Page 1

Products ServicesSolutions

Operating Instructions

Liquiline To Go Ex CYM291

Page 2

Page 3

Basics

Warranty

Defects occurring within 3 years from delivery date shall be remedied free of charge

at our plant (carriage and insurance paid by sender).

Subject to change.

Return of Products Under Warranty

Please contact our Service Team before returning a defective device.

Ship the cleaned device to the address you have been given.

If the device has been in contact with process uids, it must be decontaminated/

disinfected before shipment. In that case, please attach a corresponding certicate,

for the health and safety of our service personnel.

Disposal

Please observe the applicable local or national regulations concerning

the disposal of “waste electrical and electronic equipment”.

3

Registered Trademarks

The following names are registered trademarks. For practical reasons they are shown

without trademark symbol in this manual.

• Memosens®

• Liquiline®

• Sensocheck®

• Sensoface®

Page 4

4

Package Contents ............................................................................... 6

Documentation ................................................................................... 7

Overview ............................................................................................. 8

Value-Added Features ..............................................................................................9

Protective Cover ....................................................................................................... 10

Hook ............................................................................................................................10

Display ........................................................................................................................ 11

Keypad ........................................................................................................................12

Start-Up ............................................................................................. 13

Inserting the Batteries ........................................................................................... 13

Batteries for Application in Hazardous Locations........................................ 14

Connecting a Sensor .............................................................................................. 15

Switching On the Meter ........................................................................................ 16

Icons ............................................................................................................................ 16

Conguring .......................................................................................17

Conguration (pH) .................................................................................................. 17

Conguration (Cond) ............................................................................................. 18

Conguration (Oxy) ................................................................................................ 19

pH Calibration ................................................................................... 20

Conductivity Calibration .................................................................. 24

Oxygen Calibration ..........................................................................27

Measuring .........................................................................................31

Toggling the Measured Value Display .............................................................31

Adjusting the Temperature .................................................................................. 31

Data Logger ......................................................................................32

Operating Modes of the Data Logger (Logger Type) .................................33

Data Logger Menu .................................................................................................. 35

Conguring the Data Logger .............................................................................. 36

Starting the Data Logger using CONT ............................................................. 37

Starting the Data Logger using START ............................................................ 37

Displaying the Logger Data ................................................................................. 38

Stopping the Data Logger ...................................................................................39

Clearing the Data Logger ..................................................................................... 39

Table of Contents

Page 5

Table of Contents

Clock ..................................................................................................40

Error and Status Messages ...............................................................41

”Sensoface” Messages ............................................................................................ 42

Error Messages ......................................................................................................... 43

pH Product Line ................................................................................ 44

pH Sensors ................................................................................................................. 44

Endress+Hauser Buer Solutions (pH) ...........................................................45

Ready-to-use quality pH buer solutions.......................................................45

Accessories for pH ................................................................................................... 45

Conductivity Product Line ............................................................... 46

Conductivity Sensors ............................................................................................. 46

CLY11 Conductivity Calibration Solutions......................................................47

Accessories for Conductivity ............................................................................... 47

Oxygen Product Line ........................................................................ 48

Oxygen Sensors ....................................................................................................... 48

Accessories for Oxygen ......................................................................................... 48

Specications .................................................................................... 49

Index .................................................................................................. 54

5

Page 6

6

Check the shipment for transport damage and completeness.

The package of the Liquiline To Go Ex CYM291 includes:

Meter incl. 4 AA batteries

and premounted quiver

Carrying strap

Data carrier with detailed user manuals

USB cable, 1.5 m

Safety instructions

Quickstart instructions in various languages

Certicates

Package Contents

Liquiline To Go Ex CYM291

Page 7

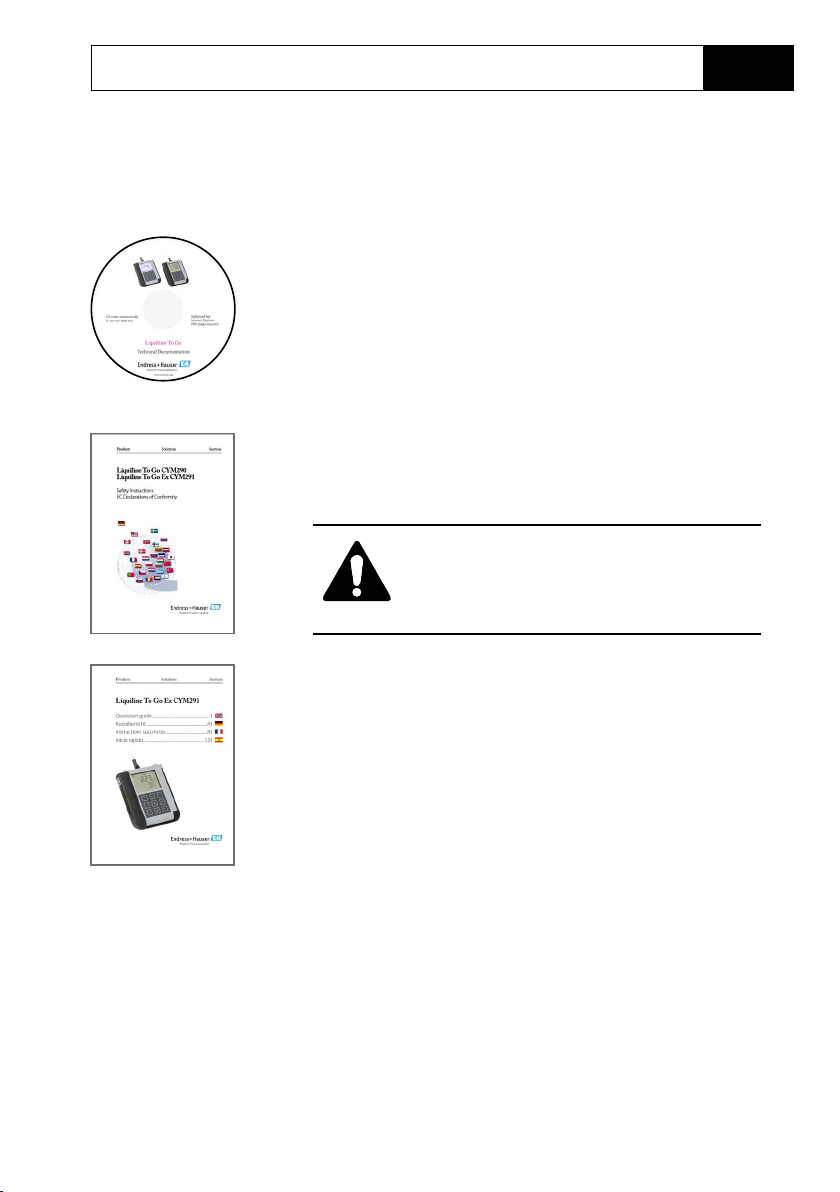

Documentation

Specic Test Report

CD-ROM

Complete documentation:

• User manuals in dierent languages

• Safety instructions

• Certicates

• Quickstart guides

Safety Instructions

In ocial EU languages and others.

• EU Declarations of Conformity

7

CAUTION!

These safety instructions are part of the

product documentation and must be

observed.

Quickstart Guides

Installation and rst steps:

• Operation

• Menu structure

• Calibration

• Error messages and recommended actions

Various languages on CD-ROM:

• German

• English

• French

• Italian

• Spanish

• Portuguese (Brazil)

Certicates

Page 8

8

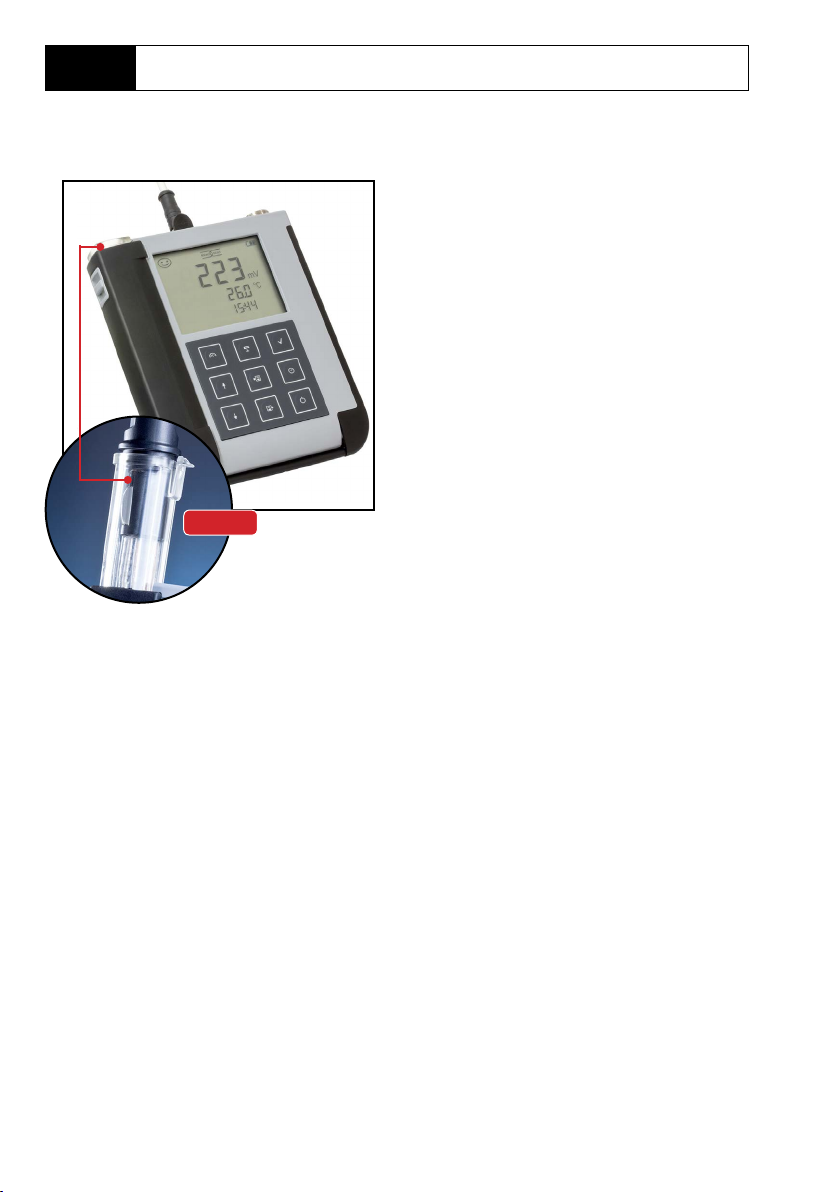

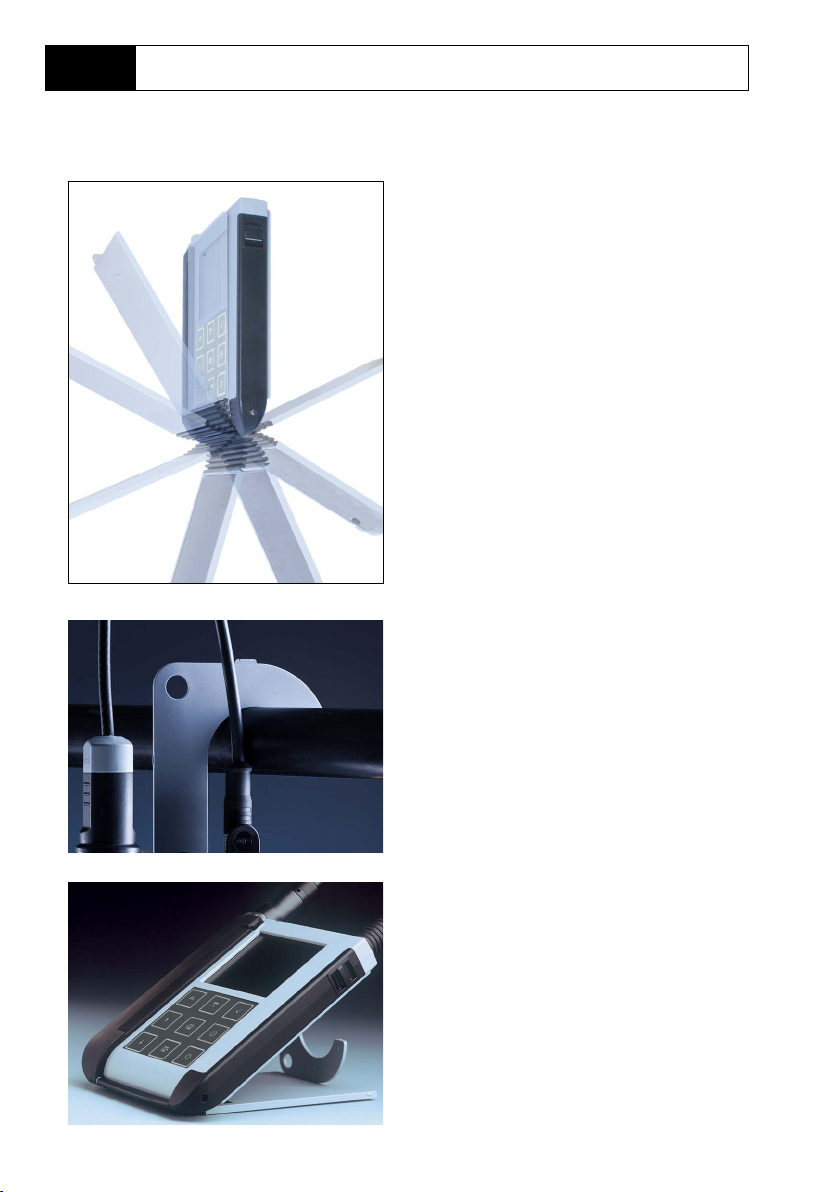

Overview

The Liquiline To Go Ex CYM291 is

a portable multiparameter meter for

measuring pH, ORP, conductivity

or oxygen. With a plain text line on a

high-contrast LCD, operation is largely

intuitive.

Quiver

The meter stands out by the following features:

• Application in hazardous locations up to Zone 0

• Use of digital Memosens sensors

• A detachable quiver protects the sensor and prevents it from drying out.

Furthermore, it can be used for calibration.

• The rugged housing is made of a high-performance polymer. It provides high

impact resistance and dimensional stability even when exposed to extreme

moisture.

• Scratch-proof clear glass display, perfectly readable even after years

• Very long operating time with one set of batteries (4 x AA) for reliable operation

even at high or very low operating temperatures

• Data logger with 5000 values

• Micro USB port

• Sensoface icons provide single-glance information on the sensor condition

(page9)

• Real-time clock and indication of battery charging level

Page 9

Overview

Value-Added Features

Memosens

The Liquiline To Go Ex CYM291 can communicate

with Memosens sensors. These digital sensors are

automatically identied and the meter switches to

the appropriate measurement method.

When a Memosens sensor is connected to the

meter, it is indicated by the logo shown on the

right. Furthermore, Memosens allows the storage

of calibration data, which will be available and

can still be used when the sensor is connected to

another Memosens-capable device.

Sensoface

Sensoface provides quick information on the

sensor condition. The three “smiley” faces as shown

on the right represent the sensor condition during

measurement and after a calibration. When the

condition deteriorates, an “INFO …” message gives

a hint to the cause.

9

Programmed buers

“Programmed buers” is a very convenient method

for pH calibration with automatic buer recognition. You only have to select the buer set with the

buers used. The buers can then be used in any

order.

Page 10

10

Overview

Protective Cover

The front of the meter is protected

by a cover, which can be completely

ipped over and secured to the back for

operation.

Hook

A fold-out hook on the back allows

suspending the meter. This leaves your

hands free for the actual measurement.

The rating plate is located beneath the

hook.

Protective Cover and Hook

Combined

Cover and hook can be joined together

to form a benchtop stand allowing comfortable and fatigue-free working at a lab

bench or desk.

Page 11

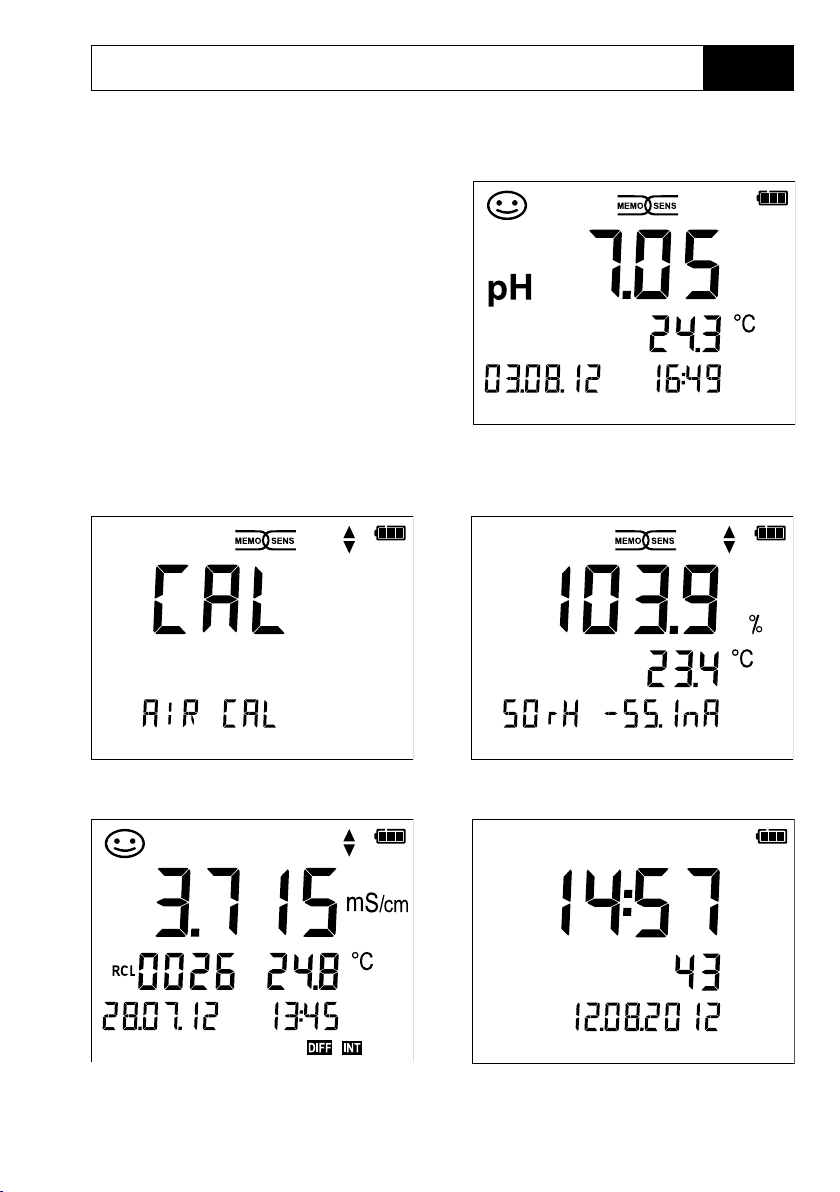

Overview

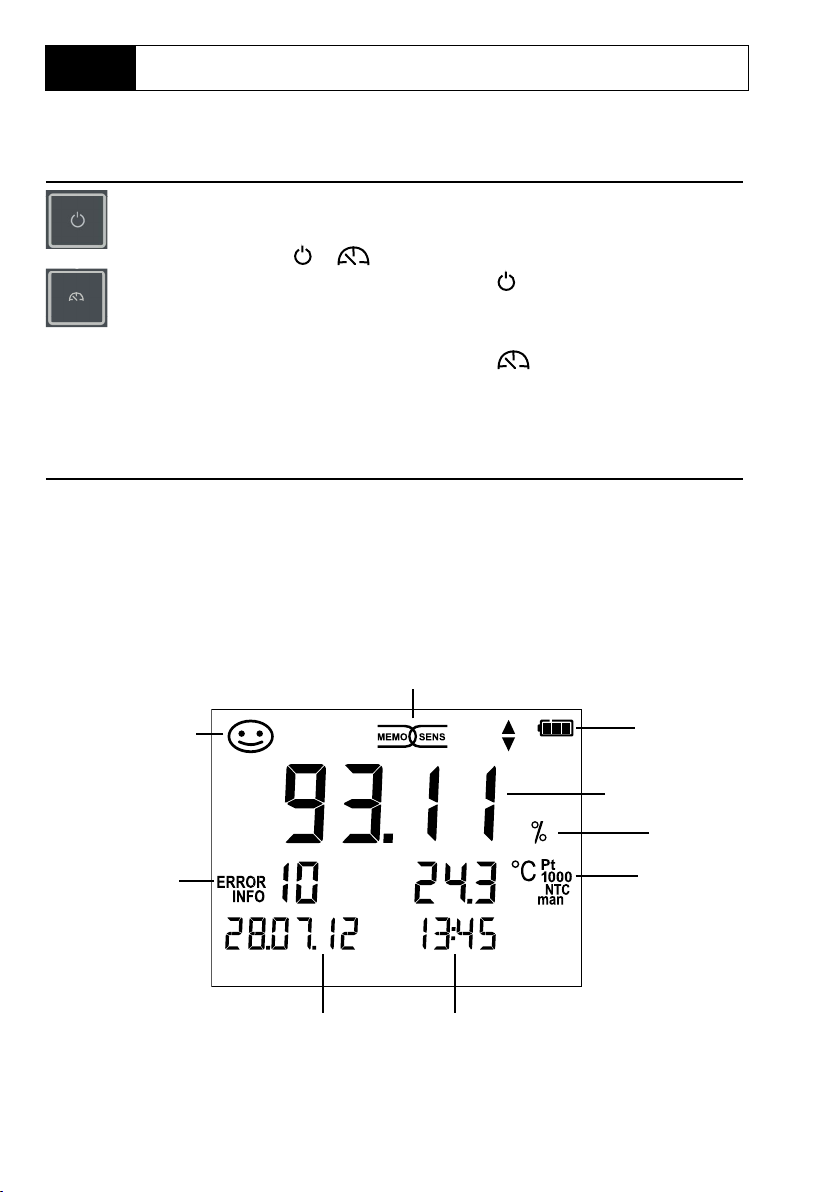

Display

The meter has a three-line display for

representing alphanumeric information such as measurement and calibration data, temperatures and date/time.

Additional information is provided by

means of icons (Sensoface, battery

icon, etc.).

Some typical displays are shown here.

11

pH measurement

(display of measured value, temperature, date and time)

Oxygen calibration – step 1

(calibration in air)

Logger data for conductivity

(display of measured value, memory

location, temperature, date and time)

Oxygen calibration – step 2

(adjusting the relative humidity)

Clock

(display of hours and minutes, seconds

and date)

Page 12

12

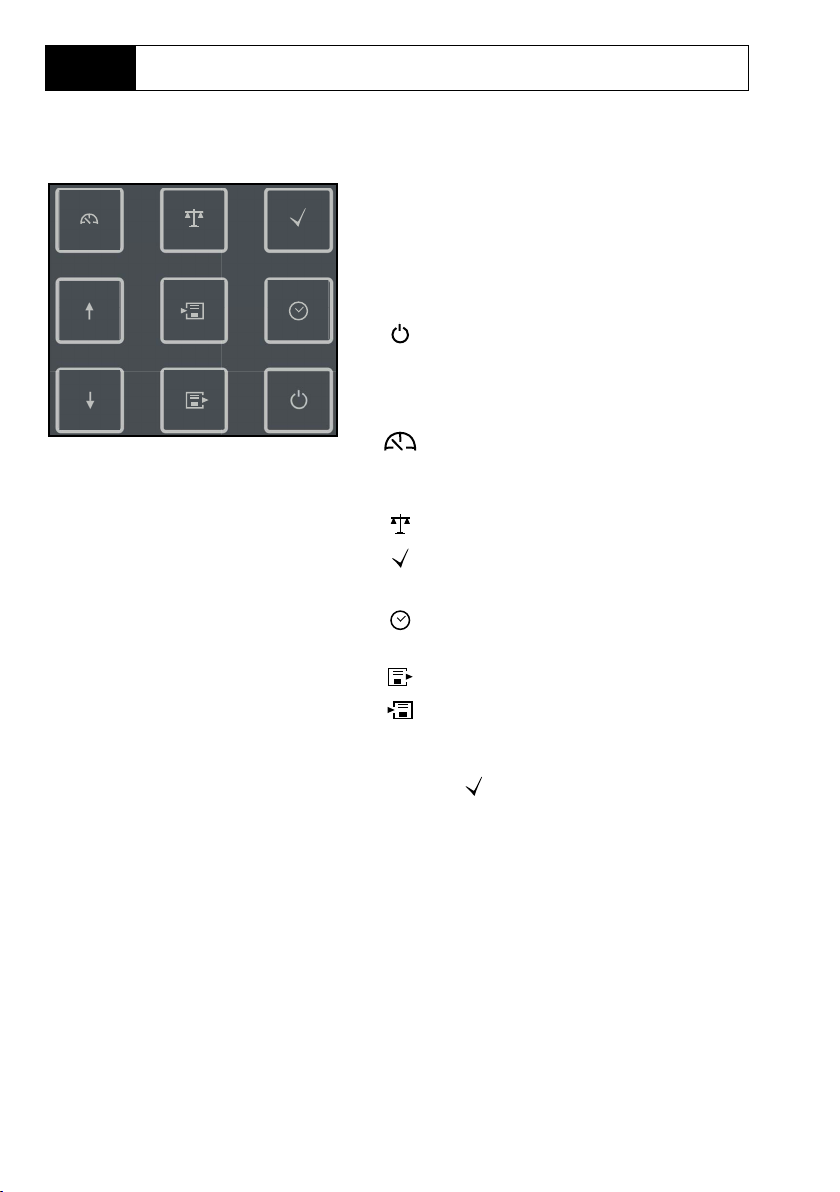

Overview

Keypad

The keys of the membrane keypad

have a noticeable pressure point.

They have the following functions:

Switches the meter on and

displays the device and

calibration data

(see Start-up)

Switches the meter on /

Activates measuring mode /

Stops the data logger

Starts calibration

Activates conguration /

Conrms entries

Displays time and date, allows

setting the clock using set

View stored values

Holds and saves a measured

value, allows setting and

starting the logger by pressing (page 32)

When this icon is displayed,

▲

▼

you can use the arrow keys

for navigation.

Page 13

Start-Up

Check the shipment for transport damage and completeness (see Package

Contents).

NOTICE!

Do not operate the device when one of the following conditions applies:

• the device shows visible damage

• the device fails to perform the intended function

• prolonged storage at temperatures above 70 °C

• severe transport stresses

In this case, a professional routine test must be performed.

This test should be carried out at our factory.

Precautions for application in hazardous locations

WARNING!

• Only open the battery compartment of the Liquiline To Go Ex CYM291

outside the hazardous location.

• Never try to open the device. If a repair should be required, return the

device to our factory.

• Never use the USB port within the hazardous location.

13

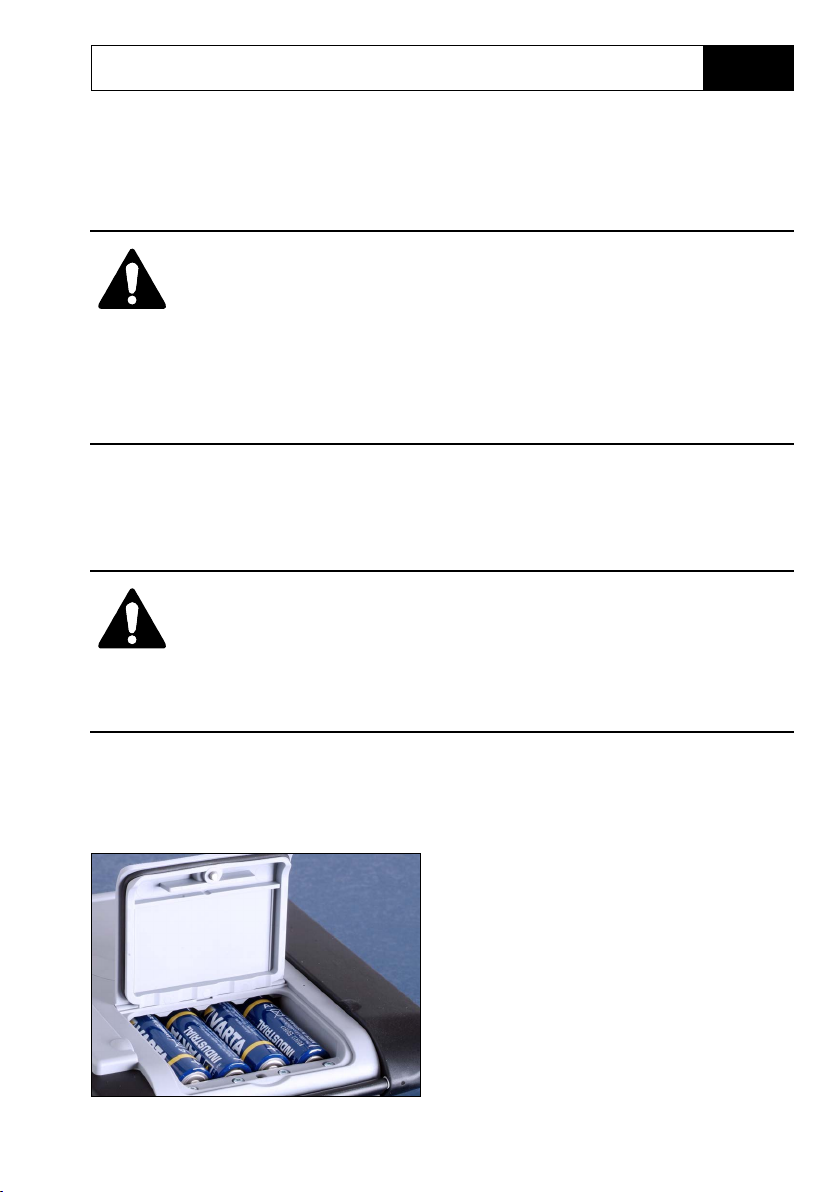

Inserting the Batteries

With four AA batteries, the Liquiline ToGo

Ex CYM291 has an operating time of

approx. 500h.

Open the battery compartment on the

rear of the device. Be sure to observe the

correct polarity when inserting the batter‑

ies (see markings in the battery chamber).

Close the battery compartment cover and

screw it handtight.

Page 14

14

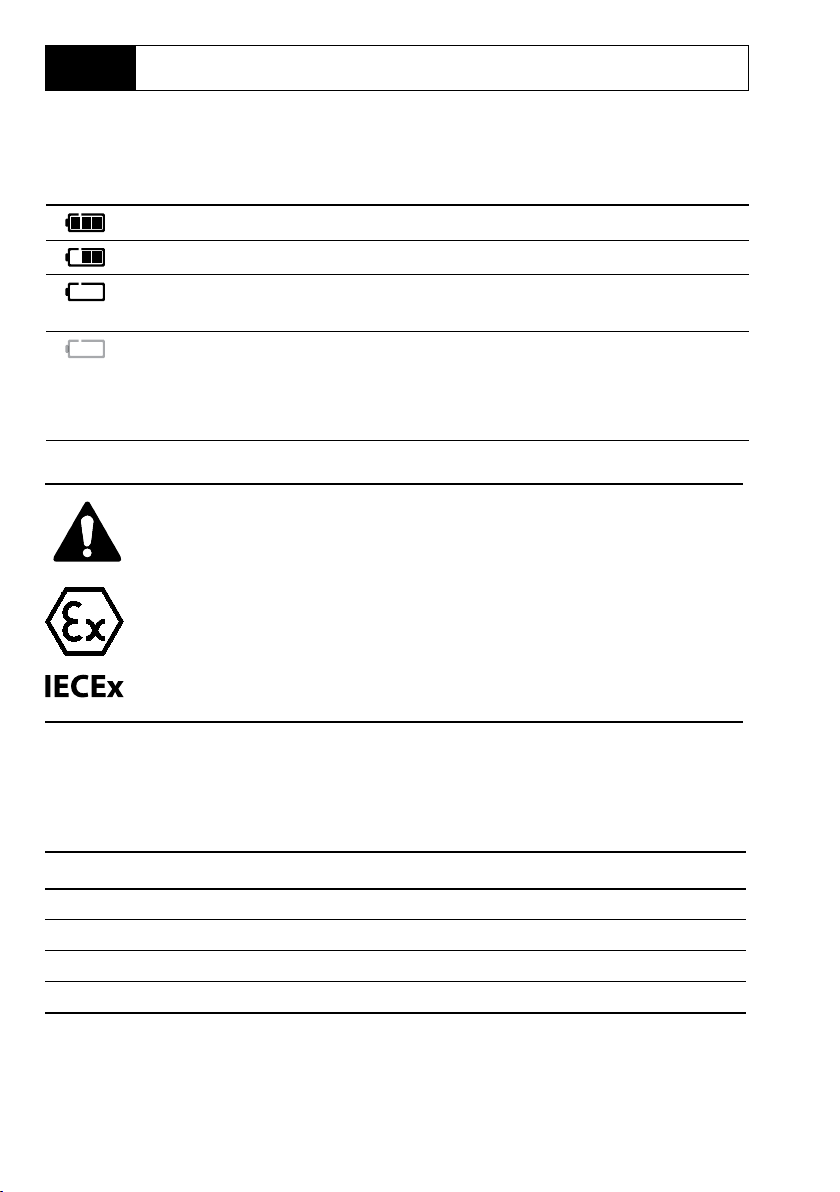

A battery icon in the display indicates the battery power level:

Icon fully lled Batteries at full capacity

Icon partially lled Battery capacity is sucient

Icon empty Battery capacity not sucient;

calibration is possible, no logging

Icon blinks Only a few operating hours remaining,

measurement is still possible

NOTICE! It is absolutely necessary to replace

the batteries.

WARNING!

When operating the Liquiline To Go Ex CYM291 in a hazardous loca‑

tion, only the battery types listed below may be used. The batteries

must be from the same manufacturer and of identical type and

capacity. Never use new and used batteries together (“Certicates”,

Control Drawing 209.009‑150).

Start-Up

Batteries for Application in Hazardous Locations

Batteries (4x each) Temp. class Ambient temperature range

Duracell MN1500 T4 –10 °C ≤ Ta ≤ +40 °C

Energizer E91 T3 –10 °C ≤ Ta ≤ +50 °C

Power One 4106 T3 –10 °C ≤ Ta ≤ +50 °C

Panasonic Pro Power LR6 T3 –10 °C ≤ Ta ≤ +50 °C

Page 15

Start-Up

15

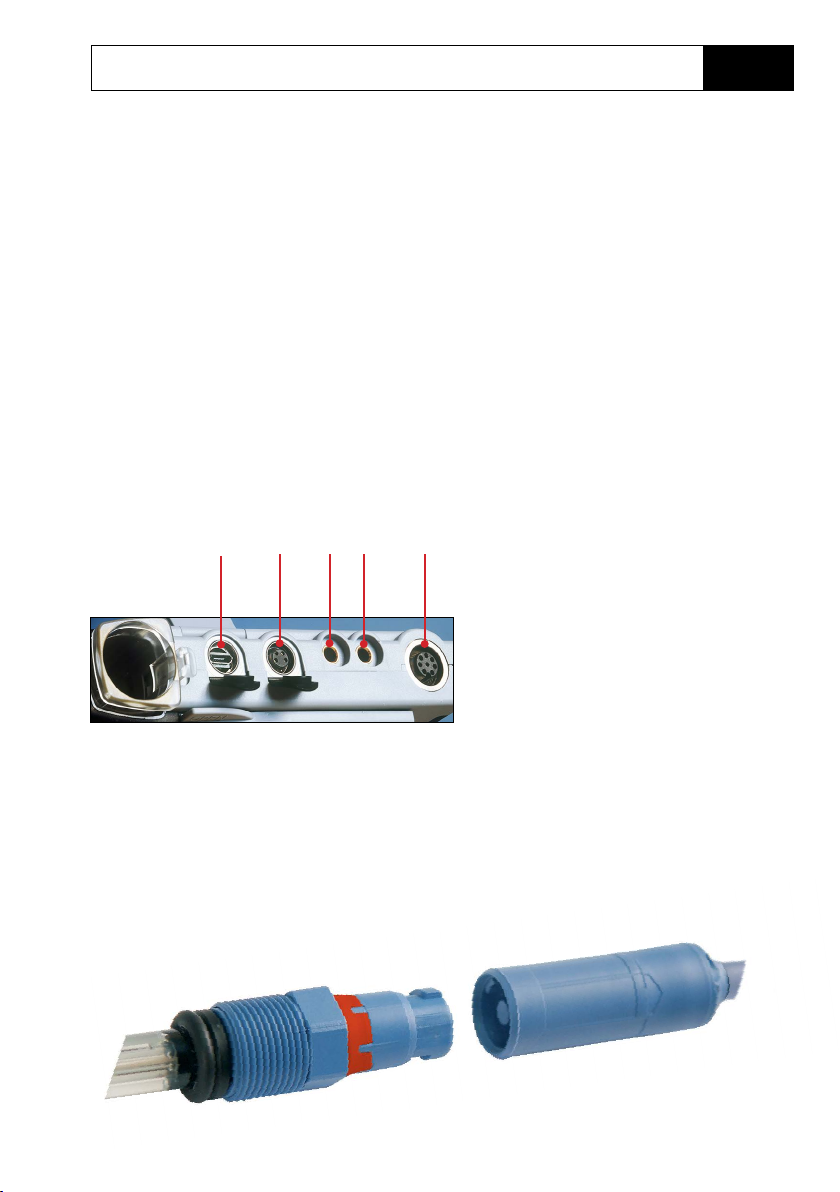

Connecting a Sensor

The Liquiline To Go Ex CYM291 provides several connections so that many types of

sensors can be used for measurement (see illustration below). Note that only one

sensor may be connected to the meter at a time. The meter recognizes the connected Memosens sensor and displays the Memosens logo.

Separate temperature probe

After power-on, a separate temperature probe is automatically recognized. When

you want to replace the temperature probe, you must switch o the meter and then

switch it on again.

a b c d

Memosens sensors have a cable coupling, which allows convenient replacement

of sensors while the cable remains connected to the meter. The connecting cable is

connected to socket b (M8, 4 pins) or e (M12, 8 pins).

e

Connections

a - Micro USB port

b - M8, 4 pins, for Memosens lab cable

c - Temperature probe – GND

d - Temperature probe

e - M12, 8 pins, for Memosens sensors

Page 16

16

Switching On the Meter

When you have connected the sensor, you can switch the meter on

by pressing the or key.

When the meter is switched on with the key, rst a self test is

performed and then the calibration data and settings are displayed

before the meter switches to measuring mode.

When the meter is switched on with the key, it immediately

switches to measuring mode.

Depending on the connected sensor and the specic measuring task, several steps for conguration and calibration must be

performed as described on the following pages.

Icons

Important information about the state of the device:

Start-Up

Sensor condition

Error message

Memosens sensor

Date

Battery

charging level

Measured value

Measured

variable

Temperature

detection

(sensor,

separate or

manual)

Time

Page 17

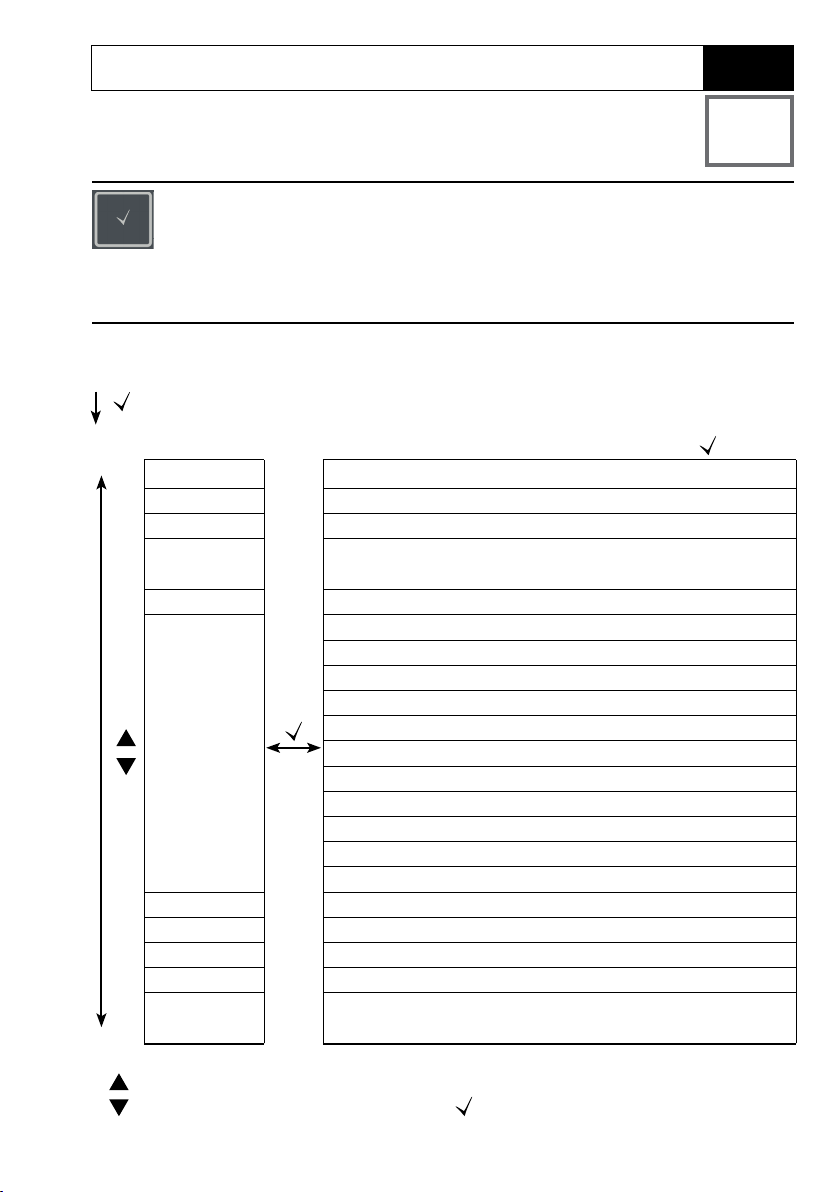

Conguring

Conguration (pH)

Conguration is required to match the connected sensor and the

desired measurement performance. Furthermore, you can select the

suitable calibration method. The following table gives you an overview. Factory settings are shown in bold print.

Measurement

17

pH

“Setup” display

Display 1 pH x.xx | pH x.xxx | mV

Display 2 OFF | date + time | date | time

CAL Timer OFF | 1 ... 99 days

CAL

CAL POINTS 1 | 2 | 3 | 1-2-3 (for PROG.BUFFERS, Manual, FREE CAL)

BUFFER SET

(PROG.BUFFERS, FREE

CAL)

Auto OFF OFF| 0.1h | 1h | 6h | 12h

Temp Unit °C | °F

Time Format 24h | 12h

Date Format dd.mm.yy | mm.dd.yy

Default

Select using arrow keys, conrm by pressing .

PROG.BUFFERS|Manual|DATA INPUT|(ISFET-Zero)|

FREE CAL

-01- Endress+Hauser 2.00|4.01|6.98|9.95|11.87

-02- Mettler-Toledo 2.00|4.01|7.00|9.21

-03- Knick CaliMat 2.00|4.00|7.00|9.00|12.00

-04- Ciba (94) 2.06|4.00|7.00|10.00

-05- NIST technical 1.68|4.00|7.00|10.01|12.46

-06- NIST standard 1.679|4.006|6.865|9.180

-07- HACH 4.01|7.00|10.01|12.00

-08- WTW techn. buers 2.00|4.01|7.00|10.00

-09- Hamilton 2.00|4.01|7.00|10.01|12.00

-10- Reagecon 2.00|4.00|7.00|9.00|12.00

-11- DIN 19267 1.09|4.65|6.79|9.23|12.75

NO | YES (reset to factory settings)

Note: All data logger entries will be deleted.

This icon prompts you to select a menu item using the arrow keys –

the selection is conrmed by pressing .

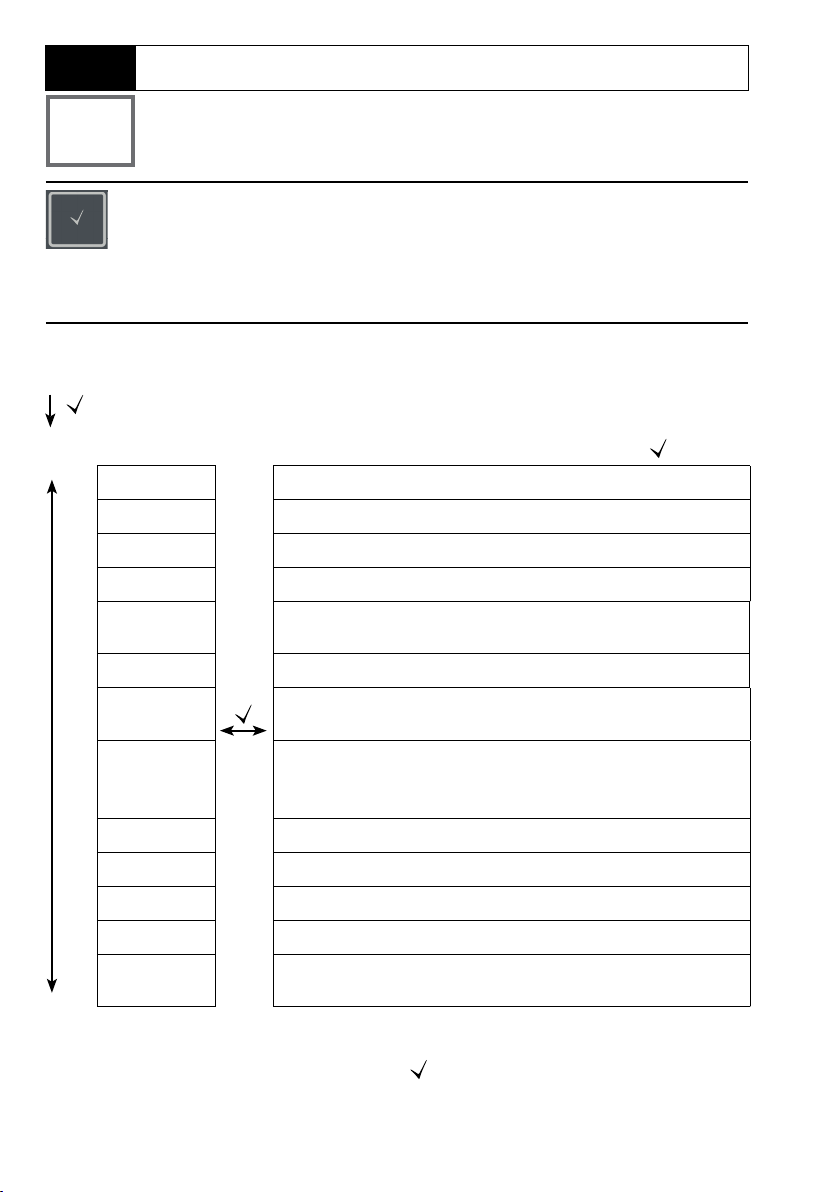

Page 18

18

Cond

Measurement

Conguration (Cond)

Conguration is required to match the connected sensor and the

desired measurement performance. Furthermore, you can select the

suitable calibration method. The following table gives you an overview. Factory settings are shown in bold print.

“Setup” display

Display Cond | SAL g/kg | TDS mg/l

MOHM cm OFF | On

Cond Unit mS/cm | S/m

TDS Factor 0.0 … 1.0 (if display = TDS)

TC * OFF | LINEAR | NLF | NACL | HCL | NH3 | NAOH

TC LINEAR 0.0 … 20.0 %/K | 2.0 %/K (if TC = LINEAR)

REF. Temp. 0 … 100 °C | 25 °C ( 32 … 212 °F | 77 °F)

s

t

CAL CELL CONST. | COND | <25°C> 74.0µS/cm |

Auto OFF OFF | 0.1h | 1h | 6h | 12h

Temp. Unit °C | °F

Time Format 24h | 12h

Date Format dd.mm.yy | mm.dd.yy

Default NO | YES (reset to factory settings)

Select using arrow keys, conrm by pressing .

(if display = Cond)

(if TC = LINEAR)

<25°C> 149.6µS/cm | <25°C> 1.406mS/cm |

<25°C> 12.64mS/cm | <25°C> 107.00mS/cm |FREE CAL

Note: All data logger entries will be deleted.

s

This icon prompts you to select a menu item using the arrow keys –

t

the selection is conrmed by pressing

* Temperature compensation

.

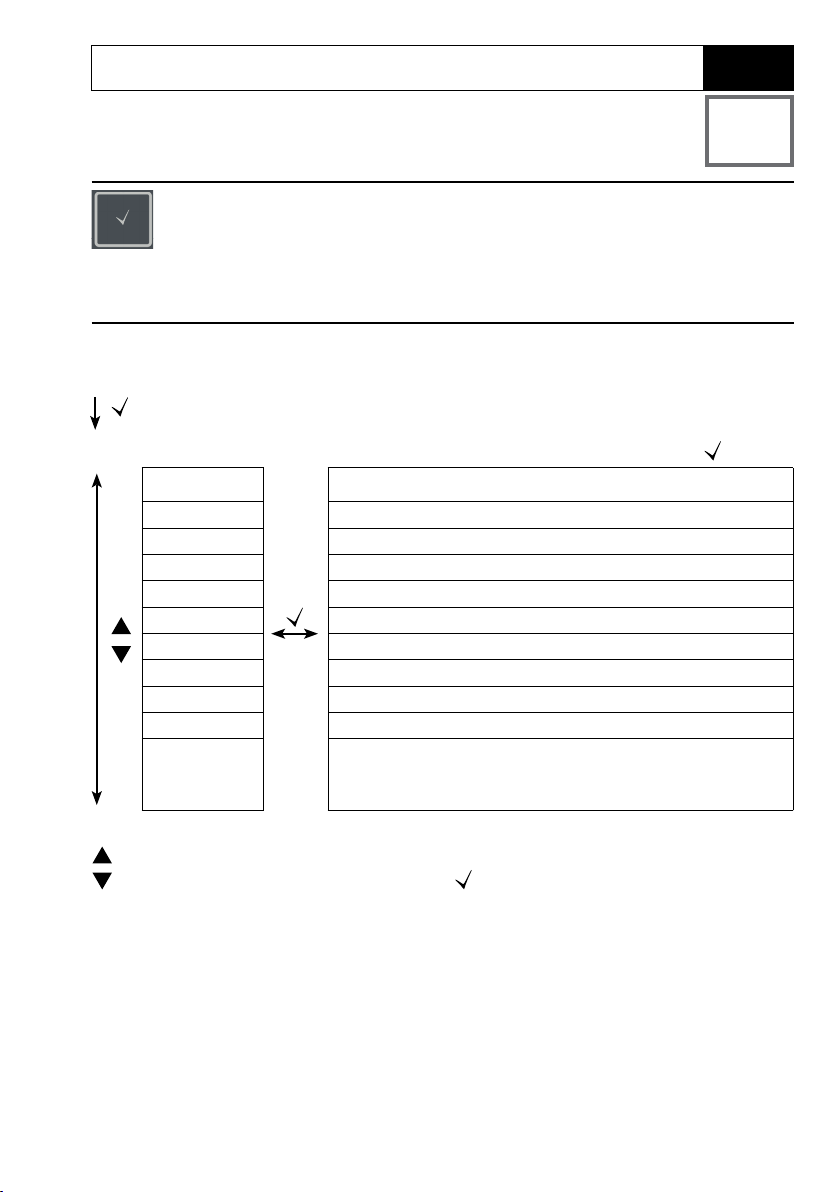

Page 19

Conguring

Conguration (Oxy)

Conguration is required to match the connected sensor and the

desired measurement performance. Furthermore, you can select the

suitable calibration method. The following table gives you an overview. Factory settings are shown in bold print.

Measurement

19

Oxy

“Setup” display

Display 1 Saturation in % air | Concentration in mg/l

Display 2 OFF | date + time | date | time

Altitude 0 … 4000 m

Salt Correct 0.0 … 45.0 g/kg

CAL AIR CAL | ZERO CAL | DATA INPUT | FREE CAL

CAL Timer OFF | 1 … 99 days

Auto OFF OFF | 0.1h | 1h | 6h | 12h

Temp Unit °C | °F

Time Format 24h | 12h

Date Format dd.mm.yy | mm.dd.yy

Default NO | YES (reset to factory settings)

This icon prompts you to select a menu item using the arrow keys –

the selection is conrmed by pressing .

Select using arrow keys, conrm by pressing .

Note: All data logger entries will be deleted.

Page 20

20

pH

Measurement

pH Calibration

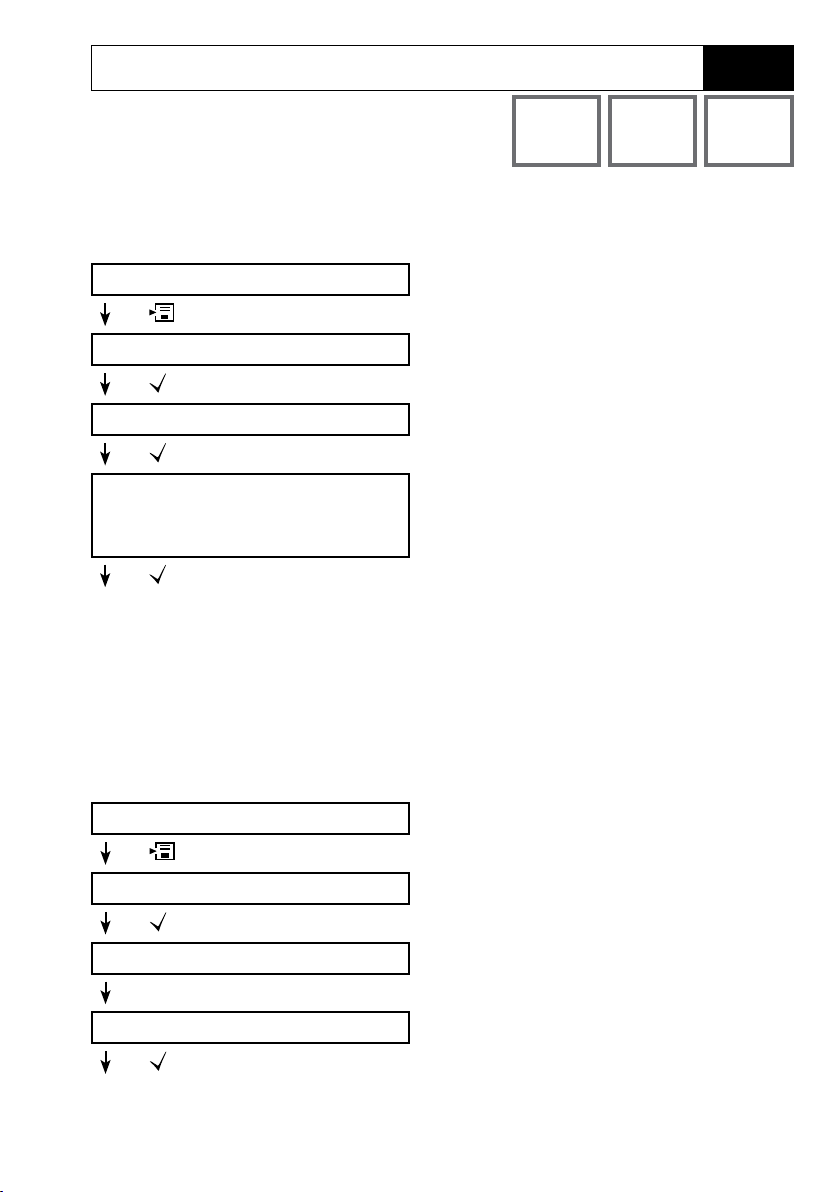

“Programmed Buers” Calibration

(Calibration with automatic buer recognition)

The calibration method is selected in the conguration menu.

Calibration is required to adjust the sensor to the meter. It is indis‑

pensable for achieving comparable and reproducible measurement

results.

CAL

PROG. BUFFERS

CAL 1/2/3

PRESS CAL

pH, mV value,

Calibration method, the number of calibration points and

the buer set have been selected in the conguration

menu.

Dip sensor in 1st/2nd/3rd buer solution.

It does not matter which buer solution is taken rst.

temperature

Depending on the number of calibration points, the

procedure described above for CAL 1/2/3 is repeated.

mV value blinks until calibration is completed, then successive display of:

CAL DATA

1/2/3 CAL POINTS

ZERO POINT

SLOPE

Then the meter switches to measuring mode.

Please note: To abort calibration, you can press at any time.

This will be conrmed by the display message “CAL ABORTED”.

Exception: When you have selected “CAL POINTS 1‑2‑3” and the rst calibration step

has been completed, the calibration process cannot be stopped any more.

Page 21

pH Calibration

DATA INPUT Calibration

(Calibration by entering known sensor values)

The calibration method is selected in the conguration menu.

Measurement

CAL

DATA INPUT

21

pH

ZERO POINT

SLOPE

The calibration data will be displayed successively:

Date and time

ZERO POINT

SLOPE

Then the meter switches to measuring mode.

Please note: To abort calibration, you can press at any time.

st to select the value for the zero point.

Use

st to select the value for the slope.

Use

Page 22

22

pH

Measurement

pH Calibration

MANUAL Calibration

(Manual calibration)

The calibration method is selected in the conguration menu.

CAL

MANUAL

CAL 1/2/3

PRESS CAL

pH display blinks

PRESS CAL

mV display blinks

mV value blinks until calibration is completed, then successive display of:

CAL DATA

1/2/3 CAL POINTS

ZERO POINT

SLOPE

Then the meter switches to measuring mode.

The number of calibration points has been

selected in the conguration menu.

Take the temperature‑corrected pH value from

the buer description and enter it using

Depending on the number of calibration points,

the procedure described above for CAL 1/2/3 is

repeated.

st.

Please note: To abort calibration, you can press

This will be conrmed by the display message “CAL ABORTED”.

Exception: When you have selected “CAL POINTS 1‑2‑3” and the rst calibration step

has been completed, the calibration process cannot be stopped any more.

at any time.

Page 23

Measurement

23

pH

FREE CAL Calibration

(Free selection of calibration method)

FREE CAL calibration is selected in the conguration menu.

CAL

PROG. BUFFERS blinks

Perform the selected calibration (see PROG. BUFFERS, DATA INPUT or MANUAL

calibration).

st to select the required calibration

Use

method (PROG. BUFFERS, DATA INPUT or

MANUAL).

Page 24

24

Cond

Measurement

Conductivity Calibration

CELL CONST. Calibration

(Calibration by entry of cell constant)

The calibration method is selected in the conguration menu.

CAL

CELL CONST.

Value blinks

Calibration will be performed. Automatic return to measuring mode.

The conductivity will be shown in the display

and can be compared with a reference solution

(temperature‑corrected).

st to select the value for the cell constant.

Use

COND Calibration

(Calibration by entry of conductivity)

The calibration method is selected in the conguration menu.

Measurement

CAL

COND

Dip sensor in solution.

Value blinks

Calibration will be performed. Automatic return to measuring mode.

Use st to adjust the temperature‑corrected

conductivity value. NOTICE: Here, the meter

does not perform a temperature compensation!

Page 25

Conductivity Calibration

Calibration with Calibration Solution

(Automatic calibration with preselected calibration solution)

The calibration method is selected in the conguration menu.

NOTICE!

• Make sure that the values of the calibration solutions used

correspond exactly to those specied in this manual.

If not, the resulting cell constant will be incorrect.

• When calibrating in a liquid, make sure that the sensor, the

separate temperature probe (if present) and the calibration

solution have the same temperature. Only this ensures that the

cell constant is determined correctly.

Measurement

25

Cond

CAL

<25°C> 107.00mS/cm

PRESS CAL

Measured value

Temperature

Cal solution conductivity

Hourglass blinks

Calibration will be performed. Automatic return to measuring mode.

Dip sensor in calibration solution.

The meter automatically compensates for the

temperature deviation!

Page 26

26

Cond

Measurement

Conductivity Calibration

FREE CAL Calibration

(Free selection of calibration method)

FREE CAL calibration is selected in the conguration menu.

CAL

CELL CONST. blinks

Perform the selected calibration (see CELL CONST., COND or calibration solution).

st to select the desired calibration

Use

method (CELL CONST., COND, <25°C>

74.0µS/cm, <25°C> 149.6µS/cm, <25°C>

1.406mS/cm, <25°C> 12.64mS/cm, <25°C>

107.00mS/cm).

Page 27

Oxygen Calibration

AIR CAL Calibration

(Calibrating the slope in air)

The calibration method is selected in the conguration menu.

Measurement

27

Oxy

CAL

AIR CAL

Measured value

Temperature

xxx rH blinks

xxx nA blinks

Hourglass blinks

CAL DATA

Date

SLOPE xxx nA

Automatic return to measuring mode.

Place sensor in air and wait until the measured

values have stabilized.

Use

humidity.

Calibration will be performed.

Slope calibration data is displayed.

st to adjust the correct value for relative

Please note: To abort calibration, you can press

at any time.

Page 28

28

Oxy

Measurement

CAL

ZERO CAL

Oxygen Calibration

ZERO CAL Calibration

(Zero calibration with oxygen-free medium)

The calibration method is selected in the conguration menu.

xxx

nA

PRESS CAL blinks

CAL DATA Calibration will be performed.

Date

ZERO P. xxx nA

Date

SLOPE xxx nA

Automatic return to measuring mode.

Please note: To abort calibration, you can press

Place sensor in oxygen‑free medium (e.g.,

nitrogen 5.0) and wait until the measured values

have stabilized.

Zero calibration data is displayed.

Slope calibration data is displayed.

at any time.

Page 29

Oxygen Calibration

DATA INPUT Calibration

(Calibration by entering known sensor values)

The calibration method is selected in the conguration menu.

Measurement

CAL

DATA INPUT

29

Oxy

xx blinks

nA

ZERO POINT

xxx blinks

nA

SLOPE

Calibration will be performed. Automatic return to measuring mode.

Please note: To abort calibration, you can press

st to adjust the known value for the

Use

sensor zero point.

st to adjust the known value for the

Use

sensor slope.

at any time.

Page 30

30

Oxy

Measurement

Oxygen Calibration

FREE CAL Calibration

(Free selection of calibration method)

FREE CAL calibration is selected in the conguration menu.

CAL

AIR CAL blinks

Perform the selected calibration (see AIR CAL, ZERO CAL or DATA INPUT

calibration).

st to select the desired calibration

Use

method (AIR CAL, ZERO CAL, DATA INPUT).

Page 31

Measuring

31

pH Oxy Cond

Once you have completed all preparations, you can start with

the actual measurement.

1) Connect the desired sensor to the meter. Some sensors

require a special preparation. Please proceed according to

the operating instructions for the sensor.

2) Switch the device on using the

3) Depending on the measurement method and the sensor

used, immerse the sensing part of the sensor in the medium

to be measured.

4) Watch the display and wait for the reading to stabilize.

5) By pressing the

value (see data logger, page 32).

key, you can hold and save a measured

or key.

Toggling the Measured Value Display

During measurement, you can toggle the measured value

display by pressing :

• pH: between pH and mV

• Cond: between compensated and uncompensated

measured value (when temperature compensation, SAL or

TDS are activated)

• Oxy: not applicable

Keys for

measurement

Adjusting the Temperature

When you connect a sensor without temperature detector,

you can manually adjust the temperature for measurement or

calibration:

1) Press to access measuring mode.

The adjusted temperature will be displayed.

2) Set the desired temperature value using the or arrow.

Holding the key depressed changes the temperature value

at high speed.

Page 32

32

Data Logger

pH Oxy Cond

Data Logger

The meter provides a data logger. Prior to use, it must be congured and then

activated. You can choose from the following logger types:

• DIFF (signal-controlled logging of measured variable and temperature)

• INT (time-controlled logging at a xed interval)

• DIFF+INT (combined time- and signal-controlled logging)

• SHOT (manual logging by pressing the key)

The data logger records up to 5000 entries and saves them in a circular buer.

Already existing entries will be overwritten.

The following data are recorded: primary value, temperature, time stamp and device

status.

Display: Icons related to the data logger

Memory

address

(0026)

Measured

value is being

saved:

:

Measured

values are

displayed

Next value

Primary

process

variable

Temperature

DateData logger activated

Time

Logger type

Page 33

Data Logger

pH Oxy Cond

Operating Modes of the Data Logger (Logger Type)

Manual logging when logger is activated (SHOT)

In this mode, a measured value is recorded when the key is pressed.

Measurement

Logger activated

The measured value is saved to the address of the last recorded value + 1

Manual logging when logger is deactivated

Measurement

Logger deactivated

33

Measured value is maintained

Proposed address blinks

(address of the last recorded

value + 1)

Measured value is saved to the desired address (e.g., for overwriting an incorrect

measurement).

Interval (INT)

In this mode, the measured values are cyclically recorded.

Measured parameter

= entry

If desired: Select start address

using st.

Example: Logger type “INT”

Time

Page 34

34

Data Logger

pH Oxy Cond

Dierence (DIFF)

When the delta range (process variable and/or temperature) related to the last entry

is exceeded, a new entry is created and the delta range is displaced upwards or

downwards by the delta value. The rst entry is automatically created when the data

logger is started.

Example: First entry = 2, Delta = 1

Measured parameter

4

Delta

3

Delta

2

Delta

1

Delta

= entry

Dierence + Interval combined (DIFF+INT)

When the delta range related to the last DIFF entry is exceeded, a new entry is created (example: entry A) and the delta range is displaced upwards or downwards by the

delta value. As long as the measured value remains within the delta range, logging

is performed at the preset interval. The rst DIFF entry is automatically created when

the data logger is started.

Measured parameter

4

3

Delta

2

Delta

1

Start logger

Delta

A

Example: Logger type “Interval + Dierence”

Interval

= entry

Time

Time

Page 35

Data Logger

Data Logger Menu

Logger display

CONT Select start address and start the data logger

START Deletes all entries and starts the data logger at start

s

t

DEL Deletes all entries

SET Select logger type and congure:

Overview of data logger menu (default in bold print)

Select using arrow keys, conrm by pressing

address 0001

DIFF, INT, DIFF+INT, SHOT (see table below)

35

pH Oxy Cond

.

Logger

type

DIFF Delta % air OFF | 0.1 … 100 % air | 1.0 % air

OFF | 0.01 … 20 mg/l | 1.00 mg/l

Delta pH OFF | pH 0.01…14.00 | pH 1.00

OFF | 1… 1000 mV | 1 mV

Delta Cond OFF | 1 … 1000 mS/cm

OFF | 0.1 … 100 S/m | 1 S/m

Delta SAL OFF | 0.1 … 45.0 g/kg

Delta TDS OFF | 1 … 1999 mg/l

Delta °C / °F OFF | 0.1 … 50.0 °C | 1.0 °C

OFF | 0.1 …90 °F | 1.0 °F

INT Interval h:mm:ss

0:00:01 … 9:59:59 | 12:02:00 AM

DIFF+INT DIFF See logger type DIFF

INT See logger type INT

SHOT Currently selected process variable is recorded

Page 36

36

pH Oxy Cond

Conguring the Data Logger

Prerequisite: The data logger is stopped (press ).

Measurement

Measured value is maintained

Logger: CONT blinks

t

Logger: START blinks

t

Logger: DEL blinks

t

Logger: SET blinks

Data Logger

Logger: Current logger type

blinks

Select the appropriate parameters using st and conrm each selection by pressing . When conguration is nished, CONT blinks. You can start the data logger

by selecting START or CONT (see page 37).

Select desired logger type using st:

DIFF, INT, DIFF+INT or SHOT.

Page 37

Data Logger

37

pH Oxy Cond

Starting the Data Logger using CONT

Prerequisite: Data logger is congured. Every time the meter has been switched o,

the data logger must be restarted (exception: SHOT).

Measurement

Measured value is maintained

Logger: CONT blinks

Address of the last recorded value

+1 blinks

(proposed start address)

The measured value is saved to the selected start address (exception: SHOT).

“… FREE MEMORY” is displayed.

“LOGGER” and “active logger type” icons are displayed.

If desired: Select start address using st.

Starting the Data Logger using START

Prerequisite: Data logger is congured. All existing entries are deleted.

The start address for saving the values is 0001. Every time the meter has been

switched o, the data logger must be restarted (exception: SHOT).

Measurement

Measured value is maintained

Logger: CONT blinks

t

Logger: START blinks

All entries will be deleted. “5000 FREE MEMORY” is displayed.

“LOGGER” and “active logger type” icons are displayed.

Page 38

38

pH Oxy Cond

Displaying the Logger Data

Pressing the key displays all stored values.

Measurement

Data Logger

The “RCL” icon and the last recorded value is displayed.

or

Return to measurement

Use st to select the desired address. Empty

memory locations will also be displayed.

Example:

Measured value stored at location 0026

Example:

Empty memory location 0004

Page 39

Data Logger

39

pH Oxy Cond

Stopping the Data Logger

You can stop the data logger at any time by pressing the key.

Measurement, logger activated

Data logger is stopped. “LOGGER” and “active logger type” icons are no longer

displayed. It is still possible to hold a measured value by pressing and send it to

any desired address.

Clearing the Data Logger

Selecting “DEL” deletes all data records.

Measurement

Measured value is maintained

Logger: CONT blinks

t

Logger: START blinks

t

Logger: DEL blinks

PRESS SET

All stored data are deleted.

“0000 DELETED” is displayed.

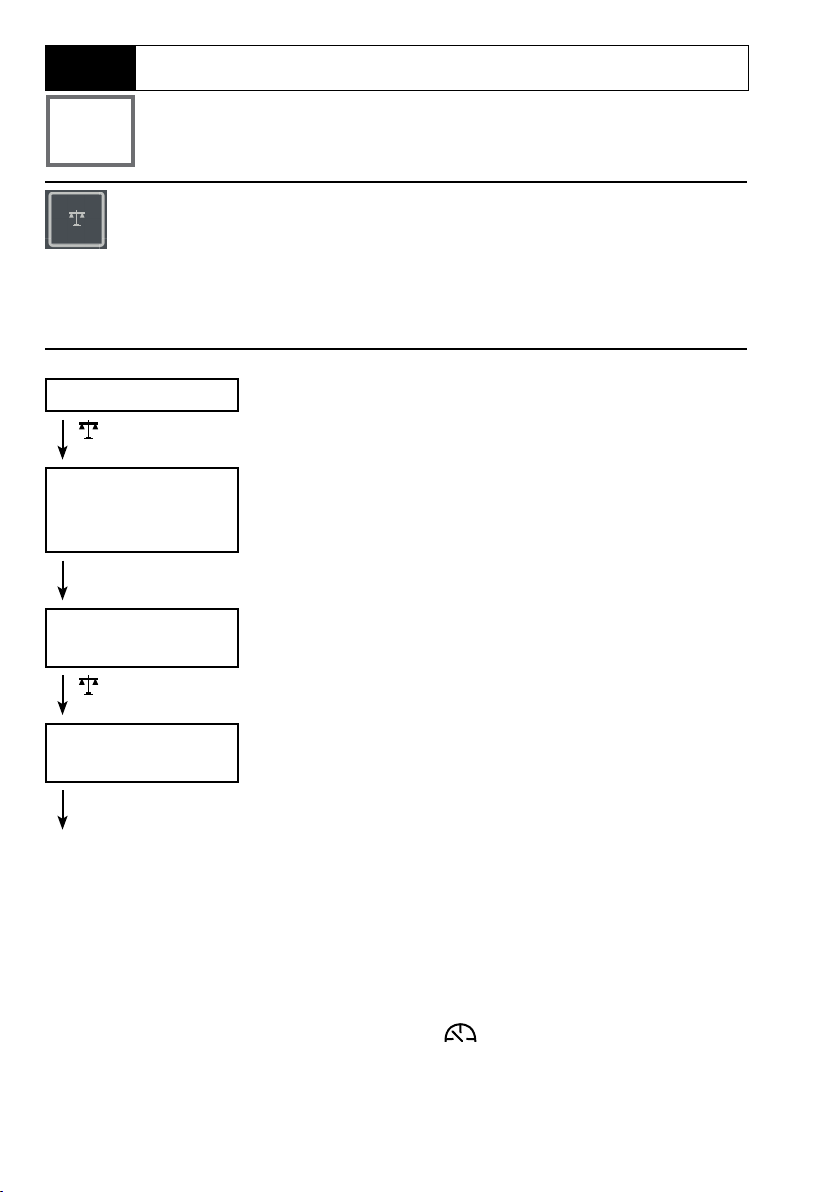

Page 40

40

pH Oxy Cond

Press the key to access the clock mode. Date and time will be

displayed in the format as set in the conguration menu.

To set the clock, proceed as follows:

Display of

time+date

Clock

Hour display blinks

SET HOUR

Minute display blinks

SET MINUTE

Seconds display blinks

and shows 00

Year display blinks

SET YEAR

Month display blinks

SET MONTH

Day display blinks

SET DAY

Set value.

Set value.

Clock is started, the seconds count up.

Set value.

Set value.

Set value.

Display of

corrected time+date

Page 41

Error and Status Messages

41

pH Oxy Cond

Error messages are indicated as “ERROR …” on the display. Information on the sensor

condition is indicated by the “Sensoface” icon (friendly, neutral, sad) possibly accompanied by an info message (“INFO …”).

Example of an error message:

ERROR 1 (value out of range)

Sensoface (the “smiley” icon) provides

information on the sensor condition (maintenance request). Measurement can still be

performed. After a calibration, the corresponding Sensoface icon (friendly, neutral,

sad) is shown together with the calibration

data. Otherwise, Sensoface is only visible in

measuring mode.

The most important error messages and

“Sensoface” info messages are shown on

the inside of the protective cover.

A complete list of messages and their

meanings is provided in the following

tables.

Example of a “Sensoface” message:

INFO 1 (cal timer expired)

Page 42

42

pH Oxy Cond

”Sensoface” Messages

The “Sensoface” icon provides information on the sensor condition:

Sensoface Meaning

Sensor is okay

Calibrate the sensor soon

Calibrate or replace the sensor

The “neutral” and “sad” Sensoface icons are accompanied by an “INFO …” message to

give a hint to the cause of deterioration.

Sensoface Message Cause

INFO 1 Calibration timer

INFO 3 Sensocheck

INFO 5 Zero/Slope

INFO 6 Response time

INFO 7 Operating point (asymmetry potential)

INFO 8 Leakage current

INFO 9 ORP oset

INFO 10 Polarization

Page 43

Error and Status MessagesError and Status Messages

pH Oxy Cond

Error Messages

The following error messages can be shown in the display.

Message Cause Remedy

43

blinks

ERROR 1 Value out of range

ERROR 2 ORP value out of range

ERROR 3 Temperature value out of

ERROR 4 Zero point too high/low Thoroughly rinse the sensor and recal-

ERROR 5 Slope too high/low

ERROR 6 Cell constant too high/low Enter nominal cell constant or calibrate

ERROR 8 Calibration error:

ERROR 9 Calibration error:

ERROR 10 Calibration media

ERROR 11 Measured value unstable

ERROR 14 Time and date invalid Set time and date

ERROR 18 Conguration invalid Restart, reset to factory settings,

ERROR 19 Factory settings error Device defective, send it in.

ERROR 21 Sensor error

ERROR 22 Sensor conict Connect only one sensor.

Battery empty Replace batteries

Check whether the measurement

conditions correspond to the adjusted

range

Identical buers

Buer unknown

interchanged

Stability criterion not met

(Memosens)

measuring range.

ibrate. If this does not help, replace the

sensor.

the sensor using a known solution.

Use a buer solution with a dierent

nominal value before starting the next

calibration step.

Make sure that you use the same

buer set as congured.

Repeat calibration.

Leave the sensor in the liquid until the

temperature is stable. If this does not

help, replace the sensor.

congure and calibrate. If this does not

help, send in the device for repair.

Connect operational Memosens

sensor.

Page 44

44

pH

pH Sensors

pH Product Line

Product Name

(Link to Product Congurator)

Orbisint CPS11D Digital pH sensor

Orbisint CPS12D Digital ORP sensor

Memosens CPS16D Combined digital pH/ORP sensor

Memosens CPS31D Digital pH sensor

Ceraliquid CPS41D Digital pH sensor

Ceraliquid CPS42D Digital ORP sensor

Ceragel CPS71D Digital ORP sensor

Ceragel CPS72D Digital ORP sensor

Memosens CPS76D Combined digital pH/ORP sensor

Orbipore CPS91D Digital pH sensor

Orbipore CPS92D Digital ORP sensor

Memosens CPS96D Combined digital pH/ORP sensor

Ceramax CPS341D Digital non-glass pH sensor

Tophit CPS441D Digital non-glass pH sensor

Tophit CPS471D Digital non-glass pH sensor

Tophit CPS491D Digital non-glass pH sensor

Orbipac CPF81D Digital pH sensor

Orbipac CPF82D Digital ORP sensor

The Product Congurator can be accessed at: www.endress.com/<product name>

Sensor Type

Memosens sensors have a cable coupling, which allows convenient replacement of

sensors while the cable remains connected to the meter.

Page 45

45

pH

Endress+Hauser Buer Solutions (pH)

Ready-to-use quality pH buer solutions

Quality buers from Endress+Hauser - CPY20

Solutions which are traced by a DAkkS-accredited Endress+Hauser buer laboratory

(DkkS = German Accreditation Body) to a primary reference material of the PTB and

to standard reference material of the National Institute of Standards and Technology (NIST) in accordance with DIN 19266 are used as secondary reference buer

solutions.

CPY20 Buer Sets Quantity

pH 2.00 5000 ml / 100 ml / 250 ml

pH 4.01 5000 ml / 100 ml / 250 ml / 18 ml

pH 6.98 5000 ml / 100 ml / 250 ml / 18 ml

pH 9.95 5000 ml / 100 ml / 250 ml

pH 11.87 5000 ml / 100 ml / 250 ml

Accessories for pH

Item

1.5 m sensor cable ATEX CYK20 BAB1C2

CPY7 electrolyte vessel, reservoir for KCI electrolyte, 150ml

The Product Congurator can be accessed at:

www.endress.com

Page 46

46

Cond

Conductivity Sensors

Conductivity Product Line

Product Name

(Link to Product Congurator)

Condumax CLS15D Conductivity sensor

Condumax CLS16D Conductivity sensor

Condumax CLS21D Conductivity sensor

Memosens sensors have a cable coupling, which allows convenient replacement of

sensors while the cable remains connected to the meter.

Sensor Type

Page 47

47

Cond

CLY11 Conductivity Calibration Solutions

CLY11-A, 74 μS/cm (reference temp. 25°C (77 °F)), 500ml (16.9 fl.oz)

CLY11-B, 149.6 μS/cm (reference temp. 25°C (77 °F)), 500ml (16.9 fl.oz)

CLY11-C, 1.406 mS/cm (reference temp. 25°C (77 °F)), 500ml (16.9 fl.oz)

CLY11-D, 12.64 mS/cm (reference temp. 25°C (77 °F)), 500ml (16.9 fl.oz)

CLY11-E, 107.00 mS/cm (reference temp. 25°C (77 °F)), 500ml (16.9 fl.oz)

Accessories for Conductivity

Item (Link to Product Congurator)

1.5 m sensor cable ATEX CYK20 BAB1C2

Conducal CLY421 calibration set

• Conductivity calibration set (case) for ultrapure water applications

• Complete, factory-calibrated measuring set with certicate, traceable to SRM

of NIST and DKD, for comparative measurement in ultrapure water up to

max.20μS/cm

• Product Congurator on the product page: www.endress.com/cly421

The Product Congurator can be accessed at:

www.endress.com

Page 48

48

Oxygen Product Line

Oxy

Oxygen Sensors

Product Name

(Link to Product Congurator)

Oxymax COS22D digital oxygen sensor

Accessories for Oxygen

Item

COS22Z maintenance kit

1.5 m sensor cable ATEX CYK20 BAB1C2

The Product Congurator can be accessed at:

www.endress.com

Page 49

Specications

49

pH Oxy Cond

Connections 1x M8 socket, 4 pins, for Memosens lab cable

Display LCD STN 7-segment display with 3 lines and icons

Sensoface Status indication (friendly, neutral, sad)

Status indicators For battery power level, logger

Notices Hourglass

Keypad

Data logger With up to 5000 memory locations

Recording Manual, interval- or event-controlled

Communication USB 2.0

Profile HID, driverless installation

Usage Data exchange

Diagnostics

Sensor data

(Memosens only)

Calibration data Calibration date; zero and slope, or cell constant, resp.

Device self-test Automatic memory test (FLASH, EEPROM, RAM)

Device data Device type, software version, hardware version

Data retention Parameters, calibration data > 10 years

EMC EN 61326-1 (General Requirements)

Emitted interference Class B (residential area)

Immunity to interference Industry

Explosion protection CYM291

1 x M12 socket, 8 pins, for Memosens sensors

2 x 4-mm socket for separate temperature detector

1 x micro USB-B

Be sure to observe the safety instructions when using the USB port.

], [ ], [ ], [ ], [▲], [▼], [ ], [ ], [ ]

[

Manufacturer, sensor type, serial number, operating time

EN 61326-2-3

(Particular Requirements for Transmitters)

Global IECEx Ex ia IIC T4/T3 Ga

Europe ATEX II 1 G Ex ia IIC T4/T3 Ga

Page 50

50

pH Oxy Cond

RoHS conformity According to directive 2011/65/EU

Power supply 4 x AA batteries

Operating time Approx. 500 h (alkaline)

Nominal operating conditions

Ambient temperature -10 °C ≤ Ta ≤ +40 °C (+14 ... +104 °F) T4 Duracell MN1500

Transport/Storage temp. -25 … +70 °C (-13 ... +158 °F)

Relative humidity 0 … 95 %, short-term condensing allowed

Housing

Material PA12 GF30 (silver gray RAL 7001) + TPE (black)

Protection IP 66/67 with pressure compensation

Dimensions Approx. (132 x 156 x 30) mm

Weight Approx. 500 g

For battery types, see Control Drawing No. 209.009-150

-10 °C ≤ Ta ≤ +50 °C (+14 ... +122 °F) T3 Energizer E91,

Power One 4106

and Panasonic Pro Power LR6

Page 51

Specications

51

pH

Memosens pH input

(also ISFET)

Display ranges

Memosens input

ORP

Display ranges

Sensor standardization * ORP calibration (zero adjustment)

Permissible calibration range ΔmV (offset) -700 … +700 mV

Sensor standardization * pH calibration

Operating modes * PROG.BUFFERS Calibration with automatic buffer recognition

“Programmed buffers”

buffer sets *

Permissible calibration range Zero point 6 ... 8 pH

Calibration timer * Interval 1 … 99 days, can be switched off

Sensoface Provides information on the sensor condition

Evaluation of zero/slope, response, calibration interval

1)

1)

M8 socket, 4 pins, for Memosens lab cable or

M12 socket, 8 pins, for Memosens sensors

pH -2.00 … +16.00

mV -1999 … +1999 mV

Temperature -50 … +250 °C (-58 ... +482 °F)

M8 socket, 4 pins, for Memosens lab cable or

M12 socket, 8 pins, for Memosens sensors

mV -1999 … +1999 mV

Temperature -50 … +250 °C (-58 ... +482 °F)

MANUAL Manual calibration with entry of individual

DATA INPUT Data entry of zero and slope

-01- Endress+Hauser 2.00/4.01/6.98/9.95/11.87

-02- Mettler-Toledo 2.00/4.01/7.00/9.21

-03- Knick CaliMat 2.00/4.00/7.00/9.00/12.00

-04- Ciba (94) 2.06/4.00/7.00/10.00

-05- NIST technical 1.68/4.00/7.00/10.01/12.46

-06- NIST standard 1.679/4.006/6.865/9.180

-07- HACH 4.01/7.00/10.01/12.00

-08- WTW techn. buffers 2.00/4.01/7.00/10.00

-09- Hamilton 2.00/4.01/7.00/10.01/12.00

-10- Reagecon 2.00/4.00/7.00/9.00/12.00

-11- DIN 19267 1.09/4.65/6.79/9.23/12.75

With ISFET:

Operating point

(asymmetry)

Slope Approx. 74 … 104 %

(possibly restricting notes from Sensoface)

buffer values

-750 … +750 mV

* User-defined

1) Ranges depending on Memosens sensor

Page 52

52

Cond

Conductivity input M8 socket, 4 pins, for Memosens lab cable

Measuring ranges CLS15D k = 0.01 : 0-20 µS/cm

CLS16D k = 0.1 : 0.04 µS/cm - 500 µS/cm

CLS21D k = 1 : 10.0 µS/cm - 20.0 mS/cm

Permissible cell constant 0.005 … 200.0 cm

Measuring cycle Approx. 1 s

Temperature compensation Linear 0 … 20 %/K, reference temperature adjustable

Display resolution

(autoranging)

Sensor standardization Cell constant Input of cell constant with simultaneous dis-

Measurement error

1,2,3)

nLF: 0 … 120 °C

NaCl

HCl (ultrapure water with traces)

NH3 (ultrapure water with traces)

NaOH (ultrapure water with traces)

Conductivity 0.001 μS/cm (c < 0.05 cm

Resistivity 00.00 … 99.99 MΩ cm

Salinity 0.0 … 45.0 g/kg (0 … 30 °C)

TDS 0 … 1999 mg/l (10 … 40 °C)

Input of solution Input of conductivity of the calibration

Auto Automatic determination of the cell constant

< 0.5 % meas.val. + 0.4 µS * c

k = 0.1 : 0-200 µS/cm

-1

(adjustable)

0.01 μS/cm (c = 0.05 … 0.2 cm–1)

0.1 μS/cm (c > 0.2 cm–1)

play of conductivity value and temperature

solution with simultaneous display of cell

constant and temperature

with calibration solution

4)

–1

)

1) according to EN 60746-1, at nominal operating conditions

2) ± 1 count

3) plus sensor error

4) c = cell constant

Page 53

Specications

53

Oxy

Memosens input, oxygen M8 socket, 4 pins, for Memosens lab cable or

Display ranges

Temperature meas. range 1)-20 … +150 °C

Sensor standardization Automatic calibration in air (100 % RH)

1) Ranges depending on Memosens sensor

1)

M12 socket, 8 pins, for Memosens sensors

Saturation 0.000 ... 200.0 %

Concentration 000 μg/l … 20.00 mg/l

Zero calibration

Page 54

54

0000 DELETED (“data deleted” display) 39

A

AA batteries 13

Accessories for conductivity 47

Accessories for oxygen 48

Accessories for pH 45

AIR CAL (Oxy calibration) 27

Altitude (Oxy conguration) 19

Arrow keys 12

Automatic calibration (Cond) 25

Automatic pH calibration (Programmed buers) 20

B

Batteries 14

Batteries for application in hazardous locations 14

Battery capacity 14

Battery charge indicator 14

Battery compartment 13

Battery icon 14

Battery replacement 13

Benchtop stand 10

Buer sets CPY20 45

Buer set selection 17

Buer solutions 45

C

Calibration, conductivity 24

Calibration set Conducal CLY421 47

CD-ROM 7

Cell constant (Cond calibration) 24

Certicates 7

Charge level of batteries 14

Clearing the datalogger 39

Clock 40

Cond conguration 18

Conductivity calibration, CELL CONST 24

Conductivity calibration, FREE CAL 26

Conductivity calibration solutions CLY11 47

Index

Page 55

Conductivity calibration, with cal solution 25

Conductivity sensors 46

Conductivity sensors, product line 46

Conguration (Cond) 18

Conguration (Oxy) 19

Conguration (pH) 17

Conguring the data logger 36

Connecting a sensor 15

Connecting cable for Memosens 15

Connections 15

Continuous recording of measured values 33

Control functions 12

CONT, starting the data logger 37

Cyclic recording of measured values 33

D

DATA INPUT (Oxy calibration) 29

DATA INPUT (pH calibration) 21

Data logger 32

Data logger conguration 36

Data logger icons 32

Data logger menu 35

Data memory 32

Data of the meter 49

Date 40

Default (conguration) 17

Deleting data logger entries 39

Delta range (data logger) 34

Device conguration (Cond) 18

Device conguration (Oxy) 19

Device conguration (pH) 17

Device messages 41

Dierence (data ogger mode) 34

Dierence+Interval (data logger mode) 34

Digital sensors, conductivity 46

Digital sensors, oxygen 48

Digital sensors, pH 44

55

Page 56

56

Display 11

Display icons 16

Displaying the data logger 32

Displaying the time and date 40

Disposal 3

Documentation 7

Duracell MN1500 battery 14

E

Electrolyte vessel, CPY7 45

Energizer E91 battery 14

ERROR (error codes) 43

Error messages 41

Error messages, overview 43

EU Declarations of Conformity 7

F

FREE CAL, free selection of calibration method (Cond) 26

FREE CAL, free selection of calibration method (Oxy) 30

FREE CAL, free selection of calibration method (pH) 23

H

Hazardous location, batteries 14

Holding the measured value 33

Hook 10

Hours, display 40

I

Icons 16

Icons for data logger 32

INFO messages 42

Inserting the batteries 13

Interrupting the data logger 39

Interval (data logger mode) 33

Introduction 8

Index Index

Page 57

Index

K

Keypad 12

L

Logger 32

Logger display 35

Logger type (data logger modes) 33

M

Manual calibration (Cond) 24

Manual calibration (pH) 22

Measured-value recording 33

Measuring 31

Memory for measured values 32

Memosens cable, description 9

Memosens connecting cable 15

Memosens sensors, conductivity 46

Memosens sensors, pH 44

Menu of data logger 35

Menu structure of Cond conguration 18

Menu structure of data logger 35

Menu structure of Oxy conguration 19

Menu structure of pH conguration 17

Messages 41

Messages, “Sensoface” 42

Micro USB port 15

Minutes, display 40

N

Nitrogen 5.0 28

O

on/o key 12

Operating modes of the data logger 33

ORP sensors 44

Overview of Cond conguration 18

Overview of error messages 43

Overview of Oxy conguration 19

Overview of pH conguration 17

57

Page 58

58

Oxy conguration 19

Oxygen calibration, AIR CAL 27

Oxygen calibration, DATA INPUT 29

Oxygen calibration, FREE CAL 30

Oxygen calibration, ZERO CAL 28

Oxygen-free medium 28

Oxygen sensors 48

P

Package contents 6

Panasonic Pro Power LR6 battery 14

Parameter setting, data logger 36

Parameter settings (Cond conguration) 18

Parameter settings (Oxy conguration) 19

Parameter settings (pH conguration) 17

pH buer solutions 45

pH calibration, DATA INPUT 21

pH calibration, FREE CAL 23

pH calibration, MANUAL 22

pH calibration, PROG. BUFFERS 20

pH conguration 17

pH sensors 44

Ports 15

Power-on 16

Power One 4106 battery 14

Product range 44

Programmed buers, description 9

Programmed buers (pH calibration) 20

Protective cover 10

Q

Quickstart guides 7

Index Index

Page 59

Index

R

Rating plate 10

Real-time clock 40

Recorded data, display 38

Redox sensors 44

Registered trademarks 3

Replacing the batteries 13

Reservoir for KCI electrolyte 45

Reset to factory settings (Default) 17

Return of products under warranty 3

S

Safety instructions 7

Saving the currently measured value 33

Seconds, display 40

Sensoface, description 9

Sensoface messages 42

Sensor connection 15

Sensors for oxygen, product line 48

Sensors for pH, product line 44

Sensor without temperature detector 31

Settings for conductivity measurement 18

Settings for oxygen measurement 19

Settings for pH measurement 17

Setting the data logger 36

Setup (Cond conguration) 18

Setup (Oxy conguration) 19

Setup (pH conguration) 17

SHOT (data logger mode) 33

Smiley 42

Specications 49

Specic test report 7

Start address (data logger) 33

Starting the data logger using CONT 37

Starting the data logger using START 37

START, starting the data logger 37

Start-up 13

59

Page 60

60

Status messages 41

Stopping the data logger 39

Structure of data logger 35

Suspending the meter 10

Switching on the meter 12, 16

Switching the measured value display 31

Symbols in display 16

T

T3, temperature class 14

T4, temperature class 14

Table of Cond conguration 18

Table of error messages 43

Table of Oxy conguration 19

Table of pH conguration 17

Technical data 49

Temperature class 14

Temperature, manual adjustment 31

Temperature probe 15

Toggling the measured value display 31

Trademarks 3

Triangle icons 12

V

Value-added features 9

Viewing recorded data 38

Viewing the logger data 38

W

Warranty 3

Z

ZERO CAL (Oxy calibration) 28

Index

Page 61

Page 62

Page 63

Page 64

088989

www.addresses.endress.com

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

70839 Gerlingen - Germany

Phone: +49 7156 209 790

Fax: +49 7156 28 158

TA-209.4MU-EHE01 20150413 Software version: 1.x

71265352

Loading...

Loading...