Endress+Hauser CPA442 Operating Manual

BA01166C/07/EN/01.13

71202122

Products Solutions Services

Operating Instructions

Unifit CPA442

Process assembly

Document information

DANGER

!

WARNING

!

CAUTION

!

NOTICE

Warning notices

The structure, signal words and safety colors of the warning notices comply with the

specifications of ANSI Z535.6 ("Product safety information in product manuals, instructions

and other collateral materials").

Safety message structure Meaning

This symbol alerts you to a dangerous situation.

Causes (/consequences)

Consequences of noncompliance (if applicable)

‣ Corrective action

Causes (/consequences)

Consequences of noncompliance (if applicable)

‣ Corrective action

Causes (/consequences)

Consequences of noncompliance (if applicable)

‣ Corrective action

Failure to avoid the situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more

serious injuries.

Cause/situation

Consequences of noncompliance (if applicable)

‣ Action/note

Symbols used

Additional information, tips

Permitted or recommended

Forbidden or not recommended

This symbol alerts you to situations that can result in

damage to property and equipment.

Endress+Hauser

Unifit CPA442

Table of contents

1 Basic safety instructions . . . . . . . . . . . . . 4

1.1 Requirements for personnel . . . . . . . . . . . . . . . . . . 4

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Workplace safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Post-installation check . . . . . . . . . . . . . . . . . . . . . 11

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Cleaning the assembly . . . . . . . . . . . . . . . . . . . . . 12

4.2 Cleaning agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Leak monitoring (optional) . . . . . . . . . . . . . . . . . 13

4.4 Replacing the seals . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Replacing damaged parts . . . . . . . . . . . . . . . . . . . 15

5.2 Spare parts kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Accessories . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Installation accessories . . . . . . . . . . . . . . . . . . . . . 17

6.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Technical data . . . . . . . . . . . . . . . . . . . .20

7.1 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3 Mechanical construction . . . . . . . . . . . . . . . . . . . 21

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Endress+Hauser 3

Basic safety instructions Unifit CPA442

1 Basic safety instructions

1.1 Requirements for personnel

Installation, commissioning, operation and maintenance of the measuring system must

‣

only be carried out by specially trained technical personnel.

‣ The technical personnel must be authorized to perform such tasks by the owner-

operator.

‣ The electrical connection must only be performed by an electrical technician.

‣ Technical personnel must have read and understood these Operating Instructions and

must adhere to them.

‣ Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions supplied may only be carried out

directly at the manufacturer’s or by the service organization.

1.2 Designated use

The Unifit CPA442 process assembly is designed for the installation of 12 mm sensors in

tanks, bio-reactors and pipelines.

Thanks to its mechanical construction, operation in pressurized systems is possible (see

"Technical data").

Any use other than the one described here compromises the safety of persons and the entire

measuring system and is not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Explosion protection guidelines (only devices approved for use in explosion hazardous

areas)

• Installation specifications

• Local standards and regulations

1.4 Operational safety

Before commissioning the entire measuring point, make sure all the connections are

‣

correct. Ensure that electrical cables and hose connections are not damaged.

‣ Do not operate damaged products, and secure them against unintentional

commissioning. Mark the damaged product as defective.

‣ If faults cannot be rectified, the products must be taken out of service and secured against

unintentional commissioning.

1.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested and

left the factory in a condition in which it is safe to operate.

The applicable regulations and European standards have been considered.

4 Endress+Hauser

Unifit CPA442 Incoming acceptance and product identification

2 Incoming acceptance and product

identification

2.1 Incoming acceptance

• Make sure the packaging is undamaged!

• Inform the supplier about damage to the packaging. Keep the damaged packaging until

the matter has been settled.

• Make sure the contents are undamaged!

• Inform the supplier about damage to the delivery contents. Keep the damaged products

until the matter has been settled.

• Check the delivery to make sure nothing is missing. Compare it against the shipping

documents and your order.

• Pack the product for storage and transportation in such a way that it is reliably protected

against impact and moisture. The original packaging provides optimum protection.

Furthermore, the permitted ambient conditions must also be observed (see "Technical

data").

• If you have any questions, contact your supplier or your local sales center.

2.2 Product identification

2.2.1 Nameplate

The nameplate contains the following information:

• Manufacturer data

•Order code

• Extended order code

• Serial number

• Operating conditions

•Safety symbols

Compare the order code indicated on the nameplate with your order.

2.2.2 Identifying the product

The order code and serial number of your device can be found in the following locations:

•On the nameplate

• In the shipping documents

To discover what product version you have, enter the order code on the nameplate into

the search screen at the following address:

www.products.endress.com/order-ident

2.3 Scope of delivery

The scope of delivery comprises:

• Ordered assembly version

• Operating Instructions, English

• Process seal for process connections A, B, M and N

If you have any questions, contact your supplier or your local sales center.

Endress+Hauser 5

Installation Unifit CPA442

15°

15°

A B

10°

10°

C

3Installation

3.1 Installation conditions

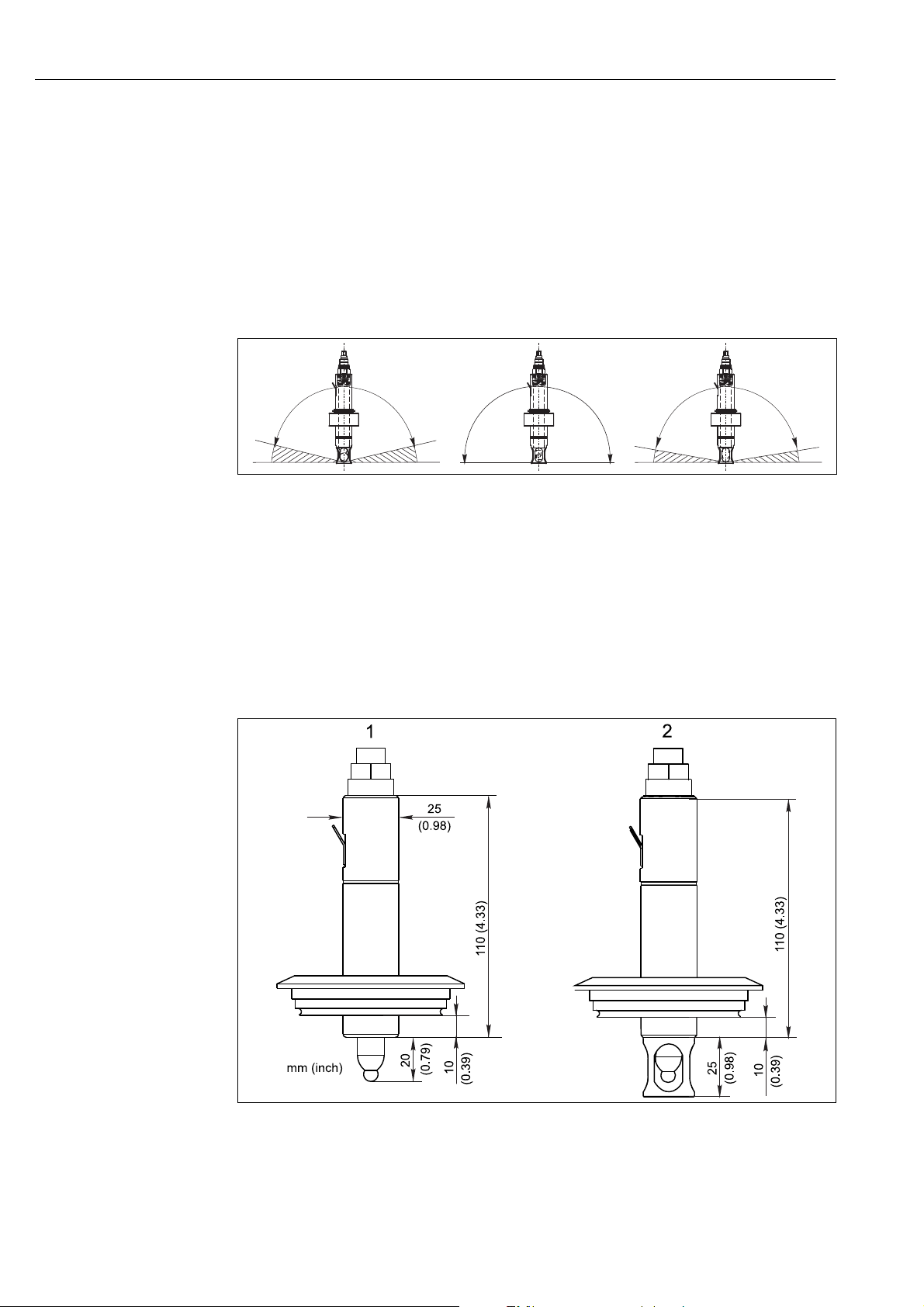

3.1.1 Installation angle

A

Glass sensor:

B

ISFET pH sensor:

C

Oxygen sensor:

Fig. 1: Permitted installation angles depending on the sensor

Installation angle of at least 15° from the horizontal

No restrictions, recommended 0 ... 180°

Installation angle of at least 10° from the horizontal

a0001792

• The assembly can only be installed when the tank is empty and the process is

unpressurized.

• The assembly is designed for mounting on tanks and pipes. Suitable sockets must be

available for this.

• The mounting seal that seals the adapter from the process socket must be provided by the

customer (except for versions A, B, M and N, DN 25 Standard and DN 25 B.Braun Port).

3.1.2 Dimensions

Fig. 2: Dimensions (1 = version G, 2 = Varivent)

1 Without sensor protection guard

2 With sensor protection guard

6 Endress+Hauser

a0019357

Unifit CPA442 Installation

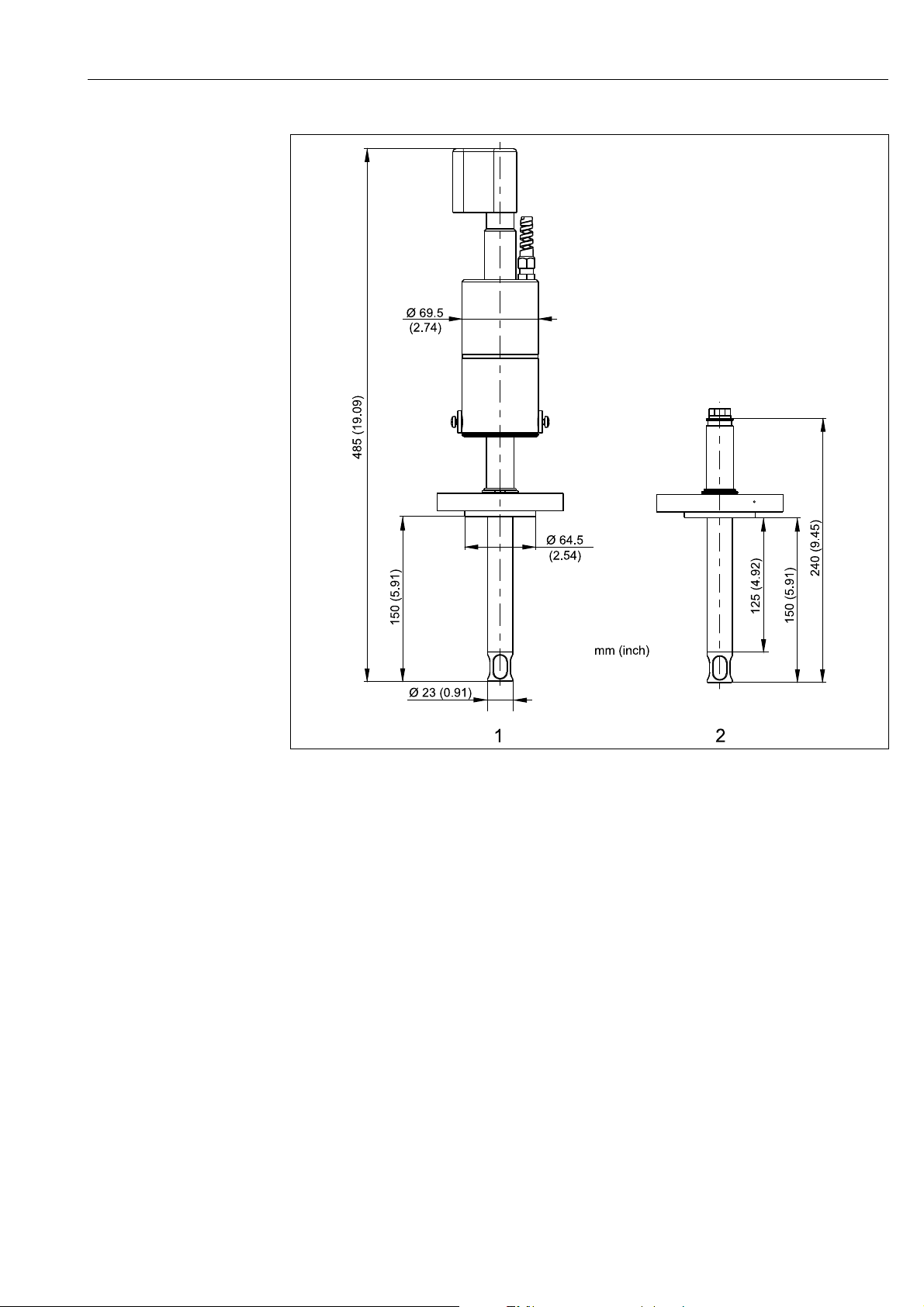

Fig. 3: Dimensions (version V, flange)

1 With sensor protection cover

2 Without sensor protection cover

a0019353

Endress+Hauser 7

Installation Unifit CPA442

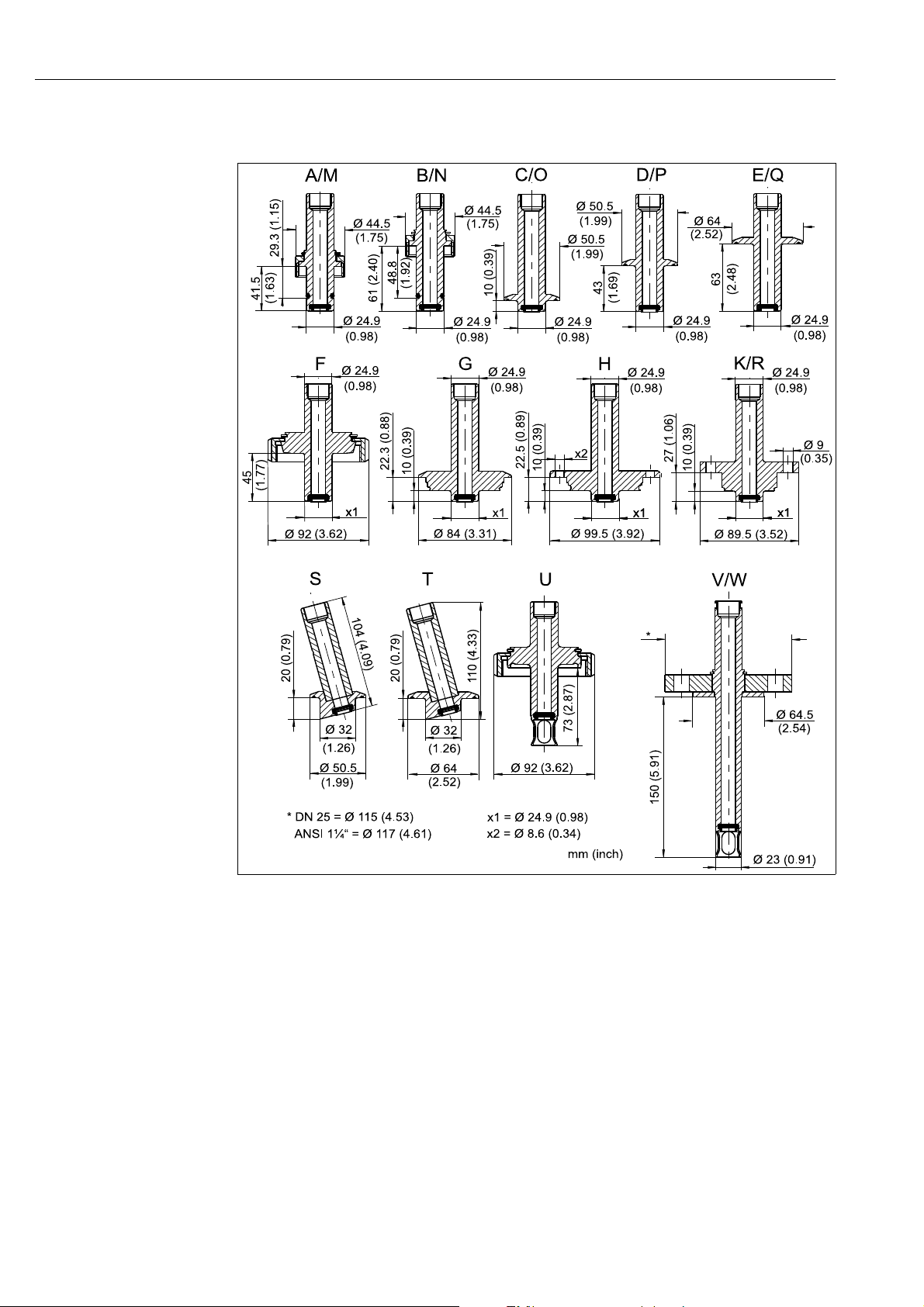

3.1.3 Process connections

a0019356

Fig. 4: Process connections

DN 25 standard / 41.5 mm (1.6" ) / without PM

DN 25 standard / 41.5 mm (1.6" ) / with PM

A

DN 25 B.Braun port / 61 mm (2.4" ) / with PM

B

Clamp 1.5" / 10 mm (0.4" ) / with PM

C

Clamp 1.5" / 43 mm (1.7") / with PM

D

Clamp 2" / 63 mm (2.5" ) / with PM

E

Dairy fitting DN 50 DIN 11851 / 45 mm (1.8") / with

F

PM

Varivent DN 40-125 / 10 mm (0.4" ) / with PM

G

APV DN 40-100 / 10 mm (0.4") / with PM

H

Neumo BioControl D 50 / 10 mm (0.4") / with PM

K

M

DN 25 B.Braun port / 61 mm (2.4" ) / without PM

N

Clamp 1.5" / 10 mm (0.4" ) / without PM

O

Clamp 1.5" / 43 mm (1.7") / without PM

P

Clamp 2" / 63 mm (2.5" ) / without PM

Q

Neumo BioControl D 50 / 10 mm (0.4") / without

R

PM

S

Clamp 1.5" angular 15° / 20 mm (0.8") / without PM

T

Clamp 2" angular 15° / 20 mm (0.8") / without PM

U

DIN 11864-1-A / aseptic DN 50 / without PM

V

Flange DN 25 / 150 mm (5.9") / without PM

W

Flange ANSI 150 lbs 1¼" / 150 mm (5.9") / without

PM

8 Endress+Hauser

Loading...

Loading...