Page 1

TI01254C/07/EN/02.18

71399701

Products

Solutions Services

Technical Information

Memosens CPS171D

pH electrodes for bioreactors with digital

Memosens technology

For biotechnology production processes with ion

trap for long-term stable reference

Application

Hygienic and sterile applications (sterilizable, autoclavable)

• Bioreactor/fermenter

• Biotechnology

• Pharmaceutical industry

• Foods

With ATEX/IECEx, FM, CSA, NEPSI, FDA and USP approval for use in hazardous

areas.

Your benefits

• Biocompatibility with regard to cytotoxicity and bioreactivity has been tested

successfully

• Documentation to certify compliance with requirements of pharmaceutical

industry with serial number of sensor (optional)

• Durable inscription on shaft, verified as non-cytotoxic

• Suitable for CIP/SIP cleaning, autoclavable, up to 140 °C (284 °F) depending on

version

• Pressurized reference, specially for fermentation processes

• Integrated pressure indicator

• Long-term stable reference with ion trap, resulting in a very long service life,

bridging electrolyte free of silver ions

• No change in color of gel

• Ceramic diaphragm

• Integrated temperature sensor for effective temperature compensation

• No materials derived from animals were used in the manufacture of parts in

contact with the process media

Page 2

[Continued from front page]

Other advantages of Memosens technology

• Maximum process safety thanks to non-contact, inductive signal transmission

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Recording of sensor load data in the sensor enables predictive maintenance with the Memobase Plus CYZ71D

Page 3

Memosens CPS171D

1

2

3

4

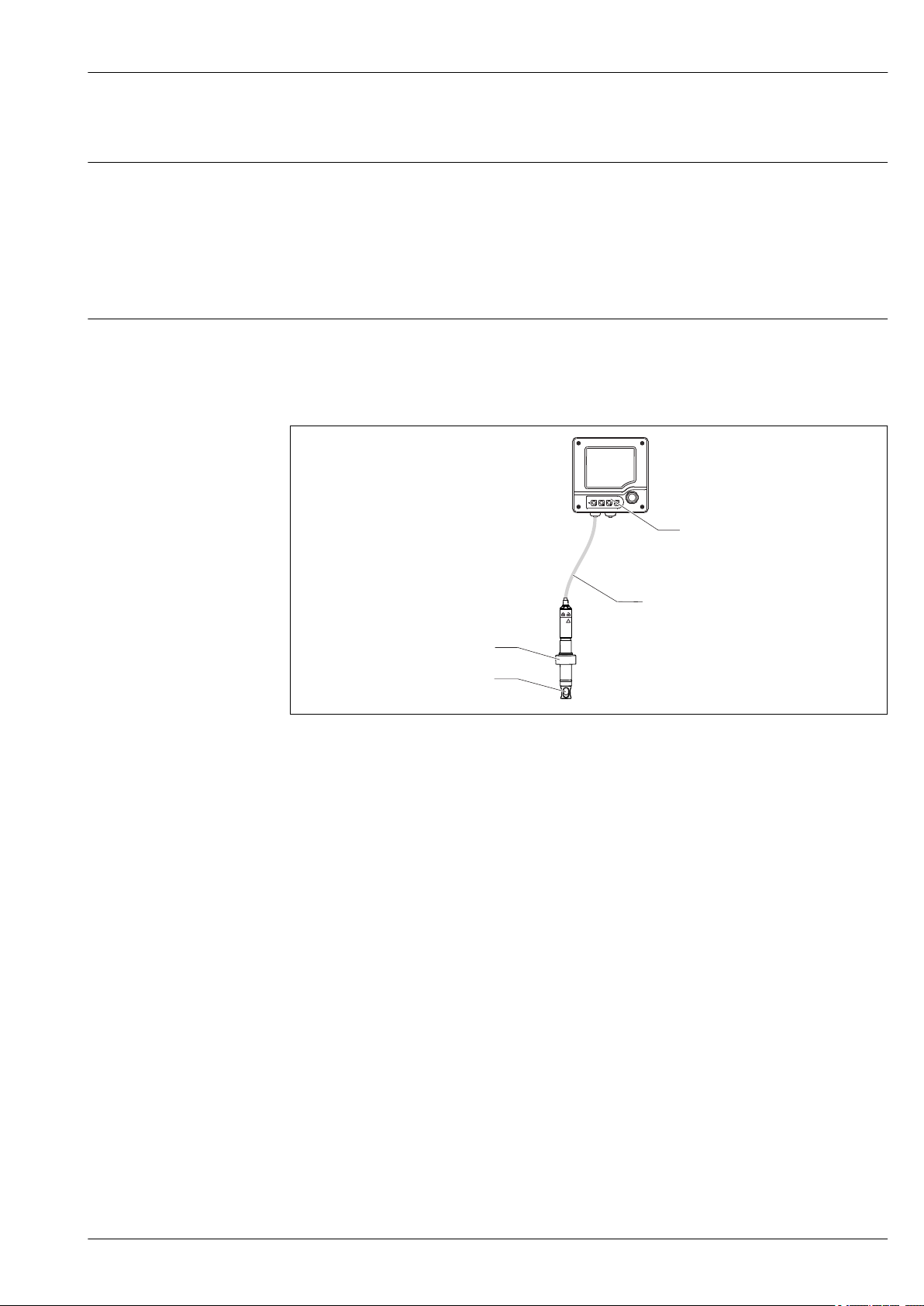

Function and system design

Measuring principle

Measuring system

pH measurement

The pH value is used as a unit of measurement for the acidity or alkalinity of a liquid medium. The

membrane glass of the electrode delivers an electrochemical potential that depends on the pH value

of the medium. This potential is generated by the selective penetration of H+ ions through the outer

layer of the membrane. An electrochemical boundary layer with an electric potential forms at this

point. An integrated Ag/AgCl reference system serves as the required reference electrode.

The transmitter converts the measured voltage into the corresponding pH value using the Nernst

equation.

A complete measuring system consists of the following components at least:

• pH electrode CPS171D

• Transmitter, e.g. Liquiline M CM42, CM44x/R

• Memosens data cable CYK10

• Assembly, e.g. Unifit CPA442

A0028291

1 Example of a measuring system for pH measurement

1 Installation assembly Unifit CPA442

2 pH electrode CPS171D

3 Memosens data cable CYK10 for Memosens sensors

4 Transmitter Liquiline M CM42

Endress+Hauser 3

Page 4

Memosens CPS171D

Communication and data processing

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. Data transmission to a transmitter for analog sensors is not possible.

Digital sensors can store measuring system data in the sensor. These include the following:

• Manufacturer data

– Serial number

– Order code

– Date of manufacture

• Calibration data

– Calibration date

– Slope at 25 °C (77 °F)

– Zero point at 25 °C (77 °F)

– Temperature offset

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operating data

– Temperature application range

– pH application range

– Date of initial commissioning

– Hours of operation under extreme conditions

– Number of sterilizations

– Resistance of glass membrane

Display the data listed above with Liquiline CM42, CM44x/R and Memobase Plus CYZ71D.

4 Endress+Hauser

Page 5

Memosens CPS171D

Dependability Reliability

Easy handling

Sensors with Memosens technology have integrated electronics that store calibration data and other

information (such as total hours of operation or operating hours under extreme measuring

conditions). Once the sensor has been connected, the sensor data are transferred automatically to

the transmitter and used to calculate the current measured value. As the calibration data are stored

in the sensor, the sensor can be calibrated and adjusted independently of the measuring point. The

result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point.

• Thanks to the availability of the sensor data, maintenance intervals can be accurately defined and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs, such

as Memobase Plus CYZ71D,. Thus, the current application of the sensors can be made to depend

on their previous history.

Integrity

Data security thanks to digital data transmission

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter via a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Safety

Maximum process safety

With inductive transmission of the measured value using a non-contact connection, Memosens

guarantees maximum process safety and offers the following benefits:

• All problems caused by moisture are eliminated:

– Plug-in connection free from corrosion

– Measured values cannot be distorted by moisture.

– Can even be connected under water

• The transmitter is galvanically decoupled from the medium. Issues concerning "symmetrical highimpedance" or "asymmetry" or an impedance converter are a thing of the past.

• EMC safety is guaranteed by screening measures for the digital transmission of measured values.

• Intrinsically safe electronics mean operation in hazardous areas is not a problem.

Endress+Hauser 5

Page 6

Input

Memosens CPS171D

Measured variable

Measuring range

pH value

Temperature

pH: 1 to 12 pH (measuring range at 0 to 100 °C (32 to 212 °F))/0 to 14 pH (application)

Temperature: 0 to 140 °C (32 to 284 °F)

Pay attention to the operating conditions in the process.

6 Endress+Hauser

Page 7

Memosens CPS171D

Detail A

pH range

Measuring range: 1 to 12 pH

Application range: 0 to 14 pH

NOTICE

Risk of damage to electrode!

Never use the electrode outside of the listed specifications!

‣

Performance characteristics

Reference operating conditions

Reference system

Ag/AgCl reference lead with ion trap, bridging electrolyte 3M KCl, non-cytotoxic, pressurized

approx. 7 bar (102 psi) (abs.); indicated via pressure indicator (→ 2).

A0036310

2 Pressure indicator

Endress+Hauser 7

Page 8

Installation

15°

15°

A

B

Memosens CPS171D

Installation instructions

Do not install the electrode upside-down.

NOTICE

The angle of inclination of the electrode must be at least 15° from the horizontal.

A smaller angle of inclination would cause an air bubble to form in the glass ball. There is then no

guarantee that the pH membrane is completely covered with inner electrolyte.

Select the installation angle of the electrode so that it does not drop below 15°.

‣

1. Before screwing in the electrode, make sure the assembly threaded connection is clean and

runs smoothly.

2. Screw in the electrode hand-tight 3 Nm (2.2 lbf ft). (Data apply only if installing with

Endress+Hauser CPA assemblies.)

3. Make sure to also follow the installation instructions in the Operating Instructions of the

assembly used.

3 installation angle at least 15° from the horizontal

A Permitted orientation

B Forbidden orientation

CAUTION

L

Glass electrode with pressurized reference

Possibility of sudden rupture and injury from glass splinters!

Always wear protective goggles when working with these electrodes.

‣

A0024316

8 Endress+Hauser

Page 9

Memosens CPS171D

0

40

80

50

100

150

200

250

120

160

212

A

400 20 60 80 100

0

4

6

8

10

2

[°C]

T

[°F]

[psi] p [bar]

120

140

284

1

7

102

15

B

C

Environment

Ambient temperature range

Storage temperature

Degree of protection

Electromagnetic compatibility

Process temperature range

Process pressure range (absolute)

NOTICE

Risk of damage from frost!

Do not use the sensor at temperatures below 0 °C (32 °F).

‣

0 to 50 °C (32 to 122 °F)

IP 68: Memosens plug-in head (10 m (33 ft) water column, 25 °C (77 °F), 45 days, 1 M KCl)

Interference emission and interference immunity as per

• EN 61326-1:2013

• EN 61326-2-3:2013

• EN 61326-2-5: 2013

• NAMUR NE21: 2012

Process

• 0 to 100 °C (32 to 212 °F) (sterilizable up to 140 °C (284 °F)

• 0 to 135 °C (32 to 275 °F) for sensors with Ex approval

1 to 7 bar (14.5 to 101.5 psi) (abs.)

0.8 bar (12 psi) (abs.) is possible as minimum.

CAUTION

L

Pressurization of sensor due to prolonged use under increased process pressure

Risk of injury from glass breakage!

Avoid excessive heating of sensors that are used under reduced process pressure or under

‣

atmospheric pressure.

When handling these sensors, wear protective goggles and suitable gloves.

‣

Minimum conductivity

Pressure-temperature ratings

Endress+Hauser 9

Min. 100 μS/cm (at atmospheric pressure, without flow)

4 Pressure temperature load curve

A Continuous operation

B Short-term for SIP/ autoclaving

C Atmospheric pressure

A0025632

Page 10

Design, dimensions

8

9

120,

225,

360, 425

(4.72,

8.86,

14.2,

16.7)

12

(0.47)

1

2

3

4

5

6

7

Memosens CPS171D

Mechanical construction

5 CPS171D with Memosens plug-in head. Engineering unit: mm (in)

1 Memosens plug-in head

2 FKM O-ring with thrust collar

3 Spacer

4 Pressure indicator with air bubble

5 Ag/AgCl reference lead with ion trap

6 Diaphragm

7 Temperature sensor

8 Ag/AgCl internal reference lead

9 pH membrane

Weight

Materials

0.1 kg (0.2 lb) at a length of 120 mm (4.7 in)

Electrode shaft:

Glass to suit process

pH membrane glasses: Glass to suit process

Metal lead: Ag/AgCl

Diaphragm: Ceramic, sterilizable and autoclavable

Gel: Bridging electrolyte, non-cytotoxic

Nameplate: ceramic metal oxide

Temperature sensor

NTC 30K

Plug-in heads

CPS171D:

Memosens plug-in head for digital, non-contact data transmission,

16 bar (232 psi) (rel.)

10 Endress+Hauser

A0019104

Page 11

Memosens CPS171D

Process connections

Ex approval

Biocompatibility

Pg 13.5

Certificates and approvals

IECEx

Ex ia IIC T3/T4/T6 Ga

ATEX

II 1G Ex ia IIC T3/T4/T6 Ga

NEPSI

Ex ia IIC T3/T4/T6 Ga

FM

IS/NI CL. I. Div 1, Group A-D

CSA

IS/NI CL. I. Div 1, Group A-D

Hazardous area versions of the digital sensors with Memosens technology are indicated by a

red/orange ring on the plug-in head.

Biocompatibility successfully tested with regard to

• Biological reactivity, in vitro (cytotoxicity) according to USP <87>

For process-sealing O-ring, bridging electrolyte and inscription on shaft

• Biological reactivity, in vivo according to USP <88> Class VI, 121 °C (250 °F)

For process-sealing O-ring

TÜV certificate for Memosens plug-in head

Pressure resistance 16 bar (232 psi) (rel.), minimum three times the safety pressure

Endress+Hauser 11

Page 12

Ordering information

Memosens CPS171D

Product page

Product Configurator

Scope of delivery

www.endress.com/cps171d

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

The delivery comprises:

• Sensor in the version ordered

• Operating Instructions

• Safety instructions for hazardous area

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Assemblies

Unifit CPA442

• Installation assembly for food, biotechnology and pharmaceutics

• With EHEDG and 3A certificate

• Product Configurator on the product page: www.endress.com/cpa442

Technical Information TI00306C

Cleanfit CPA875

• Retractable process assembly for sterile and hygienic applications

• For in-line measurement with standard sensors with 12 mm diameter, e.g. for pH, ORP, oxygen

• Product Configurator on the product page: www.endress.com/cpa875

Technical Information TI01168C

Cleanfit CPA475

• Retractable assembly for pH/ORP measurement in tanks and pipes under sterile measuring

conditions

• Product Configurator on the product page: www.endress.com/cpa475

Technical Information TI00240C

Dipfit CPA140

• pH/ORP immersion assembly with flange connection for very demanding processes

• Product Configurator on the product page: www.endress.com/cpa140

Technical Information TI00178C

12 Endress+Hauser

Page 13

Memosens CPS171D

Buffer solutions

Measuring cable

Software

Handheld instrument

High-quality buffer solutions from Endress+Hauser - CPY20

The secondary buffer solutions have been referenced to primary reference material of the PTB

(German Federal Physico-technical Institute) or to standard reference material of NIST (National

Institute of Standards and Technology) according to DIN 19266 by a laboratory accredited by the

DAkkS (German accreditation body) according to DIN 17025.

Product Configurator on the product page: www.endress.com/cpy20

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens laboratory cable CYK20

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk20

Memobase Plus CYZ71D

• PC software to support laboratory calibration

• Visualization and documentation of sensor management

• Sensor calibrations saved in the database

• Product Configurator on the product page: www.endress.com/cyz71d

Technical Information TI00502C

Liquiline To Go CYM290, CYM291

• Portable multiparameter device for Memosens pH, conductivity and oxygen sensors

• Product Configurator on the product page: www.endress.com/cym290, www.endress.com/cym291

Technical Information TI01198C

Refer to the Operating Instructions for CYM290 or CYM291 for information on the sensors that

can be connected.

Endress+Hauser 13

Page 14

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...