Page 1

Technical Information

Ceramax CPS341D

Electrode with pH sensitive enamel and digital Memosens technology

Meets highest demands of measuring accuracy, pressure, temperature,

sterility and durability

Application

• Food production, also highly pasty media

• Beverage production and filling

• Quality control

• Pharmaceutical industry:

– Water treatment

– Active ingredient production

– Active ingredient preparation

– Fermentation

– Biotechnology

Your benefits

• Continuous online measurement is possible in the ongoing

process

• Direct installation in container nozzles or piping

• Self-cleaning by the flowing medium

• Long-term stability over many years

• High mechanical loading capacity due to a steel substrate

• Extremely corrosion-resistant to acids

• Hygienic design: Inline CIP and SIP-capable

Further benefits offered by Memosens technology

• Maximum process safety through contactless inductive signal

transmission

• Data safety through digital data transmission

• Easy handling thanks to storage of sensor-specific data in the

sensor

• Predictive maintenance possible thanks to registration of

sensor load data in the sensor

TI468C/07/EN/06.10

71114968

Page 2

Function and system design

Measuring principle pH measurement

The pH value is a measure of the acid or base character of a medium. Depending on the pH value of the

medium, the electrode's pH-sensitive enamel provides an electrochemical potential. This is the result of H

selectively penetrating the outer layer of the enamel. As a result, an electrochemical boundary layer forms here

with an electric potential. An integrated Ag/AgCl reference system forms the required reference electrode.

The transmitter converts the measured voltage into the corresponding pH value according to the NERNST

equation.

General properties Mechanical stability

The substrate of the sensor is steel. That makes the sensor mechanically stable when confronted with solids

and turbulent flows from agitators. To protect the steel from corrosion and product deposits, it is covered with

highly resistant enamel.

Working electrode

The working electrode consists of yellow, pH-sensitive enamel that is melted onto a large area of the lower end

of the sensor in the shape of a ring. This ensures an area many times larger compared to pH glass electrodes or

ISFET sensors.

The working electrode is connected directly to the metallic reference lead. An inner buffer is not necessary.

Reference electrode

The Ag/AgCl reference electrode is integrated into the head of the sensor. A sterile 3M KCl solution is used as

an electrolyte. This also contains an inhibitor that prevents the reference from aging and thus enables the long

operating life.

The electrolyte CPS341Z-D5 is delivered in PE bottles with septum and simply used in the stainless steel

electrolyte vessel CPS341Z-D1.

The conductive connection between reference and medium guarantees a shrunk, aseptic ground joint

diaphragm.

The pressure in the reference system must be continuously above the operating pressure.

Easy installation

The sensor is installed, without a basket protector or additional assembly, directly in container nozzles or in

the main stream of piping. The orientation can be selected at random.

The sensor remains in the process room permanently, even in empty containers.

Ceramax CPS341D

+

ions

Durability and calibration cycles

Important properties Maximum process safety

Data storage The sensor is connected to the cable connection (CYK10) without contact. The power and data are transferred

The sensor is factory-calibrated and ready for measurement immediately after being connected to a transmitter

with Memosens functionality.

Due to the mechanical design, aging of the sensor is very minor and there is no measuring error.

In most applications it is sufficient for the sensor to be adjusted once a year with a sample calibration.

The inductive and non-contacting measured value transmission of Memosens guarantees maximum process

safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– The plug-in connection is non-contacting and therefore free from corrosion.

– Measured value distortion from moisture is not possible.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium. The result: No more need to ask about

"symmetrically high-impedance" or "unsymmetrical" (for pH/ORP measurement) or an impedance

converter.

• EMC safety is guaranteed by screening measures for the digital measured value transmission.

Data safety through digital data transfer

The Memosens technology digitalizes the measured values in the sensor and transfers them to the transmitter

contactlessly and free from interference potential. The result:

• An automatic error message is generated if the sensor fails or the connection between sensor and transmitter

is interrupted.

• The availability of the measuring point is dramatically increased by immediate error detection.

Communication with the transmitter

Always connect digital sensors to a transmitter with Memosens technology. Data transmission to a transmitter

for analog sensors is not possible.

inductively

2 Endress+Hauser

Page 3

Ceramax CPS341D

3

1

2

Once connected to the transmitter, the data saved in the sensor are read digitally. You can call up these data

using the corresponding DIAG menu.

Data that digital sensors save include the following:

• Manufacturer data

– Serial number

– Order code

– Date of manufacture

• Calibration data

– Calibration date

– Calibration values

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operational data

– Date of commissioning

– Hours of operation under extreme conditions

– Number of sterilizations

– Data for sensor monitoring.

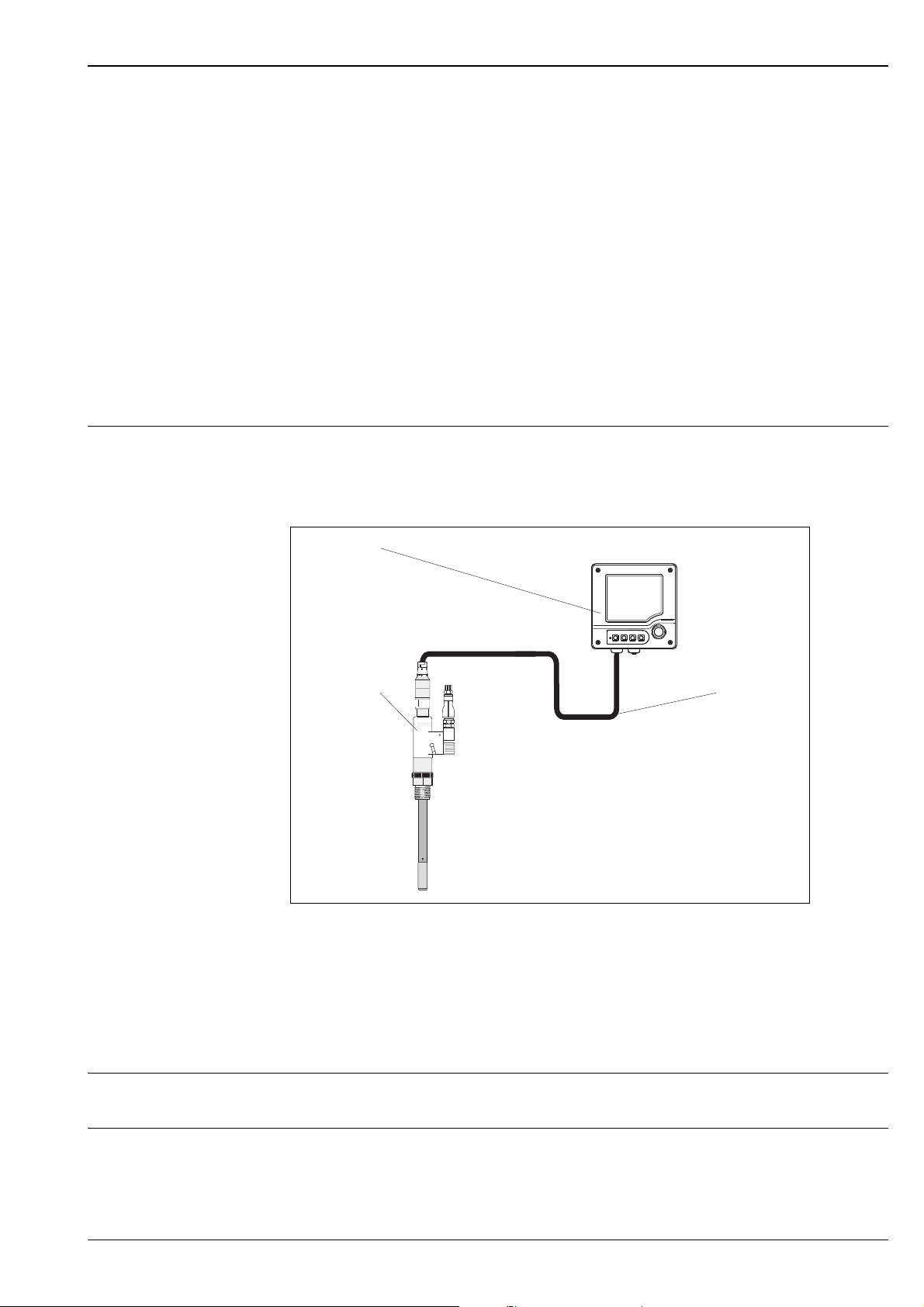

Measuring system A complete measuring system comprises:

• Ceramax CPS341D pH sensor

• Transmitter, e.g. Liquiline CM42

• CYK10 measuring cable

Measuring system

4 CM42 transmitter

3 CYK10 measuring cable

2 CPS341D pH sensor

a0013857

Input

Measured variables pH value

Measuring range 0 to 10 pH (linear range)

Endress+Hauser 3

Temperature

-2 to 14 pH (application range)

0 to 140 °C (32 to 280 °F)

Page 4

Installation

0 ... 360°

Installation position CPS341D can be installed in any position.

Ceramax CPS341D

Fig. 1: Installation position

a0013862

Environment

Ambient temperature range The sensor must not be used at temperatures below 0 °C (32 °F).

Storage temperature 0 to 50 °C (32 to 120 °F)

Degree of protection IP 68 (10 m (33 ft) water column, 25 °C (77 °F), 45 days, 1 M KCl)

Electromagnetic compatibility Interference emission and interference immunity as per EN 61326: 2006

Process

Process temperature 0 to 140 °C (32 to 280 °F)

Process pressure 0 to 6 bar (0 to 87 psi)

Minimum conductivity 50 μS/cm

pH range -2 to 14 pH

4 Endress+Hauser

Page 5

Ceramax CPS341D

Dimensions

Mechanical construction

Dimensions

Weight 600 g (1.3 lbs)

Material

Process connections M20

Temperature sensor NTC 30KΩ

Reference system Ag/AgCl with 3 M KCl and inhibitor

Sensor body: Porcelain enamel metal substrate (PEMS), chemically

resistant and shock resistant

Adapter and plug-in head: Stainless steel 1.4404 (AISI 316 L), PVDF, PTFE

Electrolyte vessel: Stainless steel 1.4301 (AISI 304)

Process connection adapters: Stainless steel 1.4404 (AISI 316 L)

Pg 13.5

3/4"

1"

Nozzle, DN25

Nozzle, DN30

Varivent DN50/40

Dairy pipe DN50

Dairy pipe DN25

Triclamp DN50

a0013874

Endress+Hauser 5

Page 6

Ordering information

Ceramax CPS341D

Product structure

Version

7 Basic

Application range

A 0 to 10 pH, 0 to 140 °C (32 to 280 °F), 0 to 6 bar (0 to 87 psi)

Process connection adapter

1A Without

1B M20

1C Pg 13.5

1D 3/4"

1E 1"

1F Nozzle DN25

1G Nozzle DN30

1H Varivent DN50/40

1K Dairy pipe DN50

1L Dairy pipe DN25

1M Triclamp, compatible to DN50

Approval

1Non-Ex area

CPS341D- complete order code

Accessories

In the following sections, you find the accessories available at the time of issue of this documentation.

For information on accessories that are not listed here, please contact your local service or sales

representation.

CPS341Z Correct function of Ceramax CPS341D depends on reliable supply of KCl to the reference part of the

sensor. The pressurized electrolyte vessel CPS341Z-D1 is best suited for this.

The electrolyte supply can be monitored by the ultrasonic sensor for level monitoring CPS341Z-D2 (air bubble

sensor). The ultrasonic sensor requires a supply voltage of 18 to 30 V DC at a max. of 70 mA (without switching

current).

The signal is output via the relay CPS341Z-D4 as well as optically via the LED display CPS341Z-D3.

Accessories for Ceramax CPS341D

A1 Welding nozzle DN30, straight

A2 Dummy plug for welding nozzle DN30

A3 Welding nozzle DN25, straight

A4 Welding nozzle DN25, inclined

D1 Electrolyte vessel, stainless steel

D2 Ultrasonic sensor level monitoring

D3 Cable with LED display

D4 Relay, type KCD2-R, P+F

D5 KCl electrolyte, sterile, 1 l plastic bottle

D6 Purified water, sterile, 1 l plastic bottle

D7 Plastic bottle, empty

D8 Protection cap

CPS341Z-

To obtain a valid order code, simply attach the optional features to the order code. If you have any questions,

please contact our sales office.

Transmitters Liquiline CM44x

• Multiple-channel transmitter for the connection of digital sensors with Memosens technology

• Power supply: 85 to 265 V AC, 18 to 36 V DC or 20 to 28 V AC (not CM448)

• Universally upgradeable

• SD card slot

• Alarm relay

• IP 66

• Ordering acc. to product structure (Technical Information TI444C/07/en)

6 Endress+Hauser

Page 7

Ceramax CPS341D

Liquiline CM42

• Modular two-wire transmitter for Ex and non-Ex areas

®

, PROFIBUS or FOUNDATION Fieldbus available

•Hart

• Ordering acc. to product structure, Technical Information TI381C/07/en

Mycom S CPM153

• Transmitter for pH and redox, one or two channel version, Ex or Non-Ex

• HART or PROFIBUS available

• Ordering acc. to product structure, Technical Information TI233C/07/en

Buffer solutions High-quality buffer solutions of Endress+Hauser - CPY20

The secondary buffer solutions have been referenced to primary reference material of the PTB (German Federal

Physico-technical Institute) and to standard reference material of NIST (National Institute of Standards and

Technology) according to DIN 19266 by a DKD (German Calibration Service) accredited laboratory.

pH value

A pH 2.00 (accuracy ± 0.02 pH)

C pH 4.00 (accuracy ± 0.02 pH)

E pH 7.00 (accuracy ± 0.02 pH)

G pH 9.00 (accuracy ± 0.02 pH)

I pH 9.20 (accuracy ± 0.02 pH)

K pH 10.00 (accuracy ± 0.05 pH)

M pH 12.00 (accuracy ± 0.05 pH)

Quantity

01 20 x 18 ml (0.68 fl.oz) only buffer solutions pH 4.00 and 7.00

02 250 ml (8.45 fl.oz)

10 1000 ml (0.26 US gal)

50 5000 ml (1.32 US gal) canister for Topcal S

Certificates

A Buffer analysis certificate

Version

1Standard

CPY20- complete order code

Measuring cables CYK10 Memosens data cable

• For digital sensors with Memosens technology

• Ordering according to product structure, see Technical Information (TI376C/07/en)

Endress+Hauser 7

Page 8

Instruments International

Endress+Hauser

Instruments International AG

Kaegenstrasse 2

4153 Reinach

Switzerland

Tel.+41 61 715 81 00

Fax+41 61 715 25 00

www.endress.com

info@ii.endress.com

TI468C/07/EN/06.10

71114968

FM9

Loading...

Loading...