Page 1

Technical Information

Oxymax COS51D

Digital sensor for measuring dissolved oxygen

Longterm-stable sensor for water and wastewater applications

Application

The continuous measurement of the dissolved oxygen

concentration is very important in many areas of water

management:

• Sewage treatment plants:Oxygen measurement and

regulation in the activated sludge basin for a highly efficient

biological cleaning process

• Water monitoring:

Oxygen measurement in rivers, lakes or seas as an indicator of

the water quality

• Water treatment:

Oxygen measurement for status monitoring of drinking water

for example (oxygen enrichment, corrosion protection etc.)

• Fish farming:

Oxygen measurement and regulation for optimum living and

growth conditions

Your benefits

• Sensor with digital data transmission:

– Storage of calibration data in sensor

– Insensitive to electromagnetic interferences thanks to

digital communication to the transmitter

• Maximum measurement accuracy:

– Longterm-stable measurement thanks to potentiostatic

amperometric three-electrode system

– Long maintenance intervals

– Intelligent sensor self monitoring

• Membrane covered sensor, i.e.:

air

selectivity

2

– high O

– Minimum maintenance effort

– Minimum calibration effort thanks to simple calibration in

Further benefits offered by Memosens technology

• Maximum process safety through contactless inductive signal

transmission

• Data safety through digital data transmission

• Easy handling thanks to storage of sensor-specific data in the

sensor

• Predictive maintenance possible thanks to registration of

sensor load data in the sensor

TI00413C/07/EN/13.12

71153930

Page 2

Oxymax COS51D

Function and system design

Measuring principle The oxygen molecules diffused through the membrane are reduced to hydroxide ions (OH-) at the cathode.

Silver is oxidized to silver ions (Ag+) at the anode (this forms a silver halogenide layer).

A current flows due to the electron donation at the cathode and the electron acceptance at the anode. Under

constant conditions, this flow is proportional to the oxygen content of the medium.

This current is converted in the transmitter and indicated on the display as an oxygen concentration in mg/l,

μg/l, ppm, ppb or Vol%, as a saturation index in % SAT or as an oxygen partial pressure in hPa.

Potentiostatic amperometric three-electrode system

Memosens technology Maximum process safety

The high-impedance, current-free reference electrode plays an important role.

The formation of a silver bromide or silver chloride coating on the anode uses up the bromide or chloride ions

dissolved in the electrolyte

In the case of conventional membrane-covered sensors working with the two-electrode system, this causes an

increase in signal drift.

This is not the case with the three-electrode system:

The change in bromide or chloride concentration is registered by the reference electrode and an internal control

circuit holds the working electrode potential constant. The advantages of this principle are significantly

increased accuracy of the signal and considerably extended calibration intervals.

The inductive and non-contacting measured value transmission of Memosens guarantees maximum process

safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– The plug-in connection is free from corrosion.

– Measured value distortion from moisture is not possible.

Correct transfer of minimum measured values, e.g. with amperometric sensors.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium. The result: No more need to ask about

"symmetrically high-impedance" or "unsymmetrical" (for pH/ORP measurement) or an impedance

converter.

• EMC safety is guaranteed by screening measures for the digital measured value transmission.

• Application in explosion-hazardous areas is unproblematic; the integrated electronics are intrinsically safe.

Data safety through digital data transfer

The Memosens technology digitalizes the measured values in the sensor and transfers them to the transmitter

contactlessly and free from interference potential. The result:

• An automatic error message is generated if the sensor fails or the connection between sensor and transmitter

is interrupted.

• The availability of the measuring point is dramatically increased by immediate error detection.

Easy handling

Sensors with Memosens technology have integrated electronics that allow for saving calibration data and

further information such as total hours of operation and operating hours under extreme measuring conditions.

When the sensor is mounted, the calibration data are automatically transferred to the transmitter and used to

calculate the current measured value. Storing the calibration data in the sensor allows for calibration away from

the measuring point. The result:

• Sensors can be calibrated under optimum external conditions in the measuring lab. Wind and weather do

neither affect the calibration quality nor the operator.

• The measuring point availability is dramatically increased by the quick and easy replacement of precalibrated

sensors.

• The transmitter does not need to be installed close to the measuring point but can be placed in the control

room.

• Maintenance intervals can be defined based on all stored sensor load and calibration data and predictive

maintenance is possible.

• The sensor history can be documented on external data carriers and evaluation programs at any time. Thus,

the current application of the sensors can be made to depend on their previous history.

2 Endress+Hauser

Page 3

Oxymax COS51D

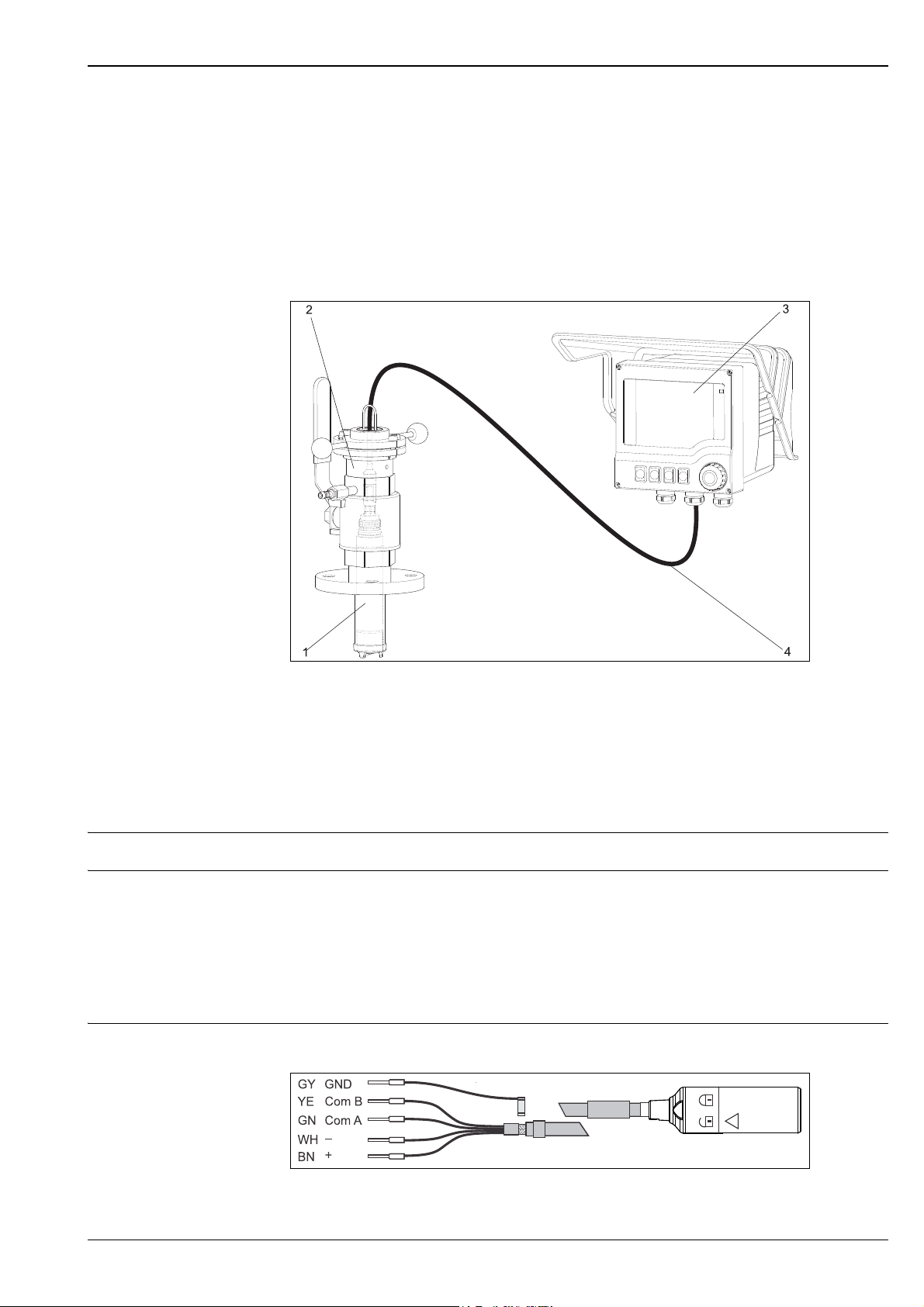

Measuring system A complete measuring system comprises at least:

• the digital oxygen sensor Oxymax COS51D

• a transmitter, e.g. Liquiline CM42

• a special measuring cable, CYK10

• an assembly, e.g. immersion assembly CYA112 or retractable assembly COA451

Optional (see accessories):

• Holder system CYH112 for immersion operation

• Junction box RM (with cable extension)

• Automatic cleaning system Chemoclean with spray head

Measuring system (example)

1 Digital oxygen sensor Oxymax W COS51D

2 Retractable assembly COA451

3 Liquiline M CM42

4 Measuring cable CYK10

a0006735

Input

Measured variable Dissolved oxygen [mg/l, μg/l, ppm, ppb, % SAT or hPa]

Measuring range 0.01 to 100 mg/l

0.00 to 1000 % SAT

0 to 2000 hPa

Wiring

Electrical connection The sensor is electrically connected to the transmitter by means of the special measuring cable CYK10.

Special measuring cable CYK10

a0003350

Endress+Hauser 3

Page 4

Performance characteristics

10° 10°

Not permissible!

Not permissible!

Permissible angle of installation

Response time • COS51D-***0* (black membrane cap for normal response time):

: 3 minutes

–t

90

–t98: 8minutes (each at 20 ˚C / 68 ˚F)

• COS51D-***1* (white membrane cap for fast response time):

: 0.5 minutes

–t

90

–t98: 1.5 minutes (each at 20 ˚C / 68 ˚F)

Oxymax COS51D

Reference operating conditions

Signal current in air

1)

Reference temperature: 25 ˚C (77 ˚F)

Reference pressure: 1013 hPa (15 psi)

• COS51D-***0* (black membrane cap):

approx. 300 nA

• COS51D-***1* (white membrane cap):

approx. 1100 nA

Measured value resolution 0.01 mg/l (0.01 ppm)

Maximum measured error ±1 % of measured value

2)

Repeatability ±1 % of measured value

Long-term drift

Zero-point drift: < 0.1 % per week at 30 ˚C (86 ˚F)

Measuring range drift: < 0.1 % per week at 30 ˚C (86 ˚F)

1) under constant conditions each

Influence of medium pressure Pressure compensation not necessary

Polarization time < 60 minutes

Oxygen intrinsic consumption • COS51D-***0*:

Approx. 90 ng/h in air at 25 ˚C (77 ˚F)

• COS51D-***1*:

Approx. 270 ng/h in air at 25 ˚C (77 ˚F)

1)

Installation

Angle of installation

Permissible angle of installation

1) For the reference operating conditions indicated

2) In accordance with IEC 61298-2 at nominal operating conditions

4 Endress+Hauser

a0006741-en

Page 5

Oxymax COS51D

Environment

Ambient temperature range –5 to 50 ˚C (20 to 120 ˚F)

Storage temperature filled with electrolyte: –5 to 50 ˚C (20 to 120 ˚F)

without electrolyte: –20 to 60 ˚C (0 to 140 ˚F)

Ingress protection IP 68 (test conditions: 10 m (33 ft) water column at 25 ˚C (77 ˚F) in 30 days)

Process

Process temperature –5 to 50 ˚C (20 to 120 ˚F)

Process pressure max. 10 bar (145 psi)

Underpressure operation is not permissible.

Design, dimensions

Mechanical construction

Dimensions

Weight 0.3 kg (0.7 lbs)

a0006742

Endress+Hauser 5

Page 6

Oxymax COS51D

Material

Process connection G1 and NPT ¾"

Membrane thickness • COS51D-***0*: approx. 50 μm

Temperature compensation internal

Electrolyte Alkaline electrolyte

Sensor shaft:

Membrane cap:

Cathode:

Anode/Reference electrode:

• COS51D-***1*: approx. 25 μm

POM

POM

Gold

Silver / silver bromide

Ordering information

Product page You can create a complete and valid order code by using the configurator on the internet product page.

Product page link:

www.products.endress.com/cos51d

Product configurator 1. You can choose from the following options on the product page located on the right:

2. Click "Configure this product".

3. The configurator opens in a separate window. You can now configure your device and receive the

complete order code that applies for the device.

4. Afterwards, export the order code as a PDF or Excel file. To do so, click the appropriate button at the top

of the page.

Scope of delivery The following items are included in the delivery:

• Oxygen sensor with transport protection cap for membrane protection

• Accessories set with the following contents:

– 2 replacement cartridges (replacement membrane caps)

– 10 plastic ampoules containing electrolyte

– 1 sealing kit with 3 O-rings

–6 abrasive sheets

• Operating Instructions (on CD only)

• Brief Operating Instructions (paper version)

With sensor version COS51D-**8** you must order the measuring cable CYK10 separately (see

accessories).

Certificates and approvals

Ex approval Version COS51D-G****

ATEX II 1G/IECEx Ex ia IIC T6 Ga

Version COS51D-O****

FM/CSA IS/NI CL I DIV 1&2 GP A-D

6 Endress+Hauser

Page 7

Oxymax COS51D

Accessories

In the following sections, you find the accessories available at the time of issue of this documentation.

For information on accessories that are not listed here, please contact your sales center.

Assemblies (selection) Retractable assembly Cleanfit COA451

• manually driven retractable assembly, stainless steel, with ball valve, for oxygen sensors;

• ordering acc. to product structure (Technical Information TI368C/07/en)

Flow assembly COA250

• for sensor installation in pipe lines, PVC

• ordering acc. to product structure (Technical Information TI111C/07/en)

Wastewater assembly Flexdip CYA112

• Modular assembly system for sensors in open basins, channels and tanks

• Versions in stainless steel or PVC

• Ordering per product structure (--> Online configurator: www.products.endress.com/cya112)

• Technical Information TI00432C/07/EN

Assembly holder Holder system Flexdip CYH112 for water

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• The holder system CYH112 works for nearly any type of fixing - fixing on the floor, wall or directly on a rail.

• Material: stainless steel

• Ordering acc. to product structure (--> Online configurator, www.products.endress.com/cyh112)

• Technical Information TI00430C/07/EN

Zero solution • 3 units to produce 3 x 1 liter oxygen-free solution

• order no. 50001041

Measuring cable CYK10 Memosens data cable

• For digital sensors with Memosens technology

pH, redox, oxygen (amperometric), chlorine, conductivity (conductive)

• Ordering as per product structure (-> online Configurator, www.products.endress.com/cyk10)

CYK11 Memosens data cable

• Extension cable for digital sensors with Memosens protocol

• Ordering as per product structure (--> Online configurator, www.products.endress.com/cyk11)

Protection guard Baffle plate OP

• extra protection for extreme current conditions

• order no. 50028712

Membrane protection guard COY3-SK

• for sensor use in fish ponds

• order no. 50081787

Cleaning unit Pressurized air cleaning system for COSXX

• Connection: 6/8 mm or 6.35 mm (¼")

• Materials: POM/V4A

• Order numbers

– 6/8 mm: 71110801

– 6.35 mm (¼"): 71110802

Compressor

• For cleaning system

• 230 V AC order number: 71072583

• 115 V AC order number: 71096199

Chemoclean

• Injector CYR10

• Ordering acc. to product structure

• Technical Information TI00046C/07/EN

Chemoclean COR3

• Spray head for sensor cleaning in immersion operation

• Material: PVC

• order no.: COR3-0

Endress+Hauser 7

Page 8

TI00413C/07/EN/13.12

71153930

FM9

Loading...

Loading...