Page 1

Technical Information

Ceraliquid CPS42/CPS42D/CPS43

ORP electrodes, analog and digital with Memosens technology and

reference electrode

Each with ceramic diaphragm and liquid KCl electrolyte

Application

Media with very low conductivities or a high percentage of

organic solvents or alcohols:

• Food industry

• Biotechnology

• Laboratory measurements

• Power plants

With ATEX, FM1 and CSA1 approval

0

for application in hazardous areas

Your benefits

• Liquid KCl electrolyte enabling use at very low conductivities

• Ceramic diaphragm with defined KCl flow

• Application under pressures of up to 10 bar / 145 psi with

counter pressure

• Resistant to poisoning thanks to separate reference lead

• Suitable for CIP / SIP cleaning

• Three lengths available: 120, 225 and 425 mm / 4.72, 8.86

and 16.73 inches

Further benefits offered by Memosens technology

• Maximum process safety through contactless inductive signal

transmission

• Data safety through digital data transmission

• Easy handling due to storage of sensor-specific data

• Predictive maintenance possible thanks to registration of

sensor load data

TI373C/07/en/05.05

51513589

1

approval for digital sensors pending

Page 2

Function and system design

Measuring principle Redox measurement

The redox potential is a unit of measurement for the state of equilibria between oxidising and reducing

components of a medium. Redox potential is measured similarly to the pH value. A platinum or gold electrode

is used instead of pH-sensitive membrane glass. Analog to the pH measurement, an integrated Ag/AgCl

reference system is used as a reference electrode.

General properties • Application at low conductivity

Thanks to its liquid KCl electrolyte filling, the CPS42 can be applied at very low conductivities (≥ 5µS/cm).

• Sterilisable

The electrode can be used in applications with steam sterilisation (max. 130 °C / 266 °F).

• Durability

The electrode can be applied under pressures of up to 10 bar /145 psi with counter pressure.

Important properties CPS42D Maximum process safety

The inductive and non-contacting measured value transmission of Memosens guarantees maximum process

safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– The plug-in connection is free from corrosion.

– Measured value distortion from moisture is not possible.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium. The result: No more need to ask about

"symmetrically high-impedance" or "unsymmetrical" or an impedance converter.

• EMC safety is guaranteed by screening measures for the digital measured value transmission.

Data safety through digital data transfer

The Memosens technology digitalizes the measured value in the sensor and transfers it to the transmitter via a

contactless connection. The result:

• An automatic error message is generated if the sensor fails or the connection between sensor and transmitter

is interrupted.

• The availability of the measuring point is dramatically increased by immediate error detection.

• The digital signals are suitable for application in hazardous areas; the integrated electronics are intrinsically

safe.

Easy handling

Sensors with Memosens technology have integrated electronics that allow for saving calibration data and

further information such as total hours of operation and operating hours at very high temperatures. When the

sensor is mounted, the calibration data are automatically transferred to the transmitter and used to calculate

the current redox potential. Storing the calibration data in the sensor allows for calibration and adjustment

away from the measuring point. The result:

• The sensors can be calibrated unter optimum external conditions in the measuring lab. Wind and weather

do neither affect the calibration quality nor the operator.

• The measuring point availability is dramatically increased by the quick and easy replacement of precalibrated

sensors.

• The transmitter does not need to be installed close to the measuring point but can be placed in the control

room.

• Maintenance intervals can be defined based on all stored sensor load and calibration data and predictive

maintenance is possible.

• The sensor history can be documented on external data carriers and evaluation programs at any time. Thus,

the current application of the sensors can be made to depend on their previous history.

Communication with the transmitter

Always connect the digital sensor to a digital transmitter with Memosens technology. Data transmission to an

analog transmitter is not possible.

Ceraliquid CPS42 / CPS42D / CPS43

2 Endress+Hauser

Page 3

Ceraliquid CPS42 / CPS42D / CPS43

Data storage of the CPS42D Digital sensors are able to store the following system data in the sensor.

• Manufacturing data

– Serial number

–Order code

– Date of manufacture

• Calibration data

– Calibration date

– Calibrated offset (operating mode "mV")

– % slope (operating mode "%")

– Number of calibrations

– Serial number of the transmitter used for the last calibration

• Application data

– Temperature application range

– Redox application range

– Date of first commissioning

– Operating hours

These system data can be displayed with the Mycom S or the Liquiline M CM42 transmitter.

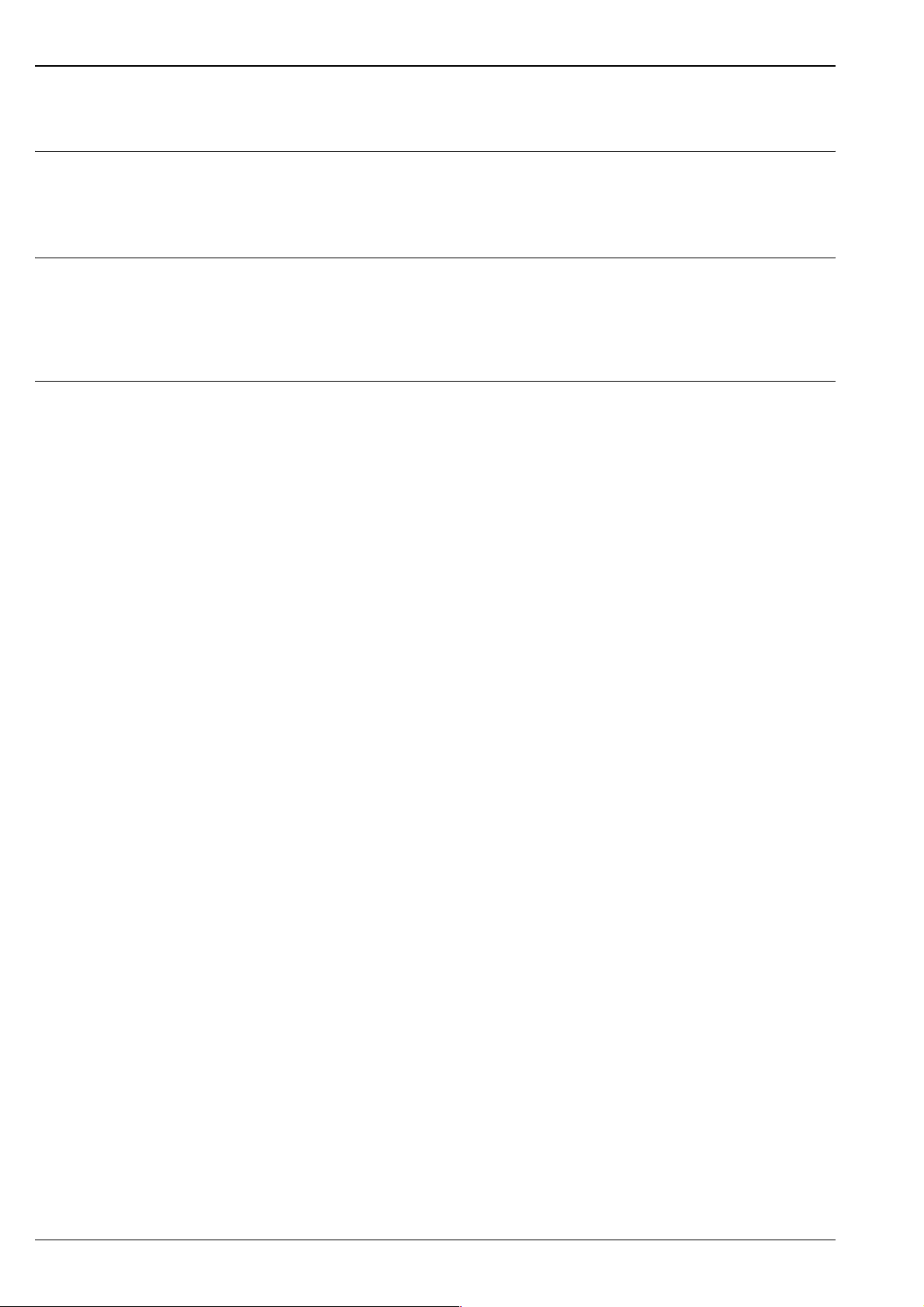

Measuring system A complete measuring system comprises:

• CPS42 or CPS42D ORP electrode

• Transmitter, e.g. Liquisys M CPM223/253 (with Memosens technology for CPS42D)

• Special measuring cable, e.g. CPK9 or CYK Memosens data cable for CPS42D

• Immersion, flow or retractable assembly, e.g. Unifit H CPA441

ENDRESS+HAUSER

LIQUISYS

REL1

ALARM

REL2

CAL REL

REL1

E

REL2

4

1

3

2

Measuring system for redox measurement

1 Unifit H CPA441

2 CPS42 or CPS42D ORP electrode

3 CPK9 special measuring cable (for electrodes with TOP68 plug-in head) / CYK10 for digital sensors

4 Liquisys M CPM253 transmitter

a0003114

Input

Measured variables Redox potential

Measuring range -1500 ... 1500 mV

Caution!

"

Please note the process operating conditions.

Endress+Hauser 3

Page 4

Ceraliquid CPS42 / CPS42D / CPS43

Installation

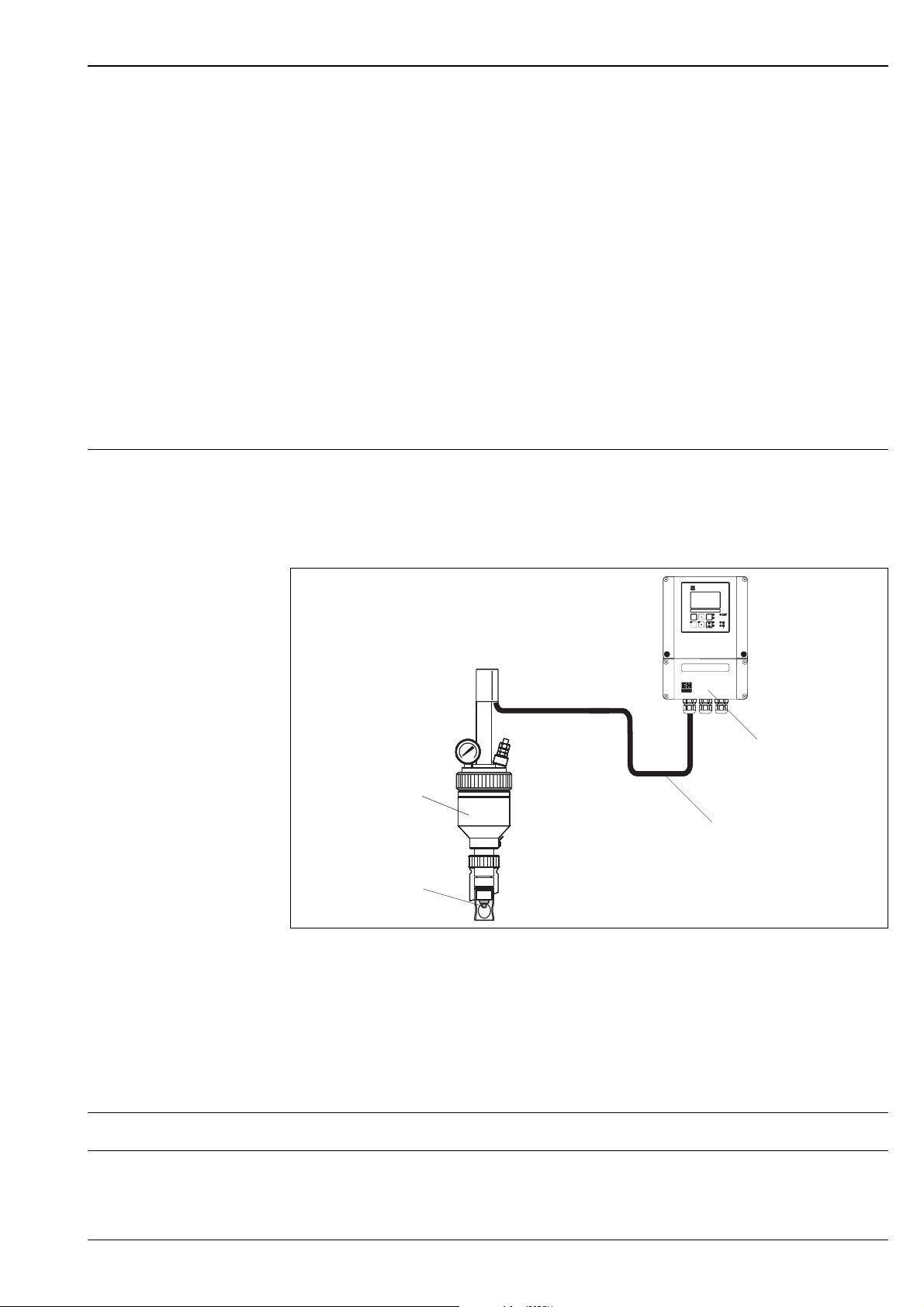

Installation instructions Do not install the electrode upside down. The inclination angle must be at least 15° from the horizontal. A

smaller inclination angle is not permitted as such an inclination results in air cushion forming. This might impair

the contact of reference and metal lead.

Caution!

"

• Make sure that the assembly’s threaded connection for the electrode is clean and well running before

installing the electrode.

• Hand tighten the electrode (3 Nm)! (Given value only applies to installation in Endress+Hauser assemblies.)

• Make sure to follow the installation instructions in the operating instructions of the used assembly.

A

Electrode installation; inclination angle min. 15° from the horizontal

A Permitted inclination angle

B Non-permitted inclination angle

Environment

Ambient temperature

Caution!

"

Danger of frost damage

Never use the electrode at temperatures below -15 °C / 5 °F.

Storage temperature 0 ... 50 °C / 32 ... 122 °F

Ingress protection

IP 67: GSA/SSA plug-in head (with closed plug-in system)

IP 68: TOP68 plug-in head (1 m / 3.28 ft water column, 50 °C / 122 °F, 168 h)

IP 68: Memosens plug-in head (10 m / 32.8 ft water column, 25 °C / 77 °F, 45 days, 1 M KCl)

15°

15°

B

a0003686

Process

Process temperature

Process pressure 0 ... 10 bar / 0 ... 145 psi with counter pressure via a separate KCl vessel

Application

4 Endress+Hauser

CPS42, CPS43: -15 ... 130 °C / 5 ... 266 °F

CPS42D: -15 ... 135 °C / 5 ... 275 °F

CPS42, CPS42D: Reducing media, e.g. chromate reduction, chlorine dosing in swimming pools

CPS43: Single reference electrode, used in combination with the CPS64 single pH electrode

Page 5

Ceraliquid CPS42 / CPS42D / CPS43

KCl consumption

C

32

68

104

140

176

16

12

8

A

4

0

0204060

1

2

3

80

B

KCl consumption dependent on medium temperature

A KCl consumption (ml/d)

B Temperature (°C)

C Temperature (°F)

1 800 mbar / 11.6 psi overpressure

2 400 mbar / 5.8 psi overpressure

3 100 mbar / 1.5 psi overpressure

Mechanical construction

212

1.5 2.9

16

5.8

12

8

A

4

100

a0003112-en

0

200100

KCl consumption dependent on process pressure

A KCl consumption (ml/d)

B Overpressure to process (mbar)

C Overpressure to process (psi)

1 Medium temperature 80 °C / 176 °F

2 Medium temperature 50 °C / 122 °F

3 Medium temperature 20 °C / 68 °F

400 600 800 1000

C

8.7

11.6

14.5

1

2

3

B

a0003134-en

Design, dimensions CPS42

mm / inch

Ø 80 / 3.15

405 / 15.94

1

225 / 8.86

2

3

Unifit H CPA441 with CPS42 with GSA plug-in head

1 KCl reservoir

2 Mounting device

3 CPS42 (shaft length: 225 mm / 5.91")

a0003387-en

52.3 / 2.06

225 / 8.86

mm / inch

CPS42 with ESA plug-in head for CPA441

1 TOP68 plug-in head Pg 13.5

2 Viton O-ring with thrust collar

3 KCl refilling

4 Inner metal lead

5 Ag/AgCl lead for the reference

6 Liquid KCl electrolyte

7 Ceramic diaphragm

8Platinum ring

12 / 0.47

1

2

3

4

5

6

7

8

a0003388-en

Endress+Hauser 5

Page 6

Ceraliquid CPS42 / CPS42D / CPS43

5

mm/inch

1

120 / 4.72

12/0.47

CPS42 with SSA plug-in head

1 SSA plug-in head, Pg 13.5

2 Hose connection for KCl refilling

3 Viton O-ring with thrust collar

4 Inner metal lead

5 Ag/AgCl lead for the reference

6 Liquid KCl electrolyte

7 Ceramic diaphragm

8Platinum ring

mm / inch

2

1

3

2

3

4

4

5

6

5

6

120 / 4.72

7

8

7

8

12 / 0.47

a0003390-en

a0003389-en

CPS42 with ESS plug-in head

1 ESS plug-in head, Pg 13.5

2 Hose connection for KCl refilling

3 Viton O-ring with thrust collar

4 Inner metal lead

5 Ag/AgCl lead for the reference

6 Liquid KCl electrolyte

7 Ceramic diaphragm

8Platinum ring

Design, dimensions CPS42D

mm / inch

50 / 1.97

225 / 8.86

12/0.47

CPS42D with Memosens plug-in head

1 Memosens plug-in head

2 Viton O-ring with thrust collar

3 KCl refilling

4 Inner metal lead

5 Ag/AgCl lead for the reference

6 Liquid KCl electrolyte

7 NTC 30K temperature sensor

8 Ceramic diaphragm

9Platinum ring

mm / inch

1

2

3

1

2

3

4

4

5

6

6

7

8

9

120, 225, 425 / 4.72, 8.86, 16.73

7

8

9

12 / 0.47

a0003717-en

a0003716-en

CPS42D with Memosens plug-in head and KCl connection

1 Memosens plug-in head

2 Hose connection for KCl refilling

3 Viton O-ring with thrust collar

4 Inner metal lead

5 Ag/AgCl lead for the reference

6 Liquid KCl electrolyte

7 NTC 30K temperature sensor

8 Ceramic diaphragm

9Platinum ring

6 Endress+Hauser

Page 7

Ceraliquid CPS42 / CPS42D / CPS43

Design, dimensions CPS43

mm / inch

1

120 / 4.72

12 / 0.47

CPS43 with SSA plug-in head

1 SSA plug-in head, Pg 13.5

2 Hose connection for KCl refilling

3 Viton O-ring with thrust collar

4 Ag/AgCl reference lead

5 Liquid KCl electrolyte

6 Ceramic diaphragm

2

3

4

5

6

a0004272-en

CPS43 with ESS plug-in head

1 ESS plug-in head, Pg 13.5

2 Hose connection for KCl refilling

3 Viton O-ring with thrust collar

4Ag/AgCl reference lead

5 Liquid KCl electrolyte

6 Ceramic diaphragm

a0004271-en

Weight 0.1 kg / 0.2 lb.

Material

Electrode shaft process glass

Redox measuring element platinum ring

Diaphragm ceramic diaphragm, sterilisable

Process connection Pg 13.5

Plug-in heads

CPS42:

ESA: threaded plug-in head Pg 13.5, TOP68, 16 bar / 232 psi, Ex

ESS: hose connection Pg 13.5, TOP 68, 10 bar / 145 psi, Ex

GSA: threaded plug-in head Pg 13.5

SSA: hose connection Pg 13.5

CPS42D-****A*: Memosens plug-in head for digital, contactless data transmission, 16 bar / 232 psi,

Ex and non-Ex

CPS42D-****B*: Memosens plug-in head with hose connection for KCl refilling, for digital,

contactless data transmission, 10 bar / 145 psi, Ex and non-Ex

Reference system Ag/AgCl metal lead with liquid KCl, 3 M, AgCl free

Endress+Hauser 7

Page 8

Certificates and approvals

Ex approval CPS42 (ESA, ESS) • ATEX II 2G EEX ia IIC T3/T4/T6

• FM Class I Div. 2, in combination with the Mypro CPM431 and Mycom S CPM153 transmitters

Ex approval CPS42D • ATEX II 2G EEx ia IIC T3/T4/T6

•FMa / CSAa I Div. 2, in combination with the Liquiline M CM42 and Mycom S CPM153 transmitters

!

Biocompatibility Biocompatibility validated according to:

Note!

Ex versions of digital sensors with Memosens technology are indicated by an orange-red ring in the plug-in

head.

• ISO 10993-5:1993

• USP, current revision

Ceraliquid CPS42 / CPS42D / CPS43

TÜV certificate TOP68 and

Memosens plug-in heads

Electromagnetic compatibility of CPS42D

Product structure CPS42

Product structure CPS42D

Pressure resistance 16 bar, min. triple overpressure safety

Interference emission and interference immunity complies with EN 61326: 1997 / A1: 1998

Ordering information

Electrode type

0 Standard version

Measuring element

PB Platinum ring

Shaft length

2 120 mm / 4.72" (ESS and SSA plug-in heads only)

4 225 mm / 8.86" (ESA and GSA plug-in heads only)

Plug-in head

ESA Plug-in head Pg 13.5, TOP68, 16 bar / 232 psi, Ex

ESS Hose connection Pg 13.5, TOP68, 16 bar / 232 psi, Ex

GSA Plug-in head Pg 13.5

SSA Hose connection Pg 13.5

CPS42- complete order code

Version

0 Basic version, max. 135 °C / 275 °F

Measuring element

PB Platinum ring

Shaft length

2 120 mm / 4.72" (versions with KCl hose connection only)

4 225 mm / 8.86"

6 425 mm / 16.73" (versions with KCl hose connection only)

Electrolyte supply

A Shaft hole KCl refilling, CPA441

B KCl hose connection, CPY7

Approval

1 Non-hazardous areas

G ATEX II 2G EEx ia IIC T3/T4/T6

CPS42D- complete order code

a) approval pending

8 Endress+Hauser

Page 9

Ceraliquid CPS42 / CPS42D / CPS43

Product structure CPS43 (for

combination with single pH

Electrode type

0 Standard version

electrode CPS64)

CPS43- complete order code

Accessories

!

Assemblies • Cleanfit P CPA471

Note!

In the following sections, you find the accessories available at the time of issue of this documentation.

For information on accessories that are not listed here, please contact your responsible service.

Compact retractable stainless steel assembly for installation in tanks and pipes, manual or pneumatic

operation

Ordering acc. to product structure, see Technical Information (TI217C/07/en)

• Cleanfit P CPA472

Compact retractable plastic assembly for installation in tanks or pipes, manual or pneumatic operation

Ordering acc. to product structure, see Technical Information (TI223C/07/en)

• Cleanfit P CPA473

Retractable stainless steel process assembly with ball valve for a particularly safe and reliable separation of

the medium from the environment

Ordering acc. to product structure, see Technical Information (TI344C/07/en)

• Cleanfit P CPA474

Retractable plastic process assembly with ball valve for a particularly safe and reliable separation of the

medium from the environment

Ordering acc. to product structure, see Technical Information (TI345C/07/en)

• Cleanfit H CPA475

Retractable assembly for installation in tanks and pipes under sterile conditions

Ordering acc. to product structure, see Technical Information (TI240C/07/en)

Reference type

TB Liqid KCl

Shaft length

2 120 mm / 4.72

Plug-in head

ESS Hose connection Pg 13.5, TOP68, 16 bar / 232 psi, Ex

SSA Hose connection Pg 13.5

Cleanfit P CPA471 or 472

a0004009

Cleanfit P CPA473 or 474

a0004010

Cleanfit H CPA475

a0004011

Endress+Hauser 9

Page 10

Ceraliquid CPS42 / CPS42D / CPS43

• Unifit H CPA441

Process assembly with integrated electrolyte vessel for installation of pH/ORP electrodes

Ordering acc. to product structure, see Technical Information (TI026C/07/en)

• Unifit H CPA442

Process assembly for the food industry, biotechnology and pharmaceutical industry, complies with EHEDG

criteria and 3A standard 74-02

Ordering acc. to product structure, see Technical Information (TI306C/07/en)

• Dipfit W CPA111

Immersion and installation assembly for open and closed tanks

Ordering acc. to product structure, see Technical Information (TI112C/07/en)

Unifit H CPA441

a0003162

Unifit H CPA442

a0003139

• Dipfit P CPA140

Immersion assembly for pH/ORP electrodes, for demanding processes

Ordering acc. to product structure, see Technical Information (TI178C/07/en)

• Flowfit P CPA240

Flow assembly for pH/ORP electrodes, for demanding processes

Ordering acc. to product structure, see Technical Information (TI179C/07/en)

• Flowfit W CPA250

Flow assembly for pH/ORP electrodes

Ordering acc. to product structure, see Technical Information (TI041C/07/en)

Dipfit W CPA111

a0003140

Dipfit P CPA140

a0003141

Flowfit P CPA240

a0003142

Flowfit W CPA250

a0003143

10 Endress+Hauser

Page 11

Ceraliquid CPS42 / CPS42D / CPS43

• Probfit H CPA465

Retractable assembly for installation in tanks and pipes under sterile conditions

Ordering acc. to product structure, see Technical Information (TI146C/07/en)

• Ecofit CPA640

Process connection adapter and cable set for 120 mm / 4.72" pH/ORP electrodes

Ordering acc. to product structure, see Technical Information (TI264C/07/en)

Probfit H CPA465

a0004012

Ecofit CPA640

Electrolyte vessel • CPY7 electrolyte vessel

Reservoir for KCl electrolyte, 150 ml / 0.04 US.gal

Ordering acc. to product structure, see Operating Instructions (BA 128C/07/en)

Electrolyte solutions KCl-electrolyte solutions for liquid filled electrodes

• 3.0 mol, T = -10 ... 100 °C (14 ... 212 °F), 100 ml (3 oz), order no. CPY4-1

• 3.0 mol, T = -10 ... 100 °C (14 ... 212 °F), 1000 ml (30 oz), order no. CPY4-2

• 1.5 mol, T = -30 ... 100 °C (-22 ... 266 °F), 100 ml (3 oz), order no. CPY4-3

• 1.5 mol, T = -30 ... 100 °C (-22 ... 266 °F), 1000 ml (30 oz), order no. CPY4-4

Buffer solutions Technical buffer solutions for ORP electrodes

• +220 mV, pH 7.0, 100 ml (0.026 US gal.); order no. CPY3-0

• +468 mV, pH 0.1, 100 ml (0.026 US gal.); order no. CPY3-1

Transmitters • Liquisys M CPM223/253

Transmitter for pH and redox, field or panel-mounted housing,

®

or PROFIBUS available

Hart

Ordering acc. to product structure, see Technical Information (TI194C/07/en)

• Mycom S CPM153

Transmitter for pH and redox, one or two channel version, Ex or Non-Ex,

®

or PROFIBUS available

Hart

Ordering acc. to product structure, see Technical Information (TI233C/07/en)

• Liquiline M CM42

Modular two-wire transmitter for Ex and non-Ex areas

Hart®, PROFIBUS or FOUNDATION Fieldbus available

Ordering acc. to product structure, see Technical Information (TI381C/07/en)

a0003145

Endress+Hauser 11

Page 12

Measuring cables • CPK9 special measuring cable

For sensors with TOP68 plug-in head, for high-temperature and high-pressure applications, IP 68

Ordering acc. to product structure, see Technical Information (TI118C/07/en)

• CPK1 special measuring cable

For pH/redox electrodes with GSA plug-in head

Ordering acc. to product structure, see Technical Information (TI118C/07/en)

• CYK10 Memosens data cable

For digital sensors with Memosens technology

Ordering according to product structure, see below

Certificates

A Standard, non Ex

G ATEX II 1G EEx ia IIC T6/T4

Cable length

03 Cable length: 3 m / 9.84 ft

05 Cable length: 5 m / 16.41 ft

10 Cable length: 10 m / 32.81 ft

15 Cable length: 15 m / 49.22 ft

20 Cable length: 20 m / 65.62 ft

25 Cable length: 25 m / 82.03 ft

88 ... m length

89 ... ft length

Ready-made

1Wire terminals

CYK10- complete order code

!

Note!

Ex versions of CYK10 are indicated by an orange-red coupling end.

International Head Quarters

Endress+Hauser

GmbH+Co. KG

Instruments International

Colmarer Str. 6

79576 Weil am Rhein

Deutschland

Tel. +49 76 21 9 75 02

Fax+497621975345

www.endress.com

info@ii.endress.com

TI373C/07/en/05.05

51513589

Printed in Germany / FM+SGML 6.0 / DT

Loading...

Loading...