Page 1

Operating Instructions

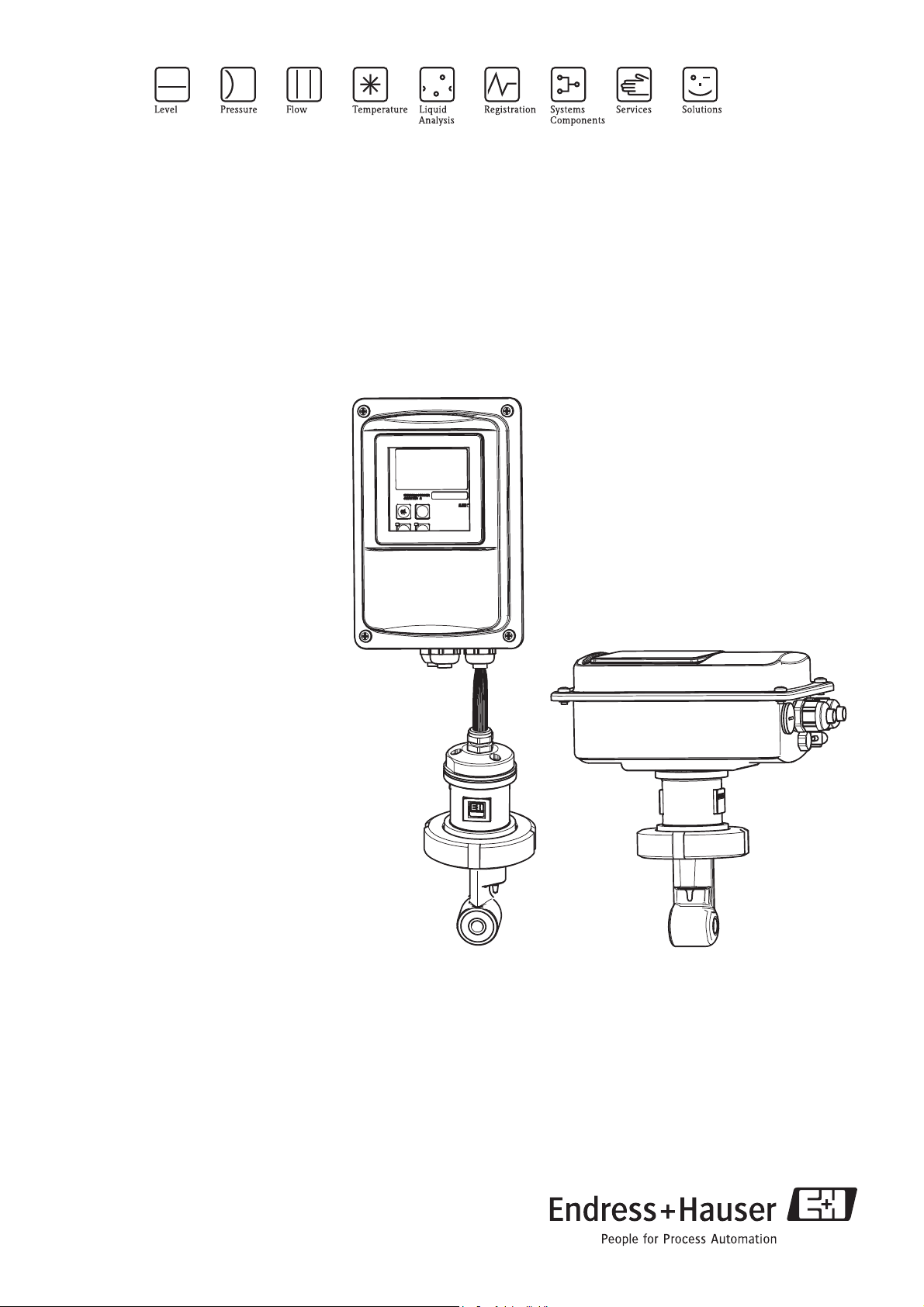

Smartec S CLD132

Conductivity Measuring System

BA207C/07/en/09.04

51501595

Software version 1.00 or later

Page 2

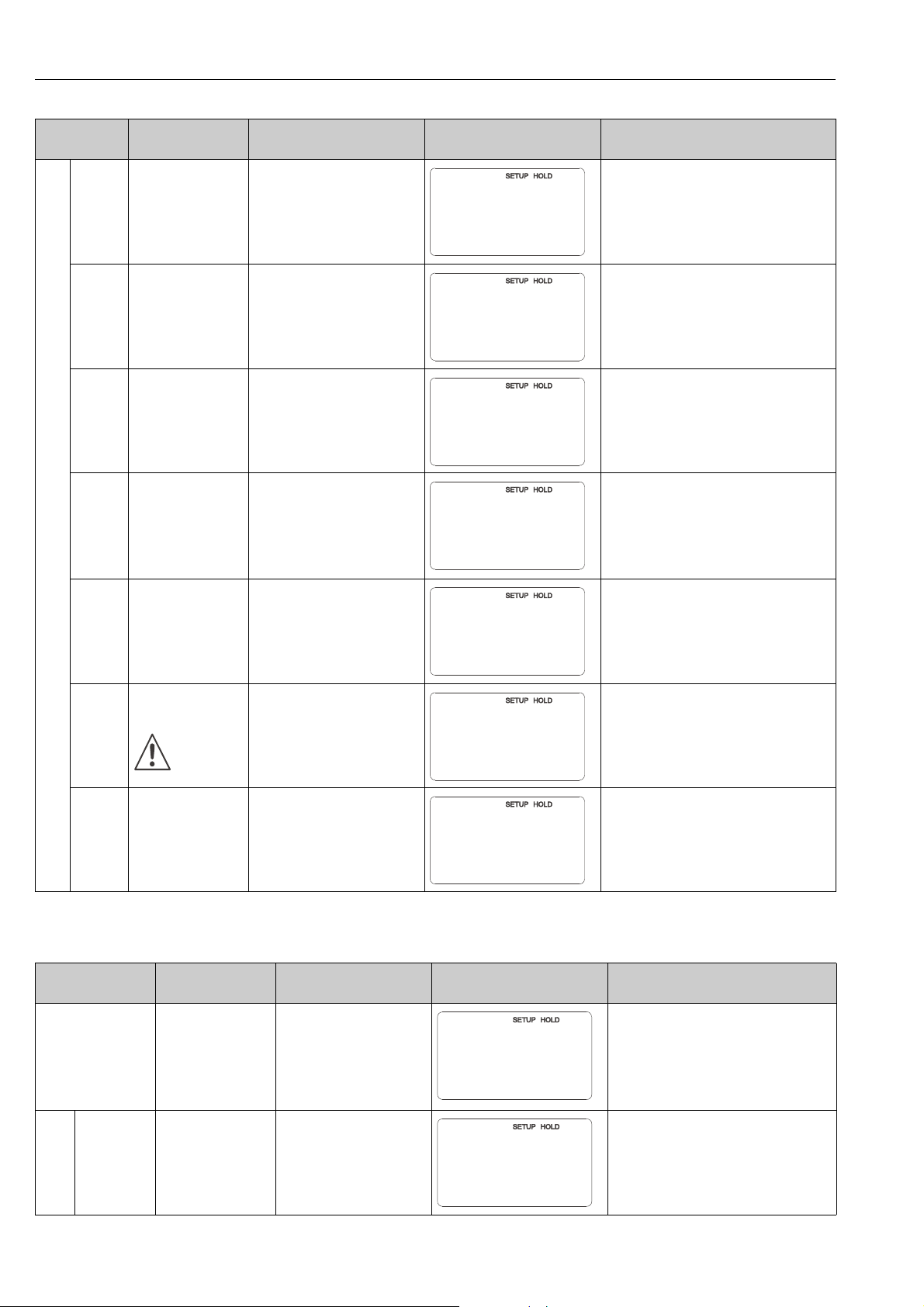

Brief overview

This overview explains how to use these Operating Instructions to commission your measuring

system quickly and safely.

Safety instructions

→ Page 5 ff.

→ Page 6 ff.

→ Page 10 ff.

→ Page 15 ff.

→ Page 18 ff. Here, you can find out how to connect your measuring system.

→ Page 23

→ Page 26

→ Page 33 ff.

→ Page 51 ff.

General safety instructions

Explanation of the warning symbols

You can find special instructions at the appropriate position in the chapter in question. The

significance is indicated with the icons Warning #, Caution " and Note !.

▼

Installation

Here, you can find information on installation conditions and the dimensions of the measuring

system.

These pages explain how to install the measuring system

▼

Wiring

You also find information on how to connect the CLS52 sensor if you are using a separate

version.

▼

Operation

The display and operating elements are described here.

The operating concept is described here.

The system configuration is explained here.

You can find information on how to calibrate the sensor here.

▼

Maintenance

→ Page 54 ff.

→ Page 59 ff.

→ Page 61 ff.

→ Page 67 ff.

→ Page 73

→ Page 73 ff.

→ Page 80 ff. The index helps you to find information and important terms easily and quickly.

Here, you can find information on the maintenance of the measuring point.

Accessories which can be supplied for the measuring system are listed on the pages indicated.

Use the trouble-shooting information given here if your system should not work properly.

Spare parts that can be delivered and a system overview are listed on these pages.

▼

Technical data

Dimensions

Process conditions, weight, material

▼

Index

Endress+Hauser

Page 3

Smartec S CLD132

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and symbols . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Product structure Smartec S CLD132 . . . . . 7

2.1.3 Basic version and function extensions . . . . . 8

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 8

3 Installation . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Measuring system . . . . . . . . . . . . . . . . . . . . 9

3.2 Incoming acceptance, transport, storage . . . . . . . . . 10

3.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 Notes on installation . . . . . . . . . . . . . . . . . 10

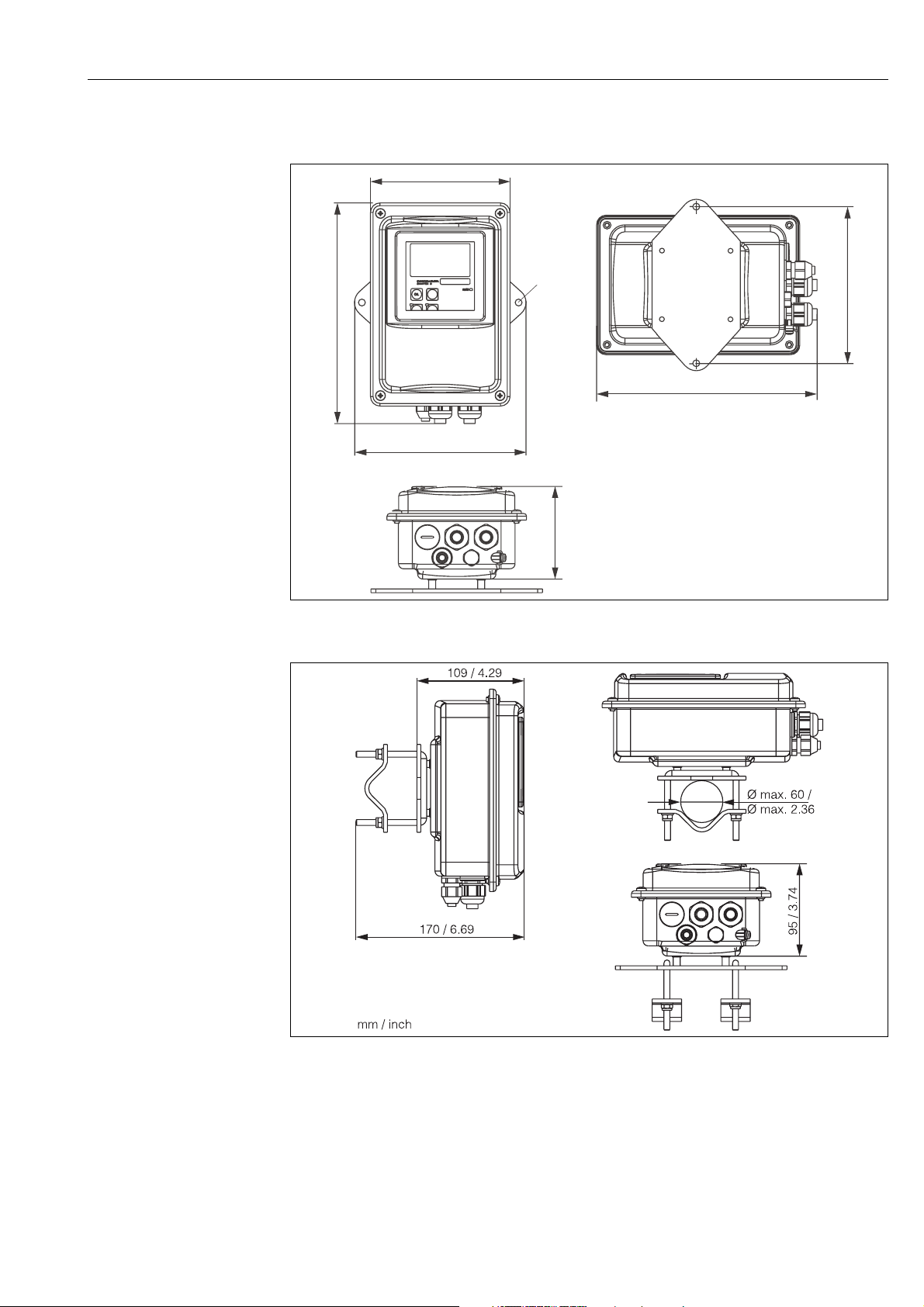

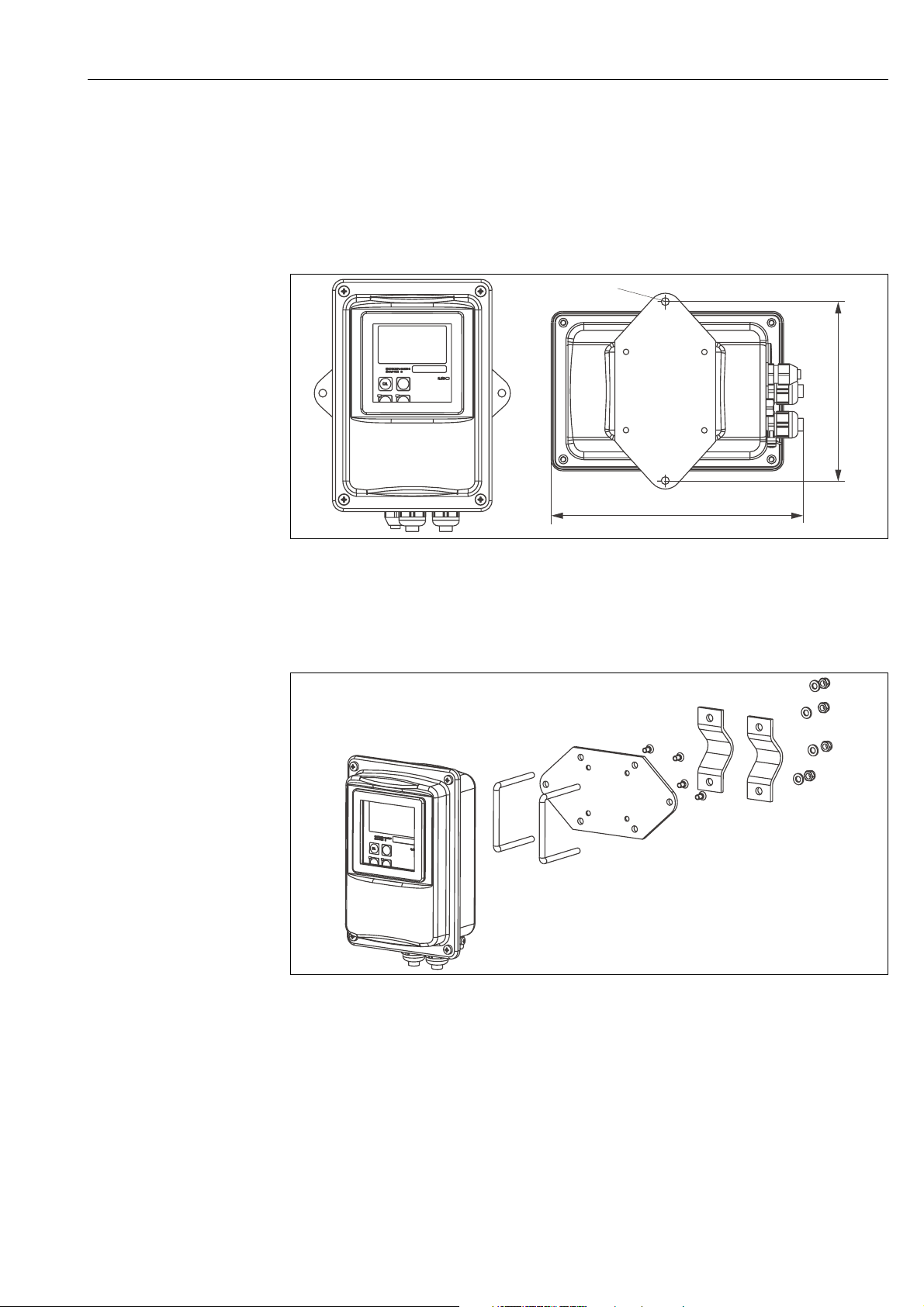

3.3.2 CLD132 separate version . . . . . . . . . . . . . . 11

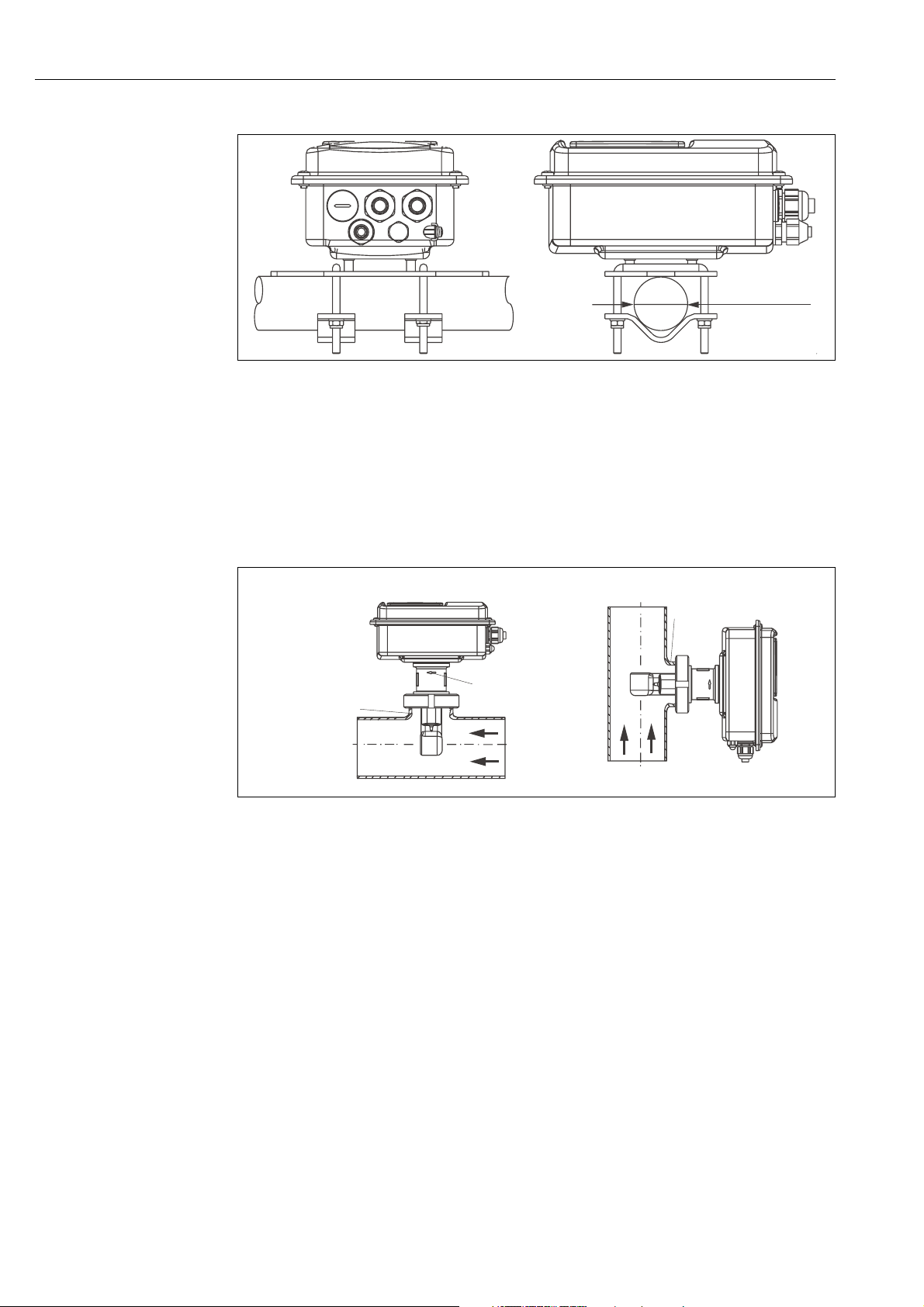

3.3.3 CLD 132 compact version . . . . . . . . . . . . . 13

3.4 Installation instructions . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 Mounting CLD132 separate version . . . . . . 15

3.4.2 Mounting CLD132 compact version or

CLS52 sensor for separate version . . . . . . . 16

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Instrument configuration . . . . . . . . . . . . . . . . . . . . 33

6.4.1 Setup 1 (conductivity, concentration) . . . . . 33

6.4.2 Setup 2 (temperature) . . . . . . . . . . . . . . . . 34

6.4.3 Current outputs . . . . . . . . . . . . . . . . . . . . . 36

6.4.4 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.5 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.6 Relay configuration . . . . . . . . . . . . . . . . . . 39

6.4.7 Temperature compensation with table . . . . 41

6.4.8 Concentration measurement . . . . . . . . . . . 42

6.4.9 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.10 E+H Service . . . . . . . . . . . . . . . . . . . . . . . 46

6.4.11 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.4.12 Determining the temperature coefficient . . 48

6.4.13 Remote parameter set switching

(measuring range switching, MRS) . . . . . . . 48

6.4.14 Calibration . . . . . . . . . . . . . . . . . . . . . . . . 51

6.5 Communication interfaces . . . . . . . . . . . . . . . . . . . 53

7 Maintenance . . . . . . . . . . . . . . . . . . . . 54

7.1 Maintenance of Smartec S CLD132 . . . . . . . . . . . . 54

7.1.1 Dismantling Smartec S CLD132 . . . . . . . . . 54

7.1.2 Special case: replacement of

central module . . . . . . . . . . . . . . . . . . . . . 55

7.2 Maintenance of measuring system . . . . . . . . . . . . . 56

7.2.1 Cleaning conductivity sensors . . . . . . . . . . 56

7.2.2 Checking inductive conductivity sensors . . 56

7.2.3 Instrument check by medium simulation . . 57

7.2.4 Checking line extension and

junction box . . . . . . . . . . . . . . . . . . . . . . . 58

7.3 Service equpipment "Optoscope" . . . . . . . . . . . . . . 58

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Electrical connection of transmitter . . . . . . 18

4.2 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 22

5 Operation . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Display and operating elements . . . . . . . . . . . . . . . 23

5.2.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.2 Operating elements . . . . . . . . . . . . . . . . . . 24

5.2.3 Key assignment . . . . . . . . . . . . . . . . . . . . . 24

5.3 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.1 Operating concept . . . . . . . . . . . . . . . . . . . 26

6 Commissioning. . . . . . . . . . . . . . . . . . 28

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Quick setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Accessories . . . . . . . . . . . . . . . . . . . . . 59

8.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.2 Extension cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3 Junction box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.4 Post mounting kit . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.5 Software upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.6 Calibration solutions . . . . . . . . . . . . . . . . . . . . . . . 60

8.7 Optoscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9 Troubleshooting . . . . . . . . . . . . . . . . . 61

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . . 61

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . . 61

9.3 Process-specific errors . . . . . . . . . . . . . . . . . . . . . . 62

9.4 Instrument-specific errors . . . . . . . . . . . . . . . . . . . 65

9.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.5.1 Exploded view . . . . . . . . . . . . . . . . . . . . . . 68

9.5.2 Spare part kits . . . . . . . . . . . . . . . . . . . . . . 69

9.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Endress+Hauser 3

Page 4

Smartec S CLD132

10 Technical Data. . . . . . . . . . . . . . . . . . . 71

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.4 Performance characteristics . . . . . . . . . . . . . . . . . . 72

10.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.6 Mechanical construction . . . . . . . . . . . . . . . . . . . . 73

10.7 Measurement data of CLS52 sensor . . . . . . . . . . . . 73

10.8 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.9 Chemical durability of CLS52 sensor . . . . . . . . . . . 75

10.10 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11 Appendix. . . . . . . . . . . . . . . . . . . . . . . 76

Index. . . . . . . . . . . . . . . . . . . . . . . . . . 80

4 Endress+Hauser

Page 5

Smartec S CLD132 Safety instructions

1 Safety instructions

1.1 Designated use

Smartec S CLD132 is a field-tested and reliable transmitter used to determine the conductivity of

liquid media.

It is particularly suitable for use in the foodstuffs industry.

Any other use than the one described here compromises the safety of persons and the entire

measuring system and is, therefore, not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Installation, commissioning and operation

Please note the following items:

• Installation, commissioning, operation and maintenance of the measuring system must only be

carried out by trained technical personnel.

The technical personnel must be authorised for the specified activities by the system operator.

• Electrical connection must only be carried out by a certified electrician.

• Technical personnel must have read and understood these Operating Instructions and must

adhere to them.

• Before commissioning the entire measuring point, check all the connections for

correctness. Ensure that electrical cables and hose connections are not damaged.

• Do not operate damaged products and secure them against unintentional

commissioning. Mark the damaged product as being defective.

• Measuring point faults may only be rectified by authorised and specially trained

personnel.

• If faults can not be rectified, the products must be taken out of service and secured against

unintentional commissioning.

• Repairs not described in these Operating Instructions may only be carried out at the

manufacturer’s or by the service organisation.

1.3 Operational safety

The transmitter has been designed and tested according to the state of the art and left the factory in

perfect functioning order.

Relevant regulations and European standards have been met.

As the user, you are responsible for complying with the following safety conditions:

• Installation instructions

• Local prevailing standards and regulations.

Immunity to interference

This instrument has been tested for electromagnetic compatibility in industrial use according to

applicable European standards. It is protected against electromagnetic interference by the following

design measures:

• cable screening

• interference suppression filter

• interference suppression capacitors.

Protection against interference as specified above is valid only for an instrument

connected according to the instructions in these Operating Instructions.

Endress+Hauser 5

Page 6

Safety instructions Smartec S CLD132

1.4 Return

If the transmitter has to be repaired, please return it cleaned to the sales centre responsible.

Please use the original packaging, if possible.

Please enclose the completed "Declaration of contamination" (copy the second last page of these

Operating Instructions) with the packaging and the transportation documents.

No repair without completed "Declaration of contamination"!

1.5 Notes on safety conventions and symbols

Safety symbols

Warning!

This symbol alerts you to hazards. They can cause serious damage to the instrument or to persons

#

"

if ignored.

Caution!

This symbol alerts you to possible faults which could arise from incorrect operation. They could

cause damage to the instrument if ignored.

!

%

&

)

*

+

/

Note!

This symbol indicates important items of information.

Electrical symbols

Direct Current (DC)

A terminal at which DC is applied or through which DC flows.

Alternating Current (AC)

A terminal at which (sine-form) AC is applied or through which AC flows.

Ground connecting

A terminal, which, from the user’s point of view, is already grounded using a grounding system.

Protective earth terminal

A terminal which must be grounded before other connections may be set up.

Equipotential connection

A connection which must be connected to the grounding system of the equipment.

This can be, i.e., a potential matching line of a star-shaped grounding system,

depending on national or company practice.

Protective insulation

The equipment is protected by double insulation.

b

6 Endress+Hauser

Alarm relay

Input

Output

Constant voltage source

Temperature sensor

Page 7

Smartec S CLD132 Identification

2 Identification

2.1 Device designation

2.1.1 Nameplate

Compare the order code on the nameplate (on the Smartec) with the product structure (see below)

and check that it agrees with your order.

You can identify the instrument variant by the order code on the nameplate. Under "Codes", you

can find the release code for the software upgrade "MRS".

ENDRESS+HAUSER

SMARTEC S

order code / Best.Nr.

serial no. / Ser.-Nr.

measuring range / Messbereich

temperature / Temperatur:

output 1 / Ausgang 1

output 2 / Ausgang 2

mains / Netz

prot. class / Schutzart

ambient temp. / Umgebungstemperatur

Fig. 1: Nameplate CLD132 (example)

conductivity ind./ Leitfähigkeit ind.

:

CLD 132-PMV130AB2

1C466C05 G00

:

:

:

:

:

10 µS ...2000 mS/cm

-10...+125 °C

0/4...20 mA

0/4...20 mA

230 VAC 50/60 Hz 7,5 VA

(+140 °C max. 30 min)

IP67

:

0...+55 °C

:

C07-CLD132xx-18-0 6-00-xx-001.eps

/Codes:

8833

131697-4B

2.1.2 Product structure Smartec S CLD132

Version

P Compact version

S Separate transmitter, cable length 20 m / 65.62 ft

W Separate transmitter, cable length 5 m / 16.41 ft

X Separate transmitter, cable length 10 m / 32.81 ft

Process connection

MV1 Dairy fitting DN 50 (acc. to DIN 11851)

CS1 Clamp connection 2" (acc. to ISO 2852)

GE1 Internal thread G 1 ½

VA1 Varivent connection DN 40 ... 125

AP1 APV connection DN 40 ... 100

SMS SMS connection 2"

Cable entry

1 Cable gland Pg 13.5

3 Cable gland M 20 x 1.5

5 Conduit adapter NPT ½ "

Power supply

0 230 V AC

1 115 V AC

5 100 V AC

824 V AC / DC

Current output / communication

AA Current output conductivity, without communication

AB Current output conductivity and temperature, without communication

HA HART, current output conductivity

HB HART, current output conductivity and temperature

PE PROFIBUS-PA, no current output

PF PROFIBUS-PA, M 12 connector, no current output

PP PROFIBUS-DP, no current output

Additional features

1 Basic version with fast temperature measurement

2 Remote parameter set switching with fast temperature measurement

6 Basic version with encapsulated Pt 100 for high loads

7 Remote parameter set switching with encapsulated Pt 100 for high loads

CLD132- complete order code

Endress+Hauser 7

Page 8

Identification Smartec S CLD132

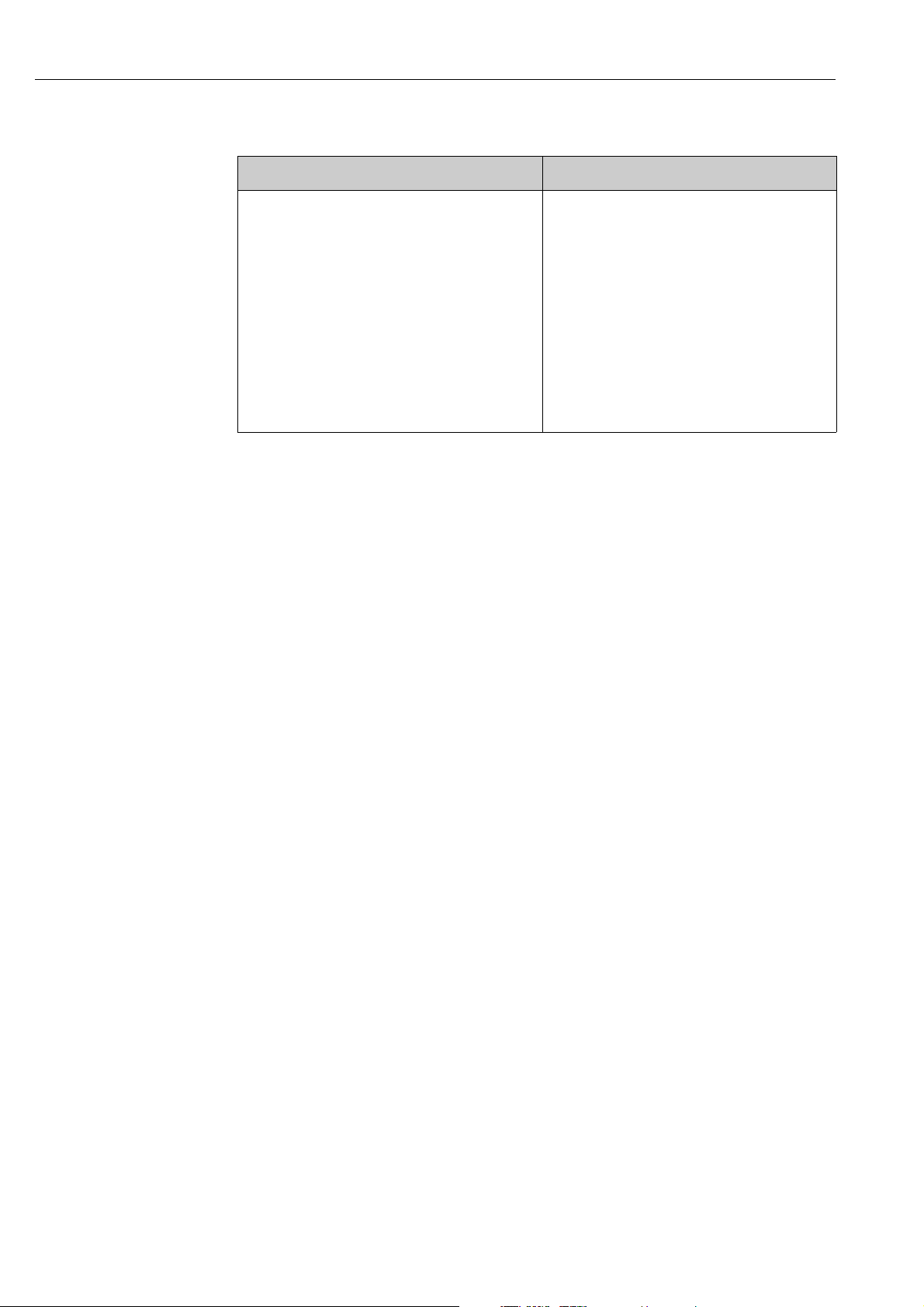

2.1.3 Basic version and function extensions

Functions of the basic version Options and their functions

•Measurement

• Calibration of cell constant

• Calibration of residual coupling

• Calibration of installation factor

• Read instrument parameters

• Linear current output

• Current output simulation

•Service functions

• Temperature compensation selectable (e.g. 1 free

coefficient table)

• Concentration measurement selectable (4 defined

curves, 1 free table)

• Relay as alarm contact

• Second current output for temperature (hardware

option)

• HART communication

• PROFIBUS communication

Remote parameter set switching (software option):

• Remote switching of max. 4 parameter sets

(measuring ranges)

• Temperature coefficients can be determined

• Temperature compensation selectable (e.g. 4 free

coefficient tables)

• Concentration measurement selectable (4 defined

curves, 4 free tables)

• Check of measuring system by PCS alarm (live check)

• Relay can be configured as alarm or limit contact

2.2 Scope of delivery

The scope of delivery of the compact version inlcudes:

• Smartec S CLD132 compact measuring system with integrated sensor

• Terminal strip set

• Expansion bellows (-*GE1***** versions only)

• Operating Instructions BA 207C/07/en

• Versions with HART communication only:

Operating Instructions Field communication with HART, BA 212C/07/en

• Versions with PROFIBUS interface only:

– Operating Instructions Field communication with PROFIBUS, BA 213C/07/en

– M12 connector (-******PF* versions only)

The scope of delivery of the separate version includes:

• Smartec S CLD132 transmitter

• CLS52 inductive sensor with fixed cable

• Terminal strip set

• Expansion bellows (-*GE1***** versions only)

• Operating Instructions BA 207C/07/en

• Versions with HART communication only:

Operating Instructions Field communication with HART, BA 212C/07/en

• Versions with PROFIBUS interface only:

– Operating Instructions Field communication with PROFIBUS, BA 213C/07/en

– M12 connector (-******PF* versions only)

2.3 Certificates and approvals

Declaration of conformity

The product meets the legal requirements of the harmonised European standards.

The manufacturer confirms compliance with the standards by affixing the 4 symbol.

8 Endress+Hauser

Page 9

Smartec S CLD132 Installation

ENDRESS+HAUSER

SMARTEC S

ALARM

3 Installation

3.1 Quick installation guide

The following procedure should be followed for a complete measuring point installation:

Compact version:

• Perform an Airset. Install the compact version at the measuring point (see chapter "Mounting

CLD132 compact version").

• Connect the compact version as described in the chapter "Electrical connection".

• Start up the compact version as described in the chapter "Commissioning".

Separate version:

• Mount the transmitter (see chapter "Mounting CLD132 separate version").

• If you have not yet installed the sensor at the measuring point, perform an Airset and install the

sensor (see the Technical Information of the sensor).

• Connect the sensor to the Smartec S CLD132 as described in the chapter "Electrical connection".

• Connect the transmitter as described in the chapter "Electrical connection".

• Start up the Smartec S CLD132 as described in the chapter "Commissioning".

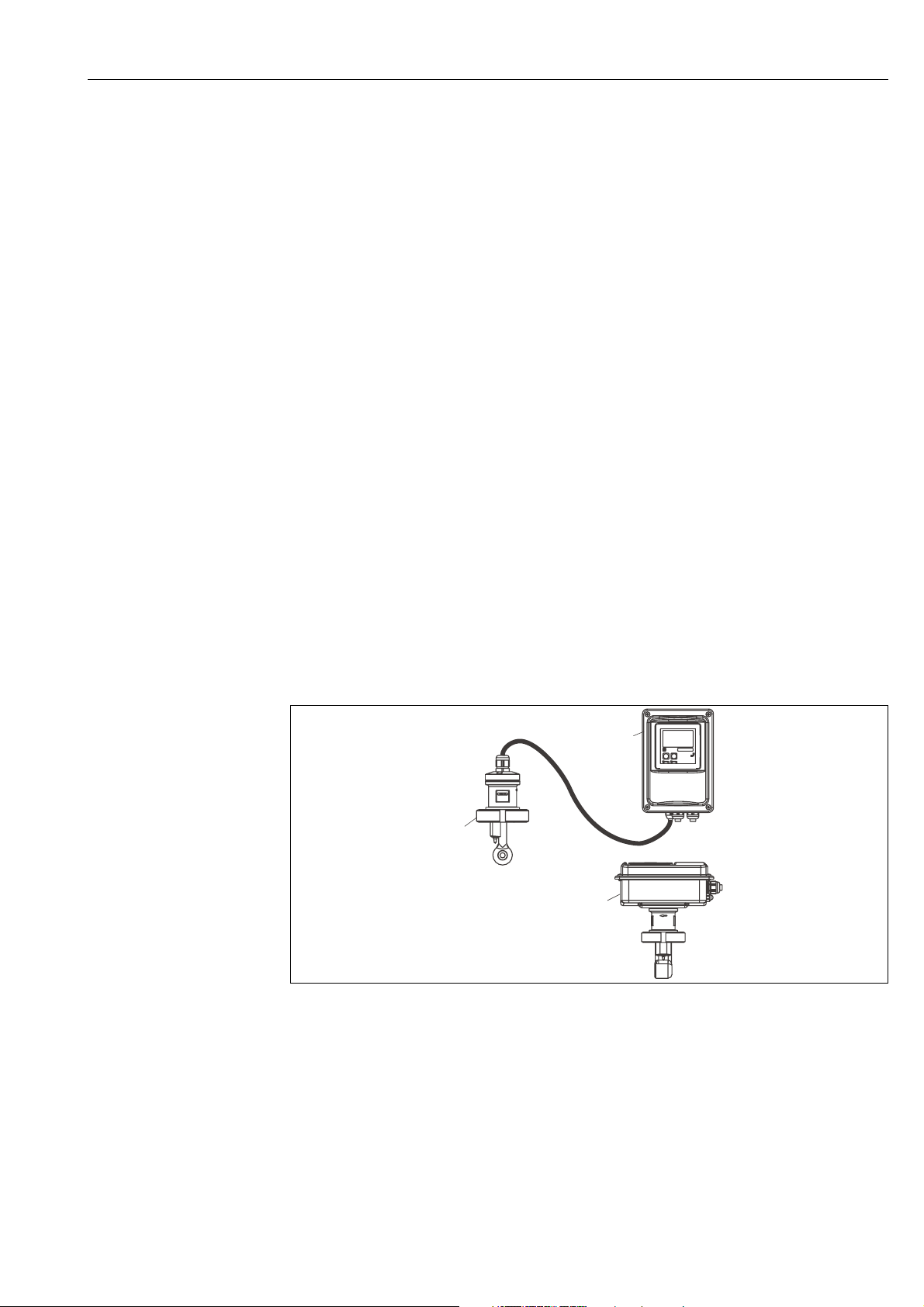

3.1.1 Measuring system

The complete measuring system comprises:

• the Smartec S CLD132 transmitter

• the conductivity sensor Indumax H CLS52 with an integrated temperature sensor and a fixed

cable

or

• the compact version with an integrated conductivity sensor

Optional for the separate version: CLK5 extension cable, VBM junction box, mounting kit for pipe

installation (see chapter "Accessories")

B

ENDRESS+HAUSER

SMARTEC S

ALARM

CAL

+

E

–

A

C

C07-CLD132xx-14-06-00-xx-001.eps

Fig. 2: Complete measuring systems Smartec S CLD132 as a separate transmitter and compact version with

integrated conductivity sensor

A CLS52 conductivity sensor

B Smartec S CLD132

C Smartec S CLD132 as compact version with integrated conductivity sensor

Endress+Hauser 9

Page 10

Installation Smartec S CLD132

3.2 Incoming acceptance, transport, storage

• Make sure the packaging is undamaged!

Inform the supplier about damage to the packaging.

Keep the damaged packaging until the matter has been settled.

• Make sure the contents are undamaged!

Inform the supplier about damage to the delivery contents.

Keep the damaged products until the matter has been settled.

• Check that the scope of delivery is complete and agrees with your order and the

shipping documents.

• The packaging material used to store or to transport the product must provide shock protection

and humidity protection. The original packaging offers the best protection. Also, keep to the

approved ambient conditions (see "Technical data").

• If you have any questions, please contact your supplier or your sales centre responsible.

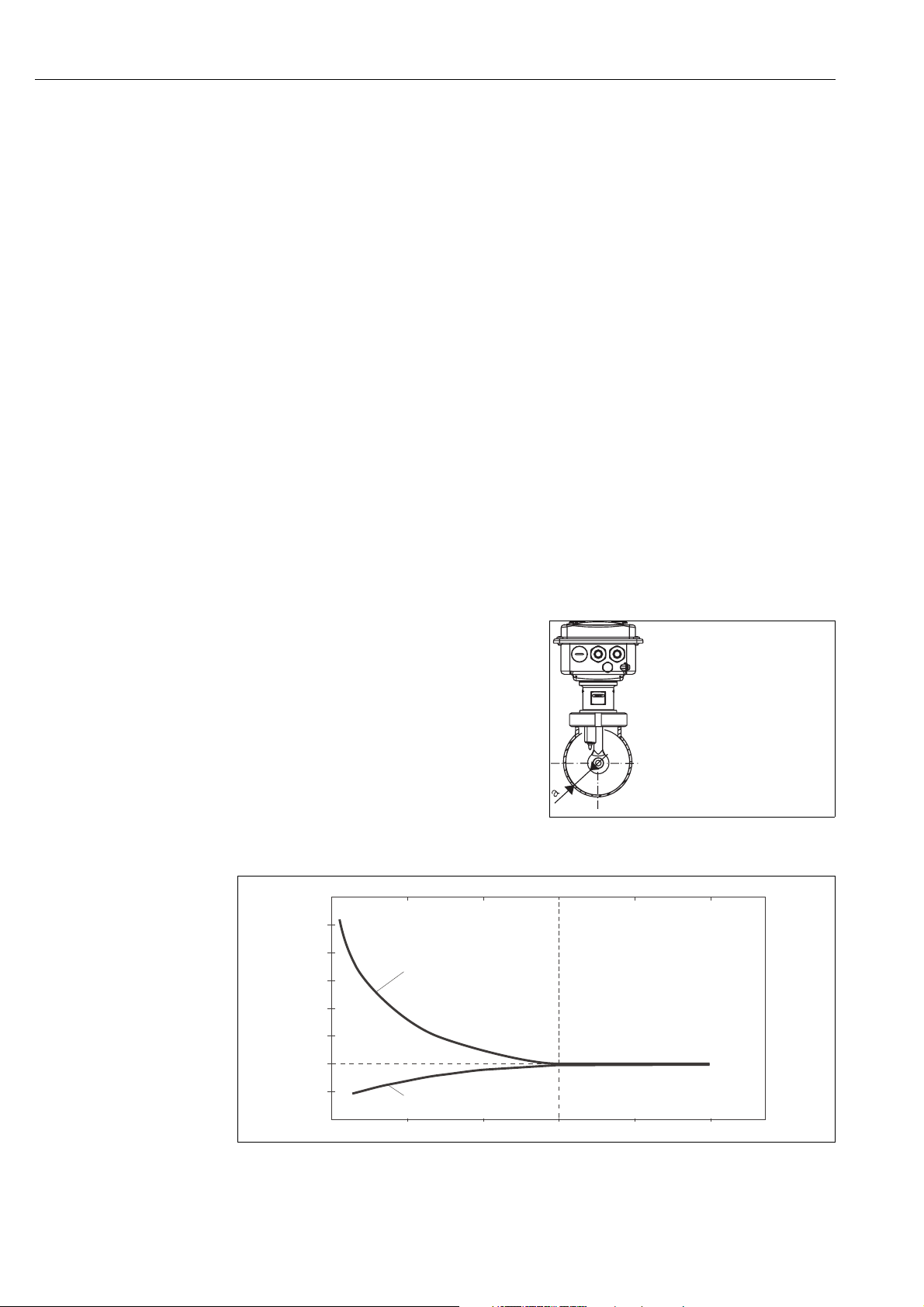

3.3 Installation conditions

3.3.1 Notes on installation

Airset

Perform an Airset before sensor installation (see chapter "Calibration"). Make sure that the

instrument is ready for operation, i.e. mains and sensor are connected.

Wall distance

The sensor’s distance from the pipe wall affects the measuring accuracy (see Fig. 4).

In narrow installation conditions, the ion flow

in the medium is affected by the pipe walls.

This effect is compensated by the so-called

installation factor.

When the distance from the wall is sufficient,

i.e. a > 15 mm / 0.59", the installation factor

can be ignored (f = 1.00). When the wall

distance is lower, the installation factor

increases in the case of electrically insulating

pipes (f > 1) while it decreases for electrically

conductive pipes (f < 1); see Fig. 4.

The determination of the installation factor is

described in the chapter "Calibration".

f

0.20

1,40

2

1,20

0.39

Fig. 3: Installation CLD132 compact version

a Wall distance

0.59

0.79

0.98

a [inch]

C07-CLD132xx-11-06 -00-xx-009.eps

1,00

1

0,80

0

Fig. 4: Relationship between installation factor and distance from wall a

1 Electrically conductive pipe wall

2Insulating pipe wall

5

10 15

20

a [mm]

2525

C07-CLD132xx-05 -06-00-en-001.eps

10 Endress+Hauser

Page 11

Smartec S CLD132 Installation

3.3.2 CLD132 separate version

142 / 5.59

Ø 7 / 0.28

160 / 6.30

225 / 8.86

225 / 8.86

175 / 6.89

95 / 3.74

Fig. 5: CLD132 wall mounting with mounting plate

mm /inch

C07-CLD132xx-11-06 -00-en-001.EPS

C07-CLD132xx-11-06 -00-en-002.EPS

Fig. 6: CLD132 mounting on pipes (Ø 60 mm / 2.36")

Endress+Hauser 11

Page 12

Installation Smartec S CLD132

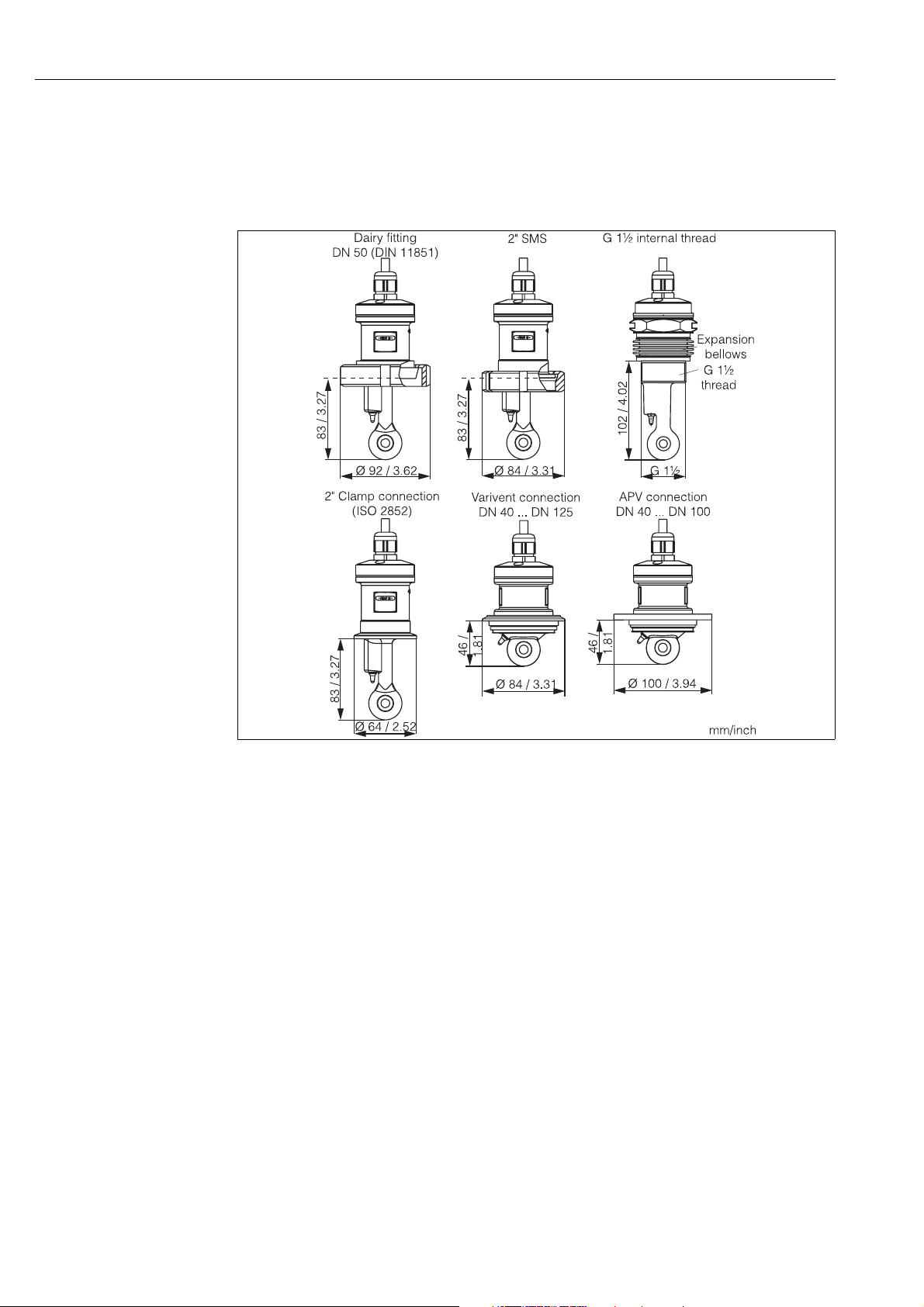

Conductivity sensors for the separate transmitter

CLS52 conductivity sensors with various process connections covering all common installation

conditions are available for the separate version.

!

Note!

Perform an Airset and calibrate the sensor before sensor installation.

!

C07-CLD132xx-11-0 6-00-en-003.EPS

Fig. 7: Process connections for CLS52 conductivity sensor

Note!

• Clamp connection

Sensors with clamp connections can be fixed using sheet metal brackets or solid brackets.

Sheet metal brackets have a lower dimensional stability, uneven bearing surfaces causing point

loads and sometimes sharp edges that can damage the clamp.

We strongly recommend to always use solid brackets because of their higher dimensional

stability. Solid brackets may be applied over the total pressure-temperature range (see diagram on

page 5).

• Threaded connection

Sensors with threaded connections are supplied with expansion bellows (compensator) to be able

to align them in flow direction. The two O-rings (Viton) of the expansion bellows have no sealing

function and are not in contact with medium. The process is usually sealed off by PTFE tape on

the G 1½ thread.

12 Endress+Hauser

Page 13

Smartec S CLD132 Installation

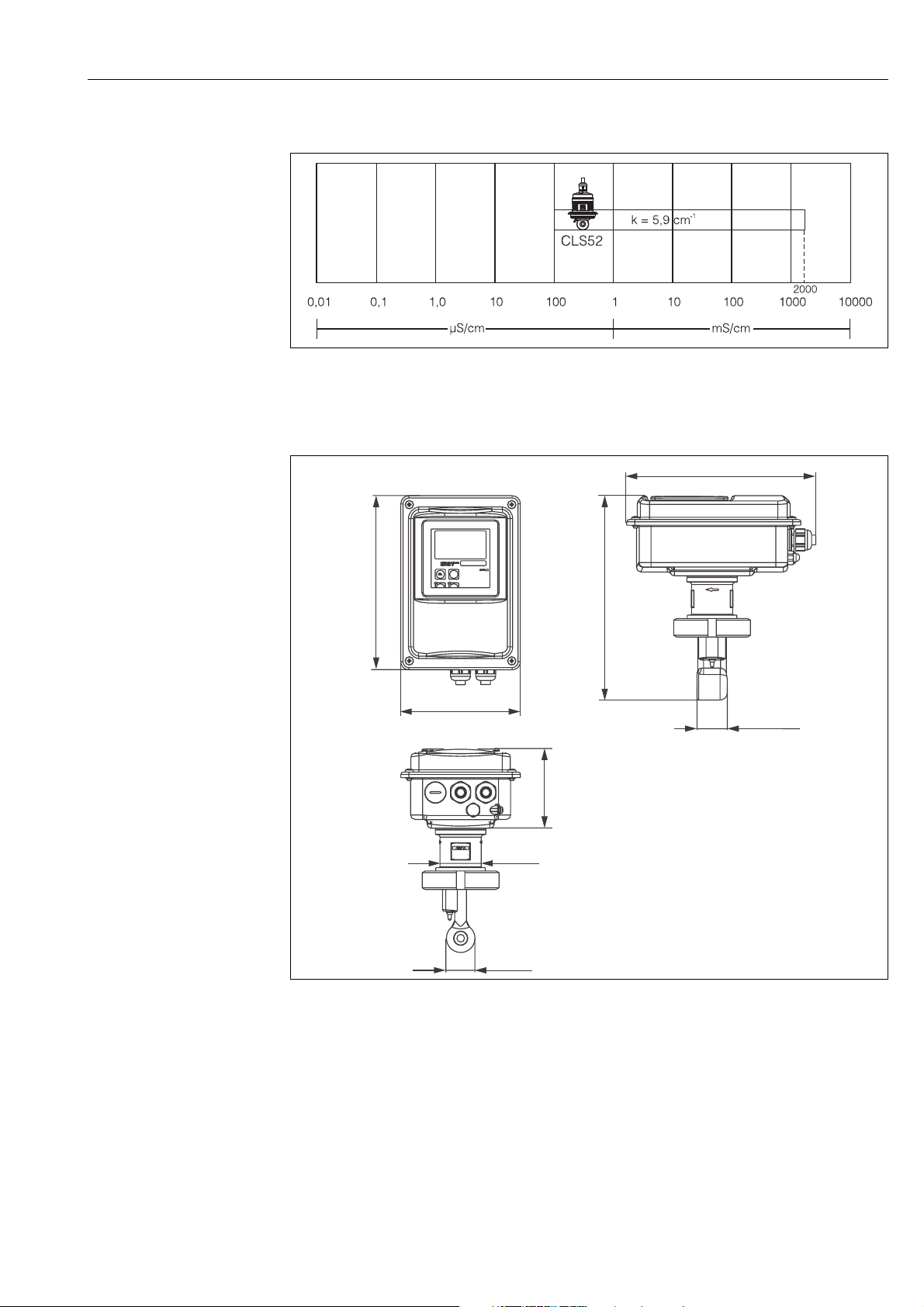

Measuring range

C07-CLD132xx-05-06-00-xx-002.eps

Fig. 8: CLS52 measuring range

3.3.3 CLD 132 compact version

225 / 8.86

207 / 8.15

142 / 5.59

∅ 49 / 1.93

34 / 1.34

Fig. 9: Dimensions of CLD132 compact version

242 (180)* / 9.53 ( 7.09)*

35.5 / 1.40

95 / 3.74

mm / inch

C07-CLD132xx-11-06 -00-en-004.eps

Endress+Hauser 13

Page 14

Installation Smartec S CLD132

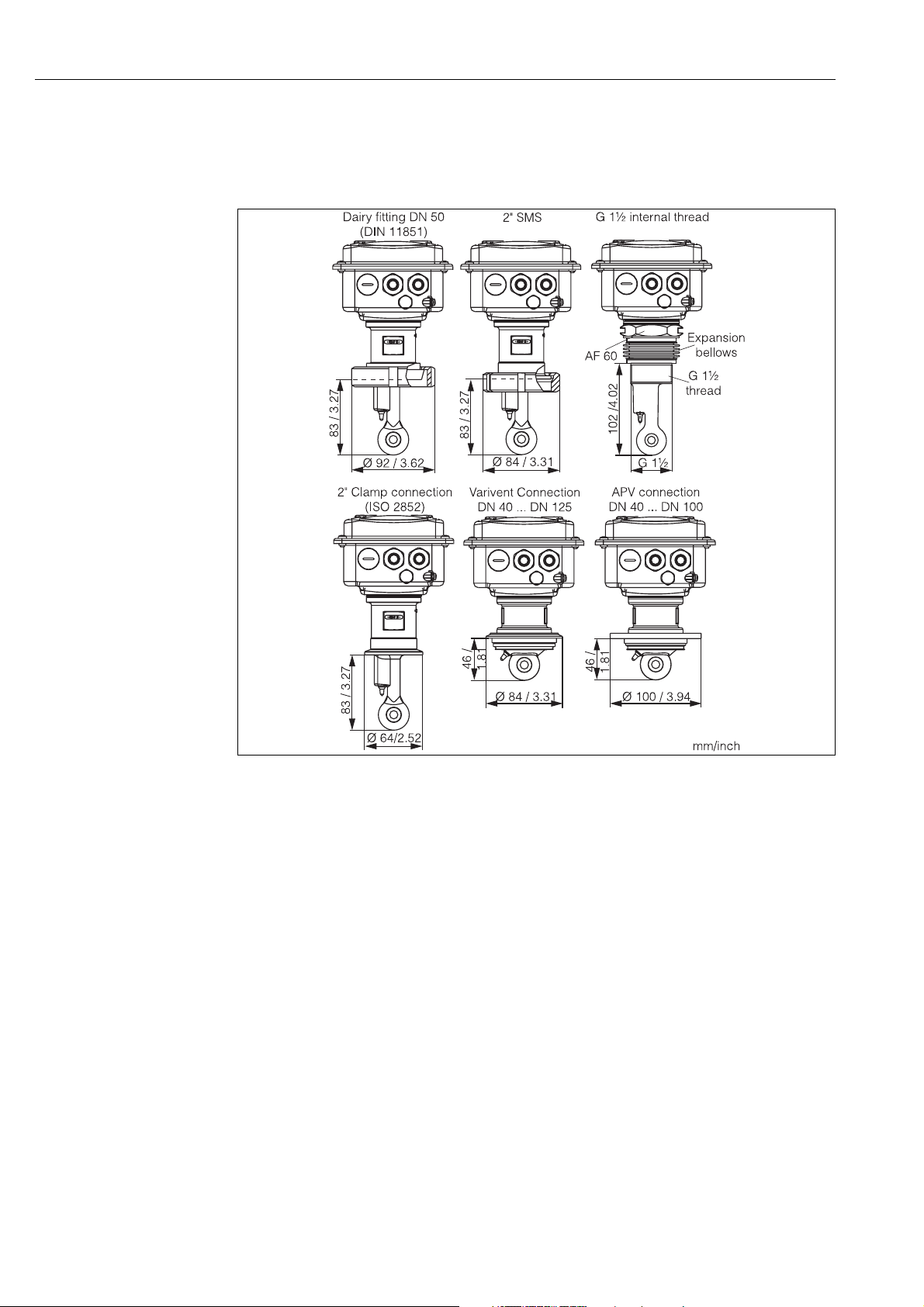

Connection variants

Various process connections covering all common installation conditions are available for the

compact version.

The compact version is installed at the measuring point with the required process connection.

!

C07-CLD132xx-11 -06-00-en-005.eps

Fig. 10: Process connections for the CLD132 compact version

Note!

• Clamp connection

Sensors with clamp connections can be fixed using sheet metal brackets or solid brackets.

Sheet metal brackets have a lower dimensional stability, uneven bearing surfaces causing point

loads and sometimes sharp edges that can damage the clamp.

We strongly recommend to always use solid brackets because of their higher dimensional

stability. Solid brackets may be applied over the total pressure-temperature range (see diagram on

page 5).

• Threaded connection

Sensors with threaded connections are supplied with expansion bellows (compensator) to be able

to align them in flow direction. The two O-rings (Viton) of the expansion bellows have no sealing

function and are not in contact with medium. The process is usually sealed off by PTFE tape on

the G 1½ thread.

14 Endress+Hauser

Page 15

Smartec S CLD132 Installation

3.4 Installation instructions

3.4.1 Mounting CLD132 separate version

Wall mounting

For wall mounting, attach the mounting plate to the wall by drilling holes as required. Anchors and

screws are to be provided by the operator.

∅ 7 / 0.28

160 / 6.30

225 / 8.86

mm / inch

C07-CLD132-11-06- 00-en-007.eps

Fig. 11: Wall mounting of CLD132 separate version

Post mounting

A mounting kit for installing the housing on horizontal or vertical posts or pipes (max. Ø 60 mm /

Ø 2.36") is available as an accessory (see chapter "Accessories").

C07-CLD132xx-00-06 -06-001.eps

Fig. 12: Mounting kit for installing the CLD132 separate version on posts

1. Remove the mounting plate.

2. Insert the holding bars through the pre-drilled holes of the mounting plate and screw the

mounting plate onto the transmitter.

3. Use the brackets to install the Smartec S on the post or pipe (Fig. 13).

Endress+Hauser 15

Page 16

Installation Smartec S CLD132

∅ max. 60 / 2.36

mm / inch

C07-CLD132xx-11 -06-00-en-008.eps

Fig. 13: Post mounting of CLD132 separate version

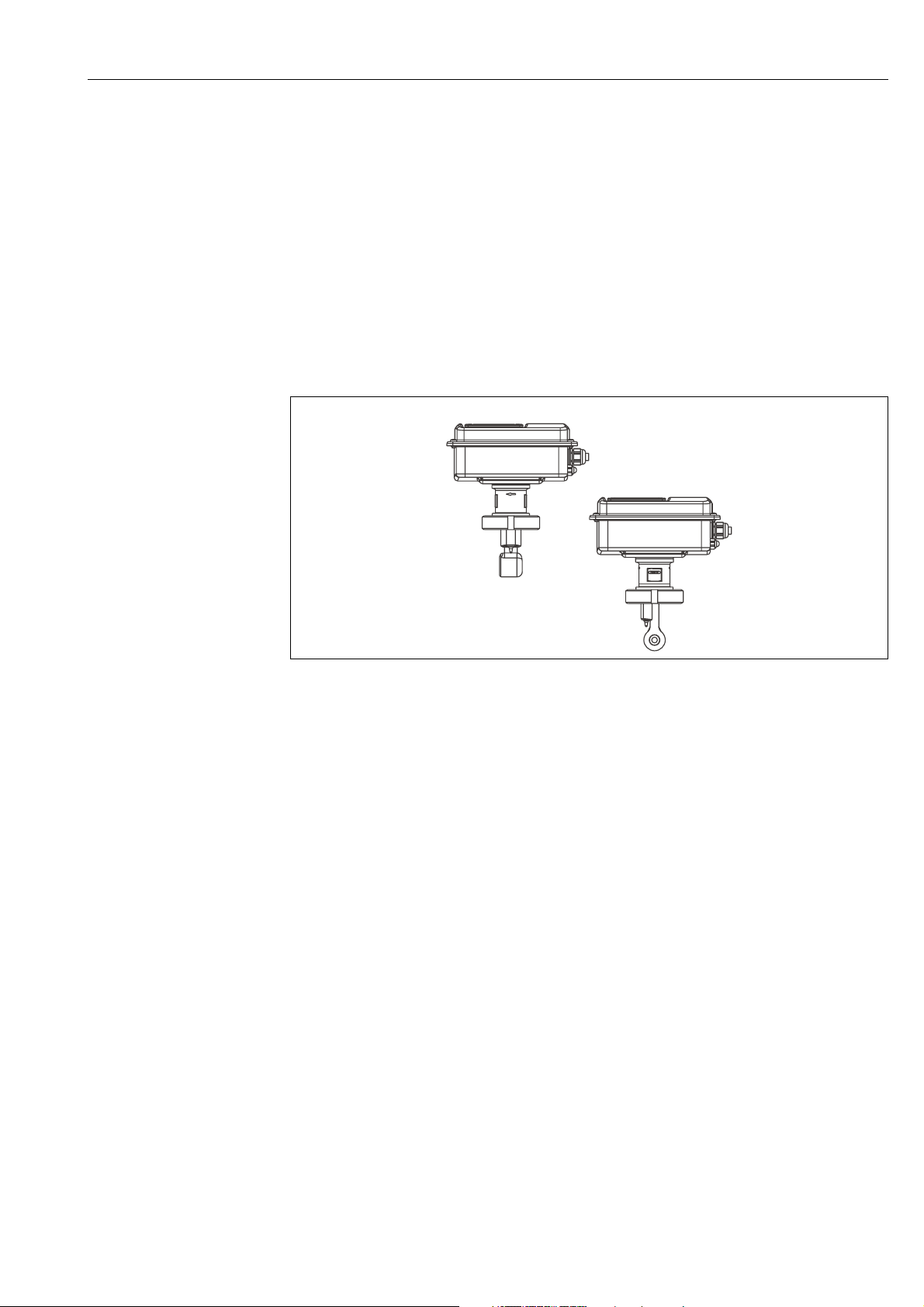

3.4.2 Mounting CLD132 compact version or CLS52 sensor for separate version

Install the compact version or the CLS52 sensor directly on the pipe or vessel socket via the process

connection (depending on ordered version).

!

!

Note!

Perform an Airset and calibrate the sensor before installing the compact version or the sensor.

Horizontal flow Vertical flow

min. DN 40*

Orientation

min. DN 40*

Fig. 14: Installation of CLD132 compact version

arrow

Flow

direction

Flow direction

C07-CLD132-11-06-0 0-en-006.eps

1. When installing the Smartec S CLD132 or the sensor, make sure that the flow opening of the

sensor is oriented in the flow direction of the medium. An orientation arrow on the sensor

facilitates orientation (see Fig. 14 above).

2. Tighten the flange.

3. For versions with internal thread G 1½, expansion bellows are supplied for length

compensation. Thus, the sensor can always be oriented in flow direction.

Note!

• Choose the immersion depth of the sensor in the medium such that the coil body is completely

immersed.

• Please observe the notes on the wall distance in the chapter "Installation conditions".

• Please observe the limits for the medium and ambient temperature when using the compact

version (see chapter "Technical data").

16 Endress+Hauser

Page 17

Smartec S CLD132 Installation

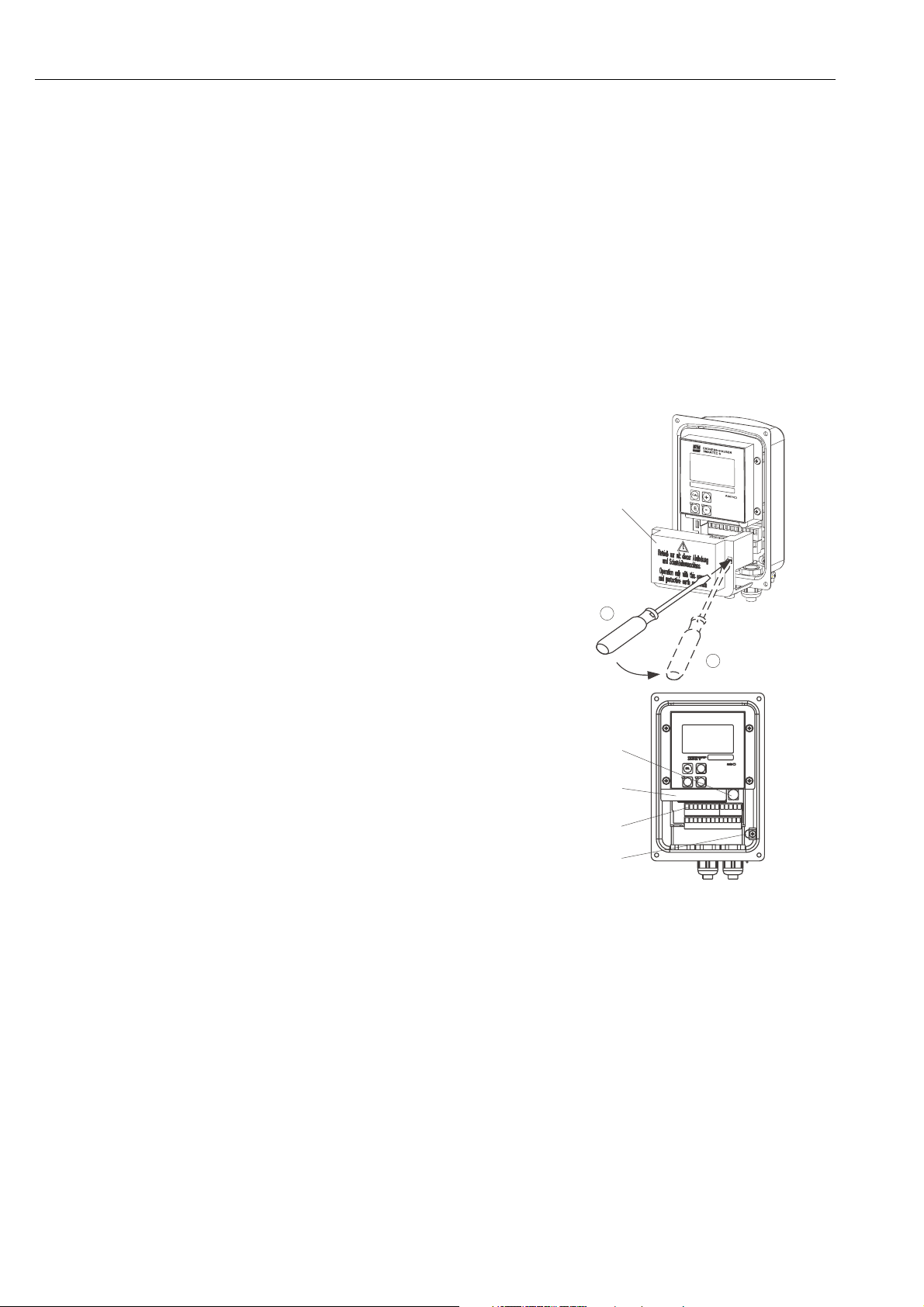

Sensor positioning: compact version

The sensor in the compact housing must be oriented in the flow direction.

If you need to reorient the sensor in relation to the housing, proceed as follows:

1. Remove the cover.

2. Loosen the screws of the electronics box and carefully remove the box from the housing.

3. Loosen the three sensor fastening screws until the sensor can be turned.

4. Align the sensor and tighten the screws. Do not exceed the maximum torque of 1.5 Nm!

5. Reassemble the transmitter housing in reverse sequence of operations.

!

Note!

For exact positions of the electronics box and the sensor screws, see the exploded view in the

chapter "Spare parts".

A

B

Fig. 15: Sensor orientation in the transmitter housing

AStandard orientation

B Sensor turned by 90°

3.5 Post-installation check

• After installation, check the measuring system for damages.

• Check the sensor orientation to the flow direction of the medium.

• Check that the coil body of the sensor is completely immersed in the medium.

C07-CLD132xx-11-06-05-xx-010.eps

Endress+Hauser 17

Page 18

Wiring Smartec S CLD132

4 Wiring

4.1 Electrical connection

#

Warning!

• The electrical connection must only be carried out by a certified electrician.

• Technical personnel must have read and understood the instructions in this manual and must

adhere to them.

• Ensure that there is no voltage at the power cable before beginning the connection work.

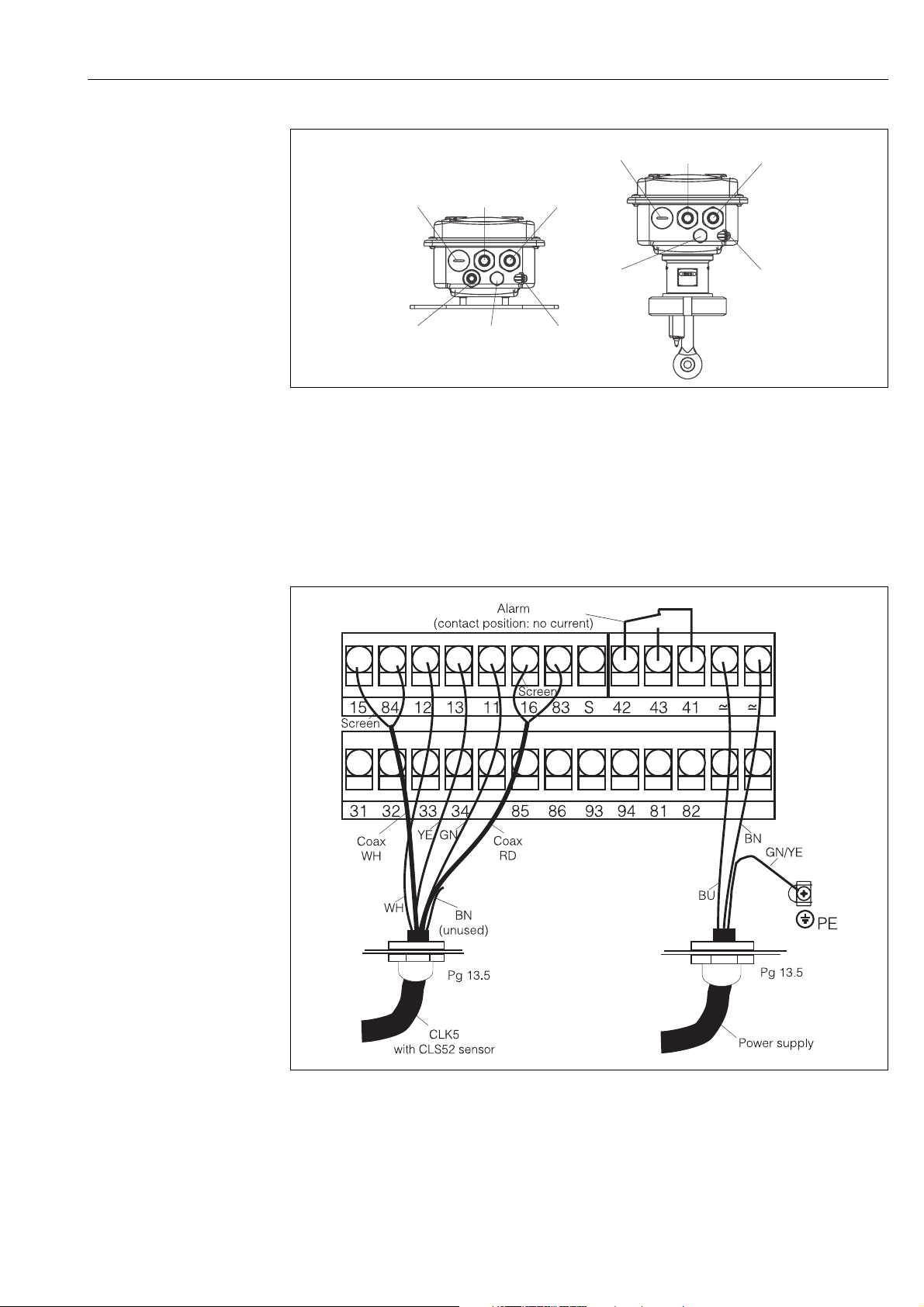

4.1.1 Electrical connection of transmitter

Proceed as follows to connect the Smartec S CLD132:

1. Loosen the 4 Phillips screws on the housing

cover and remove the cover.

2. Remove the cover frame from the terminal

blocks. To do this, introduce a screwdriver in

the recess (m) according to Fig. 16 and push

the tab inward (n).

Warning!

#

Do not remove the cover frame while the

instrument is energised!

3. Thread the cables through the open cable

glands into the housing according to the

terminal assignments in Fig. 17.

4. Connect the power wires according to the

terminal assignments in Fig. 18.

5. Connect the alarm contact according to the

terminal assignments in Fig. 18.

6. Connect the housing ground.

7. Separate version: Connect the sensor

according to the terminal assignments in

Fig. 18.

In the case of the separate version, the

conductivity sensor CLS52 is connected using

the shielded multi-core special cable CLK5.

Preparation instructions are supplied with the

cable. Use junction box VBM (see chapter

"Accessories") to extend the measuring cable.

The maximum cable length if extended using

a junction box is 55 m.

8. Tighten the cable glands firmly.

Fig. 16: View of housing with cover removed

1Cover frame

2 Fuse

3 Removable electronics box

4Terminals

5 Housing ground

1

1

2

2

3

4

5

C07-CLD132xx-04-06 -00-xx-001.eps

18 Endress+Hauser

Page 19

Smartec S CLD132 Wiring

A

12

1

2

3

5

6

5

4

Fig. 17: Terminal assignments of cable glands on Smartec S CLD132

A

Separate version

1

Plug, Pg 13.5, analog output, binary input

2

Cable gland for alarm contact, Pg 13.5

3

Cable gland for power supply, Pg 13.5

4

Housing ground

5

Pressure comp. element PCE (Goretex®- filter)

6

Cable gland for sensor connection, Pg 9

B

Compact version

1

Plug, Pg 13.5, analog output, digital input

2

Cable gland for alarm contact, Pg 13.5

3

Cable gland for power supply, Pg 13.5

4

Housing ground

5

Pressure comp. element PCE (Goretex®- filter)

Wiring diagram

B

3

4

C07-CLD132xx-04-0 6-04-xx-001.eps

C07-CLD132xx-04-06 -00-de-003.eps

Fig. 18: Electrical connection of Smartec S

Endress+Hauser 19

Page 20

Wiring Smartec S CLD132

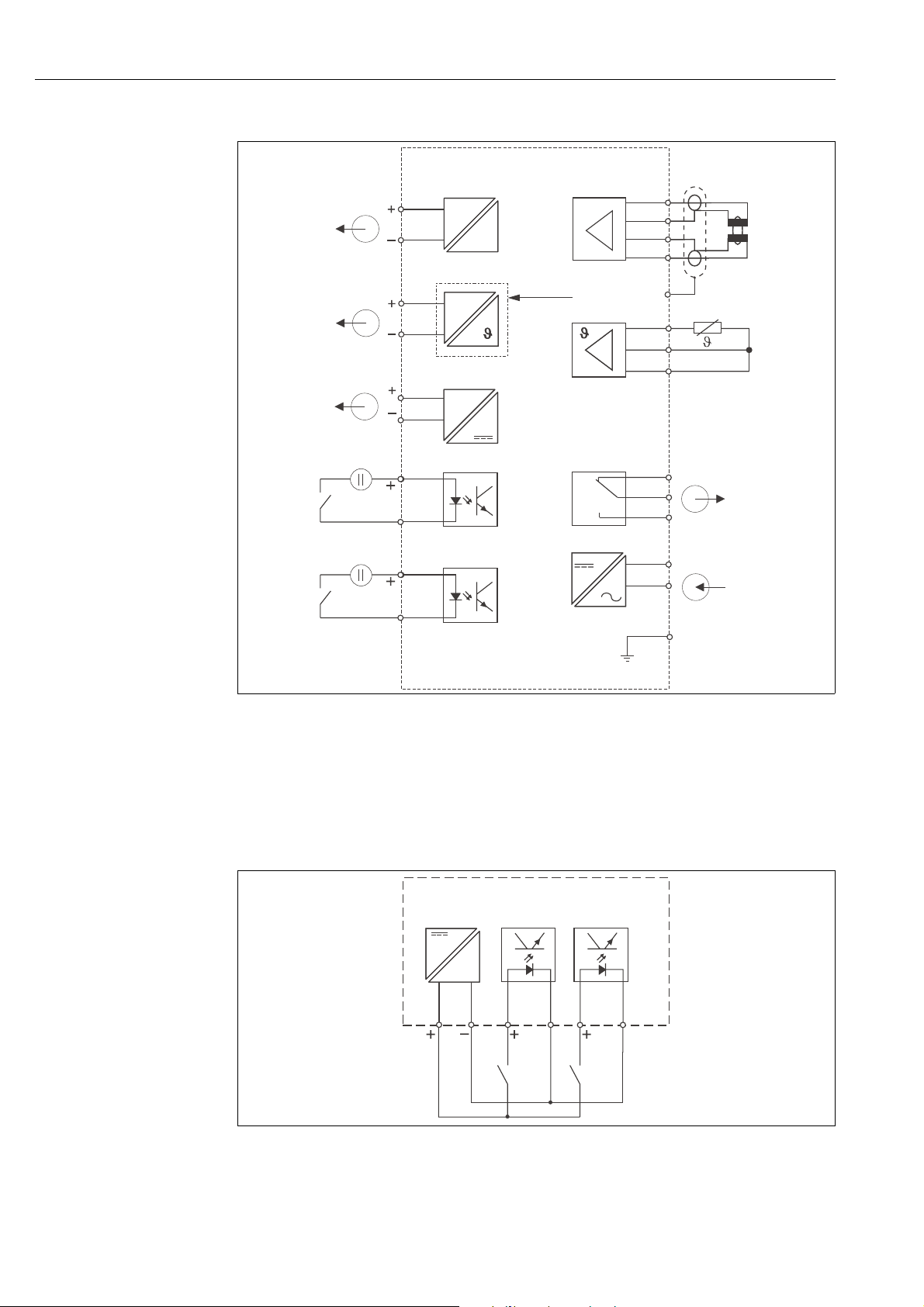

Connection diagram

31

mA

A

B

C

D

10-50 V

E

10-50 V

32

33

34

85

86

93

94

81

82

Lf

optional

mA

15 V

84

15

16

83

S

11

12

13

41

42

43

∼

–

∼

–

PE

F

G

H

I

Fig. 19: Electrical connection of Smartec S CLD132

Signal output 1 conductivity

A

Signal output 2 temperature

B

Auxiliary power output

C

Binary input 2 (MRS1+2)

D

Binary input 1 (hold / MRS 3+4)

E

F

G

H

I

MRS

Connection of binary inputs

A

15 V

85

86 81 82

S1

Fig. 20: Connection of binary inputs when using external contacts

A Auxiliary power output

B Contact inputs D1 and D2

S1 External contacts, not energised

S2 External contacts, not energised

B

D1

93

C07-CLD132xx-05-06 -00-xx-003.eps

Conductivity sensor

Temperature sensor

Alarm (contact position: no current)

Power supply

Remote parameter set switching (measuring range

switching)

D2

94

S2

C07-CLD132xx-05-0 6-00-xx-004.eps

20 Endress+Hauser

Page 21

Smartec S CLD132 Wiring

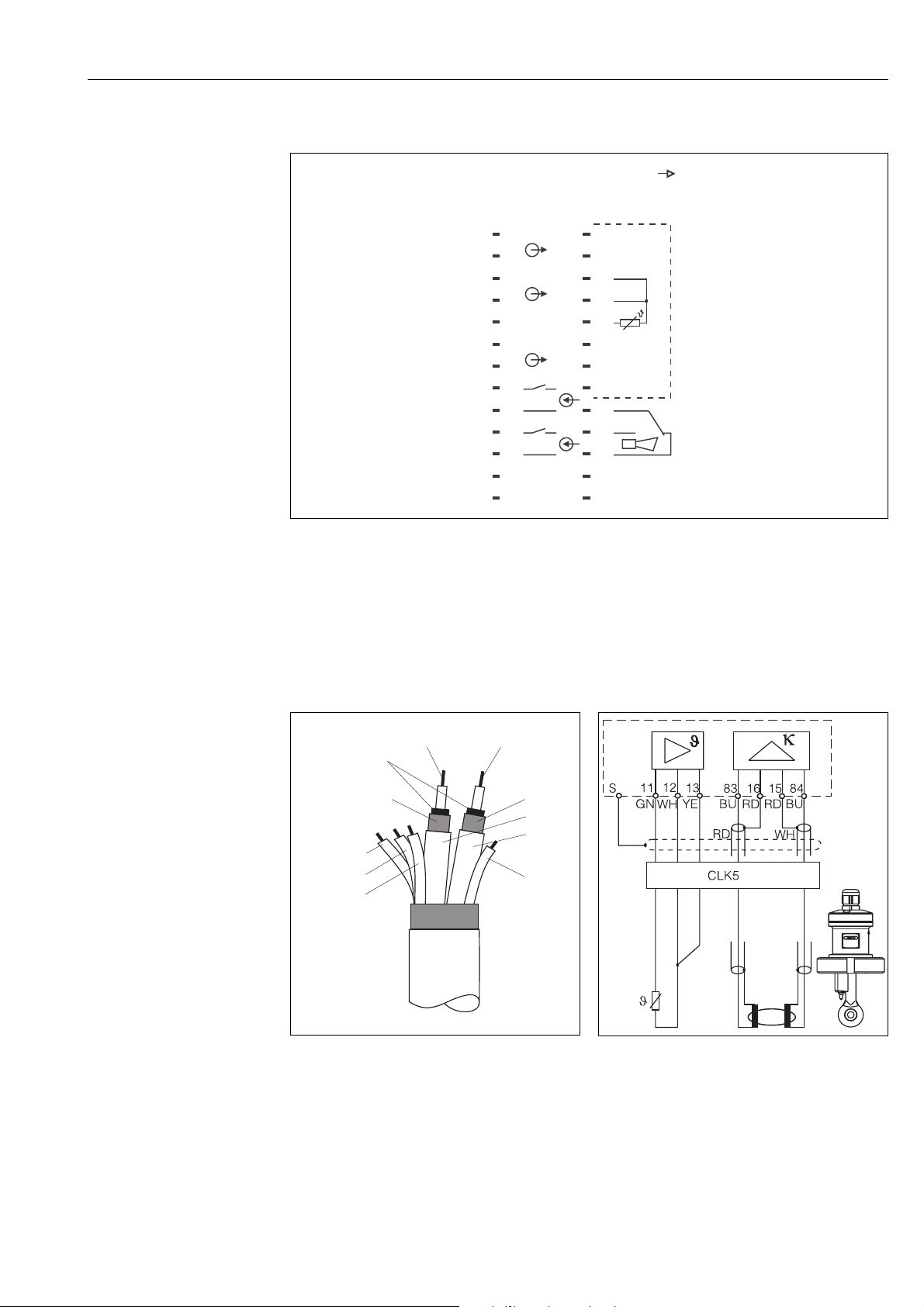

Connection compartment sticker

131082-4A

Sensor

31 +

32 -

33 +

34 -

NC

85 +

86 -

93 + S

Bin 2

94 - 42

81 + 43

Bin 1

82 - 41

NC

NC

Fig. 21: Connection compartment sticker of Smartec S

Lf

Temp.

(opt.)

+15V

10mA

15

84

12

13

11

16

83

∼

–

Mains

Hilfsenergie

∼

–

WH

YE

GN

C07-CLD132xx-05-06-00-xx-005.eps

!

"

Note!

The protection class of this instrument is I. The metal housing must be connected to PE.

Caution!

• Terminals designated as NC may not be switched.

• Undesignated terminals may not be switched.

Structure and termination of measuring cable

Semiconductor

screen

Screen

(15)

GN (11)

WH (12)

YE (13)

(84) (83)

Screen

(16)

WH

RD

BN

(unused)

CLK5

C07-CLK5xxxx-00-05-0 0-en-002.eps

Fig. 22: Structure of CLK5 measuring cable

Fig. 23: Electrical connection of the CLS52 sensor for

C07-CLD132xx-05 -06-00-xx-006.eps

the separate version

Endress+Hauser 21

Page 22

Wiring Smartec S CLD132

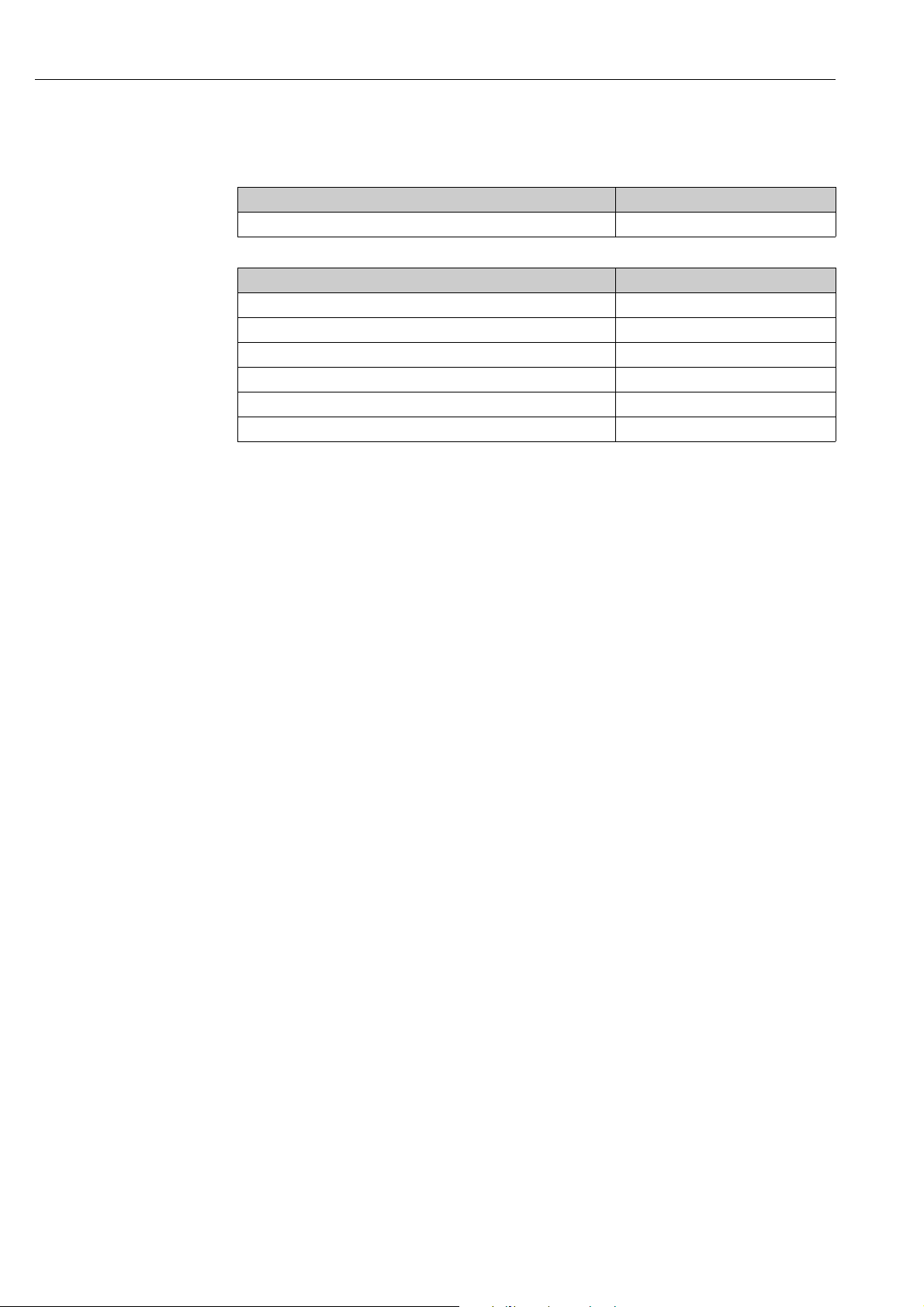

4.2 Post-connection check

After wiring up the electrical connection, carry out the following checks:

Device status and specifications Remarks

Are the transmitter or the cable externally damaged? Visual inspection

Electrical connection Remarks

Are the installed cables strain-relieved?

No loops and cross-overs in the cable run?

Are the signal cables correctly connected acc. to the wiring diagram?

Are all screw terminals tightened?

Are all cable entries installed, tightened and sealed?

Are the PE distributor rails grounded (if present)? Grounding at place of installation

22 Endress+Hauser

Page 23

Smartec S CLD132 Operation

5Operation

5.1 Quick operation guide

You have the following options of operating Smartec S:

• Local operation via operating keys

•Via HART

–HART

–PC with HART

• Via PROFIBUS PA/DP (optional, for corresponding order version)

PC with a corresponding interface and the Commuwin II software (see "Accessories") or via

programmable logic controller (PLC).

®

interface (optional, for corresponding order version) via:

®

hand-held terminal or

®

modem and Commuwin II software

!

Note!

For operation via HART or PROFIBUS PA/DP, read the corresponding chapters in the additional

operating instructions:

• PROFIBUS PA/DP, field communication with Smartec S CLD132, BA 213C/07/en

®

•HART

, field communication with Smartec S CLD132, BA 212C/07/en

The following chapters describe local operation via operating keys.

5.2 Display and operating elements

5.2.1 Display

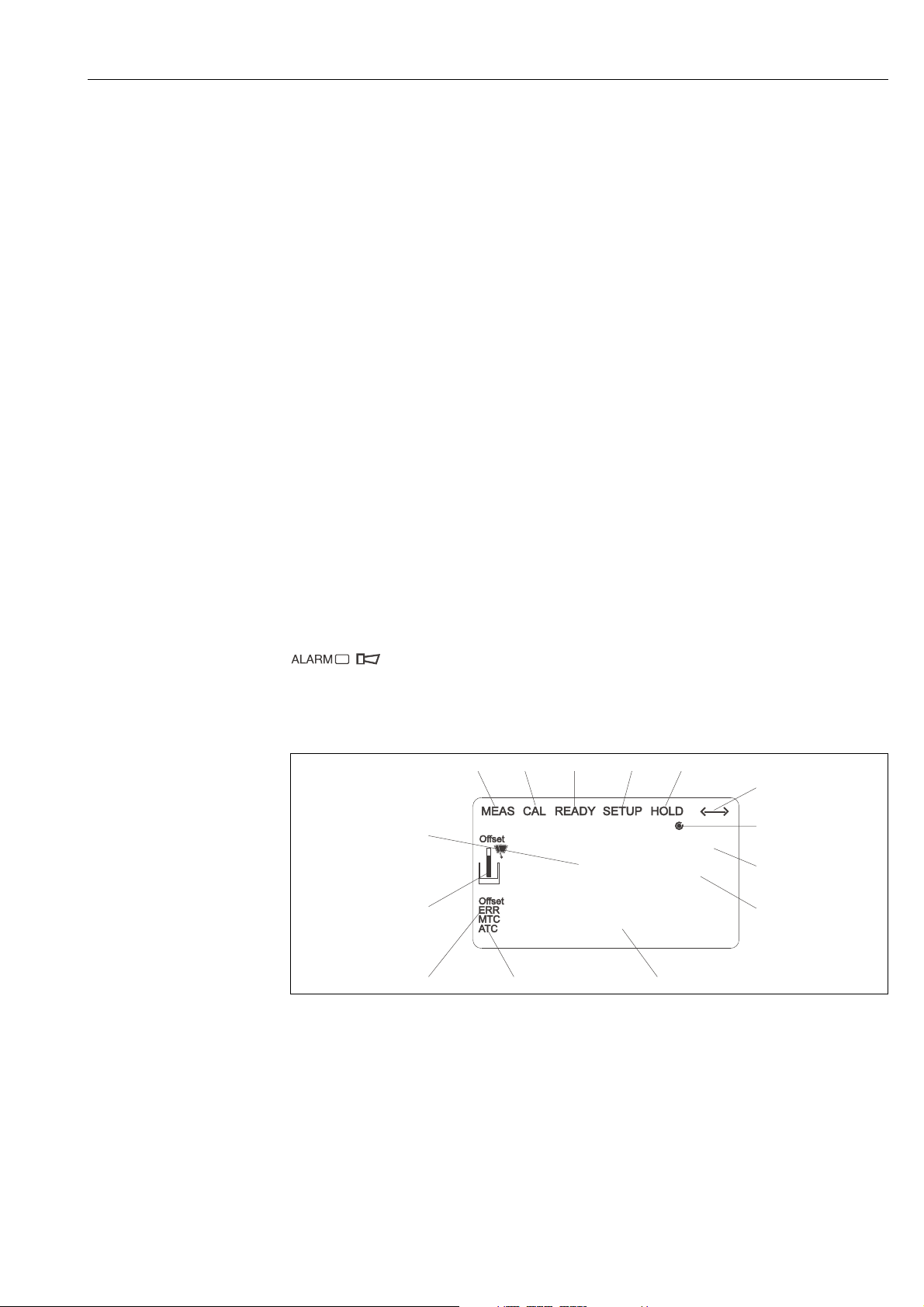

LED indicators

Alarm indication for continuous limit violation, temperature sensor failure

or system errors (see error list in chapter "Troubleshooting").

Liquid crystal display

5

mS/cm

O213

6

7

8

14

1

2

3

4

2000

13

9

20 mA

1112

Fig. 24: LCD of Smartec S CLD132

1

Measuring mode indicator (normal operation)

2

Calibration mode indicator

3

Calibration complete indicator

4

Setup mode indicator (configuration)

5

"Hold" mode indicator (outputs reflect last current

status)

6

Signal reception indicator for units with

communication

7

Indication of relay state: d inactive, c active

8

9

10

11

12

13

14

Endress+Hauser 23

10

In measuring mode: variable measured

In setup mode: parameter adjusted

Function coding display

In measuring mode: secondary measured value

In setup / calibr. mode: e.g. parameter

Manual / automatic temperature compensation

display

Error indicator

Sensor symbol, flashes during calibration

In measuring mode: Main measured valued

In setup / calibr. mode: e.g. parameter

C07-CLD132xx-07-0 6-00-xx-001.eps

Page 24

Operation Smartec S CLD132

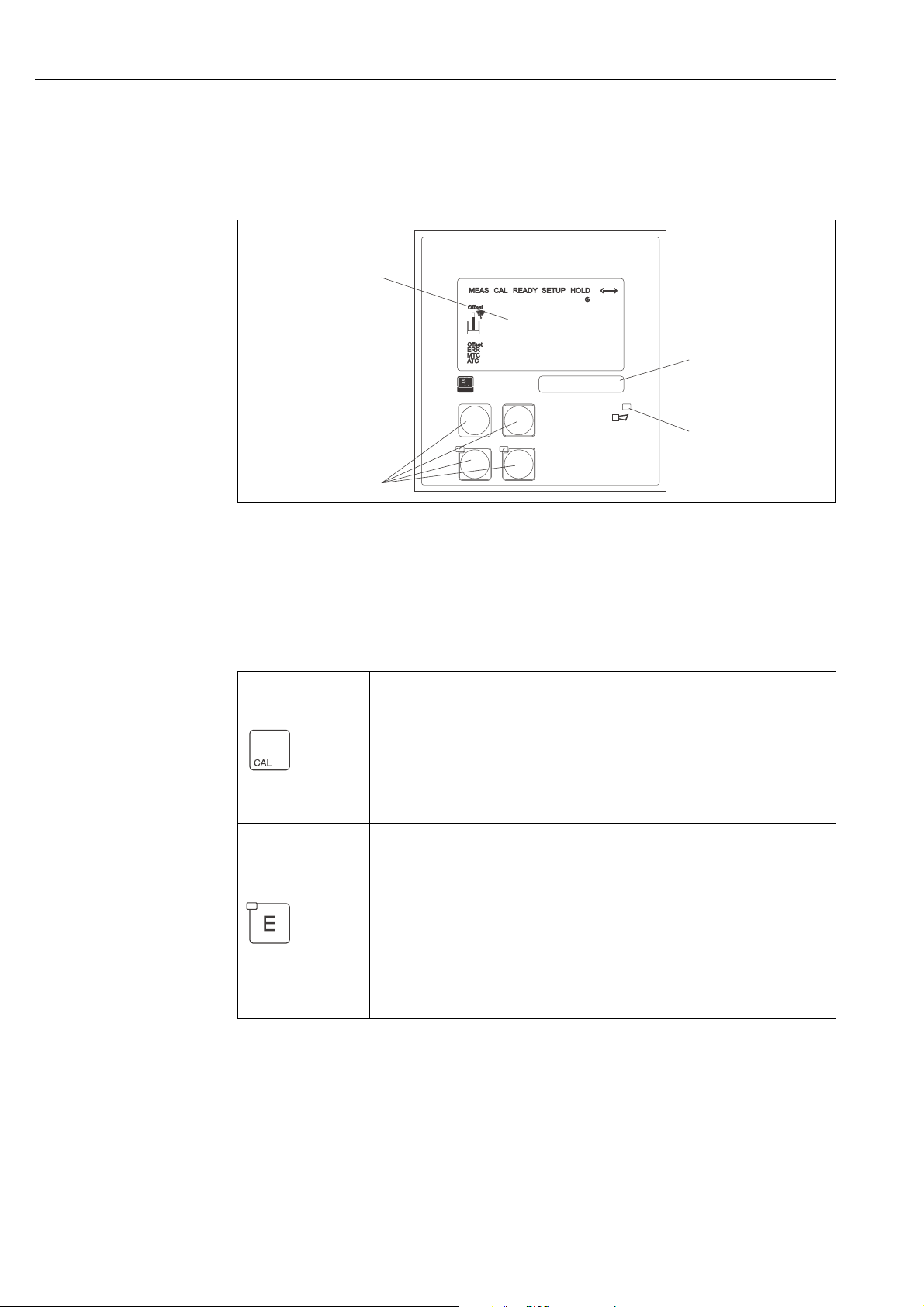

5.2.2 Operating elements

The operating keys are located underneath the housing cover. The display and the alarm LED are

visible through the viewing window. For operation, open the housing cover by removing the 4

screws.

1

mS/cm

2000

O213

20 mA

ENDRESS+HAUSER

SMARTEC S

CAL

+

E

–

2

Fig. 25: Operating elements of Smartec S CLD132

1 Liquid crystal display showing measured values and configuration data

2 4 operating keys for calibration and instrument configuration

3 Field for user labeling

4 LED indicator for alarm function

5.2.3 Key assignment

CAL key

When the CAL key is pressed, the instrument prompts for the calibration

access code:

• Code 22 for calibration

• Code 0 or any other number to view the calibration data

Use the CAL key to acknowledge calibration data and to continue through

the calibration process.

ALARM

3

4

C07-CLD132xx-19-0 6-00-xx-001.eps

ENTER key

When the ENTER key is pressed, the instrument prompts for the setup

access code:

• Code 22 for setup and configuration

• Code 0 or any other number to view the configuration data.

The ENTER key has several functions:

• It calls up the setup menus from the measuring mode

• It is used to store (acknowledge) data entered in setup mode

• It is used to move on within function groups

24 Endress+Hauser

Page 25

Smartec S CLD132 Operation

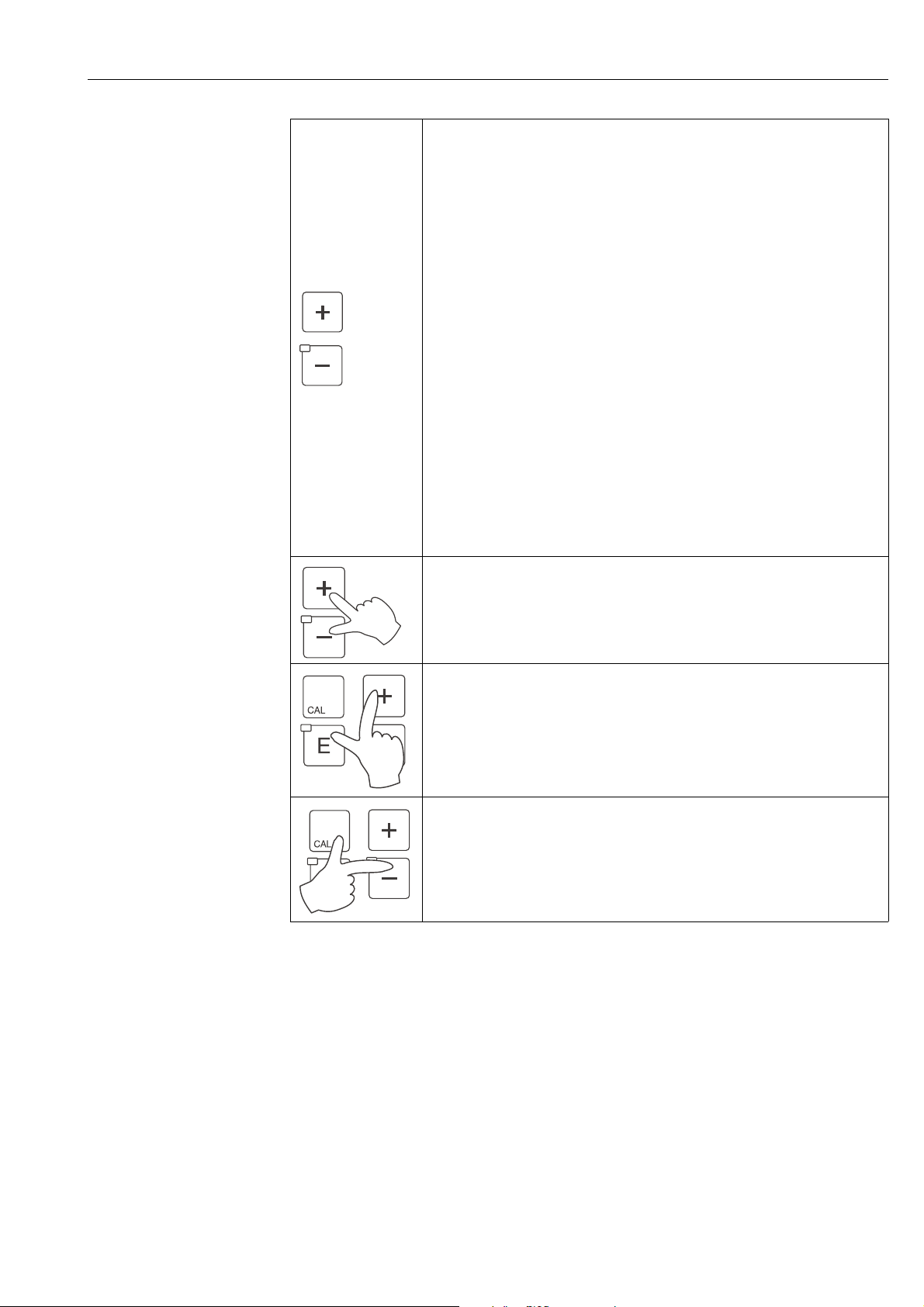

PLUS key and MINUS key

In setup mode, the PLUS and MINUS keys have the following functions:

• Selection of function groups

Note!

!

To select function groups in the order given in the chapter "Instrument

configuration", use the MINUS key.

• Setting of parameters and numeric values

In measuring mode, repeatedly pressing the PLUS key displays the

following settings in sequence:

1. Temperature display in °F

2. Hide temperature display

3. Display of uncompensated conductivity value

4. Back to basic setting

In measuring mode, repeatedly pressing the MINUS key displays the

following settings in sequence:

1. Display of current measuring range

2. Display of current errors in sequence (max. 10)

3. After all errors are displayed, the standard display is shown again. In

function group F, you can define an alarm for each error code.

Escape function

Press the PLUS and MINUS keys simultaneously to return to the main

menu. During calibration, this key combination goes directly to the end of

calibration. When the PLUS and MINUS keys are pressed once more, the

instrument returns to the measuring mode.

Locking the keypad

Pressing the PLUS and ENTER keys simultaneously for minimum 3s locks

the keypad against unintentional entries. However, all settings can still be

read.

The code prompt displays the code 9999.

Unlocking the keypad

Pressing the CAL and MINUS keys simultaneously for minimum 3s unlocks

the keypad.

The code prompt displays the code 0.

Endress+Hauser 25

Page 26

Operation Smartec S CLD132

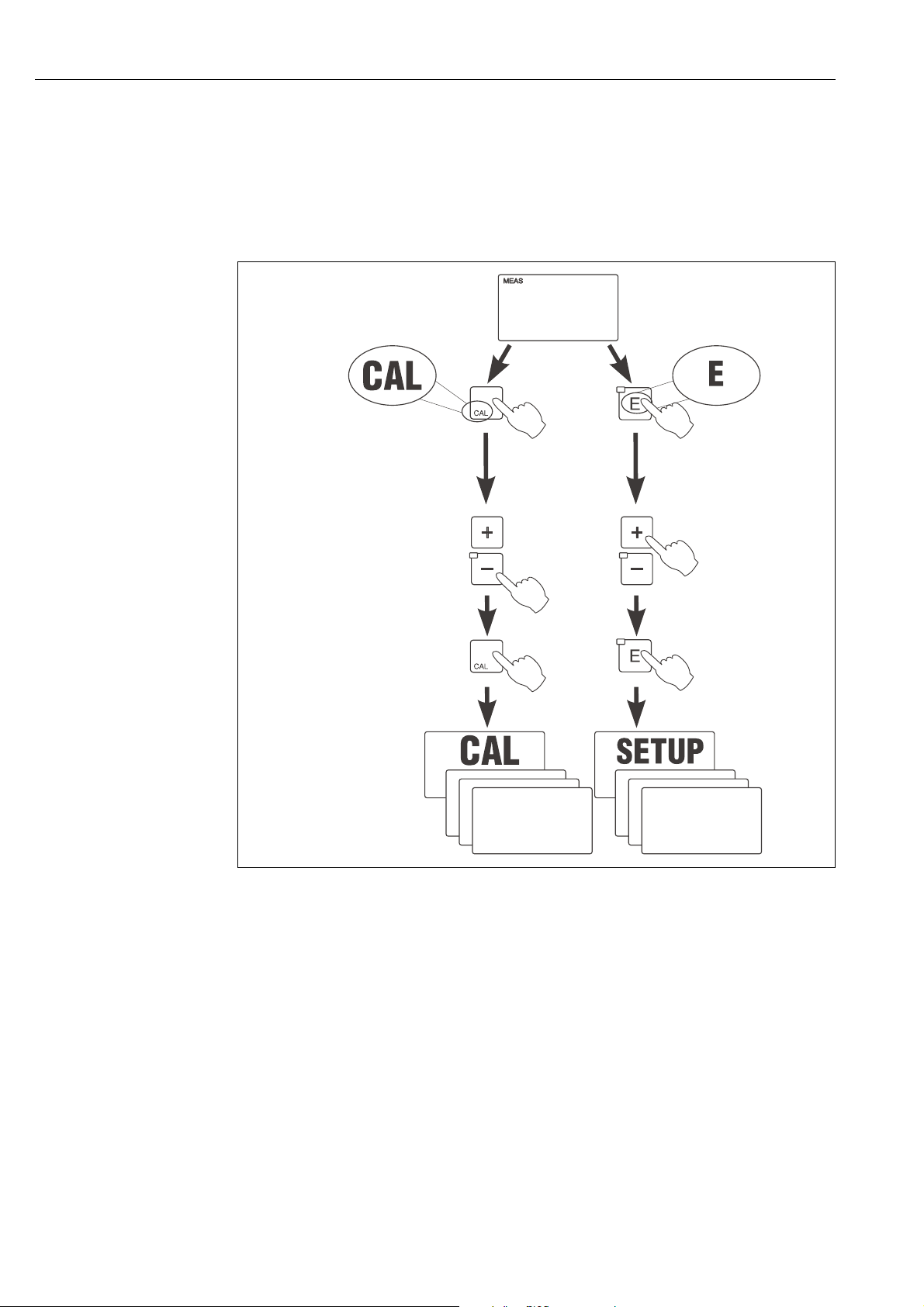

5.3 Local operation

5.3.1 Operating concept

Operating modes

Measuring mode:

standard mode of

operation, displaying

current measured values

Calibration mode:

execution of

calibration routine

The function groups

are selected with the

PLUS or MINUS key.

Fig. 26: Description of operating modes

Setup mode

access to all

configuration

settings

Code

C07-CLD132xx-19 -06-00-en-002.eps

!

Note!

If no key is pressed for 15 min. in setup mode, the instrument automatically switches back to the

measuring mode. An active Hold function (Hold at Setup) is then reset.

Access codes

All instrument access codes are fixed, i.e. they cannot be modified. When the instrument requests

the access codes, it recognises the difference between codes.

• CAL key + Code 22: access to calibration and offset menus.

• ENTER key + Code 22: access to the configuration menus, allowing configuration and

user-specific settings.

• PLUS + ENTER keys: locks the keypad.

• CAL + MINUS keys: unlocks the keypad.

• CAL or ENTER key + any code: access to Read mode, i.e. all settings can be read but not

changed.

26 Endress+Hauser

Page 27

Smartec S CLD132 Operation

Menu structure

The configuration and calibration functions are arranged in a menu structure by function groups.

The function groups are selected in the setup mode with the PLUS and MINUS keys. The ENTER

key is used to move from one function to the next within a function group.

The PLUS and MINUS keys are used for option selection and editing. Selections must be confirmed

by pressing the ENTER key. This also moves the cursor to the next function.

Pressing the PLUS and MINUS keys at the same time terminates programming (return to main

menu).

When the PLUS and MINUS keys are pressed once more, the instrument returns to the measuring

mode.

!

Note!

• If a change is made but not confirmed by pressing the ENTER key, the previous setting is retained.

• See the appendix of these operating instructions for an overview of the Smartec menu structure.

1

-

!

2

3

E

Fig. 27: Schematic of the SmarTec menu structure

E

EE E E

E

E

E

E

E

E

E

C07-CLD132xx-19-06-00-xx-010.eps

Hold function: "Freezing" the outputs

The current output can be “frozen” in the setup mode and during calibration, i.e. the last current

value is constantly output. The display shows the “HOLD” message.

Note!

• Hold settings can be found in the chapters "Service" and "Remote parameter set switching

(measuring range switching, MRS)".

• During “HOLD” in the measuring mode the contact will go to the normal position if it is

configured as a limit contact.

• An active hold has priority over all other automatic functions.

• A possibly accumulated alarm delay is reset to “0”.

• The hold function can also be activated externally via the hold input (see wiring diagram; binary

input 1).

• The manual hold (field S5) remains active even after a power failure.

Endress+Hauser 27

Page 28

Commissioning Smartec S CLD132

6 Commissioning

6.1 Function check

#

Warning!

• Check all connections for correctness.

• Make sure that the supply voltage is identical to the voltage written on the nameplate!

6.2 Start-up

Before first start-up, make sure you understand

how to operate the transmitter. You should

make particular reference to chapters 1 (Safety

instructions) and 5 (Operation).

After power-up (connection to power), the

instrument performs a self-test and then enters

the measuring mode.

Calibrate the sensor as described in the chapter

"Calibration".

Note!

!

During first start-up, calibration of the sensor is

absolutely required to enable the measuring

system to perform accurate measurement.

Configure the transmitter as described in the

chapter "Quick setup". The values set by the

user are kept even in the event of a power

failure.

The following function groups are available on

the Smartec S CLD132 (the function groups that

are only available on the version equipped with

the function extension are marked accordingly

in the function descriptions):

Setup mode

• SETUP 1 (A)

• SETUP 2 (B)

•OUTPUT (O)

•ALARM (F)

•CHECK (P)

•RELAY (R)

• ALPHA TABLE (T)

• CONCENTRATION (K)

• SERVICE (S)

• E+H SERVICE (E)

• INTERFACE (I)

• TEMPERATURE COEFFICIENT (D)

•MRS (M)

Calibration mode

• CALIBRATION (C)

Function display:

The displayed code indicates

s

2

F3

Err.delay

Fig. 28: Example for display in setup mode

C131 C132 C133

C121

C C1 C111

C07-CLD132xx-13-0 6-00-xx-005.eps

Fig. 29: Function coding

For a detailed description of the function groups available on the Smartec S CLD132 see the chapter

"Instrument configuration".

28 Endress+Hauser

the function position in the

function group.

Additional information

C07-CLD132xx-07 -06-00-en-003.eps

Selecting and locating functions is facilitated by

a code displayed for each function in a special

display field Fig. 28.

The structure of this coding is given in Fig. 29.

The first column indicates the function group as

a letter (see group designations). The functions

in the individual groups are counted from the

top to the bottom and from the left to the right.

Page 29

Smartec S CLD132 Commissioning

Factory settings

When the instrument is switched on for the first time, the factory settings are in effect. The

following table provides an overview of all major settings.

Please refer to the description of the individual functions in the chapter "Instrument configuration"

for all other factory settings (the factory settings are printed in bold letters).

Function Factory setting

Type of measurement Inductive conductivity measurement,

Temperature compensation type Linear with reference temperature 25 °C / 77 °F

Temperature compensation Automatic (ATC on)

Relay function Alarm

Hold Active during configuration and calibration

Measuring range 10 µS/cm ... 2000 mS/cm (measuring range set automatically)

Current outputs 1* and 2* 4 ... 20 mA

Current output 1: measured value for 4 mA

signal current*

Current output 1: measured value for 20 mA

signal current*

Current output 2: measured value for 4 mA

signal current*

Current output 2: measured value for 20 mA

signal current*

temperature measurement in °C

0 µS/cm

2000 mS/cm

0.0 °C / 32 °F

150.0 °C / 302 °F

* if equipped accordingly

Alarm contact

A

41

42

43

Fig. 30: Recommended fail-safe circuit for an alarm contact

A Normal operating state B Alarm state

Normal operating state

• Instrument in operation

• No error message available (Alarm LED off)

È Relay picked up

È Contact 42/43 closed

Alarm state

• Error message available (Alarm LED red)

or

• Instrument defective or voltage-free (Alarm LED

off)

È Relay dropped out

È Contact 41/42 closed

B

41

42

43

C07-CLD132xx-04-06 -00-xx-005.eps

Endress+Hauser 29

Page 30

Commissioning Smartec S CLD132

6.3 Quick setup

After switching the transmitter on, configure the major functions required for accurate

measurement. The following section gives you an example for a basic configuration.

Input Selection or range

1. Press the ENTER key.

2. Enter the code 22 to be able to edit the setup. Press

the ENTER key.

3. Press the MINUS key several times until the "Service"

function group is displayed.

4. Press the ENTER key to edit this function group.

5. Select your language, e.g. "ENG" for English.

Confirm your entry be pressing the ENTER key.

6. Press the PLUS and MINUS keys simultaneously to

quit the "Service" function group.

7. Press the MINUS key several times until the "Setup 1"

function group is displayed.

8. Press the ENTER key to edit "Setup 1".

(factory setting bold)

ENG = English

GER = German

FRA = French

ITA = Italian

NEL = Dutch

ESP = Spanish

Display

SERVICE

Language

SETUP 1

ENG

S

S1

A

9. In A1, select the operating mode, e.g.

"cond" = conductivity.

Confirm your selection by pressing the ENTER key.

10. In A2, press the ENTER key to confirm the factory

setting.

11. In A3, press the ENTER key to confirm the factory

setting.

12. In A4, press the ENTER key to confirm the factory

settting.

13. In A5, enter the cell constant for the connected

sensor. Refer to the sensor’s or the compact version’s

quality certificate for the exact value.

cond = conductivity

conc = concentration

%

ppm

mg/l

TDS = Total Dissolved

Solids

none

XX.xx

X.xxx

XXX.x

XXXX

auto, µS/cm, mS/cm,

S/cm, µS/m, mS/m,

S/m

0.10 ... 5.9 ... 9.99

cond

A1

Oper.Mode

A2

ppm

Conc.Unit

XX.xx

A3

Format

auto

A4

Unit

1/cm

5.900

A5

Cellconst

30 Endress+Hauser

Page 31

Smartec S CLD132 Commissioning

Input Selection or range

(factory setting bold)

14. In A6, press the ENTER key to confirm the factory

setting.

If your wall distance is smaller than 15 mm / 0.59",

refer to the chapters 3.3.1 and 6.4.14 for information

on determining the installation factor.

15. If you are working in applications that fluctuate a

great deal and you need to stabilise the display, enter

the required damping factor in A7.

Confirm your entry by pressing ENTER.

The display returns to the inital display of "Setup 1".

16. Press the MINUS key to go to the "Setup 2" function

group.

17. Press the ENTER key to edit "Setup 2".

18. In B1, select the temperature sensor of your

conductivity sensor. By default, your measuring

system is supplied with the CLS52 sensor with Pt 100

temperature sensor.

Confirm your entry by pressing ENTER.

0.10 ... 1 ... 5.00

1

1 ... 60

Pt100

Pt1k = Pt 1000

NTC30

fixed

Display

1.000

InstFac

Damping

SETUP 2

Pt100

ProcTemp.

1

A6

A7

B

B1

19. In B2, select the appropriate temperature

compensation for your process, e.g. "lin" = linear.

Confirm your selection by pressing ENTER.

For detailed information on temperature

compensation, see chapter 6.4.2.

20. In B3, enter the temperature coefficient

Confirm your entry by pressing ENTER.

For detailed information on determining the

temperature coefficient, see chapters 6.4.2 or 6.4.12.

21. The real temperature is displayed in B5. If necessary,

calibrate the temperature sensor to an external

measurement.

Confirm your entry by pressing ENTER.

22. The difference between the measured and the entered

temperatures is displayed.

Press the ENTER key.

The display returns to the initial display of the "Setup

2" function group.

23. Press the MINUS key to go to the "Output" function

group.

24. Press the ENTER key to edit the output settings.

α.

none

lin = linear

NaCl = common salt

(IEC 60746)

Tab 1 ... 4

2.1 %/K

0.0 ... 20.0 %/K

Display and entry of real

temperature

-35.0 ... 250.0 °C

0.0 °C

-5.0 ... 5.0 °C

B2

lin

TempComp.

%/K

2.10

B3

Alpha val

°

B5

0.0

RealTemp.

°

B6

0.0

TempOffs.

O

OUTPUT

C

C

25. In O1, select your output, e.g. "out1" = output 1.

Confirm your selection by pressing ENTER.

out 1

out 2

out1

O1

Sel. Out

Endress+Hauser 31

Page 32

Commissioning Smartec S CLD132

Input Selection or range

(factory setting bold)

26. In O2, select the linear characteristic.

Confirm your selection by pressing ENTER.

27. In O211, select the current range for your output, e.g.

4...20mA.

Confirm your selection by pressing ENTER.

28. In O212, enter the conductivity corresponding to the

minium current value at the transmitter output, e.g.

0µS/cm.

Confirm your entry by pressing ENTER.

29. In O213, enter the conductivity corresponding to the

maximum current value at the transmitter output,

e.g. 930 mS/cm.

Confirm your entry by pressing ENTER.

The display returns to the initial display of the

"Output" function group.

30. Press the PLUS and MINUS keys simultaneously to

return to measuring mode.

lin = linear (1)

sim = simulation (2)

4...20mA

0...20mA

0.00 µS/cm

0.00 µS/cm ...

2000 mS/cm

2000 mS/cm

0.0 µS/cm ...

2000 mS/cm

Display

lin

Sel.Type

4-20

Sel.Range

0/4 mA

930

20 mA

0

O2

O211

µS/cm

O212

mS/cm

O213

!

Note!

You must perform an airset before installing the sensor. To do so, refer to the chapter "Calibration".

32 Endress+Hauser

Page 33

Smartec S CLD132 Commissioning

6.4 Instrument configuration

The following sections give a detailed description of all Smartec S CLD132 functions.

6.4.1 Setup 1 (conductivity, concentration)

In the SETUP 1 function group, you can change the operating mode and the sensor settings.

You have already made all settings of this menu during the quick setup but you can modify the

settings at any time.

Coding Field Selection or range

A

A1 Select operating mode

A2

A3

Function group

SETUP 1

Select concentration

unit to be displayed

Select display format

for concentration unit

(factory settings bold)

cond = conductivity

conc = concentration

%

ppm

mg/l

TDS = Total Dissolved Solids

none

XX.xx

X.xxx

XXX.x

XXXX

Display Info

A

Basic settings.

SETUP 1

Display varies depending on instrument

version:

cond

A1

Oper.Mode

A2

ppm

–cond

–conc

"

Any change in operating mode causes an

automatic reset of user settings.

Conc.Unit

XX.xx

A3

Format

Caution!

A4

Select unit to be

displayed for

conductivity

auto, µS/cm, mS/cm, S/cm,

µS/m, mS/m, S/m

auto

A4

When “auto” is selected, the maximum

resolution possible is automatically selected.

Unit

A5

Enter cell constant for

connected sensor

0.10 ... 5.9 ... 9.99

5.900

1/cm

A5

For the exact value of the cell constant, refer

to the sensor’s or the compact version’s

quality certificate.

Cellconst

This is where the installation factor is edited.

A6 Installation factor 0.10 ... 1 ... 5.00

1.000

A6

InstFac

A7

Enter measured value

damping

1

1 ... 60

1

A7

Damping

Endress+Hauser 33

The correct factor is determined in C1(3), see

chapter "Calibration" or referring to the

installation factor diagram.

Measured value damping causes averaging

over the specified number of individual

measured values. It is used, for example, to

stabilise the display with applications that

fluctuate a great deal.

There is no damping if “1” is entered.

Page 34

Commissioning Smartec S CLD132

6.4.2 Setup 2 (temperature)

The temperature compensation only needs to be performed in the conductivity mode (selection in

field A1).

The temperature coefficient specifies the change in conductivity per degree of temperature change.

It depends on the chemical composition of the medium and the temperature itself.

In order to compensate for this dependence, three different compensation types can be selected in

the Smartec S:

Linear temperature compensation

The change between two temperature points is

considered to be constant, i.e.

α =const. The

α value can be edited for the linear

compensation type. The reference temperature is

25 °C / 77 °F.

NaCl compensation

The NaCl compensation (according to IEC

60746) is based on a fixed nonlinear curve that

defines the relationship between the temperature

coefficient and the temperature. This curve is

used for lower concentrations of up to approx.

5% NaCl.

k*

a

1

T

C07-CLD132xx-05 -06-00-xx-009.eps

Fig. 31: Linear temperature compensation

* uncompensated conductivity

2,7

a [%/K]

2,5

2,3

2,1

0

Fig. 32: NaCl compensation

48

96

C07-CLD132xx-05 -06-00-xx-010.eps

144

T [°C]

Temperature compensation with table

When using the alpha table function for temperature compensation, the following conductivity data

of the process medium to be measured are required:

Value pairs of temperature T and conductivity

κ(T

) for the reference temperature T

•

0

κ with:

0

• κ(T) for temperatures which occur in the process

34 Endress+Hauser

Page 35

Smartec S CLD132 Commissioning

A

k

1

T

k()

0

k

2

T

1

Fig. 33: Determination of temperature coefficient

A Required data

BCalculated

α values

T

0

a

a

2

a

1

T

TT

2

T1T

B

2

C07-CLD132xx-05-06-00-xx-011.eps

Use the following formula to calculate the α values for the temperatures occurring in your process:

κκ(T) - (T )

.

0

T - T

0

; T T≠

0

0

Enter the

100

α =

κ(T )

α−T value pairs calculated with this formula in the fields T5 and T6 of the function group

ALPA TABLE.

In the SETUP 2 function group, you can change the settings for temperature measurement.

You have already made the settings of this function group during quick setup but you can modify

the settings at any time.

Coding Field Selection or range

(factory settings bold)

B

B1

B2

Function group

SETUP 2

Select temperature

sensor

Select temperature

compensation type

Pt100

Pt1k = Pt 1000

NTC30

fixed

none

lin = linear

NaCl = common salt (IEC 60746)

Tab 1 ... 4

Display Info

B

Settings for temperature measurement.

SETUP 2

If set to "fixed":

Pt100

B1

no temperature measurement, a fixed

temperature value is entered instead.

ProcTemp.

This option is not displayed for concentration

measurement.

B2

lin

TempComp.

The options Tab 2 ... 4 are only available for

transmitters with the "Remote measuring

range switching" upgrade.

B3

Enter temperature

coefficient

α

2.1 %/K

0.0 ... 20.0 %/K

2.10

%/K

B3

Only if B2 = lin.

Tables defined in B2 are not active in this case.

Alpha val

Endress+Hauser 35

Page 36

Commissioning Smartec S CLD132

Coding Field Selection or range

(factory settings bold)

B4

B5

B6

Enter process

temperature

Display temperature

and calibrate

temperature sensor

Temperature

difference is displayed

25 °C

-10.0 ... 150.0 °C

Display and entry of real

temperature

-35.0 ... 250.0 °C

0.0 °C

-5.0 ... 5.0 °C

6.4.3 Current outputs

The OUTPUT function group is used to configure the individual outputs.

Furthermore, a current output value can be simulated to check the current outputs (O2 (2)).

Display Info

°

25.0

C

B4

Only if B1 = fixed.

This value can only be specified in °C.

ProcTemp.

This entry is used to calibrate the temperature

sensor to an external measurement.

Omitted if B1 = fixed.

0.0

°

C

B5

RealTemp.

°

B6

0.0

TempOffs.

C

The difference between the entered actual

value and the measured temperature is

displayed.

Omitted if B1 = fixed.

Coding Field Selection or range

(factory settings bold)

O

O1 Select current output

O2 O2 (1)

Function group

OUTPUT

Enter linear

characteristic

O211 Select current range

out1

out2

lin = linear (1)

sim = simulation (2)

4 ... 20 mA

0 ... 20 mA

Display Info

O

Configuration of the current output (not

available for PROFIBUS versions).

OUTPUT

out1

O1

A different characteristic can be selected for

each output.

Sel. Out

lin

O2

The slope of the characteristic may be

positive or negative.

Sel.Type

4-20

O211

Sel.Range

0/4 mA value:

O212

enter corresponding

measured value

Cond: 0.00 µS/cm

Conc: 0.00 %

Temp.: -10.0 °C

entire measuring range

0/4 mA

0

µS/cm

O212

Enter the measured value corresponding to

the minimum current value (0/4 mA) at the

transmitter output.

Display format from A3.

(Spreading: see Technical data.)

36 Endress+Hauser

Page 37

Smartec S CLD132 Commissioning

Coding Field Selection or range

(factory settings bold)

20 mA value:

O213

enter corresponding

measured value

O2 (2)

Current output

simulation

O221 Enter simulation value

Cond: 2000 mS/cm

Conc: 99.99 %

Temp.: 60.0 °C

entire measuring range

lin = linear (1)

sim = simulation (2)

current value

0.00 ... 22.00 mA

6.4.4 Alarm

The ALARM function group is used to define various alarms and to set output contacts.

Each individual error can be defined to be effective or not (at the contact or as an error current).

Display Info

Enter the measured value corresponding to

the maximum current value (20 mA) at the

transmitter output.

Display format from A3.

(Spreading: see Technical data.)

The simulation is terminated by selecting (1).

2000

20 mA

sim

mS/cm

O213

O2

Sel.Type

4.00

mA

O221

The current value entered here is output

through the current output.

Simulat.

Coding Field Selection or range

(factory settings bold)

F

F1 Select contact type

F2 Select time unit

F3 Enter alarm delay

Function group

ALARM

Stead = steady contact

Fleet = fleeting contact

s

min

0 s (min)

0 ... 2000 s (min)

Display Info

F

Alarm function settings.

ALARM

Stead

F1

The contact type selected here only applies to

the alarm contact.

Cont.Type

F2

s

Time unit

s

F3

0

Err.Delay

Depending on the unit selected in F2, the

alarm delay is entered in s or min.

The alarm delay does not affect the LED; it

indicates the alarm immediately

This selection must be made even if all error

messages are suppressed in F5.

Caution!

"

If you selected the "0-20 mA" range in O211,

you may not select the "2.4 mA" option here.

F4 Select error current

22 mA

2.4 mA

22mA

Err.Curr

F4

Endress+Hauser 37

Page 38

Commissioning Smartec S CLD132

Coding Field Selection or range

(factory settings bold)

F5 Select error

F6

F7

F8

Set alarm contact to be

effective for selected

error

Set error current to be

effective for selected

error

Return to menu or

select next error

1

1 ... 255

yes

no

no

yes

next = next erorr

←R

Display Info

Select the errors that are to trigger an alarm

signal.

The errors are selected via the error number.

F5

1

Sel.Error

yes

F6

Rel.Assg

F7

no

Curr.Assg

F8

R

Please refer to the table in chapter 9.2 "System

error messages" for the error numbers. The

factory settings remain in effect for all errors

not edited.

If set to “no”, all the other alarm settings (e.g.

alarm delay) are also deactivated. The settings

themselves are retained.

This setting only applies to the error selected

in F5.

Factory setting is no starting with E080!

The error current selected in F4 becomes

effective or is suppressed when an error

occurs.

This setting only applies to the error selected

in F5.

If next is selected, the software returns to F5.

If ←R is selected, it returns to F.

Select

!

6.4.5 Check

PCS alarm (Process Check System)

The PCS alarm is only available for transmitters with remote parameter set switching.

This function is used to examine the measuring signal for deviations. If the measuring signal is

constant for a specific period of time (several measured values), an alarm is issued. This type of

sensor behaviour may be caused by soiling, etc.

A

t

C07-CLD132xx-05-0 6-00-xx-007.eps

Fig. 34: PCS alarm (live check)

A Constant measuring signal = alarm is triggered after the configured PCS period

Note!

An active PCS alarm is automatically cleared when the measuring signal changes.

38 Endress+Hauser

Page 39

Smartec S CLD132 Commissioning

Coding Field Selection or range

(factory settings bold)

P

P1

Function group

CHECK

Set PCS alarm

(live check)

off

1 h

2 h

4 h

6.4.6 Relay configuration

For Smartec S CLD132 equipped with remote parameter set switching (measuring range switching),

there are three options for configuring the relay (selection in field R1):

• Alarm

The relay closes the contact 41/42 (voltage-free, safe state) if an alarm condition according to

chapter 9.2 occurs and if the setting in the “Alarm contact” column is “yes”. You can change

these settings as required (field F5 ff).

• Limit

The relay only closes the contact 42/43 if one of the defined limits is violated (value above or

below limit, see Fig. 35) but not when an alarm condition is detected.

• Alarm + Limit

The relay closes the contact 41/42 if an alarm condition occurs. Limit violations only cause the

relay to switch if error E067 is set to “yes” during relay assignment (field F6).

Display Info

P

Settings for sensor and process monitoring.

CHECK

This function is used to monitor the measuring

signal.

An alarm is triggered if it does not change for

P1

off

PCS alarm

the period selected here.

Monitoring limit:

0.3 % of mean value over selected period of

time.

(Error no.: E152)

Please refer to Fig. 35 for a graphic representation of the contact states of the alarm contact.

• When the measured value increases (max function), the relay goes into alarm state (limit

exceeded) at time t2 when the switch-on point has been exceeded (t1) and the pickup delay

(t2 – t1) has expired.

• When the measured value decreases, the relay returns to normal operating state when the

measured value drops below the switch-off point and after the dropout delay (t4 - t3).

• When the pickup and dropout delays are set to 0 s, the switch-on and switch-off points are

identical to the contact switching points.

Settings for a minimum function can be made in the same way as for a maximum function.

Endress+Hauser 39

Page 40

Commissioning Smartec S CLD132

A

3

1

2

t

1

t

2

t

4

t

t

4

3

Fig. 35: Relation of switch-on and switch-off points and pickup and dropout delays

ABSwitch-on point > switch-off point: Max. function

Switch-on point < switch-off point: Min. function12

Coding Field Selection or range

R

R1 Select function

Function group

RELAY

(factory settings bold)

alarm

limit

al+li = alarm + limit

B

2

1

3

t

t

1

2

3

4

Display Info

R

4

t

t

4

3

Switch-on point

Switch-off point

Contact ON

Contact OFF

Settings for relay contacts.

t

C07-CLD132xx-05 -06-00-xx-008.eps

RELAY

alarm

R1

When “alarm” is selected, the fields R2 ... R5

are irrelevant.

Function

Only the operating mode selected in A1

R2

R3

R4 Enter pickup delay

Enter contact

switch-on point

Enter contact

switch-off point

Cond: 2000 mS/cm

Conc: 99.99 %

entire measuring range

Cond: 2000 mS/cm

Conc: 99.99 %

entire measuring range

0 s

0 ... 2000 s

mS/cm

2000

R2

On Value

mS/cm

2000

R3

Off Value

s

0

R4

appears.

Note!

!

Never set the switch-on point and the

switch-off point to the same value.

The switch-off point entry selects a max

contact (switch-off point < switch-on point) or

a min contact (switch-off point > switch-on

point), thereby implementing a hysteresis

function (see Fig. 32).

On Delay

40 Endress+Hauser

Page 41

Smartec S CLD132 Commissioning

Coding Field Selection or range

(factory settings bold)

R5 Enter dropout delay

R6 Select simulation

R7 Switch relay on or off

0 s

0 ... 2000 s

auto

manual

on

off

6.4.7 Temperature compensation with table

This function group is used to perform a temperature compensation with table (field B2 in SETUP 2

function group).

Enter the

α−T value pairs in the fields T5 and T6.

Display Info

s

0

R5

Off Delay

auto

R6

This selection can only be made if limit has

been selected in R1.

Simulat.

This selection can only be made if manual has

off

R7

been selected in R6. The relay can be

switched on and off.

Relay

Coding Field Selection or range

T

T1 Select table

T2 Select table option

T3

Function group

ALPHA TABLE

Enter number of table

value pairs

(factory settings bold)

1

1 ... 4

read

edit

1

1 ... 10

Display Info

T

Settings for temperature compensation.

ALPHA TAB

Selection of table to be edited.

T1

1

editCurve

read

T2

Options 1 ... 4 are only available if the

instrument is equipped with the remote

measuring range switching.

Sel.Table

Up to 10 value pairs can be entered in the

1

T3

table. These are numbered from 1 ... 10 and

can be edited individually or in sequence.

No. Elem.

α

T4 Select table value pair11 ... number of table value pairs

assign

1

T4

If "assign", go to T8.

Sel.Elem.

Endress+Hauser 41

Page 42

Commissioning Smartec S CLD132

Coding Field Selection or range

(factory settings bold)

T5

T6

T8

Enter temperature

value

Enter temperature

coefficient

Enter whether or not

the table status is ok

α

0.0 °C

-10.0 ... 150.0 °C

2.10 %/K

0.00 ... 20.00 %/K

yes

no

6.4.8 Concentration measurement

The Smartec S CLD132 transmitter can convert conductivity values to concentration values. For

this, set the operating mode to Concentration measurement (see field A1).

Display Info

The temperature values must have a

°C

T5

0.0

Temp.val.

%/K

2.10

T6

minimum distance of 1 K.

Factory setting for temperature value of value

pairs in table:

0.0 °C; 10.0 °C; 20.0 °C; 30.0 °C ...

alpha val

yes

T8

If “yes”, return to T.

If “no”, return to T3.

Status ok

You must enter the basic data to which the concentration calculation should refer. For the most

common substances, the required data is already saved in your device. You can select one of these

substances in field K1.

If you want to specify the concentration of a sample, which is not saved in the device, you require

the conductivity characteristics of the medium. To get the characteristics, you can either refer to the