Page 1

TI00030C/07/EN/13.13

71201979

Products Solutions Services

Technical Information

Memosens CPS31D and

Ceratex CPS31

pH electrodes, analog and digital with Memosens

technology

For drinking water and swimming pool water

Gel-filled reference system with ceramic diaphragm

Application

•Drinking water

• Swimming pool water

• pH compensation for measuring free chlorine

Your benefits

• One or three ceramic diaphragms

• Optional salt ring for extended operating life

• Very low level of ion depletion in electrolyte

• Gel filling, no electrolyte refill required

• Can be used up to 4 bar (60 psi) absolute pressure

• Can be used up to 80˚C (176 °F)

• Shaft length 120 mm

• Memosens plug-in head

•ESA or GSA plug-in head

Further benefits offered by Memosens technology

• Maximum process safety thanks to non-contact, inductive signal transmission

• Digital data transmission ensures data security

• Very easy to use as sensor-specific data are stored in the sensor

• Recording of sensor load data in the sensor enables predictive maintenance

Page 2

Function and system design

Measuring principle pH measurement

The pH value is a measure of the acid or base character of a medium. Depending on the pH value of the

medium, the electrode's membrane glass provides an electrochemical potential. This is the result of H

ions selectively penetrating the outer layer of the membrane. As a result, an electrochemical boundary

layer forms here with an electric potential. An integrated Ag/AgCl reference system forms the required

reference electrode.

The transmitter converts the measured voltage into the corresponding pH value according to the

Nernst equation.

General characteristics Durability

Depending on the version, the electrode can withstand pressures up to 4 bar (60 psi) and temperatures

up to 80 ˚C (176 ˚F).

CPS31D/CPS31

+

Communication and data processing with CPS31D

Measuring system data which digital sensors can save in the sensor include:

• Manufacturer data

– Serial number

–Order code

–Date of manufacture

• Calibration data

– Date of calibration

– Calibrated slope at 25 ˚C (77 ˚F)

– Calibrated zero point

at 25 ˚C (77 ˚F)

– Temperature offset

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operating data

– Temperature application range

– pH application range

– Date of initial commissioning

– Maximum temperature value

– Operating hours at temperatures above 80 ˚C / 100 ˚C (176 ˚F / 212 ˚F)

– Operating hours for very low and very high pH values

(Nernst voltage below –300 mV, above +300 mV)

– Number of sterilizations

– Glass membrane impedance

The data listed above can be displayed using the Mycom S CPM153, Liquiline M CM42 and Liquiline

CM44x transmitters.

Dependability with CPS31D Reliability

Memosens technology digitizes the measured values in the sensor and transmits them to the

transmitter via a non-contact connection in a way that is free from any potential interference. The

result:

• Automatic error message generation if the sensor fails or the connection between sensor and

transmitter is interrupted

• Immediate error detection increases measuring point availability

2 Endress+Hauser

Page 3

CPS31D/CPS31

Maintainability

Sensors with Memosens technology have integrated electronics that save calibration data and other

information, such as total hours of operation and operating hours under extreme measuring conditions

etc. Once the sensor has been connected, the sensor data are automatically sent to the transmitter and

used to calculate the current measured value.

Saving the calibration data makes it possible to calibrate and adjust the sensor irrespective of the

measuring point. The result:

• Convenient calibration in the measuring lab under optimum external conditions improves the

quality of the calibration.

• Measuring point availability is dramatically increased by the quick and easy replacement of

precalibrated sensors.

• The availability of the sensor data makes it possible to accurately determine the maintenance

intervals of the measuring point and enables predictive maintenance.

• The sensor history can be documented using external storage media and evaluation programs. The

sensor's field of application can be determined based on its previous history.

Integrity

With its inductive transmission of the measured value via a non-contact plug-in connection,

Memosens guarantees maximum process safety and offers the following advantages:

• All problems caused by moisture are eliminated:

– The plug-in connection is free from corrosion

– Moisture cannot corrupt the measured value

– Plug-in system can even be connected under water

• The transmitter is galvanically decoupled from the medium.

• EMC safety is guaranteed by screening measures in the digital measured value transmission.

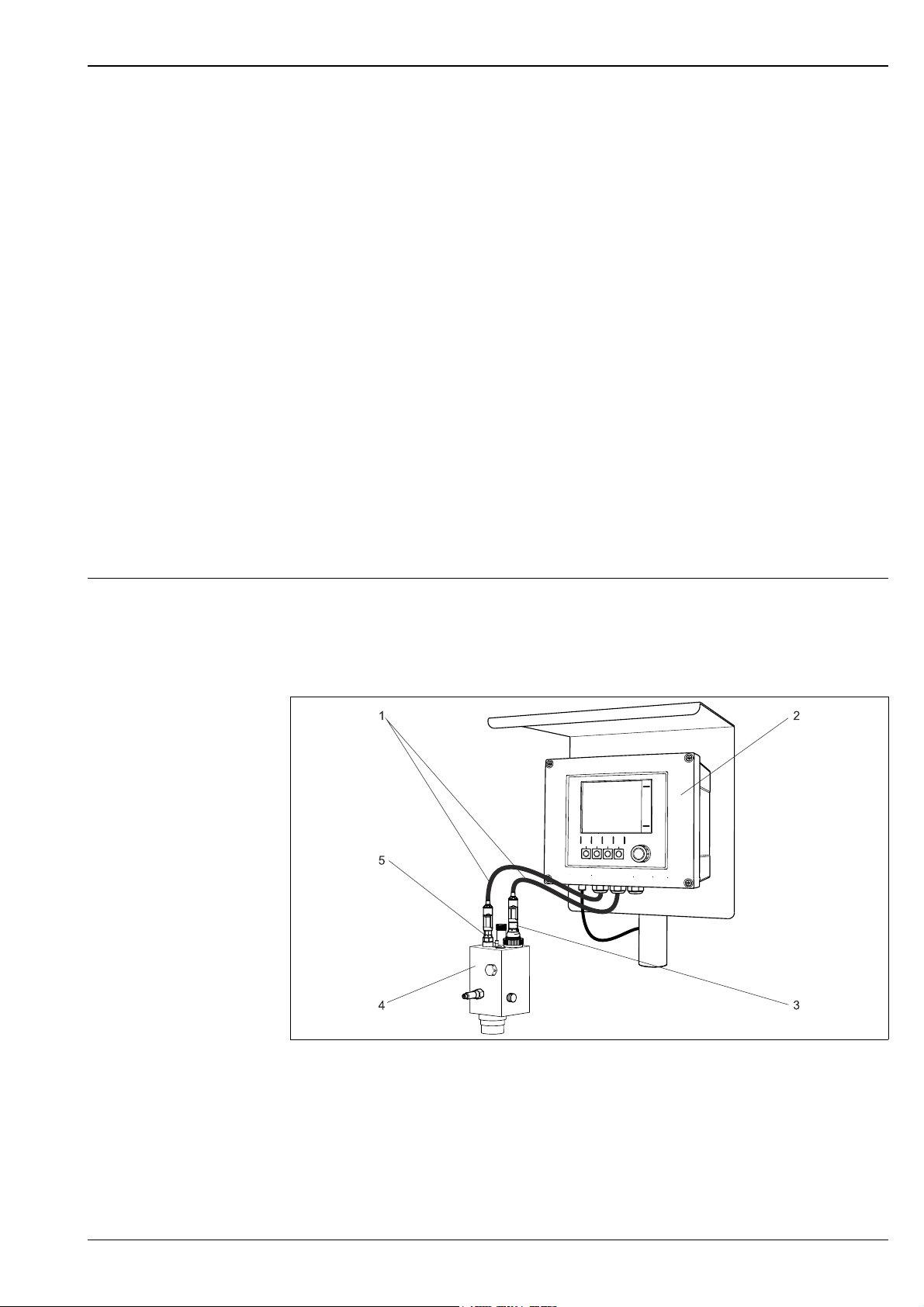

Measuring system A complete measuring system comprises:

• pH electrode CPS31D or CPS31

• Transmitter, e.g. Liquiline CM44x (for CPS31D with Memosens technology)

• Measuring cable, e.g. CYK10 for CPS31D

• Immersion, flow or retractable assembly, e.g. Flowfit CCA250

Example of a measuring system: pH compensation for chlorine measurement

1 Cable CYK10

2 Liquiline CM44x transmitter

3 Chlorine sensor CCS142D

4 Flowfit assembly CCA250

5 pH electrode CPS31D

a0019233

Endress+Hauser 3

Page 4

Input

NOTICE

15°

15°

A

B

Measured variables pH value

Temperature

CPS31D/CPS31

Measuring range

pH: 1 to 12

Temperature: 0 to 80 ˚C (32 to 176 ˚F)

Installation

Installation instructions Do not install the electrodes upside down. The inclination angle must be at least 15° from the

horizontal. A smaller inclination angle is not permitted as it could cause an air bubble to form in the

glass sphere and prevent the inner electrolyte from completely wetting the pH membrane.

Electrode installation; angle at least 15˚ from the horizontal

A Permitted orientation

B Incorrect orientation

a0003133

Before screwing in the electrode, make sure the threaded connection of the assembly is clean and

runs smoothly.

‣ Hand tighten the electrode (3 Nm)! (Information valid only when installing with Endress+Hauser

assemblies.)

‣ Also pay attention to the installation instructions provided in the Operating Instructions of the

assembly used.

4 Endress+Hauser

Page 5

CPS31D/CPS31

NOTICE

CAUTION

!

Environment

Ambient temperature range

Risk of damage due to frost

‣ The sensor must not be used at temperatures below –15 ˚C (5 ˚F).

Storage temperature 0 to 50 ˚C (32 to 120 ˚F)

Degree of protection

IP 67: GSA plug-in head (with closed connector system)

IP 68: ESA plug-in head (1 m (3.3 ft) water column, 50 ˚C (120 ˚F), 168 h)

IP 68: Memosens plug-in head (10 m (33 ft) water column, 25 ˚C (77 ˚F), 45 days, 1 M KCl)

Process

Process temperature range 0 to 80 ˚C (32 to 176 ˚F)

Process pressure (absolute) 1 to 4 bar (15 to 60 psi)

Sensor is exposed to pressure when used for longer periods under increased process pressure

Risk of injury due to glass breakage

‣ Do not apply too much heat to sensors of this type if they are being used under reduced process

pressure or under atmospheric pressure.

‣ Wear protective goggles and suitable gloves when handling this type of sensor.

Pressure-temperature load

A0019521-EN

Pressure-temperature load

Minimum conductivity 100 μS/cm

50 μS/cm for "AC" version (three diaphragms)

Endress+Hauser 5

Page 6

Design, dimensions CPS31

CPS31D/CPS31

Mechanical construction

CPS31 with ESA plug-in head

1 ESA electrode plug-in head, Pg 13.5

2 Pressure ring

3 Capillaries

4 Shaft tube

5 Diaphragm

6 Ag/AgCl internal reference lead

a0019315

CPS31 with ESA plug-in head

7 pH membrane glass

8 Temperature probe

9 Internal tube

10 Leads, external

11 O-ring

a0019319

CPS31 with GSA plug-in head

1 GSA electrode plug-in head, Pg 13.5

2 Pressure ring

3 Compression spring

4 Capillaries

5 Diaphragm

6 Ag/AgCl internal reference lead

a0019316

CPS31 with GSA plug-in head

7 pH membrane glass

8 Internal tube

9 Shaft tube

10 Lead, external

11 O-ring

a0019320

6 Endress+Hauser

Page 7

CPS31D/CPS31

Design, dimensions CPS31D

CPS31D

1 Memosens plug-in head

2 Pressure ring

3 Lead, external

4 Capillaries

5 Salt rings (optional)

6 Diaphragm

Weight 0.1 kg (0.22 lbs)

Materials

Electrode shaft Glass

pH membrane glass Type A

Metal lead Ag/AgCl

Diaphragm Ceramic

Process connection Pg 13.5

Temperature sensor

CPS31D: NTC 30K

CPS31: Pt 100

Plug-in heads

CPS31D: Memosens plug-in head for digital, non-contact data

CPS31: ESA, GSA

Reference system Ag/AgCl, gel, 3M KCl

Optional: Salt ring, KCl-saturated

a0019313

transmission

CPS31D

7 Ag/AgCl internal reference lead

8 pH membrane glass

9 Temperature probe

10 Shaft tube

11 Internal tube with leads

12 O-ring

a0019314

Endress+Hauser 7

Page 8

Certificates and approvals

CPS31D/CPS31

TÜV certificate ESA and Memosens plug-in head

Electromagnetic compatibility of CPS31D

Pressure resistance 16 bar (232 psi), minimum three times the safety pressure

Interference emission and interference immunity as per EN 61326: 2006

Ordering information

Product pages You can create a valid and complete order code on the Internet with the Configurator tool.

Enter the following addresses in the browser to access the relevant product page:

www.products.endress.com/cps31

www.products.endress.com/cps31d

Product Configurator 1. You can find the following options on the right-hand side of the product page:

2. Click "Configure this product".

3. The Configurator opens in a separate window. You can now configure your device and receive the

complete and valid order code.

4. Now export the order code as a PDF or Excel file. To do so, click the corresponding button at the

top of the page.

8 Endress+Hauser

Page 9

CPS31D/CPS31

Accessories

Assemblies (selection) Cleanfit CPA472

• Compact plastic retractable assembly for installation in tanks and pipes, for manual or pneumatically

remote-controlled operation

• Order according to product structure (--> Online Configurator, www.products.endress.com/cpa472)

• Technical Information TI00223C/07/EN

Cleanfit CPA475

• Retractable assembly for installation in tanks and pipes under sterile conditions

• Order according to product structure (--> Online Configurator, www.products.endress.com/cpa475)

• Technical Information TI00240/C/07/EN

Unifit CPA442

• Installation assembly for food, biotechnology and pharmaceutics, with EHEDG and 3A certificate,

• Order according to product structure (--> Online Configurator, www.products.endress.com/cpa442)

• Technical Information TI00306/C/07/EN

Dipfit CPA111

• Immersion and installation assembly for open and closed containers

• Order according to product structure (--> Online Configurator, www.products.endress.com/cpa111)

• Technical Information TI00112C/07/EN

Flowfit CPA250

• Flow assembly for pipe installation of pH/ORP sensors with Pg 13.5 and 120 mm (4.72") installation

length

• Order according to product structure (--> Online Configurator, www.products.endress.com/cpa250)

• Technical Information TI00041C/07/EN

Ecofit CPA640

• Adapter for 120 mm pH sensors

• Order according to product structure (--> Online Configurator, www.products.endress.com/cpa640)

• Technical Information TI00264C/07/EN

Buffer solutions High quality buffer solutions of Endress+Hauser - CPY20

Solutions which are traced by a DAkkS-accredited Endress+Hauser buffer laboratory (DkkS = German

Accreditation Body) to a primary reference material of the PTB and to standard reference material of

the National Institute of Standards and Technology (NIST) in accordance with DIN 19266 are used as

secondary reference buffer solutions.

• Order according to product structure (-> Online Configurator, www.products.endress.com/cpy20)

Measuring cable Memosens data cable CYK10

• For digital sensors with Memosens technology

• Order according to product structure (--> Online Configurator, www.products.endress.com/cyk10)

• Technical Information TI00118C/07/EN

Measuring cable CPK9

• For sensors with ESA plug-in head, for high-temperature and high-pressure applications, IP 68

• Order as per product structure

• Technical Information TI00501C/07/EN

Special measuring cable CPK1

• For pH/ORP electrodes with GSA plug-in head

• Order as per product structure

• Technical Information TI00501C/07/EN

Endress+Hauser 9

Page 10

www.addresses.endress.com

Loading...

Loading...