are open.

– A and B open (if present).

6 Carry out calibration if necessary. See also Page 41,

Section 6.6.2.

, 3, 5, 6 and 7 are closed.

1) for arrangement with 5 valves

1)

Blow out/rinse out impulse

piping.

Close valves after cleaning.

side.

Fill device completely with

fluid and remove air.

negative side.

Fig. 15: Above: preferred installation for gases

Below: preferred installation for liquids

I Deltabar S, PMD70 or PMD75

II Three-valve manifold

III Separator

1, 5 Drain valves

2, 4 Inlet valves

3 Equalizing valve

6, 7 Vent valves on Deltabar S

A, B Shutoff valve

P01-xMD7xxxx-11-xx-xx-xx-002

40 Endress+Hauser

Page 41

Deltabar S FOUNDATION Fieldbus Commissioning

1)2)1) 2)

1)

1) On-site display only

2) FieldCare only

PROFILE VIEW

POS. ZERO ADJUST

DAMPING VALUE

MEASURED VALUE

QUICK SETUP

GROUPSELECTION

MEASURING MODEMEASURING MODELANGUAGE

FlowPressure Level

OPERATING MENU

6.6.2 Information on differential pressure measurement

Note!

!

• There is a Quick Setup menu for each of the measuring modes Pressure, Level and Flow which

guides you through the most important basic functions. With the setting in the MEASURING

MODE parameter, you specify which Quick Setup menu should be displayed. See also

Page 24, Section 6.2 "Selecting the language and measuring mode". No Quick Setup menus

are available for the FF configuration programs.

• For a detailed description of the parameters, see Operating Instructions BA00303P "Cerabar

S/Deltabar S/Deltapilot S, Description of Device Functions"

– FF, Table, Pressure Transducer Block

– FieldCare, Table, POSITION ADJUSTMENT

– FieldCare, Table, BASIC SETUP

– FieldCare, Table, EXTENDED SETUP

6.6.3 Quick Setup menu for the Pressure measuring mode

Endress+Hauser 41

Fig. 16: Quick Setup menu for the "Pressure" measuring mode

P01-xMD7xxxx-19-xx-xx-xx-080

Page 42

Commissioning Deltabar S FOUNDATION Fieldbus

Onsite operation FieldCare

Measured value display

Switch from the measured value display to GROUP

SELECTION with F.

GROUP SELECTION

Select MEASURING MODE.

MEASURING MODE

Select "Pressure" option.

GROUP SELECTION

Select QUICK SETUP menu.

POS. ZERO ADJUST

Due to orientation of the device, there may be a shift in the

measured value. You correct the MEASURED VALUE via the

POS. ZERO ADJUST parameter with the "Confirm" option,

i. e. you assign the value 0.0 to the pressure present.

DAMPING TIME

Enter damping time (time constant ). The damping affects

the speed at which all subsequent elements, such as the

onsite display, measured value and OUT value of the Analog

Input Block react to a change in the pressure.

Note!

!

For onsite operation, see also Page 16, Section 5.2.3 "Function of the operating elements –

Measured value display

Select QUICK SETUP menu.

Measuring Mode

Select the Primary Value Type parameter.

Primary Value Type

Select "Pressure" option.

POS. ZERO ADJUST

Due to orientation of the device, there may be a shift in the

measured value. You correct the MEASURED VALUE via the

POS. ZERO ADJUST parameter with the "Confirm" option,

i. e. you assign the value 0.0 to the pressure present.

DAMPING TIME

Enter damping time (time constant ). The damping affects

the speed at which all subsequent elements, such as the

onsite display, measured value and OUT value of the Analog

Input Block react to a change in the pressure.

onsite display connected" and Page 17, Section 5.3 "Onsite operation via onsite display".

6.7 Scaling the OUT parameter

In the Analog Input Block, the input value or input range can be scaled in accordance with the

automation requirements.

Example:

The measuring range 0 to 500 mbar should be rescaled to 0 to 100 %.

• Select XD_SCALE group.

– For EU_0, enter "0".

– For EU_100, enter "500".

– For UNITS_INDEX, enter "mbar".

• Select OUT_SCALE group.

– For EU_0, enter "0".

– For EU_100, enter "10000".

– For UNITS_INDEX, select "%" for example.

The unit selected here does not have any effect on the scaling. This unit is not displayed on

the onsite display or in the operating program such as FieldCare.

• Result:

42 Endress+Hauser

Page 43

Deltabar S FOUNDATION Fieldbus Commissioning

0

1

0.7

0.7

1

0

700 100

L_TYPE: Indirect

Analog Input Block

XD_SCALE

OUT_SCALE

0

EU_0

500

EU_100

EU_0 EU_100

UNITS_INDEX:

mbar

UNITS_

INDEX:

%

OUT Value = 70

PRIMARY_VALUE

= 350 mbar

Output Pressure

Transducer Block

At a pressure of 350 mbar, the value 70 is output to a downstream block or to the PCS as the

OUT value.

P01-xMx7xxxx-05-xx-xx-xx-008

!

Endress+Hauser 43

Note!

• If you have selected the "Direct" mode for the L_TYPE parameter, you cannot change the

values and units for XD_SCALE and OUT_SCALE.

• The L_TYPE, XD_SCALE and OUT_SCALE parameters can only be changed in the OOS block

mode.

• Make sure that the output scaling of the Pressure Transducer Block SCALE_OUT matches the

input scaling of the Analog Input Block XD_SCALE.

Page 44

KA01024P/00/EN/15.14

71254469

71254469

CCS/FM+SGML 9

Loading...

Loading...