Page 1

Product Data Document

420DS-0d

July 16, 2007 - Page 1

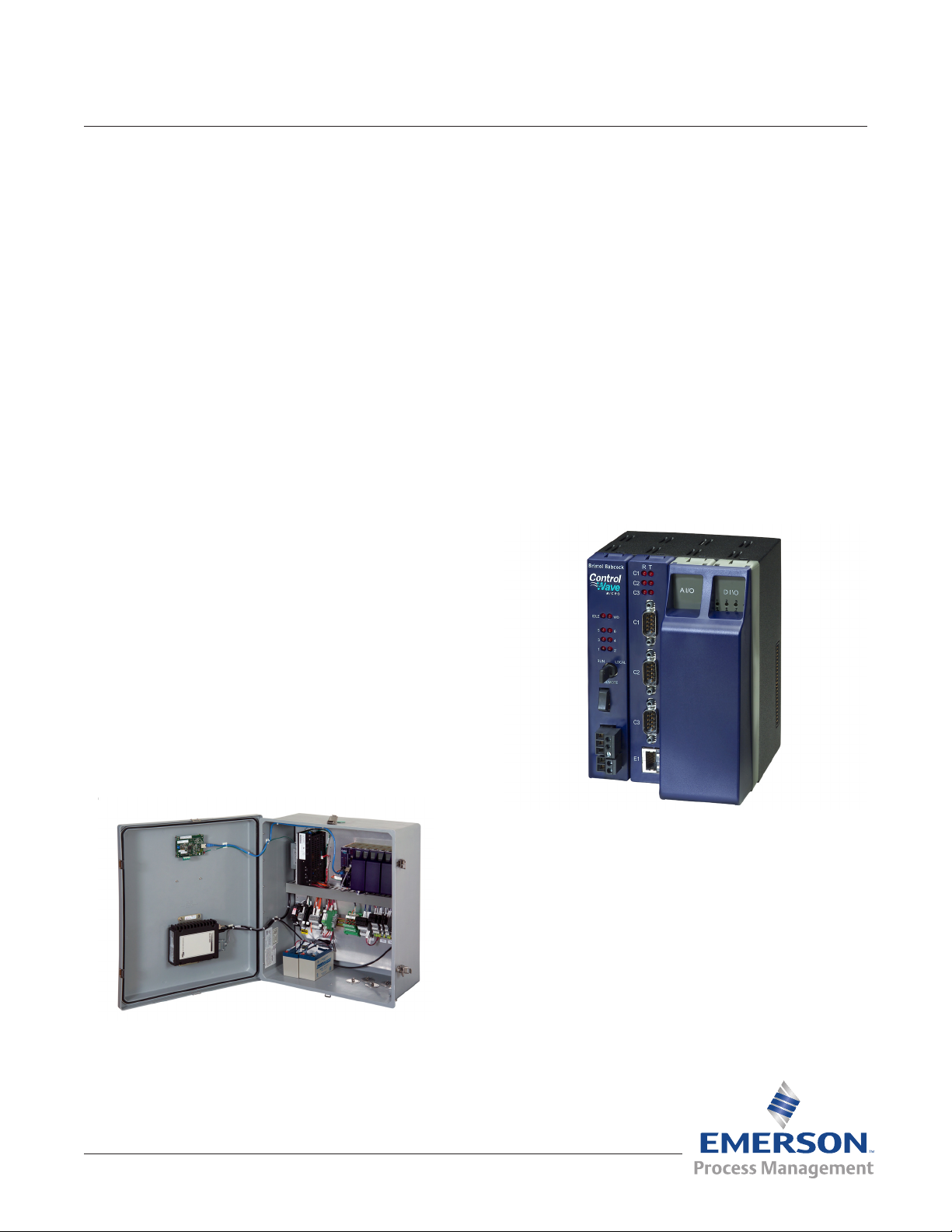

Bristol® ControlWave® Micro

Integrated Enclosure Solutions

Designed and built for out-of- the-box

installation and startup

For years, our panel shop has been setting the

standard for quality design, assembly and testing

of custom enclosures and cabinets. Now Emerson

Process Management brings that experience to the

Bristol® ControlWave® Micro to provide a plug-andplay installation solution.

Benets

Eliminates the need for in-house panel design

•

and fabrication

Design standardization minimizes cost

•

Ideal SCADA Solution

Rely on the experience of professionals for cost

•

effective packages designed for your specic

applications

Fabrication by UL 508 certied panel shop

•

assures electrical code compliance

Avoids delay in custom panel quoting

•

Two-week delivery on most common

•

congurations helps you to plan installation and

startup sooner

All components and options are tested together

•

allowing trouble-free startup

Standardizes the maintenance effort to reduce

•

maintenance cost

Emerson quality ensures long term reliability

•

and lower cost of ownership over the product

lifecycle

Emerson has been a pioneer of innovative SCADA

solutions throughout the modern era of SCADA.

Over these two decades we have gained the knowledge, experience and skill to engineer the affordable solutions you need.

The ControlWave Micro integrated enclosure solution is the ideal answer to your SCADA require-

ments for exibility, quality and budget control.

Applications

The programmability of ControlWave and the exibility of the integrated enclosure solution allows for

a wide range of water & wastewater, oil & gas and

energy distribution application.

Pump and lift station RTU

•

Gas measurement SCADA RTU

•

Pressure Recorder (1 to 4 sensors)

•

Water Quality Monitor when combined with the

•

Six-Cense™ water quality sensor

SCADA Security Monitor with event detection,

•

entry/access control and video storage

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 2

Product Data Document

420DS-0d

July 16, 2007 - Page 2

Bristol® ControlWave® Micro Enclosures

The ControlWave Micro enclosure assembly is a

fully integrated unit that combines the PLC/RTU

with a variety of options commonly required in

SCADA applications. These include a NEMA 4X

rated enclosure, power supply and battery backup

options, termination options, display and operator

input options, and wireless communication options.

The enclosures also include several convenience

and environmental suitability capabilities.

Features

4 package sizes for I/O and option exibility

•

Selection of NEMA 4 steel and NEMA

•

4X berglass or stainless steel to meet

environmental requirements. (NEMA 3X with

battery vent)

12 V and 24 V power supplies with battery

•

backup options and input AC surge protection

DIN rail mounted power distribution

•

DIN rail mounted I/O terminal block options for

•

convenient eld wiring

Optional convenience outlet, lamp and heater

•

Custom Control Panel Design

and Fabrication

We recognize that there are times when one size

does not t all. The ControlWave Micro integrated

enclosures allow some customization and still

provide the benets of standardization. However,

when your enclosure or cabinet truly needs expert

customization, our panel shop is prepared to meet

your requirements. Whatever the size or shape, our

Panel Fabrication Group designs and fabricates

control panels based on your specic application.

From a simple RTU eld enclosure to a complete

control room with large control console and monitoring stations. We design panels for controlled and

harsh environments that include all NEMA rated

enclosures and systems suitable for virtually all

worldwide climates and conditions. Our panel shop

is UL 508 certied and adheres to the latest codes

and standards for assembly, testing, and quality

control.

Multiple display and operator interface options

•

may me mounted internally or externally

Wide selection of xed frequency and spread

•

spectrum radios with polyphaser for electrical

protection

Built-in dial-line modem option for primary or

•

backup communications

Convenient Pressure Recorder conguration

•

ControlWave Micro

ControlWave Micro is the most compact of the

ControlWave family of high performance PLC/RTU

hybrids. The controller is designed to exceed the

stringent requirements for industrial control applications. With its very low power consumption of only

1.2W, and boasting a broad environmental speci-

cation, ControlWave Micro can be installed in the

most remote and inhospitable locations for control

and SCADA applications year in year out.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 3

Product Data Document

420DS-0d

July 16, 2007 - Page 3

Bristol® ControlWave® Micro Enclosures

Features

High Speed processor

•

Very low power consumption minimizes power

•

supply, solar and battery backup requirements

Worldwide standard IEC 61131-3 programming

•

with ACCOL 3

Multiple protocol support BSAP, Modbus, DNP3,

•

DF1 & CIP

Built-in 100 Mbps Ethernet port

•

Up to eleven serial communication ports

•

Built-in Modem and Radio options

•

On-board Alarm & Historical database ensures

•

highest data integrity

Built-in FTP server

•

Wide temperature range (-40 to +70ºC)

•

Industry Standard Programmability

Engineers will appreciate the ControlWave Designer

with ACCOL III programming software. Its conformance to the IEC61131-3 programming standard

enables them to quickly start projects, re-use existing code and simplify maintenance in the long term.

All ve IEC languages are supported, as well as

multitasking of up to 100 simultaneous programs.

In addition to the basic functions and function

blocks, ControlWave Designer brings the benet

of over twenty years of SCADA and plant control

experience in Emerson’s Bristol ACCOL III function

block library. ACCOL III empowers the programmer

with over sixty ready-to-use process control function

blocks valuable for use in oil & gas, water & waste

and process measurement & control applications.

ControlWave also provides local historical data storage and alarming with time stamps to ensure the

integrity of all data in the event of an interruption in

network communication.

ControlWave has been designed around open

standards to enable the engineer to employ famil-

iar technologies to maximize system exibility and

expansion. With Emerson’s Bristol OpenBSI (Open

Bristol System Interface) communications interface

and Active X controls you can even build a local

HMI or use the OPC Server to provide data to any

OPC compliant PC based HMI.

ControlWave Micro conveniently combines the

speed of a PLC, the programming power of a DCS,

the low current consumption and exible communications of an RTU. ControlWave Micro is truly the

most versatile and cost effective SCADA and control

system available.

Visit www.controlwave.com for model ordering

information and enclosure drawings.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 4

Product Data Document

420DS-0d

July 16, 2007 - Page 4

Bristol® ControlWave® Micro Enclosures

© 2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division , are wholly owned subsidiaries of Emerson Electric Co. doing business as Remote Auto-

mation Solutions (“RAS”), a division of Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co. All other marks are property of their

respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. RAS reserves the right to modify or improve the designs or

specications of such products at any time without notice. All sales are governed by RAS’ terms and conditions which are available upon request. RAS does not assume responsibility for

the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any RAS product remains solely with the purchaser and end-user.

Emerson Process Management

Remote Automation Solutions

Watertown, CT 06795 USA T 1 (860) 945-2200

Mississauga, ON 06795 Canada T 1 (905) 362-0880

Worcester WR3 8YB UK T 44 (1) 905-856950

Website: www.EmersonProcess.com/Remote

Loading...

Loading...