Page 1

BA01916C/07/EN/01.18

71412064

2018-07-31

Products Solutions Services

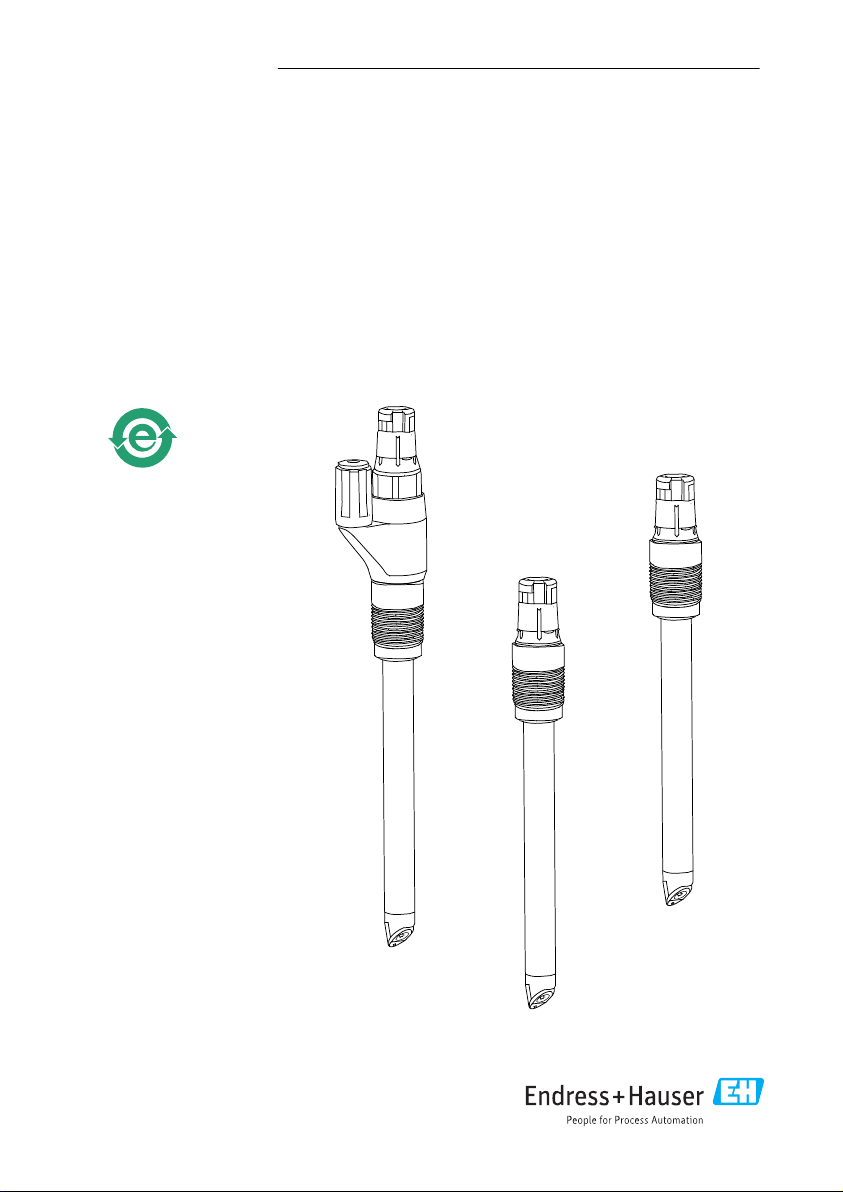

Operating Instructions

CPS47D/77D/97D

Memosens sensors for pH measurement

Page 2

Page 3

CPS47D/77D/97D Table of contents

Table of contents

1 About this document ........... 4

1.1 Symbols used ........................ 4

2 Basic safety instructions ....... 5

2.1 Requirements for personnel ........... 5

2.2 Designated use ...................... 5

2.3 Workplace safety .................... 6

2.4 Operational safety ................... 6

2.5 Product safety ....................... 6

3 Incoming acceptance and

product identification .......... 7

3.1 Product identification ................. 7

4 Installation ...................... 8

4.1 Installation conditions ................ 8

4.2 Orientation ......................... 8

4.3 Installation instructions .............. 10

5 Electrical connection .......... 11

6 Commissioning ................ 11

6.1 Calibration and measurement ......... 11

7 Maintenance .................. 13

7.1 Maintenance tasks .................. 13

8 Repair .......................... 14

8.1 Return ............................ 14

Endress+Hauser 3

Page 4

About this document CPS47D/77D/97D

1 About this document

1.1 Symbols used

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to property.

The following manuals which complement these Operating Instructions can be found on the

product pages on the Internet:

• Technical Information for the relevant sensor

• Operating Instructions for the transmitter used

4 Endress+Hauser

Page 5

CPS47D/77D/97D Basic safety instructions

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the specified

activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions and

must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The sensors are designed for the continuous measurement of the pH value in liquids.

A list of recommended applications is provided in the Technical Information for the

relevant sensor.

CPS47D:

• Long-term monitoring or limit monitoring in process engineering

– Chemical processes

– Organic chemistry with high levels of organic solvents

– Low conductivities

– Clogging media

– Incinerator plants

• Water treatment

Water with low conductivity for Food and Life Sciences

CPS77D:

Hygienic and sterile applications (sterilizable, autoclavable)

– Fermenters

– Biotechnology

– Pharmaceutical industry

– Foods

CPS97D:

• Contaminated media and suspended solids

– Dispersions

– Precipitation reactions

– Emulsions

• Process technology and monitoring of processes with:

Rapidly changing pH values

• Chemical processes

• Pulp and paper industry

Endress+Hauser 5

Page 6

Basic safety instructions CPS47D/77D/97D

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

2.5.2 Transport and storage

All sensors are individually tested and supplied in individual packs.

‣

Sensors should be stored in dry rooms at temperatures of 0 to 50 °C (32 to 122 °F).

‣

6 Endress+Hauser

Page 7

CPS47D/77D/97D Incoming acceptance and product identification

3 Incoming acceptance and product identification

3.1 Product identification

3.1.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer details

• Order code

• Serial number

• Operating conditions

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

3.1.2 Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

3.1.3 Certificates and approvals

mark

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

EAC

The product has been certified according to guidelines TP TC 004/2011 and TP TC 020/2011

which apply in the European Economic Area (EEA). The EAC conformity mark is affixed to the

product.

Endress+Hauser 7

Page 8

Installation CPS47D/77D/97D

4 Installation

4.1 Installation conditions

• Before screwing in the electrode, make sure the assembly thread is clean and runs

smoothly.

• Pay attention to the installation instructions provided in the Operating Instructions of the

assembly used.

Screw in the electrode and tighten by hand 3 Nm (2.21 lbf ft) (specifications only apply if

‣

installing in Endress+Hauser assemblies).

4.2 Orientation

Note the direction of medium flow when installing the sensor.

Position the ISFET chip so that it is at an angle of approx. 30 to 45 ° to the flow direction

‣

(item 2).

Use the rotatable terminal head for this purpose.

8 Endress+Hauser

Page 9

CPS47D/77D/97D Installation

z

y

y

x

z

1

2

30 ... 45°

A0036027

1 Sensor orientation, front view

2 Sensor orientation, 3D view

1 ISFET chip

2 Direction of medium flow

A0036028

When installing the sensor in an assembly, use the serial number engraved on the terminal

head to ensure correct sensor orientation. The engraving is always on the same plane as the

ISFET chip and the nameplate (z-y direction).

ISFET sensors are not designed for use in abrasive media. If these sensors are

nevertheless used in such applications, avoid direct flow to the chip. This increases the

sensor operating life and improves the sensor drift behavior. The disadvantage is that

the pH value displayed is not stable.

Endress+Hauser 9

Page 10

Installation CPS47D/77D/97D

A

B

4.3 Installation instructions

ISFET sensors can be installed in any position because there is no liquid inner lead. However,

in the event of upside-down installation an air bubble

1)

may form in the reference system and

interrupt the electrical contact between the medium and the junction.

Make sure to follow the installation

instructions in the Operating

Instructions of the assembly used.

A0030407

3 Angle of installation

A Recommended

B Permitted, please pay careful attention to basic

conditions!

1) The sensor is free of air bubbles when delivered from the factory. Air bubbles occur, however, when working with

negative pressure, e.g. when emptying a tank.

10 Endress+Hauser

Page 11

CPS47D/77D/97D Electrical connection

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

5 Electrical connection

The sensor is connected to the transmitter via the Memosens data cable CYK10.

A0024019

4 Memosens data cable CYK10

6 Commissioning

6.1 Calibration and measurement

Remove the protection cap for calibration and measurement.

‣

ISFET sensors which are stored dry must be immersed in water for at least 15 minutes

‣

before use. A closed-control loop is created when the measuring system is switched on. The

measured value adjusts to the real value during this time (approx. 5 to 8 minutes). This

settling behavior occurs every time the film of liquid between the pH-sensitive

semiconductor and the reference lead is interrupted. The settling time depends on the

length of the interruption.

If the protection cap is no longer used to store the sensor, store the sensor in a KCl solution

‣

(3 mol/l) or buffer solution.

Do not store the sensor in distilled water!

‣

The frequency at which a sensor calibration or sensor inspection is performed depends on

‣

the operating conditions (fouling, chemical load).

Two-point calibration is required for ISFET sensors. Use a high-quality buffer from

‣

Endress+Hauser, e.g. CPY20.

ISFET sensors with Memosens technology do not need to be calibrated when they are

connected for the first time. Calibration is only required if very strict accuracy

requirements must be met or if the sensor has been in storage for longer than three

months.

Endress+Hauser 11

Page 12

Commissioning CPS47D/77D/97D

2.

4.

5.

6.

1. Immerse the sensor into a defined buffer solution (e.g. pH 7).

2. Perform the calibration at the measuring device:

(a) In the case of pH sensors and manual temperature compensation, set the measurement

temperature.

(b) Enter the pH value of the buffer solution.

(c) Start calibration.

(d) The value is accepted once it has stabilized.

3. Rinse the sensor with distilled water. Do not dry the sensor!

4. Immerse the ISFET sensor into the second buffer solution (e.g. pH 4).

5. Perform the calibration at the measuring device:

(a) Enter the pH value of the second buffer solution.

(b) Start the calibration.

(c) The value is accepted once it has stabilized.

The device calculates the operating point and slope and displays the values. Once the

adjustment values have been accepted, the device is adjusted to the new ISFET sensor.

6. Rinse the ISFET sensor with distilled water.

12 Endress+Hauser

Page 13

CPS47D/77D/97D Maintenance

7 Maintenance

7.1 Maintenance tasks

7.1.1 Cleaning the sensor

Clean the sensor before each calibration.

‣

Clean away fouling on the sensor as follows depending on the type of fouling:

1. Oily and greasy films:

Clean with grease remover, e.g. alcohol, perhaps hot water and (alkaline) agents

containing surfactants (e.g. dishwashing detergent).

2. Lime, cyanide and metal hydroxide buildup and low solubility (lyophobic) organic

buildup:

Dissolve buildup with diluted hydrochloric acid (3 %) and then rinse thoroughly with

plenty of clear water.

3.

WARNING

L

Thiocarbamide

Harmful if swallowed. Limited evidence of carcinogenicity. Possible risk of harm to the

unborn child. Dangerous for the environment with long-term effects!

Wear protective goggles, protective gloves and appropriate protective clothing.

‣

Avoid all contact with the eyes, mouth and skin.

‣

Avoid discharge into the environment.

‣

Sulfidic buildup (from flue gas desulfurization or sewage treatment plants):

Use a mixture of hydrochloric acid (3 %) and thiocarbamide (commercially available)

and then rinse thoroughly with plenty of clear water.

4. Buildup containing proteins (e.g. food industry):

Use a mixture of hydrochloric acid (0.5 %) and pepsin (commercially available) and then

rinse thoroughly with plenty of clear water.

5.

NOTICE

Pressurized water can damage the seal!

Do not direct pressurized water straight onto the chip.

‣

Fibers, suspended substances:

Rinse with pressurized water or possibly with surface-active agents.

6. Readily soluble biological buildup:

Rinse with pressurized water.

7. Sensors with very long response time:

Use a mixture that contains hydrofluoric acid and consists of nitric acid (10%) and

ammonium fluoride (50 g/l).

Endress+Hauser 13

Page 14

Repair CPS47D/77D/97D

WARNING

L

Hydrofluoric acid

Risk of serious or fatal injury from caustic burns!

Wear goggles to protect eyes.

‣

Wear protective gloves and appropriate protective clothing.

‣

Avoid all contact with the eyes, mouth and skin.

‣

If using hydrofluoric acid, use plastic vessels only.

‣

8 Repair

8.1 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

14 Endress+Hauser

Page 15

Page 16

*71412064*

71412064

www.addresses.endress.com

Loading...

Loading...