Page 1

BA00178C/07/EN/13.18

71436282

2018-08-31

Products Solutions Services

Operating Instructions

Dipfit CPA140

Immersion assembly for pH or ORP sensors

Page 2

Page 3

Dipfit CPA140 Table of contents

Table of contents

1 About this document ................ 4

1.1 Warnings ............................ 4

1.2 Symbols used .......................... 4

1.3 Symbols on the device ................... 4

2 Basic safety instructions ............ 5

2.1 Requirements for the personnel ............ 5

2.2 Designated use ........................ 5

2.3 Workplace safety ....................... 5

2.4 Operational safety ...................... 6

2.5 Product safety ......................... 6

3 Product description ................. 7

3.1 PVDF version .......................... 7

3.2 Stainless steel version ................... 8

4 Incoming acceptance and product

identification ....................... 9

4.1 Incoming acceptance .................... 9

4.2 Scope of delivery ....................... 9

4.3 Product identification .................... 9

Index .................................. 29

5 Installation ....................... 11

5.1 Installation conditions .................. 11

5.2 Mounting the sensor ................... 15

5.3 Mounting the assembly in the process ...... 18

5.4 Post-installation check .................. 18

6 Maintenance ...................... 19

6.1 Cleaning the assembly .................. 19

6.2 Cleaning agent ....................... 19

6.3 Replacing the seal ..................... 20

6.4 Replacing the GORE-TEX® filter ........... 22

7 Repair ............................ 24

7.1 Spare parts .......................... 24

7.2 Return .............................. 24

7.3 Disposal ............................ 24

8 Accessories ....................... 25

8.1 Sensors (selection) ..................... 25

8.2 Measuring cable ...................... 26

8.3 KCl supply vessel ...................... 26

8.4 Cleaning ............................ 26

9 Technical data .................... 27

9.1 Environment ......................... 27

9.2 Process ............................. 27

9.3 Mechanical construction ................ 27

Endress+Hauser 3

Page 4

About this document Dipfit CPA140

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

4 Endress+Hauser

Page 5

Dipfit CPA140 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The assembly is designed for the installation of pH, ORP, oxygen and temperature sensors

in vessels.

The main areas of application involve pH, oxygen or ORP measurement in the following

processes:

• Chemical industry, e.g. in

• production of synthetic materials and dyes

• production or pesticides and fertilizers

• oil or wastewater separation

• condensate treatment

• Power stations and incinerator plants, e.g. in

• cooling water monitoring

• flue gas cleaning

• Metal extraction and metal processing

Thanks to its design, it can be operated in pressurized systems (→ 27).

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

2.3.1 General notes

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

2.3.2 Notes on installation in pressurized systems

Risk of injury from high pressure, high temperature or chemical hazards if process medium

escapes!

Do not exceed the permitted maximum process pressure.

‣

Prior to installing and removing the assembly, depressurize the system.

‣

Check glands and lines regularly for leaks and damage.

‣

Endress+Hauser 5

Page 6

Basic safety instructions Dipfit CPA140

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

6 Endress+Hauser

Page 7

Dipfit CPA140 Product description

2

3

4

5

1

6

7

8

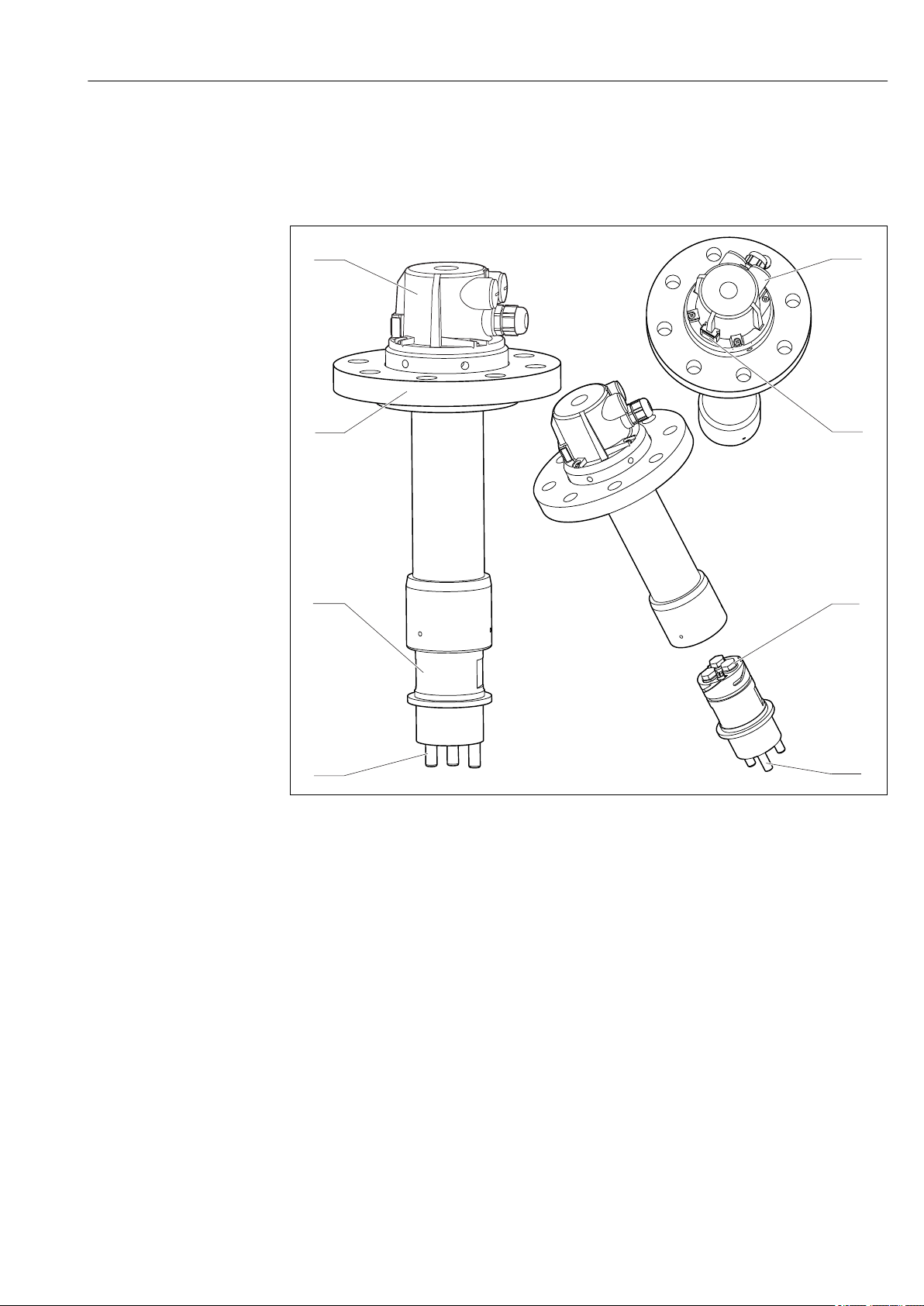

3 Product description

3.1 PVDF version

1 PVDF version

1 Assembly head

2 Cable gland Pg 13.5 and 2x dummy plug Pg 16

3 GORE-TEX® filter

4 3 sensor slots for 120 mm sensors

5 Potential matching pin

6 Shock-protection stud

7 Sensor holder with bayonet lock

8 Lap joint flange, depending on version

A0037531

Endress+Hauser 7

Page 8

Product description Dipfit CPA140

2

3

4

5

1

6

7

8

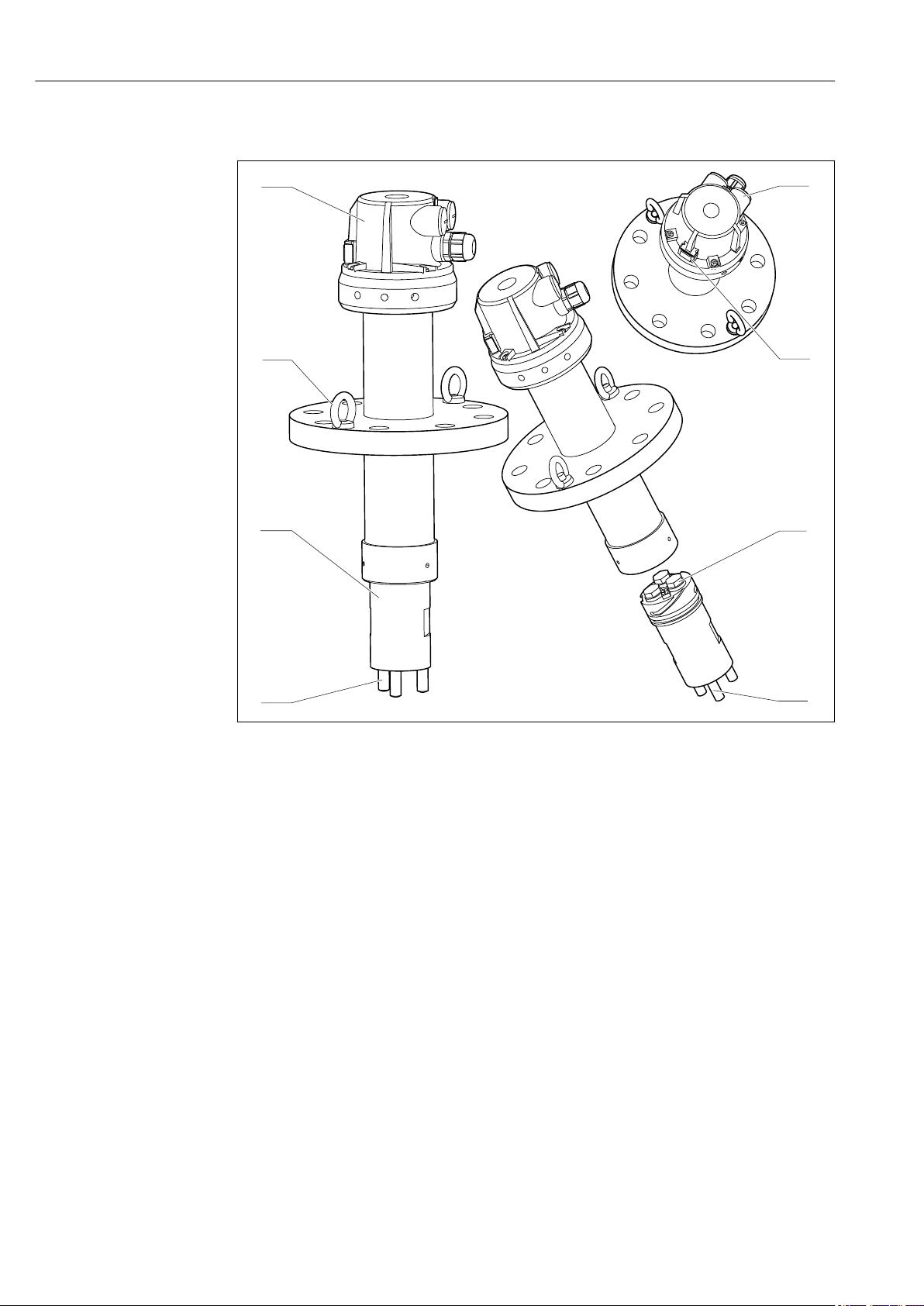

3.2 Stainless steel version

A0037532

2 Stainless steel version

1 Assembly head

2 Cable gland Pg 13.5 and 2x dummy plug Pg 16

3 GORE-TEX® filter

4 3 sensor slots for 120 mm sensors

5 Potential matching pin

6 Shock-protection stud

7 Sensor holder with bayonet lock

8 Installation aids (screw-in lifting eyes) and fixed flange, depending on the version

8 Endress+Hauser

Page 9

Dipfit CPA140 Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Scope of delivery

The scope of delivery comprises:

• Ordered version of assembly

• Operating Instructions

4.3 Product identification

4.3.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.3.2 Product identification

Product page

www.endress.com/cpa140

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Dipfit CPA140

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

4.3.3 Certificates and approvals

Pressure Equipment Directive 2014/68/EU

The assembly has been manufactured according to good engineering practice as per Article

4, Paragraph 3 of the Pressure Equipment Directive 2014/68/EU and is therefore not

required to bear the CE label.

Inspection certificate

A test certificate 3.1 in accordance with EN 10204 is supplied depending on the version (→

Product Configurator on the product page).

4.3.4 Manufacturer's address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

10 Endress+Hauser

Page 11

Dipfit CPA140 Installation

b

c

d

e

a

b

c

d

e

a

A B

5 Installation

5.1 Installation conditions

5.1.1 Dimensions

3 Flange dimensions, → Table

A Stainless steel version

B PVDF version

Stainless steel assembly version PVDF assembly version

DN80 PN16 ANSI 3"

150 lbs

a [mm (in)] 18 (0.71) 19 (0.75) 19 (0.75) 18 (0.71) 19 (0.75) 19 (0.75)

b [mm (in)] 20 (0.79) 23.8 (0.94) 18 (0.71) 22 (0.87) 22 (0.87) 18 (0.71)

c [mm (in)] 63.5 (2.50) 63.5 (2.50) 63.5 (2.50) 110 (4.33) 110 (4.33) 110 (4.33)

d [mm (in)] 160 (6.30) 152.4 (6.00) 150 (5.91) 160 (6.30) 152 (5.98) 150 (5.91)

e [mm (in)] 200 (7.87) 190.5 (7.50) 185 (7.28) 200 (7.87) 200 (7.87) 185 (7.28)

Screws M16 M16 M16 M16 M16 M16

Bore holes 8 4 4 8 4 4

JIS 10K 80A DN80 PN16 ANSI 3"

150 lbs

JIS 10K 80A

A0037380

Endress+Hauser 11

Page 12

Installation Dipfit CPA140

22 (8.74)2

y

! (4.25)108

!63.5 (2.50)

!69 (2.72)

20 (0.79)

25 (0.98)

4 Stainless steel version, dimensions in mm (in)

y Immersion depth, → Configurator on product page

A0037561

12 Endress+Hauser

Page 13

Dipfit CPA140 Installation

108 (4.25)

y

! 25 (4.92)1

! . (2.50)63 5

!75 (2.95)

!74 (2.91)

25 (0.98)

5 PVDF version, dimensions in mm (in)

y Immersion depth, → Configurator on product page

A0037563

Endress+Hauser 13

Page 14

Installation Dipfit CPA140

1 2

3

5

4

5.1.2 Measuring system

A complete measuring system comprises:

• Immersion assembly Dipfit CPA140

• 1-3 pH, ORP, pH/ORP combined sensors or temperature sensors (12 mm), e.g. CPS11D,

CPS12D

• 1-3 measuring cables, e.g. CYK10 or CPK9

• Transmitter, e.g. Liquiline CM442

Optional:

Extension cable, e.g. CYK11

6 Example of a measuring system (process and process connections are not illustrated)

1 Immersion assembly Dipfit CPA140, here as PVDF version

2 Transmitter CM442

3 Sensor cable CYK10

4 pH sensor CPS11D

5 ORP sensor CPS12D

A0037542

14 Endress+Hauser

Page 15

Dipfit CPA140 Installation

5.2 Mounting the sensor

The PVDF version is illustrated in the graphics below. The sensor mounting procedure

is identical for the stainless steel version.

1.

Release 4 screws (M4), remove the cover.

2.

Only for the PVDF version:

Remove the lap joint flange.

3.

Unscrew the sensor holder (bayonet lock).

Endress+Hauser 15

Page 16

Installation Dipfit CPA140

4.

Remove the dummy plug along with the O-ring, thrust collar and sealing plug.

Do not remove the dummy plug and sealing plug in the mounting slots that are

not used!

5.

Before installing, check that the pressure piece and O-ring are fitted on the sensor.

Remove the protection cap and screw in the sensor hand-tight. Pay attention to the

instructions in the Operating Instructions for the sensor.

Make sure the sensor O-ring is seated correctly.

6.

Connect the sensor cable to the sensor.

Only in the case of symmetrical measurement with analog sensors: connect the

PML line of the sensor cable to the PML terminal (screw) of the sensor holder.

16 Endress+Hauser

Page 17

Dipfit CPA140 Installation

7.

Screw in the sensor holder. Use a flat key wrench AF55 if necessary.

8.

Only for the PVDF version:

Fit the flange.

9.

Pull the sensor cable through the cable gland of the assembly head and then tighten

the cable gland.

10.

Screw on the cover.

You can now install the assembly in the process.

Endress+Hauser 17

Page 18

Installation Dipfit CPA140

Sensor with liquid KCl feed line

You can only install 1 sensor with a liquid KCl feed line.

1. Install the sensor in the sensor holder, see above.

2. Align the KCl feed line to the middle of the sensor holder.

3. Connect the hose of the KCl feed line to the sensor.

4. Assemble the assembly (see above). In doing so, guide the hose of the KCl feed line

through one of the two Pg 16 glands.

Only connect the KCl feed line to the liquid KCl supply vessel once the assembly is installed

in the process.

5.3 Mounting the assembly in the process

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process

medium escapes!

Do not exceed the permitted maximum process pressure.

‣

Prior to installing and removing the assembly, depressurize the system.

‣

Check that the sealing of the flange seal is tight (no leaks).

‣

The sensor must be installed before the assembly is mounted. → 15

1. Introduce the assembly with the sensor into the flange connection of the process

vessel.

2. Screw down the flange (flange screws must be provided by the customer).

3. Connect the sensor cable to the transmitter. Refer to the Operating Instructions of

the transmitter for this.

The measuring point is now ready to measure.

5.4 Post-installation check

• Assembly undamaged?

• Is a sensor installed in the assembly?

• Have all the seals been checked to ensure they are leak-tight?

18 Endress+Hauser

Page 19

Dipfit CPA140 Maintenance

6 Maintenance

CAUTION

L

Process medium and medium residues

Risk of injury from high pressure, high temperatures or chemical hazards!

Wear protective gloves, protective goggles and protective clothing.

‣

Mount or dismantle the assembly only in vessels or pipes that are empty and

‣

unpressurized.

6.1 Cleaning the assembly

For stable and reliable measurements, clean the assembly and the sensor regularly. The

‣

frequency and intensity of the cleaning process depend on the medium.

6.2 Cleaning agent

WARNING

L

Organic solvents containing halogens

Limited evidence of carcinogenicity! Dangerous for the environment with long-term

effects!

Do not use organic solvents that contain halogens.

‣

WARNING

L

Thiocarbamide

Harmful if swallowed! Limited evidence of carcinogenicity! Possible risk of harm to the

unborn child! Dangerous for the environment with long-term effects!

Wear protective goggles, protective gloves and appropriate protective clothing.

‣

Avoid all contact with the eyes, mouth and skin.

‣

Avoid discharge into the environment.

‣

The most common types of soiling and the cleaning agents used in each case are shown in

the following table.

Type of soiling Cleaning agent

Greases and oils Hot water or tempered (alkaline) agents containing

surfactants or water-soluble organic solvents (e. g.

ethanol)

Limescale deposits, metal

hydroxide buildup, lyophobic

biological buildup

Sulfide deposits Mixture of 3% hydrochloric acid and thiocarbamide

Protein buildup Mixture of 3% hydrochloric acid and pepsin

Approx. 3% hydrochloric acid

(commercially available)

(commercially available)

Fibers, suspended substances Pressurized water, possibly surface-active agents

Light biological buildup Pressurized water

Choose a cleaning agent to suit the degree and type of soiling.

‣

Endress+Hauser 19

Page 20

Maintenance Dipfit CPA140

1 2

345

6.3 Replacing the seal

6.3.1 Overview of seals

A0038721

7 O-rings and blanking plugs on sensor holder

1 O-ring ID 10.69 x 3.53

2 O-ring, bayonet lock ID 53.57 x 3.53

3 Blanking plug (if sensor is not installed)

4 O-ring, blanking plug or sensor, ID 10.69 x 3.53

5 Sealing cap (if sensor is not installed)

6.3.2 Replacing the seals

O-ring on the sensor holder

1. Remove the assembly from the medium.

2. Clean the assembly.

3.

Unscrew the sensor holder (bayonet lock). Use a flat key wrench AF55 if necessary.

4.

Remove the sensor cable from the sensor.

20 Endress+Hauser

Page 21

Dipfit CPA140 Maintenance

5.

Remove the O-ring from the sensor holder.

6.

Grease a new O-ring from the spare parts kit and fit it over the sensor holder and into

the O-ring guide.

O-rings in the sensor mounting slots

The PVDF version is depicted in the following graphics. All actions are identical for

the stainless steel version.

1.

Remove the sensor. Check the O-ring of the sensor and replace it if necessary.

2.

Remove the O-ring in the sensor guide using the tool from the O-ring kit.

Endress+Hauser 21

Page 22

Maintenance Dipfit CPA140

3.

Grease a new O-ring from the spare parts kit and fit it into the O-ring guide. Use the

tool from the kit if necessary.

4. If necessary, replace the O-rings in the other sensor mounting slots in the same way.

5.

Mount the sensor again.

6. Connect the sensor cable.

7.

Screw in the sensor holder. Use a flat key wrench AF55 if necessary.

8. Place the sensor back into the medium.

6.4 Replacing the GORE-TEX® filter

The filter must only be replaced if it is visibly contaminated and no longer fulfills its

purpose.

1. Remove the assembly from the medium.

2. Clean the assembly.

22 Endress+Hauser

Page 23

Dipfit CPA140 Maintenance

3.

Remove the cover of the filter (e.g. using a flat-blade screwdriver).

4. Check the filter.

Replace the filter if it is visibly contaminated. Otherwise, fit the cover back on

(click it into place).

5.

Remove the used filter.

6. Insert a new filter and fit the cover back on (click it into place).

7. Put the assembly back into the medium.

Endress+Hauser 23

Page 24

Repair Dipfit CPA140

7 Repair

CAUTION

L

Danger resulting from improper repair!

Any damage to the assembly that compromises pressure safety must be repaired only

‣

by authorized and qualified personnel.

Following each repair and maintenance task, check the assembly for leaks using

‣

appropriate procedures. Following this, the assembly must again comply with the

specifications in the technical data.

Replace all other damaged components immediately.

‣

7.1 Spare parts

For more detailed information on spare parts kits, please refer to the

Spare Part Finding Tool on the Internet.

7.2 Return

The product must be returned if repairs or a factory calibration are required, or if the

wrong product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

7.3 Disposal

Please observe local regulations!

‣

24 Endress+Hauser

Page 25

Dipfit CPA140 Accessories

8 Accessories

The following are the most important accessories available at the time this documentation

was issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

8.1 Sensors (selection)

Orbisint CPS11D / CPS11

• pH sensor for process technology

• Optional SIL version for connecting to SIL transmitter

• With dirt-repellent PTFE diaphragm

• Product Configurator on the product page: www.endress.com/cps11d or

www.endress.com/cps11

Technical Information TI00028C

Ceraliquid CPS41D / CPS41

• pH electrode with ceramic junction and KCl liquid electrolyte

• Product Configurator on the product page: www.endress.com/cps41d or

www.endress.com/cps41

Technical Information TI00079C

Orbipore CPS91D

pH electrode with open aperture for media with high dirt load

Technical Information TI00375C

Orbisint CPS12D / CPS12

• ORP sensor for process technology

• Product Configurator on the product page: www.endress.com/cps12d or

www.endress.com/cps12

Technical Information TI00367C

Ceraliquid CPS42D / CPS42

• ORP electrode with ceramic junction and KCl liquid electrolyte

• Product Configurator on the product page: www.endress.com/cps42d or

www.endress.com/cps42

Technical Information TI00373C

Memosens CPS16D

• Combined pH/ORP sensor for process technology

• With dirt-repellent PTFE diaphragm

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cps16D

Technical Information TI00503C

Memosens CPS96D

• Combined pH/ORP sensor for chemical processes

• With poison-resistant reference with ion trap

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cps96d

Technical Information TI00507C

Endress+Hauser 25

Page 26

Accessories Dipfit CPA140

Oxymax COS22D / COS22

• Sterilizable sensor for dissolved oxygen

• With Memosens technology or as an analog sensor

• Product Configurator on the product page: www.endress.com/cos22d or

www.endress.com/cos22

Technical Information TI00446C

Memosens COS81D

• Sterilizable, optical sensor for dissolved oxygen

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cos81d

Technical Information TI01201C

8.2 Measuring cable

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Measuring cable CPK9

• Terminated measuring cable for connecting analog sensors with TOP68 plug-in head

• Selection in accordance with product structure

• Ordering information: Endress+Hauser sales office or www.endress.com.

Measuring cable CPK12

• Terminated measuring cable for connecting analog ISFET sensors with TOP68 plug-in

head

• Selection in accordance with product structure

• Ordering information: Endress+Hauser sales office or www.endress.com

8.3 KCl supply vessel

Electrolyte vessel CPY7B

• Storage container for KCl electrolyte, 200 ml

• Product Configurator on the product page: www.endress.com/cpy7b

Operating Instructions BA00128C

8.4 Cleaning

Chemoclean CPR31

• Spray system to clean pH, ORP and temperature sensors

• Spray head and PVDF check valve, EPDM or VITON O-rings, EPDM hose, reinforced

• Cleaner up to 6 bar (87 psi) absolute, maximum 30 °C (86 °F)

• Order according to product order structure

Operating Instructions BA00201C

26 Endress+Hauser

Page 27

Dipfit CPA140 Technical data

200

2

4

6

8

10

40 60 80 100 120 140 160

a

b

p, abs

[bar][psi]

[°C]

[°F]

T

6832 104 140 176 212 248 284 320

29

58

87

116

145

-15

5

9 Technical data

9.1 Environment

Ambient temperature range

Storage temperature -10 to +70 °C (+10 to +160 °F)

Degree of protection IP65

-10 to +70 °C (+10 to +160 °F)

9.2 Process

Process temperature PVDF version 0 to 120 °C (32 to 250 °F)

Stainless steel version -15 to 150 °C (5 to 300 °F), for all seals except EPDM

-15 to 140 °C (5 to 280 °F), for EPDM seal

Process pressure PVDF version Max. 6 bar (87 psi), absolute

Stainless steel version Max. 10 bar (145 psi), absolute

Pressure-temperature ratings

8 Pressure-temperature ratings

a Stainless steel version

a PVDF version

9.3 Mechanical construction

Dimensions → 11

Endress+Hauser 27

A0037394-EN

Page 28

Technical data Dipfit CPA140

Weight Depends on version (material, immersion depth):

PVDF 2.5 to 3.0 kg (5.5 to 6.6 lbs)

Stainless steel 8.0 to 12.0 kg (17.6 to 26.5 lbs)

Materials In contact with medium, depending on version

Immersion tube PVDF / stainless steel 1.4404 (AISI 316L)

O-rings EPDM / VITON / Chemraz / Fluoraz

Sensor holder PVDF / stainless steel 1.4404 (AISI 316L)

Potential matching pin Alloy C4 / tantalum / stainless steel 1.4401 (AISI 316)

Shock-protection stud PVDF / stainless steel 1.4401 (AISI 316)

Dummy plug PEEK

Not in contact with medium, depending on version

Assembly head PP-GF 20

Lap joint flange UP-GF / stainless steel 1.4404 (AISI 316L)

Installation aids

1)

Stainless steel 1.4301 (AISI 304)

1) Only for stainless steel version

Process connections Depending on version:

• None

• Flange DN 80 / PN 16

• Flange ANSI 3" / 150 lbs

• Flange JIS 10K 80A

Cable glands 1 x Pg 13.5 and 2 x dummy plug Pg 16

Sensor mounting slots 3 x Pg 13.5

Immersion depth Depending on version:

• 500 mm (19.7 in)

• 1000 mm (39.4 in)

• 1500 mm (59.1 in)

• 2000 mm (78.7 in)

• 2500 mm (98.4 in)

28 Endress+Hauser

Page 29

Dipfit CPA140 Index

Index

A

Accessories ................................ 25

Ambient temperature range ................... 27

C

Cable gland ................................ 28

Certificates and approvals ..................... 10

Cleaning .................................. 19

Cleaning agent ............................. 19

D

Degree of protection ......................... 27

Designated use .............................. 5

Dimensions ................................11

Disposal .................................. 24

G

GORE-TEX® filter ........................... 22

I

Immersion depth ............................28

Incoming acceptance .......................... 9

Installation

Assembly ...............................18

Check ..................................18

Sensor ................................. 15

Installation conditions ........................ 11

S

Safety

Operational safety ......................... 6

Product safety ............................ 6

Workplace safety .......................... 5

Safety instructions ............................5

Scope of delivery ............................. 9

Seals .....................................20

Sensor mounting slots ........................ 28

Spare parts ................................ 24

Storage temperature ......................... 27

Symbols ................................... 4

T

Technical data ..............................27

U

Use .......................................5

W

Warnings .................................. 4

Weight ................................... 28

Workplace safety ............................ 5

M

Maintenance ...............................19

Manufacturer's address ....................... 10

Materials ................................. 28

Measuring system ........................... 14

Mechanical construction ...................... 27

Mounting conditions ......................... 11

N

Nameplate ................................. 9

O

Operational safety ............................6

Order code interpretation ...................... 9

P

Pressure-temperature ratings .................. 27

Process connections ..........................28

Process pressure ............................ 27

Process temperature ......................... 27

Product description ........................... 7

Product identification ......................... 9

Product page ................................9

Product safety ............................... 6

R

Repair ....................................24

Return ................................... 24

Endress+Hauser 29

Page 30

Page 31

Page 32

*71436282*

71436282

www.addresses.endress.com

Loading...

Loading...