Page 1

TI00387C/07/EN/14.18

71411045

2018-07-17

Products

Solutions Services

Technical Information

Oxymax COS61D/COS61

Measurement of dissolved oxygen

Digital optical sensor based on the principle of

fluorescence quenching, with or without

Memosens protocol

Application

• Wastewater treatment plants

– Oxygen measurement and regulation in the activated sludge basin for a highly

efficient biological cleaning process

– Monitoring the oxygen content in the wastewater treatment plant outlet

• Water monitoring

Oxygen measurement in rivers, lakes or seas as an indicator of the water quality

• Water treatment

Oxygen measurement for status monitoring, e.g. of drinking water (oxygen

enrichment, corrosion protection etc.)

• Fish farming

Oxygen measurement and regulation for optimum living and growth conditions

Your benefits

• Optical technology:

– Minimum maintenance

– Maximum availability

• Sensor with digital signal processing:

– Calibration data saved in sensor

– High degree of EMC protection thanks to digital communication with the

transmitter

• Extended maintenance intervals and a high degree of longterm stability

• Intelligent self-monitoring guarantees reliable measured values

• No flow needed - measurement possible in still water

• COS61D - the Liquiline sensor

– Plug&Play: Safe communication based on Memosens protocol

– Optionally with M12 plug for fast connection to the transmitter

• COS61 - the Liquisys sensor

– Compatible with tried-and-tested COS31 with COM2x3W: Easy measuring point

changeover to optical technology

– Compatible with COS41 with COM2x3D with conversion kit

Page 2

Function and system design

Oxymax COS61D/COS61

Measuring principle

Sensor structure

Oxygen-sensitive molecules (markers) are integrated into an optically active layer (fluorescence

layer).

The fluorescence layer, an optical insulating layer and a cover layer are applied on top of one another

on a carrier. The cover layer is in direct contact with the medium.

The sensor optics are directed at the rear of the carrier and therefore at the fluorescence layer.

Measurement process (principle of quenching)

If the sensor is immersed in the medium, an equilibrium is very quickly established between the

oxygen partial pressure in both the medium and the fluorescence layer.

1. The sensor optics send green light pulses to the fluorescence layer.

2. The markers "respond" (fluoresce) with red light pulses.

The duration and intensity of the response signals are directly dependent on the oxygen

contents and oxygen partial pressure.

If the medium is free from oxygen, the response signals are long and very intense.

Oxygen molecules mask the marker molecules. As a result, the response signals are shorter and less

intense.

Measurement result

The sensor returns a signal that is proportional to the oxygen concentration in the medium.

‣

The medium temperature and air pressure are already taken into account to calculate the oxygen

concentration in the sensor.

The sensor provides measured values for temperature and partial pressure as well as a raw measured

value. This value corresponds to the fluorescence decay time and is approx. 20 μs in air and

approx. 60 μs in oxygen-free media.

For optimum measurement results

1. During calibration, enter the current air pressure at the transmitter.

2. In the case of saline media:

Enter the salinity.

3. For measurements in the units %Vol or %SAT:

Also enter the current operating pressure in the measuring mode.

• Operating Instructions for Memosens, BA01245C

For all transmitters, analyzers and samplers in the Liquiline CM44x/P/R, Liquiline System

CA80XX and Liquistation CSFxx product families

• Operating Instructions for Liquisys COM2x3, BA00199C

2 Endress+Hauser

Page 3

Oxymax COS61D/COS61

1 2

3

4

5

6

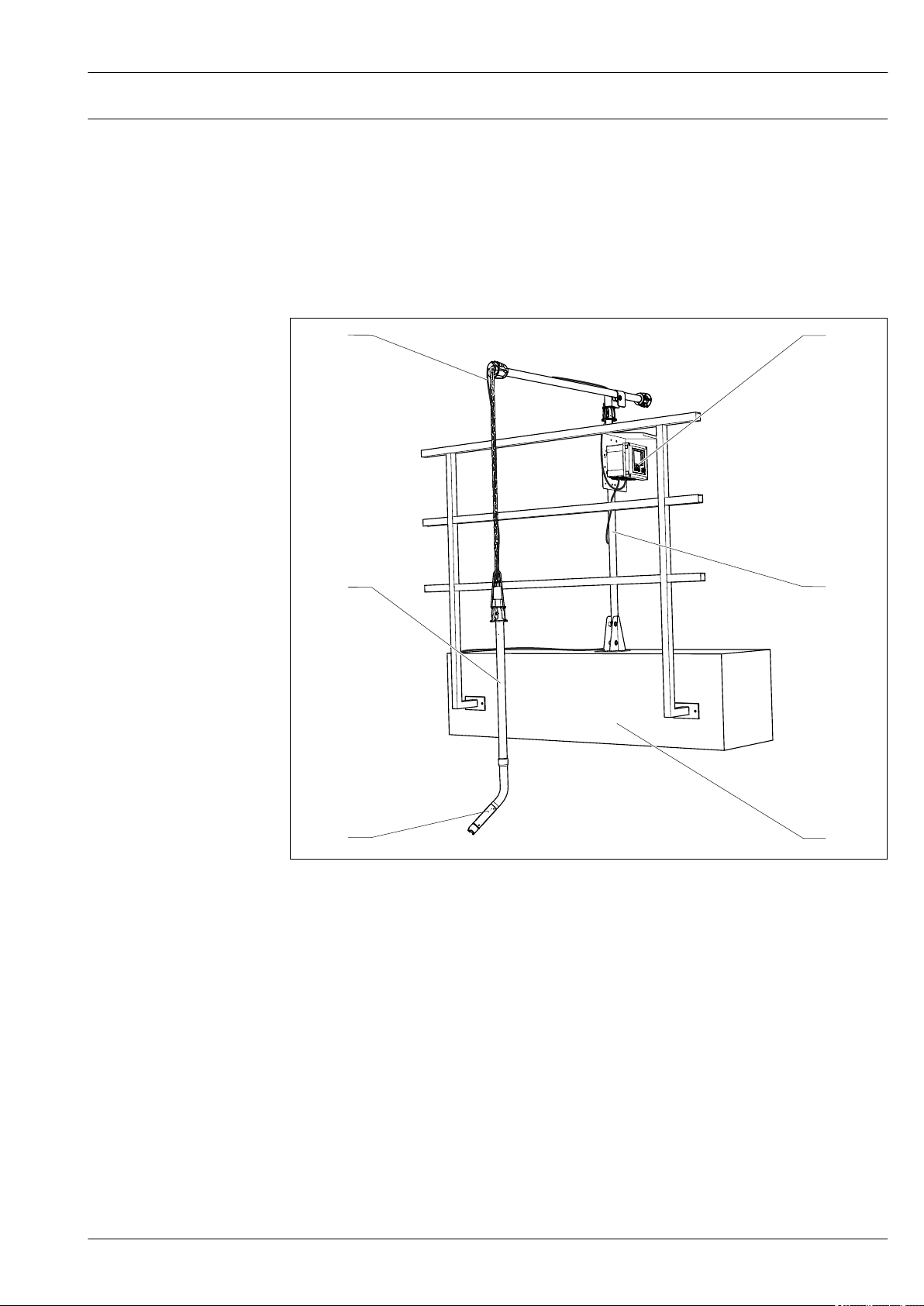

Measuring system

COS61D

A complete measuring system consists of the following components at least:

• Oxymax COS61D oxygen sensor

• Liquiline CM44x multi-channel transmitter

• Sensor cable, optionally available with M12 connector

• Assembly, e.g. flow assembly COA250, immersion assembly CYA112 or

retractable assembly COA451

Optionally:

• Assembly holder Flexdip CYH112 for immersion operation

• Extension cable CYK11

• Cleaning system

1 Example of a measuring system with COS61D

1

Sensor cable

2

Liquiline CM44x

3

Flexdip CYH112

A0012882

4

Basin rim with railing

5

Oxymax COS61D

6

FlexdipCYA112

Endress+Hauser 3

Page 4

COS61

1 2

3

4

5

6

A complete measuring system comprises:

• Oxymax COS61 oxygen sensor

• Transmitter, e.g. Liquisys COM2x3-W

• Sensor cable

• Assembly, e.g. flow assembly COA250, immersion assembly CYA112 or

retractable assembly COA451

Optionally:

• Flexdip CYH112 assembly holder for immersion operation

• VS junction box (for cable extension)

• Cleaning system

Oxymax COS61D/COS61

2 Example of a measuring system with COS61

1

Liquisys COM253

2

Oxymax COS61

3

Pipe (ascending pipe)

Input

Measured values

Measuring ranges

Dissolved oxygen [mg/l, µg/l, ppm, ppb or %SAT or hPa]

Measuring ranges apply for 25 ˚C (77 ˚F) and 1013 hPa (15 psi)

With Liquiline CM44x, CM44xR, CM44P or with Liquisys COM2x3-W:

• 0 to 20 mg/l

• 0 to 400 hPa

• 0 to 200 % SAT

A0012885

4

Direction of medium flow

5

Cleanfit COA451

6

Sensor cable

4 Endress+Hauser

Page 5

Oxymax COS61D/COS61

GN

PK

GY

YE

COM A

COM B

U

+

U

–

Power supply

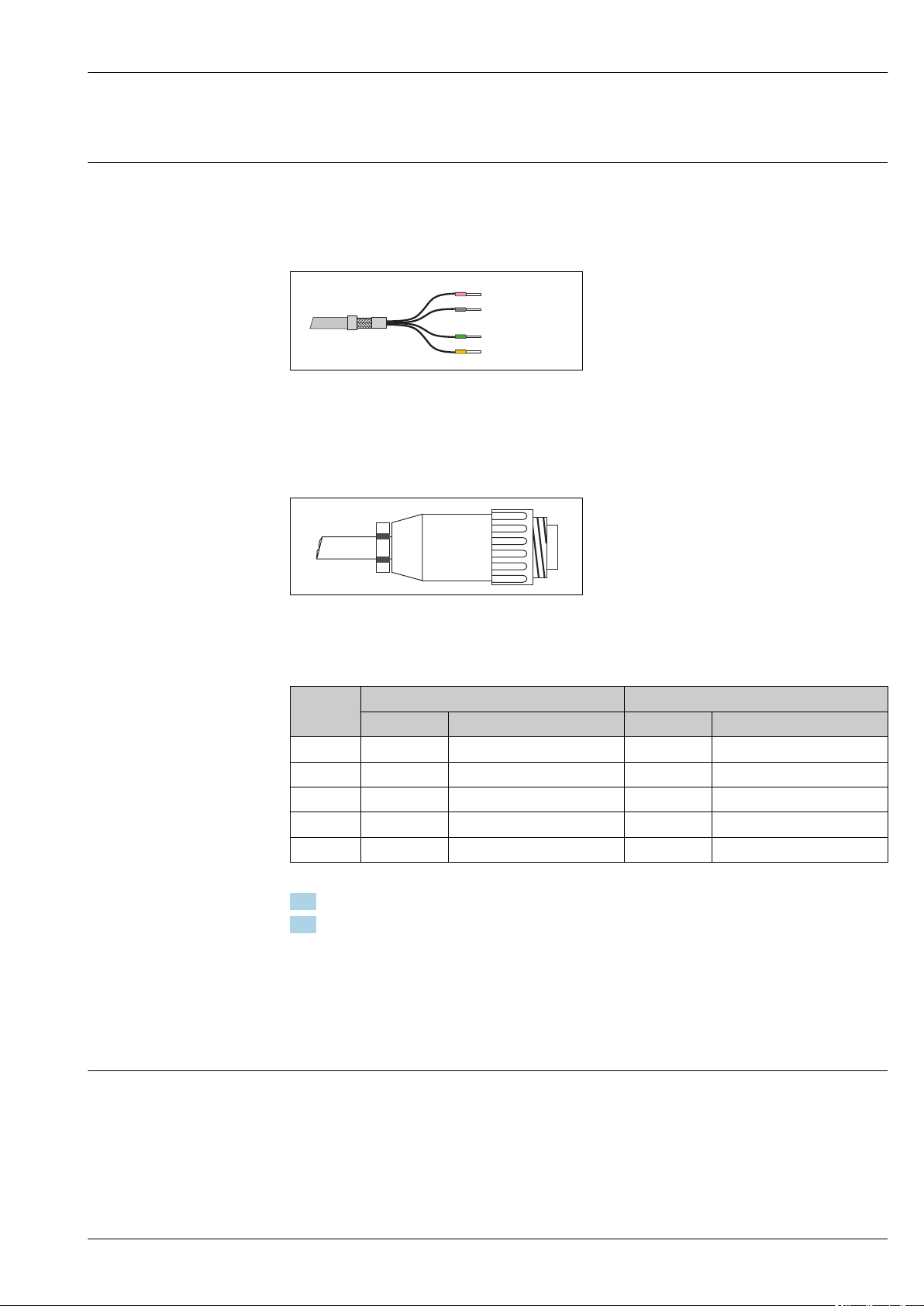

Electrical connection

COS61D

Connection data

• Sensor cable connected directly to the terminal connector of the basic module

• Optional: sensor cable plug connected to the M12 sensor socket of the transmitter

With this type of connection, the transmitter is already wired at the factory.

3 Sensor fixed cable with terminated cable cores

COS61 to field device

You connect the sensor directly to the transmitter via the special measuring cable with SXP

connector.

4 SXP connector

Response time

COS61 to cabinet device

Terminal

COM223

87 YE +U

0 GN 0 V WH 0 V

96 PK Communication (digital) GN Communication (digital)

97 BU Communication (digital) BN Communication (digital)

88 BN -U

Sensor with fixed cable (OMK) Sensor with TOP68 plug connection (CYK71)

Core Assignment Core Assignment

B

B

YE +U

Coax, inside -U

B

B

1. Remove the SXP connector (transmitter side!) from the cable.

2. Refer to the table for the cable assignment and terminals of Liquisys COM223-WX/WS.

Please note that the cable assignment varies depending on the sensor version (fixed cable

or TOP68 plug connection).

Performance characteristics

From air to nitrogen at reference operating conditions:

t90 : 60 s

Endress+Hauser 5

Page 6

Maximum measured error

1

5

2

4

3

1 2

3

6

4

5

1)

COS61D

Measuring range Maximum measured error

< 12 mg/l 0.01 mg/l or ±1 % of reading

12 mg/l to 20 mg/l ±2% of reading

COS61

Measuring range Maximum measured error

< 12 mg/l 0.02 mg/l or ±1 % of reading

12 mg/l to 20 mg/l ±2% of reading

Oxymax COS61D/COS61

Repeatability

Operating life of sensor cap

±0.5 % of end of measuring range

>2 years (under reference operating conditions, protect against direct sunlight)

Installation

Installation examples

Immersion operation Universal holder and chain assembly

A0030564

5 Chain holder on railing

1 Chain

2 Holder Flexdip CYH112

3 Rail

4 Sensor Oxymax

5 Wastewater assembly Flexdip CYA112

6 Chain holder on upright post

1 Weather protection cover CYY101

2 Controller / transmitter

3 Chain

4 Wastewater assembly Flexdip CYA112

5 Sensor Oxymax

6 Holder Flexdip CYH112

1) In accordance with IEC 60746-1 at rated operating conditions

6 Endress+Hauser

A0030565

Page 7

Oxymax COS61D/COS61

1

2

3

4

5

2

3

4

Universal holder and fixed immersion tube

A0030567

7 Assembly holder with immersion tube

1 Protective cover

2 Controller / transmitter

3 Flexdip CYA112 immersion assembly

4 Sensor Oxymax

5 Assembly holder Flexdip CYH112

Basin rim mounting with immersion tube

A0030568

8 Basin rim mounting

1 Pendulum holder CYH112

2 Assembly Flexdip CYA112

3 Assembly float

4 Sensor Oxymax

Endress+Hauser 7

Page 8

Oxymax COS61D/COS61

1

2

3

4

5

6

7

G1

800 (31.50)

500 (19.69)

220 (8.66)

Ø200 (7.87)

1

23

4

6

7

8

5

Float

The CYA112 float is for use in the case of large fluctuations in water level, for example in rivers or

lakes.

1 Cable run with strain relief and rain shield

2 Fixing ring for rope and chains with terminal screw

3 Eyelets Ø15, 3 x 120 ° for anchoring

4 Plastic float, resistant to salt water

5 Pipe 40 x 1, stainless steel 1.4571

6 Bumper and ballast

7 Oxygen sensor

Flow assembly COA250

9 Dimensions in mm (inch)

10 COA250

A0032159

A0013319

11 Bypass installation with manually actuated valves or solenoid

valves

1 Main pipe

2 Medium return

3 Oxygen sensor

4, 7 Manually actuated or solenoid valves

5 Flow assembly COA250-A

6 90 ° pipe elbow

8 Medium removal

A0030570

Environment

Ambient temperature

Storage temperature

Degree of protection

8 Endress+Hauser

–20 to 60 °C (–4 to 140 °F)

–20 to 70 °C (–4 to 158 °F)

at 95% relative air humidity, not condensating

COS61D

IP 68 (test conditions: 10 m (33 ft) water column, at 25 °C (77 °F) over 30 days)

Page 9

Oxymax COS61D/COS61

232.5 (9.15)

Ø40 (1.57)

186 (7.32)

12 (0.47)

77 (3.04) / 66 (2.59)*

197 (7.76)

243.5 (9.59)

21 (0.83)

15 (0.59)

11 (0.43)

46.5 (1.83)

NPT ¾"

G1

COS61

• Fixed cable versions:

IP 68 (test conditions: 10 m (33 ft) water column at 25 °C (77 °F) over 30 days)

• Top68 plug-in head versions:

IP 68 (test conditions: 1 m (3.3 ft) water column at 50 °C (122 °F) over 7 days)

Electromagnetic compatibility

Process temperature

Process pressure

Design, dimensions COS61D

COS61D

Interference emission and interference immunity as per EN 61326: 2005, Namur NE 21:2007

COS61

Interference emission and interference immunity as per EN 61326: 1997 / A1: 1998

Process

–5 to +60 ˚C (20 to 140 ˚F)

Ambient pressure ... 10 bar (... 145 psi) abs.

Mechanical construction

Endress+Hauser 9

12 With optional M12 connector

Dimensions in mm (inch)

A0037103

13 With optional cleaning unit

* depending on version of cleaning unit

A0037093

Page 10

design, dimensions COS61

G1

220 (8.66)

Ø40 (1.57)

186 (7.32)

G1

220 (8.66)

Ø40 (1.57)

186 (7.32)

50 (1.97)

19 (0.75)

19 (0.75)

Ø40 (1.57)

24°

61 (2.40)

28.5 (1.12)

A

B

77 (3.04)

11 (0.43)

Oxymax COS61D/COS61

Optional cleaning unit

14 Version with fixed cable

Dimensions in mm (inch)

A0027092

15 Version with TOP68 - plug-in head

A0027093

Weight

16 Dimensions in mm (inch)

with cable length 7 m (23 ft):

0.7 kg (1.5 lbs)

with cable length 15 m (49 ft): 1.1 kg (2.4 lbs)

Materials

with TOP68 plug connection: 0.3 kg (0.66 lbs) depending on version

Parts in contact with medium

Sensor shaft Stainless steel 1.4435 (AISI 316L)

10 Endress+Hauser

A0013314

Page 11

Oxymax COS61D/COS61

Cap with fluorescence layer POM

Fluorescence layer Silicone

Process connection

Sensor cable

Cable connection at transmitter

Maximum cable length

Temperature compensation

COS61D

G1, NPT 3/4"

COS61

G1

COS61D

Shielded 4-core fixed cable

COS61

Shielded 7-wire fixed cable or double-shielded coaxial cable with 4 pilot wires (with TOP68 plug

connection)

COS61D

• Terminal connection, end ferrules

• Optional: M12 connector

COS61

• SXP connector (field device)

• Terminal connection (panel-mounted instrument)

max. 100 m (330 ft), incl. Cable extension

Internal

Endress+Hauser 11

Page 12

Oxymax COS61D/COS61

Interface

Product page

Product Configurator

COS61D

Memosens protocol

COS61

RS 485

Ordering information

www.endress.com/cos61

www.endress.com/cos61d

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

Scope of delivery

Assemblies (selection)

Scope of delivery of sensor

• Oxygen sensor with protection cap or mounted cleaning system (optional)

• Brief Operating Instructions

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

FlexdipCYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Flowfit COA250

• Flow assembly for oxygen measurement

• Product Configurator on the product page: www.endress.com/coa250

Technical Information TI00111C

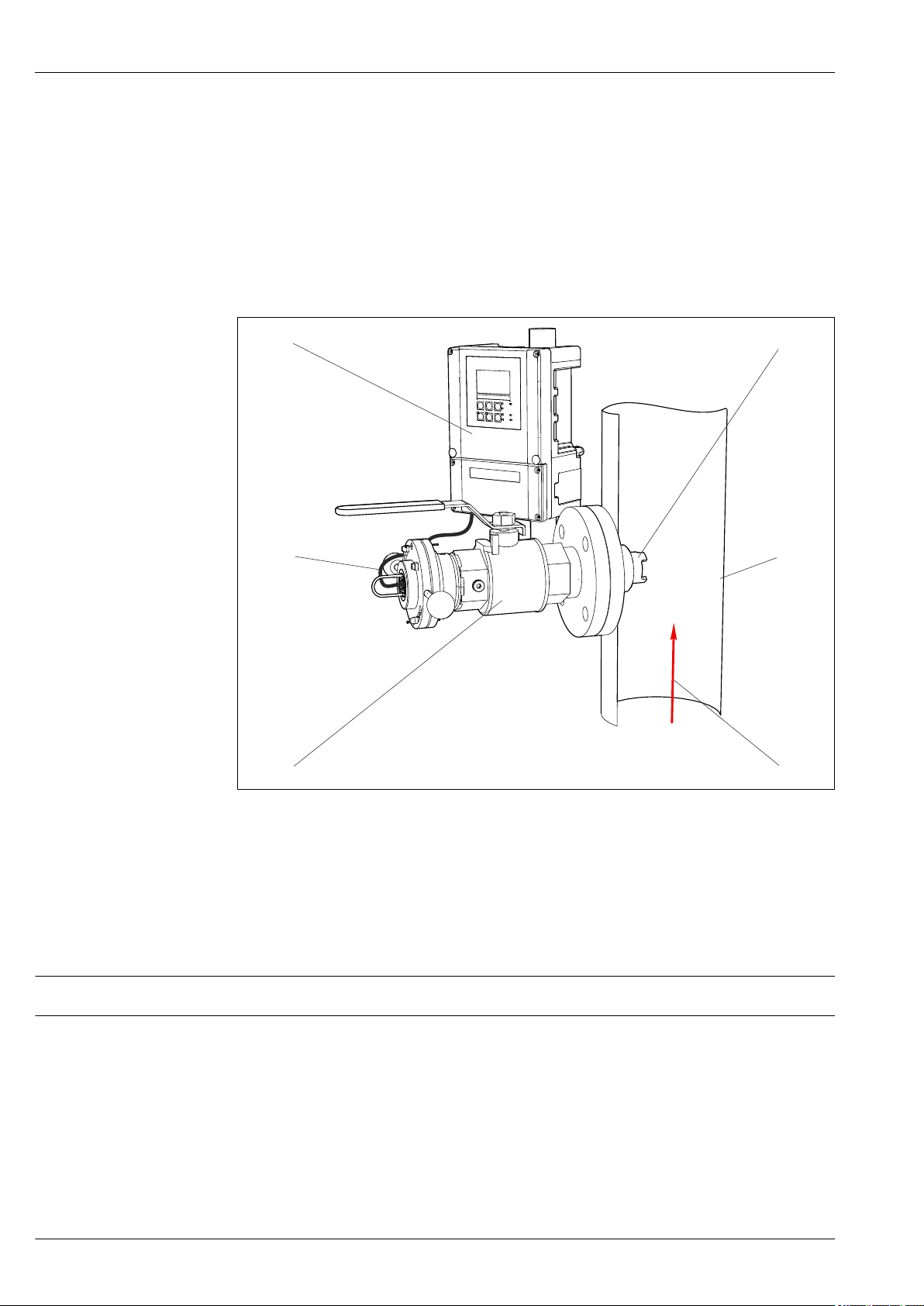

Cleanfit COA451

• Manual retractable assembly made of stainless steel with ball valve shutoff

• For oxygen sensors

• Product Configurator on the product page: www.endress.com/coa451

Technical Information TI00368C

12 Endress+Hauser

Page 13

Oxymax COS61D/COS61

Assembly holder

Measuring cable

Zero-point gel

Junction box (COS61 only)

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the capstone, on the wall or directly onto railings.

• Stainless steel version

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

COY8

Zero-point gel for oxygen and chlorine sensors

• Oxygen-free gel for the validation, calibration and adjustment of oxygen measuring cells

• Product Configurator on the product page: www.endress.com/coy8

Technical Information TI01244C

VS

• Junction box for cable extension of COS61 sensor with SXP plug-in connector

• With socket and 7-pin connector

• Degree of protection: IP 65

• Order number: 50001054

Protection guard

Cleaning unit

Calibration vessel

Membrane basket protector COY3-SK

• For using the sensor in fish farming tanks

• Order No.: 50081787

Compressed air cleaning for COSXX

• Connection: AD 6/8 mm (incl. hose reducer coupling) or AD 6.35 mm (¼")

• Materials: POM/V4A

• Order No.

– AD 6/8 mm: 71110801

– AD 6.35 mm (¼"): 71110802

Compressor

• For compressed air cleaning

• Order No.

– 230 V AC order no. 71072583

– 115 V AC order no. 71194623

Calibration vessel

• For COS61D/61

• Order No.: 51518599

Endress+Hauser 13

Page 14

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...