Page 1

TI00446C/07/EN/04.15

71306865

Products Solutions Services

Technical Information

Oxymax COS22D/COS22

Digital or analog sensor for the measurement of

oxygen

Sensor with long-term stability for frequent

sterilizations and autoclavability

Application

• Pharmaceutics and biotechnology

– Process control in enzyme production

– Control of culture processing

• Beverage industry

• Chemical industry

• Water treatment

– Boiler feedwater

– WFI (water for injection)

• Inertization

• Residual oxygen measurement in processes

Your benefits

• Sensor version suitable for pharmaceutical industry:

– Stainless steel 1.4435 (AISI 316L)

– Sterilizable and autoclavable

• Application-specific versions:

– Sensor for standard applications, e.g. for fermenter control

– Trace sensor, e.g. for use in the power station sector and for the beverage

industry (CO2-compatible sensor)

• Very versatile:

– Standard process connection Pg 13.5

– Installation possible in standard pH assemblies

• Short response time: t98 < 60 s

• Integrated temperature sensor

Other advantages of Memosens technology

• Maximum process safety thanks to non-contact, inductive signal transmission

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Recording of sensor load data in the sensor enables predictive maintenance

Page 2

Function and system design

1

2

3

4

Oxymax COS22D/COS22

Measuring principle

Application in gaseous media

Measuring system

The oxygen molecules that diffuse through the membrane are reduced at the cathode to hydroxide

ions (OH-). At the anode, silver is oxidized to silver ions (Ag+) (this forms a silver halide layer). A

current flows due to the electron donation at the cathode and the electron acceptance at the anode.

Under constant conditions, this flow is proportional to the oxygen content of the medium. This

current is converted in the transmitter and indicated on the display as an oxygen concentration in

mg/l, µg/l, ppm, ppb or Vol%, as a saturation index in % SAT or as an oxygen partial pressure in hPa.

The trace sensor version can be used in gaseous media, such as for inertizations and quality control

in the trace range. Process monitoring in gaseous media can be performed with the standard sensor.

The measured value is displayed in Vol% or as oxygen partial pressure in hPa. Sensors that are used

in dry media consume more electrolyte and must therefore be maintained more frequently.

A complete measuring system comprises:

• An Oxymax COS22 or Oxymax COS22D oxygen sensor

• A transmitter, see table

• An appropriate measuring cable, see table

• Optional: an assembly, e.g. permanent installation assembly CPA442, flow assembly CPA240, or

retractable assembly CPA875

Transmitter COS22D- standard, trace COS22- standard COS22- trace

Liquiline CM44x

Liquiline CM42

Liquisys COM2x3 -

Third-party provider Memosens partner Possible, cable: COK21 Possible, cable: COK21

, cable: CYK10

, cable: CYK10

- -

- -

, cable: COK21

-

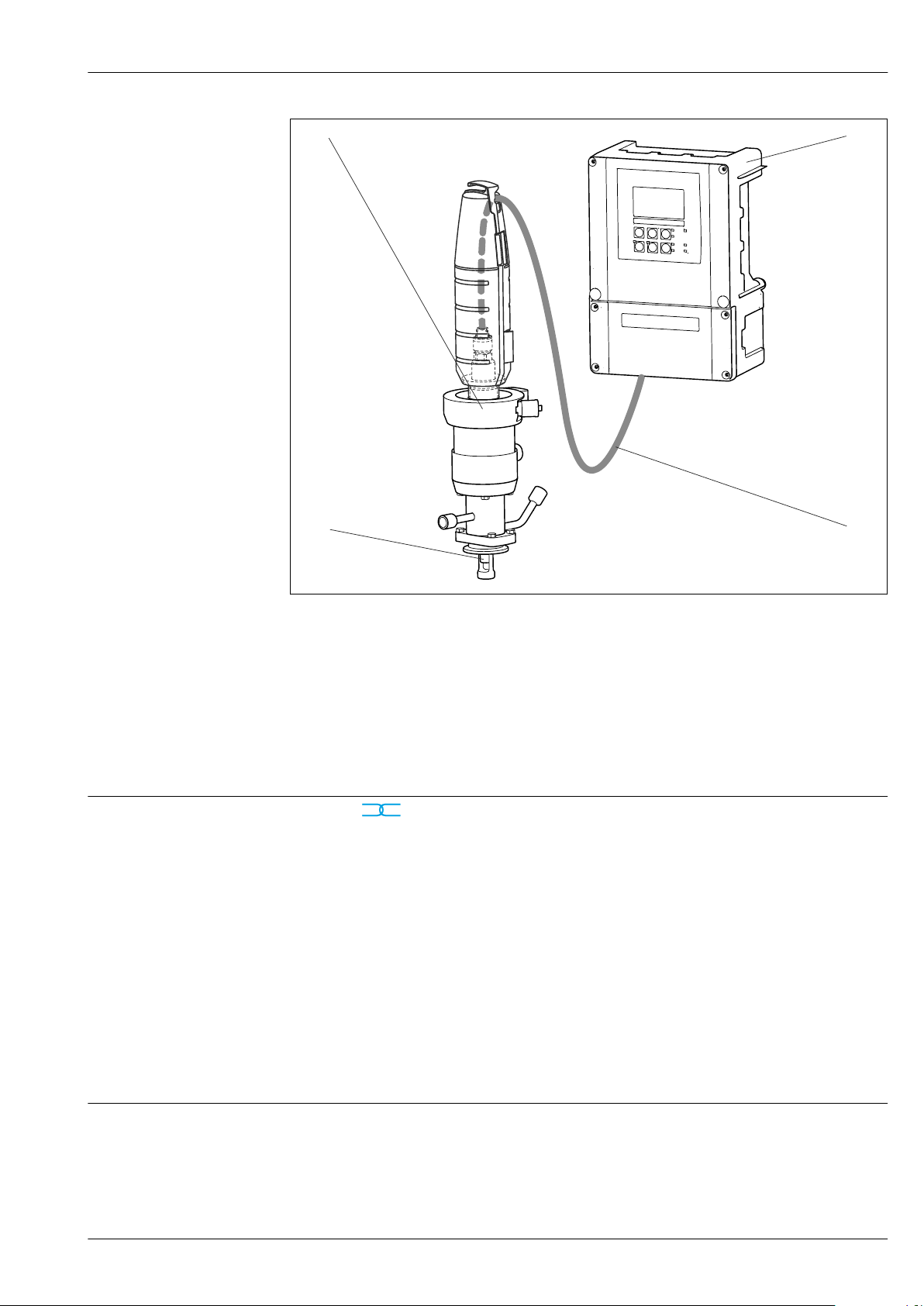

1 Example of a measuring system with COS22D-*1

1 Liquiline CM42

2 Measuring cable CYK10

3 Digital oxygen sensor Oxymax COS22D-*1

4 Permanent installation assembly CPA442

2 Endress+Hauser

A0022853

Page 3

Oxymax COS22D/COS22

1 2

3

4

MEMO SENS

2 Example of a measuring system with COS22-*1

1 Retractable assembly CPA875

2 Transmitter Liquisys COM253

3 Measuring cable COK21

4 Oxygen sensor COS22

Dependability

Reliability

Memosens

Memosens makes your measuring point safer and more reliable:

• Non-contact, digital signal transmission enables optimum galvanic isolation

• Completely watertight

– Can even be connected under water

– No contact corrosion

– Measured value not affected by moisture. Correct transmission of even the smallest values, e.g.

from amperometric sensors.

• Sensor can be calibrated in a lab, thus increasing the availability of the measuring point in the

process

• Intrinsically safe electronics mean operation in hazardous areas is not a problem.

• Predictive maintenance thanks to recording of sensor data, e.g.:

– Total hours of operation

– Hours of operation with very high or very low measured values

– Hours of operation at high temperatures

– Number of steam sterilizations

– Sensor condition

A0024029

Maintainability

Easy handling

Sensors with Memosens technology have an integrated electronics unit that stores calibration data

and other information (e.g. total operating hours and operating hours under extreme measuring

conditions). Once the sensor has been connected, the sensor data are transferred automatically to

the transmitter and used to calculate the current measured value. As the calibration data are stored

Endress+Hauser 3

Page 4

Oxymax COS22D/COS22

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

in the sensor, the sensor can be calibrated and adjusted independently of the measuring point. The

result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point .

• Maintenance intervals can be defined based on all stored sensor load and calibration data and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs. Thus,

the current application of the sensors can be made to depend on their previous history.

Safety

Measured values

Measuring ranges

Data security thanks to digital data transmission

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter using a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Input

Dissolved oxygen [mg/l, µg/l, ppm, ppb or % SAT or hPa]

Temperature [˚C, ˚F]

Measuring ranges apply for 20 ˚ (68 ˚F) and 1013 hPa (15 psi)

Measuring range Optimum operational range

COS22/22D-*1 0.01 to 60 mg/l

0 to 600 % SAT

0 to 1200 hPa (0 to 6 psi)

0 to 100 Vol%

COS22/22D-*3

COS22D-*4

0.001 to 10 mg/l

0 to 120 % SAT

0 to 250 hPa (0 to 6 psi)

0 to 25 Vol%

0.01 to 20 mg/l

0 to 200 % SAT

0 to 400 hPa (0 to 6 psi)

0 to 40 Vol%

0.001 to 2 mg/l

0 to 20 % SAT

0 to 40 hPa (0 to 6 psi)

0 to 4 Vol%

1)

1) Applications in this range guarantee a long service life and minimum maintenance

Power supply

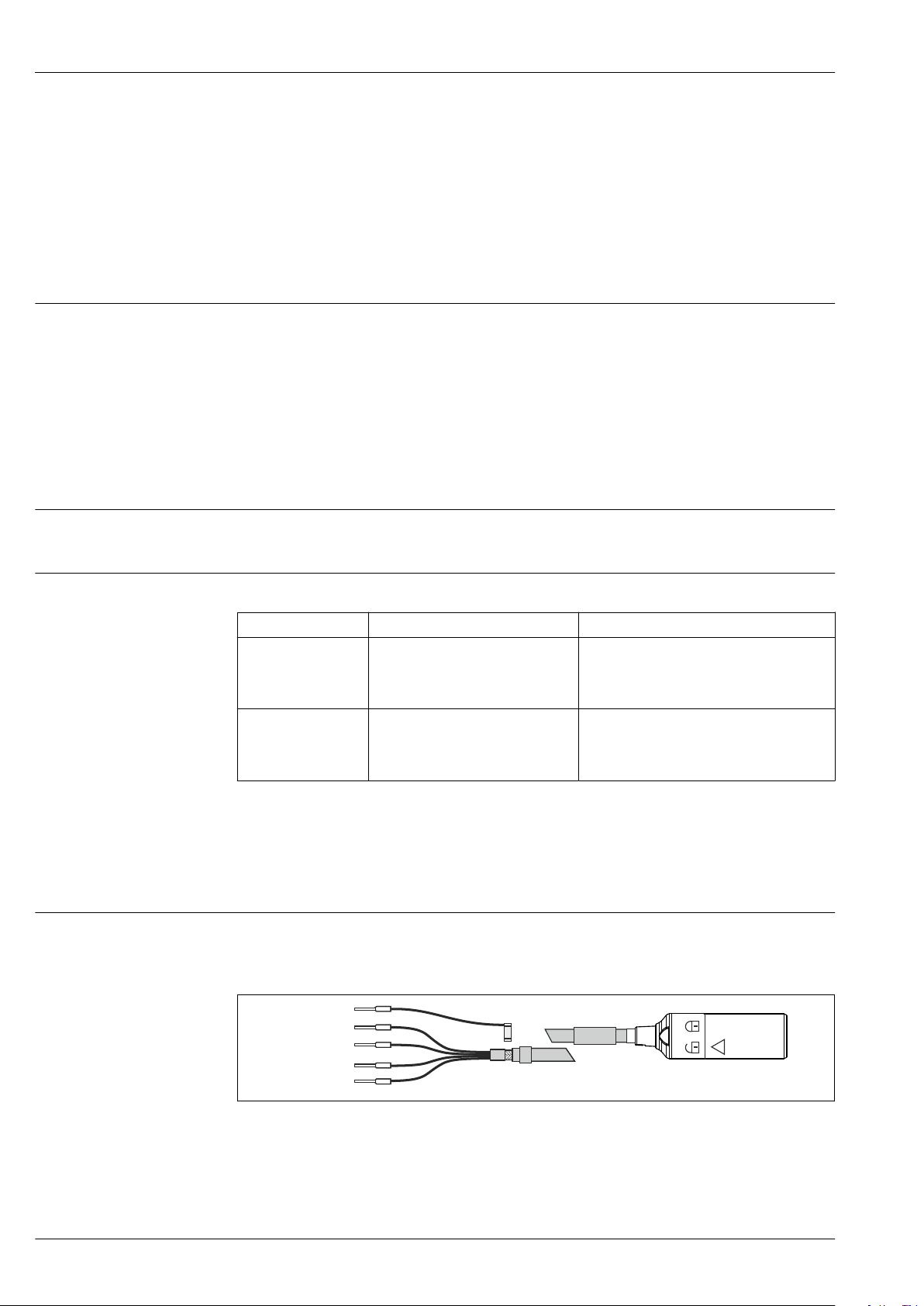

Electrical connection COS22D

The electrical connection of the sensor to the transmitter is performed using the measuring cable

CYK10.

3 Measuring cable CYK10

4 Endress+Hauser

A0024019

Page 5

Oxymax COS22D/COS22

PK

GN / YE

BN

YE

BU

S

12

90

91

11

Assignment Terminal

External shield

Cathode

Anode

NTC temp. sensor

Active internal shield

(NTC temp. sensor)

COS22

A multi-core COK21 measuring cable is used for the electrical connection of the sensor to the

transmitter.

A0005583-EN

4 Measuring cable COK21

The polarization voltage must be set at the transmitter as follows:

Standard measuring range: -650mV

Trace measuring range: -550mV

The voltage is applied between the working electrode (cathode) and the reference electrode (anode).

Response time

Reference operating conditions

Signal current in air

Zero current

Measured value resolution

Maximum measured error

Performance characteristics

From air to nitrogen at reference operating conditions:

• t90 : < 30 s

• t98 : < 60 s

Reference temperature:

Reference pressure: 1013 hPa (15 psi)

Reference application: Air-saturated water

COS22/22D-*1 (standard sensor):

COS22/22D-*3, COS22D-*4 (trace sensor): 210 to 451 nA

COS22/22D-*1 (standard sensor):

COS22/22D-*3, COS22D-*4 (trace sensor): < 0.03 % of the signal current in air

COS22/22D-*1 (standard sensor):

COS22/22D-*3, COS22D-*4 (trace sensor): 1 ppb in aqueous, 0.02 hPa or 0.002 Vol% in

Corresponds to the recommended measured value resolution at the transmitter

COS22/22D-*1 (standard sensor):

COS22/22D-*3, COS22D-*4 (trace sensor): ≤ ±1 % of measuring range + 1 ppb

*

at reference operating conditions

25 ˚C (77 ˚F)

40 to 100 nA

< 0.1 % of the signal current in air

10 ppb in aqueous, 0.2 hPa or 0.02 Vol% in

gaseous media

gaseous media

≤ ±1 % of measuring range + 10 ppb

*

*

Long-term drift

Influence of the medium pressure

Endress+Hauser 5

< 4 % per month in reference operating conditions

≤ 1 % per month in operation with reduced oxygen concentration (< 4 Vol% O2)

Pressure compensation not required

Page 6

Oxymax COS22D/COS22

80

176

-5230

32

A B

90

194

C

T

[°C]

T

[°F]

10° 10°

Not permissible!

Not permissible!

Permissible angle of installation

Polarization time

Intrinsic oxygen consumption

Operating time of the electrolyte

Temperature compensation

COS22/22D-*1 (standard sensor): < 30 min for 98% signal value, 2 h for 100%

COS22/22D-*3, COS22D-*4 (trace sensor): < 3 h for 98% signal value, 12 h for 100%

COS22/22D-*1 (standard sensor): Approx. 20 ng/h in air at 25 ˚C (77 ˚F)

COS22/22D-*3, COS22D-*4 (trace sensor): Approx. 100 ng/h in air at 25 ˚C (77 ˚F

Theoretical operating time at pO2 = 210 mbar and T=25 ˚C (77 ˚F)

COS22/22D-*1 (standard sensor): > 1.5 years

COS22/22D-*3, COS22D-*4 (trace sensor): > 3 months

COS22D

Compensation of the membrane properties takes place in the transmitter between -5 and 90˚C (23

to 194 ˚F); above 90˚C (194 ˚F), extrapolation takes place

• Measured variable as partial pressure [hPa] or in Vol%: -5 to 90 ˚C (23 to 194 ˚F)

• Measured variable as concentration [mg/l]: 0 to 80 ˚C (32 to 176 ˚F)

• Measured variable as saturation [%SAT]: -5 to 90 ˚C (23 to 194 ˚F)

Installation instructions

Installation angle

A0011887

COS22

Compensation of the membrane properties depending on the transmitter, recommended:

2.4 % per K

Installation

Installation in suitable assembly is required (depending on the application)

NOTICE

If the unit is installed without an assembly, there is the danger of rupturing cables or losing the

sensor

Do not install the sensor suspended from the cable!

‣

5 Permitted orientations

6 Endress+Hauser

A0005584-EN

Page 7

Oxymax COS22D/COS22

p

T

[bar]

[°C]

6

12

135

80

[psi]

174

87

T

[°F]

176

275

-5230

32

The sensor must be installed at an angle of inclination of 10 to 170 ° in an assembly, bracket or

appropriate process connection. Recommended angle: 45°, to prevent the formation of air bubbles.

Inclination angles other than those mentioned are not permitted. Do not install the sensor overhead.

Observe the instructions for installing sensors in the Operating Instructions for the assembly

used.

Environment

Ambient temperature range

Storage temperature

Degree of protection

Humidity

Process temperature

Process pressure

Temperature-pressure ratings

COS22/22D-*1 /3:

-5 to +135 °C (23 to 275 °F), non-freezing

COS22D-*4: -5 to +50 °C (23 to 120 °F), non-freezing

–5 to +50 ˚C (20 to 120 ˚F) at 95% relative humidity, non-condensing

NOTICE

Danger of sensor drying out

Store the sensor with the watering cap only (filled with tap water).

‣

IP 68 (10 m (33 ft) head of water at 25 ˚C (77 ˚F) over 45 days, 1 mol/l KCl)

0 to 100%, COS22D: condensating, COS22: not condensating in area of T-82 connection

Process

COS22/22D-*1 /3:

COS22D-*4: -5 to +80 °C (23 to 180 °F), non-freezing

Ambient pressure ... 12 bar (... 174 psi) absolute

-5 to +135 °C (23 to 275 °F), non-freezing

Minimum flow

COS22/22D-*1 (standard sensor):

0.02 m/s (0.07 ft/s)

COS22/22D-*3, COS22D-*4 (trace sensor): 0.1 m/s (0.33 ft/s)

Chemical resistance

Parts in contact with the medium are chemically resistant to:

• Diluted acids and alkalis

• Hot water and superheated steam up to max. 135 ˚C (275 ˚F)

• CO2 up to 100 %, only with trace sensor COS22/22D-*3

Endress+Hauser 7

A0028771-EN

Page 8

Oxymax COS22D/COS22

1 2

3

4

5

78

9

6

1 2

3

4

5

78

9

6

Pg 13,5

50 (1.97)

120 / 225 / 360 / 420 (4.72 / 8.86 / 14.2 / 16.5)*

12 - 0.1

(0.47)

NOTICE

Hydrogen sulfide and ammonia shorten the operating life of the sensor.

Do not use the sensor in applications where it is exposed to hydrogen sulfide or ammonia vapors.

‣

Cross-sensitivity

CIP compatibility

SIP compatibility

Autoclavability

Design

COS22/22D-*1/3

Molecular hydrogen causes false low readings and can, in a worst-case scenario, result in total

failure of the sensor.

No cross interference from hydrogen with the COS22D-*4 version.

Yes (COS22/22D-*1/3)

Yes, max. 140 °C (284 °F) (COS22/22D-*1/3)

Yes, max. 140 °C (284 °F), max. 30 min. (COS22/22D-*1/3)

Mechanical construction

Dimensions

6 COS22D

7 COS22

1

Plug-in head

2

Thrust collar

3

Sensor shaft

4

O-ring 8.5 x 1.5 mm

5

Membrane body

6

Shaft sleeve

7

Glass portion with anode and cathode

8

Process seal 10.77 x 2.62 mm

9

Process connection Pg 13.5

A0011869

A0011868

8 Dimensions in mm (inch)

8 Endress+Hauser

A0011881

Page 9

Oxymax COS22D/COS22

Pg 13,5

54 (2.13)

120 / 225 / 360 / 420 (4.72 / 8.86 / 14.2 / 16.5)*

12 - 0.1

(0.47)

28 (1.10)

Ø6 (0.24)

39 (1.54)

160 (6.30)

30

(1.18)

Ø6 (0.24)

Ø 29 x 1.5 (1.14 x 0.06)

Flow assembly for sensors with Ø 12 mm (accessories)

A0011886

9 Dimensions in mm (inch)

Weight

Materials

Process connection

Surface roughness

Temperature sensor

10 Dimensions in mm (inch)

Depending on the design (length)

0.2 kg (0.44 lbs) to 0.7 kg (1.54 lbs)

Parts in contact with medium

Sensor shaft (depending on the version) Stainless steel 1.4435 (AISI 316L)

Electrode combination COS22/22D-*1/3: silver / platinum

Process seal VITON (FDA-compliant)

Process seal for ATEX/FM/CSA/NEPSI/TIIS VITON (not FDA-compliant)

Seals/O-rings

Membrane body, sealing ring for shaft sleeve

Membrane Silicone (FDA-compliant, in compliance with

Pg 13.5

Ra < 0.38 µm

NTC 22 kΩ

A0015019

Titanium

Alloy C22

COS22D-*4: silver / gold

VITON (FDA-compliant)

Perfluoroelastomer with USP88 Class VI

USP87/88 class VI), PTFE, steel mesh

Endress+Hauser 9

Page 10

Oxymax COS22D/COS22

Electrolyte

COS22/22D-*1 (standard sensor): Slightly alkaline electrolyte

COS22/22D-*3 (trace sensor): Neutral electrolyte

COS22D-*4 (trace sensor, gold): Slightly alkaline electrolyte

Certificates and approvals

mark

Ex approvals

Material certificates Manufacturer declaration of FDA compatibility

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EC directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

Version COS22D-BA

ATEX II 1G / IECEx Ex ia IIC T3/T4/T6 Ga

FM/CSA IS/NI Cl.1 Div.1 GP: A-D

Version COS22D-NA

NEPSI Ex ia IIC T3/T4/T6 Ga

Version COS22D-TA

TIIS Ex ib IIC T4

The manufacturer declares the use of FDA-listed materials.

Ask your Sales Center for the certificates.

Product FDA certificate for

COS22/22D-****22 Membrane, O-rings, process seal

COS22Z-*2*2 Membrane, O-rings, process seal

COS22/22D-****23 Membrane, O-rings

COS22Z-*2*3 Membrane, O-rings

Hazardous area versions

For operation in FDA processes, another FDA-approved seal must be installed before the

process seal (e.g. CPA442). Doing so will sufficiently separate the process from the Ex

connection.

Material test certificate

A test certificate 3.1 in accordance with EN10204 is supplied depending on the version (→ Product

Configurator on the product page).

EHEDG

Compliance with EHEDG's criteria for hygienic design

• TÜV Rheinland, Apeldorn, Netherlands

• Certificate type: Type EL Class I

Ordering information

Product page

10 Endress+Hauser

www.endress.com/cos22

www.endress.com/cos22d

Page 11

Oxymax COS22D/COS22

Product Configurator

Scope of delivery

Assemblies (selection)

The navigation area is located on the right of the product page.

1. Under "Device support" click "Configure your selected product".

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button at the top of

the screen.

The scope of delivery comprises:

• Oxygen sensor with watering cap (filled with tap water) for protecting the membrane

• Electrolyte, 1 bottle, 10 ml (0.34 fl.oz.)

• Tool to push out the membrane body

• Brief Operating Instructions

Accessories

The following are the most important accessories available at the time this documentation was

issued. For accessories not listed here, please contact your service or sales office.

Cleanfit CPA875

• Retractable process assembly for sterile and hygienic applications

• For in-line measurement with standard 12 mm sensors for parameters such as pH, ORP and

oxygen

• Product Configurator on the product page: www.endress.com/cpa875

Technical Information TI01168C

Flowfit CPA240

• pH/redox flow assembly for processes with stringent requirements

• Product Configurator on the product page: www.endress.com/cpa240

Technical Information TI00179C

Unifit CPA442

• Installation assembly for food, biotechnology and pharmaceutics

• With EHEDG and 3A certificate

• Product Configurator on the product page: www.endress.com/cpa442

Technical Information TI00306C

Cleanfit CPA450

• Manual retractable assembly for installing 120 mm sensors in tanks and pipes

• Product Configurator on the product page: www.endress.com/cpa450

Technical Information TI00183C

Flow assembly

• For sensors with Ø 12 mm and length 120 mm

• Compact stainless steel assembly with low sampling volume

• Order No. Order No.: 71042404

Measuring cable Cable for COS22D

CYK10 Memosens data cable

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Endress+Hauser 11

Page 12

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Cable for COS22

COK21

• Cable length 3 m (9.8 ft)

Order No. 51505870

• Cable length 10 m (33 ft)

Order No. 51505868

Oxymax COS22D/COS22

Zero-point gel

Maintenance kit

COY8

Zero-point gel for oxygen sensors

• Oxygen-depleting gel for test purposes

• Product Configurator on the product page: www.endress.com/coy8

Technical Information TI01244C

COS22Z

• Service Kit, COS22 and COS22D

• Ordering information: www.endress.com/cos22d under "Accessories/spare parts"

www.addresses.endress.com

Loading...

Loading...