Page 1

TI00182C/07/EN/17.18

71420290

2018-10-31

Products

Solutions Services

Technical Information

Indumax CLS50D/CLS50

Inductive conductivity sensor for standard, Ex and

high-temperature applications

Digital sensor with Memosens protocol or analog

sensor

Application

Indumax CLS50D or CLS50 sensor is particularly suitable for use in the chemical and

process technology sectors. The six-decade measuring range and the excellent

chemical resistance properties of the materials in contact with the medium (PFA or

PEEK) make it possible to use this sensor in a wide range of applications, such as:

• Concentration measurement of acids and bases

• Quality monitoring of chemical products in tanks and pipes

• Phase separation of product/product mixtures

The digital sensor CLS50D is used in conjunction with the Liquiline CM44x/R or

Liquiline M CM42, while the analog sensor CLS50 is used with the Liquiline M CM42

or Liquisys CLM223/253.

Your benefits

• High durability

– High chemical resistance thanks to PFA coating

– PEEK version for temperatures up to 180 °C (356 °F)

• Low risk of soiling

– Dirt-repellent PFA surface

– Large sensor opening

• Easy installation

– Can be installed in pipes ≥ DN 80

– Total cable length up to 55 m (180 ft)

• Large measuring range from 2 μS/cm to 2000 mS/cm

• Integrated, coated Pt 100 temperature sensor, error class A

• Ex approval Ex ia IIC T4/T6

Other advantages of Memosens technology

• Maximum process safety

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Recording of sensor load data in the sensor enables predictive maintenance

Page 2

Function and system design

3

4

1 2

3

4

5

Indumax CLS50D/CLS50

Measuring principle

Inductive conductivity measurement

An oscillator (1) generates an alternating magnetic field in the primary coil (5), which induces a

current flow (4) in the medium. The strength of the current depends on the conductivity and thus on

the ion concentration in the medium. The current flow in the medium, in turn, generates a magnetic

field in the secondary coil (3). The resulting induced current is measured by the receiver (2) and used

to determine the conductivity.

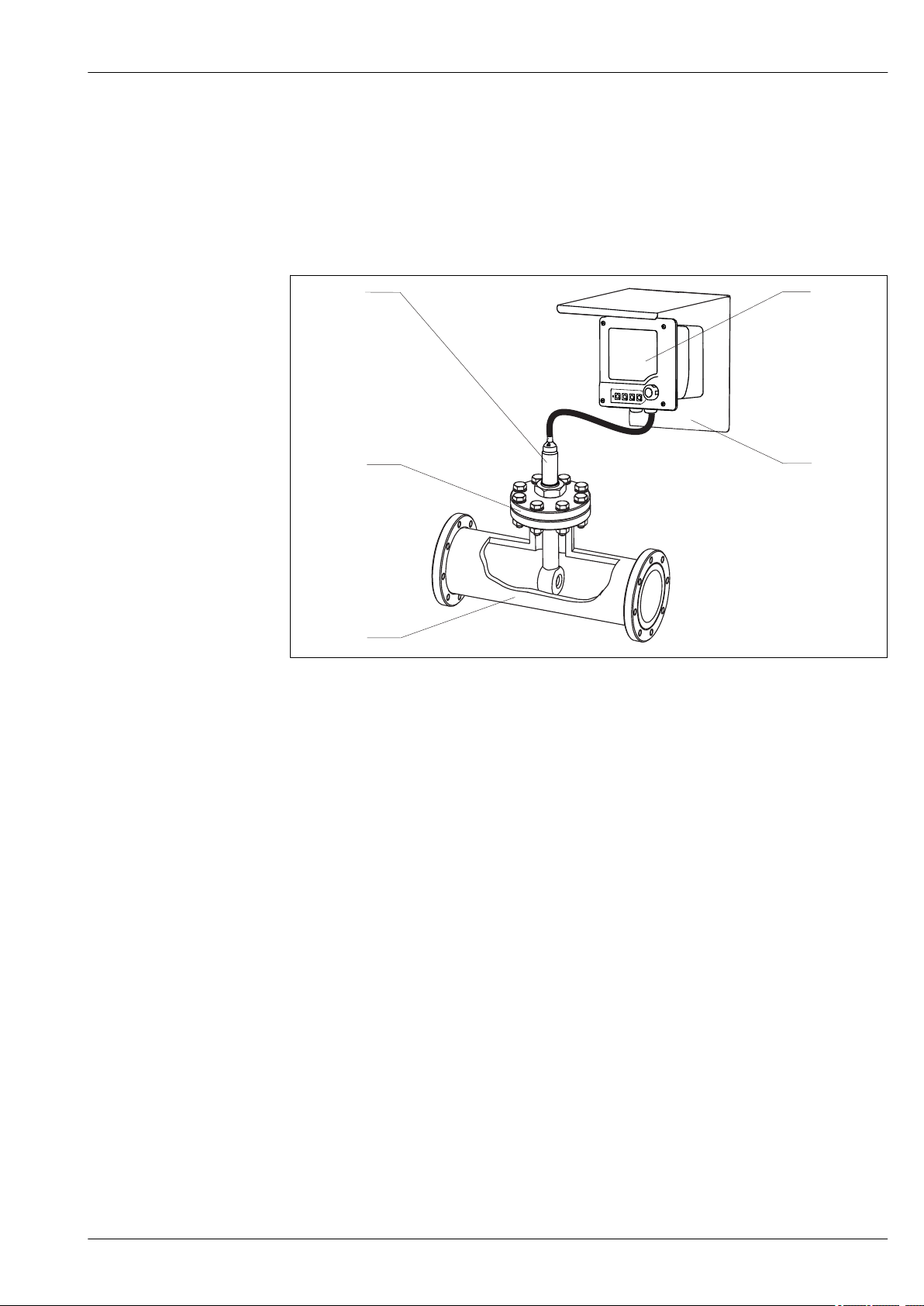

Measuring system CLS50D

1

Oscillator

2

Receiver

3

Secondary coil

4

Current flow in the medium

5

Primary coil

Advantages of inductive conductivity measurement:

• No electrodes and therefore no polarization effects

• Accurate measurement in media with a high degree of

pollution and a tendency to form buildup

• Complete galvanic isolation of the measurement and the

medium

A0024926

A complete measuring system comprises:

• A CLS50D inductively measuring conductivity sensor with fixed cable

• A transmitter, e.g. Liquiline CM44x

Optional:

• Weather protection for the field installation of the transmitter

• Assembly to install the sensor in vessels or pipes, e.g. CLA111

1 Example of a measuring system

1 Liquiline CM44x transmitter

2 Protective cover

3 Pipe nozzle with flange DN50 PN16

4 CLS50D sensor, version with flange DN50 PN16 and fixed cable with M12 connector

5 Pipe

A0024929

2 Endress+Hauser

Page 3

Indumax CLS50D/CLS50

21

3

4

5

CLS50

A complete measuring system comprises:

• A CLS50 inductively measuring conductivity sensor with fixed cable

• A transmitter, e.g. Liquiline M CM42

Optional:

• Weather protection for the field installation of the transmitter

• Assembly to install the sensor in vessels or pipes, e.g. CLA111

2 Example of a measuring system

1 CLS50 sensor, version with lap joint flange and fixed cable with ferrules

2 Liquiline CM42 transmitter

3 Protective cover

4 Pipe

5 Pipe nozzle with flange connection

A0024930

Endress+Hauser 3

Page 4

Indumax CLS50D/CLS50

Communication and data processing (CLS50D only)

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. Data transmission to a transmitter for analog sensors is not possible.

Digital sensors can store measuring system data in the sensor. These include the following:

• Manufacturer data

– Serial number

– Order code

– Date of manufacture

• Calibration data

– Calibration date

– Cell constant

– Delta cell constant

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operating data

– Temperature application range

– Conductivity application range

– Date of initial commissioning

– Maximum temperature value

– Hours of operation at high temperatures

Input

Measured variables

Measuring ranges

Cell constant

Measuring frequency

Temperature measurement CLS50D

• Conductivity

• Temperature

Conductivity

Temperature -20 to +180 °C (-4 to +350 °F)

k = 1.98 cm

2 kHz

Pt1000 (Class A according to IEC 60751)

CLS50

Pt100 (Class A according to IEC 60751)

2 μS/cm to 2000 mS/cm (uncompensated)

–1

4 Endress+Hauser

Page 5

Indumax CLS50D/CLS50

GY

GY

GN

WH

BN

YE

PK

Shield

-

Com A

-

+

Com B

+

Memosens

U

U

Additional

sensor supply

WH

RD

Pt 100

YE

GN

RD

WH

BU

BN n.c.

RD

BU

Power supply

Electrical connection

Conductivity response time

The sensor is supplied with a fixed cable. The cable between the sensor and transmitter can be

extended using the CYK11 (CLS50D) or CLK6 (CLS50) measuring cable (does not apply for use in a

hazardous environment).

A0017984

3 CYK11 for extension of CLS50D

Total cable length (max.): 100 m (330 ft)

CLS50 only:

The residual coupling of the sensor increases when the fixed cable is extended.

4 CLK6 for extension of CLS50

Total cable length (max.): 55 m (180 ft)

A0024937

Performance characteristics

t95 ≤ 2 s

Temperature response time

Maximum measured error

Repeatability

Linearity

PEEK version:

PFA version: t90 ≤ 11 min

-20 to 100 °C (-4 to 212 °F):

> 100 °C (212 °F): ±(10 μS/cm + 0.5 % of reading)

0.2% of reading

1.9 % (only applies in the 1 to 20 mS/cm measuring range)

t90 ≤ 7 min

±(5 μS/cm + 0.5 % of reading)

Endress+Hauser 5

Page 6

Installation

1

2

a

max. 100

(3.94)

1

2

a [inch]

0

5

10 15

20

2525

a [mm]

0 80.

1 00.

1 20.

1 40.

f

0.20

0.39

0.59

0.79

0.98

Indumax CLS50D/CLS50

Orientation

When installing, align the sensor in such a way that the medium flows through the flow opening

‣

of the sensor in the direction of medium flow.

The sensor head must be completely immersed in the medium.

5 Sensor orientation, dimensions in mm (in)

1 Direction of medium flow

2 Minimum water level in the pipe

a Distance from pipe wall

A0036463

Installation factor

In confined installation conditions, the conductivity measurement is affected by the pipe walls. The

installation factor compensates for this effect. The transmitter corrects the cell constant by

multiplying by the installation factor. The value of the installation factor depends on the diameter

and the conductivity of the pipe nozzle as well as the sensor's distance to the wall. The installation

factor f can be disregarded (f = 1.00) if the distance to the wall is sufficient (a > 15 mm (0.59"), from

DN 80). If the distance to the wall is smaller, the installation factor increases for electrically

insulating pipes (f > 1) and decreases for electrically conductive pipes (f < 1). It can be measured

using calibration solutions, or a close approximation determined from the following diagram.

6 Relationship between installation factor f and wall distance

1 Electrically conductive pipe wall

2 Electrically insulating pipe wall

A0034874

6 Endress+Hauser

Page 7

Indumax CLS50D/CLS50

1 2

3

5

4

Air set CLS50D

The digital sensor has already been adjusted at the factory. Onsite compensation is not required.

CLS50

To compensate residual coupling in the cable and between the two sensor coils, zero adjustment in

air ("air set") must be performed before installing the sensor. Follow the instructions provided in the

Operating Instructions of the transmitter used.

Installation with flange

The sensor is suitable for installation in T-pieces ≥ DN 80, with the outgoing diameter reduced to ≥

DN 50.

WARNING

L

Leakage

Risk of injury if medium escapes!

Tighten sensor nut using a torque of 20 Nm.

‣

To avoid leakages, regularly check the tightness of the nut.

‣

Flange, not in contact with medium

7 Fixed flange, not in contact with medium (for order option: "Process connection" = 5, 6, 7)

1 Flange (stainless steel)

2 Nut

3 Sealing disk (GYLON)

4 O-ring

5 Sensor

A0024949

Endress+Hauser 7

Page 8

Indumax CLS50D/CLS50

1 2

4

3

1 2

3

5

4

Flange, in contact with medium

8 Fixed flange, in contact with medium (for order option: "Process connection" = 3, 4)

1 Flange (stainless steel)

2 Nut

3 O-ring

4 Sensor

A0024953

Lap joint flange, not in contact with medium

9 Lap joint flange, not in contact with medium (for order option: "Process connection" = A, B, C)

1 Lap joint flange (PP-GF)

2 Nut (stainless steel)

3 Flange (PVDF)

4 O-ring

5 Sensor

A0024954

8 Endress+Hauser

Page 9

Indumax CLS50D/CLS50

1 2

3

4

Installation in assembly

A0024960

10 Installation of sensor with assembly

1 CLA111 with suspension bracket

2 CLA111 with flange connection

3 CLA140 with flange connection

4 CYA112

Environment

Ambient temperature range CLS50D

-10 to +60 °C (+10 to +140 °F)

CLS50

-10 to +70 °C (+10 to +160 °F)

Storage temperature

Degree of protection

-20 to +80 °C (0 to +180 °F)

IP 68 / NEMA type 6 (sensor in installed state with genuine seal)

Process

Process temperature

Sensor

material

PEEK –20 to 125 °C

PFA –20 to 110 °C

CLS50D-*1/2

Without flange

(-4 to 260 °F)

(-4 to 230 °F)

CLS50D-*3/4/5/6/8

DN50, ANSI 2"

–20 to 125 °C

(-4 to 260 °F)

–20 to 110 °C

(-4 to 230 °F)

CLS50D-*7

JIS

–20 to 125 °C

(-4 to 260 °F)

–20 to 110 °C

(-4 to 230 °F)

CLS50D-*A/B/C

PVDF lap joint flange

–20 to 125 °C

(-4 to 260 °F)

–20 to 110 °C

(-4 to 230 °F)

Endress+Hauser 9

CLS50

Sensor

material

PEEK –20 to 180 °C

PFA –20 to 125 °C

CLS50-*1/2

Without flange

(-4 to 360 °F)

(-4 to 260 °F)

CLS50-*3/4/5/6/8

DN50, ANSI 2"

–20 to 180 °C

(-4 to 360 °F)

–20 to 125 °C

(-4 to 260 °F)

CLS50-*7

JIS

–20 to 180 °C

(-4 to 360 °F)

–20 to 125 °C

(-4 to 260 °F)

CLS50-*A/B/C

PVDF lap joint flange

–20 to 125 °C

(-4 to 260 °F)

–20 to 125 °C

(-4 to 260 °F)

Page 10

Indumax CLS50D/CLS50

21

17

11

–20 +20

125

1

2

3

4

[°C]

[bar]

[°F]

247

–4

257+68

5

110

230

0

+23

1006040 80

Ex

PFA

T

p (abs.)

1

305

15

21

17

11

–20 +20

125

180

1

2

3

4

[°C]

[bar]

[°F]

[psi]

247

–4

257

356

+68

5

0

+23

10060 140 16040 80

6

T

p (abs.)

305

1

15

Process pressure (absolute)

Temperature/pressure ratings

Max. 21 bar (305 psi), depending on the sensor version, see pressure-temperature ratings

CLS50D

A0024981

11 Pressure temperature ratings CLS50D

1 PEEK sensor, without a flange

2 PFA sensor, without a flange (blue line)

3 PEEK or PFA sensor, with DN50/ANSI 2" flange (red line)

4 PEEK or PFA sensor, with JIS flange

5 PEEK or PFA sensor, with PVDF lap joint flange (green line)

CLS50

12 Pressure-temperature ratings for CLS50

1 PEEK sensor, without a flange

2 PFA sensor, without a flange or with DN50/ANSI 2" flange (blue line)

3 PEEK sensor, with DN50/ANSI 2" flange (red line)

4 PFA sensor, with JIS flange (black line)

5 PEEK or PFA sensor, with PVDF lap joint flange (green line)

6 PEEK sensor, with JIS flange (gray line)

A0024979

10 Endress+Hauser

Page 11

Indumax CLS50D/CLS50

28 (1.10)

! 24 (0.94)*

! 39 (1.54)

! 15.0 (0.59)

! 47.5 (1.87)

SW 36

G3/4

95 (3.74)

151 (5.94) / 153 (6.02)*

! 15.5 (0.61)*

! 23.3 (0.92)

! 49.9 (1.96)

NPT 1"

SW 46

35 (1.38)

Dimensions

Mechanical construction

Weight

Materials

A0037977

13 Version with G¾ thread, dimensions in mm

(inch)

* Dimension for PEEK version

14 Version with NPT 1" thread, dimensions in mm

(inch)

Approx. 0.65 kg (1.43 lbs)

Sensor PEEK, PFA (depending on version)

Sensor seal VITON, CHEMRAZ (depending on version)

Process connections

G¾ CLS50D-*1B/C**: PEEK GF30

CLS50D-*1D**: stainless steel (AISI 316Ti)

CLS50-*1A*: stainless steel 1.4571 (AISI 316Ti)

CLS50-*1B/C/1/2/3: PEEK GF30

CLS50-*1B/C5/6: stainless steel 1.4571 (AISI 316Ti)

NPT 1" PEEK

Fixed flange Stainless steel 1.4404 (AISI 316L)

Sealing disk GYLON (PTFE ceramic-filled)

Lap joint flange PP-GF

Flange combined with lap joint flange PVDF

A0037978

Endress+Hauser 11

Page 12

Indumax CLS50D/CLS50

d

2

a

Ø k

D

b

d

2

a

Ø k

D

b

1

2

Process connections

• G¾ thread

• NPT 1" thread

• Lap joint flange EN 1092 DN50 PN10

• Lap joint flange ANSI 2" 150 lbs

• Lap joint flange JIS 10K 50A

• Flange EN 1092-1 DN50 PN16

• Flange ANSI 2" 300 lbs

• Flange JIS 10K 50A

Flange dimensions

A0024986

15 Flange dimensions

1 Lap joint flange (PP-GF)

2 Fixed flange (stainless steel)

Dimensions in mm

Lap joint flange PP-GF DN50 PN10 ANSI 2" 150 lbs JIS 10K 50A

D 165 165 152

Ø k 125 121 120

d

2

b 18 18 18

a 78 78 78

Screws M16 M16 M16

4 x 18 8 x 19 4 x 19

Dimensions in mm

Fixed flange SS 316 L DN50 PN10 ANSI 2" 300 lbs JIS 10K 50A

D 165 165.1 155

Ø k 125 127 120

d

2

b 18 22.2 16

a 27 27 27

Screws M16 M16 M16

4 x 18 8 x 19 4 x 19

12 Endress+Hauser

Page 13

Indumax CLS50D/CLS50

Chemical resistance

Medium Concentration PEEK PFA CHEMRAZ VITON

Sodium

hydroxide

solution

NaOH

Nitric acid

HNO

3

Phosphoric acid

H3PO

4

Sulfuric acid

H2SO

4

Hydrochloric

acid

HCl

0 to 50 % 20 to 100 °C

(68 to 212 °F)

0 to 10 % 20 to 100 °C

(68 to 212 °F)

0 to 40 % 20 °C (68 °F) 20 to 60 °C

0 to 80 % 20 to 100 °C

(68 to 212 °F)

0 to 2.5 % 20 to 80 °C

(68 to 176 °F)

0 to 30 % 20 °C (68 °F) 20 to 100 °C

0 to 5 % 20 to 100 °C

(68 to 212 °F)

0 to 10 % 20 to 100 °C

(68 to 212 °F)

20 to 50 °C

(68 to 122 °F)

20 to 80 °C

(68 to 176 °F)

(68 to 140 °F)

20 to 60 °C

(68 to 140 °F)

20 to 100 °C

(68 to 212 °F)

(68 to 212 °F)

20 to 80 °C

(68 to 176 °F)

20 to 80 °C

(68 to 176 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

0 to 150 °C

(32 to 302 °F)

Not suitable

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

0 to 120 °C

(32 to 248 °F)

Certificates and approvals

mark

Ex approvals

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

CLS50D-BA**** and CLS50-G***

ATEX II 1G Ex ia IIC T4/T6 Ga

CLS50D-BV****

ATEX II 3G Ex ic IIC T4/T6 Gc

CLS50D-IA****

IECEx Ex ia IIC T4/T6 Ga

CLS50-V***

ATEX II 3G Ex ic IIC T4/T6 Gc + NEPSI Ex ic IIC T4/T6 Gc

CLS50D-NA**** and CLS50-H***

NEPSI Ex ia IIC T4/T6 Ga

CLS50D-FB**** and CLS50-O***

FM IS NI Cl.I Div.1&2,G. A-D

CLS50D-C2**** and CLS50-S***

CSA IS NI Cl.I Div.1&2,Gr. A-D

CLS50D-TA**** and CLS50-T***

TIIS Ex ib IIC T4 Gb

CLS50D-GB**** and CLS50-K***

• EAC Ex, 0Ex ia IIC T6/T4 Ga X

• Zone 0

• Certificate number: TC RU C-DE.AA87.B.00088 and TC RU C-DE.ГБ05.B.00172 (only CLS50K***)

• The product has been certified in accordance with Directive TR CU 012/2011 which applies in the

European Economic Area (EEA). The EAC conformity mark has been affixed to the product.

Endress+Hauser 13

Page 14

Ordering information

Indumax CLS50D/CLS50

Product page

Product Configurator

www.endress.com/cls50d

www.endress.com/cls50

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Measuring cable For CLS50D

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Assemblies

For CLS50

Measuring cable CLK6

• Extension cable for inductive conductivity sensors, for extension via VBM junction box

• Sold by the meter, order number: 71183688

VBM

• Junction box for cable extension

• 10 terminal strips

• Cable entries: 2 x Pg 13.5 or 2 x NPT ½"

• Material: aluminum

• Degree of protection: IP 65

• Order numbers

– Cable entries Pg 13.5 : 50003987

– Cable entries NPT ½": 51500177

Dipfit CLA111

• Immersion assembly for open and closed vessels with flange DN 100

• Product Configurator on the product page: www.products.endress.com/cla111

Technical Information TI00135C

Dipfit CLA140

• For the CLS50/CLS50D inductive sensor

• Immersion assembly with flange connection for very demanding processes

• Product Configurator on the product page: www.products.endress.com/cla140

Technical Information TI00196C

14 Endress+Hauser

Page 15

Indumax CLS50D/CLS50

FlexdipCYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Calibration solutions

Conductivity calibration solutions CLY11

Precision solutions referenced to SRM (Standard Reference Material) by NIST for qualified

calibration of conductivity measuring systems in accordance with ISO 9000

• CLY11-B, 149.6 μS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081903

• CLY11-C, 1.406 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081904

• CLY11-D, 12.64 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081905

• CLY11-E, 107.00 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081906

Technical Information TI00162C

Endress+Hauser 15

Page 16

www.addresses.endress.com

Loading...

Loading...