Page 1

0

BA00182C/07/EN/21.19

71464663

2019-12-31

Products Solutions Services

Operating Instructions

Indumax CLS50D/CLS50

Digital sensor with Memosens protocol or analog

sensor

For inductive measurement of conductivity in

liquids

Page 2

EU Declaration of Conformity Indumax CLS50D/CLS50

EU Declaration of Conformity

CLS50D-BA****

2 Endress+Hauser

Page 3

Indumax CLS50D/CLS50 EU Declaration of Conformity

CLS50-G***

Endress+Hauser 3

Page 4

EU Declaration of Conformity Indumax CLS50D/CLS50

CLS50D-BV****

4 Endress+Hauser

Page 5

Indumax CLS50D/CLS50 EU Declaration of Conformity

CLS50-V***

Endress+Hauser 5

Page 6

Table of contents Indumax CLS50D/CLS50

Table of contents

1 About this document ........... 7

1.1 Warnings ........................... 7

1.2 Symbols used ........................ 7

1.3 Symbols on the device ................ 8

10.2 Performance characteristics .......... 36

10.3 Environment ....................... 36

10.4 Process ............................ 37

10.5 Mechanical construction ............. 39

2 Basic safety instructions ....... 9

2.1 Requirements for personnel ........... 9

2.2 Designated use ...................... 9

2.3 Workplace safety .................... 9

2.4 Operational safety .................. 10

2.5 Product safety ...................... 10

3 Incoming acceptance and

product identification ......... 14

3.1 Incoming acceptance ................ 14

3.2 Product identification ................ 14

3.3 Scope of delivery .................... 17

3.4 Certificates and approvals ............ 18

4 Installation .................... 19

4.1 Installation conditions ............... 19

4.2 Mounting the sensor ................ 21

4.3 Post-installation check ............... 24

5 Electrical connection .......... 24

5.1 Connection conditions ............... 25

5.2 Connecting the sensor ............... 29

5.3 Ensuring the degree of protection ..... 30

5.4 Post-connection check ............... 30

6 Commissioning ................ 31

Index ................................. 42

7 Maintenance .................. 31

8 Repair .......................... 32

8.1 Spare parts ........................ 32

8.2 Return ............................ 33

8.3 Disposal ........................... 33

9 Accessories .................... 33

9.1 Measuring cable .................... 34

9.2 Assemblies ........................ 34

9.3 Calibration solutions ................ 35

10 Technical data ................. 35

10.1 Input .............................. 35

6 Endress+Hauser

Page 7

Indumax CLS50D/CLS50 About this document

1 About this document

1.1 Warnings

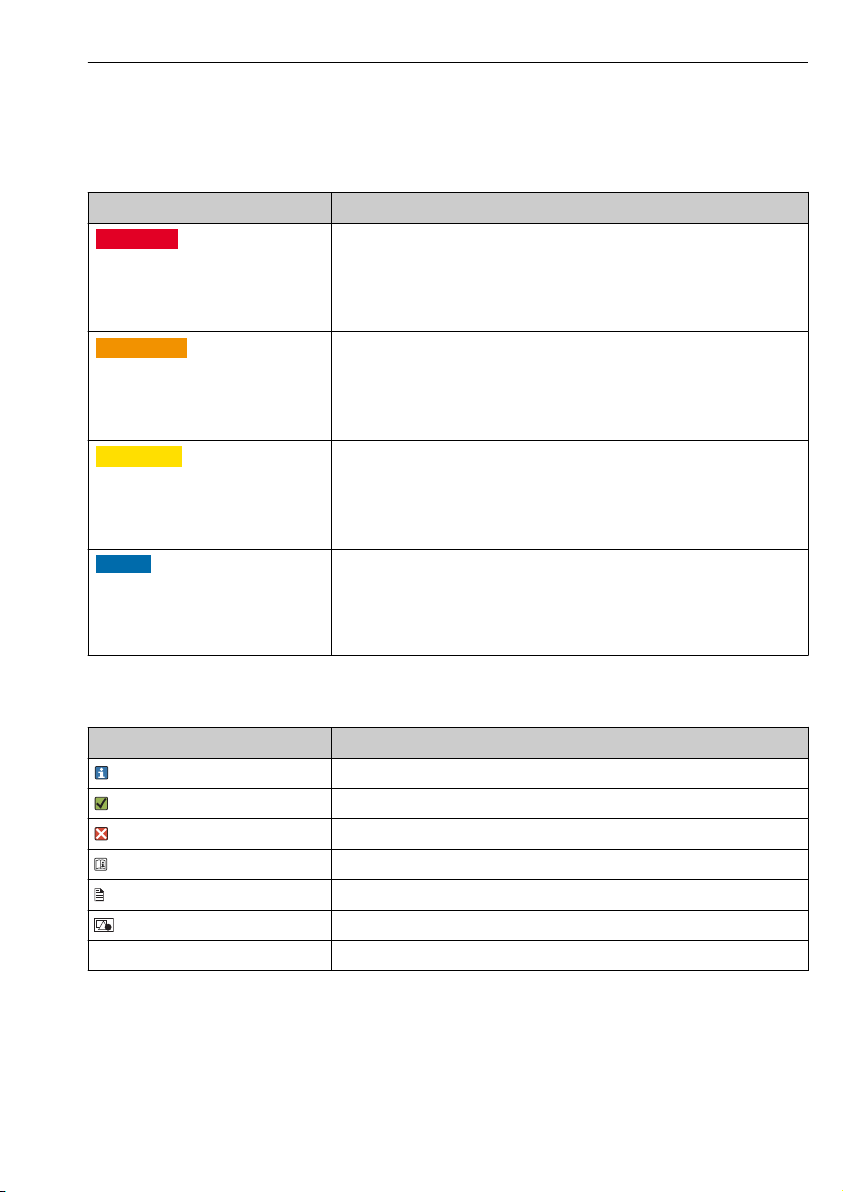

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

Endress+Hauser 7

Page 8

About this document Indumax CLS50D/CLS50

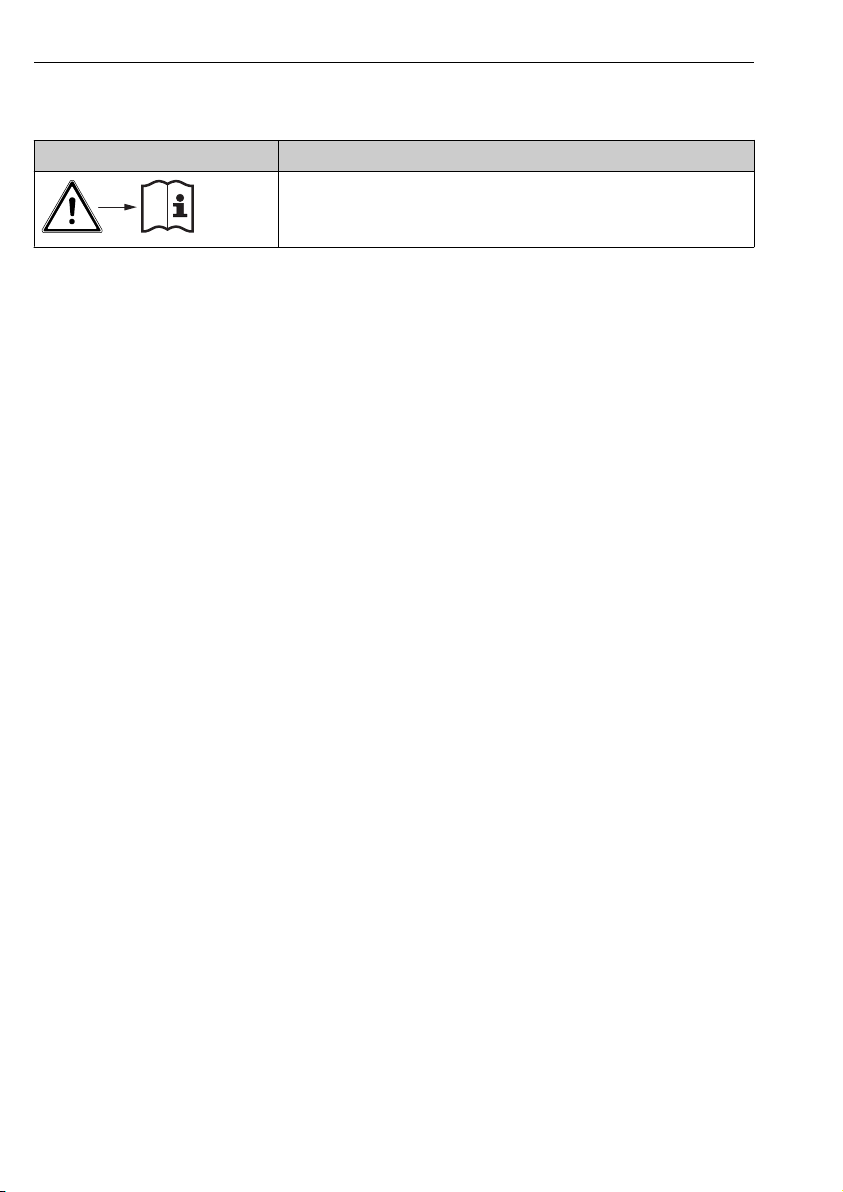

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

8 Endress+Hauser

Page 9

Indumax CLS50D/CLS50 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the specified

activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions and

must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

Indumax CLS50D or CLS50 sensor is particularly suitable for use in the chemical and process

technology sectors. The six-decade measuring range and the excellent chemical resistance

properties of the materials in contact with the medium (PFA or PEEK) make it possible to use

this sensor in a wide range of applications, such as:

• Concentration measurement of acids and bases

• Quality monitoring of chemical products in tanks and pipes

• Phase separation of product/product mixtures

The digital sensor CLS50D is used in conjunction with the Liquiline CM44x/R or Liquiline M

CM42, while the analog sensor CLS50 is used with the Liquiline M CM42 or

Liquisys CLM223/253.

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable international standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

Endress+Hauser 9

Page 10

Basic safety instructions Indumax CLS50D/CLS50

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

2.5.1 State-of-the-art technology

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

2.5.2 Electrical equipment in hazardous areas

Sensors with ATEX approval (CLS50-G*** and CLS50D-BA**** for Zone 0, CLS50-V*** and

CLS50D-BV**** for Zone 2) have been developed and manufactured in compliance with

applicable European standards and guidelines and are suitable for use in hazardous areas. The

Declaration of Conformity confirms compliance with the harmonized European standards for

using the sensors in hazardous areas.

CLS50D-BA****, CLS50D-IA****, CLS50D-GB****, CLS50D-NA****, CLS50D-H****,

CLS50-G*** and CLS50-K***

• The sensors may be operated in an environment specified as Ex Zone 0 (1G).

• The sensors may only be used in liquid media with a conductivity >10 nS/cm.

• If the connecting cable runs through Ex Zone 0 (1G), it must be protected against

electrostatic charge.

CLS50D-BA****, CLS50D-IA****, CLS50D-NA**** and CLS50D-GB****

• The sensor is a digital sensor with the Memosens protocol and its connection values are

those specified below.

• The sensor may also be connected to the intrinsically safe Memosens connection of the

FSDG1 module of the Liquiline transmitter, types CM42-LE, CM42-LF, CM42-LI, EC typeexamination certificate EX5 05 03 30266 012 (ATEX or IECEx) or CM42-LK (EAC Ex).

• The maximum permitted length of the measuring cable is 100 m (330 ft) here.

Connection values of the CLS50D-BA****, CLS50D-IA**** and CLS50D-GB**** sensor

U

i

I

i

P

i

10 Endress+Hauser

5.1 V

130 mA

166 mW

Page 11

Indumax CLS50D/CLS50 Basic safety instructions

C

i

L

i

18 µF

72 µH

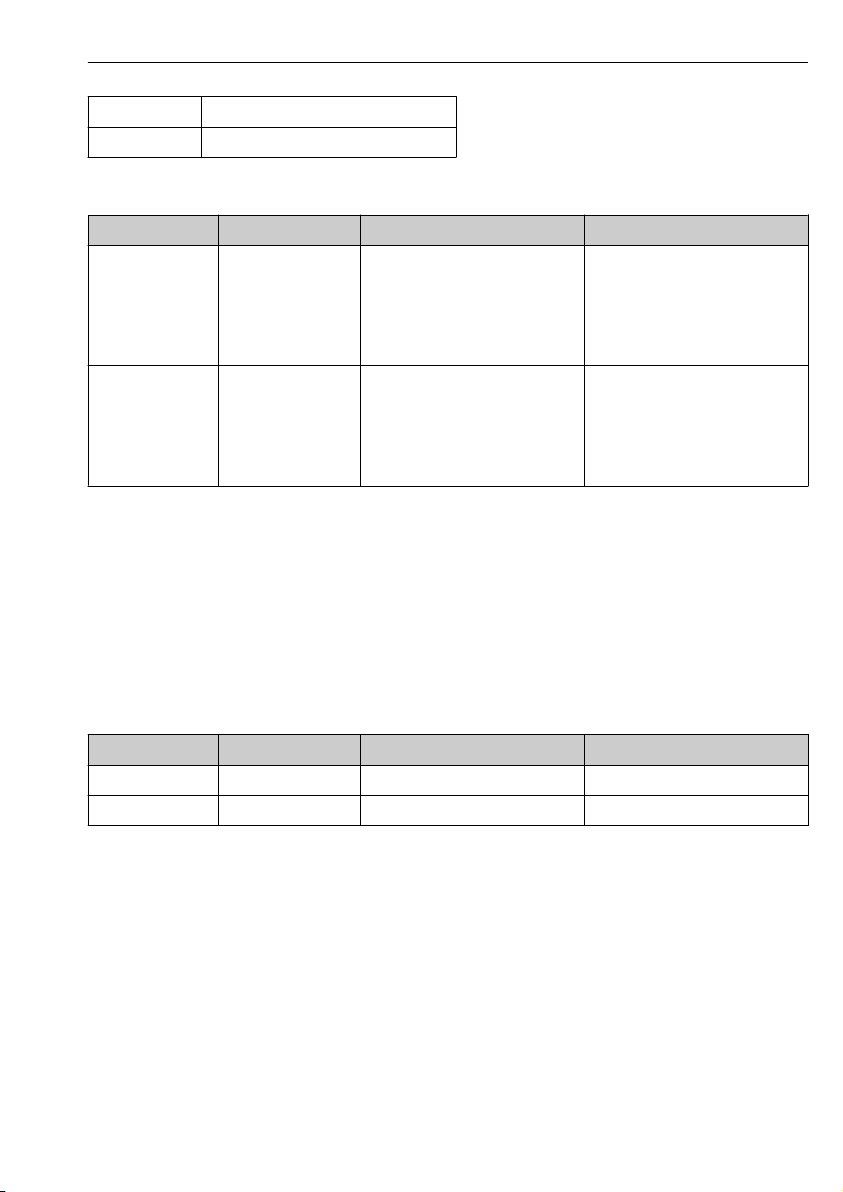

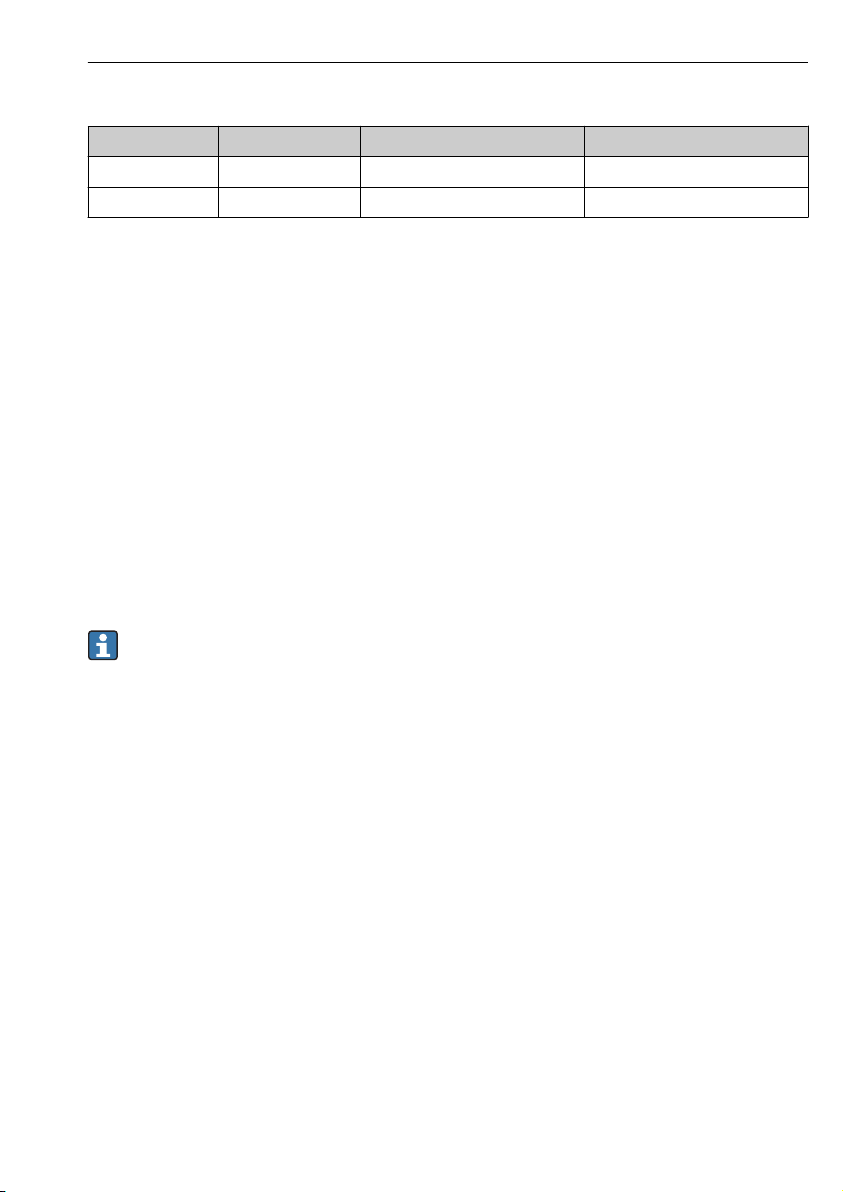

Temperature classes of CLS50D-BA****, CLS50D-IA**** and CLS50D-GB****

Temperature class Sensor Ambient temperature range TaMedium temperature range T

T4 CLS50D-BA/IA/

GB*D**

CLS50D-BA/IA/

GB*C**

CLS50D-BA/IA/

GB*B**

T6 CLS50D-BA/IA/

GB*D**

CLS50D-BA/IA/

GB*C**

CLS50D-BA/IA/

GB*B**

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +110 ˚C

-20 to +120 ˚C

-20 to +120 ˚C

-20 to +70 ˚C

-20 to +70 ˚C

-20 to +70 ˚C

CLS50-G***

• The sensor may only be connected to the following transmitters:

• Liquiline types CM42-IG, CM42-IE, CM42-IF, EC type-examination certificate TÜV 13

ATEX 7459 X

• Mycom type CLM153-Z with transmitter module type FCL1, EC type-examination

certificate DMT 99 ATEX E 076

• Mycom type CLM153-G, EC type-examination certificate DMT 01 ATEX E 174

• The maximum permitted length of the measuring cable is 55 m (180 ft) here.

med

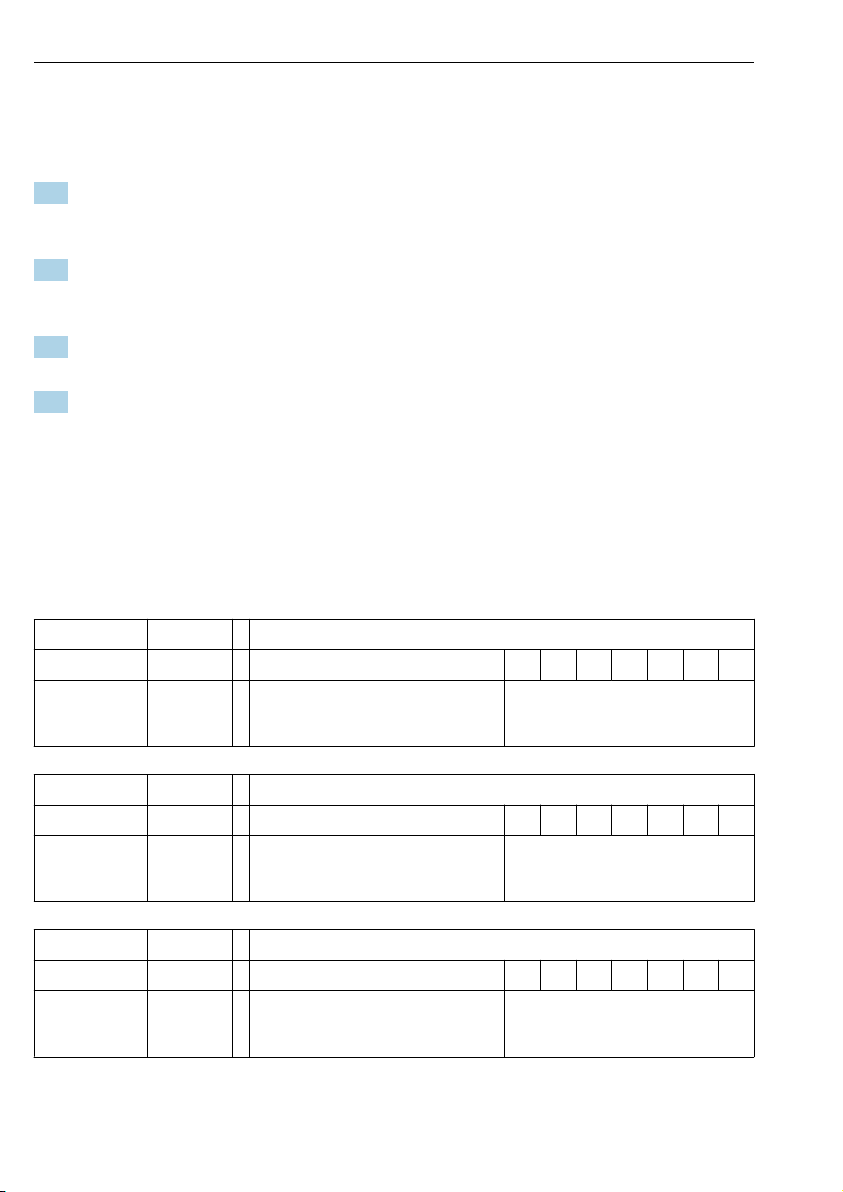

Temperature classes of CLS50-G***

Temperature class Sensor Ambient temperature range TaMedium temperature range T

T4 CLS50-G*** -20 to +125 ˚C -20 to +125 ˚C

T6 CLS50-G*** -20 to +75 ˚C -20 to +75 ˚C

med

CLS50D-BV**** and CLS50-V***

• The sensor may be operated in an environment specified as Ex Zone 2 (3G).

• The sensor may only be connected to the following transmitter:

Liquiline type CM42-LV (CLS50D) or CM42-IV (CLS50), EU Declaration of Conformity

EC_00143_01.16

• Only CLS50-V***: The maximum permitted length of the measuring cable is 55 m (180 ft)

here.

Endress+Hauser 11

Page 12

Basic safety instructions Indumax CLS50D/CLS50

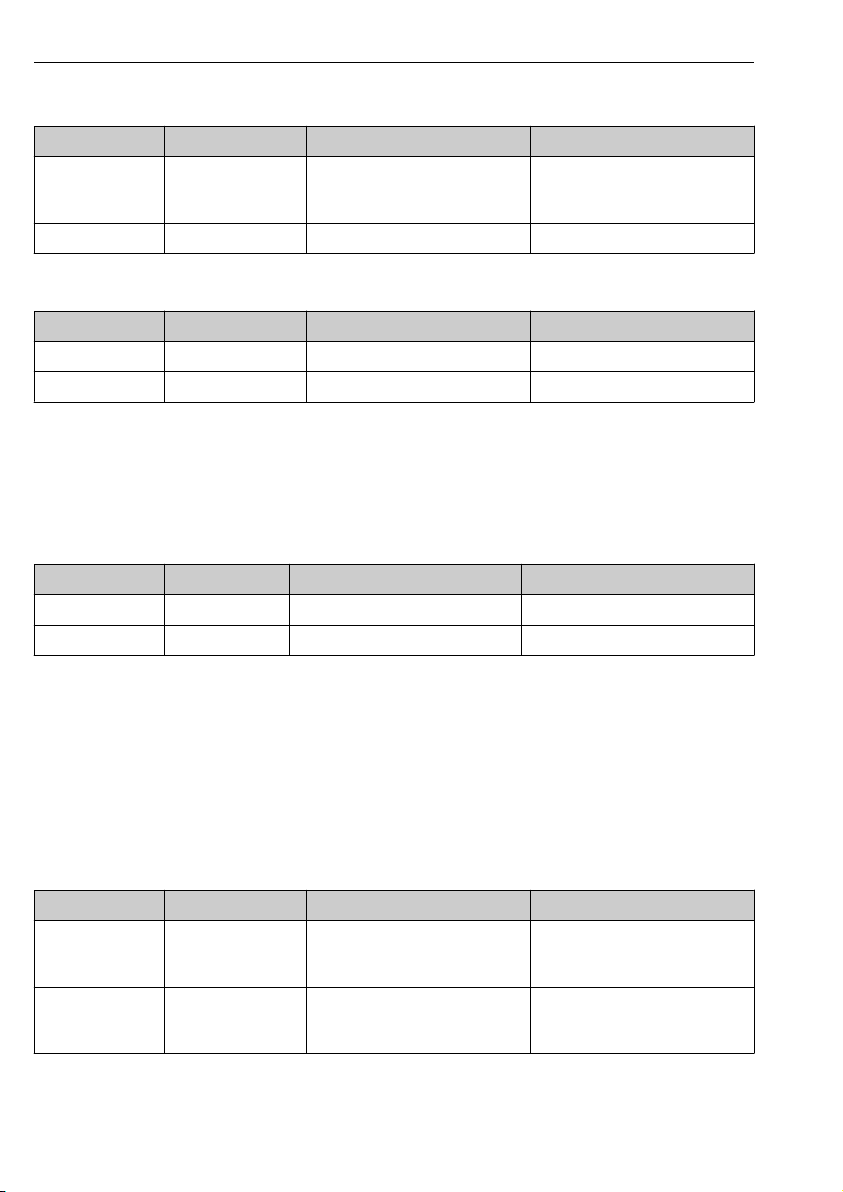

Temperature classes of CLS50D-BV****

Temperature class Sensor Ambient temperature range TaMedium temperature range T

T4 CLS50D-BV*D**

CLS50D-BV*C**

CLS50D-BV*B**

T6 CLS50D-BV**** -20 to +60 ˚C -20 to +70 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +110 ˚C

-20 to +120 ˚C

-20 to +120 ˚C

med

Temperature classes of CLS50-V***

Temperature class Sensor Ambient temperature range TaMedium temperature range T

T4 CLS50-V*** -20 to +125 ˚C -20 to +125 ˚C

T6 CLS50-V*** -20 to +75 ˚C -20 to +75 ˚C

med

CLS50-K***

• The sensor may only be connected to the following transmitter:

Liquiline type CM42-IK

• The maximum permitted length of the measuring cable is 55 m (180 ft) here.

Temperature classes of CLS50-K***

Temperature class Sensor Ambient temperature range T

T4 CLS50-K*** -20 to +125 ˚C -20 to +125 ˚C

T6 CLS50-K*** -20 to +75 ˚C -20 to +75 ˚C

Medium temperature range T

a

med

Sensors with FM and CSA approval (CLS50D-FB****, CLS50D-C2****, CLS50-O***,

CLS50-S***)

Observe the documentation and the control drawings of the transmitter.

Sensors with NEPSI approval (CLS50D-NA**** and CLS50-H*** for Zone 0, CLS50-V***

for Zone 2)

Pay attention to the information on the NEPSI certificates. You can download these

certificates from the product page: www.endress.com/cls50d or www.endress.com/cls50.

Temperature classes of CLS50D-NA****

Temperature class Sensor Ambient temperature range TaMedium temperature range T

T4 CLS50D-NA*D**

CLS50D-NA*C**

CLS50D-NA*B**

T6 CLS50D-NA*D**

CLS50D-NA*C**

CLS50D-NA*B**

12 Endress+Hauser

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +60 ˚C

-20 to +110 ˚C

-20 to +120 ˚C

-20 to +120 ˚C

-20 to +70 ˚C

-20 to +70 ˚C

-20 to +70 ˚C

med

Page 13

Indumax CLS50D/CLS50 Basic safety instructions

Temperature classes of CLS50-H***

Temperature class Sensor Ambient temperature range TaMedium temperature range T

T4 CLS50-H*** -20 to +125 ˚C -20 to +125 ˚C

T6 CLS50-H*** -20 to +75 ˚C -20 to +75 ˚C

med

Sensors with TIIS approval (CLS50D-TA****, CLS50-T***)

Sensors with TIIS approval may only be used in a Zone 1 (2G) environment.

The following also applies for all the sensors listed

• Compliance with the specified ambient and medium temperature ranges is a prerequisite

for safe use.

• The sensor must be connected and operated in accordance with the Operating Instructions

of the sensor and of the transmitter to be connected. All sensor operating data must be

observed.

• Avoid electrostatic charge. Metal process connections must be electrostatically connected (R

≤ 1 MΩ).

• Non-metal process connections must be protected against electrostatic charge.

• In order to avoid electrostatic charge clean the sensor with a damp cloth only.

• Full compliance with regulations for electrical systems in hazardous locations

(EN60079-14) is mandatory when using the devices and sensors.

• Ensure correct installation to maintain the housing protection type. (Use original seal. Fit

cable entry properly. Tighten nut).

• The degree of protection only applies when the flange is mounted.

CLS50 only

In the CLS50 sensor, the internal sensor circuits are connected with the shielded wire of

the supply cable. When installing the CM42 or CLM153 transmitter, the shielding of the

sensor cable must be connected to functional ground as prescribed. As a result, the

intrinsically safe sensor circuits of CLS50 are also connected to ground. Therefore, the

power supply of the transmitter must be galvanically isolated and connected to ground.

The CM42 and CLM153 transmitters already have secure internal galvanic isolation and

therefore safely separate the sensor circuit from the other circuits.

Endress+Hauser 13

Page 14

Incoming acceptance and product identification Indumax CLS50D/CLS50

3 Incoming acceptance and product identification

3.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

3.2 Product identification

3.2.1 Type code for versions with explosion protection

Name Type Version

Indumax - BA x x x x + x x

For use in hazardous areas, ATEX II 1G

Ex ia IIC T4/T6 Ga

Name Type Version

Indumax CLS50D - IA x x x x + x x

For use in hazardous areas, IECEx Ex ia

IIC T4/T6 Ga

Name Type Version

Indumax CLS50D - BV x x x x + x x

For use in hazardous areas, ATEX II 3G

Ex ic IIC T4/T6 Gc

14 Endress+Hauser

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Page 15

Indumax CLS50D/CLS50 Incoming acceptance and product identification

Name Type Version

Indumax CLS50D - NA x x x x + x x

For use in hazardous areas, NEPSI Ex ia

IIC T4/T6 Ga

Name Type Version

Indumax CLS50D - C2 x x x x + x x

For use in hazardous areas, CSA IS NI

Cl.I Div.1&2,Gr. A-D

Name Type Version

Indumax CLS50D - FB x x x x + x x

For use in hazardous areas, FM IS NI

C1.I Div.1&2, Gr. A-D

Name Type Version

Indumax CLS50D - GB x B/C/Dx x + x x

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

For use in hazardous areas, EAC Ex, 0Ex

ia IIC T6/T4 Ga X

Name Type Version

Indumax CLS50D - TA x x x x + x x

For use in hazardous areas, TIIS Ex ib IIC

T4 Gb

Name Type Version

Indumax CLS50 - G x x x

For use in hazardous areas, ATEX II 1G

Ex ia IIC T4/T6 Ga

Endress+Hauser 15

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Page 16

Incoming acceptance and product identification Indumax CLS50D/CLS50

Name Type Version

Indumax CLS50 - V x x x

For use in hazardous areas, ATEX II 3G

Ex ic IIC T4/T6 Gc / NEPSI Ex ic IIC

T4/T6 Gc

Name Type Version

Indumax CLS50 - H x x x

For use in hazardous areas, NEPSI Ex ia

IIC T4/T6 Ga

Name Type Version

Indumax CLS50 - O x x x

For use in hazardous areas, FM IS NI Cl.I

Div.1&2,Gr. A-D

Name Type Version

Indumax CLS50 - S x x x

For use in hazardous areas, CSA IS NI

Cl.I Div.1&2,Gr. A-D

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Name Type Version

Indumax CLS50 - T x x x

For use in hazardous areas, TIIS Ex ib IIC

T4 Gb

Name Type Version

Indumax CLS50 - K x x 1/2

For use in hazardous areas, EAC Ex, 0Ex

ia IIC T6/T4 Ga X

16 Endress+Hauser

Process connections, materials, cable

connection, calibration, service

No Ex relevance

/3/

4

Process connections, materials, cable

connection, calibration, service

No Ex relevance

Page 17

Indumax CLS50D/CLS50 Incoming acceptance and product identification

3.2.2 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

• Cell constant (nominal value)

• Degree of protection

• Ex labeling on hazardous area versions

Compare the information on the nameplate with the order.

‣

3.2.3 Product identification

Product page

www.endress.com/cls50d

www.endress.com/cls50

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

Manufacturer's address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

3.3 Scope of delivery

The scope of delivery includes:

• Sensor in the version ordered

• Operating Instructions

Endress+Hauser 17

Page 18

Incoming acceptance and product identification Indumax CLS50D/CLS50

If you have any queries:

‣

Please contact your supplier or local sales center.

3.4 Certificates and approvals

3.4.1

mark

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

3.4.2 Ex approvals CLS50D-BA**** and CLS50-G***

ATEX II 1G Ex ia IIC T4/T6 Ga

CLS50D-BV****

ATEX II 3G Ex ic IIC T4/T6 Gc

CLS50D-IA****

IECEx Ex ia IIC T4/T6 Ga

CLS50-V***

ATEX II 3G Ex ic IIC T4/T6 Gc + NEPSI Ex ic IIC T4/T6 Gc

CLS50D-NA**** and CLS50-H***

NEPSI Ex ia IIC T4/T6 Ga

CLS50D-FB**** and CLS50-O***

FM IS NI Cl.I Div.1&2,G. A-D

CLS50D-C2**** and CLS50-S***

CSA IS NI Cl.I Div.1&2,Gr. A-D

CLS50D-TA**** and CLS50-T***

TIIS Ex ib IIC T4 Gb

CLS50D-GB**** and CLS50-K***

• EAC Ex, 0Ex ia IIC T6/T4 Ga X

• Zone 0

• Certificate number: TC RU C-DE.AA87.B.00088 and TC RU C-DE.ГБ05.B.00172 (only

CLS50-K***)

• The product has been certified in accordance with Directive TR CU 012/2011 which applies

in the European Economic Area (EEA). The EAC conformity mark has been affixed to the

product.

3.4.3 Certification body (only CLS50D-GB and CLS50-K)

OOO "НАНИО ЦСВЭ"

Russian Federation

18 Endress+Hauser

Page 19

Indumax CLS50D/CLS50 Installation

1

2

a

max. 100

(3.94)

3.4.4 Marine approvals

A selection of sensors have type approval for marine applications, issued by the following

classification societies: ABS (American Bureau of Shipping), BV (Bureau Veritas), DNV-GL

(Det Norske Veritas-Germanische Lloyd) and LR (Lloyd’s Register). Details of the order codes

of the approved sensors, and the installation and ambient conditions, are provided in the

relevant certificates for marine applications on the product page on the Internet.

4 Installation

4.1 Installation conditions

4.1.1 Installation position

When installing, align the sensor in such a way that the medium flows through the flow

‣

opening of the sensor in the direction of medium flow.

The sensor head must be completely immersed in the medium.

1 Sensor orientation, dimensions in mm (in)

1 Direction of medium flow

2 Minimum water level in the pipe

a Distance from pipe wall

4.1.2 Installation factor

In confined installation conditions, the conductivity measurement is affected by the pipe walls.

The installation factor compensates for this effect. The transmitter corrects the cell constant

Endress+Hauser 19

A0036463

Page 20

Installation Indumax CLS50D/CLS50

1

2

a [inch]

0

5

10 15

20

2525

a [mm]

0 80.

1 00.

1 20.

1 40.

f

0.20

0.39

0.59

0.79

0.98

by multiplying by the installation factor. The value of the installation factor depends on the

diameter and the conductivity of the pipe nozzle as well as the sensor's distance to the wall.

The installation factor f can be disregarded (f = 1.00) if the distance to the wall is sufficient (a

> 15 mm (0.59"), from DN 80). If the distance to the wall is smaller, the installation factor

increases for electrically insulating pipes (f > 1) and decreases for electrically conductive pipes

(f < 1). It can be measured using calibration solutions, or a close approximation determined

from the following diagram.

2 Relationship between installation factor f and wall distance

1 Electrically conductive pipe wall

2 Electrically insulating pipe wall

4.1.3 Air set

CLS50D

The digital sensor has already been adjusted at the factory. Onsite compensation is not

required.

CLS50

To compensate residual coupling in the cable and between the two sensor coils, zero

adjustment in air ("air set") must be performed before installing the sensor. Follow the

instructions provided in the Operating Instructions of the transmitter used.

20 Endress+Hauser

A0034874

Page 21

Indumax CLS50D/CLS50 Installation

1 2

3

5

4

4.2 Mounting the sensor

4.2.1 Installation with flange

The sensor is suitable for installation in T-pieces ≥ DN 80, with the outgoing diameter reduced

to ≥ DN 50.

WARNING

L

Leakage

Risk of injury if medium escapes!

Tighten sensor nut using a torque of 20 Nm.

‣

To avoid leakages, regularly check the tightness of the nut.

‣

Flange, not in contact with medium

A0024949

3 Fixed flange, not in contact with medium (for order option: "Process connection" = 5, 6, 7)

1 Flange (stainless steel)

2 Nut

3 Sealing disk (GYLON)

4 O-ring

5 Sensor

Endress+Hauser 21

Page 22

Installation Indumax CLS50D/CLS50

1 2

4

3

Flange, in contact with medium

A0024953

4 Fixed flange, in contact with medium (for order option: "Process connection" = 3, 4)

1 Flange (stainless steel)

2 Nut

3 O-ring

4 Sensor

22 Endress+Hauser

Page 23

Indumax CLS50D/CLS50 Installation

1 2

3

5

4

Lap joint flange, not in contact with medium

A0024954

5 Lap joint flange, not in contact with medium (for order option: "Process connection" = A, B, C)

1 Lap joint flange (PP-GF)

2 Nut (stainless steel)

3 Flange (PVDF)

4 O-ring

5 Sensor

Endress+Hauser 23

Page 24

Electrical connection Indumax CLS50D/CLS50

1 2

3

4

4.2.2 Installation in assembly

A0024960

6 Installation of sensor with assembly

1 CLA111 with suspension bracket

2 CLA111 with flange connection

3 CLA140 with flange connection

4 CYA112

4.3 Post-installation check

Put the sensor into operation only if you can answer yes to the following questions:

1. Are the sensor and cable undamaged?

2. Is the orientation correct (arrow on threaded sleeve=flow direction=installation

direction)?

3. Has the sensor been installed in the process connection, and does not suspend freely

from the cable?

5 Electrical connection

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions and

‣

must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

24 Endress+Hauser

Page 25

Indumax CLS50D/CLS50 Electrical connection

II 2G

II 1G

II 3G

Ex ia

Zone 1

Zone 0

Zone 2

CLS50-G

CLS50D-BA

CLS50-G

5.1 Connection conditions

5.1.1 Connection diagram: sensors for Zone 0 (ATEX/EAC Ex)

A0013258

Endress+Hauser 25

Page 26

Electrical connection Indumax CLS50D/CLS50

II 2G

II 1G

Ex ia

Zone 1

Zone 0

CLS50D-IA

5.1.2 Connection diagram: sensors for Zone 0 (IECEx)

A0025482

26 Endress+Hauser

Page 27

Indumax CLS50D/CLS50 Electrical connection

II 2G

II 1G

Ex ia

Zone 1

Zone 0

CLS50-H

CLS50D-NA

5.1.3 Connection diagram: sensors for Zone 0 (NEPSI)

A0025481

Endress+Hauser 27

Page 28

Electrical connection Indumax CLS50D/CLS50

Ex ic

CLS50-V

4...20 mA

II 3G

Zone 2

CLS50D-BV

5.1.4 Connection diagram: sensors for Zone 2 (ATEX/NEPSI)

A0010316

5.1.5 Sensors with FM or CSA approval

The instructions in the Control Drawing apply for sensors with FM or CSA approval. You can

find the Control Drawing in the Operating Instructions of the transmitter used.

28 Endress+Hauser

Page 29

Indumax CLS50D/CLS50 Electrical connection

BN

YE

Sensor cable

588

587

187

188

197

Device

198

387

388

Sensor

U

+

WH

GN

U

–

Com A

Com B

GN

WH

YE

Cable

217

218

215

216

112

CM42

111

113

J

Sensor

RD

BU

RD

BU

RD

WH

5.2 Connecting the sensor

5.2.1 Direct connection, e.g. to CM42

7 CLS50D to CM42

A0001078

8 CLS50 to CM42

Endress+Hauser 29

A0001082

Page 30

Electrical connection Indumax CLS50D/CLS50

GY

GY

GN

WH

BN

YE

PK

Shield

-

Com A

-

+

Com B

+

Memosens

U

U

Additional

sensor supply

WH

RD

Pt 100

YE

GN

RD

WH

BU

BN n.c.

RD

BU

5.2.2 Cable extension

The sensor is supplied with a fixed cable. The cable between the sensor and transmitter can be

extended using the CYK11 (CLS50D) or CLK6 (CLS50) measuring cable (does not apply for use

in a hazardous environment).

9 CYK11 for extension of CLS50D

Total cable length (max.): 100 m (330 ft)

A0017984

10 CLK6 for extension of CLS50

Total cable length (max.): 55 m (180 ft)

A0024937

CLS50 only:

The residual coupling of the sensor increases when the fixed cable is extended.

5.3 Ensuring the degree of protection

Only the mechanical and electrical connections which are described in these instructions and

which are necessary for the required, designated use, may be carried out on the device

delivered.

Exercise care when carrying out the work.

‣

Otherwise, the individual types of protection (Ingress Protection (IP), electrical safety, EMC

interference immunity) agreed for this product can no longer be guaranteed due, for example

to covers being left off or cable (ends) that are loose or insufficiently secured.

5.4 Post-connection check

Device condition and specifications Action

Are the sensor, assembly, or cables free from damage on the

outside?

Electrical connection Action

Are the mounted cables strain-relieved and not twisted?

Is a sufficient length of the cable cores stripped, and are the

cores positioned in the terminal correctly?

Are all the screw terminals properly tightened?

Are all cable entries mounted, tightened and leak-tight? In the case of lateral cable entries:

Are all cable entries installed downwards or mounted laterally?

30 Endress+Hauser

Perform a visual inspection.

‣

Untwist the cables.

‣

Pull gently to check they are seated correctly.

‣

Tighten the screw terminals.

‣

Point cable loops downward so that water can

‣

drip off.

Page 31

Indumax CLS50D/CLS50 Commissioning

6 Commissioning

Prior to initial commissioning, ensure that:

• The sensor is correctly installed

• The electrical connection is correct

If using an assembly with automatic cleaning function:

Check that the cleaning medium (water or air, for example) is connected correctly.

‣

WARNING

L

Escaping process medium

Risk of injury from high pressure, high temperatures or chemical hazards!

Before applying pressure to an assembly with cleaning system, ensure that the system has

‣

been connected correctly.

If you cannot reliably establish the correct connection, do not install the assembly in the

‣

process.

At the transmitter, enter all the settings specific to the parameters and measuring point.

‣

The measuring point is then ready to measure.

Following commissioning, the sensor must be serviced at regular intervals, as only then

can reliable measurement be guaranteed.

Operating Instructions for the transmitter used, such as BA01245C if using the Liquiline

CM44x or CM44xR.

7 Maintenance

WARNING

L

Thiocarbamide

Harmful if swallowed! Limited evidence of carcinogenicity! Possible risk of harm to the unborn

child! Dangerous for the environment with long-term effects!

Wear protective goggles, protective gloves and appropriate protective clothing.

‣

Avoid all contact with the eyes, mouth and skin.

‣

Avoid discharge into the environment.

‣

Clean away fouling on the sensor as follows depending on the type of fouling:

1. Oily and greasy films:

Clean with fat solvent, e.g. alcohol, or hot water and agents containing surfactants

(alkaline) (e.g. dishwashing detergent).

2. Lime and metal hydroxide buildup and low solubility (lyophobic) organic buildup:

Dissolve buildup with diluted hydrochloric acid (3 %) and then rinse thoroughly with

plenty of clear water.

Endress+Hauser 31

Page 32

Repair Indumax CLS50D/CLS50

150

280, 285, 286

260, 270

250, 255

3. Sulfidic buildup (from flue gas desulfurization or wastewater treatment plants):

Use a mixture of hydrochloric acid (3 %) and thiocarbamide (commercially available)

and then rinse thoroughly with plenty of clear water.

4. Buildup containing proteins (e.g. food industry):

Use a mixture of hydrochloric acid (0.5 %) and pepsin (commercially available) and then

rinse thoroughly with plenty of clear water.

5. Readily soluble biological buildup:

Rinse with pressurized water.

After cleaning, rinse the sensor thoroughly with water.

8 Repair

8.1 Spare parts

Item No. Spare parts kit Order No.

150, 255 CHEMRAZ seal kit

150, 250 VITON seal kit

260 PTFE disk kit for DN 50 71086372

270 PTFE disk kit for ANSI 2" and JIS 10K 50A 71086374

150, 280 Fixed flange kit, DN 50, stainless steel 1.4404 (AISI

150, 285 Fixed flange kit, ANSI 2", stainless steel 1.4404 (AISI

150, 286 Fixed flange kit, JIS, stainless steel 1.4404 (AISI 316L)

A0025483

• Nut (item 150)

• CHEMRAZ O-ring, 2 pcs. (item 255)

• Nut (item 150)

• VITON O-ring, 3. pcs., (item 250)

316L)

• Nut (item 150)

• Flange DN 50 (item 280)

316L)

• Nut (item 150)

• Flange ANSI 2" (item 285)

• Nut (item 150)

• Flange DN 50 (item 286)

71086368

71086369

51500525

51500527

51500934

32 Endress+Hauser

Page 33

Indumax CLS50D/CLS50 Accessories

291, 292, 293

150

287, 288, 289

260, 270

250, 255

Item No. Spare parts kit Order No.

150, 288,

292

150, 287,

291

150, 289,

293

A0025484

Lap joint flange kit, ANSI 2", PVDF

• Nut (item 150)

• Flange ANSI 2", PVDF (item 288)

• Lap joint flange, UP-GF (item 292)

Lap joint flange kit, DN 50, PVDF

• Nut (item 150)

• Flange DN 50, PVDF (item 287)

• Lap joint flange, UP-GF (item 291)

Lap joint flange kit, JIS, PVDF

• Nut (item 150)

• Flange JIS, PVDF (item 289)

• Lap joint flange, UP-GF (item 293)

51500937

51500936

51500935

8.2 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

‣

8.3 Disposal

The device contains electronic components. The product must be disposed of as electronic

waste.

‣

9 Accessories

The following are the most important accessories available at the time this documentation

was issued.

‣

Endress+Hauser 33

Refer to the website www.endress.com/support/return-material for information on the

procedure and conditions for returning devices.

Observe the local regulations.

For accessories not listed here, please contact your Service or Sales Center.

Page 34

Accessories Indumax CLS50D/CLS50

9.1 Measuring cable

9.1.1 For CLS50D Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

9.1.2 For CLS50

Measuring cable CLK6

• Extension cable for inductive conductivity sensors, for extension via VBM junction box

• Sold by the meter, order number: 71183688

VBM

• Junction box for cable extension

• 10 terminal strips

• Cable entries: 2 x Pg 13.5 or 2 x NPT ½"

• Material: aluminum

• Degree of protection: IP 65

• Order numbers

• Cable entries Pg 13.5 : 50003987

• Cable entries NPT ½": 51500177

9.2 Assemblies

Dipfit CLA111

• Immersion assembly for open and closed vessels with flange DN 100

• Product Configurator on the product page: www.products.endress.com/cla111

Technical Information TI00135C

Dipfit CLA140

• For the CLS50/CLS50D inductive sensor

• Immersion assembly with flange connection for very demanding processes

• Product Configurator on the product page: www.products.endress.com/cla140

Technical Information TI00196C

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

34 Endress+Hauser

Page 35

Indumax CLS50D/CLS50 Technical data

9.3 Calibration solutions

Conductivity calibration solutions CLY11

Precision solutions referenced to SRM (Standard Reference Material) by NIST for qualified

calibration of conductivity measuring systems in accordance with ISO 9000

• CLY11-B, 149.6 μS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081903

• CLY11-C, 1.406 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081904

• CLY11-D, 12.64 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081905

• CLY11-E, 107.00 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081906

Technical Information TI00162C

10 Technical data

10.1 Input

10.1.1 Measured variables

• Conductivity

• Temperature

10.1.2 Measuring range

Conductivity

Temperature -20 to +180 °C (-4 to +350 °F)

10.1.3 Cell constant

k = 1.98 cm

10.1.4 Measuring frequency

2 kHz

10.1.5 Temperature measurement

CLS50D

Pt1000 (Class A according to IEC 60751)

CLS50

Pt100 (Class A according to IEC 60751)

Endress+Hauser 35

–1

2 μS/cm to 2000 mS/cm (uncompensated)

Page 36

Technical data Indumax CLS50D/CLS50

10.2 Performance characteristics

10.2.1 Conductivity response time

t95 ≤ 2 s

10.2.2 Temperature response time

PEEK version: t90 ≤ 7 min

PFA version: t90 ≤ 11 min

10.2.3 Maximum measured error

-20 to 100 °C (-4 to 212 °F): ±(5 μS/cm + 0.5 % of reading)

> 100 °C (212 °F): ±(10 μS/cm + 0.5 % of reading)

10.2.4 Repeatability

For T < 100 °C (212 °F): 0.2 % of reading + 1 µS/cm

For T > 100 °C (212 °F): 0.2 % of reading + 2 µS/cm

10.2.5 Linearity

1.9 % (only applies in the 1 to 20 mS/cm measuring range)

10.3 Environment

10.3.1 Ambient temperature

CLS50D

-10 to +60 °C (+10 to +140 °F)

CLS50

-10 to +70 °C (+10 to +160 °F)

10.3.2 Storage temperature

-20 to +80 °C (0 to +180 °F)

10.3.3 Degree of protection

IP 68 / NEMA type 6 (sensor in installed state with genuine seal)

36 Endress+Hauser

Page 37

Indumax CLS50D/CLS50 Technical data

10.4 Process

10.4.1 Process temperature

Sensor

material

PEEK –20 to 125 °C

PFA –20 to 110 °C

CLS50D-*1/2

Without flange

(-4 to 260 °F)

(-4 to 230 °F)

CLS50D-*3/4/5/6/8

DN50, ANSI 2"

–20 to 125 °C

(-4 to 260 °F)

–20 to 110 °C

(-4 to 230 °F)

CLS50D-*7

JIS

–20 to 125 °C

(-4 to 260 °F)

–20 to 110 °C

(-4 to 230 °F)

CLS50D-*A/B/C

PVDF lap joint flange

–20 to 125 °C

(-4 to 260 °F)

–20 to 110 °C

(-4 to 230 °F)

CLS50

Sensor

material

PEEK –20 to 180 °C

PFA –20 to 125 °C

CLS50-*1/2

Without flange

(-4 to 360 °F)

(-4 to 260 °F)

CLS50-*3/4/5/6/8

DN50, ANSI 2"

–20 to 180 °C

(-4 to 360 °F)

–20 to 125 °C

(-4 to 260 °F)

CLS50-*7

JIS

–20 to 180 °C

(-4 to 360 °F)

–20 to 125 °C

(-4 to 260 °F)

CLS50-*A/B/C

PVDF lap joint flange

–20 to 125 °C

(-4 to 260 °F)

–20 to 125 °C

(-4 to 260 °F)

10.4.2 Process pressure (absolute)

Max. 21 bar (305 psi), depending on the sensor version, see pressure-temperature ratings

Endress+Hauser 37

Page 38

Technical data Indumax CLS50D/CLS50

21

17

11

–20 +20

125

1

2

3

4

[°C]

[bar]

[°F]

[psi]

247

160

–4

257+68

5

110

230

0

+23

1006040 80

Ex

PFA

T

p (abs.)

1

305

15

10.4.3 Temperature/pressure ratings

CLS50D

A0024981

11 Pressure temperature ratings CLS50D

1 PEEK sensor, without a flange

2 PFA sensor, without a flange (blue line)

3 PEEK or PFA sensor, with DN50/ANSI 2" flange (red line)

4 PEEK or PFA sensor, with JIS flange

5 PEEK or PFA sensor, with PVDF lap joint flange (green line)

38 Endress+Hauser

Page 39

Indumax CLS50D/CLS50 Technical data

21

17

11

–20 +20

125

180

1

2

3

4

[°C]

[bar]

[°F]

[psi]

247

160

–4

257

356

+68

5

0

+23

10060 140 16040 80

6

T

p (abs.)

305

1

15

CLS50

A0024979

12 Pressure-temperature ratings for CLS50

1 PEEK sensor, without a flange

2 PFA sensor, without a flange or with DN50/ANSI 2" flange (blue line)

3 PEEK sensor, with DN50/ANSI 2" flange (red line)

4 PFA sensor, with JIS flange (black line)

5 PEEK or PFA sensor, with PVDF lap joint flange (green line)

6 PEEK sensor, with JIS flange (gray line)

10.5 Mechanical construction

10.5.1 Weight

Approx. 0.65 kg (1.43 lbs)

10.5.2 Materials

Sensor PEEK, PFA (depending on version)

Sensor seal VITON, CHEMRAZ (depending on version)

Endress+Hauser 39

Page 40

Technical data Indumax CLS50D/CLS50

d

2

a

Ø k

D

b

d

2

a

Ø k

D

b

1

2

Process connections

G¾ CLS50D-*1B/C**: PEEK GF30

NPT 1" PEEK

Fixed flange Stainless steel 1.4404 (AISI 316L)

Sealing disk GYLON (PTFE ceramic-filled)

Lap joint flange PP-GF

Flange combined with lap joint flange PVDF

CLS50D-*1D**: stainless steel (AISI 316Ti)

CLS50-*1A*: stainless steel 1.4571 (AISI 316Ti)

CLS50-*1B/C/1/2/3: PEEK GF30

CLS50-*1B/C5/6: stainless steel 1.4571 (AISI 316Ti)

10.5.3 Process connections

• G¾ thread

• NPT 1" thread

• Lap joint flange EN 1092 DN50 PN10

• Lap joint flange ANSI 2" 150 lbs

• Lap joint flange JIS 10K 50A

• Flange EN 1092-1 DN50 PN16

• Flange ANSI 2" 300 lbs

• Flange JIS 10K 50A

Flange dimensions

13 Flange dimensions

1 Lap joint flange (PP-GF)

2 Fixed flange (stainless steel)

40 Endress+Hauser

A0024986

Page 41

Indumax CLS50D/CLS50 Technical data

Dimensions in mm

Lap joint flange PP-GF DN50 PN10 ANSI 2" 150 lbs JIS 10K 50A

D 165 165 152

Ø k 125 121 120

d

2

4 x 18 8 x 19 4 x 19

b 18 18 18

a 78 78 78

Screws M16 M16 M16

Dimensions in mm

Fixed flange SS 316 L DN50 PN10 ANSI 2" 300 lbs JIS 10K 50A

D 165 165.1 155

Ø k 125 127 120

d

2

b 18 22.2 16

a 27 27 27

Screws M16 M16 M16

4 x 18 8 x 19 4 x 19

10.5.4 Chemical resistance

Medium Concentration PEEK PFA CHEMRAZ VITON

Sodium hydroxide

solution

NaOH

Nitric acid

HNO

3

Phosphoric acid

H3PO

4

Sulfuric acid

H2SO

4

Hydrochloric acid

HCl

Endress+Hauser 41

0 to 50 % 20 to 100 °C

(68 to 212 °F)

0 to 10 % 20 to 100 °C

(68 to 212 °F)

20 to 50 °C

(68 to 122 °F)

20 to 80 °C

(68 to 176 °F)

0 to 40 % 20 °C (68 °F) 20 to 60 °C

(68 to 140 °F)

0 to 80 % 20 to 100 °C

(68 to 212 °F)

0 to 2.5 % 20 to 80 °C

(68 to 176 °F)

20 to 60 °C

(68 to 140 °F)

20 to 100 °C

(68 to 212 °F)

0 to 30 % 20 °C (68 °F) 20 to 100 °C

(68 to 212 °F)

0 to 5 % 20 to 100 °C

(68 to 212 °F)

0 to 10 % 20 to 100 °C

(68 to 212 °F)

20 to 80 °C

(68 to 176 °F)

20 to 80 °C

(68 to 176 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

Not suitable

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

Page 42

Index Indumax CLS50D/CLS50

Index

A

Accessories ..................... 33

Air set ........................ 20

Ambient temperature ............... 36

Approvals ...................... 18

Marine .....................19

Assembly ...................... 24

C

Cable extension ...................30

Calibration solutions ................35

Cell constant .................... 35

Certificates ..................... 18

Check

Connection .................. 30

Installation .................. 24

Chemical resistance ................ 41

Cleaning agent ................... 31

Conductivity response time ............36

Connection

Check ..................... 30

Ensuring the degree of protection ..... 30

Connection conditions ...............25

D

Declaration of Conformity ........... 2, 18

Degree of protection ................36

Ensuring ....................30

Designated use ....................9

Direct connection to transmitter .........29

Disposal ....................... 33

E

Electrical connection ................24

Environment .................... 36

EU Declaration of Conformity ........... 2

Ex approvals .................... 18

F

Flange ........................ 21

H

Hazardous areas .................. 10

Input .........................35

Installation ..................... 19

Installation conditions ...............19

Installation factor ................. 19

Installation position ................ 19

Interpreting the order code ............ 17

L

Linearity .......................36

M

Maintenance .................... 31

Manufacturer's address .............. 17

Marine ........................19

Materials ...................... 39

Maximum measured error ............ 36

Measured variables ................ 35

Measuring frequency ............... 35

Measuring ranges ................. 35

Mechanical construction ............. 39

N

Nameplate ..................... 17

O

Operational safety ................. 10

P

Performance characteristics ........... 36

Post-installation check .............. 24

Pressure/temperature ratings .......... 38

Process ........................37

Process connections ................ 40

Process pressure .................. 37

Process temperature ................37

Product identification .............14, 17

Product page .................... 17

Product safety ................... 10

R

Repair ........................ 32

Repeatability .................... 36

Requirements for personnel ............ 9

Return ........................ 33

I

Incoming acceptance ................14

42 Endress+Hauser

Page 43

Indumax CLS50D/CLS50 Index

S

Safety

Electrical equipment in hazardous areas . 10

Safety instructions ..................9

Scope of delivery .................. 17

Sensor

Connecting .................. 29

Connection in hazardous area ....... 25

Mounting ................... 21

State-of-the-art technology ............10

Storage temperature ................36

Symbols ........................ 7

T

Technical data ................... 35

Environment ................. 36

Mechanical construction .......... 39

Performance characteristics ........ 36

Process .....................37

Temperature measurement ............35

Temperature response time ............36

Temperature/pressure ratings .......... 38

Type code ...................... 14

U

Use ...........................9

W

Warnings ....................... 7

Weight ........................39

Wiring ........................29

Workplace safety .................. 9

Endress+Hauser 43

Page 44

*71464663*

71464663

www.addresses.endress.com

Loading...

Loading...