Page 1

BA01279C/07/EN/03.16

71324469

Products Solutions Services

Operating Instructions

Cleanfit CPA875

Retractable process assembly for sterile and hygienic

applications

Page 2

Page 3

Table of contents

Table of contents

1 Document information .............. 4

1.1 Warnings ............................ 4

1.2 Symbols used .......................... 4

1.3 Symbols on the device ................... 4

2 Basic safety instructions ............ 5

2.1 Requirements for the personnel ............ 5

2.2 Designated use ........................ 5

2.3 Occupational safety ..................... 5

2.4 Operational safety ...................... 6

2.5 Product safety ......................... 6

3 Incoming acceptance and product

identification ....................... 7

3.1 Incoming acceptance .................... 7

3.2 Scope of delivery ....................... 7

3.3 Product identification .................... 8

3.4 Certificates and approvals ................ 9

4 Installation ....................... 10

4.1 Installation conditions .................. 10

4.2 Installation .......................... 16

4.3 Installing the sensor ................... 23

4.4 Post-installation check .................. 27

Index .................................. 53

5 Operation options ................. 28

5.1 Commissioning ....................... 28

5.2 Operating elements .................... 29

5.3 Manual operation ..................... 30

5.4 Pneumatic operation ................... 30

6 Maintenance ...................... 32

6.1 Maintenance intervals .................. 32

6.2 Cleaning the assembly .................. 33

6.3 Cleaning the sensor .................... 33

6.4 Cleaning agent ....................... 34

6.5 Replacing seals ....................... 35

7 Repairs ........................... 44

7.1 Spare parts .......................... 44

7.2 Return .............................. 44

7.3 Disposal ............................ 44

8 Accessories ....................... 45

8.1 Installation material for rinse connections ... 46

8.2 Sensors ............................. 47

9 Technical data .................... 50

Endress+Hauser 3

Page 4

Document information Cleanfit CPA875

1 Document information

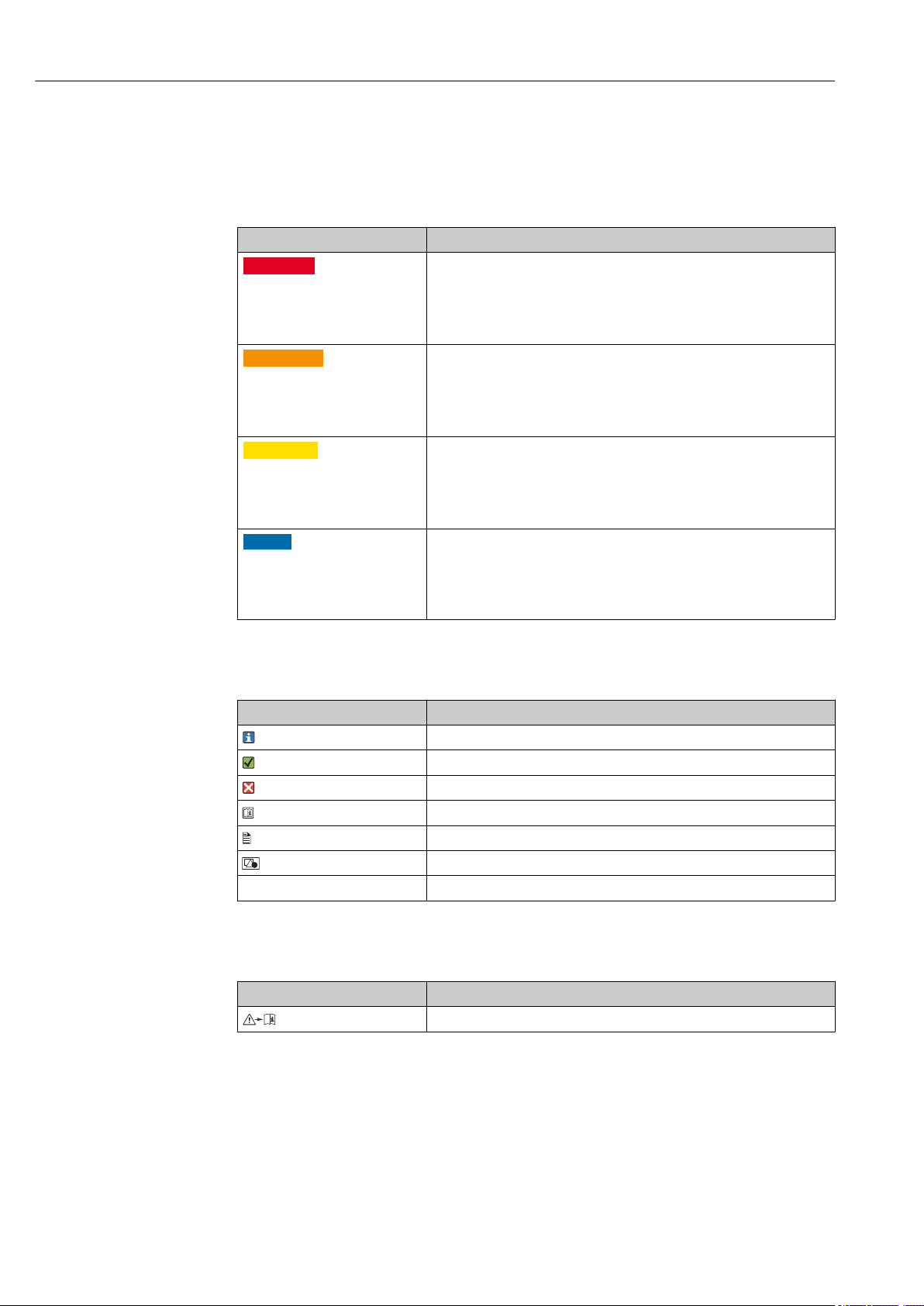

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

Consequences of non-compliance

(if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

Consequences of non-compliance

(if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

Consequences of non-compliance

(if applicable)

Corrective action

‣

NOTICE

Cause/situation

Consequences of non-compliance

(if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

4 Endress+Hauser

Page 5

Cleanfit CPA875 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Measuring point faults may be repaired only by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided may only be carried out

directly by the manufacturer or by the service organization.

2.2 Designated use

The Cleanfit CPA875 retractable assembly, which can be manually or pneumatically

operated, is designed for the installation of sensors in vessels and pipes.

Thanks to its design, it can be used in pressurized systems (see "Technical data").

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Endress+Hauser 5

Page 6

Basic safety instructions Cleanfit CPA875

2.4 Operational safety

1. Before commissioning the entire measuring point, verify that all connections are

correct. Ensure that electrical cables and hose connections are undamaged.

2. Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Label the damaged product as defective.

3. If faults cannot be rectified:

Take the products out of operation and safeguard them to ensure that they are not

operated inadvertently.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

6 Endress+Hauser

Page 7

Cleanfit CPA875 Incoming acceptance and product identification

3 Incoming acceptance and product

identification

3.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify your supplier of any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

2. Verify that the contents are undamaged.

Notify your supplier of any damage to the delivery contents.

Keep the damaged products until the matter has been settled.

3. Check the delivery for completeness.

Check it against the delivery papers and your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

The permitted ambient conditions must be observed (see "Technical data").

If you have any questions, please contact your supplier or your local sales center.

3.2 Scope of delivery

The scope of delivery comprises:

• Assembly in the version ordered

• Operating Instructions

Endress+Hauser 7

Page 8

Incoming acceptance and product identification Cleanfit CPA875

3.3 Product identification

3.3.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

Compare the data on the nameplate with your order.

3.3.2 Product identification

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to the product page for your product on the Internet.

2. At the bottom of the page, select the "Online Tools" link followed by "Check your

device features".

An additional window opens.

3. Enter the order code from the nameplate into the search field, and then select "Show

details".

You will receive information on each feature (selected option) of the order code.

8 Endress+Hauser

Page 9

Cleanfit CPA875 Incoming acceptance and product identification

3.4 Certificates and approvals

Pharma CoC

No materials or ingredients derived from animals are used during the entire production of

all the parts in contact with the process.

Biological reactivity (USP Class VI) (optional)

The plastic and elastomer product components that are in contact with the medium have

passed the biological reactivity tests as per USP <87> and <88> Class VI.

EHEDG

The assembly was certified in accordance with the requirements of EHEDG TYP EL Class I

(cleanability). The double-chamber version with sensor cleaning in the "inner" service

chamber is certified in accordance with EHEDG type EL aseptic class I (cleanability and

sterility).

ASME BPE

The Cleanfit CPA875 retractable assembly has been developed following ASME BPE

Standard 2012 and meets the relevant requirements of sections GR, SD, DT, MJ, SF, SG,

PM, MM and PI which are significant for a retractable assembly.

FDA

All materials in contact with the product are listed by the FDA.

Suitable process connections and seals must be used for hygienic designs as per

EHEDG, ASME BPE or 3-A.

RL 94/9/EC (ATEX)

The assembly does not fall within the scope of the directive. However, if conditions for safe

use are adhered to, it may be deployed in the hazardous area.

CE/PED

The CPA875 assembly has been manufactured according to good engineering practice in

accordance with Article 3, Paragraph 3 of the Pressure Equipment Directive 97/23/EC and

therefore is not required to bear the CE label.

EC VO 1935/2004

The assembly meets the requirements for materials that come into contact with food.

Endress+Hauser 9

Page 10

Installation Cleanfit CPA875

4 Installation

4.1 Installation conditions

4.1.1 Orientation

The assembly is designed for installation on tanks and pipes. Suitable process connections

must be available for this.

NOTICE

Frost damage to the assembly

If used outdoors, ensure that water cannot penetrate the drive.

‣

For 3-A-compliant installation, please observe the following:

After the device has been mounted, hygienic integrity must be guaranteed. To do so,

the leakage hole must be located at the lowest point on the device. In addition, 3-Acompliant process connections must be used.

The assembly is designed in such a way that there are no restrictions with regard to the

orientation.

The sensor that is used can restrict the orientation.

The "inner" service chamber and "front" service chamber can drain on their own with an

installation position of between 0° and 15° to the horizontal.

10 Endress+Hauser

Page 11

Cleanfit CPA875 Installation

XM/XS = 443/479 (17.44/18.86)

A

B

XP

XP

168 (6.61)

73

(2.87)

61

(2.40)

117

(4.61)

XA

XM/XS = 443/479 (17.44/18.86)

165 (6.50)

73

(2.87)

40

(1.57)

61

(2.40)

107

(4.21)

XA

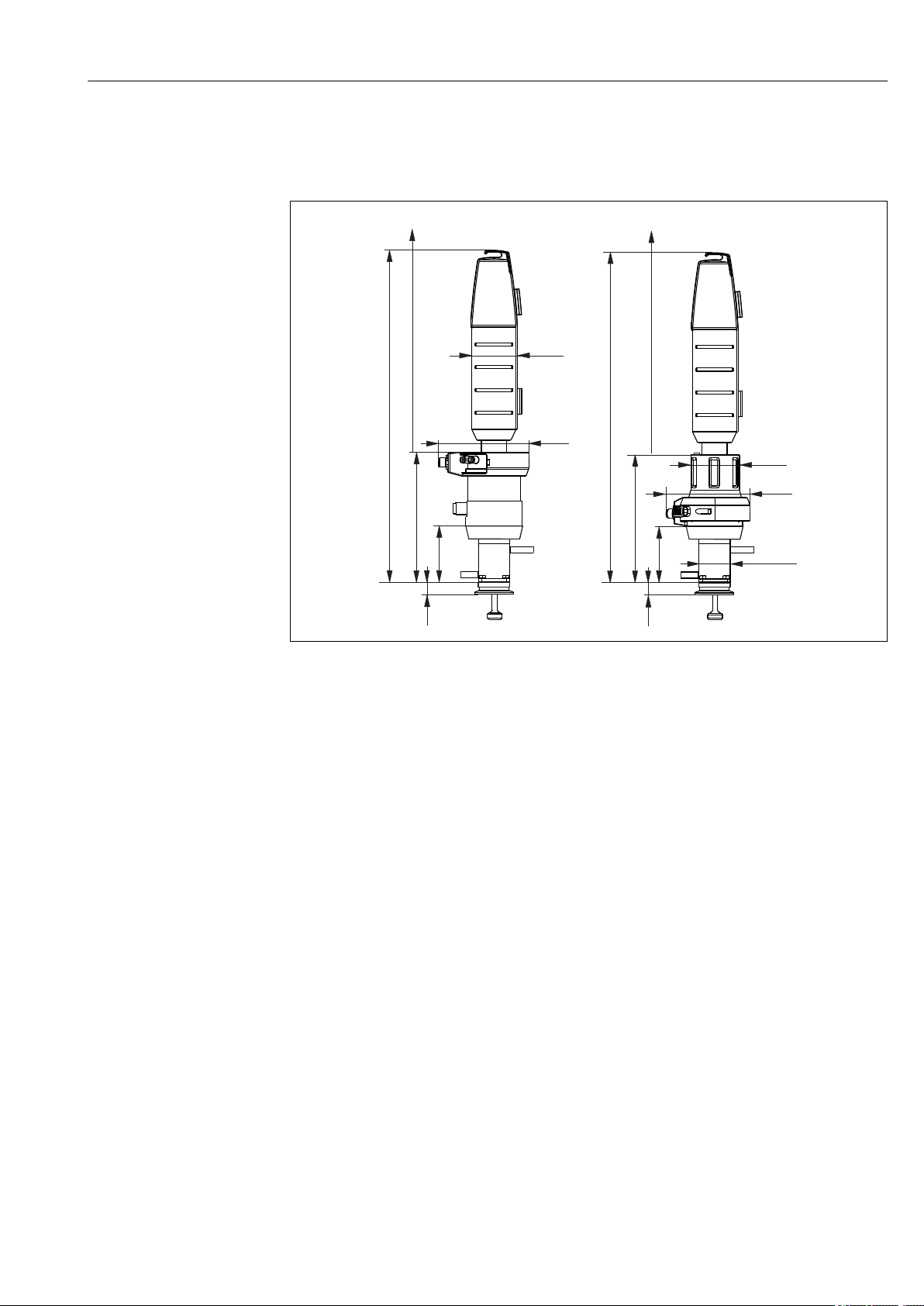

4.1.2 Dimensions

Short version

A0018665

1 Dimensions for short version (36 mm stroke)

A Pneumatic drive

B Manual drive

XM Assembly in measuring position

XS Assembly in service position

XP Height of particular process connection (see table below)

XA Necessary mounting distance for sensor replacement = 425 mm (16.73")

Endress+Hauser 11

Page 12

Installation Cleanfit CPA875

A

B

XM/XS = 558/635 (21.97/25.0)

XM/XS = 524/604 (20.63/23.82)

XP

283 (11.14)

141 (5.55)

61

(2.40)

117

(4.61)

XA

XA

246 (9.69)

107 (4.21)

XP

61

(2.40)

107

(4.21)

40

(1.57)

C

XM/XS = 318/396 (12.52/15.59

XA

246 (9.69)

107 (4.21)

XP

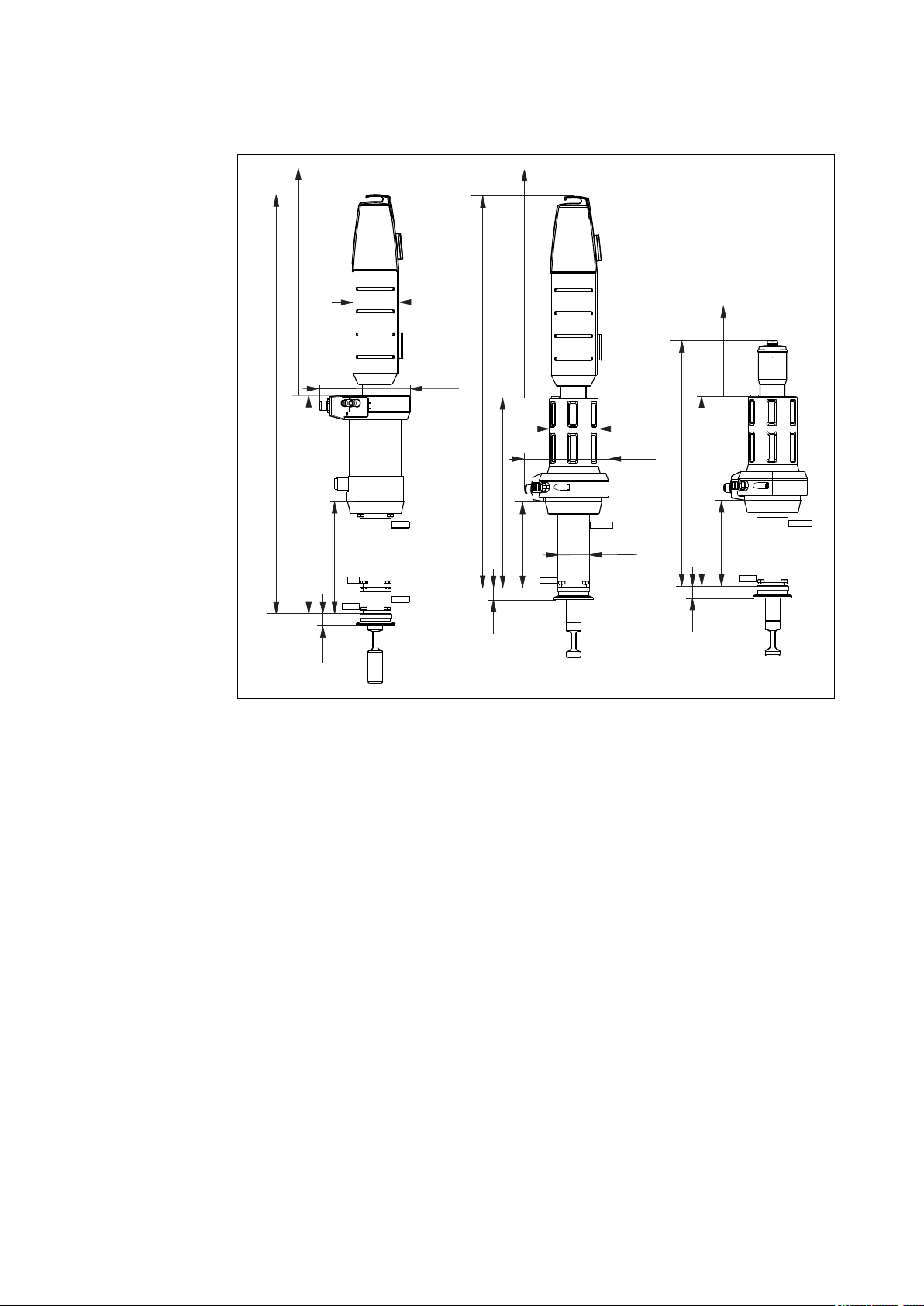

Long version

2 Dimensions for long version (78 mm stroke)

A Pneumatic drive

B Manual drive

C Manual drive with small protection cap

XM Assembly in measuring position

XS Assembly in service position

XP Height of particular process connection (see table below)

XA Necessary mounting distance for sensor replacement

The mounting distance XA is 440 mm (17.32") for 225 mm sensors

The mounting distance XA is 610 mm (24.02") for 360 mm sensors

A0018666

12 Endress+Hauser

Page 13

Cleanfit CPA875 Installation

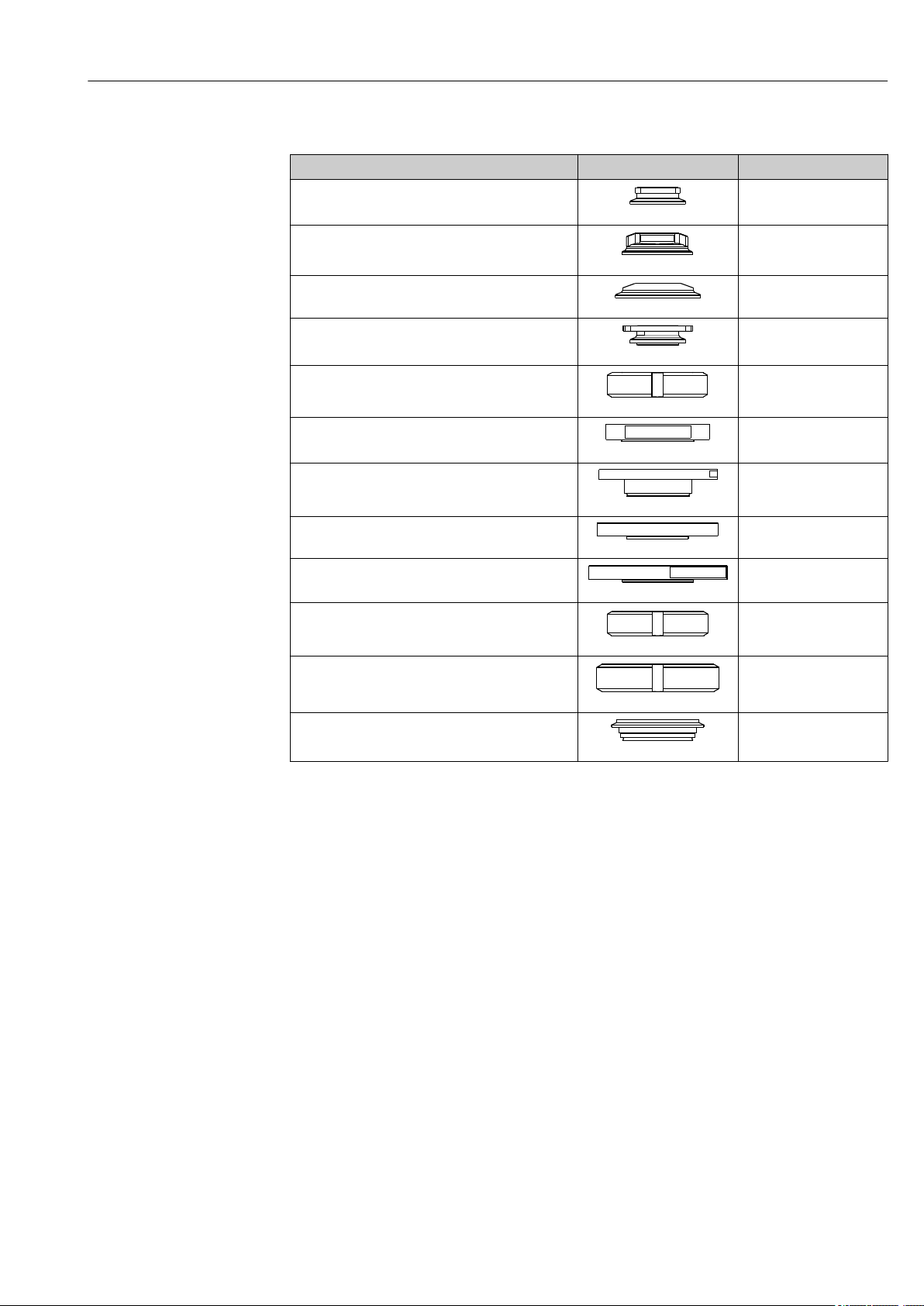

Process connection height

Process connection Height XP in mm (inch)

CA Clamp ISO 2852, ASME BPE-2012, 1½"

CB Clamp ISO 2852, ASME BPE-2012, 2"

CC Clamp ISO 2852, ASME BPE-2012, 2½"

DA Aseptic DN 25 clampable DIN 11864-3 A

DC Aseptic DN 50 screw-in DIN 11864-1 A

DF Aseptic DN 50 grooved flange DIN 11864-2 A

EA Neumo BioControl D 65

EB Neumo BioConnect D 50

EF Neumo BioConnect D 65

MA Dairy fitting DN 50 DIN 11851

(EHEDG approval only with seal from Siersema)

MB Dairy fitting DN 65 DIN 11851

(EHEDG approval only with seal from Siersema)

VA Varivent flange N (DN 40 to 100)

14.9 (0.59)

A0021866

19.5 (0.77)

A0021867

13.0 (0.51)

A0021869

16.0 (0.63)

A0021871

16.0 (0.63)

A0021872

14.2 (0.56)

A0021874

25.0 (0.98)

A0021875

10.5 (0.41)

A0021877

10.5 (0.41)

A0021876

14.5 (0.57)

A0021879

13.8 (0.54)

A0021878

19.0 (0.75)

A0021873

Endress+Hauser 13

Page 14

Installation Cleanfit CPA875

X1

X2

X1

X2

X2

X1

1 2 / 3 / 6

4 / 5

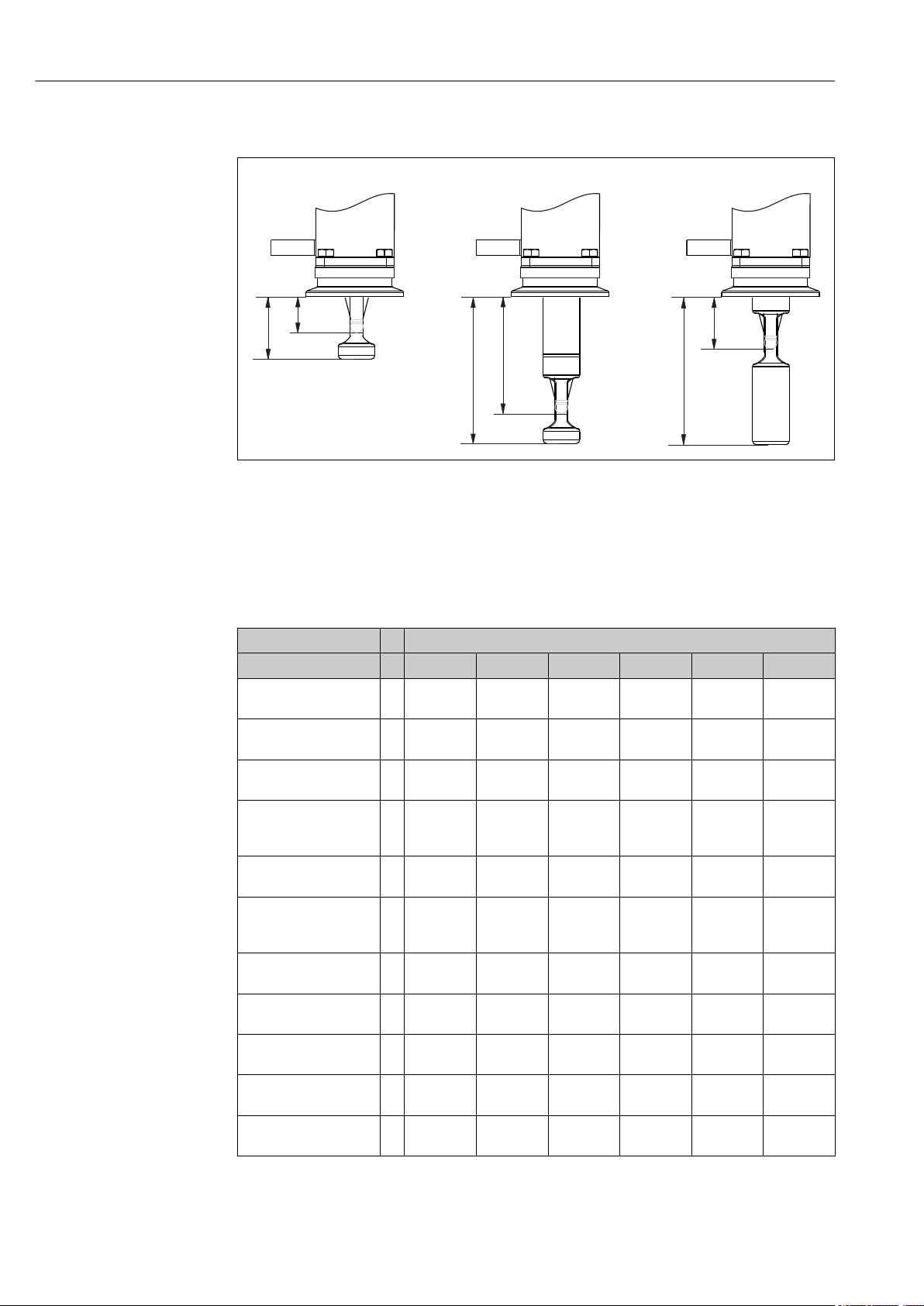

4.1.3 Immersion depths

A0017745

3 Immersion depths for different service chambers

1 Single chamber / 36 mm stroke / sensor 225 mm incl. KCl

2 Single chamber / 78 mm stroke / sensor 225 mm excl. KCI

3 Single chamber / 78 mm stroke / sensor 360 mm incl. KCl

4 Double chamber / 78 mm stroke / sensor 225 mm excl. KCl / service position, "inner" service chamber

5 Double chamber / 78 mm stroke / sensor 360 mm incl. KCl / service position, "inner" service chamber

6 Double chamber / 78 mm stroke / sensor 360 mm incl. KCl / service position, "front" service chamber

Immersion depths in mm (inch)

Process connection 1 2 3 4 5 6

CA Clamp ISO2852

ASME BPE-2012 1½"X1X2

CB Clamp ISO2852

ASME BPE-2012 2"

CC Clamp ISO2852

ASME BPE-2012 2½"X1X2

DA Aseptic DN 25

clampable DIN11864-3

A

DC Aseptic DN 50

screw-in DIN11864-1 AX1X2

DF Aseptic DN 50

Grooved flange

DIN11864-2 A

EA Neumo Biocontrol

D65

EB Neumo Bioconnect

D50

EF Neumo Bioconnect

D65

MA Dairy fitting

DN 50 DIN11851

MB Dairy fitting

DN 65 DIN11851

20.6 (0.81)

31.6 (1.24)

X1X216.1 (0.63)

27.1 (1.07)

22.6 (0.89)

33.6 (1.32)

X1X219.6 (0.77)

30.6 (1.20)

27.1 (1.07)

38.1 (1.50)

X1X221.4 (0.84)

32.4 (1.28)

X1X227.6 (1.09)

38.6 (1.52)

X1X222.6 (0.89)

33.6 (1.32)

X1X220.6 (0.81)

31.6 (1.24)

X1X221.1 (0.83)

32.1 (1.26)

X1X221.8 (0.86)

32.8 (1.29)

62.1 (2.44)

73.1 (2.88)

57.6 (2.27)

68.6 (2.70)

64.1 (2.52)

75.1 (2.96)

61.1 (2.41)

72.1 (2.84)

68.6 (2.70)

79.6 (3.13)

62.9 (2.48)

73.9 (2.91)

69.1 (2.72)

80.1 (3.15)

64.1 (2.52)

75.1 (2.96)

62.1 (2.44)

73.1 (2.88)

62.6 (2.46)

73.6 (2.90)

63.3 (2.49)

74.3 (2.93)

Service chamber

62.1 (2.44)

73.1 (2.88)

57.6 (2.27)

68.6 (2.70)

64.1 (2.52)

75.1 (2.96)

61.1 (2.41)

72.1 (2.84)

68.6 (2.70)

79.6 (3.13)

62.9 (2.48)

73.9 (2.91)

69.1 (2.72)

80.1 (3.15)

64.1 (2.52)

75.1 (2.96)

62.1 (2.44)

73.1 (2.88)

62.6 (2.46)

73.6 (2.90)

63.3 (2.49)

74.3 (2.93)

28.1 (1.11)

73.1 (2.88)

23.6 (0.93)

68.6 (2.70)

30.1 (1.19)

75.1 (2.96)

27.1 (1.07)

72.1 (2.84)

34.6 (1.36)

79.6 (3.13)

28.9 (1.14)

73.9 (2.91)

35.1 (1.38)

80.1 (3.15)

30.1 (1.19)

75.1 (2.96)

28.1 (1.11)

73.1 (2.88)

28.6 (1.13)

73.6 (2.90)

29.3 (1.16)

74.3 (2.93)

28.1 (1.11)

73.1 (2.88)

23.6 (0.93)

68.6 (2.70)

30.1 (1.19)

75.1 (2.96)

27.1 (1.07)

72.1 (2.84)

34.6 (1.36)

79.6 (3.13)

28.9 (1.14)

73.9 (2.91)

35.1 (1.38)

80.1 (3.15)

30.1 (1.19)

75.1 (2.96)

28.1 (1.11)

73.1 (2.88)

28.6 (1.13)

73.6 (2.90)

29.3 (1.16)

74.3 (2.93)

62.1 (2.44)

73.1 (2.88)

57.6 (2.27)

68.6 (2.70)

64.1 (2.52)

75.1 (2.96)

61.1 (2.41)

72.1 (2.84)

68.6 (2.70)

79.6 (3.13)

62.9 (2.48)

73.9 (2.91)

69.1 (2.72)

80.1 (3.15)

64.1 (2.52)

75.1 (2.96)

62.1 (2.44)

73.1 (2.88)

62.6 (2.46)

73.6 (2.90)

63.3 (2.49)

74.3 (2.93)

14 Endress+Hauser

Page 15

Cleanfit CPA875 Installation

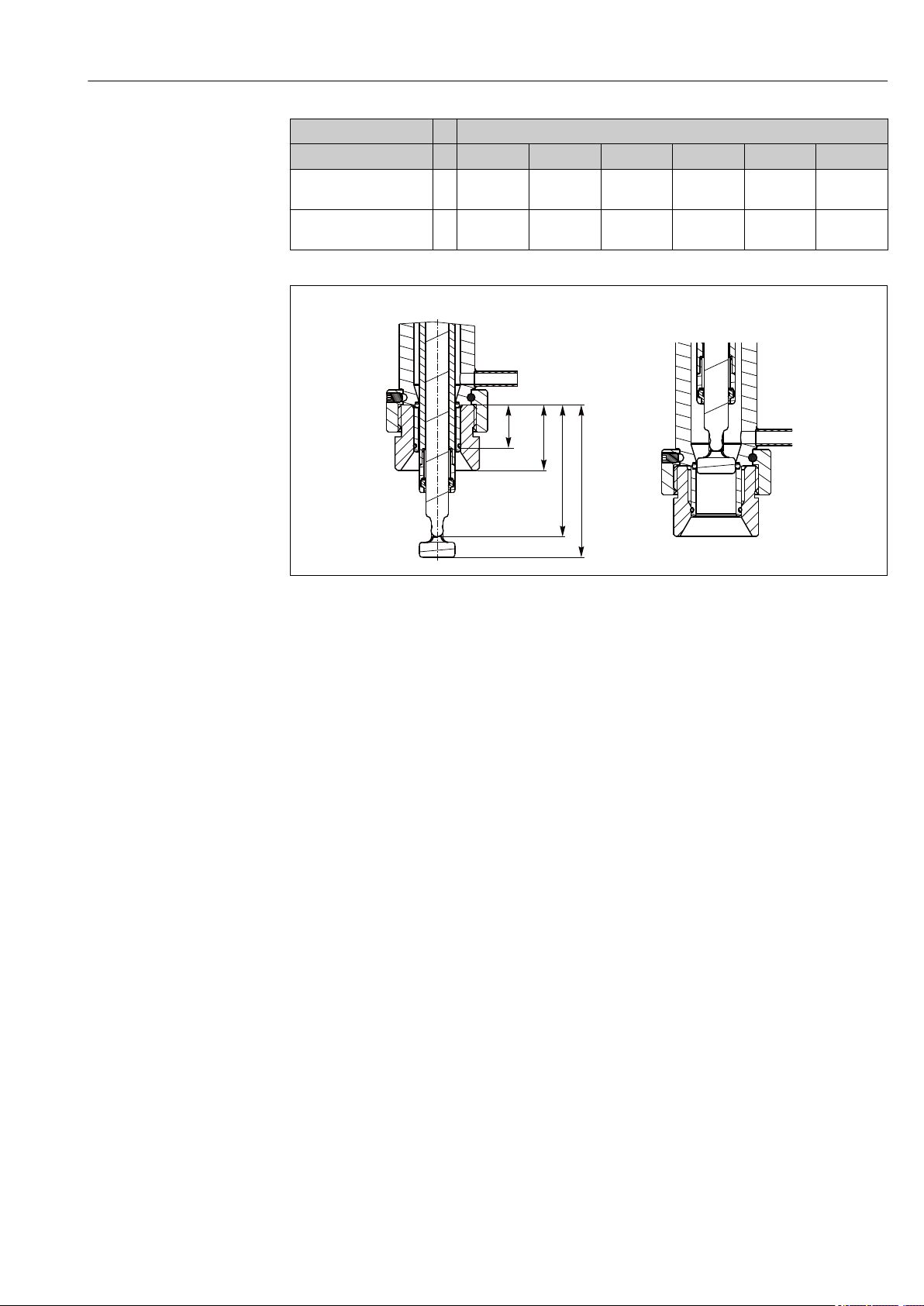

81.4 (3.20)

70.4 (2.77)

35 (1.38)

23

(0.91)

A B

Service chamber

Process connection 1 2 3 4 5 6

NA Thread ISO228

G1¼

VA Varivent flange

N (DN 40 to DN 100)X1X2

X1

X2

16.6 (0.65)

27.6 (1.09)

70.4 (2.77)

81.4 (3.20)

58.1 (2.29)

69.1 (2.72)

70.4 (2.77)

81.4 (3.20)

58.1 (2.29)

69.1 (2.72)

24.1 (0.95)

69.1 (2.72)

24.1 (0.95)

69.1 (2.72)

58.1 (2.29)

69.1 (2.72)

A0022162

4 Immersion depth in mm (inch) for process connection NA thread ISO228 G1¼ (service chamber 2 and 3)

in measurement and service position

Endress+Hauser 15

Page 16

Installation Cleanfit CPA875

2

3

4

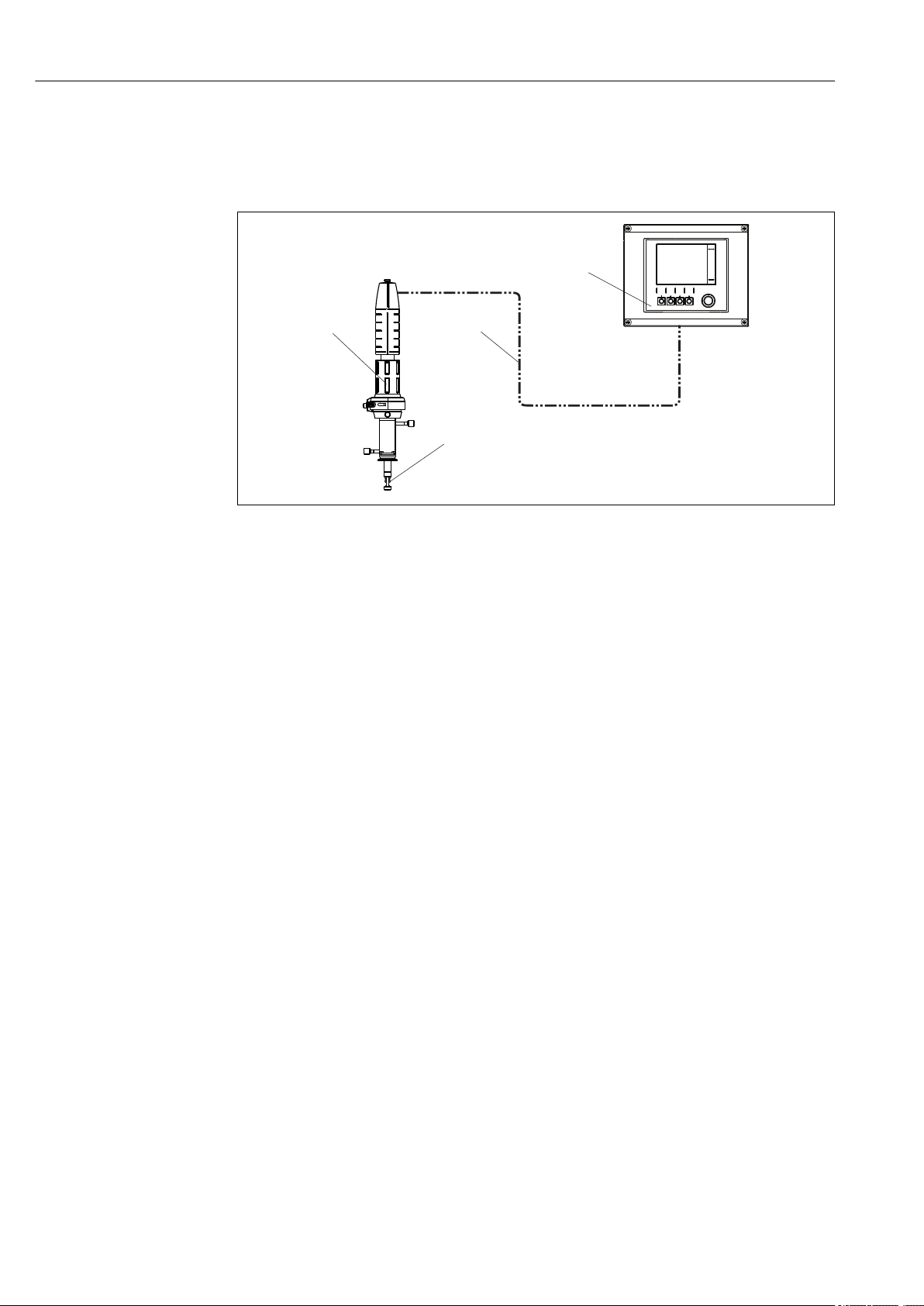

4.2 Installation

4.2.1 Measuring system with single chamber

A0017811

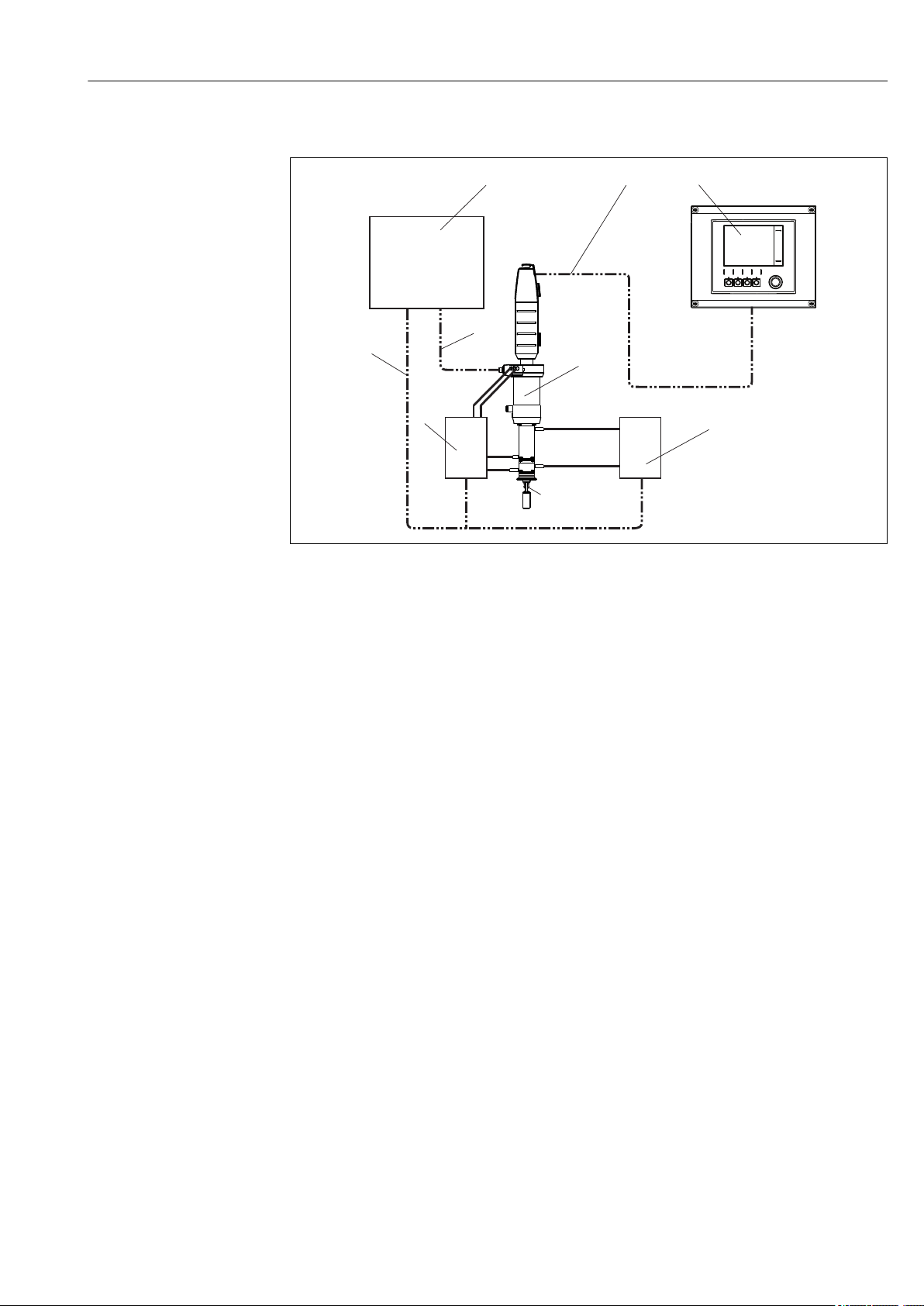

5 Measuring system (example)

1 Cleanfit assembly CPA875

2 Measuring cable

3 Liquiline CM44x transmitter

4 Sensor

16 Endress+Hauser

Page 17

Cleanfit CPA875 Installation

3

4

1 2

3

5

6

6

7

8

11

12

21

22

31 32

4.2.2 Measuring system with double chamber

A0022821

6 Measuring system with pneumatic drive and double chamber (example)

1 Control unit 7 Limit position switch relay signal

2 Measuring cable 8 Control signals (electric/pneumatic)

3 Liquiline CM44x transmitter 11/12Inlet/outlet of "inner" service chamber

4 Cleanfit assembly CPA875 21/22Inlet/outlet of "front" service chamber

5 Sensor 31/32Drive control

6 Valve block

Endress+Hauser 17

Page 18

Installation Cleanfit CPA875

4.2.3 Installing the assembly in the process

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process

medium escapes.

Wear protective gloves, protective goggles and protective clothing.

‣

Only mount the assembly if the containers or pipes are empty and unpressurized.

‣

Prior to installation, check the flange seal between the flanges.

1. Move the assembly to the service position (the triangle position marking is visible

(→ 7).

2. Secure the assembly to the tank or piping using the process connection.

3. Follow the instructions in the next section to connect pipes for compressed air and

rinse water (for the relevant assembly version).

7 Position markings (service position)

A0023307

18 Endress+Hauser

Page 19

Cleanfit CPA875 Installation

1

2

3

4

5

6

7

8

9

4.2.4 Pneumatic connection for automatic operation

Prerequisites:

• Air pressure 4 to 7 bar (58 to 102 psi)

• Compressed air quality in accordance with ISO 8573-1:2001

Quality class 3.3.3 or 3.4.3

• Solids class 3 (max. 5 μm, max. 5 mg/m3, contamination with particles)

• Water content for temperatures ≥ 15 °C: class 4 pressure condensation point 3 °C or

lower

• Water content for temperatures of 5 to 15 °C: class 3 pressure condensation point -20 °C

or lower

• Oil content class 3 (max. 1 mg/m3)

• Air temperature: 5 °C or higher

• No continuous air consumption

• Minimum nominal diameter of air pipes: 2 mm (0.08 ")

Connection: Push-in fitting M5, hose 4/2 mm OD/ID (adapter for 6/4 mm OD/ID

enclosed)

Damage to seals due to excessive air pressure!

If the air pressure can increase to more than 7 bar (102 psi) (even short pressure surges),

a pressure-reducing valve must be installed upstream.

1 Rinse connection

2 Automatic limit position lock, process

3 Connection for limit position switch

4 Automatic limit position lock, service

5 Sensor head

6 Fastening ring for protection cap

7 Pneumatic connection (move to

measuring position)

8 Pneumatic connection (move to service

position)

9 Rinse connection

A0029435

8 Assembly with pneumatic drive (without

protection cap)

Use a pneumatic change-over valve (4/2-way valve) to move the assembly. Connect

both inputs. If you connect only one input (e.g. for test purposes), the piston will be

blocked, as the sensor guide moves before the limit position lock is deactivated.

Endress+Hauser 19

Page 20

Installation Cleanfit CPA875

3

3

4

5

A B

C

1

2

1

2

1

2

4.2.5 Rinse connections

The service chamber connections of the sterile CPA875 retractable assembly make it

possible to clean the chamber and the sensor with water or a cleaning solution at a

pressure of 6 bar (87 psi) max. or to sterilize it with steam (SIP).

The retractable assembly can be selected with a single- or double-chamber system. If the

double-chamber system is used, all four connections must be connected to inlet and outlet

pipes.

Seals can be damaged if the water pressure is too high.

Install an pressure-reducing valve upstream if there is a possibility that the water

pressure will increase to more than 6 bar (87 psi) (including any short pressure

surges).

4.2.6 Assignment of rinse connections for double chamber

A0023348

9 Changing the chamber volume

3 "Moving" seals in the double chamber

4 Chamber volume in service position

5 Chamber volume in measuring position

10 Assignment of rinse inlet and outlet

A "Cleaning" state

B "Move from service position to measuring position" state

C "Move from measuring position to service position" state

1 Service chamber inlet

2 Service chamber outlet

A0022805

20 Endress+Hauser

Page 21

Cleanfit CPA875 Installation

BN

BN

BU

BU

L+

L+

L-

L-

A

B

C D

E

In the "Cleaning" state (A), the inlet and outlet of the "inner" service chamber are used as

follows (the internal volume of the "front" service chamber does not change, and so no

pressure compensation measures are required here):

• Depending on the cleaning method, cleaning agent and purge gas are supplied via the

inlet (1).

• These media are removed via the outlet (2).

In the "Move from service position to measuring position" state (B), the pressure conditions

in the service chamber must be balanced when moving. The inlet and outlet of the service

chamber are assigned as follows:

• The air is removed via the inlet (1) (inlet is open).

• The air is supplied via the outlet (2).

In the "Move from measuring position to service position" state (C), the pressure conditions

in the service chamber must be balanced when moving. The inlet and outlet of the service

chamber are assigned as follows:

• The air is supplied via the inlet (1).

• The air is removed via the outlet (2) (outlet is open).

The drive must be controlled simultaneously with the control of the inlets and outlets

of the "inner service chamber".

The controller for the inlets, outlets and the drive is installed at the place of

installation. It is not included in the delivery for the assembly.

4.2.7 Connecting the limit position switches

With limit position detection, you can notify a system located downstream (transmitter,

switching amplifier, output interface terminal) whether the assembly is in the

measurement or service position(in the case of a manual drive, only the measurement

position is queried).

The assembly can be ordered directly with limit position detection, or it can be retrofitted

at a later stage.

Switching element function: NAMUR NC contact (inductive)

Switching distance: 1.5 mm (0.06 ")

Nominal voltage: 8 V

Switching frequency: 0 to 5000 Hz

Housing material: Stainless steel

A0017831

Endress+Hauser 21

11 Inductive limit position switches

A Limit position switch, service position

B Limit position switch, measuring position

C Connector, M12, solder side (inside of assembly)

D Coding

E Connector, Pin side (outside of assembly)

Page 22

Installation Cleanfit CPA875

BN

BK

BU

WH

1

2

3

4

+

+

-

-

A0022163

12 Connecting cable for limit position switch on transmitter, switching amplifier, output interface terminal

etc.

1 "Measuring" position

2 "Measuring" position

3 "Service" position

4 "Service" position

Only pins 1 and 2 are assigned for manually activated assemblies with one switch

(measuring position).

Signal table for limit position switches

Position of assembly Limit position switch for "measuring"

position

Measurement Active LOW (≥ 3 mA) Active LOW (≥ 3 mA)

Service Active HIGH (≤ 1 mA) Active HIGH (≤ 1 mA)

Limit position switch for "service"

position

22 Endress+Hauser

Page 23

Cleanfit CPA875 Installation

1

1

2

A B

1

2

4.3 Installing the sensor

4.3.1 Preparing the sensor and assembly

A0030154

13 Installing the sensor

1 Thrust collar with O-ring

1. Remove the protection cap from the sensor. Ensure that the O-ring and thrust collar

(→ 13, item 1) are present.

2. Immerse the sensor shaft in water. This makes for easier installation.

3. Move the assembly to the service position.

4.3.2 Installing and removing sensors

A0030155

14 Sensor installation options

1 Sensor adapter

2 Retraction pipe

A Sensor adapter is on top of the retraction pipe

B Sensor adapter is below the retraction pipe (not visible)

Depending on the assembly version, the sensor adapter is either visible (→ 14, A) or

installed inside the retraction pipe where it is not visible (B). As a result, the procedures

for installing and removing the sensors differ as follows:

Endress+Hauser 23

Page 24

Installation Cleanfit CPA875

1

2

3

4

Installing and removing sensors if the sensor adapter is visible (pos. A)

A0030186

15 Installing the sensor

1 Open-ended wrench (AF 17/19 mm)

2 Protection cover

3 Dummy plug

4 Sensor

Gel and KCl sensors can be installed in this version.

Install the sensor as follows:

1. Remove the protection cap (→ 15, item 2) (this is possible only if the assembly is

in the service position).

2. Remove the yellow dummy plug (pos. 3).

3. Using the open-ended wrench (item 1), screw in the sensor (item 4) in the place of

the dummy plug and hand-tighten (3 Nm (2.2 lbf ft)).

4. Attach the open-ended wrench back into the protection cap.

5. Put the protection cap on the assembly. When doing so, guide the measuring cable

through the cable run (top of protection cap).

Always install the protection cap before moving the assembly to the measuring

position. The protection cap cannot be removed in the measuring position. This

prevents the sensor from being removed.

24 Endress+Hauser

Page 25

Cleanfit CPA875 Installation

3

4

5

1

2

Installing and removing sensors if the sensor adapter is not visible (pos. B)

A0030187

16 Installing the sensor

1 Socket wrench (AF 17/19 mm)

2 Protection cover

3 Dummy plug (protection cap)

4 Sensor

5 Retraction pipe

Gel sensors can be installed in this version. To install KCl sensors, you will need a "Gel

- KCl adapter".

Install the sensor as follows:

1. Remove the protection cap (→ 16, item 2) (this is possible only if the assembly is

in the service position).

2. Unscrew and remove the retraction pipe (pos. 5) (in an anticlockwise direction).

3. Remove the yellow dummy plug (pos. 3).

4. Using the open-ended wrench (item 1), screw in the sensor (item 4) in the place of

the dummy plug and hand-tighten (3 Nm (2.2 lbf ft)).

5. Screw the retraction pipe back in.

6. Attach the open-ended wrench back into the protection cap.

7. Put the protection cap on the assembly. When doing so, guide the measuring cable

through the cable run (top of protection cap).

Always install the protection cap before moving the assembly to the measuring

position. The protection cap cannot be removed in the measuring position. This

prevents the sensor from being removed.

Endress+Hauser 25

Page 26

Installation Cleanfit CPA875

1

2

3

5

6

7

Installation of 360 mm gel and KCL sensors with "Gel - KCl adapter"

A0030188

17 Sensor installation, Part 1

1 Open-ended wrench (AF 17/19 mm)

2 Protection cover

3 Dummy plug (protection cap)

5 Retraction pipe

6 Gel - KCl adapter

7 Lock nut

Gel sensors can be installed in this version. To install KCl sensors, you will need a "Gel

- KCl adapter".

Install the sensor as follows:

1. Remove the protection cap (→ 17, item 2) (this is possible only if the assembly is

in the service position).

2. Unscrew and remove the retraction pipe (pos. 5) (in an anticlockwise direction).

3. Turn the lock nut (pos. 7) on the "Gel - KCl adapter" (pos. 6) as far as it will go in an

upward direction.

4. Remove the yellow dummy plug (pos. 3).

5. Screw in the "Gel - KCl adapter" (item 6) in the place of the dummy plug and handtighten (3 NM (2.2 lbf ft)).

6. Hand-tighten the lock nut in a clockwise direction, and then use an open-ended

wrench (AF 24 mm) to tighten it by ¼ turn.

7. Screw the retraction pipe back in.

26 Endress+Hauser

Page 27

Cleanfit CPA875 Installation

4

1

2

8. Use the open-ended wrench (item 1) to screw in the sensor (→ 18, item 4) and

hand-tighten (3 Nm (2.2 lbf ft)).

9. Attach the open-ended wrench back into the protection cap.

10. Put the protection cap on the assembly. When doing so, guide the measuring cable

through the cable run (top of protection cap).

A0030189

18 Sensor installation, Part 2

1 Open-ended wrench

2 Protection cover

4 360 mm gel or KCl sensor

Always install the protection cap before moving the assembly to the measuring

position. The protection cap cannot be removed in the measuring position. This

prevents the sensor from being removed.

4.4 Post-installation check

• After installation, check the transmitter for damage.

• Check whether the transmitter is protected against moisture and direct sunlight (e.g. by

the weather protection cover).

Endress+Hauser 27

Page 28

Operation options Cleanfit CPA875

5 Operation options

5.1 Commissioning

Prior to initial commissioning, ensure that:

• all seals are correctly seated (on the assembly and on the process connection)

• the sensor is correctly installed and connected

• the water connection at the rinse connections is correct (if present).

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process

medium escapes.

Before subjecting the assembly to process pressure, verify that all connections are

‣

sealed!

Note that when moving the assembly, an open connection exists for a short period

between the process and service chamber. This intermediate position can be used for

what is known as "sealing water" or for the third rest position (see "Optional cleaning /

sterilization of process seal").

Install the service chamber connections accordingly.

28 Endress+Hauser

Page 29

Cleanfit CPA875 Operation options

3

8

6

5.2 Operating elements

A0023307

19 Position markings (service position)

Assembly with pneumatic drive

The assembly with pneumatic drive does not have any operating elements.

Assembly with manual drive

3 Manual drive

6 Unlocking button (service position)

8 Unlocking button (measuring position)

A0030299

20 Operating elements

Endress+Hauser 29

Page 30

Operation options Cleanfit CPA875

O

U

T

-

I

N

A

B

5.3 Manual operation

A0030330

21 Direction of rotation

A Unlocking button (service position)

B Unlocking button (measuring position)

Moving the assembly from the service position to the measuring position

1. Press the unlocking button (A).

2. Rotate the drive in a clockwise direction, so that the sensor holder enters the process

(this is possible only if a sensor is installed).

3. Rotate the drive until the lock engages.

Moving the assembly from the measuring position to the service position

1. Press the unlocking button (B).

2. Rotate the drive in an anti-clockwise direction as far as it will go (service position).

3. Perform the required service activities.

5.4 Pneumatic operation

The assembly can be moved only if a sensor is installed.

The operation of the pneumatic version depends on the controller in question. The

Operating Instructions can be found in the manual for the controller.

Use a pneumatic change-over valve (4/2-way valve) to move the assembly. Connect

both inputs. If you connect only one input (e.g. for test purposes), the piston will be

blocked, as the sensor guide moves before the limit position lock is deactivated.

30 Endress+Hauser

Page 31

Cleanfit CPA875 Operation options

1

2

3

4

5.4.1 Moving the assembly if the compressed air supply fails

A0030302

22 Failure of compressed air supply

1 Limit position lock for service position

2 Limit position lock for measuring position

3 Normal position (flat side is on left)

4 Position for optional sterilization of seal (flat side is on top)

CAUTION

L

Risk of injury due to high medium pressure

Depressurize the system

‣

If the compressed air supply fails, you can still move the assembly manually. Proceed as

follows here:

1. Use an open-ended wrench (AF 17 mm) to unscrew and remove both limit position

locks (items 1 and 2), and also remove the internal component. If the internal

component is stuck (if an attempt was made to move the assembly without

deactivating the limit position lock), move the assembly manually to the respective

limit position.

2. Move the assembly to the desired position.

3. Screw the limit position lock back in. (Only in the case of optional sterilization of the

process seal: Re-install the lock in the normal position (pos. 3)).

5.4.2 Optional cleaning/sterilization of process seal

With this version you can clean/sterilize the process seal (third rest position). Proceed as

follows here:

1. Move the assembly to the service position.

2. Use the open-ended wrench to rotate the pin for the limit position lock (→ 22,

item 1) from pos. 3 to pos. 4.

3. Move the assembly to the measuring position. The assembly now moves in the

direction of the measuring position and remains in the "third rest position". When

cleaning/sterilizing the service chamber, the process seal is now also cleaned/

sterilized.

Endress+Hauser 31

4. Following cleaning/sterilization, move the assembly to the service position.

5. Use the open-ended wrench to rotate the pin for the limit position lock from pos. 4 to

pos. 3.

You can now move the assembly to the measuring position and continue measuring.

Page 32

Maintenance Cleanfit CPA875

6 Maintenance

WARNING

L

Risk of injury if medium escapes

Before each maintenance task, ensure that the process pipe is empty and rinsed.

‣

Move the assembly to the "Service" position.

‣

The assembly drive is maintenance-free. It is not possible to carry out maintenance or

repair work on the drive.

6.1 Maintenance intervals

The specified intervals serve as a guide. For harsh process or ambient conditions, it is

recommended that the intervals be reduced accordingly. Cleaning intervals for the

sensor and assembly are dependent on the medium.

Interval Maintenance measures

Monthly

or after 500 strokes (whatever comes

first)

Biannually

or after 5000 strokes (whichever comes

first)

Biannually

or after 5000 strokes (whichever comes

first)

Check the following for leaks:

• rinse lines

• process connection

• compressed air hoses (pneumatic version).

Does medium escape from the leakage hole when the assembly is

moving? This may indicate that the internal O-rings in the service

chamber are defective or that the immersion tube O-rings in the

double-chamber assembly are defective.

Check the leakage hole in the service chamber.

‣

1. Remove the sensor and check the sensor for deposits.

2. If deposits are present, check the cleaning cycle (cleaning

agents, temperature, duration, flow volume).

When process pressure is applied and the rinse lines are detached,

there should be no discharge of medium from the assembly's rinse

connections.

Check for defective process seal(s).

‣

In addition:

Replace the seals that are in contact with medium.

‣

1. Check the locking mechanism is not blocked.

2. Remove the sensor.

The contact surface of the sensor in the assembly is

spring-loaded and must be free to move.

Possible cause of failure: Contamination inside the drive, e.g. caused

by a broken sensor.

32 Endress+Hauser

Page 33

Cleanfit CPA875 Maintenance

6.2 Cleaning the assembly

To ensure stable and reliable measurements, the assembly and the sensor must be cleaned

regularly. The frequency and intensity of the cleaning process depend on the medium.

6.2.1 Manually operated assembly

All parts in contact with the medium, such as the sensor and the sensor guide, must be

cleaned regularly. To do so, remove the sensor

• Remove light dirt and fouling with suitable cleaning solutions. (→ 34)

• High levels of contamination are removed using a soft brush and a suitable cleaning

agent.

• For very persistent dirt, soak the parts in a cleaning solution. Then clean the parts with a

brush.

A typical example of a cleaning interval would be 6 months in the case of drinking

water.

1)

.

6.2.2 Pneumatically controlled assembly

Regular, pneumatically controlled cleaning is possible using the rinse water connection

and the appropriate equipment.

6.3 Cleaning the sensor

Clean the ORP electrodes mechanically only and always use water. Never clean with

‣

chemical cleaning agents. Such cleaning agents cause a potential to build up at the

electrode which takes a few hours to dissipate. The potential causes errors in the

measurement.

Do not use abrasive cleaners. These can cause irreparable damage to the sensor.

‣

Where necessary, perform a new calibration following the cleaning process.

‣

You must clean the sensor:

• Before every calibration

• Regularly during operation

• Before returning it for repairs

You can remove the sensor and clean it manually, or you can clean it in automatic mode

using the rinse water connection.

2)

1) same as sensor installation, but in reverse order

2) only if the assembly is fitted out accordingly

Endress+Hauser 33

Page 34

Maintenance Cleanfit CPA875

6.4 Cleaning agent

The choice of cleaning agent depends on the degree and type of contamination. The most

common types of contamination and the appropriate cleaning agents can be found in the

following table.

Type of soiling Cleaning agent

Greases and oils Hot water or tempered, surfactant-containing (alkaline)

media

1)

or water-soluble, organic solvents (e.g.

ethanol)

Limescale deposits, metal

Approx. 3% hydrochloric acid

hydroxide buildup, lyophobic

biological buildup

Sulfide deposits Mixture of 3% hydrochloric acid and thiocarbamide

(commercially available)

Protein buildup Mixture of 3% hydrochloric acid and pepsin

(commercially available)

Fibers, suspended substances Pressurized water, possibly surface-active agents

Light biological buildup Pressurized water

1) Do not use with the Tophit ISFET sensor! Instead, use commercially available acid cleaners for the food

industry (e.g. P3-horolith CIP, P3-horolith FL, P3-oxonia active).

NOTICE

Health hazard due to solvents

Do not use any halogen-containing, organic solvents or acetone. These solvents may

‣

destroy plastic components of the sensor and are also suspected carcinogens (e.g.

chloroform).

34 Endress+Hauser

Page 35

Cleanfit CPA875 Maintenance

6.5 Replacing seals

To replace the seals in the assembly, you must interrupt the process and remove the

assembly completely.

CAUTION

L

Risk of injury due to residual medium and elevated temperatures

When handling parts that are in contact with the medium, protect yourself from

‣

residual medium and elevated temperatures. Wear protective goggles and safety

gloves.

Clean the assembly before replacing the seals. (→ 33)

‣

Preparation:

1. Interrupt the process. Pay attention to residual medium, residual pressure as well as

elevated temperatures.

2. Move the assembly to the service position.

3. Completely detach the assembly from the process connection.

4. Clean the assembly. (→ 33)

The following sections describe how to replace the seals. The following table serves as a

guide to the relevant sections.

A0023215 A0023216

A0023214 A0023213 A0023212

Molded seal process connection

(A)

O-rings - single

chamber (B)

Molded seal process

connection, double

chamber (C)

Molded seal front chamber (D)

Seals - inner

double chamber

(E)

Endress+Hauser 35

Page 36

Maintenance Cleanfit CPA875

5

8

2

3

4

6.5.1 Molded seal - process connection (A)

A0030357

23 Replacing seals, Part 1

1 Fixing screws

1. Release the four securing screws (, pos. 1).

24 Replacing seals, Part 2

2 Process connection

3 Sealing disk

4 Service chamber

5 Molded seal

6 Immersion tube

2. Remove the process connection (pos. 2).

3. Remove the molded seal (item 5) from the process connection.

4. Apply a thin layer of grease to the new molded seal (e.g. Klüber Paraliq GTE 703).

5. Slide the molded seal over the immersion tube (pos. 8) and into the guide groove of

the service chamber. Ensure that the molded seal is seated correctly.

6. Position the gasket (pos. 3) on the service chamber.

7. Place the process connection on the service chamber.

8. Tighten the four securing screws with a torque of 4 Nm.

36 Endress+Hauser

A0030365

Page 37

Cleanfit CPA875 Maintenance

1

2

3

4

5

6

7

4

8

9

6.5.2 O-rings - single chamber (B)

O-rings

A0030356

25 Replacing seals, Part 1

1 Fixing screws

1. Release the four securing screws.

2. Remove the service chamber (pos. 3) together with the process connection (pos. 2).

2

Process connection

3

Service chamber

4

O-rings (inner service chamber)

5

Molded seal

6

Positioning pin

7

O-ring (top of service chamber) (pneumatic drive

only)

8

Slide bushing (pneumatic drive only)

9

Leakage hole

A0030364

26 Replacing seals, Part 2

3. Use a tweezers to remove both o-rings (pos. 4) from the service chamber.

4. Pneumatic drive only: Use a thin screwdriver to push through the leakage hole (item

9). This pushes the slide bushing (item 8) out of the guide groove. You can now

remove the slide bushing using a tweezers.

5. Apply a thin layer of grease (e.g. Klüber Paraliq GTE 703) to the new O-rings and the

new slide bushing.

6. Pneumatic drive only: Insert the slide bushing into the middle guide groove.

7. Place both O-rings into the appropriate grooves in the service chamber.

Molded seal

1. Remove the molded seal (→ 26, 37 item 5) using a tweezers or long-nosed

pliers.

Endress+Hauser 37

Page 38

Maintenance Cleanfit CPA875

2. Apply a thin layer of grease to the molded seal and press the molded seal into the

guide groove of the immersion tube. Ensure that the molded seal is seated correctly.

If you insert a dummy sensor or circular rod (Ø 12 mm) until it protrudes just above

the seal, the molded seal cannot move upwards while it is being inserted.

Pneumatic drive

Pneumatic drive only:

1. Remove the O-ring (→ 26, 37 item 7). Apply a thin layer of grease to the new

o-ring, and position the o-ring in the guide groove.

2. Apply a thin layer of grease to the molded seal and press the molded seal into the

guide groove of the immersion tube. Ensure that the molded seal is seated correctly.

3. Mount the service chamber together with the process connection onto the assembly.

Pay attention to the positioning pin (item 6).

4. Tighten the four securing screws with a torque of 4 Nm.

38 Endress+Hauser

Page 39

Cleanfit CPA875 Maintenance

1

1

6.5.3 Molded seal - process connection, double chamber (C)

A0030358

27 Replacing seals, Part 1

1 Fixing screws

1. Release the four securing screws (, pos. 1).

A0030359

28 Replacing seals, Part 2

2 Process connection

3 Sealing disk

4 Molded seal

8 Immersion tube

2. Remove the process connection (pos. 2).

3. Remove the molded seal (pos. 4) from the process connection

4. Apply a thin layer of grease to the new molded seal (e.g. Klüber Paraliq GTE 703).

5. Slide the molded seal over the immersion tube (pos. 8) and into the guide groove of

the service chamber. Ensure that the molded seal is seated correctly.

6. Position the gasket (pos. 3) on the rinse chamber.

7. Place the process connection on the "inner" service chamber.

8. Tighten the four securing screws with a torque of 4 Nm.

Endress+Hauser 39

Page 40

Maintenance Cleanfit CPA875

1

2

3

5

8

6.5.4 Molded seal - "front" service chamber (D)

A0030360

29 Replacing seals, Part 1

1 Fixing screws

1. Release the four securing screws (item 1).

30 Replacing seals, Part 2

2 "Front" service chamber with process connection

3 Sealing disk

5 Molded seal

8 Immersion tube

A0030366

2. Remove the "front" service chamber together with the process connection (item 2).

3. Remove the molded seal (item 5) from the "front" chamber.

4. Apply a thin layer of grease to the new molded seal (e.g. Klüber Paraliq GTE 703).

5. Slide the molded seal over the immersion tube (pos. 8) and into the guide groove of

the service chamber. Ensure that the molded seal is seated correctly.

6. Position the gasket (pos. 3) on the front chamber.

7. Place the front chamber together with the process connection on the "inner" service

chamber.

40 Endress+Hauser

Page 41

Cleanfit CPA875 Maintenance

8. Tighten the four securing screws with a torque of 4 Nm.

Endress+Hauser 41

Page 42

Maintenance Cleanfit CPA875

1

1

2

3

2

6

6.5.5 Seals - inner double chamber (E)

O-ring in process connection

A0030361

31 Replacing seals, Part 1

1 Fixing screws

2 Service chamber with front chamber and process connection

1. Release the four securing screws (item 1).

2. Remove the service chamber with front chamber and process connection (pos. 2).

A0030363

32 Replacing seals, Part 2

2 "Inner" service chamber with "front" service chamber and process connection

3 O-ring

6 Positioning pin

3. Remove the O-ring (item 3).

4. Apply a thin layer of grease to the new o-ring (e.g Klüber Paraliq GTE 703) and

position the o-ring in the groove.

42 Endress+Hauser

Page 43

Cleanfit CPA875 Maintenance

4

5

Molded seal

A0030362

33 Replacing seals, Part 3

4 O-rings

5 Molded seal

1. Remove the molded seal (pos. 5) using a tweezers or long-nose pliers.

2. Apply a thin layer of grease to the new molded seal (e.g. Klüber Paraliq GTE 703).

3. Press the molded seal into the guide groove of the immersion tube. Ensure that the

molded seal is seated correctly.

If you insert a dummy sensor or circular rod (Ø 12 mm) until it protrudes just above

the seal, the molded seal cannot move upwards while it is being inserted.

O-rings in the immersion tube

1. Remove both O-rings (→ 33, 43 item 4).

2. Apply a thin layer of grease to the new o-rings, and position the o-rings in both

grooves.

3. Place the "inner" service chamber together with the "front" service chamber and

process connection on the assembly (pay attention to the positioning pin (item 6).

4. Tighten the four securing screws with a torque of 4 Nm.

Endress+Hauser 43

Page 44

Repairs Cleanfit CPA875

7 Repairs

WARNING

L

Danger resulting from improper repair

Damage to the assembly, which compromises pressure safety, must be repaired only by

‣

authorized and qualified personnel.

Damage to the drive can be repaired only at the place of manufacture. Repairs cannot

‣

be carried out onsite.

Following each repair and maintenance task, the assembly must be checked for leaks

‣

using appropriate procedures. Following this, the assembly must again comply with the

specifications in the technical data.

Replace all other damaged components immediately.

7.1 Spare parts

For more detailed information on spare parts kits, please refer to the "Spare Part Finding

Tool" on the Internet:

www.endress.com/spareparts_consumables

7.2 Return

The product must be returned if repairs or a factory calibration are required, or if the

wrong product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure swift, safe and professional device returns, please read the return procedures

and conditions at www.endress.com/support/return-material.

7.3 Disposal

The device contains electronic components and must therefore be disposed of in

accordance with regulations on the disposal of electronic waste.

Observe the local regulations.

44 Endress+Hauser

Page 45

Cleanfit CPA875 Accessories

G 1¼

12

Ø 42

Ø 25

Ø 25

12

Ø 42

G 1¼

15°

35 (1.38)

(1.65)

(0.98)

(0.47)

(1.65)

(0.98)

(0.47)

35 (1.38)

20

(0.79)

23.5

(0.93)

35

(1.38)

20

(0.79)

23.5

(0.93)

35

(1.38)

8 Accessories

The following are the most important accessories available at the time this

documentation was issued. For accessories not listed here, please contact your service

or sales office.

The following accessories can be ordered via the product structure (see ordering

information):

• Weld-in adapter G1¼, straight, 35 mm, 1.4435 (AISI 316 L), safety nozzle

• Weld-in adapter G1¼, angled, 35 mm, 1.4435 (AISI 316 L), safety nozzle

34 Weld-in adapter (safety nozzle), dimensions in mm (inch)

• Dummy plug G1¼, 1.4435 (AISI 316 L), FPM - FDA

• Sensor dummy 225 mm, 1.4435 (AISI 316 L), Ra = 0.38 µm

• Sensor dummy 360 mm, 1.4435 (AISI 316 L), Ra = 0.38 µm

• Kit, EPDM FDA seals only for process connection G1¼, wetted parts, single chamber

• Kit, FKM FDA seals only for process connection G1¼, wetted parts, single chamber

• Kit, FFKM FDA seals only for process connection G1¼, wetted parts, single chamber

• Kit, EPDM FDA seals, wetted parts, single chamber, not for process connection G1¼

• Kit, FKM FDA seals, wetted parts, single chamber, not for process connection G1¼

• Kit, FFKM FDA seals, wetted parts, single chamber, not for process connection G1¼

• Kit, EPDM FDA seals, wetted parts, double chamber, all process connections

• Kit, FKM FDA seals, wetted parts, double chamber, all process connections

• Kit, FFKM FDA seals, wetted parts, double chamber, all process connections

• Kit, seals not in contact with the medium

• Cable, plug-in, limit switch, M12, 5 m

• Cable, plug-in, limit switch, M12, 10 m

• Tool in case for installation/removal

A0028744

Endress+Hauser 45

Page 46

Accessories Cleanfit CPA875

8.1 Installation material for rinse connections

Filter set CPC310, CVC400

• Water filter (dirt trap) 100 µm, complete, incl. angle bracket

• Order No. 71031661

Pressure reducer kit

• Complete, incl. manometer and angle bracket

• Order No. 51505755

Hose connection set G¼, DN 12

• 1.4404 (AISI 316L) 2 x

• Order No. 51502808

Hose connection set G¼, DN 12

• PVDF (2 x)

• Order No. 50090491

46 Endress+Hauser

Page 47

Cleanfit CPA875 Accessories

8.2 Sensors

8.2.1 pH sensors

Orbisint CPS11D / CPS11

• pH electrode for process technology

• Optional SIL version for connecting to SIL transmitter

• With dirt-repellent PTFE diaphragm

• Product Configurator on the product page: www.endress.com/cps11d or

www.endress.com/cps11

Technical Information TI00028C

Memosens CPS31D

• pH electrode with gel-filled reference system with ceramic diaphragm

• Product Configurator on the product page: www.endress.com/cps31d

Technical Information TI00030C

Ceraliquid CPS41D / CPS41

• pH electrode with ceramic junction and KCl liquid electrolyte

• Product Configurator on the product page: www.endress.com/cps41d or

www.endress.com/cps41

Technical Information TI00079C

Ceragel CPS71D / CPS71

• pH electrode with reference system including ion trap

• Product Configurator on the product page: www.endress.com/cps71d or

www.endress.com/cps71

Technical Information TI00245C

Orbipore CPS91D / CPS91

• pH electrode with open aperture for media with high dirt load

• Product Configurator on the product page: www.endress.com/cps91d or

www.endress.com/cps91

Technical Information TI00375C

8.2.2 ORP sensors

Orbisint CPS12D / CPS12

• ORP sensor for process technology

• Product Configurator on the product page: www.endress.com/cps12d or

www.endress.com/cps12

Technical Information TI00367C

Ceraliquid CPS42D / CPS42

• ORP electrode with ceramic junction and KCl liquid electrolyte

• Product Configurator on the product page: www.endress.com/cps42d or

www.endress.com/cps42

Technical Information TI00373C

Ceragel CPS72D / CPS72

• ORP electrode with reference system including ion trap

• Product Configurator on the product page: www.endress.com/cps72d or

www.endress.com/cps72

Technical Information TI00374C

Endress+Hauser 47

Page 48

Accessories Cleanfit CPA875

8.2.3 pH ISFET sensors

Tophit CPS441D / CPS441

• Sterilizable ISFET sensor for low-conductivity media

• Liquid KCl electrolyte

• Product Configurator on the product page: www.endress.com/cps441d or

www.endress.com/cps441

Technical Information TI00352C

Tophit CPS471D / CPS471

• Sterilizable and autoclavable ISFET sensor for food and pharmaceutics, process

engineering

• Water treatment and biotechnology

• Product Configurator on the product page: www.endress.com/cps471d or

www.endress.com/cps471

Technical Information TI00283C

Tophit CPS491D / CPS491

• ISFET sensor with open aperture for media with high dirt load

• Product Configurator on the product page: www.endress.com/cps491d or

www.endress.com/cps491

Technical Information TI00377C

8.2.4 pH and ORP combined sensors

Memosens CPS16D

• Combined pH/ORP sensor for process technology

• With dirt-repellent PTFE diaphragm

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cps16D

Technical Information TI00503C

Memosens CPS76D

• Combined pH/ORP sensor for process technology

• Hygienic and sterile applications

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cps76d

Technical Information TI00506C

Memosens CPS96D

• Combined pH/ORP sensor for chemical processes

• With poison-resistant reference with ion trap

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cps96d

Technical Information TI00507C

8.2.5 Conductivity sensors

Memosens CLS82D

• Four-electrode sensor

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cls82d

Technical Information TI01188C

48 Endress+Hauser

Page 49

Cleanfit CPA875 Accessories

8.2.6 Oxygen sensors

Oxymax COS22D / COS22

• Sterilizable sensor for dissolved oxygen

• With Memosens technology or as an analog sensor

• Product Configurator on the product page: www.endress.com/cos22d or

www.endress.com/cos22

Technical Information TI00446C

Endress+Hauser 49

Page 50

Technical data Cleanfit CPA875

p [bar]

T[°C]

20 8060

40

T[°F]

p [psi]

0

32

0

0

16232

100 120 140

68 104 140 176

212

248 284

A

B

9 Technical data

9.1 Environment

Ambient temperature

-10 to +70 °C (+10 to +160 °F)

range

Storage temperature -10 to +70 °C (+10 to +160 °F)

9.2 Process

Process temperature -10 to 140 °C (14 to 284 °F)

Process pressure Pneumatic drive 16 bar (232 psi) up to 140 °C (284 °F)

Manual drive 8 bar (116 psi) up to 140 °C (284 °F)

The service life of the seals is reduced if process temperatures are constantly high or if

SIP is used. The other process conditions may also reduce the service life of the seals.

Pressure-temperature ratings

35 Pressure-temperature ratings for pneumatic drive

A Dynamic range

B Static range

50 Endress+Hauser

A0029360-EN

Page 51

Cleanfit CPA875 Technical data

p [bar]

T[°C]

20 8060

40

T[°F]

p [psi]

0

32

0

0

8

100 120 140

68 104 140 176

212

248 284

A

B

A0029361-EN

36 Pressure-temperature ratings for manual drive

A Dynamic range

B Static range

Endress+Hauser 51

Page 52

Technical data Cleanfit CPA875

9.3 Mechanical construction

Design, dimensions → Section "Installation"

Weight

Materials

Depends on version:

Pneumatic drive: 3.8 to 6 kg (8.4 to 13.2 lbs) depending on version

Manual drive: 3 to 4.5 kg (6.6 to 9.9 lbs) depending on version

In contact with medium

Seals: EPDM-FDA (USP Class VI) / FKM-FDA (USP Class VI) /

FFKM-FDA (USP Class VI)

Immersion tube: Stainless steel 1.4435 (AISI 316L) Ra < 0.76 / Ra < 0.38

Process connection, service

chamber

Rinse connections: Stainless steel 1.4435 (AISI 316L)

Not in contact with medium

Manual drive: Stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316L), plastics PPS

CF15, PBT, PP

Pneumatic drive: Stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316L), plastics PBT,

PP

Stainless steel 1.4435 (AISI 316L) Ra < 0.76

Sensors

Limit position switches Switching element function: NAMUR NC contact (inductive)

Short version Gel sensors, ISFET 225 mm

KCl sensors 225 mm

Long version Gel sensors, ISFET 225 mm

Gel sensors, ISFET 360 mm

KCl sensors 360 mm

Switching distance: 1,5 mm (0.06 ")

Nominal voltage: 8 V

Switching frequency: 0 to 5000 Hz

Housing material: Stainless steel

52 Endress+Hauser

Page 53

Index

Index

A

Accessories ................................ 45

Approvals .................................. 9

C

Certificates ................................. 9

Cleaning .................................. 33

Cleaning agent ............................. 34

Cleaning process seal .........................31

Connection

Pneumatics ............................. 19

D

Designated use .............................. 5

Dimensions ................................11

Disposal .................................. 44

F

Failure of compressed air supply ................ 31

I

Immersion depths ........................... 14

Incoming acceptance .......................... 7

Installation ............................. 10, 16

Installation conditions ........................ 10

Installing the sensor ......................... 23

S

Safety instructions ............................5

Scope of delivery ............................. 7

Seals .....................................35

Spare parts ................................ 44

Symbols ................................... 4

T

Technical data ..............................50

U

Use .......................................5

W

Warnings .................................. 4

L

Limit position switches ....................... 21

M

Maintenance ...............................32

Maintenance intervals ........................32

Manual operation ........................... 30

Measuring system ........................... 16

N

Nameplate ................................. 8

O

O-rings ................................... 35

Operating elements ..........................29

Operation ................................. 28

Manual ................................ 30

Pneumatic: ..............................30

P

Pneumatic connection ........................ 19

Pneumatic operation ......................... 30

Post-installation check ....................... 27

Product identification ......................... 7

R

Repairs ................................... 44

Return ................................... 44

Rinse connections ........................... 20

Endress+Hauser 53

Page 54

Page 55

Page 56

*71324469*

71324469

www.addresses.endress.com

Loading...

Loading...