Endress+Hauser CLD132 Specifications

Technical Information

Smartec S CLD132

Measuring system with inductive sensor for conductivity and

concentration measurement in the food industry

6 8

Application

• Product monitoring in breweries, dairies and the beverage

industry

• CIP system control

• Phase separation of product/water and product/product

mixtures in pipe systems

• Alkali and acid concentration control in remaking

• Monitoring and control of bottle cleaning systems

Your benefits

• Transmitter housing made of stainless steel

• Sensor made of highly resistant plastic (PEEK)

• Sterilisable sensor

• High measuring reliability due to extensive self-monitoring

functions

• Insensitive to polarisation and soiling

• Versions with ultrafast temperature response (t

available

• Sensor versions for all process connections used in hygienic

applications

• Various operating possibilities:

– Keys

–HART

–PROFIBUS PA/DP

– PC with Commuwin II software

• Large two-line display allows simultaneous display of

measured value and temperature

• Standard version extendable by function extension with

remote parameter set switching (measuring range switching)

®

hand-held terminal

90

<5s)

TI207C/07/en/08.04

51501593

Function and system design

Measuring principle Inductive conductivity measurement

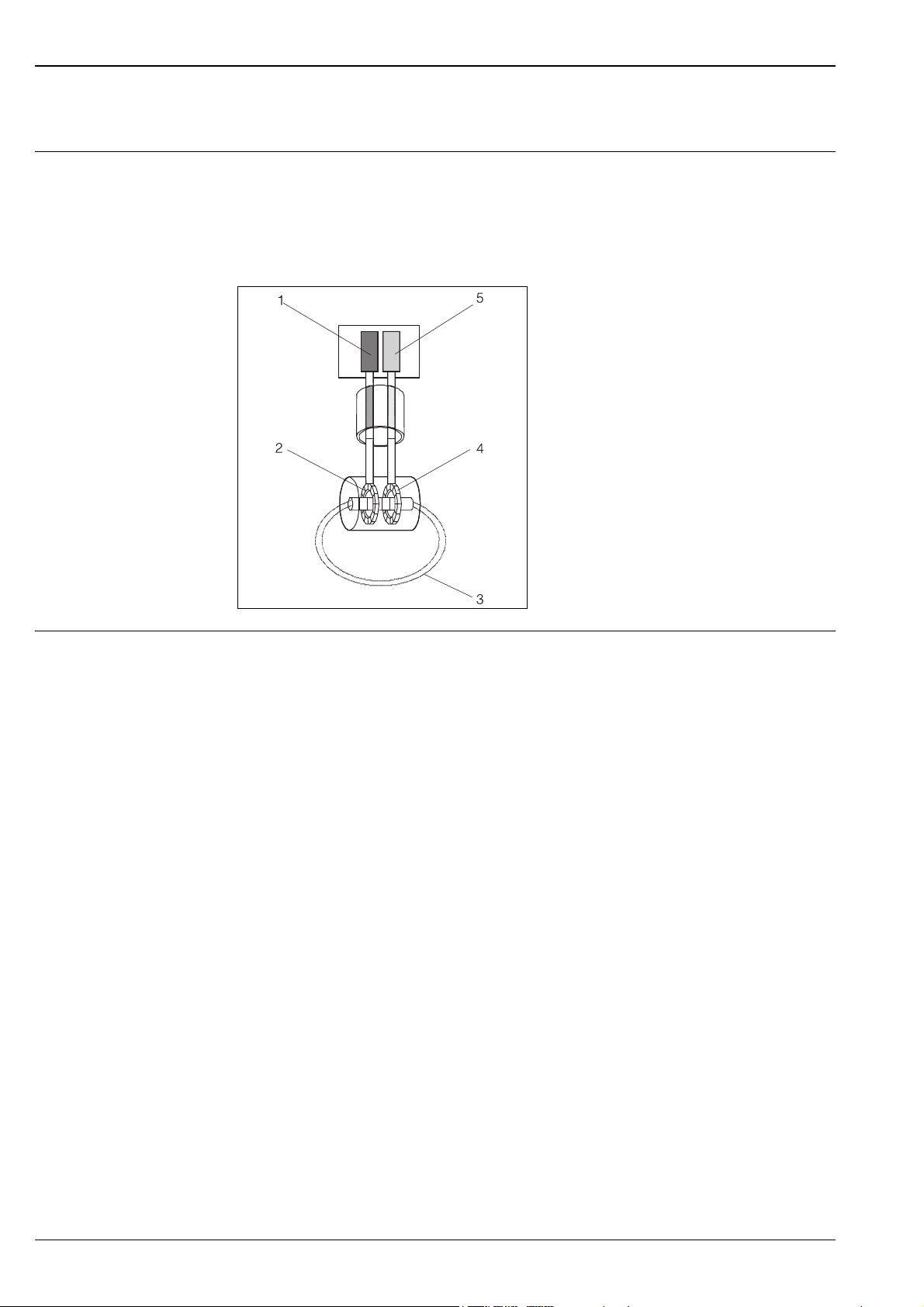

A generator (1) generates an alternating magnetic field in the primary coil (2) which induces a current in the

medium (3). The strength of the induced current depends on the conductivity and thus the ion concentration

of the medium. The current flow in the medium generates another magnetic field in the secondary coil (4).

The resulting current induced in the coil is measured by the receiver (5) and processed to determine the

conductivity.

Smartec S CLD132

Inductive conductivity measurement

1

Generator

2

Primary coil

3

Current flow in the medium

4

Secondary coil

5

Receiver

Benefits of inductive conductivity measurement

• No electrodes, therefore no polarisation

• Accurate measurement in media or solutions with

a high soiling degree and a tendency to deposition

• Complete galvanic separation of measurement and

medium

Important properties of

Smartec S CLD132

C07-CLXixxxx-15-0x-00-xx-001.eps

• Hygiene

The sensor, injection-moulded from highly chemically, mechanically and thermally resistant PEEK

(polyether ether keton), does not have joints or crevices and is therefore hygienically safe.

• Temperature measurement

– For applications requiring quick temperature measurement (e.g. CIP return, phase separation at various

temperatures), the Pt 100 temperature sensor is installed in a stainless-steel thermal conductivity socket

that is sealed by a Chemraz O-ring. This ensures extremely fast temperature response times (t

< 5 s).

90

– For high-load applications, particularly for alternating thermal load due to very frequent sterilisation cycles

or temperature shocks, the Pt 100 temperature sensor is embedded in the PEEK sensor body thus

eliminating the need for a seal. This ensures a long service life.

This sensor version can also be applied at underpressure.

• Temperature compensation

Smartec S CLD132 offers the following types of temperature compensation:

– Linear compensation with freely selectable temperature coefficient α

– Compensation according to IEC 746-3 for NaCl

– Compensation with freely programmable coefficient table with 10 elements maximum

• Process temperature

The use of special components and materials makes the sensor suitable for continuous exposure to

temperatures of +125 °C. Short-time (max. 30 min.), it will work at +140 °C for sterilisation.

• Concentration measurement

The transmitter can be switched from conductivity operating mode to concentration operating mode. The

concentration operating mode provides one freely programmable as well as various predefined concentration

curves, especially for common CIP solutions. This enables a direct display of the concentration in %.

• Remote parameter set switching

Smartec S CLD132 can be ordered with remote parameter set switching (measuring range switching, MRS)

enabling you

– to cover a wide measuring range

– to adjust temperature compensation when changing the product

– to switch between concentration curves.

2 Endress+Hauser

Smartec S CLD132

ENDRESS+HAUSER

SMARTEC S

ALARM

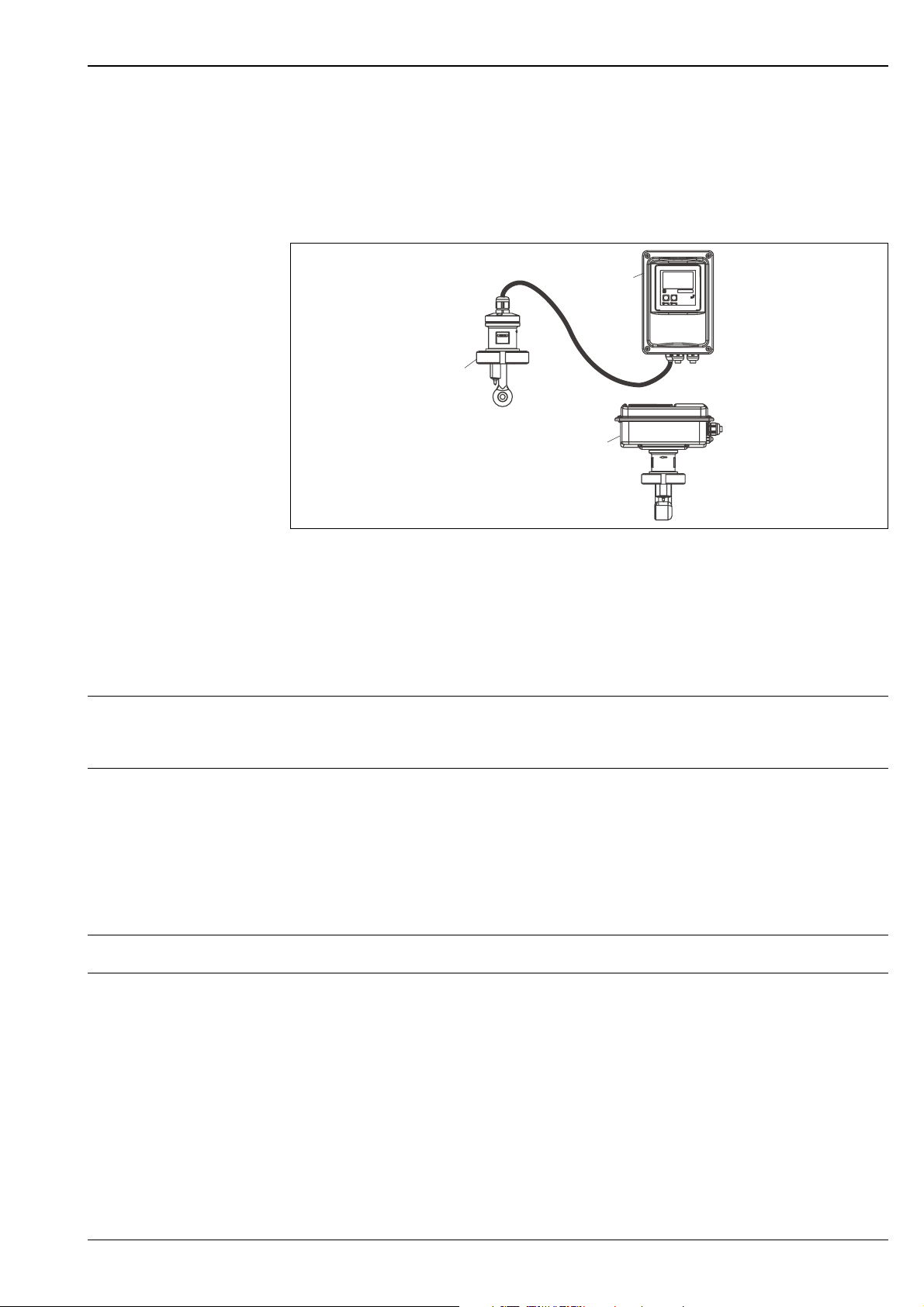

Measuring system A complete measuring system comprises:

• the Smartec S CLD132 transmitter

• the CLS52 conductivity sensor with integrated temperature sensor and fixed cable

or

• the CLD132 compact version with integrated CLS52 conductivity sensor

Optional for the separate version: CLK5 extension cable, VBM junction box, mounting kit for pipe mounting

A

B

ENDRESS+HAUSER

SMARTEC S

ALARM

CAL

+

E

–

C

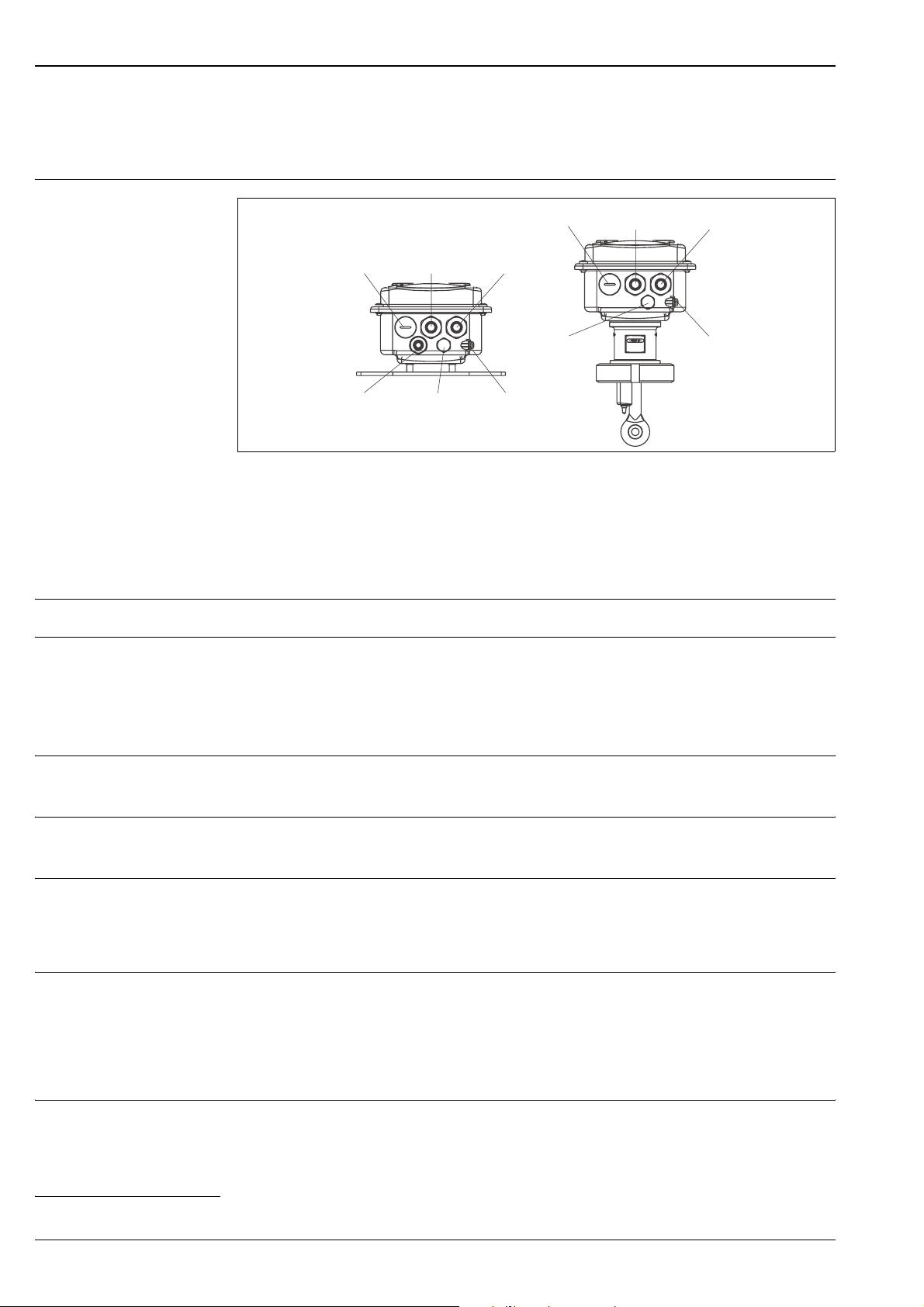

Complete measuring systems Smartec S CLD132 as separate transmitter and compact version

A CLS52 conductivity sensor

B Smartec S CLD132 transmitter

C Smartec S CLD132 compact version with integrated CLS52

Input

Measured variables Conductivity

Concentration

Temperature

Measuring range

Sensor cable max. cable length 55 m / 180.46 ft with CLK5 cable (separate version)

Conductivity: recommended range: 100 µS/cm ... 2000 mS/cm (uncompensated)

Concentration:

NaOH: 0 ... 15 %

: 0 ... 25 %

HNO

3

H

: 0 ... 30 %

2SO4

H3PO4: 0 ... 15 %

User 1 (... 4): (4 tables available in versions with remote parameter set switching)

Temperature: –35 ... +250 °C / -31 ... +482 °F

C07-CLD132xx-14 -06-00-xx-001.EPS

Binary inputs 1 and 2

Voltage: 10 ... 50 V DC

Current consumption: max. 10 mA at 50 V

Endress+Hauser 3

Output

Smartec S CLD132

Output signal

Signal on alarm 2.4 mA or 22 mA error current

Load max. 500 Ω

Output range

Signal resolution max. 700 digits/mA

Separation voltage max. 350 V

Minimum distance of

output signal

Conductivity: 0 / 4 ... 20 mA, galvanically isolated

Temperature (optional second current output)

Conductivity: adjustable

Temperature: adjustable

/ 500 V DC

RMS

Conductivity:

Measured value 0 ... 19.99 µS/cm: 2 µS/cm

Measured value 20 ... 199.9 µS/cm: 20 µS/cm

Measured value 200 ... 1999 µS/cm: 200 µS/cm

Measured value 0 ... 19.99 mS/cm: 2 mS/cm

Measured value 20 ... 200 mS/cm: 20 mS/cm

Measured value 200 ... 2000 mS/cm: 200 mS/cm

Concentration: no minimum distance

Temperature: 15 °C / 59 °F

Overvoltage protection acc. to EN 61000-4-5:1995

Auxiliary voltage output

Contact outputs

Limit contactor

Alarm

Output voltage: 15 V ± 0.6 V

Output current: max. 10 mA

Switching current with ohmic load (cos ϕ = 1): max. 2 A

Switching current with inductive load (cos ϕ = 0.4): max. 2 A

Switching voltage: max. 250 V AC, 30 V DC

Switching power with ohmic load (cos ϕ = 1): max. 500 VA AC, 60 W DC

Switching power with inductive load (cos ϕ = 0.4): max. 500 VA AC

Pickup / dropout delay: 0 ... 2000 s

(versions with remote parameter set switching only)

Function (switchable): steady / fleeting contact

Alarm delay: 0 ... 2000 s (min)

4 Endress+Hauser

Smartec S CLD132

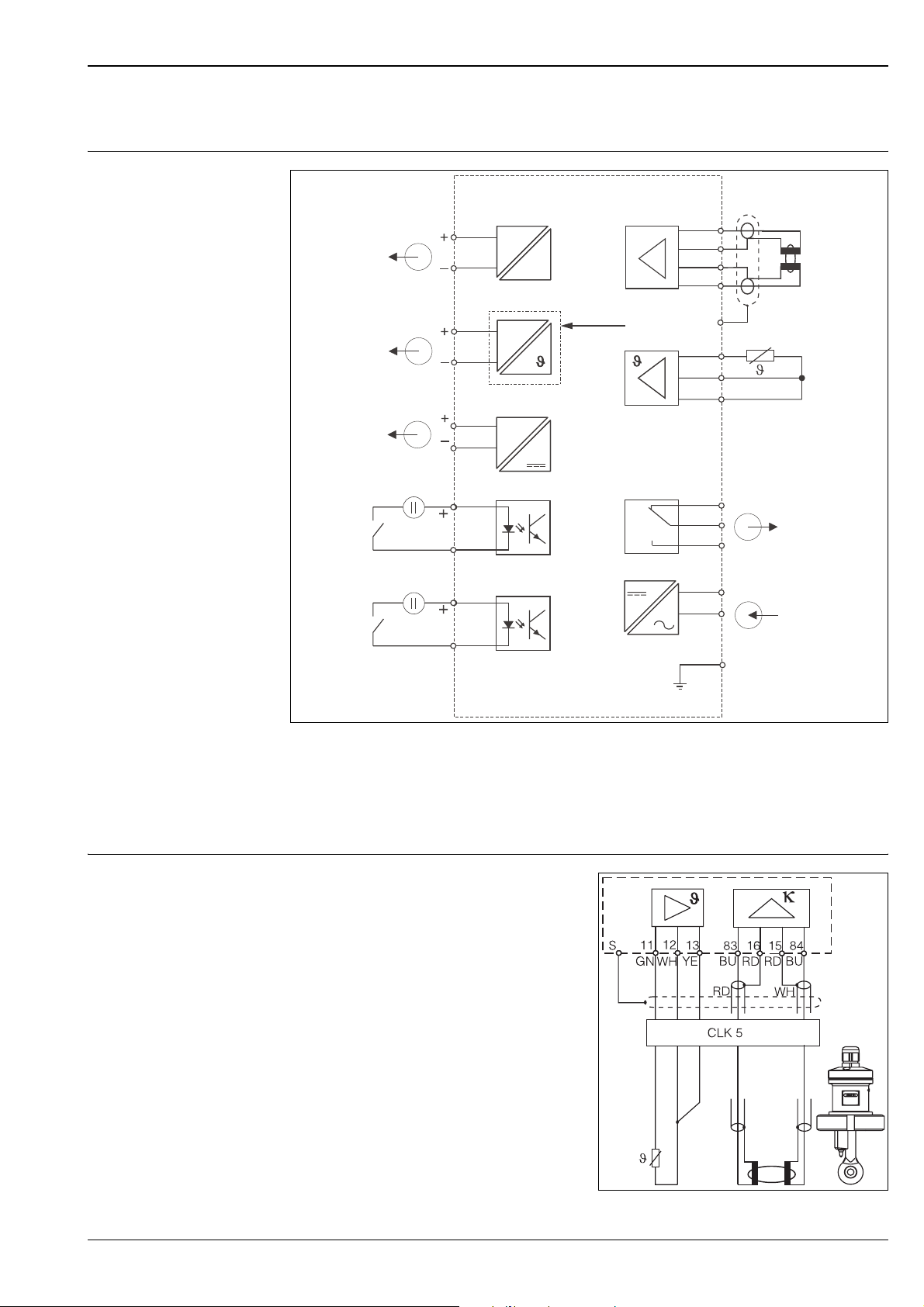

Electrical connection

Power supply

31

mA

A

B

C

D

10-50 V

E

10-50 V

32

85

86

93

94

81

82

33

34

Lf

optional

mA

15 V

84

15

16

83

S

11

12

13

41

42

43

∼

–

∼

–

PE

F

G

H

I

Sensor connection

Electrical connection of CLD132

Signal output 1 conductivity

A

Signal output 2 temperature

B

Auxiliary power output

C

Binary input 2 (MRS 1+2)

D

Binary input 1 (hold / MRS 3+4)

E

The conductivity sensor of the separate version is

connected using the shielded multi-core fixed cable.

Use the junction box VBM and the CLK5 extension

cable (see Accessories) to extend the cable length.

C07-CLD132xx-05-06-00-xx-003.EPS

Conductivity sensor

F

Temperature sensor

G

Alarm (contact position: no current)

H

Power supply

I

Remote parameter set switching (measuring range

MRS:

switching)

Electrical connection of CLS52

C07-CLD132xx-05-06 -00-xx-006.EPS

Endress+Hauser 5

Supply voltage Depending on ordered version:

100 / 115 / 230 V AC +10 / -15 %, 48 ... 62 Hz

24 V AC/DC +20 / -15 %

Smartec S CLD132

Cable entries

Terminal assignments of cable glands on Smartec S CLD132

A Separate version B Compact version

Plug, analog output, binary input

1

Cable gland for alarm contact

2

Cable gland for power supply

3

Housing ground

4

Pressure comp. element PCE (Goretex

5

6

Cable gland for sensor connection, Pg 9

Power consumption max. 7.5 VA

A

®

filter)

3

4

1

6

2

5

12

5

Plug, analog output, binary input

1

Cable gland for alarm contact

2

Cable gland for power supply

3

Housing ground

4

Pressure comp. element PCE (Goretex

5

B

3

4

C07-CLD132xx-04-06 -04-xx-001.eps

®

filter)

Mains fuse Fine-wire fuse, medium time lag, 250 V / 3.15 A

Performance characteristics

Measured value resolution

Temperature response time

Measured error of the sensor

Measured error of the transmitter

a

Temperature: 0.1 °C / 0.18 °F

< 5 s versions with stainless steel socket (CLD132-********1/2)

t

90

t90 < 3.5 min versions with encapsulated Pt 100 (CLD132-********6/7)

a

Conductivity:

– -5 ... +100 °C / 23 ... 212 °F

– > 100 °C / > 212 °F

± (10 µS/cm + 0.5 % of measured value)

± (30 µS/cm + 0.5 % of measured value)

Temperature: Pt 100 class A acc. to IEC 751

Conductivity:

– Display:

– Conductivity signal output:

max. 0.5 % of measured value ± 4 digits

max. 0.75 % of current output range

Temperature

– Display:

– Temperature signal output:

max. 0.6 % of measuring range

max. 0.75 % of current output range

Repeatability

a) acc. to IEC 60746 part 1, at nominal operating conditions

a

Conductivity: max. 0.2% of measured value ± 2 digits

6 Endress+Hauser

Loading...

Loading...