Page 1

BA01300C/07/EN/02.14

71261315

Products Solutions Services

Operating Instructions

CYR52

Ultrasonic cleaning

Page 2

Document information

DANGER

!

WARNING

!

CAUTION

!

NOTICE

Warnings

The structure, signal words and safety colors of the signs comply with the specifications of ANSI

Z535.6 ("Product safety information in product manuals, instructions and other collateral

materials").

Safety message structure Meaning

This symbol alerts you to a dangerous situation.

Causes (/consequences)

Consequences if safety message

is not heeded

‣ Corrective action

Causes (/consequences)

Consequences if safety message

is not heeded

‣ Corrective action

Causes (/consequences)

Consequences if safety message

is not heeded

‣ Corrective action

Failure to avoid the situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more

serious injuries.

Cause/situation

Consequences if safety message

is not heeded

‣ Action/note

Symbols used

Additional information, tips

Permitted or recommended

Forbidden or not recommended

This symbol alerts you to situations that can result in

damage to property and equipment.

Page 3

CYR52

Table of contents

1 Basic safety instructions . . . . . . 4

1.1 Requirements for personnel . . . . . . . . . . . 4

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Workplace safety . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational safety . . . . . . . . . . . . . . . . . . . 4

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . 5

2 Incoming acceptance and

product identification . . . . . . . . 6

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . 6

2.3 Product identification . . . . . . . . . . . . . . . . 7

2.4 Certificates and approvals . . . . . . . . . . . . 7

3 Installation . . . . . . . . . . . . . . . . . 8

3.1 Quick installation guide . . . . . . . . . . . . . . 8

3.2 Installation conditions . . . . . . . . . . . . . . 13

3.3 Mounting the ultrasonic transducer . . . 17

3.4 Mounting the ultrasonic generator . . . . 18

3.5 Post-installation check . . . . . . . . . . . . . . 21

4 Electrical connection . . . . . . . . 22

4.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Post-connection check . . . . . . . . . . . . . . 23

5 Commissioning. . . . . . . . . . . . . 24

5.1 Function check . . . . . . . . . . . . . . . . . . . . . 24

5.2 Configuration . . . . . . . . . . . . . . . . . . . . . . 24

9 Accessories . . . . . . . . . . . . . . . . 28

10 Technical data. . . . . . . . . . . . . . 29

10.1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . 29

10.3 Environment . . . . . . . . . . . . . . . . . . . . . . . 29

10.4 Mechanical construction . . . . . . . . . . . . . 30

Index. . . . . . . . . . . . . . . . . . . . . . 31

6 Diagnostics and troubleshooting

25

7 Maintenance. . . . . . . . . . . . . . . 26

7.1 Cleaning the transmitter, ultrasonic

transducer and ultrasonic generator . . . 26

8 Repair. . . . . . . . . . . . . . . . . . . . . 27

8.1 Spare part kits . . . . . . . . . . . . . . . . . . . . . 27

8.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Endress+Hauser

Page 4

Basic safety instructions CYR52

1 Basic safety instructions

1.1 Requirements for personnel

‣ Installation, commissioning, operation and maintenance of the measuring system must only

be carried out by specially trained technical personnel.

‣ The technical personnel must be authorized for the specified activities by the system

operator.

‣ Electrical connection must only be carried out by a certified electrician.

‣ Technical personnel must have read and understood these Operating Instructions and must

adhere to them.

‣ Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the enclosed Operating Instructions may only be carried out

directly at the manufacturer’s or by the service organization.

1.2 Designated use

The CYR52 ultrasonic cleaning unit is used to clean turbidity sensors in liquid medium that are

installed in pipes.

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is therefore not permitted.

The manufacturer is not liable for damage resulting from improper or non-designated use.

1.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Explosion protection guidelines (only devices approved for use in explosion hazardous areas)

• Installation instructions

• Local prevailing standards and regulations

Electromagnetic compatibility

The product has been tested for electromagnetic compatibility in accordance with the applicable

European standards for industrial applications.

The electromagnetic compatibility indicated only applies to a product that has been connected

in accordance with the instructions in these Operating Instructions.

1.4 Operational safety

‣ Before commissioning the entire measuring point, make sure all the connections are correct.

Ensure that electrical cables and hose connections are not damaged.

‣ Do not operate damaged products, and secure them against unintentional commissioning.

Label and identify the damaged product as defective.

‣ If faults cannot be rectified, you must take the products out of service and secure them

against unintentional commissioning.

4 Endress+Hauser

Page 5

CYR52 Basic safety instructions

1.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate.

Relevant regulations and European standards have been observed.

Endress+Hauser 5

Page 6

Incoming acceptance and product identification CYR52

2 Incoming acceptance and product identification

2.1 Incoming acceptance

• Make sure the packaging is undamaged!

• Notify the supplier of any damage to the packaging. Keep the damaged packaging until the

matter has been settled.

• Make sure the contents are not damaged!

• Notify the supplier of any damage to the delivery contents. Keep the damaged products until

the matter has been settled.

• Check the delivery to make sure nothing is missing. Compare it against the shipping

documents and your order.

• Pack the product for storage and transportation in such a way that it is reliably protected

against impact and moisture. The original packaging offers the best protection. Furthermore,

the permitted ambient conditions must also be observed (see "Technical data").

• If you have any questions, contact your supplier or your local sales center.

2.2 Scope of delivery

The scope of delivery of the ultrasonic cleaning system comprises:

• 1 Ultrasonic generator

• 1 Ultrasonic transducer

• Mounting material depending on the order version

• 1 Set of Operating Instructions BA01300C/07/EN

If you have any questions, please contact your supplier or your local sales center.

6 Endress+Hauser

Page 7

CYR52 Incoming acceptance and product identification

2.3 Product identification

2.3.1 Nameplate

You can find the following information on the nameplate:

• Manufacturer details

•Order code

• Serial number

• Operating conditions

• Safety information symbols

Compare the order code on the nameplate with your order.

2.3.2 Identifying the product

The order code and serial number of your device can be found in the following locations:

• On the nameplate

• In the shipping documents

To find out the version of your product, enter the order code indicated on the nameplate in

the search screen at the following address:

www.products.endress.com/order-ident

2.4 Certificates and approvals

2.4.1 4 mark

Declaration of Conformity

The product meets the requirements of the harmonized European standards.

As such, it complies with the legal specifications of the EC directives.

The manufacturer confirms successful testing of the product by affixing to it the 4 mark.

Endress+Hauser 7

Page 8

Installation CYR52

3Installation

3.1 Quick installation guide

Proceed as follows for the full installation of the measuring point:

• Install the ultrasonic transducer face to face with the turbidity sensor (see the "Mounting the

ultrasonic transducer" section).

• Install the ultrasonic generator (see the "Mounting the ultrasonic generator" section).

• Connect the ultrasonic transducer and the ultrasonic generator as illustrated in the graphic in

the "Electrical connection" section.

• Put the ultrasonic cleaning system into operation as described in the "Commissioning" section.

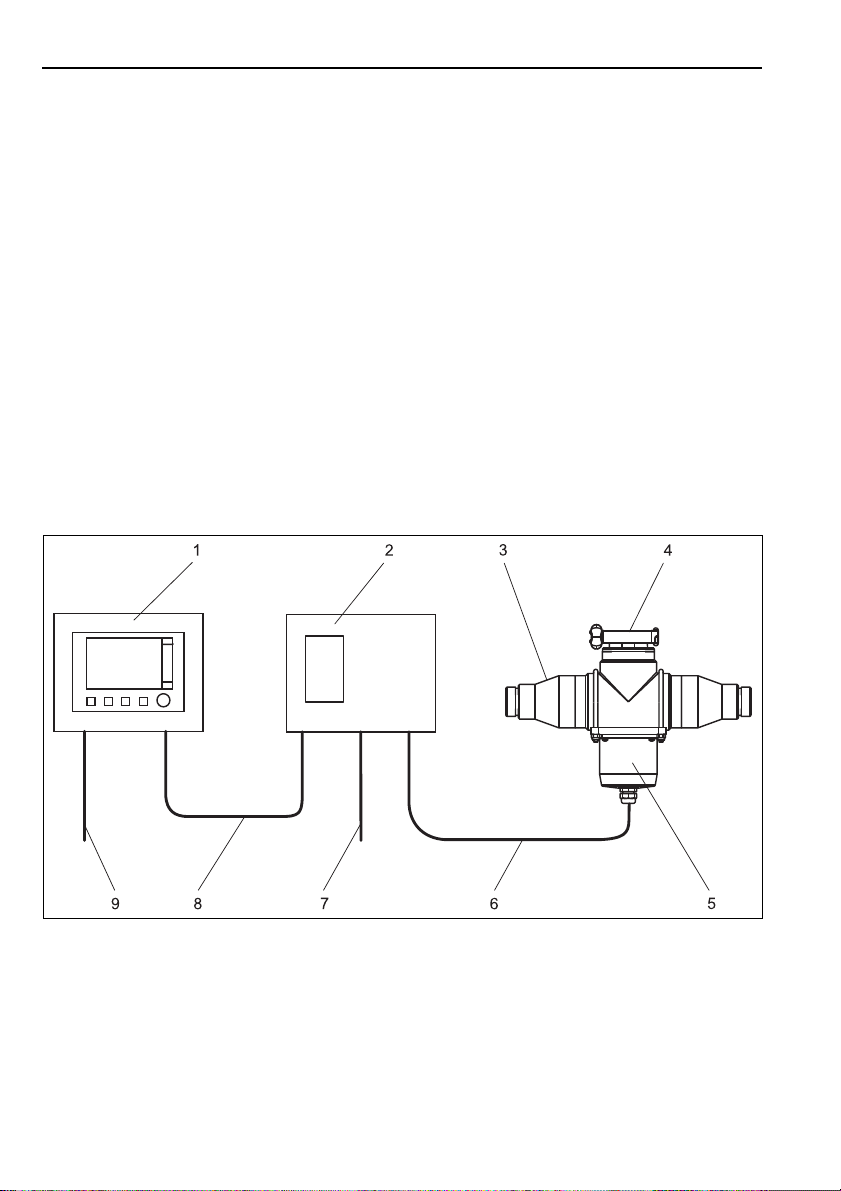

3.1.1 Overview

The complete ultrasonic cleaning system comprises:

• Ultrasonic generator

• Ultrasonic transducer

• Assembly or pipe with turbidity sensor

• Liquiline CM44x transmitter

Fig. 1: Ultrasonic cleaning with Flowfit CUA252 assembly

1

Liquiline CM44x transmitter

2

Ultrasonic generator

3

Flowfit CUA252 flow assembly

4

Clamp connection for turbidity sensor

5

Ultrasonic transducer

6

Power supply cable for ultrasonic transducer

7

Mains voltage cable for ultrasonic generator

8

Control cable

9

Mains voltage cable for transmitter

a0022749

8 Endress+Hauser

Page 9

CYR52 Installation

3.1.2 Installation options

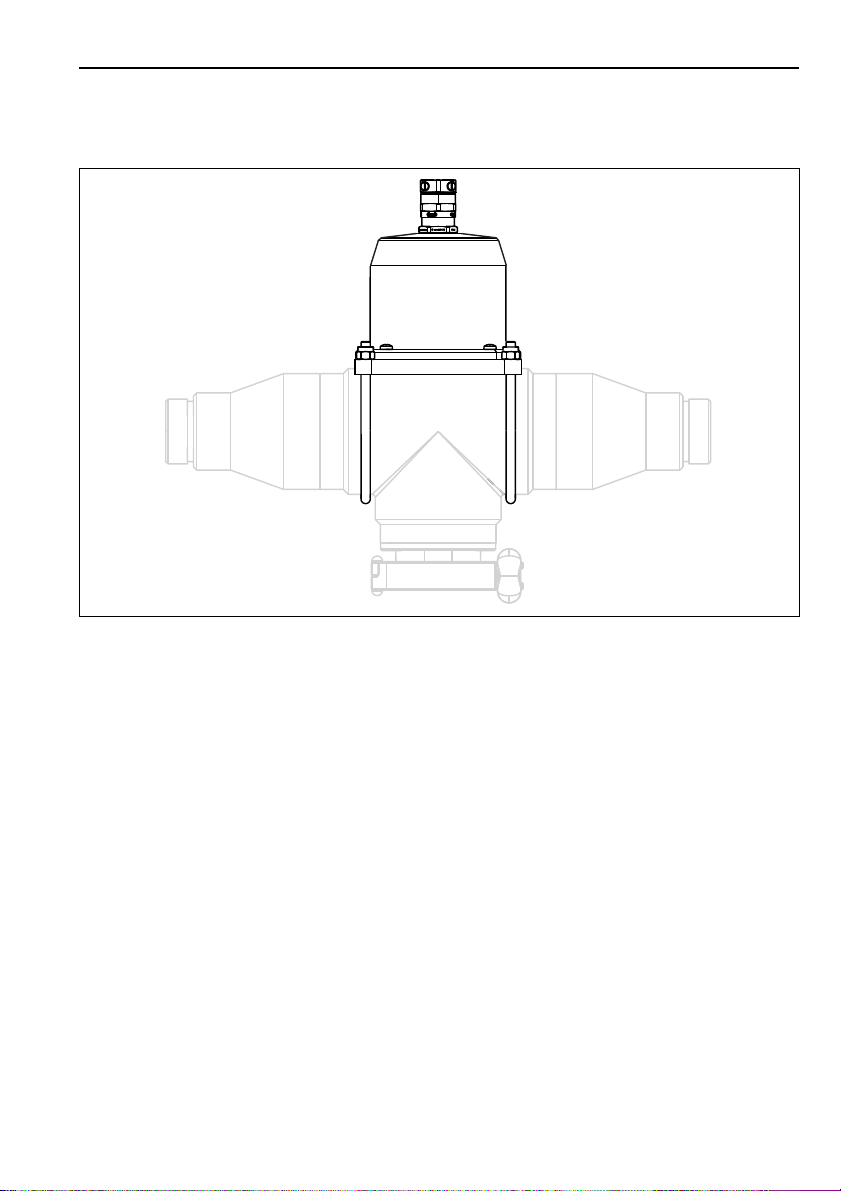

With Flowfit CUA252 flow assembly

Fig. 2: Ultrasonic transducer on Flowfit CUA252 assembly

Endress+Hauser 9

a0022751

Page 10

Installation CYR52

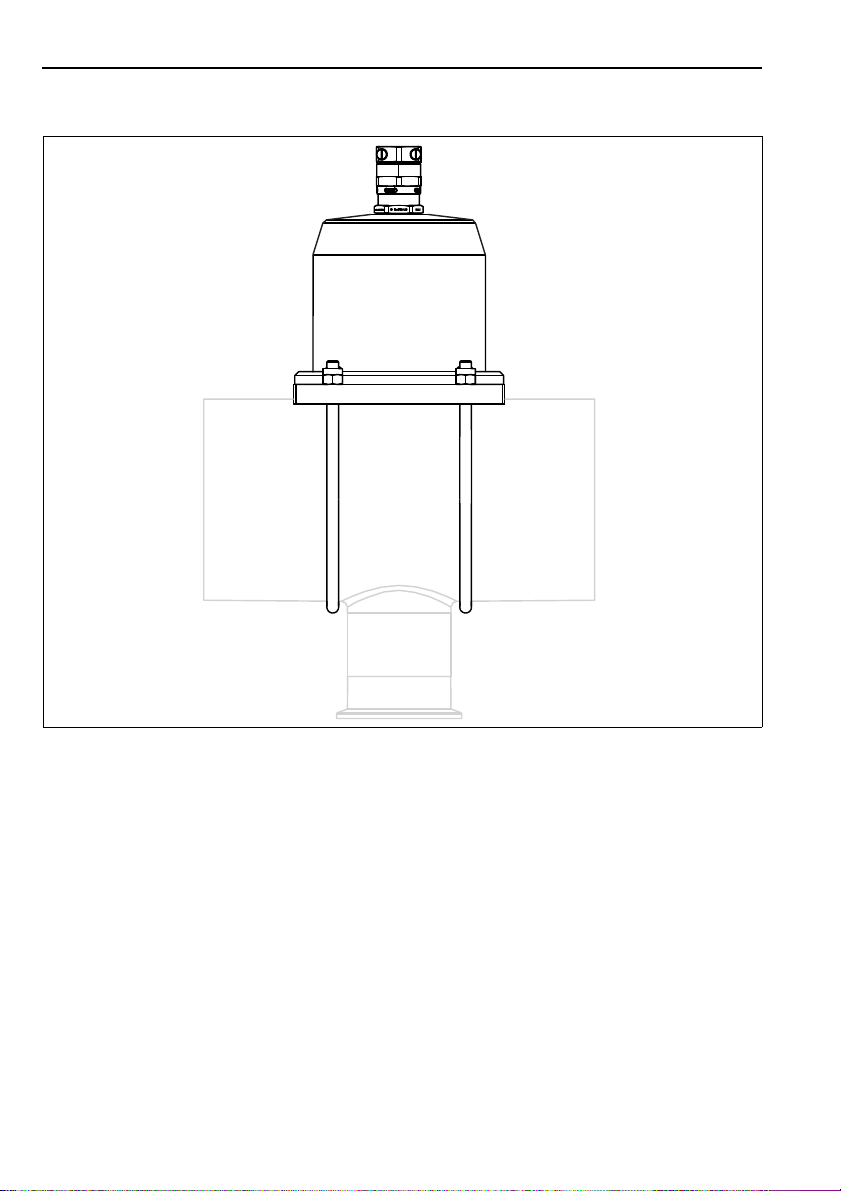

With Flowfit CUA262 flow assembly

Fig. 3: Ultrasonic transducer on Flowfit CUA262 assembly

a0022752

10 Endress+Hauser

Page 11

CYR52 Installation

With assembly of CUS31

Fig. 4: Ultrasonic transducer with assembly of CUS31

Endress+Hauser 11

a0022754

Page 12

Installation CYR52

Mounted on a pipe

Fig. 5: Ultrasonic transducer mounted on a pipe

a0022757

12 Endress+Hauser

Page 13

CYR52 Installation

3.2 Installation conditions

3.2.1 Ultrasonic transducer

Fig. 6: Dimensions in mm (inch) for CUA252 and CUA262

a0022750

In the case of the ultrasonic transducer factor in a clearance of approx. 100 mm (4 inch)

above the cable gland for the power supply cable.

Endress+Hauser 13

Page 14

Installation CYR52

Fig. 7: Dimensions in mm (inch) for assembly of CUS31

a0022753

14 Endress+Hauser

Page 15

CYR52 Installation

Fig. 8: Dimensions in mm (inch) for pipe mounting

a0022756

Endress+Hauser 15

Page 16

Installation CYR52

199 (7.38)

162 (6.38)

237 (9.33)

194 (7.64)

128 (5.04)

3.2.2 Ultrasonic generator

Fig. 9: Dimensions in mm (inch)

a0022755

16 Endress+Hauser

Page 17

CYR52 Installation

3.3 Mounting the ultrasonic transducer

The ultrasonic transducer is secured to assemblies with two brackets that are supplied, and to

pipes with two worm drive hose clips that are supplied.

Fig. 10: Ultrasonic contact paste(1)

Mount the ultrasonic transducer as follows:

1. Using the cleaning cloth (scope of delivery) clean the contact surface of the ultrasonic

transducer and the contact surface of the assembly or pipe.

2. Coat the contact surface of the ultrasonic transducer ( å 10, item 1) with a 5 mm

(0.2")stripe ultrasonic contact paste.

3. Mount the ultrasonic transducer face to face with the turbidity sensor.

4. In the case of pipes:

Tighten the two worm drive hose clips with a torque of 2.5 Nm (1.85 lbf ft).

In the case of assemblies:

Tighten the nuts of the brackets with a torque of 2 Nm (1.47 lbf ft).

a0022759

Endress+Hauser 17

Page 18

Installation CYR52

NOTICE

320 (12.6)

270 (10.6)

300 (11.8)

mm (inch)

3.4 Mounting the ultrasonic generator

3.4.1 Mounting plate

Fig. 11: Dimensions in mm (inch)

3.4.2 Weather protection cover (optional)

Effect of climatic conditions (rain, snow, direct sun etc.)

Impaired operation to complete failure of the ultrasonic generator

‣ When installing outside, always use the weather protection cover (accessory)

Fig. 12: Weather protection cover for ultrasonic generator

a0012426

a0019166

18 Endress+Hauser

Page 19

CYR52 Installation

3.4.3 Mounting the ultrasonic generator

Post mounting

You require the post mounting kit (optional) to mount the unit on a pipe, post or railing (square

or round, clamping range 20 to 61 mm (0.79 to 2.40")).

Fig. 13: Post mounting

Spring washers and nuts (post mounting kit)

Weather protection cover (optional)

1

Post mounting plate (post mounting)

2

Spring washers and nuts (post mounting kit)

3

Pipe clamps (post mounting kit)

4

Fig. 14: Post mounting

Endress+Hauser 19

a0012666

5

Pipe or post

6

Mounting plate

7

Threaded rods /post mounting kit)

8

Fig. 15: Attach the device and click it into place

a0012665

a0022760

Page 20

Installation CYR52

2.

1.

Rail mounting

Fig. 16: Rail mounting

Weather protection cover (optional)

1

Post mounting plate (post mounting)

2

Spring washers and nuts (post mounting kit)

3

Pipe clamps (post mounting kit)

4

Spring washers and nuts (post mounting kit)

5

Fig. 17: Rail mounting

a0012669

Pipe or railing /round/square)

6

Mounting plate

7

Threaded rods /post mounting kit)

8

Screws (post mounting kit)

9

Fig. 18: Attach the device and click it into place

a0012668

a0022762

20 Endress+Hauser

Page 21

CYR52 Installation

1.

2.

Wall mounting

Fig. 20: Wall mounting

1Wall

2 4 drill holes

3 Mounting plate

4 Screws Ø 6 mm (no t included in

Fig. 19: Mounting distance in

mm (inch)

1) The size of the drill holes depends on the wall plugs used. The wall plugs and screws must be provided by the customer.

a0012686

the delivery)

1)

a0012684

Fig. 21: Attach the device and click it

into place

a0022767

3.5 Post-installation check

• After installing, check the ultrasonic transducer and ultrasonic generator for damage.

• Check whether the ultrasonic generator is protected against moisture and direct sunlight.

Endress+Hauser 21

Page 22

Electrical connection CYR52

WARNING

!

NOTICE

4 Electrical connection

The device is live!

Incorrect connection may result in injury or death.

‣ The electrical connection may only be established by an electrical technician.

‣ The electrical technician must have read and understood these Operating Instructions and

must follow the instructions they contain.

‣ Prior to beginning any wiring work, make sure voltage is not applied to any of the cables.

‣ It is absolutely imperative to observe the order in which the individual components are

connected.

4.1 Wiring

The device does not have a mains switch

‣ The customer must provide a protected circuit breaker in the vicinity of the device.

‣ The circuit breaker must be a switch or a power-circuit breaker, and you must label it as the

circuit breaker for the device.

Fig. 22: Wiring diagram

AUltrasonic transducer

B Terminal block in ultrasonic generator

C Relay in transmitter

1 Control cable

2Power supply cable

3 Mains connection

22 Endress+Hauser

a0022771

Page 23

CYR52 Electrical connection

Connect the ultrasonic cleaning system in the following order:

1. Connect the control cable (not included in the delivery, H03VV-F 2x0.75 is recommended)

to terminals 1 and 2 at the ultrasonic generator, and to a free relay at the transmitter at

terminals 41 and 42. The assignment of the individual wires is not relevant here. The

maximum cable length is 3 m (9.84 ft). Make sure that the control cable is strain-relieved

in both devices.

2. Connect the cable secured to the ultrasonic transducer to the terminal block of the

ultrasonic generator as follows: connect the yellow-green protective conductor first. Then

connect the gray cable to the negative end (minus) and then the pink cable to the positive

end (plus). Ensure strain relief in the ultrasonic generator.

3. Connect the mains connection cable (not included in the delivery, H05VV-F3 G0.75 is

recommended) to the appropriate terminals of the ultrasonic generator ( å 22,

item 3). Ensure strain relief in the ultrasonic generator.

4.2 Post-connection check

Carry out the following checks after electrical connection:

Device condition and specifications Notes

Are the devices and cables free from damage on the outside? Visual inspection

Does the mains voltage match the specifications on the nameplate?

Electrical connection Notes

Are the mounted cables strain-relieved?

Cable runs without loops and cross-overs?

Are the cables correctly connected according to the wiring diagram?

Are all the screw terminals firmly tightened?

Endress+Hauser 23

Page 24

Commissioning CYR52

WARNING

!

NOTICE

5 Commissioning

5.1 Function check

Incorrect connection, incorrect supply voltage

Safety risks for staff and incorrect operation of the device

‣ Check that all connections have been established correctly in accordance with the wiring

diagram.

‣ Make sure that the supply voltage matches the voltage indicated on the nameplate.

Electrostatic discharge (ESD)

Damage to electronic components

‣ Take personal protective measures to avoid ESD, such as discharging beforehand at PE or

permanent grounding with a wrist strap.

5.2 Configuration

For optimum cleaning performance, the ultrasonic generator is switched on cyclically for a few

seconds. The cleaning cycle is configured in the "Cleaning" menu in the transmitter (see

Operating Instructions of the transmitter).

Fig. 23: Cleaning interval (example)

Enter the following parameters to prevent the ultrasonic transducer from overheating:

Cleaning time: max. 5 seconds

Cleaning interval: min. 5 minutes

Operate the cleaning system only with medium in the pipe system (not dry!).

As soon the transmitter activates the cleaning cycle, the ultrasonic generator starts producing

the sound waves.

24 Endress+Hauser

a0022773

Page 25

CYR52 Diagnostics and troubleshooting

6 Diagnostics and troubleshooting

Error Possible cause Test

Cleaning effect declines Ultrasonic cleaning system is defective Acoustic check (if the ultrasonic

The position of the ultrasonic

transducer has changed.

transducer hums during the cleaning

routine, the cleaning is working)

Check the installation, pay attention to

torque specifications

Endress+Hauser 25

Page 26

Maintenance CYR52

WARNING

!

NOTICE

NOTICE

7 Maintenance

Process pressure and temperature, contamination, electrical voltage

Risk of serious or fatal injury

‣ If the sensor has to be removed during maintenance work, avoid hazards posed by pressure,

temperature and contamination.

‣ De-energize the device before opening it.

‣ Power can be supplied to switching contacts from separate circuits. Also de-energize these

circuits before working on the terminals.

Take all the necessary precautions in time to ensure the operational safety and reliability of the

entire measuring point.

Maintenance of the measuring point comprises:

• Cleaning the transmitter, assembly, ultrasonic transducer and ultrasonic generator

• Checking cables and connections

When performing any work on the device, bear in mind any potential impact this may have on

the process control system or on the process itself.

Electrostatic discharge (ESD)

Damage to electronic components

‣ Take personal protective measures to avoid ESD, such as discharging beforehand at PE or

permanent grounding with a wrist strap.

‣ For your own safety, only use genuine spare parts. With genuine parts, the function,

accuracy and reliability are also ensured after maintenance work.

7.1 Cleaning the transmitter, ultrasonic transducer and ultrasonic generator

Clean the front of the housing with commercially available cleaning agents only.

The front is resistant to the following as per DIN 42 115:

• Ethanol (short periods)

• Diluted acids (max. 2% HCl)

• Diluted bases (max. 3% NaOH)

• Soap-based household cleaners

Prohibited cleaning agents

Danger of damaging the housing surface or housing seal

‣ For cleaning purposes, never use concentrated mineral acids or bases.

‣ Never use organic cleaners such as benzyl alcohol, methanol, methylene chloride, xylene or

concentrated glycerol cleaner.

‣ Never use high-pressure steam for cleaning purposes.

Clean the housing of the ultrasonic transducer with a damp cloth only.

26 Endress+Hauser

Page 27

CYR52 Repair

8Repair

8.1 Spare part kits

Order number Description

71247412 Ultrasonic transducer with 3 m cable

71247419 Ultrasonic transducer with 7 m cable

71247421 Ultrasonic transducer with 15 m cable

71247422 Electronic module 230 V

71247423 Electronic module 115 V

8.2 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product has been ordered or delivered. According to legal regulations Endress+Hauser, as an

ISO-certified company, is required to follow certain procedures when handling returned

products that are in contact with the medium.

To ensure swift, safe and professional device returns:

Visit our website to obtain information about the return procedure and basic conditions.

www.services.endress.com/return-material

8.3 Disposal

The device contains electronic components, and must therefore be disposed of in accordance

with regulations on the disposal of electronic waste.

Please observe local regulations.

Endress+Hauser 27

Page 28

Accessories CYR52

320 (12.6)

270 (10.6)

300 (11.8)

mm (inch)

9 Accessories

Description Order number

Mounting paste for CYR52 71242140

Mounting kit for CUA252 71242141

Mounting kit for CUA262 71242142

Mounting kit for flow assembly CUS31 E/S 71242143

Mounting kit, variable 71242145

Post mounting kit for securing the ultrasonic generator to horizontal and

vertical posts and pipes

The CYY101 weather protection cover for field devices is absolutely essential

• Material: stainless steel 1.4301 (AISI 304)

• Order No. CYY101-A

71096920

Fig. 24: Weather protection cover for field devices

a0019166

28 Endress+Hauser

Page 29

CYR52 Technical data

10 Technical data

10.1 Output

10.1.1 Operating frequency of the ultrasonic cleaning system

Approx. 40 kHz

10.2 Power supply

10.2.1 Supply voltage

Depends on the order version:

230 VAC / 50 Hz

115 VAC / 60 Hz

10.2.2 Power consumption

Max. 50 VA

10.3 Environment

10.3.1 Ambient temperature range

Ultrasonic transducer: 0 to 60 °C (32 to 140 °F), non-freezing, non-condensing

Ultrasonic generator: -10 to +60 °C (+14 to 140 °F), non-condensing

10.3.2 Storage temperature

0 to 60 °C (32 to 140 °F)

10.3.3 Electromagnetic compatibility

Interference emission and interference immunity as per EN 61326-1:2006, EN

61326-2-3:2006

10.3.4 Degree of protection

Ultrasonic transducer: IP 68

Ultrasonic generator: IP 66/67

10.3.5 Humidity

10 to 95 %, non-condensing

Endress+Hauser 29

Page 30

Technical data CYR52

10.4 Mechanical construction

10.4.1 Dimensions

See the "Installation" section

10.4.2 Weight

Ultrasonic transducer: 0.72 kg (1.59 lbs), with 3 m cable

Ultrasonic generator: 2.2 kg (4.85 lbs)

10.4.3 Material

Ultrasonic transducer

Cover: PE

Floor: Aluminum

Cable: TPE-U mix; 3xLi9Y 0.75; sheath: Ø 6.6 mm

Minimum bending radius: 66 mm (2.6 inch) when cable

can move freely

33 mm (1.3 inch) when cable cannot move freely

Ultrasonic generator

Housing: PC-FR

Housing seal: EPDM

Cable glands: Polyamide

30 Endress+Hauser

Page 31

CYR52

Index

A

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

C

Check

Electrical connection . . . . . . . . . . . . . . . . . . 23

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Post-installation. . . . . . . . . . . . . . . . . . . . . . 21

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 24

D

Degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

E

Electrical connection . . . . . . . . . . . . . . . . . . . . 22

Electrical technician . . . . . . . . . . . . . . . . . . . . . 22

Electromagnetic compatibility . . . . . . . . . . . . . . 4

EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

H

Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

I

Incoming acceptance and product identification 6

Installation . . . . . . . . . . . . . . . . . . . . . . 8, 13, 21

Installation conditions . . . . . . . . . . . . . . . . . . . 13

Installation options . . . . . . . . . . . . . . . . . . . . . . 9

P

Post-connection check . . . . . . . . . . . . . . . . . . 23

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

R

Requirements for personnel . . . . . . . . . . . . . . . . 4

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

S

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . 4

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare part kits . . . . . . . . . . . . . . . . . . . . . . . . . 27

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

T

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . 29

U

Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

W

Weather protection cover . . . . . . . . . . . . . . . . 18

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . 4

M

Maintenance

Entire measuring point . . . . . . . . . . . . . . . . 26

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mechanical construction . . . . . . . . . . . . . . . . . 30

Mounting plate. . . . . . . . . . . . . . . . . . . . . . . . . 18

N

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

O

Operational safety . . . . . . . . . . . . . . . . . . . . . . . 4

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Endress+Hauser

Page 32

www.addresses.endress.com

71261315

Loading...

Loading...