Page 1

Technical Information

Tophit CPS441 and CPS441D

ISFET sensor with liquid KCl reference electrode for pH measurement in

blocking media

Analog or digital sensors with Memosens technology

Application

Special applications for:

• Maximum measuring accuracy

• Blocking media (pressurized)

• High organic solvent contents

• Low conductivities

With ATEX, FM and CSA approval for application in hazardous

areas

Your benefits

• Resistant to breaking

– Sensor body made completely of PEEK (FDA compliant)

– Direct installation into the process, reduces effort and costs

for sampling and laboratory analysis

• Re-fillable liquid KCl reference electrolyte

• Application possible at low temperatures

– Short response time

– Constantly high accuracy

• Sterilizable

• Longer calibration intervals than glass electrodes

– Lower hysteresis with alternating temperatures

– Low measuring error after high-temperature loading

– Almost no acid and alkaline errors

• With built-in temperature sensor for effective temperature

compensation

• Ideal for CIP processes when combined with an automatic

retractable assembly

Further benefits offered by Memosens technology

• Maximum process safety through contactless inductive signal

transmission

• Data safety through digital data transmission

• Easy handling thanks to storage of sensor-specific data in the

sensor

• Predictive maintenance possible thanks to registration of

sensor load data in the sensor

TI352C/24/EN/05.10

Page 2

Tophit CPS441/CPS441D

U

D

U

GS

1

2

S

D

Si (p)

Si (n)

Si (n)

I

D

U

D

U

GS

13

4

5

6

2

S

D

Si (p)

Si (n)

Si (n)

I

D

U =U+

GS 0

lg a

ion

RT

nF

2.3

RT

nF

2.3

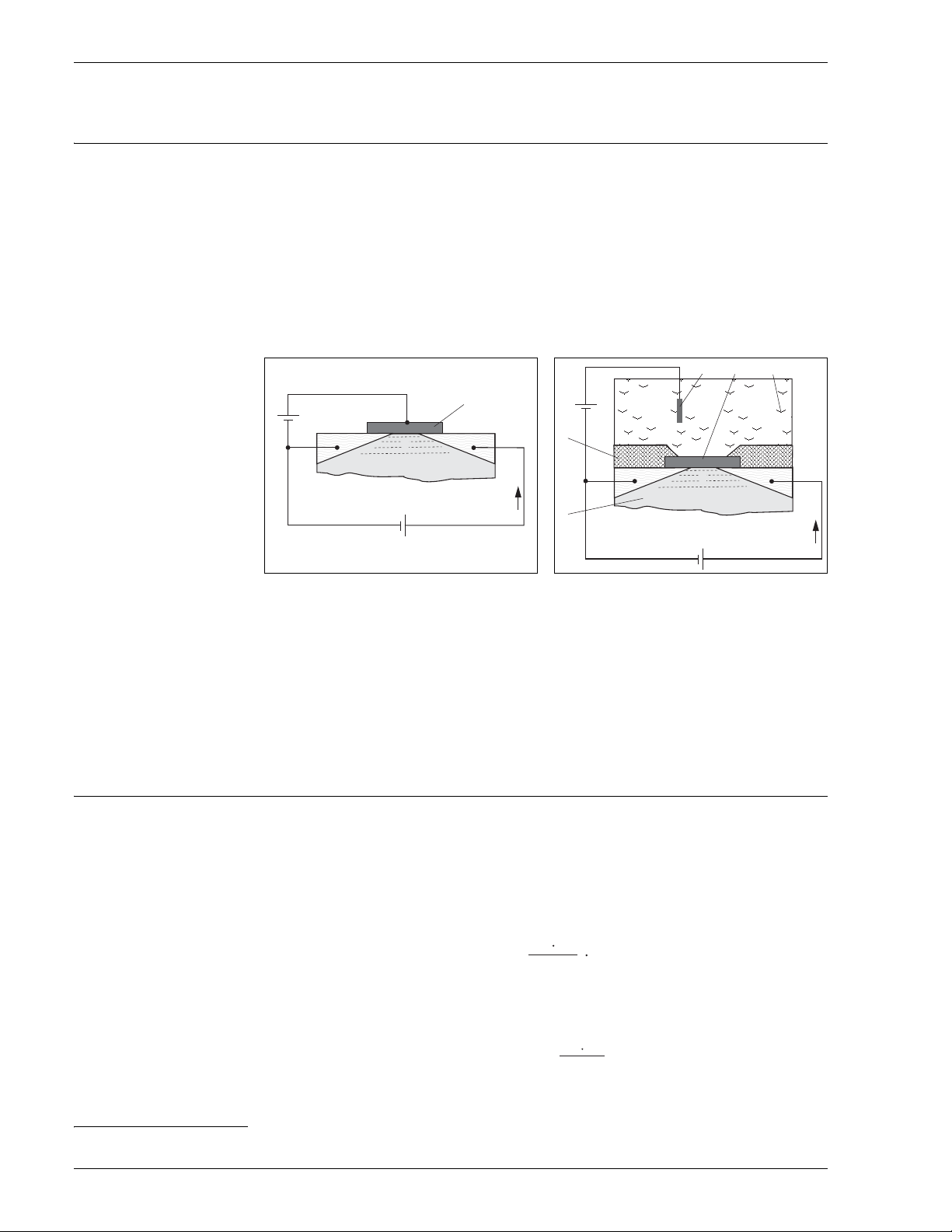

Function and system design

Measuring principle Ion-selective, or more generally ion-sensitive field effect transistors (ISFET) were developed in the 1970s as

an alternative to the glass electrode for pH measurement.

Basics

Ion-selective field effect transistors use an MOS

(pos. 1) is not a control electrode. Instead, the medium (see Fig 2, pos. 3) in the ISFET is in direct contact with

the gate isolator layer (pos. 2).Two strongly N-conducting areas are diffused in P-conducting substrate (see Fig

2, pos. 5) of the semiconductor material (Si). These N-conducting areas are current supplying ("Source", S)

and current accepting ("Drain", D) electrodes. The metallic gate electrode (in case of the MOSFET) resp. the

medium (in case of the ISFET) forms a capacitor with the substrate below. A potential difference between gate

and substrate (U

) causes a higher electron density between "Source" and "Drain". A N-conducting channel

GS

(pos. 2) is formed, i.e. a drain current (I

1)

) is induced.

D

transistor arrangement (see Fig 1) where the metallic gate

Fig. 1: Principle MOSFET

1 Metallic gate

2 N-conducting channel

With the ISFET, the medium is in direct contact with the gate isolator layer. Therefore, H

medium, which are located in the medium / gate isolator boundary layer, create the electric field (gate

potential). Depending on the effect described above, a N-conducting channel is formed and a current between

"Source" and "Drain" is induced. Suitable sensor circuits use the dependence on the ion-selective gate potential

to create an output signal proportional to the concentration of the ion type.

pH selective IsFET The gate isolator serves as an ion-selective layer for H

well (isolator effect) but allows reversible surface reactions with the H

Depending on the acidic or alkaline character of the measurement solutions, functional groups in the isolator

surface accept or reject H

+

ions (amphoteric character of the functional groups). This leads to a positive (H+

acceptance in the acidic medium) or negative (H

surface. Depending on the pH value, a defined surface charge can be used to control the field effect in the

channel between "Source" and "Drain".The processes which lead to the creation of a charge potential and

therefore to a control voltage U

UGS ...

U

R ...

T ...

n ...

Potential between gate and source

...

Offset voltage

0

Gas constant (8.3143 J/molK)

Temperature [K]

electrochemical valueability (1/mol)

between "Gate" and "Source" are described with the Nernst equation:

GS

a0003855

Fig. 2: Principle ISFET

1 Reference electrode

2 N-conducting channel

3 Gate isolator layer

4 Medium

5 P-doped silicon substrate

6 Sensor shaft

+

ions available in the

+

ions. The gate isolator is impermeable to the ions as

+

rejection in the alkaline medium) charging of the isolator

F ...

...

a

ion

+

ions.

Faraday constant (26.803 Ah)

Activity of ion kind (H+)

Nernst factor

a0003856

1) Metal Oxide Semiconductor

2 Endress+Hauser

At 25 °C (77 °F), the Nernst factor is –59.16 mV/pH.

Page 3

Tophit CPS441/CPS441D

pH (25 °C)

ΔpH

1 M NaOH1 M HCl

E+H ISFET

pH 1 … 13

Glass 1

Glass 2

-0.2

0.0

0.2

0.4

0.6

0.8

500

300

100

-100

-300

-500

024 68101214

pH

mV

a

b

c

Important characteristics of

Tophit CPS441

• Resistance to breaking: This is the most obvious feature of the sensor. The complete sensor technology is

embedded in a PEEK shaft. Only the highly resistant isolator layer and the reference have direct contact with

the medium.

• Acid or alkaline errors: A further, important benefit compared with the glass electrode is the considerably

reduced number of acid or alkaline errors in extreme pH ranges. In contrast to glass electrodes, practically

no foreign ions can build up at the ISFET gate. The measuring error of < 0.01 pH (between pH 1 and 13) at

25°C (77 °F) is near by the detection limit.

The figure below shows the acid or alkaline error of the ISFET between pH 1 and 13 and the comparison to

the glass electrode (two different pH glasses) at pH values 0.09 and 13.86.

a0003867-en

Fig. 3: Comparison of acid and alkaline errors

• Measurement stability and sensor response time: The ISFET response times are very short over the whole

temperature range. With the ISFET sensor, there is no (temperature-dependent) equilibrium setting as in the

source layer of a pH glass of a glass electrode. They can also be used at low temperatures without a

deceleration in response time.Large and fast temperature and pH value fluctuations have a smaller effect on

the measuring error (hysteresis) than with a glass electrode, as there is no stress exerted on the pH glass.

• Reference system: The integrated reference electrode of the sensor is a double-chamber reference system

with a bridge electrolyte. The benefits are an efficient and stable contact between the diaphragm and the

reference lead, and the extremely long poisoning path. The bridge electrolyte is highly resistant to

temperature and pressure changes.

• Isothermic curves

– The Nernst equation defines the dependence of the measuring voltage on the hydrogen ion content (pH

value) and the temperature. It is the basis of pH measuring technology and for ISFET sensors too. A

temperature-dependent value for the potential change per pH value can be worked out from this equation

(isothermic curve, potential change per pH value at a defined temperature).

– The isothermic curves of the ISFET sensor are very close to the theoretical values (see Fig 4). This is further

proof for the high pH measurement precision of the sensor.

Endress+Hauser 3

Fig. 4: Isothermic curves

a Isothermic curve at 8 °C (46 °F), slope –55.8 mV/pH

b Isothermic curve at 37 °C (99 °F), slope –61.5 mV/pH

c Isothermic curve at 61 °C (142 °F), slope –66.3 mV/pH

a0003868-de

Page 4

Memosens (CPS441D) Maximum process safety

The inductive and non-contacting measured value transmission of Memosens guarantees maximum process

safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– The plug-in connection is free from corrosion.

– Measured value distortion from moisture is not possible.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium. The result: No more need to ask about

"symmetrically high-impedance" or "unsymmetrical" (for pH/ORP measurement) or an impedance

converter.

• EMC safety is guaranteed by screening measures for the digital measured value transmission.

• Application in explosion-hazardous areas is unproblematic; the integrated electronics are intrinsically safe.

Data safety through digital data transfer

The Memosens technology digitalizes the measured values in the sensor and transfers them to the transmitter

contactlessly and free from interference potential. The result:

• An automatic error message is generated if the sensor fails or the connection between sensor and transmitter

is interrupted.

• The availability of the measuring point is dramatically increased by immediate error detection.

Easy handling

Sensors with Memosens technology have integrated electronics that allow for saving calibration data and

further information such as total hours of operation and operating hours under extreme measuring conditions.

When the sensor is mounted, the calibration data are automatically transferred to the transmitter and used to

calculate the current measured value. Storing the calibration data in the sensor allows for calibration away from

the measuring point. The result:

• Sensors can be calibrated under optimum external conditions in the measuring lab. Wind and weather do

neither affect the calibration quality nor the operator.

• The measuring point availability is dramatically increased by the quick and easy replacement of precalibrated

sensors.

• The transmitter does not need to be installed close to the measuring point but can be placed in the control

room.

• Maintenance intervals can be defined based on all stored sensor load and calibration data and predictive

maintenance is possible.

• The sensor history can be documented on external data carriers and evaluation programs at any time. Thus,

the current application of the sensors can be made to depend on their previous history.

Communication with the transmitter

Always connect digital sensors to a transmitter with Memosens technology. Data transmission to a transmitter

for analog sensors is not possible.

The sensor is connected to the cable connection (CYK10) without contact. The power and data are transferred

inductively

Once connected to the transmitter, the data saved in the sensor are read digitally. You can call up these data

using the corresponding DIAG menu.

Data that digital sensors save include the following:

• Manufacturer data

– Serial number

–Order code

– Date of manufacture

• Calibration data

– Calibration date

– Calibration values

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operational data

– Date of commissioning

– Hours of operation under extreme conditions

– Number of sterilizations

– Data for sensor monitoring.

Tophit CPS441/CPS441D

4 Endress+Hauser

Page 5

Tophit CPS441/CPS441D

1

2

3

4

5

6

7

8

9

10

11

MEAS CAL

DIAG

PARAM

PARAM

?

12

Measuring system The complete measuring system comprises at least:

•ISFET sensor Tophit

• Measuring cable CPK12 (analog, with TOP68 connection) or CYK10 (digital, with Memosens)

• Transmitter, e.g. Liquiline CM4x, Liquisys CPM223 (for panel mounting) or Liquisys CPM253 (field

instrument) or Mycom CPM153.

•Assembly

– Immersion assembly, e.g. Dipfit CPA111

– Flow assembly, e.g. Flowfit CPA250

– Retractable assembly, e.g. Cleanfit CPA471

(CPA450 only with CPS471D, CPS491D or special versions CPS471-ESA and CPS491-ESA, --> Ordering

information)

– Fixed installation assembly, e.g. Unifit CPA442

There are additional accessories available depending on the application:

• Topclean CPC30 or Topcal CPC310 automatic cleaning system

• Extension cable, VBA, VBM or RM junction box

Food industry

a0003883

Fig. 5: Measuring system with Topcal fully automatic measuring, cleaning and calibration system

1

Tophit

2

Cleanfit CPA475

3

Mycom CPM153

4

Power supply

5

Control unit CPG310

6

Cleaner, buffer solutions

7

Steam, water, cleaner

8

Rinse block

9

Power cable

10

Compressed air

11

Liquids / cleaner

12

CPY7 KCl electrolyte vessel

Process sterilizibility is no problem due to the wide range of applications for the ISFET pH sensor, not only

relating to temperature but also to pH. There is only a small range of high pH values connected with high

temperatures where the sensor is not constantly stable (see "Process"). Media with these characteristics remove

the isolator oxide from the ISFET chip. As this is the pH and temperature range of CIP cleaning media, the

ISFET pH sensor should only be used in combination with an automatic retractable assembly.

Endress+Hauser 5

Page 6

Tophit CPS441/CPS441D

1

2

4

5

3

RD

GN

Coaxial shield

WH

Coaxial cable

YE

BN

Shield

DRN

SRC (pH)

Source

Drain

Pt 1000

Pt 1000

Reference

Pt 1000

PM

GND

Benefits of the Topcal fully automatic measurement, cleaning and calibration system:

• CIP cleaning

The sensor built into the retractable assembly is automatically "moved" out of the medium before cleaning.

In the rinse chamber of the retractable assembly the sensor is cleaned with suitable cleaning solutions.

• Calibration cycles can individually be set.

• Low maintenance costs due to fully automatic cleaning and calibration functions.

• Measuring results are optimally reproducable and the individual value tolerances are very low due to the

automatic calibration.

Biotechnology

Fig. 6: Measuring system for pharmaceutical and biotechnology applications

1 ISFET sensor

2 Installation assembly Unifit CPA442

3 KCl electrolyte vessel

4 Special measuring cable CPK12 or CYK10

5 Transmitter Liquiline CM42

Input

Measured values pH value

Temperature

Measuring range 0 to 14 pH

–15 to 135 °C (5 to 275 °F)

Caution!

Note the process operating conditions.

Power supply

Electrical connection CPS441 The sensor is connected to the measuring transmitter using the special measuring cable CPK12.

a0004287

Fig. 7: Special measuring cable CPK12

6 Endress+Hauser

a0003887-en

Page 7

Tophit CPS441/CPS441D

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

Note!

• The cable cores Yellow and White are connected on the sensor side.

• Make sure you comply with the instructions for connecting the sensor (wiring diagram) in the Operating

Instructions of the transmitter. The transmitter has to be appropriate for the use of ISFET sensors (e.g.

Liquiline CM42, Mycom CPM153 or Liquisys CPM223/253-IS).

A transmitter with only a standard pH input is inappropriate.

Electrical connection

The sensor is electrically connected to the transmitter by means of the special measuring cable CYK10.

CPS441D

Special measuring cable CYK10

a0003350

Performance characteristics

Response time < 5 s

for buffer change from pH 4 to pH 7 under reference operating conditions

Note!

The response of the integrated temperature sensor can be slower with extreme temperature changes.

Reference operating

conditions

Maximum measured error

Repeatability ± 0.1 % of measuring range

Start-up drift Everytime when switching on the measuring device a control loop is set up. During this time the measured

Reference temperature: 25 °C (77 °F)

Reference pressure: 1013 mbar (15 psi)

pH: ± 0.2 % of measuring range

Temperature: Class B acc. to DIN IEC 60751

value moves to the true value.

The settling time depends on the kind of interruption and the interruption time:

• Supply voltage interruption, sensor left in medium: approx. 3 to 5 minutes

• Interruption of the fluid film between pH sensitive ISFET and reference lead: approx. 5 to 8 minutes

• Longer dry storage of the sensor: up to 30 minutes

Endress+Hauser 7

Page 8

Installation

advised angle of installation

permissible with respect to

the application specific

conditions

Tophit CPS441/CPS441D

Installation angle ISFET sensors can be installed in any position, as there is no liquid internal lead. However, in case of an

overhead installation, a possible air cushion

2)

in the reference system might interrupt the electrical contact

between the medium and the diaphragm.

Fig. 8: Angle of installation

a0003898-en

Note!

• Especially in case of overhead installation, make sure you connect the KCl electrolyte vessel without air

cushions!

• The installed sensor may be held under dry conditions for maximum 6 hours (also applies to overhead

installation).

• Make sure you comply with the instructions in the Operating Instructions for the assembly used.

2) The sensor is delivered without air cushions. Air cushion formation is possible in case of working with vacuum, e.g. cleaning out of tanks.

8 Endress+Hauser

Page 9

Tophit CPS441/CPS441D

z

1

2

z

y

081566

y

08156768

30...45 °

1

3

5

4

x

z

y

Sensor orientation When installing the sensor, note the flow-past direction of the medium. The ISFET chip should be fixed at an

angle of approx 45° to the flow-past direction (see Fig 10). Fixing at the correct angle is very easy because of

the rotable plug-in head.

Fig. 9: Sensor orientation, front view

1 Serial number

2 Nameplate

a0003894

Fig. 10: Sensor orientation, 3d view

1 Serial number

3 Rotable part of the connection head

a0003892

4 Medium flow-past direction

5 ISFET chip

When installing the sensor in an assembly, use the engraved serial number on the connection head for correct

sensor orientation. The serial number is always located in the same plane as the ISFET chip and the nameplate

(z-y-direction, see Fig 9).

Note!

ISFET sensors are not designed for the use in abrasive media. If you use them in such applications anyhow, you

must avoid direct flow against the chip. This considerably lengthens the service life and improves the drift

behavior of the sensor. You have however the disadvantage that the display of the pH value is not stable.

Environment

Ambient temperature range Caution!

Danger of frost damage

Do not operate the sensor at temperatures below –15°C (5 °F).

Storage temperature 0 to 50 °C (32 to 120 °F)

Ingress protection TOP68:

• IP 68, 1 m (3.3 ft) water column, 50 °C (122 °F), 168 h, autoclavable up to 135 °C (275 °F)

Memosens:

Endress+Hauser 9

• IP 68, 10 m (32.8) ft water column, 25 °C (77 °F), 45 d, 1M KCl, autoclavable up to 135 °C (275 °F)

Page 10

Tophit CPS441/CPS441D

120

100

80

60

40

20

0

024 6 81012

°C

14

pH

248

212

176

140

104

68

32

°F

Restricted

lifetime!

application range

ISFET

3

100

10

bar

°F

°C

psi

145

212

275

135

43.5

bar

ISFET application range

Sensitivity to light As every semiconductor the ISFET is light-sensitive (fluctuations of measured value). Avoid direct sunlight

during calibration and operation!

Normal environment light does not influence the measurement.

Process

Medium temperature

depending on pH

Application at low

temperatures

Pressure-temperature

diagram

At high temperatures over a long period of time, alkalis irreversibly destroy the gate isolator oxide.The sensor

can only be used in the indicated range (see Fig 11) at a cost to its life span. If it is constantly subjected to the

effects of a 2% sodium hydroxide solution at 80°C (176 °F), the sensor life span drops to approx. 10-15 hours.

a0003899-en

Fig. 11: Temperature and pH

Application range of the sensor according to the order code (see ordering information, product structure)

The process pressure must not be higher than the back pressure to the KCl electrolyte vessel. Otherwise the

process pressure effects medium penetration into the KCl electrolyte vessel.

Using the CPY7 electrolyte vessel, the maximum permitted pressure is 10 bar at 20 °C (150 psi at 68 °F). This

means, the process pressure has to be lower than 10 bar (150 psi)!

Please, refer to the corresponding chapters in the Operating Instructions of your electrolyte vessel.

Max. 10 bar / 100 °C (145 psi / 212 °F)

Sterilizable: 3 bar / 135 °C (44 psi / 275 °F), 1 h

Fig. 12: Pressure and temperature

Caution!

Danger of damage to the sensor

Never use the Tophit for applications outside the given specifications!

10 Endress+Hauser

a0003900-en

Page 11

Tophit CPS441/CPS441D

6

3

4

1

2

12

(0.47)

12

(0.47)

mm

(inch)

120 / 225 /

360 / 425 *

(4.72 / 8.86 /

14.2 / 16.7)

120 / 225 /

360 / 425 *

(4.72 / 8.86 /

14.2 / 16.7)

4

5

3

Recommended cleaning Depending on the degree of pollution:

• Hot water / soap (to be preferred)

• Isopropanole

• Chlorine cleaner

• Storing in KCl solution

Mechanical construction

Design, dimensions

Fig. 14: Sensor head

1 KCl electrolyte connection

2 Plug-in head

3 Reference electrode

a0003906

Fig. 13: Tophit CPS441

* depending on the sensor version

Weight 0.1 to 0.5 kg (0.2 to 1.1 lbs), depending on the sensor version

Material

Sensor shaft PEEK (FDA, 3-A)

4 ISFET chip

5 Seal (EPDM or perfluoro elastomer)

6 Sensor shaft

Seals EPDM (FDA, 3-A) / Perfluoro elastomer

Diaphragm Ceramics

Process connection Pg 13.5

Surface roughness R

< 0.8 μm (31.5 μin)

a

Temperature sensor Pt 1000 (class B acc. to DIN IEC 60751)

Plug-in head CPS441:

• ESS; TOP68, rotatable

Diaphragm Ceramics, sterilizable

CPS441D:

• Memosens, rotatable

a0003904

Endress+Hauser 11

Page 12

Ordering information

PEEK ISFET sensor for glass free pH measurement

• For blocking media

• Integrated Pt 1000 temperature sensor

• With liquid KCl electrolyte reference system and ceramics diaphragm

• Application range: pH 0 to 14, –15 to 135 °C (5 to 275 °F)

• For Ex and Non-Ex applications

Tophit CPS441/CPS441D

Product structure CPS441

Product structure CPS441D

Shaft length

2 120 mm (4.72 in)

4 225 mm (8.86 in)

5 360 mm (14.2 in)

6 425 mm (16.7 in)

Plug-in head

ESS Threaded plug-in head, Pg 13.5, TOP68 rotatable

Options

1 Chip sealing: EPDM, hygienic

2 Chip sealing: Perfluoro elastomer

CPS441- complete order code

Version

7 Basic version

Shaft length

2 120 mm (4.72 in)

4 225 mm (8.86 in)

5 360 mm (14.2 in)

6 425 mm (16.7 in)

Electrolyte supply

A Shaft hole for KCl refilling, CPA441

B KCl hose connection, CPY7

Additional option

1 EPDM, hygienic version

2 Perfluoro elastomer

Approval

G ATEX II 2G Ex ia IIC T3/T4/T6, FM/CSA IS/NI Cl I DIV 1&2 GP A-D

1 Non-hazardous location

CPS441D- complete order code

Certificates and approvals

Ex approval FM/CSA •FM

IS/NI Cl I DIV 1&2 GP A-D, associated apparatus Mycom 153-O/-P or Liquiline CM42-*P

•CSA

IS/NI Cl I DIV 1&2 GP A-D, associated apparatus Mycom 153-S or Liquiline CM42-*S

Ex approval ATEX Device group II, Category 2G

Explosion protection Ex ia IIC T3/T4/T6

12 Endress+Hauser

Page 13

Tophit CPS441/CPS441D

Sanitary compatibilty Cleanability validated acc. to EHEDG test criteria (TNO Report V3640 RE)

Original of report summary

"At the request of Endress+Hauser Conducta, Postfach 100154, D-70826 Gerlingen, Germany the in-place

cleanability of the ISFET-Sensor Tophit CPS471 was assessed according to the test procedure of the

European Hygienic Engineering & Design Group (EHEDG).

The test results show that the ISFET-Sensor Tophit CPS471, including the seals, is cleanable in-place at least

as well as the reference pipe. The tests were conducted five times on one test object. The results of the tests

are comparable with each other. The ISFET-Sensor Tophit CPS471 complies with the hygienic criteria of

the Machinery Directive 98/37/EC, annex 1 (additional essential health and safety requirements for certain

categories of machinery) section 2.1 (agri-foodstuffs machinery), the hygienic requirements of EN 1672 part 2 and with the hygienic equipment design criteria of the EHEDG.

The test results obtained are representative of the ISFET-Sensor TopHit type CPS471 and type CPS441."

• Only sensor version with EPDM chip sealing is hygienic

• Materials in contact with medium are FDA certified

• Certified acc. to the 3-A standard no. 74-03

Accessories

Note!

In the following sections, you find the accessories available at the time of issue of this documentation.

For information on accessories that are not listed here, please contact your local service or sales representation.

Transmitters Liquiline CM42

• Modular two-wire transmitter for Ex and non-Ex areas

®

, PROFIBUS or FOUNDATION Fieldbus available

•Hart

• Ordering acc. to product structure, Technical Information TI381C/07/en

Liquisys CPM223/253

• Transmitter for pH and redox, field or panel-mounted housing

• HART or PROFIBUS available

• Ordering acc. to product structure, Technical Information TI194C/07/en

Mycom CPM153

• Transmitter for pH and redox, one or two channel version, Ex or Non-Ex

• HART or PROFIBUS available

• Ordering acc. to product structure, Technical Information TI233C/07/en

Fully automatic measuring

systems

Service tool Memocheck Plus CYP01D, Memocheck CYP02D

Topcal CPC310

• Fully automatic measuring, cleaning and calibration system; Ex or non-Ex

• In-situ cleaning and calibration, automatic sensor monitoring

• Ordering acc. to product structure, Technical Information TI404C/07/en

Topclean CPC30

• Fully automatic measuring and cleaning system; Ex or non-Ex

• In-situ cleaning, automatic sensor monitoring

• Ordering acc. to product structure, see Technical Information TI235C/07/en

• Tool for the qualification of measuring chains

• Service tool for quick, on-site checks of measuring systems with Memosens technology

• Verification of data transmission

• Ordering acc. to product structure, KA399C/07/a2

Endress+Hauser 13

Page 14

Buffer solutions High-quality buffer solutions of Endress+Hauser - CPY20

The secondary buffer solutions have been referenced to primary reference material of the PTB (German Federal

Physico-technical Institute) and to standard reference material of NIST (National Institute of Standards and

Technology) according to DIN 19266 by a DKD (German Calibration Service) accredited laboratory.

pH value

A pH 2.00 (accuracy ± 0.02 pH)

C pH 4.00 (accuracy ± 0.02 pH)

E pH 7.00 (accuracy ± 0.02 pH)

G pH 9.00 (accuracy ± 0.02 pH)

I pH 9.20 (accuracy ± 0.02 pH)

K pH 10.00 (accuracy ± 0.05 pH)

M pH 12.00 (accuracy ± 0.05 pH)

Quantity

01 20 x 18 ml (0.68 fl.oz) only buffer solutions pH 4.00 and 7.00

02 250 ml (8.45 fl.oz)

10 1000 ml (0.26 US gal)

50 5000 ml (1.32 US gal) canister for Topcal S

Certificates

A Buffer analysis certificate

Version

1Standard

CPY20- complete order code

Tophit CPS441/CPS441D

Assemblies (selection) Dipfit CPA111

• Immersion and installation assembly for open and closed tanks

• Technical Information TI112C/07/en

Flowfit CPA250

• Flow assembly for installation in pipework

• Technical Information TI041C/07/en

Cleanfit CPA471

• Retractable assembly for tank and pipe installation

• Technical Information TI217C/07/en

Cleanfit CPA475

• Retractable assembly for installation in tanks and pipework under sterile conditions

• Technical Information TI240C/07/en

Unifit CPA442

• Installation assembly for food, biotechnology and pharmaceuticals, with EHEDG and 3A certificate

• Technical Information TI306C/07/en

Note!

Ordering of assemblies is acc. to product structure. Please refer to the corresponding Technical Information.

14 Endress+Hauser

Page 15

Tophit CPS441/CPS441D

Cables CPK12 (TOP68)

Cable length

HA Cable length: 5 m (16.41 ft), TPE sheath, max. 130 °C (266 °F)

HB Cable length: 10 m (32.82 ft), TPE sheath, max. 130 °C (266 °F)

HC Cable length: 15 m (49.23 ft), TPE sheath, max. 130 °C (266 °F)

HD Cable length: 20 m (65.64 ft), TPE sheath, max. 130 °C (266 °F)

HF Cable length: 5 to 20 m (16.41 to 65.64 ft), TPE sheath, max. 130 °C (266 °F)

HG Cable length: 16 - 160 ft, TPE sheath, max. 130 °C (266 °F)

CPK12- complete order code

CYK10 (Memosens)

CYK10 Memosens data cable

• For digital sensors with Memosens technology

• Ordering according to product structure, see below

Certificates

A Standard, non-Ex

G ATEX II 1G Ex ia IIC T6/T4/T3, FM/CSA IS/NI Cl I DIV 1&2 GP A-D

L LABS free, non-Ex

O FM IS/NI Cl I DIV 1&2 GP A-D

S CSA IS/NI Cl I DIV 1&2 GP A-D

TTIIS

V ATEX/NEPSI II 3G Ex nL IIC

CYK10- complete order code

Version

AStandard version

Termination

1 End sleeve on device side, braided cable screening

Potential matching

A External potential matching with flat plug

Cable length

03 Cable length: 3 m (9.8 ft)

05 Cable length: 5 m (16 ft)

10 Cable length: 10 m (33 ft)

15 Cable length: 15 m (49 ft)

20 Cable length: 20 m (66 ft)

25 Cable length: 25 m (82 ft)

88 ... m length

89 ... ft length

Ready-made

1Wire terminals

2 M12 plug

Note!

Ex versions of CYK10 are indicated by an orange-red coupling end.

Cable extension CYK12

CYK12 measuring cable

• Non-terminated cable for extension of sensor cables, used in combination with CPK1, CPK9 and CPK12

• Coax and 5 pilot wires

• Sold by the meter:

– Non-Ex version, black: order no. 51506598

– Ex-version, blue: order no. 51506616

CYK81

CYK81 measuring cable

• Non-terminated measuring cable for extension of sensor cables of e.g. Memosens sensors, CUS31/CUS41

• 2 wires, twisted pair with shield and PVC-sheath (2 x 2 x 0.5 mm

2

+ shield)

• Sold by the meter, order no.: 51502543

Endress+Hauser 15

Page 16

Junction boxes

United States

Endress+Hauser, Inc.

2350 Endress Place

Greenwood, IN 46143

Tel. 317-535-7138

Sales 888-ENDRESS

888-363-7377

Service 800-642-8737

fax 317-535-8498

inquiry@us.endress.com

www.us.endress.com

TI352C/24/en/05.10

© 2010 Endress+Hauser, Inc.

Canada

Endress+Hauser Canada

1075 Sutton Drive

Burlington, ON L7L 5Z8

Tel. 905-681-9292

800-668-3199

Fax 905-681-9444

info@ca.endress.com

www.ca.endress.com

Mexico

Endress+Hauser, México, S.A. de C.V.

Fernando Montes de Oca 21 Edificio A Piso 3

Fracc. Industrial San Nicolás

54030. Tlalnepantla de Baz

Estado de México

México

Tel: +52 55 5321 2080

Fax +52 55 5321 2099

eh.mexico@mx.endress.com

www.mx.endress.com

Junction box VBA

• For cable extension of pH/ORP sensors

• 10 terminals, protection class: IP 65 (i NEMA 4X)

• Cable entries: 2 x Pg 13.5, 2 x Pg 16

• Material: polycarbonate

• Order no.: 50005276

Junction box RM

• For cable extension (e.g. for Memosens sensors or CUS31/CUS41)

•5 terminals

• Cable entries: 2 x Pg 13.5

•Material: PC

• Ingress protection: IP 65 (i NEMA 4X)

• Order no.: 51500832

Junction box VBM

• For cable extension

•10 terminals

• Cable entries: 2 x Pg 13.5 or 2 x NPT ½"

• Material: aluminum

• Ingress protection: IP 65 (i NEMA 4X)

• Order numbers:

– cable entries Pg 13.5: 50003987

– cable entries NPT ½": 51500177

Tophit CPS441/CPS441D

16 Endress+Hauser

Loading...

Loading...